Page 1

www.ti.com

BiCMOS LOW-POWER CURRENT-MODE PWM CONTROLLERS

UCC28C4x-EP

SGLS352B – DECEMBER 2006 – REVISED MAY 2007

FEATURES

• Low Operating Current of 2.3 mA at 52 kHz

• Controlled Baseline • Fast 35 ns Cycle-by-Cycle Overcurrent

– One Assembly/Test Site, One Fabrication

Limiting

Site • ± 1 A Peak Output Current

– Extended Temperature Performance of • Rail-to-Rail Output Swings With 25 ns Rise

–55 ° C to 125 ° C and 20 ns Fall Times

• Enhanced Diminishing Manufacturing Sources • ± 1% Initial Trimmed 2.5 V Error Amplifier

(DMS) Support Reference

• Enhanced Product-Change Notification • Trimmed Oscillator Discharge Current

• Qualification Pedigree

(1)

• New Undervoltage Lockout Versions

• Enhanced Replacements for UC2842A Family • MSOP-8 Package Minimizes Board Space

With Pin-to-Pin Compatibility

• 1 MHz Operation

• 50 µ A Standby Current, 100 µ A Maximum

(1) Component qualification in accordance with JEDEC and

industry standards to ensure reliable operation over an

extended temperature range. This includes, but is not limited

to, Highly Accelerated Stress Test (HAST) or biased 85/85,

temperature cycle, autoclave or unbiased HAST,

electromigration, bond intermetallic life, and mold compound

life. Such qualification testing should not be viewed as

justifying use of this component beyond specified

performance and environmental limits.

APPLICATIONS

• Switch Mode Power Supplies

• DC-to-DC Converters

• Board Mount Power Modules

DESCRIPTION

The UCC28C4x family are high performance current mode PWM controllers. They are enhanced BiCMOS

versions with pin-for-pin compatibility to the industry standard UC284xA family and UC284x family of PWM

controllers. In addition, lower startup voltage versions of 7 V are offered as UCC28C40 and UCC28C41.

Providing necessary features to control fixed frequency, peak current mode power supplies, this family offers

several performance advantages. These devices offer high frequency operation up to 1 MHz with low start up

and operating currents, thus minimizing start up loss and low operating power consumption for improved

efficiency. The devices also feature a fast current sense to output delay time of 35 ns, and a ± 1 A peak output

current capability with improved rise and fall times for driving large external MOSFETs directly.

The UCC28C4x family is offered in 8-pin package SOIC (D).

Please be aware that an important notice concerning availability, standard warranty, and use in critical applications of Texas

Instruments semiconductor products and disclaimers thereto appears at the end of this data sheet.

PRODUCTION DATA information is current as of publication date.

Products conform to specifications per the terms of the Texas

Instruments standard warranty. Production processing does not

necessarily include testing of all parameters.

Copyright © 2006–2007, Texas Instruments Incorporated

Page 2

www.ti.com

Note:Toggleflip-flopusedonlyinUCC28C41,UCC28C44,andUCC28C45.

UCC28C4x-EP

BiCMOS LOW-POWER CURRENT-MODE PWM CONTROLLERS

SGLS352B – DECEMBER 2006 – REVISED MAY 2007

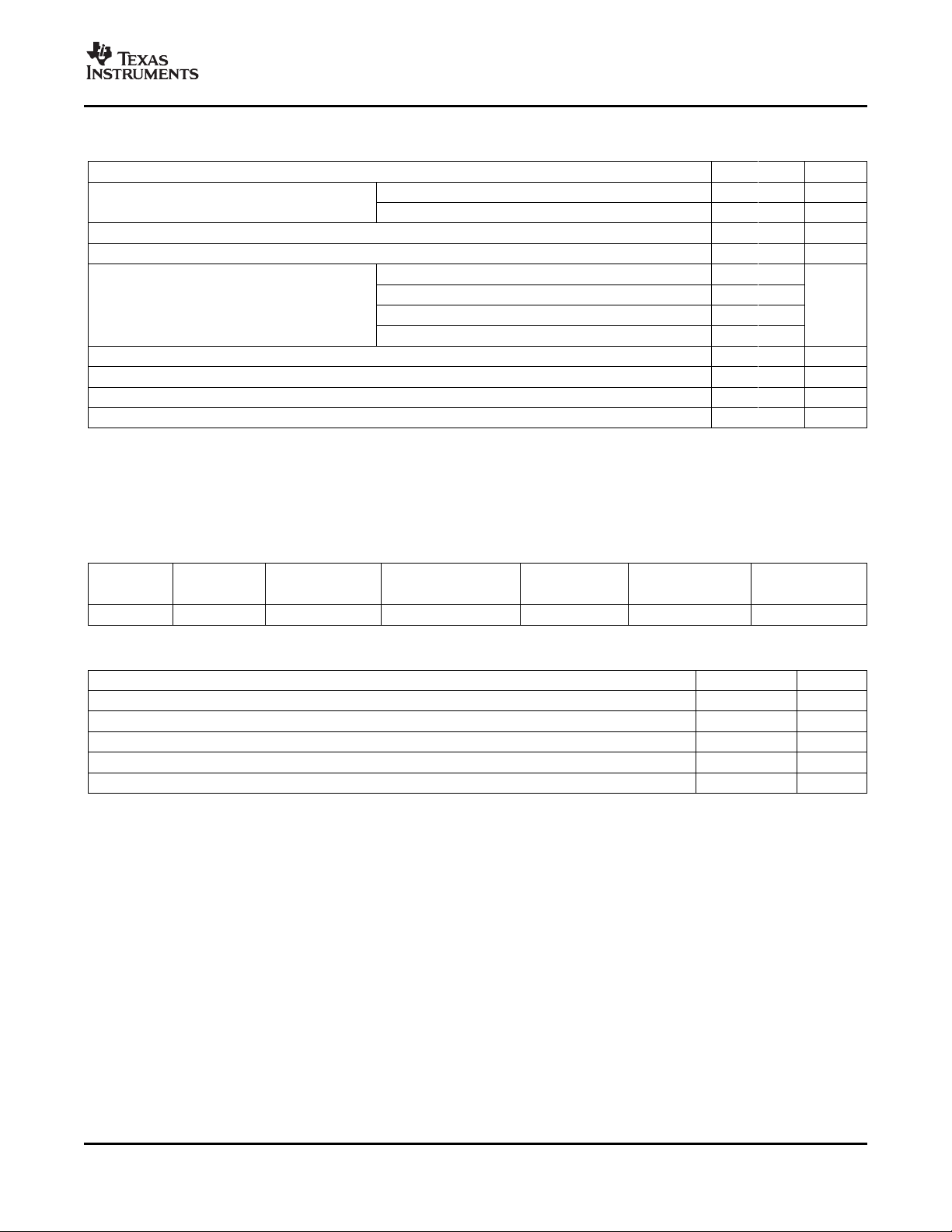

AVAILABLE OPTIONS

T

A

MAXIMUM UVLO

DUTY CYCLE ON/OFF

14.5 V/9 V UCC28C42MDREP

100% 8.4 V/7.6 V UCC28C43MDREP

–55 ° C to 125 ° C

7 V/6.6 V UCC28C40MDREP

14.5 V/9 V UCC28C44MDREP

50% 8.4 V/7.6 V UCC28C45MDREP

7 V/6.6 V UCC28C41MDREP

(1) D (SOIC-8) packages are available taped and reeled. Add R suffix to device type (e.g., UCC28C42DREP) to order quantities of 2500

devices per reel. Tube quantities are 75 for D packages (SOIC-8).

