Datasheet UCC3941D-ADJ, UCC3941D-5, UCC3941D-3, UCC3941N-ADJ, UCC3941N-5 Datasheet (Texas Instruments)

...

UCC2941-3/-5/-ADJ

UCC3941-3/-5/-ADJ

SLUS242 - JULY 1999

FEATURES

•

1V Input Voltage Operation Startup

Guaranteed Under Full Load on Main

Output With Operation Down to 0.4V

•

Input Voltage Range of 1V to V

OUT

+

0.5V

•

500mW Output Power at Battery

Voltages as Low as 0.8V

•

Secondary 9V Supply From a Single

Inductor

•

Adjustable Output Power Limit Control

•

Output Fully Disconnected in

Shutdown

•

Adaptive Current Mode Control for

Optimum Efficiency

• 8µA Shutdown Supply Current

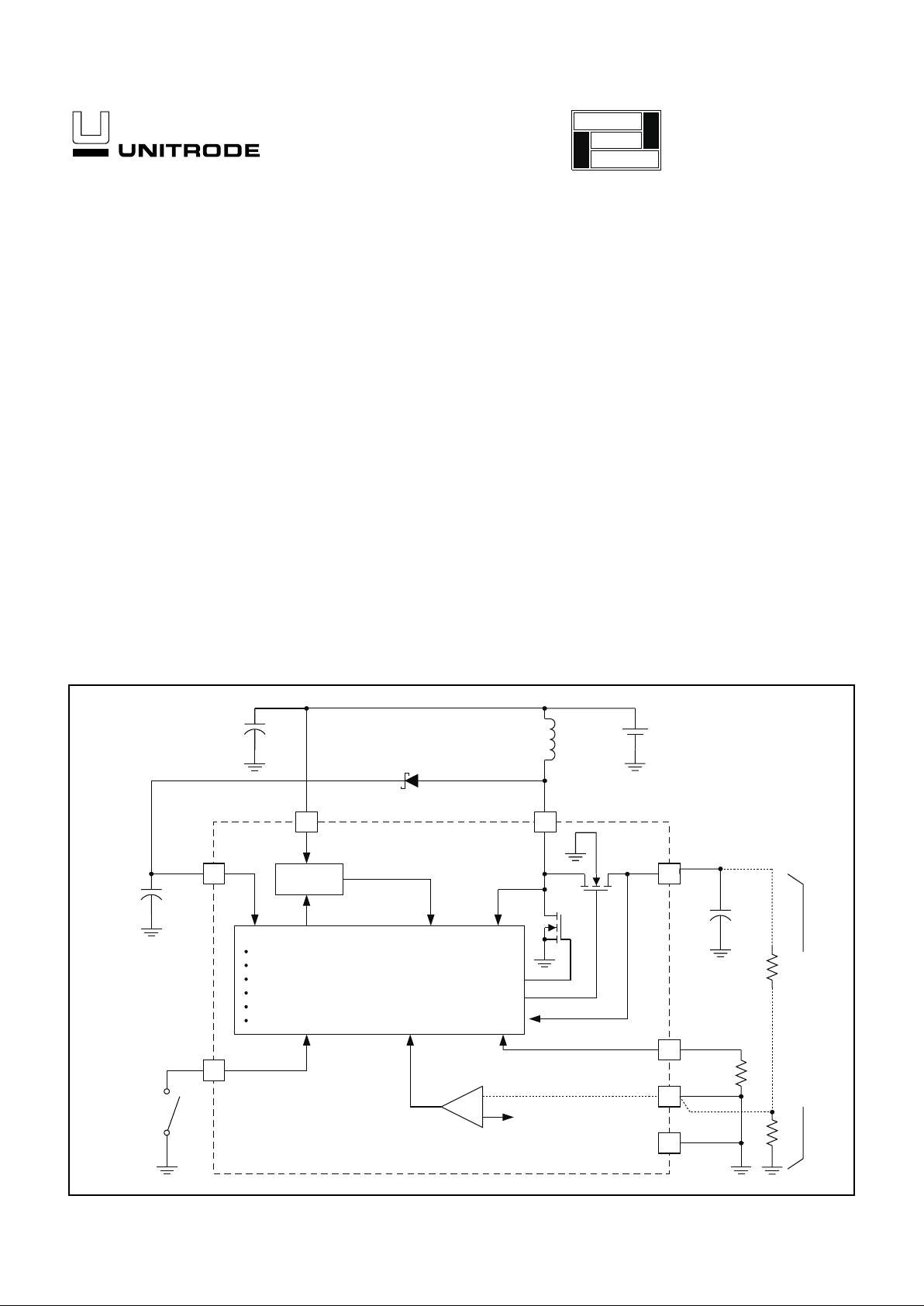

1V Synchronous Boost Converter

MODULATOR CONTROL CIRCUIT

SYNCHRONOUS RECTIFICATION CIRCUITRY

ANTI-CROSS CONDUCTION

STARTUP

MULTIPLEXING LOGIC

MAXIMUM INPUT POWER CONTROL

ADAPTIVE CURRENT CONTROL

4

5

6

7

1

8

3

2

+

–

1.25V

UCC3941-ADJ

OPEN=SD

SD

10µF

VGD

8V

STARTUP

CIRCUITRY

VIN SW

+

10µF

22µH

0.8V TO VOUT +0.5V

100µF

0.4Ω

VOUT

PGND

*SGND/FB

PLIM

0.25Ω

UCC3941-3 = 3.3V

UCC3941-5 = 5.0V

UCC3941-ADJ = 1.30V TO 6V

*FOR UCC3941-ADJ ONLY:

PIN 7 = SGND & PGND, PIN 6 = OUTPUT SENSE FEEDBACK,FB.

FOR UCC3941-ADJ ONLY

SIMPLIFIED BLOCK DIAGRAM AND APPLICATION CIRCUIT

UDG-98147

DESCRIPTION

The UCC3941 family of low input voltage single inductor boost converters

are optimized to operate from a single or dual alkaline cell, and step up to

a 3.3V, 5V, or an adjustable output at 500mW. The UCC3941 family also

provides an auxiliary 9V 100mW output, primarily for the gate drive supply,

which can be used for applications requiring an auxiliary output such as a

5V supply by linear regulating. The primary output will start up under full

load at input voltages typically as low as 0.8V, with a guaranteed maximum

of 1V, and will operate down to 0.4V once the converter is operating, maxi

-

mizing battery utilization.

Demanding applications such as Pagers and PDA’s require high efficiency

from several milli-watts to several hundred milli-watts, and the UCC3941

