Page 1

User's Guide

SLUU280B – May 2007 – Revised July 2008

UCC28060EVM 300-W Interleaved PFC Pre-Regulator

The UCC28060 is a dual-phase, transition-mode Power Factor Correction (PFC) pre-regulator. The

UCC28060EVM is an evaluation module (EVM) with a 390-V, 300-W, dc output that operates from a

universal input of 85 V

Throughout this document, the acronym EVM and the phrases evaluation board and evaluation module

are synonymous with the UCC28060EVM.

1 Description

The pre-regulator uses the UCC28060 PFC interleaved controller to shape the input current wave to

provide power-factor correction. This device uses TI’s Natural Interleaving™ technology to interleave

boost phases.

This user’s guide provides the schematic, List of Materials list, assembly drawing for a single-sided printed

circuit board application, and test set-up information necessary to evaluate the UCC28060 in a typical

PFC application.

2 Thermal Requirements

This evaluation module will operate up to 300 W without external cooling in ambient tempatures of 25 ° C.

to 265 V

RMS

and provides power-factor correction.

RMS

3 Electrical Characteristics

Table 1 summarizes the electrical specifications of the UCC28060EVM.

Table 1. UCC28060EVM Electrical Specifications

PARAMETER CONDITIONS UNITS

RMS input voltage (ac line) 85 265 V

Output voltage, V

Line frequency 47 63 Hz

Power factor (PF) at maximum load 0.9

Output power 300 W

Full load efficiency

OUT

AC line = 115 V 94%

AC line = 230 V 97%

MIN TYP MAX

UCC28060EVM

RMS

390 V

Natural Interleaving is a trademark of Texas Instruments.

All other trademarks are the property of their respective owners.

SLUU280B – May 2007 – Revised July 2008 UCC28060EVM 300-W Interleaved PFC Pre-Regulator 1

