Page 1

AN-2255 LM3463 Evaluation Board

1 Introduction

The LM3463 is a 6-channel linear LED driver with Dynamic Headroom Control (DHC) designed to drive six

strings of high brightness LEDs at maximum supply voltage up to 95V. Each output channel of the

LM3463 evaluation board is designed to deliver 200 mA of LED driving current. The LED turn on voltage

is set to 48V by default, thus the board is able to deliver up to 57.6W total output power. The six output

channels are divided into 4 individual groups to facilitate average LED current control by means of PWM

dimming. The PWM dimming control interface of the LM3463 can accept standard TTL level PWM signals,

analog voltage or serial data to control the dimming duty of the four LED groups individually. The analog

dimming control interface accepts an analog control voltage in the range from 0V to 2.5V to adjust the

reference voltage of the linear current regulators, which enables true LED current adjustment. This

evaluation board is designed to be connected to an external primary power supply. Using three connection

wires, the VIN, GND and VFB, the dynamic Headroom Control (DHC) circuit of the LM3463 adjusts the

output voltage of the primary power supply to maximize system efficiency.

2 Standard Settings of the LM3463 Evaluation Board

• Input voltage range: 12V to 95V

• LED turn on voltage: 48V

• Nominal forward voltage of a LED string: 42V

• Output current per ch.: 200 mA

• System clock freq.: 246 kHz

• DHC cut-off freq.: 0.1Hz

• Mode of dimming control: Direct PWM Mode

User's Guide

SNVA642A–May 2012–Revised May 2013

All trademarks are the property of their respective owners.

SNVA642A–May 2012–Revised May 2013 AN-2255 LM3463 Evaluation Board

Submit Documentation Feedback

Copyright © 2012–2013, Texas Instruments Incorporated

1

Page 2

GD0

OutP

REFRTN

VIN

SE0

U1

LM3463

VREF

IOUTADJ

FCAP

CDHC

ISR

VCC

VLedFB

GND

Faultb

MODE

DIM01

DIM23

DIM4

DIM5

EN

DRVLIM

0

REFRTN

R10

NC

R11

0.47 µF

25V

C6

22 nF

25V

C5

1 µF

16V

C4

NC

R9

NC

R7

0

R37

GND

GNDGNDGNDGNDGNDGND

1

2

J9

1

2

3

J8

1

2

3

J4

1

2

3

J5

1

2

3

J6

1

2

3

J7

1.54 k

R6

D2

(Blue LED)

