Page 1

AN-2061 LM3445 A19 Edison Retrofit Evaluation Board

1 Introduction

The evaluation board included in this shipment converts 85VACto 135VACinput and drives five to thirteen

series connected LED’s at the currents listed in the Evaluation Board Operating Conditions section. This is

a two-layer board using the bottom and top layer for component placement. The board is surrounded by a

larger area allowing for extra test points and connectors for ease of evaluation. The actual board size is

contained inside the larger outer area and can be cut out for the smallest size possible. The evaluation

board can be modified to adjust the LED forward current and the number of series connected LEDs. The

topology used for this evaluation board eliminates the need for passive power factor correction and results

in high efficiency and power factor with minimal component count which results in a size that can fit in a

standard A19 Edison socket. This board also operates correctly and dims smoothly using most standard

triac dimmers. Output current is regulated within ±15% of nominal from circuit to circuit and over line

voltage variation. For details on the LM3445 IC, see the LM3445 Triac Dimmable Offline LED Driver Data

Sheet (SNVS570).

A bill of materials shown in Table 2 describes the parts used on this demonstration board. A schematic

and layout have also been included along with measured performance characteristics including EMI/EMC

data. The above restrictions for the input voltage are valid only for the demonstration board as shipped

with the schematic below. for detailed information regarding the LM3445 device, see the LM3445 Triac

Dimmable Offline LED Driver Data Sheet (SNVS570). The board is currently set up to drive five to thirteen

series connected LEDs, but the evaluation board may be modified to accept more series LEDs. Refer to

the tables in this document to modify the board to accept more LEDs and/or adjust for different current

levels.

User's Guide

SNVA442C–June 2010–Revised May 2013

2 Evalution Board Operating Conditions

VIN= 85VACto 135V

5 to 13 series connected LEDs as configured with the currents listed below:

• Can drive up to 18 series LEDs (see table)

• I

• I

• I

• I

• I

All trademarks are the property of their respective owners.

= 340 mA (5 LEDs)

LED

= 300 mA (7 LEDs)

LED

= 260 mA (9 LEDs)

LED

= 230 mA (11 LEDs)

LED

= 205 mA (13 LEDs)

LED

AC

SNVA442C–June 2010–Revised May 2013 AN-2061 LM3445 A19 Edison Retrofit Evaluation Board

