Page 1

T

T

查询UCC27223供应商

SLUS558 − DECEMBER 2003

FEATURES

Maximizes Efficiency by Minimizing

D

Body-Diode Conduction and Reverse

Recovery Losses

D Transparent Synchronous Buck Gate Drive

Operation From the Single Ended PWM Input

Signal

D 12-V or 5-V Input Operation

D 3.3-V Input Operation With Availability of

12-V Bus Bias

D High-Side and Low-Side ±3-A Dual Drivers

D On-Board 6.5-V Gate Drive Regulator

D ±3-A TrueDrive Gate Drives for High

Current Delivery at MOSFET Miller

Thresholds

D Automatically Adjusts for Changing

Operating Conditions

D Thermally Enhanced 14-Pin PowerPAD

HTSSOP Package Minimizes Board Area and

Junction Temperature Rise

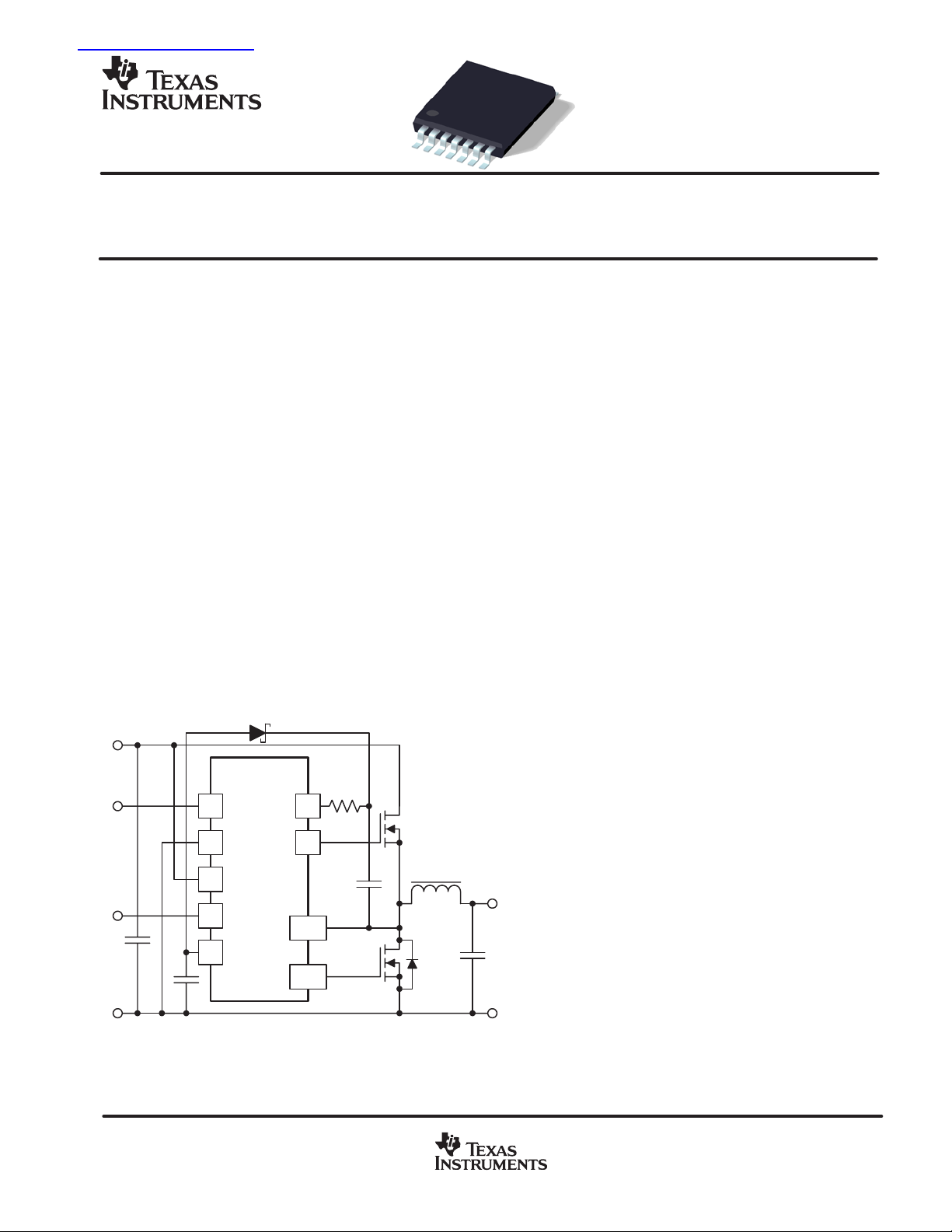

FUNCTIONAL APPLICATION DIAGRAM

V

IN

UCC27223

IN

GND

VDD

VLO

VHI

SW

G2

G1

14

13

11,12

9,10

GND

PWM

IN

GND

IN

Note: 12-V input system shown. For 5-V input only systems, see Figure 6.

7

6,8

3

2 ENBL

4,5

APPLICATIONS

Multiphase Converters in Combination With

D

the TPS40090

D Non-Isolated 3.3-V, 5-V and 12-V Input

dc-to-dc Converters for Processor Power,

General Computer, Telecom and Datacom

Applications

DESCRIPTION

The UCC27223 is a high-speed synchronous

buck drivers for today’s high-efficiency,

lower-output voltage designs. Using Predictive

Gate Drivet (PGD) control technology, these

drivers reduce diode conduction and reverse

recovery losses in the synchronous rectifier

MOSFET(s).

The UCC27223 includes an enable pin that

controls the operation of both outputs. A logic

latch is also included to keep both outputs low until

the first PWM input pulse comes in. The RDS(on)

of the SR pull-down sourcing device is also

minimized for higher frequency operations.

This closed loop feedback system detects

body-diode conduction, and adjusts deadtime

delays to minimize the conduction time interval.

This virtually eliminates body-diode conduction

while adjusting for temperature, load- dependent

delays, and for different MOSFETs. Precise gate

timing at the nanosecond level reduces the

reverse recovery time of the synchronous rectifier

V

OU

OU

MOSFET body-diode, reducing reverse recovery

losses seen in the main (high-side) MOSFET. The

lower junction temperature in the low-side

MOSFET increases product reliability. Since the

power dissipation is minimized, a higher switching

frequency can also be used, allowing for smaller

component sizes.

The UCC27223 is offered in the thermally

enhanced 14-pin PowerPADt package with

2°C/W θ

.

jc

Predictive Gate Drivet and PowerPADt are trademarks of Texas Instruments Incorporated.