VCC

GND

1

2

3

4

5

6

7

8

J10

EN

Faultb

DIM01

DIM23

DIM4

DIM5

MODE

GND

GND

1

2

3

J3

VFB

NC

GND

TP4 TP6

TP18

TP16

TP14

TP12

TP20

TP8

TP10

TP22

TP24TP27 TP28 TP29

FS

64.9 k

R8

TP26

TP30

TP31

TP41

TP47

TP42

TP48

TP43

TP49

TP44

TP50

TP45

TP51

TP46

TP52

TP64TP62TP60TP58TP56TP54 TP63TP61TP59TP57TP55TP53

FDD2572

Q1

FDD2572

Q2

FDD2572

Q3

FDD2572

Q4

FDD2572

Q5

FDD2572

Q6

1

R13

NC

R12

1

R15

NC

R14

1

R17

NC

R16

1

R19

NC

R18

1

R21

NC

R20

1

R23

NC

R22

J16J15J14J13J12J11

CH0 CH1 CH2 CH3 CH4 CH5

SE1

SE2

SE3

SE4

SE5

GD1

GD2

GD3

GD4

GD5

DR0

DR1

DR2

DR3

DR4

DR5

CLKOUT

SYNC

TP34TP33

TP36TP35

GND

150 k

R2

8.25 k

R4

1 µF

100V

C2

1µF

100V

C1

J0

J1

J2

GND

TP3

TP1 TP2

TP38TP37 TP39 TP40

Power pad of the LM3463 connected to GND

BAV20W-TP

D1

2.94 k

R5

VRAIL

GND

1 µF

16V

C3

VCC

LM3463 Evaluation Board Schematic

3 LM3463 Evaluation Board Schematic

www.ti.com

Figure 1. Circuit diagram of the LM3463 evaluation board

2

AN-2255 LM3463 Evaluation Board SNVA642A–May 2012–Revised May 2013

Copyright © 2012–2013, Texas Instruments Incorporated

Submit Documentation Feedback

Page 3

www.ti.com

4 Bill Of Materials

Designator Description Package Part Number Manufacturer

U1 LED driver WQFN-48 LM3463 Texas Instruments

C1, C2 Capacitor, 1uF, 100V, X7R 1206 GRM31CR72A105KA01L MuRata

C3, C4 Capacitor, 1uF, 16V, X7R 0603 C1608X7R1C105K TDK

C5 Capacitor, 2200 pF, 25V, X7R 0603 GRM188R71E222KA01D MuRata

C6 Capacitor, 0.47uF, 25V, X5R 0603 GRM188R61E474KA12D MuRata

D1 Diode, 200V, 200 mA SOD-123 BAV20W-TP Micro Commercial

D2 Green LED Gull-wing HLMP-6500-F0011 Avago Technologies

J0, J1, J2 Terminal screw vertical, snap- 7693 Keystone

J3 3 Pos. connector 100 mil pitch 3-641216-3 TE Connectivity

J4, J5, J6, J7, J8 3 Pos. header 100 mil pitch TSW-103-07-G-S Samtec

J9 2 Pos. header 100 mil pitch TSW-102-07-G-S Samtec

J10 8 Pos. connector 100 mil pitch 3-641216-8 TE Connectivity

J11, J12, J13, J14, Banana jack connector 8.9 mm dia. 575-8 Keystone

J15, j16

Q1, Q2, Q3, Q4, MOSFET, N-CH, 150V, 29A DPAK FDD2572 Fairchild Semiconductor

Q5, Q6

R2 Resistor, 150 kΩ, 1%, 0.1W 0603 CRCW0603150KFKEA Vishay-Dale

R4 Resistor, 8.25 kΩ, 1%, 0.1W 0603 CRCW06038K25FKEA Vishay-Dale

R5 Resistor, 2.94 kΩ, 1%, 0.1W 0603 CRCW06032K94FKEA Vishay-Dale

R6 Resistor, 1.54 kΩ, 1%, 0.1W 0603 CRCW06031K54FKEA Vishay-Dale

R8 Resistor, 64.9 kΩ, 1%, 0.1W 0603 CRCW060364K9FKEA Vishay-Dale

R10, R37 Resistor, 0Ω, 5%, 0.1W 0603 CRCW06030000Z0EA Vishay-Dale

R13, R15, R17, Resistor, 1.00Ω, 1%, 0.125W 0805 CRCW08051R00FKEA Vishay-Dale

R19, R21, R23

R7, R9, R11 Resistor, 1.00kΩ, 1%, 0.1W 0603 CRCW06031K00FKEA Vishay-Dale

R12, R14, R16, Resistor, 1.00 kΩ, 1%, 0.125W 0603 CRCW08051K00FKEA Vishay-Dale

R18, R20, R22

TP1, TP4, TP6, Terminal, Turret 1502–2 Keystone

TP8, TP10, TP12,

TP14, TP16, TP18,

TP20, TP22, TP24,

TP31, TP33, TP35,

TP37, TP40, TP54,

TP56, TP58, TP60,

TP62, TP64

TP3, TP26, TP27, Orange 5008 Keystone

TP28, TP29, TP30,

TP34, TP36, TP41,

TP42, TP43, TP44,

TP45, TP46, TP47,

TP48, TP49, TP50,

TP51, TP52, TP53,

TP55, TP57, TP59,

TP61, TP63

TP2 Test Point Red 5005 Keystone

TP38 Test Point White 5007 Keystone

TP39 Test Point Black 5006 Keystone

Bill Of Materials

in

SNVA642A–May 2012–Revised May 2013 AN-2255 LM3463 Evaluation Board

Submit Documentation Feedback

Copyright © 2012–2013, Texas Instruments Incorporated

3

Page 4

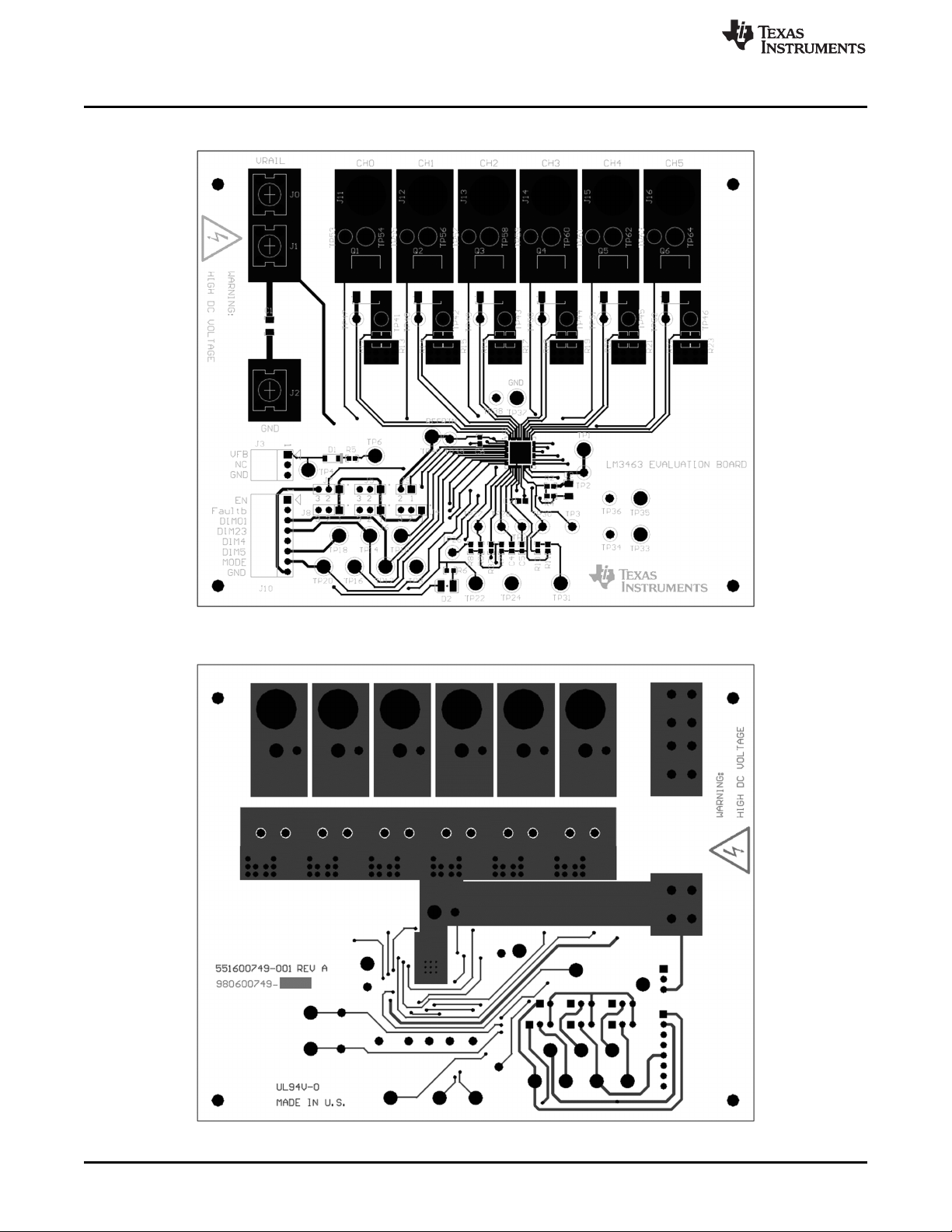

Board Layout

5 Board Layout

www.ti.com

Figure 2. Top Layer

Figure 3. Bottom Layer

4

AN-2255 LM3463 Evaluation Board SNVA642A–May 2012–Revised May 2013

Copyright © 2012–2013, Texas Instruments Incorporated

Submit Documentation Feedback

Page 5

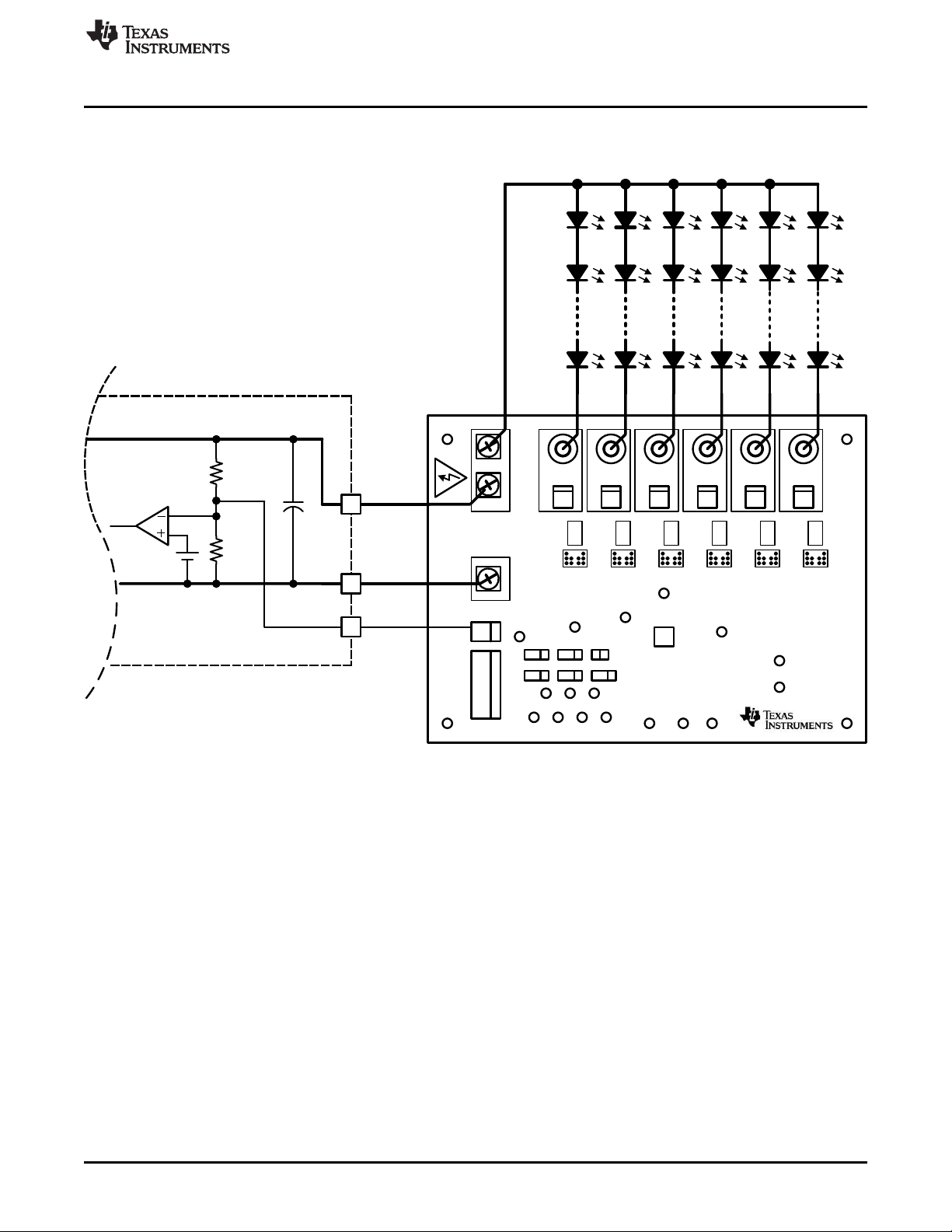

Primary power supply

(e.g. AC/DC offline converter, DC power supply)