Submit Documentation Feedback

Page 2

+

+

Schematics

www.ti.com

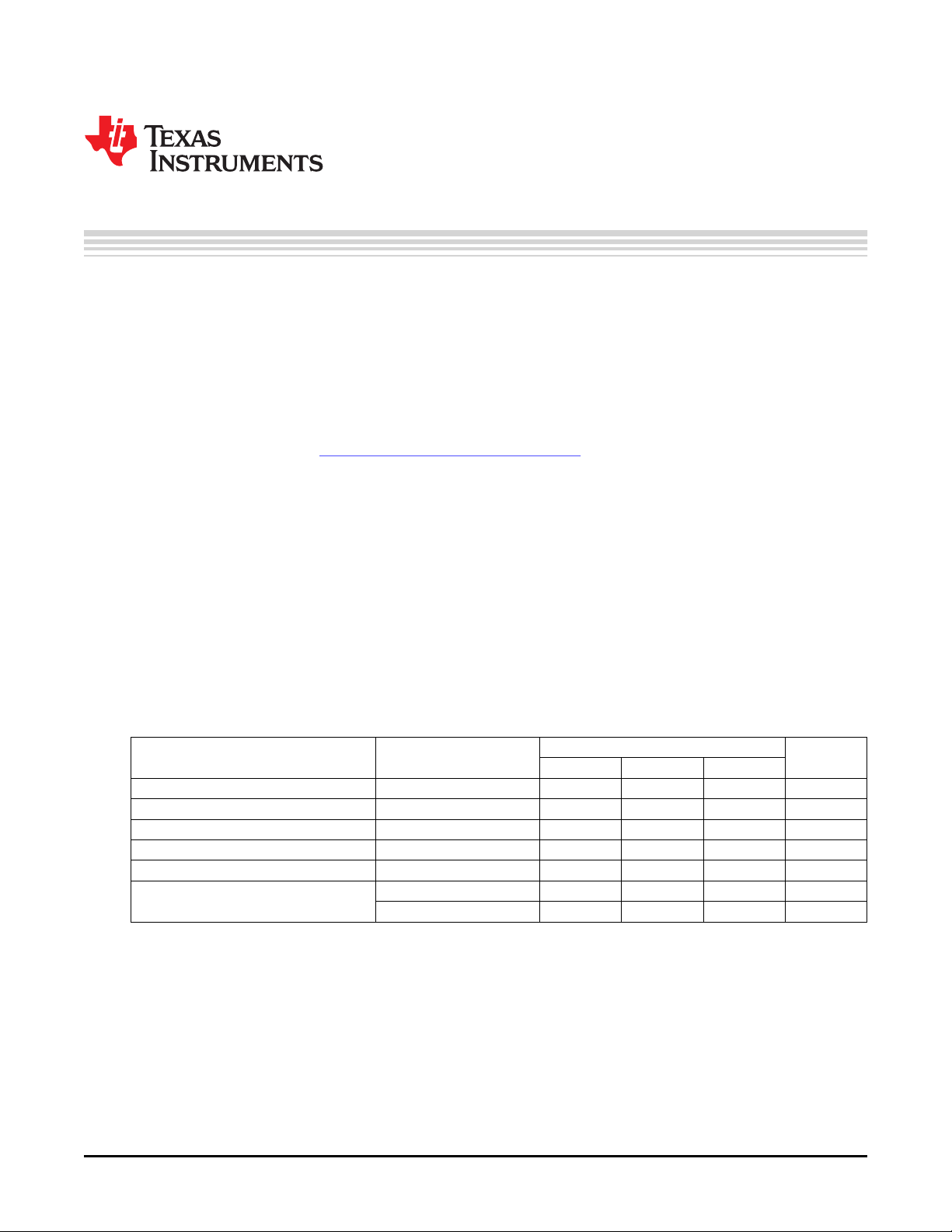

4 Schematics

Figure 1 and Figure 2 show the schematics for this EVM. See the List of Materials for specific values.

To evaluate inductor ripple currents, Jumpers JP8 and JP9 can be removed and replaced with current

loops.

Figure 1. Interleaved PFC Power Stage

2 UCC28060EVM 300-W Interleaved PFC Pre-Regulator SLUU280B – May 2007 – Revised July 2008

Submit Documentation Feedback

Page 3

+

www.ti.com

Schematics

Figure 2. Controller Circuitry

SLUU280B – May 2007 – Revised July 2008 UCC28060EVM 300-W Interleaved PFC Pre-Regulator 3

