Datasheet UCC3750N, UCC3750DWTR, UCC3750DW, UCC2750DWTR, UCC2750DW Datasheet (Texas Instruments)

UCC2750

UCC3750

PRELIMINARY

DESCRIPTION

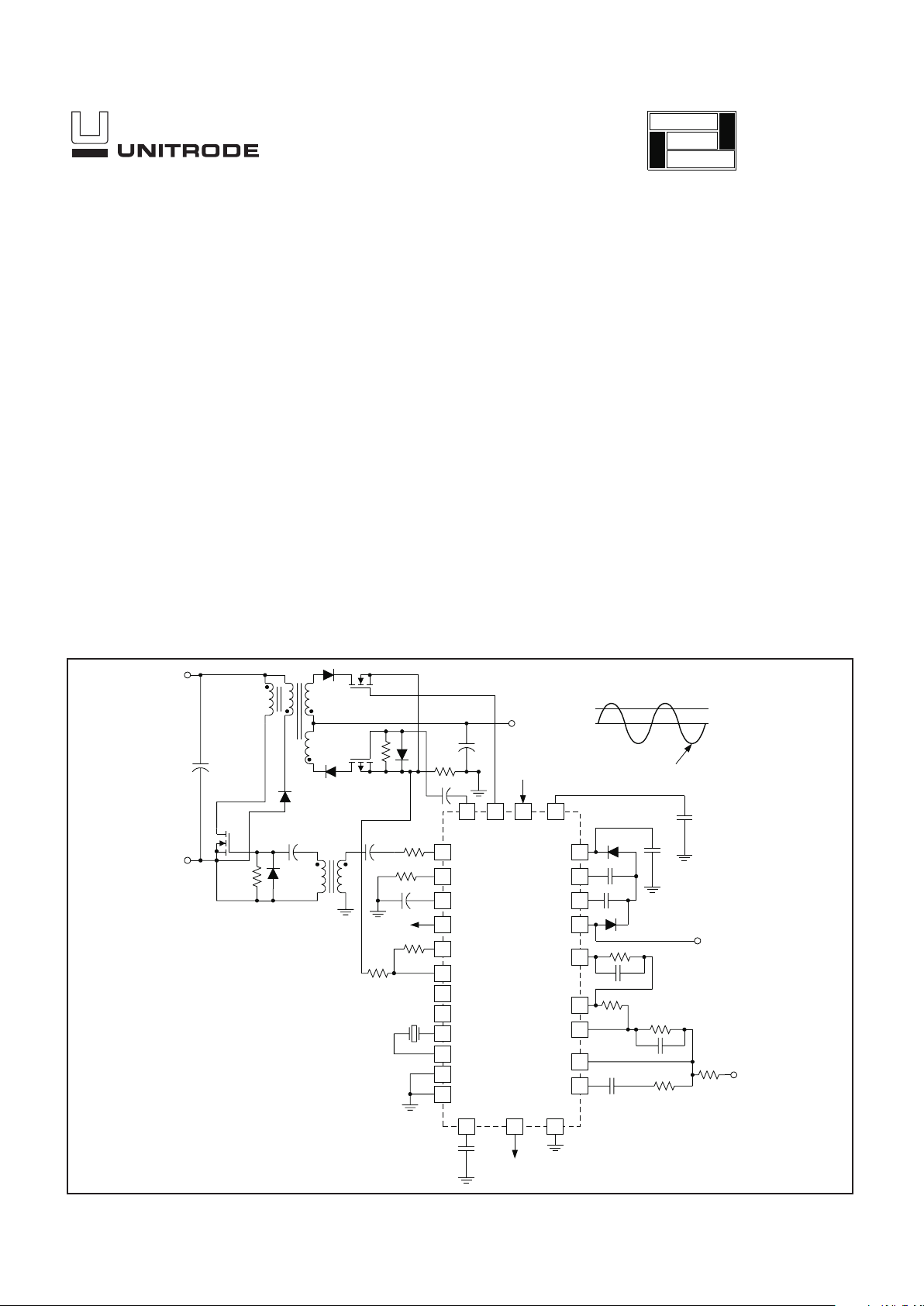

The UCC3750 Source Ringer Controller provides a complete control and

drive solution for a four quadrant flyback-based ring generator circuit. The

IC controls a primary side switch, which is modulated when power transfer

is taking place from input to output. It also controls two secondary

switches which act as synchronous rectifier switches during positive

power flow. These switches are pulse-width-modulated when the power is

being delivered back to the source.

The UCC3750 has an onboard sine wave reference with programmable

frequencies of 20Hz, 25Hz and 50Hz. The reference is derived from a

high-frequency (32kHz) crystal connected externally. Two fre

quency-select pins control an internal divider to give a sinusoidal output at

20Hz, 25Hz or 50Hz. The ring generator can also be used at other fre

quencies by supplying externally generated sine-waves to the chip or by

clocking the crystal input at a fixed multiple of the desired frequency.

Other features included in the UCC3750 are programmable DC current

limit (with buffer amplifier), a charge-pump circuit for gate drive voltage, in

ternal 3V and 7.5V references, a triangular clock oscillator and a buffer

amplifier for adding programmable DC offset to the output voltage. The

UCC3750 also provides an uncommitted amplifier (AMP) for other signal

processing requirements.

