UCC3588

PRELIMINARY

DESCRIPTION

The UCC3588 synchronous step-down (Buck) regulator provides accurate

high efficiency power conversion. Using few external components, the

UCC1588 converts 5V to an adjustable output ranging from 3.5VDC to

2.1VDC in 100mV steps and 2.05VDC to 1.3VDC in 50mV steps with 1%

DC system accuracy. A high level of integration and novel design allow this

16-pin controller to provide a complete control solution for today’s

demanding microcontroller power requirements. Typical applications

include on board or VRM based power conversion for Intel Pentium II

microprocessors, as well as other processors from a variety of

manufacturers. High efficiency is obtained through the use of synchronous

rectification.

The softstart function provides a controlled ramp up of the system output

voltage. Overcurrent circuitry detects a hard (or soft) short on the system

output voltage and invokes a timed softstart/shutdown cycle to reduce the

PWM controller on time to 5%.

The oscillator frequency is externally programmed with RT and operates

over a range of 50kHz to 800kHz. The gate drivers are low impedance totem pole output stages capable of driving large external MOSFETs. Cross

conduction is eliminated by fixed delay times between turn off and turn on

of the external high side and synchronous MOSFETs. The chip includes

undervoltage lockout circuitry which assures the correct logic states at the

outputs during power up and power down.

(continued)

