Datasheet UCC384DPTR-ADJ, UCC384DPTR-5, UCC384DP-ADJ, UCC384DP-5, UCC384DP-12 Datasheet (Texas Instruments)

...

Low Dropout 0.5A Negative Linear Regulator

UCC284-5/-12/-ADJ

UCC384-5/-12/-ADJ

FEATURES

Precision Negative Series

•

Pass Voltage Regulation

0.2V Drop Out at 0.5A

•

Wide Input voltage Range

•

–3.2V to –15V

Low Quiescent Current

•

Irrespective of Load

Simple Logic Shutdown

•

Interfacing

–5V, –12V and Adjustable

•

Output

2.5% Duty Cycle Short Circuit

•

Protection

• Remote Load Sensing for

Accurate Load Regulation

• 8-Pin DP Package

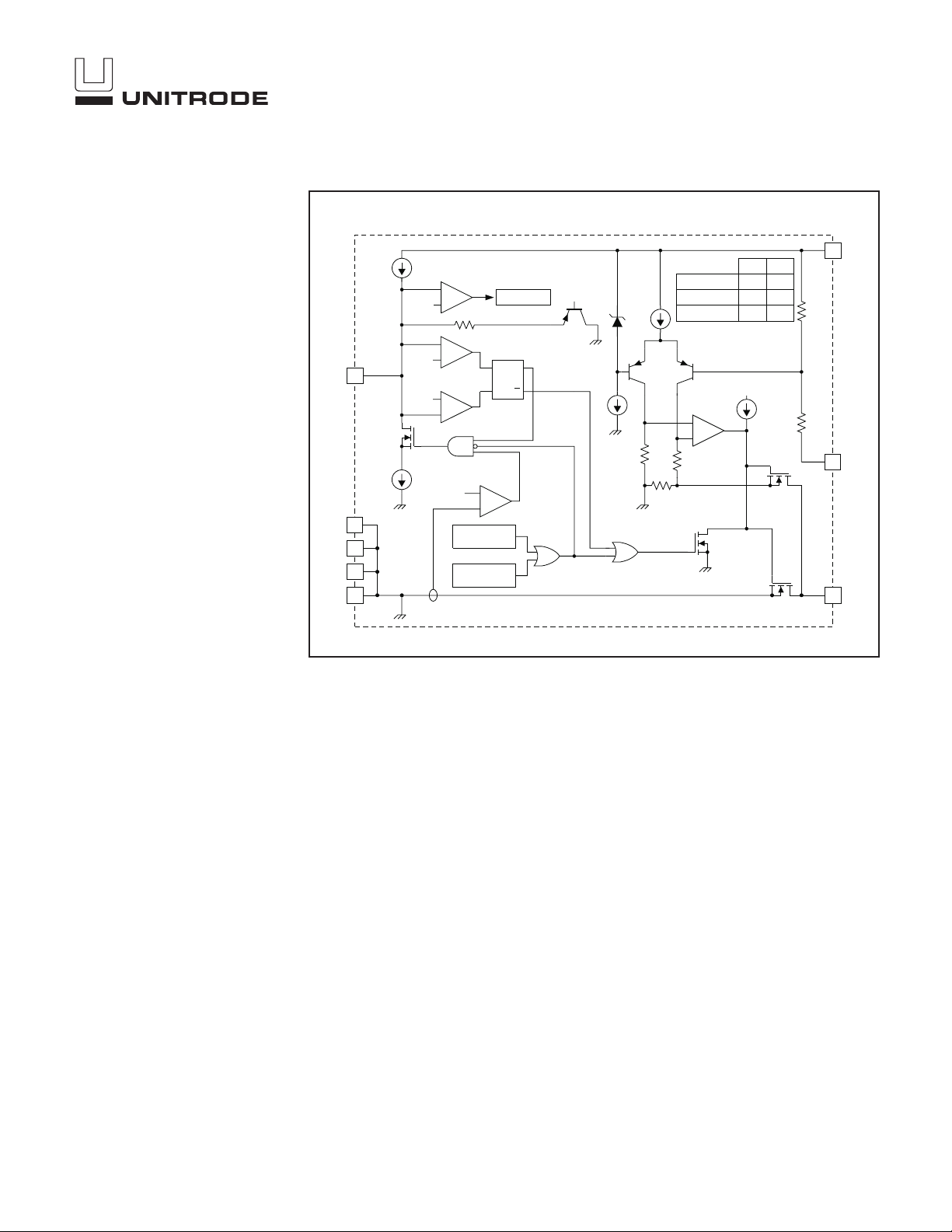

BLOCK DIAGRAM

1µA

DISCHARGE

+

–

–0.6V

+

–

–1.6V

8

SD/CT

–2.6V

+

–

40µA

CHARGE

OVERCURRENT

700mA

2

VIN

VIN

3

VIN

6

VIN

7 5

(–) (–)

50k

S

–

+

THERMAL

SHUTDOWN

UVLO

SHUTDOWN

Q

QR

TON

TOFF

–2.2V

1.25V

UCC384-5

UCC384-12

+

GM

–

R1 R2

375K

375K

VPUMP

0 OPENUCC384-ADJ

125K

R2

43.6K

R1

(+)

4 GND

1

VOUTS

VOUT

UDG-99030

DESCRIPTION

The UCC384 family of negative linear series pass regula

tors is tailored for low drop out applications where low

quiescent power is important. Fabricated with a

BCDMOS technology ideally suited for low input to out

put differential applications, the UCC384 will pass 0.5A

while requiring only 0.2V of input voltage headroom.