Source Ringer Controller

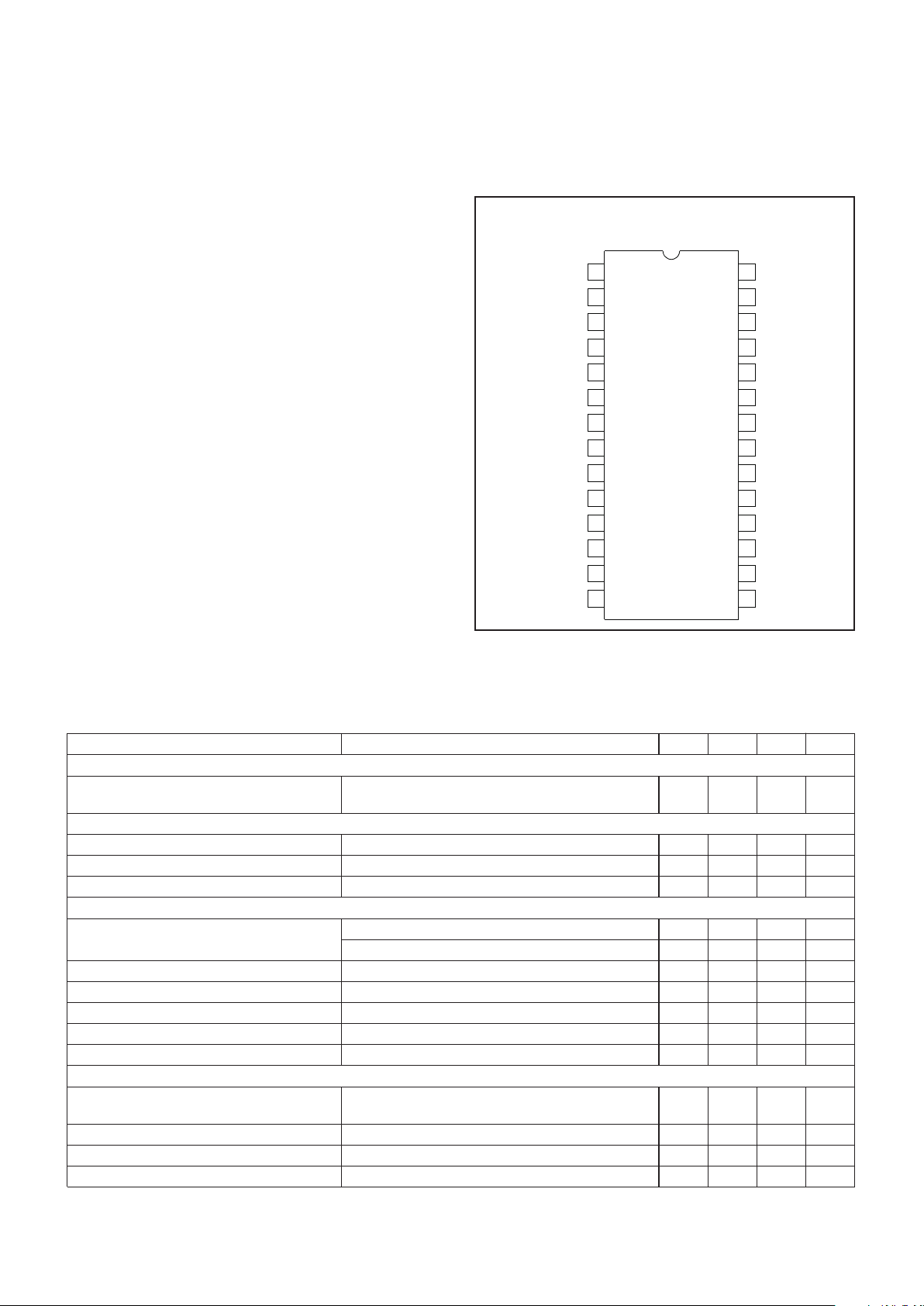

15

28

2

4

26

27

25

6

5

7

18

16

17

10

OUT2

NEG2

VS2

VDD

VS1

VCP

OUT1

NEG1

REFENBLGD3GD2

5V

SINFLT

24

23

1

11

12

OUTDC

NEGDC

RT

RGOOD

CT

GD1

AMPOUT

XTAL1

XTAL2

13

14

22

21

AMPIN

FS0

FS1

20

19

V

IN

48V

UCC3750

9

8

3

SINREF SWRLY GND

C17

0.047µF

V

OUT

0V

–48V

V

OUT

TYPICAL APPLICATION

FEATURES

•

Provides Control for Flyback Based

Four Quadrant Amplifier Topology

•

Onboard Sine Wave Reference with

Low THD

•

Selectable Ringing Frequency for

Different Phone Systems (20Hz,

25Hz and 50Hz)