Submit Documentation Feedback

Copyright © 2010–2013, Texas Instruments Incorporated

1

Page 2

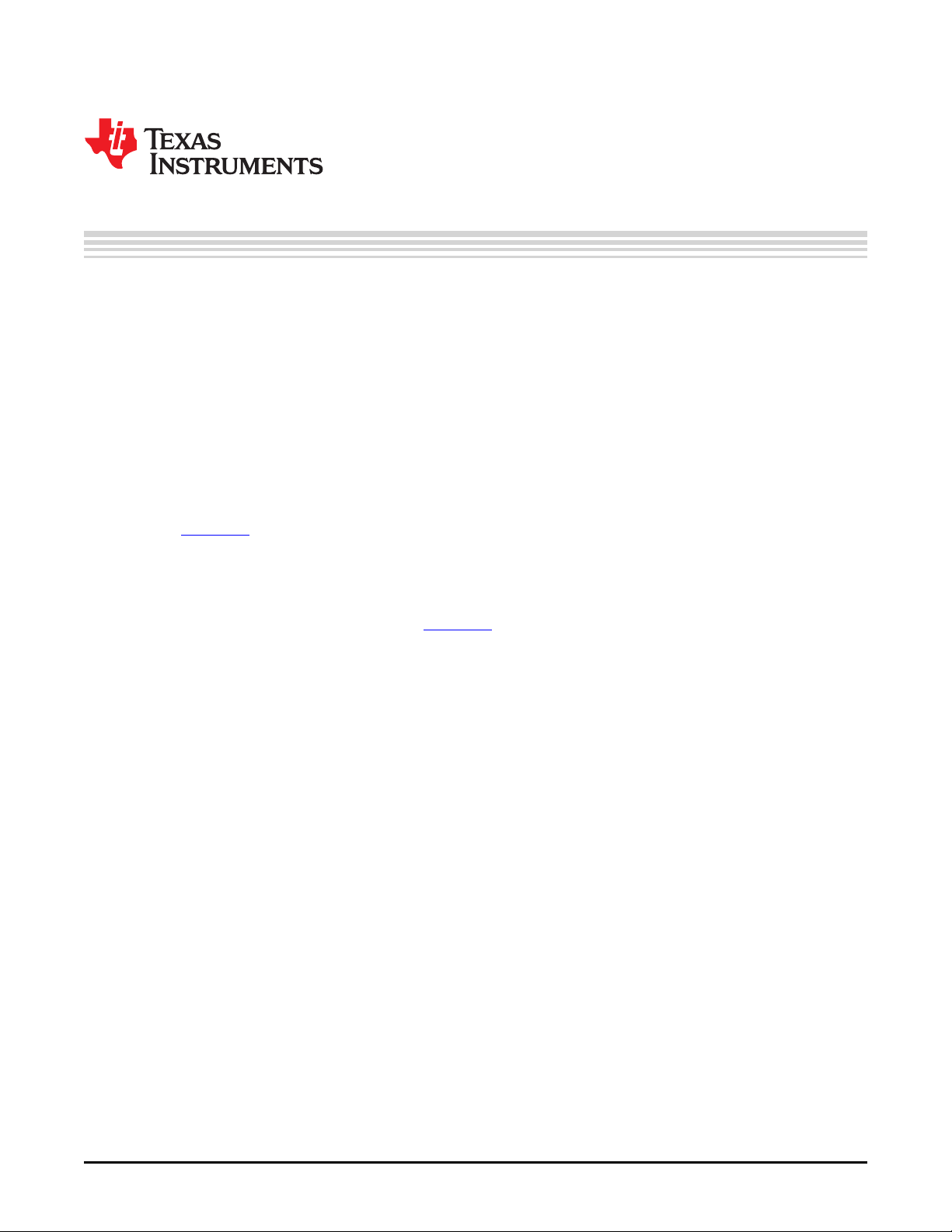

R15 C15

FLTR2

R2

R7

DIM

R9

COFF

C13

R1

R3

D7

Q1

R8

ASNS

FLTR1

DIM

COFF

FLTR2

BLDR

VCC

GND

GATE

ISNS

LM3445

1

2

3

4

5

10

9

8

7

6

V+

C8

V

CC

R22

D8

R12

R14

+

VLED+

VLED±

L1

C6

D2

V+

LINE NEUTRAL

LINE EMI FILTER

Q4

D4

C4

C3

V

CC

COFF

R16

C12

L2

C2

C

OFF

Current Source

C1

L3

C5

R4

C10

C14

RT1

F1

R6

R24

R5C9

D1

Simplified LM3445 Schematic

3 Simplified LM3445 Schematic

www.ti.com

WARNING

The LM3445 evaluation boards have no isolation or any type of

protection from shock. Caution must be taken when handling

evaluation board. Avoid touching evaluation board, and removing

any cables while evaluation board is operating. Isolating the

evaluation board rather than the oscilloscope is highly

recommended.

This LM3445 evaluation PCB is a non-isolated design. The ground

connection on the evaluation board is NOT referenced to earth

ground. If an oscilloscope ground lead is connected to the

evaluation board ground test point for analysis, and AC power is

applied, the fuse (F1) will fail open. The oscilloscope should be

powered via an isolation transformer before an oscilloscope

ground lead is connected to the evaluation board.

