Page 1

www.ti.com

UCD9224

SLVSA35 –JANUARY 2010

Digital PWM System Controller

1

FEATURES

2

• Fully Configurable Multi-Output and Multi-

Tool to Simulate, Configure, and Monitor

Power Supply Performance

Phase Non-Isolated DC/DC PWM Controller

• Controls Up to 2 Voltage Rails and Up to 4

Phases

• Supports Switching Frequencies Up to 2MHz

with 250 ps Duty-Cycle Resolution

• Up To 1mV Closed Loop Resolution

• Hardware-Accelerated, 3-Pole/3-Zero

Compensator with Non-Linear Gain for

APPLICATIONS

• Industrial/ATE

• Networking Equipment

• Telecommunications Equipment

• Servers

• Storage Systems

• FPGA, DSP and Memory Power

Improved Transient Performance

• Supports Multiple Soft-Start and Soft-Stop

Configurations Including Prebias Start-up

• Supports Voltage Tracking, Margining and

Sequencing

• Supports Current and Temperature Balancing

for Multi-Phase Power Stages

• Supports Phase Adding/Shedding for

Multi-Phase Power Stages

• Sync In/Out Pins Align DPWM Clocks Between

Multiple UCD92xx Devices

• 12-Bit Digital Monitoring of Power Supply

Parameters Including:

– Input/Output Current and Voltage

– Temperature at Each Power Stage

• Multiple Levels of Over-current Fault

Protection:

– External Current Fault Inputs

– Analog Comparators Monitor Current

Sense Voltage

– Current Continually Digitally Monitored

• Over- and Under-voltage Fault Protection

• Over-temperature Fault Protection

• Enhanced Nonvolatile Memory with Error

Correction Code (ECC)

• Device Operates From a Single Supply with an

Internal Regulator Controller That Allows

DESCRIPTION

The UCD9224 is a multi-rail, multi-phase

synchronous buck digital PWM controller designed for

non-isolated DC/DC power applications. This device

integrates dedicated circuitry for DC/DC loop

management with flash memory and a serial interface

to support configurability, monitoring and

management.

The UCD9224 was designed to provide a wide

variety of desirable features for non-isolated DC/DC

converter applications while minimizing the total

system component count by reducing external

circuits. The solution integrates multi-loop

management with sequencing, margining, tracking

and intelligent phase management to optimize for

total system efficiency. Additionally, loop

compensation and calibration are supported without

the need to add external components.

To facilitate configuring the device, the Texas

Instruments Fusion Digital Power™ Designer is

provided. This PC based Graphical User Interface

offers an intuitive interface to the device. This tool

allows the design engineer to configure the system

operating parameters for the application, store the

configuration to on-chip non-volatile memory and

observe both frequency domain and time domain

simulations for each of the power stage outputs.

TI has also developed multiple complementary power

stage solutions – from discrete drivers in the UCD7k

family to fully tested power train modules in the PTD

Operation Over a Wide Supply Voltage Range family. These solutions have been developed to

• Supported by Fusion Digital Power™

Designer, a Full Featured PC Based Design

complement the UCD9k family of system power

controllers.

1

Please be aware that an important notice concerning availability, standard warranty, and use in critical applications of Texas

Instruments semiconductor products and disclaimers thereto appears at the end of this data sheet.

2Fusion Digital Power, Auto-ID are trademarks of Texas Instruments.

PRODUCTION DATA information is current as of publication date.

Products conform to specifications per the terms of the Texas

Instruments standard warranty. Production processing does not

necessarily include testingof all parameters.

Copyright © 2010, Texas Instruments Incorporated

Page 2

UCD9224

SLVSA35 –JANUARY 2010

This integrated circuit can be damaged by ESD. Texas Instruments recommends that all integrated circuits be handled with

appropriate precautions. Failure to observe proper handling and installation procedures can cause damage.

ESD damage can range from subtle performance degradation to complete device failure. Precision integrated circuits may be more

susceptible to damage because very small parametric changes could cause the device not to meet its published specifications.

www.ti.com

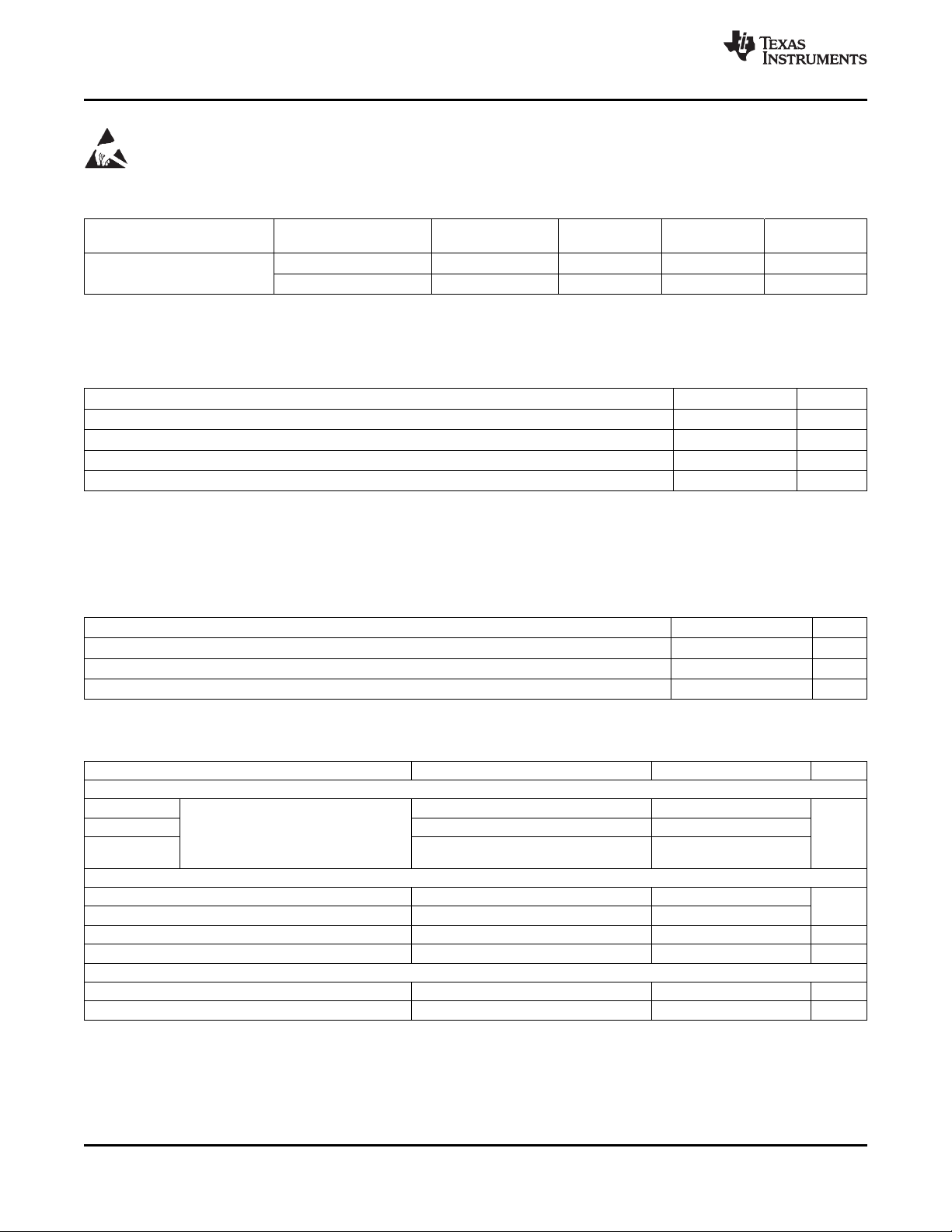

ORDERING INFORMATION

(1)

OPERATING TEMPERATURE ORDERABLE PART PIN COUNT SUPPLY PACKAGE TOP SIDE

RANGE, T

A

–40°C to 125°C

NUMBER MARKING

UCD9224RGZR 48-pin Reel of 2500 QFN UCD9224

UCD9224RGZT 48-pin Tray of 250 QFN UCD9224

(1) For the most current package and ordering information, see the Package Option Addendum at the end of this document, or see the TI

web site at www.ti.com.

ABSOLUTE MAXIMUM RATINGS

(1)

VALUE UNIT

Voltage applied at V

Voltage applied at V

Voltage applied to any pin

Storage temperature (T

to DGND1 –0.3 to 3.8 V

33D

to AGND –0.3 to 3.8 V

33A

(2)

) –40 to 150 °C

STG

–0.3 to 3.8 V

(1) Stresses beyond those listed under absolute maximum ratings may cause permanent damage to the device. These are stress ratings

only and functional operation of the device at these or any other conditions beyond those indicated under recommended operating

conditions is not implied. Exposure to absolute-maximum-rated conditions for extended periods may affect device reliability.

(2) All voltages referenced to GND.

RECOMMENDED OPERATING CONDITIONS

over operating free-air temperature range (unless otherwise noted)

MIN NOM MAX UNIT

V Supply voltage during operation, V

T

A

T

J

Operating free-air temperature range

Junction temperature

(1)

(1) When operating, the UCD9224’s typical power consumption causes a 15°C temperature rise from ambient.

33D

(1)

, V

33DIO

, V

33A

3 3.3 3.6 V

–40 125 °C

125 °C

ELECTRICAL CHARACTERISTICS

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

SUPPLY CURRENT

I

V33A

I

V33D

I

V33D

INTERNAL REGULATOR CONTROLLER INPUTS/OUTPUTS

V

33

V

33FB

I

V33FB

Beta Series NPN pass device 40

EXTERNALLY SUPPLIED 3.3 V POWER

V

33D

V

33A

Supply current mA

3.3-V linear regulator Emitter of NPN transistor 3.25 3.3 3.6

3.3-V linear regulator feedback 4 4.6

Series pass base drive V

Digital 3.3-V power TA= 25° C 3.0 3.6 V

Analog 3.3-V power TA= 25°C 3.0 3.6 V

2 Submit Documentation Feedback Copyright © 2010, Texas Instruments Incorporated

V

= 3.3 V 8 15

33A

V

= 3.3 V 42 55

33D

V

= 3.3 V storing configuration parameters

33D

in flash memory

= 12 V, curent into V

VIN

pin 10 mA

33FB

53 65

V

Page 3

UCD9224

www.ti.com

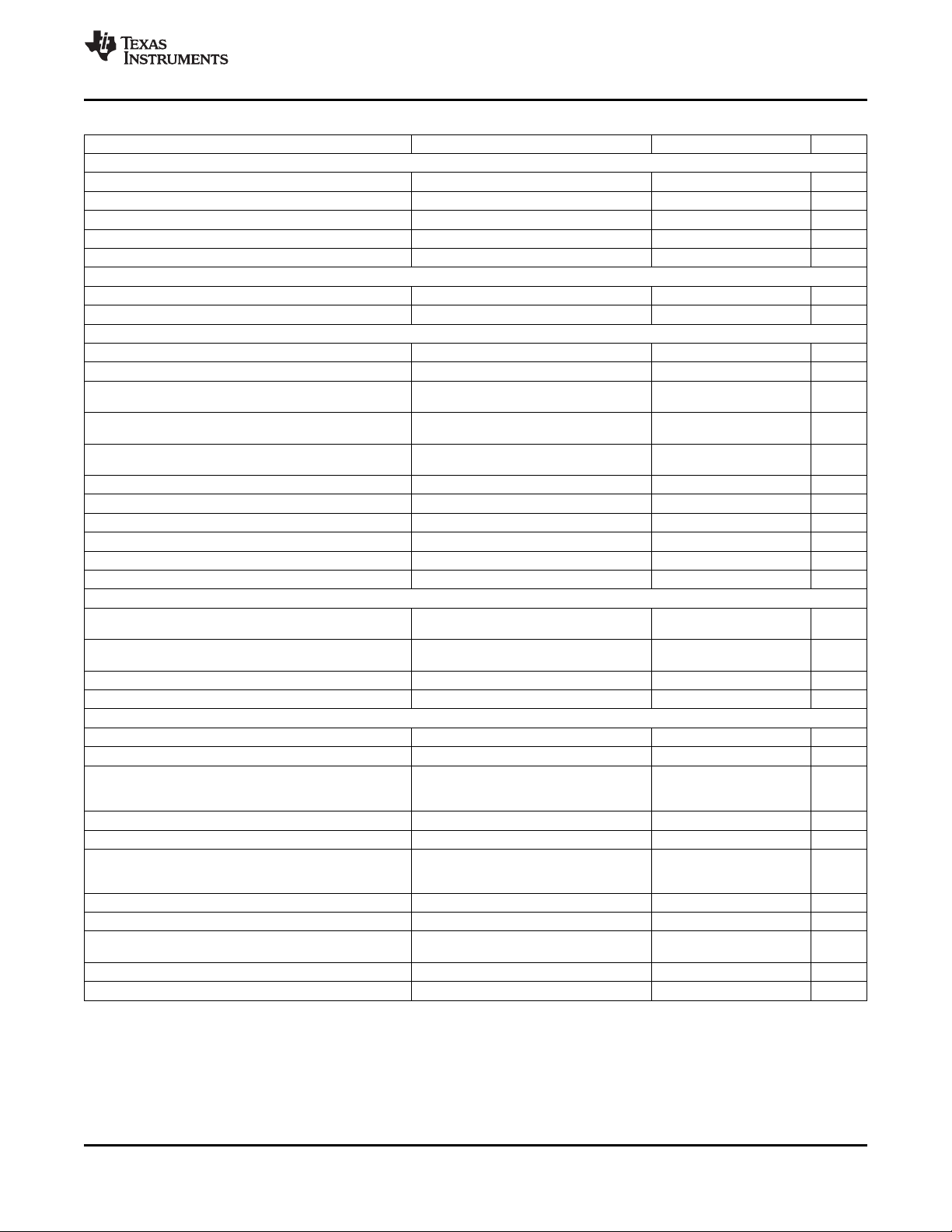

ELECTRICAL CHARACTERISTICS (continued)

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

ERROR AMPLIFIER INPUTS EAPn, EANn

V

CM

V

ERROR

EAP-EAN Error voltage digital resolution AFE_GAIN field of CLA_GAINS = 3 1 mV

R

EA

I

OFFSET

Vref 10-bit DAC

V

ref

V

refres

ANALOG INPUTS CS-1A, CS-1B, CS-2A, CS-3A, Vin/Iin, Temperature, ADDR-0, ADDR-1, Vtrack, ADCref

V

ADDR_OPEN

V

ADDR_SHORT

V

ADC_RANGE

V

OC_THRS

V

OC_RES

ADCref External reference input 1.8 V33A V

Temp

internal

INL ADC integral nonlinearity –2.5 2.5 mV

I

lkg

R

IN

C

IN

DIGITAL INPUTS/OUTPUTS

V

OL

V

OH

V

IH

V

IL

SYSTEM PERFORMANCE

V

RESET

t

RESET

V

RefAcc

V

DiffOffset

t

Delay

F

SW

Duty Max and Min duty cycle 0% 100%

V33Slew Minimum V33slew rate during power on 0.25 V/ms

t

retention

Write_Cycles Number of nonvolatile erase/write cycles TJ= 25°C 20 K cycles

(1) See the UCD92xx PMBus Command Reference for the description of the AFE_GAIN field of CLA_GAINS command.