Drop out voltage decreases linearly with output current,

so that drop out at 50mA is less than 20mV.

Quiescent current consumption for the device under nor

mal (non-drop out) conditions is typically 200µA. An inte

grated charge pump is internally enabled only when the

device is operating near drop out with low VIN. This

guarantees that the device will meet the drop out specifi

cations even for maximum load current and a VIN of

–3.2V with only a modest increase in quiescent current.

Quiescent current is always less than 350µA, with the

charge pump enabled. Quiescent current of the UCC384

does not increase with load current.

SLUS234A - JANUARY 2000

-

Short circuit current is internally limited. The device re

sponds to a sustained over current condition by turning

off after a T

-

riod, T

OFF

then begins pulsing on and off at the T

delay. The device then stays off for a pe

ON

, that is 40 times the TONdelay. The device

ON/TOFF

duty cycle

of 2.5%. This drastically reduces the power dissipation

during short circuit such that heat sinking, if at all re

quired, must only accommodate normal operation. An

external capacitor sets the on time. The off time is al

ways 40 times T

-

ON

.

The UCC384 can be shutdown to 45µA (maximum) by

pulling the SD/CT pin more positive than –0.6V. To allow

-

for simpler interfacing, the SD/CT pin may be pulled up

to +6V above the ground pin without turning on clamping

diodes.

Internal power dissipation is further controlled with ther

mal overload protection circuitry. Thermal shutdown oc

curs if the junction temperature exceeds 140°C. The chip

will remain off until the temperature has dropped 20°C.

