Page 1

C535676

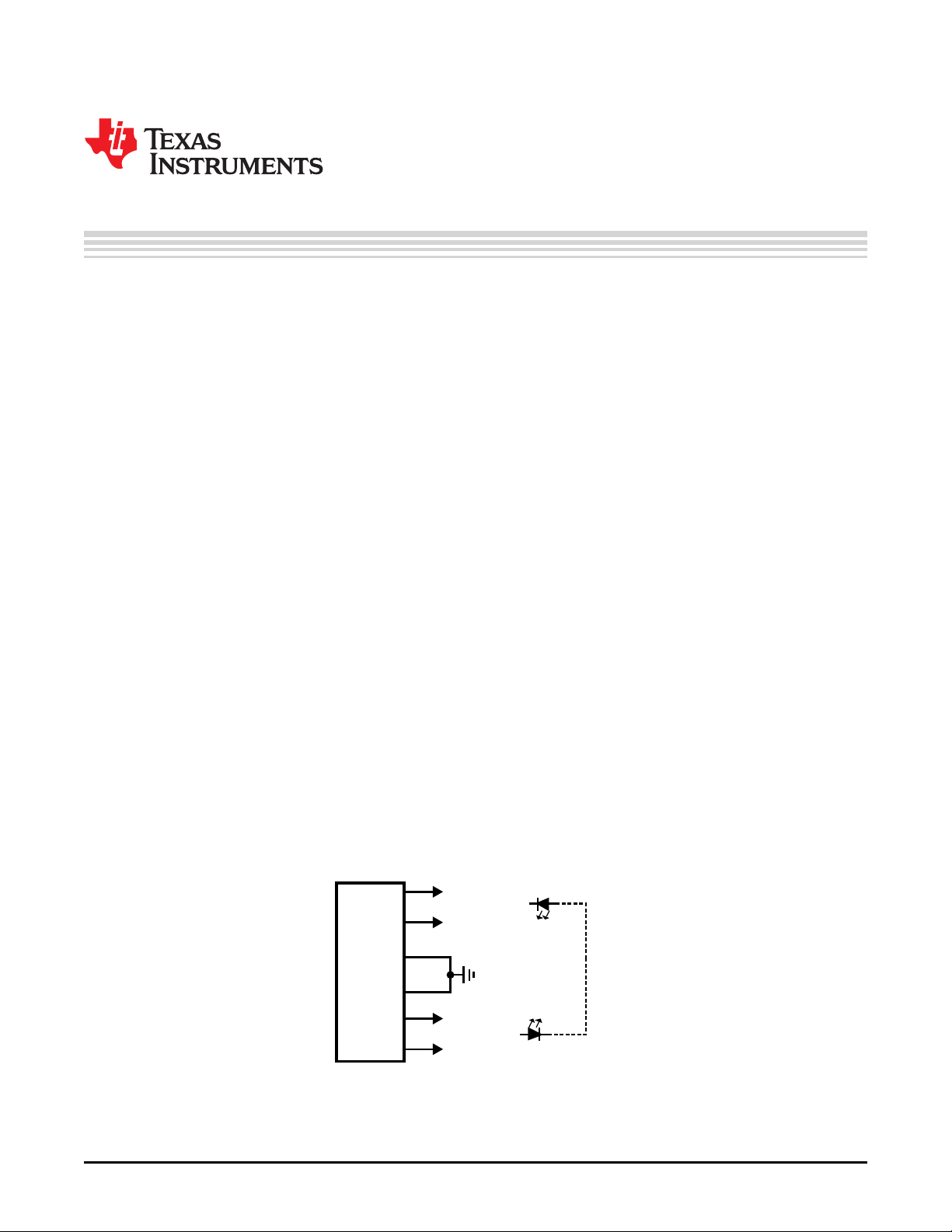

Connector

P6

P1

Anode of

First LED

Cathode of

Last LED

User's Guide

SNVA175C–September 2006–Revised April 2013

AN-1500 LM3402/02HV Demo Board

1 Introduction

The LM3402/LM3402HV is a buck regulator derived controlled current source designed to drive a series

string of high power, high brightness LEDs (HBLEDs) such as the Luxeon™ I Emitter at forward currents

of up to 500 mA. The board can accept an input voltage ranging from 6V to 42V when using the LM3402.

