Datasheet UCC3912PWP, UCC3912N, UCC3912DPTR, UCC3912DPRTR, UCC3912DPR Datasheet (Texas Instruments)

...

UCC3912

SLUS241A - NOVEMBER 1999

FEATURES

•

Integrated 0.15Ω Power MOSFET

•

3V to 8V Operation

•

Digital Programmable Current Limit

from 0 to 3A

•

Electronic Circuit Breaker Function

•

1µA I

CC

when Disabled

•

Programmable on Time

•

Programmable Start Delay

•

Fixed 3% Duty Cycle

•

Uni-Directional Switch

•

Thermal Shutdown

• Fault Output Indicator

• Maximum Output Current can be set

to 1A above the Programmed Fault

Level or to a full 4A

• Power SOIC, Low Thermal

Resistance Packaging

DESCRIPTION

The UCC3912 Hot Swap Power Manager provides complete power man

-

agement, hot swap capability, and circuit breaker functions. The only com

ponent required to operate the device, other than supply bypassing, is the

fault timing capacitor, C

T

. All control and housekeeping functions are inte

grated, and externally programmable. These include the fault current level,

maximum output sourcing current, maximum fault time,and start-up delay.

In the event of a constant fault, the Internal fixed 3% duty cycle ratio limits

average output power.

The internal 4 bit DAC allows programming of the fault level current from 0

to 3A with 0.25A resolution. The IMAX control pin sets the maximum sour

cing current to 1A above the fault level when driven low, and to a full 4A

when driven high for applications which require fast output capacitor charg

ing.

When the output current is below the fault level, the output MOSFET is

switched on with a nominal on resistance of 0.15

. When the output cur

rent exceeds the fault level, but is less than the maximum sourcing level,

the output remains switched on, but the fault timer starts charging C

T

.

Once C

T

charges to a preset threshold, the switch is turned off, and remains off for 30 times the programmed fault time. When the output current

reaches the maximum sourcing level, the MOSFET transitions from a

switch to a constant current source.

(continued)