(2) Product Preview

FUNCTIONAL BLOCK DIAGRAM

SOIC-8

SMALL OUTLINE

(1)

(D)

(2)

(2)

(2)

(2)

2

Submit Documentation Feedback

Page 3

www.ti.com

UCC28C4x-EP

BiCMOS LOW-POWER CURRENT-MODE PWM CONTROLLERS

SGLS352B – DECEMBER 2006 – REVISED MAY 2007

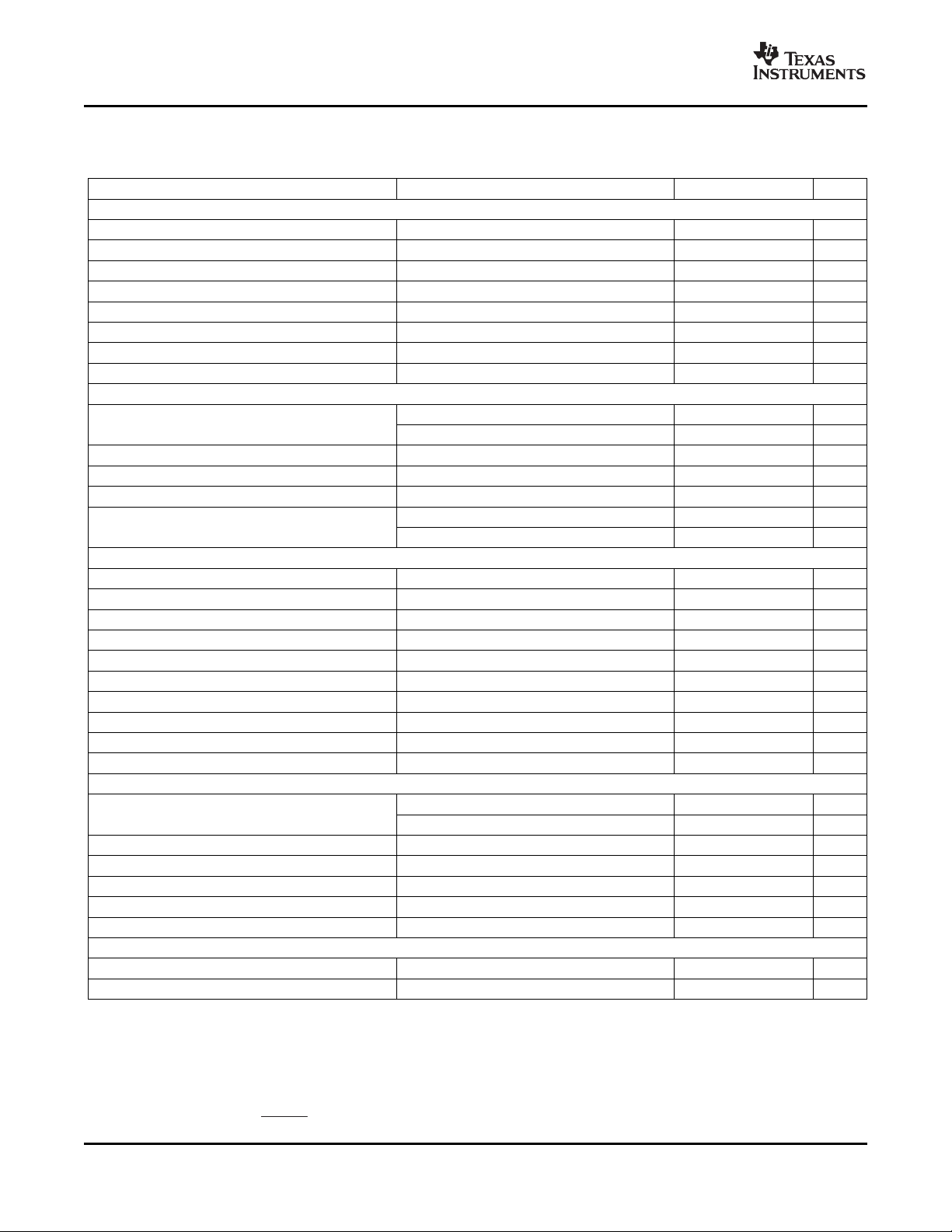

Absolute Maximum Ratings

over operating free-air temperature range (unless otherwise noted)

Supply voltage

Output current, I

Output energy, capacitive load 5 µ J

Voltage rating V

Error amplifier output sink current 10 mA

T

Operating junction temperature range

J

T

Storage temperature range –65 150 ° C

stg

Lead temperature (soldering, 10 s) 300 ° C

(1) Stresses beyond those listed under "absolute maximum ratings" may cause permanent damage to the device. These are stress ratings

only, and functional operation of the device at these or any other conditions beyond those indicated under "recommended operating

conditions" is not implied. Exposure to absolute-maximum-rated conditions for extended periods may affect device reliability.

(2) All voltages are with respect to ground. Currents are positive into and negative out of the specified terminals.

(3) Long-term high temperature storage and/or extended use at maximum recommended operating conditions may result in a reduction of

overall device life. See http://www.ti.com/ep_quality for additional information about enhanced plastic packaging.

peak ± 1 A

OUT

(1) (2)

MIN MAX UNIT

VDD 20 V

Max I

CC

30 mA

COMP, CS, FB –0.3 6.3

OUT –0.3 20

RT/CT –0.3 6.3

VREF 7

(3)

–55 150 ° C

Dissipation Ratings

θ

PACKAGE

ja

( ° C/W) POWER RATING ABOVE TA= 25 ° C POWER RATING POWER RATING POWER RATING

D 176 710 mW 5.68 mW/ ° C 454 mW 369 mW 142 mW

TA< 25 ° C DERATING FACTOR TA= 70 ° C TA= 85 ° C TA= 125 ° C

Recommended Operating Conditions

MIN MAX UNIT

V

DD

V

OUT

(1)

I

OUT

I

OUT(ref

(1)

T

J

(1) It is not recommended that the device operate under conditions beyond those specified in this table for extended periods of time.

Input voltage 18 V

Output voltage range 18 V

Average output current 200 mA

(1)

)

Reference output current –20 mA

Operating junction temperature –55 150 ° C

Submit Documentation Feedback

3

Page 4

www.ti.com

ACS +

DV

COM

DV

CS

,0Vv VCSv 900 mV

UCC28C4x-EP

BiCMOS LOW-POWER CURRENT-MODE PWM CONTROLLERS

SGLS352B – DECEMBER 2006 – REVISED MAY 2007

Electrical Characteristics

V

DD

UCC28C4x

Reference

Oscillator

Error Amplifier

A

VOL

PSRR Power-supply rejection ratio V

V

OH

V

OL

Current Sense

PSRR Power-supply rejection ratio V

Output

(1)

= 15 V

, RT= 10 k Ω , CT= 3.3 nF, C

VDD

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

Output voltage, initial accuracy TA= 25 ° C , I

Line regulation V

Load regulation 1 mA to 20 mA 3 25 mV

Temperature stability

Total output variation

Output noise voltage 10 Hz to 10 kHz, TA= 25 ° C 50 µ V

Long term stability 1000 hours, TA= 125 ° C

Output short circuit –30 –45 –55 mA

Initial accuracy

Voltage stability V

Temperature stability T

Amplitude RT/CT pin peak to peak 1.9 V

Discharge current

Feedback input voltage, initial accuracy V

Feedback input voltage, total variation V

Input bias current –0.1 –2 µ A

Open-loop voltage gain V

Unity gain bandwidth 1.5 MHz

Output sink current V

Output source current V

High-level output voltage V

Low-level output voltage V

Gain

Maximum input signal V

Input bias current –0.1 –2 µ A

CS to output delay 35 70 ns

COMP to CS offset V

V

low (R

OUT

V

high (R

OUT

pull-down) I

DS(on)

pull-up) I

DS(on)

