www.ti.com

FEATURES DESCRIPTION

APPLICATIONS

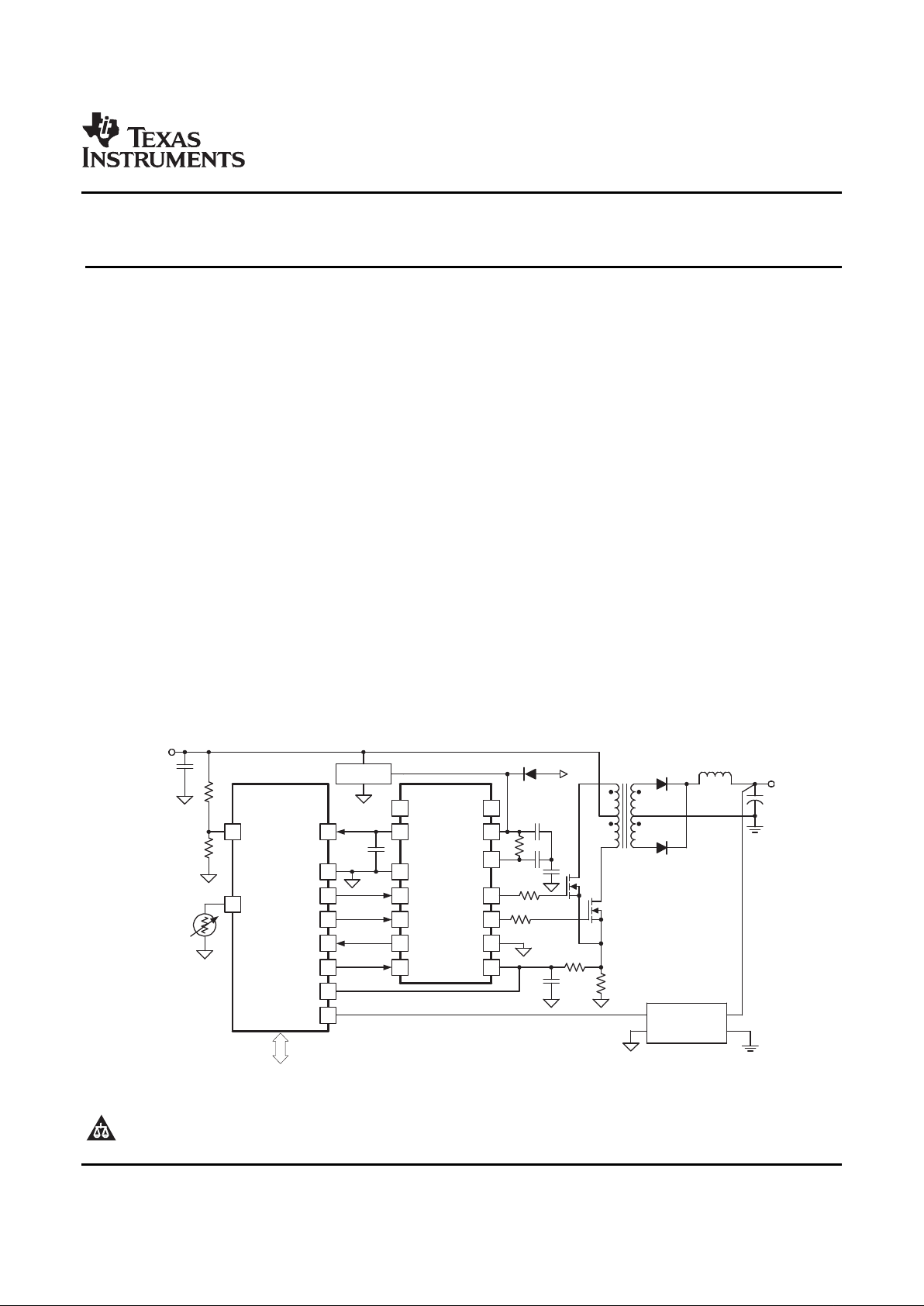

TYPICAL APPLICATION DIAGRAM (Push-Pull Converter)

Isolation

Amplifier

COMMUNICATION

(Programming & Status Reporting)

141

12

8

VDD

PVDD

CS

10OUT2

3

4

2

5

6

IN1

AGND

3V3

IN2

CLF

7

UCD7201PWP

11OUT1

9PGND

13

NC

ILIM

NC

Bias Supply

Bias Winding

VIN

VOUT

DIGITAL

CONTROLLER

GND

PWMA

ADC4

INTERRUPT or CCR

PWMB

ADC3

VCC

PWM or GPIO

ADC1

ADC2

UCD7201

SLUS645C – FEBRUARY 2005 – REVISED DECEMBER 2006

Digital Control Compatible Dual Low-Side ±4 Amp MOSFET Drivers with Programmable

Common Current Sense

• Adjustable Current Limit Protection

The UCD7201 is a member of the UCD7K family of

digital control compatible drivers for applications

• 3.3-V, 10-mA Internal Regulator

utilizing digital control techniques or applications

• DSP/µC Compatible Inputs

requiring fast local peak current limit protection.

• Dual ±4-A TrueDrive™ High Current Drivers

The UCD7201 includes dual low-side ±4-A

• 10-ns Typical Rise and Fall Times with 2.2-nF

high-current MOSFET gate drivers. It allows the

Loads

digital power controllers such as UCD9110 or

• 20-ns Input-to-Output Propagation Delay

UCD9501 to interface to the power stage in double

ended topologies. It provides a cycle-by-cycle current

• 25-ns Current Sense-to-Output Propagation

limit function for both driver channels, a

Delay

programmable threshold and a digital output current

• Programmable Current Limit Threshold

limit flag which can be monitored by the host

• Digital Output Current Limit Flag

controller. With a fast cycle-by-cycle current limit

protection, the driver can turn off the power stage in

• 4.5-V to 15-V Supply Voltage Range

the event of an overcurrent condition.

• Rated from -40°C to 105°C

For fast switching speeds, the UCD7201 output

• Lead(Pb)-Free Packaging

stages use the TrueDrive™ output architecture,

which delivers rated current of ±4 A into the gate of a

MOSFET during the Miller plateau region of the

• Digitally Controlled Power Supplies

switching transition. It also includes a 3.3-V, 10-mA

• DC/DC Converters

linear regulator to provide power to the digital

controller.

• Motor Controllers

• Line Drivers

Please be aware that an important notice concerning availability, standard warranty, and use in critical applications of Texas

Instruments semiconductor products and disclaimers thereto appears at the end of this data sheet.

TrueDrive, PowerPAD are trademarks of Texas Instruments.

PRODUCTION DATA information is current as of publication date.

Copyright © 2005–2006, Texas Instruments Incorporated

Products conform to specifications per the terms of the Texas

Instruments standard warranty. Production processing does not

necessarily include testing of all parameters.

www.ti.com

DESCRIPTION (CONT.)

