Page 1

1 Introduction

The LM3434 is an adaptive constant on-time DC/DC buck constant current controller designed to drive a

high brightness LEDs (HB LED) at high forward currents. It is a true current source that provides a

constant current with constant ripple current regardless of the LED forward voltage drop. The board can

accept an input voltage ranging from -9V to -30V with respect to GND. The output configuration allows the

anodes of multiple LEDs to be tied directly to the ground referenced chassis for maximum heat sink

efficacy when a negative input voltage is used.

2 LM3434 Board Description

The evaluation board is designed to provide a constant current in the range of 4A to 20A. The LM3434

requires two input voltages for operation. A positive voltage with respect to GND is required for the bias

and control circuitry and a negative voltage with respect to GND is required for the main power input. This

allows for the capability of using common anode LEDs so that the anodes can be tied to the ground

referenced chassis. The evaluation board only requires one input voltage of -9V to -30V with respect to

GND. The positive voltage is supplied by the LM5002 circuit. The LM5002 circuit also provides a UVLO

function to remove the possibility of the LM3434 from drawing high currents at low input voltages during

startup. Initially the output current is set at the minimum of approximately 4A with the POT P1 fully

counter-clockwise. To set the desired current level a short may be connected between LED+ and LED-,

then use a current probe and turn the POT clockwise until the desired current is reached. The current may

be adjusted with P1 up to 18A. 20A output may be achieved either by bypassing P1 and applying an

analog voltage directly to ADJ or by adjusting the values of R1 and/or R2 to get higher than 1.5V with P1

fully clockwise. PWM dimming FETs are included on-board for testing when the LED can be connected

directly next to the board. A shutdown test post on J2, ENA, is included so that startup and shutdown

functions can be tested using an external voltage.

User's Guide

SNVA431B–March 2010–Revised May 2013

AN-2041 LM3434 20A Evaluation Board

3 Setting the LED Current

The LM3434 evaluation board is designed so that the LED current can be set in multiple ways. There is a

shunt on J2 initially connecting the ADJ pin to the POT allowing the current to be adjusted using the POT

P1. This POT will apply a voltage to the ADJ pin between 0.3V and 1.5V with respect to GND to adjust the

voltage across the sense resistor (R

positive with respect to GND can then be applied to the ADJ test point on the board. A 5MΩ resistor (two

10MΩ resistors in parallel) comes mounted on the board so using the V

the current can be set using the following equation:

I

= V

LED

SENSE/RSENSE

Alternatively the shunt can be removed and the ADJ test point can be connected to the VINX test point to

fix V

All trademarks are the property of their respective owners.

SNVA431B–March 2010–Revised May 2013 AN-2041 LM3434 20A Evaluation Board

Submit Documentation Feedback

SENSE

at 60mV.

Copyright © 2010–2013, Texas Instruments Incorporated

) R15. The shunt may also be removed and an external voltage

SENSE

SENSE

vs. V

graph in Section 7

ADJ

(1)

1

Page 2

Life

ACTUAL

= Life

RATED

X 2

T

CORE

- T

ACTUAL

7

( )

I

RMS

=

V

LED

(|VEE|-V

LED

)

|VEE|

I

LED

PWM Dimming

4 PWM Dimming

The LM3434 is capable if high speed PWM dimming in excess of 40kHz. Dimming is accomplished by

shorting across the LED with a FET(s). Dimming FETs are included on the evaluation board for testing

LEDs placed close to the board. The FETs on the evaluation board should be removed if using dimming

FETs remotely placed close to the LED (recommended). If the FETs cannot be placed directly next to the

LED then a snubber across the FETs may be required to protect the FETs and the LM3434 from v=Ldi/dt

voltage transients induced by the fast current changes in the line inductance leading to the LED. This will

slow the edges and limit PWM dimming capabilities at high frequencies.

To use the dimming function apply square wave to the PWM test point on the board that has a positive

voltage with respect to GND. When this pin is pulled high the dimming FET is enabled and the LED turns

off. When it is pulled low the dimming FET is turned off and the LED turns on. A scope plot of PWM

dimming is included in Section 7 showing 30kHz dimming at 50% duty cycle.

5 High Current Operation and Component Lifetime

When driving high current LEDs, particularly when PWM dimming, component lifetime may become a

factor. In these cases the input ripple current that the input capacitors are required to withstand can

become large. At lower currents long life ceramic capacitors may be able to handle this ripple current

without a problem. At higher currents more input capacitance may be required. To remain cost effective

this may require putting one or more aluminum electrolytic capacitors in parallel with the ceramic input

capacitors. Since the operational lifetime of LEDs is very long (up to 50,000 hours) the longevity of an

aluminum electrolytic capacitor can become the main factor in the overall system lifetime. The first

consideration for selecting the input capacitors is the RMS ripple current they will be required to handle.