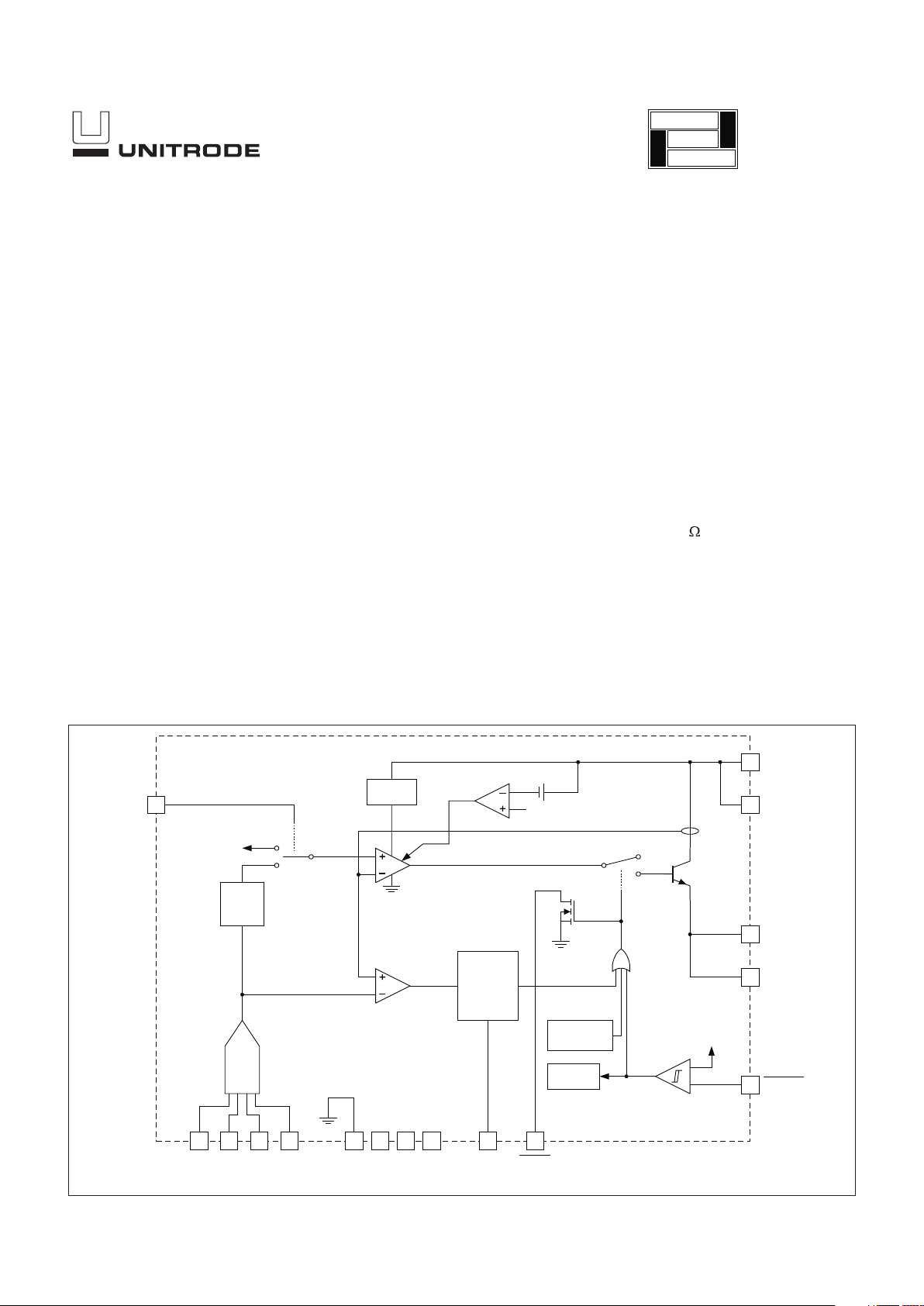

6 7 8 9

1A

ABOVE

FAU LT

OVER CURRENT

COMPARATOR

CURRENT FAULT

LEVEL 0–3 AMPS

10

H=4A

MAX

CURRENT

LEVEL

4A

ON TIME

CONTROL

3% DUTY

CYCLE

0–3A

0.25

RES

1113 1245

B3 B2 B1 B0

4BITDAC

GND

HEAT SINK

GND PINS

CT

CHARGE

PUMP

+

16

LINEAR CURRENT

AMPLIFIER

POWER

FET

2

3

V

OUT

REVERSE VOLTAGE

COMPARATOR

30mV

FAU LT

THERMAL

SHUTDOWN

INTERNAL

BIAS

+

–

1

15

14

VOUT

VIN

CURRENT SENSE

H = OPEN

1.5V

SHTDWN

IMAX

BLOCK DIAGRAM

Programmable Hot Swap Power Manager

UDG-99146

application

INFO

available

2

UCC3912

VIN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . +8 V

FAULT

Sink Current . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50mA

FAULT

Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . –0.3 to V

IN

Output Current . . . . . . . . . . . . . . . . . . . . . . . . . . . . Self Limiting

Input Voltage

(B0, B1, B2, B3, IMAX, SHTDWN

) . . . . . . . . . . . –0.3 to V

IN

Storage Temperature Range . . . . . . . . . . . . . –65°C to +150°C

Operating Junction Temperature Range . . . . –55°C to +150°C

Lead Temperature (Soldering, 10 sec.) . . . . . . . . . . . . . +300°C

Currents are positive into, negative out of the specified termi

-

nal. Consult Packaging Section of Databook for thermal limita

-

tions and considerations of packages.

ABSOLUTE MAXIMUM RATINGS

ELECTRICAL CHARACTERISTICS:

Unless otherwise stated, these specifications apply for TJ = 0°C to 70°C, VIN = 5V,

IMAX = 0.4V, SHTDWN

= 2.4V.