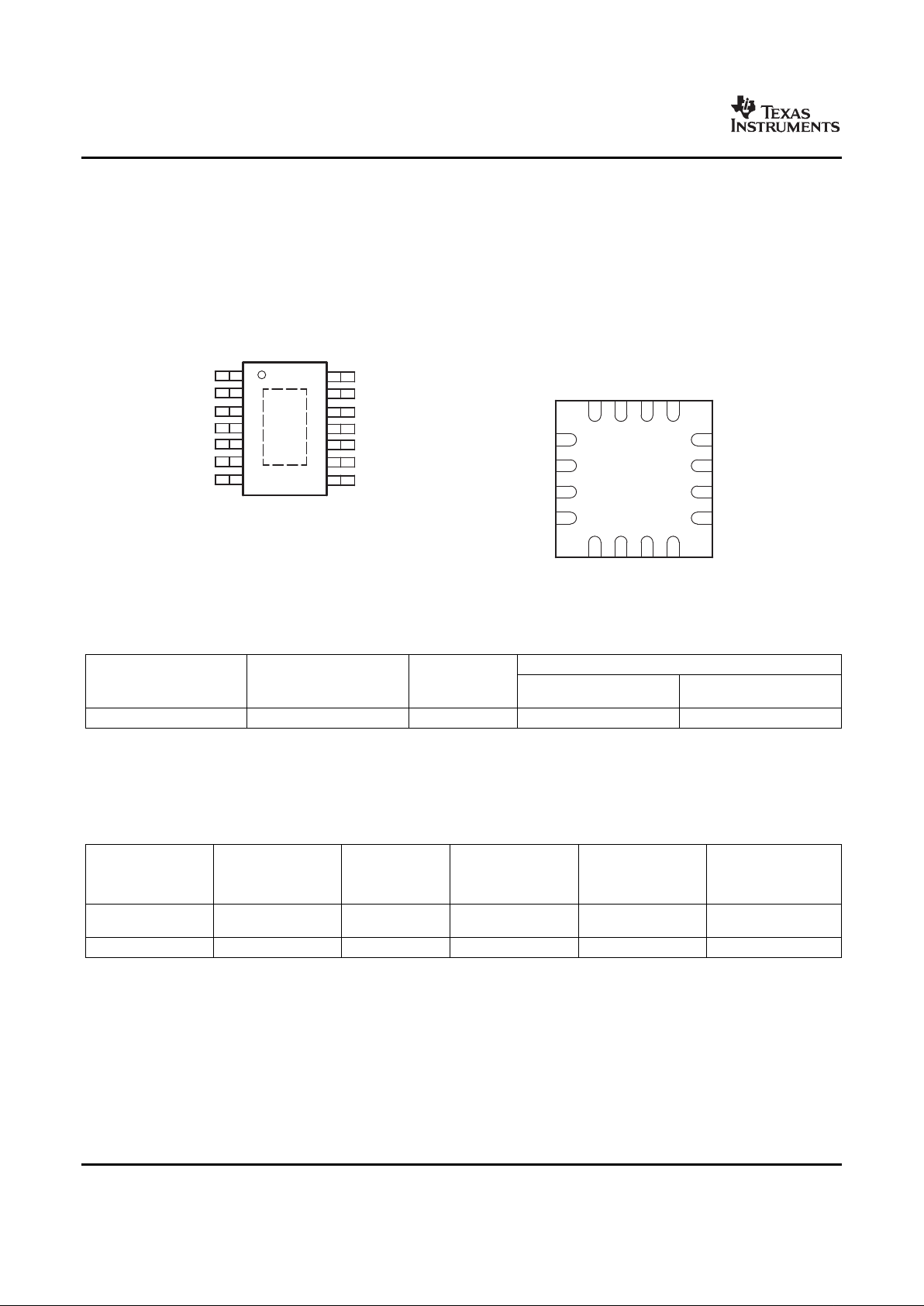

CONNECTION DIAGRAMS

3V3

IN1

AGND

IN2

16

15

14

13

NC

NC

NC

VDD

RSA−16 PACKAGE

(BOTTOM VIEW)

5

6

7

8

1

CLF

ILM

CS

PGND

2 3 4

12 11 10 9

PVDD

OUT1

OUT2

PGND

1

2

3

4

5

6

7

14

13

12

11

10

9

8

PWP−14 PACKAGE

(TOP VIEW)

NC − No internal connection

NC

3V3

IN1

AGND

IN2

CLF

ILIM

NC

VDD

PVDD

OUT1

OUT2

PGND

CS

UCD7201

SLUS645C – FEBRUARY 2005 – REVISED DECEMBER 2006

For similar applications requiring direct start-up capability from higher voltages such as the 48-V telecom input

line, the UCD7601 includes a 110-V high-voltage startup circuit.

The UCD7K driver family is compatible with standard 3.3-V I/O ports of DSPs, Microcontrollers, or ASICs.

UCD7201 is offered in PowerPAD™ HTSSOP-14 or space-saving QFN-16 packages.

ORDERING INFORMATION

PACKAGED DEVICES

(1) (2)

110-V HV

CURRENT SENSE LIMIT

TEMPERATURE RANGE STARTUP

PowerPAD™ HTSSOP-14

PER CHANNEL

QFN-16 (RSA)

(3)

CIRCUIT

(PWP)

-40°C to 105°C Common No UCD7201PWP UCD7201RSA

(1) These products are packaged in Pb-Free and Green lead finish of Pd-Ni-Au which is compatible with MSL level 1 at 255°C to 260°C

peak reflow temperature to be compatible with either lead free or Sn/Pb soldering operations.

(2) HTSSOP-14 (PWP) and QFN-16 (RSA), packages are available taped and reeled. Add R suffix to device type (e.g. UCD7201PWPR) to

order quantities of 2,000 devices per reel for the PWP package and 1,000 devices per reel for the RSA packages.

(3) Contact factory for availability of QFN packaging.

PACKAGING INFORMATION

θ

JC

θ

JA

POWER RATING

DERATING FACTOR,

PACKAGE SUFFIX TA= 70 ° C,

ABOVE 70 ° C (mW/ ° C)

( ° C/W) ( ° C/W)

TJ= 125 ° C (mW)

PowerPAD™

PWP 2.07 37.47

(1)

1470 27

HTSSOP- 14

QFN-16 RSA - - - -

(1) PowerPAD™ soldered to the PWB (TI recommended PWB as defind in TI's application report SLMA002 pg.33) with OLFM.

2

Submit Documentation Feedback

www.ti.com

ABSOLUTE MAXIMUM RATINGS

(1) (2)

ELECTRICAL CHARACTERISTICS

UCD7201

SLUS645C – FEBRUARY 2005 – REVISED DECEMBER 2006

SYMBOL PARAMETER UCD7201 UNIT

V

DD

Supply Voltage 16 V

Quiescent 20

I

DD

Supply Current mA

Switching, TA= 25°C, , TJ= 125 ° C, V

DD

= 12 V 200

Output Gate Drive

V

OUT

OUT -1 to PVDD V

Voltage

I

OUT(sink)

4.0

Output Gate Drive

OUT A

Current

I

OUT(source)

-4.0

ISET, CS -0.3 to 3.6

Analog Input

ILIM -0.3 to 3.6 V

Digital I/O’s IN, CLF -0.3 to 3.6

TA= 25°C (PWP-14 package), TJ= 125 ° C 2.67

Power Dissipation W

TA= 25°C (QFN-16 package), TJ= 125 ° C -

Junction Operating

T

J

UCD7201 -55 to 150

Temperature

°C

T

str

Storage Temperature -65 to 150

HBM Human body model 2000

ESD Rating V

CDM Change device model 500

T

SOL

Lead Temperature (Soldering, 10 sec) +300 °C

(1) Stresses beyond those listed under “absolute maximum ratings” may cause permanent damage to the device. These are stress ratings

only, and functional operation of the device at these or any other conditions beyond those indicated under “recommended operating

conditions” is not implied. Exposure to absolute-maximum-rated conditions for extended periods may affect device reliability.

(2) All voltages are with respect to GND. Currents are positive into, negative out of the specified terminal.

V

DD

= 12 V, 4.7-µF capacitor from V

DD

to GND, 0.22 µ F from 3V3 to AGND, TA= TJ= -40°C to 105°C, (unless otherwise

noted).

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

SUPPLY SECTION

Supply current, OFF V

DD

= 4.2 V - 200 400 µA

Supply current Outputs not switching IN = LOW - 1.5 2.5 mA

LOW VOLTAGE UNDER-VOLTAGE LOCKOUT

VDD UVLO ON 4.25 4.5 4.75

V

VDD UVLO OFF 4.05 4.25 4.45

VDD UVLO hysteresis 150 250 350 mV

REFERENCE / EXTERNAL BIAS SUPPLY

3V3 initial set point TA= 25°C, I

LOAD

= 0 3.267 3.3 3.333

V

3V3 set point over temperature 3.234 3.3 3.366

3V3 load regulation I

LOAD

= 1 mA to 10 mA, VDD = 5 V - 1 6.6

mV

3V3 line regulation VDD = 4.75 V to 12 V, I

LOAD

= 10 mA - 1 6.6

Short circuit current VDD = 4.75 to 12 V 11 20 35 mA

3V3 OK threshold, ON 3.3 V rising 2.9 3.0 3.1

V

3V3 OK threshold, OFF 3.3 V falling 2.7 2.8 2.9

INPUT SIGNAL

HIGH, positive-going input threshold

1.65 - 2.08

voltage (VIT+)

LOW negative-going input threshold

1.16 - 1.5 V

voltage (VIT-)

Input voltage hysteresis, (VIT+ -

0.6 - 0.8

VIT-)

3

Submit Documentation Feedback

www.ti.com

UCD7201

SLUS645C – FEBRUARY 2005 – REVISED DECEMBER 2006

ELECTRICAL CHARACTERISTICS (continued)

V

DD

= 12 V, 4.7-µF capacitor from V

DD

to GND, 0.22 µ F from 3V3 to AGND, TA= TJ= -40°C to 105°C, (unless otherwise

noted).

