Datasheet UCC3837N, UCC3837DTR, UCC3837D, UCC2837N, UCC2837DTR Datasheet (Texas Instruments)

...

UCC1837

UCC2837

UCC3837

SLUS228A - AUGUST 1999

FEATURES

•

On Board Charge Pump to Drive

External N-MOSFET

•

Input Voltage as Low as 3V

•

Duty Ratio Mode Over Current

Protection

•

Extremely Low Dropout Voltage

•

Low External Parts Count

•

Output Voltages as Low as 1.5V

8-Pin N-FET Linear Regulator Controller

1

5

28

6

3

47

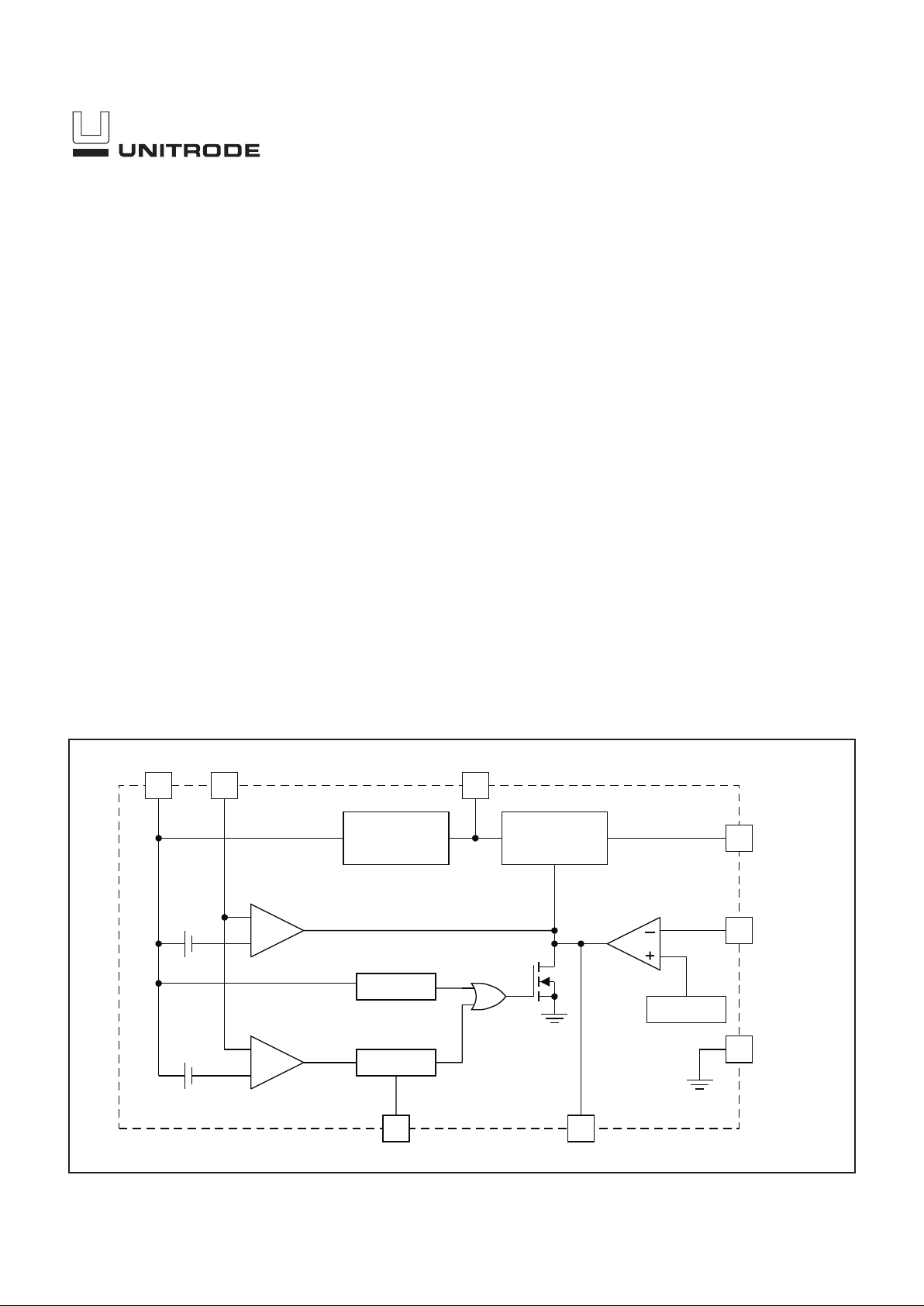

CHARGE

PUMP

CAP

LEVEL

SHIFT

1.5V REF

UVLO

TIMER

CURRENT SENSE

COMPARATOR

COMPCT

CSVDD

CURRENT SENSE

AMPLIFIER

++

VOUT

FB

GND100mV

140mV

ERROR AMPLIFIER

BLOCK DIAGRAM

UDG-99145

DESCRIPTION

The UCC3837 Linear Regulator Controller includes all the features re

quired for an extremely low dropout linear regulator that uses an external

N-channel MOSFET as the pass transistor. The device can operate from

input voltages as low as 3V and can provide high current levels, thus pro

viding an efficient linear solution for custom processor voltages, bus ter

mination voltages, and other logic level voltages below 3V. The on board

charge pump creates a gate drive voltage capable of driving an external

N-MOSFET which is optimal for low dropout voltage and high efficiency.

