Datasheet UCC3913N, UCC3913DTR, UCC3913D, UCC2913D, UCC2913N Datasheet (Texas Instruments)

...

UCC1913

UCC2913

UCC3913

DESCRIPTION

The UCC1913 family of negative voltage circuit breakers provides complete power management, hot swap, and fault handling capability. The IC is

referenced to the negative input voltage and is driven through an external

resistor connected to ground, which is essentially a current drive as opposed to the traditional voltage drive. The on-board 10V shunt regulator

protects the IC from excess voltage and serves as a reference for programming the maximum allowable output sourcing current during a fault. All

control and housekeeping functions are integrated, and externally programmable. These include the fault current level, maximum output sourcing current, maximum fault time, soft start time, and average power limiting. In the

event of a constant fault, the internal timer will limit the on-time from less

than 0.1% to a maximum of 3%. The duty cycle modulates depending on

the current into the PL pin, which is a function of the voltage across the

FET, and will limit average power dissipation in the FET. The fault level is

fixed at 50mV across the current sense amplifier to minimize total dropout.

The fault current level is set with an external current sense resistor. The

maximum allowable sourcing current is programmed with a voltage divider

from VDD to generate a fixed voltage on the IMAX pin. The current level,

when the output appears as a current source, is equal to V

IMAX/RSENSE

.If

desired, a controlled current startup can be programmed with a capacitor

on the IMAX pin.

When the output current is below the fault level, the output device is

switched on. When the output current exceeds the fault level, but is less

than the maximum sourcing level programmed by the IMAX pin, the output

remains switched on, and the fault timer starts charging CT. Once CT

charges to 2.5V, the output device is turned off and performs a retry some

time later. When the output current reaches the maximum sourcing current

level, the output appears as a current source, limiting the output current to

the set value defined by IMAX.

Other features of the UCC1913 family include undervoltage lockout, and

8-pin small outline (SOIC) and Dual-In-Line (DIL) packages.