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

Frequency - - 2 MHz

CURRENT LIMIT (ILIM)

ILIM internal current limit threshold ILIM = OPEN 0.51 0.55 0.58

ILIM maximum current limit threshold I

LIM

= 3.3 V 1.05 1.10 1.15

ILIM current limit threshold I

LIM

= 0.75 V 0.700 0.725 0.750

V

ILIM minimum current limit threshold I

LIM

= 0.25 V 0.21 0.23 0.25

CLF output high level CS > I

LIM

, I

LOAD

= -7 mA 2.64 - -

CLF output low level CS ≤ I

LIM

, I

LOAD

= 7 mA - - 0.66

Propagation delay from IN to CLF IN rising to CLF falling after a current limit event - 10 20 ns

CURRENT SENSE COMPARATOR

Bias voltage Includes CS comp offset 5 25 50 mV

Input bias current - –1 - uA

Propagation delay from CS to OUTx

I

LIM

= 0.5 V, measured on OUTx, CS = threshold + 60 mV - 25 40

(1)

ns

Propagation delay from CS to CLF

(1)

I

LIM

= 0.5 V, measured on CLF, CS = threshold + 60 mV - 25 50

CURRENT SENSE DISCHARGE TRANSISTOR

Discharge resistance IN = low, resistance from CS to AGND 10 35 75 Ω

OUTPUT DRIVERS

Source current

(1)

VDD = 12 V, IN = high, OUTx = 5 V 4

Sink current

(1)

VDD = 12 V, IN = low, OUTx = 5 V 4

A

Source current

(1)

VDD = 4.75 V, IN = high, OUTx = 0 2

Sink current

(1)

VDD = 4.75 V, IN = low, OUTx = 4.75 V 3

Rise time, t

R

C

LOAD

= 2.2 nF, VDD = 12 V 10 20

ns

Fall time, t

F

C

LOAD

= 2.2 nF, VDD = 12 V 10 15

Output with VDD < UVLO VDD =1.0 V, I

SINK

= 10 mA 0.8 1.2 V

Propagation delay from IN to OUT1,

C

LOAD

= 2.2 nF, VDD = 12 V, CLK rising 20 35

t

D1

ns

Propagation delay from IN to OUT2,

C

LOAD

= 2.2 nF, VDD = 12 V, CLK falling 20 35

t

D2

(1) Ensured by design. Not 100% tested in production.