!" # $%&" !# '%()$!" *!"&+

*%$"# $ " #'&$$!"# '& ",& "&# &-!# #"%&"#

#"!*!* .!!"/+ *%$" '$&##0 *&# " &$&##!)/ $)%*&

"&#"0 !)) '!!&"&#+

www.ti.com

Copyright 2003, Texas Instruments Incorporated

1

Page 2

PWM INPUT

SLUS558 − DECEMBER 2003

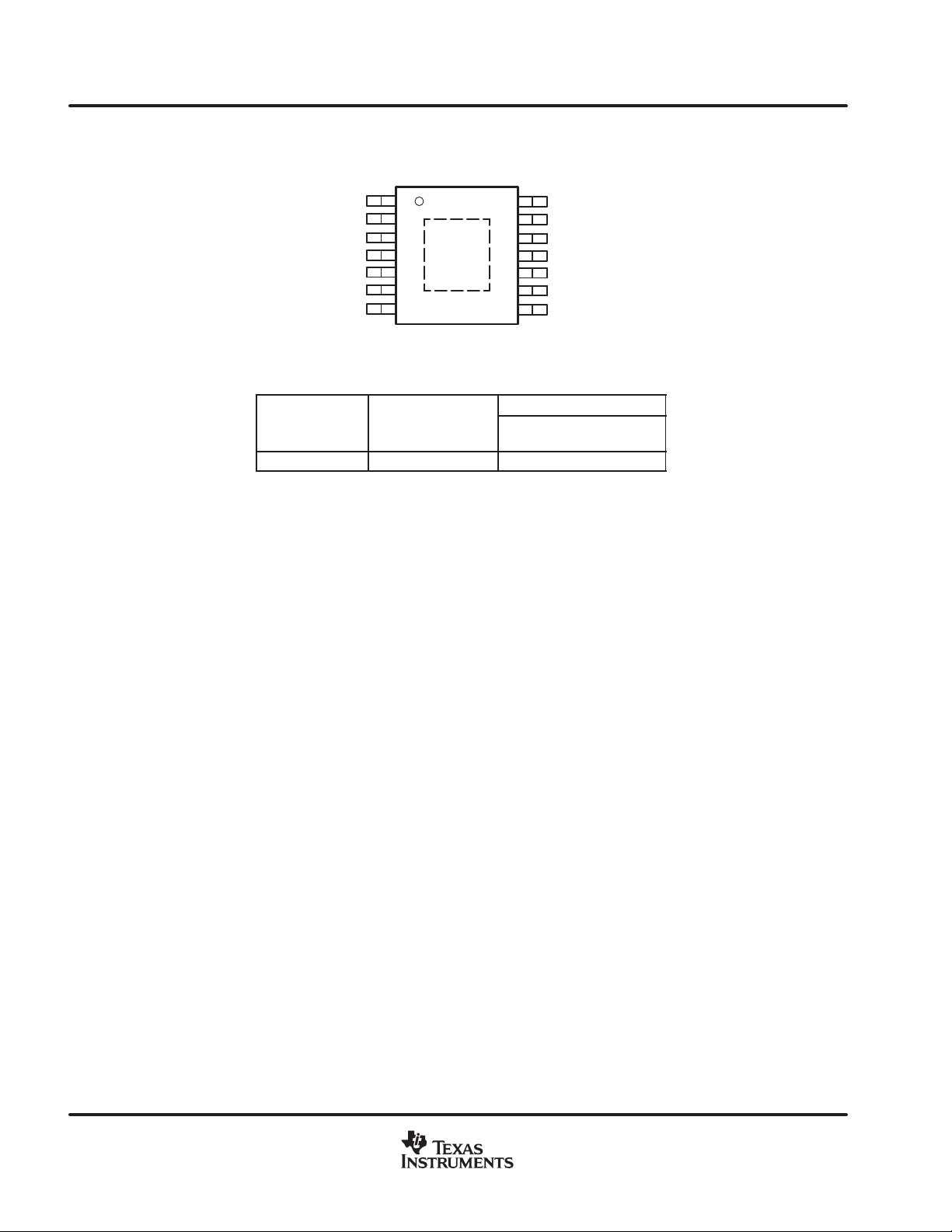

PWP PACKAGE

(TOP VIEW)

N/C

ENBL

VDD

VLO

PVLO

AGND

IN

T

A

−40_C to 105_C NON-INVERTING UCC27223PWP

{The PWP package is available taped and reeled. Add R suffix to device type

(e.g. UCC27223PWPR) to order quantities of 2,000 devices per reel and 90

units per tube.

1

2

3

4

5

6

7

N/C − No internal connection

AVAILABLE OPTIONS

(IN)

absolute maximum ratings over operating free-air temperature (unless otherwise noted)

14

13

12

11

10

9

8

VHI

G1

SW

SWS

G2S

G2

PGND

PACKAGED DEVICES

PowerPADt

HTSSOP−14 (PWP)

†}

Supply voltage range, VDD −0.3 to 20 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Input voltage, VHI 30 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SW, SWS 20 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Supply current, I

including gate drive current .100 mA. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DD,

Sink current (peak) pulsed, G1/G2 4.0 A. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Source current (peak) pulsed, G1/G2 −4.0 A. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Analog inputs, IN, ENBL −3.0 V to V

Power Dissipation at T

Operating junction temperature range, T

Storage temperature range, T

= 25°C (PWP package) 3 W. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A

J

stg

DD

+ 0.3 V, not to exceed 15 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

−55°C to 115°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

−65°C to 150°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Lead temperature soldering 1.6 mm (1/16 inch) from case for 10 seconds 300°C. . . . . . . . . . . . . . . . . . . . . . .