Negative Voltage Hot Swap Power Manager

FEATURES

• Precision Fault Threshold

• Programmable Average Power

Limiting

• Programmable Linear Current Control

• Programmable

• Overcurrent Limit

• Programmable Fault Time

• Fault Output Indication

• Shutdown Control

• Undervoltage Lockout

• 8-Pin SOIC

SLUS274 - JANUARY 1999

1

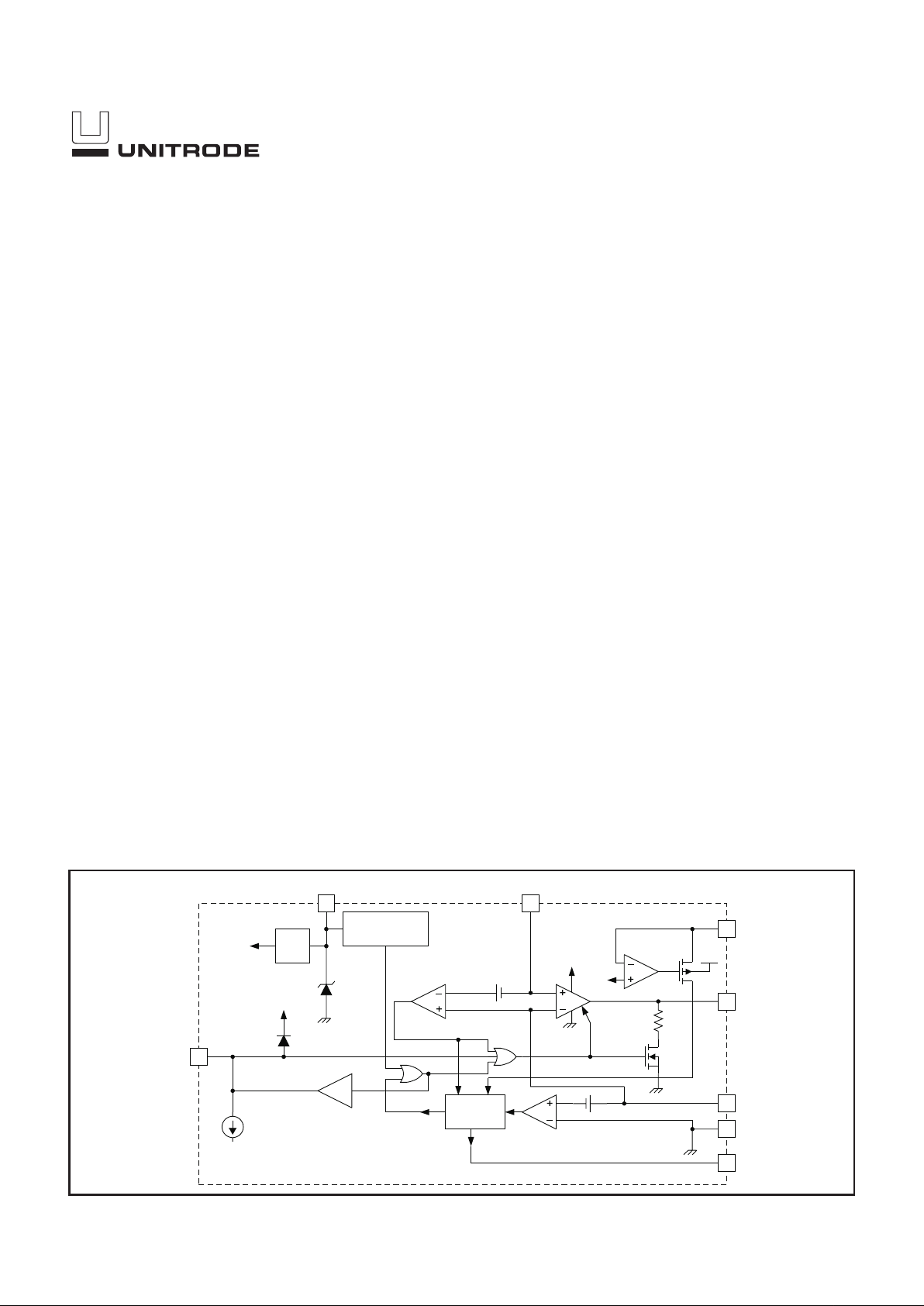

2

LINEAR

CURRENT

AMPLIFIER

PL

7OUT

IMAX

+

V

DD

50Ω

8

V

DD

6 SENSE

5 VSS

4CT

ON-TIME

CONTROL

3

VDD

UVLO

5.0V

REF

LOGIC

SUPPLY

9.5V SHUNT REGULATOR

+

20µA

1=

UNDERVOLTAGE

SOURCE

ONLY

SD/FLT

V

DD

0.2V

OVERCURRENT

COMPARATOR

DISABLE

5.0V

OVERLOAD COMPARATOR

50mV

BLOCK DIAGRAM

UDG-99001

2

UCC1913

UCC2913

UCC3913

ABSOLUTE MAXIMUM RATINGS

I

VCC

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50mA

SHUTDOWN Current . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10mA

PL Current . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10mA

IMAX Input Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . VCC

Storage Temperature . . . . . . . . . . . . . . . . . . . –65°C to +150°C

Junction Temperature. . . . . . . . . . . . . . . . . . . –55°C to +150°C

Lead Temperature (Soldering, 10 sec.). . . . . . . . . . . . . +300°C

All voltages are with respect to VSS (The most negative voltage). All currents are positive into, negative out of the specified

terminal. Consult Packaging Section of Databook for thermal

limitations and considerations of packages.