-

-

-

-

-

-

UCC284-5/-12/-ADJ

UCC384-5/-12/-ADJ

ABSOLUTE MAXIMUM RATINGS

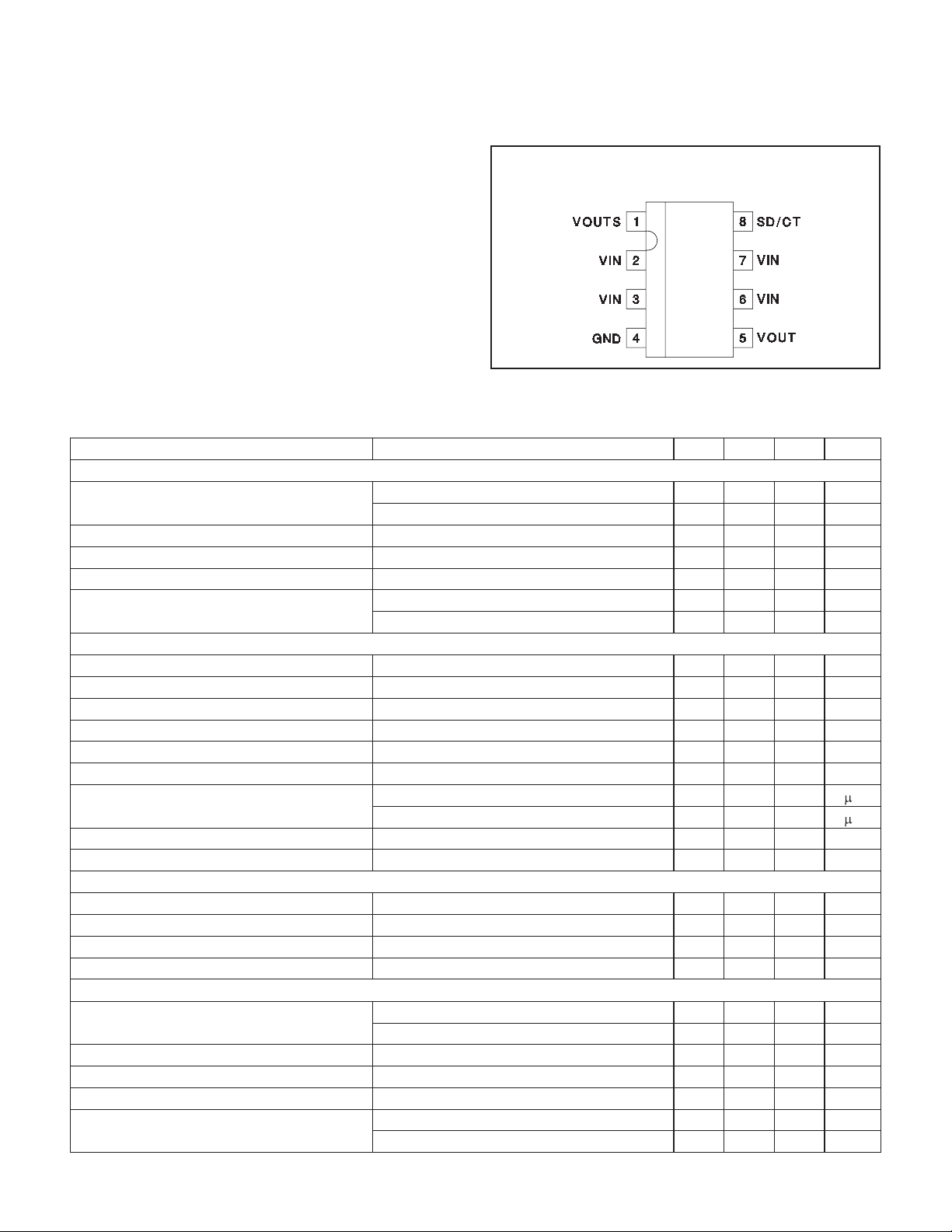

CONNECTION DIAGRAM

Supply Voltage, VIN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . –16V

Shutdown Voltage, SD/CT . . . . . . . . . . . . . . . . . . . . +6V to –5V

Storage Temperature . . . . . . . . . . . . . . . . . . . −65°C to +150°C

SOIC-8 (Top View)

DP Package

Junction Temperature. . . . . . . . . . . . . . . . . . . –55°C to +150°C

Lead Temperature (Soldering, 10 sec.) . . . . . . . . . . . . . +300°C

All voltages are with respect to ground. Currents are positive

into, negative out of the specified terminal. All voltages are with

respect to ground. Consult Packaging Section of Databook for

thermal limitations and considerations of packages.

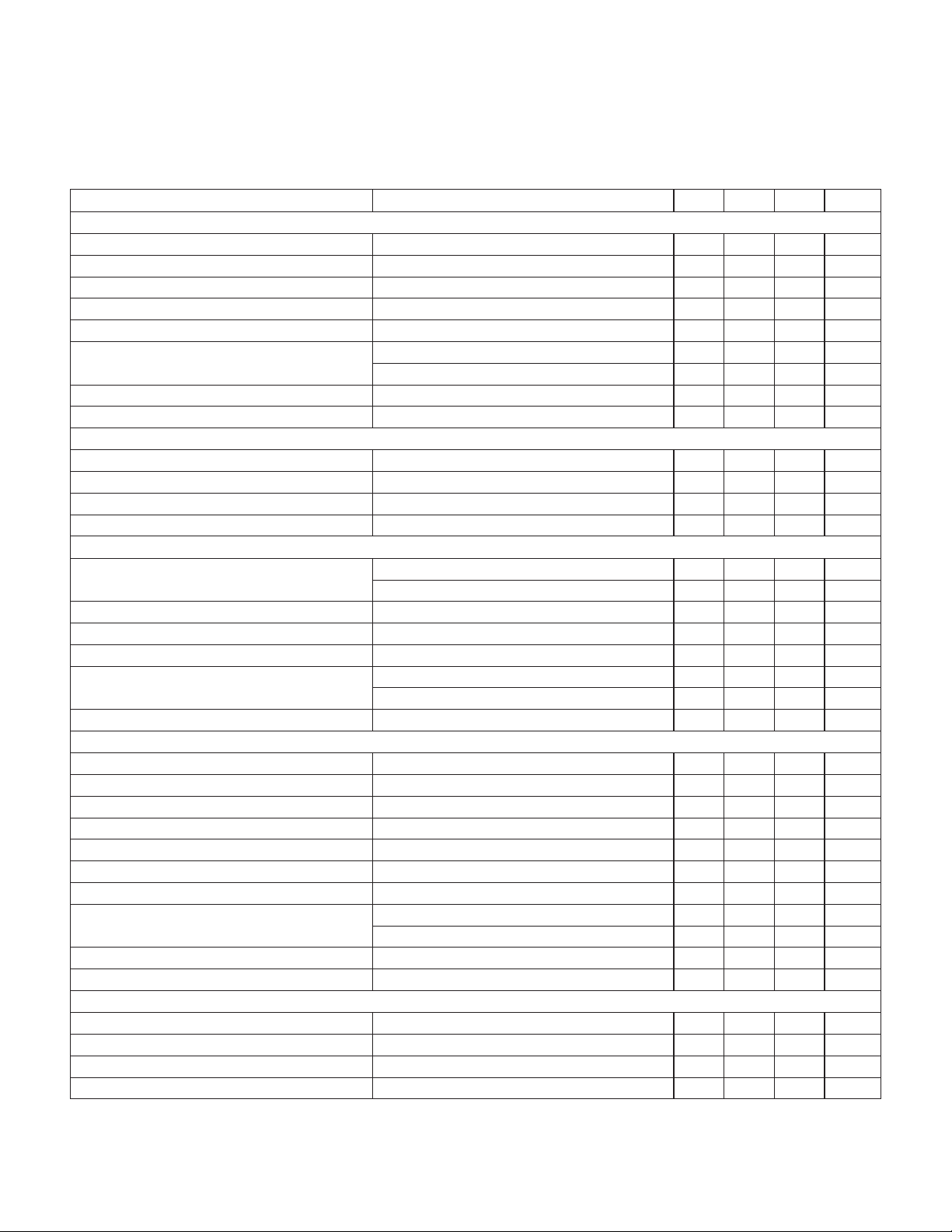

ELECTRICAL CHARACTERISTICS:

for the UCC284, VIN = VOUT – 1.5V, I

T

= TA.

