Page 1

User's Guide

SLOU352–November 2012

VCA5807 Development Guide

This development guide describes the characteristics, operation and use of the VCA5807EVM

demonstration kit. This demonstration kit is an evaluation module for the VCA5807 device. The VCA5807

is an integrated Voltage Controlled Amplifier (VCA) that integrates a complete time-gain-control (TGC)

imaging path and a continuous wave Doppler (CWD) path. The VCA5807 is intended for prototyping and

evaluation. This user's guide includes a complete circuit description, schematic diagram, and bill of

materials (BOM).

The following related documents are available through the Texas Instruments web site at

http://www.ti.com.

Table 1. Related Document

Device Literature Number

VCA5807 SLOS727

Contents

1 VCA5807 Overview ......................................................................................................... 3

1.1 Important Disclaimer Information ................................................................................ 3

2 Overview ..................................................................................................................... 3

2.1 Introduction ......................................................................................................... 3

2.2 Default Configuration .............................................................................................. 4

3 Software Installation and Operation ...................................................................................... 5

3.1 Minimum Requirements ........................................................................................... 5

3.2 Installing the Software (PC Application) ........................................................................ 5

3.3 GUI Overview ....................................................................................................... 6

4 Hardware ................................................................................................................... 11

4.1 Introduction ........................................................................................................ 11

4.2 Board Configuration .............................................................................................. 12

4.3 Power .............................................................................................................. 13

4.4 Clock Buffer ....................................................................................................... 13

4.5 VCA Inputs ........................................................................................................ 13

4.6 VCA5807 Device ................................................................................................. 13

4.7 VCA Outputs ...................................................................................................... 13

4.8 CW Mode .......................................................................................................... 14

4.9 VControl ........................................................................................................... 16

4.10 Serial Interface .................................................................................................... 16

5 Quick Start .................................................................................................................. 17

5.1 Test Setup ......................................................................................................... 17

5.2 Power Up VCA5807EVM ........................................................................................ 17

5.3 Launch the VCA5807 GUI ....................................................................................... 17

Appendix A Bill of Materials (BOM) ........................................................................................... 18

Appendix B PCB Layout and Schematics ................................................................................... 22

List of Figures

1 VCA5807EVM Basic Configuration....................................................................................... 4

Pentium, Celeron are registered trademarks of Intel.

Windows is a registered trademark of Microsoft Corporation.