•

Programmable Output Amplitude and

DC Offset

•

DC Current Limiting for Short Circuit

Protection

•

Secondary Side Voltage Mode

Control

• Operates from a Single 5V Supply

SLUS172A - DECEMBER 1999

UDG-99073

application

INFO

available

2

UCC2750

UCC3750

ABSOLUTE MAXIMUM RATINGS

Input Supply Voltage

VDD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7.5V

Maximum Forced Voltage

VCP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . –0.3V to 13.2V

VS1, VS2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . –0.3V to 5V

OUT1, OUT2, AMPOUT, OUTDC

Maximum Forced Voltage . . . . . . . . . . . . . . . . –0.3V to 7.5V

Maximum Forced Current. . . . . . . . . . . . . . Internally Limited

NEG1, NEG2, AMPIN, NEGDC

Maximum Forced Voltage . . . . . . . . . . . . . . . . –0.3V to 7.5V

SINREF, SINFLT

Maximum Forced Voltage . . . . . . . . . . . . . . . . –0.3V to 7.5V

Logic Inputs

Maximum Forced Voltage . . . . . . . . . . . . . . . . –0.3V to 7.5V

Reference Output Current (REF) . . . . . . . . . . Internally Limited

Output Current (GD1, GD2, GD3)

Pulsed. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.5A

Storage Temperature . . . . . . . . . . . . . . . . . . . –65°C to +150°C

Junction Temperature. . . . . . . . . . . . . . . . . . . –55°C to +150°C

Lead Temperature (Soldering, 10 Sec.). . . . . . . . . . . . . +300°C

Unless otherwise indicated, voltages are reference to ground

and currents are positive into, negative out of the specified terminal. Pulsed is defined as a less than 10% duty cycle with a

maximum duration of 500ns. Consult Packaging Section of

Databook for thermal limitations and considerations of packages.

OUTDC

REF

GD3

ENBL

FS1

RT

CT

XTAL1

GD2

GND

GD1

SINFLT

VDD

SINREF

VCP

VS1

VS2

RGOOD

SWRLY

NEGDC NEG1

XTAL2

FS0

NEG2

AMPOUT

AMPIN OUT2

OUT1

14

13

12

11

10

9

8

7

6

5

4

3

2

1

15

16

17

18

19

20

21

22

23

24

25

26

27

28

CONNECTION DIAGRAM

DIL-28, SOIC- 28 (Top

View)

ELECTRICAL CHARACTERISTICS: Unless otherwise stated, these specifications apply for T

A

= 0°C to 70°C for the

UCC3750, –40°C to +85°C for the UCC2750, RT = 14k, CT = 470pF, C

REF

= 0.1µF, FS0 = 0, FS1 = 0, VDD = 5V. TA=TJ.

