Page 1

Application Report

SNVA429C–August 2010–Revised May 2013

AN-2034 LM3445 -120VAC, 8W Isolated Flyback

LED Driver

.....................................................................................................................................................

ABSTRACT

This demonstration board highlights the performance of a LM3445 based Flyback LED driver solution that

can be used to power a single LED string consisting of 4 to 8 series connected LEDs from an 90 V

135 V

, 60 Hz input power supply. The key performance characteristics under typical operating

RMS

conditions are summarized in this application report.

Contents

1 Introduction .................................................................................................................. 3

2 Key Features ................................................................................................................ 3

3 Applications .................................................................................................................. 3

4 Performance Specifications ................................................................................................ 3

5 LM3445 120VAC, 8W Isolated Flyback LED Driver Demo Board Schematic ...................................... 5

6 LM3445 Device Pin-Out .................................................................................................... 7

7 Bill of Materials .............................................................................................................. 7

8 Demo Board Wiring Overview ............................................................................................. 9

9 Demo Board Assembly ................................................................................................... 10

10 Typical Performance Characteristics .................................................................................... 11

11 PCB Layout ................................................................................................................. 14

12 Transformer Design ....................................................................................................... 15

13 Experimental Results ..................................................................................................... 16

13.1 Non-Dimming Performance ..................................................................................... 16

13.2 Dimming Performance ........................................................................................... 17

13.3 Power Factor Performance ...................................................................................... 19

14 Circuit Operation With Rotary Forward Phase TRIAC Dimmer ..................................................... 20

15 Circuit Operation With Reverse Phase TRIAC Dimmer .............................................................. 21

16 Electromagnetic Interference (EMI) ..................................................................................... 22

17 Thermal Analysis .......................................................................................................... 24

18 Circuit Analysis and Explanations ....................................................................................... 26

18.1 Injecting Line Voltage into Filter-2 (Achieving PFC > 0.95) ................................................. 26

RMS

to

List of Figures

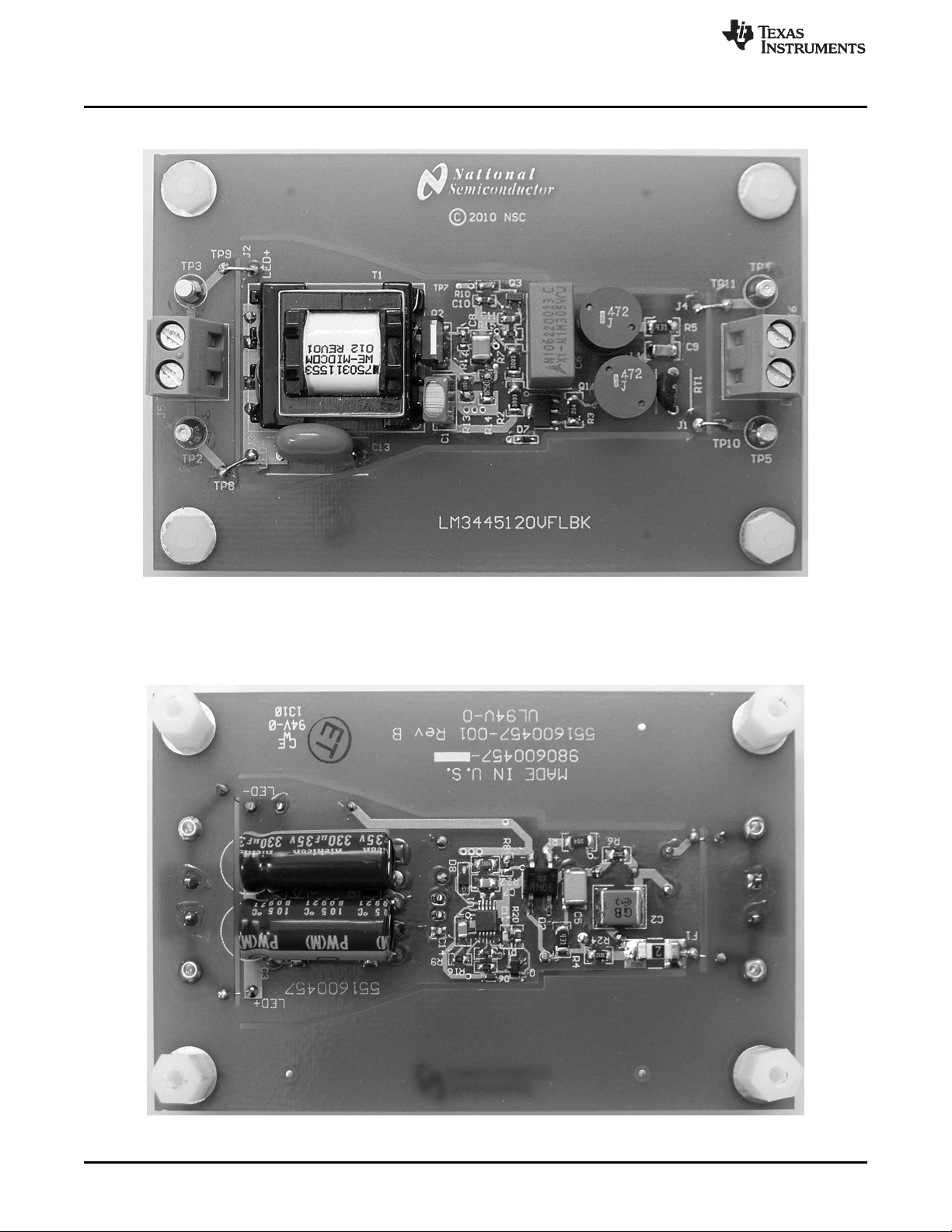

1 Demo Board ................................................................................................................. 4

2 LED Current vs. Input Voltage (using Dimmer)......................................................................... 4

3 Demo Board Schematic.................................................................................................... 6

4 LM3445 Device Pin-Out.................................................................................................... 7

5 Wiring Connection Diagram ............................................................................................... 9

6 Top View.................................................................................................................... 10

7 Bottom View................................................................................................................ 10

8 Efficiency vs. Line Voltage Original Circuit............................................................................. 11

9 Efficiency vs. Line Voltage Modified Circuits .......................................................................... 11

10 LED Current vs. Line Voltage Original Circuit ......................................................................... 11

PowerWise is a trademark of Texas Instruments.

All other trademarks are the property of their respective owners.

SNVA429C–August 2010–Revised May 2013 AN-2034 LM3445 -120VAC, 8W Isolated Flyback LED Driver

Submit Documentation Feedback

Copyright © 2010–2013, Texas Instruments Incorporated

1

Page 2

www.ti.com

11 LED Current vs. Line Voltage Modified Circuits....................................................................... 11

12 Power Factor vs. Line Voltage Original Circuit ........................................................................ 11

13 Power Factor vs. Line Voltage Modified Circuits...................................................................... 11

14 Output Power vs. Line Voltage Original Circuit........................................................................ 12

15 Output Power vs. Line Voltage Modified Circuits ..................................................................... 12

16 Power MOSFET Drain Voltage Waveform (VIN= 120V

17 Current Sense Waveform (VIN= 120V

18 FLTR2 Waveform (VIN= 120V

, 6 LEDs, I

RMS

, 6 LEDs, I

RMS

LED

= 350mA) ........................................................... 12

, 6 LEDs, I

RMS

= 350mA) .................................................. 12

LED

= 350mA)............................... 12

LED

19 Top Layer................................................................................................................... 14

20 Bottom Layer............................................................................................................... 14

21 LED Current vs. Input Voltage (using Dimmer) ....................................................................... 18

22 Current Harmonic Performance vs. EN/IEC61000-3-2 Class C Limits............................................. 19

23 Forward Phase Circuit at Full Brightness .............................................................................. 20

24 Forward Phase Circuit at 90° Firing Angle............................................................................. 20

25 Forward Phase Circuit at 150° Firing Angle ........................................................................... 20

26 Reverse Phase Circuit at Full Brightness .............................................................................. 21

27 Reverse Phase Circuit at 90° Firing Angle............................................................................. 21

28 Reverse Phase Circuit at 150° Firing Angle ........................................................................... 21

29 Input EMI Filter and Rectifier Circuit.................................................................................... 22

30 Peak Conductive EMI Scan per CISPR-22, Class B Limits.......................................................... 22

31 Peak Conductive EMI Scan with Additional 33nF of Input Capacitance........................................... 23

32 Top Side Thermal Scan .................................................................................................. 24

33 Bottom Side Thermal Scan............................................................................................... 25

34 Line Voltage Injection Circuit............................................................................................. 26

35 FLTR2 Waveform with No Dimmer ..................................................................................... 26

36 Typical Operation of FLTR2 Pin ........................................................................................ 27

List of Tables

1 Pin Description 10 Pin VSSOP............................................................................................ 7

2 Wiring Connection .......................................................................................................... 9

3 Measured Efficiency and Line Regulation (6 LEDs, No TRIAC Dimmer).......................................... 16

4 LED Current, Output Power Versus Number of LEDs for Various Circuit Modifications (VIN= 120 VAC, no

TRIAC Dimmer)............................................................................................................ 16

5 Measured Efficiency and Line Regulation Data (with TRIAC Dimmer)............................................. 17

2

AN-2034 LM3445 -120VAC, 8W Isolated Flyback LED Driver SNVA429C–August 2010–Revised May 2013

Copyright © 2010–2013, Texas Instruments Incorporated

Submit Documentation Feedback

Page 3

www.ti.com

1 Introduction

This is a two-layer board using the bottom and top layer for component placement. The demonstration

board can be modified to adjust the LED forward current, the number of series connected LEDs that are

driven and the switching frequency. For detailed instructions, see Triac Dimmable Offline LED Driver

(SNVS570).