LM3463 EVALUATION

BOARD

WARNING:

HIGH DC

VOLTAGE

J0

J1

J11

J12

J13

J14

J15

J16

J2

J9J5J7

J4J6J8

J10

J3

CH0 CH1 CH2 CH3 CH4 CH5VRAIL

GND

2.5V

VFB

RVFB1

RVFB2

VRAIL

GND

VFB

LM3463 evaluation board

LED strings x 6

Default operation conditions of the board:

I

OUT

per channel: 200 mA

No. of LED per string: 14 (~3.2V forward voltage per LED)

LED turn on voltage: V

RAIL

= 48V

Dimming mode: Direct PWM dimming mode

@ 100% dimming duty

Assumed characteristics of the primary power supply:

VFB = 2.5V

RVFB1 = 39.8 k

RVFB2 = 3.9 k

www.ti.com

6 Connection Diagram

Connection Diagram

Figure 4. Connecting the LM3463 evaluation board to a primary power supply

7 Primary Power Supply

The LM3463 evaluation board is designed to operate with an external primary power supply. A primary

power supply can be any kind of DC power supply with an accessible output voltage feedback node. For

instance, either an AC/DC off-line power converter or a DC/DC switching converter can be used as a

primary power supply. The LM3463 evaluation board should connect to the primary power supply via three

terminals, the VRAIL, GND and VFB as shown in Figure 1.

The board includes three screw type connectors for high current connections, namely J0, J1 and J2. The

J1 and J2 should connect to the positive and GND output terminals of the primary power supply

accordingly with minimum of wire 18 AWG.

Generally, the board is designed to drive from one to six LED strings of 14 serial LEDs per string. The

driving current of each sting is set to 200 mA by default, thus assuming each LED carries a 3.2V forward

voltage, the maximum total output power of this evaluation board under steady state is about 54W.

Because the output voltage of the primary power supply, V

Control (DHC) circuit of the LM3463 to maintain maximum system efficiency, therefore the V

a wide and adjustable voltage range.

RAIL

is controlled by the Dynamic Headroom

must have

RAIL

SNVA642A–May 2012–Revised May 2013 AN-2255 LM3463 Evaluation Board

Submit Documentation Feedback

Copyright © 2012–2013, Texas Instruments Incorporated

5

Page 6

0

V

DHC_READY

V

RAIL(nom)

V

RAIL(steady)

V

RAIL(peak)

V

RAIL

Time

Pushed up

by LM3463

Initiated by

primary power

supply

DHC activated

Primary Power Supply

www.ti.com

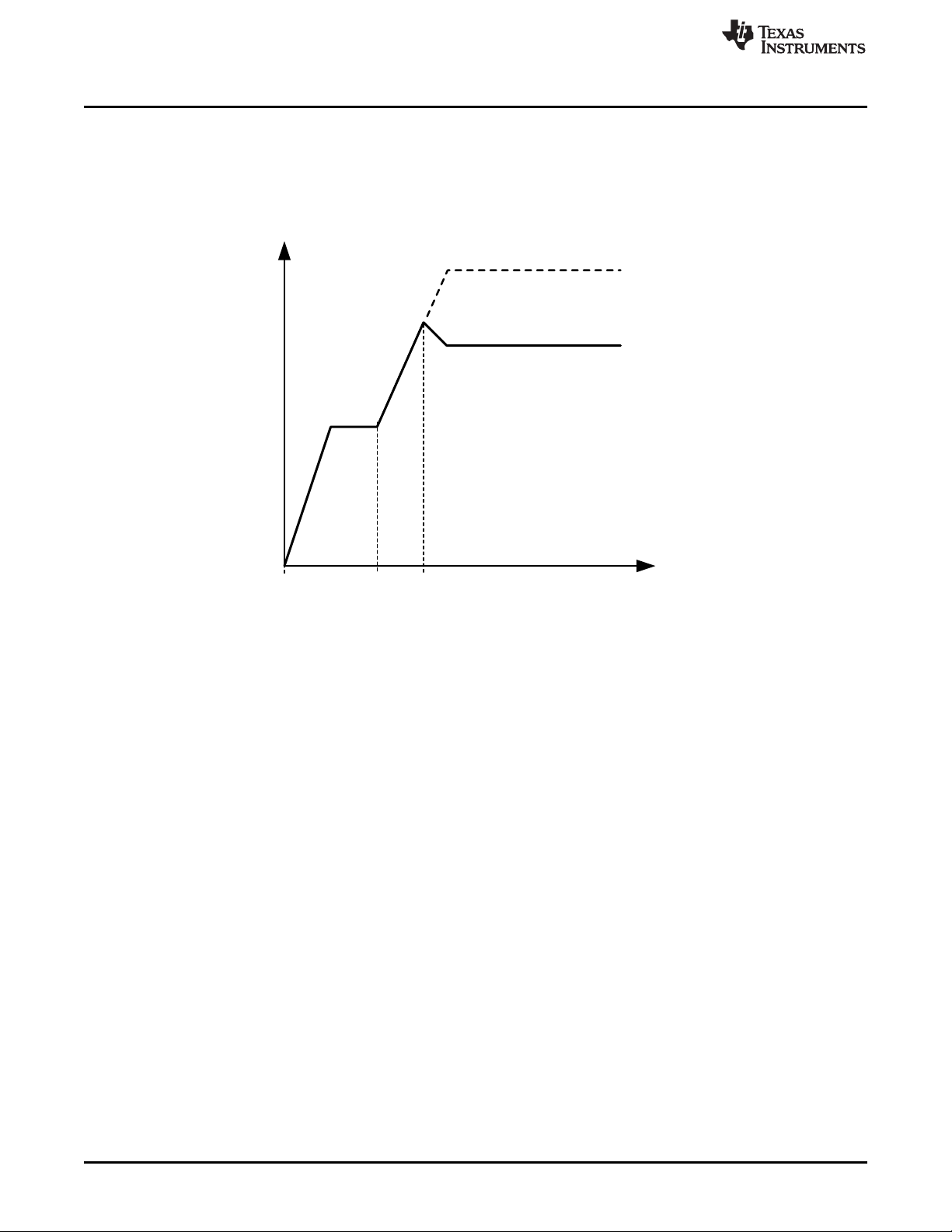

Generally the required range of the V

voltages of the LED strings (respectively, V

is determined by the highest and lowest possible forward

RAIL

LED-MAX-COLD

and V

LED-MIN-HOT

). Since the forward voltage of the

LED strings varies according to the changing of the ambient temperature, the voltage for turning the LEDs

on at system startup must be set higher than the V

V

at system startup.

RAIL

LED-MAX-COLD

.Figure 5 shows the different voltage level of

Figure 5. Different voltage levels of the V

In Figure 5, the V

V

RAIL(peak)

is the highest level of V

is the output voltage of the primary power supply under the control of the LM3463.

RAIL

when the voltage of the OutP pin of the LM3463 equals 0V. V

RAIL

is the voltage level that the LM3463 turns all output channels on. V

at system startup

RAIL

RAIL(nom)

is the nominal output voltage of

the primary power supply when the OutP pin voltage is higher than VFB+0.6V (i.e. prior to DHC starting)

In order to secure sufficient rail voltage to maintain regulated LED currents when enabling the output

channels, the V

RAIL(peak)

and V

DHC_READY

must be set higher than V

LED-MAX-COLD

(the highest forward voltage of

the LED strings under low ambient temperature). The following settings are suggested to ensure correct

system startup sequence:

1. V

RAIL(nom)

2. V

DHC_READY

3. V

RAIL(peak)

Figure 6 shows a suggested procedure to determine the V

= V

LED-MIN-HOT

= V

= V

LED-MAX-COLD

DHC_READY

- 5V

+ 5V

+ 5V

RAIL(nom)

, V

DHC_READY

and V

RAIL(peak)

.