PARAMETER TEST CONDITIONS MIN TYP MAX UNITS

VDD Supply

Supply Current - Active With 12V Supplied to V

CP

and Charge Pump

Disabled

0.5 1 mA

Internal Reference w/External Bypass

Output Voltage (REF) 7.3 7.55 7.8 V

Load Regulation I

REF

= 0mA – 2mA 30 60 mV

Line Regulation VCP = 10V to 13V, I

REF

= 1mA 3 15 mV

Amplifier

Input Voltage Error, DC Offset and Amp Amplifiers 2.9 3 3.1 V

DC Limit Amplifier 0.7125 0.75 0.7875 V

Input Bias Current 500 600 nA

AVOL V

OUT

= 2V to 4V 70 dB

VOH Source 100µA 5.35 6 7.0 V

VOL Sink 100µA 0.2 0.65 V

Short Circuit Current V

IN

= 0V and 5V with V

OUT

= 0V and 5V 0.5 2 3 mA

Sine Reference

Accuracy T

J

= 25°C, Program Frequency–Reference

Frequency

–1 0 1 Hz

Total Harmonic Distortion (Note 1) 2 %

Amplitude Peak 0.475 0.5 0.525 V

Offset 2.85 3.0 3.15 V

3

UCC2750

UCC3750

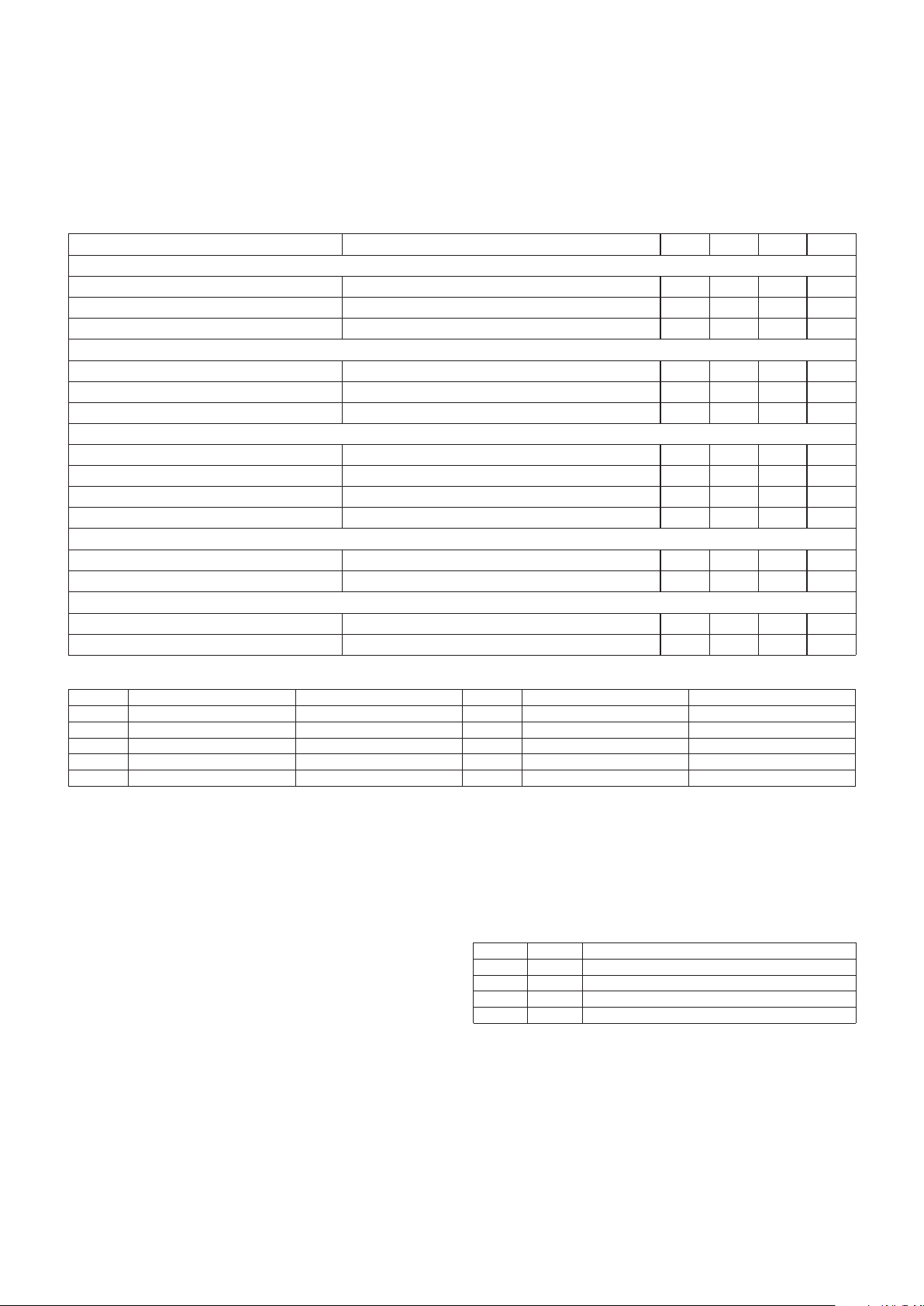

ELECTRICAL CHARACTERISTICS:

Unless otherwise stated, these specifications apply for TA= 0°C to 70°C for the

UCC3750, –40°C to +85°C for the UCC2750, RT = 14k, CT = 470pF, C

REF

= 0.1µF, FS0 = 0, FS1 = 0, VDD = 5V. TA=TJ.

PARAMETER TEST CONDITIONS MIN TYP MAX UNITS

Oscillator

Accuracy 108 128 148 kHz

Peak Voltage 4.6 4.75 4.9 V

Valley Voltage 2.9 3.05 3.2 V

Charge Pump

Switch Pull Up Resistance (VS1, VS2) 10 30 Ω

Switch Pull Down Resistance (VS1, VS2) 10 30 Ω

Output Voltage (VCP) VDD = 5V, I

VCP

= 10mA 11 12 14 V

Output Drivers

Pull Up Resistance 915Ω

Pull Down Resistance 915Ω

Rise Time CL = 2.7nF 50 100 ns

Fall Time CL = 2.7nF 50 100 ns

Current Limit

DC Limit Threshold Voltage Positive R5/R6 = 3 0.4 0.5 0.6 V

DC Limit Threshold Voltage Negative R5/R6 = 3 –0.6 –0.5 –0.4 V

Duty Cycle

Maximum PWM Duty Cycle 48 50 %

Rectifier Duty Cycle 50 %

Note 1: Guaranteed by measuring the steps of the PWL Sine Wave.

STATE % VCC VALUE FOR REF = 7.5 STATE % VCC VALUE FOR REF = 7.5

0 0.3333 2.5 5 0.4255 3.191

1 0.3384 2.538 6 0.4471 3.353

2 0.3528 2.646 7 0.4616 3.462

3 0.3745 2.808 8 0.4666 3.5

4 0.4 3

AMPIN: Inverting input of the uncommitted amplifier.

AMPOUT: Output of the uncommitted amplifier.

CT: This pin programs the internal PWM oscillator

frequency. Capacitor from CT to GND sets the charge

and discharge time of the oscillator.

ENBL: Logic input which enables the outputs and the

charge pump when high. ENBL should be pulled low to

turn the outputs off.

FS0, FS1: Frequency select pins for the internal

sine-wave generator. Table 1 provides the SINREF

frequencies as a function of FS0 and FS1 when a 32kHz

crystal is used at the crystal inputs (XTAL1, XTAL2).

Other proportional frequencies can be obtained with a

different crystal. Inputs FS0 and FS1 are TTL compatible.

Table I. Frequency selection table

(for 32kHz crystal).

FS0 FS1 SINREF (Hz)

00 20

10 25

01 50

1 1 High Impedance

GD1: Output driver that controls the primary side switch

in a flyback converter through a gate drive transformer.

The output signal on this pin is PWM during positive

power transfer modes and zero during negative power

transfer modes.

PIN DESCRIPTIONS

4

UCC2750

UCC3750

GD2: Output driver that controls the p-channel secondary

side switch in the flyback converter. The output signal on

this pin is PWM during mode 4 (Fig. 2) when the

reference signal is negative and power is being returned

to the input. This pin functions as a synchronous rectifier

output during mode 1 with positive reference signal and

positive power transfer. This output is logically inverted to

provide the correct polarity drive signal for a p-channel

switch.

