Page 1

AN-1839 LM3402/LM3404 Fast Dimming and True

Constant LED Current Evaluation Board

1 Introduction

The LM3402/02HV and LM3404/04HV are buck regulator derived controlled current sources designed to

drive a series string of high power, high brightness LEDs (HBLEDs) at forward currents of up to 0.5A

(LM3402/02HV) or 1.0A (LM3404/04HV). This evaluation board demonstrates the enhanced thermal

performance, fast dimming, and true constant LED current capabilities of the LM3402 and LM3404

devices.

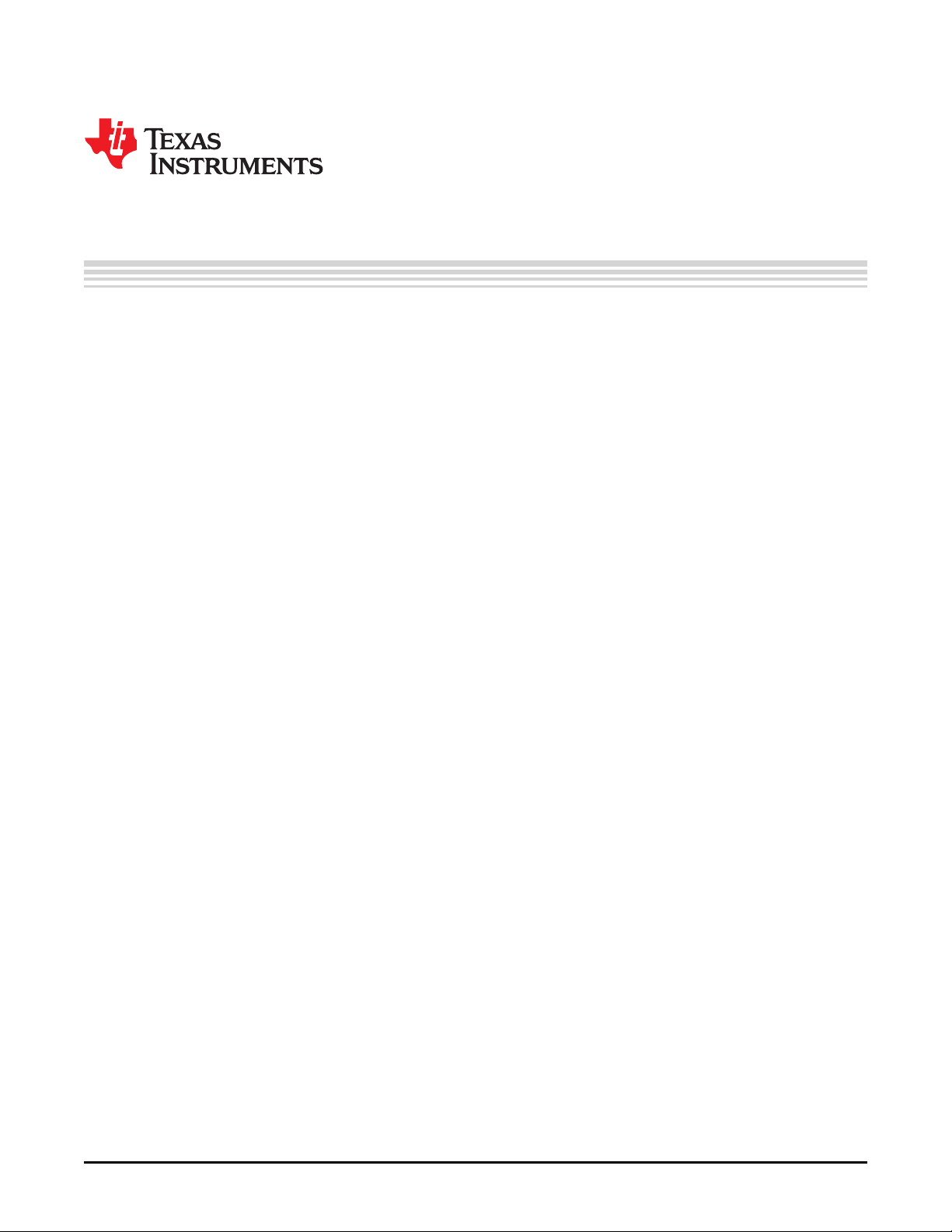

2 Circuit Performance with LM3404

This evaluation board (see Figure 1) uses the LM3404 to provide a constant forward current of 700 mA

±10% to a string of up to five series-connected HBLEDs with a forward voltage of approximately 3.4V

each from an input of 18V to 36V.

3 Thermal Performance

User's Guide

SNVA342E–July 2008–Revised April 2013

The PSOP-8 package is pin-for-pin compatible with the SO-8 package with the exception of the thermal

pad, or exposed die attach pad (DAP). The DAP is electrically connected to system ground. When the

DAP is properly soldered to an area of copper on the top layer, bottom layer, internal planes, or

combinations of various layers, the θJAof the LM3404/04HV can be significantly lower than that of the SO8 package. The PSOP-8 evaluation board is two layers of 1oz copper each, and measures 1.25" x 1.95".

The DAP is soldered to approximately 1/2 square inch of top and two square inches of bottom layer

copper. Three thermal vias connect the DAP to the bottom layer of the PCB. A recommended DAP/via

layout is shown in Figure 2.

All trademarks are the property of their respective owners.

SNVA342E–July 2008–Revised April 2013 AN-1839 LM3402/LM3404 Fast Dimming and True Constant LED Current

Submit Documentation Feedback

Copyright © 2008–2013, Texas Instruments Incorporated

Evaluation Board

1

Page 2

90 mil

10 mil

35 mil

10 mil

35 mil

90 mil

2

1

3

4

C1

V

IN

V

OUT

7

8

6

5

SW

BOOT

GND

DIM

VIN

VCC

RON

CS

C3

R1A

Q1

Q4

L1

R3

LEDs on separate PCB

Optional

R5

Q3

2

CONN-1

C4

V

DIM

C6

JMP-1

U1

External Voltage

Source Optional

4V to 6V

Single package (SC70-6)

Complementary N+P Channel

D1

D2

C2

C5

LM3404

R2

Q3

1

R1B

R4

R6

V

DIM

1N4148

Dual

Thermal Performance

www.ti.com

Figure 1. LM3402 / 04 Schematic

Figure 2. LM3402/04 PSOP Thermal PAD and Via Layout

2

AN-1839 LM3402/LM3404 Fast Dimming and True Constant LED Current SNVA342E–July 2008–Revised April 2013

Evaluation Board

Copyright © 2008–2013, Texas Instruments Incorporated

Submit Documentation Feedback

Page 3

L

T

S

DT

S

t

I

LED(t)

I

F

V

OUT

L

VIN - V

OUT

'i

L

D =

t

ON

t

ON

+ t

OFF

=

= tON x f

SW

t

ON

T

S

www.ti.com

4 Connecting to LED Array

The LM3402/04 evaluation board includes two standard 94 mil turret connectors for the cathode and

anode connections to a LED array.

5 Low Power Shutdown

The LM3402/04 can be placed into a low power shutdown state (IQtypically 90 µA) by grounding the DIM

terminal. During normal operation this terminal should be left open-circuit.