A bill of materials is included that describes the parts used on this demonstration board. A schematic and

layout have also been included along with measured performance characteristics.

2 Key Features

• Drop-in compatibility with TRIAC dimmers

• Line injection circuitry enables PFC values greater than 0.95

• Adjustable LED current and switching frequency

• Flicker free operation

3 Applications

• Retro-fit TRIAC Dimming

• Solid State Lighting

• Industrial and Commercial Lighting

• Residential Lighting

Introduction

4 Performance Specifications

Based on an LED Vf= 3.4V

Symbol Parameter Min Typ Max

V

IN

V

OUT

I

LED

P

OUT

f

sw

Input voltage 90 V

LED string voltage 13 V 20 V 27 V

LED string average current - 365 mA -

Output power - 7.3 W -

Switching frequency - 78.5 kHz -

RMS

120 V

RMS

135 V

RMS

SNVA429C–August 2010–Revised May 2013 AN-2034 LM3445 -120VAC, 8W Isolated Flyback LED Driver

Submit Documentation Feedback

Copyright © 2010–2013, Texas Instruments Incorporated

3

Page 4

Input Voltage (V

rms

)

I

LED

(mA)

400

320

240

160

80

0

10 32 54 76 98 120

Performance Specifications

www.ti.com

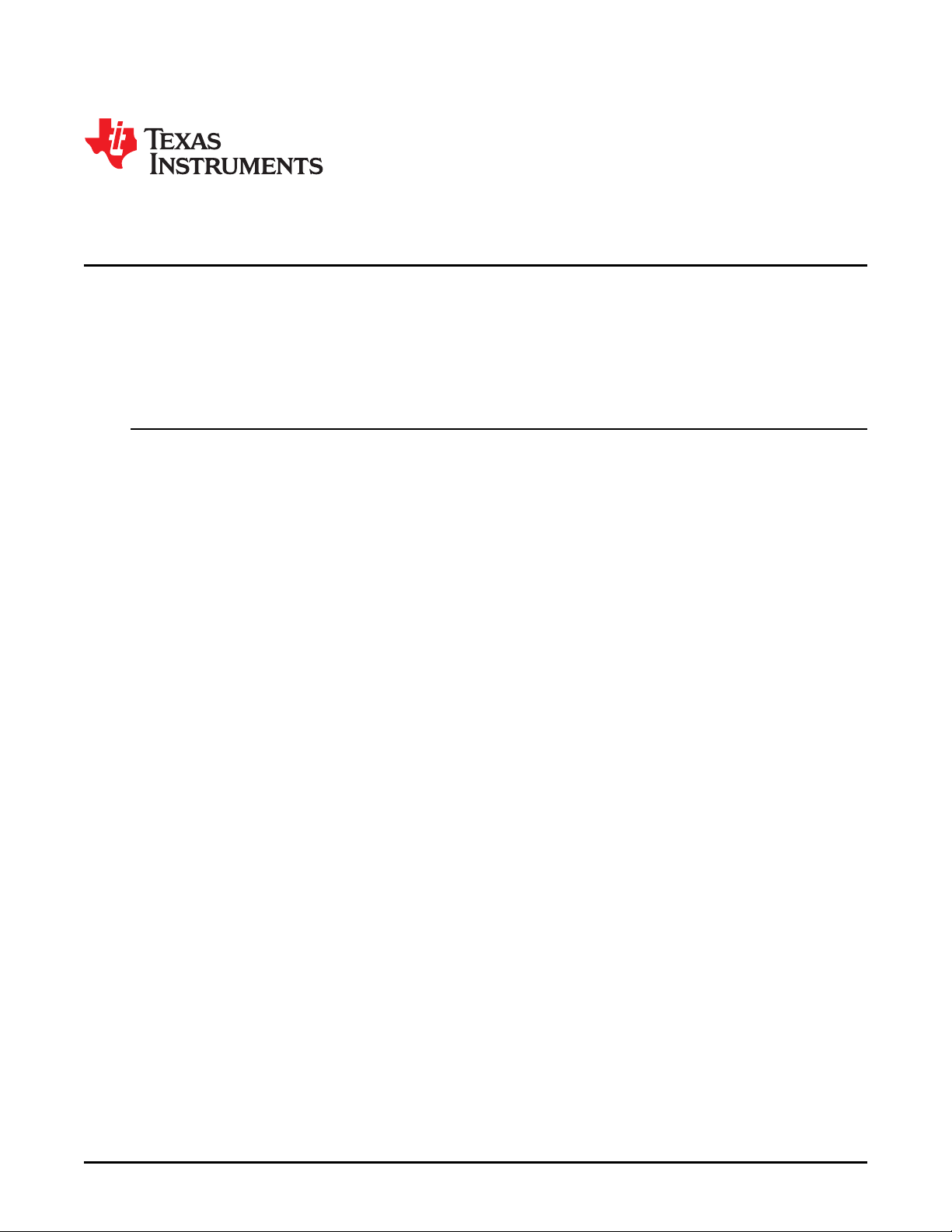

Figure 1. Demo Board

4

AN-2034 LM3445 -120VAC, 8W Isolated Flyback LED Driver SNVA429C–August 2010–Revised May 2013

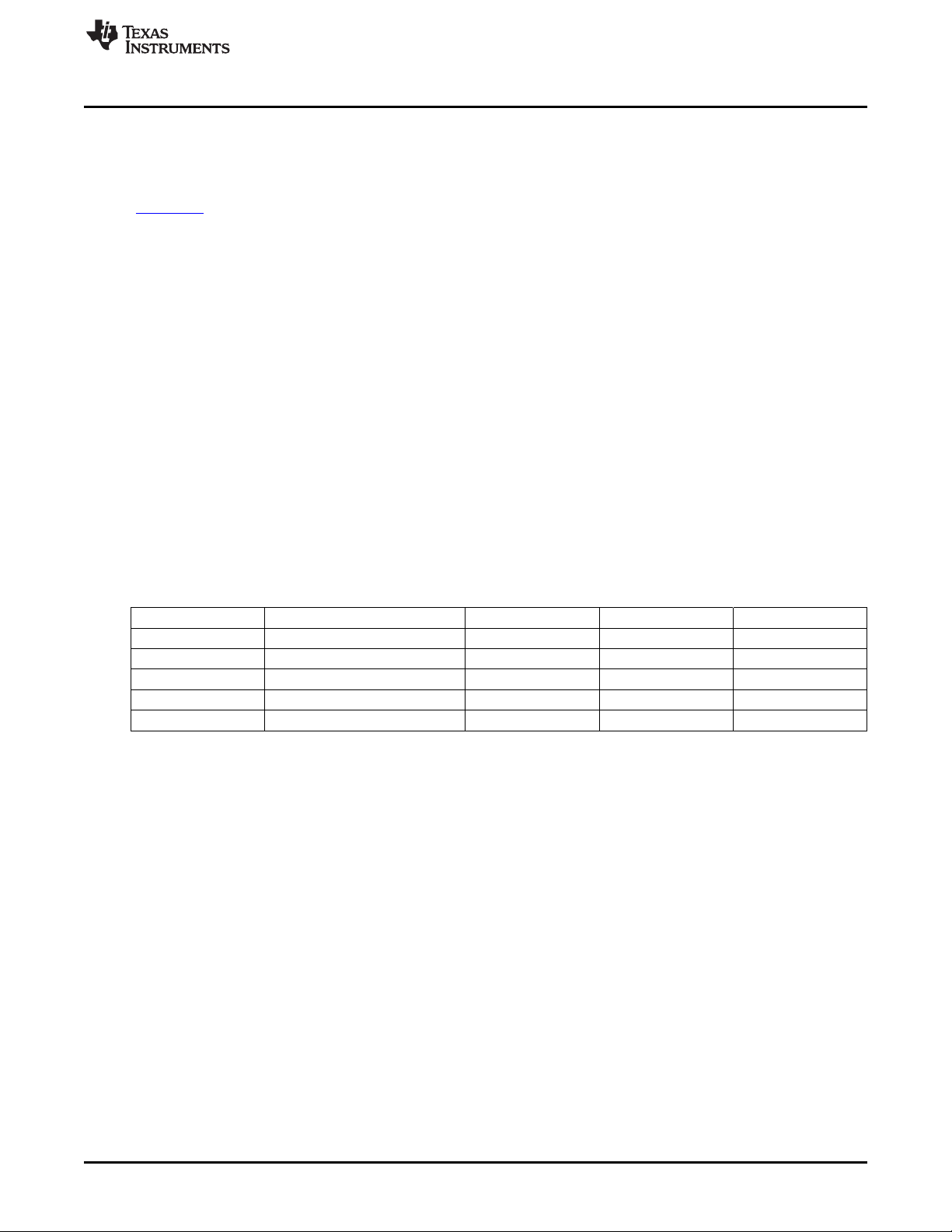

Figure 2. LED Current vs. Input Voltage (using Dimmer)