SLOU352–November 2012 VCA5807 Development Guide

Submit Documentation Feedback

Copyright © 2012, Texas Instruments Incorporated

1

Page 2

www.ti.com

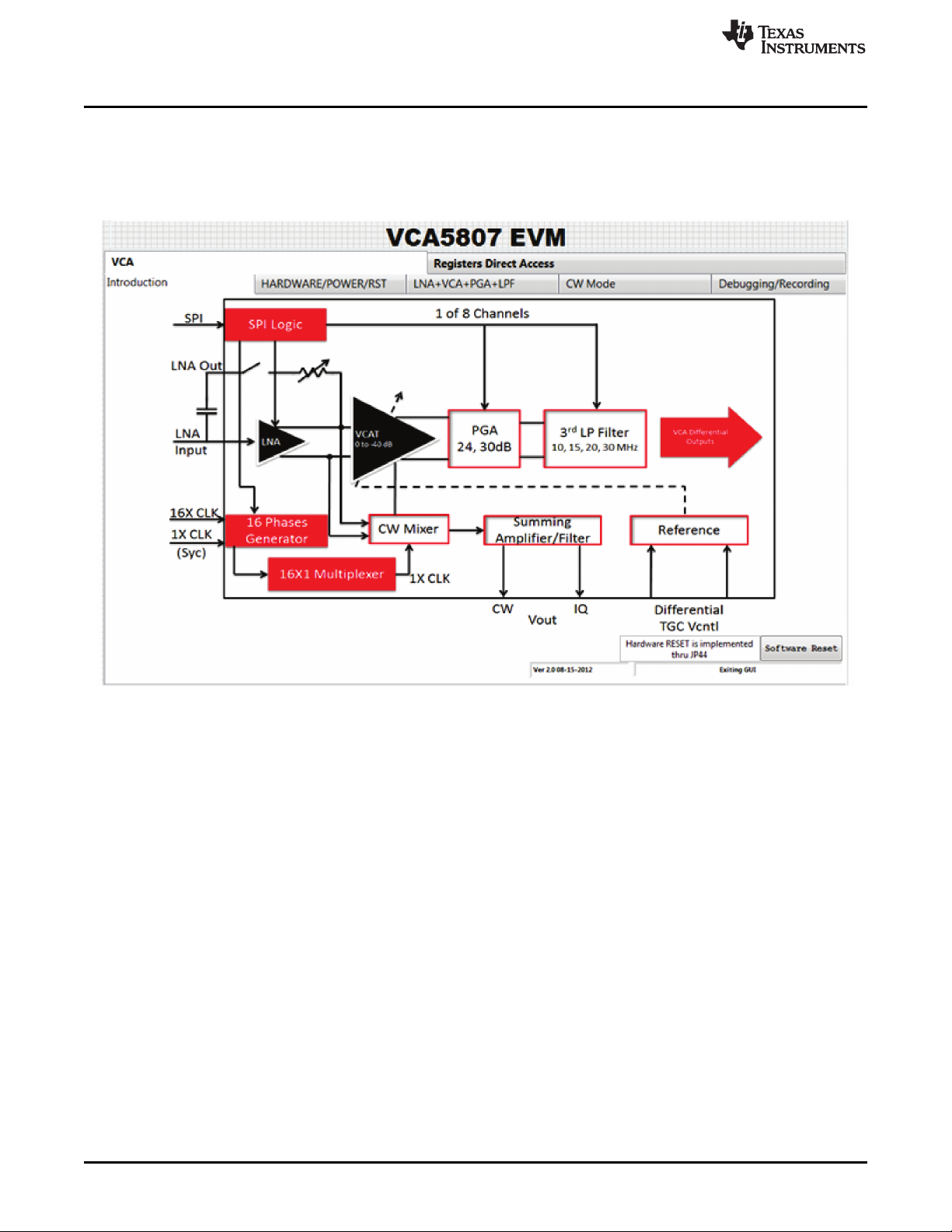

2 Introduction Tab of the VCA5807EVM GUI ............................................................................. 6

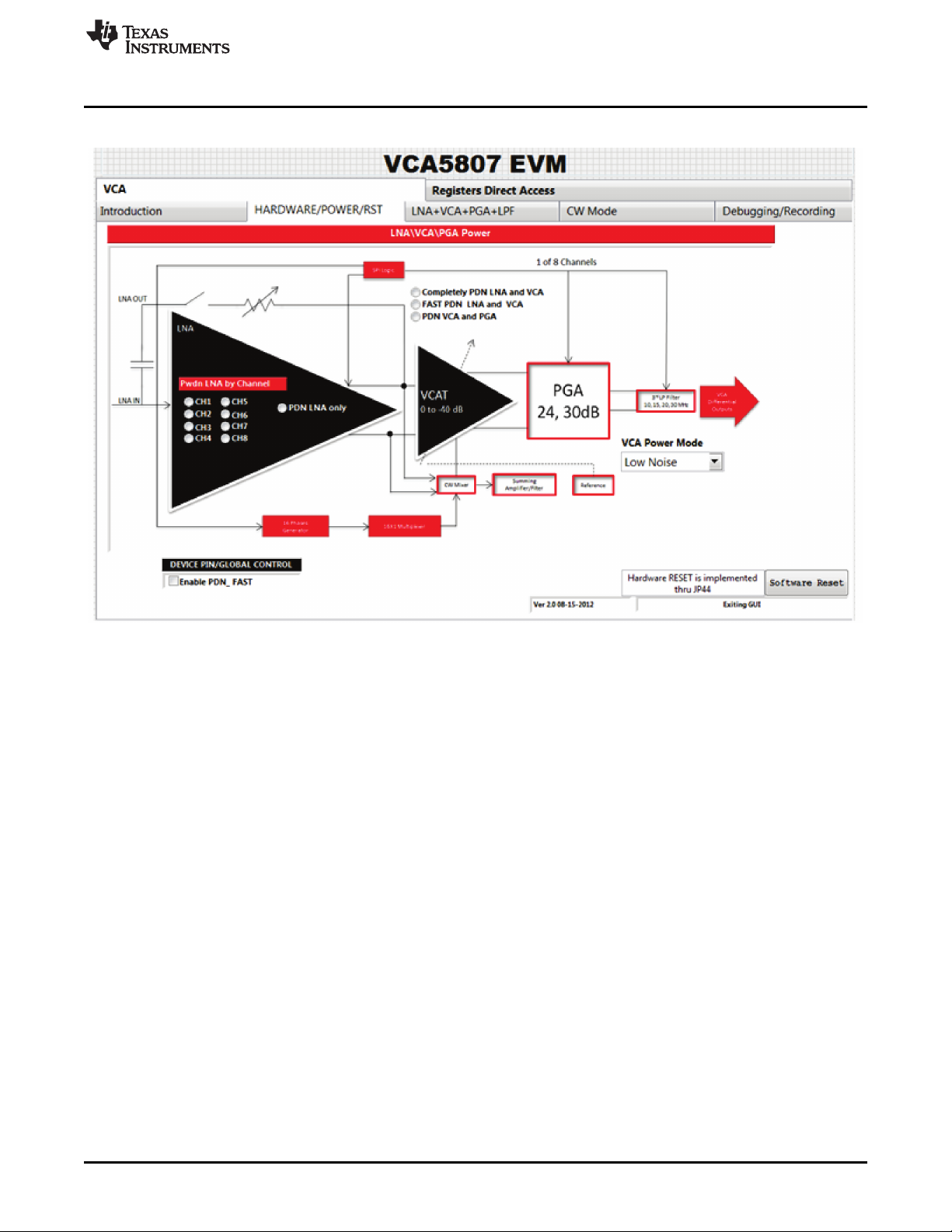

3 Hardware/Power/RST Tab of the VCA5807EVM GUI ................................................................. 7

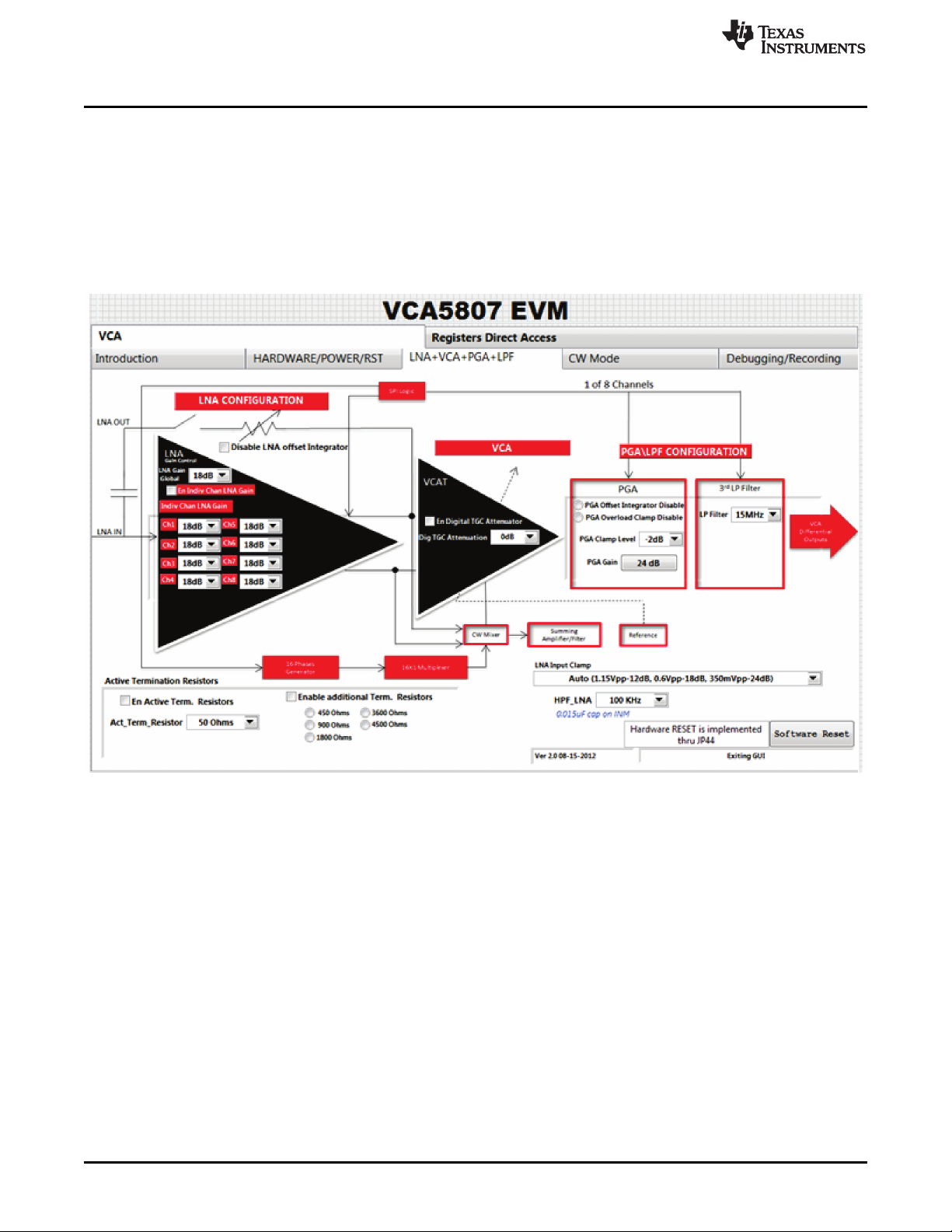

4 VCA LNA+VCA+PGA+LPF Tab of the VCA5807EVM GUI........................................................... 8

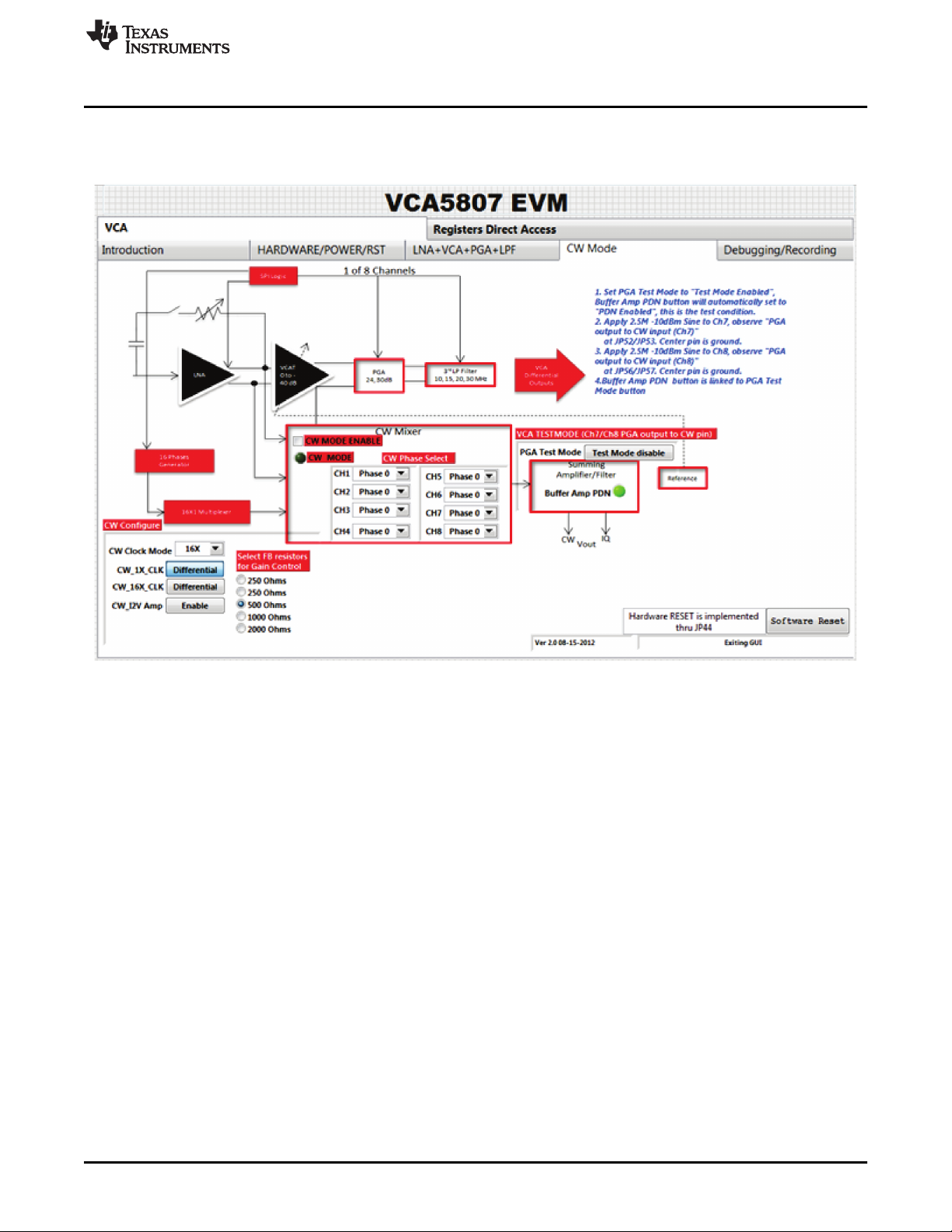

5 VCA CW Mode Tab......................................................................................................... 9

6 VCA Debugging/Recording Tab......................................................................................... 10

7 HW Setup................................................................................................................... 11

8 PCB Layout With Jumper Positions..................................................................................... 12

9 CW Mode Hardware Configuration...................................................................................... 14

10 Switching to CW Mode ................................................................................................... 15

11 Oscilloscope................................................................................................................ 16

12 Top Layer - Signal......................................................................................................... 22

13 Second Layer - Ground................................................................................................... 23

14 Third Layer - Power....................................................................................................... 24

15 Fourth Layer - Signal...................................................................................................... 25

16 Fifth Layer - Ground....................................................................................................... 26

17 Bottom Layer - Signal..................................................................................................... 27

18 Schematic 1 of 10 ......................................................................................................... 28

19 Schematic 2 of 10 ......................................................................................................... 29

20 Schematic 3 of 10 ......................................................................................................... 30

21 Schematic 4 of 10 ......................................................................................................... 31

22 Schematic 5 of 10 ......................................................................................................... 32

23 Schematic 6 of 10 ......................................................................................................... 33

24 Schematic 7 of 10 ......................................................................................................... 34

25 Schematic 8 of 10 ......................................................................................................... 35

26 Schematic 9 of 10 ......................................................................................................... 36

27 Schematic 10 of 10........................................................................................................ 37

List of Tables

1 Related Document.......................................................................................................... 1

2 Power Table................................................................................................................ 13

3 Bill of Materials............................................................................................................. 18

2

VCA5807 Development Guide SLOU352–November 2012

Copyright © 2012, Texas Instruments Incorporated

Submit Documentation Feedback

Page 3

www.ti.com

1 VCA5807 Overview

1.1 Important Disclaimer Information

The VCA5807EVM is intended for feasibility and evaluation testing only in

laboratory and development environments. This product is not for diagnostic

use.

Use the VCA5807 only under the following conditions:

• The VCA5807EVM is intended only for electrical evaluation of the features of the VCA5807 device in a

laboratory, simulation, or development environment.

• The VCA5807EVM is not intended for direct interface with a patient, or patient diagnostics.

• The VCA5807EVM is intended only for development purposes. It is not intended to be used as all or

part of an end-equipment application.

• The VCA5807EVM should be used only by qualified engineers and technicians who are familiar with

the risks associated with handling electrical and mechanical components, systems, and subsystems.

• The user is responsible for the safety of themself, fellow employees, contractors, and coworkers when

using or handling the VCA5807EVM. Furthermore, the user is fully responsible for the contact interface

between the human body and electronics; consequently, the user is responsible for preventing

electrical hazards such as shock, electrostatic discharge, and electrical overstress of electric circuit

components.

VCA5807 Overview

CAUTION

2 Overview

2.1 Introduction

This document is intended as a step-by-step guide through the VCA5807 Evaluation Module (EVM) setup

and test. The EVM is shipped with a default configuration from the manufacturer. With this configuration,

the onboard CMOS clock is used for an analog-to-digital converter sampling clock; the onboard oscillator

is used for CW mode operation. No external clock generator is required. The input signal for measurement

from a signal generator must be provided.