5-Bit Programmable Output BiCMOS Power Supply Controller

FEATURES

•

5-Bit Digital-to-Analog Converter

(DAC) supports Intel Pentium II

•

Microprocessor VID Codes

•

Compatible with 5V or 12V Systems

•

1% Output Voltage Accuracy

Guaranteed

•

Drives 2 N-Channel MOSFETs

•

Programmable Frequency to 800kHz

•

Power Good OV / UV / OVP Voltage

Monitor

•

Undervoltage Lockout and Softstart

Functions

• Short Circuit Protection

• Low Impedance MOSFET Drivers

• Chip Disable

SLUS311 - JULY 1999

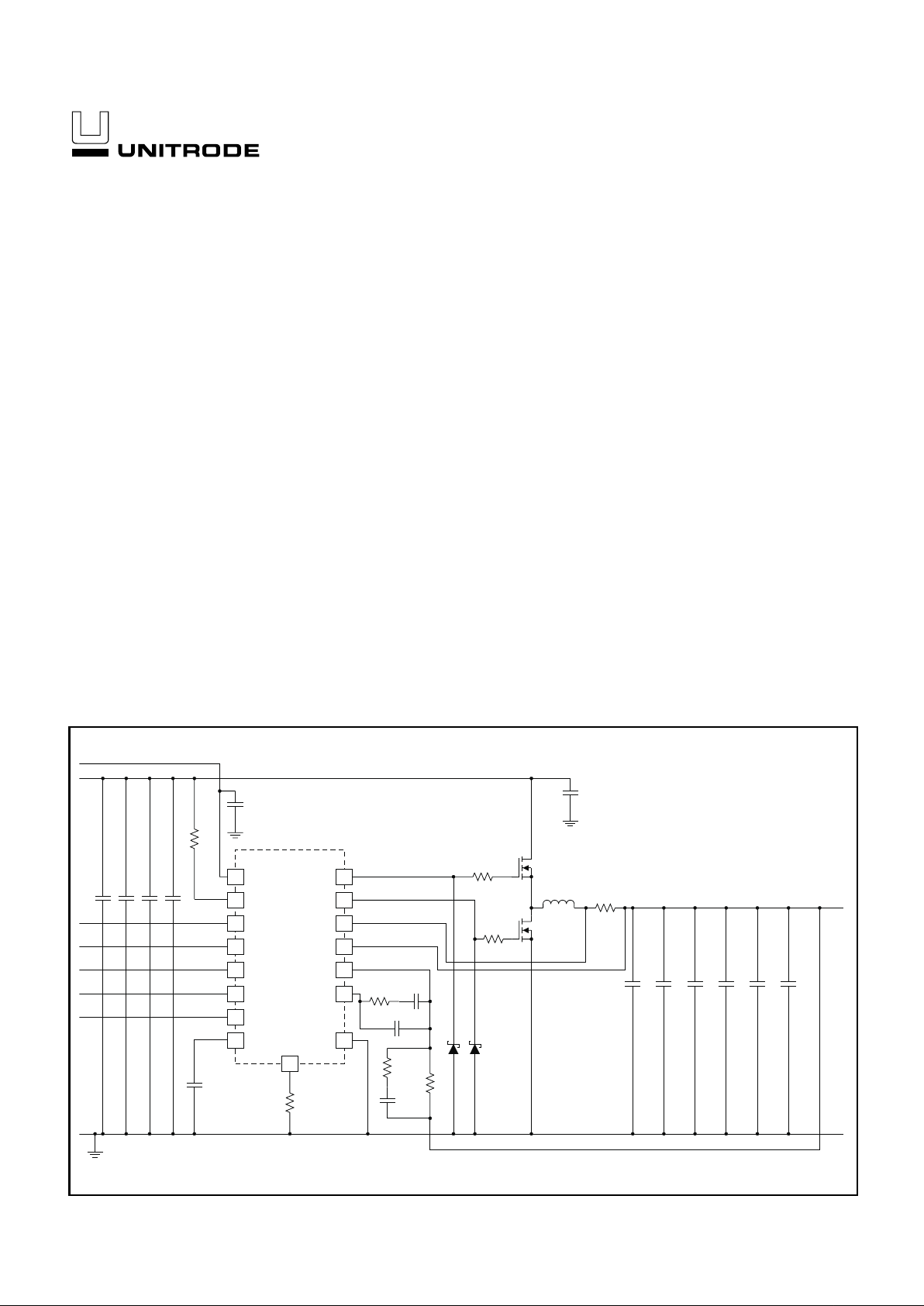

4

11

15

5

6

7

8

3

16

12

9

10

1

2

14

13

UCC3588

VCC DRVHI

PWRGOOD

D0

D1

D2

D3

D4

SS/ENBL GND

COMP

VFB

VSENSE

ISNS

DRVLO

RT

R2

47k

C5

33nF

C16

10µF

R1

10K

C4C3C2C1

++++

RTN

D0

D1

D2

D3

D4

R3

200k

C6

220pF

C7 22pF

R7

15k

C13

1nF

R8

20k

R4

3Ω

R5

3Ω

R6

0.003Ω

C15

150µF

C12C11C10C8

+

+

RTN

VOUT

L1

1.6µH

Q2

IRL3103

Q1

IRL3103

D2D1

12V IN

5V IN

C8-C12 1500µF

+++

C1-C4

1500µF

+

C14

150µF

C9

+

APPLICATION DIAGRAM

UDG-98158

2

UCC3588

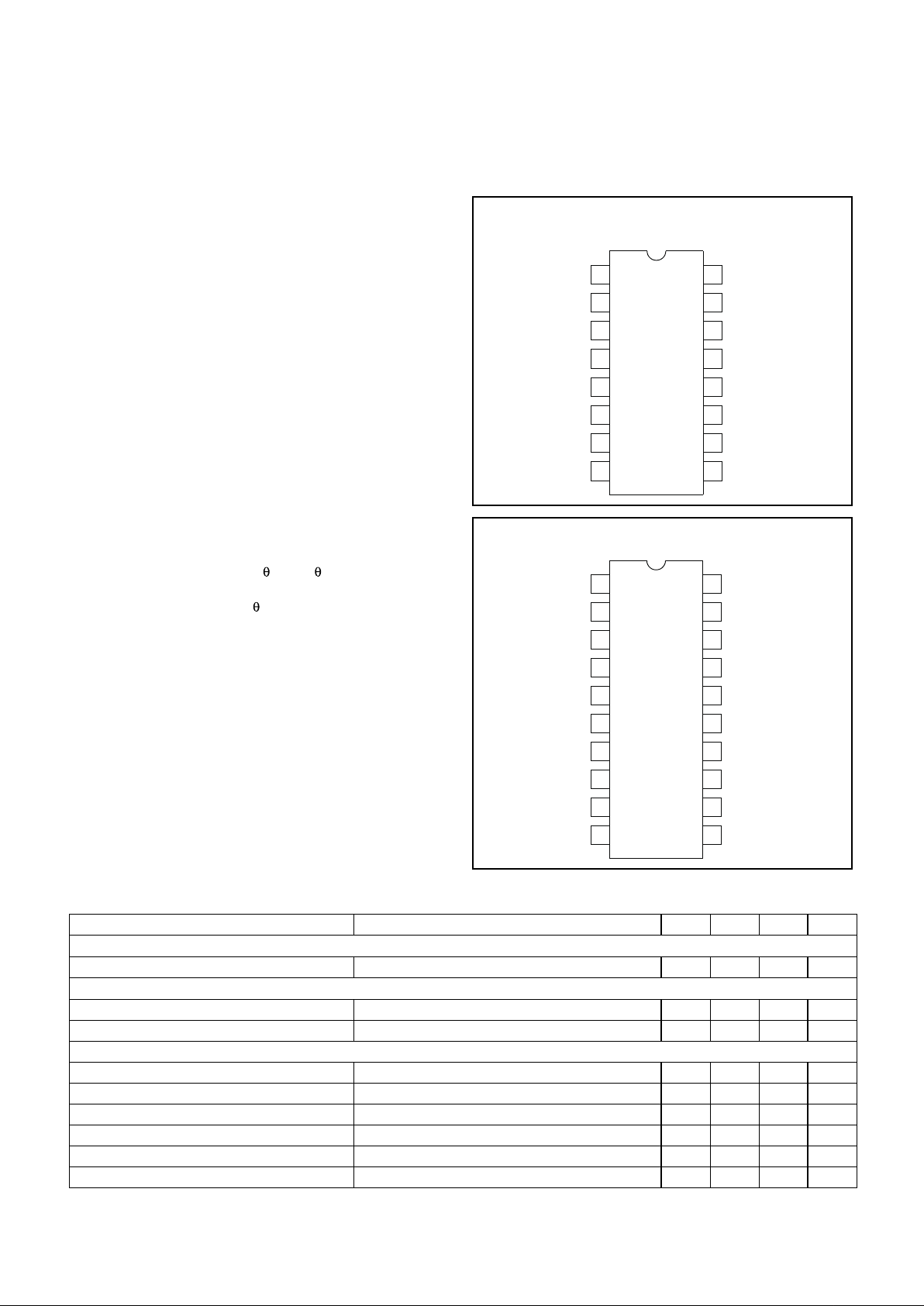

DIP-16, SOIC-16, TSSOP-16 (TOP VIEW)

N, J, D and PW Packages

ABSOLUTE MAXIMUM RATINGS

Supply Voltage VCC. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15V

Gate Drive Current, 50% Duty Cycle. . . . . . . . . . . . . . . . . . 1A

Input Voltage, V

SENSE,VFB

, SS, COMMAND, COMP. . . . . 5V

Input Voltage, D0, D1, D2, D3, D4 . . . . . . . . . . . . . . . . . . . 6V

Input Current, RT, COMP . . . . . . . . . . . . . . . . . . . . . . . . . 5mA

Currents are positive into, negative out of the specified termi

-

nal. Consult Packaging Section of Databook for thermal limita

tions and considerations of packages. All voltages are

referenced to GND.

