1/98

FEATURES

• Precision 4.1V Reference (1%)

• High Efficiency Battery Charger Solution

• Average Current Mode Control from

Trickle to Over Charge

• Resistor Programmable Charge Currents

• Internal State Logic Provides Four

Charge States

• Programmable Over Charge Time

• Fully Differential Switch Mode Current

Sensing

• CHG Pin Initiates Charging

Switch Mode Lithium-Ion Battery Charger Controller

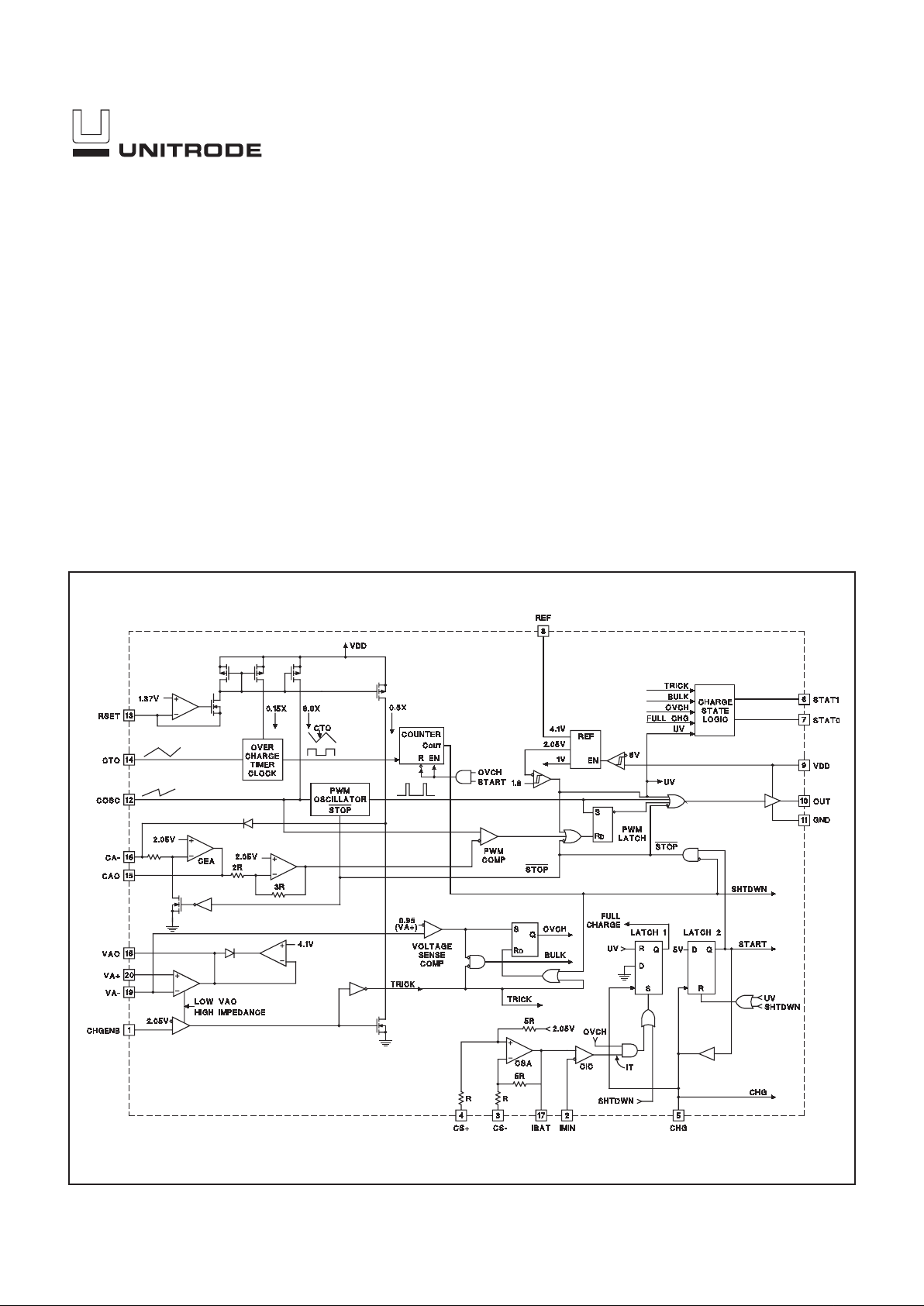

BLOCK DIAGRAM

UDG-96197-1

UCC2956

UCC3956

PRELIMINARY

DESCRIPTION

The UCC3956 family of Switch Mode Lithium-Ion Battery Charger

Controllers accurately control lithium-ion battery charging with a

highly efficient average current control loop.This chip is designed to

work as a stand alone charger controller for a single cell or multiple

cell battery pack. This chip combines charge state logic and average current PWM control circuitry with a 14 bit counter to program

the over charge time. The charge state logic indicates current or

voltage control depending on the charge state. The chip includes

undervoltage lockout circuitry to insure sufficient supply voltage is

present before output switching starts. Additional circuit blocks include a differential current sense amplifier, a 1% voltage reference,

voltage and current error amplifiers, PWM latch, charge state decode bits, and a 500mA output driver.