The wide versatility of this IC allows the user to optimize the setting of

both current limit and output voltage for applications beyond or between

standard 3-terminal linear regulator ranges.

This 8-pin controller IC features a duty ratio current limiting technique that

provides peak transient loading capability while limiting the average

power dissipation of the pass transistor during fault conditions. See the

Application Section for detailed information.

2

UCC1837

UCC2837

UCC3837

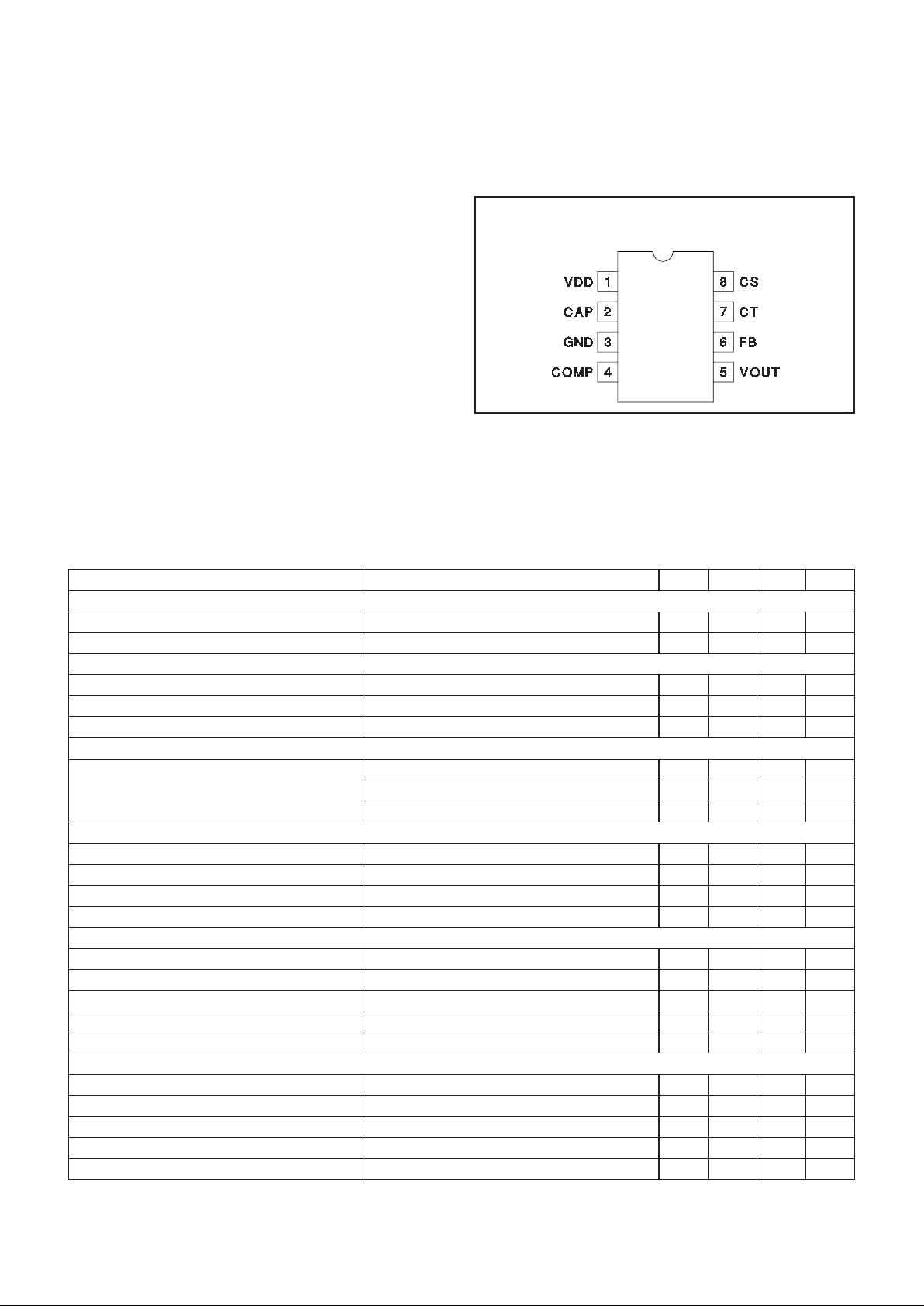

CONNECTION DIAGRAM

ELECTRICAL CHARACTERISTICS:

Unless otherwise specified, TA= –55°C to 125°C for the UCC1837, –25°C to 85°C

for the UCC2837 and 0°C to 70°C for UCC3837; VDD = 5V, CT= 10nF, C

CAP

= 100nF.