THERMAL DATA

Plastic DIP Package

Thermal Resistance Junction to Leads, θjc . . . . . . . . 45°C/W

Thermal Resistance Junction to Ambient, θja . . . . . . 90°C/W

Ceramic DIP Package

Thermal Resistance Junction to Leads, θjc . . . . . . . . 28°C/W

Thermal Resistance Junction to Ambient, θja . . . . . 120°C/W

Standard Surface Mount Package

Thermal Resistance Junction to Leads, θjc . . . . . . . . 35°C/W

Thermal Resistance Junction to Ambient, θja . . . . . 120°C/W

Note: The above numbers for ja and jc are maximums for

the limiting thermal resistance of the package in a standard

mounting configuration. The

ja numbers are meant to be

guidelines for the thermal performance of the device and

PC-board system. All of the above numbers assume no ambient airflow, see the packaging section of Unitrode Product Data

Handbook for more details.

RT16

15

14

13

12

11

10

9

1

2

3

4

5

6

7

8

VCC

DRVLO

DRVHI

GND

PWRGOOD

VFB

COMP

VSENSE

ISNS

SS/ENBL

D0

D1

D2

D3

D4

CONNECTION DIAGRAMS

ELECTRICAL CHARACTERISTICS:

Unless otherwise stated, these specifications hold for TA= 0°C to 70°C. TA=TJ.

V

CC

= 12V, RT = 49k.

PARAMETER TEST CONDITIONS MIN TYP MAX UNITS

Supply Current Section

Supply Current, On V

CC

= 12V, VRT= 2V 4.5 5.5 mA

UVLO Section

VCC UVLO Turn-On Threshold 10.05 10.50 10.85 V

UVLO Threshold Hysteresis 350 450 550 mV

Voltage Error Amplifier Section

Input Bias Current V

CM

= 2.0V –0.025 –0.050 µA

Open Loop Gain (Note 5) 77 dB

Output Voltage High I

COMP

= –500µA 3.5 3.6 V

Output Voltage Low I

COMP

= +500µA 0.2 0.5 V

Output Source Current V

VFB

= 2V, V

COMMAND=VCOMP

= 2.5V –400 –500 µA

Output Sink Current V

VFB

= 3V, V

COMMAND=VCOMP

= 2.5V 5 10 mA

This device is available in 16- pin surface mount, plastic

and ceramic DIP, TSSOP packages, and 20 pin surface

mount. The UCC3588 is specified for operation from 0°C

to +70°C.

DESCRIPTION (cont.)

PVCC

VCC

RT

DRVLO

DRVHI

GND

PGND

PWRGOOD

ISNS

VSENSE

N/C

D1

D2

SS/ENBL

N/C

D0

D4

D3 VFB

20

19

18

17

16

15

14

13

12

11

1

2

3

4

5

6

7

8

9

10 COMP

SOIC-20 (TOP VIEW)

DW Package

3

UCC3588

ELECTRICAL CHARACTERISTICS:

Unless otherwise stated, these specifications hold for TA= 0°C to 70°C. TA=TJ.

V

CC

= 12V, RT = 49k.

PARAMETER TEST CONDITIONS MIN TYP MAX UNITS

Oscillator/PWM Section

Initial Accuracy 0°C <T

A

< 70°C 250 270 290 kHz

Ramp Amplitude (p–p) 1.85 V

Ramp Valley Voltage 0.65 V

PWM Max Duty Cycle COMP = 3V (Note 5) 100 %

PWM Min Duty Cycle COMP = 0. 3V (Note 5) 0 %

PWM Delay to Outputs (High to Low) COMP = 1.5V (Note 5) 150 ns

PWM Delay to Outputs (Low to High) COMP = 1.5V (Note 5) 150 ns

Transient Window Comparator Section

Detection Range High (Duty Cycle = 0) % Over V

COMMAND

, (Note 1) 3 %

Detection Range Low (Duty Cycle = 1) % Under V

COMMAND

, (Note 1) –3 %

Propagation Delay (V

SENSE

to Outputs) 150 200 nS

Soft Start/ Shutdown Section

SS Charge Current (Normal Start Up) Measured on SS –6 –12 µA

SS Charge Current (Short Circuit Fault

Condition)

Measured on SS –60 –100 –120 µA

SS Discharge Current (During Timeout

Sequence)

Measured on SS 1 2.5 5 µA

Shutdown Threshold Measured on SS 4.1 4.2 4.3 V

Restart Threshold Measured on SS 0.4 0.5 0.6 V

Soft Start Complete Threshold (Normal

Start-Up)

Measured on SS 3.5 3.7 3.9 V

DAC / Reference Section

COMMAND Voltage Accuracy 10.8V <V

CC

< 13.2V, measured on COMP,

0°C < T

A

< +70°C, (Note 2)

–1.0 1.0 %

D0–D4 Voltage High 5.5 6 6.5 V

D0–D4 Voltage Threshold 2.5 3.0 3.5 V

D0–D4 Voltage Input Bias Current V(D4,...,D0) < 0.5V –80 –100 µA

Overvoltage Comparator Section

Trip Point % Over V

COMMAND

, (Note 1) 8 12 %

Hysteresis 10 20 35 mV

Undervoltage Comparator Section

Trip Point % Under V

COMMAND

, (Note 1) –8.0 –12.0 %

Hysteresis 10 20 35 mV

PWRGOOD Signal Section

Output Impedance V

CC

= 12V, I

PWRGOOD

= 1mA 470 Ω

Overvoltage Protection Section

Trip Point % Over V

COMMAND

, (Note 1) 15 17.5 20 %

Hysteresis 20 35 mV

VSENSE Input Bias Current OV, OVP, UV Combined –8 –12 –16 µA

4

UCC3588

ELECTRICAL CHARACTERISTICS:

Unless otherwise stated, these specifications hold for TA= 0°C to 70°C. TA=TJ.

V

CC

= 12V, RT = 49k.