J

OUT

Unless otherwise specified, TA= 0°C to 70°C for the UCC384 and –40°C to 85°C

= 0mA, C

= 4.7µF, and CT = 0.015µF. For UCC384-ADJ, VOUT is set to –3.3V.

OUT

PARAMETER TEST CONDITIONS MIN TYP MAX UNITS

UCC384-5 Fixed –5V 0.5A Regulation Section

Output Voltage T

= 25°C –5.075 –5 –4.925 V

A

Over all conditions –5.100 –4.850 V

Line Regulation VIN = –5.3V to –15V 1.5 10 mV

Load Regulation I

Output Noise Voltage T

Drop Out Voltage, VOUT – VIN I

= 0mA to 0.5A 0.1 0.25 %

OUT

= 25°C, BW = 10Hz to 10kHz 200 µVRMS

A

0.5A, VOUT = –4.8V 0.20 0.50 V

OUT

50mA, VOUT = –4.8V 20 50 mV

I

OUT

UCC384-5 Fixed –5V 0.5A Power Supply Section

Input Voltage Range –15 –5.2 V

Quiescent Current Charge Pump On VIN = –4.85V (Note 1) 280 350 µA

Quiescent Current VIN = –15V 200 250 µA

Quiescent Current in Shutdown VIN = –15V, SD/CT = 0V, No Load 24 45 µA

Shutdown Threshold At Shutdown Pin –1.0 –0.6 –0.4 V

Shutdown Input Current SD/CT = 0V 5 17 25 µA

Output Leakage in Shutdown VIN = –15V, VOUT = 0, 25°C110

Over Temperature 50

A

A

Over Temperature Shutdown 140 °C

Over Temperature Hysteresis 20 °C

UCC384-5 Fixed –5V 0.5A Current Limit Section

Peak Current Limit VOUT = 0V 0.7 1.1 1.5 A

Over Current Threshold 0.55 0.7 0.9 A

Current Limit Duty Cycle VOUT = 0V 2.5 4 %

Overcurrent Time Out, T

ON

VOUT = 0V 300 450 650 µs

UCC384-12 Fixed 12V 0.5A Regulation Section

Output Voltage T

= 25°C –12.18 –12 –11.82 V

A

Over all conditions –12.24 –11.64 V

Line Regulation VIN = –12.5V to –15V 5 15 mV

Load Regulation I

Output Noise Voltage T

Drop Out Voltage, VOUT - VIN I

= 0mA to 0.5A 0.1 0.3 %

OUT

= 25°C, BW = 10Hz to 10kHz 200 µVRMS

A

0.5A, VOUT = –11.6V 0.15 0.5 V

OUT

50mA, VOUT = –11.6V 15 50 mV

I

OUT

2

UCC284-5/-12/-ADJ

UCC384-5/-12/-ADJ

ELECTRICAL CHARACTERISTICS:

for the UCC284, VIN = VOUT – 1.5V, I

T

= TA.

J

OUT

Unless otherwise specified, TA= 0°C to 70°C for the UCC384 and –40°C to 85°C

= 0mA, C

= 4.7µF, and CT = 0.015µF. For UCC384-ADJ, VOUT is set to –3.3V.