This current is given by the following equation:

www.ti.com

The parallel combination of the ceramic and aluminum electrolytic input capacitors must be able to handle

this ripple current. The aluminum electrolytic in particular should be able to handle the ripple current

without a significant rise in core temperature. A good rule of thumb is that if the case temperature of the

capacitor is 5°C above the ambient board temperature then the capacitor is not capable of sustaining the

ripple current for its full rated lifetime and a more robust or lower ESR capacitor should be selected.

The other main considerations for aluminum electrolytic capacitor lifetime are the rated lifetime and the

ambient operating temperature. An aluminum electrolytic capacitor comes with a lifetime rating at a given

core temperature, such as 5000 hours at 105°C. As dictated by physics the capacitor lifetime should

double for each 7°C below this temperature the capacitor operates at and should halve for each 7°C

above this temperature the capacitor operates at. A good quality aluminum electrolytic capacitor will also

have a core temperature of approximately 3°C to 5°C above the ambient temperature at rated RMS

operating current. So as an example, a capacitor rated for 5,000 hours at 105°C that is operating in an

ambient environment of 85°C will have a core temperature of approximately 90°C at full rated RMS

operating current. In this case the expected operating lifetime of the capacitor will be approximately just

over 20,000 hours. The actual lifetime (Life

Where Life

is the rated lifetime at the rated core temperature T

RATED

) can be found using the equation:

ACTUAL

CORE

.

For example: If the ambient temperature is 85°C the core temperature is 85°C + 5°C = 90°C. (105°C 90°C)/7°C = 2.143. 2^2.413 = 4.417. So the expected lifetime is 5,000 × 4.417 = 22,085 hours. Long life

capacitors are recommended for LED applications and are available with ratings of up to 20,000 hours or

more at 105°C.

(2)

(3)