PARAMETER TEST CONDITIONS MIN TYP MAX UNITS

Supply Section

Voltage Input Range 3.0 8.0 V

Supply Current 1.0 2.0 mA

Sleep Mode Current SHTDWN

= 0.2V 0.5 5.0 µA

Output Section

Voltage Drop I

OUT

= 1A 0.15 0.22 V

I

OUT

= 2A 0.3 0.45 V

I

OUT

= 3A 0.45 0.68 V

I

OUT

= 1A, VIN = 3V 0.17 0.27 V

I

OUT

= 2A, VIN = 3V 0.35 0.56 V

I

OUT

= 3A, VIN = 3V 0.5 0.8 V

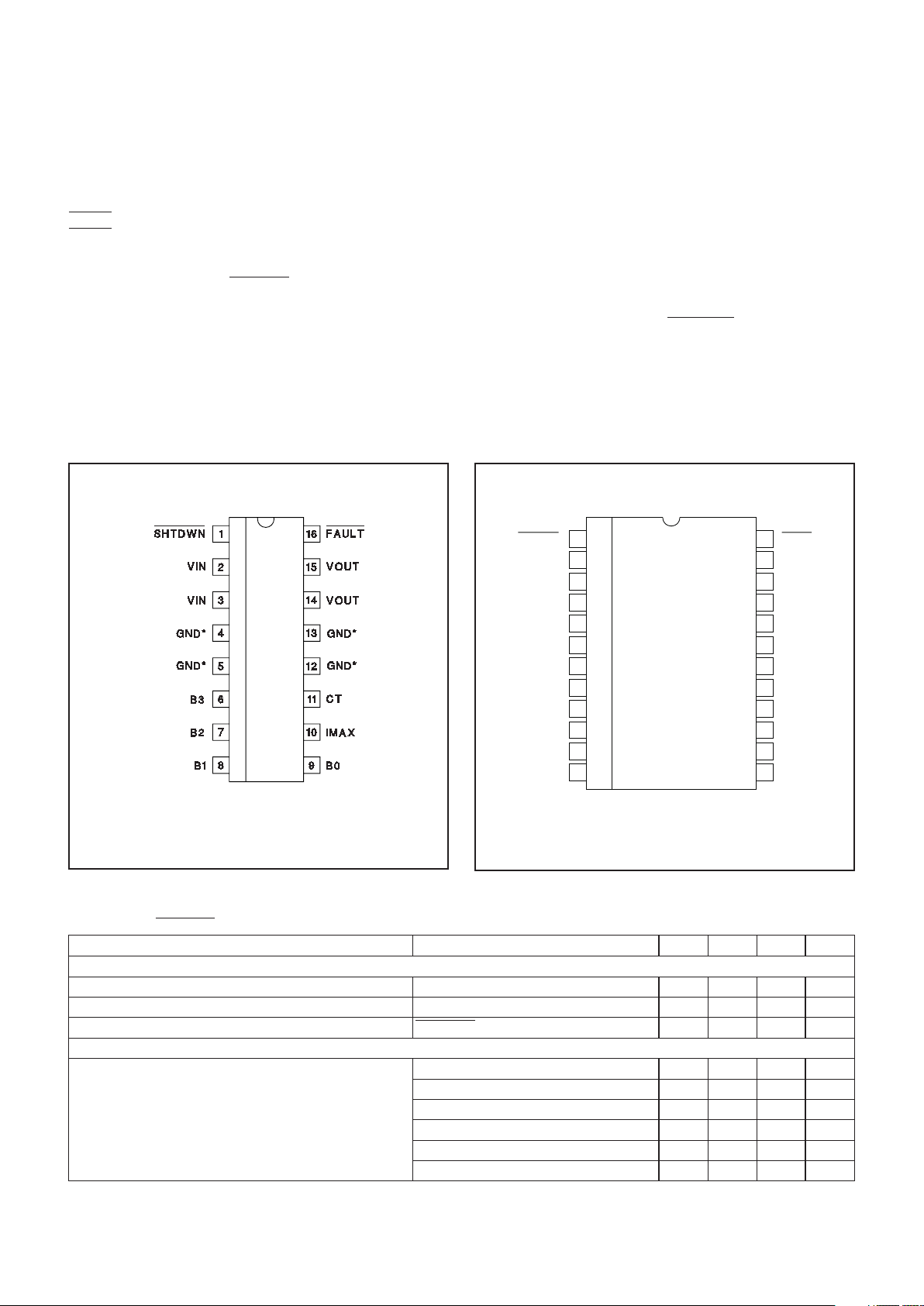

CONNECTION DIAGRAMS

*Pin 5 serves as lowest impedance to the electrical ground;

Pins 4, 12, and 13 serve as heat sink/ground. These pins

should be connected to large etch areas to help dissipate

heat. For N package, pins 4, 12, and 13 are N/C.

The UCC3912 is designed for unidirectional current flow,

emulating an ideal diode in series with the power switch.

This feature is particularly attractive in applications

where many devices are powering a common bus, such

as with SCSI Termpwr.

The UCC3912 can be put into sleep mode drawing only

1µA of supply current. The SHTDWN

pin has a preset

threshold hysteresis which allows the user the ability to

set a time delay upon start-up to achieve sequencing of

power. Other features include an open drain FAULT out

-

put indicator, Thermal Shutdown, Under Voltage Lock

-

out, and a low thermal resistance Small outline package.

DESCRIPTION (cont.)