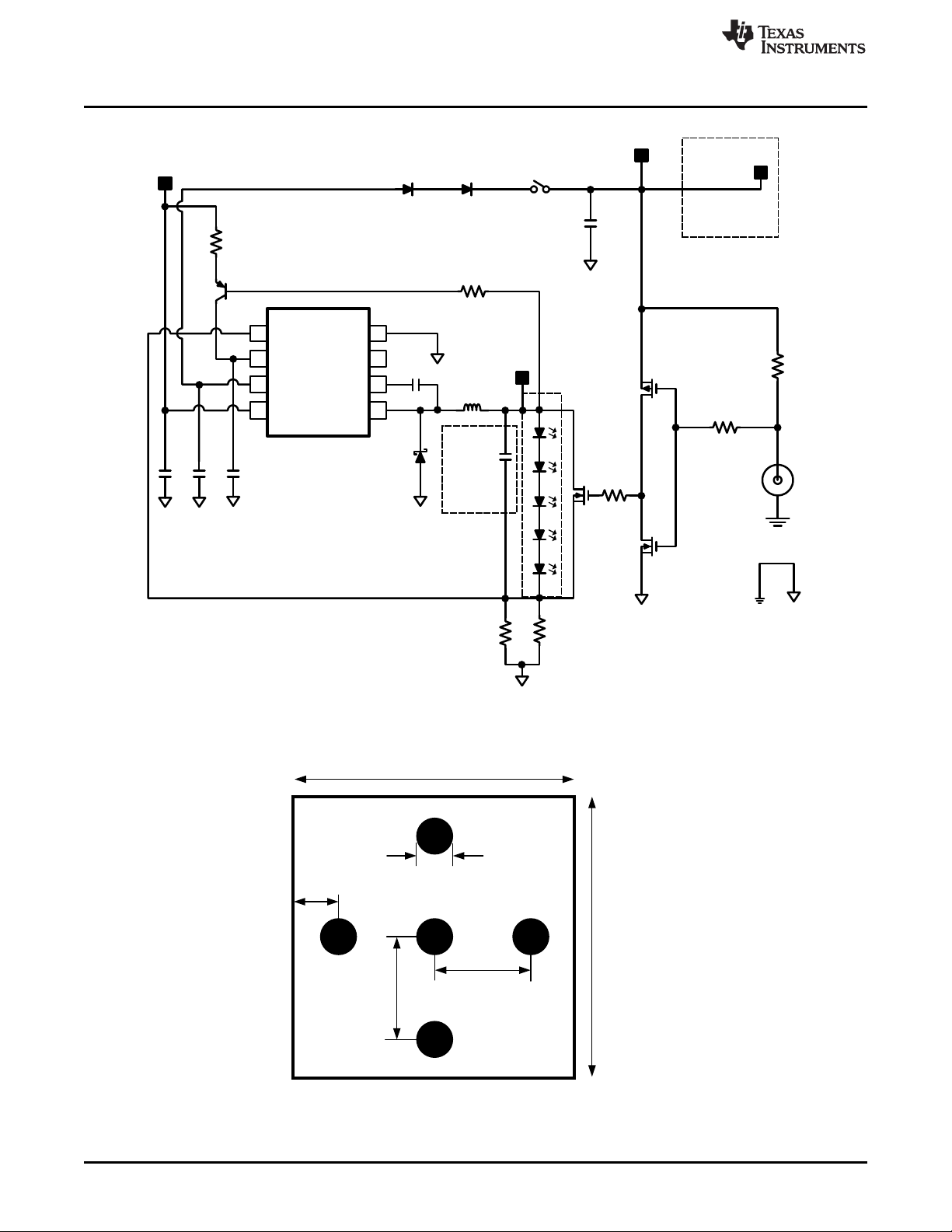

6 Constant On Time Overview

The LM3402 and LM3404 are buck regulators with a wide input voltage range and a low voltage

reference. The controlled on-time (COT) architecture is a combination of hysteretic mode control and a

one-shot on-timer that varies inversely with input voltage. With the addition of a PNP transistor, the ontimer can be made to be inversely proportional to the input voltage minus the output voltage. This is one of

the application improvements made to this demonstration board that will be discussed later (improved

average LED current circuit).

The LM3402 / 04 were designed with a focus of controlling the current through the load, not the voltage

across it. A constant current regulator is free of load current transients, and has no need for output

capacitance to supply the load and maintain output voltage. Therefore, in this demonstration board in

order to demonstrate the fast transient capabilities, I have chosen to omit the output capacitor. With any

Buck regulator, duty cycle (D) can be calculated with the following equations.

Connecting to LED Array

The average inductor current equals the average LED current whether an output capacitor is used or not.

Figure 3. Buck Converter Inductor Current Waveform

A voltage signal, V

ground. V

is fed back to the CS pin, where it is compared against a 200 mV reference (V

SNS

comparator turns on the power MOSFET when V

, is created as the LED current flows through the current setting resistor, R

SNS

falls below V

SNS

. The power MOSFET conducts for a

REF

REF

). A

SNS

, to

controlled on-time, tON, set by an external resistor, RON.

(1)

SNVA342E–July 2008–Revised April 2013 AN-1839 LM3402/LM3404 Fast Dimming and True Constant LED Current

Submit Documentation Feedback

3

Copyright © 2008–2013, Texas Instruments Incorporated

Evaluation Board

Page 4

I

LED-MIN

= IF -

'i

L

2

t

I

LED(t)

i

PEAK

t

ON

I

F

'i

D

'i

L

i

TARGET

i

LED-MIN

t

OFF

t

D

R

SNS

V

SNS

C

S

I

LED

+

-

Constant On Time Overview

www.ti.com

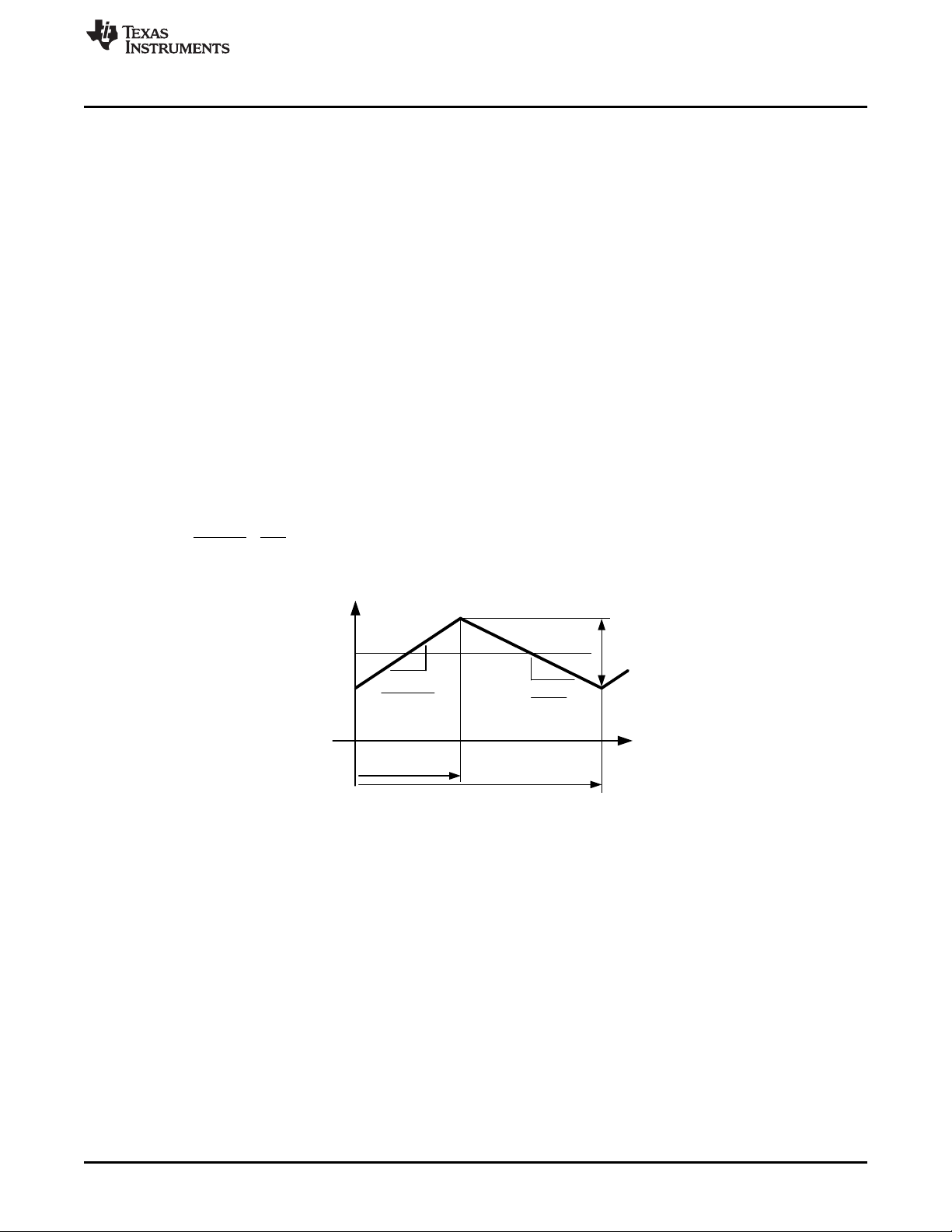

6.1 Setting the Average LED Current

Knowing the average LED current desired and the input and output voltages, the slopes of the currents

within the inductor can be calculated. The first step is to calculate the minimum inductor current (LED

current) point. This minimum level needs to be determined so that the average LED current can be

determined.

Figure 5. I

Figure 4. V

Current Waveform

SENSE

SNS

Circuit

Using Figure 3 and Figure 5 and the equations of a line, calculate I

LED-MIN

.

