Datasheet UCC3919PWTR, UCC3919PW, UCC3919N, UCC3919DTR, UCC3919D Datasheet (Texas Instruments)

...

UCC1919

UCC2919

UCC3919

07/99

FEATURES

•

Precision Fault Threshold

•

Charge Pump for Low RDS

ON

High Side

Drive

•

Differential Sense Inputs

•

Programmable Average Power Limiting

•

Programmable Linear Current Control

•

Programmable Fault Time

•

Fault Output Indicator

•

Manual and Automatic Reset Modes

•

Shutdown Control w/Programmable

Softstart

•

Undervoltage Lockout

• Electronic Circuit Breaker Function

3V to 8V Hot Swap Power Manager

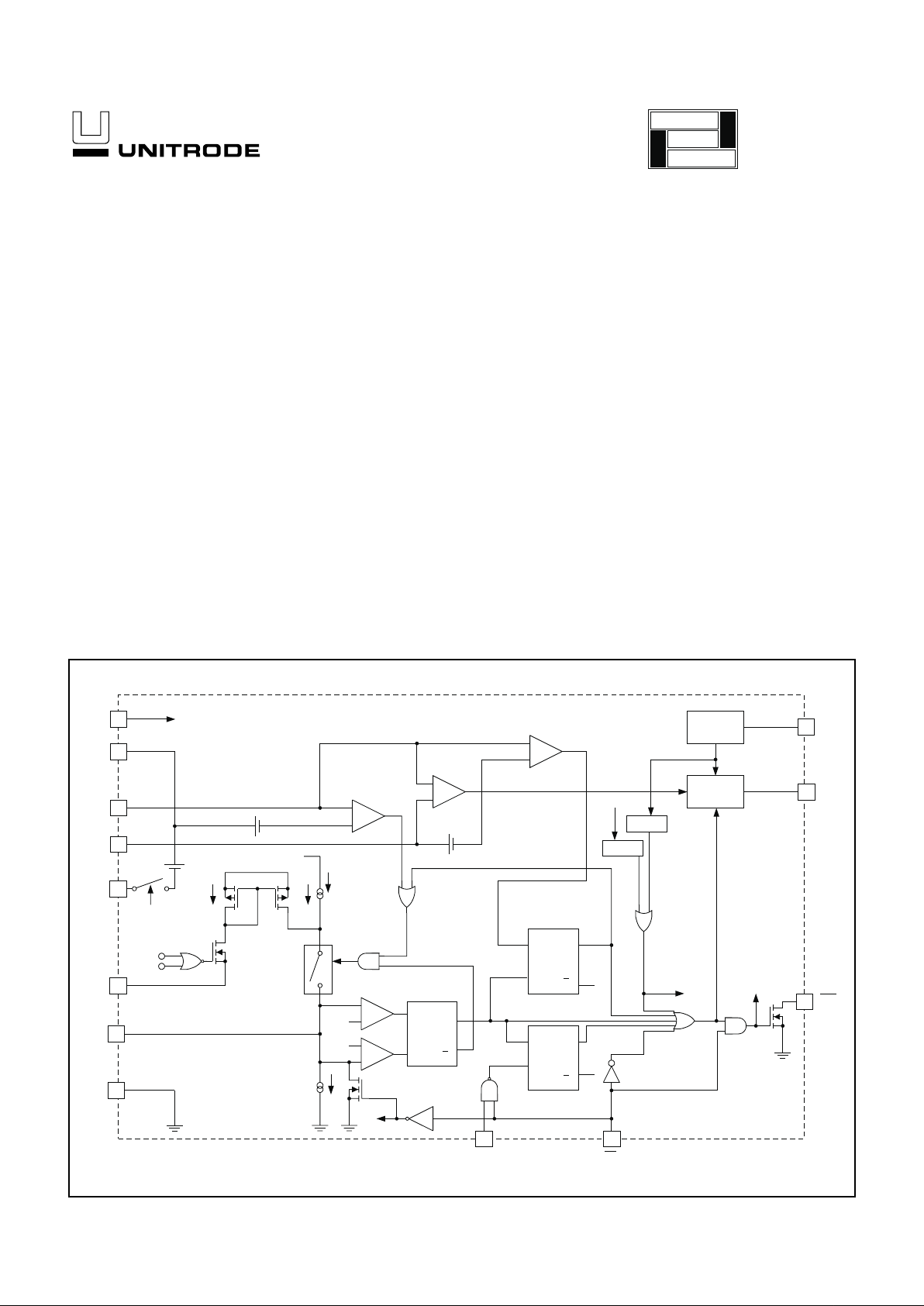

10

7

5 6

11

8

9

2

1

12

14

4

GND

CHARGE

PUMP

DRIVER

UVLO

VDD

+

–

UVLO

+

–

+

+

–

200mV

LINEAR

CURRENT

AMPLIFIER

OVERLOAD

COMPARATOR

SRQ

Q

RESET

DOMINANT

SET

DOMINANT

+

–

+

–

1.5V

0.5V

1.2µA

+

+

1.5v

13

VDD

36µA

50mV

VDD

CSP

CSN

IMAX

IBIAS

PL

CT

FLT

GATE

CAP

LR SD

UVBIAS

VDD

1X

OVERCURRENT

COMPARATOR

UVBIAS

SRQ

Q

SRQ

Q

FLT

SD

FLT

SD

1X

BLOCK DIAGRAM

UDG-98123

DESCRIPTION

The UCC3919 family of Hot Swap Power Managers provide complete

power management, hot swap, and fault handling capability. The

UCC3919 features a duty ratio current limiting technique, which pro

-

vides peak load capability while limiting the average power dissipa

tion of the external pass transistor during fault conditions. The

UCC3919 has two reset modes, selected with the TTL/CMOS com

patible L/R pin. In one mode, when a fault occurs the IC repeatedly

tries to reset itself at a user defined rate, with user defined maximum

output current and pass transistor power dissipation. In the other

mode the output latches off and stays off until either the L/R pin is re

set or the shutdown pin is toggled. The on board charge pump circuit

provides the necessary gate voltage for an external N-channel power

FET.