2

UCC2956

UCC3956

ELECTRICAL CHARACTERISTICS: Unless otherwise specified, TA = –40°C to +85 for UCC2956 and 0°C to +70°C for

UCC3956, COSC = 500pF, RSET = 70k, CTO = 169nF, VDD = 12V, TA =TJ.

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

Current Sense Amplifier (CSA)

DC Gain CS– = 0, CS+ = –50mV and CS+ = –250mV 4.9 5 5.1 V/V

CS+ = 0, CS– = 50mV and CS– = 250mV 4.9 5 5.1 V/V

CAO CS+ = CS– = 0V 1.99 2.05 2.11 mV

CMRR V

CM = 1.1V to 18V, VDD = 18V 50 65 dB

VOL CS+ = –0.2V, CS– = 0.5V, IO = 1mA 0.3 V

V

OH CS+ = 0.5V, CS– = –0.2V, IO = –500µA 3.7 4.1 4.4 V

Output Source Current IBAT = 3V, VID = 700mV –500 µA

Output Sink Current IBAT = 1V, VID = –700mV 500 µA

3dB Bandwidth V

CM = 0V, CS+ - CS– = 100mV (Note 2) 0.1 3 MHz

Current Error Amplifier (CEA)

IB 8V < V

DD< 18V, CHGENB = REF 0.1 0.5 µA

CA– Voltage 8V < V

DD < 18V, CAO = CA– 1.99 2.05 2.11 V

AVO 60 90 dB

GBW T

J = 25°C, F = 100kHz 1 3 MHz

V

OL IO = 250µA, CA– = 3V 0.5 V

VOH IO = –1mA, CA– = 2V 3.7 4.1 4.4 V

I

CA–, Itrck_control VCHGENB = GND 8 10 12 µA

Voltage Error Amplifier (VEA)

IB Total Bias Current; Regulating Level 0.5 3 µA

VIO 8V < V

DD < 18V, –0.2 < VCM < 5V 10 mV

AVO 60 90 dB

GBW T

J = 25°C, F = 100kHz 0.75 3 MHz

VOL IO = 500µA, VA– = 3.8V 0.2 1 V

V

OH IO = –500µA, VA– = 4.4V 3.8 4.1 4.3 V

VAO Leakage V

CHGENB = GND, STAT0 = 0 and STAT1 = 0, VAO = 2.05V –1 1 µA

Pulse Width Modulator

Maximum Duty Cycle CAO = 0.5V 85 92 100 %

Modulator Gain CAO = 1.7V, 2.1V 57 64 71 %/V

ABSOLUTE MAXIMUM RATINGS

Supply Voltage VDD, OUT .........................20V

Output Current Sink

Continuous ................................120mA

Peak .....................................600mA

Output Current Source

Continuous ................................120mA

Peak .....................................600mA

CS+, CS–

Voltage ...............................–0.5 to VDD

Current with CS+, CS– less than –0.5.............50mA

Remaining Pin Voltages .....................–0.3V to 6V

Storage Temperature ...................–65°C to +150°C

Junction Temperature...................–55°C to +150°C

Lead Temperature (Soldering, 10 sec.).............+300°C

Currents are positive into, negative out of the specified terminal. Consult Packaging Section of Databook for thermal limitations and considerations of packages.