A detailed explanation regarding the jumpers, connectors, and test points appears in Section 2.2. The

graphical user interface (GUI) is available from the TI Web Site. Go to the software section of the product

folder (VCA5807).

Throughout this document, the abbreviation EVM and the term evaluation module are synonymous with

the VCA5807EVM.

SLOU352–November 2012 VCA5807 Development Guide

Submit Documentation Feedback

Copyright © 2012, Texas Instruments Incorporated

3

Page 4

Overview

2.2 Default Configuration

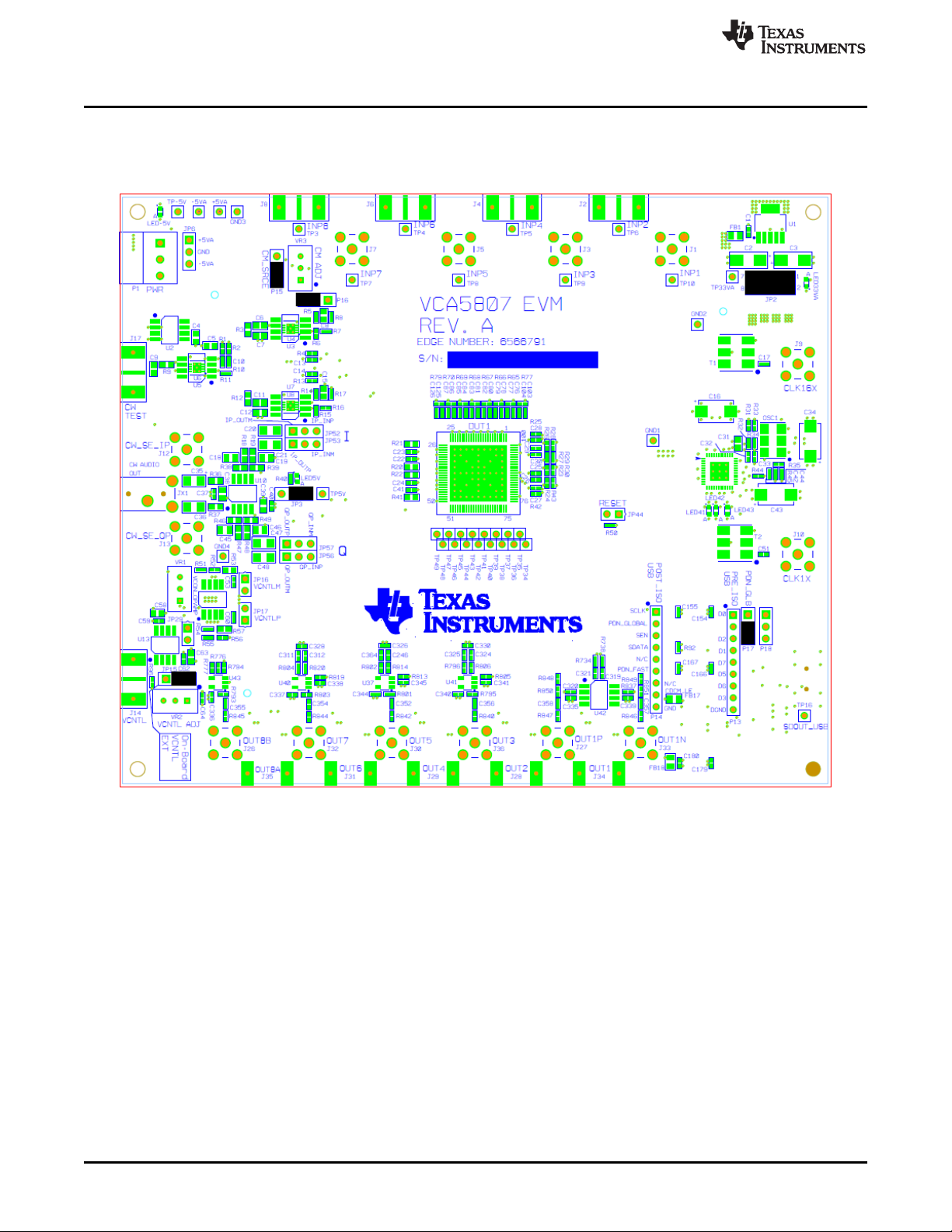

Figure 1 shows the default configuration of the EVM from the factory. The accompanying list identifies the

basic components on the EVM board.

www.ti.com

Figure 1. VCA5807EVM Basic Configuration

1. P1 – Power supplies connector

2. JP2, and JP3 are set to enable 3.3-V and 5-V power supplies to the device

3. JP15: Enables onboard VCNT

4. P17: Disables PDB_Global

5. P15: Chooses the device Common Mode for the I/V Amp Common Mode

6. P16: Chooses Vss as –5 V for low-side power supply on I/V Amp

4

VCA5807 Development Guide SLOU352–November 2012

Copyright © 2012, Texas Instruments Incorporated

Submit Documentation Feedback

Page 5

www.ti.com

3 Software Installation and Operation

3.1 Minimum Requirements

Before installing the software, verify that your PC meets the minimum requirements outlined in this

section.

3.1.1 Required Setup for VCA5807EVM GUI Software

• PC-compatible computer

• Pentium®III or Celeron®processor, 866 MHz or equivalent

• Minimum 256 MB of RAM (512 MB or greater recommended)

• Hard disk drive with at least 200 MB free space

• Windows®XP operating system with SP2, or Windows 7 operating system

• 1280 × 1024 or greater display screen resolution

• Mouse or other pointing device

• Available USB input

3.1.2 Additional Requirements for Use with Hardware

• VCA5807EVM

• USB cable

• Power supply to supply ±5 V

Software Installation and Operation

3.2 Installing the Software (PC Application)

The GUI software to evaluate the VCA5807 device is available at the Texas Instruments web site at

www.ti.com (VCA5807).

Before installing the software, make sure the VCA5807EVM is not connected to the PC. If using a

machine with Windows 7, it is recommended to have administrator rights to avoid problems during

installation.

Unzip the installer file to a temporary directory, and then double click setup.exe from the directory. The

installation creates a program menu item to execute the software.

Windows should automatically install the correct device drivers, but if there are problems installing the

device drivers please refer to this e2e post.

http://e2e.ti.com/support/other_analog/imaging_afes/f/239/p/213841/754871.aspx#754871

Follow these directions to ensure proper installation of the PC application.

SLOU352–November 2012 VCA5807 Development Guide

Submit Documentation Feedback

Copyright © 2012, Texas Instruments Incorporated

5

Page 6

Software Installation and Operation

3.3 GUI Overview

Every tab in the VCA5807EVM GUI has a software reset option available by clicking the Software Reset

button located at the bottom right of the GUI.

The VCA Introduction tab: This tab gives a block diagram of the VCA5807 device.

www.ti.com

Figure 2. Introduction Tab of the VCA5807EVM GUI

6

VCA5807 Development Guide SLOU352–November 2012

Copyright © 2012, Texas Instruments Incorporated

Submit Documentation Feedback

Page 7

www.ti.com

The VCA HARDWARE/POWER/RST tab: This tab allows the execution of different power down options.

Software Installation and Operation

Figure 3. Hardware/Power/RST Tab of the VCA5807EVM GUI

SLOU352–November 2012 VCA5807 Development Guide

Submit Documentation Feedback

Copyright © 2012, Texas Instruments Incorporated

7

Page 8

Software Installation and Operation

The VCA LNA+VCA+PGA+LPF tab: The settings of the Low Noise Amplifier (LNA), VCA, Programmable

Gain Amplifier (PGA), and the Low Pass Filter (LPF) are adjusted in this tab.

• LNA: Adjusts the gain of each channel, adjust the active termination resistors, and disable the LNA

offset Integrator

• VCA: Adjusts the digital Time Gain Control (TGC) Attenuator

• PGA: Adjusts the PGA gain, Clamp Level, and disable both the overload clamp and the offset

integrator

• LPF: Adjusts the LPF frequency

www.ti.com

Figure 4. VCA LNA+VCA+PGA+LPF Tab of the VCA5807EVM GUI

8

VCA5807 Development Guide SLOU352–November 2012

Copyright © 2012, Texas Instruments Incorporated

Submit Documentation Feedback

Page 9

www.ti.com

The VCA CW Mode tab: The Continuous-wave (CW) Doppler mode is adjusted in this tab as well as the

phases of each CW channel (1-8), the CW CLK, and the feedback resistors to control the gain. CH7 and

CH8 are brought to the CW pins by using the PGA Test Mode.