family accommodates these applications with >80% typical efficiencies

over the wide range of operation. The high efficiency at low output current

is achieved by optimizing switching and conduction losses along with low

quiescent current. At higher output current the 0.25Ωswitch, and 0.4Ω syn

-

chronous rectifier, along with continuous mode conduction, provide high ef

ficiency. The wide input voltage range on the UCC3941 family can

accommodate other power sources such as NiCd and NiMH.

Other features include maximum power control and shutdown control.

Packages available are the 8-pin SOIC (D) and 8-pin DIP (N or J).

application

INFO

available

2

UCC2941-3/-5/-ADJ

UCC3941-3/-5/-ADJ

ELECTRICAL CHARACTERISTICS: Unless otherwise specified, for UCC3941, T

A

= 0°C to 70°C; for UCC2941, TA= –40°C

to 85°C; VIN = 1.25V, T

A=TJ

.

PARAMETER TEST CONDITIONS MIN TYP MAX UNITS

VIN Section

Minimum Startup Voltage No External VGD Load, T

J

= 25°C, IOUT = 100mA (Note 1) 0.8 1.0 V

Minimum Start Voltage No External VGD Load, I

OUT

= 100mA, TJ= 0°C to 85° C

(Note 1)

0.9 1.1 V

Minimum Startup Voltage No External VGD Load, T

J

= –40°C to 0°C 0.9 1.5 V

Minimum Dropout Voltage No External VGD Load, I

OUT

= 100mA, VGD = 6.3V

(Note 1)

0.5 V

Input Voltage Range 1 VOUT

+0.5

V

Quiescent Supply Current (Note 2) 13 25 µA

Supply Current at Shutdown SD = Open 8 20 µA

Output Section

Quiescent Supply Current (Note 2) 32 80 µA

Supply Current at Shutdown SD = Open 6 15 µA

Regulation Voltage (UCC3941-3) 1V < VIN < 3V 3.18 3.25 3.37 V

1V < VIN < 3V, 0mA < I

OUT

< 150mA (Note 1) 3.17 3.30 3.43 V

Regulation Voltage (UCC3941-5) 1V < VIN < 5V 4.85 5.00 5.15 V

1V < VIN < 5V, 0mA < I

OUT

100mA (Note 1) 4.8 5.0 5.2 V

FB Voltage (UCC3941-ADJ) 1V < VIN < 3V 1.212 1.250 1.288 V

VGD Output Section

Quiescent Supply Current (Note 2) 25 60 µA

Supply Current at Shutdown SD = Open 8 20 µA

Regulation Voltage 1V < VIN < 3V 7.5 8.7 9.2 V

1V < VIN < 3V, 0mA < I

OUT

< 10mA (Note 1) 7.4 8.7 9.3 V

Inductor Charging Section (L = 22µH)