Submit Documentation Feedback

Page 4

Isolation Transformer

0 to 300W Load

VM

+

13V Bias Supply

Test Setup and Power-Up/Power-Down Instructions

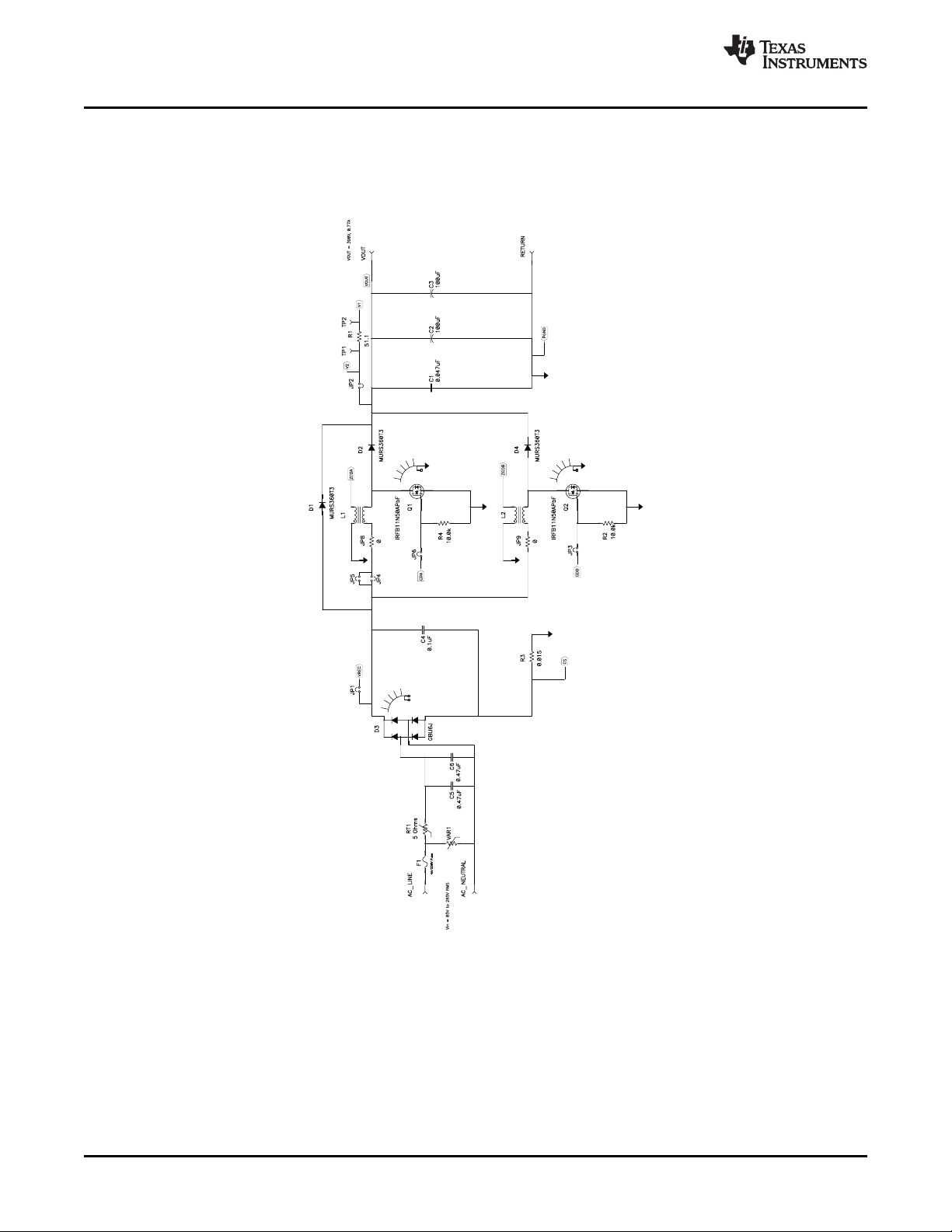

5 Test Setup and Power-Up/Power-Down Instructions

There are high voltages present on the pre-regulator. It should only

be handled by experienced power supply professionals. To

evaluate this board as safely as possible, the following test

configuration should be used:

• Connect an isolation transformer between the source and unit

• Attach a voltmeter and a resistive or electronic load to the unit

output before supplying power to the EVM.

A separate 13-V bias supply is required to power the UCC28060 control circuitry. The unit will start up

under no-load conditions. However, for safety, a load should be connected to the output of the device

before it is powered up. The unit should also never be handled while power is applied to it or when the

output voltage is above 50-V dc. Refer to Figure 3 for a recommended test setup diagram.

There are very high voltages on the board. Components can and will reach

temperatures greater than 100 ° C. Use caution when handling the EVM.

www.ti.com

WARNING

CAUTION

UCC28060EVM 300-W Interleaved PFC Pre-Regulator4 SLUU280B – May 2007 – Revised July 2008

Figure 3. Test Setup

Submit Documentation Feedback

Page 5

Efficiency

90.0%

91.0%

92.0%

93.0%

94.0%

95.0%

96.0%

97.0%

98.0%

99.0%

100.0%

10% 20% 30% 40% 50% 60% 70% 80% 90% 100%

% Output Powe r

Efficiency (%)

Efficency at Vin 85V RMS

Efficency at Vin = 265V RMS

Efficiency at Vi n = 115V RMS

91.0%

92.0%

93.0%

94.0%

95.0%

96.0%

97.0%

98.0%

10% 20% 30% 40% 50% 60% 70% 80% 90% 100%

% Output Powe r

Efficiency (%)

With Phase Manage ment

Without Phas e Manage ment

www.ti.com

6 Typical Performance Data

Figure 4 through Figure 7 present characteristic performance data for the UCC28060EVM.

Typical Performance Data

Figure 4. Efficiency at 85V

The UCC28060 control device has phase management capability to improve light load efficiency. To

demonstrate the light load efficiency, the unit efficiency was measured with phase management enabled

and disabled at 115 V

RMS

and 230 V

efficiency up to 3%. Refer to the UCC28060 data sheet for details on how to use the phase management

function of this device.