When using the pin-for-pin compatible LM3402HV the upper bound of input voltage is 75V. The converter

output voltage adjusts as needed to maintain a constant current through the LED array. The

LM3402/02HV is a true step-down regulator with an output voltage range extending from a V

mV (the reference voltage) to a V

maintain regulated current through any number of LEDs as long as the combined forward voltage of the

array does not exceed V

O(MAX).

.

2 Circuit Performance LM3402

The LM3402 circuit and BOM have been designed to provide a constant forward current of 350 mA to a

single LED with a forward voltage of approximately 3.5V. (Typical of white, blue, and green LEDs using

InGaN technology.) When powered from a 24V ±5% input the demo board will maintain the average LED

current, IF, to within 10% of 350 mA. The ripple current, ΔiF, will not exceed 70 mA peak-to-peak.

Switching frequency for the demo board is 600 kHz ± 10% over the input voltage range of 6V to 42V.

determined by the minimum off time (typically 300 ns). It can

O(MAX)

O(MIN)

of 200

3 Circuit Performance LM3402HV

The LM3402HV circuit and BOM have been designed to provide a constant forward current of 350 mA to

a single LED with a forward voltage of approximately 3.5V. When powered from a 48V ± 5% input the

demo board will maintain IFto within ±5% of 350 mA. Ripple current will not exceed 70 mA peak-to-peak.

Switching frequency for the demo board is 250 kHz ±10% over the input voltage range of 6V to 75V.

4 Connecting to LED Array

The LM3402/02HV demo board includes a female 6-pin SIP, J1, connector as well as two standard 94mil

turret connectors for the cathode and anode connections of the LED array. Figure 1 shows the pinout of

J1. Solid, 18 or 20 gauge wire with about 1 cm of insulation stripped away makes a convenient, solderless

connection to J1.

Figure 1. Connecting to LED Array

All trademarks are the property of their respective owners.

SNVA175C–September 2006–Revised April 2013 AN-1500 LM3402/02HV Demo Board

Submit Documentation Feedback

Copyright © 2006–2013, Texas Instruments Incorporated

1

Page 2

T

D

t

D

t

SD

tDtSUt

SD

tDt

SU

t

SD

D

MIN

D

MAX

T T

DIM

I

F

f

PWM

T =

1

T

tD + t

SU

D

MIN

=

T

T + t

SD

D

MAX

=

t

SU

R

SNS

=

2

VIN - V

O

0.2 x L

IF x L + VO x t

SNS

-

x t

ON

Setting the LED Current

5 Setting the LED Current

www.ti.com

The default forward current I

this value the current setting resistor R

t

= 220 ns (2)

SNS

delivered to the LED array is 350 mA, typical of many 1W LEDs. To adjust

LED

can be changed according to the following equation:

SNS

This resistor should be rated to handle the power dissipation of the LED current. For example, the closest

5% tolerance resistor to set an LED current of 350 mA is 0.56 Ω. In steady state this resistor will dissipate

(0.352 × 0.56) = 69 mW, indicating that a resistor with a 1/8W power rating is appropriate.