Peak Discontinuous Current Over Operating Range 0.50 0.85 A

Peak Continuous Current R

PLIM

= 6.2Ω, UCC3941-3 and UCC3941-5 0.5 0.8 1.1 A

UCC3941-ADJ 0.6 0.9 1.3 A

ABSOLUTE MAXIMUM RATINGS

VIN Voltage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . –0.3V to 10V

SD Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . –0.3V to VIN

PLIM Voltage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . –0.3V to 10V

VGD Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . –0.3V to 15V

SW Voltage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . –0.3V to 15V

VOUT Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . –0.3V to 10V

Storage Temperature . . . . . . . . . . . . . . . . . . . –65°C to +150°C

Junction Temperature. . . . . . . . . . . . . . . . . . . –55°C to +150°C

Lead Temperature (Soldering, 10 sec.). . . . . . . . . . . . . +300°C

Currents are positive into, negative out of the specified terminal.

Consult Packaging Section of Databook for thermal limitations

and considerations of packages.

Pin 6 is FB for UCC3941-ADJ.

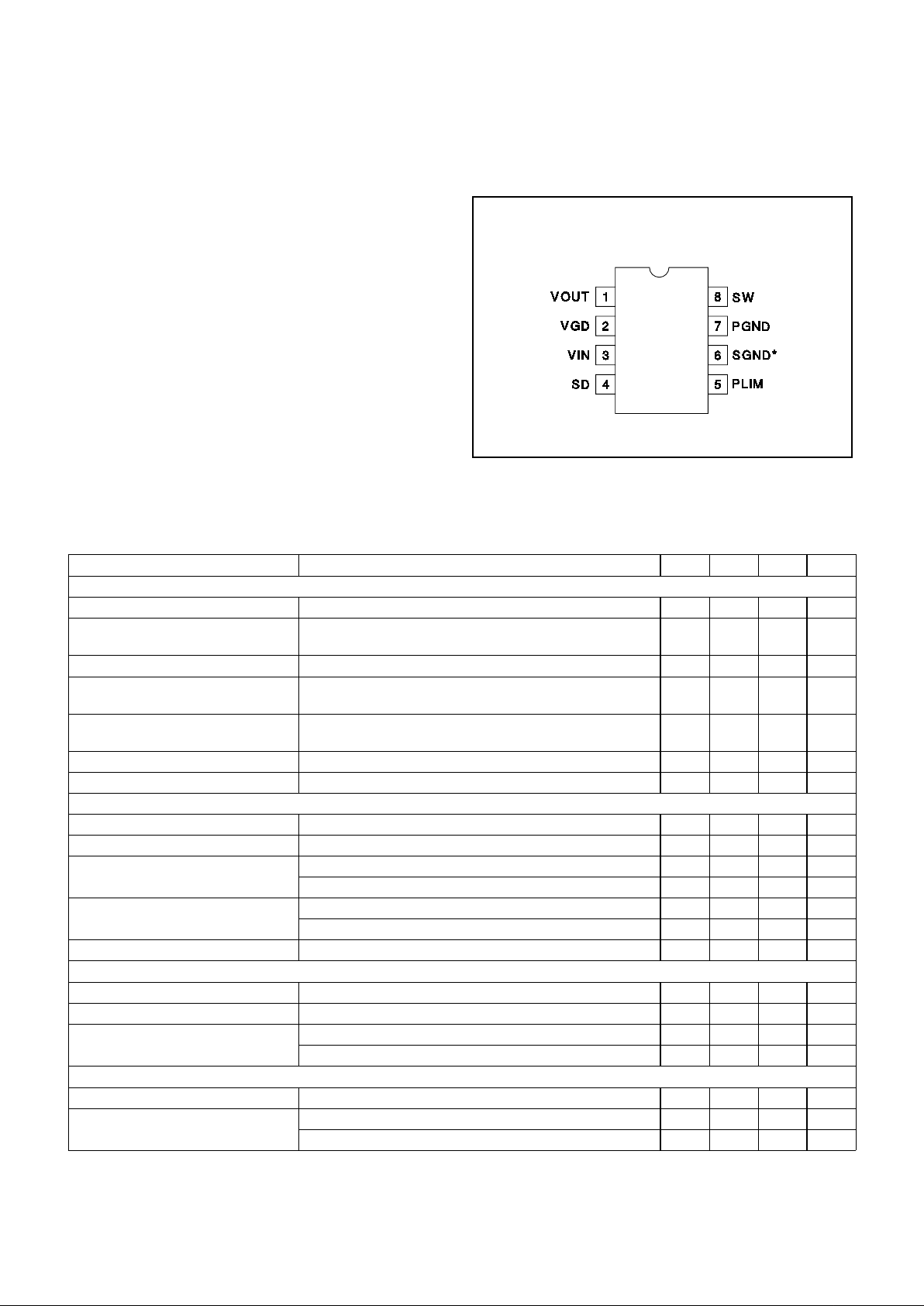

CONNECTION DIAGRAM

DIL-8, SOIC-8 (Top View)

N or J Package, D Package

3

UCC2941-3/-5/-ADJ

UCC3941-3/-5/-ADJ

ELECTRICAL CHARACTERISTICS: Unless otherwise specified, for UCC3941, T

A

= 0°C to 70°C; for UCC2941, TA= –40°C

to 85°C; VIN = 1.25V, T

A=TJ

.