OUT

PARAMETER TEST CONDITIONS MIN TYP MAX UNITS

UCC384-12 Fixed –12V 0.5A Power Supply Section

Input Voltage Range –15 –12.2 V

Quiescent Current VIN = –15V 220 350 µA

Quiescent Current in Shutdown VIN = –15V, SD/CT = 0V, No Load 24 45 µA

Shutdown Threshold At Shutdown Pin –1.0 –0.6 –0.4 V

Shutdown Input Current SD/CT = 0V 5 17 25 µA

Output Leakage in Shutdown VIN = –15V, VOUT = 0, 25°C110µA

Over Temperature 50 µA

Over Temperature Shutdown 140 °C

Over Temperature Hysteresis 20 °C

UCC384-12 Fixed -12V 0.5A Current Limit Section

Peak Current Limit VOUT = 0V 0.7 1.2 1.5 A

Over Current Threshold 0.55 0.7 0.9 A

Current Limit Duty Cycle VOUT = 0V 2.5 4 %

Over Current Time Out, T

ON

VOUT = 0V 300 450 650 µs

UCC384-ADJ Adjustable 0.5A Regulation Section

Reference Voltage T

= 25°C –1.27 –1.25 –1.23 V

A

Over Temperature –1.275 –1.215 V

Line Regulation VIN = –3.5V to –15V, VOUT = VOUTS 0.5 3 mV

Load Regulation I

Output Noise Voltage T

Drop Out Voltage, VOUT - VIN I

= 0mA to 0.5A 0.1 0.18 %

OUT

= 25°C, BW = 10Hz to 10kHz 200 µVRMS

A

0.5A, VOUT = –3.15V 0.25 0.5 V

OUT

50mA, VOUT = 3.15V 25 50 mV

I

OUT

Sense Pin Input Current 100 250 nA

UCC384-ADJ Adjustable 0.5A Power Supply Section

Input Voltage Range –15 –3.5 V

Undervoltage Lockout –3.2 –2.7 V

Quiescent Current Charge Pump On VIN = –3.15V (Note 1) 200 350 µA

Quiescent Current VIN = –15V 200 250 µA

Quiescent Current in Shutdown VIN = –15V, SD/CT = 0V, No Load 24 45 µA

Shutdown Threshold At Shutdown Pin –1.0 –0.6 –0.4 V

Shutdown Input Current SD/CT = 0V 5 17 25 µA

Output Leakage in Shutdown VIN = –15V, VOUT = 0, 25°C110µA

Over Temperature 50 µA

Over Temperature Shutdown 140 °C

Over Temperature Hysteresis 20 °C

UCC384-ADJ Adjustable 0.5A Current Limit Section

Peak Current Limit VOUT = 0V 0.7 1.1 1.5 A

Over Current Threshold 0.55 0.7 0.9 A

Current Limit Duty Cycle VOUT = 0V 2.5 4 %

Over Current Time Out, T

ON

Note 1: Internal Charge Pump is enabled only for drop-out condition with low VIN. Only in this condition is the Charge Pump re

VOUT = 0V 300 450 650 µs

quired to provide additional output FET gate drive to maintain drop-out specifications. For conditions where the Charge

Pump is not required, it is disabled, which lowers overall device power consumption.

3

PIN DESCRIPTIONS

GND: This is the low noise ground reference input. All

voltages are measured with respect to the GND pin.

SD/CT: This is the shutdown pin and also the short cir

cuit timing pin. Pulling this pin more positive than –0.6V

will put the circuit in a low current shutdown mode.

Placing a timing capacitor between this pin and GND will

set the short circuit charging time, TON during an

overcurrent condition. During an overcurrent condition,

the output will be pulsed at approximately a 2.5% duty

cycle.

Note: The CT capacitor must be connected between this pin

and GND, not VIN, to assure that the SD/CT pin is not pulled

significantly negative during power-up. This pin should not be

externally driven more negative than –5V or the device will be

damaged.

VIN: This is the negative input supply. Bypass this pin to

GND with at least 1µF of low ESR, ESL capacitance.

UCC284-5/-12/-ADJ

UCC384-5/-12/-ADJ

VOUT: Regulated negative output voltage. A single

4.7µF capacitor should be connected between this pin

and GND. Smaller value capacitors can be used for light

loads, but this will degrade the load step performance of

the regulator.

VOUTS: This is the feedback pin for sensing the output

of the regulator. For the UCC384-5 and UCC384-12 ver

sions, VOUTS can be connected directly to VOUT. If the

load is placed at a considerable distance from the regu

lator, the VOUTS lead can be used as a Kelvin connec

tion to minimize errors due to lead resistance.

Connecting VOUTS at the load will move the resistance

of the VOUT wire into the control loop of the regulator,

thereby effectively canceling the IR drop associated with

the load path.

When using a UCC384-ADJ, the output voltage can be

programmed by placing a resistor divider across the out

put to GND. VOUTS is connected to the center tap of the

divider providing the feedback for the regulator. This configuration is shown in Fig. 1.

-

-

-

-

APPLICATION INFORMATION

Overview

The UCC384 family of NEGATIVE low dropout linear

(LDO) regulators provides a regulated output voltage for

applications with up to 0.5A of load current. The regulators feature a low dropout voltage and short circuit protection, making their use ideal for demanding

applications requiring fault protection.

Programming the output voltage on the UCC384

The UCC384-5 and UCC384-12 have fixed output volt

ages of –5V and –12V respectively. Connecting VOUTS

to VOUT will give the proper output voltage with respect

to ground.

The UCC384-ADJ can be programmed for any output

voltage between –1.25V and –15V. This is easily accom

plished with the addition of an external resistor divider

connected between GND and VOUT with VOUTS con

nected to the center tap of the divider. For an output of

–1.25V, no resistors are needed and VOUTS is con

nected directly to VOUT. The regulator input voltage can

not be more positive than the UVLO threshold, or

approximately –3V. Thus, low drop out cannot be

achieved when programming the output voltage more

positive than approximately –3.3V. A typical Application

circuit is shown in Fig. 1.

(+)

VIN

CT

0.015µF

8

SD/CT

CIN

+

1µF

4

GND

UCC384-ADJ

VOUTS

VOUT

R2

1

C1

5

+

R1

-

VIN VIN VIN VIN

32

6 7

(–)

Note 1: R1 and R2 for –ADJ version only. For –5 and –12

-

versions, connect VOUTS to VOUT.

-

Figure 1. Typical application schematic.

For the UCC384-ADJ, the output voltage is programmed

by the following equation:

-

R

1

VOUT

=− • +

125 1

.