PARAMETER TEST CONDITIONS MIN TYP MAX UNITS

Input Supply

Supply Current VDD = 5V 1 1.5 mA

VDD = 10V 1.2 2 mA

Under Voltage Lockout

Minimum Voltage to Start 2.00 2.65 3.00 V

Minimum Voltage After Start 1.6 2.2 2.6 V

Hysteresis 0.25 0.45 0.65 V

Reference ( Note 1 )

V

REF 25°C 1.485 1.5 1.515 V

0°C to 70°C 1.470 1.5 1.530 V

–55°C to 125°C 1.455 1.5 1.545 V

Current Sense

Comparator Offset 0°C to 70°C 90 100 110 mV

Comparator Offset –55°C to 125°C 85 100 115 mV

Amplifier Offset 120 140 160 mV

Input Bias Current V

CS = 5V 0.5 5 µA

Current Fault Timer

CT Charge Current V

CT = 1V 16 36 56 µA

CT Discharge Current V

CT = 1V 0.4 1.2 1.9 µA

CT Fault Low Threshold 0.4 0.5 0.6 V

CT Fault Hi Threshold 1.3 1.5 1.7 V

Fault Duty Cycle 2 3.3 5 %

Error Amplifier

Input Bias Current 0.5 2 µA

Open Loop Gain 60 90 dB

Transconductance –10µA to 10µA 2 5 8 mMho

Charge Current V

COMP = 6V 20 40 60 µA

Discharge Current V

COMP = 6V 10 25 40 µA

DIL-8, SOIC-8 (Top View)

J or N Package, D Package

ABSOLUTE MAXIMUM RATINGS

All pins referenced to GND . . . . . . . . . . . . . . . . .–0.3V to +15V

CS, CT, FB. . . . . . . . . . . . . . . . . . . . . . . . –0.3V to VDD + 0.3V

Storage Temperature . . . . . . . . . . . . . . . . . . . –65°C to +150°C

Junction Temperature. . . . . . . . . . . . . . . . . . . –55°C to +150°C

Lead Temperature (Soldering, 10sec.) . . . . . . . . . . . . . +300°C

Currents are positive into, negative out of the specified terminal.

Consult Packaging Section of Databook for thermal limitations

and considerations of packages.

3

UCC1837

UCC2837

UCC3837

ELECTRICAL CHARACTERISTICS:

Unless otherwise specified, TA= –55°C to 125°C for the UCC1837, –25°C to 85°C

for the UCC2837 and 0°C to 70°C for UCC3837; VDD = 5V, CT= 10nF, C

CAP

= 100nF.

PARAMETER TEST CONDITIONS MIN TYP MAX UNITS

FET Driver

Peak Output Current V

CAP = 10V, VOUT = 1V 0.5 1.5 2.5 mA

Average Output Current VOUT = 1V 25 100 175 µA

Max Output Voltage VDD = 4.5V, I

OUT = 0µA 8.4 9.7 V

VDD = 4.5V, I

OUT = 10µA, 0°C to 70°C 8 9 V

VDD = 4.5V, I

OUT = 10µA, –55°C to 125°C 7.5 9 V

Charge Pump

CAP Voltage VDD = 4.5V, C/S = 0V 11 12.5 V

VDD = 12V, C/S = 0V 15 16.5 V

Note 1: This is defined as the voltage on FB which results in a DC voltage of 8V on VOUT.

PIN DESCRIPTIONS

CAP: The output of the charge pump circuit. A capacitor

is connected between this pin and GND to provide a

floating bias voltage for an N-Channel MOSFET gate

drive. A minimum of a 0.01µF ceramic capacitor is rec-

ommended. CAP can be directly connected to an external regulated source such as +12V, in which case the

external voltage will be the source for driving the

N-Channel MOSFET.

COMP: The output of the transconductance error amplifier and current sense amplifier. Used for compensating

the small signal characteristics of the voltage loop (and

current loop when Current Sense Amplifier is active in

over curret mode).

CS: The negative current sense input signal. This pin

should be connected through a low noise path to the low

side of the current sense resistor.

CT: The input to the duty cycle timer circuit. A capacitor

is connected from this pin to GND, setting the maximum

ON time of the over current protection circuits. See the

Application Section for programming instructions.