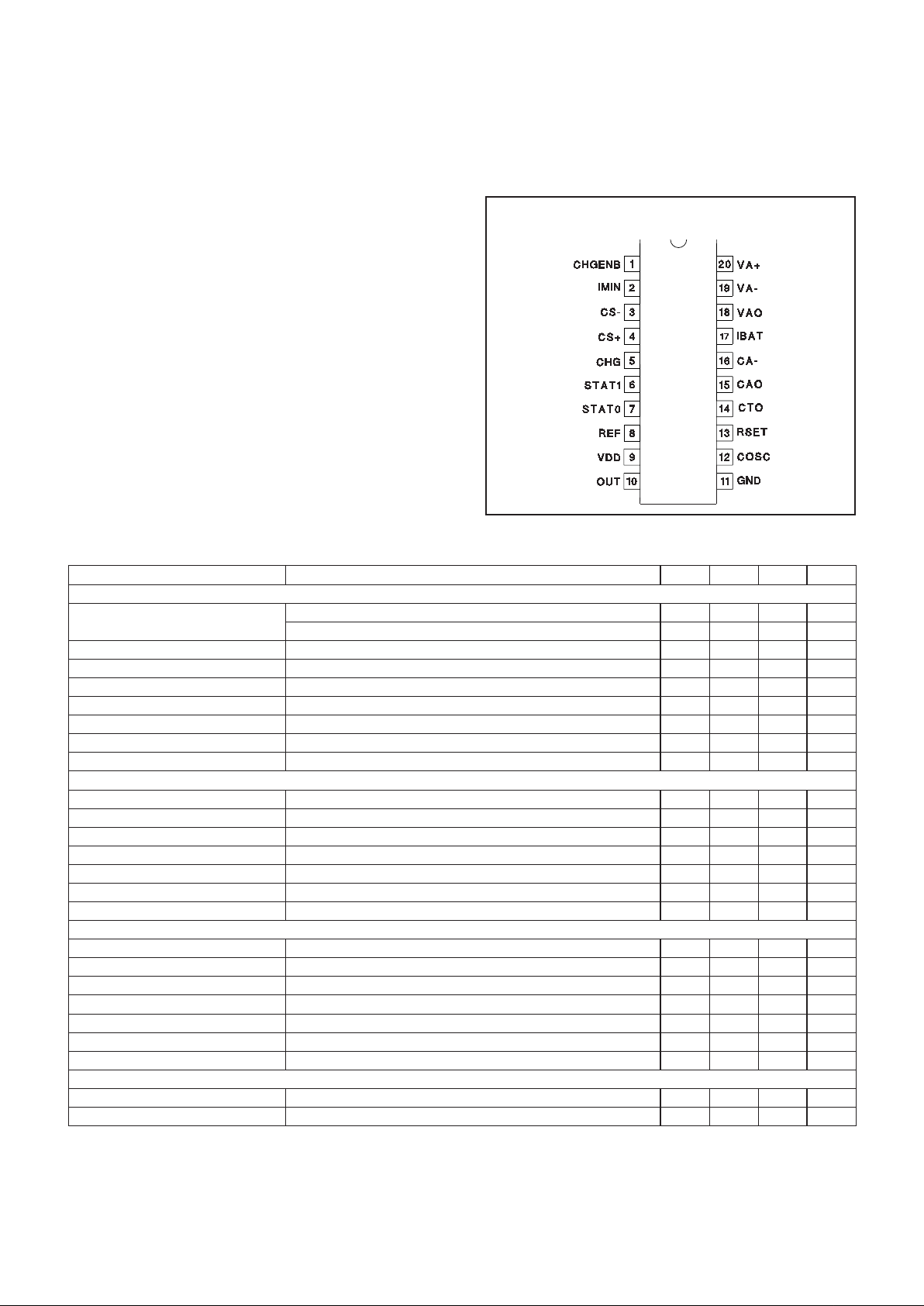

CONNECTION DIAGRAM

DIP-20, SOIC-20 (Top View)