Software Installation and Operation

Figure 5. VCA CW Mode Tab

SLOU352–November 2012 VCA5807 Development Guide

Submit Documentation Feedback

Copyright © 2012, Texas Instruments Incorporated

9

Page 10

Software Installation and Operation

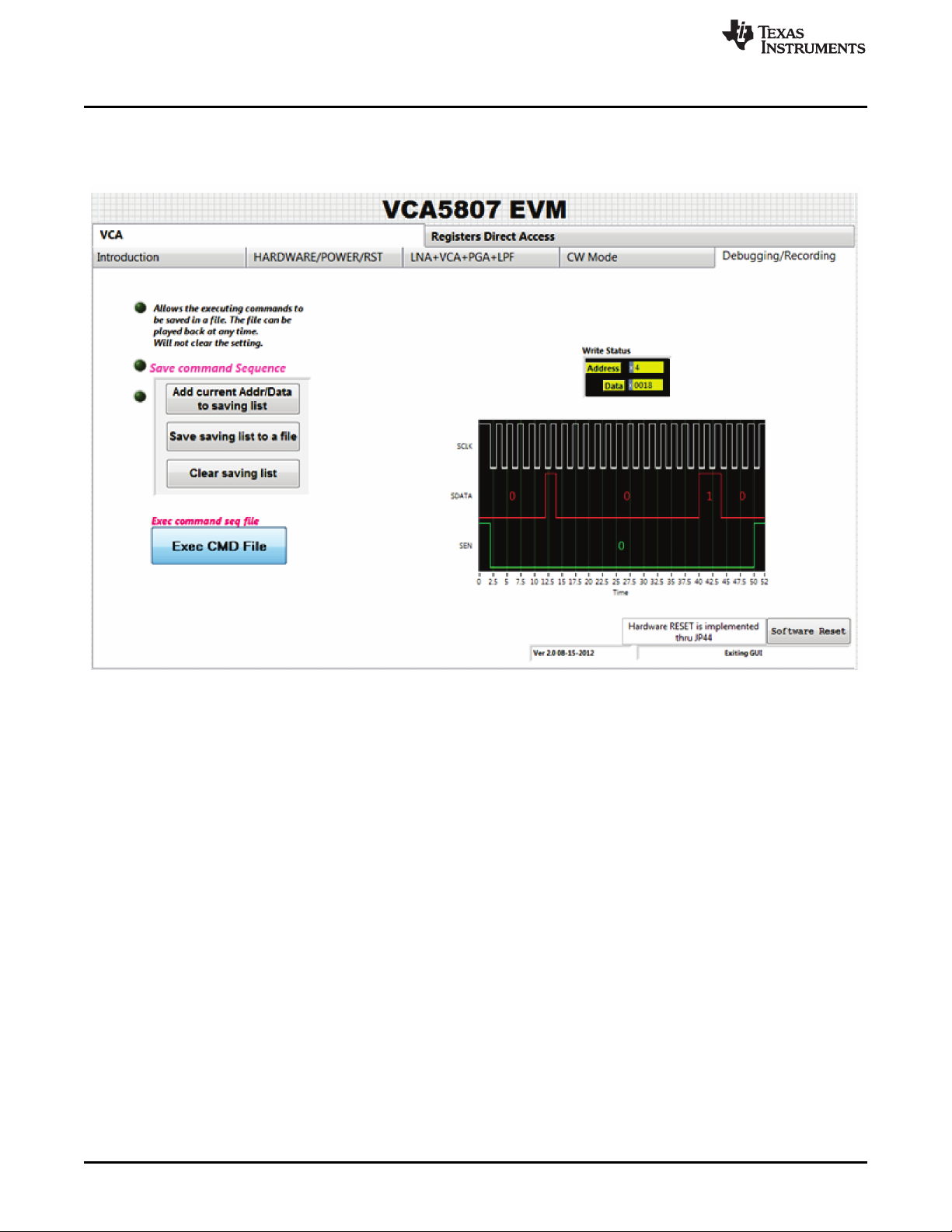

The VCA Debugging/Recording tab: Command executions are saved to a file in this tab. The file can be

played back at any time by clicking on the Exec CMD File button. This tab also displays the Write Status,

and the ability to see the digital waveform of the SCLK, SDATA, and SEN pins.

www.ti.com

Figure 6. VCA Debugging/Recording Tab

10

VCA5807 Development Guide SLOU352–November 2012

Copyright © 2012, Texas Instruments Incorporated

Submit Documentation Feedback

Page 11

www.ti.com

4 Hardware

4.1 Introduction

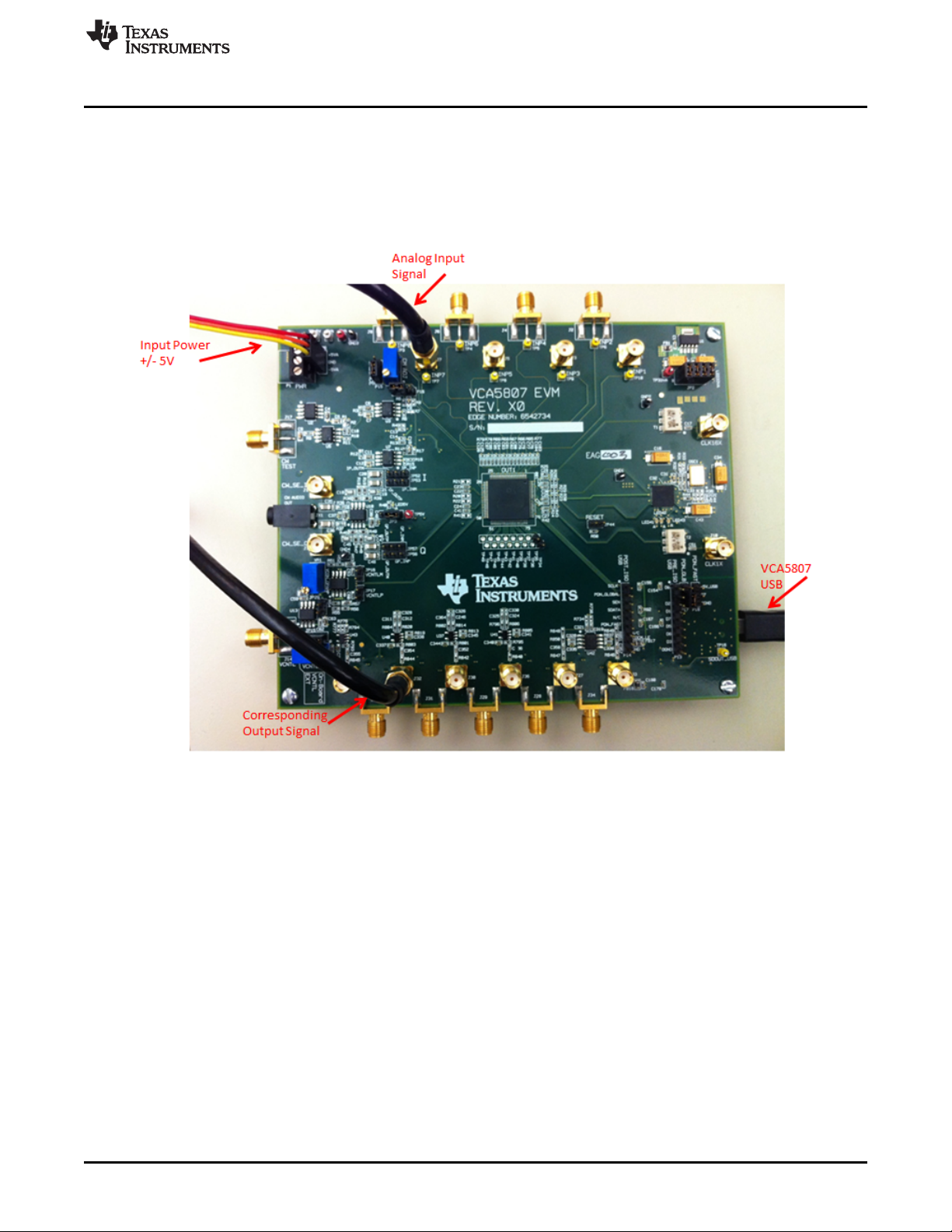

The following illustration shows the setup of the VCA5807EVM and external connectors. For the default

configuration as shown in Figure 1, it is unnecessary to have an external sampling clock and external

Vcntl supply. The onboard CMOS clock and onboard Vcntl are used.

Hardware

Figure 7. HW Setup

SLOU352–November 2012 VCA5807 Development Guide

Submit Documentation Feedback

Copyright © 2012, Texas Instruments Incorporated

11

Page 12

Hardware

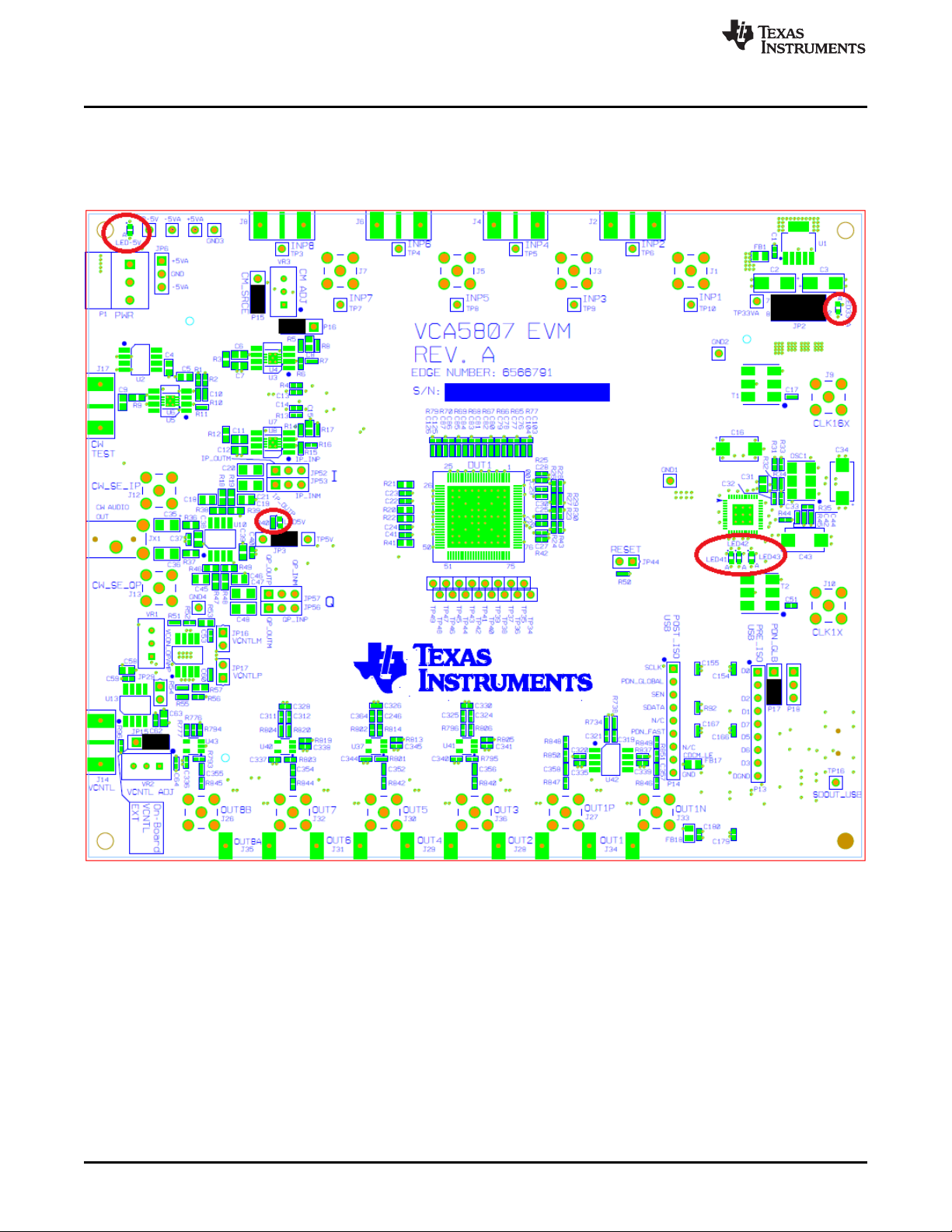

4.2 Board Configuration

Power up the VCA5807EVM by applying +5 V and –5 V to the P1 connector. After power up is complete,

three green LEDs and three red LEDs (LED 41, LED42, and LED 43) are turned. Locations of LEDs are

shown in Figure 8.

www.ti.com

12

Figure 8. PCB Layout With Jumper Positions

VCA5807 Development Guide SLOU352–November 2012

Copyright © 2012, Texas Instruments Incorporated

Submit Documentation Feedback

Page 13

www.ti.com

4.3 Power

The power configuration of the board is shown in Figure 18, page 1 of the schematic. Refer to Table 2 for

a list of important power components.