GD3: Output driver that controls the n-channel secondary

side switch in the flyback converter. The output signal on

this pin is PWM during mode 2 (Fig. 2) when the

reference signal is positive and power is being returned

to the input. This pin functions as a synchronous rectifier

output during mode 3 with a negative reference signal

and positive power transfer.

GND: Reference point for the internal reference and all

thresholds. Also provides the signal return path for all

other pins.

NEG1: Inverting input of the buffer amplifier that acts as

a summing junction for the DC (battery) offset voltage

and sinewave reference.

NEG2: Inverting input of the error amplifier where the

ringer output voltage and the reference signal with the

desired offset are applied with a weighted sum.

Feedback compensation is connected between NEG2

and OUT2.

NEGDC: Inverting input of the amplifier used for DC

current limiting.

OUT1: Output of the buffer amplifier that provides scaling

and filtering for the reference signal before feeding it into

the error amplifier. This output is also used internally to

select the PWM mode for the flyback converter.

OUT2: Output of the error amplifier. Used to connect

compensation components. This output’s absolute value

determines the duty cycle of the PWM pulse. The polarity

of this signal also determines the PWM mode.

OUTDC: Output of the DC current limit amplifier. The DC

current limit is activated when this pin is above 4.5V or

below 1.5V.

REF: Internal 7.5V reference. For best results, bypass to

GND with a ceramic capacitor(>0.1µF).

RGOOD: Logic output that indicates that the error

amplifier output is within range (0< D< 0.5). This pin can

source upto 0.5mA of current.

RT: Resistor from RT to GND helps set the oscillator

frequency. RT programs the charge and discharge

currents of CT.

SINFLT: This signal is the buffered version of SINREF.

This signal is summed with the DC offset level with

appropriate scaling.

SINREF: This pin is the output of the sine-wave

reference generator. It has a high output impedance

(≈25kΩ). A 0.01µF capacitor to GND is recommended to

provide smoothing of the sinewave. When FS0 and FS1

are both set high, the sine reference generator is

disabled allowing this pin to accept an external sinewave

input.

SWRLY: Logic output that leads the battery offset

crossings (by typically 5ms) to allow “zero voltage” relay

switching. This pin can typically source 250µA.

XTAL1: Crystal connection for external crystal. This pin

can be also used to clock the internal sine wave

generator when XTAL2 is connected to VDD/2.

XTAL2: Crystal connection for external crystal.

VCP: External connection for charge pump storage

capacitor. A capacitance ≥2.2mF is recommended for

low charge pump output ripple. The voltage at this pin is

used by the output drivers for gate drive voltages.

Alternatively, a regulated gate drive voltage (>10V) can

be connected at this pin while leaving the charge pump

circuit at nodes VS1, VS2 disconnected.

VDD: External supply input used to bias internal logic

functions. Typically a regulated 5V supply is connected

between this pin and GND. It also is the input voltage for

the voltage tripler circuit to generate the gate drive

voltage.

VS1, VS2: Voltage switches for the voltage tripler

(charge pump circuit). They provide different voltage

PIN DESCRIPTIONS (cont.)

5

UCC2750

UCC3750

The UCC3750 provides complete control and protection

functions for a four quadrant flyback converter used to

generate ring signals for telephone circuits. A typical ap

plication circuit for a 15 REN ring generator is shown in

Fig. 1.

As shown, the flyback converter takes a DC input (typi

cally 48V) and provides an isolated output with a pro

grammable frequency (and amplitude) AC signal

superimposed on a programmable DC offset. The power

path consists of a primary side PWM switch Q1, primary

return rectifier DR1, a 4-winding transformer T1, output

rectifiers DR2 and DR3, synchronous/PWM switches Q2

and Q3, and output filter CF. Resistor R

SENSE provides

the output current sensing for protection circuits.

Different operating modes of the converter are depicted

in Table 2. Fig. 2 shows the output voltage and current

waveforms for a purely capacitive load and identifies the

four operating modes. Fig. 3 shows the PWM waveforms

for the circuit and Fig. 4a - 4d show the equivalent cir

cuits under the operating modes. The addition of Q2, Q3

and primary diode facilitates true four quadrant operation

where both the output voltage and power transfer can be

bi-directional. Mode 1 is similar to the commonly used

DC-DC converter operation where Q1 is modulated with

the PWM signal and rectification is provided through the

Q2, DR2 path to provide a positive output proportional to

the increasing, positive reference voltage. The

pulse-width is controlled by the error amplifier output to

increase or decrease the output as dictated by the refer

-

ence. The maximum duty cycle is limited to 50% to pre

-

vent DR1 from turning on prior to Q2/DR2.

In mode 2, the reference begins to decrease, necessitat

ing that the power transfer back to the input. For this

mode, switch Q3 needs to be modulated while DR1 acts

as the rectifier back to the input. The UCC3750 has

mode decoding circuitry which automatically directs the

PWM signal to Q3 and turns off Q1.