B3

N/C

GND*

GND*

FAU LT

VIN

EGND*

GND*

GND*

VIN

N/C

GND*

SHTDWN

GND*

B2

GND*

GND*

CT

12

11

10

9

8

7

6

5

4

3

2

1

13

14

15

16

17

18

19

20

21

22

23

24

IMAX

VOUT

VOUT

B1 B0

GND*

TSSOP-24 (Top View)

PWP Package

DIL-16, SOIC-16 (Top View)

N, DP Package

*Pin 9 serves as lowest impedance to the electrical ground;

other GND pins serve as heat sink/ground. These pins

should be connected to large etch areas to help dissipate

heat.

3

UCC3912

ELECTRICAL CHARACTERISTICS:

Unless otherwise stated, these specifications apply for TJ = 0°C to 70°C, VIN = 5V,

IMAX = 0.4V, SHTDWN

= 2.4V.

PARAMETER TEST CONDITIONS MIN TYP MAX UNITS

Output Section (cont.)

Reverse Leakage Current V

IN<VOUT

,

SHTDWN = 0.2V,

V

OUT

= 5V

520µA

Initial Start-up Time (Note 2) 100 µs

Short Circuit Response (Note 2) 100 ns

Thermal Shutdown (Note 2) 170 °C

Thermal Hysteresis (Note 2) 10 °C

DAC Section

Output Leakage Code = 0000-0011 0 20 µA

Trip Current Code = 0100 0.1 0.25 0.45 A

Code = 0101 0.25 0.50 0.75 A

Code = 0110 0.5 0.75 1.0 A

Code = 0111 0.75 1.00 1.25 A

Code = 1000 1.0 1.25 1.5 A

Code = 1001 1.25 1.50 1.75 A

Code = 1010 1.5 1.75 2.0 A

Code = 1011 1.7 2.00 2.3 A

Code = 1100 1.9 2.25 2.58 A

Code = 1101 2.1 2.50 2.9 A

Code = 1110 2.3 2.75 3.2 A

Code = 1111 2.5 3.0 3.5 A

Max Output Current Code = 0000 to 0011 0.02 mA

Max Output Current Over Trip (Current Source

Mode)

Code = 0100 to 1111, IMAX = 0V 0.5 1.0 1.8 A

Max Output Current (Current Source Mode) Code = 0100 to 1111, I

MAX = 2.4V 3.0 4.0 5.2 A

Timer Section

CT Charge Current V

CT

= 1.0V −45.0 −36.0 −22.0 µA

CT Discharge Current V

CT

= 1.0V 0.72 1.2 1.5 µA

Output Duty Cycle V

OUT

= 0V 2.0 3.0 6.0 %

CT Fault Threshold 1.3 1.5 1.7 V

CT Reset Threshold 0.4 0.5 0.6 V

Shutdown Section

Shutdown Threshold 1.1 1.5 1.9 V

Shutdown Hysteresis 100 mV

Input Current SHTDWN

= 1V 100 500 nA

Fault Output Section

Output Leakage Current 500 nA

Low Level Output Voltage I

OUT

= 10mA 0.4 0.8 V

TTL Input DC Characteristics Section

TTL Input Voltage High (can be connected to V

IN

) 2.0 V

TTL Input Voltage Low 0.8 V

TTL Input High Current V

IH

= 2.4V 3 10 µA

TTL Input Low Current V

IL

= 0.4V 1 µA

Note 1: All voltages are with respect to Ground. Current is positive into and negative out of the specified terminal.

Note 2: Guaranteed by design. Not 100% tested in production.

4

UCC3912

PIN DESCRIPTIONS

B0 - B3: These pins provide digital input to the DAC

which sets the fault current threshold. They can be used

to provide a digital soft-start, adaptive current limiting.

CT: A capacitor connected to ground sets the maximum

fault time. The maximum fault time must be more than

the time to charge the external capacitance in one cycle.

The maximum fault time is defined as FAULT = 27.8 •10

3

• CT. Once the fault time is reached the output will shut

-

down for a time given by: T

SD

= 833 •103• CT, this

equates to a 3% duty cycle.

FAULT

: Open drain output which pulls low upon any con

dition which causes the output to open: Fault, Thermal

Shutdown, or Shutdown.

IMAX: When this pin is set to logic low the maximum

sourcing current will always be 1A above the pro

-

grammed fault level. When set to logic high, the maxi

mum sourcing current will be a constant 4A for

applications which require fast charging of load capaci

tance.

SHTDWN

: When this pin is brought to a logic low, the IC

is put into a sleep mode drawing typically less than 1µA

of I

CC. The input threshold is hysteretic, allowing the user

to program a start-up delay with an external RC circuit.