Note: Pins shown for 14-pin package.

application

INFO

available

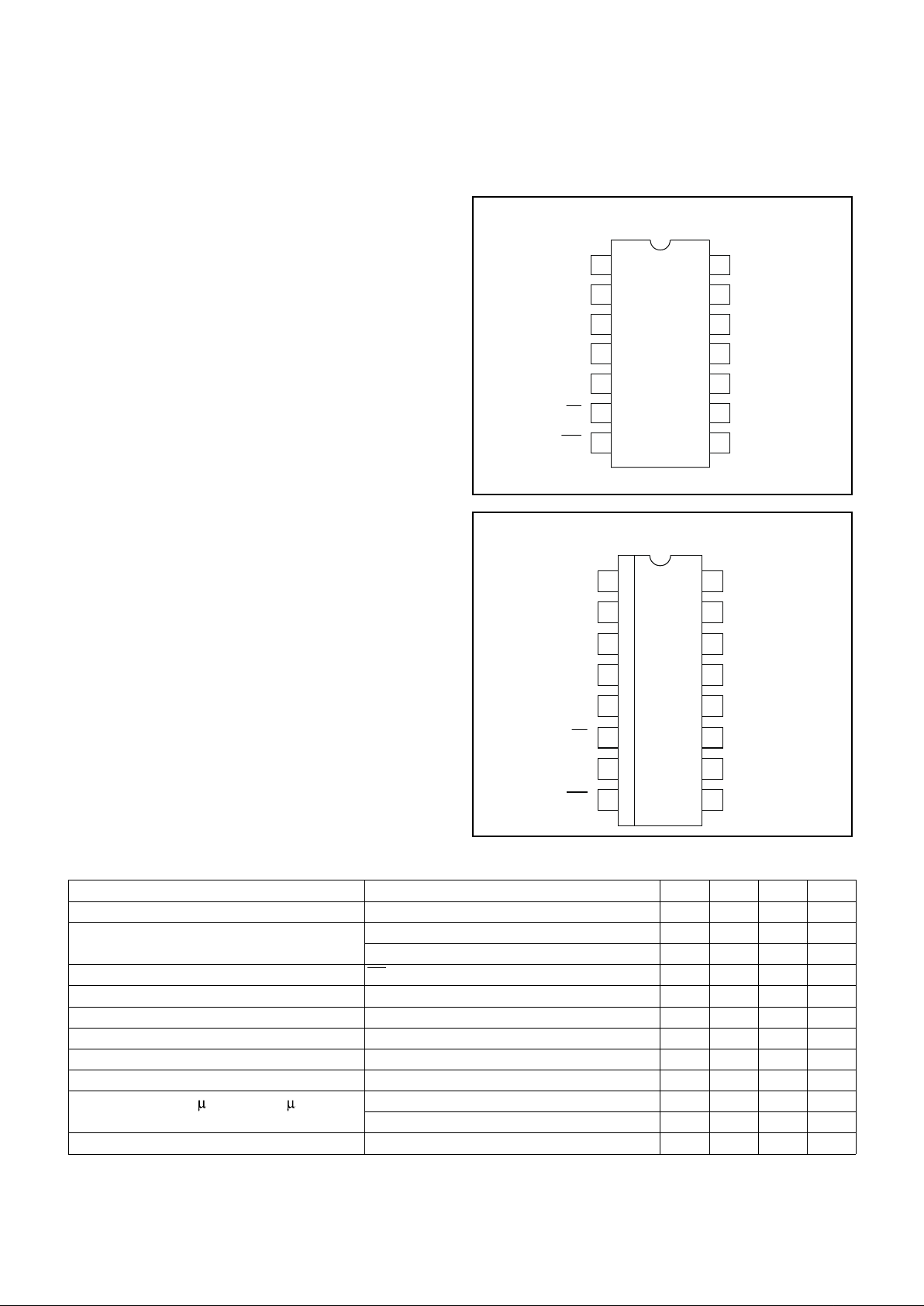

2

UCC1919

UCC2919

UCC3919

CSN

VDD

CSP

GND

GATE

CT

PL

1

2

3

4

5

6

7

14

13

12

11

10

9

8

IBIAS

IMAX

SD

FLT

N/C

CAP

L/R

CONNECTION DIAGRAMS

ELECTRICAL CHARACTERISTICS:

Unless otherwise specified, VDD = 5V, TA = 0°C to 70°C for the UCC3919, –40°C

to 85°C for the UCC2919 and –55°C to 125°C for the UCC1919. All voltages are with respect to GND. T

A =TJ.

PARAMETER TEST CONDITIONS MIN TYP MAX UNITS

Input Supply

Supply Current VDD = 3V 0.5 1 mA

VDD = 8V 1 1.5 mA

Shutdown Current SD

= 0.2V 1 7 µA

Undervoltage Lockout

Minimum Voltage to Start 2.35 2.75 3 V

Minimum Voltage after Start 1.9 2.25 2.5 V

Hysteresis 0.25 0.5 0.75 V

IBIAS

Output Voltage, (0

A < I

OUT

< 15 A) 25°C, referred to CSP 1.47 1.5 1.53 V

Over Temperature Range, referred to CSP 1.44 1.5 1.56 V

Maximum Output Current 12 mA

CSN

VDD

CSP

GND

GATE

N/C

PL

CT

1

2

3

4

5

6

7

8

16

15

14

13

12

11

10

9

IBIAS

IMAX

N/C

N/C

CAP

L/R

FLT

SD

DIL-14, (Top View)

N, J Packages

SOIC-16, TSSOP-16 (Top View)

D or PW Package

ABSOLUTE MAXIMUM RATINGS

VDD. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . –0.3V to 10V

Pin Voltage

(All pins except CAP and GATE). . . . . . –0.3V to VDD + 0.3V

Pin Voltage

(CAP and GATE) . . . . . . . . . . . . . . . . . . . . . . . . –0.3V to 15V

PL Current. . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.5mA to –10mA

IBIAS Current. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0mA to 3mA

Storage Temperature . . . . . . . . . . . . . . . . . . . –65°C to +150°C

Junction Temperature. . . . . . . . . . . . . . . . . . . –55°C to +150°C

Lead Temperature (Soldering, 10sec.) . . . . . . . . . . . . . +300°C

Currents are positive into, negative out of the specified termi

-

nal. Consult Packaging Section ofDatabook for thermal limita

-

tions and considerations of package.