†

Stresses beyond those listed under “absolute maximum ratings” may cause permanent damage to the device. These are stress ratings only , a nd

functional operation of the device at these or any other conditions beyond those indicated under “recommended operating conditions” is not

implied. Exposure to absolute-maximum-rated conditions for extended periods may affect device reliability.

‡

All voltages are with respect to AGND and PGND. Currents are positive into, negative out of the specified terminal.

2

www.ti.com

Page 3

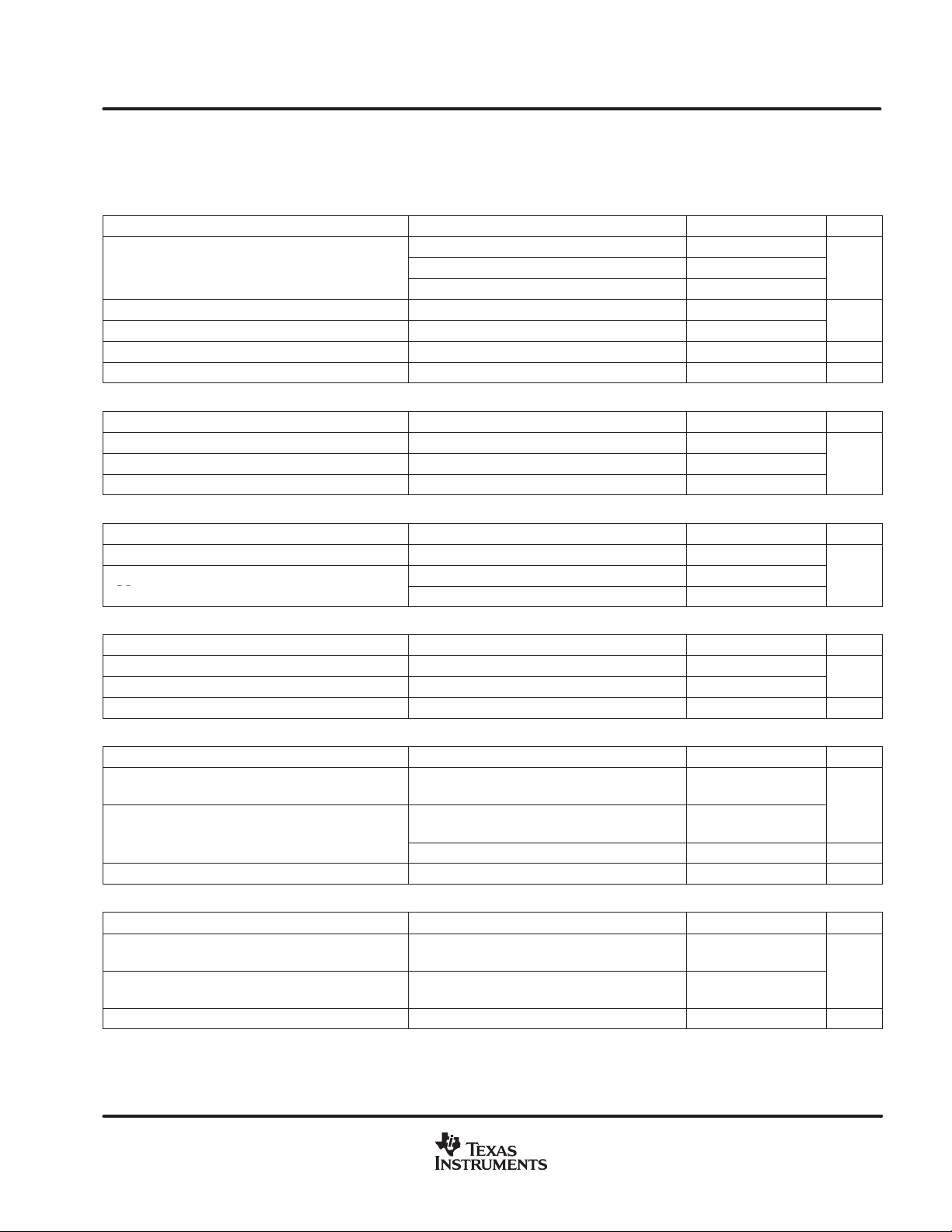

Regulator output voltage

V

V

mA

Low-level input threshold voltage

Low-level input threshold voltage

SLUS558 − DECEMBER 2003

ELECTRICAL CHARACTERISTICS

V

= 12-V, 1-µF capacitor from VDD to GND, 1-µF capacitor from VHI to SW, 0.1-µF and 2.2-µF capacitor from

DD

PVLO to PGND, PVLO tied to VLO, T

VLO regulator

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

Regulator output voltage

Line Regulation VDD = 12 V to 20 V 2 10

Load Regulation I

Short-circuit current

Dropout voltage, (VDD at 5% VLO drop) VLO = 6.175 V, I

(1)

undervoltage lockout

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

Start threshold voltage Measured at VLO 3.30 3.82 4.40

Minimum operating voltage after start 3.15 3.70 4.15