Copyright © 2010–2013, Texas Instruments Incorporated

Submit Documentation Feedback

Page 5

www.ti.com

LM3445 120VAC, 8W Isolated Flyback LED Driver Demo Board Schematic

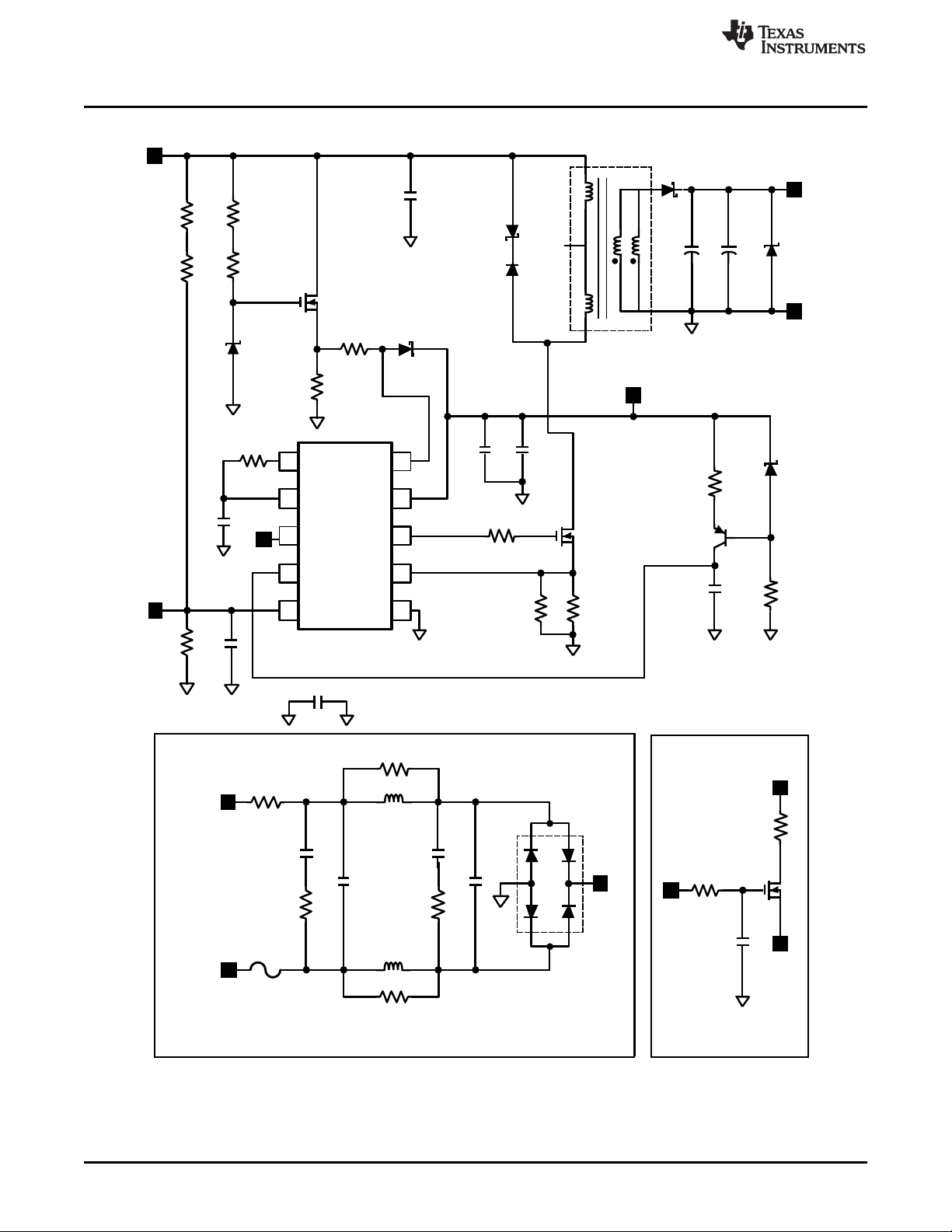

5 LM3445 120VAC, 8W Isolated Flyback LED Driver Demo Board Schematic

WARNING

The LM3445 evaluation board has exposed high voltage

components that present a shock hazard. Care must be taken when

handling the evaluation board. Avoid touching the evaluation

board and removing any cables while the evaluation board is

operating. Isolating the evaluation board rather than the

oscilloscope is highly recommended.

CAUTION

The ground connection on the evaluation board is NOT referenced to earth

ground. If an oscilloscope ground lead is connected to the evaluation board

ground test point for analysis and AC power is applied, the fuse (F1) will fail

open. The oscilloscope should be powered via an isolation transformer before

an oscilloscope ground lead is connected to the evaluation board.

The LM3445 evaluation board should not be powered with an open load. For

proper operation, ensure that the desired number of LEDs are connected at the

output before applying power to the evaluation board.

SNVA429C–August 2010–Revised May 2013 AN-2034 LM3445 -120VAC, 8W Isolated Flyback LED Driver

Submit Documentation Feedback

Copyright © 2010–2013, Texas Instruments Incorporated

5

Page 6

R15

C11

FLTR2

R2

R7

DIM

R9

C14

R1

R3

D7

Q1

R8

ASNS

FLTR1

DIM

COFF

FLTR2

BLDR

VCC

GND

GATE

ISNS

LM3445

1

2

3

4

5

10

9

8

7

6

V+

C7 C8

V

CC

R22 D8

R12

R13 R14

+

VLED+

VLED±

L1

C5

R4

V+

LINE

NEUTRAL

INPUT EMI FILTER AND RECTIFIER CIRCUIT

Q2

D1

D3

D4

D5C3

C4

DIM

V

CC

FLTR2

R11

C10

R10

TRIAC HOLDING

CIRCUIT

R16

C12

Q3

Q4

R20

C1

D6

C6

L2

R6

R24

C9

R5

C2

RT1

D2

F1

T1

C13

+

LM3445 120VAC, 8W Isolated Flyback LED Driver Demo Board Schematic

www.ti.com

6

AN-2034 LM3445 -120VAC, 8W Isolated Flyback LED Driver SNVA429C–August 2010–Revised May 2013