4

Submit Documentation Feedback

www.ti.com

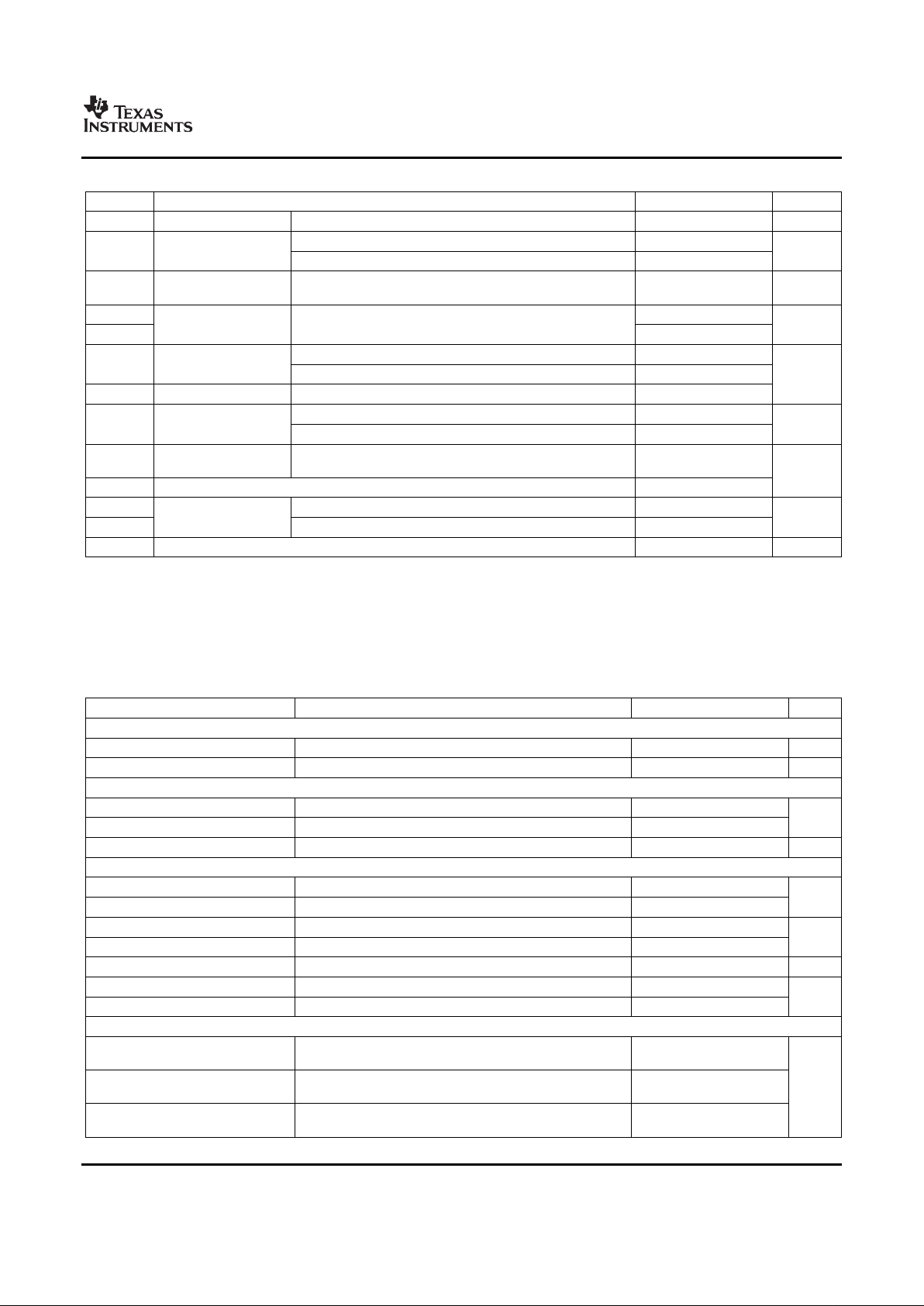

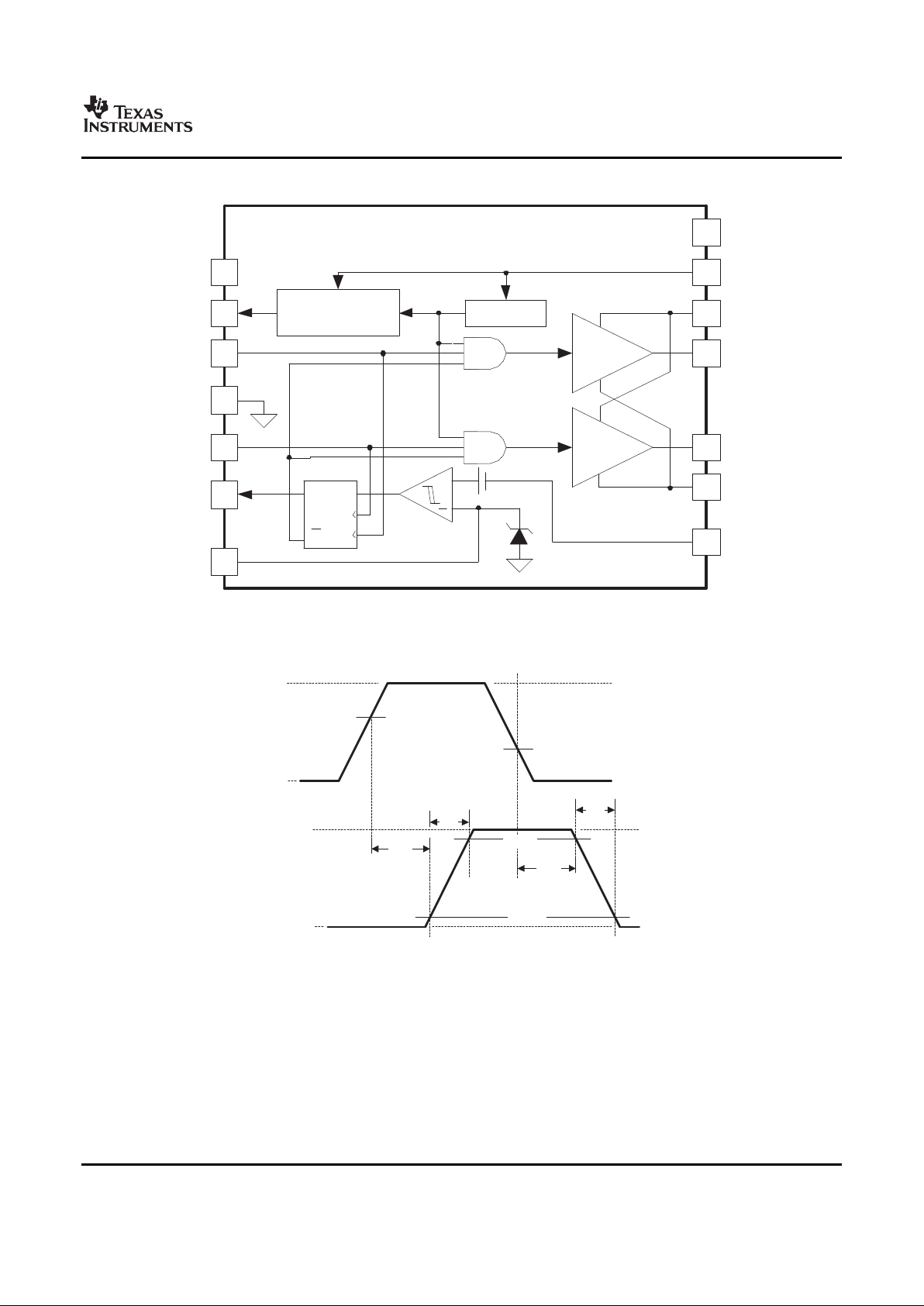

FUNCTIONAL BLOCK DIAGRAM

3

1

4

2

5

6

7

3V3 Regulator

and Reference

UVLO

12

14

11

13

10

9

8

NC

NC

3V3

IN1

AGND

IN2

CLF

ILIM

VDD

PVDD

OUT1

OUT2

PGND

CS

+

S

D

Q

Q R

R

+

25 mV

VIT−

10%

90%

INPUT

OUTPUT

VIT+

t

D1

t

F

t

F

t

D2

UCD7201

SLUS645C – FEBRUARY 2005 – REVISED DECEMBER 2006

Figure 1. UCD7201

Timing Diagram

5

Submit Documentation Feedback

www.ti.com

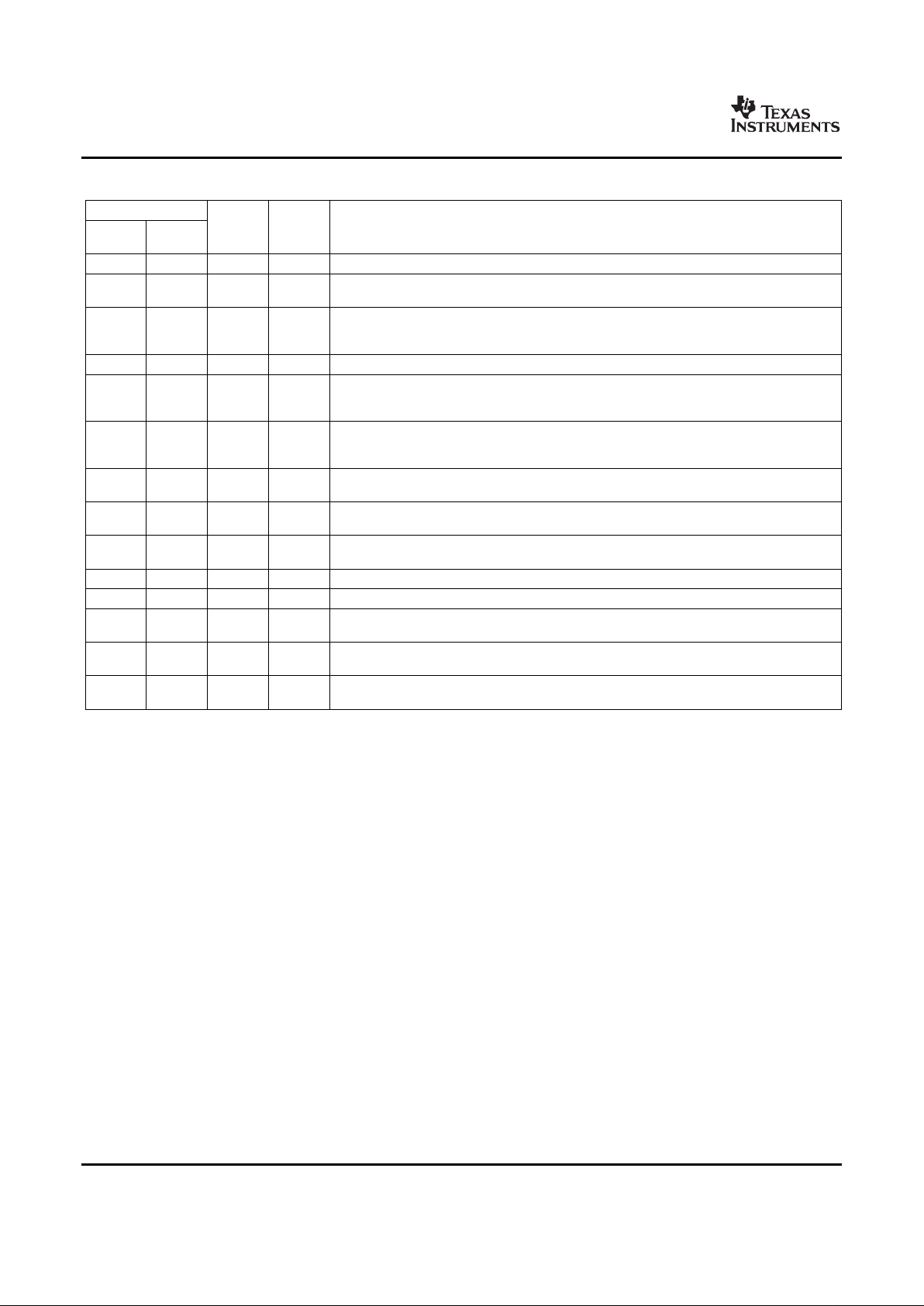

TERMINAL FUNCTIONS

UCD7201

SLUS645C – FEBRUARY 2005 – REVISED DECEMBER 2006

UCD7201

PIN

I/O FUNCTION

HTSSOP QFN-16

NAME

-14 PIN # PIN #

1 - NC - No Connection

Regulated 3.3-V rail. The onboard linear voltage regulator is capable of sourcing up to 10 mA

2 1 3V3 O

of current. Place 0.22 µF of ceramic capacitance from this pin to ground.

The IN pin is a high impedance digital input capable of accepting 3.3-V logic level signals up

3 2 IN1 I to 2 MHz. There is an internal Schmitt trigger comparator which isolates the internal circuitry

from any external noise.

4 3 AGND - Analog ground return.

The IN pin is a high impedance digital input capable of accepting 3.3-V logic level signals up

5 4 IN2 I to 2 MHz. There is an internal Schmitt trigger comparator which isolates the internal circuitry

from any external noise.

Current limit flag. When the CS level is greater than the ILIM voltage minus 25 mV, the

6 5 CLF O output of the driver is forced low and the current limit flag (CLF) is set high. The CLF signal is

latched high until the device receives the next rising edge on the IN pin.

Current limit threshold set pin. The current limit threshold can be set to any value between

7 6 ILIM I

0.25 V and 1.0 V. The default value while open is 0.5 V.

Current sense pin. Fast current limit comparator connected to the CS pin is used to protect

8 7 CS I

the power stage by implementing cycle-by-cycle current limiting.

Power ground return. The pin should be connected very closely to the source of the power

9 8, 9 PGND -

MOSFET.

10 10 OUT2 O The high-current TrueDrive™ driver output.

11 11 OUT1 O The high-current TrueDrive™ driver output.

Supply pin provides power for the output drivers. It is not connected internally to the VDD

12 12 PVDD I

supply rail. The bypass capacitor for this pin should be returned to PGND.

Supply input pin to power the driver. The UCD7K devices accept an input range of 4.5 V to

13 13 VDD I

15 V. Bypass the pin with at least 4.7 µF of capacitance, returned to AGND.

14, 15, No Connection.

14 NC -

16

6

Submit Documentation Feedback

www.ti.com

APPLICATION INFORMATION

Supply Current Sensing and Protection

Reference / External Bias Supply

Input Pin

UCD7201

SLUS645C – FEBRUARY 2005 – REVISED DECEMBER 2006

The UCD7201 is member of the UCD7K family of If limiting the rise or fall times to the power device is

digital compatible drivers targeting applications desired then an external resistance may be added

utilizing digital control techniques or applications that between the output of the driver and the load device,

require local fast peak current limit protection. which is generally the gate of a power MOSFET.