Hysteresis 0.07 0.12 0.20

= −40_C to 105_C for the UCC27223, TA = TJ (unless otherwise noted)

A

VDD = 12 V, I

VDD = 20 V, I

VDD = 10 V, I

= 0 mA to 100 mA 15 40

VLO

VDD = 8.5 V 220 mA

= 0 mA 6.2 6.5 6.8

VLO

= 0 mA 6.2 6.5 6.8

VLO

= 100 mA 6.1 6.5 6.9

VLO

= 100 mA 7.1 7.8 8.5 V

VLO

V

mV

V

bias currents

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

VLO bias current at VLO (ON), 5 V applications only VLO = 4.5 V, VDD = no connect 3.6 4.7 5.8

VDD bias current

VDD = 8.5 V 5.5 7.1 8.5

fIN = 500 kHz, No load on G1/G2 8 16 25

input command (IN)

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

High-level input voltage 10 V < VDD < 20 V 3.3 3.6 3.9

Low-level input voltage 10 V < VDD < 20 V 2.2 2.5 2.8

Input bias current VDD = 15 V 1 µA

input (SWS)

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

High-level input threshold voltage

Input bias current SWS = 0.0 V −0.9 −1.2 −1.5 mA

fIN = 500 kHz, t

G2S = 0.0 V

fIN = 500 kHz, t

G2S = 0.0 V

fIN = 500 kHz, t

maximum,

ON, G2

minimum,

ON, G2

minimum −100 −300 −500 mV

ON, G1

1.4 2.0 2.6

0.7 1.0 1.3

input (G2S)

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

High-level input voltage

Low-level input voltage

Input bias current G2S = 0 V −370 −470 −570 µA

NOTE 1: Ensured by design. Not production tested.