3

UCC1919

UCC2919

UCC3919

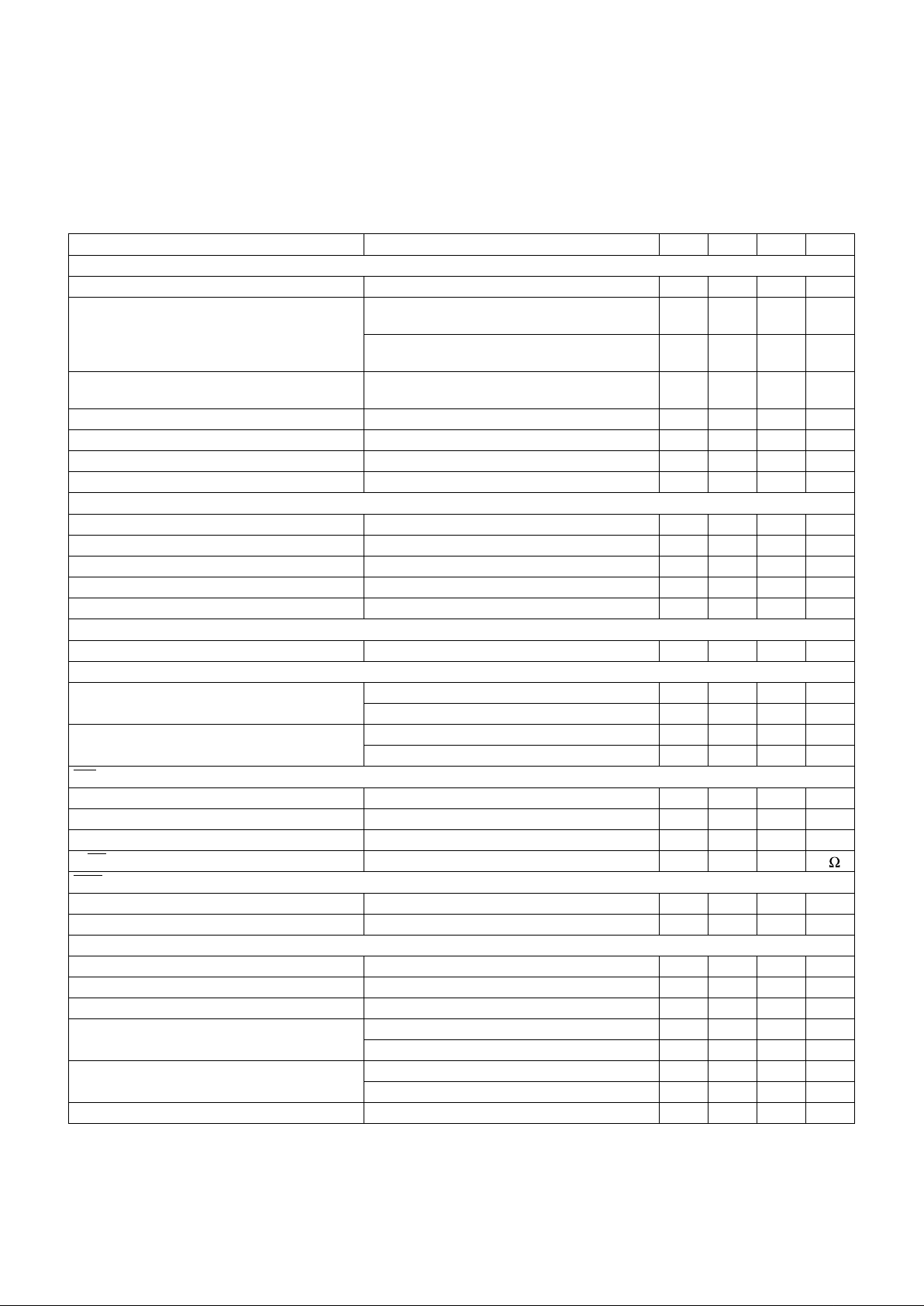

ELECTRICAL CHARACTERISTICS:

Unless otherwise specified, VDD = 5V, TA = 0°C to 70°C for the UCC3919, –40°C

to 85°C for the UCC2919 and –55°C to 125°C for the UCC1919. All voltages are with respect to GND. T

A =TJ.