(2) Can be disabled by setting to '0'0

(3) The maximum IOL, for all outputs combined, should not exceed 12 mA to hold the maximum voltage drop specified.

(4) The maximum IOH, for all outputs combined, should not exceed 48 mA to hold the maximum voltage drop specified.

(5) With default device calibration. PMBus calibration can be used to improve the regulation tolerance

Common mode voltage each pin –0.15 1.848 V

Internal error voltage range AFE_GAIN field of CLA_GAINS = 0

(1)

Input Impedance Ground reference 0.5 1.5 3 MΩ

Input offset current 1 kΩ source impedence –5 5 µA

Reference voltage setpoint 0 1.6 V

Reference voltage resolution 1.56 mV

Voltage indicating open pin ADDR-0, ADDR-1 open 2.37 V

Voltage indicating shorted pin ADDR-0, ADDR-1 short to ground 0.36 V

Measurement range for voltage monitoring 0 2.5 V

Over-current comparator threshold voltage

(2)

range

Over-current comparator threshold voltage

range

Inputs: Vin/Iin, V

CS-1B, CS-2A, CS-3A

Inputs: CS-1A, CS-1B, CS-2A, CS-3A 0.032 2 V

Inputs: CS-1A, CS-1B, CS-2A, CS-3A 31.25 mV

track

, V

temperature

CS-1A,

Int. temperature sense accuracy Over range from 0°C to 125°C –5 5 °C

Input leakage current 3V applied to pin 100 nA

Input impedance Ground reference 8 MΩ

Current Sense Input capacitance 10 pF

Low-level output voltage IOL= 6 mA

High-level output voltage IOH= -6 mA

High-level input voltage V

Low-level input voltage V

Voltage where device comes out of reset V

(3)

, V

= 3 V V

33D

(4)

, V

= 3 V V

33D

= 3V 2.1 3.6 V

33D

= 3.5 V 1.4 V

33D

Pin 2.3 2.4 V

33D

Pulse width needed for reset nRESET pin 2 µs

V

commanded to be 1V at 25°C,

Setpoint reference accuracy –10 10 mV

ref

AFEgain = 4, 1V input to EAP/N measured at

output of the EADC

(5)

Setpoint reference accuracy over temperature –40°C to 125°C –20 20 mV

Differential offset between gain settings AFEgain = 4 compared to AFEgain = 1, 2, or 8 –4 4 mV

Digital compensator delay 240 switching ns

Switching frequency 15.260 2000 kHz

V33slew rate between 2.3V and 2.9V,

V

= V

33A

33D

Retention of configuration parameters TJ= 25°C 100 Years

SLVSA35 –JANUARY 2010

–256 248 mV

DGND1

+0.25

V

33D

–0.6V

240 + 1

cycle

Copyright © 2010, Texas Instruments Incorporated Submit Documentation Feedback 3

Page 4

UCD9224

SLVSA35 –JANUARY 2010

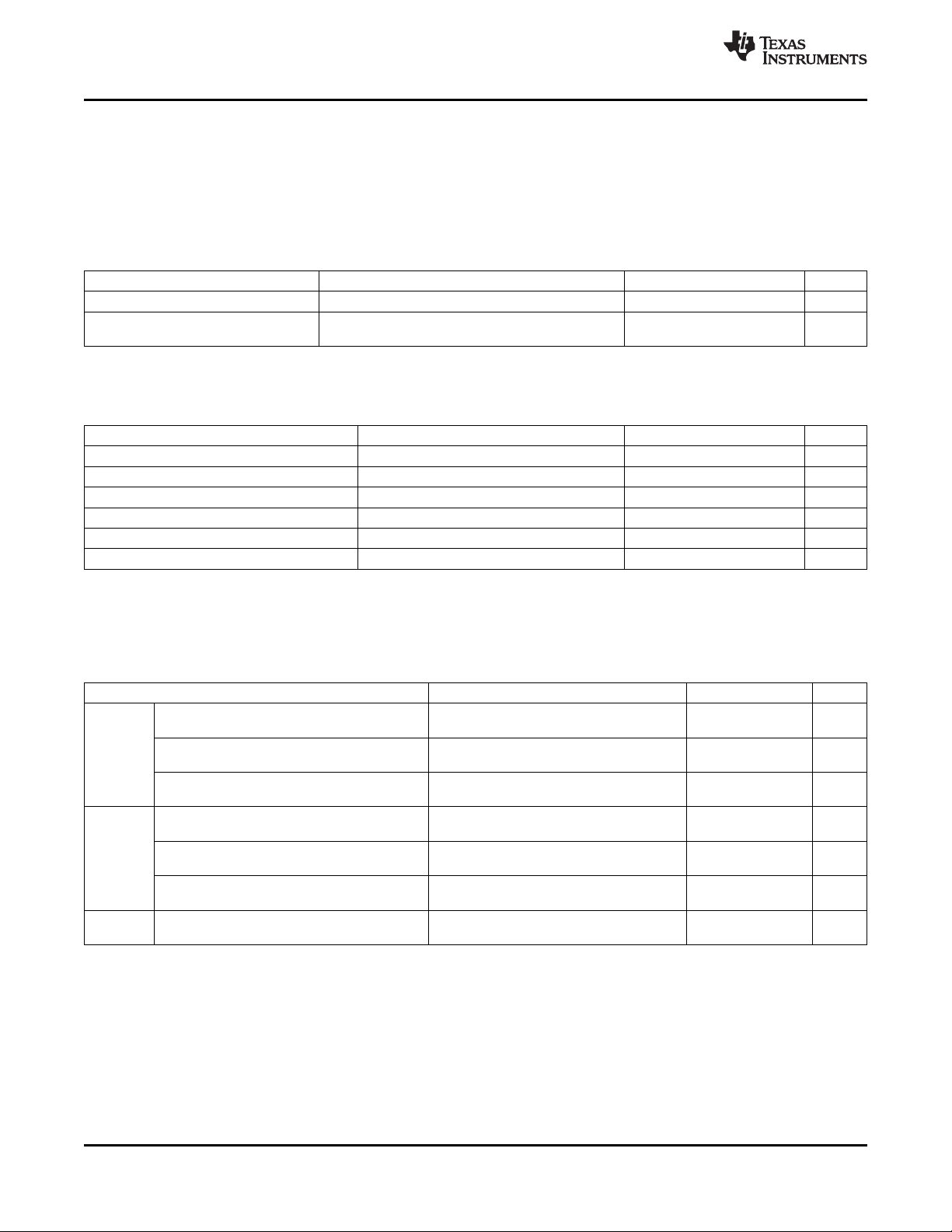

ADC MONITORING INTERVALS AND RESPONSE TIMES

The ADC operates in a continuous conversion sequence that measures each rail's output voltage, each power

stage's output current, plus four other variables (external temperature, Internal temperature, input voltage and

current, and tracking input voltage). The length of the sequence is determined by the number of output rails

(NumRails) and total output power stages (NumPhases) configured for use. The time to complete the monitoring

sampling sequence is give by the formula:

t

ADC_SEQ

t

ADC

t

ADC_SEQ

The most recent ADC conversion results are periodically converted into the proper measurement units (volts,

amperes, degrees), and each measurement is compared to its corresponding fault and warning limits. The

monitoring operates asynchronously to the ADC, at intervals shown in the table below.

t

Vout

t

Iout

t

Vin

t

Iin

t

TEMP

t

Ibal

= t

× (NumRAILS + NumPHASE + 4)

ADC

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

ADC single-sample time 3.84 µs

ADC sequencer interval 23.04 38.4 µs

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

Output voltage monitoring interval 200 µs

Output current monitoring interval 200 × NRails µs

Input voltage monitoring interval 2 ms

Input current monitoring interval 2 ms

Temperature monitoring interval 100 ms

Output current balancing interval 2 ms

Min = 1 Rail + 1 Phase + 4 = 6 samples

Max = 2 Rails + 4 Phases + 4 = 10 samples

www.ti.com

Because the ADC sequencer and the monitoring comparisons are asynchronous to each other, the response

time to a fault condition depends on where the event occurs within the monitoring interval and within the ADC

sequence interval. Once a fault condition is detected, some additional time is required to determine the correct

action based on the FAULT_RESPONSE code, and then to perform the appropriate response. The following

table lists the worse-case fault response times.

PARAMETER TEST CONDITIONS MAX TIME UNIT

Over-/under-voltage fault response time during Normal regulation, no PMBus activity, 4

normal operation stages enabled

t

, t

OVF

t

, t

OCF

t

OTF

(1) During a STORE_DEFAULT_ALL command, which stores the entire configuration to nonvolatile memory, the fault detection latency can

be up to 10 ms.

Over-/under-voltage fault response time, during

UVF

data logging

Over-/under-voltage fault response time, when

tracking or sequencing enable

Over-/under-current fault response time during Normal regulation, no PMBus activity, 4

normal operation stages enabled 75% to 125% current step

Over-/under-current fault response time, during During data logging to nonvolatile memory

UCF

data logging 75% to 125% current step

Over-/under-current fault response time, when During tracking and soft start ramp 75% to

tracking or sequencing enable 125% current step

Over-temperature fault response time 2.5 S

During data logging to nonvolatile memory

During tracking and soft-start ramp. 400 µs

Temperature rise of 10°C/sec,

OT threshold = 100°C

(1)

100 + (600 × NRails) µs

300 µs

800 µs

600 + (600 × N

300 + (600 × N

Rails

Rails

) µs

) µs

4 Submit Documentation Feedback Copyright © 2010, Texas Instruments Incorporated

Page 5

UCD9224

www.ti.com

HARDWARE FAULT DETECTION LATENCY

The controller contains hardware fault detection circuits that are independent of the ADC monitoring sequencer.

PARAMETER TEST CONDITIONS MAX UNIT

t

Time to disable DPWM output based on corresponding 15 + 3 ×

t

FLT

active FLT pin NumPhases

Time to disable the first DPWM output based on internal Step change in CS voltage from 0V to Switch

analog comparator fault 2.5V Cycles

CLF

Time to disable all remaining DPWM and SRE outputs

configured for the voltage rail after an internal analog µs

comparator fault

High level on FLT pin µs

Step change in CS voltage from 0V to 10 + 3 ×

2.5V NumPhases

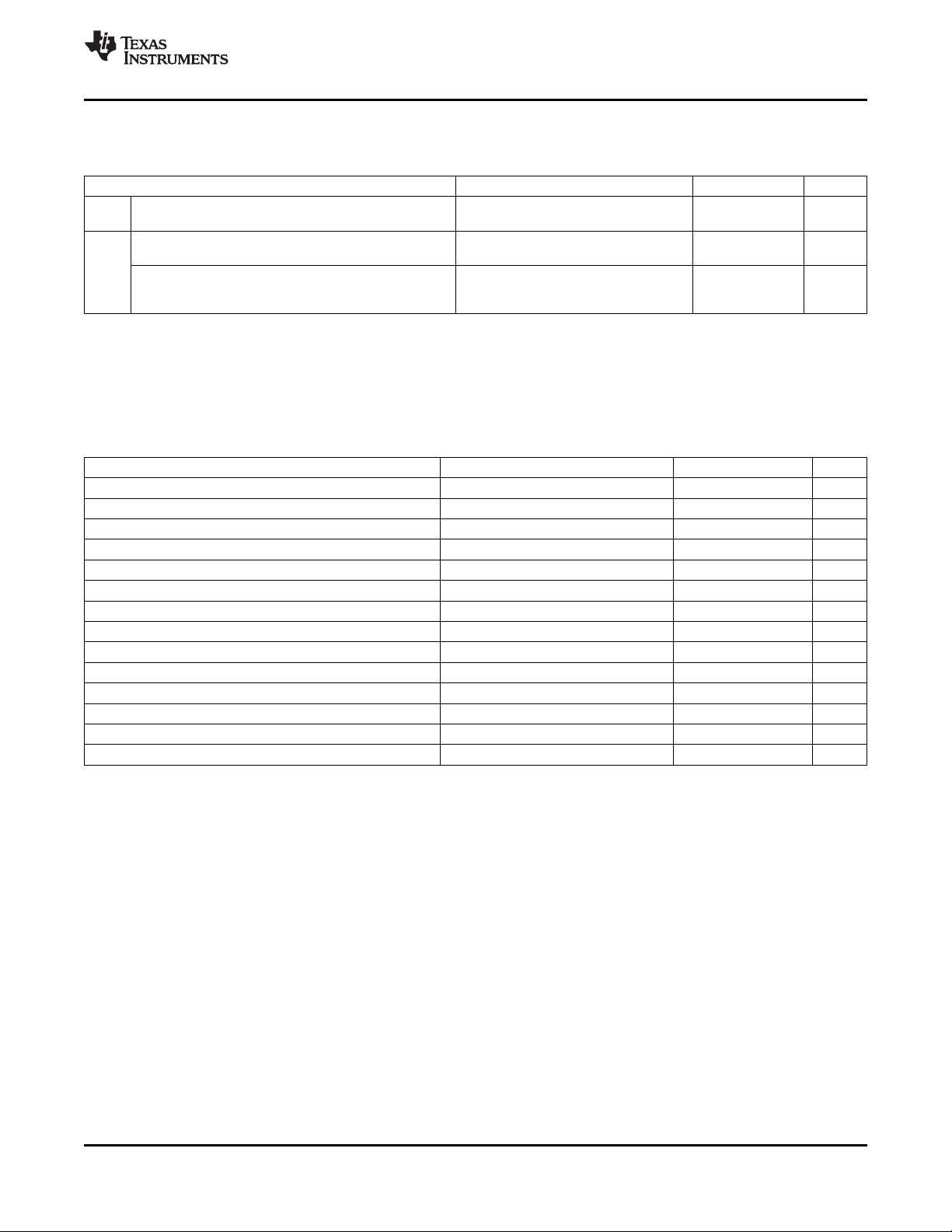

PMBUS/SMBUS/I2C

The timing characteristics and timing diagram for the communications interface that supports I2C, SMBus and

PMBus are shown below.