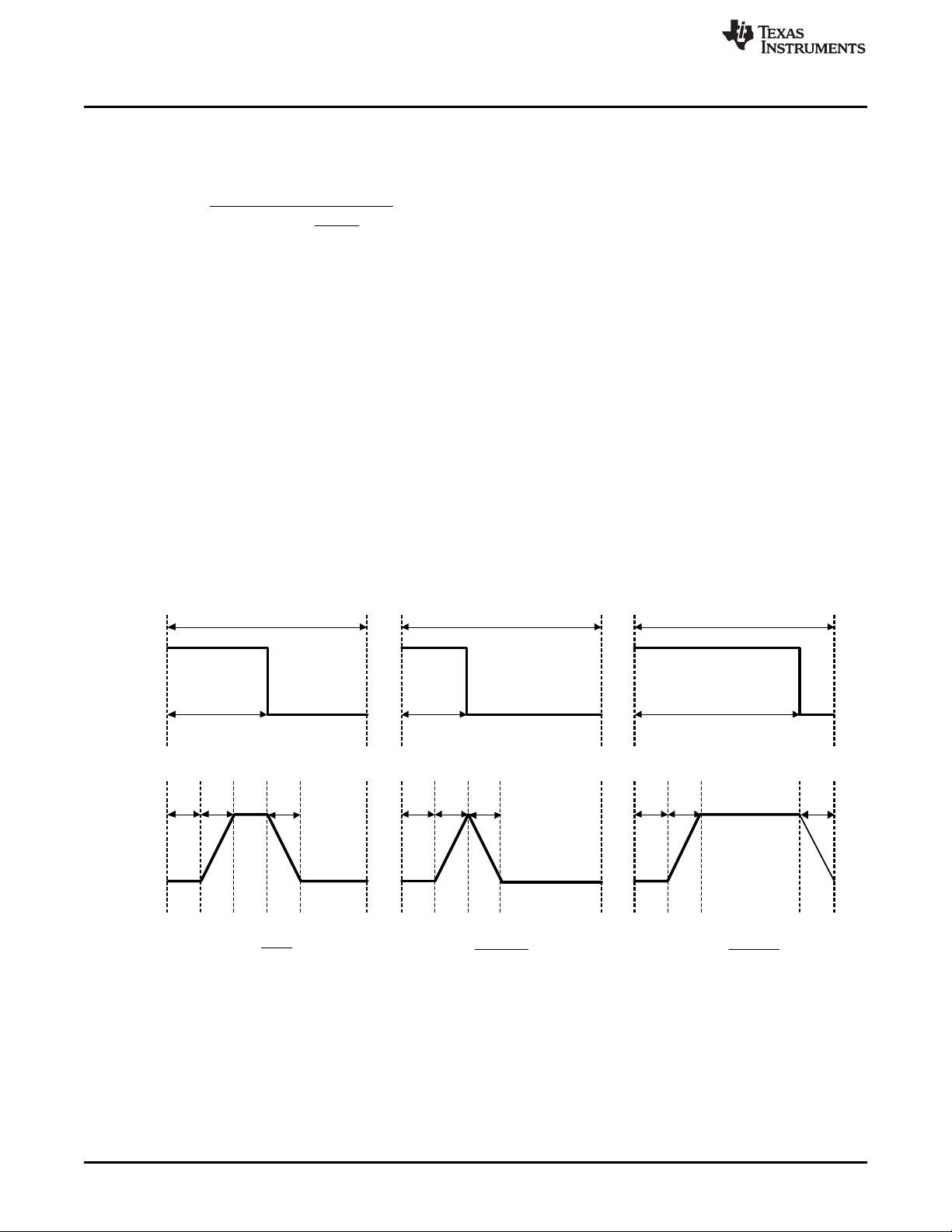

6 PWM Dimming

The DIM1 terminal on the PCB provides an input for a pulse width modulation signal for dimming of the

LED array. In order to fully enable and disable the LM3402/02HV the PWM signal should have a

maximum logic low level of 0.8V and a minimum logic high level of 2.2V. The maximum PWM dimming

frequency, minimum PWM duty cycle and maximum duty cycle are illustrated in Figure 2. PWM frequency

should be at least one order of magnitude below the LM3402/02HV switching frequency. The interval t

represents the delay from a logic high at the DIM pin to the onset of the output current. The quantities t

and tSDrepresent the time needed for the output current to slew up to steady state and slew down to zero,

respectively. Typical response times for the standard LM3402 and LM3402HV demo boards circuits are

shown in Section 11.

(1)

D

SU

Figure 2. PWM Dimming Limits

The logic of DIM1 is direct, hence the LM3402/02HV will deliver regulated output current when the voltage

at DIM1 is high, and the current output is disabled when the voltage at DIM1 is low. Connecting a constant

logic low will disable the output, and the LM3402/02HV is enabled if the DIM pin is open-circuited. The

DIM1 function disables only the power NFET, leaving all other circuit blocks functioning to minimize the

converter response time.