fIN = 500 kHz, t

SWS = 0.0 V

fIN = 500 kHz, t

SWS = 0.0 V

ON, G2

ON, G2

maximum,

minimum,

1.4 2.0 2.6

0.7 1.0 1.3

mA

V

V

V

www.ti.com

3

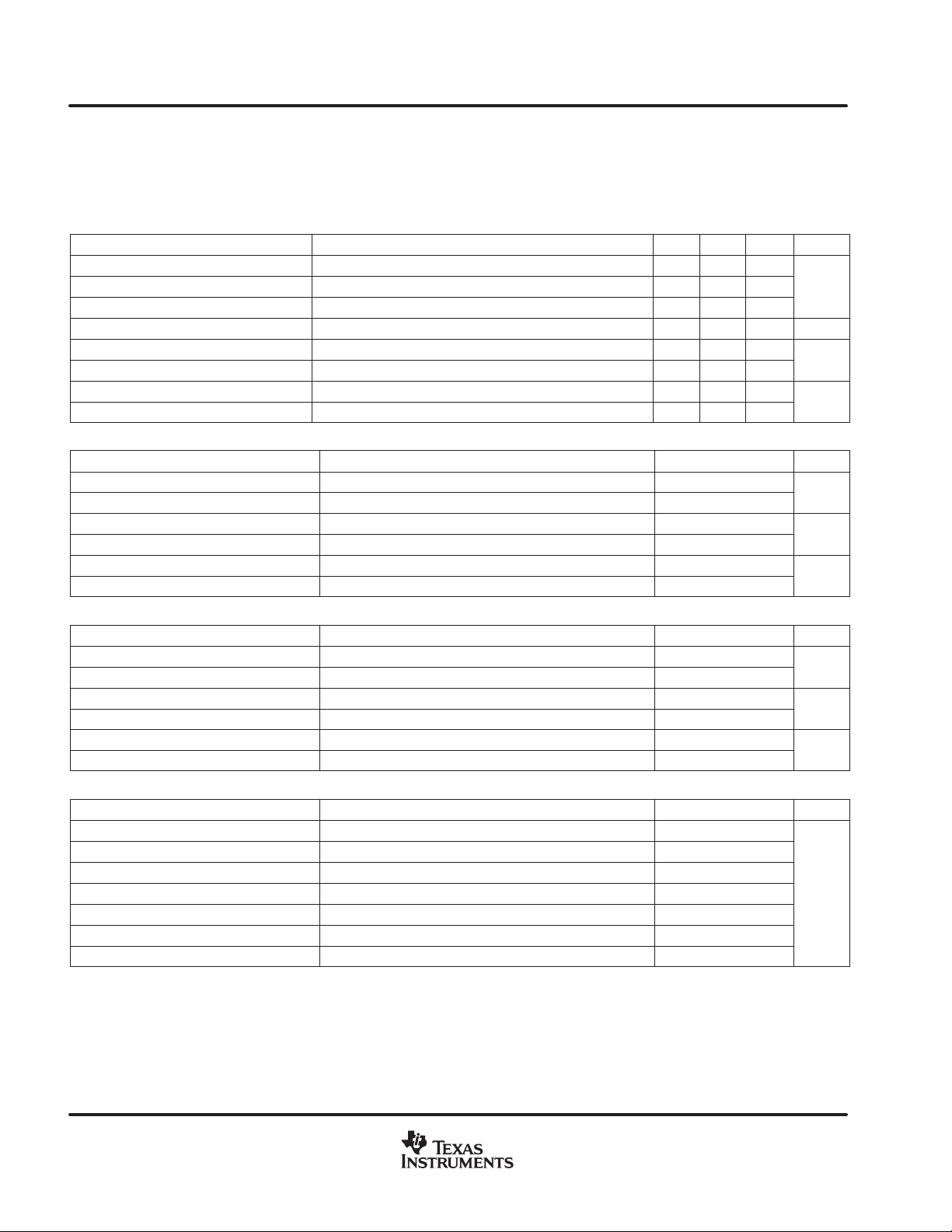

Page 4

V

ns

SLUS558 − DECEMBER 2003

ELECTRICAL CHARACTERISTICS

V

= 12-V, 1-µF capacitor from VDD to GND, 1-µF capacitor from VHI to SW, 0.1-µF and 2.2-µF capacitor from

DD

PVLO to PGND, PVLO tied to VLO, T

enable (ENBL)

PARAMETER TEST CONDITION MIN TYP MAX UNITS

V

, high-level input voltage LO to HI transition 2.25 2.45 2.85

IN_H

V

, low-level input voltage HI to LO transition 1.55 1.70 1.90

IN_L

Hysteresis 1.1

R

, enable impedance VDD = 14 V, ENBL = GND 75 112 150 kΩ

ENBL

tD3, propagation delay time

tD4, propagation delay time

tr, Rise time VLO = PVLO = 8.5 V 2.5

tf, Fall time VLO = PVLO = 8.5 V 2.5

G1 main output

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

Sink resistance SW = 0 V, VHI = 6 V , IN = 0 V, G1 = 0.5 V 0.5 0.9 1.5

Source resistance

Source current

Sink current

Rise time C = 2.2 nF from G1 to SW, VDD = 20 V 17 25

Fall time C = 2.2 nF from G1 to SW, VDD = 20 V 17 25

(2)