PARAMETER TEST CONDITIONS MIN TYP MAX UNITS

Inductor Charging Section

Charge Switch R

DS(on)

N and D Package, I = 200mA 0.25 0.4 Ω

Current Limit Delay (Note 1) 50 ns

Synchronous Rectifier Section

Rectifier R

DS(on)

N and D Package, I = 200mA, UCC3941-ADJ V

OUT

= 3.3V

and UCC3941–3

0.35 0.6 Ω

N and D Package, I = 200mA, UCC3941-5 0.5 0.8 Ω

Shutdown Section

Shutdown Bias Current –10 –7 µA

Note 1: Performance from application circuit shown in Figures 3 - 5 guaranteed by design and alternate testing methods, but not

100% tested as shown in production.

Note 2: For the UCC3941-3, VOUT = 3.47V and VGD = 9.3V.For the UCC3941-5, VOUT = 5.25V, VGD = 9.3V.For the UCC3941-

ADJ, FB = 1.315V, VGD = 9.3V.

PIN DESCRIPTIONS

FB: Feedback control pin used in the UCC3941-ADJ

version only. The internal reference for this comparator is

1.25V and external resistors provide the gain to the

output voltage.

PGND: Power ground of the IC. The inductor charging

current flows through this pin. For the UCC3941-ADJ

signal ground and power ground lines are tied to a

common pin.

PLIM: This pin is programmed to set the maximum input

power for the converter. For example a 1A current limit at

1V would have a 333mA limit at 3V input keeping the

input power constant at 1W. The peak current at VIN =

1V is programmed to 1.5A (1.5W) when this pin is

grounded.The power limit is given by:

PL

n

R

V

W

PL

IN

()

.

.

(. )=

•

+

+

11 8

67

026

where R

PL

is equal to the external resistor from the PLIM

pin to ground and

n

is the expected efficiency of the

converter.The peak current limit is given by:

()

I

n

VR

PK

A

IN PL

()

.

.

.=

•

•+

+

11 8

67

026

Constant power gives several advantages over constant

current such as lower output ripple.

SD: When this pin is open, the built in 7µA current source

pulls up on the pin and programs the IC to go into

shutdown mode. This pin requires an open circuit for

shutdown and will not operate correctly when driven to a

logic level high with TTL or CMOS logic. When this pin is

connected to ground, (either directly or with a transistor)

the IC is enabled and both output voltages will regulate.

SGND: Signal ground of the IC. For the UCC3941-ADJ

signal ground and power ground lines are tied to a

common pin.

SW: An inductor is connected between this node and

VIN. The VGD (Gate Drive Supply) flyback diode is also

connected to this pin. When servicing the 3.3V supply,

this pin will go low charging the inductor, then shut off,

dumping the energy through the synchronous rectifier to

the output. When servicing the VGD supply, the internal

synchronous rectifier stays off, and the energy is diverted

to VGD through the flyback diode. During discontinuous

portions of the inductor current a MOSFET resistively

connects VIN to SW damping excess circulating energy

to eliminate undesired high frequency ringing.

VGD: The VGD pin which is coarsely regulated around

9V and is primarily used for the gate drive supply for the

power switches in the IC. This pin can be loaded with up

to 10mA as long as it does not present a load at voltages

below 2V. This ensures proper startup of the IC. The

VGD supply can go as low as 7.5V without interfering

with the servicing of the 3.3V output. Below 7.5V, VGD

will have the highest priority, although practically the

voltage should not decay to that level if the output

capacitor is sized properly.

VIN: Input voltage to supply the IC during startup. After

the output is running the IC draws power from VOUT or

VGD.

VOUT: Main output voltage (3.3V, 5V or adjustable)

which has highest priority in the multiplexing scheme, as

long as VGD is above the critical level of 7.5V. Loads

over 150mA are achievable at 1V input voltage. This

output will startup with 1V input at full load.