= 0.1 µ F and no load on the outputs, TA= TJ= –55 ° C to 125 ° C for the

= 1 mA 4.9 5 5.1 V

OUT

= 12 V to 18 V 0.2 20 mV

DD

(2)

(2)

(2)

TA= 25 ° C

TA= Full Range

DD

MIN

TA= 25 ° C, RT/CT = 2 V

RT/CT = 2 V

COMP

COMP

OUT

DD

FB

FB

FB

FB

TA= 25 ° C

TA= Full Range

FB

DD

CS

SINK

SOURCE

(3)

(3)

= 12 V to 18 V 0.2 2.85 %

(2)

to T

MAX

(4)

(4)

= 2.5 V, TA= 25 ° C 2.475 2.500 2.525 V

= 2.5 V 2.45 2.50 2.55 V

= 2 V to 4 V 65 90 dB

= 12 V to 18 V 60 dB

= 2.7 V, V

= 2.3 V, V

= 2.3 V, R

= 2.7 V, R

(5) (6)

= 1.1 V 2 14 mA

COMP

= 5 V –0.5 –1 mA

COMP

= 15 k to GND 5 6.8 V

LOAD

= 15 k to VREF 0.1 1.1 V

LOAD

(5) (6)

< 2.4 V 0.9 1 1.1 V

= 12 V to 18 V

(2) (5)

= 0 V 1.15 V

= 200 mA 5.5 15 Ω

= 200 mA 10 25 Ω

4.82 5.18 V

50.5 53 55 kHz

50.5 57 KHz

2.85 3 3.15 V/V

2.825 3.15 V/V

0.2 0.4 mV/ ° C

7.7 8.4 9 mA

7.2 8.4 9.5 mA

70 dB

5 25 mV

1 2.5 %

(1) Adjust V

(2) Not production tested.

above the start threshold before setting at 15 V.

DD

(3) Output frequencies of the UCC28C41, UCC28C44, and UCC28C45 are one-half the oscillator frequency.

(4) Oscillator discharge current is measured with RT= 10 k Ω to V

(5) Parameter measured at trip point of latch with V

= 0 V.

FB

.

REF

(6) Gain is defined as

4

Submit Documentation Feedback

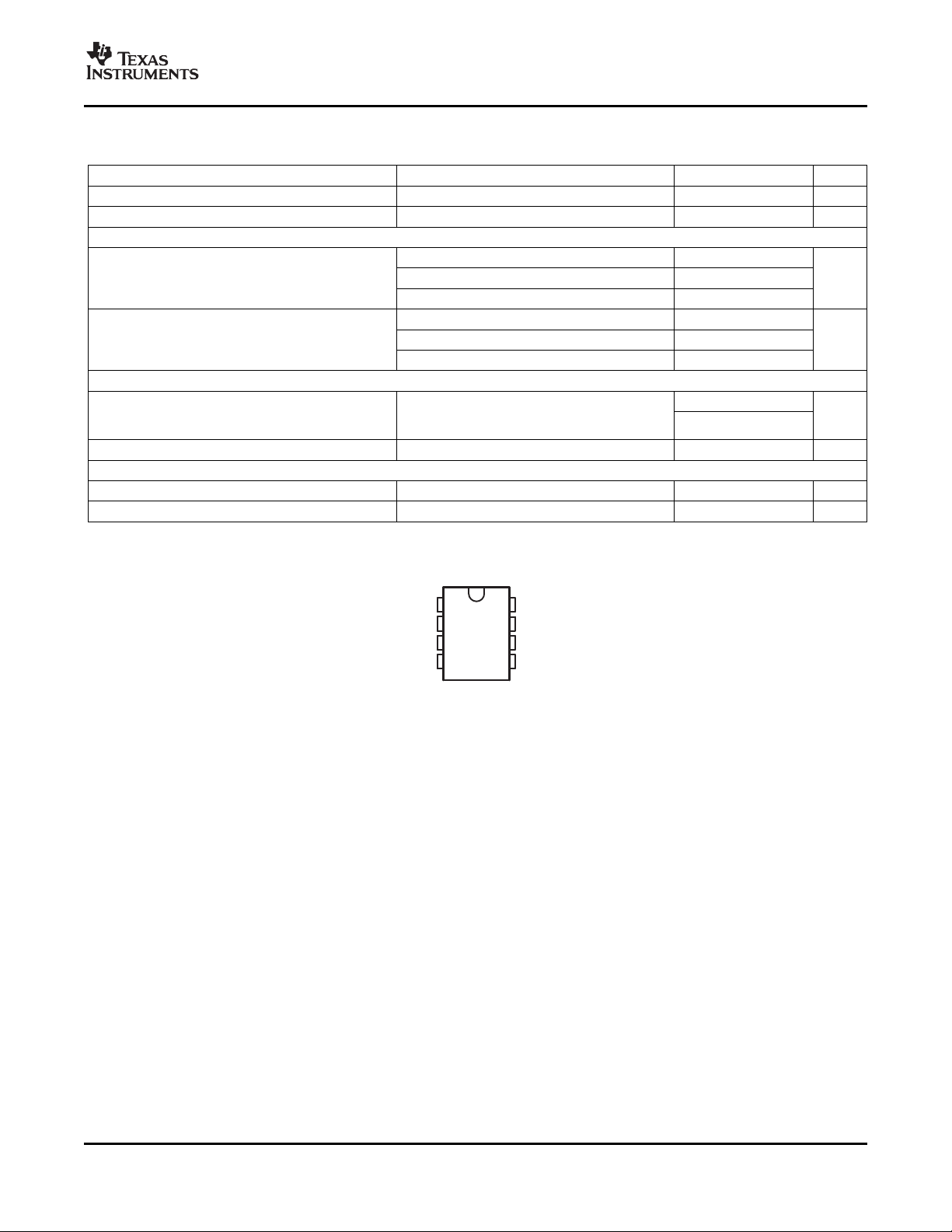

Page 5

www.ti.com

1

2

3

4

8

7

6

5

COMP

FB

CS

RT/CT

VREF

VDD

OUT

GND

PDIP (P) or SOIC (D) PACKAGE

(TOP VIEW)

Electrical Characteristics (continued)

V

= 15 V , RT= 10 k Ω , CT= 3.3 nF, C

DD

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

Rise tIme TA= 25 ° C, C

Fall time TA= 25 ° C, C

Undervoltage Lockout (UVLO)

Start threshold UCC28C43-EP, UCC28C45-EP 7.8 8.4 9 V

Minimum operating voltage UCC28C43-EP, UCC28C45-EP 7 7.6 8.2 V

PWM

Maximum duty cycle UCC28C40-EP, UCC28C44-EP, %

Minimum duty cycle 0%

Current Supply

I

START-UP

I

DD

Start-up current V

Operating supply current V

BiCMOS LOW-POWER CURRENT-MODE PWM CONTROLLERS

SGLS352B – DECEMBER 2006 – REVISED MAY 2007

= 0.1 µ F and no load on the outputs, TA= TJ= –55 ° C to 125 ° C for the UCC28C4x

VDD

= 1 nF 25 50 ns

LOAD

= 1 nF 20 40 ns

LOAD

UCC28C42-EP, UCC28C44-EP 13.5 14.5 15.5

UCC28C40-EP, UCC28C41-EP 6.5 7 7.5

UCC28C42-EP, UCC28C44-EP 8 9 10

UCC28C40-EP, UCC28C41-EP 6.1 6.6 7.1

UCC28C42-EP, UCC28C43-EP, 94 96

UCC28C45-EP, UCC28C41-EP

= UVLO start threshold (–0.5 V) 50 100 µ A

DD

= V

FB

= 0 V 2.3 3 mA

CS

UCC28C4x-EP

47 48

Pin Assignments

COMP: This pin provides the output of the error amplifier for compensation. In addition, the COMP pin is

frequently used as a control port by utilizing a secondary-side error amplifier to send an error signal across the

secondary-primary isolation boundary through an opto-isolator.