(1)(2)

(1)(2)

(5)

(5)

= −40_C to 105_C for the UCC27223, TA = TJ (unless otherwise noted)

A

TBD

TBD

SW = 0 V, VHI = 6 V, IN = 6.5 V, G1 = 5.5 V 10 25 45

SW = 0 V, VHI = 6 V, IN = 6.5 V, G1 = 3.0 V −3 −3.3

SW = 0 V, VHI = 6 V, IN = 0 V, G1 = 3.0 V 3 3.3

V

ns

ms

Ω

A

ns

G2 SR output

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

(2)

(2)

(1)(2)

(1)(2)

(2)

PVLO = 6.5 V, IN = 6.5 V, G1 = 0.25 V 0.5 1.6 4.0

PVLO = 6.5 V, IN = 0 V, G2 = 6.0 V 10 20 35

PVLO = 6.5 V, IN = 0 V G2 = 3.25 V 3 3.3

PVLO = 6.5 V, IN = 6.5 V G2 = 3.25 V −3 3.3

C = 2.2 nF from G2 to PGND VDD = 20 V 17 25

Ω

A

ns

Sink resistance

Source resistance

Source current

Sink current

Rise time

Fall time C = 2.2 nF from G2 to PGND VDD = 20 V 20 35

deadtime delay

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

t

OFF, G2

t

OFF, G1

Delay Step Resolution 4.0 4.5 5.2

t

ON, G1

t

ON, G1

t

ON, G2

tON, G2 maximum 54

NOTE 1: Ensured by design. Not production tested.

2: The pullup / pulldown circuits of the drivers are bipolar and MOSFET transistors in parallel. The peak output current rating is the

, IN to G2 falling 40 80 125

, IN to G1 falling 55 80 110

minimum −17

maximum 49

minimum −15

combined current from the bipolar and MOSFET transistors. The output resistance is the R

voltage on the driver output is less than the saturation voltage of the bipolar transistor.