JorN,DWPackages

3

UCC2956

UCC3956

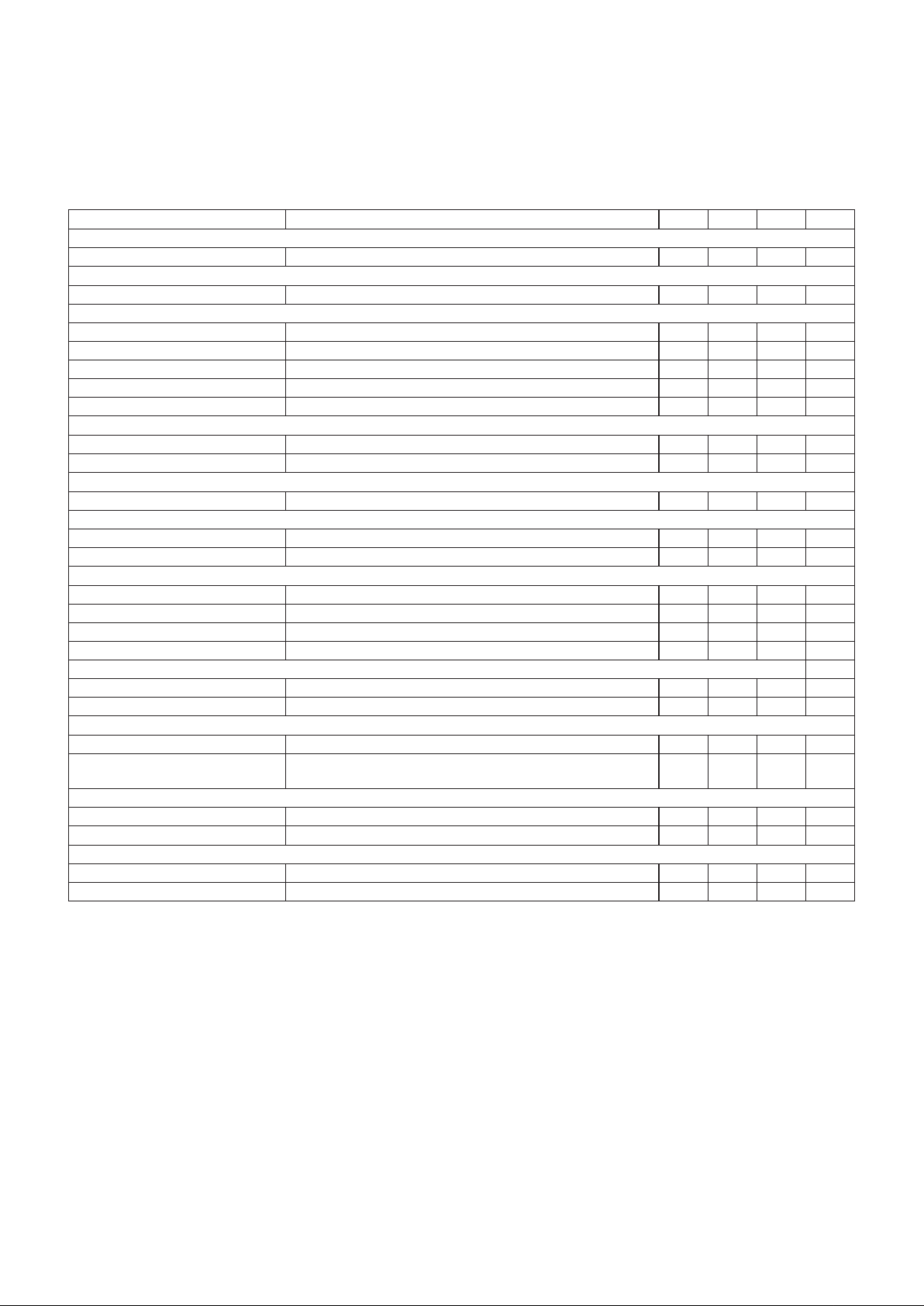

ELECTRICAL CHARACTERISTICS: Unless otherwise specified, TA = –40°C to +85 for UCC2956 and 0°C to +70°C for

UCC3956, COSC = 500pF, RSET = 70k, CTO = 169nF, VDD = 12V, TA =TJ.

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

PWM Oscillator (OSC)

Frequency 7V < V

DD < 18V 90 100 110 kHz

Over Charge Timer (OCT)

Frequency 7V < V

DD < 18V (Note 1) 4.65 5 5.35 Hz

Reference

Initial Accuracy T

J = 25°C 4.06 4.1 4.14 V

Accuracy 0 < T

J < 70°C, VDD = 8V to 18V 4.05 4.1 4.15 V

Load Regulation 0 < I

O < 2mA 3 15 mV

Accuracy –40°C < T

J < 85°C, VDD = 8V to 18V 4.03 4.1 4.17 V

Short Circuit I REF = 0V 8 20 30 mA

Charge Enable Comparator (CEC)

Threshold Voltage 1.9 2.05 2.15 V

Input Bias Current –0.5 –0.2 µA

Voltage Sense Comparator (VSC)

Threshold Voltage Volts below VA+ 50 125 200 mV

Charge Current Comparator (CIC)

Threshold Voltage CS+ = CS– = 0, Function of IBAT = 2.05V 2 2.05 2.1 V/V

Input Bias Current Total Bias Current; Regulating Level –0.5 –0.2 µA

Output Stage

V

OL IO = 10mA 0.1 0.3 V

V

OH, Volts Below VDD IO = –10mA 0.1 0.5 V

Rise Time COUT = 1nF 30 70 ns

Fall Time C

OUT = 1nF 30 70 ns

STAT0 and STAT1 Open Drain Outputs

Maximum Sink Current V

OUT = 12V 15 30 mA

V

OL IOUT = 1mA 0.1 0.2 V

Charge Control (CHG)

Threshold Voltage 1.5 1.8 2.1 V

Charge Pin Pull Down

Resistance

3.0 5.0 kΩ

UVLO Section

Turn-on Threshold 6.0 6.5 6.75 V

Hysteresis 100 150 400 mV

IDD

IDD (Run) 58mA

IDD (UVLO) V

DD = 5V 0.25 0.75 mA

PIN DESCRIPTIONS

CA–: The inverting input to the current error amplifier.

CAO: The output of the current error amplifier and invert-

ing input of the PWM comparator. This pin is driven high

during shutdown.

CS–, CS+: The inverting and non-inverting inputs to the

current sense amplifier. This amplifier has a fixed gain of

5.

CHG: A rising edge triggered input pin that indicates

charging. Once the internal 14 bit timer has timed out the

chip enters its shutdown charge state. At this point CHG

is pulled low by an internal buffer. Another low to high

transition is required to reset the timer and restart charging.

CHGENB: The input to a comparator that detects when

the battery voltage is low and places the charger in

trickle charge. The charge enable comparator forces the

output of the voltage error amplifier to a high impedance

state while forcing a fixed 10µA current into the CA– to

set the trickle charge.

COSC: The oscillator ramp pin which has a capacitor

(COSC) to ground. The ramp oscillates between 0.8V to

3.2V and the frequency is determined by:

4

UCC2956

UCC3956

Frequency =

3.475

(COSC+ 20pF) RSET

A rising edge on CHG initiates the oscillator.

CTO: The slow oscillator ramp pin which is used to gen-

erate a clock signal for the 14 bit timer to program the

over charge time. A capacitor to ground is charged and

discharged with equal currents at a frequency programmed between 0.75Hz to 5Hz. The ramp oscillates

between 1.0V to 3.0V and the frequency is determined

by:

Frequency =

0.06

CTO RSET

The oscillator operates only while in overcharge.

GND: The reference point for the internal reference, all

thresholds, and the return for the remainder of the device.