FB: The inverting terminal of the voltage error amplifier,

used to feedback the output voltage for comparison with

the internal reference voltage. The nominal DC operating

voltage at this pin is 1.5V

GND: Ground reference for the device. For accurate output voltage regulation, GND should be referenced to the

output load ground.

VDD: The system input voltage is connected to this

point. VDD must be above 3V. VDD also acts as one

side of the Current Sense Amplifier and Comparator.

VOUT: This pin directly drives the gate of the external

N-MOSFET pass element. The typical output impedance

of this pin is 6.5kΩ.

Topology and General Operation

Unitrode Application Note U-152 is a detailed design of a

low dropout linear regulator using an N-channel

MOSFET as a pass element, and should be used as a

guide for understanding the operation of the circuit

shown in Fig. 1.

Charge Pump Operation

The internal charge pump of the UCC3837 is designed to

create a voltage equal to 3 times the input VDD voltage

at the CAP pin. There is an internal 5V clamp at the input

of the charge pump however that insures the voltage at

CAP does not exceed the ratings of the IC. This CAP

voltage is used to provide gate drive current to the exter

-

nal pass element as well as bias current to internal sec

-

tions of the UCC3837 itself. The charge pump output has

a typical impedance of 80kΩ and therefore the loading of

the IC and the external gate drive reduces the voltage

from its ideal level. The UCC3837 can operate in several

states including having the error amplifier disabled (shut

down), in normal linear regulation mode, and in overdrive

mode where the linear regulator is responding to a tran

sient load or line condition. The maximum output voltage

available at VOUT is shown in Fig. 2 for these various

modes of operation.

The charge pump output is designed to supply 10µAof

average current to the load which is typically the

MOSFET gate capacitance present at the VOUT pin.The

capacitor value used at CAP is chosen to provide holdup

APPLICATION INFORMATION

4

UCC1837

UCC2837

UCC3837

of the CAP voltage should the external load exceed the

average current, which occurs during load and line transient conditions. The value of CAP also determines the

startup time of the linear regulator. The voltage at CAP

charges up with a time constant determined by the

charge pump output impedance (typically 80kΩ) and the

value of the capacitor on CAP.

An external voltage such as +12V may be tied to the

CAP pin directly to insure a higher value of VOUT, which

may be useful when a standard level MOSFET is used or

when VDD is very low and the resulting VOUT voltage

may need to be higher. With an external source applied

to CAP, the maximum voltage at VOUT will be approxi

mately 1V below the external source.The external +12V

source should be decoupled to GND using a minimum of

a 0.01µF capacitor.

Choosing a Pass Element

The UCC3837 is designed for use with an N-channel

MOSFET pass element only. The designer may choose

a logic level or standard gate level MOSFET depending

on the input voltage, the required gate drive, and the

available voltage at VOUT as discussed previously.

MOSFET selection should be based on required dropout

voltage and gate drive characteristics. A lower R

DS(on)

MOSFET is used when low dropout is required, but this

type of MOSFET will have higher gate capacitance which

may result in a slower transient response.