PARAMETER TEST CONDITIONS MIN TYP MAX UNITS

Gate Drivers (DRVHI, DRVLO) Section

Output High Voltage I

GATE

= 100mA, VCC= 12V 10.8 11.5 V

Output Low Voltage I

GATE

=– 100mA, VCC= 12V 0.5 0.8 V

Driver Non-overlap Time

(DRVHI– to DRVLO+)

(Note 3) 90 120 150 ns

Driver Non-overlap Time

(DRVLO– to DRVHI+)

(Note 3) 50 80 120 ns

Driver Rise Time 3nF Capacitive Load 80 100 ns

Driver Fall Time 3nF Capacitive Load 80 100 ns

Current Limit Section

Start of Quick Charge to Shutdown

Threshold

V

ISNS=VSENSE

+ 75mV, CSS= 10nF, (Note 4)

(Note 5)

50 µs

Current Limit Threshold Voltage V

THRESHOLD=VISNS–VVSENSE

40 54 70 mV

ISNS Input Bias Current –8 –12 –16 µA

Note 1: This percentage is measured with respect to the ideal command voltage programmed by the VID(D0,....,D4) pins and ap

-

plies to all DAC codes from 1.3 to 3.5V.

Note 2: Reference and error amplifier offset trimmed while the voltage amp is set in unity gain mode.

Note 3: Deadtime delay is measured from the 50% point of DRVHI falling to the 50% point of DRVLO rising, and vice-verse.

Note 4: This time is dependent on the value of C

SS

.

Note 5: Guaranteed by design.Not 100% tested in production.

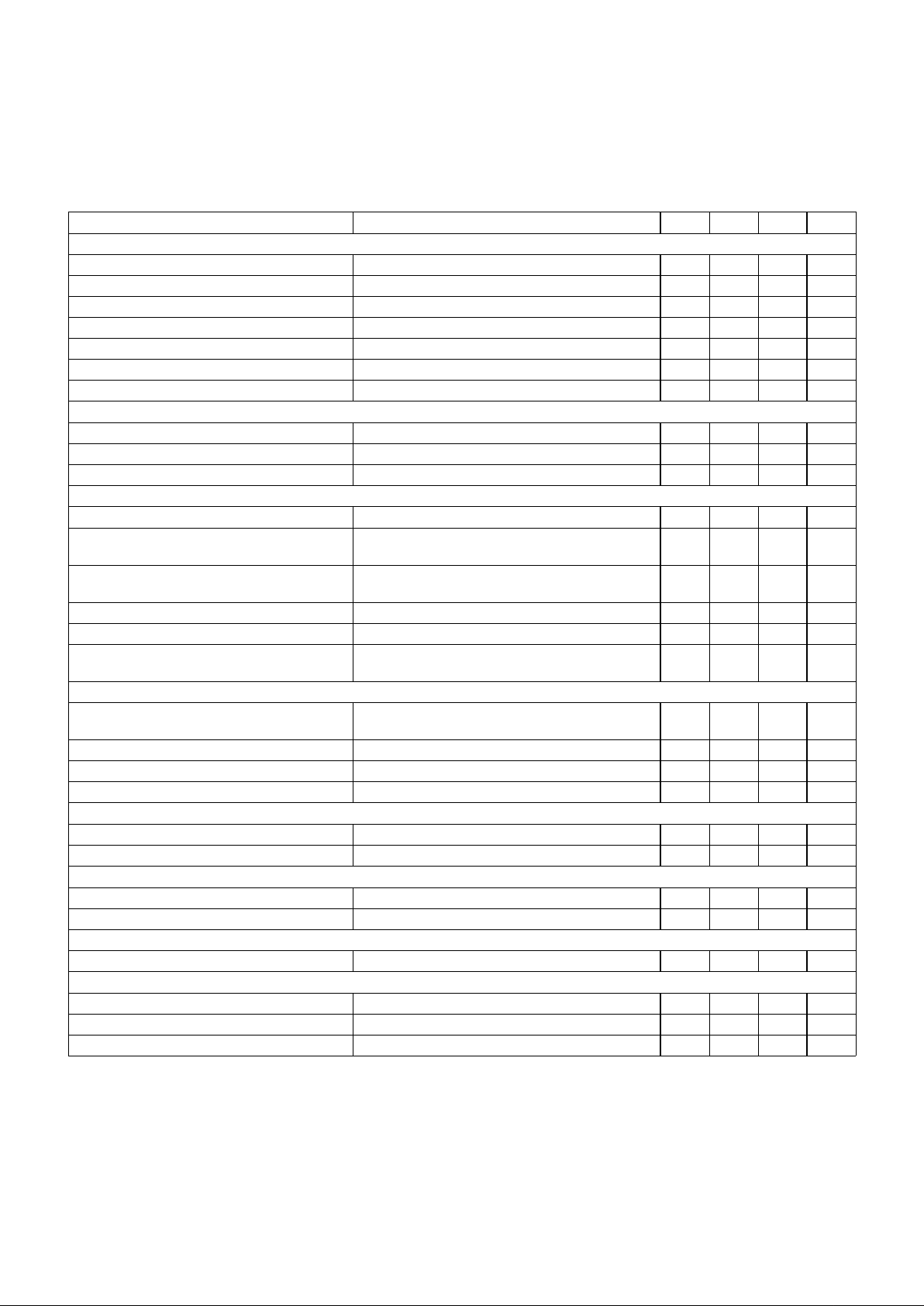

10

8

7

6

5

4

3

DAC

OVP

OV/UV

+

–

9

1

SOFTSTART

CURRENT

LIMIT

BLOCK

OVER-

CURRENT

2 11

OSC

16

R

S

Q

VREF

15

12

TURN

ON

DELAY

TURN

ON

DELAY

ANTI CROSS-

CONDUCTION

13

14

V

CC

UVLO

10.5V

VBIAS

VOLTAGE

AMPLIFIER

COMP

VFB

D4

D3

D2

D1

D0

SS/ENBL

ISNS VSENSE PWRGOOD RT

GND

VCC

DRVHI

DRVLO

COMMAND

–3%

COMMAND

+3%

VSENSE

DUTY=1

DUTY=0

SHUTDOWN

PWM

COMP.

COMMAND

SHUTDOWN

TO

VREF

SHUTDOWN

+

+

–+

–

BLOCK DIAGRAM

UDG-98152

5

UCC3588

COMP: (Voltage Amplifier Output) The system voltage

compensation network is applied between COMP and

VFB.