PARAMETER TEST CONDITIONS MIN TYP MAX UNITS

Current Sense

Over Current Comparator Offset Referred to CSP, 3V ≤VDD ≤8V –55 –50 –45 mV

Linear Current Amplifier Offset V

IMAX

= 100mV, Referred to CSP,

3V ≤VDD ≤8V

–120 –100 –80 mV

V

IMAX

= 400mV, Referred to CSP,

3V ≤VDD ≤8V

–440 –400 –360 mV

Overload Comparator Offset V

IMAX

= 100mV, Referred to CSP,

3V ≤VDD ≤8V

–360 –300 –240 mV

CSN Input Common Mode Voltage Range Referred to VDD, 3V ≤VDD ≤8V, (Note 1) –1.5 0.2 V

CSP Input Common Mode Voltage Range Referred to VDD, 3V ≤VDD ≤8V, (Note 1) 0 0.2 V

Input Bias Current CSN 15µA

Input Bias Current CSP 100 200 µA

Current Fault Timer

CT Charge Current V

CT

= 1V –56 –35 –16 µA

CT Discharge Current V

CT

= 1V 0.5 1.2 1.9 µA

On Time Duty Cycle in Fault I

PL

= 0 1.5 3 6 %

CT Fault Threshold 1.0 1.5 1.7 V

CT Reset Threshold 0.25 0.5 0.75 V

IMAX

Input Bias Current V

IMAX

= 100mV, Referred to CSP –1 0 1 µA

Power Limiting Section

Voltage on PL I

PL

= –250µA, Referred to VDD –1.0 –1.4 –1.9 V

I

PL

= –1.5mA, Referred to VDD –0.5 –1.8 –2.2 V

On Time Duty Cycle in Fault I

PL

= –250µA 0.25 0.5 1 %

I

PL

= –1.5mA 0.05 0.1 0.2 %

SD

and L/R Inputs

Input Voltage Low 0.8 V

Input Voltage High 2V

L/R Input Current 136µA

SD

Internal Pulldown Impedance 100 270 500 k

FLT Output

Output Leakage Current VDD = 5V 10 µA

Output Low Voltage I

OUT

= 10mA 1 V

FET GATE Driver and Charge Pump

Peak Output Current V

CAP

= +15V, V

GATE

= 10V –3 –1 –0.25 mA

Peak Sink Current V

GATE

= 5V 20 mA

Fault Delay 100 300 nS

Maximum Output Voltage VDD = 3V, Average I

OUT

= 1µA 8 10 12 V

VDD = 8V, Average I

OUT

= 1µA 121416 V

Charge Pump UVLO Minimum Voltage to

Start

VDD = 3V 6.5 7.5 V

VDD = 8V 6.5 8 V

Charge Pump Source Impedance VDD = 5V, Average I

OUT

= 1µA 50 100 150 kΩ

Note 1: Guaranteed by design.Not 100% tested in production.

4

UCC1919

UCC2919

UCC3919

PIN DESCRIPTIONS

CAP: A capacitor is placed from this pin to ground to fil

-

ter the output of the on board charge pump. A .01µFto

0.1µF capacitor is recommended .

CSN: The negative current sense input signal.

CSP: The positive current sense input signal.

CT: Input to the duty cycle timer. A capacitor is con

nected from this pin to ground, setting the off time and

the maximum on time of the overcurrent protection cir

cuits.

FLT

: Fault indicator. This open drain output will pull low

under any fault condition where the output driver is dis

abled. This output is disabled when the IC is in low cur

rent standby mode.

GATE: The output of the linear current amplifier. This pin

drives the gate of an external N-channel MOSFET pass

transistor. The linear current amplifier control loop is in

ternally compensated, and guaranteed stable for output

load (gate) capacitance between 100pF and .01µF. In

applications where the GATE voltage (or charge pump

voltage) exceeds the maximum Gate-to-Source voltage

ratings (V

GS

) for the external N-channel MOSFET, a

Zener clamp may be added to the gate of the MOSFET.

No additional series resistance is required since the internal charge pump has a finite output impedance of

100k

typical.

GND: The ground reference for the device.

IBIAS: Output of the on board bias generator internally

regulated to 1.5V below CSP. A resistor divider between

this pin and CSP can be used to generate the IMAX volt

-

age. The bias circuit is internally compensated, and re

quires no bypass capacitance. If an external bypass is

required due to a noisy environment, the circuit will be

stable with up to .001µF of capacitance. The bypass

must be to CSP, since the bias voltage is generated with

respect to CSP. Resistor R2 (Figure 4) should be greater

than 50k

to minimize the effect of the finite input imped

-

ance of the IBIAS pin on the IMAX threshold.

IMAX: Used to program the maximum allowable sourcing

current. The voltage on this pin is with respect to CSP. If

the voltage across the shunt resistor exceeds this voltage

the linear current amplifier lowers the voltage at GATE to

limit the output current to this level. If the voltage across

the shunt resistor goes more than 200mV beyond this

voltage, the gate drive pin GATE is immediately driven

low and kept low for one full off time interval.

L/R: Latch/Reset. This pin sets the reset mode. If L/R is

low and a fault occurs the device will begin duty ratio cur

rent limiting. If L/R is high and a fault occurs, GATE will

go low and stay low until L/R is set low. This pin is inter

nally pulled low by a 3µA nominal pulldown.

PL: Power Limit. This pin is used to control average

power dissipation in the external MOSFET.If a resistor is

connected from this pin to the source of the external

MOSFET, the current in the resistor will be roughly proportional to the voltage across the FET. As the voltage

across the FET increases, this current is added to the

fault timer charge current, reducing the on time duty cycle from its nominal value of 3% and limiting the average

power dissipation in the FET.

SD

: Shutdown pin. If this pin is taken low, GATE will go

low, and the IC will go into a low current standby mode

and CT will be discharged. This TTL compatible input

must be driven high to turn on.

VDD: The power connection for the device.

The UCC3919 monitors the voltage drop across a high

side sense resistor and compares it against three differ

-

ent voltage thresholds. These are discussed below. Fig

ure 1 shows the UCC3919 waveforms under fault

conditions.

Fault Threshold

The first threshold is fixed at 50mV. If the current is high

enough such that the voltage on CSN is 50mV below

CSP, the timing capacitor C

T begins to charge at about

35µA if the PL pin is open. (Power limiting will be dis

cussed later). If this threshold is exceeded long enough

for C

T

to charge to 1.5V, a fault is declared and the exter

-

nal MOSFET will be turned off. It will either be latched off

(until the power to the circuit is cycled, the L/R pin is

taken low, or the SD

pin is toggled), or will retry after a

fixed off time (when C

T has discharged to 0.5V), depend

ing on whether the L/R pin is set high or low by the user.