Figure 3. Demo Board Schematic

Copyright © 2010–2013, Texas Instruments Incorporated

Submit Documentation Feedback

Page 7

1

4

3

2

10

7

8

9

I

SNS

FLTR1

GATE

BLDR

COFF

V

CC

ASNS

DIM

5 6FLTR2 GND

www.ti.com

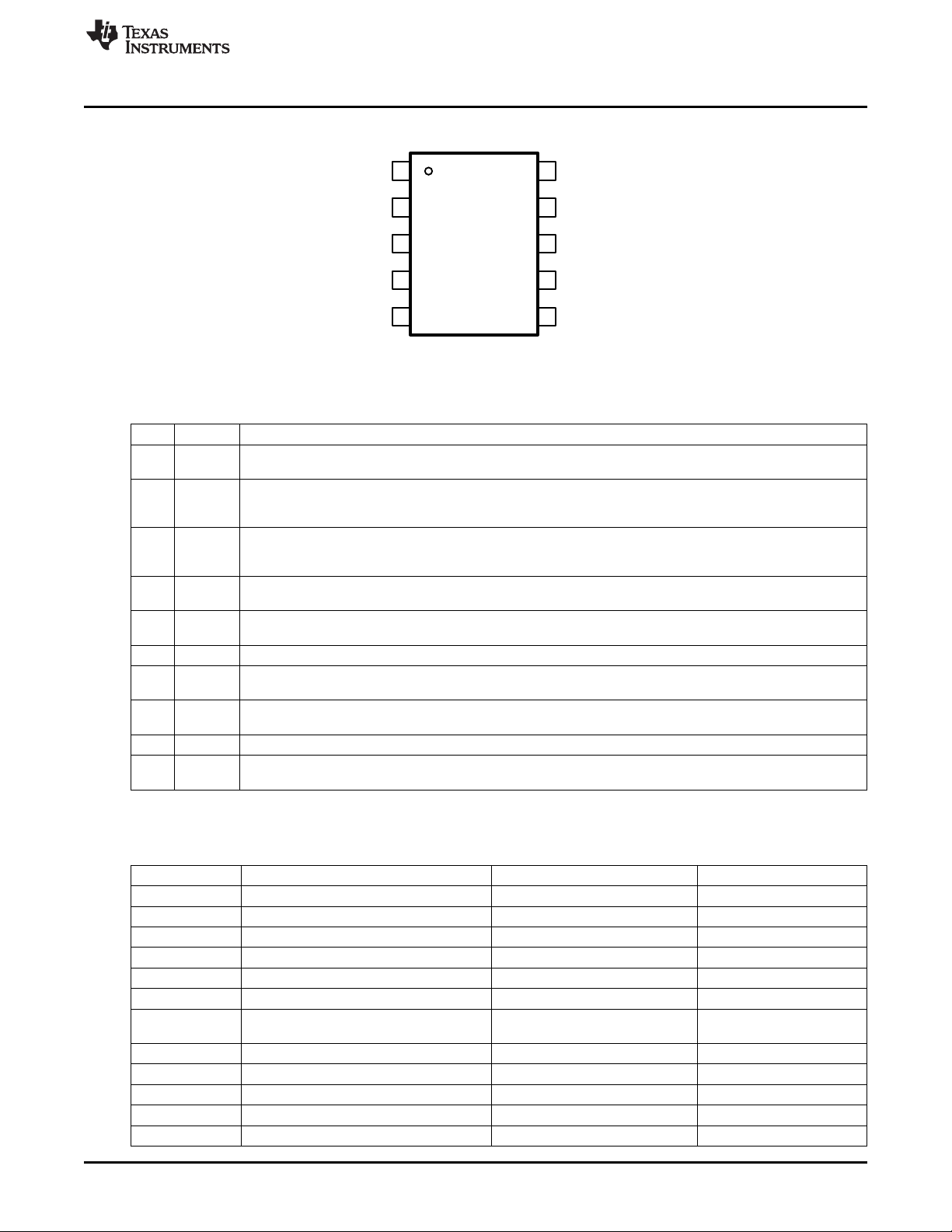

6 LM3445 Device Pin-Out

Pin # Name Description

1 ASNS PWM output of the TRIAC dimmer decoder circuit. Outputs a 0 to 4V PWM signal with a duty cycle proportional

2 FLTR1 First filter input. The 120Hz PWM signal from ASNS is filtered to a DC signal and compared to a 1 to 3V, 5.85

3 DIM Input/output dual function dim pin. This pin can be driven with an external PWM signal to dim the LEDs. It may

4 COFF OFF time setting pin. A user set current and capacitor connected from the output to this pin sets the constant

5 FLTR2 Second filter input. A capacitor tied to this pin filters the PWM dimming signal to supply a DC voltage to control

6 GND Circuit ground connection.

7 ISNS LED current sense pin. Connect a resistor from main switching MOSFET source, ISNS to GND to set the

8 GATE Power MOSFET driver pin. This output provides the gate drive for the power switching MOSFET of the buck

9 V

10 BLDR Bleeder pin. Provides the input signal to the angle detect circuitry as well as a current path through a switched

to the TRIAC dimmer on-time.

kHz ramp to generate a higher frequency PWM signal with a duty cycle proportional to the TRIAC dimmer firing

angle. Pull above 4.9V (typical) to tri-state DIM.

also be used as an output signal and connected to the DIM pin of other LM3445 or LED drivers to dim multiple

LED circuits simultaneously.

OFF time of the switching controller.

the LED current. Could also be used as an analog dimming input.

maximum LED current.

controller.

Input voltage pin. This pin provides the power for the internal control circuitry and gate driver.

CC

230Ω resistor to ensure proper firing of the TRIAC dimmer.

LM3445 Device Pin-Out

Figure 4. LM3445 Device Pin-Out

Table 1. Pin Description 10 Pin VSSOP

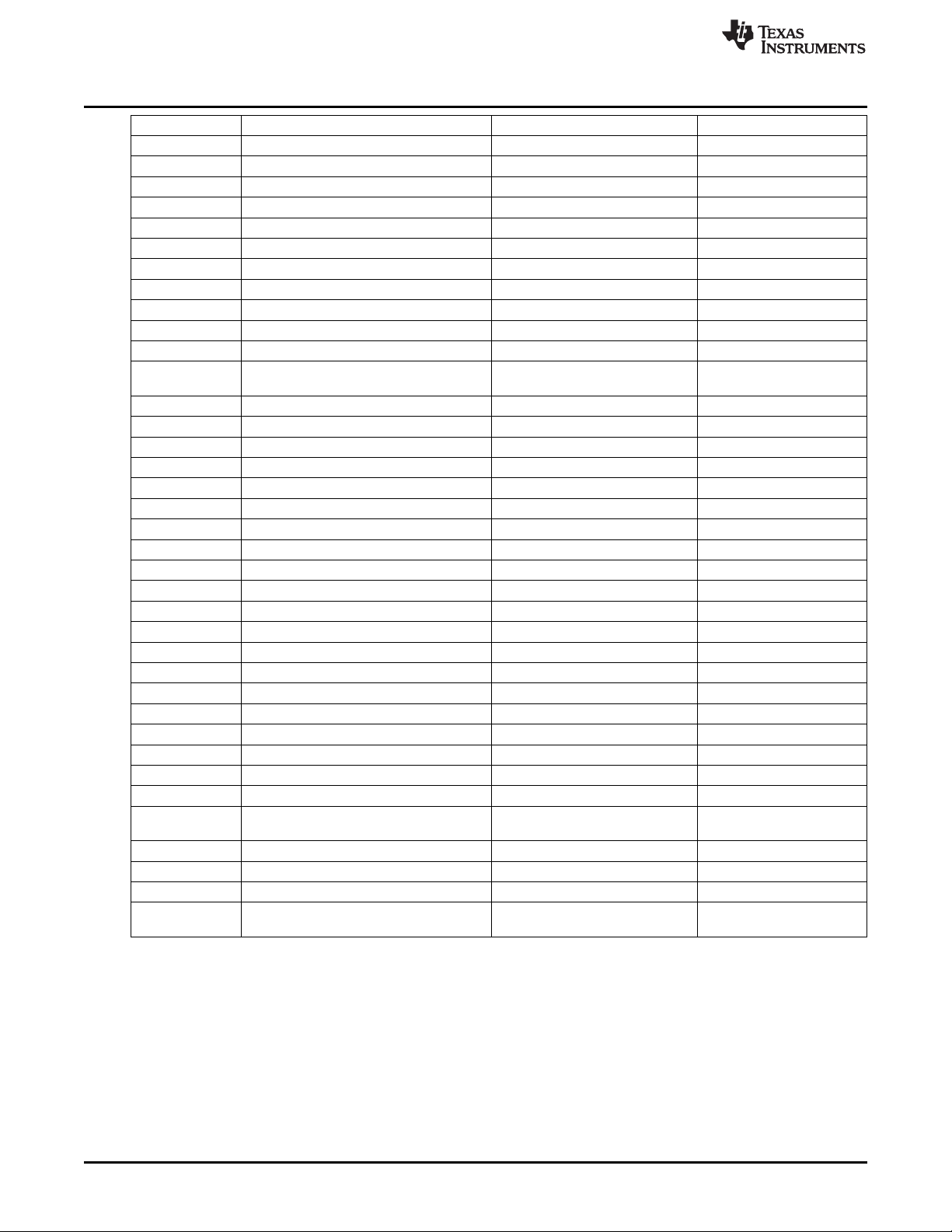

7 Bill of Materials

Designator Description Manufacturer Part Number

AA1 Printed Circuit Board - 551600457-001A

C1 CAP .047UF 630V METAL POLYPRO EPCOS Inc B32559C6473K000

C2 CAP 10000PF X7R 250VAC X2 2220 Murata Electronics North America GA355DR7GB103KY02L

C3, C4 CAP 330UF 35V ELECT PW Nichicon UPW1V331MPD6

C5 CAP CER .33UF 250V X7R 1812 TDK Corporation C4532X7R2E334K

C6 CAP .10UF 305VAC EMI SUPPRESSION EPCOS B32921C3104M

C7 CAP, CERM, 0.1µF, 16V, +/-10%, X7R, Kemet C0805C104K4RACTU

SNVA429C–August 2010–Revised May 2013 AN-2034 LM3445 -120VAC, 8W Isolated Flyback LED Driver