The UCD7K devices accept a supply range of 4.5 V A very fast current limit comparator connected to the

to 15 V. The device has an internal precision linear CS pin is used to protect the power stage by

regulator that produces the 3V3 output from this implementing cycle-by-cycle current limiting.

VDD input. A separate pin, PVDD, not connected

The current limit threshold may be set to any value

internally to the VDD supply rail provides power for

between 0.25 V and 1.0 V by applying the desired

the output drivers. In all applications the same bus

threshold voltage to the current limit (ILIM) pin. If the

voltage supplies the two pins. It is recommended that

ILIM pin is left floating, the internal current limit

a low value of resistance be placed between the two

threshold will be 0.5 volts. When the CS level is

pins so that the local capacitance on each pin forms

greater than the I

LIM

voltage minus 25 mV, the output

low pass filters to attenuate any switching noise that

of the driver is forced low and the current limit flag

may be on the bus.

(CLF) is set high. The CLF signal is latched high until

Although quiescent VDD current is low, total supply the device receives the next rising edge on either of

current depends on the gate drive output current the IN pins.

required for capacitive load and switching frequency.

When the CS voltage is below I

LIM

, the driver output

Total VDD current is the sum of quiescent VDD

follows the PWM input. The CLF digital output flag

current and the average OUT current. Knowing the

can be monitored by the host controller to determine

operating frequency and the MOSFET gate charge

when a current limit event occurs and to then apply

(Q

G

), average OUT current can be calculated from:

the appropriate algorithm to obtain the desired

I

OUT

= Q

G

x f, where f is frequency. current limit profile (i.e. straight time, fold back,

hickup or latch-off).

For the best high-speed circuit performance, VDD

bypass capacitors are recommended to prevent A benefit of this local protection feature is that the

noise problems. A 4.7-µF ceramic capacitor should UCD7K devices can protect the power stage if the

be located closest to the VDD and the AGND software code in the digital controller becomes

connection. In addition, a larger capacitor with corrupted. If the controller’s PWM output stays high,

relatively low ESR should be connected to the PVDD the local current sense circuit turns off the driver

and PGND pin, to help deliver the high current peaks output when an over-current event occurs. The

to the load. The capacitors should present a low system would then likely go into retry mode because

impedance characteristic for the expected current most DSP and microcontrollers have on-board

levels in the driver application. The use of surface watchdog, brown-out, and other supervisory

mount components for all bypass capacitors is highly peripherals to restart the device in the event that it is

recommended. not operating properly. But these peripherals typically

do not react fast enough to save the power stage.

The UCD7K’s local current limit comparator provides

the required fast protection for the power stage.

All devices in the UCD7K family are capable of

supplying a regulated 3.3-V rail to power various The CS threshold is 25 mV below the I

LIM

voltage. If

types of external loads such as a microcontroller or the user attempts to command zero current while the

an ASIC. The onboard linear voltage regulator is CS pin is at ground the CLF flag will latch high until

capable of sourcing up to 10 mA of current. For the IN pin receives a pulse. At start-up it is

normal operation, place 0.22-µF of ceramic necessary to ensure that the ILIM pin will always be

capacitance between the 3V3 pin to the AGND pin. greater than the CS pin for the handshaking to work

as described below. If for any reason the CS pin

comes to within 25 mV of the ILIM pin during

start-up, then the CLF flag will be latched high and

The input pins are high impedance digital inputs

the digital controller must poll the UCD7K device, by

capable of accepting 3.3-V logic level signals up to 2

sending it a narrow IN pulse. If a fault condition is not

MHz. There is an internal Schmitt Trigger comparator

present the IN pulse will reset the CLF signal to low

which isolates the internal circuitry from any external

indicating that the UCD7K device is ready to process

noise.

power pulses.

7

Submit Documentation Feedback

www.ti.com

Handshaking Drive Current and Power Requirements

Driver Output

E +

1

2

CV

2

P + CV2 f

Source/Sink Capabilities During Miller Plateau

P + 2.2 nF 122 300 kHz + 0.095 W

I +

P

V

+

0.095 W

12 V

+ 7.9 mA

Operational Waveforms

UCD7201

SLUS645C – FEBRUARY 2005 – REVISED DECEMBER 2006

The UCD7K family of devices have a built-in The UCD7K family of drivers can deliver high current

handshaking feature to facilitate efficient start-up of into a MOSFET gate for a period of several hundred

the digitally controlled power supply. At start-up the nanoseconds. High peak current is required to turn

CLF flag is held high until all the internal and external the device ON quickly. Then, to turn the device OFF,

supply voltages of the UCD7K device are within their the driver is required to sink a similar amount of

operating range. Once the supply voltages are within current to ground. This repeats at the operating

acceptable limits, the CLF goes low and the device frequency of the power device.

will process input drive signals. The micro-controller

Reference [1] discusses the current required to drive

should monitor the CFL flag at start-up and wait for

a power MOSFET and other capacitive-input

the CLF flag to go LOW before sending power

switching devices.

pulses to the UCD7K device.

When a driver device is tested with a discrete,

capacitive load it is a fairly simple matter to calculate

the power that is required from the bias supply. The

The high-current output stage of the UCD7K device

energy that must be transferred from the bias supply

family is capable of supplying ±4-A peak current

to charge the capacitor is given by:

pulses and swings to both PVDD and PGND. The

driver outputs follow the state of the IN pin provided

that the VDD and 3V3 voltages are above their

respective under-voltage lockout threshold.

where C is the load capacitor and V is the bias

The drive output utilizes Texas Instruments'

voltage feeding the driver.

TrueDrive™ architecture, which delivers rated

There is an equal amount of energy transferred to

current into the gate of a MOSFET when it is most

ground when the capacitor is discharged. This leads

needed, during the Miller plateau region of the

to a power loss given by the following:

switching transition providing efficiency gains.

TrueDrive™ consists of pullup pulldown circuits with

bipolar and MOSFET transistors in parallel. The peak

where f is the switching frequency.

output current rating is the combined current from

the bipolar and MOSFET transistors. This hybrid

This power is dissipated in the resistive elements of

output stage also allows efficient current sourcing at

the circuit. Thus, with no external resistor between

low supply voltages.

the driver and gate, this power is dissipated inside

the driver. Half of the total power is dissipated when

Each output stage also provides a very low

the capacitor is charged, and the other half is

impedance to overshoot and undershoot due to the

dissipated when the capacitor is discharged.

body diode of the external MOSFET. This means

that in many cases, external-schottky-clamp diodes

With V

DD

= 12 V, C

LOAD

= 2.2 nF, and f = 300 kHz,

are not required.

the power loss can be calculated as:

Large power MOSFETs present a large load to the

With a 12-V supply, this would equate to a current of:

control circuitry. Proper drive is required for efficient,

reliable operation. The UCD7K drivers have been

optimized to provide maximum drive to a power

MOSFET during the Miller plateau region of the

switching transition. This interval occurs while the

drain voltage is swinging between the voltage levels

Figure 24 shows the circuit performance achievable

dictated by the power topology, requiring the

with the output driving a 10-nF load at 12-V V

DD

. The

charging/discharging of the drain-gate capacitance

input pulsewidth (not shown) is set to 200 ns to show

with current supplied or removed by the driver

both transitions in the output waveform. Note the

device. See Reference [1]

linear rising and falling edges of the switching

waveforms. This is due to the constant output current

characteristic of TrueDrive™ stage as opposed to

the resistive output impedance of traditional

MOSFET-based gate drivers.

8

Submit Documentation Feedback

www.ti.com

Thermal Information

Circuit Layout Recommendations

UCD7201

SLUS645C – FEBRUARY 2005 – REVISED DECEMBER 2006

Note that the PowerPAD™ is not directly connected

to any leads of the package. However, it is

The useful range of a driver is greatly affected by the

electrically and thermally connected to the substrate

drive power requirements of the load and the thermal

which is the ground of the device. The PowerPad™

characteristics of the device package. In order for a

should be connected to the quiet ground of the

power driver to be useful over a particular

circuit.

temperature range the package must allow for the

efficient removal of the heat produced while keeping

the junction temperature within rated limits. The

UCD7K family of drivers is available in PowerPAD™ In a power driver operating at high frequency, it is

TSSOP and QFN/DFN packages to cover a range of critical to minimize stray inductance to minimize

application requirements. Both have an exposed pad overshoot/undershoots and ringing. The low output

to enhance thermal conductivity from the impedance of these drivers produces waveforms with

semiconductor junction. high di/dt. This tends to induce ringing in the

parasitic inductances. It is advantageous to connect

As illustrated in Reference [2], the PowerPAD™

the driver device close to the MOSFETs. It is

packages offer a leadframe die pad that is exposed

recommended that the PGND and the AGND pins be

at the base of the package. This pad is soldered to

connected to the PowerPad™ of the package with a

the copper on the PC board (PCB) directly

thin trace. It is critical to ensure that the voltage

underneath the device package, reducing the T

JC

potential between these two pins does not exceed

down to 2.07°C/W. The PC board must be designed

0.3 V. The use of schottky diodes on the outputs to

with thermal lands and thermal vias to complete the

PGND and PVDD is recommended when driving

heat removal subsystem, as summarized in

gate transformers.