Connector Description

P1/JP6 P1 is the +5-V and –5-V power supply connector. JP6 is the test point for +5-V/-5-V

JP3 Onboard 5-V enable. The configuration must be set up as shown in Figure 7 in order to

TP-5V -5-V supply test point

+5VA +5-V supply test point

JP2 Onboard 3.3-VA enable. The configuration must be set up as shown in Figure 7 in order

TP33VA +3.3-VA supply test point

TP1 through TP4 Ground test points

4.4 Clock Buffer

The clock buffer drives the VCA5807 device. Each clock buffer output should only drive one VCA5807. Do

not use one clock to drive multiple VCA5807s. This is due to the fact that the clock buffer's load

capacitance increases by a factor of N, which then results in degraded falling and rising times. Select

different clock inputs in the GUI. LEDs 41 and 42 demonstrate the PLL status of the clock buffer.

Hardware

Table 2. Power Table

power supply.

use onboard 5-V supply.

to use the onboard 3.3 V.

4.5 VCA Inputs

J1 through J8 are the analog input signals for CH1 through CH8. Connect to a signal generator. If the

signal is too noisy, apply a bandpass filter between the generator and the SMA to get a better result. Use

TP3-TP10 to see the input signal to the board.

4.6 VCA5807 Device

The VCA5807 device is a suitable ultrasound analog front end solution for high-end systems and portable

systems. This device contains eight channels of VCA, and CW mixer. The VCA includes an LNA, Voltagecontrolled Attenuator (VCAT), PGA, and an LPF. Each of these features is adjusted via the VCA5807

EVM GUI. For a more detailed explanation of the VCA5807 device please refer to the datasheet. The

datasheet is found on the TI product folder at www.ti.com. (SLOS727)

4.7 VCA Outputs

J26 through J36 are the output signals for CH1 through CH8. All channels have a single-ended output

through an OPA842 buffer amplifier. However, CH1 has the option of a fully differential output signal

through a THS4130 amplifier. In order to use this amplifier, install R734 and R738 and remove R837,

C317, and C318. CH8 also provides an added feature by allowing the choice of the OPA830 as the buffer

amplifier. In order to use this amplifier, install R776 and R777 and remove U35.

SLOU352–November 2012 VCA5807 Development Guide

Submit Documentation Feedback

Copyright © 2012, Texas Instruments Incorporated

13

Page 14

Hardware

4.8 CW Mode

www.ti.com

Figure 9. CW Mode Hardware Configuration

14

VCA5807 Development Guide SLOU352–November 2012

Copyright © 2012, Texas Instruments Incorporated

Submit Documentation Feedback

Page 15

www.ti.com

• Go to the CW Mode tab on the GUI.

• Check CW MODE ENABLE. LED41, LED42, and LED43 on the VCA5807EVM should all illuminate.

• Select 500 Ω for the gain control feedback resistor.

Hardware

Figure 10. Switching to CW Mode

SLOU352–November 2012 VCA5807 Development Guide

Submit Documentation Feedback

Copyright © 2012, Texas Instruments Incorporated

15

Page 16

Hardware

• Apply an analog signal (2.51 MHz, –10 dBm) to any analog input SMA.

• The CW outputs (J12, J13) display the frequency I and Q signals at 10 kHz as shown in Figure 11.

www.ti.com

The GUI Gain Control Feedback Resistor can vary the amplitude of the outputs.

4.9 VControl

Switch between using the onboard Vcntl or the external Vcntl by using JP15. External Vcntl can range

from 0 V to 1.5 V. If using the external Vcntl, then a DC voltage source must be connected to J14. The

default setup uses onboard Vcntl. VR2 is used to make onboard Vcntl adjustments.

4.10 Serial Interface

The serial interface of the board is located on the bottom right-hand side. USB1 is the USB interface

connector. P13 and P14 are test points for the USB data bus: From pin 1 to pin 9, the signals are D0, D4,

D2, D1, D7, D5, D6, D3, and DGND. P14 on the VCA5807EVM is not installed.

Figure 11. Oscilloscope

16

VCA5807 Development Guide SLOU352–November 2012

Copyright © 2012, Texas Instruments Incorporated

Submit Documentation Feedback

Page 17

www.ti.com

5 Quick Start

This section assumes all engineering knowledge on the device and basic overview of the VCA5807EVM.

5.1 Test Setup

Connect the EVM as shown in . Typical input signals are 5 MHz at –32 dBm. This can be applied to any

VCA input (J1-J8). If the signal is noisy, consider using a 5-MHz filter. Connect a scope or a spectrum

analyzer to the corresponding VCA output in order to measure the gain on the channel.

5.2 Power Up VCA5807EVM

Connect ±5-V power to the board. No other power connection is needed.

5.3 Launch the VCA5807 GUI

Launch the VCA5807EVM GUI. Execute a software reset with the GUI and verify the current consumption

drops from ≈0.762 A to ≈0.646 A. Enable the Active Termination Resistor of 50 Ohms (check the box) on

the LNA+VCA+PGA+LPF tab. This tab is also used to vary the gain on each channel. However, with the

default settings as shown in , the gain should be 42 dB overall. Therefore, with an input signal of 5 MHz at

–32 dBm, load resistance of 50 Ω, and an overall gain of 42 dB, the output should read ≈4 dBm or 1 Vpp.

For more details and other modes for testing and evaluating the VCA5807 device, please refer to the

previous pages of this development guide.

Quick Start

SLOU352–November 2012 VCA5807 Development Guide

Submit Documentation Feedback

Copyright © 2012, Texas Instruments Incorporated

17

Page 18

www.ti.com

Appendix A Bill of Materials (BOM)

This section contains Table 3, the BOM for the VCA5807EVM.

Table 3. Bill of Materials

Item Qty MFG MFG Part# REF DES Description Value or Function

1 41 AVX 0402YC104KAT2A C17, C25, C26, C29, C30, C33, C37, CAP,SMT,0402 CAPACITOR,SMT,0402,CER,16V,10

2 2 AVX 0402YC471KAT2A C53,C60 CAP,SMT,0402 CAPACITOR,SMT,0402,CER,16V,10

3 40 0402YC104KAT2A C160,C162, C163, C165, C166,

4 2 AVX 0402YC222KAT2A C10, C74 CAP,SMT,0402 CAPACITOR,SMT,0402,CER,16V,10

5 11 KEMET C0402C103K3RACTU C290, C350, C351, C352, C353, CAP,SMT,0402 CAPACITOR,SMT,0402,CER,0.01uF,

6 23 KEMET C0402C104K8PAC C1, C68, C69, C152, C291, C333, CAP,SMT,0402 CAPACITOR,SMT,0402,CER,0.1uF,1

7 2 KEMET C0402C152J5GACTU C73, C89 CAP,SMT,0402 CAPACITOR,SMT,0402,CERAMIC,1

8 8 TDK C1005X5R0J105M C77, C79, C81, C83, C85, C87, CAP,SMT,0402 CAPACITOR,SMT,0402,CER,1.0uF,6

9 2 AVX 0402ZD105KAT2A C71, C72 CAP,SMT,0402 CAPACITOR,SMT,0402,CERAMIC,1.

10 8 AVX 0402YC153KAT2A C107, C108, C109, C116, C118, CAP,SMT,0402 CAPACITOR,SMT,0402,CER,15000p

11 1 AVX 04025C102KAT2A C32 CAP,SMT,0402 CAPACITOR,SMT,0402,CER,1000pF

12 4 AVX 04025C332KAT2A C22, C23, C24, C41 CAP,SMT,0402 CAPACITOR,SMT,0402,CER,3300pF

13 2 AVX 04025A470JAT2A C175, C176 CAP,SMT,0402 CAPACITOR,SMT,0402,CER,47pF,5

14 7 AVX 06033C104JAT2A C5, C7, C8, C12, C15, C88, C90 CAP,SMT,0603 CAPACITOR,SMT,0603,CERAMIC,0.

15 7 AVX 0603YD105KAT2A C38, C39, C58, C63, C159, C161, CAP,SMT,0603 CAPACITOR,SMT,0603,CERAMIC,1.

16 1 TAIYO YUDEN AMK107BJ226MA-T C9 CAP,SMT,0603 CAPACITOR,SMT,0603,CERAMIC,2

17 1 AVX 06036D106MAT2A C4 CAP,SMT,0603 CAPACITOR,SMT,0603,CERAMIC,1

18 2 AVX 0603YD105KAT2A C75, C129 CAP,SMT,0603 CAPACITOR,SMT,0603,CERAMIC,1.

19 2 MURATA GRM188C80G475KE19 C6, C11 CAP,SMT,0603 CAPACITOR,SMT,0603,CERAMIC,4.