Submit Documentation Feedback

C8 CAP CER 47UF 16V X5R 1210 MuRata GRM32ER61C476ME15L

C9 CAP CER .10UF 250V X7R 10% 1206 TDK C3216X7R2E104K

C10 CAP CER .22UF 16V X7R 0603 MuRata GRM188R71C224KA01D

C11 CAP CER 2200PF 50V 10% X7R 0603 MuRata GRM188R71H222KA01D

C12 CAP CER 330PF 50V 5% C0G 0603 MuRata GRM1885C1H331JA01D

0805

Copyright © 2010–2013, Texas Instruments Incorporated

7

Page 8

Bill of Materials

Designator Description Manufacturer Part Number

J1, J2, J3, J4, 16 GA WIRE HOLE, 18 GA WIRE HOLE 3M 923345-02-C

TP8, TP9, TP10

R1, R3 RES 200K OHM 1/4W 5% 1206 SMD Vishay-Dale CRCW1206200KJNEA

R2, R7 RES, 309k ohm, 1%, 0.25W, 1206 Vishay-Dale CRCW1206309KFKEA

R4, R5 RES, 430 ohm, 5%, 0.25W, 1206 Vishay-Dale CRCW1206430RJNEA

R6, R24 RES, 10.5k ohm, 1%, 0.125W, 0805 Vishay-Dale CRCW080510K5FKEA

R8, R11 RES 49.9K OHM 1/10W 1% 0603 SMD Vishay-Dale CRCW060349K9FKEA

TP2-TP5 Terminal, Turret, TH, Double Keystone Electronics 1502-2

www.ti.com

C13 CAP CER 2200PF 250VAC X1Y1 RAD TDK Corporation CD12-E2GA222MYNS

C14 CAP CERM .47UF 10% 25V X5R 0805 AVX 08053D474KAT2A

D1 DIODE TVS 150V 600W UNI 5% SMB Littlefuse SMAJ120A

D2 RECT BRIDGE GP 600V 0.5A MINIDIP Diodes Inc. RH06-T

D3 DIODE RECT GP 1A 1000V MINI-SMA Comchip Technology CGRM4007-G

D4 DIODE SCHOTTKY 100V 1A SMA ST Microelectronics STPS1H100A

D5 DIODE ZENER 30V 1.5W SMA ON Semiconductor 1SMA5936BT3G

D6 DIODE ZENER 5.1V 200MW SOD-523F Fairchild Semiconductor MM5Z5V1

D7 DIODE ZENER 12V 200MW Fairchild Semiconductor MM5Z12V

D8 DIODE SWITCH 200V 200MW Diode Inc BAV20WS-7-F

F1 FUSE BRICK 1A 125V FAST 6125FA Cooper/Bussmann 6125FA

J5, J6 Conn Term Block, 2POS, 5.08mm PCB Phoenix Contact 1715721

L1, L2 INDUCTOR 4700UH .13A RADIAL TDK Corporation TSL0808RA-472JR13-PF

Q1 MOSFET N-CH 600V 90MA SOT-89 Infineon Technologies BSS225 L6327

Q2 MOSFET N-CH 600V 1.8A TO-251 Infineon Technology SPU02N60S5

Q3 MOSFET N-CH 100V 170MA SC70-3 Diodes Inc BSS123W-7-F

Q4 TRANS GP SS PNP 40V SOT323 On Semiconductor MMBT3906WT1G

R9 RES 100K OHM 1/10W 1% 0603 SMD Vishay-Dale CRCW0603100KFKEA

R10 DNP - R12 RES 4.7 OHM 1/10W 5% 0603 SMD Vishay-Dale CRCW06034R70JNEA

R13 RES 10 OHM 1/8W 5% 0805 SMD Vishay-Dale CRCW080510R0JNEA

R14 RES 1.50 OHM 1/4W 1% 1206 SMD Vishay-Dale CRCW12061R50FNEA

R15 RES 3.48K OHM 1/10W 1% 0603 SMD Vishay-Dale CRCW06033K48FKEA

R16 RES 75.0K OHM 1/10W 1% 0603 SMD Vishay-Dale CRCW060375K0FKEA

R20 RES 30.1K OHM 1/10W 1% 0603 SMD Vishay-Dale CRCW060330K1FKEA

R22 RES 40.2 OHM 1/8W 1% 0805 SMD Vishay-Dale CRCW080540R2FKEA

RT1 CURRENT LIMITOR INRUSH 60OHM Cantherm MF72-060D5

20%

T1 Transformer Wurth Electronics 750311553 Rev. 01

TP7 TEST POINT ICT - -

U1 TRIAC Dimmable Offline LED Driver, Texas Instruments LM3445

PowerWise™

8

AN-2034 LM3445 -120VAC, 8W Isolated Flyback LED Driver SNVA429C–August 2010–Revised May 2013

Copyright © 2010–2013, Texas Instruments Incorporated

Submit Documentation Feedback

Page 9

LED +

LED -

LINE

NEUTRAL

J5

J6

TP3

TP2

TP4

TP5

www.ti.com

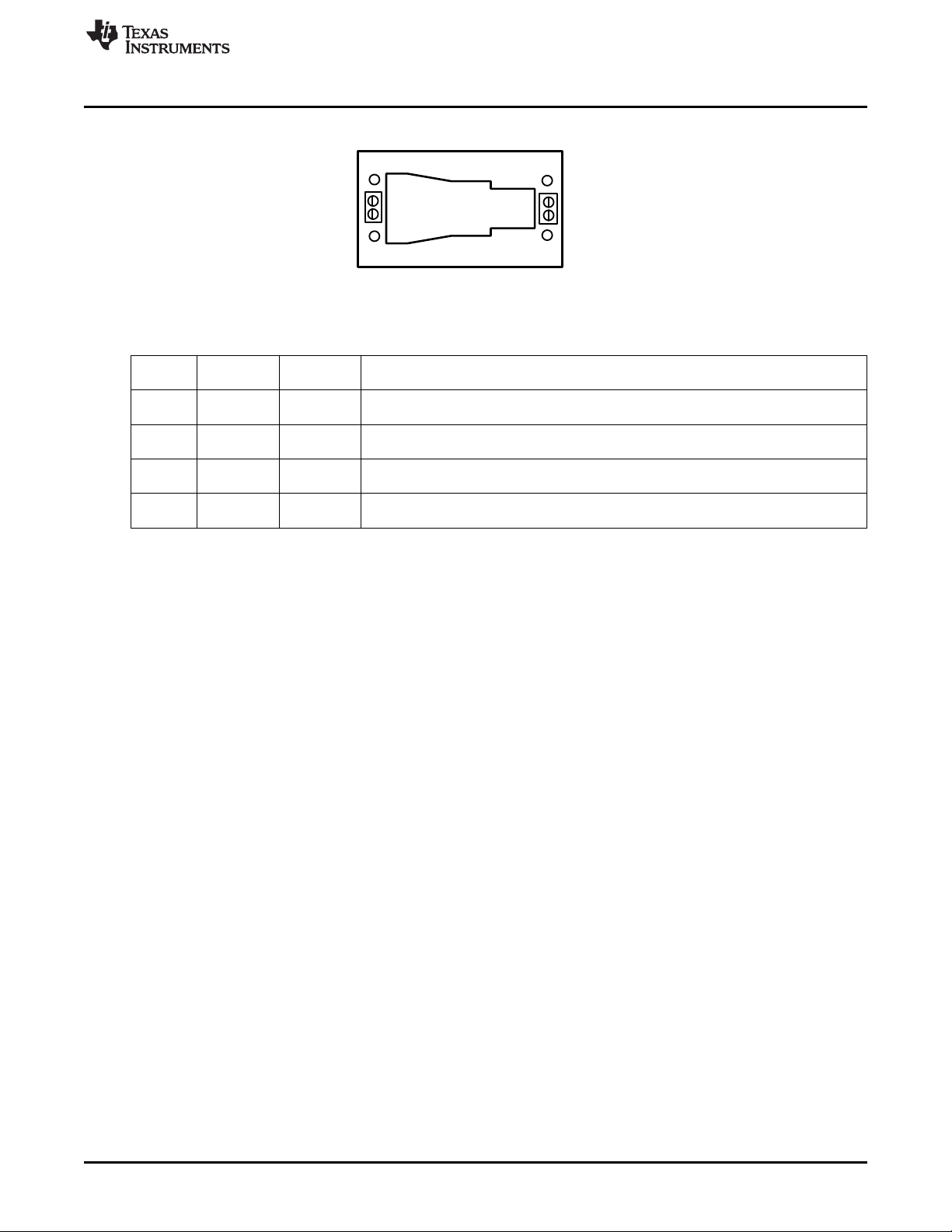

8 Demo Board Wiring Overview

Figure 5. Wiring Connection Diagram

Test Name I/O Description

Point

TP3 LED + Output LED Constant Current Supply

TP2 LED - Output LED Return Connection (not GND)

TP4 LINE Input AC Line Voltage

TP5 NEUTRAL Input AC Neutral

Demo Board Wiring Overview

Table 2. Wiring Connection

Supplies voltage and constant-current to anode of LED string.

Connects to cathode of LED string. Do NOT connect to GND.

Connects directly to AC line or output of TRIAC dimmer of a 120VAC system.

Connects directly to AC neutral of a 120VAC system.

SNVA429C–August 2010–Revised May 2013 AN-2034 LM3445 -120VAC, 8W Isolated Flyback LED Driver

Submit Documentation Feedback

Copyright © 2010–2013, Texas Instruments Incorporated

9

Page 10

Demo Board Assembly

9 Demo Board Assembly

www.ti.com

Figure 6. Top View

10

Figure 7. Bottom View

AN-2034 LM3445 -120VAC, 8W Isolated Flyback LED Driver SNVA429C–August 2010–Revised May 2013

Copyright © 2010–2013, Texas Instruments Incorporated

Submit Documentation Feedback

Page 11

80 90 100 110 120 130 140

0.0

0.2

0.4

0.7

0.8

1.0

I

LED

(A)

LINE VOLTAGE (V

RMS

)

4 LEDs

6 LEDs

8 LEDs

80 90 100 110 120 130 140

0.0

0.2

0.4

0.7

0.8

1.0

I

LED

(A)

LINE VOLTAGE (V

RMS

)

Original

Mod A

Mod B

Mod C

80 90 100 110 120 130 140

72

74

76

78

80

82

EFFICIENCY (%)

LINE VOLTAGE (V

RMS

)

4 LEDs

6 LEDs

8 LEDs

80 90 100 110 120 130 140

72

74

76

78

80

82

EFFICIENCY (%)

LINE VOLTAGE (V

RMS

)