APPLICATION INFORMATION

18

21

22

15

FULLW AVE

RECTIFIER

MAG

SIGN

OUT2

MODE SIGN OUT1 OUT2 OUT3

0 0 PWM OFF RECIRC

01 PWMOFF

OFF OFF PWM

OFF

1

1

0

1 PWM RECIRC OFF

CONTROL LOGIC

REF

ERROR

AMP

V

CM

NEG2

17 16

OUT1

REF

DC OFFSET AMP

V

CM

NEG1

2

28

26

V

CP

V

CP

V

CP

GD1

GD2

GD3

MODE

SIGN

PWM

DC

CURRENT

LIMIT

SINE REFERENCE

GENERA T OR

REF

10

SINFLT

9

SINREF

20

FS0

8

SWRLY

19

FS1

XTAL

OSC

14

13

12

11

5

4

7

6

CHARGE

PUMP

INTERNAL

REFERENCE

REF=7.5V

V

CM

=3.0V

25

V

CM

3

GNDREF

VDD

VS2

VS1

NEGDC

VCP

OUTDC

V

CM

4

REF

AMPIN

AMPOUT

XTAL2

XTAL1

MAG

RAMP

CLOCK

GENERA T OR

24

RT

23

CT1RGOOD27ENBL

V

CM

AMP

V

CM

DETAILED BLOCK DIAGRAM

UDG-99074

Note: All pin numbers are for N or DW Packages.

Mode Reference

Polarity

Power

Flow

E.A.

Output

Source

(PWM)

Switch

Rectifier

Switch

1 + + – Q1 Q2

2 + – + Q3 (D1)

3 – + + Q1 Q3

4 – – – Q2 (D1)

Table II. Operating modes.

6

UCC2750

UCC3750

Figure 1. Typical application circuit.

APPLICATION INFORMATION (cont.)

UDG-99075

15

28

2

4

26 27 25

6

CR5

C10

2.2µF

C11 0.22

µF

CR7

5

C12 0.22

µF

7

18

16

17

10

R11 148k

C14 1nF

R12 2.7k

R13 62k

C16 2.2

µF

R15 15k

R14 3.3M

OUT2

NEG2

VS2

VDD

VS1

VCP

OUT1

NEG1

REF

ENBL

GD3

GD2

VDD

5V

SINFLT

C9

0.47µF

24

23

1

11

12

OUTDC

NEGDC

RT

RGOOD

CT

GD1

AMPOUT

XTAL1

XTAL2

13

14

22

21

AMPIN

FS0

FS1

20

19

R3

R4 16k

C7 470pF

C5

0.47µF

R5 30k

R6

10k

X1 32kHz

C6 0.1

µF

R2Q2

CR2

BYV99

R9

C4

1µF

250V

CR8

CR3 BYV26C Q3

CR1

BYV99

R18

VDD

C19

100µF

CR6

R25 10k

C13

1µF

C18

22µF

R26

R27

R10

148k

9 8 3

SINREF SWRLY

GND

C17

0.047µF

S4S1S3

S2

VDD

R17

CR12

IRF840

C20 R20

T1

10

7,9

6

4

5

1

T2

4

3

2

1

C3 0.1

µF

Q4

Q6

MPSA06

Q5

2N5457

3

2

1

3

2

1

3

2

1

R23

CR9

R1

10k

R22

C22

C2

100µF

C1

100µF

C23

0.47

µF

V

IN

RTN

REF

VB

REF

V

OUT

GND

2N7001DICT

R21 C21

CR10

MTP2P50E

7

UCC2750

UCC3750

Figure 2. Operating modes.

Figure 3. Circuit waveforms.

UDG-96172-1 UDG-96173

Figure 4a. Mode 1: Forward power transfer, positive

output.

Figure 4b. Mode 2: Reverse power transfer, positive

output.

UDG-96162-1

UDG-96163

When the reference signal goes from positive to nega

tive, a transition is made from mode 2 to mode 3. In

mode 3, the converter once again acts as a DC-DC

flyback converter (with negative output). Similar to mode

1, Q1 is controlled by the PWM output, however, the rec

tifying path is now through Q3/DR3 as the output polarity

is reversed. At the mode boundaries, there could be

some distortion which won’t affect the THD too much as

it is near zero crossings. Finally, as the reference signal

starts increasing towards zero, the direction of power

transfer is again reversed and Q2 is PWMed in mode 4.

It should be noted that in modes 2 and 3 when the refer

-

ence is decreasing, the phase of the feedback path is in

verted compared to the other two modes. Traditional

PWM methods will result in instability due to this charac

teristic. The UCC3750 separates the error signal magni

tude and polarity and determines the correct PWM signal

based on a separate mode determination circuit.

APPLICATION INFORMATION (cont.)

Figure 4c. Mode 3: Forward power transfer, negative

output.

UDG-96164-1

Figure 4d. Mode 4: Reverse power transfer, negative

output.

UDG-96165-1

8

UCC2750

UCC3750

Sine Reference Generator

The IC has a versatile low frequency sinewave reference

generator with low harmonic distortion and good fre

quency accuracy. In its intended mode as shown in Fig.

5, the reference generator will take an input from a

32kHz crystal (connected between XTAL1 and XTAL2)

and generate a sine-wave at 20Hz, 25Hz or 50Hz based

on the programming of pins FS0 and FS1 (See Table 2).

If the crystal frequency is changed, the output frequen

cies will be appropriately shifted. C-2 type Quartz crystals

(Epson makes available through DigiKey) are recom

mended for this application. If the frequency accuracy is

not a major concern, the more common and less expen

sive clock crystal (C-type) at 32.768kHz can be used with

a minor output frequency offset (20.5Hz instead of 20Hz).