2

AN-2041 LM3434 20A Evaluation Board SNVA431B–March 2010–Revised May 2013

Copyright © 2010–2013, Texas Instruments Incorporated

Submit Documentation Feedback

Page 3

www.ti.com

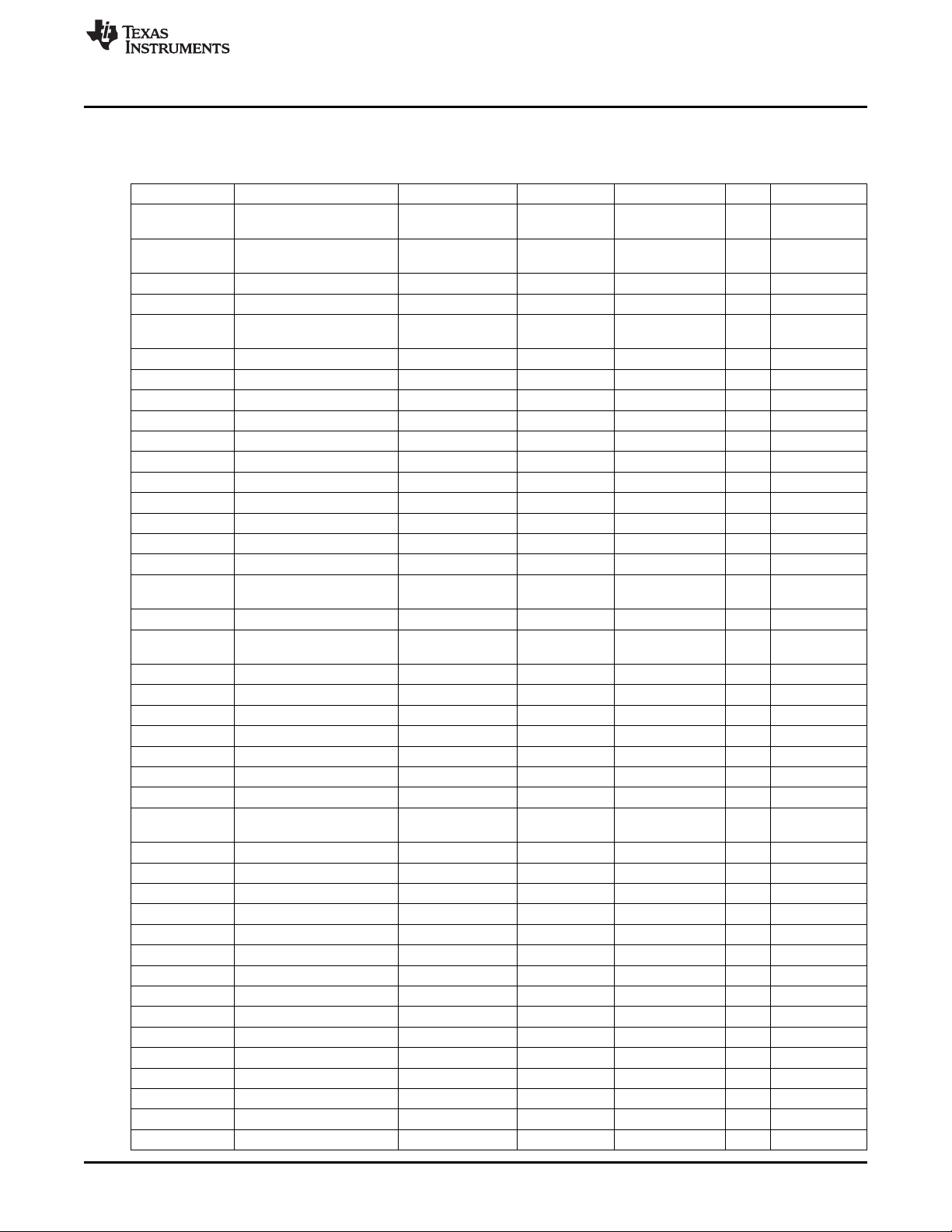

6 Bill of Materials

ID Part Number Type Size Parameters Qty Vendor

U1 LM3434 LED Driver WQFN-24 1 Texas

U2 LM5002 Boost Regulator SOIC-8 1 Texas

C1 C0805C331J5GACTU Capacitor 0805 330pF, 50V 1 Kemet

C2 GRM31CR60J476KE19L Capacitor 1206 47µF, 6.3V 1 Murata

C3 EKY-350ELL151MHB5D Capacitor MULTICAP 150µF, 35V 1 United Chemi-

C4, C5, C6 GRM32ER6YA106KA12 Capacitor 1210 10µF, 35V 2 Murata

C7 C0805C104J5RACTU Capacitor 0805 0.1µF, 50V 1 Kemet

C8, C13 HMK212BJ103KG-T Capacitor 0805 10nF, 100V 2 Taiyo Yuden

C9 OPEN 0805

C10, C11 GRM21BC81E475MA12 Capacitor 0805 4.7µF, 25V 2 Murata

C12 0805YD105KAT2A Capacitor 0805 1µF, 16V 1 AVX

C14 B37941K9474K60 Capacitor 0805 0.47µF, 16V 1 EPCOS Inc .

C15 GRM21BF51E225ZA01L Capacitor 0805 2.2µF, 25V 1 Murata

C17 OPEN 0805

C18 08055C104JAT2A Capacitor 0805 0.1µF, 50V 1 AVX

D1, D2 MBR0540 Diode SOD-123 40V, 500mA 2 Fairchild

D3 MBRS240LT3 Diode SMB 40V, 2A 1 ON

D4 OPEN SMB

J2 B8B-EH-A(LF)(SN) Connector 1 JST Sales

J1 1761582001 Connector 1 Weidmuller

Jled 87438-0843 Connector 1 Molex

L1 LPS3008-104ML Inductor 3008 100µH, 150mA 1 Coilcraft

L2 SER2915H-103KL Inductor SER2900 10µH, 21.5A 1 Coilcraft

L3, L4, L5, L6 MPZ2012S300A Ferrite Bead 0805 30Ω @ 100MHz 4 TDK

L7 MPZ2012S101A Ferrite Bead 0805 100Ω @ 100MHz 1 TDK

P1 3352T-1-103LF Potentiometer BOURNS2 10kΩ 1 Bourns

Q1, Q2, Q3, Q4, Si7790DP FET PowerPAK 40V, 6mΩ 2 Vishay-Siliconix

Q5, Q6

Q7 MMDT3906-7-F Dual PNP SOT363_N 1 Diodes Inc.