Reference [3].

9

Submit Documentation Feedback

www.ti.com

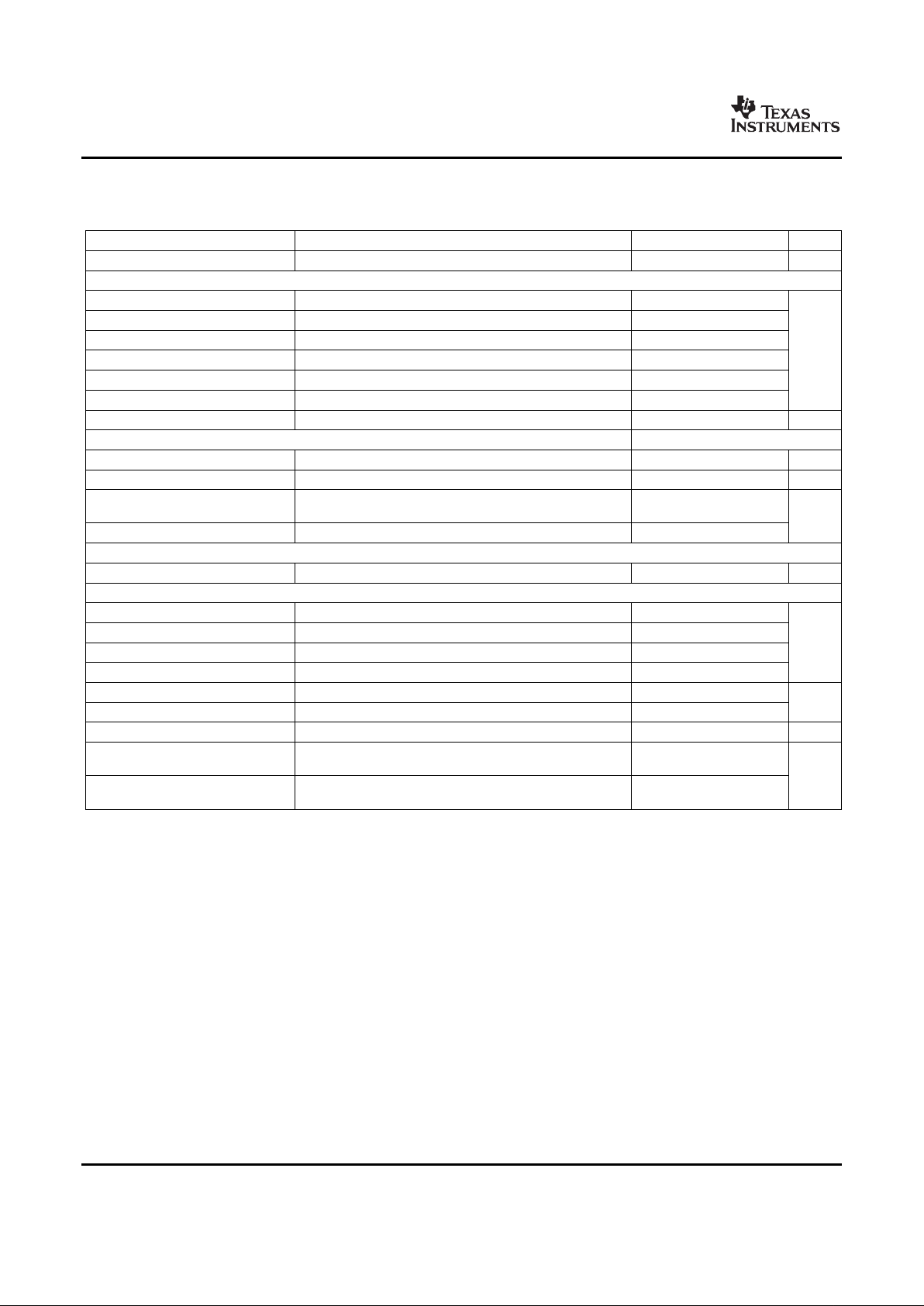

Additional Application Circuits

Isolation

Amplifier

COMMUNICATION

(Programming & Status Reporting)

141

13

8

PVDD

VDD

CS

10OUT2

3

4

2

5

6

IN1

AGND

3V3

IN2

CLF

7

UCD7201PWP

11OUT1

9PGND

12

NC

ILIM

NC

Bias Supply

Bias Winding

VIN

VOUT

DIGITAL

CONTROLLER

GND

PWMA

ADC4

INTERRUPT or CCR

PWMB

ADC3

VCC

PWM or GPIO

ADC1

ADC2

CS

XFMR

Gate Drive

Transformer

(3 winding)

15

16

14

2

4

141

13

8

PVDD

VDD

CS

10OUT2

3

4

2

5

6

IN1

AGND

3V3

IN2

CLF

7

UCD7201

11OUT1

9PGND

12

NC

ILIM

NC

Bias Supply

Bias Winding

VIN

VOUT

13

UCC28089

GND

OUTA

OUTB

VDD

DIS

CS

3

1 SYNC

CT

UCD7201

SLUS645C – FEBRUARY 2005 – REVISED DECEMBER 2006

Figure 2 shows the UCD7201 in a half-bridge converter design. The digital controller is performing the output

voltage compensation and all supervisory functions. The isolation amplifier is made up of a linear opto-coupler

configured for a gain of 1/10, so the output voltage is transformed to a level comparable with the ADC of the

digital controller.

Figure 2. Half-Bridge Converter

Figure 3 shows the UCD7201 in an analog only implementation of an intermediate bus converter. The ILIM pin

of the UCD7201 is exponentially increased at start-up, which minimizes overshoot on the output voltage. The

UCC28089 is a push-pull controller with fixed dead-time. The UCC28089 operates at a fixed duty cycle close to

100% so the circuit acts like a DC transformer linearly transforming the input voltage via the turns ratio of the

transformer.

Figure 3. Intermediate Bus Converter

10

Submit Documentation Feedback

www.ti.com

Typical Characteristics

−50 50 125−25 0 25 75 100

3.24

3.26

3.28

3.30

3.32

3.34

3.36

t − Temperature − °C

3V3 − Reference Voltage − V

−50 50

5.0

4.5

2.5

2.0

1.5

0.5

0.0

−25 0 25 75 100

4.0

1.0

3.5

3.0

UVLO on

UVLO off

UVLO hysteresis

t − Temperature − °C

125

V

UVLO

− UVLO Thresholds − V

−50 50 125−25 0 25 75 100

20.0

20.5

21.0

21.5

22.0

22.5

23.0

t − Temperature − °C

I

SHORT_CKT

− Short Circuit Current − mA

VDD = 4.75 V

VDD = 12 V

0 1000 1500500

0

20

40

60

80

100

120

140

160

f − Frequency − kHz

I

DD

− Supply Current − mA

C

LOAD

= 10 nF

C

LOAD

= 4.7 nF

C

LOAD

= 2.2 nF

C

LOAD

= 1 nF

UCD7201

SLUS645C – FEBRUARY 2005 – REVISED DECEMBER 2006

UVLO THRESHOLDS 3V3 REFERENCE VOLTAGE

vs vs

TEMPERATURE TEMPERATURE

Figure 4. Figure 5.

3V3 SHORT CIRCUIT CURRENT SUPPLY CURRENT

vs vs

TEMPERATURE FREQUENCY (V

DD

= 5 V)

Figure 6. Figure 7.