WARNING

2

AN-2061 LM3445 A19 Edison Retrofit Evaluation Board SNVA442C–June 2010–Revised May 2013

Copyright © 2010–2013, Texas Instruments Incorporated

Submit Documentation Feedback

Page 3

1

4

3

2

10

7

8

9

I

SNS

FLTR1

GATE

BLDR

COFF

V

CC

ASNS

DIM

5 6FLTR2 GND

www.ti.com

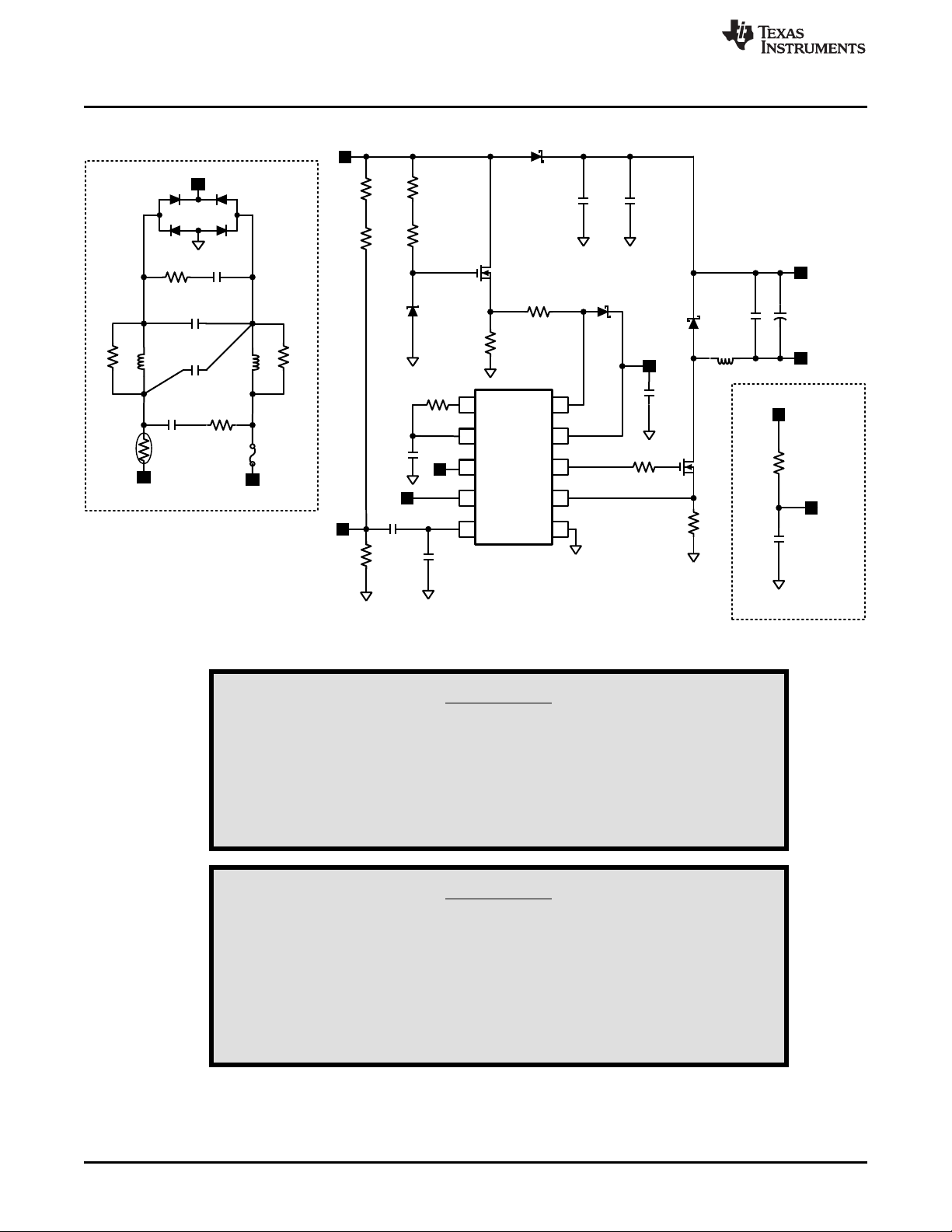

4 Pin-Out

Pin No Name Description

1 ASNS PWM output of the triac dim decoder circuit. Outputs a 0 to 4V PWM signal with a duty cycle proportional to

2 FLTR1 First filter input. The 120Hz PWM signal from ASNS is filtered to a DC signal and compared to a 1 to 3V,

3 DIM Input/output dual function dim pin. This pin can be driven with an external PWM signal to dim the LEDs. It

4 COFF OFF time setting pin. A user set current and capacitor connected from the output to this pin sets the

5 FLTR2 Second filter input. A capacitor tied to this pin filters the PWM dimming signal to supply a DC voltage to

6 GND Circuit ground connection.

7 ISNS LED current sense pin. Connect a resistor from main switching MOSFET source, ISNS to GND to set the

8 GATE Power MOSFET driver pin. This output provides the gate drive for the power switching MOSFET of the

9 V

10 BLDR Bleeder pin. Provides the input signal to the angle detect circuitry as well as a current path through a

Figure 1. 10-Pin VSSOP

Table 1. Pin Description 10 Pin VSSOP

the triac dimmer on-time.

5.85 kHz ramp to generate a higher frequency PWM signal with a duty cycle proportional to the triac

dimmer firing angle. Pull above 4.9V (typical) to tri-state DIM.

may also be used as an output signal and connected to the DIM pin of other LM3445 or LED drivers to dim

multiple LED circuits simultaneously.

constant OFF time of the switching controller.

control the LED current. Could also be used as an analog dimming input.

maximum LED current.

buck controller.

Input voltage pin. This pin provides the power for the internal control circuitry and gate driver.

CC

switched 230Ω resistor to ensure proper firing of the triac dimmer.

Pin-Out

SNVA442C–June 2010–Revised May 2013 AN-2061 LM3445 A19 Edison Retrofit Evaluation Board