Additionally, the XTAL1 input can be clocked at a desired

frequency to get a different set of output frequencies at

the sine-wave output (with divide ratios of 1600, 1280

and 640). The sine-wave output is centered around an internal reference of 3V. A capacitor from SINREF to GND

helps provide smoothing of the sine wave reference.

Recommended value is at least 0.01µF and maximum of

0.1µF. When FS0 and FS1 are both 1 (high), the sine reference is disabled and external sine-wave can be fed

into the SINREF pin. This signal should have the same

DC offset as the internal sine-wave (3V).

Reference and Error Amplifier

The recommended circuit connections for these circuits

are shown in Fig. 6. The sine-wave is added to a DC offset to create the composite reference signal for the error

amplifier. The DC reference can vary over a wide range.

For pure AC outputs it is zero, while in many common

applications, it is the talk battery voltage (–48V). The

UCC3750 accomplishes this task by summing the two

signals weighted by resisting R14 and R15. The output of

AMP1 also helps determine the mode of the circuit.

Referring to Fig. 6, the output of AMP1 is given by :

VOUT1= 1+

R13

R14

+

R13

R26

•VCM–

R13

R26

•REF

(1)

–

R13

R14

•VB–

R13

R15

• VAC

In order to nullify the effect of V

CM

on this value, the ratio

of R26 to R14 should be made 1.5. With this ratio, the

equation becomes:

VOUT1= VCM–

R13

R14

•VB–

R13

R15

• VAC

(2)

VOUT1 is the reference voltage that the second amplifier

(AMP2) uses to program the output voltage. Assuming

that Z4 is high DC impedance, the output voltage is de

rived by summing the currents into pin 18. The output is

given as:

VO = 1+

R10

R27

+

R10

R12

•VCM

(3)

–

R10

R27

•REF –

R10

R12

•VOUT1

Again, if the ratio of R27 to R10 is made 1.5, the effect of

V

CM is nullified and the output voltage becomes (after

substituting for VOUT1):

VO =

R10 •R13

R12 •R14

•VB+

R10 •R13

R12 •R15

• VAC

(4)

From equation 4, it can be seen that if the output voltage

DC value has to track VB directly, the following condition

should be forced:

R10 • R13 = R12 • R14 (5)

However, in some cases, this becomes impractical due

to large AC gain required form VACto VO.Only a small

part of the gain can be accommodated in the first ampli

fier stage due to its output voltage limitations. As a result,

the required resistance values become very high. This

APPLICATION INFORMATION (cont.)

Figure 5. Sine-wave generator. Figure 6. Error amplifier setup.

UDG-96166-1

UDG-96167-1

9

UCC2750

UCC3750

problem is only manifested for high values of VB (e.g.

48V) and can be alleviated by using a fraction of the re

quired DC offset as the VB input and regaining the offset

with resistive ratios.

The error amplifier compares the reference signal with

the output voltage by way of weighted sum at its invert

ing input. The error signal is further processed to sepa

rate its polarity and magnitude. An absolute value circuit

(precision full-wave rectifier) is used to get the magnitude

information. The polarity is used along with the reference

signal polarity to determine the mode information. The

absolute value circuit provides phase inversion when ap

propriate for modes 2 and 3 to maintain the correct loop

gain polarity. While the output of the error amplifier

swings around 3V, the full-wave rectifier output (MAG)

converts it into a signal above 3V. This signal is com

pared to the oscillator ramp to generate the PWM output.

Oscillator and PWM Comparator

The UCC3750 has an internal oscillator capable of high

frequency (>250kHz) operation. A resistor on the RT pin

programs the current that charges and discharges CT,

resulting in a triangular ramp waveform. Fig 7. shows the

oscillator hook-up circuit. The ramp peak and valley are

4.75V and 3V respectively. The nominal frequency is

given by:

f=

1

1.17 •RT • CT

OSC

The ramp waveform and the rectified output of the error

amplifier are compared by the PWM comparator to gen

erate the PWM signal. The PWM action is disabled on

the positive slope of the ramp signal. Leading edge mod

-

ulation turns on the PWM signal when the ramp signal

falls below MAG on the falling slope and turns it off at the

end of the clock cycle. This technique enables synchro

nized turn-on of the rectifier switches immediately after

the PWM pulse is turned off. The triangular nature of the

ramp ensures that the maximum duty cycle of the PWM

output is 50%, providing inherent current limiting.

Control Logic and Outputs

The PWM signal is processed through control logic which

takes into account the operating mode and output polar

ity to determine which output to modulate. The logic table

for the outputs is given in Table 2. For example, assume

that the reference signal is in the first quadrant (positive

and increasing). The output will lag the reference by a

certain delay and hence the error amp output will be pos

itive, resulting in SIGN = 0. The logic table indicates that

GD1 is modulated during this phase allowing power

transfer to increase the output voltage to keep up with

the reference. Increasing error (MAG) will result in larger

duty cycle and enable the output to increase and catch

up with the reference. If the output becomes higher than

the reference (as is likely in the second quadrant when

the reference is dropping), the SIGN becomes 1 and

GD3 is modulated to decrease the output level by transferring power to the input. At the boundary of the first and

second quadrant, there may be some switching back and

forth between modes as the reference slope crosses

through zero. Some of this switching can be eliminated

by judicious selection of error amplifier filtering and compensation components. In the first quadrant, when PWM

is applied to Q1, Q2 is turned on in the rectifier mode by

the clock signal to allow the flyback transformer flux to

APPLICATION INFORMATION (cont.)