IBAT: The output of the current sense amplifier.

IMIN: The minimum charge current programming pin is

provided to program an optional charge termination in

addition to the programmable timer.

OUT:The output of the PWM driver.

REF: The 4.1V precision reference which should be by-

passed with a 0.1µF capacitor.

RSET: This pin programs the charge current for the oscillator ramp. The oscillator charge current is determined

by:

1.37V

RSET

.

The trickle control current (Itrck_control) is determined

by:

0.68V

RSET

.

STAT0, STAT1: CMOS open drain binary output decode

pins indicating the four different charge states. The maximum high voltage sense comparator.

VA–: The inverting input to the voltage error amplifier that

is used as a battery sense input. It is also the input to the

voltage sense comparator. The bulk charge state is completed and over charge state is initiated when VA–

reaches 95% of VA+.

VA+: The non-inverting input to the voltage error amplifier that is used as the battery charge reference voltage.

VAO: The output of the voltage error amplifier. The upper

output clamp of this amplifier is 4.1V.

VDD: The input voltage of the chip. This chip is operational between 6V and 18V and should be bypassed with

a 0.1µF capacitor.

PIN DESCRIPTIONS (cont.)

STAT1 STAT0

Trickle Charge 0 0 CHGENB < 2.05V

Bulk Charge 0 1 VA– < 95% VA+ and CHGENB > 2.05V

Over Charge 1 0 VA– > 95% VA+ and VIBAT<VIMIN

Over Charge (Top Off) 1 1 VIBAT >VIMIN

CHARGE STATE DECODE CHART

APPLICATION INFORMATION

The UCC3956 contains all the necessary control functions for implementing an efficient switch mode LithiumIon battery charger. Lithium-Ion batteries are rapidly becoming the battery of choice for rechargeable portable

and lap top products. When compared to NiCd, NiMH,

and Lead Acid batteries, Lithium-Ion offer less weight

and volume for the same energy.Lithium-Ion batteries do

not suffer from the memory effect found in NiCd batteries.

This effect, caused by not completely discharging and

charging a battery, will reduce battery capacity over several charge cycles. Because Lithium-Ion batteries have a

high average cell voltage of around 3.6V, they can often

replace 2 to 3 Nickel based cells.

The advantages that Lithium-Ion batteries offer come at

the cost of a wide operating voltage. Near zero capacity,

the cell will typically have a voltage of 2.5V. A fully

charged cell will typically have a voltage of 4.1V. Unlike

many so called “smart” or “universal” chargers, the

UCC3956 is optimized for Lithium-Ion characteristics. In

order to restore capacity quickly, the chip features both

constant current and constant voltage modes of operation. A programmable over charge time, provided by the

UCC3956 timer, allows the charger to predictably restore

100% capacity to the battery.

Charger Operation

When CHG is transitioned from a low to high logic level,

the chip will cycle through several charge states. If the

battery voltage is severely depleted, the charger will begin in a low current trickle charge state. When the bat-

5

UCC2956

UCC3956

APPLICATION INFORMATION (cont.)

tery voltage is above a user set threshold, the charger

will initiate a constant current bulk charge state. Once the

battery reaches 95% of it’s final voltage, the charger will

enter an over charge state. During the over charge state,

the converter will transition from a constant current to a

constant voltage mode of operation. Figure 2 shows typical current, voltage, and capacity levels of a Lithium-Ion

battery during a complete charge cycle.

A Block Diagram of the UCC3956 is shown on the first

page of the data sheet, while Figure 1 shows a typical

application circuit for a Buck derived switch mode

charger.The UCC3956 can be used for charging a single

cell or multiple cells in series. If more than two cells are

stacked in series, however, a level shifting gate drive will

be needed to operate the buck switch. The application

circuit charges a 1200mAh 2 cell stack at a 1C rate.

Setting the Oscillator Frequency

The frequency of operation for the converter is set by

picking values for RSET and COSC.

fOSC =

3.475

(COSC+ 20pF) RSET

The UCC3956 is capable of operating at frequencies

higher than 200kHz. However, the actual operating frequency of the buck converter will ultimately be determined by the usual tradeoffs of size, cost and efficiency.

The application circuit frequency is set at 100kHz with

COSC = 180pF and RSET = 162k.

Trickle Charge State

When the battery’s voltage is below a predetermined

threshold, the battery is either deeply discharged or has

shorted cells. The trickle charge state offers a low charging current to bring the battery up above zero capacity.In

the case of shorted cells, the trickle charge state prevents the charger from delivering high currents during

this fault condition. Stacking several cells makes the detection of a shorted cell more difficult.

For Lithium-Ion batteries, the trickle charge threshold is

typically set to a value around 2.5V per cell (this corresponds to near zero capacity). When the cell voltage is

below the threshold, only a trickle current will be applied

to the battery. The threshold is established by programming CHGENB to 2.05V when the battery (or stack) voltage is at the threshold.Referring to the application circuit

Figure 1. Typical Application Circuit

UDG-96198-1

IBULK = 1.2A

ITRICKLE =90mA

f

OSC = 100kHz

Timeout = 120 minutes

6

UCC2956

UCC3956

APPLICATION INFORMATION (cont.)

of Figure 1, the trickle charge voltage threshold is determined by:

VTRICKLE_ THRESHOLD =

RS1+ RS2+ RS3

RS3

2.05

With a trickle threshold of 5V (for 2 cells) and setting RS3

to 10k, RS1+ RS2 should be approximately 14.4k.