The equation for this current threshold is simply:

I

R

FAULT

SENSE

=

005.

(1)

The first time a fault occurs, C

T is at ground, and must

charge 1.5V. Therefore:

()

tt

CF

FAULT ON

T

==

•

(sec)

.µ 15

35

(2)

APPLICATION INFORMATION

5

UCC1919

UCC2919

UCC3919

In the retry mode, the timing capacitor will already be

charged to 0.5V at the end of the off time, so all subse

-

quent cycles will have a shorter ton time, given by:

()

tt

CF

FAULT ON

T

≅=(sec)

µ

35

(3)

Note that these equations for ton are without the power

limiting feature (R

PL pin open). The effects of power limit

-

ing on ton will be discussed later.

The off time in the retry mode is set by C

T and an inter

-

nal 1.2µA sink current. It is the time it takes C

T to dis

charge from 1.5V to 0.5V. The equation for the off time is

therefore:

t

CF

OFF

T

(sec).=

µ

12

(4)

Shutdown Characteristics

When the SD pin is set to TTL high (above 2V) the

UCC3919 is guaranteed to be enabled. When SD

is set

to a low TTL (below 0.8V) the UCC3919 is guaranteed to

be disabled, but may not be in ultra low current sleep

mode. When SD

is set to 0.2V or less, the UCC3919 is

guaranteed to be disabled and in ultra low current sleep

mode.See Fig.1.

IMAX Threshold

The second threshold is programmed by the voltage on

IMAX (measured with respect to the CSP pin). This con

-

trols the maximum current, I

MAX, that the UCC3919 will

allow to flow into the load during the MOSFET on time. A

resistive divider connected between IBIAS and CSP gen

erates the programming voltage. When the drop across

the sense resistor reaches this voltage, a linear amplifier

reduces the voltage on GATE to control the external

MOSFET in a constant current mode.

During this time C

T is charging, as described above. If

this condition lasts long enough for C

T to charge to 1.5V,

a fault will be declared and the MOSFET will be turned

off.The I

MAX

current is calculated as follows:

I

VV

R

MAX

CSP IMAX

SENSE

=

–

(5)

Note that if the voltage on the IMAX pin is programmed

to be less than 50mV below CSP, then the UC3919 will

control the MOSFET in a constant current mode all the

time. No fault will be declared and the MOSFET will re

-

main on because I

MAX

is less than I

FAULT

.

Overload Threshold

There is a third threshold which, if exceeded, will declare

a fault and shutdown the external MOSFET immediately,

without waiting for CT to charge. This “Overload” threshold is 200mV greater than the IMAX threshold (again,

this is with respect to CSP). This feature protects the circuit in the event that the external MOSFET is on, with a

load current below I

MAX, and a short is quickly applied

across the output. This allows hot-swapping in cases

where the UCC3919 is already powered up (on the backplane) and capacitors are added across the output bus.

In this case, the load current could rise too quickly for the

linear amplifier to reduce the voltage on GATE and limit

the current to I

MAX. If the overload threshold is reached,

the MOSFET will be turned off quickly and a fault de

-

clared. A latch is set so that C

T can be charged, guaran

teeing that the MOSFET will remain off for the same

period as defined above before retrying. The overload

current is:

I

VV

R

I

R

OVERLOAD

CSP IMAX

SENSE

MAX

SENSE

=

+

=+

–.

.

02

02

(6)

Note that I

OVERLOAD

may be much greater than IMAX,

depending on the value of R

SENSE

.