ELECTRICAL CHARACTERISTICS: Unless otherwise stated these specifications apply for T

A

= –55°C to +125°C for

UCC1913; –40°C to +85°C for UCC2913; 0°C to +70°C for UCC3913; I

VDD

= 2mA, CT = 4.7pF, TA= T

J

PARAMETER TEST CONDITIONS MIN TYP MAX UNITS

VDD Section

IDD 1.0 2.0 mA

Regulator Voltage I

SOURCE

= 2mA to 10mA 8.5 9.5 10.5 V

UVLO Off Voltage 678V

Fault Timing Section

Overcurrent Threshold T

J

= 25°C 47.5 50 53 mV

Over Operating Temperature 46 50 53.5 mV

Overcurrent Input Bias 50 500 nA

CT Charge Current VCT= 1.0V, IPL= 0 –50 –36 –22 µA

Overload Condition, V

SENSE

– V

IMAX

= 300mV –1.7 –1.2 –0.7 mA

CT Discharge Current VCT= 1.0V, IPL= 0 0.6 1 1.5 µA

CT Fault Threshold 2.2 2.4 2.6 V

CT Reset Threshold 0.32 0.5 0.62 V

Output Duty Cycle Fault Condition, IPL= 0 1.7 2.7 3.7 %

Output Section

Output High Voltage I

OUT

= 0A 8.5 10 V

I

OUT

= –1mA 6 8 V

Outut Low Voltage I

OUT

= 0A; V

SENSE

– V

IMAX

= 100mV 0 0.01 V

I

OUT

= 2mA; V

SENSE

– V

IMAX

= 100mV 0.2 0.6 V

Linear Amplifier Section

Sense Control Voltage IMAX = 100mV 85 100 115 mV

IMAX = 400mV 370 400 430 mV

Input Bias 50 500 nA

Shutdown/Fault Section

Shutdown Threshold 1.4 1.7 2.0 V

Input Current Shutdown = 5V 15 25 45 µA

Fault Output High 6 7.5 9 V

Fault Output Low 0 0.01 V

Delay to Output (Note 1) 150 300 ns

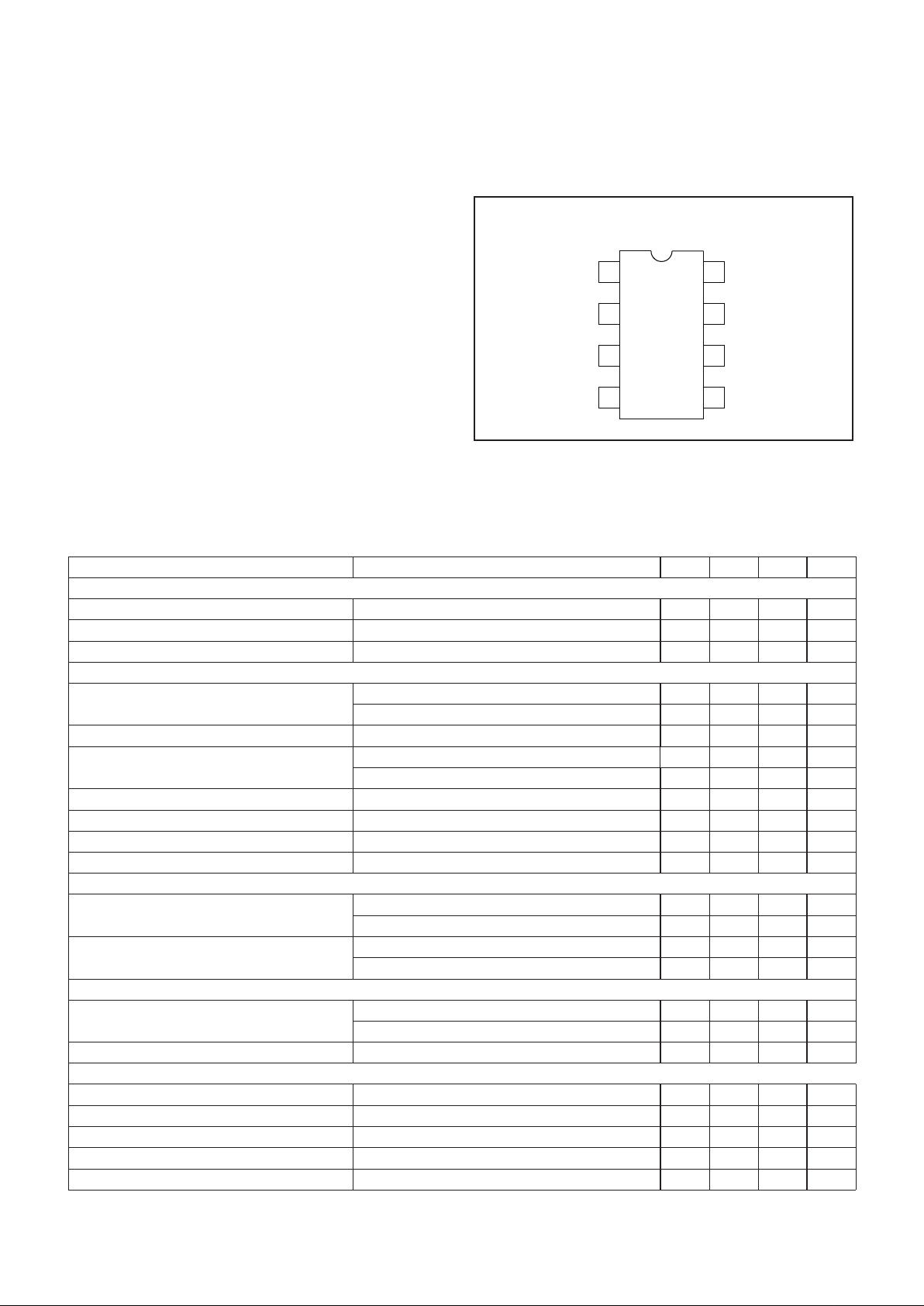

SENSE

OUT

PL

VSS

IMAX

SD/FLT

VDD

CT

1

2

3

4

8

7

6

5

CONNECTION DIAGRAMS

DIL-8, SOIC-8 (Top View)

N or J, D Package

3

UCC1913

UCC2913

UCC3913

ELECTRICAL CHARACTERISTICS:

Unless otherwise stated these specifications apply for TA= –55°C to +125°C for

UCC1913; –40°C to +85°C for UCC2913; 0°C to +70°C for UCC3913; I

VDD

= 2mA, CT = 4.7pF, TA= T

J

PARAMETER TEST CONDITIONS MIN TYP MAX UNITS

Power Limiting Section

V

SENSE

Regulator Voltage IPL= 64 A 4.35 4.85 5.35 V

Duty Cycle Control IPL= 64µA 0.6 1.2 1.7 %