SLUU280B – May 2007 – Revised July 2008 UCC28060EVM 300-W Interleaved PFC Pre-Regulator 5

Submit Documentation Feedback

Figure 5. Efficiency at 115 V

and 265V

RMS

input voltages. Phase management improved the light load

RMS

, With and Without Phase Management

RMS

RMS

Page 6

Efficiency at Vi n = 230V RMS

85.0%

87.0%

89.0%

91.0%

93.0%

95.0%

97.0%

99.0%

10% 20% 30% 40% 50% 60% 70% 80% 90% 100%

% Output Powe r

Efficiency (%)

With Phase Manage ment

Without Phas e Manage ment

1.40706

1.17256

0.93805

0.70354

0.46904

0.23453

0.00002

Amplitude(A)

0 6 12 18 24 30 36 42 48

HarmonicNo.

V =230V

IN RMS

Typical Performance Data

www.ti.com

Figure 6. Efficiency at 230 V

Figure 7. Current Harmonics

, With and Without Phase Management

RMS

UCC28060EVM 300-W Interleaved PFC Pre-Regulator6 SLUU280B – May 2007 – Revised July 2008

Submit Documentation Feedback

Page 7

www.ti.com

6.1 Output Ripple Voltage at Full Load

Figure 8 illustrates the output ripple voltage.

Typical Performance Data

6.2 Input Ripple Current Cancellation

Figure 9 through Figure 14 show the input current (M

rectified line voltage. From these graphs, it can be observed that interleaving reduces the magnitude of

input ripple current caused by the inductor ripple current.

Figure 9. Inductor and Input Ripple Current at Figure 10. Inductor and Input Ripple Current

85 V

Figure 8. V

at Peak of Line Voltage at 85 V

RMS

OUT

Ripple, P

= IL1+ IL2), Inductor Ripple Current (IL1, IL2) versus

1

= 300 W

OUT

Input at Half the Line Voltage

RMS

SLUU280B – May 2007 – Revised July 2008 UCC28060EVM 300-W Interleaved PFC Pre-Regulator 7

Submit Documentation Feedback

Page 8

Typical Performance Data

Figure 11. Inductor and Input Ripple Current Figure 12. Inductor and Input Ripple Current

at 265 V

Input at Peak Line Voltage at 265 V

RMS

Input at Half Peak Line Voltage

RMS

www.ti.com

Figure 13. Inductor and Input Ripple Current Figure 14. Inductor and Input Ripple Current

at V

= 85 V

IN

, P

RMS

= 300 W at V

OUT

IN

= 265 V

, P

RMS

OUT

= 350 W

UCC28060EVM 300-W Interleaved PFC Pre-Regulator8 SLUU280B – May 2007 – Revised July 2008

Submit Documentation Feedback

Page 9

www.ti.com

Typical Performance Data

6.3 Startup Characteristics

Figure 15 and Figure 16 illustrate the UCC28060EVM startup characteristics.

6.4 Brownout Protection

Figure 15. Start-Up at V

= 85 V

IN

, P

RMS

= Figure 16. Start-Up at V

OUT

IN

= 265 V

, P

RMS

OUT

350 W W

The UCC28060 has a brownout protection that shuts down both gate drives (GDA and GDB) when the

VINAC pin detects that the RMS input voltage is too low. This EVM was designed to go into a brownout

state when the line drops below 64 V

. Once the UCC28060 control device has determined that the

RMS

input is in a brownout condition, a 400-ms timer starts to allow the line to recover before shutting down the

gate drivers. After 400 ms of brownout, both gate drivers turn off, as shown in Figure 17 and Figure 18 .