2

AN-1500 LM3402/02HV Demo Board SNVA175C–September 2006–Revised April 2013

Copyright © 2006–2013, Texas Instruments Incorporated

Submit Documentation Feedback

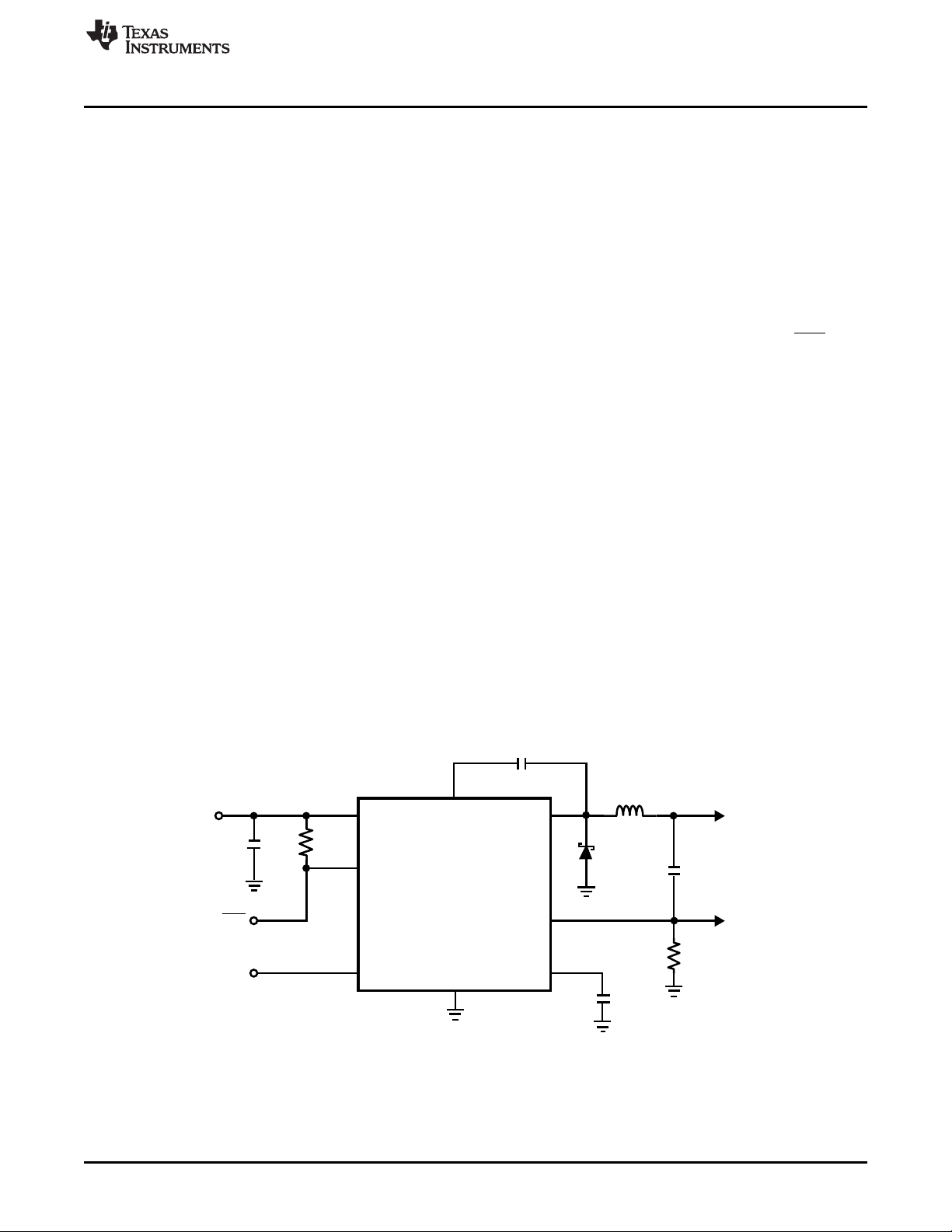

Page 3

GND

DIM

BOOT

SW

CS

RON

LM3402/02HV

VIN

D1

L1

C

B

R

SNS

C

F

R

ON

C

IN

VIN = 6V to 42V (LM3402)

VIN = 6V to 75V (LM3402HV)

VCC

C

O1

OFF

DIM1

LED

ANODE

LED

CATHODE

1

2

3

4

5

6

7

8

(used in BOM 2 only)

www.ti.com

Low Power Shutdown

The DIM2 terminal provides a second method for PWM dimming by connecting to the gate of an optional

NFET, Q1. Note that Q1 is not provided on the standard BOM, and must be added for the DIM2 function

to operate. Q1 provides a parallel path for the LED current. This small NFET can be turned on and off

much more quickly than the LM3402/02HV can shutdown the internal NFET, providing faster response

time for higher frequency and/or greater resolution in the PWM dimming signal. The tradeoff in this

method is that the full current flows through Q1 while the LED is off, resulting in lower efficiency.