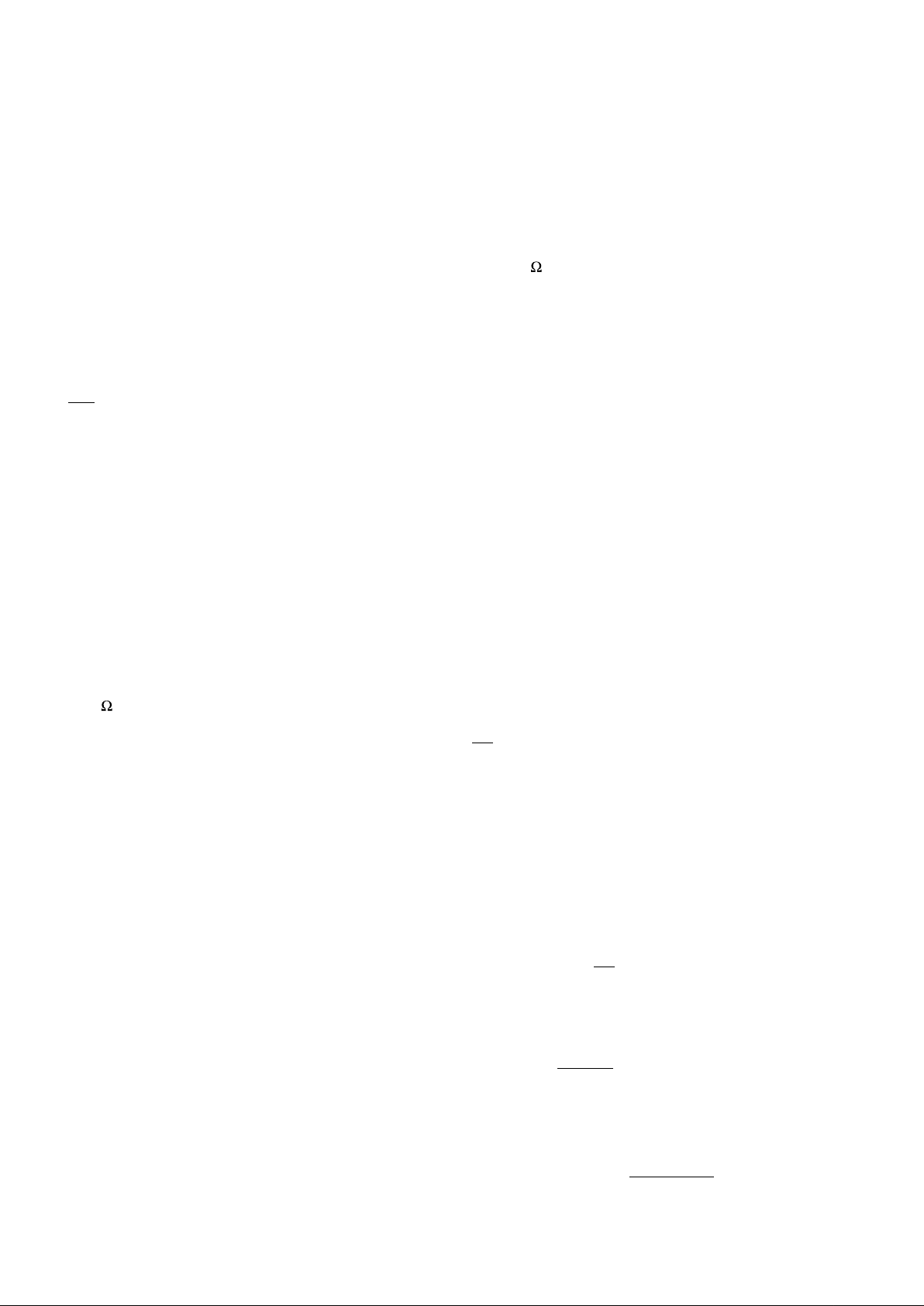

Power Limiting

A power limiting feature is included which allows the

power dissipated in the external MOSFET to be held

relatively constant during a short, for different values of

input voltage. This is accomplished by connecting a re

sistor from the output (source of the external MOSFET)

to PL. When the output voltage drops due to a short or

overload, an internal bias current is generated which is

equal to:

()

I

VV V

R

PL

IN OUT PL

PL

≅

––

(7)

APPLICATION INFORMATION

1.e-08

1.e-07

1.e-06

1.e-05

1.e-04

1.e-03

1.e-02

0 0.25 0.5 0.75 1 1.25 1.5 1.75 2

V

SD

I

CC

Figure 1. Typical Shutdown Current

6

UCC1919

UCC2919

UCC3919

This current is used to help charge the timing capacitor

in the event that the load current exceeds I

FAULT

. (A sim

plified schematic of the circuit internal to the UCC3919 is

shown in Figure 2.) The result is that the on time of the

MOSFET during current limit is reduced as the input volt

age is increased. This reduces the effective duty cycle,

holding the average power dissipated constant.

It can be seen that power limiting will only occur when I

PL

is > 0 (it cannot be negative). For power limiting to begin

to occur, the voltage drop across the MOSFET must be

greater than VDD-V

PL

or 1.4V(typ).

VV V

IN OUT

−≥14.

(8)

The on time using R

PL is defined as:

t

CV

I

ON

T

PL

=

•

+•

−

∆

35 10

6

where V = 1V

(9)

The graph in Figure 4 illustrates the effect of R

PL

on the

average MOSFET power dissipation into a short. The

equation for the average power dissipation during a short

is:

P

IV

I

DISS

MAX IN

PL

=

•••

+•

−

−

12 10

35 10

6

6

.

, or

(10)

P

IVt

tt

DISS

MAX IN ON

ON OFF

=

••

+

If PL is left unconnected, the power limiting feature will

not be exercised. In the retry mode, the duty cycle during

a fault will be nominally 3%, independent of input voltage.

The average power dissipation in the external MOSFET

with a shorted output will be proportional to input voltage,

as shown by the equation:

PIV

DISS MAX IN

=••0 033.

(11)

Calculating C

T

(min) for a Given Load Capacitance

without Power Limiting

To guarantee recovery from an overload when operating

in the retry mode, there is a maximum total output ca

-

pacitance which can be charged for a given t

ON

(fault

time) before causing a fault. For a worst case situation of

a constant current load below the fault threshold, C

T(min)

for a given output load capacitance (without power limit

-

ing) can be calculated from:

C

VC

II

T

IN OUT

MAX LOAD

(min)=

•••

−

−

35 10

6

(12)

A larger load capacitance or a smaller C

T will cause a

fault when recovering from an overload, causing the cir

cuit to get stuck in a continuous hiccup mode. To handle

larger capacitive loads, increase the value of C

T.

The

equation can be easily re-written, if desired, to solve for

C

OUT(max)

for a given value of CT.

For a resistive load of value RL and an output cap C

OUT

,

C

Tmin

can be smaller than in the constant current case,

and can be estimated from:

C

CRn

V

IR

T

OUT L

IN

MAX L

(min)=

−••−

•

•

1

28 10

3

(13)

Note that in the latch mode (or when first turning on in

the retry mode), since the timing capacitor is not recover

ing from a previous fault, it is charging from 0V rather

than 0.5V. This allows up to 50% more load capacitance

without causing a fault.

Estimating C

T

(min) When Using Power Limiting

If power limiting is used, the calculation of C

T

min for a

given C

OUT

becomes considerably more complex, espe

cially with a resistive load. This is because the C

T

charge

current becomes a function of V

OUT

, which is changing

with time. The amount of capacitance that can be

charged (without causing a fault) when using power limit

-

ing will be significantly reduced for the same value C

T

,

due to the shorter ton time.

The charge current contribution from the power limiting

circuit is defined as:

()

I

VV V

R

PL

IN OUT PL

PL

≅

−−

(14)

APPLICATION INFORMATION (cont.)

RPL

CT

VDD

UCC3919

POWER LIMIT

1X 1X

TO

GATE

TO

LOAD

VDD

SD

PL

FLT

I

PL

Figure 2. Power limiting circuit.

UGD-98124

7

UCC1919

UCC2919

UCC3919

APPLICATION INFORMATION (cont.)