R

2

When R1 or R2 are selected to be greater than about

100kΩ, a small ceramic capacitor should be placed

across R1 to cancel the input pole created by R1 and the

parasitic capacitance appearing on VOUTS. Values of

approximately 20pF should be adequate.

(+)

VOUT

COUT

4.7µF

(–)

UDG-99029

(1)

4

APPLICATION INFORMATION (cont.)

Dropout Performance

The UCC384 is tailored for low dropout applications

where low quiescent power is important. Fabricated with

a BCDMOS technology ideally suited for low input to out

put differential applications, the UCC384 will pass 0.5A

while requiring only 0.2V of headroom. The dropout volt

age is dependent on operating conditions such as load

current, input and load voltages, and temperature. The

UCC384 achieves a low R

internal charge-pump that drives the MOSFET gate.

Fig. 2 shows typical dropout voltages versus output volt

age for the UCC384–5V and –12V versions as well as

the UCC384-ADJ version programmed between –3.3V

and –15V. Since the dropout voltage is also affected by

output current, Fig. 3 shows typical dropout voltages vs.

load current for different values of V

Operating temperatures also effect the R

dropout voltage of the UCC384. Fig. 4 shows typical

dropout voltages for the UCC384 over temperature under a full load of 0.5A.

(on) through the use of an

DS

.

OUT

(on) and the

DS

UCC284-5/-12/-ADJ

UCC384-5/-12/-ADJ

Iout=0.1A Iout=0.2A Iout=0.3A

Iout=0.4A Iout=0.5A

0.3

-

-

-

0.25

0.2

0.15

0.1

Vin - Vout (V)

0.05

0

3 6 9 12 15

–Vout (V)

Figure 2. Dropout voltage vs. output voltage.

0.25

VOUT= -15V VOUT= -12V

0.2

VOUT= -5V VOUT= -3.3V

Short Circuit Protection

The UCC384 provides unique short circuit protection circuitry that reduces power dissipation during a fault.

When an overcurrent condition is detected, the device

enters a pulsed mode of operation, limiting the output to

a 2.5% duty cycle. This will reduce the heat sink requirements during a fault. The operation of the UCC384 during an overcurrent condition is shown in Fig. 5.

UCC384 Short Circuit Timing

During normal operation the output voltage is in regula

tion and the SD/CT pin is held to –1.5V via a 50kΩ inter

nal source impedance. If the output current rises above

the Overcurrent Threshold, the CT capacitor will be

charged by a 40µA current sink. The voltage on the

SD/CT pin will move in a negative direction with respect

to GND.

During an overcurrent condition, the regulator will ac

tively limit the maximum output current to the Peak Cur

rent Limit. This will limit the output voltage of the

regulator to:

VI R

=•

OUT PEAK L

If the output current stays above the Overcurrent Thresh

old, the voltage on the SD/CT pin will reach –2.6V with

respect to GND and the output will turn off. The CT ca

pacitor is then discharged by a 1µA current source.

When the voltage on the SD/CT pin reaches –1.6V with

respect to GND, the output will turn back on. This pro

cess will repeat until the output current falls below the

Overcurrent Threshold.

0.15

0.1

Vin - Vout (V)

0.05

0

0.05 0.1 0.15 0.2 0.25 0.3 0.35 0.4 0.45 0.5

-

-

Figure 3. Dropout voltage vs. load current.

Vout = -3.3v Vout = -5v

Vout = -12v Vout = -15v

0.4

-

-

-

-

-

0.35

0.3

0.25

0.2

0.15

VIN-VOUT(v)

0.1

0.05

0

-50 -25 0 25 50 75 100

TEMPERATURE (°C)

Iout (A)

Iout = –500mA

Figure 4. Dropout voltage vs. temperature.

5

APPLICATION INFORMATION (cont.)

UCC284-5/-12/-ADJ

UCC384-5/-12/-ADJ

IOUT=0A

IOUT (NOM)

IOVER

IPEAK

VOUT = 0V

VOUT

=(IPEAK)(RL)

VOUT NOM. (–V)

T

OFF

T

ON

~40xTON

NOTE: CURRENT FLOW IS INTO THE DEVICE

T

T

ON

OFF

~40xTON

T

ON

CT = 0V

CT (NOM) = – 1.6V

CT = – 2.6V

Figure 5. Short circuit timing.

TON, the time the output is on during an overcurrent con

dition is determined by the following equation:

TCTF

=•µ

ON

()

V

µ140

A

seconds

(2)

TOFF, the time the output is off during an overcurrent

condition is determined by the following equation:

TCTF

=•µ

OFF

()

V

A

µ11

seconds

(3)

-

Capacitive Loads

A capacitive load on the regulator’s output will appear as

a short circuit during start-up. If the capacitance is too

large, the output voltage will not come into regulation

during the initial TON period and the UCC384 will enter a

pulsed mode operation. For a constant current load the

maximum allowed output capacitance is calculated as

follows:

C

[]

max

()

OUT

=

T

IAIA

PEAK LOAD

−•

() ()

VV

sec

()

ON

OUT

Farads

()

UDG-99031

(4)

6

APPLICATION INFORMATION (cont.)