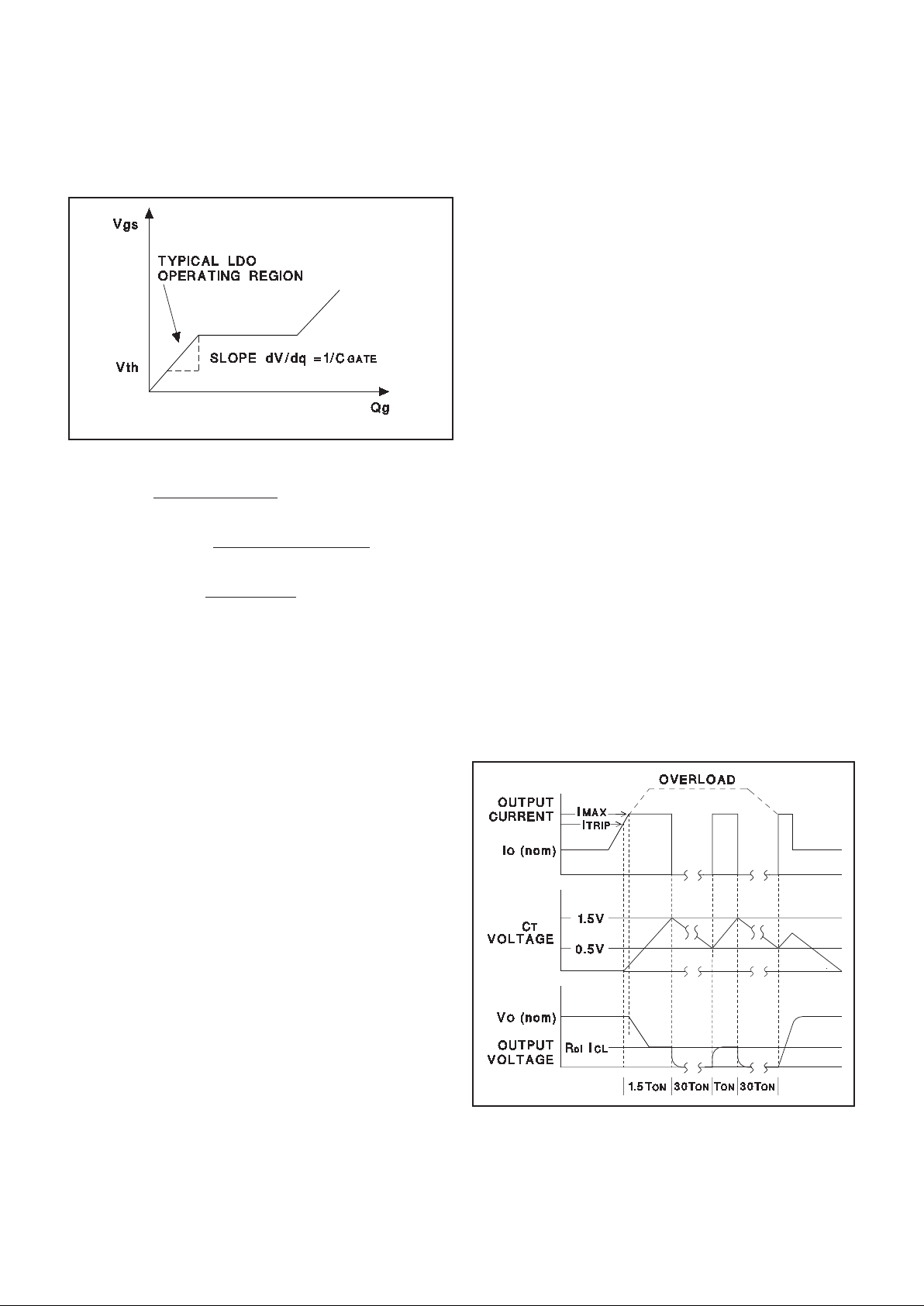

A MOSFET used in linear regulation is typically operated

at a gate voltage between the threshold voltage and the

gate plateau voltage in order to maintain high gain. This

mode of operation is linear, and therefore the channel resistance is higher than the manufacturer’s published

R

DS(on)

value. The MOSFET should only be operated in

the non-linear (switch) mode under transient conditions,

when minimum dropout voltage is required.

Disabling the UCC3837

Grounding the CAP pin will remove the drive voltage and

effectively disable the output voltage. The device used to

short the output of CAP should have a very low leakage

current when in the OPEN state, since even a few

microamps will lower the charge pump voltage.

A second method of disabling the UCC3837 is to place a

short circuit across C

COMP

. This will have an advantage

of a quicker restart time as the voltage at CAP will not be

completely discharged. The charge pump will be loaded

down by the typical 40µA charging current of the error

amplifier with this configuration, resulting in a lower volt

-

age at CAP.

Compensating the Error Amplifier

Using a MOSFET as an external pass element intro

duces a pole in the control loop that is a function of the

UCC3837 output impedance, R

OUT

, typically 6.5kΩ, and

the MOSFET input gate capacitance. Fig. 3 indicates

that in the normal operation of a linear regulator using a

MOSFET, the gate capacitance can be predicted directly

from the MOSFET characteristic charge curve, using the

relationship:

C

Qgth

Vgth

IN

=

∆

∆

This pole can be canceled by programming a zero fre

quency on the output of the UCC3837 error amplifier

equal to the pole frequency. Therefore:

8

1VDD

CS

5VOUT

2CAP

7CT

4COMP

6FB

3GND

Q1

IRL2203N

OR EQUIVALENT

R2

1.8k

R3

1.5k

C3

1000µF

3.3V

R1

0.020

R

COMP

10k

C

COMP

820pF

0.1µF

0.1µFQ1

C1

330µF

5V

ON/OFF

UCC3837

Figure 1. Typical application 5V to 3.3V, 5A

APPLICATION INFORMATION

5

6

7

8

9

10

11

12

13

14

15

3456789101112

VDD

VOUT

E/A DISABLED

LINEAR REGULATOR

OVERDRIVE

Figure 2. Typical V

OUT(max)

vs. VDD.

UDG-99137

5

UCC1837

UCC2837

UCC3837

F

CR

POLE

IN OUT

=

•• •

1

2

π

FF

RC

ZERO POLE

COMP COMP

==

•• •

1

2 π

RC

F

COMP COMP

POLE

=

••

1

2 π

where CINis the MOSFET input capacitance and R

OUT

is

the output impedance of VOUT.