Figure 3. Typical Timing Diagram

t0: Normal condition - Output current is nominal, output

voltage is at positive rail, V

CC

.

t

1: Fault control reached - Output current rises above

the programmed fault value, C

T

begins to charge with

35µA + I

PL

.

t

2: Maximum current reached - Output current reaches

the programmed maximum level and becomes a con

-

stant current with value I

MAX

.

t

3: Fault occurs - C

T

has charged to 1.5V, fault output

goes low, the FET turns off allowing no

output current to flow, V

OUT

discharges to GND.

t

4: Retry - CT has discharged to 0.5V, but fault current

is still exceeded, C

T begins charging again, FET is on,

V

OUT increases.

t

3 to t5: Illustrates <3% duty cycle depending upon

R

PL selected.

t

6 = t4

t7: Fault released, normal condition - return to normal

operation of the circuit breaker

UDG-97073

8

UCC1919

UCC2919

UCC3919

Constant Current Load

For a constant current load, the output capacitor will

charge linearly. During that time:

()

Iavg

VV

RV

PL

IN PL

PL IN

()≅

−

••

2

2

(15)

Modifying equation (12) yields:

()

C

VC

VV

RV

T

IN OUT

IN PL

PL IN

(min)≅

••

−

••

+•

−26

2

35 10

II

MAX LOAD

−

(16)

Resistive Load

Determining C

T

(min) for a resistive load is more complex.

First, the expression for the output voltage as a function

of time is:

VtI R e

OUT MAX LOAD

T

RC

START

LOAD OUT

()=• −

−

•

1

(17)

Solving for T

START

when V

OUT

= VINyields:

T

RC n

V

IR

START

LOAD OUT

IN

MAX LOAD

=

−••−

•

1

(18)

Assuming that the device is operating in the retry mode,

where C

T

is charging from 0.5V to just below 1.5V in time

t, C

T

is defined as:

C

Idt

dV

Idt

T

CT

CT

=

•

=•

Where

()

II

CT PL

=+•

−

35 10

6

(19)

APPLICATION INFORMATION (cont.)

14

13

12

11

0.01Ω

10

9

8

1CSP

VDD

IMAX

GND

N/C

IBIAS CSN

PL

RPL10k

C

T

0.01µF

C

OUT

R

LOAD

V

OUT

C

IN

2

3

4

5

6

7

0.01µF

CAP

L/R

SD

FLT

R1

4.99k

R2

100k

GATE

CT

V

IN

Figure 5. Application circuit.

UDG-98137

0

0.05

0.1

0.15

0.2

0.25

0.3

123456

VDD (Volts)

POWER DISSIPATION (Watts)

24.9K

20K

15K

10K

RPL=

Figure 4. MOSFET average short circuit power

dissipation vs. V

IN

for values of RPL.

For I

MAX

=7A

9

UCC1919

UCC2919

UCC3919

Substituting equation (15) into (19) yields:

()

C

VV

RV

dt

T

IN PL

PL IN

(min)=

−

••

+•

•

−26

2

35 10

(20)

This yields the following expression for C

T

(min) for a re

sistive load with power limiting. By substituting the value

calculated for T

START

in equation (18) for dt, CT(min) is

determined.

()

C

VV

RV

T

T

IN PL

PL IN

START

(min)=

•

••

+•

•

−26

2

35 10

(21)

Example

The example in Figure 5 shows the UCC3919 in a typical

application. A low value sense resistor and N-channel

MOSFET minimize losses. With the values shown for R1,

R2, and R

S, the overcurrent fault will be 5A nominal. Lin

ear current limiting (I

MAX)

will occur at 7.14A and the

overload comparator will trip at 27A. The calculations are

shown below.

I

R

A

FAULT

S

===

005 005

001

5

..

.

(22)

()

I

VV

R

R

RR R

A

MAX

CSP IMAX

SS

=

−

=

•

+•

=

15 1

12

714..

(23)

IIRAA

OVERLOAD MAX

S

=+=+=

02

714

02

001

2714

.

.

.

.

.

(24)

T

CF

ms

OFF

T

(sec)

.

.

.

.===

µ

12

001

12

833

(25)

With the value shown for R

PL

:

I output shorted

VV

R

PL typ

IN PL

PL

()

()

.

=

−

=

−516

10

k

A

=340µ

(26)

t shorted

C

I

A

s

ON

T

PL

()

.

=

+•

=

•

=

−

−

35 10

001 10

375

27

6

6

µ

µ

(27)

P shorted

IVt

tt

s

DISS

MAX IN ON

ON OFF

()

.

=

••

+

=

••714 5 2727µ

µ

s

W

+•

=

−

833 10

012

3

.

.

(28)

For a worst case 1Ωresistive load: C

OUT

(max) ≅ 47µF.

For a worst case 5A constant current load: C

OUT

(max) ≅

27µF.

With L/R grounded, the part will operate in the retry or

“hiccup” mode. The values shown for C

T

and RPLwill

yield a nominal duty cycle of 0.32% and an off time of

8.3ms. With a shorted output, the average steady state

power dissipation in Q1 will be less than 100mW over the

full input voltage range.

If power limiting is disabled by opening R

PL

, then:

tt

CF

s

FAULT ON

T

==•=sec

µµ1

35

287

(29)

()

P shorted

IVt

tt

DISS

MAX IN ON

OFF ON

=

••

+

=

•• •

−

714 5 287 10

2

6

.

()

87 10 833 10

12 5

63

•+•

==

−−

.

.

WwithV V

IN

(30)

For a worst case 1Ωresistive load: C

OUT

(max) ≅ 220µF.

For a worst case 5A constant current load: C

OUT

(max) ≅

120µF.