4

UCC2941-3/-5/-ADJ

UCC3941-3/-5/-ADJ

4

5

2

3 8

1

6

6

7

SD

PLIM

VGD

VIN

SW

VOUT

FB FOR

UCC3941-ADJ

ONLY

PGND

SGND FOR

UCC3941-3/-5

5Ω

+

–

+

–

+

–

VGD

+

–

+

–

+

–

+

–

* 3.3VFOR UCC3941-3

5.0V FORUCC3941-5

1.25V FORUCC3941-ADJ

VGD

** 8.7VFOR UCC3941-3

9.6V FORUCC3941-5/-ADJ

VGD

*** 7.7VFOR UCC3941-3

8.8V FORUCC3941-5/-ADJ

FROM

SD

5V

1.4A

MAX

CURRENT

LIMIT

50mV

VIN

VIN

SD

50mV

MAXIMUM

200kHz

STARTUP

OSCILATOR

AND CONTROL

VGD

VGD

VGD ZERO

DETECT

VOUT ZERO

DETECT

ANTI-RINGING

SWITCH

1.7µS

OFF TIME

CONTROLLER

RECTIFIER

CONTROL

FROM SD

CLK

DQ

L1

RQ

SD

BOOST

LATCH

ON TIME

CONTROLLER

T

ON

=

11µSEC

VIN

VSAT

*

**

***

THERMAL

SHUTDOWN

RQ

SD

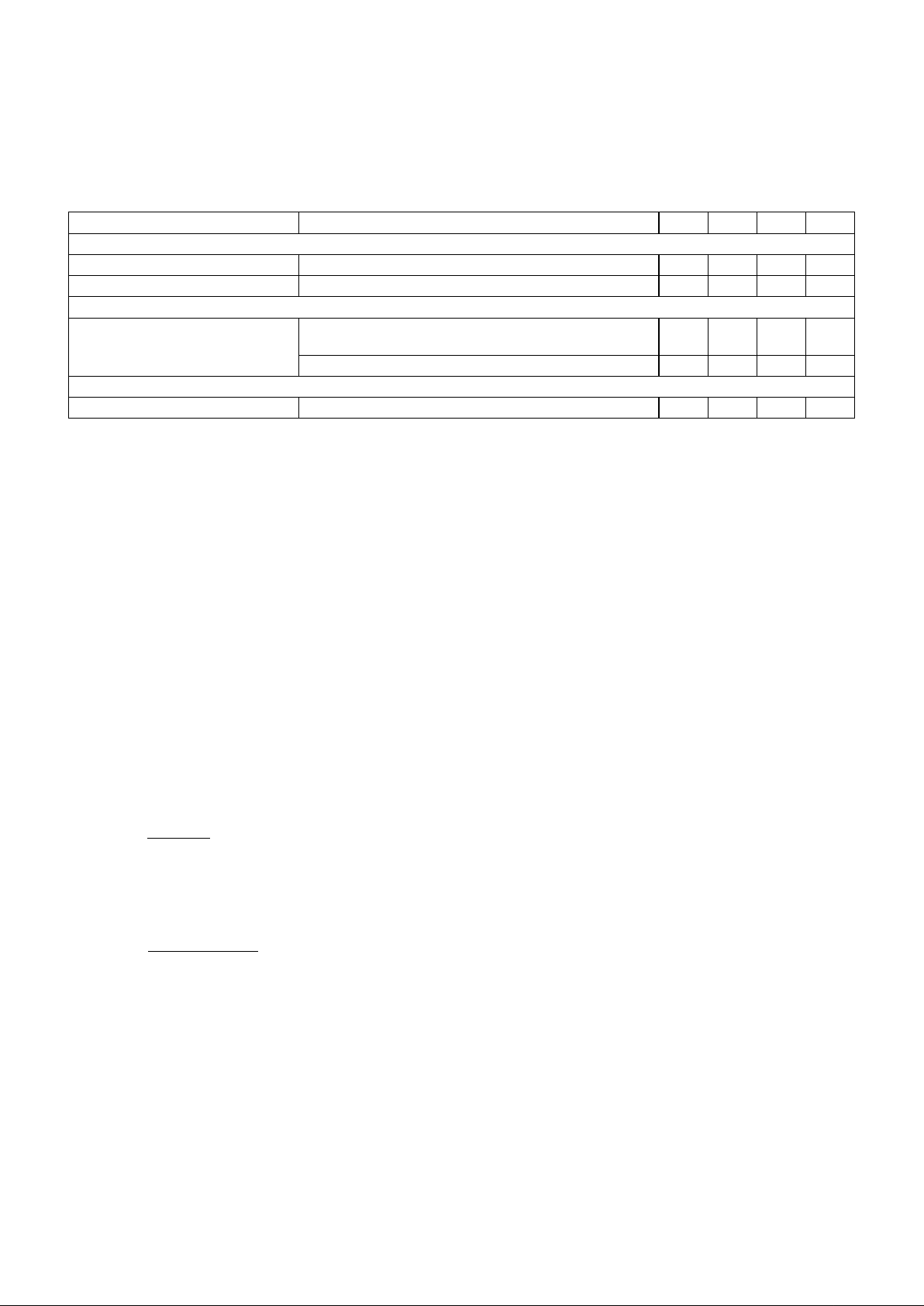

Figure 1. 1V Synchronous boost.