I

PL

= 1mA 0.045 0.1 0.17 %

Overload Section

Delay to Output (Note 1) 300 500 ns

Output Sink Current V

SENSE

= V

IMAX

= 300mV 40 100 mA

Threshold Relative to IMAX 140 200 260 mV

Note 1: Guaranteed by design. Not 100% tested in production.

CT: A capacitor is connected to this pin in order to set the

maximum fault time. The maximum fault time must be

more than the time to charge external load capacitance.

The maximum fault time is defined as:

()

T

CT

I

FAULT

CH

=

•2

where

IAI

CH PL

=+36µ

,

and I

PL

is the current into the power limit pin. Once the

fault time is reached the output will shutdown for a time

given by:

TCT

SD

=• •2 106

IMAX: This pin programs the maximum allowable sour-

cing current. Since VDD is a regulated voltage, a voltage

divider can be derived from VDD to generate the program level for the IMAX pin. The current level at which

the output appears as a current source is equal to the

voltage on the IMAX pin over the current sense resistor.

If desired, a controlled current startup can be programmed with a capacitor on the imax pin, and a programmed start delay can be achieved by driving the

shutdown with an open collector/drain device into an RC

network.

OUT: Output drive to the MOSFET pass element.

PL: This feature ensures that the average MOSFET

power dissipation is controlled. A resistor is connected

from this pin to the drain of the NMOS pass element.

When the voltage across the NMOS exceeds 5V, current

will flow into the PL pin which adds to the fault timer

charge current, reducing the duty cycle from the 3%

level. When I

PL

>>36µA then the average MOSFET

power dissipation is given by:

PIMAX R

FET avg PL

()

=•••

−

110

6

SENSE: Input voltage from the current sense resistor.

When there is greater than 50mV across this pin with respect to VSS, then a fault is sensed, and CT starts to

charge.