I2C/SMBus/PMBus TIMING CHARACTERISTICS

TA= –40°C to 125°C, 3V < V33< 3.6V, typical values at TA= 25°C

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

f

SMB

f

I2C

t

(BUF)

t

(HD:STA)

t

(SU:STA)

t

(SU:STO)

t

(HD:DAT)

t

(SU:DAT)

t

(TIMEOUT)

t

(LOW)

t

(HIGH)

t

(LOW:SEXT)

t

FALL

t

RISE

(1) The UCD9224 times out when any clock low exceeds t(TIMEOUT).

(2) t

(HIGH)

in progress.

(3) t

(LOW:SEXT)

(4) Rise time t

(5) Fall time t

SMBus/PMBus operating frequency Slave mode; SMBC 50% duty cycle 10 1000 kHz

I2C operating frequency Slave mode; SCL 50% duty cycle 10 1000 kHz

Bus free time between start and stop 4.7 µs

Hold time after (repeated) start 0.26 µs

Repeated start setup time 0.26 µs

Stop setup time 0.26 µs

Data hold time Receive mode 0 ns

Data setup time 50 ns

Error signal/detect See

(1)

Clock low period 0.5 µs

Clock high period See

Cumulative clock low slave extend time See

Clock/data fall time See

Clock/data rise time See

(2)

(3)

(4)

(5)

, max, is the minimum bus idle time. SMBC = SMBD = 1 for t > 50 ms causes reset of any transaction involving UCD9224 that is

is the cumulative time a slave device is allowed to extend the clock cycles in one message from initial start to the stop.

= V

RISE

= 0.9 V33to (V

FALL

ILMAX

– 0.15) to (V

ILMAX

IHMIN

– 0.15)

+ 0.15)

SLVSA35 –JANUARY 2010

4

35 ms

0.26 50 µs

25 ms

120 ns

120 ns

Copyright © 2010, Texas Instruments Incorporated Submit Documentation Feedback 5

Page 6

UCD9224

SLVSA35 –JANUARY 2010

www.ti.com

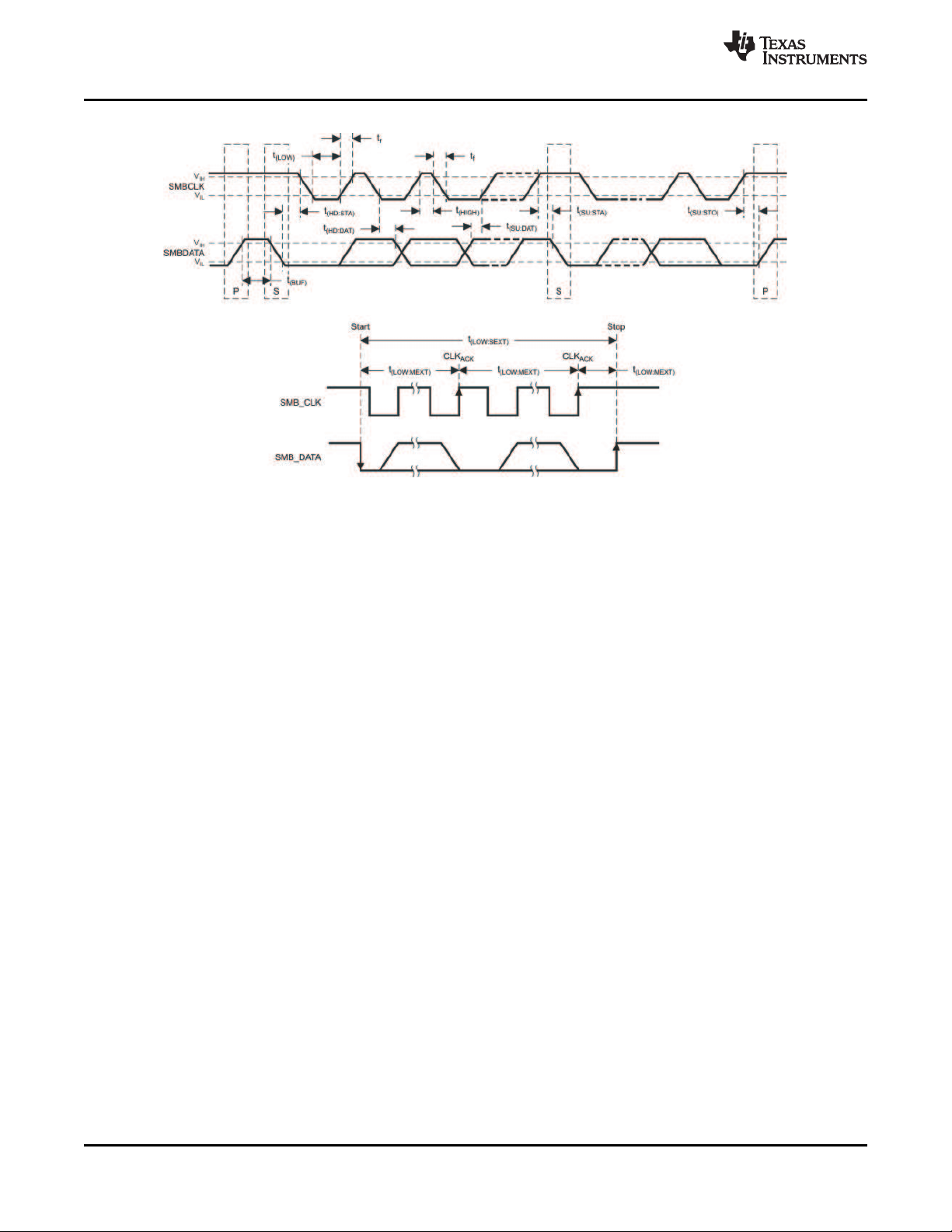

Figure 1. \I2C/SMBus/PMBus Timing in Extended Mode Diagram

6 Submit Documentation Feedback Copyright © 2010, Texas Instruments Incorporated

Page 7

Digital

HighRes

PWM

Digital

HighRes

PWM

Digital

HighRes

PWM

Digital

HighRes

PWM

12-bit

ADC

260 ksps

Osc

ARM-7 core

PMBus

EAP2

EAN2

PWR

GND

Analogfrontend

(AFE)

Ref

ADC

6 bit

IIR

3P/3Z

Err

Amp

EAP1

EAN1

Coeff.