Q8 ZXTN25040DFHTA NPN SOT-23B 1 Zetex

Q9 ZXTP25040DFHTA PNP SOT-23B 1 Zetex

R1 ERJ-6ENF2942V Resistor 0805 29.4kΩ 1 Panasonic

R2 ERJ-6ENF2491V Resistor 0805 2.49kΩ 1 Panasonic

R3, R30, R31 ERJ-6ENF1002V Resistor 0805 10kΩ 3 Panasonic

R4 ERJ-6GEYJ393V Resistor 0805 39kΩ 1 Panasonic

R5 ERJ-6GEYJ101V Resistor 0805 100Ω 1 Panasonic

R7 OPEN

R14 ERJ-6ENF49R9V Resistor 0805 49.9Ω 1 Panasonic

R8 ERJ-6ENF2002V Resistor 0805 20kΩ 1 Panasonic

R10 ERJ-6ENF4991V Resistor 0805 4.99kΩ 1 Panasonic

R11, R12 ERJ-6ENF6192V Resistor 0805 61.9kΩ 2 Panasonic

R13 ERJ-6GEYJ103V Resistor 0805 10kΩ 1 Panasonic

R15a, R15b WSL25125R0100FEA Resistor CR6332-2512 0.01Ω 2 Vishay

Bill of Materials

Table 1. Bill of Materials

Instruments

Instruments

con

Semiconductor

America, Inc.

SNVA431B–March 2010–Revised May 2013 AN-2041 LM3434 20A Evaluation Board

Submit Documentation Feedback

Copyright © 2010–2013, Texas Instruments Incorporated

3

Page 4

Bill of Materials

R16, R17, R18, ERJ-6GEYJ2R7V Resistor 0805 2.7Ω 6 Panasonic

R19, R20, R21

LED+, LED- 1502-2 Test Post TP 1502 0.109" 2 Keystone

ADJ, PWM, 1593-2 Test Post TP 1593 0.084" 3 Keystone

www.ti.com

Table 1. Bill of Materials (continued)

ID Part Number Type Size Parameters Qty Vendor

R22 ERJ-6GEYJ100V Resistor 0805 10Ω 1 Panasonic

R25 ERJ-6ENF7502V Resistor 0805 75kΩ 1 Panasonic

R26 OPEN 0805

VINX

4

AN-2041 LM3434 20A Evaluation Board SNVA431B–March 2010–Revised May 2013

Copyright © 2010–2013, Texas Instruments Incorporated

Submit Documentation Feedback

Page 5

80

82

84

86

88

90

92

94

96

1 2 3 4 5 6 7

V

LED

(V)

2A

4A

6A

8A

EFFICIENCY (%)

0

10

20

30

40

50

60

70

80

90

100

0.2 0.4 0.6 0.8 1 1.2 1.4 1.6

ADJ VOLTAGE (V)

V

SENSE

(mV)

84

86

88

90

92

94

96

1 2 3 4 5 6 7

V

LED

(V)

2A

4A

6A

8A

EFFICIENCY (%)

87

88

89

90

91

92

93

94

95

96

97

1 2 3 4 5 6 7

2A

4A

6A

8A

V

LED

(V)

EFFICIENCY (%)

www.ti.com

7 Typical Performance Characteristics

Figure 1. Efficiency vs. LED Forward Voltage Figure 2. Efficiency vs. LED Forward Voltage

(V

- VEE= 9V) (V

CGND

Typical Performance Characteristics

- VEE= 12V)

CGND

Figure 3. Efficiency vs. LED Forward Voltage Figure 4. V

SNVA431B–March 2010–Revised May 2013 AN-2041 LM3434 20A Evaluation Board

Submit Documentation Feedback

ILED = 6A nominal, VIN = 3.3V, VEE = -12V Top trace: DIM input, 2V/div, DC Bottom trace: ILED, 2A/div, DC T = 10µs/div

vs. V

(V

CGND

- VEE= 14V)

SENSE

Figure 5. 30kHz PWM Dimming Waveform Showing Inductor Ripple Current

Copyright © 2010–2013, Texas Instruments Incorporated

ADJ

5

Page 6

Layout

8 Layout

www.ti.com

Figure 6. Top Layer and Top Overlay

Figure 7. Upper Middle Layer

6

AN-2041 LM3434 20A Evaluation Board SNVA431B–March 2010–Revised May 2013

Copyright © 2010–2013, Texas Instruments Incorporated

Submit Documentation Feedback

Page 7

www.ti.com

Layout

Figure 8. Lower Middle Layer

Figure 9. Bottom Layer and Bottom Overlay

SNVA431B–March 2010–Revised May 2013 AN-2041 LM3434 20A Evaluation Board

Submit Documentation Feedback

Copyright © 2010–2013, Texas Instruments Incorporated

7

Page 8

Evaluation Board Schematic

9 Evaluation Board Schematic

www.ti.com

Figure 10. LM3434 Evaluation Board Schematic

8

AN-2041 LM3434 20A Evaluation Board SNVA431B–March 2010–Revised May 2013

Copyright © 2010–2013, Texas Instruments Incorporated

Submit Documentation Feedback

Page 9

IMPORTANT NOTICE

Texas Instruments Incorporated and its subsidiaries (TI) reserve the right to make corrections, enhancements, improvements and other

changes to its semiconductor products and services per JESD46, latest issue, and to discontinue any product or service per JESD48, latest

issue. Buyers should obtain the latest relevant information before placing orders and should verify that such information is current and

complete. All semiconductor products (also referred to herein as “components”) are sold subject to TI’s terms and conditions of sale

supplied at the time of order acknowledgment.