The logic of DIM2 is inverted, hence the LM3402/02HV will deliver regulated output current when the

voltage at DIM2 is low, and the current output is disabled when the voltage at DIM2 is high. Connecting a

constant logic high to the DIM2 will turn off the LED but will not shut down the LM3402/02HV.

7 Low Power Shutdown

The LM3402/02HV can be placed into a low power shutdown (typically 90 µA) by grounding the OFF

terminal. During normal operation this terminal should be left open-circuit.

8 Output Open Circuit

With either DIM terminal floating or connected to logic high, the LM3402/02HV will begin to operate as

soon as it has an input of at least 6V. In the case that the input is powered but no LED array is connected

the output voltage will rise to equal the input voltage. The output of the circuit is rated to 50V (LM3402) or

100V (LM3402HV) and will not suffer damage, however care should be taken not to connect an LED array

if the output voltage is higher than the target forward voltage of the LED array in steady state.

Alternatively, a zener diode and zener current limiting resistor can be placed in the positions Z1 and RZ. In

the case of an accidental open circuit at the output Z1 will enter reverse bias and attempt to pull the CS

pin voltage up to the output voltage. An internal comparator monitors the CS pin voltage and will disable

the internal NFET in this case. The result is a low power hiccup mode, designed to prevent excessive

voltage at the output and thermal stress on the inductor, internal NFET, and input voltage source.