CS: The current-sense pin is the noninverting input to the PWM comparator. This is compared to a signal

proportional to the error amplifier output voltage. A voltage ramp can be applied to this pin to run the device with

a voltage mode control configuration.

FB: This pin is the inverting input to the error amplifier. The noninverting input to the error amplifier is internally

trimmed to 2.5 V ± 1%.

GND: Ground return pin for the output driver stage and the logic-level controller section.

OUT: The output of the on-chip drive stage. OUT is intended to directly drive a MOSFET. The OUT pin in the

UCC28C40, UCC28C42, and UCC28C43 is the same frequency as the oscillator, and can operate near 100%

duty cycle. In the UCC28C41, UCC28C44, and the UCC28C45, the frequency of OUT is one-half that of the

oscillator due to an internal T flipflop. This limits the maximum duty cycle to <50%.

RT/CT: Timing resistor and timing capacitor. The timing capacitor should be connected to the device ground

using minimal trace length.

VDD: Power supply pin for the device. This pin should be bypassed with a 0.1 µ F capacitor with minimal trace

lengths. Additional capacitance may be needed to provide hold up power to the device during startup.

Submit Documentation Feedback

5

Page 6

www.ti.com

UCC28C4x-EP

BiCMOS LOW-POWER CURRENT-MODE PWM CONTROLLERS

SGLS352B – DECEMBER 2006 – REVISED MAY 2007

VREF: 5-V reference. For stability, the reference should be bypassed with a 0.1 µ F capacitor to ground using

the minimal trace length possible.

6

Submit Documentation Feedback

Page 7

www.ti.com

UCC28C4x-EP

BiCMOS LOW-POWER CURRENT-MODE PWM CONTROLLERS

SGLS352B – DECEMBER 2006 – REVISED MAY 2007

APPLICATION INFORMATION

This device is a pin-for-pin replacement of the bipolar UC2842 family of controllers—the industry standard PWM

controller for single-ended converters. Familiarity with this controller family is assumed.

The UCC28C4x series is an enhanced replacement with pin-to-pin compatibility to the bipolar UC284x and

UC284xA families. The new series offers improved performance when compared to older bipolar devices and

other competitive BiCMOS devices with similar functionality. Note that these improvements discussed below

generally consist of tighter specification limits that are a subset of the older product ratings, maintaining drop-in

capability. In new designs these improvements can be utilized to reduce the component count or enhance circuit

performance when compared to the previously available devices.

Advantages

This device increases the total circuit efficiency whether operating off-line or in dc input circuits. In off-line

applications the low start-up current of this device reduces steady state power dissipation in the startup resistor,

and the low operating current maximizes efficiency while running. The low running current also provides an

efficiency boost in battery-operated supplies.

Low-Voltage Operation

Two members of the UCC28C4x family are intended for applications that require a lower start-up voltage than

the original family members. The UCC28C40 and UCC28C41 have a turn-on voltage of 7 V typical and exhibit

hysteresis of 0.4 V for a turn-off voltage of 6.6 V. This reduced start-up voltage enables use in systems with

lower voltages, such as 12 V battery systems that are nearly discharged.

High-Speed Operation

The BiCMOS design allows operation at high frequencies that were not feasible in the predecessor bipolar

devices. First, the output stage has been redesigned to drive the external power switch in approximately

one-half the time of the earlier devices. Second, the internal oscillator is more robust, with less variation as

frequency increases. In addition, the current sense to output delay has been reduced by a factor of three, to 45

ns typical. These features combine to provide a device capable of reliable high-frequency operation.

The UCC28C4x family oscillator is true to the curves of the original bipolar devices at lower frequencies, yet

extends the frequency programmability range to at least 1 MHz. This allows the device to offer pin-to-pin

capability where required, yet capable of extending the operational range to the higher frequencies typical of

latest applications. When the original UC2842 was released in 1984, most switching supplies operated between

20 kHz and 100 kHz. Today, the UCC28C4x can be used in designs cover a span roughly ten times higher than

those numbers.

Start/Run Current Improvements

The start-up current is only 60 µ A typical, a significant reduction from the bipolar device's ratings of 300 µ A

(UC284xA). For operation over the temperature range of –55 ° C to 125 ° C, the UCC28C4x devices offer a

maximum startup current of 100 µ A, an improvement over competitive BiCMOS devices. This allows the

power-supply designer to further optimize the selection of the start-up resistor value to provide a more efficient

design. In applications where low component cost overrides maximum efficiency the low run current of 2.3 mA

typical may allow the control device to run directly through the single resistor to (+) rail, rather than needing a

bootstrap winding on the power transformer, along with a rectifier. The start/run resistor for this case must also

pass enough current to allow driving the primary switching MOSFET, which may be a few milliamps in small

devices.

± 1% Initial Reference Voltage

The BiCMOS internal reference of 2.5 V has an enhanced design and utilizes production trim to allow initial

accuracy of ± 1% at room temperature and ± 2% over the full temperature range. This can be used to eliminate

an external reference in applications that do not require the extreme accuracy afforded by the additional device.

This is very useful for nonisolated dc-to-dc applications where the control device is referenced to the same

common as the output. It is also applicable in offline designs that regulate on the primary side of the isolation

boundary by looking at a primary bias winding, or perhaps from a winding on the output inductor of a

buck-derived circuit.

Submit Documentation Feedback

7

Page 8

www.ti.com

UCC28C42

8

1COMP

5

GND

UDG-01072

V

REF

UCC28C4x-EP

BiCMOS LOW-POWER CURRENT-MODE PWM CONTROLLERS

SGLS352B – DECEMBER 2006 – REVISED MAY 2007

APPLICATION INFORMATION (continued)

Reduced Discharge Current Variation

The original UC2842 oscillator did not have trimmed discharged current, and the parameter was not specified on

the data sheet. Since many customers attempted to use the discharge current to set a crude dead-time limit, the

UC2842A family was released with a trimmed discharge current specified at 25 ° C. The UCC28C4x series now

offers even tighter control of this parameter, with approximately ± 3% accuracy at 25 ° C, and less than 10%

variation over temperature using the UCC28C4x devices. This level of accuracy can enable a meaningful limit to

be programmed, a feature not currently seen in competitive BiCMOS devices. The improved oscillator and

reference also contribute to decreased variation in the peak-to-peak variation in the oscillator waveform, which is

often used as the basis for slope compensation for the complete power system.

Soft-Start

Figure 1 provides a typical soft-start circuit for use with the UCC28C42. The values of R and C should be

selected to bring the COMP pin up at a controlled rate, limiting the peak current supplied by the power stage.

After the soft-start interval is complete, the capacitor continues to charge to V

transistor from circuit considerations.

The optional diode in parallel with the resistor forces a soft-start each time the PWM goes through UVLO and

the reference (V

) goes low. Without the diode, the capacitor otherwise remains charged during a brief loss of

REF

supply or brownout, and no soft-start is enabled upon reapplication of VIN.

, effectively removing the PNP

REF

Figure 1.

Oscillator Synchronization

The UCC28C4x oscillator has the same synchronization characteristics as the original bipolar devices. Thus, the

information in the application report U-100A, UC2842/3/4/5 Provides Low-Cost Current-Mode Control (SLUA143)

still applies. The application report describes how a small resistor from the timing capacitor to ground can offer

an insertion point for synchronization to an external clock (see Figure 2 and Figure 3 ). Figure 2 shows how the

UCC28C42 can be synchronized to an external clock source. This allows precise control of frequency and dead

time with a digital pulse train.

8

Submit Documentation Feedback

Page 9

www.ti.com

UDG-01069

8

4

V

REF

RT/ C

T

UCC28C42

PWM

R

T

C

T

24

SYNCHRONIZATION

CIRCUIT INPUT

ON .