D0, D1, D2, D3, D4: These are the digital input control

codes for the DAC. The DAC is comprised of two ranges

set by D4, with D0 representing the least significant bit

(LSB) and D3, the most significant bit (MSB). A bit is set

low by being connected the pin to GND; a bit is set high

by floating the pin. Each control pin is pulled up to ap

proximately 6V by an internal pull-up. If one of the low

voltage codes is commanded on the DAC inputs, the out

puts will be disabled. The outputs will also be disabled for

all 1’s, the NO CPU command.

DRVHI: (PWM Output, MOSFET Driver) This output pro

vides a low Impedance totem pole driver. Use a series

resistor between this pin and the gate of the external

MOSFET to prevent excessive overshoot. Minimize cir

cuit trace length to prevent DRVHI from ringing below

GND. DRVHI is disabled during UVLO conditions.

DRVHI has a typical output impedance of 5Ω for a V

CC

voltage of 12V.

DRVLO: (synchronous rectifier output, MOSFET driver)

This output provides a low Impedance totem pole driver

to drive the low-side synchronous external MOSFET.

Use a series resistor between this pin and the gate of the

external MOSFET to prevent excessive overshoot. Minimize circuit trace length to prevent DRVLO from ringing

below GND. DRVLO is disabled during UVLO conditions.

DRVLO has a typical output impedance of 5Ωfor a V

CC

voltage of 12V.

GND: (Ground) All voltages measured with respect to

ground. Vcc should be bypassed directly to GND with a

0.1µF or larger ceramic capacitor. The timing capacitor

discharge current also returns to this pin, so the lead

from the oscillator timing to GND should be as short and

direct as possible.

ISNS: (Current Limit Sense Input) A resistance con

nected between this sense connection and Vsense sets

up the current limit threshold (54mV typical voltage

threshold).

PWRGOOD: This pin is an open drain output which is

driven low to reset the microprocessor when VSNS rises

above or falls below its nominal value by 8.5%(typ). The

on resistance of the open-drain switch is no higher than

470Ω. This output should be pulled up to a logic level

voltage and should be programmed to sink 1mA or less.

RT: (Oscillator Charging Current) This pin is a low im

pedance voltage source set at ~1.25V. A resistor from

RT to GND is used to program the internal PWM oscilla

tor frequency. The equation for R

T

follows:

()

R

fpF

T

=

•

−

1

67 2

800

.

(1)

SS/ENBL: (Soft Start/Shut Down) A low leakage capaci

tor connected between SS and GND will provide a

softstart function for the converter. The voltage on this

capacitor will slowly charge on start-up via an internal

current source (10µA typ.) and ultimately clamp at ap

proximately 3.7V. The output of the voltage error ampli

fier (COMP) tracks this voltage thereby limiting the

controller duty ratio. If a short circuit is detected, the

clamp is released and the cap on SS charges with a

100µA (typ) current source. If the SS voltage exceeds

4.2V, the converter shuts down, and the 100µA current

source is switched off. The SS cap will then be discharged with a 2.5µA (typ) current sink. When the voltage on SS falls below 0.5V, a new SS cycle is started.

The equation for softstart time follows:

T

C

A

SS

SS

=

3710.

µ

.

(2)

Shutdown is accomplished by pulling SS/SD below 0.5V.

VCC: (Positive Supply Voltage) This pin is normally con

nected to a 12V ±10% system voltage. The UCC1588 will

commence normal operation when the voltage on VCC

exceeds 10.5V (typ). Bypass VCC directly to GND with a

0.1µF (minimum) ceramic capacitor to supply current

spikes required to charge external MOSFET gate capaci

tances.

VFB: (Voltage Amplifier Inverting Input) This is normally

connected to a compensation network and to the power

converter output through a divider network.

VSENSE: (Direct Output Voltage Connection) This pin is

a direct kelvin connection to the output voltage used for

over voltage, under voltage, and current sensing.