UDG-98146

Note: Switches are shown in the logic low state.

A detailed block diagram of the UCC3941 is shown in

Fig. 1. Unique control circuitry provides high efficiency

power conversion for both light and heavy loads by tran

-

sitioning between discontinuous and continuous conduc

-

tion based on load conditions. Fig. 2 depicts converter

waveforms for the application circuit shown in Fig. 3. A

single 22µH inductor provides the energy pulses required

for a highly efficient 3.3V converter at up to 500mW out

-

put power.

APPLICATION INFORMATION

5

UCC2941-3/-5/-ADJ

UCC3941-3/-5/-ADJ

Figure 2. Inductor current and output ripple waveforms.

APPLICATION INFORMATION (cont.)

UDG-96117

At time t1, the 3.3V output drops below its lower threshold, and the inductor is charged with an on time deter

-

mined by:

T

s

VIN

ON

=

12µ

For a 1.25V input, and a 22µH inductor, the resulting

peak current is approximately 500mA. At time

t2, the in

-

ductor begins to discharge with a minimum off time of

1.7µs. Under lightly loaded conditions, the amount of en

-

ergy delivered in this single pulse would satisfy the volt

age control loop, and the converter would not command

any more energy pulses until the output again drops be

low the lower voltage threshold.

At time

t3, the VGD supply has dropped below its lower

threshold, but the output voltage is still above its thresh

old point. This results in an energy pulse to the gate drive

supply at

t4. However, while the gate drive is being serv

iced, the output voltage has dropped below its lower

threshold, so the state machine commands an energy

pulse to the output as soon as the gate drive pulse is

completed.

Time

t6, represents a transition between light and heavy

load. A single energy pulse is not sufficient to force the

output voltage above its upper threshold before the mini

mum off time has expired, and a second charge cycle is

commanded. Since the inductor current does not reach

zero in this case, the peak current is greater than 0.5A at

the end of the next charge on time. The result is a

ratcheting of inductor current until either the output volt

age is satisfied, or the converter reaches its programmed

current limit. At time

t7, the gate drive voltage has

dropped below its threshold but the converter continues

to service the output because it has highest priority, un

less VGD drops below 7.5V.

Between

t7 and t8, the converter reaches its peak current

limit which is determined by R

PL

and VIN. Once the limit

is reached, the converter operates in continuous mode

with approximately 200mA of ripple current. At time

t8,

the output voltage is satisfied, and the converter can ser

-

vice VGD, which occurs at

t9.

6

UCC2941-3/-5/-ADJ

UCC3941-3/-5/-ADJ

Programming the Power Limit

The UCC3941 incorporates an adaptive power limit con

-

trol which modifies the converter current limit as a func

tion of input voltage.In order to program the function, the

user simply determines the output power requirements

and makes an initial converter efficiency estimate. The

programming resistor is chosen by:

R

n

PnV

PL

OUT BAT

=

•

••

11 8

026

67

.

–.

–.

Where

n

is the initial efficiency estimate. For 500mW of

output power, with a 1.0V input, and an efficiency esti

mate of 0.75:

()

()()

R

PL

==

11 8 0 75

05 026075 10

67 22

..

.–. . .

–. Ω

For decreasing values of R

PL

, the power limit increases.

Therefore, to insure that the converter can supply

500mW of output power, a power limiting resistor of less

than 22Ωmust be chosen.

()

PV I

L BAT L

=•= =

11.8

2+6.7

+1.0 0.26 0.67W

2

This power limiting setting will support 0.5W of output

power. It should be noted that the power limit equation

contains an approximation which results in slightly less

actual input power than the equation predicts. This discrepancy results from the fact that the average current

delivered to the load will be less than the peak current

set by the power limit function due to current ripple. How

ever, if the ripple component of the current is kept low,

the power limit equation can be used as an adequate es

timate of input power. Furthermore, since an initial effi

ciency estimate was required, sufficient margin can be

built into this estimate to insure proper converter opera

tion. The 6.2Ω external power limit resister in Fig. 3-5 will

result in approximately 700mW of power capability with a

APPLICATION INFORMATION (cont.)

5

8

1

7

6

VOUT

SW

10SN100M

100µF

R

PL

6.2Ω

WCR0805-6R207

4

3.3V AT 500mW

2SDVGD

10µF

OPEN =

SD

3

VIN

10µF

MMSZ5240BT1

+

1V TO 3.5V

DT3316P-223

22µH

PLIM

SGND

PGND

UCC3941-3

8V

Figure 3. Dual output synchronous boost 3.3V

version.