Regs

CompensatorAnalogFrontEnd

POR/BOR

Ref 1

AnalogComparators

TRIP1

TRIP2

DPWM-1B

DPWM-2A

DPWM-3A

PMBus-Clk

SYNC-IN

SYNC-OUT

3

3

BPCAP

TRIP4

SRE-3A

SRE-2A

SRE-1B

SRE-1A

SRE

control

Compensator

3P/3ZIIR

Flash

memorywith

ECC

Diff

Amp

FusionPowerPeripheral 2

FusionPowerPeripheral 1

internal

Tempsense

internal

3.3V &

1.8V

regulator

Ref 2

Ref 4

PMBus-Data

PMBus-Alert

PMBus-Cntl

UCD9224

FLT-1B

DPWM-1A

FLT-1A

ADDR-0

ADDR-1

CS-1A

CS-1B

CS-2A

CS-3A

VIN_IIN

Vtrack

Temperature

TMUX-0

TMUX-1

FLT-2A

FLT-3A

www.ti.com

UCD9224

SLVSA35 –JANUARY 2010

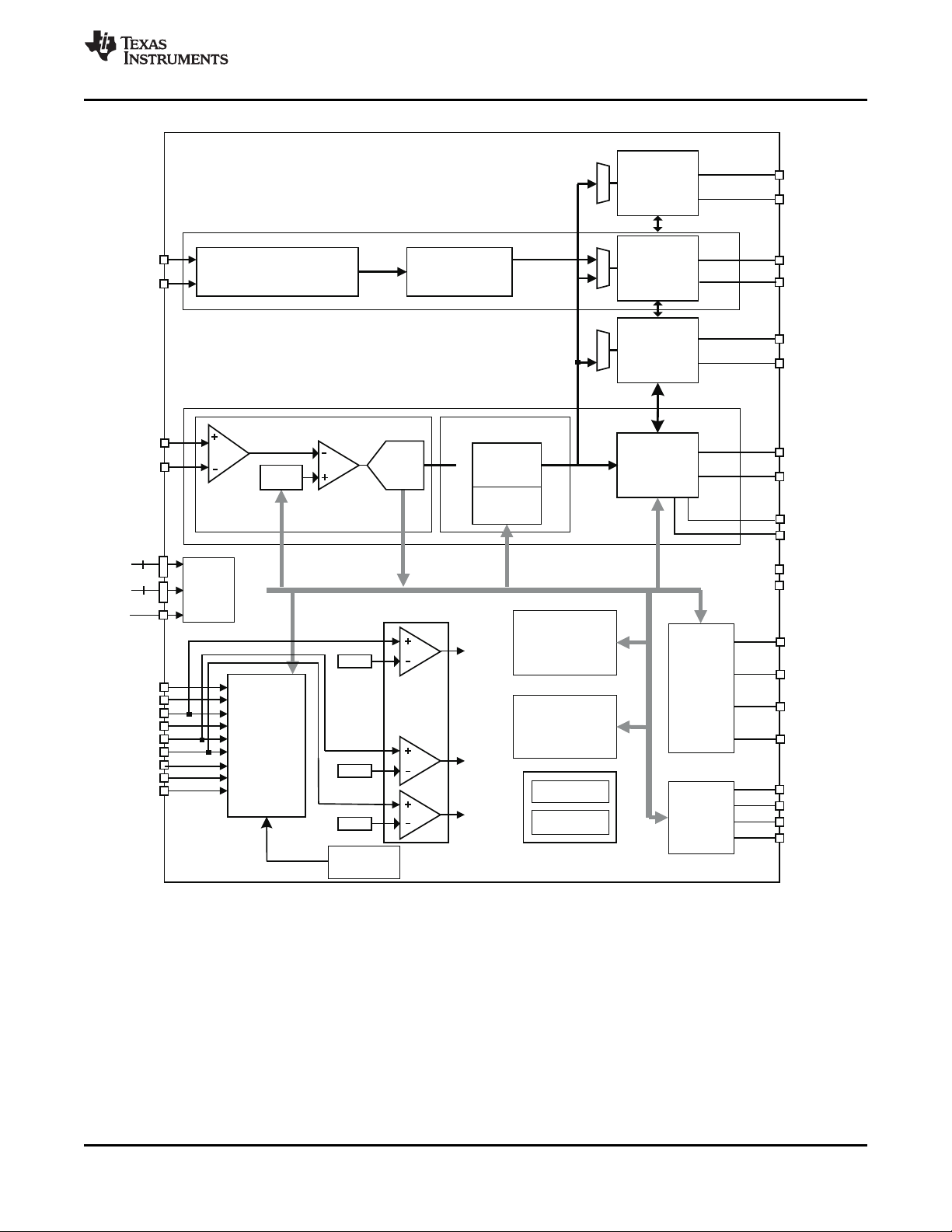

Figure 2. Functional Block Diagram

Copyright © 2010, Texas Instruments Incorporated Submit Documentation Feedback 7

Page 8

Temp erat u r e

Vt r ack

UCD9224

48

47

46

45

44

43

42

41

40

39

33

32

31

30

29

28

27

26

25

13

14

15

18

19

21

16

17

3

4

5

6

7

8

9

10

11

12

34

22

20

RESET

Vin/Iin

FLT-1 B

SRE-1A

PMBus _Data

FLT-2 A

PMBus _CLK

DPWM -1A

DPWM -1B

SEQ- 1

DPWM -2A

SRE-2A

DWPM-3A

PMBu s_Alert

PMBu s_CNTL

SEQ- 2

SRE-1B

TMS

TRST

ADCref

TDI / Sync_In

TDO/ Sync _Out

TCK

PGood

FLT-3 A

DGND 1

AGND 2

EAN2

EAP2

ADDR- 0

CS-2 A

V33FB

FLT-1 A

SRE-3A

ADDR- 1

V33 A

CS-1 A

V33 D

23

24

TMUX-0

TMUX-1

38

37

EAN1

EAP1

1

2

CS-1 B

CS-3 A

35

36

AGND 1

BPCap

UCD9224

SLVSA35 –JANUARY 2010

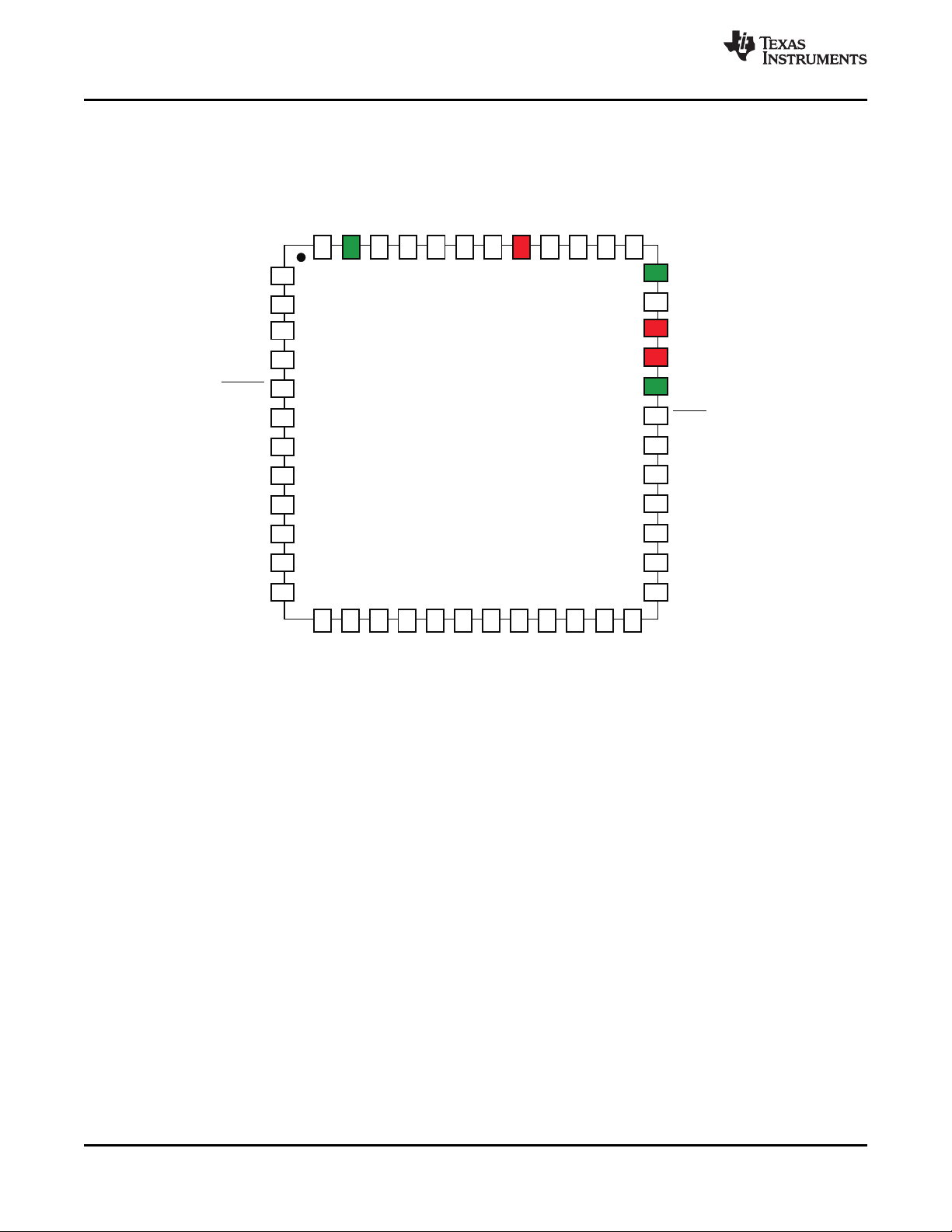

The UCD9224 is available in an 48-pin QFP package (RGZ).

www.ti.com

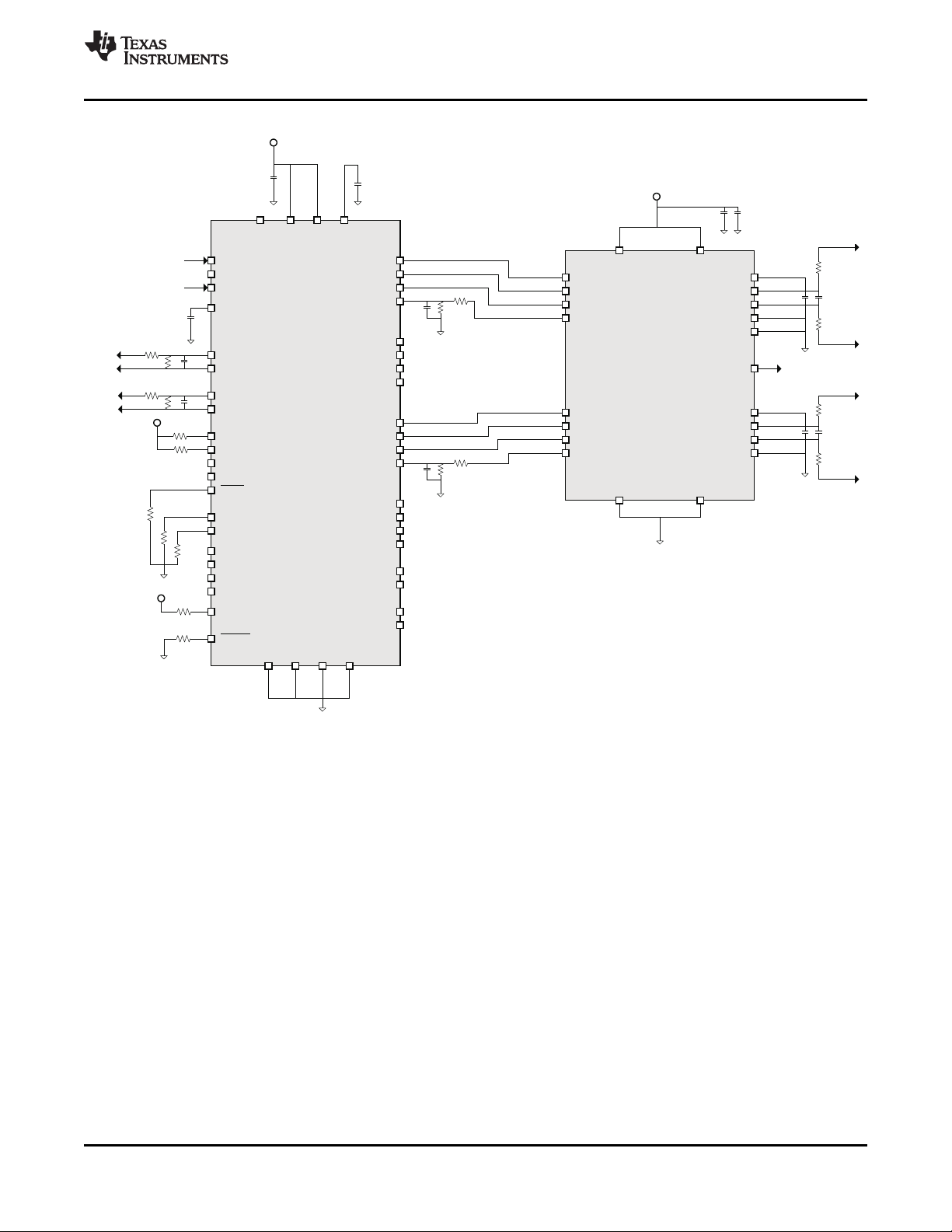

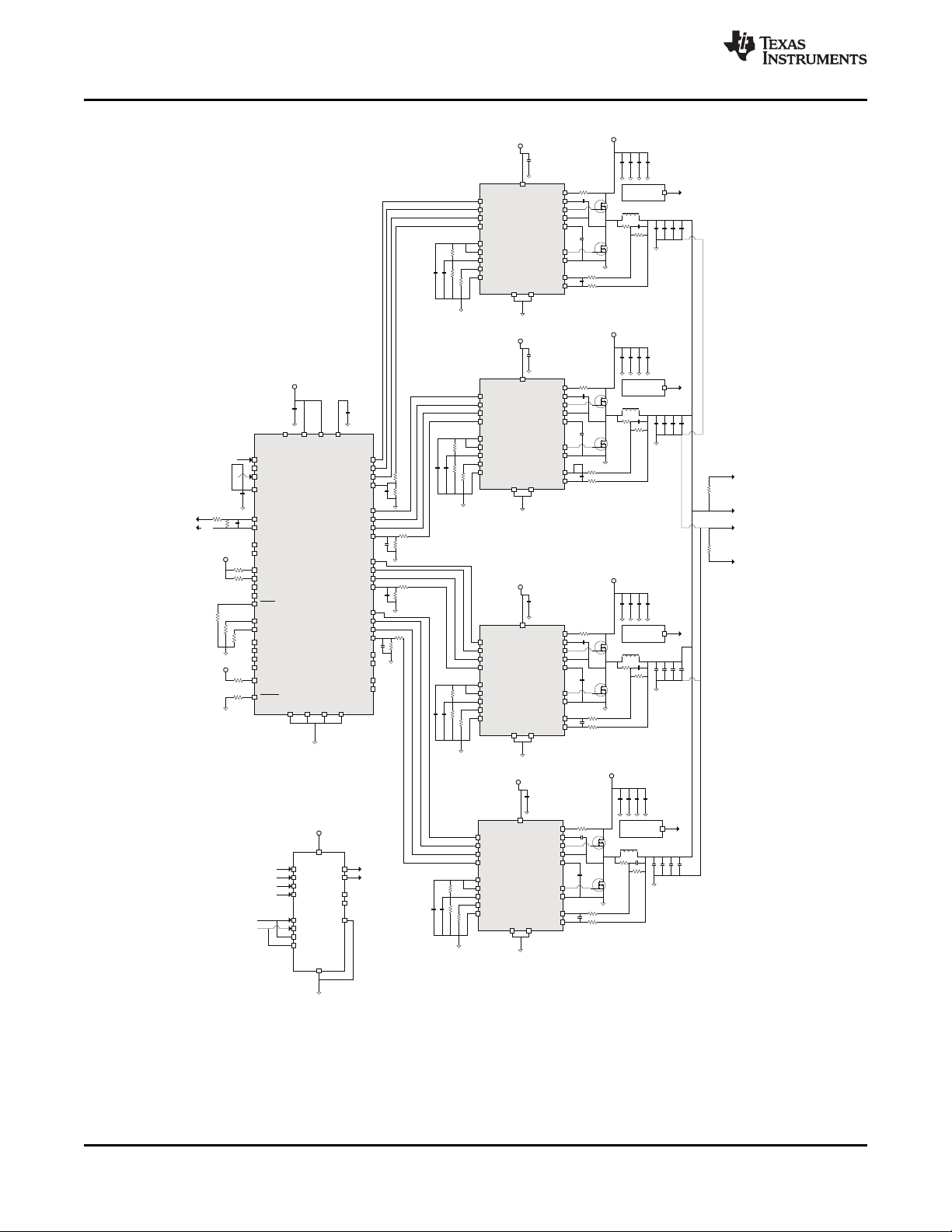

TYPICAL APPLICATION SCHEMATIC

Figure 4 shows the UCD9224 power supply controller as part of a system that provides the regulation of one

eight-phase power supply. The loop for the power supply is created by the voltage output feeding into the

differential voltage error ADC (EADC) input, and completed by DPWM outputs feeding into the gate drivers for

each power stage (PTD modules in this example).

The ±VsA and ±VsB signal must be routed to the EAp/EAn input that matches the number of the lowest DPWM

configured as part of the rail. (See more detail in Flexible Rail/Power Stage Configuration.)