DHC_READY

6

AN-2255 LM3463 Evaluation Board SNVA642A–May 2012–Revised May 2013

Copyright © 2012–2013, Texas Instruments Incorporated

Submit Documentation Feedback

Page 7

V

LED-MAX-COLD

, the highest forward

voltage of LED strings under low

temperature

Identify V

LED-MAX-COLD

Identify V

LED-MIN-HOT

Adjust the nominal output voltage of the

primary power supply,

V

RAIL(nom)

= V

LED-MIN-HOT

- 5V

Set the peak output voltage of the primary

power supply (at V

OutP

= 0.15V),

V

RAIL(peak)

= V

LED-MAX-COLD

+ 10V

Set the LED turn on voltage,

V

DHC_READY

= V

LED-MAX-COLD

+ 5V

Begin of design

End of design

V

LED-MIN-HOT

, the lowest forward voltage

of LED strings under high temperature

V

RAIL(nom)

, the nominal output voltage

of the primary power supply.

e.g. Assume V

FB

= 2.5V,

REMARKSPROCEDURES

V

RAIL(peak)

, the output voltage of the

primary power supply when the OutP

pin is pulling to its minimum.

R1 + R

2

R

2

2.5V x

V

RAIL(nom)

=

V

DHC_READY

, the LED turn on voltage is

defined by R

FB1

and R

FB2

connected to

the VLedFB pin.

R

FB1

+ R

FB2

R

FB2

2.5V +

V

DHC_READY

=

V

FB

R

2

V

FB

- 0.15 - 0.6

R

DHC

+ V

FB

R

1

xV

RAIL(peak)

=

+

www.ti.com

Primary Power Supply

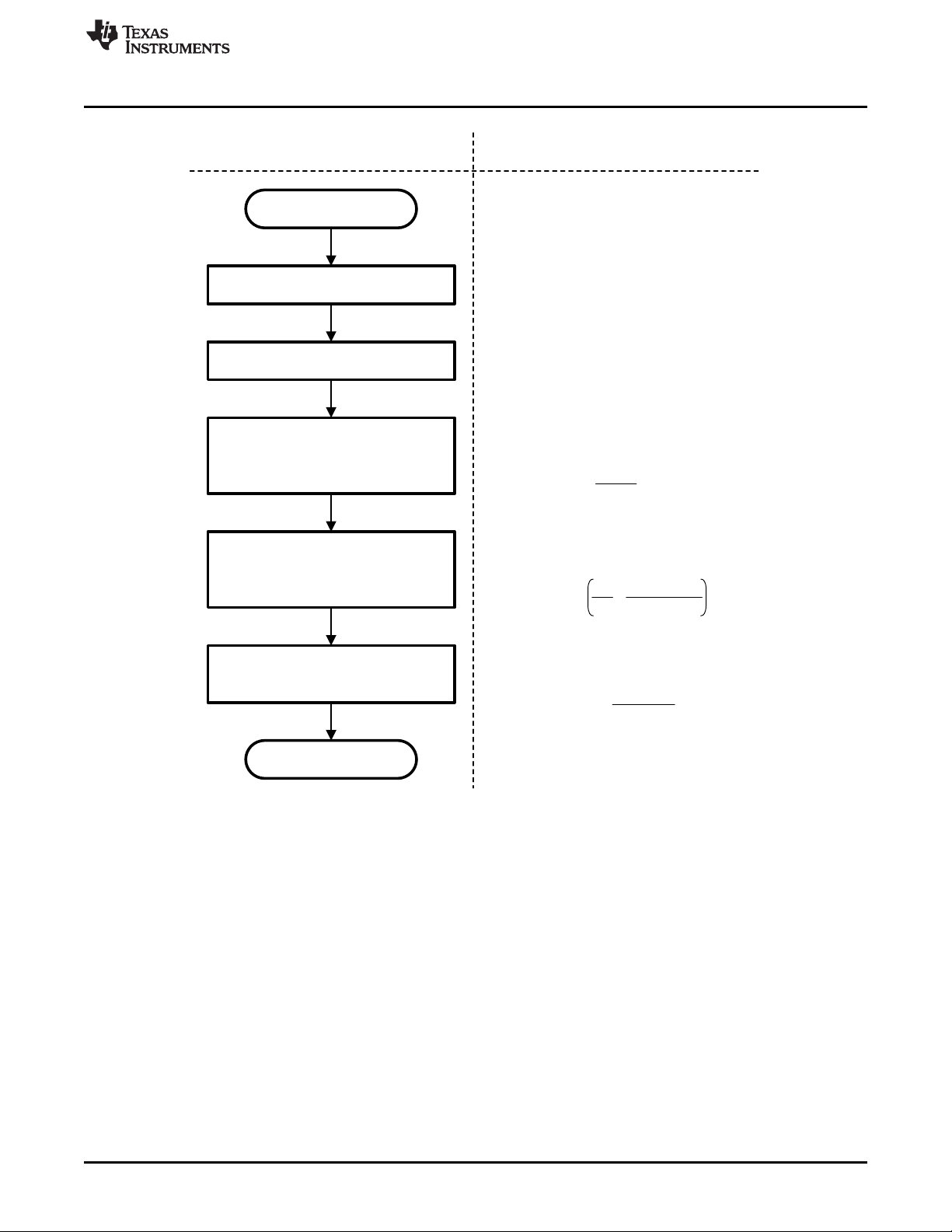

Because the V

RAIL(peak)

turned on, the primary power supply must be able to deliver an output power no less than the total LED

current multiplied by the V

selecting a power supply for the LM3463 evaluation board. If the power supply is an off-the-shelf product,

the output voltage and value of the output voltage feedback resistor divider may need to be changed to

allow DHC.

Figure 6. Procedures of setting the rail voltage levels.

is the possible highest output voltage of the primary power supply with the LEDs

RAIL(peak)

. The flow chart in Figure 7 shows the recommended procedure of

SNVA642A–May 2012–Revised May 2013 AN-2255 LM3463 Evaluation Board

Submit Documentation Feedback

Copyright © 2012–2013, Texas Instruments Incorporated

7

Page 8

V

RAIL(peak)

is the highest output voltage

that the power converter needs to

deliver.

I

LEDx

is the forward current of an LED

string.

Determine:

I

LEDx

, V

RAIL(peak)

and V

RAIL(nom)

Prepare a power converter which has a

maximum output power > P

OUT(nom)

and a

maximum output voltage > V

RAIL(peak)

Adjust R1 and R2 to reduce the nominal

output voltage of the power converter to

V

RAIL(nom)

Begin of power

supply selection

The power converter must be able to

deliver a power no less than P

RAIL(peak)

even if the V

RAIL

is pushed to the

maximum by the LM3463, V

RAIL(peak)

REMARKSPROCEDURES

Adjust the value of R1 and R2 so as to

meet the equation:

V

FB

x

R

2

V

RAIL(nom)

=

Calculate the required maximum output

Power, P

RAIL(peak)

of the power supply

End of power

supply selection

x I

LEDx

No. of output ch.

P

RAIL(peak)

=

x V

RAIL(peak)

R1 + R

2

Response of the DHC Loop

www.ti.com

Going through the above procedures, the value of the R5, R2 and R4 are determined. The values of the

R5, R2 and R4 on the LM3463 evaluation board are 2.94 kΩ, 150 kΩ and 8.25 kΩ respectively. The

resistors may need replacing as needed to interface the board to a primary power supply.