The applications circuit trickle charge current is set to

about 7.5% of the bulk charge current. The current value

is set by picking the appropriate value for RG1. Referring

to the Block Diagram and Figure 1, during trickle charge

a fixed current

0.68

RSET

flows out of the current amplifier’s inverting input and into

RG1. The voltage amplifier output is disabled during

trickle charge and acts as a high impedance node. The

resulting voltage at the output of the current sense am-

plifier sets the trickle charge current.

ITRICKLE =

RG1

7.5 RSET RSENSE

In the application circuit the sense resistor is 0.18Ω and

R

SET is 162k, for a trickle current of about 90mA a 20k

resistor is selected for RG1.

The converter is typically designed to run in discontinu-

ous conduction mode during trickle charge. This allows a

reasonably small value of inductance to be used. The average current mode of the UCC3956 provides improved

discontinuous duty cycle control, when compared to peak

current mode implementations.

In Figure 2, the trickle charge state corresponds to the

time interval between t0 (when CHG is transitioned from

low to high) and t1.During the trickle charge state STAT0

and STAT1 are logic level lows. At time t1 the trickle

threshold is met, and the charger transitions to the bulk

charge state. In many instances, the battery voltage will

initially be above the trickle threshold. In this case, the

trickle charge state will not be needed.

Bulk Charge State

As the name implies, the bulk charge state is responsible

for restoring a majority of the charge back into the battery. The bulk charge current is determined by the C

rate and the capacity of the battery. In the application circuit, 2 stacked 1200mAH batteries are charged at a 1C

rate. This will require 1.2A of current during bulk

charge. In this case, a fully discharged battery will take

about 60 minutes to reach approximately 80% capacity.

Battery packs with a high ESR will typically have a

shorter bulk period, due to the voltage drop generated by

the bulk current and the ESR of the battery.

Both the voltage and current sense amplifiers are enabled during bulk charge. The voltage amplifier is saturated in this state as the battery voltage is slowly rising,

but is not yet high enough to drive the voltage amplifier

into regulation. The output of voltage amplifier is clamped

at a nominal voltage of 4.1V. The current sense amplifier

is configured such that its output voltage increases with

decreasing R

SENSE current. RSENSE should be sized

such that the output voltage of the current sense amplifier V

IBAT is within specification during bulk charge.

VIBAT(BULK) = 2.05 - 5 IBULK RSENSE

With 1.2A of bulk current and setting the current sense

amplifier output at 1V, a sense resistor of 0.18Ω is required. As always, power dissipation and converter efficiency must be considered when choosing R

SENSE.

Referring to the Feedback Diagram of Figure 3, the output of the voltage and current sense amplifiers are

summed together at the inverting input of the current amplifier. Assuming that the current amplifier is within regulation, the required value of RG2 can be calculated. The

application circuit uses a value of 38.3k for RG2, setting

the bulk current to 1.2A.

RG2 =

2.05 RG1

5 IBULK RSENSE

Referring to Figure 2, the bulk charge state corresponds

Figure 2. Typical Charge Cycle Levels

UDG-96262-1

7

UCC2956

UCC3956

APPLICATION INFORMATION (cont.)

to the interval between t1 and t2. The step in voltage at

time t1 is caused by bulk current flowing into the battery

ESR and sense resistor. In the bulk charge state STAT0

is a logic level high and STAT1 is a logic level low.

Over Charge State

The over charge state of the converter starts when the

battery reaches 95% of its final voltage (time t2 of Figure

2). The over charge state is initiated when the voltage at

the inverting input of the voltage amplifier is 95% of the

non-inverting input voltage.Using 95% rather than 100%

of the final battery voltage assures that the over charge

timer will always be set, before the battery current tapers

off. At the beginning of over charge STAT0 indicates a

logic level low and STAT1 indicates a logic level high.

In the application circuit of Figure 1, the voltage at which

over charge is initiated is set by resistors RS1, RS2 and

RS3. These resistors are also used to set the trickle

charge threshold. A 0.1µF decoupling capacitor is added

to this node as a filter. The battery (or stack) voltage that

will initiate the over charge state is:

VOC_ THRESHOLD = 0.95

RS1+ RS2+ RS3

RS2+ RS3

4.1

For a single cell stack, RS1 should be 0Ω. This results in

a final battery voltage of 4.1V. It is important not to

charge a Lithium-Ion battery above 4.2V. When charging

a battery stack, RS1 should be selected to properly set

the final stack voltage. In the application circuit, RS1 is

selected to be 12.21k and RS2 is selected to be 2.21k.

This sets the over charge level at 8.2V, while setting the

trickle charge threshold to about 5V.