UDG-98163

5

8

1

7

6

VOUT

SW

10SN100M

100µF

R

PL

6.2Ω

WCR0805-6R207

4

5.0V AT 500mW

2SDVGD

10µF

OPEN =

SD

3

VIN

10µF

MMSZ5240BT1

+

1V TO 5.5V

DT3316P-223

22µH

PLIM

ADJ

PGND

UCC3941-5

8V

Figure 4. Dual output synchronous boost 5V version.

UDG-98159

5

8

1

7

6

VOUT

SW

10SN100M

100µF

R

PL

6.2Ω

WCR0805-6R207

4

3.3V AT 500mW

2SDVGD

10µF

OPEN =

SD

3

VIN

10µF

MMSZ5240BT1

+

1V TO VOUT+ 0.5V

DT3316P-223

22µH

PLIM

SGND

PGND

UCC3941-3

10V

R1

R2

VOUT=1.25(1+ )

R1

R2

Figure 5. Dual output synchronous boost ADJ

version.

UDG-98164

7

UCC2941-3/-5/-ADJ

UCC3941-3/-5/-ADJ

1.0V input.

Inductor Section

An inductor value of 22µH will work well in most applica

-

tions, but values between 10µH and 100µH are also ac

ceptable. Lower value inductors typically offer lower ESR

and smaller physical size. Due to the nature of the

“bang-bang” controllers, larger inductor values will typi

cally result in larger overall voltage ripple, because once

the output voltage level is satisfied the converter goes

discontinuous, resulting in the residual energy of inductor

causing overshoot.

It is recommended to keep the ESR of the inductor below

0.15Ω for 500mW applications. A Coilcraft DT3316P-223

surface mount inductor is one choice since it has a cur

rent rating of 1.5A and an ESR of 84mΩ. Other choices

for surface mount inductors are shown in Table 1.

Output Capacitor Selection

Once the inductor value is selected the capacitor value

will determine the ripple of the converter. The worst case

peak to peak ripple of a cycle is determined by two com

ponents, one is due to the charge storage characteristic,

and the other is the ESR of the capacitor.The worst case

ripple occurs when the inductor is operating at maximum

current and is expressed as follows:

()

()

∆

V

IL

CV V

IC

CL

OI

CL ESR

=

•

•• −

+•

2

2

where

I

CL

= the peak inductor current

I

Power Limit

V

CL

IN

=

∆V = output ripple

V

O

= output voltage

V

I

= input voltage

C

ESR

= ESR of the output capacitor

A Sanyo OS-CON series surface mount capacitor

(10SN100M) is one recommendation. This part has an

ESR rating of 90mΩ at 100µF. Other potential capacitor

sources are shown in Table 2.

Input Capacitor Selection

Since the UCC3941 family does not require a large de

-

coupling capacitor on the input voltage to operate prop

erly, a 10µF capacitor is sufficient for most applications.

Optimum efficiency will occur when the capacitor value is

large enough to decouple the source impedance. This

usually occurs for capacitor values in excess of 100µF.

APPLICATION INFORMATION (cont.)

MANUFACTURER PART NUMBER

Sanyo Video

Components

San Diego, California OS-CON Series

Tel: 619-661-6322

Fax: 619-661-1055

AVX

Sanford, Maine TPS Series

Tel: 207-282-5111

Fax: 207-283-1941

Sprague

Concord, New Hampshire 695D Series

Tel: 603-224-1961

Table 2. Capacitor Suppliers

MANUFACTURER PART NUMBERS

Coilcraft

Cary, Illinois DT Series

Tel: 708-639-2361

Fax: 708-639-1469

Coiltronics

Boca Raton, Florida CTX Series

Tel: 407-241-7876

Table 1. Inductor Suppliers

8

UCC2941-3/-5/-ADJ

UCC3941-3/-5/-ADJ

Figure 8. Startup characteristics.

T0: 200kHz startup oscillator starts VGD rising.

T

1

: VGD gets to a sufficient voltage (5V) to run IC in normal operating mode.

T

2

: VGD has reached a sufficient voltage (7.5V) to get VOUT started.

T

3

: VOUT is serviced and starting up.

T

4

: VOUT has reached a sufficient voltage and VGD is serviced until it reaches = 8.5V.

0

10

20

30

40

50

60

70

80

90

100

0.1 1 10 100

IOUT (mA)

EFFICIENCY (%)

VIN= 2V VIN= 2.5V VIN= 3V

Figure 7. UCC3941 Efficiency vs. I

OUT,VOUT

= 3.3V.