20 3 TAIYO YUDEN JMK107BJ106MA-T C31, C348, C349 CAP,SMT,0603 CAPACITOR,SMT,0603,CERAMIC,1

21 4 KEMET C0805C332F3GACTU C18, C19, C45, C46 CAP,SMT,0805 CAPACITOR,SMT,0805,CERAMIC,3

22 6 AVX 1206YD226KAT2A C20, C21, C35, C36, C47, C48 CAP,SMT,1206 CAPACITOR,SMT,1206,CERAMIC,2

23 4 VISHAY SPRAGE 293D226X9016D2TE3 C16, C34, C43, C128 CAP,SMT,7343 CAP,TAN,SMT, 22uF,16V,+/-10%,-

24 4 AVX TPSC226K016R0375 C2, C3, C70, C151 CAPACITOR,SMT,TA 10%, 16V, 22uF

25 14 AMPHENOL 901-144-8 J1, J3, J5, J7, J9, J10, J12, J13, J26, CONNECTOR,SMA SMA COAX STRAIGHT PCB

C40, C51, C59, C62, C64, C76, C78, %,0.1uF

C80, C82, C84, C86, C94, C95, C96,

C97, C98, C99, C101, C103, C125,

C130, C131, C132, C133, C134,

C135, C136, C137, C138, C139,

C140, C141, C154, C155

%,470pF

C167, C170, C171, C173, C174,

C177, C178, C179, C180, C246,

C265, C267, C294, C295, C308,

C309, C310, C311, C312, C313,

C314, C315, C316, C317, C318,

C319, C320, C321, C322, C323,

C324, C325, C364, C365, C366

%,2200pF

C354, C355, C356, C357, C358, 25V,10%,X7R

C363

C334, C335, C336, C337, C338, 0V,10%,X5R

C339, C340, C341, C342, C343,

C344, C345, C346, C347, C360,

C361, C362

500pF,50V,5%,C0G/NP0

C104, C126 .3V,20%,X5R

0uF,10V,20%,X5R

C119, C121, C123 F,16V,10%,X7R

,50V,10%,X7R

,50V,10%,X7R

0V,5%,NPO

1uF,25V,5%,X7R

C172 0uF,16V,10%,X5R

2uF,4V,20%,X5R

0uF,6.3V,20%,X5R

0uF,16V,10%,X5R

7uF,4V,10%,X6S ( TI-F )

0uF,6.3V,20%,X5R

300pF,25V,1%,C0G(NP0)

2uF,10V,10%,X5R

55~85C

NT

J27, J30, J32, J33, J36 CURRENT P/N IS 901-144-8RFX

18

Bill of Materials (BOM) SLOU352–November 2012

Copyright © 2012, Texas Instruments Incorporated

Submit Documentation Feedback

Page 19

www.ti.com

Appendix A

Table 3. Bill of Materials (continued)

Item Qty MFG MFG Part# REF DES Description Value or Function

26 12 STEWARD HI0805R800R-00 FB1, FB6, FB7, FB8, FB9, FB10, FERRITE FERRITE,SMT,0805,80

27 1 MOLEX 39357-0003 P1 HEADER, THRU, 3P HEADER, THRU, POWER,

28 1 SAMTEC TSW-104-07-G-D JP2 HEADER,THU HEADER,THU,8P,2X4,MALE,DUAL

29 1 PBC09SAAN P13 HEADER,THU,9P HEADER,THU,MALE,0.1LS,9P,1X9,3

30 4 TYCO ELECTRONICS 4-103239-0x2 JP16, JP17, JP29, JP44 HEADER,THU,JUMP MALE,2PIN,.100CC MAKE FROM 4-

31 11 TYCO ELECTRONICS 4-103239-0x3 JP3, JP6, JP15, JP52, JP53, JP56, HEADER,THU,JUMP MAKE FROM 4-103239-0

32 3 NATIONAL SEMI LME49990MA/NOPB U3, U5, U7 IC,SMT,8P ULTRA LOW DISTORTION ULTRA

33 1 TI THS4130CD U42 IC,SMT,8P HI-SPEED,LOW NOISE,FULL-

34

35 1 TEXAS INSTRUMENTS CDCM7005RGZ CLK_BUF IC,SMT,QFN-48 3.3-V HIGH PERFORMANCE

36 3 TI ISO7240MDW U16, U20, U21 IC,SMT,SOIC-16W QUADDIGITAL ISOLATORS

37 1 TI / BURR-BROWN OPA211AID U13 IC,SMT,SOIC-8 1.1nV/Hz NOISE LOW POWER

38 1 TI OPA2614ID U10 IC,SMT,SOIC-8 DUAL HI GAIN BWIDTH HI OUTPUT

39 1 BURR-BROWN / TI REF5025AID U2 IC,SMT,SOIC-8 LOW-NOISE VERY LOW DRIFT

40 2 TI THS4131ID U15, VCON_OPAMP IC,SMT,SOIC-8 HIGH-SPEED LOW NOISE

41 1 TI TPS79633DCQR U1 IC,SMT,SOT223-6 ULTRALOW-NOISE HI PSRR FAST

42 1 TI / BURR-BROWN OPA830IDBV U43 IC,SMT,SOT23-5 LOW POWER SINGLE SUPPLY

43 8 TI / BURR-BROWN OPA842IDBV U35,U36, U37, U38, U39, U40, U41, IC,SMT,SOT23-5 WIDEBAND,LOW DIST,UNITY-GAIN

44 1 FUTURE TECHNOLOGY FT245RL U19 IC,SMT,SSOP-28 USB FIFO IC INCORPORATE

45 3 PANASONIC LNJ208R82RA LED41, LED42, LED43 LED,SMT,0603 LED,SMT,0603,ULTRA BRIGHT

46 3 PANASONIC LNJ308G8PRA LED-5V, LED33VA, LED5V LED,SMT,0603 LED,SMT,0603,PURE GREEN,2.03V

47

48

49 6 VENKEL CR0402-16W-000T R2, R5, R14, R63, R71, R93 RES,SMT,0402 RESISTOR,SMT,0402,0

50 17 VISHAY CRCW0402000Z R821, R822, R823, R824, R825, RES,SMT,0402 ZERO OHM

51 2 VISHAY CRCW04021001F100 R50, R92 RES,SMT,0402 RESISTOR,SMT,0402,1K,1/16W,1%,

52 1 VISHAY CRCW04021002F100 R95 RES,SMT,0402 RESISTOR,SMT,0402,10K,1/16W,1%

53 2 VISHAY CRCW04022002F100 R44, R91 RES,SMT,0402 RESISTOR,SMT,0402,20K,1/16W,1%

54

55 37 VISHAY CRCW04024990F100 R80, R81, R82, R730, R731, R736, RES,SMT,0402 RES,SMT,499

DEVICE INT. FTDICHIP-ID SECURITY DONGLE

FB11, FB12, FB13, FB14, FB17, BEAD,SMT,2P OHM@100MHz,5A

FB18

3P,3.5MM, EUROSTYLE

ROW,100LS,100TL

35H,120TL

ER 103239-0x2

JP57, P15, P16, P17, P18 ER

LOW NOISE OPAMP

DIFF,1I/O AMP,SO-8

CLOCK SYNTHESIZER AND JITTER

CLEANER

PRECISION OPERATIONAL

AMPLIFIER

CURRENT OPAMP WITH CURRENT

LIMIT

PRECISION VOLTAGE

REFERENCE,2.5V

DIFFERENTIAL I/O AMPLIFIERS

RF 1-A LDO LINEAR

REGULATOR,3.3V

WIDEBAND OPAMP

U44 STABLE,VOLTAGE-FEEDBACK

R826, R827, R828, R829, R830, JUMPER,SMT,0402,THICK FILM,0

R831, R832, R833, R834, R835, OHM,1/16W,5%

R836, R837

R793, R794, R795, R796, R797, OHM,1/16W,1%,100ppm

R798, R799, R800, R801, R802,

R803, R804, R805, R806, R807,

R808, R809, R810, R811, R812,

R813, R814, R815, R816, R817,

R818, R819, R820, R852, R853,

R854

OPAMP

RED,1.92V

OHM,1/16W,ZERO JUMPER

100ppm

,100ppm

,100ppm

SLOU352–November 2012 Bill of Materials (BOM)

Submit Documentation Feedback

Copyright © 2012, Texas Instruments Incorporated

19

Page 20

Appendix A

www.ti.com

Table 3. Bill of Materials (continued)

Item Qty MFG MFG Part# REF DES Description Value or Function

56 11 VISHAY CRCW040249R9F100 R838, R839, R840, R841, R842, RES,SMT,0402 RES,SMT,49.9

57 1 VISHAY CRCW04025110F100 R58 RES,SMT,0402 RESISTOR,SMT,0402,511

58 1 PANASONIC ERJ-2GE0R00X R56 RES,SMT,0402 RESISTOR/JUMPER,SMT,0402,0

59 5 PANASONIC ERJ-2GEJ131 R28, R29, R30, R32, R43 RES,SMT,0402 RESISTOR,SMT,0402,THICK

60

61 4 PANASONIC ERJ-2GEJ391 R51, R52, R54, R55 RES,SMT,0402 RESISTOR,SMT,0402,THICK

62

63 5 PANASONIC ERJ-2GEJ820 R23, R24, R26, R27, R34 RES,SMT,0402 RESISTOR,SMT,0402,THICK

64 5 PANASONIC ERJ-2RKF1000X R25, R40, R42, R76, R78 RES,SMT,0402 RESISTOR,SMT,0402,100

65 2 PANASONIC ERJ-2RKF2001X R850, R851 RES,SMT,0402 RESISTOR,SMT,0402,2.00K,1%,1/16

66 1 PANASONIC ERJ-2RKF3320X R59 RES,SMT,0402 RESISTOR,SMT,0402,332

67 2 PANASONIC ERJ-2RKF4020X R848, R849 RES,SMT,0402 RESISTOR,SMT,0402,402

68 1 PANASONIC ERJ-2RKF49R9X R96 RES,SMT,0402 RESISTOR,SMT,0402,49.9

71 2 VISHAY/DALE CRCW0603200RFKEA R53, R57 RES,SMT,0603 RESISTOR,SMT,0603,1%,1/10W,200

73 1 PANASONIC ERJ-3GSYJ153 R60 RES,SMT,0603 RESISTOR,SMT,0603,5%,1/10W,15K

74 2 VISHAY TNPW0603475RBEEA R3, R12 RES,SMT,0603 RESISTOR,SMT,0603,THIN

75 8 VISHAY TNPW0603499RBEEA R18, R19, R38, R39, R46, R47, R48, RES,SMT,0603 RESISTOR,SMT,0603,THIN

76 3 VISHAY TNPW060349R9BEEA R9, R36, R37 RES,SMT,0603 RESISTOR,SMT,0603,THIN

77 1 KYCON STX-3000 JX1 STEREO PHONE STEREO PHONE JACK,THU,3

78 3 KEYSTONE ELECTRONICS 5000 TP2, TP33VA, TP5V TESTPOINT,THU,1P TESTPOINT,THU,MINIATURE,0.1LS,

79 4 KEYSTONE ELECTRONICS 5001 GND1, GND2, GND3, GND4 TESTPOINT,THU,1P TESTPOINT,THU,MINIATURE,0.1LS,

80 2 KEYSTONE ELECTRONICS 5002 TP1, TP-5V TESTPOINT,THU,1P TESTPOINT,THU,MINIATURE,0.1LS,

81 9 KEYSTONE ELECTRONICS 5004 TP3, TP4, TP5, TP6, TP7, TP8, TP9, TESTPOINT,THU,1P TESTPOINT,THU,MINIATURE,0.1LS,

82

83 2 MINI-CIRCUITS ADT4-1WT T1, T2 TRANSF,SMT,6P RF TRANSFORMER WIDEBAND, 2-

84 2 BOURNS 3296W-1-103 VR2, VR3 TRIMPOT,THU,3P TRIMPOT,THU,10K,10%,0.5W,100pp

85 1 BOURNS 3296W-1-205 VR1 TRIMPOT,THU,3P TRIMPOT,THU,2M,10%,0.5W,100pp

86 2 PANASONIC ERA-2AEB152X R10, R64 RES,SMT,0402 RESISTOR,SMT,0402,THIN FILM,1.5

87 2 PANASONIC ERA-2AEB202X R61, R74 RES,SMT,0402 RESISTOR,SMT,0402,THIN FILM,2

88 8 PANASONIC ERJ-2GEJ49R9(UN) R65, R66, R67, R68, R69, R70, R77, RES,SMT,0402 ( UNINSTALLED PART )