Figure 3. Pin Assignment Diagram

8 Submit Documentation Feedback Copyright © 2010, Texas Instruments Incorporated

Page 9

+3.3 V

Temperature

Vin/Iin

+VsA

-VsA

Vin

Temperature

PTD08D210W

FF-A

PWM-A

SRE-A

Isense-A

Tsense

Vout-A

PGND

AGND

VIN VIN

AGND

Vout-A

FF-B

PWM-B

SRE-B

Isense-B

Vout-B

PGND

Vout-B

PGND

PGND

PGND

+VsA

+VsB

-VsA

-VsB

+VsB

-VsB

+3.3 V

UCD9224

TRST

TMS

TDI/Sync_In

TDO/Sync_Out

FLT-1A

DPWM-1A

SRE-1A

AGND1

V33A

FLT-1B

DPWM-1B

SRE-1B

FLT-2A

DPWM-2A

SRE-2A

FLT-3A

DPWM-3A

SRE-3A

TMUX-0

TMUX-1

TCK

RESET

PMBus_Clock

PMBus_Data

PMBus_Alert

PMBus_Cntl

V33D

BPCAP

AGND2

DGND1

PowerPad

EAP1

ADDR-0

ADDR-1

EAN1

EAP2

EAN2

Vin/Iin

Vtrack

Temperature

CS-1A

CS-1B

CS-2A

CS-3A

V33FB

PGood

ADCref

SEQ-1

SEQ-2

+3.3 V

www.ti.com

UCD9224

SLVSA35 –JANUARY 2010

Figure 4. Typical Application Schematic Using PTD Driver Module

Copyright © 2010, Texas Instruments Incorporated Submit Documentation Feedback 9

Page 10

UCD7231

RDLY

VGG

HS_SNS

HS_Gate

ILIM

IOUT

BP3

Vin

AGND

CSP

SRE_Mode

CSN

LS_Gate

SWSRE

FF BST

PWM

PwPd

PGND

VGG_DIS

CD74HC4052

Vcc

1Y0 1Z

Gnd

1Y1

1Y2

1Y3

2Y0

2Y1

2Y2

2Y3

2Z

S1

S0

E

Vin

Vin

Temperature

Sensor

Temp_A

UCD7231

RDLY

VGG

HS_SNS

HS_Gate

ILIM

IOUT

BP3

Vin

AGND

CSP

SRE_Mode

CSN

LS_Gate

SWSRE

FF BST

PWM

PwPd

PGND

VGG_DIS

Vin

Vin

Temperature

Sensor

Temp_B

UCD7231

RDLY

VGG

HS_SNS

HS_Gate

ILIM

IOUT

BP3

Vin

AGND

CSP

SRE_Mode

CSN

LS_Gate

SWSRE

FF BST

PWM

PwPd

PGND

VGG_DIS

Vin

Vin

Temperature

Sensor

Temp_C

UCD7231

RDLY

VGG

HS_SNS

HS_Gate

ILIM

IOUT

BP3

Vin

AGND

CSP

SRE_Mode

CSN

LS_Gate

SWSRE

FF BST

PWM

PwPd

PGND

VGG_DIS

Vin

Vin

Temperature

Sensor

Temp_D

Temp_D

Temp_C

Temp_B

Temp_A

Vinput

Iin

+3.3V

Temperature

Vin/Iin

+3.3V

Temperature

Vin/Iin

+Vs1

-Vs1

+Vs1

-Vs1

+Vout1

-Vout1

+3.3V

UCD9224

TRST

TMS

TDI/Sync_In

TDO/Sync_Out

FLT-1A

DPWM-1A

SRE-1A

AGND1

V33A

FLT-1B

DPWM-1B

SRE-1B

FLT-2A

DPWM-2A

SRE-2A

FLT-3A

DPWM-3A

SRE-3A

TMUX-0

TMUX-1

TCK

RESET

PMBus_Clock

PMBus_Data

PMBus_Alert

PMBus_Cntl

V33D

BPCAP

AGND2

DGND1

PowerPad

EAP1

ADDR-0

ADDR-1

EAN1

EAP2

EAN2

Vin/Iin

Vtrack

Temperature

CS-1A

CS-1B

CS-2A

CS-3A

V33FB

PGood

ADCref

SEQ-1

SEQ-2

+3.3V

UCD9224

SLVSA35 –JANUARY 2010

www.ti.com

Figure 5. Typical Application Schematic Using UCD7231 Drivers

10 Submit Documentation Feedback Copyright © 2010, Texas Instruments Incorporated

Page 11

www.ti.com

SLVSA35 –JANUARY 2010

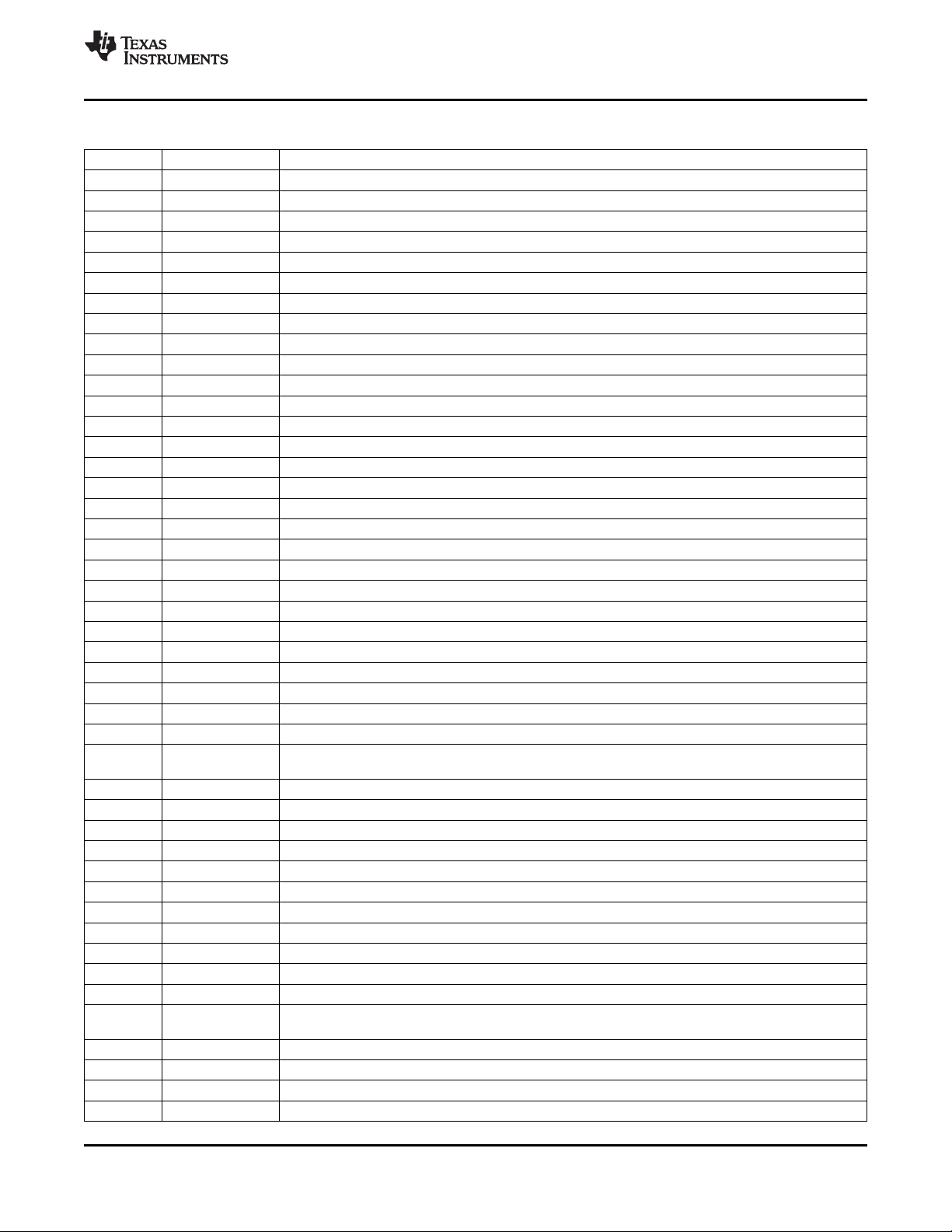

PIN DESCRIPTIONS

PIN NO. PIN NAME DESCRIPTION

1 CS-3A Power stage 3A current sense input and input to analog comparator 4

2 CS-1B Power stage 1B current sense input

3 CS-2A Power stage 2A current sense input and input to analog comparator 2

4 Vin/I

5 nRESET Active low device reset input, pullup to 3.3V with 10kΩ resistor

6 FLT-1A External fault input 1A, active high

7 FLT-1B External fault input 1B, active high

8 FLT-2A External fault input 2A, active high

9 SRE-1A Synchronous rectifier enable output 1A, active high

10 PMBus_Clock PMBus Clock, pullup to 3.3V with 2kΩ resistor

11 PMBus_Data PMBus Data, pullup to 3.3V with 2kΩ resistor

12 DPWM-1A Digital Pulse Width Modulator output 1A

13 DPWM-1B Digital Pulse Width Modulator output 1B

14 DPWM-2A Digital Pulse Width Modulator output 2A

15 SRE-2A Synchronous rectifier enable output 2A, active high

16 DPWM-3A Digital Pulse Width Modulator output 3A

17 SRE-3A Synchronous rectifier enable output 3A, active high

18 SRE-1B Synchronous rectifier enable output 1B, active high

19 PMBus_Alert PMBus Alert, pullup to 3.3V with 2kΩ resistor

20 PMBus_Cntl PMBus Control, pullup to 3.3V with 2kΩ resistor

21 SEQ-1 Sequencing Input/Output

22 SEQ-2 Sequencing Input/Output

23 TMUX-0 Temperature multiplexer select output S0, Vin/Iinselect

24 TMUX-1 Temperature multiplexer select output S1

25 FLT-3A External fault input 3A, active high

26 PGood Power Good indication, Active high open-drain output. Pull-up to 3.3V with 10kΩ resistor.

27 TCK JTAG Test clock

28 TDO / Sync_Out JTAG Test data out (muxed with Sync_Out for synchronizing switching frequency across devices)

29 TDI / Sync_In JTAG Test data in (muxed with Sync_In for synchronizing switching frequency across devices) tie to

30 TMS JTAG Test mode select – tie to V33D with 10kΩ resistor

31 nTRST JTAG Test reset – tie to ground with 10kΩ resistor

32 DGND1 Digital ground

33 V33D Digital core 3.3V supply

34 V33A Analog 3.3V supply

35 BPCap 1.8V bypass capacitor connection

36 AGND1 Analog ground

37 EAP1 Error analog, differential voltage. Positive channel #1 input

38 EAN1 Error analog, differential voltage. Negative channel #1 input

39 EAP2 Error analog, differential voltage. Positive channel #2 input

40 EAN2 Error analog, differential voltage. Negative channel #2 input

41 V33FB Connection to the base of the 3.3V linear regulator transistor. (no connect if not using an external

42 CS-1A Power stage 1A current sense input and input to analog comparator 1

43 ADDR-1 Address sense input. Channel 1

44 ADDR-0 Address sense input. Channel 0

45 Vtrack Voltage track input

in

Input supply sense, alternates between Vinand I

V33D with 10kOhm resistor

transistor)

in

UCD9224

Copyright © 2010, Texas Instruments Incorporated Submit Documentation Feedback 11

Page 12

UCD9224

SLVSA35 –JANUARY 2010

PIN NO. PIN NAME DESCRIPTION

46 Temperature Temperature sense input

47 AGND2 Analog ground

48 ADCref ADC Decoupling capacitor – tie 0.1µF capacitor to ground

PowerPad PowerPad It is recommended that this pad be connected to analog ground

www.ti.com

12 Submit Documentation Feedback Copyright © 2010, Texas Instruments Incorporated

Page 13

V33

10 Am

I

BIAS

To12- bit ADC

Resistorto

setPMBus

Address

ADDR-0,

ADDR-1pins

UCD9224

UCD9224

www.ti.com

FUNCTIONAL OVERVIEW

The UCD9224 contains two fusion power peripherals (FPP). Each FPP can be configured to regulated up to four

DC/DC converter outputs. There are four PWM outputs that can be assigned to drive the converter outputs. Each

FPP consists of:

• A differential input error voltage amplifier

• A 10-bit DAC used to set the output regulation reference voltage.

• A fast ADC with programmable input gain to digitally measure the error voltage.

• A dedicated 3-pole/3-zero digital filter to compensate the error voltage.

• A digital PWM (DPWM) engine that generates the PWM pulse width based on the compensator output.

Each controller is configured through a PMBus serial interface.

PMBus Interface

The PMBus is a serial interface specifically designed to support power management. It is based on the SMBus

interface that is built on the I2C physical specification. The UCD9224 supports revision 1.1 of the PMBus

standard. Wherever possible, standard PMBus commands are used to support the function of the device. For

unique features of the UCD9224, MFR_SPECIFIC commands are defined to configure or activate those features.

These commands are defined in the UCD92xx PMBUS Command Reference.

The UCD9224 is PMBus compliant, in accordance with the "Compliance" section of the PMBus specification. The

firmware is also compliant with the SMBus 1.1 specification, including support for the SMBus ALERT function.

The hardware can support 100 kHz, 400 kHz, or 1 MHz PMBus operation.

SLVSA35 –JANUARY 2010

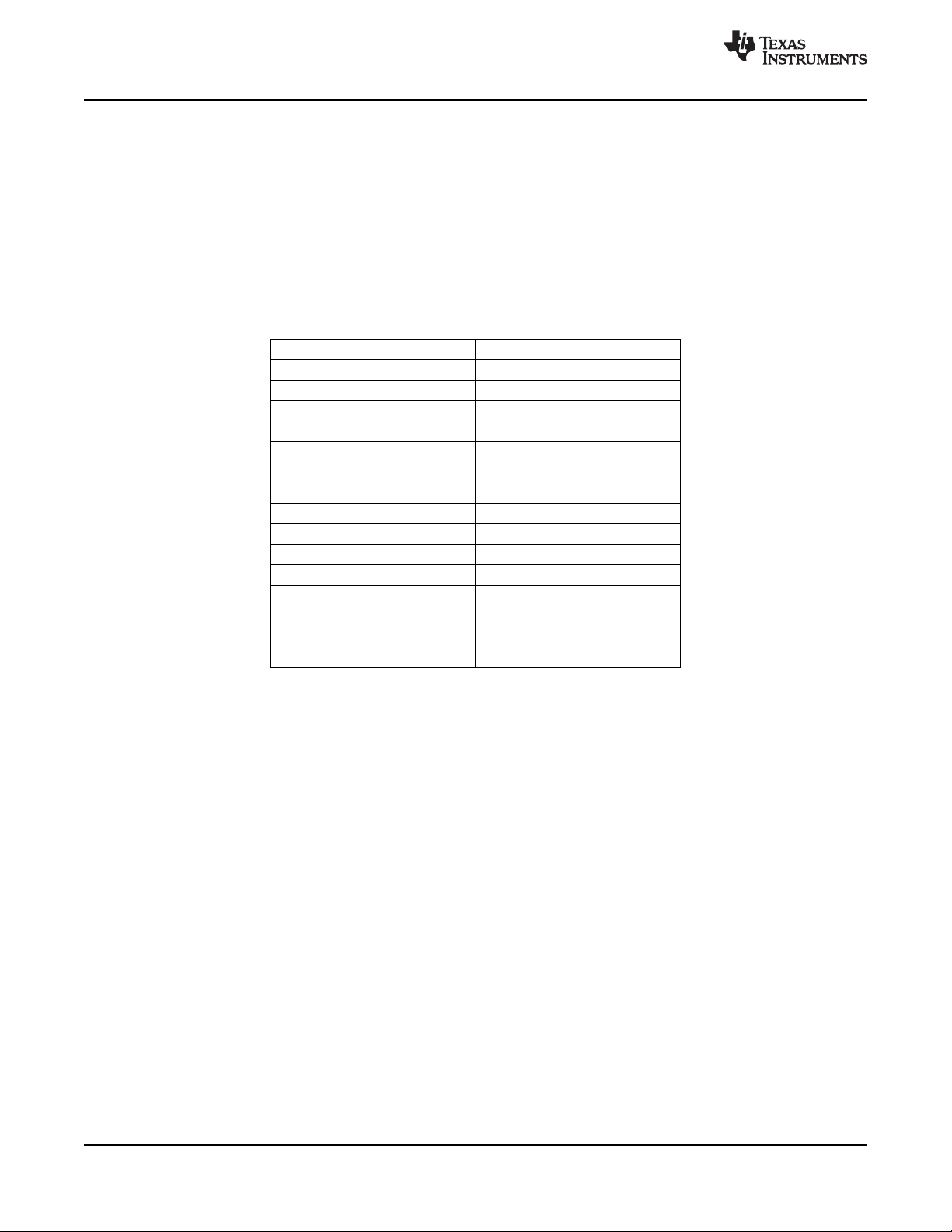

Resistor Programmed PMBus Address Decode

Two pins are allocated to decode the PMBus address. At power-up, the device applies a bias current to each

address detect pin, and the voltage on that pin is captured by the internal 12-bit ADC. The PMBus address is

calculated as follows:

Where PMBus Address 1 and 0 are selected from Table 1.