0

10

20

30

40

50

60

70

80

90

0.1 1 10 100

IOUT (mA)

EFFICIENCY (%)

VIN = 1V VIN = 1.25V VIN = 1.5V

Figure 6. UCC3941 Efficiency vs. I

OUT,VOUT

= 3.3V.

9

UCC2941-3/-5/-ADJ

UCC3941-3/-5/-ADJ

Figure 10. Pseudo continuous mode operation.

VOUT RIPPLE

20mV/DIV

I

INDUCTOR

CURRENT

0.2A/DIV

L = 22

H

C = 100

F

C

VGD

= 22 H

R

PL

= 6

VIN= 1.25

I

OUT

= 100mA

20

s/DIV

Figure 9. Dual output example.

APPLICATION INFORMATION (cont.)

T1: VOUT is service and inductor current goes continuous.

T

2

: VGD is serviced with discontinuous operation and reaches 1st threshold (7.5V).

T

3

: VOUT requires servicing so since VGD has at least reached its first threshold of 7.5V the VOUT has priority.

T

4

: VOUT is satisfied and VGD is serviced until 2nd threshold is reached.

T

5

: Both outputs are satisfied.

10

UCC2941-3/-5/-ADJ

UCC3941-3/-5/-ADJ

0.300

0.500

0.700

0.900

1.100

1.300

1.500

1.700

1.900

2.100

0 2 4 6 8 10 12 14 16 18 20

R

P

(Ω)

I

LIM

(A)

1V 1.25V 1.5V 1.75V 2V 3V

Figure 13. UCC3941-ADJ I

LIM

vs. RP(J package only).

0.300

0.500

0.700

0.900

1.100

1.300

1.500

1.700

1.900

2.100

0 2 4 6 8 10 12 14 16 18 20

R

P

(Ω)

I

LIM

(A)

1V 1.25V 1.5V 1.75V 2V 3V

Figure 14. UCC3941-ADJ I

LIM

vs. RP(all other

packages).

UNITRODE CORPORATION

7 CONTINENTAL BLVD. • MERRIMACK, NH 03054

TEL. (603) 424-2410 FAX (603) 424-3460

()

()()

IL

RV

Rp

P BAT

=

+•

+

11 5

61

02

.

.

.

()

()()

IL

RV

Rp

P BAT

=

+•

+

11 8

67

026

.

.

.

0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1

1.1

1.2

0 50 100 150

I

OUT

(mA)

VBAT at DROPOUT (V)

Figure 11. UCC3941-3 Dropout vs. I

OUT

.

APPLICATION INFORMATION (cont.)

0.8

0.84

0.88

0.92

0.96

1

1.04

1.08

1.12

1.16

1.2

0 50 100 150

I

OUT

(mA)

V

START

(V)

Figure 12. Minimum start voltage vs. I

OUT

.

Figure 15. VINstartup vs. temp.

IMPORTANT NOTICE

T exas Instruments and its subsidiaries (TI) reserve the right to make changes to their products or to discontinue

any product or service without notice, and advise customers to obtain the latest version of relevant information

to verify, before placing orders, that information being relied on is current and complete. All products are sold

subject to the terms and conditions of sale supplied at the time of order acknowledgement, including those

pertaining to warranty, patent infringement, and limitation of liability.

TI warrants performance of its semiconductor products to the specifications applicable at the time of sale in

accordance with TI’s standard warranty. Testing and other quality control techniques are utilized to the extent

TI deems necessary to support this warranty. Specific testing of all parameters of each device is not necessarily

performed, except those mandated by government requirements.

CERT AIN APPLICATIONS USING SEMICONDUCTOR PRODUCTS MAY INVOLVE POTENTIAL RISKS OF

DEATH, PERSONAL INJURY, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE (“CRITICAL

APPLICATIONS”). TI SEMICONDUCTOR PRODUCTS ARE NOT DESIGNED, AUTHORIZED, OR

WARRANTED TO BE SUITABLE FOR USE IN LIFE-SUPPORT DEVICES OR SYSTEMS OR OTHER

CRITICAL APPLICATIONS. INCLUSION OF TI PRODUCTS IN SUCH APPLICA TIONS IS UNDERSTOOD T O

BE FULLY AT THE CUSTOMER’S RISK.

In order to minimize risks associated with the customer’s applications, adequate design and operating

safeguards must be provided by the customer to minimize inherent or procedural hazards.

TI assumes no liability for applications assistance or customer product design. TI does not warrant or represent

that any license, either express or implied, is granted under any patent right, copyright, mask work right, or other

intellectual property right of TI covering or relating to any combination, machine, or process in which such

semiconductor products or services might be or are used. TI’s publication of information regarding any third

party’s products or services does not constitute TI’s approval, warranty or endorsement thereof.

Copyright 1999, Texas Instruments Incorporated

Loading...

Loading...