(2)

4

AN-1839 LM3402/LM3404 Fast Dimming and True Constant LED Current SNVA342E–July 2008–Revised April 2013

Evaluation Board

Copyright © 2008–2013, Texas Instruments Incorporated

Submit Documentation Feedback

Page 5

tON = k x

R

ON

V

IN

R

SNS

=

VIN - V

OUT

2L

x tON +

V

OUT

x t

D

L

(IF) -

0.20V

0.2V = R

SNS

VIN - V

OUT

2L

x tON +

V

OUT

L

x t

D

IF -

i

TARGET

= IF -

VIN - V

OUT

2L

x tON +

V

OUT

L

x t

D

V

OUT

L

'iD =

t

D

I

TARGET

= IF -

'i

L

2

+'i

D

=

VIN - V

OUT

2L

'i

2

x t

ON

www.ti.com

Where

The delta of the inductor current is given by:

There is a 220 ns delay (tD) from the time that the current sense comparator trips to the time at which the

control MOSFET actually turns on. We can solve for i

ΔiDis the magnitude of current beyond the target current and equal to:

Therefore:

The point at which you want the current sense comparator to give the signal to turn on the FET equals:

Therefore:

IF= I

i

TARGET

LED-Average

x R

SNS

Standard On-Time Set Calculation

(3)

(4)

knowing there is a delay.

TARGET

(5)

(6)

(7)

= 0.20V (8)

Finally R

can be calculated.

SNS

7 Standard On-Time Set Calculation

The control MOSFET on-time is variable, and is set with an external resistor RON(R2 from Figure 1). Ontime is governed by the following equation:

Where

k = 1.34 x 10

At the conclusion of tONthe control MOSFET turns off for a minimum OFF time (t

once t

OFF-MIN

The LM3402/04 have minimum ON and OFF time limitations. The minimum on time (tON) is 300 ns, and

the minimum allowed off time (t

Designing for the highest switching frequency possible means that you will need to know when minimum

ON and OFF times are observed.

Minimum OFF time will be seen when the input voltage is at its lowest allowed voltage, and the output

voltage is at its maximum voltage (greatest number of series LEDs).

The opposite condition needs to be considered when designing for minimum ON time. Minimum ON time

is the point at which the input voltage is at its maximum allowed voltage, and the output voltage is at its

lowest value.

-10

is complete the CS comparator compares V

) is 300 ns.

OFF

SNS

and V

) of 300 ns, and

again, waiting to begin the next cycle.

REF

OFF-MIN

(9)

(10)

(11)

(12)

SNVA342E–July 2008–Revised April 2013 AN-1839 LM3402/LM3404 Fast Dimming and True Constant LED Current

Submit Documentation Feedback

Copyright © 2008–2013, Texas Instruments Incorporated

Evaluation Board

5

Page 6

Application Circuit Calculations

8 Application Circuit Calculations

To better explain the improvements made to the COT LM3402/04 demonstration board, a comparison is

shown between the unmodified average output LED current circuit to the improved circuit. Design

Examples 1 and 2 use two original LM3402 / 04 circuits. The switching frequencies will be maximized to

provide a small solution size.

Design Example 3 is an improved average current application. Example 3 will be compared against

example 2 to illustrate the improvements.

Example 4 will use the same conditions and circuit as example 3, but the switching frequency will be

reduced to improve efficiency. The reduced switching frequency can further reduce any variations in

average LED current with a wide operating range of series LEDs and input voltages.

Design Example 1

• VIN= 48V (±20%)

• Driving three HB LEDs with VF= 3.4V

• V

• IF= 500 mA (typical application)

• Estimated efficiency = 82%

• fSW= fast as possible

• Design for typical application within tONand t

LED (inductor) ripple current of 10% to 60% is acceptable when driving LEDs. With this much allowed

ripple current, you can see that there is no need for an output capacitor. Eliminating the output capacitor is

actually desirable. An LED connected to an inductor without a capacitor creates a near perfect current

source, and this is what we are trying to create.

In this design we will choose 50% ripple current.

ΔiL= 500 mA x 0.50 = 250 mA

I

PEAK

Calculate tON, t

From the datasheet there are minimum control MOSFET ON and OFF times that need to be met.

t

OFF

tONminimum = 300 ns

The minimum ON time will occur when VINis at its maximum value. Therefore calculate RONat VIN= 60V,

and set tON= 300 ns.

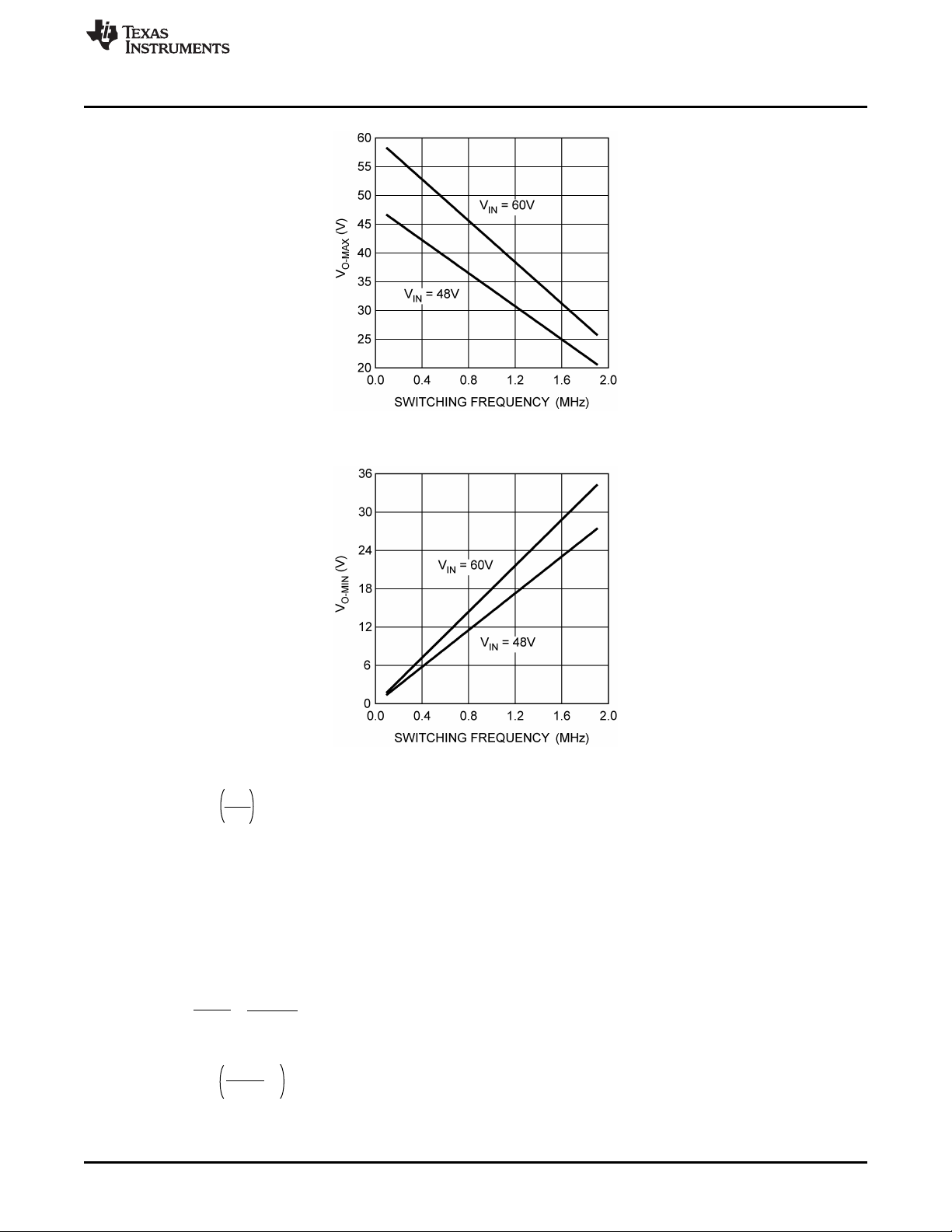

A quick guideline for maximum switching frequency allowed versus input and output voltages are in

Figure 6 and Figure 7.

= (3 x 3.4V +200 mV) = 10.4V

OUT

= 500 mA + 125 mA = 625 mA

and R

OFF

ON

minimum = 300 ns

limitations

OFF

www.ti.com

6

AN-1839 LM3402/LM3404 Fast Dimming and True Constant LED Current SNVA342E–July 2008–Revised April 2013

Evaluation Board

Copyright © 2008–2013, Texas Instruments Incorporated

Submit Documentation Feedback

Page 7

V

OUT

V

IN

x K

t

OFF

= t

ON

- 1

D =

V

OUT

V

IN

x K

=

t

ON

t

ON

+ t

OFF

tON = k x

R

ON

V

IN

www.ti.com

Application Circuit Calculations

Figure 6. V

Figure 7. V

OUT-MAX

OUT-MIN

vs f

vs f

SW

SW

RON= 135 kΩ (use standard value of 137 kΩ)

tON= 306 ns

Check to see if t

minimum is satisfied. This occurs when VINis at its minimum value.