Figure 3. Standard Schematic

SNVA175C–September 2006–Revised April 2013 AN-1500 LM3402/02HV Demo Board

Submit Documentation Feedback

Copyright © 2006–2013, Texas Instruments Incorporated

3

Page 4

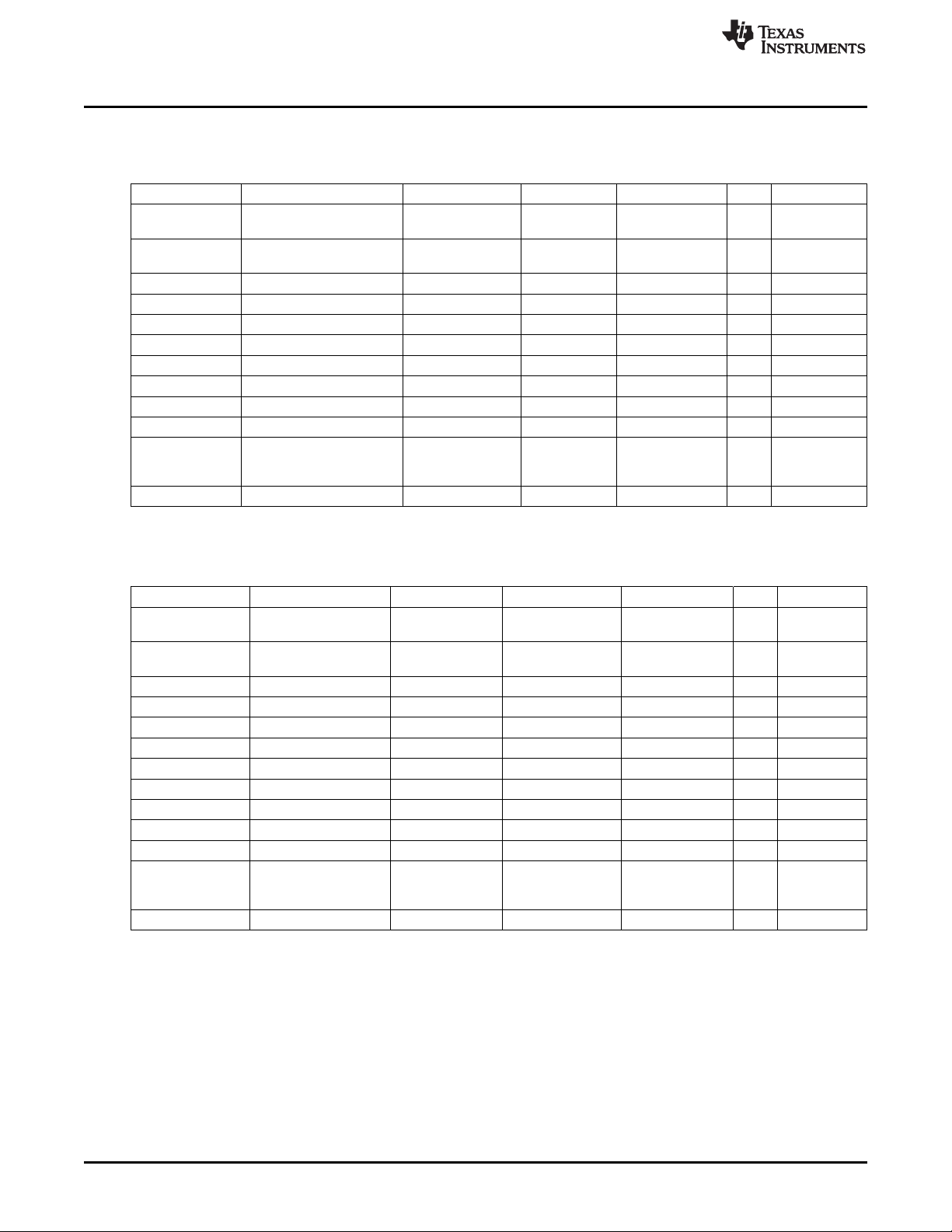

Bill of Materials

9 Bill of Materials

ID Part Number Type Size Parameters Qty Vendor

U1 LM3402 LED Driver VSSOP-8 42V, 0.5A 1 Texas

L1 SLF10145T-101M1R0 Inductor 10.1 × 10.1 × 100µH, 1A, 0.2Ω 1 TDK

D1 CMSH1-60M Schottky Diode SMA 60V, 1A 1 Central Semi

Cf VJ0805Y104KXXAT Capacitor 0805 100nF 10% 1 Vishay

Cb VJ0805Y103KXXAT Capacitor 0805 10nF 10% 1 Vishay

Cin C3216X7R1H105M Capacitor 1206 1µF 50V 1 TDK

Rsns ERJ6BQFR56V Resistor 0805 0.56Ω 1% 1 Panasonic

Ron CRCW08054642F Resistor 0805 46.4kΩ 1% 1 Vishay

Rz CRCW08050R00F Resistor 0805 0Ω 1 Vishay

DIM1, DIM2 160-1512 Terminal Silver 0.062” 2 Cambion

GND1, GND2, 160-1026 Terminal Silver 0.094” 7 Cambion

GND3, VIN, ISNS

/ C, Vo / A, SW

J1 535676-5 Connector Custom 6 Pins 1 Tyco/AMP

www.ti.com

Table 1. Bill of Materials (LM3402)

Instruments

4.5mm

Table 2. Bill of Materials (LM3402HV)