PIN DESCRIPTION

6

UCC3588

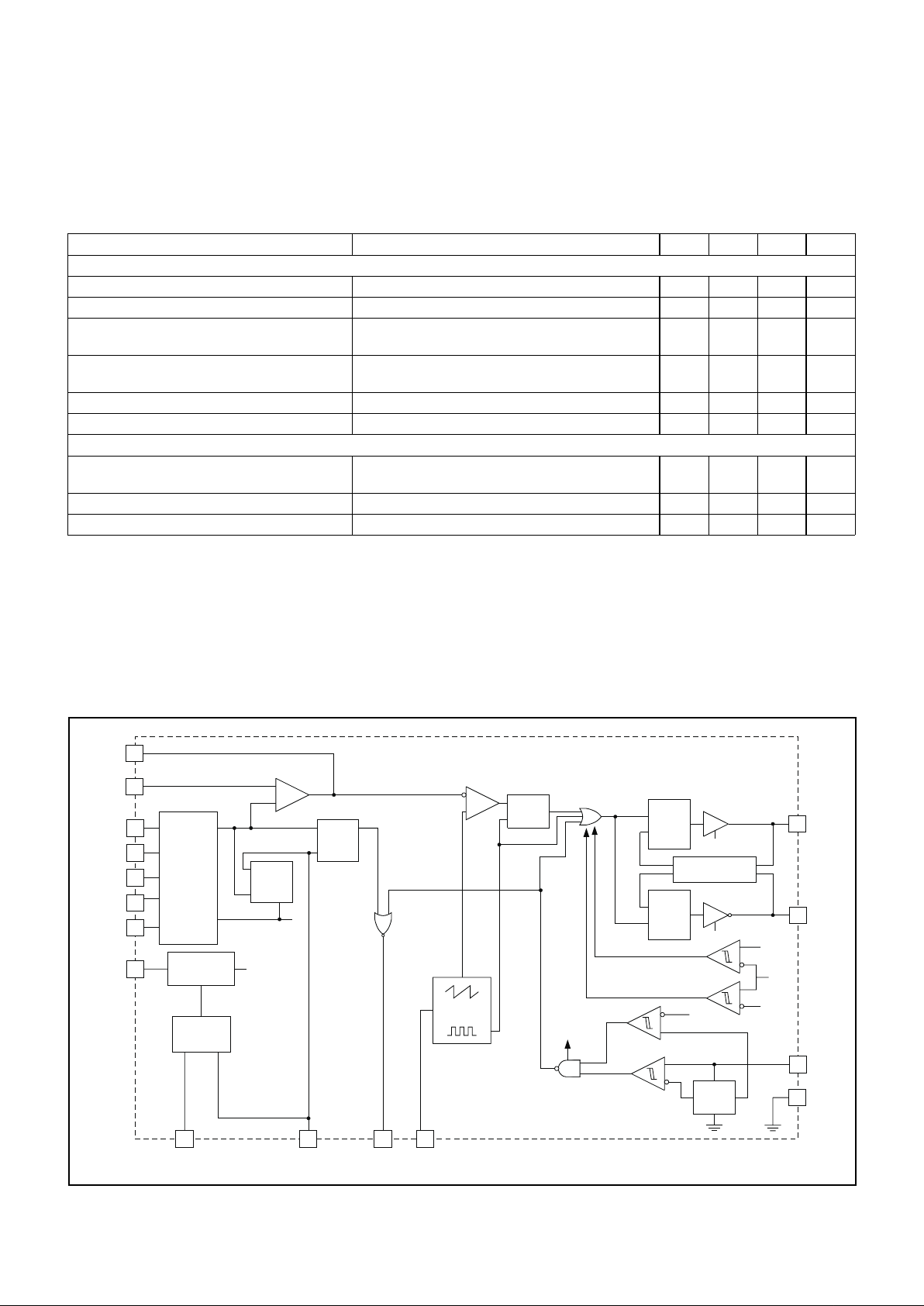

Figure 1 shows a synchronous regulator using the

UCC3588. It accepts +5V and +12V as input, and deliv

-

ers a regulated DC output voltage. The value of the out

put voltage is programmable via a 5-bit DAC code to a

value between 1.3V and 3.5V. The example given here is

for a 12A regulator, running from a 10% tolerance

source, and operating at 300kHz.

The design of the power stage is straightforward buck

regulator design. Assuming an output noise requirement

of 50mV, and an output ripple current of 20% of full load,

the value of the output inductor should be calculated at

the highest input voltage and lowest output voltage that

the regulator is likely to see. This insures that the ripple

current will decrease as the input voltage and output volt

age differential decreases. The minimum duty cycle, δ

min

,

should also be calculated under this condition.

1) The current sense resistor is chosen to allow current

limit to occur at 1.4 times the full load current.

()

R

V

I

mV

A

m

TRIP

OUT

6

14

50

16 8

3=

•

==

.

.

Ω

(3)

2) To properly approximate the full load duty cycle oper

ating range, assumptions are made regarding the

MOSFETs’ Rds

ON

, and the output inductor’s DC resis

tance. Q1 and Q2 are IRF3103s, each with an Rds

ON

of

0.014Ω. The output inductor is allowed to dissipate one

watt under full load, giving a DC resistance of 6.9mΩ,

and R6 is 3mΩ. The resulting duty cycle at the operating

extremes is then:

()

()

()

()

δ

min

..

.

=

+•+ +

=

+•

=

VIRRdsR

V

OUT lo

OUT ON

IN hi

6

1 8 12 0024

55

0 379.

(4)

()

()

()

()

δ

max

..

.

=

+•+ +

=

+•

=

VIRRdsR

V

OUT hi

OUT ON

IN lo

6

3 5 12 0024

45

0 842.

(5)

3) The value of the output inductor is chosen at the worst

case ripple current point.

APPLICATION INFORMATION

4

11

15

5

6

7

8

3

16

12

9

10

1

2

14

13

UCC3588

VCC DRVHI

PWRGOOD

D0

D1

D2

D3

D4

SS/ENBL GND

COMP

VFB

VSENSE

ISNS

DRVLO

RT

R2

47k

C5

33nF

C16

10µF

R1

10K

C4C3C2C1

++++

RTN

D0

D1

D2

D3

D4

R3

200k

C6

220pF

C7 22pF

R7

15k

C13

1nF

R8

20k

R4

3Ω

R5

3Ω

R6

0.003Ω

C15

150µF

C12C11C10C8

+

+

RTN

VOUT

L1

1.6µH

Q2

IRL3103

Q1

IRL3103

D2D1

12V IN

5V IN

C8-C12 1500µF

+++

C1-C4

1500µF

+

C14

150µF

C9

+

APPLICATION DIAGRAM

UDG-98158

7

UCC3588

() ()

()

()

L

VV T

I

IN hi OUT lo

S

OUT

=

−•

=

−• •δµ

min

.. . .

.

∆

5 5 1 8 0 379 3 333

24

=19. µ

H

(6)

Four turns of #16 on a micrometals T51-52C core has an

inductance of 1.9µH, has a DC resistance of 6.6mΩ, and

will dissipate about 1W under full load conditions. With

an output inductor value of 1.9µH, the ripple current will

be 1750mA under the low-input-high-output condition.

4) To meet the output noise voltage requirement, the out

-

put capacitor(s) must be chosen so that the ripple volt

age induced across the ESR of the capacitors by the

output ripple current is less than 50mv.

ESR

mV

I

m

OUT

<=

50

42∆Ω

(7)

Additionally, to meet output load transient response requirements, the capacitors’ ESL and ESR must be low

enough to avoid excessive voltage transient spikes. (See

Application Note U-157 for a discussion of how to determine the amount and type of load capacitance.) For this

example, four Sanyo MV-GX 1500µf, 6.3V capacitors will

be used. The ESR of each capacitor is approximately

44mΩ so the parallel combination of four results in an

equivalent ESR of 11mΩ.