The value of C

COMP

should be large enough that

parasitics connected to COMP do not effect the zero frequency. A minimum of 220pF is recommended.

Transient Response

The transient performance of a linear regulator built using the UCC3837 can be predicted by understanding the

dynamics of the transient event. Consider a load tran

sient on the application circuit of Fig. 1, where the output

current steps from a low value to a high value. Initially,

the output voltage will drop as a function of the output

capacitors ESR times the load current change. In re

sponse to the decrease in feedback voltage at FB, the

UCC3837 error amplifier will increase its charge current

to a typical value of 40µA. The output of the amplifier will

therefore respond by first stepping the voltage propor

tional to 40µA times R

COMP

, and then ramping up pro

portional to 40µA and the value of C

COMP

. Dynamic

response can therefore be improved by increasing

R

COMP

and decreasing C

COMP

.

The value of VOUT will increase the same amount as the

increase in the error amplifier output. The UCC3837 out

-

put gate drive current, however, is internally limited to

1.5mA. The response of the voltage at the gate of the ex

ternal pass element is therefore a function of the 1.5mA

drive current and the external gate charge, as obtained

from the MOSFET data sheet gate charge curve.

For the application circuit shown in Fig. 1, the voltage at

the error amplifier output will increase quickly by 400mV

due to the 40µA current through R

COMP

. The error am

-

plifier will then slew at approximately 50mV per micro

-

second as the 40µA charges C

COMP

.

From the IRL2203N data sheet, the typical required gate

voltage at room temperature, to deliver 5A is 2.6V. The

threshold for the device is approximately 1.5V. From the

gate charge curve for the IRL2203N, approximately 7nC

charge is required to change the gate voltage from 1.5V

to 2.6V. With 1.5mA gate drive current, the required time

to charge the gate is therefore 4.7µs.

Overcurrent Protection and Thermal Management:

Overcurrent protection is provided via the UCC3837’s in

ternal current amplifier and overcurrent comparator. If at

any time the voltage across the current sense resistor

crosses the comparator threshold, the UCC3837 begins

to modulate the output driver at a 3% duty cycle. During

the 3% on time, if the current forces 140mV across the

sense amplifier, the UCC3837 will enter a constant output current mode. Fig. 4 illustrates the cyclical retry of

the UCC3837 under fault conditions. Note that the initial

fault time is longer than subsequent cycles due to the

fact that the timing capacitor is completely discharged

and must initially charge to the reset threshold of 0.5V.

Figure 3. MOSFET turn-on characteristics.

APPLICATION INFORMATION (cont.)

UDG-97046

Figure 4. Load current, timing capacitor voltage and

output voltage under fault conditions.

UDG-97046

6

UCC1837

UCC2837

UCC3837

Fault time duration is controlled by the value of the timing

capacitor, CT, according to the following equation:

tC

V

I

CC

FAULT T T T

=• =•

−

•

=••

−

∆

15 0 5

36 10

278 10

6

3

..

.

(1)