LOW LOWHIGH

ON . OFF .

CLOCK

INPUT

PWM

OUT

UPPER THRESHOLD

LOWER THRESHOLD

OUTPUT A

COMBINED

UPPER THRESHOLD

LOWER THRESHOLD

V

CT

VCT(ANALOG)

V

SYNC

(DIGITAL)

UDG−01070

BiCMOS LOW-POWER CURRENT-MODE PWM CONTROLLERS

APPLICATION INFORMATION (continued)

Figure 2. Oscillator Synchronization Circuit

UCC28C4x-EP

SGLS352B – DECEMBER 2006 – REVISED MAY 2007

Precautions

The absolute maximum supply voltage is 20 V, including any transients that may be present. If this voltage is

exceeded, device damage is likely. This is in contrast to the predecessor bipolar devices that could survive up to

30 V. Thus, the supply pin should be decoupled as close to the ground pin as possible. Also, since no clamp is

included in the device, the supply pin should be protected from external sources that could exceed the 20 V

level.

Careful layout of the printed board has always been a necessity for high-frequency power supplies. As the

device switching speeds and operating frequencies increase, the layout of the converter becomes increasingly

important.

This 8-pin device has only a single ground for the logic and power connections. This forces the gate drive

current pulses to flow through the same ground that the control circuit uses for reference. Thus, the interconnect

inductance should be minimized as much as possible. One implication is to place the device (gate driver)

circuitry close to the MOSFET it is driving. Note that this can conflict with the need for the error amplifier and the

feedback path to be away from the noise generating components.

Circuit Applications

Figure 4 shows a typical off-line application.

Figure 3. Synchronization to an External Clock

Submit Documentation Feedback

9

Page 10

www.ti.com

UDG-01071

C53

1 COMP

2 FB

3 CS

4 RT/CT

8REF

7VCC

6OUT

5GND

UCC28C44

R6

C13

R16

T1

R12

C5

C12

D50

C52

D51

C3

R10

R11

C18C1A

F1

BR1

+

RT1

L50

C54

R55

R53

R56

C55

R52

SEC

COMMON

12 V

OUT

R50

C50

C51

R50

IC3

R54

A R

K

Q1

5 V

OUT

AC INPUT

100 Vac - 240 Vac

EMI FILTER

REQUIRED

D2

D6

IC2

IC2

UCC28C4x-EP

BiCMOS LOW-POWER CURRENT-MODE PWM CONTROLLERS

SGLS352B – DECEMBER 2006 – REVISED MAY 2007

APPLICATION INFORMATION (continued)

Figure 4. Typical Off-Line Application

Figure 5 shows the forward converter with synchronous rectification. This application provides 48 V to 3.3 V at

10 A with over 85% efficiency, and uses the UCC28C42 as the secondary-side controller and UCC3961 as the

primary-side startup control device.

Submit Documentation Feedback

10

Page 11

www.ti.com

R28

100

D3

BAR74

C26

2uF

D5

BAR74

R14

20k40%

C16

5.6nF

+

C15

1uF

C14

1uF

C13

0.22uF

C12

3300pF

C11

1500pF

D6

BZX84C15LT1

UCC28C4x

1

COMP

2FB3CS4

Rt/Ct

5

GND

6

OUT

7

Vcc

8

REF

U2

C22

4.7nF

C23

680pF

C24

0.1uF

C10

2.7nF

1

2

3

4

T2

Q4

Q3

L1

4.7uH

C21

0.1uF

+

C20

470uF

+

C19

470uF

3r3V

PWRGND

D2

C2

1nF

C18

4700pF

C25

0.047uF

VinN

VinP

C9

0.1uF

ucc3961

4FB5Rt6

Ref7AGnd

8Vs9CS10

PGnd

11

Out

1

OVS

2SD3

SS

12

Vdd

13

St

14

UVS

U1

+

C1

470uF

C3

10nF

C4

0.22uF

C5

0.1uF

C6

470pF

C7

100pF

C8

1uF

C17

4700pF

D1

Q1

Q2

TPS2832

8

BOOT

1

IN

6

BTLO

3

DT

7

HIDR

4

Vcc

2

PGND

5

LODR

U4

T1

R19

20

R22

100

R18

7.5k

R17

20k

R16

21.5k

R15

50k

R23

402

R24

20k

R25

20k

R12

200

R13

300

R27

4.7

R26

4.7

R7

10k

R21

10

R1

32.4k

R2

1.2k

R3

2.4k

R4

1.5k

R5

76.8k

R6

4.7

R8

5.1k

R9

0.33

R10

1k

R11

46.4k

R20

10

UCC28C4x-EP

BiCMOS LOW-POWER CURRENT-MODE PWM CONTROLLERS

SGLS352B – DECEMBER 2006 – REVISED MAY 2007

APPLICATION INFORMATION (continued)