UCC284-5/-12/-ADJ

UCC384-5/-12/-ADJ

Figure 6. UCC384-ADJ operation during overcurrent

condition (1ms/div).

For worst case calculations, the minimum value for TON

should be used, which is based on the value of CT capacitor selected. For a resistive load the maximum output

capacitor can be estimated as follows:

C

Fig. 6 and Fig. 7 are oscilloscope photos of the

UCC384-ADJ operating during an overcurrent condition.

Fig. 6 shows operation of the circuit as the output current

initially rises above the Overcurrent Threshold. This is

shown on a 1ms/div. scale. Fig. 7 shows operation of the

same circuit on a 25ms/div. scale allowing us to see one

complete cycle of operation during an overcurrent condi

tion.

Shutdown Feature of the UCC384

The shutdown feature of the UCC384 allows the device

to be placed in a low quiescent current mode. The

UCC384 is shut down by pulling the SD/CT pin more

positive than –0.6V with respect to GND. Fig. 8 shows

how a shutdown circuit can be configured for the

UCC384 using a standard TTL signal to control it.

max

()

Ω

=

T

sec

()

ON

l

•

1

−

IAR

MAX LOAD

()

OUT

Rn

LOAD

1

VV

()

OUT

•

() ()

Ω

(5)

Farads

Figure 7. UCC384-ADJ operation during overcurrent

condition (25ms/div.).

Controlling the SD/CT Pin

Forcing the SD/CT pin to any fixed voltage will affect the

operation of the circuit. As mentioned before, pulling the

SD/CT pin more positive than –0.6V will put the circuit in

a shutdown mode, limiting the quiescent current to less

than 45µA. Pulling this pin more positive than +6V with

respect to GND will damage the device.

Forcing the SD/CT pin to any fixed voltage between

–0.6V and –2.6V with respect to GND will cause the cir

cuit to ignore an overcurrent condition. In this situation,

the output will not be pulsed at a 2.5% duty cycle, but the

output current will still be limited to the Peak Current

Limit. This circuit maybe used where a fixed current limit

is needed, while a 2.5% duty cycle is undesirable. The

UCC384 will supply a maximum current in this configura

tion as long as the temperature of the device does not

exceed the Over Temperature Shutdown. This will be de

termined by the Peak Current being supplied, the input

-

and output voltages, and the type of heat sink being

used. Thermal Design will be discussed later on in this

data sheet.

Forcing the SD/CT pin to a voltage level between ap

proximately –2.6V and –5V with respect to GND will turn

the output off completely. The output will stay off as long

as the voltage is applied. Pulling this pin more negative

than –5V with respect to GND will damage the device.

-

-

-

-

7

APPLICATION INFORMATION (cont.)

TTL SHUTDOWN CIRCUIT

+5V

470k

+5V

LOGIC

INPUT

GND

UCC284-5/-12/-ADJ

UCC384-5/-12/-ADJ

(+)

+

VIN

(-)

1µF

CIN

0.015µF

CT

GND

SD/CT

8

UCC384-ADJ

VIN VIN VIN VIN

32

4

Figure 8. TTL controlled shutdown circuit for the UCC384.

Fig. 9 shows typical VOUT leakage current as a function

of temperature during shutdown.

VIN to VOUT Delay

During power-up there is a delay between VIN and

VOUT. The majority of this delay time is due to the

charging time of the CT capacitor. When VIN moves

more negative than the UVLO of the device with respect

to GND, the CT capacitor will start to charge. A 17

current sink is used only during power-up to charge the

the CT capacitor, the greater the delay time between VIN

and VOUT. Fig. 10 shows the VIN to VOUT startup delay, approximately 16ms, for a circuit with CT = 0.22µF.

Shorter delay times can be achieved with a smaller CT

capacitor. The problem with a smaller CT capacitor is

that with a very large load, the circuit may stay in

overcurrent mode and never turn on. A circuit with a

large capacitive load will need a large CT capacitor to

A

operate properly.

CT capacitor. When the voltage on the SD/CT pin

reaches approximately –1.6V with respect to GND, the

output will turn on and regulate. The larger the value of

VOUTS

VOUT

6 7

(+)

R2

1

5

+

R1

C1

VOUT

COUT

4.7µF

(–)

UDG-99032

Figure 9. VOUT leakage current in shutdown (VIN=

–15V).

Figure 10. VIN to VOUT delay time during power-up

with CT = 0.22

µ

F.

8

APPLICATION INFORMATION (cont.)

UCC284-5/-12/-ADJ

UCC384-5/-12/-ADJ

(+)

CT

0.22µF

8

SD/CT

+

(–)

CINVIN

1µF

QUICK START CURRENT

C2

0.1µF

Q1

2N7000

R3

12k

R4

18k

VIN VIN VIN VIN

Figure 11. Quick start-up circuit for UCC384.

One way to shorten the delay from VIN to VOUT during

power-up, is by the use of the Quick Start-up circuit

shown in Fig. 11.

With the Quick Start-Up circuit, the delay time between

VIN and VOUT during start-up can be reduced dramatically. Fig. 12 shows that with the Quick Start-Up circuit,

the VIN to VOUT delay time has been reduced to approximately 1ms.