Submit Documentation Feedback

Copyright © 2010–2013, Texas Instruments Incorporated

3

Page 4

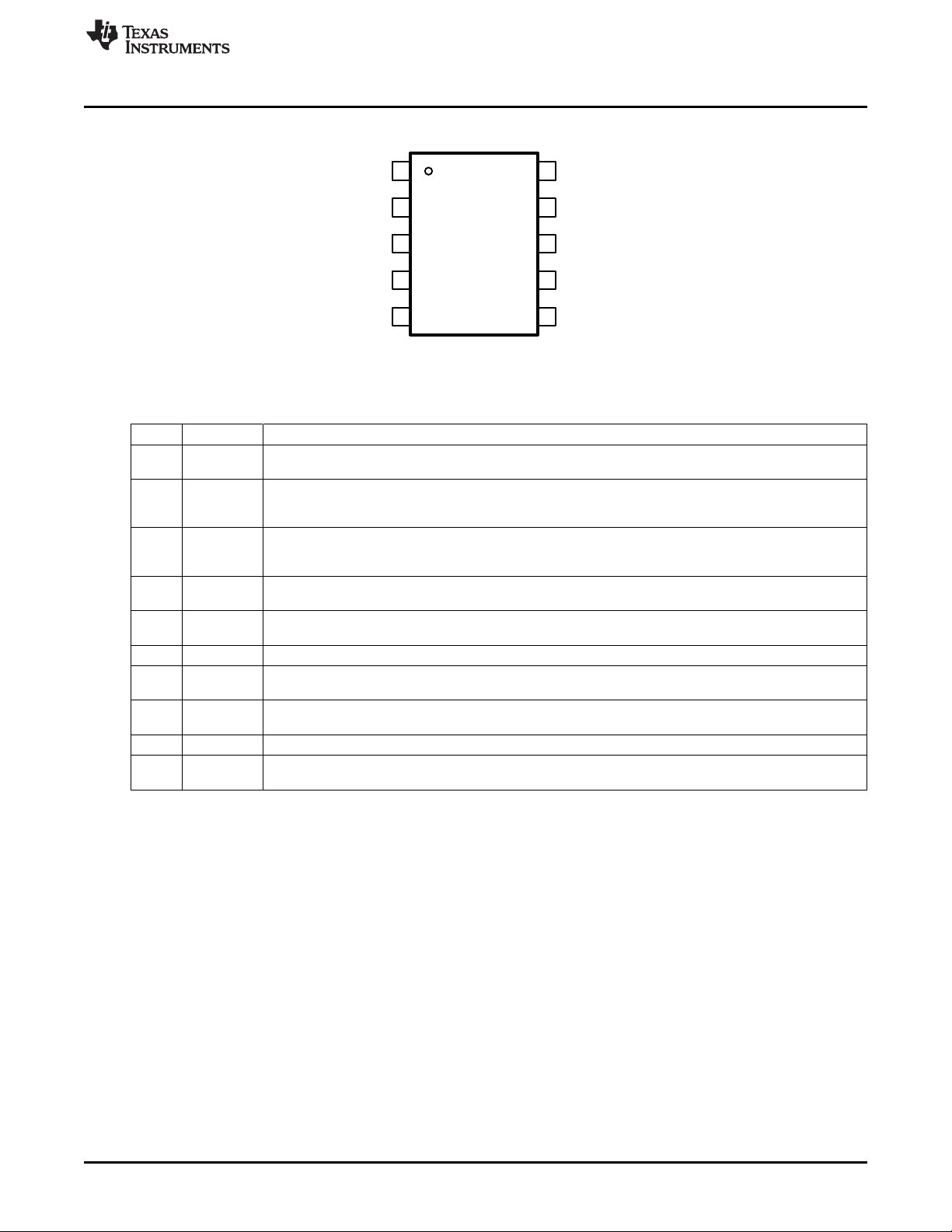

LM3445 Evaluation Board Schematic

5 LM3445 Evaluation Board Schematic

www.ti.com

4

AN-2061 LM3445 A19 Edison Retrofit Evaluation Board SNVA442C–June 2010–Revised May 2013

Copyright © 2010–2013, Texas Instruments Incorporated

Submit Documentation Feedback

Page 5

www.ti.com

Bill of Materials (BOM) LM3445 Evaluation Board

6 Bill of Materials (BOM) LM3445 Evaluation Board

Table 2. Bill of Materials (BOM)

REF DES Description MFG MFG Part Number

U1 IC DRIVER LED W/TRIAC DIM 10VSSOP Texas Instruments LM3445

C1, C10 Ceramic, 47000pF, 500V, X7R, 1210 Johanson Dielectrics 501S41W473KV4E

C2 CAP FILM MKP .0047µF 310VAC X2 Vishay/BC Components BFC233820472

C3 CAP 470µF 50V ELECT PW RADIAL Nichicon UPW1H471MHD

C4/RBLDR

C13, C15 Ceramic, 0.1µF, 16V, X7R, 0603 MuRata GRM188R71C104KA01D

J5, J10 CONN HEADER .312 VERT 2POS TIN Tyco Electronics 1-1318301-2

L1, L2 INDUCTOR 3900µH .12A RADIAL J.W. Miller/Bourns RL875S-392K-RC

R1, R3 RES 200kΩ, 0.25W, 1%, 1206 Vishay-Dale CRCW1206200kFKEA

R2, R7 RES 274kΩ, 0.25W, 1%, 1206 Vishay-Dale CRCW1206274kFKEA

R6, R24 RES 30.1kΩ, 0.25W, 1%, 1206 Vishay-Dale CRCW120630k1FKEA

TP1, TP2, TP3, TP4 Terminal, Turret, TH, Double Keystone Electronics 1502-2

(1)

C4/RBLDR is a dual purpose pad which is unpopulated by default. A ceramic capacitor (C4) may be used here if extra high frequency

bypassing is desired across the LED load. Alternatively a bleeder resistor (RBLDR) in the range of 10kΩ to 100kΩ may be placed here to

quickly discharge C3 and prevent prolonged LED glow due to the energy stored in C3.