SD/FLT: This pin provides fault output indication and

shutdown control. Interface into and out of this pin is usually performed through level shift transistors. When 20µA

is sourced into this pin, shutdown drives high causing the

output to disable the NMOS pass device. When opened,

and under a non-fault condition, the SD/FLT pin will pull

to a low state. When a fault is detected by the fault timer,

or undervoltage lockout, this pin will drive to a high state,

indicating the output FET is off.

VDD: Current driven with a resistor to a voltage at least

10V more positive than VSS. Typically a resistor is connected to ground. The 10V shunt regulator clamps VDD

at 10V above the VSS pin, and is also used as an output

reference to program the maximum allowable sourcing

current.

VSS: Ground reference for the IC and the most negative

voltage available.

PIN DESCRIPTIONS

4

UCC1913

UCC2913

UCC3913

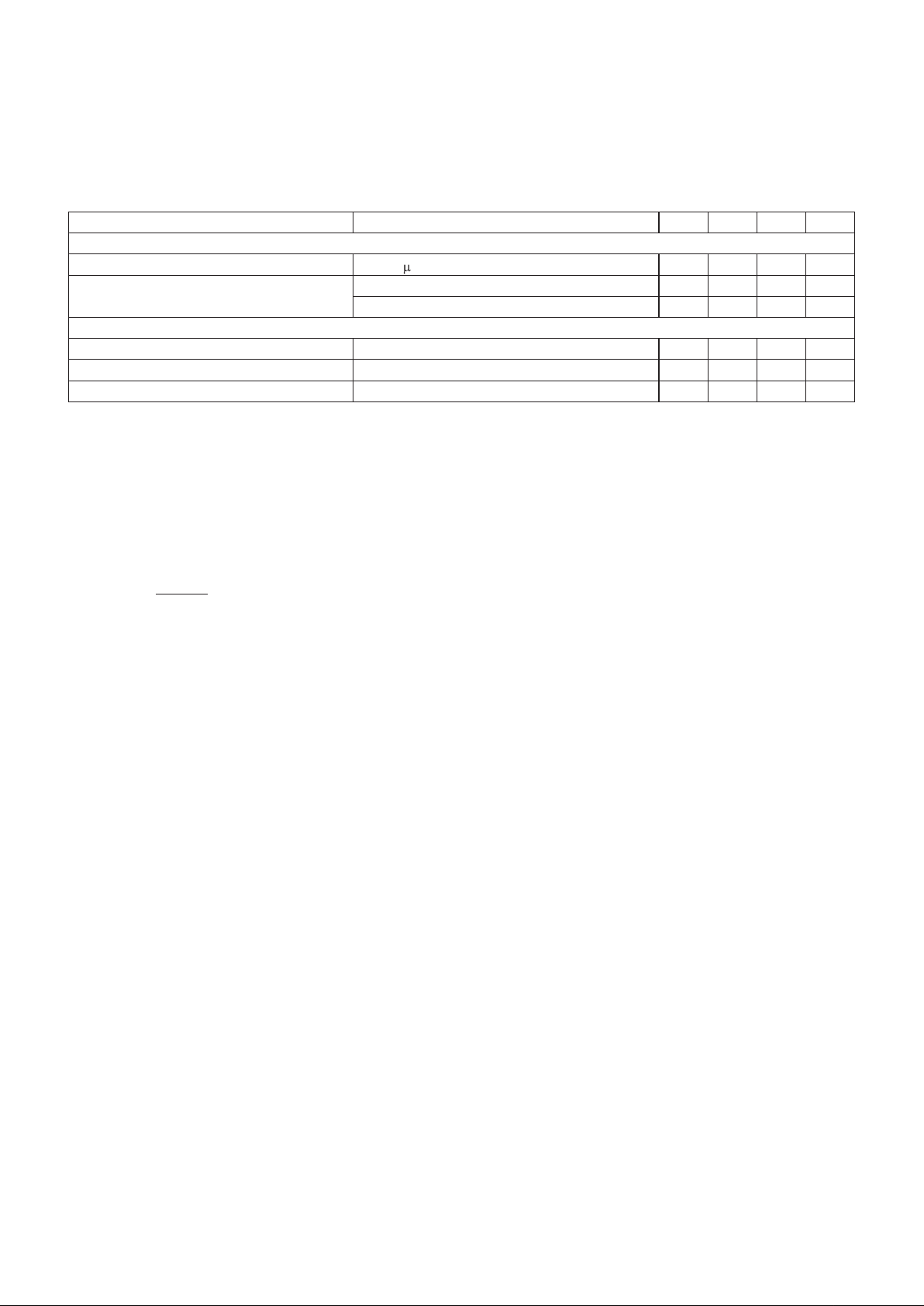

8

5

6

4

OVERCURRENT

COMPARATOR

R

PL

PL

R

S

SENSE

VSS

VSS

INPUT VOLTAGE

OUTPUT

LOAD

V

DD

I1

36µA

+

SQ

QR

H=CLOSE

I2

1µA

I3

1mA

+

SENSE

IMAX

H=CLOSE

0.5V

2.5V

C

T

VSS

TO OUTPUT

DRIVE

H=OFF

OVERLOAD COMPARATOR

CT

FAULT TIMING CIRCUITRY

0.2V

5.0V

50mV

APPLICATION INFORMATION

Figure 1. Fault timing circuitry for the UCC1913, including power limit overload.

Figure 1 shows the detailed circuitry for the fault timing

function of the UCC1913. For the time being, we will discuss a typical fault mode, therefore, the overload comparator, and current source I3 does not work into the

operation. Once the voltage across the current sense resistor, R

S

, exceeds 50mV, a fault has occurred. This

causes the timing capacitor to charge with a combination

of 36µA plus the current from the power limiting amplifier.

The PL amplifier is designed to only source current into