PMBus Address = 12 × PMBus Address 1 + PMBus Address 0

Figure 6. PMBus Address Detection Method

Table 1. PMBus Address Bins

R

PMBus RESISTANCE

PMBus

PMBus ADDRESS

open –

11 205

10 178

9 154

8 133

7 115

6 100

(kΩ)

Copyright © 2010, Texas Instruments Incorporated Submit Documentation Feedback 13

Page 14

UCD9224

SLVSA35 –JANUARY 2010

Table 1. PMBus Address Bins (continued)

R

PMBus RESISTANCE

PMBus ADDRESS

5 86.6

4 75

3 64.9

2 56.2

1 48.7

0 42.2

short –

PMBus

(kΩ)

A low impedance (short) on either address pin that produces a voltage below the minimum voltage causes the

PMBus address to default to address 126. A high impedance (open) on either address pin that produces a

voltage above the maximum voltage also causes the PMBus address to default to address 126.

Some addresses should be avoid, see Table 2

Table 2. PMBus Address Assignment Rules

ADDRESS STATUS REASON

0 Prohibited SMBus generall address call

1-10 Avaliable

11 Avoid Causes confilcts with other devices during program flash updates.

12 Prohibited PMBus alert response protocol

13–125 Avaliable

126 Avoid Default value; may cause conflicts with other devices.

127 Prohibited Used by TI manufacturing for device tests.

www.ti.com

JTAG Interface

The JTAG interface can provide an alternate interface for programming the device. It is disabled by default in

order to enable the Sync_Out and Sync_In pins with which it is multiplexed. There are three conditions under

which the JTAG interface is enabled:

1. When the ROM_MODE PMBus command is issued.

2. On power-up if the Data Flash is blank. This allows JTAG to be used for writing the configuration parameters

to a programmed device with no PMBus interaction.

3. When an invalid address is detected at power-up. By opening or shorting one of the address pins to ground,

an invalid address can be generated that enables JTAG. When the JTAG port is enabled the JTAG pins are

not available as sequencing pins.

Bias Supply Generator (Shunt Regulator Controller)

Internally, the circuits in the UCD9224 require 3.3V to operate. This can be provided using an existing 3.3V

supply or it can be generated from the power supply input voltage using an internal shunt regulator and an

external transistor. The requirements for the external transistor are that it be an NPN device with a beta of at

least 40. Figure 7 shows the typical application using the external series pass transistor. The base of the

transistor is driven by a resistor to Vin and a transconduction amplifier whose output is on the V33FB pin. The

NPN emitter becomes the 3.3 V supply for the chip and requires bypass capacitors of 0.1 µF and 4.7 µF.

The transconductance amplifier sinks current into the V33FB pin, in order to regulate the amount of current

allowed into the base of the transistor, which regulates the collector current, which determines the emitter voltage

(3.3V). The resistor value should be sized low enough to give sufficient base drive at minimum input voltage, yet

large enough to not exceed the maximum current sink capability of the V33FB pin at maximum input voltage.

Higher beta transistors help in increasing the minimum resistance value, as less base current is needed to

sufficiently drive the higher beta transistor. A resistor value of 10kΩ works well for most applications that use the

FCX491A BJT

14 Submit Documentation Feedback Copyright © 2010, Texas Instruments Incorporated

Page 15

Vin

FCX491A

UC9224

ToPowerStage

+3.3V

+1.8V

10kW

0.1 Fm

0.1 Fm

4.7 Fm

V33FB

V33A

V33D

BOCap

UCD9224

www.ti.com

Some circuits in the device require 1.8V that is generated internally from the 3.3V supply. This voltage requires a

0.1 µF to 1 µF bypass capacitor from BPCap to ground.

Figure 7. Series-Pass 3.3V Regulator Controller I/O

Power On Reset

The UCD9224 has an integrated power-on reset (POR) circuit that monitors the supply voltage. At power-up, the

POR circuit detects the V33D rise. When V33D is greater than V

sequence. At the end of the delay sequence, the device begins normal operation, as defined by the downloaded

device PMBus configuration.

, the device initiates an internal startup

RESET

SLVSA35 –JANUARY 2010

External Reset

The device can be forced into the reset state by an external circuit connected to the nRESET pin. A logic low

voltage on this pin holds the device in reset. To avoid an erroneous trigger caused by noise, a 10 kΩ pull up

resistor to 3.3V is recommended.

Output Voltage Adjustment

The nominal output voltage is programmed by a combination of PMBus commands: VOUT_COMMAND,

VOUT_CAL_OFFSET, VOUT_SCALE_LOOP, and VOUT_MAX. Their relationship is shown in Figure 8. These

PMBus parameters need to be set such that the resulting Vref DAC value does not exceed the maximum value

of V

.

ref

Output voltage margining is configured by the VOUT_MARGIN_HIGH and VOUT_MARGIN_LOW commands.

The OPERATION command selects between the nominal output voltage and either of the margin voltages. The

OPERATION command also includes an option to suppress certain voltage faults and warnings while operating

at the margin settings.

Copyright © 2010, Texas Instruments Incorporated Submit Documentation Feedback 15

Page 16

VrefDAC

VOUT_MARGIN_HIGH

VOUT_CAL_OFFSET

VOUT_MARGIN_LOW

VOUT_COMMAND

+

Limiter

VOUT_

SCALE_

LOOP

OPERATION

Command

VOUT_MAX

3:1

Mux

VrefDAC

CPU

V

EA

V

EAP

V

ead

PMBus

V

EAN

Vref = 1.563 mV/LSB

G

AFE

= 1, 2, 4, or 8

G

eADC

= 8 mV/LSB

6-bit

result

EADC

UCD9224

SLVSA35 –JANUARY 2010

Figure 8. PMBus Voltage Adjustment Methods

For a complete description of the commands supported by the UCD9224 see the UCD92xx PMBUS Command

Reference (SLUU337). Each of these commands can also be issued from the Texas Instruments Fusion Digital

Power™ Designer program. This Graphical User Interface (GUI) PC program issues the appropriate commands

to configure the UCD9224 device.

www.ti.com

Calibration

To optimize the operation of the UCD9224, PMBus commands are supplied to enable fine calibration of output

voltage, output current, and temperature measurements. The supported commands and related calibration

formulas may be found in the UCD92xx PMBUS Command Reference (SLUU337).

Analog Front End (AFE)

The UCD9224 senses the power supply output voltage differentially through the EAP and EAN pins. The error

amplifier utilizes a switched capacitor topology that provides a wide common mode range for the output voltage

sense signals. The fully differential nature of the error amplifier also ensures low offset performance.

The output voltage is sampled at a programmable time (set by the EADC_SAMPLE_TRIGGER PMBus

command). When the differential input voltage is sampled, the voltage is captured in internal capacitors and then

transferred to the error amplifier where the value is subtracted from the set-point reference which is generated by

the 10-bit Vref DAC as shown in Figure 9. The resulting error voltage is then amplified by a programmable gain

circuit before the error voltage is converted to a digital value by the error ADC. This programmable gain is

configured through the PMBus and affects the dynamic range and resolution of the sensed error voltage as

shown in Table 3.

Figure 9. Analog Front End Block Diagram

16 Submit Documentation Feedback Copyright © 2010, Texas Instruments Incorporated

Page 17

+Vout

-Vout

R1

R2

EAP

EAN

C2

Rin

Ioff

P

1

R

R =

K

p

2

R

R =

1 K-

UCD9224

www.ti.com

Table 3. Analog Front End Resolution

AFE_GAIN for EFFECTIVE ADC RESOLUTION DIGITAL ERROR VOLTAGE

PMBus COMMAND (mV) DYNAMIC RANGE (mV)

0 1 8 –256 to 248

1 2 4 –128 to 124

2 4 2 –64 to 62

3 8 1 –32 to 31

AFE GAIN

The AFE variable gain is one of the compensation coefficients that are stored when the device is configured by

issuing the CLA_GAINS PMBus command. Compensator coefficients are arranged in several banks: one bank

for start/stop ramp or tracking, one bank for normal regulation mode and one bank for light load mode. This

allows the user to trade-off resolution and dynamic range for each operational mode.

The EADC, which samples the error voltage, has high accuracy, high resolution, and a fast conversion time.

However, its range is limited as shown in Table 3. If the output voltage is different from the reference by more

than this, the EADC reports a saturated value at –32 LSBs or 31 LSBs. The UCD9224 overcomes this limitation

by adjusting the Vref DAC up or down in order to bring the error voltage out of saturation. In this way, the

effective range of the ADC is extended. When the EADC saturates, the Vref DAC is slewed at a rate of 0.156

V/ms, referred to the EA differential inputs.

The differential feedback error voltage is defined as VEA= V

EAP

– V

. An attenuator network using resistors R1

EAN

and R2 (see Figure 10) should be used to ensure that VEAdoes not exceed the maximum value of V

operating at the commanded voltage level. The commanded voltage level is determined by the PMBus settings

described in the Output Voltage Adjustment section.

SLVSA35 –JANUARY 2010

when

ref

Figure 10. Input Offset Equivalent Circuit

Voltage Sense Filtering

Conditioning should be provided on the EAP and EAN signals. Figure 10 shows a divider network between the

output voltage and the voltage sense input to the controller. The resistor divider is used to bring the output

voltage within the dynamic range of the controller. When no attenuation is needed, R2 can be left open and the

signal conditioned by the low-pass filter formed by R1 and C2.

As with any power supply system, maximize the accuracy of the output voltage by sensing the voltage directly

across an output capacitor as close to the load as possible. Route the positive and negative differential sense

signals as a balanced pair of traces or as a twisted pair cable back to the controller. Put the divider network close

to the controller. This ensures that there is low impedance driving the differential voltage sense signal from the

voltage rail output back to the controller. The resistance of the divider network is a trade-off between power loss

and minimizing interference susceptibility. A parallel resistance (RP) of 1kΩ to 4kΩ is a good compromise. Once

RPis chosen, R1and R2can be determined from the following formulas.

(1)

(2)

Copyright © 2010, Texas Instruments Incorporated Submit Documentation Feedback 17

Page 18

EA

OUT

V

K = VOUT_SCALE_LOOP

V

@

2

SW P

1

C =

2 0.35 F R´ ´ ´p

2 1 2

EA O UT OFFS ET

1 2 1 2

1 2 1 2

EA E A

R R R

V = V + I

R R R R

R + R + R + R +

R R

æ ö æ ö

ç ÷ ç ÷

è ø è ø

UCD9224

SLVSA35 –JANUARY 2010

Where

It is recommended that a capacitor be placed across the lower resistor of the divider network. This acts as an

additional pole in the compensation and as an anti-alias filter for the EADC. To be effective as an anti-alias filter,

the corner frequency should be 35% to 40% of the switching frequency. Then the capacitor is calculated as:

To obtain the best possible accuracy, the input resistance and offset current on the device should be considered

when calculating the gain of a voltage divider between the output voltage and the EA sense inputs of the

UCD9224. The input resistance and input offset current are specified in the parametric tables in this datasheet.

VEA= V

EAP

– V

in the equation below.

EAN

The effect of the offset current can be reduced by making the resistance of the divider network low.

Digital Compensator

Each voltage rail controller in the UCD9224 includes a digital compensator. The compensator consists of a

nonlinear gain stage, followed by a digital filter consisting of a second order infinite impulse response (IIR) filter

section cascaded with a first order IIR filter section.

The Texas Instruments Fusion Digital Power™ Designer development tool can be used to assist in defining the

compensator coefficients. The design tool allows the compensator to be described in terms of the pole

frequencies, zero frequencies and gain desired for the control loop. In addition, the Fusion Digital Power™

Designer can be used to characterize the power stage so that the compensator coefficients can be chosen based

on the total loop gain for each feedback system. The coefficients of the filter sections are generated through

modeling the power stage and load.

www.ti.com

(3)

(4)

(5)

Additionally, the UCD9224 has three banks of filter coefficients: Bank-0 is used during the soft start/stop ramp or

tracking; Bank-1 is used while in regulation mode; and Bank-2 is used when the measured output current is

below the configured light load threshold.