8 Response of the DHC Loop

The cut-off frequency of the DHC loop f

The f

C(LM3463)

The default value of the C4 on the board is 1 uF which sets the cut-off frequency of the DHC loop to

0.1Hz.

In order to secure stable operation of the system, the cut-off frequency of the DHC loop of the LM3463

must be set lower than that of the primary power supply. Usually a DHC response of 1/10 of which of the

primary power supply is enough to secure stable operation. In the case where the primary power supply

has an unknown frequency response, the selection of the value of the C4 can be based on estimation.

Use a 1 uF ceramic capacitor as an initial value and reduce the value of C4 to increase the DHC loop

response as needed.

Figure 7. Procedure of selecting a primary power supply

C(LM3463)

is determined by the value of the external capacitor, C4.

is governed by the following equation.

(1)

8

AN-2255 LM3463 Evaluation Board SNVA642A–May 2012–Revised May 2013

Copyright © 2012–2013, Texas Instruments Incorporated

Submit Documentation Feedback

Page 9

0

V

DHC_READY

V

RAIL(nom)

V

LED

V

RAIL

Time

t

ST-1

t

ST-2

t

ST-3

t

ST-1

open

R

ISR

Startup time

t

ST-2

high

t

ST-3

low

V

IN-UVLO

6.67V

www.ti.com

9 Reducing the System Startup Time

The total system startup time is generally dependent on the frequency response of both the primary power

supply and DHC loop of the LM3463. The slower response of the two circuits, the longer time the system

takes to startup. Because the response of the primary is usually not user programmable, the overall

system startup time can be reduced by shortening the time for the V

V

DHC_READY

RISR, which governed by the following equation:

where

, namely the tST. as shown in Figure 8. The tSTis adjusted dependent on the value of the C4 and

Reducing the System Startup Time

to increase from V

RAIL

RAIL(nom)

to

(2)

(3)

Figure 8. Adjusting the tST with different value of RISR

The R9 on this evaluation board is opened by default, thus the system startup time is set to the longest.

The startup time of the board can be reduced by putting a 0603 resistor to the position of R9. The value of

the R9 should be no less than 130kΩ.

10 MOSFET Power Dissipation Limit

As the drain voltage of the MOSFETs (Q1, Q2, Q3, Q4, Q5 and Q6) exceeds four times the voltage of the

DRVLIM pin, the output currents are reduced to reduce the power dissipations on the MOSFETs. The

DRVLIM of the LM3463 of this evaluation board is connected to VCC via a 0Ω resistor, R37. Thus the

drain voltage threshold to perform MOSFET power dissipation limit is about 26.4V by default.

11 Analog Dimming Control

The reference voltage for the LED current regulators can be adjusted by changing the voltage at the

IOUTADJ pin of the LM3463. In this evaluation board, the reference voltage for current regulation is set to

200mV by connecting the IOUTADJ pin to VCC via a 0Ω resistor, R10. By default the pull-down resistor to

the IOUTADJ pin, R11 is opened. To adjust the IOUTADJ pin voltage, the R10 and R11 should be

replaced according to the required output current following the equation below:

SNVA642A–May 2012–Revised May 2013 AN-2255 LM3463 Evaluation Board

Submit Documentation Feedback

Copyright © 2012–2013, Texas Instruments Incorporated

9

Page 10

PWM Dimming Control

The IOUTADJ pin can be biased by a positive voltage in the range of 0V to 2.5V across the terminals

TP31and TP39. If the IOUTADJ pin is going to be biased by an external voltage source, the R10 and R11

should be removed.

12 PWM Dimming Control

The LM3463 evaluation board allows three different modes of PWM dimming control:

• Direct PWM Dimming Mode

• Serial Interface Mode

• DC Interface Mode

• The mode of PWM dimming control is selected by changing the position of the shunt jumper of J8.

Mode of dimming control Setting of J8

Direct PWM dimming mode Short Pos. 2–3

Serial interface mode Open

DC interface mode Short Pos. 1–2

Using PWM dimming control, the six output channels of the board are grouped into four individual groups

which are controlled by four individual PWM signals at the terminals TP12, TP14, TP16 and TP18.

www.ti.com

(4)

Terminal Involved channels

TP12 CH0, CH1

TP14 CH2, CH3

TP16 CH4

TP18 CH5

The terminals J4, J5, J6 and J7 are used to connect the DIM01(TP12), DIM23(TP14), DIM4(TP16) and

DIM5(TP18) pins of the LM3463 to either VCC or GND. The jumpers on these terminals should be

removed if external dimming control signals are applied to the board.

Direct PWM Dimming Mode

In the direct PWM dimming mode, the board accepts standard active high TTL level PWM signals to

perform dimming control. The minimum on duty is generally limited by the gate capacitance of the external

MOSFETs. Normally, an 8 µs minimum on time is suggested.

Serial Interface Mode

In the serial interface mode, the on duty of each output channel is controlled by a data byte of 8 bits wide.

In this mode the terminals TP12, TP14 and TP16 on the board comprise a serial data interface to receive

data bytes from external data source. The connection to the DIM5 pin is not used and should be

connected to GND by shortening the pins 2 and 3 of J7. The functions of the TP12, TP14 and TP16 in the

serial interface mode are as listed in the following table:

Serial Interface Mode

Terminal Function

TP12 Serial data input

TP14 Clock signal input

TP16 End Of data Frame (EOF) signal input

10

AN-2255 LM3463 Evaluation Board SNVA642A–May 2012–Revised May 2013

Copyright © 2012–2013, Texas Instruments Incorporated

Submit Documentation Feedback

Page 11

BIT7BIT6BIT5BIT4BIT3BIT2BIT1BIT0

One data byte

DIM01

DIM23

(Clock signal)

(Data)

DIM01

DIM23

(Clock signal)

(Data)

BYTE1

(Group D)

BYTE2

(Group C)

BYTE3

(Group B)

BYTE4

(Group A)

DIM4

(End of Frame)