the CT pin and to begin sourcing current once the voltage across the output FET exceeds 5V. The current I

PL

is related to the voltage across the FET with the following

expression:

I

VV

R

PL

FET

PL

=

−5

Where V

FET

is the voltage across the NMOS pass de-

vice.

Later it will be shown how this feature will limit average

power dissipation in the pass device. Note that under a

condition where the output current is more than the fault

level, but less than the max level, V

OUT

~ VSS (input

voltage), IPL= 0, the CT charging current is 36µA.

During a fault, CT will charge at a rate determined by the

internal charging current and the external timing capacitor. Once CT charges to 2.5V, the fault comparator

switches and sets the fault latch. Setting of the fault latch

causes both the output to switch off and the charging

switch to open. CT must now discharge with the 1µA current source, I2, until 0.5V is reached. Once the voltage at

CT reaches 0.5V, the fault latch resets, which re-enables

the output and allows the fault circuitry to regain control

of the charging switch. If a fault is still present, the fault

comparator will close the charging switch causing the cycle to begin. Under a constant fault, the duty cycle is

given by:

DutyCycle

A

IA

PL

=

+136µµ

Average power dissipation in the pass element is given

by:

PVIMAX

A

IA

FET avg FET

PL

()

=• •

+136µµ

where V

FET

>> 5V IPLcan be approximated as :

V

R

FET

PL

and where IPL>>36µA, the duty cycle can be approximated as :

UDG-99004

5

UCC1913

UCC2913

UCC3913

IOUT

IMAX

IFAULT

Io(nom)

0A

V

CT

2.5V

0.5V

0V

0V

V

OUT

VSS

t

0

t1 t2 t3 t4 t5 t6 t7 t8 t9 t10

t

t

t

Output

Current

C

T

Voltage

(w/respectto VSS)

Output

Voltage

(w/respectt oGND)

APPLICATION INFORMATION (cont.)