OFF

At VIN= 36V, and RON= 137 kΩ calculate tONfrom previous equation.

tON= 510 ns

(13)

We know that:

Rearranging the above equation and solving for t

t

= 938 ns (satisfied)

OFF

SNVA342E–July 2008–Revised April 2013 AN-1839 LM3402/LM3404 Fast Dimming and True Constant LED Current

Submit Documentation Feedback

Copyright © 2008–2013, Texas Instruments Incorporated

with tONset to 510 ns

OFF

(14)

(15)

7

Evaluation Board

Page 8

I

LED(t)

i

PEAK

t

ON

I

F

'i

L

i

LED-MIN

t

OFF

t

Application Circuit Calculations

VIN(V) V

36 10.4 5.10E-07 9.38E-07

48 10.4 3.82E-07 1.06E-06

60 10.4 3.06E-07 1.14E-06

Calculate Switching Frequency

VIN= 36V, 48 and 60V.

Substituting equations:

fSW= 691kHz (VIN= 36V, 48V, and 60V)

Calculate Inductor Value

With 50% ripple at VIN= 48V

• IF= 500 mA

• ΔiL= 250 mA (target)

• L = 57 µH (68 µH standard value)

Calculate Δi for VIN= 36V, 48V, and 60V with L = 68 µH

VIN(V) V

36 10.4 0.192

48 10.4 0.211

60 10.4 0.223

Table 1. Example 1 ON and OFF Times

(V) t

OUT

ON

Table 2. Example 1 Ripple Current

(V) ΔiL(A)

OUT

t

OFF

www.ti.com

Calculate R

Calculate R

SNS

at VINtypical (48V), and average LED current (IF) set to 500 mA.

SNS

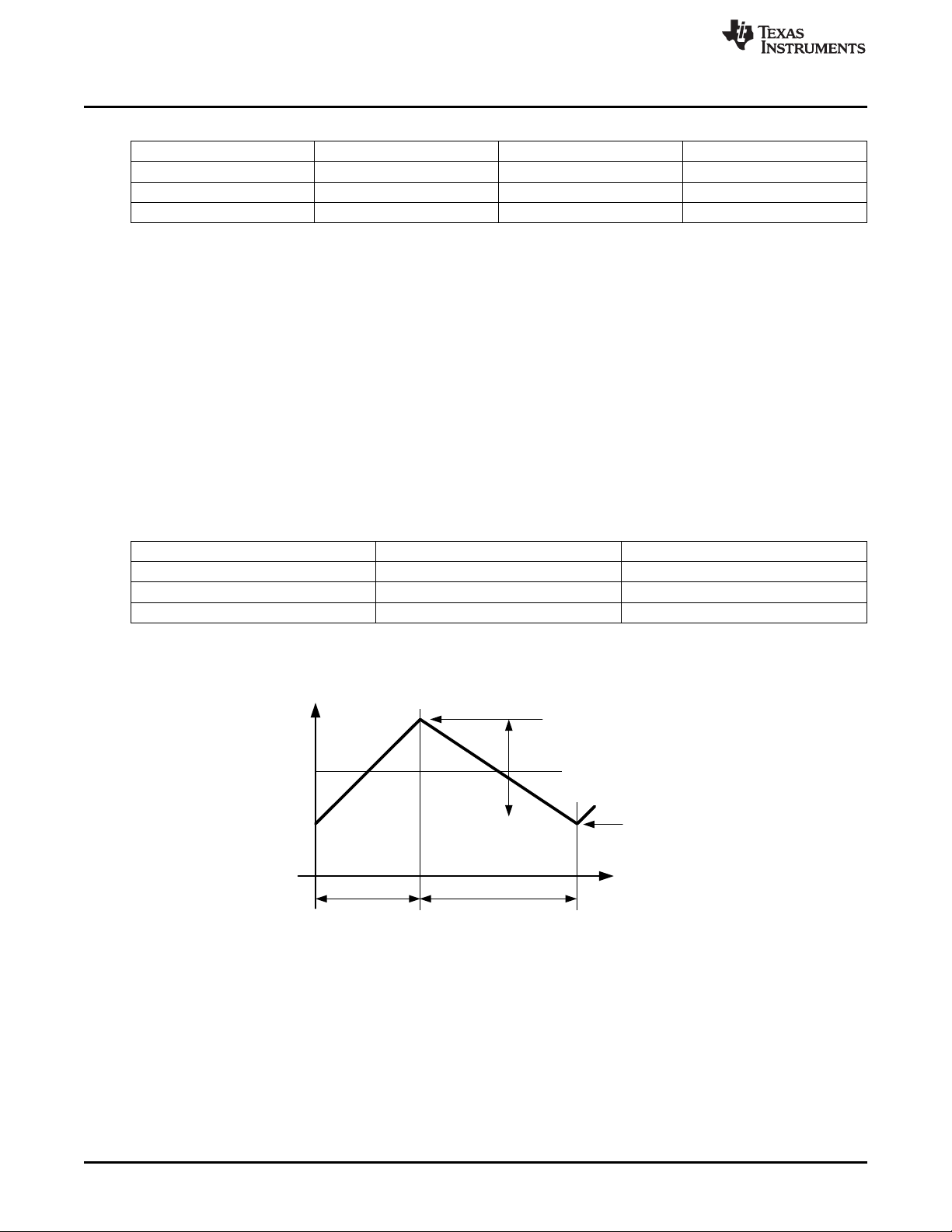

Figure 8. Inductor Current Waveform

• IF= 500 mA

• VIN= 48V

• V

• L = 68 µH

• tD= 220 ns

• tON= 382 ns

Using equations from the COT Overview section, calculate R

8

AN-1839 LM3402/LM3404 Fast Dimming and True Constant LED Current SNVA342E–July 2008–Revised April 2013

Evaluation Board

OUT

= 10.4V

.

SNS

Copyright © 2008–2013, Texas Instruments Incorporated

Submit Documentation Feedback

Page 9

tON = k x

R

ON

V

IN

IF =

R

SNS

0.20V

+

VIN - V

OUT

2L

(tON) -

V

OUT

x t

D

L

R

SNS

=

VIN - V

OUT

2L

x tON +

V

OUT

x t

D

L

(IF) -

0.20V

R

SNS

=

VIN - V

OUT

2L

V

OUT

x t

D

L

(IF) -

0.20V

Or:

k x R

ON

V

IN

+

www.ti.com

Therefore: R

Calculate Average LED current (IF)

Calculate average current through the LEDs for VIN= 36V and 60V.

Design Example 2

Design example 2 demonstrates a design if a single Bill of Materials (Bom) is desired over many different

applications (number of series LEDs, VIN, V

• VIN= 48V (±20%)

• Driving 3, 4, or 5 HB LEDs with VF= 3.4V

• IF= 500 mA (typical application)

• Estimated efficiency = 82%

• fSW= fast as possible

• Design for typical application within tONand t

The inductor, RONresistor, and the R

• V

• V

• V

Calculate tON, t

In this design we will maximize the switching frequency so that we can reduce the overall size of the

design. In a later design, a slower switching frequency is utilized to maximize efficiency. If the design is to

use the highest possible switching frequency, you must ensure that the minimum on and off times are

adhered to.

Minimum on time occurs when VINis at its maximum value, and V

Calculate RONat VIN= 60V, V

= 467 mΩ

SNS

VIN(V) V

36 10.4 0.490

48 10.4 0.500

60 10.4 0.506

= 3 x 3.4V + 200 mV = 10.4V

OUT

= 4 x 3.4V + 200 mV = 13.8V

OUT

= 5 x 3.4V + 200 mV = 17.2V

OUT

and R

OFF

ON

Table 3. Example 1 Average LED Current

(V) IF(A)

OUT

etc).

OUT

limitations

OFF

resistor is calculated for a typical or average design.

SNS

is at its lowest value.