= 0

Figure 17. Brownout at 85 V

SLUU280B – May 2007 – Revised July 2008 UCC28060EVM 300-W Interleaved PFC Pre-Regulator 9

Submit Documentation Feedback

RMS

Figure 18. Brownout at 265 V

RMS

Page 10

Typical Performance Data

6.5 Line Transient

A line transient test was conducted with an ac source on the reference design. The line was varied from

230 V

RMS

oscilloscope image in Figure 19 , it can be observed that the output recovered from line transients within

300ms at full load.

to 115 V

www.ti.com

to 230 V

RMS

and the transient response was evaluated in each case. From the

RMS

Figure 19. Line Transient, P

= 300W

OUT

UCC28060EVM 300-W Interleaved PFC Pre-Regulator10 SLUU280B – May 2007 – Revised July 2008

Submit Documentation Feedback

Page 11

C3

C2

Output 390V

Maximum Load 0.77A

13

www.ti.com

7 Reference Design Assembly Drawing

Figure 20 and Figure 22 show the top and bottom layers (respectively) of the UCC28060EVM.

Note: Board layouts are not to scale. These figures are intended to show how the board is laid out;

they are not intended to be used for manufacturing UCC28060EVM PCBs.

Reference Design Assembly Drawing

Figure 20. Top Layer Assembly

Figure 21. Bottom Layer Copper

SLUU280B – May 2007 – Revised July 2008 UCC28060EVM 300-W Interleaved PFC Pre-Regulator 11

Submit Documentation Feedback

Page 12

13

C17

D2

Output 390V

Maximum Load 0.77A

JP8

JP9

List of Materials

www.ti.com

Figure 22. Bottom Layer Assembly

8 List of Materials

Table 2 lists the EVM components as configured according to the schematics (see Section 4 ).

Table 2. List of Materials

Qty RefDes Value Description Size Part Number MFR

4 AC_LINE, 3267 Connector, Banana Jack, Uninsulated 0.500 dia. inch 3267 Pomona

AC_NEUTRAL,

VOUT,

RETURN

1 C1 0.047 µ F Capacitor, Polyester, 630V, 10% 0.256in × 0.650in ECQ-E6473KZ Panasonic

1 C11 220nF Capacitor, Ceramic, 16V, X7R, 10% 1206 Std Std

2 C12, C13 2.2 µ F Capacitor, Ceramic, 16V, X7R, 10% 0805 Std Std

1 C14 22 µ F Capacitor, Aluminum, 35V, ± 20% 0.200in × 0.435in ECA-1VM220 Panasonic

1 C15 1nF Capacitor, Ceramic, 25V, X7R, 10% 0805 Std Std

1 C16 10nF Capacitor, Ceramic, 25V, X7R, 10% 0805 Std Std

2 C2, C3 100 µ F Capacitor, Aluminum, 450VDC, ± 20% 18mm × 40 mm EKXG451ELL101 Nippon

1 C4 0.1 µ F Capacitor, Film, 275VAC, ± 20% 0.689in × 0.236in ECQU2A104BC1 Panasonic

2 C5, C6 0.47 µ F Capacitor, Film, 275VAC, ± 20% 0.236 × 0.591 ECQ-U2A474MG Panasonic

2 C7, C8 22pF Capacitor, Ceramic, 25V, X7R, 10% 0805 Std Std

3 C9, C10, C17 1.2nF Capacitor, Ceramic, 25V, X7R, 10% 0805 Std Std

3 D1, D2, D4 MURS360T3 Diode, 3000mA, 600V SMC MURS360T3 On Semi

1 D3 GBU6J Diode, Bridge, 6A, 600V BU6 GBU6J Vishay

2 F1 0100056H Fuse Clip, 5mm x 20mm 0.205in × 0.220in 0100056H Wickmann

x2

1 F1 BK/GDA-4A 4A, Fast Acting Fuse 5mm × 20mm BK/S501-4-R Cooper/

3 HS1, HS2, HS3 7-345-2PP Heatsink, Universal-mount TO-220 1.500in × 2.000in 7-345-2PP IERC-CTS

1 J1 ED1609-ND Terminal Block, 2-pin, 15-A, 5.1mm 0.40in × 0.35in ED1609 OST

MM40S Chemi-con

Bussman

12 UCC28060EVM 300-W Interleaved PFC Pre-Regulator SLUU280B – May 2007 – Revised July 2008

Submit Documentation Feedback

Page 13

www.ti.com

List of Materials

Table 2. List of Materials (continued)