The battery voltage at the beginning of the over charge

state may not correspond to the voltage amplifier coming

out of saturation. Therefore, bulk current may continue in

the battery during the initial portion of the over charge

state (see Figure 2). When the voltage amplifier comes

into regulation, the amplifier’s output voltage will begin to

decrease. The current sense amplifier’s output voltage

will need to increase, in order for the current amplifier’s

inverting input to remain at 2.05V. This will translate into

a decreasing battery current. The battery current will continue to decrease as the battery approaches 100% capacity.

Although the bulk charge state restores a majority of the

capacity to the battery, the over charge state will typically

take a majority of the charge cycle time. The bulk charge

state will usually take 1/3 of the total charge time, while

the over charge state will take the remaining 2/3. Different methods are used to terminate the charge of

Lithium-Ion batteries. Many chargers use a current

threshold to terminate charge. While this method is simple to implement, the current tail near the end of charge

is often quite flat (see Figure 2). To make matters worse,

the current level versus battery capacity may differ from

cell to cell. This makes it difficult to accurately terminate

at 100% capacity. In order to avoid the possibility of over

charging the battery, the design may require termination

at a higher current level (before 100% capacity is

reached). A more predictable method of charge termination is to use a fixed over charge time.

The UCC3956 provides both a current level detection as

well as a timer. In a typical design, the current level detection is used to give an indication of near full charge. In

Figure 2 this occurs at time t4. This indication is useful

since the time to charge from t4 to t5 may be quite long.

Since Lithium-Ion batteries have no memory effect, there

is little reason to have the user wait for the battery to be

Figure 3. Simplified Feedback Diagram

UDG-96263-1

8

UCC2956

UCC3956

APPLICATION INFORMATION (cont.)

100% charged. If the battery is not taken from the

charger at time t4, the charger will continue charging.

The timer will expire and the charge cycle will terminate

at time t5.

A typical value of current used to indicate near full

charge is 1/10 of the bulk current value. This current level

is established by setting the appropriate voltage on IMIN.

IMIN is tied to an internal comparator along with the output of the current sense amplifier. When the current

sense amplifier voltage becomes greater than the voltage

on IMIN, the internal state machine indicates near full

charge by setting STAT0 and STAT1 to logic level

highs. In the application circuit of Figure 1, resistors RS4

and RS5 determine the voltage at IMIN. With RS4 at 11k

and RS5 at 10k, near full charge is indicated at 120mA.

VIMIN = 4.1

RS5

RS4+ RS5

INEAR_FULL =

2.05 - VIMIN

5 RSENSE

The UCC3956 timer has a 14 bit counter that allows long

over-charge times with reasonable component values.

As stated above, the charger will continue charging the

battery until the timer expires (unless the battery is pulled

from the charger). Referring to Figure 2, the timer starts

at time t2 and expires at time t5. The frequency of the

timer can be determined as follows:

fTIMER =

0.06

RSET CTO

With a 14 bit counter the time-out period in minutes becomes:

TIMEOUT = 4550 CTO RSET

In the application circuit, a value of 0.15µF is used for

CTO to give 120 minutes of overcharge (more than twice

the bulk charge time). When the timer expires, CHG is

pulled low by an internal buffer and the charge cycle terminates. If tied to a bi-directional port, CHG can be read

by a microprocessor.

Inductor Sizing

For good efficiency, the inductor should be sized to give

continuous current in the bulk charge state. For a buck

converter, duty cycle in continuous mode is given by:

D=

VBATTERY+ VSCHOTTKY

VINPUT+ VSCHOTTKY

Allowing a 25% ripple in the bulk current will give a reasonable value of inductance. The inductor value can be

calculated as follows:

L=

4 (VINPUT - VBAT) D

IBULK fOSC

A 150µH inductor is used in the application circuit.

Current Control Loop

The UCC3956 features an outer voltage loop and an inner average current loop. The virtues of average current

mode control are well documented in Reference [1]. A

simplified block diagram of the feedback elements is provided in Figure 3. The network for the current amplifier

could be as simple as a single capacitor, providing a

dominant pole response, which may be adequate for a

battery charger application. The current amplifier network

of Figure 3 provides improved transient performance.

The component values for CF3, CF4, and RF4 will be selected to give a constant gain from approximately

f

OSC/10 to fOSC. At frequencies below fOSC/10, the net-

work gain will increase at 20dB/decade, giving a high DC

gain. The network will attenuate at 20dB/decade above

the switching frequency, giving noise immunity.