24

23

CT

I

R

S

Q

R

I

R

C

T

RT

3V

I

R

R

T

4.75V

3.0V

Figure 7. Oscillator setup.

UDG-99077

10

UCC2750

UCC3750

reset (and to transfer power to the output). Operation in

quadrants 3 and 4 is symmetrical to the first two quad

rants with Q2 and Q3 interchanged. Note that the output

signal for Q2 is logically inverted to allow for driving the

p-channel switch. An n-channel switch can also be used

for Q2, but the drive circuit must be transformer isolated

and the polarity inverted. The outputs are designed for

high peak current drive and low internal impedance. In

isolated systems, GD1 must be coupled to Q1 using a

gate-drive transformer.

DC Current Limit

The DC current limit function provides protection against

short circuit conditions by limiting the maximum current

level and shutting off the PWM function when the limit

point is reached.

The DC limit is activated when DC out is below 0.5 V

CM

or above 1.5 • VCM. The DC current limit can be pro

grammed by setting:

R5

R6

=3

.

With this ratio, a symmetric DC limit with thresholds of

±0.5V is obtained. For other ratios, the positive and neg

ative voltage thresholds for current sense signal are

given by:

V (POS) =

V

4

•1-

R6

R5

SENSE

CM

V(NEG)=

V

4

•1-

5R6

R5

SENSE

CM

Even though the DC current is typically sensed in the

secondary, the currentl limit is applied fo the active PWM

switch at the time. For example, if Q1 is the PWM switch

and DCLIM is activated, the UCC3750 will prevent

trun-on for Q1 during the negative slope of the ramp (Fig.

2). The DC limit is functional on a cycle-by-cycle basis.

Charge Pump and Reference

The UCC3750 is designed to work on the secondary side

of an isolated power supply. It requires a 5V power supply with respect to its GND pin to operate. Note that the

GND pin of the IC is also the reference point of the ring

signal that is generated by the converter. If the converter

output is connected in series with any other voltage, it

should be ensured that the available supply voltage is

referenced to the converter output return. The IC along

with its associated charge pump components shown in

Fig. 9 generates all the other voltages the system re

-

quires. The UCC3750 typically requires about 5mA to op

erate without any loads on the drive outputs. The charge

pump capacitor should be large enough to keep the VCP

fairly constant when driving Q1-Q3 in the converter.

12

11

V

CM

TO

PWM

NEGDC

OUTDC

DC

R5

R6

R

SENSE

R6

4

Figure 8. Current limiting.

APPLICATION INFORMATION (cont.)

Figure 9. Charge pump circuits.

UDG-96170-1

-20

0

20

40

60

80

100

120

1 10 100 1000 10000 100000 10000001E+07

FREQUENCY (Hz)

MAGNITUDE (dB)

0

20

40

60

80

100

120

140

160

180

MAG.

PHASE

10k

100k 1M

10M

PHASE (Degree)

1000

10010

1

Figure 10. Frequency response to error amplifiers.

UNITRODE CORPORATION

7 CONTINENTAL BLVD. • MERRIMACK, NH 03054

TEL. (603) 424-2410 FAX (603) 424-3460

IMPORTANT NOTICE

T exas Instruments and its subsidiaries (TI) reserve the right to make changes to their products or to discontinue

any product or service without notice, and advise customers to obtain the latest version of relevant information

to verify, before placing orders, that information being relied on is current and complete. All products are sold

subject to the terms and conditions of sale supplied at the time of order acknowledgement, including those

pertaining to warranty, patent infringement, and limitation of liability.

TI warrants performance of its semiconductor products to the specifications applicable at the time of sale in

accordance with TI’s standard warranty. Testing and other quality control techniques are utilized to the extent

TI deems necessary to support this warranty. Specific testing of all parameters of each device is not necessarily

performed, except those mandated by government requirements.

CERT AIN APPLICATIONS USING SEMICONDUCTOR PRODUCTS MAY INVOLVE POTENTIAL RISKS OF

DEATH, PERSONAL INJURY, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE (“CRITICAL

APPLICATIONS”). TI SEMICONDUCTOR PRODUCTS ARE NOT DESIGNED, AUTHORIZED, OR

WARRANTED TO BE SUITABLE FOR USE IN LIFE-SUPPORT DEVICES OR SYSTEMS OR OTHER

CRITICAL APPLICATIONS. INCLUSION OF TI PRODUCTS IN SUCH APPLICA TIONS IS UNDERSTOOD T O

BE FULLY AT THE CUSTOMER’S RISK.

In order to minimize risks associated with the customer’s applications, adequate design and operating

safeguards must be provided by the customer to minimize inherent or procedural hazards.

TI assumes no liability for applications assistance or customer product design. TI does not warrant or represent

that any license, either express or implied, is granted under any patent right, copyright, mask work right, or other

intellectual property right of TI covering or relating to any combination, machine, or process in which such

semiconductor products or services might be or are used. TI’s publication of information regarding any third

party’s products or services does not constitute TI’s approval, warranty or endorsement thereof.

Copyright 2000, Texas Instruments Incorporated

Loading...

Loading...