ID Part Number Type Size Parameters Qty Vendor

U1 LM3402HV LED Driver VSSOP-8 75V, 0.5A 1 Texas

L1 SLF10145T-151MR79 Inductor 10.1 × 10.1 × 150µH, 0.8A, 1 TDK

4.5mm 0.2Ω

D1 CMSH1-100M Schottky Diode SMA 100V, 1A 1 Central Semi

Cf VJ0805Y104KXXAT Capacitor 0805 100nF 10% 1 Vishay

Cb VJ0805Y103KXXAT Capacitor 0805 10nF 10% 1 Vishay

Cin C3225X7R2A105M Capacitor 1210 1µF 100V 1 TDK

Co1 C3216X7R1E225M Capacitor 1206 2.2µF 25V 1 TDK

Rsns ERJ6BQFR68V Resistor 0805 0.68Ω 1% 1 Panasonic

Ron CRCW08051303F Resistor 0805 130kΩ 1% 1 Vishay

Rz CRCW08050R00F Resistor 0805 0Ω 1 Vishay

DIM1, DIM2 160-1512 Terminal Silver 0.062” 2 Cambion

GND1, GND2, 160-1026 Terminal Silver 0.094” 7 Cambion

GND3, VIN, ISNS /

C, Vo / A, SW

J1 535676-5 Connector Custom 6 Pins 1 Tyco/AMP

Instruments

4

AN-1500 LM3402/02HV Demo Board SNVA175C–September 2006–Revised April 2013

Copyright © 2006–2013, Texas Instruments Incorporated

Submit Documentation Feedback

Page 5

GND

DIM

BOOT SW

CS

RON

LM3402/02HV

VIN

D1

L1

C

B

R

SNS

C

F

R

ON

C

IN

VIN = 6V to 42V (LM3402)

VIN = 6V to 75V (LM3402HV)

VCC

C

O1

OFF

DIM1

LED

ANODE

LED

CATHODE

R

Z

C

O2

R

ESR

R

PD

DIM2

R

SNB

C

SNB

Z1

Q1

7

5

1

2

4

3

6

8

www.ti.com

10 Evaluation Board Schematic

Figure 4. Complete Evaluation Board Schematic

Evaluation Board Schematic

SNVA175C–September 2006–Revised April 2013 AN-1500 LM3402/02HV Demo Board

Submit Documentation Feedback

Copyright © 2006–2013, Texas Instruments Incorporated

5

Page 6

Typical Performance Characteristics

11 Typical Performance Characteristics

Efficiency for Table 1 Efficiency for Table 2

TA= 25°C, IF= 350 mA TA= 25°C, IF= 350 mA

IFvs VINfor Table 1 IFvs VINfor Table 2

TA= 25°C TA= 25°C

www.ti.com

6

AN-1500 LM3402/02HV Demo Board SNVA175C–September 2006–Revised April 2013

Copyright © 2006–2013, Texas Instruments Incorporated

Submit Documentation Feedback

Page 7

10 és/DIV

5V/DIV

100 mA/DIV

I

F

DIM

4 és/DIV

5V/DIV

100 mA/DIV

I

F

DIM

1 és/DIV

10V/DIV

100 mA/DIV

SW

I

F

1 és/DIV

10 mA/DIV

I

F

1 és/DIV

5V/DIV

100 mA/DIV

I

F

DIM

2 és/DIV

5V/DIV

100 mA/DIV

I

F

DIM

www.ti.com

Typical Performance Characteristics

DIM Pin Enable Table 1 DIM Pin Disable Table 1

Switching Waveforms for Table 1 Output Ripple Current Table 1

DIM Pin Enable Table 2 DIM Pin Disable Table 2

SNVA175C–September 2006–Revised April 2013 AN-1500 LM3402/02HV Demo Board

Submit Documentation Feedback

Copyright © 2006–2013, Texas Instruments Incorporated

7

Page 8

2 és/DIV

20V/DIV

100 mA/DIV

SW

I

F

2 és/DIV

5 mA/DIV

I

F

Typical Performance Characteristics

Switching Waveforms for Table 2 Output Ripple Current Table 2

www.ti.com

8

AN-1500 LM3402/02HV Demo Board SNVA175C–September 2006–Revised April 2013

Copyright © 2006–2013, Texas Instruments Incorporated

Submit Documentation Feedback

Page 9

www.ti.com

12 Layout

Layout

Figure 5. Top Layer and Top Overlay

SNVA175C–September 2006–Revised April 2013 AN-1500 LM3402/02HV Demo Board

Submit Documentation Feedback

Copyright © 2006–2013, Texas Instruments Incorporated

9

Page 10

Layout

www.ti.com

Figure 6. Bottom Layer and Bottom Overlay

10

AN-1500 LM3402/02HV Demo Board SNVA175C–September 2006–Revised April 2013

Copyright © 2006–2013, Texas Instruments Incorporated

Submit Documentation Feedback

Page 11

IMPORTANT NOTICE

Texas Instruments Incorporated and its subsidiaries (TI) reserve the right to make corrections, enhancements, improvements and other

changes to its semiconductor products and services per JESD46, latest issue, and to discontinue any product or service per JESD48, latest

issue. Buyers should obtain the latest relevant information before placing orders and should verify that such information is current and

complete. All semiconductor products (also referred to herein as “components”) are sold subject to TI’s terms and conditions of sale

supplied at the time of order acknowledgment.