OUT

= 10.4V, and set tON= 300 ns:

OUT

Application Circuit Calculations

(16)

(17)

RON= 137 kΩ, tON= 306 ns

Check to see if t

t

minimum occurs when VINis at its lowest value, and V

SNVA342E–July 2008–Revised April 2013 AN-1839 LM3402/LM3404 Fast Dimming and True Constant LED Current

Submit Documentation Feedback

OFF

At VIN= 36V, V

minimum is satisfied:

OFF

is at its maximum value.

= 17.2V, and RON= 137 kΩ calculate tONfrom the above equation:

OUT

Copyright © 2008–2013, Texas Instruments Incorporated

OUT

(18)

9

Evaluation Board

Page 10

'i

V

IN

- V

OUT

L =

x t

ON

fSW =

1

tON + t

OFF

fSW =

V

OUT

K x k x R

ON

fSW =

V

OUT

VIN x K x t

ON

V

OUT

V

IN

x K

t

OFF

= t

ON

- 1

V

OUT

V

IN

x K

=

t

ON

t

ON

+ t

OFF

Application Circuit Calculations

tON= 510 ns

Rearrange the above equation and solve for t

t

= 365 ns (satisfied)

OFF

Three Series LEDs

VIN(V) V

36 10.4 137 kΩ 5.10E-07 9.38E-07

48 10.4 137 kΩ 3.82E-07 1.06E-06

60 10.4 137 kΩ 3.06E-07 1.14E-06

Four Series LEDs

36 13.8 137 kΩ 5.10E-07 5.81E-07

48 13.8 137 kΩ 3.82E-07 7.08E-07

60 13.8 137 kΩ 3.06E-07 7.85E-07

Five Series LEDs

36 17.2 137 kΩ 5.10E-07 3.65E-07

48 17.2 137 kΩ 3.82E-07 4.93E-07

60 17.2 137 kΩ 3.06E-07 5.69E-07

with tONset to 510 ns

OFF

Table 4. Example 2 On and Off Time

(V) R

OUT

ON

www.ti.com

(19)

(20)

t

ON

t

OFF

Calculate Switching Frequency

The switching frequency will only change with output voltage.

Substituting equations:

Or:

• fSW= 691 kHz (V

• fSW= 916 kHz (V

• fSW= 1.14 MHz (V

OUT

OUT

OUT

= 10.4V)

= 13.8V)

= 17.2V)

Calculate Inductor Value

With 50% ripple at VIN= 48V, and V

• I

= 500 mA

AVG

OUT

= 10.4V

• ΔiL= 250 mA (target)

• L = 53 µH (68 uH standard value)

(21)

(22)

(23)

(24)

Calculate Δi for VIN= 36V, 48V, and 60V with L = 68 µH.

10

AN-1839 LM3402/LM3404 Fast Dimming and True Constant LED Current SNVA342E–July 2008–Revised April 2013

Evaluation Board

Copyright © 2008–2013, Texas Instruments Incorporated

Submit Documentation Feedback

Page 11

IF =

R

SNS

0.20V

+

VIN - V

OUT

2L

(tON) -

V

OUT

x t

D

L

R

SNS

=

VIN - V

OUT

2L

x tON +

V

OUT

x t

D

L

(IF) -

0.20V

www.ti.com

Three Series LEDs

Four Series LEDs

Four Series LEDs

Application Circuit Calculations

Table 5. Example 2 Ripple Current

VIN(V) V

36 10.4 0.192

48 10.4 0.211

60 10.4 0.223

36 13.8 0.166

48 13.8 0.192

60 13.8 0.208

36 17.2 0.141

48 17.2 0.173

60 17.2 0.193

(V) ΔiL(A)

OUT

Calculate R

Calculate R

SNS

at VINtypical (48V), with four series LEDs (13.8V = V

SNS

to 500 mA.

• IF= 500 mA

• VIN= 48V

• V

OUT

= 13.8V

• L = 68 µH

• tD= 220 ns

• tON= 382 ns

R

= 446 mΩ

SNS

Calculate Average Current through LED

All combinations of VIN, V

OUT

with R

= 446 mΩ

SNS

Table 6. Example 2 Average LED Current

VIN(V) V

Three Series LEDs

36 10.4 0.511

48 10.4 0.521

60 10.4 0.526

Four Series LEDs

36 13.8 0.487

48 13.8 0.500

60 13.8 0.508

Five Series LEDs

36 17.2 0.463

48 17.2 0.479

60 17.2 0.489

), and average LED current (IF) set

OUT

(V) IF(A)

OUT

(25)

(26)

SNVA342E–July 2008–Revised April 2013 AN-1839 LM3402/LM3404 Fast Dimming and True Constant LED Current

Submit Documentation Feedback

Copyright © 2008–2013, Texas Instruments Incorporated

Evaluation Board

11

Page 12

V

OUT

V

IN

x K

t

OFF

= t

ON

- 1

VIN - V

OUT

k

R

ON

= t

ON

VIN - V

OUT

R

ON

t

ON

= k x

Modified COT Application Circuit

In this application you can see that there is a difference of 63 mA between the low and high of the

average LED current.

9 Modified COT Application Circuit

With the addition of one pnp transistor and one resistor (Q1 and R3) the average current through the

LEDs can be made to be more constant over input and output voltage variations. Refer to page one,

Figure 1. Resistor RON(R2) and Q1 turn the tONequation into:

Ignore the PNP transistor’s VBEvoltage drop.

Design to the same criteria as the previous example with the improved application and compare results.

10 Modified Application Circuit Design Example 3

Design Example 1

• VIN= 48V (±20%)

• Driving 3, 4, or 5 HB LEDs with VF= 3.4V

• IF= 500 mA (typical application)

• Estimated efficiency = 82%

• fSW= fast as possible

• Design for typical application within tONand t

The inductor, RONresistor, and the R

• V

= 3 x 3.4V + 200 mV = 10.4V

OUT

• V

= 4 x 3.4V + 200 mV = 13.8V

OUT

• V

= 5 x 3.4V + 200 mV = 17.2V

OUT

Calculate tON, t

OFF

and R

ON

resistor are calculated for a typical or average design.

SNS

Minimum ON time occurs when VINis at its maximum value, and V

Calculate RONat VIN= 60V, V

= 10.4V, and set tON= 300 ns:

OUT

limitations

OFF

is at its lowest value.

OUT

www.ti.com

(27)

12

RON= 111 kΩ (113 kΩ) tON= 306 ns

Check to see if t

At VIN= 36V, V

minimum is satisfied.

OFF

= 17.2V, and RON= 113 kΩ calculate t

OUT

ON:

.

tON= 806 ns

t

= 577 ns (satisfied)

OFF

AN-1839 LM3402/LM3404 Fast Dimming and True Constant LED Current SNVA342E–July 2008–Revised April 2013

Evaluation Board

Copyright © 2008–2013, Texas Instruments Incorporated

Submit Documentation Feedback

(28)

(29)

Page 13

2

1

3

4

7

8

6

5

C1

V

IN

V

OUT

SW

BOOT

GND

DIM

VIN

VCC

RON

CS

C3

Q1

L1

R3

LEDs on separate PCB

Optional

C4

U1

D1

C2

C5

LM3404

R2

R1

Improved Average

Current Circuit

www.ti.com

Modified Application Circuit Design Example 3

Figure 9. Improved Average LED Current Application Circuit

Table 7. Example 3 On and Off Times

Three Series LEDs

Four Series LEDs

Five Series LEDs

VIN(V) V

36 10.4 113 kΩ 5.92E-07 1.09E-07

48 10.4 113 kΩ 4.03E-07 1.12E-06

60 10.4 113 kΩ 3.06E-07 1.14E-06

36 13.8 113 kΩ 6.83E-07 7.78E-07

48 13.8 113 kΩ 4.43E-07 8.21E-07

60 13.8 113 kΩ 3.28E-07 8.41E-07

36 17.2 113 kΩ 8.06E-07 5.77E-07

48 17.2 113 kΩ 4.92E-07 6.34E-07

60 17.2 113 kΩ 3.54E-07 6.59E-07

(V) R

OUT

ON

t

ON

t

OFF

SNVA342E–July 2008–Revised April 2013 AN-1839 LM3402/LM3404 Fast Dimming and True Constant LED Current

Submit Documentation Feedback

Copyright © 2008–2013, Texas Instruments Incorporated

Evaluation Board

13

Page 14

R

SNS

=

VIN - V

OUT

2L

V

OUT

x t

D

L

(IF) -

0.20V

R

ON

VIN - V

OUT

+

k x

R

SNS

=

VIN - V

OUT

2L

x tON +

V

OUT

x t

D

L

(IF) -

0.20V

'i

R

ON

L =

x k

VIN - V

OUT

R

ON

t

ON

= k x

'i

V

IN

- V

OUT

L =

x t

ON

fSW =

V

OUT

VIN x K x t

ON

Or:

fSW =

1

tON + t

OFF

Modified Application Circuit Design Example 3

Calculate Switching Frequency

Table 8. Example 3 Switching Frequency

VIN(V) V

Three Series LEDs

36 10.4 595

48 10.4 656

60 10.4 692

Four Series LEDs

36 13.8 685

48 13.8 791

60 13.8 855

Five Series LEDs

36 17.2 723

48 17.2 888

60 17.2 987

(V) fSW(kHz)

OUT

www.ti.com

(30)

Calculate Inductor Value

Therefore:

You can quickly see one benefit of the modified circuit. The improved circuit eliminates the input and

output voltage variation on RMS current.