THERMAL CONSIDERATIONS

Steady State Conditions

In normal operation, with a steady state load current below I

FAULT

, the power dissipation in the external MOSFET

will be:

P RDS I

DISS ON LOAD

=•

2

(31)

The junction temperature of the MOSFET can be calcu

-

lated from:

()

TT P

JA DISSJA

=+ •θ

(32)

Where T

A

is the ambient temperature and θJA is the

MOSFET’s thermal resistance from junction to ambient.

If the device is on a heatsink, then the following equation:

θθθθ

JA JC CS SA

+++

(33)

Where

JC

is the MOSFET’s thermal resistance from

junction to case, θ

CS is the thermal resistance from case

to sink, and θ

SA

is the thermal resistance of the heatsink

to ambient.

The calculated T

J

must be lower than the MOSFET’s

maximum junction temperature rating, therefore:

θ

JA

JA

DISS

TT

P

<

−(max)

(34)

APPLICATION INFORMATION (cont.)

10

UCC1919

UCC2919

UCC3919

Transient Thermal Impedance

During a fault condition in the retry mode, the average

MOSFET power dissipation will generally be quite low

due to the low duty cycle, as defined by:

Pavg

IVt

tt

DISS

MAX IN ON

ON OFF

()=

••

+

(w/output shorted)

(35)

(In the latch mode, t

OFF

will be the time between a fault

and the time the device is reset.)

However, the pulse power in the MOSFET during t

ON

,

with the output shorted, is:

P pulse I V

DISS MAX IN

()=•

(w/output shorted) (36)

In choosing t

ON

for a given VIN,I

MAX

, and duty cycle it is

important to consult the manufacturer’s transient thermal

impedance curves for the MOSFET to make sure the de

-

vice is within its safe operating area. These curves pro

vide the user with the effective thermal impedance of the

device for a given time duration pulse and duty cycle.

Note that some of the impedance curves are normalized

to one, in which case the transient impedance values

must be multiplied by the DC (steady state) thermal resistance, θ

JC

.

For duty cycles not shown in the manufacturer’s curves,

the transient thermal impedance for any duty cycle and

ton time (given a square pulse) can be estimated from

[1]:

()

()

θθθ

JC JC SP

trans D D

()=• +−•1

(37)

where D is the duty cycle:

t

tt

ON

ON OFF

+

.

and θ

SP

is the single pulse thermal impedance given in

the transient thermal impedance curves for the time du

ration of interest (t

ON

). Note that these are absolute num

bers, not normalized. If the given single pulse impedance

is normalized, it must first be multiplied by θ

JC before us

ing in the equation above.

This effective transient thermal impedance, when multi

-

plied by the pulse power, will give the transient tempera

ture rise of the die. To keep the junction temperature

below the maximum rating, the following must be true:

()

()

θ

JC

JC

DISS

trans

TT

P pulse

()

max=−

(38)

If necessary, the junction temperature rise can be re

duced by reducing ton (using a smaller value for C

T

), or

by reducing the duty cycle using the power limiting fea

ture already discussed. Note that in either case, the

amount of load capacitance, C

OUT

, that can be charged

before causing a fault, will also be reduced.

Safety Recommendations

Although the UCC3919 is designed to provide system

protection for all fault conditions, all integrated circuits

can ultimately fail short. for this reason, if the UCC3919

is intended for use in safety critical applications where

UL or some other safety rating is required, a redundant

safety device such as a fuse should be placed in series

with the device. The UCC3919 will prevent the fuse from

blowing for virtually all fault conditions, increasing system

reliability and reducing maintenance cost, in addition to

providing the hot swap benefits of the device.

References

[1] International Rectifier, HEXFET Power MOSFET Design-

er’s Manual, Application Note 949B,

Current Ratings, Safe

Operating Area, and High Frequency Switching Perform

-

ance of Power HEXFETs,

pp.1553-1565, September 1993.

APPLICATION INFORMATION

UNITRODE CORPORATION

7 CONTINENTAL BLVD.• MERRIMACK, NH 03054

TEL. (603) 424-2410 FAX (603) 424-3460

IMPORTANT NOTICE

T exas Instruments and its subsidiaries (TI) reserve the right to make changes to their products or to discontinue

any product or service without notice, and advise customers to obtain the latest version of relevant information

to verify, before placing orders, that information being relied on is current and complete. All products are sold

subject to the terms and conditions of sale supplied at the time of order acknowledgement, including those

pertaining to warranty, patent infringement, and limitation of liability.

TI warrants performance of its semiconductor products to the specifications applicable at the time of sale in

accordance with TI’s standard warranty. Testing and other quality control techniques are utilized to the extent

TI deems necessary to support this warranty. Specific testing of all parameters of each device is not necessarily

performed, except those mandated by government requirements.

CERT AIN APPLICATIONS USING SEMICONDUCTOR PRODUCTS MAY INVOLVE POTENTIAL RISKS OF

DEATH, PERSONAL INJURY, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE (“CRITICAL

APPLICATIONS”). TI SEMICONDUCTOR PRODUCTS ARE NOT DESIGNED, AUTHORIZED, OR

WARRANTED TO BE SUITABLE FOR USE IN LIFE-SUPPORT DEVICES OR SYSTEMS OR OTHER

CRITICAL APPLICATIONS. INCLUSION OF TI PRODUCTS IN SUCH APPLICA TIONS IS UNDERSTOOD T O

BE FULLY AT THE CUSTOMER’S RISK.

In order to minimize risks associated with the customer’s applications, adequate design and operating

safeguards must be provided by the customer to minimize inherent or procedural hazards.

TI assumes no liability for applications assistance or customer product design. TI does not warrant or represent

that any license, either express or implied, is granted under any patent right, copyright, mask work right, or other

intellectual property right of TI covering or relating to any combination, machine, or process in which such

semiconductor products or services might be or are used. TI’s publication of information regarding any third

party’s products or services does not constitute TI’s approval, warranty or endorsement thereof.

Copyright 1999, Texas Instruments Incorporated

Loading...

Loading...