TI warrants performance of its components to the specifications applicable at the time of sale, in accordance with the warranty in TI’s terms

and conditions of sale of semiconductor products. Testing and other quality control techniques are used to the extent TI deems necessary

to support this warranty. Except where mandated by applicable law, testing of all parameters of each component is not necessarily

performed.

TI assumes no liability for applications assistance or the design of Buyers’ products. Buyers are responsible for their products and

applications using TI components. To minimize the risks associated with Buyers’ products and applications, Buyers should provide

adequate design and operating safeguards.

TI does not warrant or represent that any license, either express or implied, is granted under any patent right, copyright, mask work right, or

other intellectual property right relating to any combination, machine, or process in which TI components or services are used. Information

published by TI regarding third-party products or services does not constitute a license to use such products or services or a warranty or

endorsement thereof. Use of such information may require a license from a third party under the patents or other intellectual property of the

third party, or a license from TI under the patents or other intellectual property of TI.

Reproduction of significant portions of TI information in TI data books or data sheets is permissible only if reproduction is without alteration

and is accompanied by all associated warranties, conditions, limitations, and notices. TI is not responsible or liable for such altered

documentation. Information of third parties may be subject to additional restrictions.

Resale of TI components or services with statements different from or beyond the parameters stated by TI for that component or service

voids all express and any implied warranties for the associated TI component or service and is an unfair and deceptive business practice.

TI is not responsible or liable for any such statements.

Buyer acknowledges and agrees that it is solely responsible for compliance with all legal, regulatory and safety-related requirements

concerning its products, and any use of TI components in its applications, notwithstanding any applications-related information or support

that may be provided by TI. Buyer represents and agrees that it has all the necessary expertise to create and implement safeguards which

anticipate dangerous consequences of failures, monitor failures and their consequences, lessen the likelihood of failures that might cause

harm and take appropriate remedial actions. Buyer will fully indemnify TI and its representatives against any damages arising out of the use

of any TI components in safety-critical applications.

In some cases, TI components may be promoted specifically to facilitate safety-related applications. With such components, TI’s goal is to

help enable customers to design and create their own end-product solutions that meet applicable functional safety standards and

requirements. Nonetheless, such components are subject to these terms.

No TI components are authorized for use in FDA Class III (or similar life-critical medical equipment) unless authorized officers of the parties

have executed a special agreement specifically governing such use.

Only those TI components which TI has specifically designated as military grade or “enhanced plastic” are designed and intended for use in

military/aerospace applications or environments. Buyer acknowledges and agrees that any military or aerospace use of TI components

which have not been so designated is solely at the Buyer's risk, and that Buyer is solely responsible for compliance with all legal and

regulatory requirements in connection with such use.

TI has specifically designated certain components as meeting ISO/TS16949 requirements, mainly for automotive use. In any case of use of

non-designated products, TI will not be responsible for any failure to meet ISO/TS16949.

Products Applications

Audio www.ti.com/audio Automotive and Transportation www.ti.com/automotive

Amplifiers amplifier.ti.com Communications and Telecom www.ti.com/communications

Data Converters dataconverter.ti.com Computers and Peripherals www.ti.com/computers

DLP® Products www.dlp.com Consumer Electronics www.ti.com/consumer-apps

DSP dsp.ti.com Energy and Lighting www.ti.com/energy

Clocks and Timers www.ti.com/clocks Industrial www.ti.com/industrial

Interface interface.ti.com Medical www.ti.com/medical

Logic logic.ti.com Security www.ti.com/security

Power Mgmt power.ti.com Space, Avionics and Defense www.ti.com/space-avionics-defense

Microcontrollers microcontroller.ti.com Video and Imaging www.ti.com/video

RFID www.ti-rfid.com

OMAP Applications Processors www.ti.com/omap TI E2E Community e2e.ti.com

Wireless Connectivity www.ti.com/wirelessconnectivity

Mailing Address: Texas Instruments, Post Office Box 655303, Dallas, Texas 75265

Copyright © 2013, Texas Instruments Incorporated

Loading...

Loading...