5) Q1 and Q2 are chosen to be IRF3103 N-Channel

MOSFETs. Each MOSFET has an Rds

ON

of approxi

mately 0.014Ω, a gate charge requirement of 50nC, and

a turn OFF time of approximately 54ns.

To calculate the losses in the upper MOSFET, Q1, first

calculate the RMS current it will be conducting.

()

IQ I

I

RMS OUT

OUT

1

12

2

2

=+

δ

∆

(8)

Notice that with a higher output voltage, the duty cycle in

creases, and therefore so does the RMS current. Any

heat sink design should take into account the worst case

power dissipation the device will experience.

With the highest programmable output voltage of 3.5

volts and the lowest possible input voltage of 4.5V, the

RMS current Q1 will conduct is 10.5 amps, and the con

duction loss is

()

PQI Rds W

CON Q

RMS

ON

115

1

2

=•=.

(9)

Next, the gate drive losses are found.

()

PQQV F W

GATE G

IN hi

S

1008=• •=.

(10)

And the Turn OFF losses are estimated as

() () ()

PQV I tfF W

TOFF INhi Dpk

S

1056

1

2

=•••=.

(11)

The total loss in Q1is the sum of the three components,

or about 2.1 watts.

The gate drive losses in Q2 will be the same as in Q1,

but the turn OFF losses will be associated with the re

verse recovery of the body diode, instead of the turn OFF

of the channel. This is due to the UCC3588’s delay built

into the switching of the upper and lower MOSFET’s

drive. For example, when Q1 is turned OFF, the turn ON

of Q2 is delayed for about 100ns, insuring that the circuit

has time to commutate and that current has begun to

flow in the body diode of Q2. When Q2 is turned OFF,

current is diverted from the channel of Q2 into the body

diode of Q2, resulting in virtually no power dissipation.

When Q1 is turned ON 100ns later however, the circuit is

forced to commutate again. This time causing reverse re

covery loss in the body diode of Q2 as its polarity is reversed.The loss in the diode is expressed as:

PQ Q V F W

RR RR IN hi S

2026

1

2

=• • • =().

(12)

Where Q

RR

, the reverse recovery of the body diode, is

310nC.

100ns before the turn ON of Q2, and 100ns after the turn

OFF of Q2, current flows through Q2’s intrinsic body diode.The power dissipation during this interval is:

PQ

IV

ns

s

W

COM DIODE

OUT DIODE

2

200

333

12 1 4 0 0 6 1

=

•• =••=

.

..

µ

(13)

During the ON period of Q2, current flows through the

Rds

ON

of the device. Where the highest RMS current in

Q1 was at the low-input-and-high-output condition, the

highest RMS current in Q2 is found when the input is at

its highest, and the output is at its lowest. The equation

for the RMS current in Q2 is:

()

IQ

ns

s

I

I

RMS

OUT

OUT

2

1

200

333 12

2

2

=

−−

•+

δ

µ

min

.

∆

=87.

A

(14)

()

PQIQ Rds W

CON RMS ON

22 106

2

=•=.

(15)

The worst case loss in Q2 comes to about 2.4 watts.

6) Repeating the preceding procedure for various input

and output voltage combinations yields a table of operat

-

ing conditions.

APPLICATION INFORMATION (cont.)

8

UCC3588

7) Assuming the converter’s input current is DC, the re

maining switching current drawn by Q1 must come from

the input capacitors. The next step then, is to find the

worst case RMS current the capacitors will experience.

(Equation 16). Where I

IN

(avg) is the average input cur-

rent.

Repeating the above calculation over the operating range

of the regulator (see Table 2.) reveals that the worst case

capacitor ripple current is found at low input, and at low

output voltage. A Sanyo MV-GX, 1500µF, 6.3V capacitor

is rated to handle 1.25 amps at 105°C. Derating the de

-

sign to 70°C allows the use of four capacitors, each one

experiencing one fourth of the total ripple current.

8) The voltage feedback loop is next. The gain and fre

quency response of the PWM and LC filter is shown in

Equation 17.

To compensate the loop with as high a bandwidth as

practical, additional gain is added to the loop with the

voltage error amplifier.

APPLICATION INFORMATION (cont.)

VIN=

4.5 5.0 5.5

V

OUT

=3.5

Pd Q1

Pd Q2

Pd L

Pd Total

Average Input

Duty Cycle

2.2

1.5

0.95

5.1

10.50

0.84

2.1

1.6

0.95

5.2

9.5

0.76

2

1.8

0.95

5.4

8.70

0.69

V

OUT

=1.8

Pd Q1

Pd Q2

Pd L

Pd Total

Average Input

Duty Cycle

1.5

2.3

0.95

5.2

6.00

0.46

1.4

2.4

0.95

5.3

5.40

0.42

1.4

2.5

0.95

5.4

4.96

0.38

Table 1. Regulator Operating Conditions

VIN=

4.5 5.0 5.5

V

OUT

= 3.5

Total Input Cap RMS Current

Total Input Cap Power Dissipation

Total Power Dissipation

Power Train Efficiency

4.4

0.21

5.1

0.89

5.2

0.29

5.3

0.88

5.6

0.34

5.4

0.87

V

OUT

=1.8

Total Input Cap RMS Current

Total Input Cap Power Dissipation

Total Power Dissipation

Power Train Efficiency

6

0.39

5.2

0.81

5.9

0.39

5.3

0.8

5.8

0.37

5.4

0.8

Table 2. Regulator Operating Conditions

-60

-50

-40

-30

-20

-10

0

10

20

0.1 1 10 100 1000

FREQUENCY (kHz)

GAIN (dB)

VIN = 4.5V VIN = 5.5V

-180

-90

0

90

180

0.1 1 10 100 1000

FREQUENCY (kHz)

PHASE (°)

Figure 1. Modulator Frequency Response

()

()

()