(1)

DNP

C5 Ceramic, .33µF, 250V, X7R, 1812 TDK Corporation C4532X7R2E334K

C6 CAP .10µF 305VAC EMI SUPPRESSION EPCOS B32921C3104M

C8 Ceramic, 47µF, X5R, 16V, 1210 MuRata GRM32ER61C476ME15L

C9 Ceramic, .1µF, 250V, X7R, 1210 Taiyo Yuden QMK325B7104KN-T

C12 Ceramic, 470pF, 50V, X7R, 0603 MuRata GRM188R71H471KA01D

C14 Ceramic, 0.47µF, 16V, X7R, 0603 MuRata GRM188R71C474KA88D

D1 DIODE SCHOTTKY 1A 200V PWRDI 123 Diodes Inc. DFLS1200-7

D2 Bridge Rectifier, Vr = 400V, Io = 0.8A, Vf = 1V Diodes Inc. HD04-T

D4 DIODE FAST 1A 300V SMA Fairchild Semi conductor ES1F

D7 DIODE ZENER 15V 500MW SOD-123 Fairchild Semi conductor MMSZ5245B

D8 DIODE SCHOTTKY 1A 200V PWRDI 123 Diodes Inc. DFLS1200-7

F1 FUSE 1A 125V FAST Cooper/Bussman 6125FA1A

L3 820µH, Shielded Drum Core Coilcraft Inc. MSS1038-824KL

M1 JUMPER WIRE 0.3" J6 TO J1 3M 923345-03-C

M2 JUMPER WIRE 0.3" J7 to J4 3M 923345-03-C

M3 JUMPER WIRE 0.3" J2 TO J8 3M 923345-03-C

M4 JUMPER WIRE 0.3" J3 TO J9 3M 923345-03-C

Q1 MOSFET N-CH 240V 260MA SOT-89 Infineon Technologies BSS87 L6327

Q2 MOSFET N-CH 250V 4.4A DPAK Fairchild Semi conductor FDD6N25TM

R4 RES 430Ω, 1/2W, 5%, 2010 Vishay-Dale CRCW2010430RJNEF

R5 RES 430Ω, 1/3W, 5%, 1210 Vishay-Dale CRCW1210430RJNEA

R8 RES 49.9kΩ, 0.1W, 1%, 0603 Vishay-Dale CRCW060349K9FKEA

R9 RES 48.7kΩ, 0.1W, 1%, 0603 Vishay-Dale CRCW060348K7FKEA

R10 DNP

R12 RES 4.7Ω, 0.1W, 5%, 0603 Vishay-Dale CRCW06034R70JNEA

R14 RES 1.54Ω, 1/4W, 1%, 1206 Vishay-Dale CRCW12061R54FNEA

R15 RES 3.16kΩ, 0.1w, 1%, 0603 Vishay-Dale CRCW06033K16FKEA

R16 RES 255kΩ, 0.1W, 1%, 0603 Vishay-Dale CRCW0603255KFKEA

R22 RES 40.2Ω, 0.125W, 1%, 0805 Vishay-Dale CRCW080540R2FKEA

RT1 CURRENT LIMITOR INRUSH 60Ω 20% Cantherm MF72-060D5

SNVA442C–June 2010–Revised May 2013 AN-2061 LM3445 A19 Edison Retrofit Evaluation Board

Submit Documentation Feedback

Copyright © 2010–2013, Texas Instruments Incorporated

5

Page 6

Output Current versus Number of LEDs for Various Modifications

7 Output Current versus Number of LEDs for Various Modifications

www.ti.com

# of LEDs Original Circuit Modification A

Output Current (mA) Output Current (mA) Output Current (mA) Output Current (mA)

(1)

Modification B

(2)

2 520

3 500

4 475

5 340 248 265 455

6 315 235 250 432

7 300 222 237 412

8 275 210 224

9 260 200 212

10 245 190 200

11 230 180 190

12 215 170 180

13 205 164 170

(4)

14

(4)

15

(4)

16

(4)

17

(4)

18

(1)

Modification A: R14 = 2.37Ω, R16 = 150kΩ, C3 = 330µF, 63V.

(2)

Modification B: R14 = 2.2Ω, R16 = 165kΩ.

(3)

Modification C: R14 = 1.2Ω, R16 = 137kΩ, L3 = 470µH, C3 = 1000µF, 25V.

(4)

For all applications using greater than 13 LEDs a 330µF, 63V output capacitor (C3) was used.