• IF= 500 mA (typical application)

• ΔiL= 250 mA (target)

• RON= 113 kΩ

• L = 59 µH (68 µH standard value)

• ΔiL= 223 mA (L = 68 µH all combinations)

Calculate R

Original R

SNS

equation:

SNS

Substitute improved circuit tONcalculation:

(31)

(32)

(33)

14

Simplified:

AN-1839 LM3402/LM3404 Fast Dimming and True Constant LED Current SNVA342E–July 2008–Revised April 2013

Evaluation Board

Copyright © 2008–2013, Texas Instruments Incorporated

Submit Documentation Feedback

(34)

Page 15

V

OUT

x t

D

L

+

0.20V

k x R

ON

2L

-

R

SNS

IF =

VIN - V

OUT

2L

V

OUT

x t

D

L

+

0.20V

k x R

ON

VIN - V

OUT

-

R

SNS

IF =

R

SNS

=

V

OUT

x t

D

L

(IF) -

0.20V

k x R

ON

2L

+

www.ti.com

Typical Application:

• V

• IF= 500 mA

• RON= 113 kΩ

• L = 68 µH

• tD= 220 ns

R

This equation shows that only variations in V

range. These variations should be very minor even with large variations in output voltage.

Calculate Average Current through LED

Modified application circuit average forward current equation.

Simplified:

OUT

= 462 mΩ

SNS

= 13.8V

Modified Application Circuit Design Example 4

will affect the average current over the entire application

OUT

(35)

(36)

(37)

Table 9. Example 3 Average LED Current

VIN(V) V

Three Series LEDs

36 10.4 0.511

48 10.4 0.511

60 10.4 0.511

Four Series LEDs

36 13.8 0.500

48 13.8 0.500

60 13.8 0.500

Five Series LEDs

36 17.2 0.489

48 17.2 0.489

60 17.2 0.489

OUT

In this application you can see that there is a difference of 22 mA between the low and high of the

average LED current.

11 Modified Application Circuit Design Example 4

• VIN= 48V (±20%)

• Driving 3, 4, or 5 HB LEDs with VF= 3.4V

• IF= 500 mA (typical application)

• Estimated efficiency = 82%

• fSW= 500 kHz (typ app)

(V) IF(A)

The inductor, RONresistor, and the R

• V

= 3 x 3.4V + 200 mV = 10.4V

OUT

SNVA342E–July 2008–Revised April 2013 AN-1839 LM3402/LM3404 Fast Dimming and True Constant LED Current

Submit Documentation Feedback

Copyright © 2008–2013, Texas Instruments Incorporated

resistor are calculated for a typical or average design.

SNS

Evaluation Board

15

Page 16

fSW =

V

OUT

VIN x K x t

ON

Or:

fSW =

1

tON + t

OFF

'i

R

ON

L =

x k

t

ON

k

R

ON

=

(V

IN

- V

OUT)

V

OUT

V

IN

x K

t

ON

=

1

f

SW

Modified Application Circuit Design Example 4

• V

= 4 x 3.4V + 200 mV = 13.8V

OUT

• V

= 5 x 3.4V + 200 mV = 17.2V

OUT

Reduce switching frequency for the typical application to about 500 kHz to increase efficiency.

Calculate tON, t

• V

OUT

= 13.8V

OFF

and R

ON

• VIN= 48V

• IF= 500 mA

• tD= 220 ns

• η = 0.85

• fSW= 500 kHz

tON≊ 705 ns

RON≊ 179 kΩ (use standard value of 182 kΩ)

Calculate Inductor Value

www.ti.com

(38)

(39)

• IF= 500 mA

• ΔiL= 250 mA (target)

• RON= 182 kΩ

• L = 100 µH

Calculate ΔiLwith L = 100 µH (VIN= 48V, V

OUT

= 13.8V)

ΔiL= 241 mA (all combinations)

Calculate Switching Frequency

Table 10. Example 4 Switching Frequency

VIN(V) V

Three Series LEDs

36 10.4 374

48 10.4 412

60 10.4 435

Four Series LEDs

36 13.8 430

48 13.8 497

60 13.8 537

Five Series LEDs

36 17.2 454

48 17.2 558

60 17.2 620

16

AN-1839 LM3402/LM3404 Fast Dimming and True Constant LED Current SNVA342E–July 2008–Revised April 2013

Evaluation Board

Copyright © 2008–2013, Texas Instruments Incorporated

(V) fSW(kHz)

OUT

Submit Documentation Feedback

(40)

(41)

Page 17

V

OUT

x t

D

L

+

0.20V

k x R

ON

2L

-

R

SNS

IF =

R

SNS

=

V

OUT

x t

D

L

(IF) -

0.20V

k x R

ON

2L

+

www.ti.com

Dimming

Calculate R

• V

OUT

SNS

= 13.8V

• VIN= 48V

• IF= 500 mA

• tD= 220 ns

• η = 0.85

• L = 100 µH

R

= 488 mΩ

SNS

Calculate Average Current through LED

Table 11. Example 4 Average LED Current

VIN(V) V

Three Series LEDs

36 10.4 0.507

48 10.4 0.507

60 10.4 0.507

Four Series LEDs

36 13.8 0.500

48 13.8 0.500

60 13.8 0.500

Five Series LEDs

36 17.2 0.493

48 17.2 0.493

60 17.2 0.493

(V) IF(A)

OUT

(42)

(43)

In the reduced frequency application you can see that there is a difference of 14 mA between the low and

high of the average current.

If the original tONcircuit was used (no PNP transistor) with the switching frequency centered around 500

kHz the difference between the high and low values would be about 67 mA.

12 Dimming

The DIM pin of the LM3402/04 is a TTL compatible input for low frequency pulse width modulation (PWM)

dimming of the LED current. Depending on the application, a contrast ratio greater than what the

LM3402/04 internal DIM circuitry can provide might be needed. This demonstration board comes with

external circuitry that allows for dimming contrast ratios greater than 50k:1.

13 LM3402/04 DIM Pin Operation

To fully enable and disable the LM3402 / 04, the PWM signal should have a maximum logic low level of

0.8V and a minimum logic high level of 2.2V. Dimming frequency, f

the LED current rise time and fall time and the delay from activation of the DIM pin to the response of the

internal power MOSFET. In general, f

should be at least one order of magnitude lower than the steady

DIM

state switching frequency in order to prevent aliasing.

SNVA342E–July 2008–Revised April 2013 AN-1839 LM3402/LM3404 Fast Dimming and True Constant LED Current