Mod C

Mod A

Mod B

Original

www.ti.com

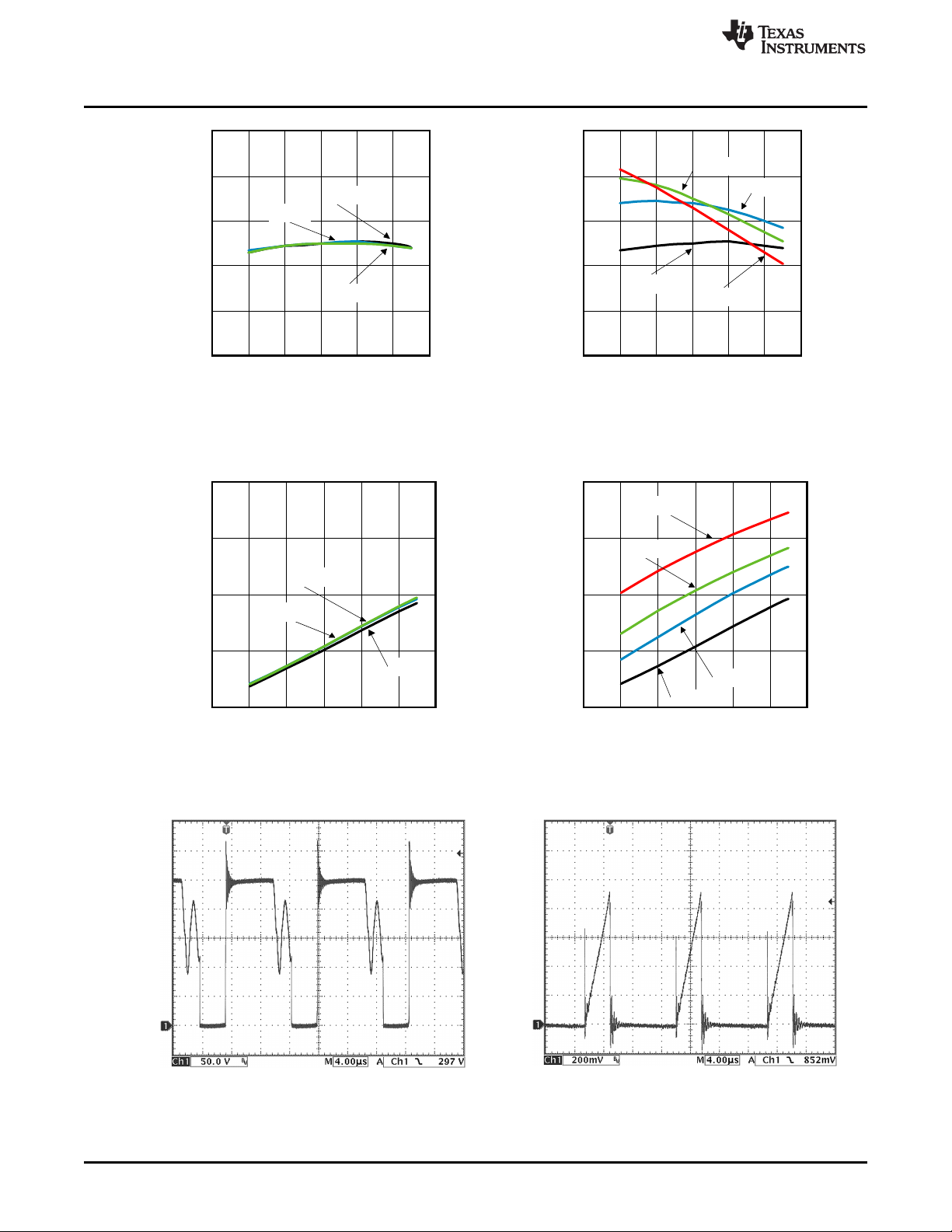

10 Typical Performance Characteristics

Original Circuit: R14 = 1.50Ω; Modification A: R14 = 1.20Ω; Modification B: R14 = 1.00Ω; Modification C:

R14 = 0.75Ω

Figure 8. Efficiency vs. Line Voltage Figure 9. Efficiency vs. Line Voltage

Original Circuit Modified Circuits

Typical Performance Characteristics

Figure 10. LED Current vs. Line Voltage Figure 11. LED Current vs. Line Voltage

Original Circuit Modified Circuits

Copyright © 2010–2013, Texas Instruments Incorporated

SNVA429C–August 2010–Revised May 2013 AN-2034 LM3445 -120VAC, 8W Isolated Flyback LED Driver

Submit Documentation Feedback

11

Page 12

80 90 100 110 120 130 140

3

6

9

12

15

P

OUT

(W)

LINE VOLTAGE (V

RMS

)

4 LEDs

6 LEDs

8 LEDs

80 90 100 110 120 130 140

3

6

9

12

15

P

OUT

(W)

LINE VOLTAGE (V

RMS

)

Original

Mod A

Mod B

Mod C

80 90 100 110 120 130 140

90

92

94

96

98

100

POWER FACTOR

LINE VOLTAGE (V

RMS

)

4 LEDs

8 LEDs

6 LEDs

80 90 100 110 120 130 140

90

92

94

96

98

100

POWER FACTOR

LINE VOLTAGE (V

RMS

)

Original

Mod A

Mod B

Mod C

Typical Performance Characteristics

Figure 12. Power Factor vs. Line Voltage Figure 13. Power Factor vs. Line Voltage

Original Circuit Modified Circuits

www.ti.com

Figure 14. Output Power vs. Line Voltage Figure 15. Output Power vs. Line Voltage

(VIN= 120V

Figure 16. Power MOSFET Drain Voltage Waveform Figure 17. Current Sense Waveform

12

AN-2034 LM3445 -120VAC, 8W Isolated Flyback LED Driver SNVA429C–August 2010–Revised May 2013

Original Circuit Modified Circuits

RMS

, 6 LEDs, I

= 350mA) (VIN= 120V

LED

Copyright © 2010–2013, Texas Instruments Incorporated

, 6 LEDs, I

RMS

Submit Documentation Feedback

= 350mA)

LED

Page 13

www.ti.com

Figure 18. FLTR2 Waveform

(VIN= 120V

, 6 LEDs, I

RMS

= 350mA)

LED

Typical Performance Characteristics

SNVA429C–August 2010–Revised May 2013 AN-2034 LM3445 -120VAC, 8W Isolated Flyback LED Driver

Submit Documentation Feedback

Copyright © 2010–2013, Texas Instruments Incorporated

13

Page 14

PCB Layout

11 PCB Layout

www.ti.com

Figure 19. Top Layer

14

Figure 20. Bottom Layer

AN-2034 LM3445 -120VAC, 8W Isolated Flyback LED Driver SNVA429C–August 2010–Revised May 2013

Copyright © 2010–2013, Texas Instruments Incorporated

Submit Documentation Feedback

Page 15

www.ti.com

12 Transformer Design

Mfg: Wurth Electronics, Part #: 750311553 Rev. 01

Transformer Design

SNVA429C–August 2010–Revised May 2013 AN-2034 LM3445 -120VAC, 8W Isolated Flyback LED Driver

Submit Documentation Feedback

Copyright © 2010–2013, Texas Instruments Incorporated

15

Page 16

Experimental Results

13 Experimental Results

The LED driver is designed to accurately emulate an incandescent light bulb and therefore behave as an

emulated resistor. The resistor value is determined based on the LED string configuration and the desired

output power. The circuit then operates in open-loop, with a fixed duty cycle based on a constant on-time

and constant off-time that is set by selecting appropriate circuit components. Like an incandescent lamp,

the driver is compatible with both forward and reverse phase dimmers.

13.1 Non-Dimming Performance

In steady state, the LED string voltage is measured to be 20.1 V and the average LED current is

measured as 365 mA. The 120 Hz current ripple flowing through the LED string was measured to be 182

mA

connected across the output port and the TRIAC firing angle. The ripple current can be reduced by

increasing the value of energy storage capacitor or by increasing the LED string voltage. With TRIAC

dimmers, the ripple magnitude is directly proportional to the input power and therefore reduces at lower

LED current.

The LED driver switching frequency is measured to be close to the specified 78.5 kHz. The circuit

operates with a constant duty cycle of 0.28 and consumes near 9.2 W of input power. The driver steady

state performance for an LED string consisting of 6 series LEDs without using a TRIAC dimmer is

summarized in Table 3.

at full load. The magnitude of the ripple is a function of the value of energy storage capacitors

pk-pk

Table 3. Measured Efficiency and Line Regulation (6 LEDs, No TRIAC Dimmer)

VIN(V

) IIN(mA

RMS

) PIN(W) V

RMS

89.98 64 5.44 19.24 222 4.27 78.5 94.7

95.03 67 6.03 19.40 244 4.73 78.5 94.8

100.00 70 6.62 19.55 267 5.22 78.8 94.9

104.97 73 7.24 19.69 291 5.73 79.1 95.0

110.03 76 7.90 19.83 315 6.25 79.1 95.0

115.00 78 8.55 19.95 340 6.78 79.3 95.1

120.05 81 9.21 20.06 365 7.32 79.5 95.1

125.02 83 9.84 20.14 389 7.83 79.6 95.0

129.99 85 10.44 20.22 412 8.33 79.8 94.9

135.04 86 11.02 20.29 433 8.79 79.7 94.8

(V) I

OUT

(mA) P

LED

www.ti.com

(W) Efficiency (%) Power Factor

OUT

16

Table 4. LED Current, Output Power Versus Number of LEDs for Various Circuit Modifications

(VIN= 120 VAC, no TRIAC Dimmer)

# of LEDs Original Circuit

I

(mA) P

LED

(1)

(W) I

OUT

Modification A

(mA) P

LED

4 513 7.11 627 8.83 683 10.03 805 11.91

6 365 7.32 435 9.09 481 10.22 566 12.23

8 276 7.34 334 9.16 367 10.16 431 12.12

(1)

Original Circuit: R14 = 1.50Ω; Modification A: R14 = 1.20Ω; Modification B: R14 = 1.00Ω; Modification C: R14 = 0.75Ω

AN-2034 LM3445 -120VAC, 8W Isolated Flyback LED Driver SNVA429C–August 2010–Revised May 2013

Copyright © 2010–2013, Texas Instruments Incorporated

(1)

(W) I

OUT

Modification B

(mA) P

LED

(1)

(W) I

OUT

Modification C

(mA) P

LED

Submit Documentation Feedback

OUT

(1)

(W)

Page 17

www.ti.com

13.2 Dimming Performance

The LED driver is capable of matching or exceeding the dimming performance of an incandescent lamp.