Operation of the Quick Start-Up Circuit

(+)

C1

R2

+

COUT VOUT

4.7µF

R1

(–)

4

GND

UCC384-ADJ

32

6 7

VOUTS

VOUT

1

5

Q1 will need to be turned off after a fixed time to prevent

the SD/CT pin from going too far negative with respect to

GND. If the SD/CT pin is allowed to go too far negative

with respect to GND, the output will turn off again or possibly even damage the SD/CT pin. The maximum

amount of time that Q1 should be allowed to be on is referred to as TM and can be calculated as follows:

2616.

TT

=•

MD

.

Seconds

UDG-99032

(7)

During normal start-up, the UCC384 will not turn on until

the voltage on the SD/CT pin reaches approximately

–1.6V with respect to ground. It will take a certain

amount of time for the CT capacitor to charge to this

point. For a circuit that has a very large load, the CT ca

pacitor will also need to be large in order for the

overcurrent timing to work properly. A large value of ca

pacitance on the SD/CT pin will increase the VIN to

VOUT delay time.

The quick start-up circuit uses Q1 to quickly pull the

SD/CT pin in a negative direction during start-up, thus

decreasing the VIN to VOUT delay time. When VIN is ap

plied to the circuit, Q1 turns on and starts to charge the

CT capacitor. The current pulled through R4 will deter

mine the rate at which CT is charged. R4 can be calcu

lated as follows:

VVT

R

416=

•

() ( )

IN D

CT F

•

.

()

sec

Ohms

(6)

TD is the approximate VIN to VOUT delay time you wish

to achieve.

-

-

-

-

-

Figure 12. VIN to VOUT delay time with quick

start-up circuit.

9

APPLICATION INFORMATION (cont.)

R3 along with C2 set the time that Q1 is allowed to be

on. Since TM is the maximum amount of time that Q1

should be allowed to stay on, an added safety margin

may be to use 0.9 • TM instead. This will ensure that Q1

is turned off in the proper amount of time. With a chosen

value for C2, R3 can be calculated as follows:

T

09

•

R

3

=

CF n

.sec

21

l

••−

()

M

()

VV

()

IN

VV

()

IN

−

16

.

Ohms

(8)

UCC284-5/-12/-ADJ

UCC384-5/-12/-ADJ

ja

)be

ja

shutdown, the case to ambient thermal resistance (θ

must keep the junction temperature below 150°C. If the

UCC384 is mounted on a 5 square inch pad of 1 ounce

copper, for example, the thermal resistance (θ

comes 40-70 °C/W. If a lower thermal resistance is re

quired by the application, the device heat sinking would

need to be improved.

When the UCC384 is in a pulsed mode, due to an

overcurrent condition, the maximum average power dis

sipation is calculated as follows:

)

-

-

-

After the CT capacitor has charged up for a time equal to

0.9 • TM , Q1 will turn off and allow the SD/CT pin to be

pulled back to –1.5V with respect to GND through a 50k

resistor. At this point , the SD/CT pin can be used by the

UCC384 overcurrent timing control.

Minimum V

Although it may desirable to have as short a delay time

as possible, a small portion of this delay time is fixed by

the UCC384 and cannot be shortened. This is shown in

Fig. 13, where the CT capacitor has been removed from

the circuit completely, giving a fixed VIN to VOUT delay

of approximately 150µs for a circuit with VIN = –6V and

VOUT = –5V.

Thermal Design

The Packaging Information section of this data book contains reference material for the thermal ratings of various

packages. The section also includes an excellent article

entitled

, which is the basis for the following discussion.

ages

Thermal design for the UCC384 includes two modes of

operation, normal and pulsed. In normal mode, the linear

regulator and heat sink must dissipate power equal to

the maximum forward voltage drop multiplied by the

maximum load current. Assuming a constant current

load, the expected heat rise at the regulator’s junction

can be calculated as follows:

To V

IN

Thermal Characteristics of Surface Mount Pack

Delay Time

OUT

P

=

AVE

T

VV V V I A

[]

As seen in equation 10, the average power during a fault

is reduced dramatically by the duty cycle, allowing the

heat sink to be sized for normal operation. Although the

peak power in the regulator during the T

significant, the thermal mass of the package will generally keep the junction temperature from rising unless the

T

ON

−••

() ()

IN OUT PEAK

period is increased to several milliseconds.

()

sec

()

ON

T

•

()

ON

period can be

ON

sec40

-

Watt

(10)

s

T P jc ca C

=•+°θθ

RISE DISS

Theta (

power dissipated. The junction to case thermal resis

tance (

der to prevent the regulator from going into thermal

UNITRODE CORPORATION

7 CONTINENTAL BLVD. • MERRIMACK, NH 03054

TEL. (603) 424-2410 FAX (603) 424-3460

) is the thermal resistance and P

jc

) of the SOIC-8 DP package is 22°C/W. In or

()

DISS

(9)

is the

-

Figure 13. VIN to VOUT delay with CT capacitor

-

removed.

10

Loading...

Loading...