89 4 PANASONIC ERJ-3GSYJ102(UN) R20, R21, R22, R41 UNINSTALLED ( UNINSTALLED PART )

90 12 UNINSTALLED CRCW04020000Z0ED(UN) R1, R6, R7, R8, R11, R15, R16, R17, UNINSTALLED UNINSTALLED

91 1 PBC09SAAN P14 UNINSTALLED HEADER,THU,MALE,0.1LS,9P,1X9,3

92

93 4 AVX 0402YC104KAT2A(UN) C27, C28,C100, C102 UNINSTALLED UNINSTALLED

94 2 TAIYO YUDEN LMK105BJ104KV- F C42, C44 CAP,SMT,0402 CAPACITOR,SMT,0402,CERAMIC,1

R843, R844, R845, R846, R847, OHM,1/16W,1%,100ppm

R855

OHM,1/16W,1%,100ppm

OHM,5%,1/16W

FILM,5%,1/16W,130

FILM,5%,1/16W,390

FILM,5%,1/16W,82

OHM,1%,1/10W

W

OHM,1%,1/16W

OHM,1%,1/16W

OHM,1%,1/16W

OHM

FILM,475 OHM 0.1%,1/10W,25ppm

R49 FILM,499 OHM 0.1%,1/10W,25ppm

FILM,49.9 OHM,0.1%,1/10W

JACK,THU,3 PIN PIN,3.5mm

120TL, RED

120TL, BLACK

120TL, WHITE

TP10, TP16 120TL, YELLOW

775 MHz, 50 OHM

m,25T

m,25T

K,0.1%,1/16W,10ppm, Tolerance

important

K,0.1%,1/16W,10ppm, Tolerance

important

R79

R62, R72, R73, R75

35H,120TL

0V,Y5V,0.1uF,20%

20

Bill of Materials (BOM) SLOU352–November 2012

Copyright © 2012, Texas Instruments Incorporated

Submit Documentation Feedback

Page 21

www.ti.com

Appendix A

Table 3. Bill of Materials (continued)

Item Qty MFG MFG Part# REF DES Description Value or Function

95 2 KEMET C0402C152J5GACTU C13, C14 CAP,SMT,0402 CAPACITOR,SMT,0402,CERAMIC,1

96 2 SUSUMU RG1005N202B R4, R13 UNINSTALLED RESISTOR,SMT,0402,THIN FILM,2

97 1 PANASONIC ERJ-2GEJ820 R33 RES,SMT,0402 RESISTOR,SMT,0402,THICK

98 1 PANASONIC ERJ-2GEJ131 R31 RES,SMT,0402 RESISTOR,SMT,0402,THICK

99 1 PANASONIC ERJ-2GEJ161 R35 RES,SMT,0402 RESISTOR,SMT,0402,THICK

100 3 TI LMH6629SDE/NOPB U4, U6, U8 IC,SMT,DFN-8 ULTRA-LOW NOISE,PRECISION

101 8 PANASONIC ECJ-0EC1H470J C332, C329, C330, C331, C326, CAP,SMT,0402 CAPACITOR,SMT,0402,CER,47pF,5

102 2 AVX 06033C104JAT2A C91, C92 CAP,SMT,0603 CAPACITOR,SMT,0603,CERAMIC,0.

103 1 PANASONIC ECJ-1VB1C105K C93 CAP,SMT,0603 CAPACITOR,SMT,0603,CERAMIC,1.

104 1 VISHAY CRCW04024701F100 R45 RES,SMT,0402 RESISTOR,SMT,0402,4.7K,1/16W,1

105 1 TYCO ELECTRONICS 4-103239-0x3 P18 UNINSTALLED MAKE FROM 4-103239-0, DNI

106 4 Vishay CRCW04020000Z0ED(UN) R734, R738, R776, R777 UNINSTALLED VISHAY_0402_1x0.5x0.35mm_016H

107 16 COMPONENTS CORP TP105-01-04 TP34, TP35, TP36, TP37, TP38, UNINSTALLED TEST POINTS,THU,SMALL,TL-70,

108 1 ADVANCED CONNECTEK MNE20-5K5P10 USB1 CONN,SMT,5P MINI-AB USB OTG RECEPTACLE

109 11 EFJOHNSON 142-0721-891 J2, J4, J6, J8, J14, J17, J28, J29, CONN,THU,SMA SMA JACK END LAUNCH, 0.080

110 1 CONNOR WINFIELD CWX813-10.0M X1 OSC,SMT,4P OSCILLATOR,SMT,4P,3.3V,+/-

111 1 VCA5807PZP DUT1 Customer Supplied "IC, Fully Integrated, 8-Channel

112 1 OSC,SMT,6P VX-7040-ECE-KXX-0- OSC1 OSC,SMT,6P VCXO,SMT,3.3V,40Mhz

113 15 Molex 15-29-1025 SHUNT-JUMPER CONN SHUNT CLOSED TOP .100

Special Instructions and Notes:

1. Include extra Shunt-Jumpers with board. * Alternative Part suggested

Note: Asterisk(*) next to part manufacturer's name denotes possible long lead time item. * Green= Exact part, No Substitutions

640M000 5.0x7.5x1.8mm ( Customer Supply )

C327, C328, C359 0V,5%,NPO

TP39, TP40, TP41, TP42, TP43, YELLOW, DNI

TP44, TP45, TP46, TP47, TP48,

TP49

J31, J34, J35 JACK PCB THICK, Use J630-ND for board

* Orange=Tolerance is significant

* Blue= Uninstalled

* Yellow= TI Provided part

500pF,50V,5%,C0G/NP0

K,0.1%,1/16W,10ppm,(UNINSTALLE

D)

FILM,5%,1/16W,82 (UNINSTALLED)

FILM,5%,1/16W,130

(UNINSTALLED)

FILM,5%,1/16W,160

(UNINSTALLED)

OPERATIONAL AMPLIFIERS

1uF,25V,5%,X7R

0uF,16V,10%,X5R

%,100ppm

R/A SMT TYPE, Use 670-1523-1-ND

instead.

thickness of .042 or J502-ND for

.062 or J992-ND for .068

25ppm,-20~70C,10.000 MHz, Use

FVXO-PC73B-640-ND instead

Voltage Controlled Amplifier for

Ultrasound with Passive CW Mixer,

0.75 nV/rtHz, 99 mW/CH "

GOLD

SLOU352–November 2012 Bill of Materials (BOM)

Submit Documentation Feedback

Copyright © 2012, Texas Instruments Incorporated

21

Page 22

Appendix B PCB Layout and Schematics

B.1 PCB Layout

Figure 12 through Figure 17 show the PCB layouts for this EVM.

www.ti.com

22

Figure 12. Top Layer - Signal

PCB Layout and Schematics SLOU352–November 2012

Copyright © 2012, Texas Instruments Incorporated

Submit Documentation Feedback

Page 23

www.ti.com

PCB Layout

Figure 13. Second Layer - Ground

SLOU352–November 2012 PCB Layout and Schematics

Submit Documentation Feedback

Copyright © 2012, Texas Instruments Incorporated

23

Page 24

PCB Layout

www.ti.com

24

Figure 14. Third Layer - Power

PCB Layout and Schematics SLOU352–November 2012

Copyright © 2012, Texas Instruments Incorporated

Submit Documentation Feedback

Page 25

www.ti.com

PCB Layout

Figure 15. Fourth Layer - Signal

SLOU352–November 2012 PCB Layout and Schematics

Submit Documentation Feedback

Copyright © 2012, Texas Instruments Incorporated

25

Page 26

PCB Layout

www.ti.com

26

Figure 16. Fifth Layer - Ground

PCB Layout and Schematics SLOU352–November 2012

Copyright © 2012, Texas Instruments Incorporated

Submit Documentation Feedback

Page 27

www.ti.com

PCB Layout

Figure 17. Bottom Layer - Signal

SLOU352–November 2012 PCB Layout and Schematics

Submit Documentation Feedback

Copyright © 2012, Texas Instruments Incorporated

27

Page 28

U1

FB1

C2

C3

R59

LED33VA

FB10

C70

C151

FB11

R40

R58

LED5V

LED-5V

FB6

JP3

JP6

FB8

FB7

JP2

P1

FB12

FB13

FB9

TP33VA

TP5V

GND1

GND2

GND3

GND4

TP-5V

C1

C68

C152

C69

U2

TP2

TP1

C4

Schematics

B.2 Schematics

Figure 18 through Figure 27 show the schematics for this EVM in landscape mode, for readability.