Using a simple rotary TRIAC dimmer, smooth and near logarithmic dimming performance is achieved. By

varying the firing angle of the TRIAC dimmer and measuring the corresponding input and output

parameters, the dimming performance of the demonstration board driving 6 LEDs is summarized in

Table 5.

Table 5. Measured Efficiency and Line Regulation Data (with TRIAC Dimmer)

VIN(V

) VO(V) IO(mA) P

RMS

115.0 19.9 351 7.0

110.1 19.8 323 6.4

105.2 19.7 295 5.8

100.4 19.6 269 5.3

95.5 19.6 258 5.0

90.7 19.5 248 4.8

85.2 19.4 222 4.3

80.2 19.3 199 3.8

75.1 19.2 176 3.4

70.8 19.1 159 3.0

65.5 18.7 138 2.6

60.5 18.8 120 2.3

55.2 18.6 101 1.9

50.6 18.5 86 1.6

45.7 18.3 72 1.3

39.4 18.0 54 1.0

34.2 17.8 42 0.7

30.3 17.6 33 0.6

26.0 17.4 25 0.4

20.0 17.0 15 0.3

15.2 16.6 9 0.1

Experimental Results

(W)

OUT

SNVA429C–August 2010–Revised May 2013 AN-2034 LM3445 -120VAC, 8W Isolated Flyback LED Driver

Submit Documentation Feedback

Copyright © 2010–2013, Texas Instruments Incorporated

17

Page 18

Input Voltage (V

rms

)

I

LED

(mA)

400

320

240

160

80

0

10 32 54 76 98 120

Experimental Results

www.ti.com

Figure 21. LED Current vs. Input Voltage (using Dimmer)

18

AN-2034 LM3445 -120VAC, 8W Isolated Flyback LED Driver SNVA429C–August 2010–Revised May 2013

Copyright © 2010–2013, Texas Instruments Incorporated

Submit Documentation Feedback

Page 19

www.ti.com

13.3 Power Factor Performance

The LED driver is able to achieve close to unity power factor (P.F. ~ 0.95) which meets Energy Star

requirements. This design also exhibits low current harmonics as a percentage of the fundamental current

(as shown in the following figure) and therefore meets the requirements of the IEC 61000-3-2 Class-3

standard.

Experimental Results

Figure 22. Current Harmonic Performance vs. EN/IEC61000-3-2 Class C Limits

SNVA429C–August 2010–Revised May 2013 AN-2034 LM3445 -120VAC, 8W Isolated Flyback LED Driver

Submit Documentation Feedback

Copyright © 2010–2013, Texas Instruments Incorporated

19

Page 20

Circuit Operation With Rotary Forward Phase TRIAC Dimmer

14 Circuit Operation With Rotary Forward Phase TRIAC Dimmer

The dimming operation of the circuit was verified using a forward phase rotary TRIAC dimmer. Waveforms

captured at different dimmer settings are shown in the following figures.

www.ti.com

Figure 23. Forward Phase Circuit at Full Brightness Figure 24. Forward Phase Circuit at 90° Firing Angle

Figure 25. Forward Phase Circuit at 150° Firing Angle

20

AN-2034 LM3445 -120VAC, 8W Isolated Flyback LED Driver SNVA429C–August 2010–Revised May 2013

Copyright © 2010–2013, Texas Instruments Incorporated

Submit Documentation Feedback

Page 21

www.ti.com

Circuit Operation With Reverse Phase TRIAC Dimmer

15 Circuit Operation With Reverse Phase TRIAC Dimmer

The circuit operation was also verified using a reverse phase dimmer and waveforms captured at different

dimmer settings are shown in the following figures.

Figure 26. Reverse Phase Circuit at Full Brightness Figure 27. Reverse Phase Circuit at 90° Firing Angle

Figure 28. Reverse Phase Circuit at 150° Firing Angle

SNVA429C–August 2010–Revised May 2013 AN-2034 LM3445 -120VAC, 8W Isolated Flyback LED Driver

Submit Documentation Feedback

Copyright © 2010–2013, Texas Instruments Incorporated

21

Page 22

L1

C5

R4

V+

LINE

NEUTRAL

C6

L2

R6

R24

C9

R5

C2

RT1

D2

F1

Electromagnetic Interference (EMI)

16 Electromagnetic Interference (EMI)

The EMI input filter of this evaluation board is configured as shown in Figure 29.

Figure 29. Input EMI Filter and Rectifier Circuit

www.ti.com

In order to get a quick estimate of the EMI filter performance, only the PEAK conductive EMI scan was

measured and the data was compared to the Class B conducted EMI limits published in FCC – 47,

section 15.

Figure 30. Peak Conductive EMI Scan per CISPR-22, Class B Limits

If an additional 33nF of input capacitance (that is, C6) is utilized in the input filter, the EMI conductive

performance is further improved as shown in Figure 31.

22

AN-2034 LM3445 -120VAC, 8W Isolated Flyback LED Driver SNVA429C–August 2010–Revised May 2013

Copyright © 2010–2013, Texas Instruments Incorporated

Submit Documentation Feedback

Page 23

www.ti.com

Electromagnetic Interference (EMI)

Figure 31. Peak Conductive EMI Scan with Additional 33nF of Input Capacitance

SNVA429C–August 2010–Revised May 2013 AN-2034 LM3445 -120VAC, 8W Isolated Flyback LED Driver

Submit Documentation Feedback

Copyright © 2010–2013, Texas Instruments Incorporated

23

Page 24

Thermal Analysis

17 Thermal Analysis

The board temperature was measured using an IR camera (HIS-3000, Wahl) while running under the

following conditions:

• VIN= 120 V

• I

= 365 mA

LED

• Number of LEDs = 6

• P

OUT

The results are shown in the following figures.

RMS

= 7.3 W

www.ti.com

24

Figure 32. Top Side Thermal Scan

AN-2034 LM3445 -120VAC, 8W Isolated Flyback LED Driver SNVA429C–August 2010–Revised May 2013

Copyright © 2010–2013, Texas Instruments Incorporated

Submit Documentation Feedback

Page 25

www.ti.com

Thermal Analysis

Figure 33. Bottom Side Thermal Scan

SNVA429C–August 2010–Revised May 2013 AN-2034 LM3445 -120VAC, 8W Isolated Flyback LED Driver