18 Submit Documentation Feedback Copyright © 2010, Texas Instruments Incorporated

Page 19

www.ti.com

UCD9224

SLVSA35 –JANUARY 2010

Figure 11. Digital Compensation

The nonlinear gain block allows a different gain to be applied to the system when the error voltage deviates from

zero. Typically Limit 0 and Limit 1 would be configured with negative values between –1 and –32 and Limit 2 and

Limit 3 would be configured with positive values between 1 and 31. However, the gain thresholds do not have to

be symmetrical. For example, the four limit registers could all be set to positive values causing the Gain 0 value

to set the gain for all negative errors and a nonlinear gain profile would be applied to only positive error voltages.

The cascaded 1st order filter section is used to generate the third zero and third pole.

DPWM Engine

The output of the compensator feeds the high resolution DPWM engine. The DPWM engine produces the pulse

width modulated gate drive output from the device. In operation, the compensator calculates the necessary duty

cycle as a digital number representing a percentage from 0 to 100%. The duty cycle value is multiplied by the

configured period to generate a comparator threshold value. This threshold is compared against the high speed

switching period counter to generate the desired DPWM pulse width. This is shown in Figure 12.

Each DPWM engine can be synchronized to another DPWM engine or to an external sync signal via the

SYNC_IN pin. The SYNC_OUT pin can be used to synchronize the DPWM engine in another UCD92xx device.

Configuration of the synchronization function is done through a MFR_SPECIFIC PMBus command. See the

DPWM Synchronization section for more details.

Copyright © 2010, Texas Instruments Incorporated Submit Documentation Feedback 19

Page 20

highres

ramp

counter

Clk

reset

PWMgatedrive

output

SysClk

SyncIn

EADCtrigger

SyncOut

S

R

DPWMEngine(1of2)

Switchperiod

Currentbalanceadj

Compensatoroutput

(Calculateddutycycle)

EADCtrigger

threshold

rail-rail spread sw

3

t = t

13

UCD9224

SLVSA35 –JANUARY 2010

Figure 12. DPWM Engine

Flexible Rail/Power Stage Configuration

The UCD9224 can control one to two voltage rails, each of which can comprise a programmable number of

power stages (up to a maximum of four). The following chart shows all possible rail / power stage configurations.

Configuration is made through the PHASE_INFO command which is described in detail in the UCD92xx PMBus

Command Reference (SLUU337).

www.ti.com

DPWM Phase Distribution

When two rails are configured, the UCD9224 offsets (in time) the phase of the 1stpower stage assigned to each

rail in order to minimize input current ripple. The constant time used for this offset is:

Where tSWis the period of the rail with the fastest switching frequency.

20 Submit Documentation Feedback Copyright © 2010, Texas Instruments Incorporated

Table 4. Power Stage Configuration

NUMBER OF STAGES POWER STAGES POWER STAGES

Rail#1 : Rail#2 Rail#1 Rail#2

4:0 1A, 1B, 2A, 3A (none)

3:0 1A, 1B, 2A (none)

2:0 1A, 1B (none)

1:0 1A (none)

3:1 1A, 1B, 3A 2A

2:1 1A, 1B 2A

1:1 1A 2A

2:2 1A, 1B 2A, 3A

1:2 1A 2A, 3A

1:3 Invalid (use 3:1 instead)

0:4 Invalid (use 4:0 instead)

0:3 Invalid (use 3:0 instead)

0:2 Invalid (use 2:0 instead)

(1) Phases should be selected in the order listed. For a two single phase rail configuration, power stage

selections should be 1A and 2A.

0:1 Invalid (use 1:0 instead)

(1)

(6)

Page 21

sw

phase-phase spread

phases

t

t =

N

UCD9224

www.ti.com

The ratio 3/13 is chosen because it is close to 1/4, but it is a prime ratio. This should ensure that any

configuration of rails and power stages should not have the leading edge of the DPWM signal aligned.

The PHASE_INFO PMBus command is also used to configure the number of power stages driving each voltage

rail. When multiple power stages are configured to drive a voltage rail, the UCD9224 automatically distributes the

phase of each DPWM output to minimize ripple. This is accomplished by setting the rising edge of each DPWM

pulse to be separated by:

Where tSWis the switching period and N

is the number of power stages driving a voltage rail.

Phases

DPWM Synchronization

DPWM synchronization provides a method to link the timing between rails on two distinct devices at the switching

rate; i.e., two rails on different devices can be configured to run at the same frequency and sync forcing them not

to drift from each other. (Note that within a single device, because all rails are driven off a common clock there is

no need for an internal sync because rails will not drift.)

The PMBus SYNC_IN_OUT command sets which rails (if any) should follow the sync input, and which rail (if

any) should drive the sync output.

For rails that are following the sync input, the DPWM ramp timer for that output is reset when the sync input goes

high. This allows the slave device to sync to inputs that are faster. There is no limit to how much faster the input

is compared to the defined frequency of the rail; when the pulse comes in, the timer is reset and the frequencies

are locked. This is the standard mode of operation – setting the slave to run slower, and letting the sync speed it

up.

The Sync Input and Output Configuration Word set by the PMBus command consists of two bytes. The upper

byte (sync_out) controls which rail drives the sync output signal (0=DPWM1A, 1=DPWM1B, 2=DPWM2A,

3=DPWM3A. Any other value disables sync_out). The lower byte (sync_in) determines which rail(s) respond to

the sync input signal (each bit represents one rail – note that multiple rails can be synchronized to the input). The

DPWM period is aligned to the sync input. For more information, see the UCD92xx PMBUS Command

Reference (SLUU337).

Note that once a rail is synchronized to an external source, the rail-to-rail spacing that attempts to minimize input

current ripple is lost. Rail-to-rail spacing can only be restored by power cycling or issuing a SOFT_RESET

command.

SLVSA35 –JANUARY 2010

(7)

Phase Shedding at Light Current Load

By issuing LIGHT_LOAD_LIMIT_LOW, LIGHT_LOAD_LIMIT_HIGH, and LIGHT_LOAD_CONFIG commands, the

UCD9224 can be configured to shed (disable) power stages when at light load. When this feature is enabled, the

device disables the configured number of power stages when the average current drops below the specified

LIGHT_LOAD_LIMIT_LOW. In addition, a separate set of compensation coefficients can be loaded into the

digital compensator when entering a light load condition.

Phase Adding at Normal Current Load

After shedding phases, if the current load is increased past the LIGHT_LOAD_LIMIT_HIGH threshold, all phases

are re-enabled. If the compensator was configured for light load, the normal load coefficients are restored as

well. See the UCD92xx PMBUS Command Reference (SLUU337) for more information.

Output Current Measurement

Pins CS-1A, CS-1B, CS-2A, and CS-3A are used to measure either output current or inductor current in each of

the controlled power stages. PMBus commands IOUT_CAL_GAIN and IOUT_CAL_OFFSET are used to

calibrate each measurement. See the UCD92xx PMBus Command Reference (SLUU337) for specifics on

configuring this voltage to current conversion.

If the measured current is outside the range of either the over-current or under-current fault threshold, a current

limit fault is declared and the UCD9224 performs the PMBus configured fault recovery. ADC current

Copyright © 2010, Texas Instruments Incorporated Submit Documentation Feedback 21

Page 22

rails Io ut

N T

R = 0.45

C

( )

t

OC_thres CS_nom Imon

V = V + V 1 e

-

D -

t

det

Imon Imon OC_thres CS_nom

T

1

R =

C ln( V ) ln(ΔV V + V )D - -

UCD9224

SLVSA35 –JANUARY 2010

measurements are digitally averaged before they are compared against the over-current and under-current

warning and fault thresholds. The output current is measured at a rate of one output rail per t

Iout

The current measurements are then passed through a digital smoothing filter to reduce noise on the signal and

prevent false errors. The output of the smoothing filter asymptotically approaches the input value with a time

constant that is approximately 3.5 times the sampling interval.

Table 5. Output Current Filter Time Constants

NUMBER OF OUTPUT RAILS

1 200 0.7

2 400 1.4

OUTPUT CURRENT SAMPLING FILTER TIME CONSTANTS t

INTERVALS (µs) (ms)

For example, with a single rail, the filter has the transfer function characteristics that shows the signal magnitude

at the output of the averaging filter due to a sine wave input for a range of frequencies. This plot includes an RC

analog low pass network, with a corner frequency of 3 kHz, on the current sense inputs.

This averaged current measurement is used for output current fault detection; see “Over-Current Detection”

section.

In response to a PMBus request for a current reading, the device returns an average current value. When the

UCD9224 is configured to drive a multi-phase power converter, the device adds the average current

measurement for each of the power stages tied to a power rail.

Current Sense Input Filtering

Each power stage current is monitored by the device at the CS pins. There are 3 "A" channel pins and 1 "B"

channel pins. The B channel monitors the current with a 12-bit ADC and samples each current sense voltage in

turn. The A channels monitor the current with the same12-bit ADC and also monitor the current with a digitally

programmable analog comparator. The comparator can be disabled by writing a zero to the

FAST_OC_FAULT_LIMIT.

Because the current sense signal is both digitally sampled and compared to the programmable over-current

threshold, it should be conditioned with an RC network acting as an anti-alias filter. If the comparator is disabled,

the CS input should be filtered at 35% of the sampling rate. An RC network with this characteristic can be

calculated as

www.ti.com

microseconds.

(8)

Where N

is the number of rails configured and T

rails

is the sample period for the current sense inputs.

Iout

Therefore, when the comparator is not used, the recommended component values for the RC network are C = 10

nF and R = 35.7 kΩ.

When the fast over-current comparator is used, the filter corner frequency based on the ADC sample rate may

be too slow and a corner frequency that is a compromise between the requirements of fast over-current detection

and attenuating aliased content in the sampled current must be sought. In this case, the filter corner frequency

can be calculated based on the time to cross the over-current threshold.

(9)

Where V

OC_thres

is the programmed OC comparator threshold, V

CS_nom

is the nominal CS voltage, ΔV

Imon

is the

change in CS voltage due to an over-current fault and t is the filter time constant. Using the equation for the

comparator voltage above, the RC network values can be calculated as

(10)

Where T

= 2.0V and V

is the time to cross the over-current comparator threshold. For T

det

CS_nom

= 1.5V, the corner frequency is 6.4 kHz and the recommended RC network component

= 10 µsec, ΔV

det

Imon

= 1.5V, V

OC_thres

values are C = 10 nF and R = 2.49 kΩ.

22 Submit Documentation Feedback Copyright © 2010, Texas Instruments Incorporated

Page 23

( )

t/

smoothed 1 2 1

I (t) = I + (I I ) 1 e

-

- -

t

2 1

lag

2 limi t

I I

t = ln

I I

æ öç ÷

-

è ø

t

UCD9224

www.ti.com

Output Current Balancing

When the UCD9224 is configured to drive multiple power stage circuits from one compensator, current balancing

is implemented by adjusting each gate drive output pulse width to correct for current imbalance between the

connected power stage sections. The UCD9224 balances the current by monitoring the current at the CS analog

input for each power stage and then adding a current balance adjustment value to the DPWM ramp threshold

value for each power stage.

When there is more than one power stage connected to the voltage rail, the device continually determines which

stage has the highest measured current and which stage has the lowest measured current. To balance the

currents while maintaining a constant total current, the adjustment value for the power stage with the lowest

current is increased by the same amount as the adjustment value for the power stage with the highest current is

decreased. A slight modification to this algorithm is made to keep the adjustment values positive in order to

ensure that a positive DPWM duty cycle is commanded under all conditions.

Over-Current Detection

Several mechanisms are provided to sense output current fault conditions. This allows for the design of power

systems with multiple layers of protection.

1. An integrated gate driver, such as the UCD72xx family of integrated gate drivers, can be used to generate

the FLT signal. The driver monitors the voltage drop across the high side FET and if it exceeds a

resistor/voltage programmed threshold, the driver activates its fault output. The FLT input can be disabled by

reconfiguring the FLT pin to be a sequencing pin in the GUI. A logic high signal on the FLT input causes a

hardware interrupt to the internal CPU. The CPU then determines which DPWM outputs are configured to be

associated with the voltage rail that contained the fault and disables those DPWM and SRE outputs. This

process takes about 14 microseconds.

2. Inputs CS-1A, CS-1B, CS-2A and CS-3A each drive an internal analog comparator. These comparators can

be used to detect the voltage output of a current sense circuit. Each comparator has a separate PMBus

configurable threshold. This threshold is set by issuing the FAST_OC_FAULT_LIMIT command. Though the

command is specified in amperes, the hardware threshold is programmed with a value between 31mV and

2V in 64 steps. The relationship between amperes to sensed volts is configured by issuing the

IOUT_CAL_GAIN command. When the current sense voltage exceeds the configured threshold the

corresponding DPWM and SRE outputs are driven low on the voltage rail with the fault.

3. Each Current Sense input to the UCD9224 is also monitored by the 12-bit ADC. Each measured value is

scaled using the IOUT_CAL_GAIN and IOUT_CAL_OFFSET commands. The currents for each power stage

configured as part of a voltage rail are summed and compared to the over-current limit set by the

IOUT_OC_FAULT_LIMIT command. The action taken when a fault is detected is defined by the

IOUT_OC_FAULT_RESPONSE command.

Because the current measurement is averaged with a smoothing filter, the response time to an over-current

condition depends on a combination of the time constant (t) from Table 5, the recent measurement history, and

how much the measured value exceeds the over-current limit. When the current steps from a current (I1) that is

less than the limit to a higher current (I2) that is greater than the limit, the output of the smoothing filter is:

SLVSA35 –JANUARY 2010

At the point when I

The worst case response time to an over-current condition is the sum of the sampling interval (see Table 5) and

the smoothing filter lag, t

Current Foldback Mode

When the measured output current exceeds the value specified by the IOUT_OC_FAULT_LIMIT command, the

UCD9224 attempts to continue to operate by reducing the output voltage in order to maintain the output current

at the value set by IOUT_OC_FAULT_LIMIT. This continues indefinitely as long as the output voltage remains

above the minimum value specified by IOUT_OC_LV_FAULT_LIMIT. If the output voltage is pulled down to less

than that value, the device responds as programmed by the IOUT_OC_LV_FAULT_RESPONSE command.