196 156 162

190 150 155

183 142 148

175 135 142

170 130 137

Modification C

(3)

6

AN-2061 LM3445 A19 Edison Retrofit Evaluation Board SNVA442C–June 2010–Revised May 2013

Copyright © 2010–2013, Texas Instruments Incorporated

Submit Documentation Feedback

Page 7

LINE VOLTAGE (VAC)

EFFICIENCY (%)

90

85

80

75

70

80 90 100 110 120 130 140

18 LEDs @ 130 mA

LINE VOLTAGE (VAC)

POWER FACTOR

0.95

0.90

0.85

0.80

0.75

80 90 100 110 120 130 140

18 LEDs @ 130 mA

LINE VOLTAGE (VAC)

EFFICIENCY

(%)

90

85

80

75

70

80 90 100 110 120 130 140

9 LEDs @ 260 mA

LINE VOLTAGE (VAC)

POWER FACTOR

0.95

0.90

0.85

0.80

0.75

80 90 100 110 120 130 140

9 LEDs @ 260 mA

www.ti.com

8 Typical Performance Characteristics

Figure 2. Efficiency vs. Line Voltage Figure 3. Power Factor vs. Line Voltage

Original Circuit Original Circuit

Typical Performance Characteristics

SNVA442C–June 2010–Revised May 2013 AN-2061 LM3445 A19 Edison Retrofit Evaluation Board

Submit Documentation Feedback

Figure 4. Efficiency vs. Line Voltage Figure 5. Power Factor vs. Line Voltage

Modification A Modification A

7

Copyright © 2010–2013, Texas Instruments Incorporated

Page 8

LINE VOLTAGE (VAC)

EFFICIENCY

(%)

90

85

80

75

70

80 90 100 110 120 130 140

13 LEDs @ 170 mA

LINE VOLTAGE (VAC)

POWER FACTOR

0.95

0.90

0.85

0.80

0.75

80 90 100 110 120 130 140

13 LEDs @ 170 mA

Typical Performance Characteristics

Figure 6. Efficiency vs. Line Voltage Figure 7. Power Factor vs. Line Voltage

Modification B Modification B

www.ti.com

8

AN-2061 LM3445 A19 Edison Retrofit Evaluation Board SNVA442C–June 2010–Revised May 2013

Copyright © 2010–2013, Texas Instruments Incorporated

Submit Documentation Feedback

Page 9

www.ti.com

9 PCB Layout

PCB Layout

Figure 8. Top Layer

Figure 9. Bottom Layer

WARNING

The LM3445 evaluation boards have no isolation or any type of

protection from shock. Caution must be taken when handling

evaluation board. Avoid touching evaluation board, and removing

any cables while evaluation board is operating. Isolating the

evaluation board rather than the oscilloscope is highly

recommended.

SNVA442C–June 2010–Revised May 2013 AN-2061 LM3445 A19 Edison Retrofit Evaluation Board

Submit Documentation Feedback

Copyright © 2010–2013, Texas Instruments Incorporated

9

Page 10

EMI/EMC Information

10 EMI/EMC Information

www.ti.com

Figure 10. Radiated EMI

10

Figure 11. Conducted EMC. Line = Blue, Neutral = Black

Frequency Amplitude Limit Delta Amplitude Average Limit Delta

Neutral 154 kHz 57 66 -9 47 56 -9

Line 1.1 MHz 31 46 -15

AN-2061 LM3445 A19 Edison Retrofit Evaluation Board SNVA442C–June 2010–Revised May 2013

Quasi-Peak Quasi-Peak Quasi-Peak Average Average

Copyright © 2010–2013, Texas Instruments Incorporated

Submit Documentation Feedback

Page 11

IMPORTANT NOTICE

Texas Instruments Incorporated and its subsidiaries (TI) reserve the right to make corrections, enhancements, improvements and other

changes to its semiconductor products and services per JESD46, latest issue, and to discontinue any product or service per JESD48, latest

issue. Buyers should obtain the latest relevant information before placing orders and should verify that such information is current and

complete. All semiconductor products (also referred to herein as “components”) are sold subject to TI’s terms and conditions of sale

supplied at the time of order acknowledgment.