TI warrants performance of its components to the specifications applicable at the time of sale, in accordance with the warranty in TI’s terms

and conditions of sale of semiconductor products. Testing and other quality control techniques are used to the extent TI deems necessary

to support this warranty. Except where mandated by applicable law, testing of all parameters of each component is not necessarily

performed.

TI assumes no liability for applications assistance or the design of Buyers’ products. Buyers are responsible for their products and

applications using TI components. To minimize the risks associated with Buyers’ products and applications, Buyers should provide

adequate design and operating safeguards.

TI does not warrant or represent that any license, either express or implied, is granted under any patent right, copyright, mask work right, or

other intellectual property right relating to any combination, machine, or process in which TI components or services are used. Information

published by TI regarding third-party products or services does not constitute a license to use such products or services or a warranty or

endorsement thereof. Use of such information may require a license from a third party under the patents or other intellectual property of the

third party, or a license from TI under the patents or other intellectual property of TI.

Reproduction of significant portions of TI information in TI data books or data sheets is permissible only if reproduction is without alteration

and is accompanied by all associated warranties, conditions, limitations, and notices. TI is not responsible or liable for such altered

documentation. Information of third parties may be subject to additional restrictions.

Resale of TI components or services with statements different from or beyond the parameters stated by TI for that component or service

voids all express and any implied warranties for the associated TI component or service and is an unfair and deceptive business practice.

TI is not responsible or liable for any such statements.

Buyer acknowledges and agrees that it is solely responsible for compliance with all legal, regulatory and safety-related requirements

concerning its products, and any use of TI components in its applications, notwithstanding any applications-related information or support

that may be provided by TI. Buyer represents and agrees that it has all the necessary expertise to create and implement safeguards which

anticipate dangerous consequences of failures, monitor failures and their consequences, lessen the likelihood of failures that might cause

harm and take appropriate remedial actions. Buyer will fully indemnify TI and its representatives against any damages arising out of the use

of any TI components in safety-critical applications.

In some cases, TI components may be promoted specifically to facilitate safety-related applications. With such components, TI’s goal is to

help enable customers to design and create their own end-product solutions that meet applicable functional safety standards and

requirements. Nonetheless, such components are subject to these terms.

No TI components are authorized for use in FDA Class III (or similar life-critical medical equipment) unless authorized officers of the parties

have executed a special agreement specifically governing such use.

Only those TI components which TI has specifically designated as military grade or “enhanced plastic” are designed and intended for use in

military/aerospace applications or environments. Buyer acknowledges and agrees that any military or aerospace use of TI components

which have not been so designated is solely at the Buyer's risk, and that Buyer is solely responsible for compliance with all legal and

regulatory requirements in connection with such use.

TI has specifically designated certain components as meeting ISO/TS16949 requirements, mainly for automotive use. In any case of use of

non-designated products, TI will not be responsible for any failure to meet ISO/TS16949.

Products Applications

Audio www.ti.com/audio Automotive and Transportation www.ti.com/automotive

Amplifiers amplifier.ti.com Communications and Telecom www.ti.com/communications

Data Converters dataconverter.ti.com Computers and Peripherals www.ti.com/computers

DLP® Products www.dlp.com Consumer Electronics www.ti.com/consumer-apps

DSP dsp.ti.com Energy and Lighting www.ti.com/energy

Clocks and Timers www.ti.com/clocks Industrial www.ti.com/industrial

Interface interface.ti.com Medical www.ti.com/medical

Logic logic.ti.com Security www.ti.com/security

Power Mgmt power.ti.com Space, Avionics and Defense www.ti.com/space-avionics-defense

Microcontrollers microcontroller.ti.com Video and Imaging www.ti.com/video

RFID www.ti-rfid.com

OMAP Applications Processors www.ti.com/omap TI E2E Community e2e.ti.com

Wireless Connectivity www.ti.com/wirelessconnectivity

Mailing Address: Texas Instruments, Post Office Box 655303, Dallas, Texas 75265

Copyright © 2013, Texas Instruments Incorporated

Loading...

Loading...