Copyright © 2010, Texas Instruments Incorporated Submit Documentation Feedback 23

smoothed

exceeds the limit, the smoothing filter lags time, t

from the equation above.

lag

lag

(11)

is:

(12)

Page 24

UCD9224

SLVSA35 –JANUARY 2010

Input Voltage and Current Monitoring

The Vin/Iinpin on the UCD9224 monitors the input voltage and current. To measure both input voltage and input

current, an external multiplexer is required, see Figure 4. If measurement of only the input voltage, and not input

current, is desired, then a multiplexer is not needed. The multiplexer is switched between voltage and current

using the TMUX-0 signal. (This signal is the LSB of the temperature mux select signals, so the TMUX-0 signal is

connected both to the temperature multiplexer as well as the voltage/current multiplexer). When TMUX-0 is low

the Vin/Iinpin will be sampled for Vin. When TMUX-0 is high the Vin/Iinpin will be sampled for Iin. The Vin/Iinpin is

monitored using the internal 12-bit ADC and so has a dynamic range of 0 to V

ADC_RANGE

. The fault thresholds for

the input voltage are set using the VIN_OV_FAULT_LIMIT and VIN_UV_FAULT_LIMIT commands. The scaling

for Vinis set using the VIN_SCALE_MONITOR command, and the scaling for Iinis set using the

IIN_SCALE_MONITOR command.

Input Under-Voltage Lockout

The input supply lock-out voltage thresholds are configured with the VIN_ON and VIN_OFF commands. When

input supply voltage drops below the value set by VIN_OFF, the device starts a normal soft stop ramp. When the

input supply voltage drops below the voltage set by VIN_UV_FAULT_LIMIT, the device performs per the

configuration using the VIN_UV_FAULT_RESPONSE command. For example, when the bias supply for the

controller is derived from another source, the response code can be set to "Continue" or "Continue with delay,"

and the controller attempts to finish the soft stop ramp. If the bias voltages for the controller and gate driver are

uncertain below some voltage, the user can set the UV fault limit to that voltage and specify the response code

to be "shut down immediately" disabling all DPWM and SRE outputs. VIN_OFF sets the voltage at which the

output voltage soft-stop ramp is initiated, and VIN_UV_FAULT_LIMIT sets the voltage where power conversion is

stopped.

www.ti.com

Temperature Monitoring

Both the internal device temperature and up to four external temperatures are monitored by the UCD9224. The

controller supports multiple PMBus commands related to temperature, including READ_TEMPERATURE_1,

which reads the internal temperature, READ_TEMPERATURE_2, which reads the external power stage

temperatures, OT_FAULT_LIMIT, which sets the over temperature fault limit, and OT_FAULT_RESPONSE,

which defines the action to take when the configured limit is exceeded.

If more than one external temperature is to be measured, the UCD9224 provides analog multiplexer select pins

(TMUX0-1) to allow up to 4 external temperatures to be measured. The output of the multiplexer is routed to the

Temperature pin. The controller cycles through each of the power stage temperature measurement signals. The

signal from the external temperature sensor is expected to be a linear voltage proportional to temperature. The

PMBus commands TEMPERATURE_CAL_GAIN and TEMPERATURE_CAL_OFFSET are used to scale the

measured temperature-dependent voltage to °C.

The inputs to the multiplexer are mapped in the order that the outputs are assigned using the PHASE_INFO

PMBus command. For example, if only one power stage is wired to each DPWM, the two temperature signals

should be wired to the first two multiplexer inputs.

The UCD9224 monitors temperature using the 12-bit monitor ADC, sampling each temperature in turn with an

100 ms sample period. These measurements are smoothed by a digital filter, similar to that used to smooth the

output current measurements. The filter has a time constant 15.5 times the sample interval, or 1.55 s (15.5 × 100

ms = 1.55 seconds). This filtering reduces the probability of false fault detections.

Figure 5 is an example of a system with one output voltage rail driven by 4 power stages. The output voltage rail

is driven with DPWM-1A, DPWM-1B, DPWM-2A and DPWM-3A. The order in which the temperature multiplexer

inputs are assigned is shown in Table 6.

24 Submit Documentation Feedback Copyright © 2010, Texas Instruments Incorporated

Page 25

UCD9224

www.ti.com

Table 6. Temperature Sensor Mapping

TEMPERATURE MUX INPUT POWER STAGE

1Y0 DPWM-1A

1Y1 DPWM-1B

1Y2 DPWM-2A

1Y3 DPWM-3A

Temperature Balancing

Temperature balancing between phases is performed by adjusting the current such that cooler phases draw a

larger share of the current. Temperature balancing occurs slowly (the loop runs at a 10 Hz rate), and only when

the phase currents exceeds the PMBus settable TEMP_BALANCE_IMIN. This minimum current threshold

prevents the controller from "winding up" and forcing one phase to carry all the current under a low-load

condition, when the total current may be insufficient to significantly affect phase temperatures.

Soft Start, Soft Stop Ramp Sequence

The UCD9224 performs soft start and soft stop ramps under closed loop control.

Performing a start or stop ramp or tracking is considered a separate operational mode. The other operational

modes are normal regulation and light load regulation. Each operational mode can be configured to have an

independent loop gain and compensation. Each set of loop gain coefficients is called a "bank" and is configured

using the CLA_GAINS PMBus command.

The soft-start ramp is performed by waiting for the configured start delay TON_DELAY and then ramp the

internal reference toward the commanded reference voltage at the rate specified by the TON_RISE time and

VOUT_COMMAND. The DPWM and SRE outputs are enabled when the internal ramp reference equals the

preexisting voltage (pre-bias) on the output and the calculated DPWM pulse width exceeds the pulse width

specified by DRIVER_MIN_PULSE. This ensures that a constant ramp rate is maintained, and that the ramp is

completed at the same time it would be if there were not a pre-bias condition.

Figure 13 shows the operation of soft-start ramps and soft-stop ramps.

SLVSA35 –JANUARY 2010

Figure 13. Start and Stop Ramps

Copyright © 2010, Texas Instruments Incorporated Submit Documentation Feedback 25

Page 26

UCD9224

SLVSA35 –JANUARY 2010

When a voltage rail is in its idle state, the DPWM and SRE outputs are disabled, and the differential voltage on

the EAP/EAN pins are monitored by the controller. During idle the Vref DAC is adjusted to minimize the error

voltage. If there is a pre-bias (that is, a non-zero voltage on the regulated output), then the device can begin the

start ramp from that voltage with a minimum of disturbance. This is done by calculating the duty cycle that is

required to match the measured voltage on the rail. Nominally this is calculated as Vout / Vin. If the pre-bias

voltage on the output requires a smaller pulse width than the driver can deliver, as defined by the

DRIVER_MIN_PULSE PMBus command, then the start ramp is delayed until the internal ramp reference voltage

has increased to the point where the required duty cycle exceeds the specified minimum duty.

Once a soft start/stop ramp has begun, the output is controlled by adjusting the Vref DAC at a fixed rate and

allowing the digital compensator control engine to generate a duty cycle based on the error. The Vref DAC

adjustments are made at a rate of 10 kHz and are based on the TON_RISE or TOFF_FALL PMBus configuration

parameters.

Although the presence of a pre-bias voltage or a specified minimum DPWM pulse width affects the time when

the DPWM and SRE signals become active, the time from when the controller starts processing the turn-on

command to the time when it reaches regulation is TON_DELAY plus TON_RISE, regardless of the pre-bias or

minimum duty cycle.

During a normal ramp (i.e. no tracking, no current limiting events and no EADC saturation), the set point slews at

a pre-calculated rate based on the commanded output voltage and TON_RISE. Under closed loop control, the

compensator follows this ramp up to the regulation point.

Because the EADC in the controller has a limited range, it may saturate due to a large transient during a

start/stop ramp. If this occurs, the controller overrides the calculated set point ramp value, and adjusts the Vref

DAC in the direction to minimize the error. It continues to step the Vref DAC in this direction until the EADC

comes out of saturation. Once it is out of saturation, the start ramp continues, but from this new set point voltage;

and therefore, has an impact on the ramp time.

www.ti.com

Voltage Tracking

Each voltage rail can be configured to operate in a tracking mode. When a voltage rail is configured to track

another voltage rail, it adjusts the set point to follow the master, which can be either the other internal rail or the

external Vtrack pin. As in standard non-tracking mode, a target Vout is still specified for the voltage rail. If the

tracking input exceeds this target, the tracking voltage rail stops following the master signal, switches to

regulation gains, and regulates at the target voltage. When the tracking input drops back below the target with 20

mV of hysteresis, tracking gains are re-loaded, and the voltage rail follows the tracking reference. Note that the

target can be set above the range of the tracking input, forcing the voltage rail to always remain in tracking mode

with the start-stop gains.

During tracking, the Vref DAC is permitted to change only as fast as is possible without inducing the EADC to

saturate. This limit may be reached if the master ramps at an extremely fast rate, or if the master is at a

significantly different voltage when the rail is turned on. A current limit (current foldback) or the detection of the

EADC saturating will force the rail to temporarily deviate from the tracking reference. This behavior is the same in

normal regulation mode.

The PMBus command TRACKING_SOURCE is available to enable tracking mode and select the master to track.

The tracking mode is set individually for each rail, allowing each rail to have a different master, both rails to share

a master, or one rail to track while the other remains independent. Additionally, TRACKING_SCALE_MONITOR

permits tracking a voltage with a fixed ratio to a master voltage. For example, a ratio of 0.5 causes the rail to

regulate at one half of the master’s voltage.

Sequencing

There are three methods to sequence voltage rails controlled by the UCD9224 that allow for a variety of system

sequencing configurations. Each of these options is configurable in the GUI. These methods include:

1. Use the PMBus to set the soft start/stop parameters for each rail. Multiple start/stop sequences may be

triggered simultaneously. Each voltage rail performs its sequencing in an open-loop manner. If any rail fails

to complete its sequence, all other rails are unaffected.

2. Daisy-chain the Power Good output signal from one controller to the PMBus_Cntl input on another.

3. Use the GPIO_SEQ_CONFIG command to assign dependencies between rails, or to configure unused pins

as sequencing control inputs or sequencing status outputs.

26 Submit Documentation Feedback Copyright © 2010, Texas Instruments Incorporated

Page 27

UCD9224

www.ti.com

Method 1: Each rail has programmable delay times, TON_DELAY and TOFF_DELAY, before beginning a soft

start ramp or a soft stop ramp, and programmable ramp times, TON_RISE and TOFF_FALL determine how long

the ramp takes. These PMBus commands are defined in the UCD92xx PMBUS Command Reference

(SLUU337). The parameters can also be configured using the Fusion Digital Power™ Designer GUI

(see http://focus.ti.com/docs/toolsw/folders/print/fusion_digital_power_designer.html).

The configurable times can be used to program a time based sequence for each voltage rail. Using this method

each rail ramps independently and completes the ramp regardless of the success of the other rails.

The start/stop sequence is initiated for a single rail by the PMBus_Cntl pin or via the PMBus using the

OPERATION or ON_OFF_CONTROL commands.

The start/stop sequence may be initiated simultaneously for multiple rails within the same controller by

configuring each rail to respond to the PMBus_Cntl pin. Alternatively, after setting the PMBus PAGE variable to

255, subsequent OPERATION or ON_OFF_CONTROL commands applies to all rails at the same time.

To simultaneously initiate start/stop sequences in multiple controllers, a common PMBus_Cntl signal can be fed

into each controller. Alternatively, the PMBus Group Command Protocol may be used to send separate

commands to multiple controllers. All the commands are sent in one continuous transmission and wait for the

final STOP signal in order to start executing their commands simultaneously.

Method 2: The PGood pin can be used to coordinate multiple controllers by running the PGood pin output from

one controller to the PMBus_Cntl input pin of another. This imposes a master/slave relationship between multiple

devices. During startup, the slave controllers initiate their start sequences after the master completes its start

sequence and reaches its regulation voltage. During shut-down, as soon as the master starts its shut-down

sequence, the shut-down signals to its slaves.

Unlike Method 1, a shut-down on one or more rails on the master can initiate shut-downs of the slave devices.

The master shut-downs can initiate intentionally or by a fault condition.

The PMBus specification implies that the PGood signal is active when ALL the rails in a controller are above their

power-good “on” threshold setting. The UCD9224 allows the PGood pin to be reprogrammed using the

GPIO_SEQ_CONFIG command so that the pin responds to a desired subset of rails.

This method works to coordinate multiple controllers, but it does not enforce interdependency between rails

within a single controller.

Method 3: Using the GPIO_SEQ_CONFIG command, several sequencing options can be configured using

undedicated pins for input/output. As many as four pins can be configured as inputs, and as many as six as

outputs. The outputs can be open-drain or actively driven with selectable polarity.

Each rail can be configured to respond to a combination of the power-good status of other internal rails and/or

the state of sequencing input pins. The output pins can be configured to reflect the power-good status of a

combination of rails, or to one of several status indicators including power-good, an over-current warning, or the

“open-drain outputs valid” signal.

When using the output signals for sequencing, they may be routed to sequencing control inputs or to the

PMBus_Cntl inputs on other controllers.

Once each rail’s turn-on and stay-on dependencies are configured, the rail responds to those input pins or

internal rails. Like method 2, shut-downs on one rail or controller can initiate shut-downs of other rails or