TI warrants performance of its components to the specifications applicable at the time of sale, in accordance with the warranty in TI’s terms

and conditions of sale of semiconductor products. Testing and other quality control techniques are used to the extent TI deems necessary

to support this warranty. Except where mandated by applicable law, testing of all parameters of each component is not necessarily

performed.

TI assumes no liability for applications assistance or the design of Buyers’ products. Buyers are responsible for their products and

applications using TI components. To minimize the risks associated with Buyers’ products and applications, Buyers should provide

adequate design and operating safeguards.

TI does not warrant or represent that any license, either express or implied, is granted under any patent right, copyright, mask work right, or

other intellectual property right relating to any combination, machine, or process in which TI components or services are used. Information

published by TI regarding third-party products or services does not constitute a license to use such products or services or a warranty or

endorsement thereof. Use of such information may require a license from a third party under the patents or other intellectual property of the

third party, or a license from TI under the patents or other intellectual property of TI.

Reproduction of significant portions of TI information in TI data books or data sheets is permissible only if reproduction is without alteration

and is accompanied by all associated warranties, conditions, limitations, and notices. TI is not responsible or liable for such altered

documentation. Information of third parties may be subject to additional restrictions.

Resale of TI components or services with statements different from or beyond the parameters stated by TI for that component or service

voids all express and any implied warranties for the associated TI component or service and is an unfair and deceptive business practice.

TI is not responsible or liable for any such statements.

Buyer acknowledges and agrees that it is solely responsible for compliance with all legal, regulatory and safety-related requirements

concerning its products, and any use of TI components in its applications, notwithstanding any applications-related information or support

that may be provided by TI. Buyer represents and agrees that it has all the necessary expertise to create and implement safeguards which

anticipate dangerous consequences of failures, monitor failures and their consequences, lessen the likelihood of failures that might cause

harm and take appropriate remedial actions. Buyer will fully indemnify TI and its representatives against any damages arising out of the use

of any TI components in safety-critical applications.

In some cases, TI components may be promoted specifically to facilitate safety-related applications. With such components, TI’s goal is to

help enable customers to design and create their own end-product solutions that meet applicable functional safety standards and

requirements. Nonetheless, such components are subject to these terms.

No TI components are authorized for use in FDA Class III (or similar life-critical medical equipment) unless authorized officers of the parties

have executed a special agreement specifically governing such use.

Only those TI components which TI has specifically designated as military grade or “enhanced plastic” are designed and intended for use in

military/aerospace applications or environments. Buyer acknowledges and agrees that any military or aerospace use of TI components

which have not been so designated is solely at the Buyer's risk, and that Buyer is solely responsible for compliance with all legal and

regulatory requirements in connection with such use.

TI has specifically designated certain components as meeting ISO/TS16949 requirements, mainly for automotive use. In any case of use of

non-designated products, TI will not be responsible for any failure to meet ISO/TS16949.

Products Applications

Audio www.ti.com/audio Automotive and Transportation www.ti.com/automotive

Amplifiers amplifier.ti.com Communications and Telecom www.ti.com/communications

Data Converters dataconverter.ti.com Computers and Peripherals www.ti.com/computers

DLP® Products www.dlp.com Consumer Electronics www.ti.com/consumer-apps

DSP dsp.ti.com Energy and Lighting www.ti.com/energy

Clocks and Timers www.ti.com/clocks Industrial www.ti.com/industrial

Interface interface.ti.com Medical www.ti.com/medical

Logic logic.ti.com Security www.ti.com/security

Power Mgmt power.ti.com Space, Avionics and Defense www.ti.com/space-avionics-defense

Microcontrollers microcontroller.ti.com Video and Imaging www.ti.com/video

RFID www.ti-rfid.com

OMAP Applications Processors www.ti.com/omap TI E2E Community e2e.ti.com

Wireless Connectivity www.ti.com/wirelessconnectivity

Mailing Address: Texas Instruments, Post Office Box 655303, Dallas, Texas 75265

Copyright © 2013, Texas Instruments Incorporated

Loading...

Loading...