III

I

I

CAP OUT INavg

OUT

INavg

RMS

=−+

+−•δδ

2

2

2

12

1

∆

(16)

()

()

Kf

V

V

fR C

fLC RR

PWM

IN

RAMP

ESR OUT

OUT

==

+• •

−•• ++

12

14 6

2

π

π

2

()

+•+

RC

L

R

ESR OUT

LOAD

(17)

9

UCC3588

The equation for the gain of the voltage amplifier in this

configuration is:

()()()()()

()

()()()

K

sCRf sC R R

RsCCRf sC C sCR

EA

I

I

=

+•++

++•+

11 13 2

12 1 2 1 3 2

2

(18)

For good transient response, select the R

F

-C1 zero at

5kHz. Add additional phase margin by placing the R

I

-C3

zero also at 5kHz. To roll off the gain at high frequency,

selece the R2-C3 pole to be at 10kHz, and the final C2R

F

pole at 40kHz. Results are RI=20k, RF=200k,

R2=15k, C1=220pF, C2=20pF, C3=1000pF. The GainPhase plots of the voltage error amplifier and the overall

loop are plotted below.

9) The value of RT is given by:

RT

FpF

k

S

=

•

−=

1

67 2

800 48.Ω

(19)

10) The value of the soft start capacitor is given by:

C

t

V

SS

SS

=•1037µ

.

(20)

Where t

SS

is the desired soft start time.

To insure that soft start is long enough so that the con

verter does not enter current limit during startup, the

minimum value of soft start may be determined by:

C

CI

V

R

I

V

V

SS

OUT CH

LIM

SENSE

OUT

IN

RAMP

≥

•

−

•

(21)

Where C

OUT

is the output capacitance, Ich is the soft

start charging current (10µA typ), V

LIM

is the current limit

trip voltage (54mV typ), I

OUT

is the load current, VINis

the 5V supply, and V

RAMP

is the internal oscillator ramp

voltage (1.85V typ). For this example, C

SS

must be

greater than 35nF, and the resulting soft start time will be

13ms.

11) The output of the regulator is adjustable by programming the following codes into the D0 - D4 pins according

to the table below. To program a logic zero, ground the

pin. To program a logic 1, then leave the pin floating. Do

not tie the pin to an external voltage source.

12) A series resistor should be placed in series with the

gate of each MOSFET to prevent excessive ringing due

to parasitic effects. A value of 3Ω to 5Ω is usually sufficient in most cases. Additionally, to prevent pins 13 and

14 from ringing more than 0.5V below ground, a clamp

schottky rectifier placed as close as possible to the IC is

also recommended.

APPLICATION INFORMATION (cont.)

+

–

C1

C2

C3R2

R

I

R

F

V

IN

V

REF

V

OUT

Figure 3. Voltage error amplifier configuration.

-40

-20

0

20

40

60

0.1 1 10 100 1000

FREQUENCY (kHz)

GAIN (dB)

Error Amp VIN = 4.5V VIN = 5.5V

Figure 4. Error amplifier and loop frequency

response.

0

20

40

60

80

100

120

140

160

180

0.1 1 10 100 1000

FREQUENCY (kHz)

PHASE (deg)

Error Amp VIN = 4.5V VIN = 5.5V

Figure 5. Error amplifier and loop frequency

response.

10

UCC3588

UNITRODE CORPORATION

7 CONTINENTAL BLVD. • MERRIMACK, NH 03054

TEL. (603) 424-2410 • FAX (603) 424-3460

APPLICATION INFORMATION (cont.)

D4 D3 D2 D1 D0 V

OUT

011111.3

011101.35

011011.4

011001.45

010111.5

010101.55

010011.6

010001.65

001111.7

001101.75

001011.8

001001.85

000111.9

000101.95

000012

000002.05

11111No

outputs

111102.1

111012.2

111002.3

110112.4

110102.5

110012.6

110002.7

101112.8

101102.9

101013

101003.1

100113.2

100103.3

100013.4

100003.5

Table 3.

VID Codes and Resulting Regulator Output Voltage

IMPORTANT NOTICE

T exas Instruments and its subsidiaries (TI) reserve the right to make changes to their products or to discontinue

any product or service without notice, and advise customers to obtain the latest version of relevant information

to verify, before placing orders, that information being relied on is current and complete. All products are sold

subject to the terms and conditions of sale supplied at the time of order acknowledgement, including those

pertaining to warranty, patent infringement, and limitation of liability.

TI warrants performance of its semiconductor products to the specifications applicable at the time of sale in

accordance with TI’s standard warranty. Testing and other quality control techniques are utilized to the extent

TI deems necessary to support this warranty. Specific testing of all parameters of each device is not necessarily

performed, except those mandated by government requirements.

CERT AIN APPLICATIONS USING SEMICONDUCTOR PRODUCTS MAY INVOLVE POTENTIAL RISKS OF

DEATH, PERSONAL INJURY, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE (“CRITICAL

APPLICATIONS”). TI SEMICONDUCTOR PRODUCTS ARE NOT DESIGNED, AUTHORIZED, OR

WARRANTED TO BE SUITABLE FOR USE IN LIFE-SUPPORT DEVICES OR SYSTEMS OR OTHER

CRITICAL APPLICATIONS. INCLUSION OF TI PRODUCTS IN SUCH APPLICA TIONS IS UNDERSTOOD T O

BE FULLY AT THE CUSTOMER’S RISK.

In order to minimize risks associated with the customer’s applications, adequate design and operating

safeguards must be provided by the customer to minimize inherent or procedural hazards.

TI assumes no liability for applications assistance or customer product design. TI does not warrant or represent

that any license, either express or implied, is granted under any patent right, copyright, mask work right, or other

intellectual property right of TI covering or relating to any combination, machine, or process in which such

semiconductor products or services might be or are used. TI’s publication of information regarding any third

party’s products or services does not constitute TI’s approval, warranty or endorsement thereof.

Copyright 1999, Texas Instruments Incorporated

Loading...

Loading...