11

Submit Documentation Feedback

www.ti.com

0

40

80

120

160

200

240

280

320

0 500

1000

1500

f − Frequency − kHz

I

DD

− Supply Current − mA

C

LOAD

= 10 nF

C

LOAD

= 4.7 nF

C

LOAD

= 2.2 nF

C

LOAD

= 1 nF

0

40

80

120

160

200

240

280

0 500

1000

1500

f − Frequency − kHz

I

DD

− Supply Current − mA

C

LOAD

= 10 nF

C

LOAD

= 4.7 nF

C

LOAD

= 2.2 nF

C

LOAD

= 1 nF

0

50

100

150

200

250

300

350

400

450

500

0

500

1000

1500

f − Frequency − kHz

I

DD

− Supply Current − mA

C

LOAD

= 10 nF

C

LOAD

= 4.7 nF

C

LOAD

= 2.2 nF

C

LOAD

= 1 nF

0

50

100

150

200

250

300

350

400

0

500

1000

1500

f − Frequency − kHz

I

DD

− Supply Current − mA

C

LOAD

= 10 nF

C

LOAD

= 4.7 nF

C

LOAD

= 2.2 nF

C

LOAD

= 1 nF

UCD7201

SLUS645C – FEBRUARY 2005 – REVISED DECEMBER 2006

SUPPLY CURRENT SUPPLY CURRENT

vs vs

FREQUENCY (V

DD

= 8 V) FREQUENCY (V

DD

= 10 V)

Figure 8. Figure 9.

SUPPLY CURRENT SUPPLY CURRENT

vs vs

FREQUENCY (V

DD

= 12 V) FREQUENCY (V

DD

= 15 V)

Figure 10. Figure 11.

12

Submit Documentation Feedback

www.ti.com

−50 50 125−25 0 25 75 100

0.0

2.0

4.0

6.0

8.0

10.0

12.0

14.0

16.0

18.0

TJ − Temperature − °C

t

R,

t

F

− Rise and Fall Times − ns

tR = Rise Time

tF = Fall Time

C

LOAD

= 2.2 nF

−50 50 125−25 0 25 75 100

0.0

0.5

1.0

1.5

2.0

2.5

TJ − Temperature − °C

V

INPUT

− Input Voltage − V

Input Rising

Input Falling

5

15

25

35

45

55

65

5 7.5 10 12.5 15

VDD − Supply Voltage − V

t

R

− Rise Time − ns

C

LOAD

= 10 nF

C

LOAD

= 4.7 nF

C

LOAD

= 2.2 nF

C

LOAD

= 1 nF

5

10

15

20

25

30

35

40

45

5 7.5 10 12.5 15

VDD − Supply Voltage − V

t

F

− Fall Time − ns

C

LOAD

= 10 nF

C

LOAD

= 4.7 nF

C

LOAD

= 2.2 nF

C

LOAD

= 1 nF

UCD7201

SLUS645C – FEBRUARY 2005 – REVISED DECEMBER 2006

INPUT THRESHOLDS OUTPUT RISE TIME AND FALL TIME

vs vs

TEMPERATURE TEMPERATURE (V

DD

= 12 V)

Figure 12. Figure 13.

RISE TIME FALL TIME

vs vs

SUPPLY VOLTAGE SUPPLY VOLTAGE

Figure 14. Figure 15.

13

Submit Documentation Feedback

www.ti.com

5

10

15

20

25

5 7.5 10 12.5 15

VDD − Supply Voltage − V

t

PD

− Propagation Delay, Falling − ns

C

LOAD

= 10 nF

C

LOAD

= 4.7 nF

C

LOAD

= 2.2 nF

C

LOAD

= 1 nF

0

5

10

15

20

5 7.5 10 12.5 15

VDD − Supply Voltage − V

t

PD

− Propagation Delay, Rising − ns

C

LOAD

= 10 nF

C

LOAD

= 4.7 nF

C

LOAD

= 2.2 nF

C

LOAD

= 1 nF

−50 50 125−25 0 25 75 100

0.51

0.52

0.53

0.54

0.55

0.56

0.57

0.58

0.59

TJ − Temperature − °C

V

CS

− Current Limit Threshold − V

−50 50 125−25 0 25 75 100

0

5

10

15

20

25

30

35

40

TJ − Temperature − °C

t

PD

− CS to OUTx Propagation Delay − ns

UCD7201

SLUS645C – FEBRUARY 2005 – REVISED DECEMBER 2006

IN to OUTx PROPAGATION DELAY RISING IN to OUTx PROPAGATION DELAY FALLING

vs vs

SUPPLY VOLTAGE SUPPLY VOLTAGE

Figure 16. Figure 17.

DEFAULT CURRENT LIMIT THRESHOLD CS TO OUTx PROPAGATION DELAY

vs vs

TEMPERATURE TEMPERATURE

Figure 18. Figure 19.

14

Submit Documentation Feedback

www.ti.com

−50 50 125−25 0 25 75 100

0

5

10

15

20

25

30

35

TJ − Temperature − °C

t

PD

− Propagation Delay − ns

−50 50−25 0 25 75 100

0

5

10

15

20

25

30

35

40

45

50

TJ − Temperature − °C

t

PD

− CS to CLF Propagation Delay − ns

125

t − Time − 40 µs/div

VDD (2 V/div)

OUTx (2 V/div)

3V3 (2 V/div)

t − Time − 40 µs/div

VDD (2 V/div)

OUTx (2 V/div)

3V3 (2 V/div)

UCD7201

SLUS645C – FEBRUARY 2005 – REVISED DECEMBER 2006

CS TO CLF PROPAGATION DELAY IN TO OUT PROPAGATION DELAY

vs vs

TEMPERATURE TEMPERATURE

Figure 20. Figure 21.

START-UP BEHAVIOR AT V

DD

= 12 V (INPUT TIED TO SHUT DOWN BEHAVIOR AT V

DD

= 12 V (INPUT TIED TO

3V3) 3V3)

Figure 22. Figure 23.

15

Submit Documentation Feedback

www.ti.com

t − Time − 40 µs/div

VDD (2 V/div)

3V3 (2 V/div)

OUTx (2 V/div)

t − Time − 40 µs/div

VDD (2 V/div)

3V3 (2 V/div)

OUTx (2 V/div)

t − Time − 40 ns/div

Output Voltage − 2 V/div

UCD7201

SLUS645C – FEBRUARY 2005 – REVISED DECEMBER 2006

START-UP BEHAVIOR AT V

DD

= 12 V (INPUT SHORTED SHUT DOWN BEHAVIOR AT V

DD

= 12 V (INPUT SHORTED

TO GND) TO GND)

Figure 24. Figure 25.

OUTPUT RISE AND FALL TIME (V

DD

= 12 V, C

LOAD

= 10

nF)

Figure 26.

16

Submit Documentation Feedback

www.ti.com

REFERENCES

RELATED PRODUCTS

REVISION HISTORY

UCD7201

SLUS645C – FEBRUARY 2005 – REVISED DECEMBER 2006

1. Power Supply Seminar SEM-1400 Topic 2: Design And Application Guide For High Speed MOSFET Gate

Drive Circuits, by Laszlo Balogh, Texas Instruments Literature No. SLUP133.

2. Technical Brief, PowerPad Thermally Enhanced Package, Texas Instruments Literature No. SLMA002

3. Application Brief, PowerPAD Made Easy, Texas Instruments Literature No. SLMA004

TEMPERATURE RANGE CURRENT SENSE LIMIT PER CHANNEL FEATURES

UCD7100 Single Low Side ±4-A Driver with Independent CS 3V3, CS

(1) (2)

UCD7200 Dual Low Side ±4-A Drivers with Independent CS 3V3, CS

(1) (2)

UCD7230 ±4-A Synchronous Buck Driver with CS 3V3, CS

(1) (2)

UCD7500 Single Low Side ±4-A Driver with CS and 110-V High Voltage Startup 3v3, CS, HVS110

(1) (2) (3)

UCD7600 Dual Low Side ±4-A Drivers with Independent CS and 110-V High Voltage Startup 3V3, CS, HVS110

(1) (2) (3)

Dual Low Side ±4-A Drivers with Common CS and 110-V High Voltage Startup 3V3, CCS, HVS110

UCD7601

(1) (4) (3)

UCD9110 Digital Power Controller for High Performance Single-loop Applications

UCD9501 Digital Power Controller for High Performance Multi-Loop Applications

(1) 3V3 = 3.3-V linear regulator.

(2) CS = current sense and current limit function.

(3) HVS110 = 110-V high voltage startup circuit.

(4) CCS = Common current sense and current limit function.

DATE REVISION CHANGE DESCRIPTION

3/4/05 SLUS645 Initial release of preliminary datasheet.

4/1/05 SLUS645A Updated packaging information.

7/14/05 SLUS645B Initial release of production datasheet. Updated specification and application information.