www.ti.com

Figure 18. Schematic 1 of 10

28

PCB Layout and Schematics SLOU352–November 2012

Copyright © 2012, Texas Instruments Incorporated

Submit Documentation Feedback

Page 29

C33

R31

R34

R32

R33

R45 C42 C44

R35

R80

R81R82

C43

C98 C138 C137 C136 C135

C131 C96 C95 C133 C132

C99 C134 C139 C140 C97

CLK_BUF

CLK_BUF

C129C128

C75

C16

C93 C130C34

C94

LED41

LED42

LED43

X1

R44

OSC1

C32

C31

R27

R29

R26

R28

R23

R30

R24

R43

www.ti.com

Schematics

Figure 19. Schematic 2 of 10

SLOU352–November 2012 PCB Layout and Schematics

Submit Documentation Feedback

Copyright © 2012, Texas Instruments Incorporated

29

Page 30

C103

C76

J3

C78

C80

J5

C82

C84

J7

C86

C125

J1

J6

J2

J4

J8

R79

R70

R69

R68

R67

R66

R65

R77

C107

C108

C109

C118

C116

C119

C121

C123

C104

C77

C79

C81

C83

C85

C87

C126

TP10

TP6

TP9

TP5

TP8

TP4

TP7

TP3

Schematics

www.ti.com

30

PCB Layout and Schematics SLOU352–November 2012

Figure 20. Schematic 3 of 10

Submit Documentation Feedback

Copyright © 2012, Texas Instruments Incorporated

Page 31

C294

C295 C365 C366 C310 C309C308

C349

C348

R821

R822

R823

R824

R825

R826

R827

R828

R829

R830

R831

R832

R836

R835

R834

R833

TP34

TP35

TP36

TP37

TP38

TP39

TP40

TP41

TP42

TP43

TP44

TP45

TP46

TP47

TP48

TP49

DUT1

www.ti.com

Schematics

Figure 21. Schematic 4 of 10

SLOU352–November 2012 PCB Layout and Schematics

Submit Documentation Feedback

Copyright © 2012, Texas Instruments Incorporated

31

Page 32

U44

R731

R730

C362

C361

C363

R838

C332

C317

C318

U39

R818

R817

C343

C342

C350

R839

C329

C313

C314

U41

R806

R805

C341

C340

C356

R840

C330

C325

C324

U38

R816

R815

C347

C346

C351

R841

C331

C315

C316

U37

R814

R813

C345

C344

C352

R842

C326

C364

C246

U36

R808

R807

C334

C333

C353

R843

C327

C323

C322

U40

R820

R819

C338

C337

C354

R844

C328

C311

C312

R794

C336

C355

R845

J26

U42

C335

C320

C339

R837

R848 R849

C321

C319

R851

R850

R846

R847

C357

C358

J27

R810

R809

R798

R797

R800

R799

R802

R801

R796

R795

R812

R811

R804

R803

R793

U43

U35

R852

R736

C360

C291

C290

R855

C359

C267

C265

R854

R853

R734

R738

R776 R777

J33

J30

J32

J36

J34

J35

J31

J29

J28

Schematics

www.ti.com

Figure 22. Schematic 5 of 10

32

PCB Layout and Schematics SLOU352–November 2012

Submit Documentation Feedback

Copyright © 2012, Texas Instruments Incorporated

Page 33

T2

C141

J10

C51

T1

C101

J9

C17

R76

R25

R42

R78

C28

C100

C30

C29

C26

C25

C102

C27

www.ti.com

Schematics

Figure 23. Schematic 6 of 10

SLOU352–November 2012 PCB Layout and Schematics

Submit Documentation Feedback

Copyright © 2012, Texas Instruments Incorporated

33

Page 34

C174 C173

C160 C170C159

R53

R57

C163

R93

VR2

JP16

JP17

JP29

J14

R96

JP15

C59

C58

C62

C63

R91

R95

U13

VR1

C64

C171

C172

C162

C161

R51 R52

R54R55

R56

VCON_OPAMP

C53

C60

Schematics

www.ti.com

Figure 24. Schematic 7 of 10

34

PCB Layout and Schematics SLOU352–November 2012

Submit Documentation Feedback

Copyright © 2012, Texas Instruments Incorporated

Page 35

J12

C37

C40

C38

C39

R19

R18

R39

R38

R48

R47

R49

R46

J13

JX1

C35

C36

U10

U10

U10

JP56

JP57

JP53

C21

C20

C47

C48

JP52

C22

C23

C24

C41

R37

R36

C45

C18

R41

R22

R20

R21

C19

C46

www.ti.com

Schematics

Figure 25. Schematic 8 of 10

SLOU352–November 2012 PCB Layout and Schematics

Submit Documentation Feedback

Copyright © 2012, Texas Instruments Incorporated

35

Page 36

U19

USB1

USB1

FB14

C165

C176C175

C178 C177

U20

U16

C166

C167

C155

FB17

R92

U21

C180

FB18

C154

C179

R50

JP44

P14

P13

P17

TP16

P18

There are two ground planes here.

We isolate the USB circuit from

the rest of the board. The circuits are only

coupled through the opto-isolators.

Serial Interface

Schematics

www.ti.com

Figure 26. Schematic 9 of 10

36

PCB Layout and Schematics SLOU352–November 2012

Submit Documentation Feedback

Copyright © 2012, Texas Instruments Incorporated

Page 37

C6

R3

R12

R60

C11

VR3

C71

P15

C72

R9

R17

R1

U15

C15

R8

C8

R75

C91

R72

C88

C7

C12

C92

C90

R74

R61

R4

R13

R64

R10

C10

C74

R73

R62

R16

R7

R71

R14

R2

R15

R6

R63

R11

R5

U7

U3

U5

U8

U4

U6

P16

C5

C9

J17

U8

U4

U6

C89

C14

C13

C73

This Circuit provides 3

options for populating

Op-Amps for maximum flexibility

ALL Bypass Caps in

this circuit need to be

tied close to the pin.

Differential could fit between the

single-ended amps in the layout.

www.ti.com

Schematics

SLOU352–November 2012 PCB Layout and Schematics

Submit Documentation Feedback

Figure 27. Schematic 10 of 10

Copyright © 2012, Texas Instruments Incorporated

37

Page 38

IMPORTANT NOTICE

Texas Instruments Incorporated and its subsidiaries (TI) reserve the right to make corrections, enhancements, improvements and other

changes to its semiconductor products and services per JESD46, latest issue, and to discontinue any product or service per JESD48, latest

issue. Buyers should obtain the latest relevant information before placing orders and should verify that such information is current and

complete. All semiconductor products (also referred to herein as “components”) are sold subject to TI’s terms and conditions of sale

supplied at the time of order acknowledgment.

TI warrants performance of its components to the specifications applicable at the time of sale, in accordance with the warranty in TI’s terms

and conditions of sale of semiconductor products. Testing and other quality control techniques are used to the extent TI deems necessary

to support this warranty. Except where mandated by applicable law, testing of all parameters of each component is not necessarily

performed.

TI assumes no liability for applications assistance or the design of Buyers’ products. Buyers are responsible for their products and

applications using TI components. To minimize the risks associated with Buyers’ products and applications, Buyers should provide

adequate design and operating safeguards.

TI does not warrant or represent that any license, either express or implied, is granted under any patent right, copyright, mask work right, or

other intellectual property right relating to any combination, machine, or process in which TI components or services are used. Information

published by TI regarding third-party products or services does not constitute a license to use such products or services or a warranty or

endorsement thereof. Use of such information may require a license from a third party under the patents or other intellectual property of the

third party, or a license from TI under the patents or other intellectual property of TI.

Reproduction of significant portions of TI information in TI data books or data sheets is permissible only if reproduction is without alteration

and is accompanied by all associated warranties, conditions, limitations, and notices. TI is not responsible or liable for such altered

documentation. Information of third parties may be subject to additional restrictions.

Resale of TI components or services with statements different from or beyond the parameters stated by TI for that component or service

voids all express and any implied warranties for the associated TI component or service and is an unfair and deceptive business practice.

TI is not responsible or liable for any such statements.

Buyer acknowledges and agrees that it is solely responsible for compliance with all legal, regulatory and safety-related requirements

concerning its products, and any use of TI components in its applications, notwithstanding any applications-related information or support

that may be provided by TI. Buyer represents and agrees that it has all the necessary expertise to create and implement safeguards which

anticipate dangerous consequences of failures, monitor failures and their consequences, lessen the likelihood of failures that might cause

harm and take appropriate remedial actions. Buyer will fully indemnify TI and its representatives against any damages arising out of the use

of any TI components in safety-critical applications.

In some cases, TI components may be promoted specifically to facilitate safety-related applications. With such components, TI’s goal is to

help enable customers to design and create their own end-product solutions that meet applicable functional safety standards and

requirements. Nonetheless, such components are subject to these terms.

No TI components are authorized for use in FDA Class III (or similar life-critical medical equipment) unless authorized officers of the parties

have executed a special agreement specifically governing such use.

Only those TI components which TI has specifically designated as military grade or “enhanced plastic” are designed and intended for use in

military/aerospace applications or environments. Buyer acknowledges and agrees that any military or aerospace use of TI components

which have not been so designated is solely at the Buyer's risk, and that Buyer is solely responsible for compliance with all legal and

regulatory requirements in connection with such use.

TI has specifically designated certain components as meeting ISO/TS16949 requirements, mainly for automotive use. In any case of use of

non-designated products, TI will not be responsible for any failure to meet ISO/TS16949.

Products Applications

Audio www.ti.com/audio Automotive and Transportation www.ti.com/automotive

Amplifiers amplifier.ti.com Communications and Telecom www.ti.com/communications

Data Converters dataconverter.ti.com Computers and Peripherals www.ti.com/computers

DLP® Products www.dlp.com Consumer Electronics www.ti.com/consumer-apps

DSP dsp.ti.com Energy and Lighting www.ti.com/energy

Clocks and Timers www.ti.com/clocks Industrial www.ti.com/industrial

Interface interface.ti.com Medical www.ti.com/medical

Logic logic.ti.com Security www.ti.com/security

Power Mgmt power.ti.com Space, Avionics and Defense www.ti.com/space-avionics-defense

Microcontrollers microcontroller.ti.com Video and Imaging www.ti.com/video

RFID www.ti-rfid.com

OMAP Applications Processors www.ti.com/omap TI E2E Community e2e.ti.com

Wireless Connectivity www.ti.com/wirelessconnectivity

Mailing Address: Texas Instruments, Post Office Box 655303, Dallas, Texas 75265

Copyright © 2013, Texas Instruments Incorporated

Page 39

Authorized Distribution Brand:

Website:

Welcome to visit www.ameya360.com

Contact Us:

Address:

401 Building No.5, JiuGe Business Center, Lane 2301, Yishan Rd

Minhang District, Shanghai , China

Sales:

Direct +86 (21) 6401-6692

Email amall@ameya360.com

QQ 800077892

Skype ameyasales1 ameyasales2

Customer Service:

Email service@ameya360.com

Partnership:

Tel +86 (21) 64016692-8333

Email mkt@ameya360.com

Loading...

Loading...