Qty RefDes Value Description Size Part Number MFR

1 JP1 923345-20-C Jumper, 1.600 inch length, PVC Insulation, 0.035in dia. Cut to Dimension 3M

3 JP2, JP4, JP5 923345-20-C Jumper, 2.000 inch length, PVC Insulation, 0.035in dia. 923345-20-C 3M

1 JP3 923345-06-C Jumper, 0.600 inch length, PVC Insulation, 0.035in dia. 923345-06-C 3M

1 JP6 923345-05-C Jumper, 0.500 inch length, PVC Insulation, 0.035in dia. 923345-05-C 3M

1 JP7 923345-20-C Jumper, 1.200 inch length, PVC Insulation, 0.035in dia. Cut to Dimension 3M

2 JP8, JP9 0 Resistor, Chip, 1W, 5% 2512 Std Std

1 PCB HPA224 Printed Circuit Board

2 L1, L2 CTX16-17769R Inductor, Boost PFC With Aux. 330 µ H at 5.3 1.555in dia. CTX16-17769R Cooper

2 Q1, Q2 IRFB11N50APbF MOSFET, N-ch, 500V, 11A, 520m Ω TO-220V IRFB11N50APbF IR

1 R1 51.1 Resistor, Chip, 1/10W, 1% 0805 Std Std

2 R13, R14 47.0k Resistor, Chip, 1/10W, 1% 0805 Std Std

1 R15 121.0k Resistor, Chip, 1/10W, 1% 0805 Std Std

2 R16, R24 5.11 Resistor, Chip, 1/10W, 1% 0805 Std Std

1 R17 0.00 Resistor, Chip, 1/10W, 1% 0805 Std Std

1 R18 6.19k Resistor, Chip, 1/10W, 1% 0805 Std Std

1 R19 30.1k Resistor, Chip, 1/10W, 1% 0805 Std Std

3 R2, R4, R21 10.0k Resistor, Chip, 1/10W, 1% 0805 Std Std

1 R25 100 Resistor, Chip, 1/10W, 1% 0805 Std Std

1 R3 0.015 Resistor, Chip, 1/2W, 1% 2010 WSL2010R0150F Vishay

9 R5–R9, R10, 1.00M Resistor, Chip, 1/10W, 1% 0805 Std Std

R12, R20, R22,

R23

2 R8, R11 20.5k Resistor, Chip, 1/10W, 1% 0805 Std Std

1 RT1 5 Ω Thermistor, NTC, 5 Ω , 6A 0.180in × 0.550in CL-40 Thermo-

2 TP1, TP2 K24A/M Pin, Thru Hole, Tin Plate, for 0.062 PCBs 0.039in K24A/M Vector

1 U1 UCC28060D IC, Interleave PFC Controller SO16 UCC28060D TI

1 VAR1 SIOV-S10K275E2 VARISTOR 275V RMS 0.472in × 0.213in S10K275E2 Epcos

6 X1 at HS1 and Nut #4-40 (steel) Std Std

D3, HS2 and

Q1, HS3 and

Q2

6 X1 at HS1 and Pan Head Screw #4-40X3/8 (steel) Std Std

D3, HS2 and

Q1, HS3 and

Q2

1 X1 D3 and HS1 Thermal Grease Std Std

6 X1 at HS1 and Split Lock Washer #4(steel) Std Std

D3, HS2 and

Q1, HS3 and

Q2

6 X1 at HS1 and Nylon Shoulder Washer #4 3049 Keystone

D3, HS2 and Electronics

Q1, HS3 and

Q2

2 X1 at HS2 and Thermal Pad Silicon TO220 3223-07FR-51 BERQUIST

Q1, HS3 and

Q2

AWG 22

AWG 22

AWG 22

AWG 22

AWG 22

A PK

EA

metrics

SLUU280B – May 2007 – Revised July 2008 UCC28060EVM 300-W Interleaved PFC Pre-Regulator 13

Submit Documentation Feedback

Page 14

EVALUATION BOARD/KIT IMPORTANT NOTICE

Texas Instruments (TI) provides the enclosed product(s) under the following conditions:

This evaluation board/kit is intended for use for ENGINEERING DEVELOPMENT, DEMONSTRATION, OR EVALUATION PURPOSES

ONLY and is not considered by TI to be a finished end-product fit for general consumer use. Persons handling the product(s) must have

electronics training and observe good engineering practice standards. As such, the goods being provided are not intended to be complete

in terms of required design-, marketing-, and/or manufacturing-related protective considerations, including product safety and environmental

measures typically found in end products that incorporate such semiconductor components or circuit boards. This evaluation board/kit does

not fall within the scope of the European Union directives regarding electromagnetic compatibility, restricted substances (RoHS), recycling

(WEEE), FCC, CE or UL, and therefore may not meet the technical requirements of these directives or other related directives.

Should this evaluation board/kit not meet the specifications indicated in the User’s Guide, the board/kit may be returned within 30 days from

the date of delivery for a full refund. THE FOREGOING WARRANTY IS THE EXCLUSIVE WARRANTY MADE BY SELLER TO BUYER

AND IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESSED, IMPLIED, OR STATUTORY, INCLUDING ANY WARRANTY OF

MERCHANTABILITY OR FITNESS FOR ANY PARTICULAR PURPOSE.

The user assumes all responsibility and liability for proper and safe handling of the goods. Further, the user indemnifies TI from all claims

arising from the handling or use of the goods. Due to the open construction of the product, it is the user’s responsibility to take any and all

appropriate precautions with regard to electrostatic discharge.

EXCEPT TO THE EXTENT OF THE INDEMNITY SET FORTH ABOVE, NEITHER PARTY SHALL BE LIABLE TO THE OTHER FOR ANY

INDIRECT, SPECIAL, INCIDENTAL, OR CONSEQUENTIAL DAMAGES.

TI currently deals with a variety of customers for products, and therefore our arrangement with the user is not exclusive.

TI assumes no liability for applications assistance, customer product design, software performance, or infringement of patents or

services described herein.

Please read the User’s Guide and, specifically, the Warnings and Restrictions notice in the User’s Guide prior to handling the product. This

notice contains important safety information about temperatures and voltages. For additional information on TI’s environmental and/or

safety programs, please contact the TI application engineer or visit www.ti.com/esh .

No license is granted under any patent right or other intellectual property right of TI covering or relating to any machine, process, or

combination in which such TI products or services might be or are used.

FCC Warning

This evaluation board/kit is intended for use for ENGINEERING DEVELOPMENT, DEMONSTRATION, OR EVALUATION PURPOSES

ONLY and is not considered by TI to be a finished end-product fit for general consumer use. It generates, uses, and can radiate radio

frequency energy and has not been tested for compliance with the limits of computing devices pursuant to part 15 of FCC rules, which are

designed to provide reasonable protection against radio frequency interference. Operation of this equipment in other environments may

cause interference with radio communications, in which case the user at his own expense will be required to take whatever measures may

be required to correct this interference.

EVM WARNINGS AND RESTRICTIONS

It is important to operate this EVM within the input voltage range of 85V

Exceeding the specified input range may cause unexpected operation and/or irreversible damage to the EVM. If there are questions

concerning the input range, please contact a TI field representative prior to connecting the input power.

Applying loads outside of the specified output range may result in unintended operation and/or possible permanent damage to the EVM.

Please consult the EVM User's Guide prior to connecting any load to the EVM output. If there is uncertainty as to the load specification,

please contact a TI field representative.

During normal operation, some circuit components may have case temperatures greater than +100 ° C. The EVM is designed to operate

properly with certain components above +100 ° C as long as the input and output ranges are maintained. These components include but are

not limited to linear regulators, switching transistors, pass transistors, and current sense resistors. These types of devices can be identified

using the EVM schematic located in the EVM User's Guide. When placing measurement probes near these devices during operation,

please be aware that these devices may be very warm to the touch.

to 265V

RMS

and the output voltage range of 375V to 450V.