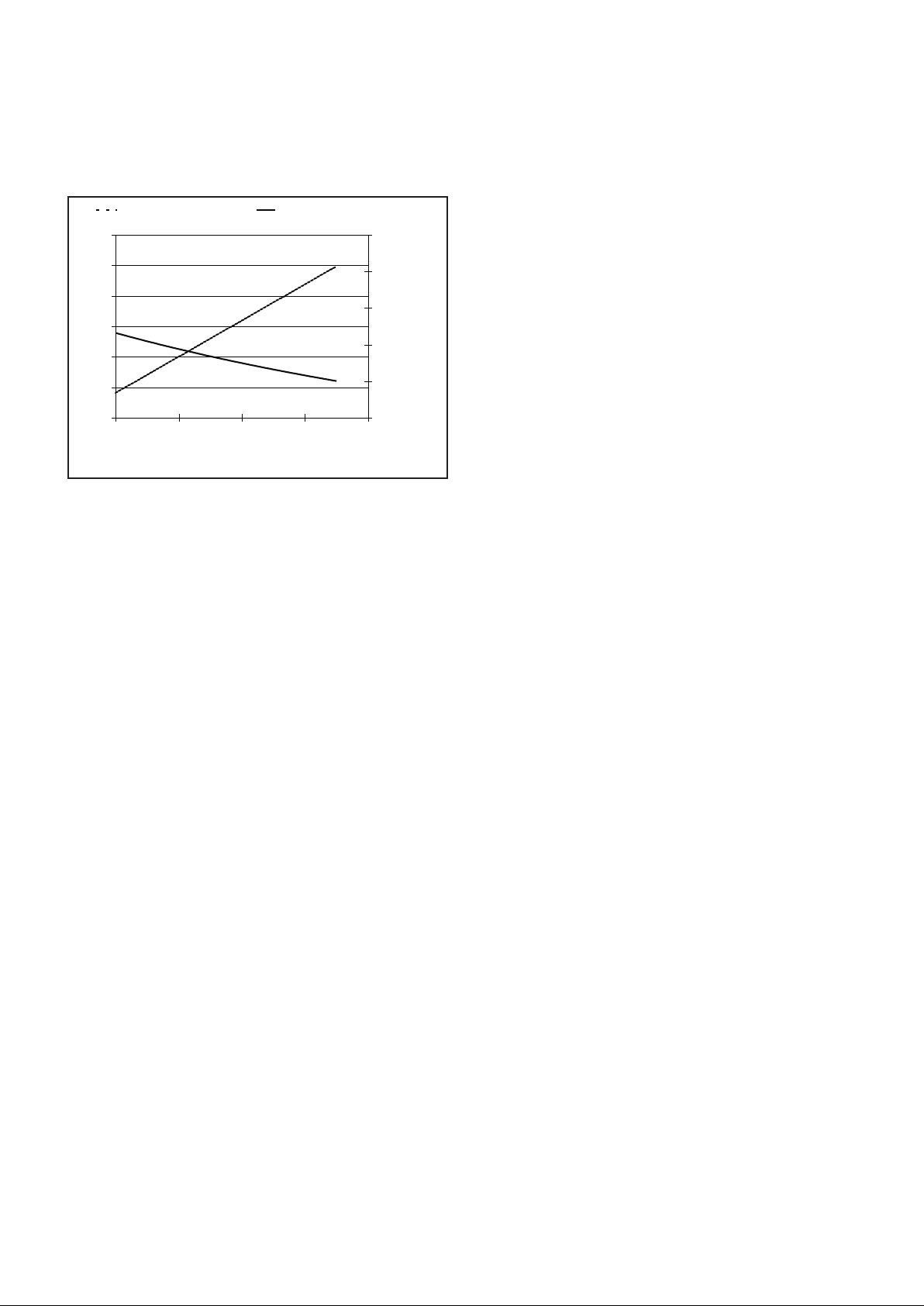

Fig. 5 provides a plot of fault time vs. timing capacitance.

The fault time duration is set based upon the load capac

itance, load current, and the maximum output current.

The “on” or fault time must be of sufficient duration to

charge the load capacitance during a normal startup se

quence or when recovering from a fault. If not, the

charge accumulated on the output capacitance will be

depleted by the load during the “off” time. The cycle will

then repeat, preventing the output from turning on.

To determine the minimum fault time, assume a maxi

mum load current just less than the trip limit. This leaves

the difference between the IMAX and I

TRIP

values as the

current available to charge the output capacitance. The

minimum required fault time can then be calculated as

follows:

()

t

CV

II

FAULT

OUT OUT

MAX TRIP

min

=

•

−

(2)

The minimum timing capacitor can be calculated by sub

-

stituting equation (1) for t

FAULT

in equation (2) and solv

-

ing for CT.

()

()

C

CV

II

T

OUT OUT

MAX TRIP

min

.

=

•

•• −27 8 10

3

(3)

Switchmode protection offers significant heat sinking ad

-

vantages when compared to conventional, constant cur

rent solutions. Since the average power during a fault

condition is reduced as a function of the duty cycle, the

heat sink need only have adequate thermal mass to ab

sorb the maximum steady state power dissipation and

not the full short circuit power. With a 5.25V input and a

maximum output current of 5A, the power dissipated in

the MOSFET is given by:

()

PV V V I

IN SENSE OUT OUT

=− − •

(4)

()

()

PW

=−•−•=5255002335925....

Given that the thermal resistivity of the MOSFET is spec

ified as 1°C/W for the TO-220 package style and assum

ing an ambient temperature of 50°C and a case to heat

sink resistivity of θ

CS

= 0.3°C/W, the heat sink required

to maintain a 125°C junction temperature can be calcu

lated as follows:

()

TTP

J

A

JC CS SA

=+ + +θθθ

(5)

()

125 50 9 25 1 03=+ •++..θ

SA

θ

SA

C

W

≤°68.

Based on this analysis, any heatsink with a thermal resistivity of 6.8 °C/W or less should suffice. The current in

the circuit of Fig. 1, under short circuit conditions, will be

limited to 7A at a 3% duty cycle, resulting in a MOSFET

power dissipation of only:

()

()

()[]

PV I R I Duty

IN OUT SENSE OUT

=−•••

max

(6)

()

()[]

PW

=−• ••=5257 002 7 003107.. ..

Without switchmode protection, the short circuit power

dissipation would be 35.8W, almost four times the nomi

nal dissipation.