Figure 2. Typical timing diagram.

t0: safe condition – output current is nominal, output

voltage is at the negative rail, VSS.

t1: fault control reached – output current rises above

the programmed fault value, CT begins to charge at

≅ 36µA.

t2: max current reached – output current reaches the

programmed maximum level and becomes a constant current with value I

MAX

.

t3: fault occurs – CT has charged to 2.5V, fault output

goes high, the FET turns off allowing no output current to flow, V

OUT

floats up to ground.

t4: retry – CT has discharged to 0.5V, but fault current

is still exceeded, CT begins charging again, FET is

on, V

OUT

pulled down to VSS.

t5: t5 = t3: illustrates 3%duty cycle.

t6: t6 = t4

t7: output short circuit - if V

OUT

is short circuited to

ground, CT charges at a higher rate depending

upon the values for VSS and R

PL

.

t8: fault occurs – output is still short circuited, but the

occurrence of a fault turns the FET off so no current

is conducted.

t9: t9 = t4; output short circuit released, still in fault

mode.

t10: t10 = t0; fault released, safe condition – return to

normal operaton of the circuit breaker.

6

UCC1913

UCC2913

UCC3913

1µ

AR

V

PL

FET

•

Therefore, the maximum average power dissipation in

the MOSFET can be approximated by:

P

VIMAX

AR

V

IMAX A R

FET avg

FET

PL

FET

PL

()

=

••

•

=••

11µ

µ

Notice that in the approximation, V

FET

cancels. therefore,

average power dissipation is limited in the NMOS pass

element.

Overload Comparator

The linear amplifier in the UCC1913 ensures that the

output NMOS does not pass more than I

MAX

(which is

V

IMAX/RS

). In the event the output current exceeds the

programmed I

MAX

by 0.2V/RS, which can only occur if

the output FET is not responding to a command from the

IC, the CT pin will begin charging with I3, 1mA, and continue to charge to approximately 8V. This allows a constant fault to show up on the SD/FLT pin, and also since

the voltage on CT will only charge past 2.5V in an overload fault mode, it can be used for detection of output

FET failure or to build in redundancy in the system.

Determining External Component Values

Referring now to Figure 3. To set R

VDD

the following

must be achieved:

()

()

V

R

V

RR

mA

IN

VDD

min

>

+

+

10

12

2

In order to estimate the minimum timing capacitor, CT,

several things must be taken into account. For example,

given the schematic below as a possible (and at this

point, a standard) application, certain external component values must be known in order to estimate C

T(min)

.

Now, given the values of C

OUT

, Load, R

SENSE

, VSS, and

the resistors determining the voltage on the IMAX pin,

the user can calculate the approximate startup time of

the node V

OUT

. This startup time must be faster than the

time it takes for CT to charge to 2.5V (relative to VSS),

and is the basis for estimating the minimum value of CT.

In order to determine the value of the sense resistor,

R

SENSE

, assuming the user has determined the fault cur-

rent, R

SENSE

can be calculated by:

R

mV

I

SENSE

FAULT

=

50

APPLICATION INFORMATION (cont.)

Figure 3.

∞

Figure 4. Plot average power vs. FET voltage for

increasing values of R

PL

.

SHUTDOWN

SD/FLT7

R4

R3

VSS

LEVEL SHIFT

LOCAL VDD

LOCAL GND

FAULT OUT

Figure 5. Possible level shift circuitry to interface to

the UCC1913.

7

UCC1913

UCC2913

UCC3913

1

2

LINEAR

CURRENT

AMPLIFIER

PL

7

OUT

IMAX

+

V

DD

50Ω

8

V

DD

6

SENSE

5

VSS

4

CT

ON-TIME

CONTROL

3

VDD

UVLO

5.0V

REF

LOGIC

SUPPLY

9.5V SHUNT REGULATOR

+

20µA

1=

UNDERVOLTAGE

SOURCE

ONLY

SD/FLT

V

DD

CSS

R2

VSS

C

VDD

R1

R

VDD

R

T

OUTPUT

R

S

C

T

VSS

FAULT=

50mV

DISABLE

Figure 6. Typical application diagram.

Next, the variable I

MAX

must be calculated. I

MAX

is the

maximum current that the UCC1913 will allow through

the transistor, M1, and it can be shown that during

startup with an output capacitor the power MOSFET, M1,

can be modeled as a constant current source of value

I

MAX

where:

I

V

R

MAX

IMAX

SENSE

=

where V

IMAX

= voltage on pin IMAX.