Submit Documentation Feedback

Copyright © 2010–2013, Texas Instruments Incorporated

25

Page 26

R15 C11

FLTR2

R2

R7

DIM

R9

COFF

ASNS

FLTR1

DIM

COFF

FLTR2

BLDR

VCC

GND

GATE

ISNS

LM3445

1

2

3

4

5

10

9

8

7

6

V+

t

V

FLTR2

Circuit Analysis and Explanations

18 Circuit Analysis and Explanations

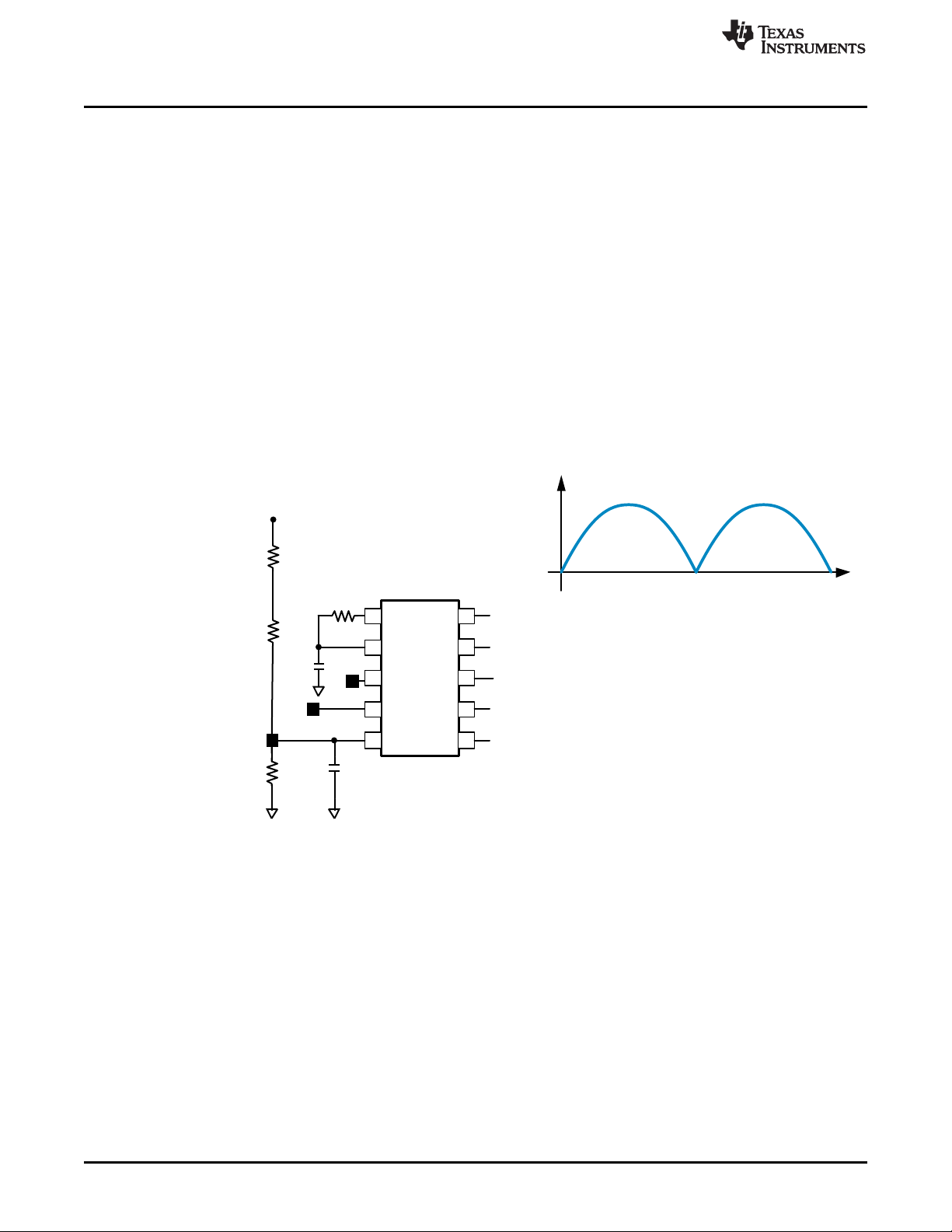

18.1 Injecting Line Voltage into Filter-2 (Achieving PFC > 0.95)

If a small portion (750mV to 1.00V) of line voltage is injected at FLTR2 of the LM3445, the circuit is

essentially turned into a constant power flyback as shown in Figure 34.

The LM3445 works as a constant off-time controller normally, but by injecting the 1.0V rectified AC voltage

into the FLTR2 pin, the on-time can be made to be constant. With a DCM Flyback, Δi needs to increase

as the input voltage line increases. Therefore a constant on-time (since inductor L is constant) can be

obtained.

By using the line voltage injection technique, the FLTR2 pin has the voltage wave shape shown in

Figure 35 on it with no TRIAC dimmer in-line. Voltage at V

current limit is tripped. C11 is small enough not to distort the AC signal but adds a little filtering.

Although the on-time is probably never truly constant, it can be observed in Figure 36 how (by adding the

rectified voltage) the on-time is adjusted.

peak should be kept below 1.25V. At 1.25V

FLTR2

www.ti.com

For this evaluation board, the following resistor values are used:

R2 = R7 = 309kΩ

R15 = 3.48kΩ

Therefore the voltages observed on the FLTR2 pin will be as follows for listed input voltages:

For VIN = 90V

For VIN = 120V

For VIN = 135V

Using this technique, a power factor greater than 0.95 can be achieved without additional passive active

power factor control (PFC) circuitry.

26

AN-2034 LM3445 -120VAC, 8W Isolated Flyback LED Driver SNVA429C–August 2010–Revised May 2013

Figure 34. Line Voltage Injection Circuit Figure 35. FLTR2 Waveform with No Dimmer

, V

RMS

RMS

RMS

FLTR2

, V

FLTR2

, V

FLTR2

= 0.71V

= 0.95V

= 1.07V

Copyright © 2010–2013, Texas Instruments Incorporated

Submit Documentation Feedback

Page 27

R

FLTR1

R

SNS

PWM

I-LIM

1.25V

I

SNS

ASNS

PGND

FLTR1

FLTR2

DIM

DIM DECODER

4.5V

Tri-State

50k

333k

C

FLTR2

C

FLTR1

1k

RAMP GEN.

5.5 kHz

3V

1V

750 mV

110 ns

LEADING EDGE BLANKING

1V

Nearly a constant on-

time as the line varies

The PWM reference increases

as the line voltage increases.

As line voltage increases, the voltage across the

inductor increases, and the peak current increases.

1V

D x LED Current

www.ti.com

Circuit Analysis and Explanations

Figure 36. Typical Operation of FLTR2 Pin

SNVA429C–August 2010–Revised May 2013 AN-2034 LM3445 -120VAC, 8W Isolated Flyback LED Driver

Submit Documentation Feedback

Copyright © 2010–2013, Texas Instruments Incorporated

27

Page 28

IMPORTANT NOTICE

Texas Instruments Incorporated and its subsidiaries (TI) reserve the right to make corrections, enhancements, improvements and other

changes to its semiconductor products and services per JESD46, latest issue, and to discontinue any product or service per JESD48, latest

issue. Buyers should obtain the latest relevant information before placing orders and should verify that such information is current and

complete. All semiconductor products (also referred to herein as “components”) are sold subject to TI’s terms and conditions of sale

supplied at the time of order acknowledgment.

TI warrants performance of its components to the specifications applicable at the time of sale, in accordance with the warranty in TI’s terms

and conditions of sale of semiconductor products. Testing and other quality control techniques are used to the extent TI deems necessary

to support this warranty. Except where mandated by applicable law, testing of all parameters of each component is not necessarily

performed.

TI assumes no liability for applications assistance or the design of Buyers’ products. Buyers are responsible for their products and

applications using TI components. To minimize the risks associated with Buyers’ products and applications, Buyers should provide

adequate design and operating safeguards.

TI does not warrant or represent that any license, either express or implied, is granted under any patent right, copyright, mask work right, or

other intellectual property right relating to any combination, machine, or process in which TI components or services are used. Information

published by TI regarding third-party products or services does not constitute a license to use such products or services or a warranty or

endorsement thereof. Use of such information may require a license from a third party under the patents or other intellectual property of the

third party, or a license from TI under the patents or other intellectual property of TI.

Reproduction of significant portions of TI information in TI data books or data sheets is permissible only if reproduction is without alteration

and is accompanied by all associated warranties, conditions, limitations, and notices. TI is not responsible or liable for such altered

documentation. Information of third parties may be subject to additional restrictions.

Resale of TI components or services with statements different from or beyond the parameters stated by TI for that component or service

voids all express and any implied warranties for the associated TI component or service and is an unfair and deceptive business practice.

TI is not responsible or liable for any such statements.

Buyer acknowledges and agrees that it is solely responsible for compliance with all legal, regulatory and safety-related requirements

concerning its products, and any use of TI components in its applications, notwithstanding any applications-related information or support

that may be provided by TI. Buyer represents and agrees that it has all the necessary expertise to create and implement safeguards which

anticipate dangerous consequences of failures, monitor failures and their consequences, lessen the likelihood of failures that might cause

harm and take appropriate remedial actions. Buyer will fully indemnify TI and its representatives against any damages arising out of the use

of any TI components in safety-critical applications.

In some cases, TI components may be promoted specifically to facilitate safety-related applications. With such components, TI’s goal is to

help enable customers to design and create their own end-product solutions that meet applicable functional safety standards and

requirements. Nonetheless, such components are subject to these terms.

No TI components are authorized for use in FDA Class III (or similar life-critical medical equipment) unless authorized officers of the parties

have executed a special agreement specifically governing such use.

Only those TI components which TI has specifically designated as military grade or “enhanced plastic” are designed and intended for use in

military/aerospace applications or environments. Buyer acknowledges and agrees that any military or aerospace use of TI components

which have not been so designated is solely at the Buyer's risk, and that Buyer is solely responsible for compliance with all legal and

regulatory requirements in connection with such use.

TI has specifically designated certain components as meeting ISO/TS16949 requirements, mainly for automotive use. In any case of use of

non-designated products, TI will not be responsible for any failure to meet ISO/TS16949.

Products Applications

Audio www.ti.com/audio Automotive and Transportation www.ti.com/automotive

Amplifiers amplifier.ti.com Communications and Telecom www.ti.com/communications

Data Converters dataconverter.ti.com Computers and Peripherals www.ti.com/computers

DLP® Products www.dlp.com Consumer Electronics www.ti.com/consumer-apps

DSP dsp.ti.com Energy and Lighting www.ti.com/energy

Clocks and Timers www.ti.com/clocks Industrial www.ti.com/industrial

Interface interface.ti.com Medical www.ti.com/medical

Logic logic.ti.com Security www.ti.com/security

Power Mgmt power.ti.com Space, Avionics and Defense www.ti.com/space-avionics-defense

Microcontrollers microcontroller.ti.com Video and Imaging www.ti.com/video

RFID www.ti-rfid.com

OMAP Applications Processors www.ti.com/omap TI E2E Community e2e.ti.com

Wireless Connectivity www.ti.com/wirelessconnectivity

Mailing Address: Texas Instruments, Post Office Box 655303, Dallas, Texas 75265

Copyright © 2013, Texas Instruments Incorporated

Loading...

Loading...