RMS

Mailing Address: Texas Instruments, Post Office Box 655303, Dallas, Texas 75265

Copyright © 2008, Texas Instruments Incorporated

Page 15

IMPORTANT NOTICE

Texas Instruments Incorporated and its subsidiaries (TI) reserve the right to make corrections, modifications, enhancements, improvements,

and other changes to its products and services at any time and to discontinue any product or service without notice. Customers should

obtain the latest relevant information before placing orders and should verify that such information is current and complete. All products are

sold subject to TI’s terms and conditions of sale supplied at the time of order acknowledgment.

TI warrants performance of its hardware products to the specifications applicable at the time of sale in accordance with TI’s standard

warranty. Testing and other quality control techniques are used to the extent TI deems necessary to support this warranty. Except where

mandated by government requirements, testing of all parameters of each product is not necessarily performed.

TI assumes no liability for applications assistance or customer product design. Customers are responsible for their products and

applications using TI components. To minimize the risks associated with customer products and applications, customers should provide

adequate design and operating safeguards.

TI does not warrant or represent that any license, either express or implied, is granted under any TI patent right, copyright, mask work right,

or other TI intellectual property right relating to any combination, machine, or process in which TI products or services are used. Information

published by TI regarding third-party products or services does not constitute a license from TI to use such products or services or a

warranty or endorsement thereof. Use of such information may require a license from a third party under the patents or other intellectual

property of the third party, or a license from TI under the patents or other intellectual property of TI.

Reproduction of TI information in TI data books or data sheets is permissible only if reproduction is without alteration and is accompanied

by all associated warranties, conditions, limitations, and notices. Reproduction of this information with alteration is an unfair and deceptive

business practice. TI is not responsible or liable for such altered documentation. Information of third parties may be subject to additional

restrictions.

Resale of TI products or services with statements different from or beyond the parameters stated by TI for that product or service voids all

express and any implied warranties for the associated TI product or service and is an unfair and deceptive business practice. TI is not

responsible or liable for any such statements.

TI products are not authorized for use in safety-critical applications (such as life support) where a failure of the TI product would reasonably

be expected to cause severe personal injury or death, unless officers of the parties have executed an agreement specifically governing

such use. Buyers represent that they have all necessary expertise in the safety and regulatory ramifications of their applications, and

acknowledge and agree that they are solely responsible for all legal, regulatory and safety-related requirements concerning their products

and any use of TI products in such safety-critical applications, notwithstanding any applications-related information or support that may be

provided by TI. Further, Buyers must fully indemnify TI and its representatives against any damages arising out of the use of TI products in

such safety-critical applications.

TI products are neither designed nor intended for use in military/aerospace applications or environments unless the TI products are

specifically designated by TI as military-grade or "enhanced plastic." Only products designated by TI as military-grade meet military

specifications. Buyers acknowledge and agree that any such use of TI products which TI has not designated as military-grade is solely at

the Buyer's risk, and that they are solely responsible for compliance with all legal and regulatory requirements in connection with such use.

TI products are neither designed nor intended for use in automotive applications or environments unless the specific TI products are

designated by TI as compliant with ISO/TS 16949 requirements. Buyers acknowledge and agree that, if they use any non-designated

products in automotive applications, TI will not be responsible for any failure to meet such requirements.

Following are URLs where you can obtain information on other Texas Instruments products and application solutions:

Products Applications

Amplifiers amplifier.ti.com Audio www.ti.com/audio

Data Converters dataconverter.ti.com Automotive www.ti.com/automotive

DSP dsp.ti.com Broadband www.ti.com/broadband

Clocks and Timers www.ti.com/clocks Digital Control www.ti.com/digitalcontrol

Interface interface.ti.com Medical www.ti.com/medical

Logic logic.ti.com Military www.ti.com/military

Power Mgmt power.ti.com Optical Networking www.ti.com/opticalnetwork

Microcontrollers microcontroller.ti.com Security www.ti.com/security

RFID www.ti-rfid.com Telephony www.ti.com/telephony

RF/IF and ZigBee® Solutions www.ti.com/lprf Video & Imaging www.ti.com/video

Mailing Address: Texas Instruments, Post Office Box 655303, Dallas, Texas 75265

Copyright © 2008, Texas Instruments Incorporated

Wireless www.ti.com/wireless

Loading...

Loading...