Given this information, calculation of the startup time is

now possible via the following:

Current Source Load:

T

CVSS

II

START

OUT

MAX LOAD

=

•

−

Resistive Load:

TCRn

IR

IRVSS

START OUT OUT

MAX OUT

MAX OUT

=••

•

•−

Once T

START

is calculated, the power limit feature of the

UCC1913 must be addressed and component values derived. Assuming the user chooses to limit the maximum

allowable average power that will be associated with the

circuit breaker, the power limiting resistor, R

PL

, can be

easily determined by the following:

APPLICATION INFORMATION (cont.)

UDG-99002

8

UCC1913

UCC2913

UCC3913

Although the UCC3913 is designed to provide system

protection for all fault conditions, all integrated circuits

can ultimately fail short. For this reason, if the UCC3913

is intended for use in safety critical applications where

UL or some other safety rating is required, a redundant

safety device such as a fuse should be placed in series

with the device. The UCC3913 will prevent the fuse from

blowing for virtually all fault conditions, increasing system

reliability and reducing maintenance cost, in addition to

providing the hot swap benefits of the device.

SAFETY RECOMENDATION

()

R

P

AI

PL

FET avg

MAX

=

•1µ

where a minimum R

PL

exists defined by

()

R

VSS

mA

PL

min

=

5

Finally, after computing the aforementioned variables,

the minimum timing capacitor can be derived as such:

Current Source Load:

()

()

C

TARVSSV

R

T

START PL

PL

min

=

•••+−

•

362 10

10

µ

Resistive Load:

()

()

C

TARVSSVIR

R

R

T

START PL MAX OUT

PL

OU

min

=

••+−−•

•

+

•

331 5

5

3

µ

TOUT

PL

VSS C

R

••

•5

APPLICATION INFORMATION (cont.)

UNITRODE CORPORATION

7 CONTINENTALBLVD. • MERRIMACK, NH 03054

TEL. (603) 424-2410 FAX (603) 424-3460

IMPORTANT NOTICE

T exas Instruments and its subsidiaries (TI) reserve the right to make changes to their products or to discontinue

any product or service without notice, and advise customers to obtain the latest version of relevant information

to verify, before placing orders, that information being relied on is current and complete. All products are sold

subject to the terms and conditions of sale supplied at the time of order acknowledgement, including those

pertaining to warranty, patent infringement, and limitation of liability.

TI warrants performance of its semiconductor products to the specifications applicable at the time of sale in

accordance with TI’s standard warranty. Testing and other quality control techniques are utilized to the extent

TI deems necessary to support this warranty. Specific testing of all parameters of each device is not necessarily

performed, except those mandated by government requirements.

CERT AIN APPLICATIONS USING SEMICONDUCT OR PRODUCTS MAY INVOLVE POTENTIAL RISKS OF

DEATH, PERSONAL INJURY, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE (“CRITICAL

APPLICATIONS”). TI SEMICONDUCTOR PRODUCTS ARE NOT DESIGNED, AUTHORIZED, OR

WARRANTED TO BE SUITABLE FOR USE IN LIFE-SUPPORT DEVICES OR SYSTEMS OR OTHER

CRITICAL APPLICATIONS. INCLUSION OF TI PRODUCTS IN SUCH APPLICA TIONS IS UNDERSTOOD T O

BE FULLY AT THE CUSTOMER’S RISK.

In order to minimize risks associated with the customer’s applications, adequate design and operating

safeguards must be provided by the customer to minimize inherent or procedural hazards.

TI assumes no liability for applications assistance or customer product design. TI does not warrant or represent

that any license, either express or implied, is granted under any patent right, copyright, mask work right, or other

intellectual property right of TI covering or relating to any combination, machine, or process in which such

semiconductor products or services might be or are used. TI’s publication of information regarding any third

party’s products or services does not constitute TI’s approval, warranty or endorsement thereof.

Copyright 1999, Texas Instruments Incorporated

Loading...

Loading...