Submit Documentation Feedback

Copyright © 2008–2013, Texas Instruments Incorporated

, and duty cycle, D

DIM

, are limited by

DIM

Evaluation Board

17

Page 18

T

D

t

D

t

SD

tDtSUt

SD

tDt

SU

t

SD

D

MIN

D

MAX

T T

DIM

I

F

f

PWM

T =

1

T

tD + t

SU

D

MIN

=

T

T - t

SD

D

MAX

=

t

SU

Contrast Ratio Definition

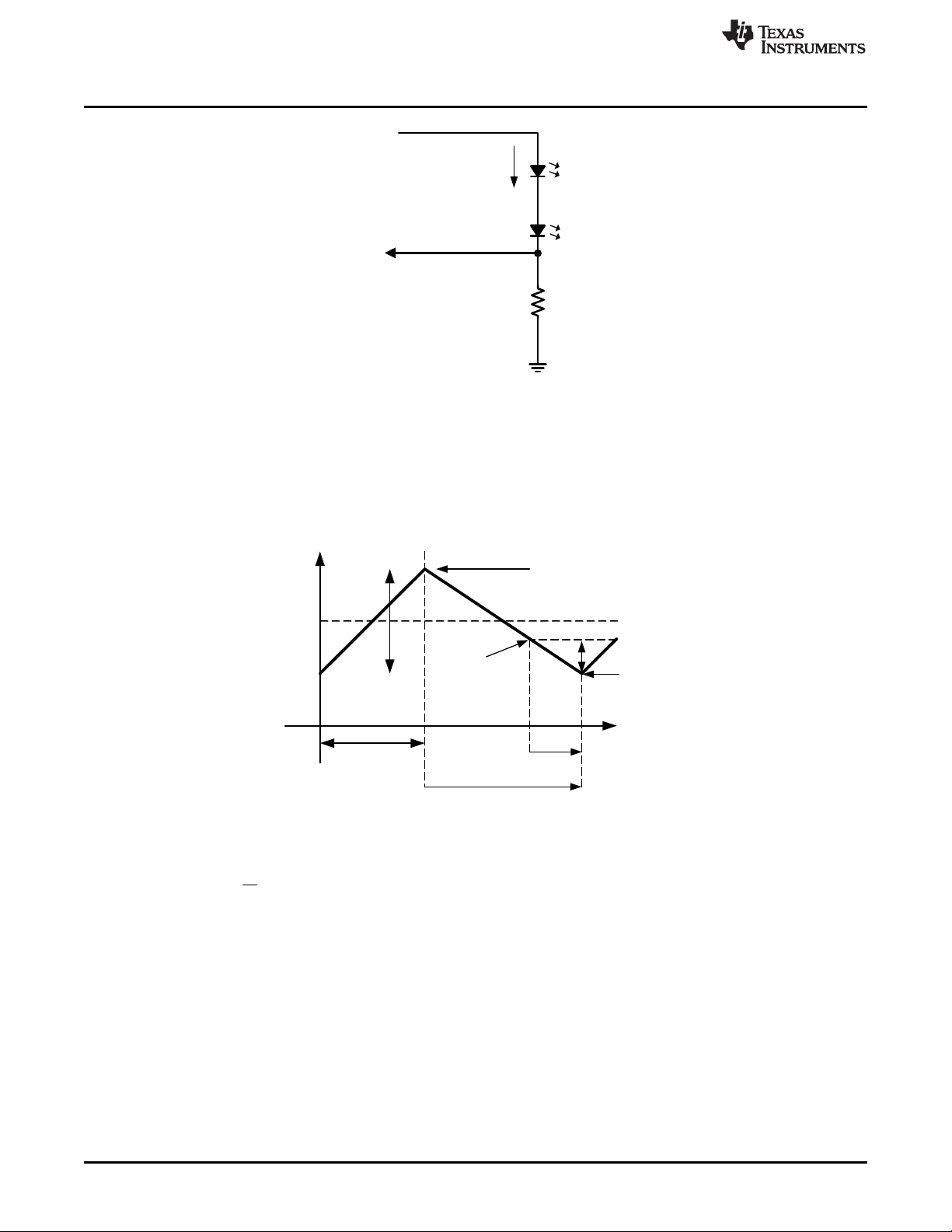

For illustrations, see Figure 10. The interval tDrepresents the delay from a logic high at the DIM pin to the

onset of the output current. The quantities tSUand tSDrepresent the time needed for the LED current to

slew up to steady state and slew down to zero, respectively.

As an example, assume a DIM duty cycle D

of current through the LED string. At D

through your LED string (250 mA). This could only be possible if there were no delays (tD) between the

on/off DIM signal and the on/off of the LED current. The rise and fall times (tSUand tSD) of the LED current

would also need to be eliminated. If we can reduce these times, the linearity between the PWM signal and

the average current will be realized.

equal to 100% (always on) and the circuit delivers 500mA

DIM

equal to 50% you would like exactly ½ of 500 mA of current

DIM

www.ti.com

Figure 10. Contrast Ratio Definitions

14 Contrast Ratio Definition

Contrast Ratio (CR) = 1/D

D

= (tD+ tSU) x f

MIN

DIM

MIN

18

AN-1839 LM3402/LM3404 Fast Dimming and True Constant LED Current SNVA342E–July 2008–Revised April 2013

Evaluation Board

Copyright © 2008–2013, Texas Instruments Incorporated

Submit Documentation Feedback

Page 19

2 Ps/DIV

I

F

200 mA/Div

DIM

5V/Div

www.ti.com

Figure 11. tDand tSU(DIM Pin)

15 External MOSFET Dimming and Contrast Ratio

MOSFET Q4 and its drive circuitry are provided on the demonstration PCB (see Figure 12). When

MOSFET Q4 is turned on, it shorts LED+ to LED-, therefore redirecting the inductor current from the LED

string to the shunt MOSFET. The LM3402 / 04 is never turned off, and therefore become a perfect current

source by providing continuous current to the output through the inductor (L1). A buck converter with an

external shunt MOSFET is the ideal circuit for delivering the highest possible contrast ratio. For typical

delays and rise time for external MOSFET dimming, see Figure 13 - Figure 15.

External MOSFET Dimming and Contrast Ratio

SNVA342E–July 2008–Revised April 2013 AN-1839 LM3402/LM3404 Fast Dimming and True Constant LED Current

Submit Documentation Feedback

Copyright © 2008–2013, Texas Instruments Incorporated

Evaluation Board

19

Page 20

8.0 0.0 8.4 16.6 24.8 33.0

V

DIM

(V)

TIME (Ps)

-1.0

2.0

5.0

8.0

11.0

I

LED

(

A

)

-0.1

0.2

0.5

0.8

1.1

I

LED

V

DIM

R1A

Q4

L1

LEDs on separate PCB

Optional

R5

Q3

2

CONN-1

C4

V

DIM

C5

JMP-1

External Voltage

Source Optional

4V to 6V

1N4148

Dual

Single package (SC70-6)

Complementary N+P Channel

D2

Q3

1

R1B

R4

R6

V

DIM

From V

CC

LM3402/04

External MOSFET Dimming and Contrast Ratio

www.ti.com

Figure 12. VIN= 24V, 3 series LEDs @ 400mA

AN-1839 LM3402/LM3404 Fast Dimming and True Constant LED Current SNVA342E–July 2008–Revised April 2013

Evaluation Board

20

Copyright © 2008–2013, Texas Instruments Incorporated

Submit Documentation Feedback

Page 21

VIN - 0.2V

R

ON

t

ON

= k x

VIN - V

OUT

R

ON

t

ON

= k x

TIME (ns)

-100

-60 -20 20 60

100

V

DIM

(V)

I

LED

(

A

)

-0.20

0.20

0.60

1.00

0.0

4.0

8.0

12.0

I

LED

V

DIM

36 ns

TIME (ns)

-100

-60 -20 20 60

100

V

DIM

(V)

I

LED

(

A

)

-0.1

0.2

0.5

0.8

1.1

-1

3

7

11

I

LED

V

DIM

40 ns

www.ti.com

Fast Dimming + Improved Average Current Circuit

Figure 13. tD+ tSUGraph

Figure 14. tD+ tSDGraph

16 Fast Dimming + Improved Average Current Circuit

Using both the Improved Average LED current circuit and the external MOSFET fast dimming circuit

together has additional benefits. If RONand the converter's switching frequency (fSW) is determined and set

with the improved average LED current circuit, the switching frequency will decrease once V

during fast dimming. With MOSFET Q4 on, V

is equal to VFB(200 mV). The tONequation then becomes

OUT

almost identical to the original unmodified circuit equation.

Setting tONand RON:

tONequation becomes:

when Q4 shunt MOSFET is on during fast dimming.

t

OFF

SNVA342E–July 2008–Revised April 2013 AN-1839 LM3402/LM3404 Fast Dimming and True Constant LED Current

Submit Documentation Feedback

equation during normal operation is:

Copyright © 2008–2013, Texas Instruments Incorporated

Evaluation Board

is shorted

OUT

(44)

(45)

21

Page 22

0 10 20 30 40 50 60 70 80 90 100

0

50

100

150

200

250

350

I

LED

(A)

DUTY CYCLE (%)

300

f

DIM

= 25 kHz

f

DIM

= 5 kHz

f

DIM

= 500 Hz

-6.0

0.5 7.0 13.5 20.0

TIME (Ps)

-2.0

4.0

10.0

16.0

22.0

28.0

34.0

V

SW

(V)

0.5

0.4

0.2

0.1

-0.1

-0.3

-0.4

I

LED

(

A

)

fSW = 650 kHz

I

LED

(A)

VSW (V)

V

DIM

(V)

fSW = 75 kHz

0.2V

V

IN

x K

t

OFF

= t

ON

- 1

V

OUT

V

IN

x K

t

OFF

= t

ON

- 1

Linearity with Fast Dimming

t

equation then becomes:

OFF

when Q2 shunt MOSFET is OFF during fast dimming.