17

Submit Documentation Feedback

PACKAGING INFORMATION

Orderable Device Status

(1)

Package

Type

Package

Drawing

Pins Package

Qty

Eco Plan

(2)

Lead/Ball Finish MSL Peak Temp

(3)

UCD7201PWP ACTIVE HTSSOP PWP 14 90 Green (RoHS &

no Sb/Br)

CU NIPDAU Level-2-260C-1 YEAR

UCD7201PWPG4 ACTIVE HTSSOP PWP 14 90 Green (RoHS &

no Sb/Br)

CU NIPDAU Level-2-260C-1 YEAR

UCD7201PWPR ACTIVE HTSSOP PWP 14 2000 Green (RoHS &

no Sb/Br)

CU NIPDAU Level-2-260C-1 YEAR

UCD7201PWPRG4 ACTIVE HTSSOP PWP 14 2000 Green (RoHS &

no Sb/Br)

CU NIPDAU Level-2-260C-1 YEAR

UCD7201RSAR PREVIEW QFN RSA 16 3000 TBD Call TI Call TI

UCD7201RSAT PREVIEW QFN RSA 16 250 TBD Call TI Call TI

(1)

The marketing status values are defined as follows:

ACTIVE: Product device recommended for new designs.

LIFEBUY: TI has announced that the device will be discontinued, and a lifetime-buy period is in effect.

NRND: Not recommended for new designs. Device is in production to support existing customers, but TI does not recommend using this part in

a new design.

PREVIEW: Device has been announced but is not in production. Samples may or may not be available.

OBSOLETE: TI has discontinued the production of the device.

(2)

Eco Plan - The planned eco-friendly classification: Pb-Free (RoHS), Pb-Free (RoHS Exempt), or Green (RoHS & no Sb/Br) - please check

http://www.ti.com/productcontent for the latest availability information and additional product content details.

TBD: The Pb-Free/Green conversion plan has not been defined.

Pb-Free (RoHS): TI's terms "Lead-Free" or "Pb-Free" mean semiconductor products that are compatible with the current RoHS requirements

for all 6 substances, including the requirement that lead not exceed 0.1% by weight in homogeneous materials. Where designed to be soldered

at high temperatures, TI Pb-Free products are suitable for use in specified lead-free processes.

Pb-Free (RoHS Exempt): This component has a RoHS exemption for either 1) lead-based flip-chip solder bumps used between the die and

package, or 2) lead-based die adhesive used between the die and leadframe. The component is otherwise considered Pb-Free (RoHS

compatible) as defined above.

Green (RoHS & no Sb/Br): TI defines "Green" to mean Pb-Free (RoHS compatible), and free of Bromine (Br) and Antimony (Sb) based flame

retardants (Br or Sb do not exceed 0.1% by weight in homogeneous material)

(3)

MSL, Peak Temp. -- The Moisture Sensitivity Level rating according to the JEDEC industry standard classifications, and peak solder

temperature.

Important Information and Disclaimer:The information provided on this page represents TI's knowledge and belief as of the date that it is

provided. TI bases its knowledge and belief on information provided by third parties, and makes no representation or warranty as to the

accuracy of such information. Efforts are underway to better integrate information from third parties. TI has taken and continues to take

reasonable steps to provide representative and accurate information but may not have conducted destructive testing or chemical analysis on

incoming materials and chemicals. TI and TI suppliers consider certain information to be proprietary, and thus CAS numbers and other limited

information may not be available for release.

In no event shall TI's liability arising out of such information exceed the total purchase price of the TI part(s) at issue in this document sold by TI

to Customer on an annual basis.

PACKAGE OPTION ADDENDUM

www.ti.com

5-Feb-2007

Addendum-Page 1

TAPE AND REEL INFORMATION

*All dimensions are nominal

Device Package

Type

Package

Drawing

Pins SPQ Reel

Diameter

(mm)

Reel

Width

W1 (mm)

A0 (mm) B0 (mm) K0 (mm) P1

(mm)W(mm)

Pin1

Quadrant

UCD7201PWPR HTSSOP PWP 14 2000 330.0 12.4 6.67 5.4 1.6 8.0 12.0 Q1

PACKAGE MATERIALS INFORMATION

www.ti.com

11-Mar-2008

Pack Materials-Page 1

*All dimensions are nominal

Device Package Type Package Drawing Pins SPQ Length (mm) Width (mm) Height (mm)

UCD7201PWPR HTSSOP PWP 14 2000 346.0 346.0 29.0

PACKAGE MATERIALS INFORMATION

www.ti.com

11-Mar-2008

Pack Materials-Page 2

IMPORTANT NOTICE

Texas Instruments Incorporated and its subsidiaries (TI) reserve the right to make corrections, modifications, enhancements, improvements,

and other changes to its products and services at any time and to discontinue any product or service without notice. Customers should

obtain the latest relevant information before placing orders and should verify that such information is current and complete. All products are

sold subject to TI’s terms and conditions of sale supplied at the time of order acknowledgment.

TI warrants performance of its hardware products to the specifications applicable at the time of sale in accordance with TI’s standard

warranty. Testing and other quality control techniques are used to the extent TI deems necessary to support this warranty. Except where

mandated by government requirements, testing of all parameters of each product is not necessarily performed.

TI assumes no liability for applications assistance or customer product design. Customers are responsible for their products and

applications using TI components. To minimize the risks associated with customer products and applications, customers should provide

adequate design and operating safeguards.

TI does not warrant or represent that any license, either express or implied, is granted under any TI patent right, copyright, mask work right,

or other TI intellectual property right relating to any combination, machine, or process in which TI products or services are used. Information

published by TI regarding third-party products or services does not constitute a license from TI to use such products or services or a

warranty or endorsement thereof. Use of such information may require a license from a third party under the patents or other intellectual

property of the third party, or a license from TI under the patents or other intellectual property of TI.

Reproduction of TI information in TI data books or data sheets is permissible only if reproduction is without alteration and is accompanied

by all associated warranties, conditions, limitations, and notices. Reproduction of this information with alteration is an unfair and deceptive

business practice. TI is not responsible or liable for such altered documentation. Information of third parties may be subject to additional

restrictions.

Resale of TI products or services with statements different from or beyond the parameters stated by TI for that product or service voids all

express and any implied warranties for the associated TI product or service and is an unfair and deceptive business practice. TI is not

responsible or liable for any such statements.

TI products are not authorized for use in safety-critical applications (such as life support) where a failure of the TI product would reasonably

be expected to cause severe personal injury or death, unless officers of the parties have executed an agreement specifically governing

such use. Buyers represent that they have all necessary expertise in the safety and regulatory ramifications of their applications, and

acknowledge and agree that they are solely responsible for all legal, regulatory and safety-related requirements concerning their products

and any use of TI products in such safety-critical applications, notwithstanding any applications-related information or support that may be

provided by TI. Further, Buyers must fully indemnify TI and its representatives against any damages arising out of the use of TI products in

such safety-critical applications.

TI products are neither designed nor intended for use in military/aerospace applications or environments unless the TI products are

specifically designated by TI as military-grade or "enhanced plastic." Only products designated by TI as military-grade meet military

specifications. Buyers acknowledge and agree that any such use of TI products which TI has not designated as military-grade is solely at

the Buyer's risk, and that they are solely responsible for compliance with all legal and regulatory requirements in connection with such use.

TI products are neither designed nor intended for use in automotive applications or environments unless the specific TI products are

designated by TI as compliant with ISO/TS 16949 requirements. Buyers acknowledge and agree that, if they use any non-designated

products in automotive applications, TI will not be responsible for any failure to meet such requirements.

Following are URLs where you can obtain information on other Texas Instruments products and application solutions:

Products Applications

Amplifiers amplifier.ti.com Audio www.ti.com/audio

Data Converters dataconverter.ti.com Automotive www.ti.com/automotive

DSP dsp.ti.com Broadband www.ti.com/broadband

Clocks and Timers www.ti.com/clocks Digital Control www.ti.com/digitalcontrol

Interface interface.ti.com Medical www.ti.com/medical

Logic logic.ti.com Military www.ti.com/military

Power Mgmt power.ti.com Optical Networking www.ti.com/opticalnetwork

Microcontrollers microcontroller.ti.com Security www.ti.com/security

RFID www.ti-rfid.com Telephony www.ti.com/telephony

RF/IF and ZigBee® Solutions www.ti.com/lprf Video & Imaging www.ti.com/video

Wireless www.ti.com/wireless

Mailing Address: Texas Instruments, Post Office Box 655303, Dallas, Texas 75265

Copyright © 2008, Texas Instruments Incorporated

Loading...

Loading...