Submit Documentation Feedback

11

Figure 5. Forward Converter With Synchronous Rectification

Using the UCC28C42 as the Secondary-Side Controller

Page 12

www.ti.com

I

DISCH

− Oscillator Discharge Current − mA

TJ − Temperature − °C

9.0

9.5

8.0

7.5

7.0

8.5

−50 −25 0 25 50 75 100 125

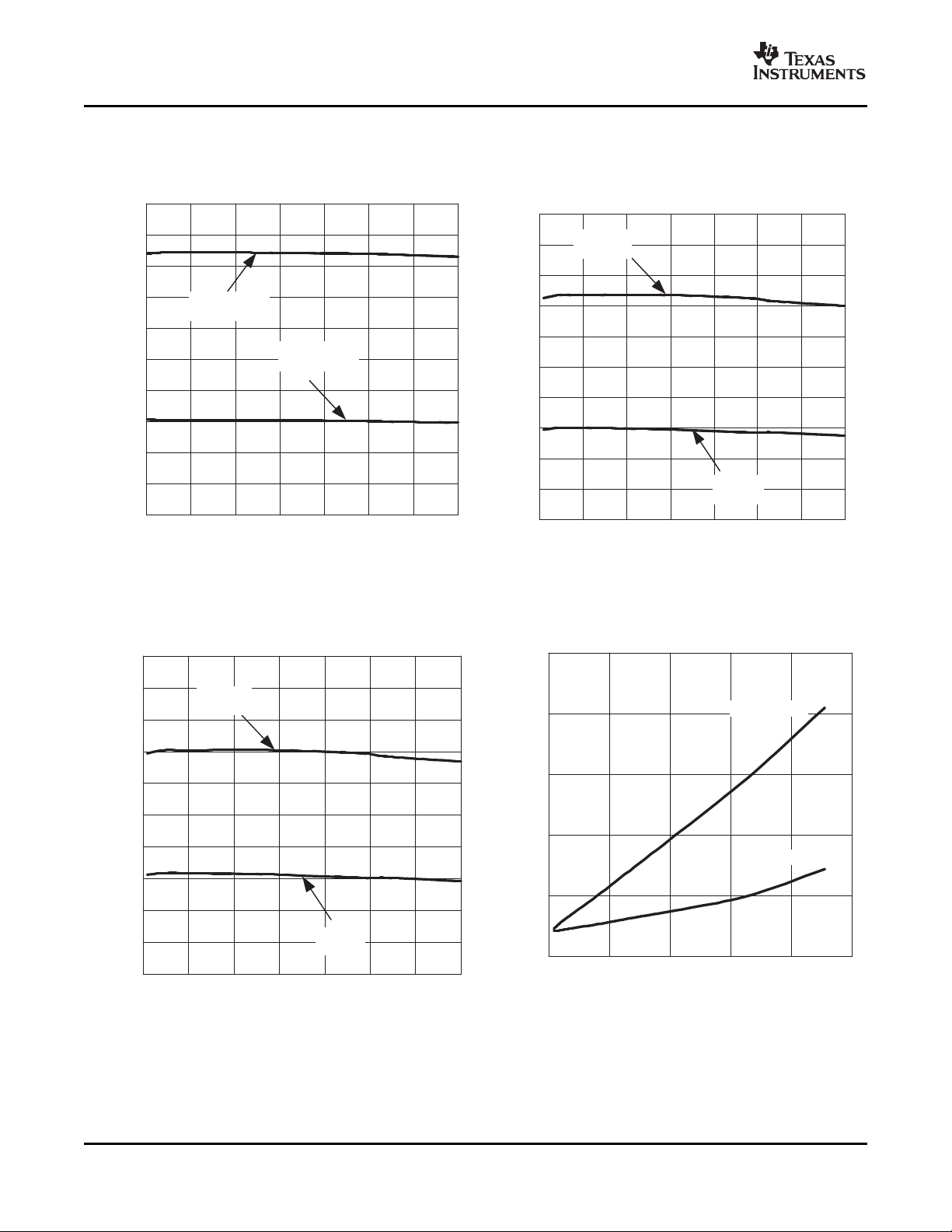

OSCILLATOR DISCHARGE CURRENT

vs

TEMPERATURE

1 k

10 k

100 k

1 k 10 k 100 k

1 M

10 M

OSCILLATOR FREQUENCY

vs

TIMING RESISTANCE AND CAPACITANCE

CT = 220 pF

CT = 4.7 nF

CT = 2.2 nF

CT = 1 nF

CT = 470 pF

RT − Timing Resistance − W

f − Frequency − Hz

f − Frequency − Hz

Gain − (dB)

ERROR AMPLIFIER

FREQUENCY RESPONSE

1 10 100 10 k 100 k 1 M 10 M1 k

10

0

20

200

180

140

120

80

40

0

60

100

160

20

30

40

50

60

70

80

90

100

Phase Margin − (°)

GAIN

PHASE

MARGIN

COMP to CS OFFSET VOLTAGE (with CS = 0)

vs

TEMPERATURE

COMP to CS

TJ − Temperature − °C

0.2

1.8

1.4

1.2

0.8

0.4

0.0

0.6

1.0

1.6

−50 −25 0 25 50 75 100 125

UCC28C4x-EP

BiCMOS LOW-POWER CURRENT-MODE PWM CONTROLLERS

SGLS352B – DECEMBER 2006 – REVISED MAY 2007

APPLICATION INFORMATION (continued)

Figure 6. Figure 7.

12

Figure 8. Figure 9.

Submit Documentation Feedback

Page 13

www.ti.com

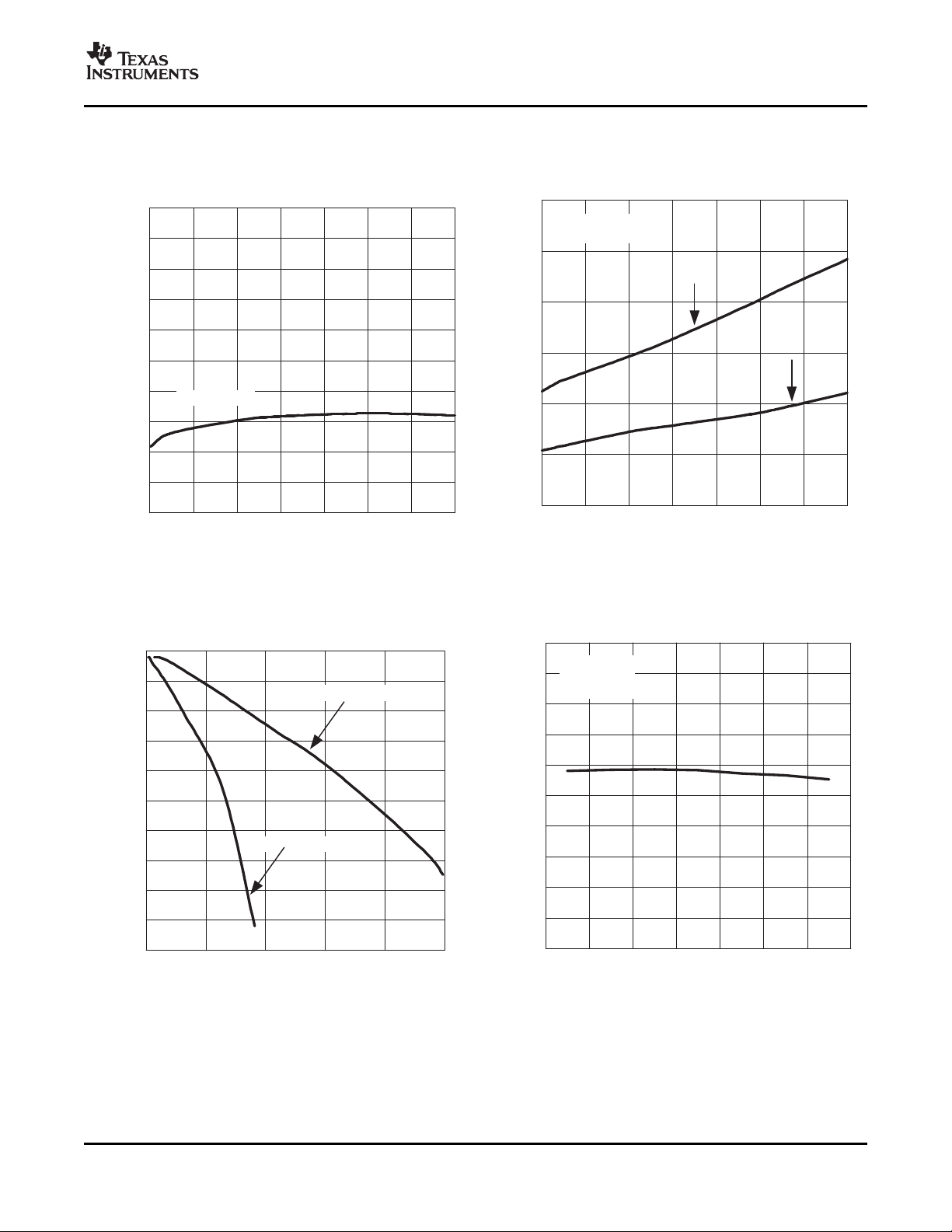

REFERENCE VOLTAGE

vs

TEMPERATURE

V

REF

− Reference Voltage − V

−50 −25 0 25 50 75 100 125

TJ − Temperature − °C

4.96

4.97

4.98

4.99

5.01

5.02

5.03

5.04

5.05

5.00

4.95

2.46

2.55

2.54

2.52

2.51

2.49

2.47

2.45

2.48

2.50

2.53

−50 −25 0 25 50 75 100 125

ERROR AMPLIFIER REFERENCE VOLTAGE

vs

TEMPERATURE

V

EAREF

− Error Amplifier Reference Voltage − V

TJ − Temperature − °C

−200

200

150

50

0

−50

−150

100

−100

ERROR AMPLIFIER INPUT BIAS CURRENT

vs

TEMPERATURE

I

BIAS

− Error Amplifier Input Bias Current − nA

TJ − Temperature − °C

−50 −25 0 25 50 75 100 125

I

SC

− Reference Short Circuit Current − mA

REFERENCE SHORT-CIRCUIT CURRENT

vs

TEMPERATURE

−55

−35

−37

−41

−45

−51

−53

−47

−49

−43

−39

−50 −25 0 25 50 75 100 125

TJ − Temperature − °C

BiCMOS LOW-POWER CURRENT-MODE PWM CONTROLLERS

APPLICATION INFORMATION (continued)

UCC28C4x-EP

SGLS352B – DECEMBER 2006 – REVISED MAY 2007

Figure 10. Figure 11.