This is an added benefit due to the fact that t

frequency is decreased, which leads to improved efficiency (see Figure 16). Inductor L1 still remains

charged, and as soon as Q4 turns off current flows through the LED string.

is greatly increased, and therefore the switching

OFF

www.ti.com

(46)

(47)

17 Linearity with Fast Dimming

Once the delays and rise/fall times have been greatly reduced, linear average current vs, duty cycle (D

can be achieved at very high dimming frequencies (f

22

AN-1839 LM3402/LM3404 Fast Dimming and True Constant LED Current SNVA342E–July 2008–Revised April 2013

Evaluation Board

Figure 15. Improved Avg I

Figure 16. Linearity With Fast Dimming

Copyright © 2008–2013, Texas Instruments Incorporated

Circuit + Fast Dimming

LED

) (see Figure 17).

DIM

DIM

Submit Documentation Feedback

)

Page 23

2

1

3

4

C1

V

IN

V

OUT

7

8

6

5

SW

BOOT

GND

DIM

VIN

VCC

RON

CS

C3

R1A

Q1

Q4

L1

R3

LEDs on separate PCB

Optional

R5

Q3

2

CONN-1

C4

V

DIM

C6

JMP-1

U1

External Voltage

Source Optional

4V to 6V

Single package (SC70-6)

Complementary N+P Channel

D1

D2

C2

C5

LM3404

R2

Q3

1

R1B

R4

R6

V

DIM

1N4148

Dual

www.ti.com

LM3404 Improved ILED Average and Fast Dimming Demonstration Board

18 LM3404 Improved ILED Average and Fast Dimming Demonstration Board

Figure 17. VIN= 9V to 18V, I

= 700 mA, 3 x 3.4V White LED Strings (fSW≊≊ 500 kHz)

LED

SNVA342E–July 2008–Revised April 2013 AN-1839 LM3402/LM3404 Fast Dimming and True Constant LED Current

Submit Documentation Feedback

Copyright © 2008–2013, Texas Instruments Incorporated

Evaluation Board

23

Page 24

Bill of Materials

19 Bill of Materials

Part ID Part Value Mfg Part Number

U1 1A Buck LED Driver NSC LM3404

C1, Input Cap 10 µF, 25V, X5R TDK C3225X5R1E106M

C2, C6 Cap 1 µF, 16V, X5R TDK C1608X5R1C105M

C3, V

C4 Output Cap 10 µF, 25V, X5R (Optional) TDK C3225X5R1E106M

C5, V

D1, Catch Diode 0.5VfSchottky 2A, 30V

R1A, R1B 0.62Ω 1% 0.25W 1206 ROHM MCR18EZHFLR620

Test Points Connector Keystone 1502-2

VIN, GND, LED+, LED- Connector Keystone 575-8

Cap 0.1 µF, X5R TDK C1608X5R1H104M

BOOST

Cap 0.01 µF, X5R TDK C1608X5R1H103M

RON

D2 Dual SMT small signal Diodes INC BAV199

L1 33 µH CoilCraft D01813H-333

R2 47.5 kΩ 1% Vishay CRCW08054752F

R3 1.0 kΩ, 1% Vishay CRCW08051001F

R4, R5 1Ω, 1% Vishay CRCW08051R00F

R6 10 kΩ, 1% Vishay CRCW08051002F

Q1 SOT23 PNP Diodes INC MMBT3906

Q4 SOT23-6 N-CH 2.4A, 20V ZETEX ZXMN2A01E6

Q3 SC70-6, P + N Channel Vishay Si1539DL

JMP-1 Jumper Molex 22-28-4023

J15 50Ω BNC Amphenol 112538

SO PowerPAD pkg

www.ti.com

R

Diodes INC B230

20 Layout

24

AN-1839 LM3402/LM3404 Fast Dimming and True Constant LED Current SNVA342E–July 2008–Revised April 2013

Evaluation Board

Copyright © 2008–2013, Texas Instruments Incorporated

Submit Documentation Feedback

Page 25

IMPORTANT NOTICE

Texas Instruments Incorporated and its subsidiaries (TI) reserve the right to make corrections, enhancements, improvements and other

changes to its semiconductor products and services per JESD46, latest issue, and to discontinue any product or service per JESD48, latest

issue. Buyers should obtain the latest relevant information before placing orders and should verify that such information is current and

complete. All semiconductor products (also referred to herein as “components”) are sold subject to TI’s terms and conditions of sale

supplied at the time of order acknowledgment.

TI warrants performance of its components to the specifications applicable at the time of sale, in accordance with the warranty in TI’s terms

and conditions of sale of semiconductor products. Testing and other quality control techniques are used to the extent TI deems necessary

to support this warranty. Except where mandated by applicable law, testing of all parameters of each component is not necessarily

performed.

TI assumes no liability for applications assistance or the design of Buyers’ products. Buyers are responsible for their products and

applications using TI components. To minimize the risks associated with Buyers’ products and applications, Buyers should provide

adequate design and operating safeguards.

TI does not warrant or represent that any license, either express or implied, is granted under any patent right, copyright, mask work right, or

other intellectual property right relating to any combination, machine, or process in which TI components or services are used. Information

published by TI regarding third-party products or services does not constitute a license to use such products or services or a warranty or

endorsement thereof. Use of such information may require a license from a third party under the patents or other intellectual property of the

third party, or a license from TI under the patents or other intellectual property of TI.

Reproduction of significant portions of TI information in TI data books or data sheets is permissible only if reproduction is without alteration

and is accompanied by all associated warranties, conditions, limitations, and notices. TI is not responsible or liable for such altered

documentation. Information of third parties may be subject to additional restrictions.

Resale of TI components or services with statements different from or beyond the parameters stated by TI for that component or service

voids all express and any implied warranties for the associated TI component or service and is an unfair and deceptive business practice.

TI is not responsible or liable for any such statements.

Buyer acknowledges and agrees that it is solely responsible for compliance with all legal, regulatory and safety-related requirements

concerning its products, and any use of TI components in its applications, notwithstanding any applications-related information or support

that may be provided by TI. Buyer represents and agrees that it has all the necessary expertise to create and implement safeguards which

anticipate dangerous consequences of failures, monitor failures and their consequences, lessen the likelihood of failures that might cause

harm and take appropriate remedial actions. Buyer will fully indemnify TI and its representatives against any damages arising out of the use

of any TI components in safety-critical applications.

In some cases, TI components may be promoted specifically to facilitate safety-related applications. With such components, TI’s goal is to

help enable customers to design and create their own end-product solutions that meet applicable functional safety standards and

requirements. Nonetheless, such components are subject to these terms.

No TI components are authorized for use in FDA Class III (or similar life-critical medical equipment) unless authorized officers of the parties

have executed a special agreement specifically governing such use.

Only those TI components which TI has specifically designated as military grade or “enhanced plastic” are designed and intended for use in

military/aerospace applications or environments. Buyer acknowledges and agrees that any military or aerospace use of TI components

which have not been so designated is solely at the Buyer's risk, and that Buyer is solely responsible for compliance with all legal and

regulatory requirements in connection with such use.

TI has specifically designated certain components as meeting ISO/TS16949 requirements, mainly for automotive use. In any case of use of

non-designated products, TI will not be responsible for any failure to meet ISO/TS16949.

Products Applications

Audio www.ti.com/audio Automotive and Transportation www.ti.com/automotive

Amplifiers amplifier.ti.com Communications and Telecom www.ti.com/communications

Data Converters dataconverter.ti.com Computers and Peripherals www.ti.com/computers

DLP® Products www.dlp.com Consumer Electronics www.ti.com/consumer-apps

DSP dsp.ti.com Energy and Lighting www.ti.com/energy

Clocks and Timers www.ti.com/clocks Industrial www.ti.com/industrial

Interface interface.ti.com Medical www.ti.com/medical

Logic logic.ti.com Security www.ti.com/security

Power Mgmt power.ti.com Space, Avionics and Defense www.ti.com/space-avionics-defense

Microcontrollers microcontroller.ti.com Video and Imaging www.ti.com/video

RFID www.ti-rfid.com

OMAP Applications Processors www.ti.com/omap TI E2E Community e2e.ti.com

Wireless Connectivity www.ti.com/wirelessconnectivity

Mailing Address: Texas Instruments, Post Office Box 655303, Dallas, Texas 75265

Copyright © 2013, Texas Instruments Incorporated

Loading...

Loading...