Using Printed Circuit Board Etch as a Sense Resistor

Unitrode Design Note DN-71 discusses the use of

printed circuit board copper etch as a low ohm sense re

sistor. This technique can easily be applied when using

the UCC3837. The application circuit shown in Fig. 1 can

be used as an example. This linear regulator is designed

with a 5A average load current, demanding a 20mΩ

sense resistor to result in a 100mV current sense com

parator signal for the UCC3837. The maximum ambient

temperature of the linear regulator is 70°C.

Using DN-71, a 1 ounce outer layer etch of 0.05 inches

wide and 1.57 inches long results in a resistance of

20mΩ at an ambient temperature of 70°C and an operat

ing current of 5A. Because the resistivity of copper is a

function of temperature, the current limit at lower temper

atures will be higher, as shown in Fig. 6.

0

5

10

15

20

25

30

0 0.2 0.4 0.6 0.8 1

CT (uF)

FAULT TIME (ms)

Figure 5. Fault time vs. timing capacitance.

7

UCC1837

UCC2837

UCC3837

Practical Considerations

In order to achieve the expected performance, careful attention must be paid to circuit layout. The printed circuit

board should be designed using a single point ground,

referenced to the return of the output capacitor. All

traces carrying high current should be made as short and

wide as possible in order to minimize parasitic resistance

and inductance effects.

To illustrate the importance of these concepts, consider

the effects of a 1.5" PCB trace located between the out

put capacitor and the UCC3837 feedback reference. A

0.07" wide trace of 1oz. copper results in an equivalent

resistance of 10.4mΩ. At a load current of 3A, 31.2mV is

dropped across the trace, contributing almost 1% error to

the DC regulation. Likewise, the inductance of the trace

is approximately 3.24nH, resulting in a 91mV spike dur

ing the 100ns it takes the load current to slew from

200mA to 3A.

The dropout voltage of a linear regulator is often a key

design parameter. Calculations of the dropout voltage of

a linear regulator based on the UCC3837 Controller

should consider all of the following:

•

Sense resistor drop, including temperature and

tolerance effects,

• Path resistance drops on both the input and output

voltages,

• MOSFET resistance as a function of temperature and

gate drive, including transient performance,

• Ground path drops.

APPLICATION INFORMATION

15

16

17

18

19

20

21

0 20406080

AMBIENT TEMPERATURE [°C]

4

5

6

7

8

9

RESISTANCE SHORT CIRCUIT LIMIT

COPPER RESISTANCE [mW]

SHORT CIRCUIT CURRENT

Figure 6. Copper resistance and short circuit limit

for example resistor.

UNITRODE CORPORATION

7 CONTINENTAL BLVD. • MERRIMACK, NH 03054

TEL. (603) 424-2410 FAX (603) 424-3460

IMPORTANT NOTICE

T exas Instruments and its subsidiaries (TI) reserve the right to make changes to their products or to discontinue

any product or service without notice, and advise customers to obtain the latest version of relevant information

to verify, before placing orders, that information being relied on is current and complete. All products are sold

subject to the terms and conditions of sale supplied at the time of order acknowledgement, including those

pertaining to warranty, patent infringement, and limitation of liability.

TI warrants performance of its semiconductor products to the specifications applicable at the time of sale in

accordance with TI’s standard warranty. Testing and other quality control techniques are utilized to the extent

TI deems necessary to support this warranty. Specific testing of all parameters of each device is not necessarily

performed, except those mandated by government requirements.

CERT AIN APPLICATIONS USING SEMICONDUCTOR PRODUCTS MAY INVOLVE POTENTIAL RISKS OF

DEATH, PERSONAL INJURY, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE (“CRITICAL

APPLICATIONS”). TI SEMICONDUCTOR PRODUCTS ARE NOT DESIGNED, AUTHORIZED, OR

WARRANTED TO BE SUITABLE FOR USE IN LIFE-SUPPORT DEVICES OR SYSTEMS OR OTHER

CRITICAL APPLICATIONS. INCLUSION OF TI PRODUCTS IN SUCH APPLICA TIONS IS UNDERSTOOD T O

BE FULLY AT THE CUSTOMER’S RISK.

In order to minimize risks associated with the customer’s applications, adequate design and operating

safeguards must be provided by the customer to minimize inherent or procedural hazards.

TI assumes no liability for applications assistance or customer product design. TI does not warrant or represent

that any license, either express or implied, is granted under any patent right, copyright, mask work right, or other

intellectual property right of TI covering or relating to any combination, machine, or process in which such

semiconductor products or services might be or are used. TI’s publication of information regarding any third

party’s products or services does not constitute TI’s approval, warranty or endorsement thereof.

Copyright 1999, Texas Instruments Incorporated

Loading...

Loading...