Figure 12. Figure 13.

Submit Documentation Feedback

13

Page 14

www.ti.com

UNDERVOLTAGE LOCKOUT

vs

TEMPERATURE (UCC28C45)

V

UVLO

− UVLO Voltage − V

TJ − Temperature − °C

7.0

9.0

8.8

8.4

8.0

7.4

7.2

7.8

7.6

8.2

8.6

−50 −25 0 25 50 75 100 125

UVLO

ON

UVLO

OFF

6

16

15

13

11

8

7

10

9

12

14

−50 −25 0 25 50 75 100 125

UVLO

ON

UVLO

OFF

UNDERVOLTAGE LOCKOUT

vs

TEMPERATURE (UCC28C44)

V

UVLO

− UVLO Voltage − V

TJ − Temperature − °C

5

0

10

15

20

25

200 k 400 k 600 k 800 k0 k 1 M

1-nF LOAD

NO LOAD

SUPPLY CURRENT

vs

OSCILLATOR FREQUENCY

I

DD

− Supply Current − mA

f − Frequency − Hz

6.3

7.3

7.2

7.0

6.8

6.5

6.4

6.7

6.6

7.1

−50 −25 0 25 50 75 100 125

6.9

UNDERVOLTAGE LOCKOUT

vs

TEMPERATURE (UCC28C41)

V

UVLO

− UVLO Voltage − V

TJ − Temperature − °C

UVLO

ON

UVLO

OFF

UCC28C4x-EP

BiCMOS LOW-POWER CURRENT-MODE PWM CONTROLLERS

SGLS352B – DECEMBER 2006 – REVISED MAY 2007

APPLICATION INFORMATION (continued)

Figure 14. Figure 15.

14

Figure 16. Figure 17.

Submit Documentation Feedback

Page 15

www.ti.com

OUTPUT RISE TIME AND FALL TIME

vs

TEMPERATURE

Output Rise and Fall TIme − ns

10

15

40

35

30

20

25

tf

tr

(1 nF)

−50 −25 0 25 50 75 100 125

TJ − Temperature − °C

(1 nF)

10% to 90%

VDD = 12 V

I

DD

− Supply Current − mA

−50

2.1

3.0

2.9

2.7

2.6

2.4

2.2

2.0

2.3

2.5

2.8

−25 0 25 50 75 100 125

SUPPLY CURRENT

vs

TEMPERATURE

TJ − Temperature − °C

NO LOAD

Duty Cycle − %

f − Frequency − kHz

MAXIMUM DUTY CYCLE

vs

OSCILLATOR FREQUENCY

50

100

90

60

0

500

80

70

CT = 220 pF

CT = 1 nF

1000 1500

2000

2500

Maximum Duty Cycle − %

MAXIMUM DUTY CYCLE

vs

TEMPERATURE

90

100

92

94

96

98

−50 −25 0 25 50 75 100 125

UCC28C40

UCC28C42

UCC28C43

TJ − Temperature − °C

BiCMOS LOW-POWER CURRENT-MODE PWM CONTROLLERS

APPLICATION INFORMATION (continued)

UCC28C4x-EP

SGLS352B – DECEMBER 2006 – REVISED MAY 2007

Figure 18. Figure 19.

Figure 20. Figure 21.

Submit Documentation Feedback

15

Page 16

www.ti.com

CURRENT-SENSE THRESHOLD VOLTAGE

vs

TEMPERATURE

V

CS_th

− Current Sense Threshold − V

0.90

0.95

1.00

1.05

1.10

−50 −25 0 25 50 75 100 125

TJ − Temperature − °C

MAXIMUM DUTY CYCLE

vs

TEMPERATURE

Output Rise and Fall TIme − ns

45

50

46

47

48

49

−50 −25 0 25 50 75 100 125

UCC28C41

UCC28C44

UCC28C45

TJ − Temperature − °C

t

D

− CS to OUT Delay Time − ns

CS TO OUT DELAY TIME

vs

TEMPERATURE

30

−50 −25 0 25 50 75 100 125

35

70

65

60

55

45

40

50

TJ − Temperature − °C

UCC28C4x-EP

BiCMOS LOW-POWER CURRENT-MODE PWM CONTROLLERS

SGLS352B – DECEMBER 2006 – REVISED MAY 2007

APPLICATION INFORMATION (continued)

Figure 22. Figure 23.

Figure 24.

16

Submit Documentation Feedback

Page 17

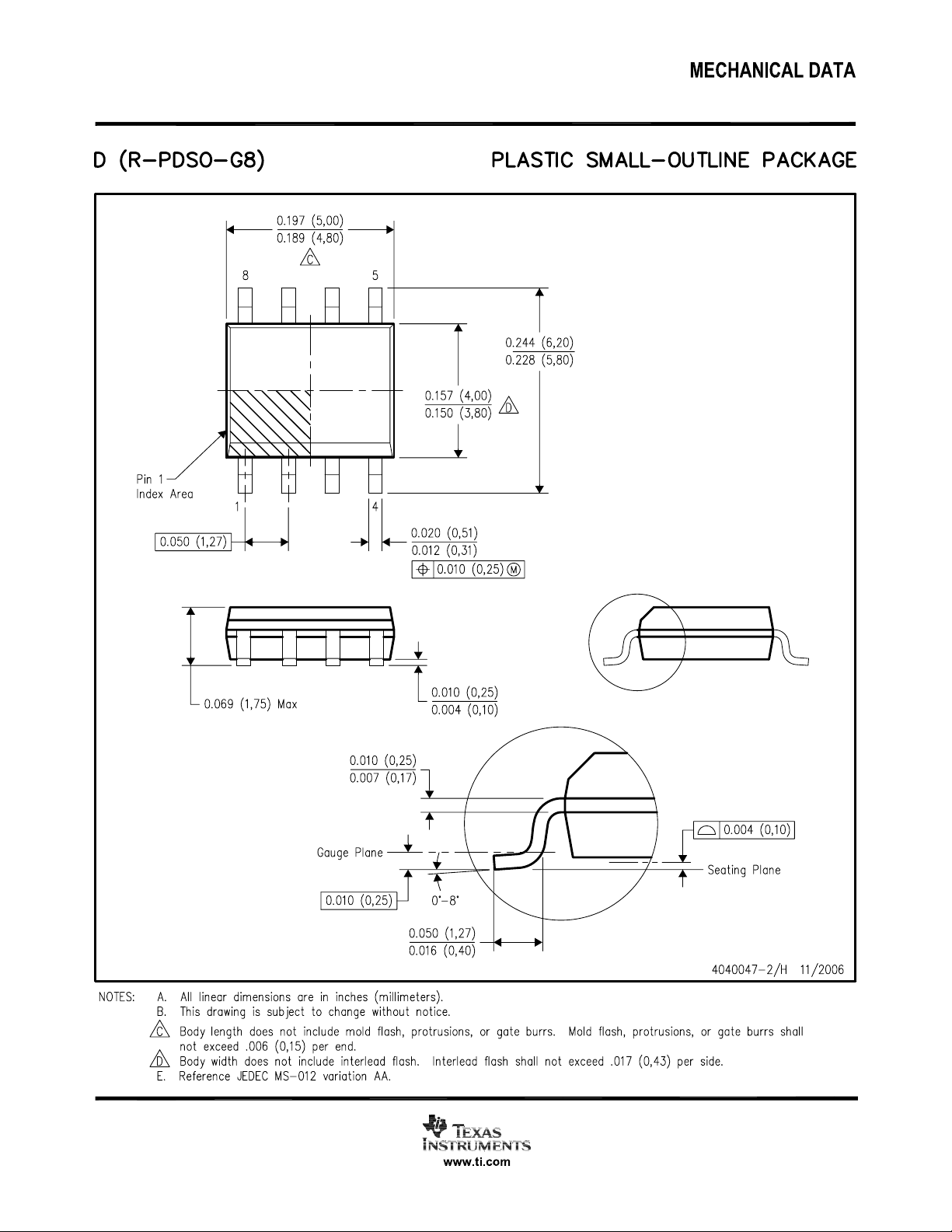

PACKAGE OPTION ADDENDUM

www.ti.com

24-May-2007

PACKAGING INFORMATION

Orderable Device Status

(1)

Package

Type

Package

Drawing

Pins Package

Qty

Eco Plan

UCC28C43MDREP ACTIVE SOIC D 8 2500 Green (RoHS &

no Sb/Br)

UCC28C45MDREP ACTIVE SOIC D 8 2500 Green (RoHS &

no Sb/Br)

V62/07615-01XE ACTIVE SOIC D 8 2500 Green (RoHS &

no Sb/Br)

V62/07615-02XE ACTIVE SOIC D 8 2500 Green (RoHS &

no Sb/Br)

(1)

The marketing status values are defined as follows:

ACTIVE: Product device recommended for new designs.