VIN: Input voltage to the UCC3912. The recommended

voltage range is 3 to 8 volts. Both VIN pins should be

connected together and to the power source.

VOUT: Output voltage from the UCC3912. When

switched the output voltage will be approximately V

IN -

(0.15Ω•I

OUT

). Both VOUT pins should be connected to

gether and to the load.

6 7 8 9115

B3B2B1B0 IMAX

16

3

2

4 12 13 5

14

15

1SHTDWN

VOUTVIN

FAU LT

CT

GND

HEAT SINK

GND PINS

UCC3912

R

L

C

OUT

V

OUT

C

SD

R

SD

V

IN

C

IN

R1

LED

D1

C

T

S1 S2 S3 S4 S5

DIP

SWITCH

S6

V

IN

V

IN

APPLICATION INFORMATION

Figure 1. Evaluation circuit.

UDG-99171

Note: For demonstration board schematic see Design Note DN-58.

Protecting The UCC3912 From Voltage Transients

The parasitic inductance associated with the power distri

-

bution can cause a voltage spike at V

IN

if the load current

is suddenly interrupted by the UCC3912. It is important to

limit the peak of this spike to less than 8V to prevent

damage to the UCC3912. This voltage spike can be mini

-

mized by:

•

Reducing the power distribution inductance (e.g., twist

the “+” and “–” leads of the power supply feeding V

IN

,

locate the power supply close to the UCC3912, use a

PCB ground plane,...etc.).

•

Decoupling V

IN

with a capacitor, CIN(refer to Fig. 1),

located close to pins 2 and 3. This capacitor is typically

less than 1µF to limit the inrush current.

•

Clamping the voltage at V

IN

below 8V with a Zener

diode, D1(refer to Fig. 1), located close to pins 2 and 3.

5

UCC3912

APPLICATION INFORMATION (cont.)

Figure 2. Load current, timing capacitor voltage, and output voltage of the UCC3912 under Fault conditions.

Estimating Maximum Load Capacitance

For hot swap applications, the rate at which the total

output capacitance can be charged depends on the

maximum output current available and the nature of the

load. For a constant-current current-limited controller,

the output will come up if the load asks for less than the

maximum available short-circuit current.

To guarantee recovery of a duty-cycle from a

short-circuited load condition, there is a maximum total

output capacitance which can be charged for a given

unit ON time (Fault time). The design value of ON or

Fault time can be adjusted by changing the timing ca

-

pacitor C

T

.

For worst-case constant-current load of value just less

than the trip limit; C

OUT(max)

can be estimated from:

()

CII

CT

V

OUT MAX LOAD

OUT

(max)

≈− •

••

28 10

3

where V

OUT

is the output voltage.

For a resistive load of value RL, the value of C

OUT(max)

can

be estimated from:

()

C

CT

RL n

V

IRL

OUT

OUT

MAX

max

≈

••

•

−

•

28 10

1

1

3

l

UDG-93019-4

6

UCC3912

Figure 3. UCC3912 on time control circuitry.

The overcurrent comparator senses both the DAC output

and a representation of the output current. When the out

-

put current exceeds the programmed level the timing ca

-

pacitor C

T

charges with 36µA of current. If the fault

occurs for the time it takes for C

T

to charge up to 1.5V,

the fault latch is set and the output switch is opened. The

output remains opened until C

T

discharges to 0.5V with a

1.2µA current source. Once the 0.5V is reached the out

put is enabled and will either appear as a switch, if the

fault is removed, or a current source if the fault remains.

If the over current condition is still present then C

T

will

begin charging, starting the cycle over, resulting in ap

proximately a 3% on time.

APPLICATION INFORMATION (cont.)

UNITRODE CORPORATION

7 CONTINENTAL BLVD. • MERRIMACK, NH 03054

TEL. (603) 424-2410 FAX (603) 424-3460

UDG-94019-1

Figure 4. RDS(on) vs temperature at 2A load current.

UDG-94101

SAFETY RECOMMENDATIONS

Although the UCC3912 is designed to provide system

protection for all fault conditions, all integrated circuits

can ultimately fail short. For this reason, if the UCC3912

is intended for use in safety critical applications where

UL or some other safety rating is required, a redundant

safety device such as a fuse should be placed in series

with the device. The UCC3912 will prevent the fuse from

blowing virtually all fault conditions, increasing system

reliability and reducing maintainence cost, in addition to

providing the hot swap benefits of the device.

Loading...

Loading...