EOF

One data frame

LSB MSB

BOF

www.ti.com

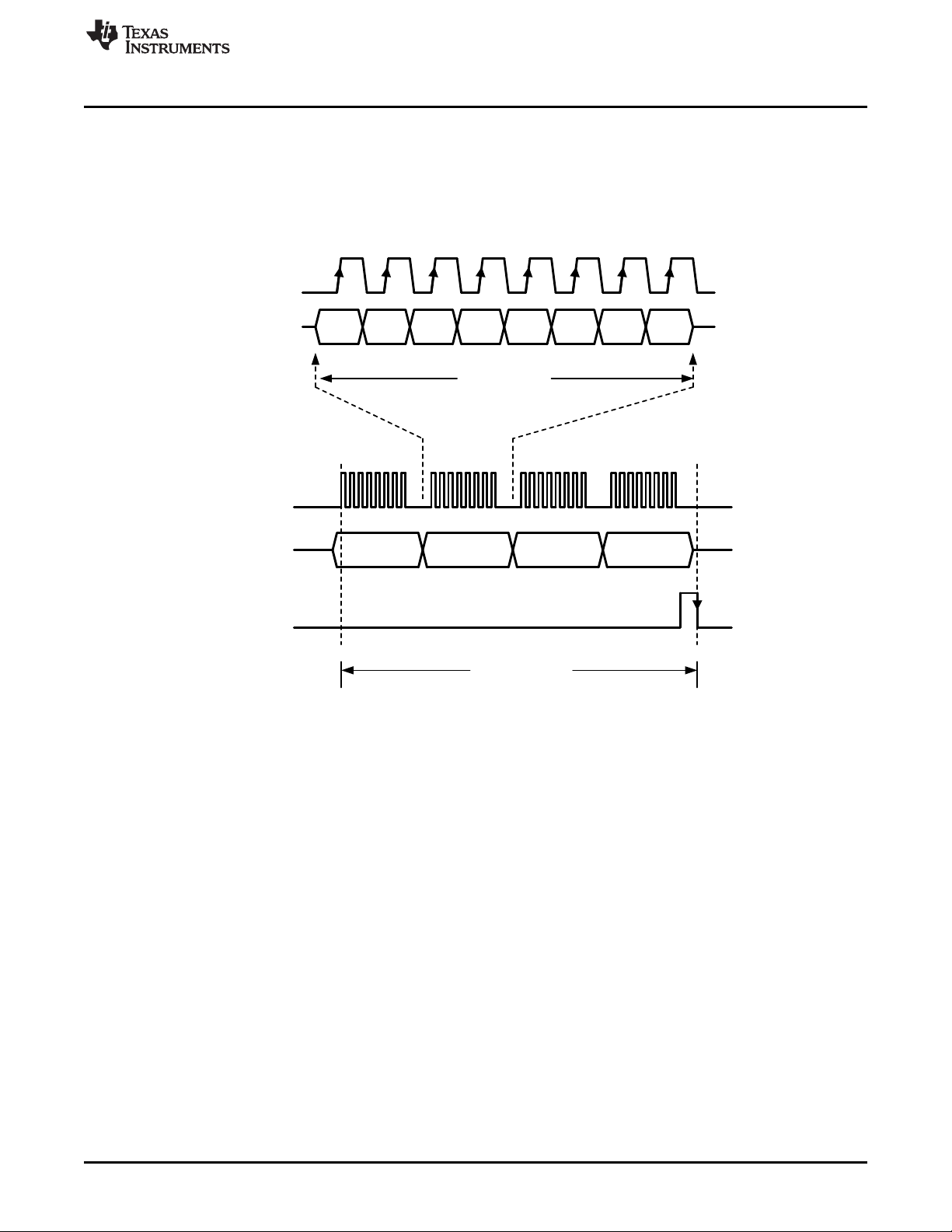

In the serial interface mode the LM3463 evaluation board accepts a data frame which consists of four data

bytes to control the on duty of the four groups of output channels via the terminal TP12 (DIM01). Every

data byte contains 8 bits in LSB (Least Significant Bit) first ordering and is clocked into the data buffer of

the LM3463 at every rising edge of clock signal at the terminal TP14 (DIM23). Every time a data frame is

clocked in to the LM3463 the terminal TP16 (DIM4) should be pulled low to generate a falling edge to

indicate an ‘End-Of-Frame (EOF)’. Figure 9 shows the typical waveform of a data frame and the

corresponding clock and EOF signals.

PWM Dimming Control

Figure 9. Typical waveforms of a complete data frame in the serial interface mode

SNVA642A–May 2012–Revised May 2013 AN-2255 LM3463 Evaluation Board

Submit Documentation Feedback

Copyright © 2012–2013, Texas Instruments Incorporated

11

Page 12

Input Data Code

(Decimal)

3/256

PWM dimming duty

4/256

5/256

0

6/256

32415

254

253

255

252

0

256/256

251

255/256

254/256

253/256

252/256

2/256

(Skipped)1/256

PWM Dimming Control

www.ti.com

Figure 10. PWM dimming duty vs code value of a data byte

In the serial interface mode, the six output channels are grouped into four individual groups. The on duty

of each group is controlled by the value of a specific data byte as listed in the following table:

Output channel Data byte

CH0, CH1 BYTE1

CH2, CH3 BYTE2

CH4 BYTE3

CH5 BYTE4

Because the data width of a data byte is fixed to 8 bits, the step size of the LED current is equal to 1/256

of the full scale current. To allow the use of 0% on duty, the steps 1 and 2 are combined to give a 2/256

on duty. Thus either applying a hexadecimal code 001h or 002h the LM3463 will give a 2/256 on duty. The

dimming duty in the serial interface mode is governed by the following equation:

(5)

Figure 10 shows the relationship of the code value of a data byte and PWM dimming duty.

DC Interface Mode

In the DC interface mode, the on duty of the output channels are adjusted according to the voltage on the

terminals TP12, TP14, TP16 and TP20. In this mode, the six output channels are grouped into four groups

and controlled by the voltage on four terminals individually as listed in the following table:

12

AN-2255 LM3463 Evaluation Board SNVA642A–May 2012–Revised May 2013

Copyright © 2012–2013, Texas Instruments Incorporated

Submit Documentation Feedback

Page 13

Analog voltage

at the DIMn pin

2/256

PWM dimming duty

3/256

4/256

0

5/256

5

.

7

V-V

LSB

5

.

7

V-2

V

LSB

5

.

7

V

5

.

7

V

-

3

V

LSB

256/256

5

.

7

V-4

V

LSB

255/256

254/256

253/256

252/256

0

.

8

V

+

3

V

LSB

0

.

8

V

+

2

V

LSB

0

.

8

V

+

4

V

LSB

0

.

8

V

+

V

LSB

0

.

8

V

6/256

V

LSB

=

5.7V - 0.8V

256

(Skipped) 1/256

www.ti.com

The voltage being applied to the terminals should be in the range of 0.8V to 5.7V. The dimming duty in the

DC interface mode is governed by the following equation:

In this mode, the conversion of analog voltage to dimming duty is accomplished by an internal 8-bit ADC

of the LM3463, thus the step size of the LED current is equal to 1/256 of the full scale current. To allow

the use of 0% on duty, the steps 1 and 2 are combined to give a 2/256 on duty. Thus either applying a

voltage in the range of 0.8V to 0.8V+V

Figure 11 shows the Conversion characteristics of the analog voltage to PWM dimming control circuit:

Disabling Output Channel(s)

Output channel Terminal

CH0, CH1 TP12

CH2, CH3 TP14

CH4 TP16

CH5 TP18

to the dimming control inputs will result in a 2/256 on duty.

LSB

(6)

Figure 11. Conversion characteristic of the analog voltage to PWM dimming control circuit

13 Disabling Output Channel(s)

An output channel of this evaluation board can be disabled by not connecting an LED string to the output

terminal. A disabled channel is excluded from the DHC loop and remained in OFF state until a falling edge

at the EN pin or system repower is applied. The channel 0 must be used regardless of the number of

disabled channel.

SNVA642A–May 2012–Revised May 2013 AN-2255 LM3463 Evaluation Board

Submit Documentation Feedback

Copyright © 2012–2013, Texas Instruments Incorporated

13

Page 14

LM3463 EVALUATION BOARD

WARNING:

HIGH DC VOLTAGE

J0

J1

J11

J12

J13

J14

J15

J16

J2

J9J5J7

J4J6J8

J10

J3

CH0 CH1 CH2 CH3 CH4 CH5VRAIL

GND

LM3463 EVALUATION BOARD

WARNING:

HIGH DC VOLTAGE

J0

J1

J11

J12

J13

J14

J15

J16

J2

J9J5J7

J4J6J8

J10

J3

CH0 CH1 CH2 CH3 CH4 CH5VRAIL

GND

LM3463 EVALUATION BOARD

WARNING:

HIGH DC VOLTAGE

J0

J1

J11

J12

J13

J14

J15

J16

J2

J9J5J7

J4J6J8

J10

J3

CH0 CH1 CH2 CH3 CH4 CH5VRAIL

GND

TP12

TP14

TP33

TP35

VFB

TP12

TP14

TP33

TP35

VFB

J4 = OPEN J7 = SHORT 2-3

J5 = OPEN J8 = OPEN

J6 = OPEN J9 = OPEN

TP22

TP3

TP22

TP3

TP22

TP3

MASTER

J4 = OPEN J7 = SHORT 2-3

J5 = OPEN J8 = OPEN

J6 = SHORT 2-3 J9 = OPEN

VLedFB = VCC

R2 = OPEN

R4 = OPEN

SLAVE 1

J4 = OPEN J7 = SHORT 2-3

J5 = OPEN J8 = OPEN

J6 = SHORT 2-3 J9 = OPEN

VLedFB = VCC

R2 = OPEN

R4 = OPEN

SLAVE 2

LED array 1 LED array 2 LED array 3VRAIL

GND

VFB

Primary Power Supply

TP12

TP14

TP16

LOAD

SCLK

SDAT

Interface to MCU for

dimming control

Cascading the LM3463 evaluation board

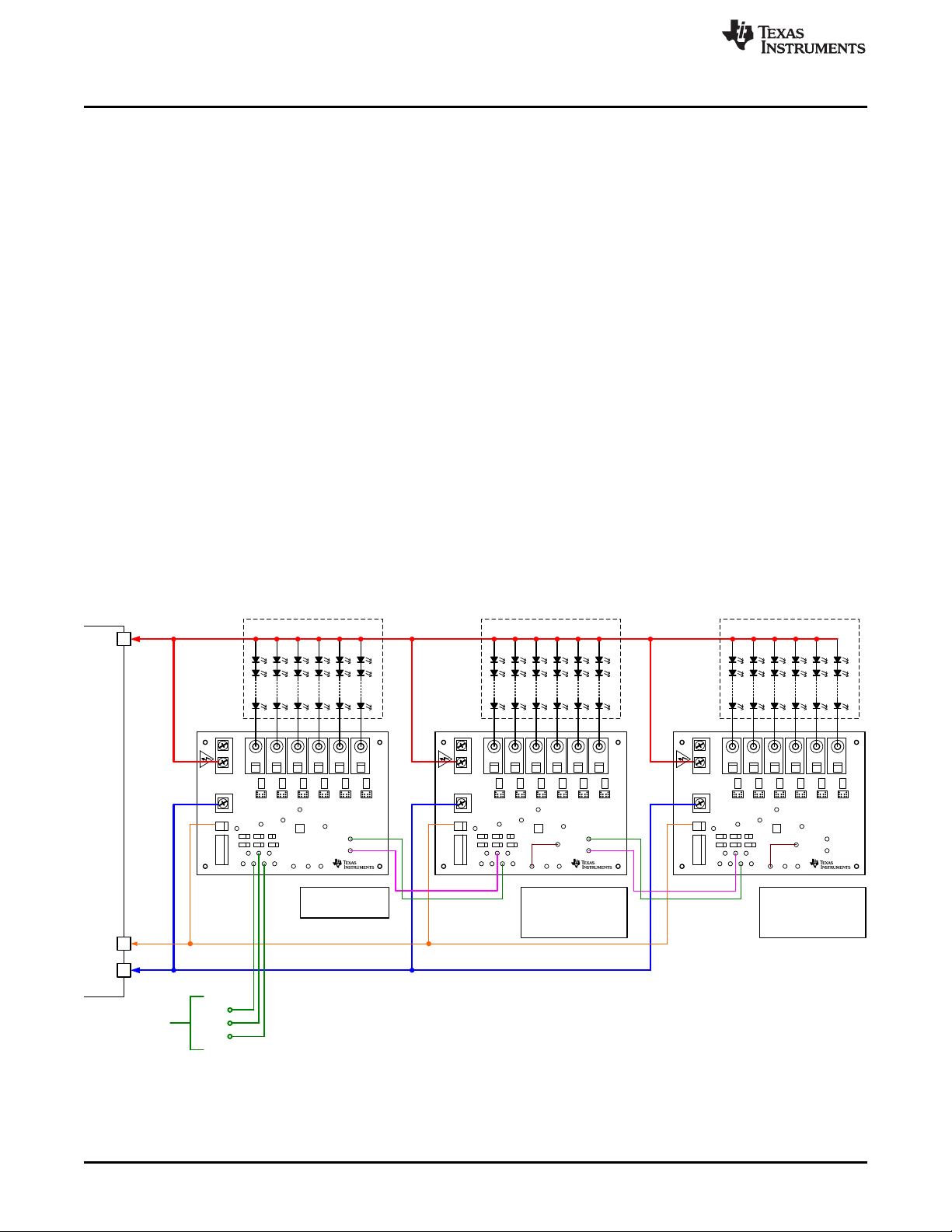

14 Cascading the LM3463 evaluation board

A number of the LM3463 evaluation boards can be cascaded to expand the number of output channels.

The connection among boards differs depending on the selected mode for dimming control. The

connection diagrams for the serial interface mode, DC interface mode and direct PWM mode are as

illustrated in the Figure 12, Figure 13, and Figure 14, respectively.

When a number of the LM3463 evaluation boards are cascaded, one of the boards must be set as master

unit and the other boards must be set as slave units. The master unit is the board which has the VFB

terminal connected to the primary power supply. The master unit controls the system startup time and

distributes dimming control signals to the slave units, the connections among the boards differs depending

on the mode of dimming control being selected.

By default, the LM3463 evaluation board is set as a master unit in direct PWM dimming mode with 100%

on duty. To set a board to be a slave unit, the resistors R2 and R4 must be removed and the terminal TP3

(VLedFB pin of the LM3463) should be connected to the terminal TP22 (VCC pin of the LM3463) using an

external connection.

In cascade operation, the number of slave units is virtually unlimited. However, in high power applications

the accumulated voltage drop on the power return part could impair the function of the DHC. Generally it

is suggested not to cascade more than four pieces of the LM3463 evaluation board to secure stable

system operation.

15 PCB Design

Good heat dissipation helps optimize the performance of the LM3463. The ground plane should be used

to connect the exposed pad of the LM3463, which is internally connected to the LM3463 die substrate.

The area of the ground plane should be extended as much as possible on the same copper layer around

the LM3463. Using numerous vias beneath the exposed pad to dissipate heat of the LM3463 to another

copper layer is also a good practice.

www.ti.com

14

Figure 12. A 12 channel lighting system using serial interface mode for dimming control

AN-2255 LM3463 Evaluation Board SNVA642A–May 2012–Revised May 2013

Copyright © 2012–2013, Texas Instruments Incorporated

Submit Documentation Feedback

Page 15

LM3463 EVALUATION BOARD

WARNING:

HIGH DC VOLTAGE

J0

J1

J11

J12

J13

J14

J15

J16

J2

J9J5J7

J4J6J8

J10

J3

CH0 CH1 CH2 CH3 CH4 CH5VRAIL

GND

LM3463 EVALUATION BOARD

WARNING:

HIGH DC VOLTAGE

J0

J1

J11

J12

J13

J14

J15

J16

J2

J9J5J7

J4J6J8

J10

J3

CH0 CH1 CH2 CH3 CH4 CH5VRAIL

GND

LM3463 EVALUATION BOARD

WARNING:

HIGH DC VOLTAGE

J0

J1

J11

J12

J13

J14

J15

J16

J2

J9J5J7

J4J6J8

J10

J3

CH0 CH1 CH2 CH3 CH4 CH5VRAIL

GND

TP33

TP35

VFB

TP33

TP35

VFB

J4 = OPEN J7 = OPEN

J5 = OPEN J8 = SHORT 2-3

J6 = OPEN J9 = OPEN

TP22

TP3

TP22

TP3

TP22

TP3

MASTER

J4 = OPEN J7 = OPEN

J5 = OPEN J8 = SHORT 2-3

J6 = OPEN J9 = OPEN

VLedFB = VCC

R2 = OPEN

R4 = OPEN

SLAVE 1

J4 = OPEN J7 = OPEN

J5 = OPEN J8 = SHORT 2-3

J6 = OPEN J9 = OPEN

VLedFB = VCC

R2 = OPEN

R4 = OPEN

SLAVE 2

LED array 1 LED array 2 LED array 3VRAIL

GND

VFB

Primary Power Supply

TP12

TP14

TP16

DIM4

DIM23

DIM01

Logic level PWM

dimming control

signals

TP18

DIM5

TP12

TP14

TP16

TP18

TP12

TP14

TP16

TP18

LM3463 EVALUATION BOARD

WARNING:

HIGH DC VOLTAGE

J0

J1

J11

J12

J13

J14

J15

J16

J2

J9J5J7

J4J6J8

J10

J3

CH0 CH1 CH2 CH3 CH4 CH5VRAIL

GND

LM3463 EVALUATION BOARD

WARNING:

HIGH DC VOLTAGE

J0

J1

J11

J12

J13

J14

J15

J16

J2

J9J5J7

J4J6J8

J10

J3

CH0 CH1 CH2 CH3 CH4 CH5VRAIL

GND

LM3463 EVALUATION BOARD

WARNING:

HIGH DC VOLTAGE

J0

J1

J11

J12

J13

J14

J15

J16

J2

J9J5J7

J4J6J8

J10

J3

CH0 CH1 CH2 CH3 CH4 CH5VRAIL

GND

TP12

TP14

TP33

TP35

VFB

TP12

TP14

TP33

TP35

VFB

J4 = OPEN J7 = OPEN

J5 = OPEN J8 = SHORT 1-2

J6 = OPEN J9 = OPEN

TP22

TP3

TP22

TP3

TP22

TP3

MASTER

J4 = OPEN J7 = SHORT 2-3

J5 = OPEN J8 = SHORT 1-2

J6 = SHORT 2-3 J9 = OPEN

VLedFB = VCC

R2 = OPEN

R4 = OPEN

SLAVE 1

J4 = OPEN J7 = SHORT 2-3

J5 = OPEN J8 = SHORT 1-2

J6 = SHORT 2-3 J9 = OPEN

VLedFB = VCC

R2 = OPEN

R4 = OPEN

SLAVE 2

LED array 1 LED array 2 LED array 3VRAIL

GND

VFB

Primary Power Supply

TP12

TP14

TP16

VDIM4

VDIM23

VDIM01

DC voltages for

dimming control

TP18

VDIM5

www.ti.com

PCB Design

Figure 13. A 12 channel lighting system using DC interface mode for dimming control

Figure 14. A 12 channel lighting system using Direct PWM mode for dimming control

SNVA642A–May 2012–Revised May 2013 AN-2255 LM3463 Evaluation Board

Submit Documentation Feedback

Copyright © 2012–2013, Texas Instruments Incorporated

15

Page 16

Typical Waveforms

16 Typical Waveforms

All curves taken at VIN= 48V with configuration in typical application for driving twelve power LEDs with six

output channels active and 200 mA output current per channel. TA= 25°C, unless otherwise specified.

Figure 15. Direct PWM Dimming Mode Figure 16. DC Interface Mode

250Hz 50% dimming duty at DIMn pin 10Hz 3V to 2V ramp at DIMn pin

www.ti.com

16

Figure 17. PWM dimming Figure 18. PWM dimming

I

delay at V

OUTn

Figure 19. I

I

OUTn

OUTn

AN-2255 LM3463 Evaluation Board SNVA642A–May 2012–Revised May 2013

rising I

DIMn

delay at V

OUTn

ch-ch delay Figure 20. I

rising I

Copyright © 2012–2013, Texas Instruments Incorporated

falling

DIMn

ch-ch delay

OUTn

falling

OUTn

Submit Documentation Feedback

Page 17

IMPORTANT NOTICE

Texas Instruments Incorporated and its subsidiaries (TI) reserve the right to make corrections, enhancements, improvements and other

changes to its semiconductor products and services per JESD46, latest issue, and to discontinue any product or service per JESD48, latest

issue. Buyers should obtain the latest relevant information before placing orders and should verify that such information is current and

complete. All semiconductor products (also referred to herein as “components”) are sold subject to TI’s terms and conditions of sale

supplied at the time of order acknowledgment.

TI warrants performance of its components to the specifications applicable at the time of sale, in accordance with the warranty in TI’s terms

and conditions of sale of semiconductor products. Testing and other quality control techniques are used to the extent TI deems necessary

to support this warranty. Except where mandated by applicable law, testing of all parameters of each component is not necessarily

performed.

TI assumes no liability for applications assistance or the design of Buyers’ products. Buyers are responsible for their products and

applications using TI components. To minimize the risks associated with Buyers’ products and applications, Buyers should provide

adequate design and operating safeguards.

TI does not warrant or represent that any license, either express or implied, is granted under any patent right, copyright, mask work right, or

other intellectual property right relating to any combination, machine, or process in which TI components or services are used. Information

published by TI regarding third-party products or services does not constitute a license to use such products or services or a warranty or

endorsement thereof. Use of such information may require a license from a third party under the patents or other intellectual property of the

third party, or a license from TI under the patents or other intellectual property of TI.

Reproduction of significant portions of TI information in TI data books or data sheets is permissible only if reproduction is without alteration

and is accompanied by all associated warranties, conditions, limitations, and notices. TI is not responsible or liable for such altered

documentation. Information of third parties may be subject to additional restrictions.

Resale of TI components or services with statements different from or beyond the parameters stated by TI for that component or service

voids all express and any implied warranties for the associated TI component or service and is an unfair and deceptive business practice.

TI is not responsible or liable for any such statements.

Buyer acknowledges and agrees that it is solely responsible for compliance with all legal, regulatory and safety-related requirements

concerning its products, and any use of TI components in its applications, notwithstanding any applications-related information or support

that may be provided by TI. Buyer represents and agrees that it has all the necessary expertise to create and implement safeguards which

anticipate dangerous consequences of failures, monitor failures and their consequences, lessen the likelihood of failures that might cause

harm and take appropriate remedial actions. Buyer will fully indemnify TI and its representatives against any damages arising out of the use

of any TI components in safety-critical applications.

In some cases, TI components may be promoted specifically to facilitate safety-related applications. With such components, TI’s goal is to

help enable customers to design and create their own end-product solutions that meet applicable functional safety standards and

requirements. Nonetheless, such components are subject to these terms.

No TI components are authorized for use in FDA Class III (or similar life-critical medical equipment) unless authorized officers of the parties

have executed a special agreement specifically governing such use.

Only those TI components which TI has specifically designated as military grade or “enhanced plastic” are designed and intended for use in

military/aerospace applications or environments. Buyer acknowledges and agrees that any military or aerospace use of TI components

which have not been so designated is solely at the Buyer's risk, and that Buyer is solely responsible for compliance with all legal and

regulatory requirements in connection with such use.

TI has specifically designated certain components as meeting ISO/TS16949 requirements, mainly for automotive use. In any case of use of

non-designated products, TI will not be responsible for any failure to meet ISO/TS16949.

Products Applications

Audio www.ti.com/audio Automotive and Transportation www.ti.com/automotive

Amplifiers amplifier.ti.com Communications and Telecom www.ti.com/communications

Data Converters dataconverter.ti.com Computers and Peripherals www.ti.com/computers

DLP® Products www.dlp.com Consumer Electronics www.ti.com/consumer-apps

DSP dsp.ti.com Energy and Lighting www.ti.com/energy

Clocks and Timers www.ti.com/clocks Industrial www.ti.com/industrial

Interface interface.ti.com Medical www.ti.com/medical

Logic logic.ti.com Security www.ti.com/security

Power Mgmt power.ti.com Space, Avionics and Defense www.ti.com/space-avionics-defense

Microcontrollers microcontroller.ti.com Video and Imaging www.ti.com/video

RFID www.ti-rfid.com

OMAP Applications Processors www.ti.com/omap TI E2E Community e2e.ti.com

Wireless Connectivity www.ti.com/wirelessconnectivity

Mailing Address: Texas Instruments, Post Office Box 655303, Dallas, Texas 75265

Copyright © 2013, Texas Instruments Incorporated

Loading...

Loading...