LIFEBUY: TI has announced that the device will be discontinued, and a lifetime-buy period is in effect.

NRND: Not recommended for new designs. Device is in production to support existing customers, but TI does not recommend using this part in

a new design.

PREVIEW: Device has been announced but is not in production. Samples may or may not be available.

OBSOLETE: TI has discontinued the production of the device.

(2)

Eco Plan - The planned eco-friendly classification: Pb-Free (RoHS), Pb-Free (RoHS Exempt), or Green (RoHS & no Sb/Br) - please check

http://www.ti.com/productcontent for the latest availability information and additional product content details.

TBD: The Pb-Free/Green conversion plan has not been defined.

Pb-Free (RoHS): TI's terms "Lead-Free" or "Pb-Free" mean semiconductor products that are compatible with the current RoHS requirements

for all 6 substances, including the requirement that lead not exceed 0.1% by weight in homogeneous materials. Where designed to be soldered

at high temperatures, TI Pb-Free products are suitable for use in specified lead-free processes.

Pb-Free (RoHS Exempt): This component has a RoHS exemption for either 1) lead-based flip-chip solder bumps used between the die and

package, or 2) lead-based die adhesive used between the die and leadframe. The component is otherwise considered Pb-Free (RoHS

compatible) as defined above.

Green (RoHS & no Sb/Br): TI defines "Green" to mean Pb-Free (RoHS compatible), and free of Bromine (Br) and Antimony (Sb) based flame

retardants (Br or Sb do not exceed 0.1% by weight in homogeneous material)

(2)

Lead/Ball Finish MSL Peak Temp

CU NIPDAU Level-1-260C-UNLIM

CU NIPDAU Level-1-260C-UNLIM

CU NIPDAU Level-1-260C-UNLIM

CU NIPDAU Level-1-260C-UNLIM

(3)

(3)

MSL, Peak Temp. -- The Moisture Sensitivity Level rating according to the JEDEC industry standard classifications, and peak solder

temperature.

Important Information and Disclaimer:The information provided on this page represents TI's knowledge and belief as of the date that it is

provided. TI bases its knowledge and belief on information provided by third parties, and makes no representation or warranty as to the

accuracy of such information. Efforts are underway to better integrate information from third parties. TI has taken and continues to take

reasonable steps to provide representative and accurate information but may not have conducted destructive testing or chemical analysis on

incoming materials and chemicals. TI and TI suppliers consider certain information to be proprietary, and thus CAS numbers and other limited

information may not be available for release.

In no event shall TI's liability arising out of such information exceed the total purchase price of the TI part(s) at issue in this document sold by TI

to Customer on an annual basis.

Addendum-Page 1

Page 18

Page 19

IMPORTANT NOTICE

Texas Instruments Incorporated and its subsidiaries (TI) reserve the right to make corrections, modifications, enhancements,

improvements, and other changes to its products and services at any time and to discontinue any product or service without notice.

Customers should obtain the latest relevant information before placing orders and should verify that such information is current and

complete. All products are sold subject to TI’s terms and conditions of sale supplied at the time of order acknowledgment.

TI warrants performance of its hardware products to the specifications applicable at the time of sale in accordance with TI’s

standard warranty. Testing and other quality control techniques are used to the extent TI deems necessary to support this

warranty. Except where mandated by government requirements, testing of all parameters of each product is not necessarily

performed.

TI assumes no liability for applications assistance or customer product design. Customers are responsible for their products and

applications using TI components. To minimize the risks associated with customer products and applications, customers should

provide adequate design and operating safeguards.

TI does not warrant or represent that any license, either express or implied, is granted under any TI patent right, copyright, mask

work right, or other TI intellectual property right relating to any combination, machine, or process in which TI products or services

are used. Information published by TI regarding third-party products or services does not constitute a license from TI to use such

products or services or a warranty or endorsement thereof. Use of such information may require a license from a third party under

the patents or other intellectual property of the third party, or a license from TI under the patents or other intellectual property of TI.

Reproduction of information in TI data books or data sheets is permissible only if reproduction is without alteration and is

accompanied by all associated warranties, conditions, limitations, and notices. Reproduction of this information with alteration is an

unfair and deceptive business practice. TI is not responsible or liable for such altered documentation.

Resale of TI products or services with statements different from or beyond the parameters stated by TI for that product or service

voids all express and any implied warranties for the associated TI product or service and is an unfair and deceptive business

practice. TI is not responsible or liable for any such statements.

TI products are not authorized for use in safety-critical applications (such as life support) where a failure of the TI product would

reasonably be expected to cause severe personal injury or death, unless officers of the parties have executed an agreement

specifically governing such use. Buyers represent that they have all necessary expertise in the safety and regulatory ramifications

of their applications, and acknowledge and agree that they are solely responsible for all legal, regulatory and safety-related

requirements concerning their products and any use of TI products in such safety-critical applications, notwithstanding any

applications-related information or support that may be provided by TI. Further, Buyers must fully indemnify TI and its

representatives against any damages arising out of the use of TI products in such safety-critical applications.

TI products are neither designed nor intended for use in military/aerospace applications or environments unless the TI products are

specifically designated by TI as military-grade or "enhanced plastic." Only products designated by TI as military-grade meet military

specifications. Buyers acknowledge and agree that any such use of TI products which TI has not designated as military-grade is

solely at the Buyer's risk, and that they are solely responsible for compliance with all legal and regulatory requirements in

connection with such use.

TI products are neither designed nor intended for use in automotive applications or environments unless the specific TI products

are designated by TI as compliant with ISO/TS 16949 requirements. Buyers acknowledge and agree that, if they use any

non-designated products in automotive applications, TI will not be responsible for any failure to meet such requirements.

Following are URLs where you can obtain information on other Texas Instruments products and application solutions:

Products Applications

Amplifiers amplifier.ti.com Audio www.ti.com/audio

Data Converters dataconverter.ti.com Automotive www.ti.com/automotive

DSP dsp.ti.com Broadband www.ti.com/broadband

Interface interface.ti.com Digital Control www.ti.com/digitalcontrol

Logic logic.ti.com Military www.ti.com/military

Power Mgmt power.ti.com Optical Networking www.ti.com/opticalnetwork

Microcontrollers microcontroller.ti.com Security www.ti.com/security

RFID www.ti-rfid.com Telephony www.ti.com/telephony

Low Power www.ti.com/lpw Video & Imaging www.ti.com/video

Wireless

Wireless www.ti.com/wireless

Mailing Address: Texas Instruments, Post Office Box 655303, Dallas, Texas 75265

Copyright © 2007, Texas Instruments Incorporated

Loading...

Loading...