A feedback design that optimizes transient response will

have the amplified inductor current down-slope approach

the PWM saw-tooth slope [1]. This occurs by designing

the total loop gain to cross unity at 1/3 to 1/6 of the

switching frequency. The applications circuit is designed

to cross unity gain at 1/10 of the switching frequency

(10kHz), with a 12V nominal input. The power stage

small signal gain can be approximated by:

GPOWER_STAGE =

VIN RSENSE

SL + RSENSE+ ESR

Referring to Figure 3, the current sense amplifier pro-

-60

-40

-20

0

20

40

60

80

10 100 1000 10000 100000 1000000

FREQUENCY

GAIN (dB

)

POWER

STAGE

FEEDBACK

GAIN

Figure 4a. Current Loop Power Stage

and Feedback Gain

9

UCC2956

UCC3956

APPLICATION INFORMATION (cont.)

vides a gain of 5, an inverting stage adds a gain of 1.5,

and the modulator has a gain of 0.64; adding a fixed gain

of 4.8 to the power stage. The current amplifier’s gain between f

OSC/10 and fOSC is equal to RF4 divided by the

parallel combination of RG1 and RG2 times the resistive

divider RG2/(RG1+RG2), simplifying to:

GCA =

RF4

RG1

RF4 is selected to be 15k, resulting in a 10kHz crossover

frequency. Once RF4 is determined, CF3 and CF4 can

be selected to give corner frequencies at f

OSC/10 and

fOSC respectively.

CF3 =

1

2 fOSC RF4

π

CF4 =

10

2 fOSC RF4

π

In the applications circuit, a value of 100pF is used for

CF3 and 1.0nF is used for CF4. Figure 4a shows the

power stage gain and feedback network gain for the current loop. Figure 4b shows the total open loop gain and

phase.

Adding the Voltage Control Loop

The voltage loop comes into regulation during the over-

charge period of operation. The output of the voltage am-

plifier begins to decrease, demanding less current to the

battery. With the current loop closed, the power stage

gain of the voltage loop is equal to 1/(5*R

SENSE) out to

the crossover frequency (10kHz). In order to avoid interactions with the current loop, the voltage loop will cross

unity at 2kHz. The voltage loop is attenuated by the divider RG1/(RG1+RG2). A single pole network is added

to the voltage amplifier, giving a high gain at DC. Referring to Figure 3, the voltage amplifier gain is equal to the

impedance of CF1 divided by RS1. A 2.2nF capacitor will

give a total crossover frequency near 2kHz. Figure 5a

shows the gain of the power and feedback stages for the

voltage loop.Figure 5b shows the total gain and phase of

the voltage loop.

-60

-40

-20

0

20

40

60

80

10 100 1000 10000 100000 1000000

FREQUENCY

GAIN (dB

)

POWER STAGE

GAIN

FEEDBACK

GAIN

Figure 5a. Voltage Loop Power Stage Gain

-150

-100

-50

0

50

100

10 100 1000 10000 100000 1000000

FREQUENCY

GAIN (dB) OR PHASE (degrees

)

TOTAL LOOP GAIN

TOTAL PHASE

Figure 5b. Voltage Loop Total Gain and Phase

-80

-60

-40

-20

0

20

40

60

80

100

120

10 100 1000 10000 100000 1000000

FREQUENCY

GAIN (dB) OR PHASE (degrees)

TOTAL LOOP GAIN

TOTAL PHASE

Figure 4b. Current Loop Total Gain and Phase

UNITRODE CORPORATION

7 CONTINENTAL BLVD.• MERRIMACK, NH 03054

TEL. (603) 424-2410 • FAX(603) 424-3460

IMPORTANT NOTICE

T exas Instruments and its subsidiaries (TI) reserve the right to make changes to their products or to discontinue

any product or service without notice, and advise customers to obtain the latest version of relevant information

to verify, before placing orders, that information being relied on is current and complete. All products are sold

subject to the terms and conditions of sale supplied at the time of order acknowledgement, including those

pertaining to warranty, patent infringement, and limitation of liability.

TI warrants performance of its semiconductor products to the specifications applicable at the time of sale in

accordance with TI’s standard warranty. Testing and other quality control techniques are utilized to the extent

TI deems necessary to support this warranty. Specific testing of all parameters of each device is not necessarily

performed, except those mandated by government requirements.

CERT AIN APPLICATIONS USING SEMICONDUCTOR PRODUCTS MAY INVOLVE POTENTIAL RISKS OF

DEATH, PERSONAL INJURY, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE (“CRITICAL

APPLICATIONS”). TI SEMICONDUCTOR PRODUCTS ARE NOT DESIGNED, AUTHORIZED, OR

WARRANTED TO BE SUITABLE FOR USE IN LIFE-SUPPORT DEVICES OR SYSTEMS OR OTHER

CRITICAL APPLICATIONS. INCLUSION OF TI PRODUCTS IN SUCH APPLICA TIONS IS UNDERSTOOD T O

BE FULLY AT THE CUSTOMER’S RISK.

In order to minimize risks associated with the customer’s applications, adequate design and operating

safeguards must be provided by the customer to minimize inherent or procedural hazards.

TI assumes no liability for applications assistance or customer product design. TI does not warrant or represent

that any license, either express or implied, is granted under any patent right, copyright, mask work right, or other

intellectual property right of TI covering or relating to any combination, machine, or process in which such

semiconductor products or services might be or are used. TI’s publication of information regarding any third

party’s products or services does not constitute TI’s approval, warranty or endorsement thereof.

Copyright 1999, Texas Instruments Incorporated

Loading...

Loading...