DS(ON) of the MOSFET transistor when the

ns

4

www.ti.com

Page 5

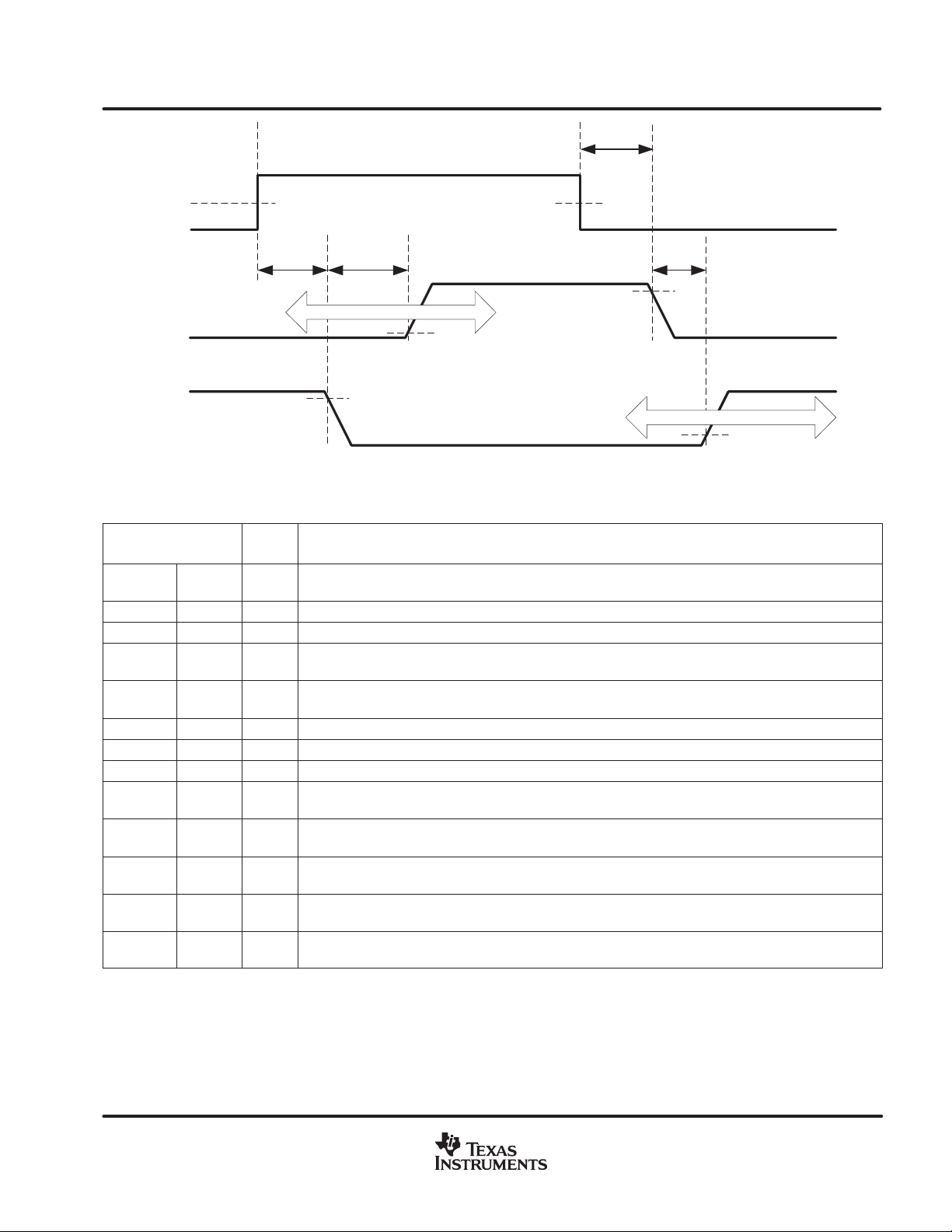

2

t

I/O

DESCRIPTION

SLUS558 − DECEMBER 2003

OFF,G1

3.25 V

G1

G2

IN

t

OFF,G2

t

On,G1

PGD

90%

10%

t

On,G2

90%

PGD

10%

UCC27223

Figure 1. Predictive Gate Drive Timing Diagram

TERMINAL FUNCTIONS

TERMINAL

NAME NO.

AGND 6 −

G1 13 O High-side gate driver output that swings between SW and VHI.

G2 9 O Low-side gate driver output that swings between PGND and PVLO.

G2S 10 I

IN 7 I

PGND 8 − Ground return for the G2 driver. Connect PGND to PCB ground plane with several vias.

PVLO 5 I PVLO supplies the G2 driver. Connect PVLO to VLO and bypass on the PCB.

SW 12 − G1 driver return connection.

SWS 11 I

VDD 3 I

VHI 14 I

VLO 4 O

ENBL 2 I

Analog ground for all internal logic circuitry. AGND and PGND should be tied to the PCB ground plane

with vias.

Used by the predictive deadtime controller for sensing the SR MOSFET gate voltage to set the

appropriate deadtime.

Digital input command pin. A logic high forces on the main switch and forces off the synchronous

rectifier.

Used by the predictive controller to sense SR body-diode conduction. Connect to SR MOSFET drain

close to the MOSFET package.

Input to the internal VLO regulator. Nominal VDD range is from 8.5 V to 20 V. Bypass with at least

0.1 µF of capacitance.

Floating G1 driver supply pin. VHI is fed by an external Schottky diode during the SR MOSFET on-time.

Bypass VHI to SW with an external capacitor.

Output of the VLO regulator and supply input for the logic and control circuitry. Connect VLO to PVLO and

bypass on the PCB with a maximum capacitor value of 4.7 µF.

Enable input that controls the operation of both outputs (G1 and G2). It is internally pulled up to VLO with

a 110-kΩ resistor for active-high operation.

DESCRIPTION

UDG−0318

www.ti.com

5

Page 6

SLUS558 − DECEMBER 2003

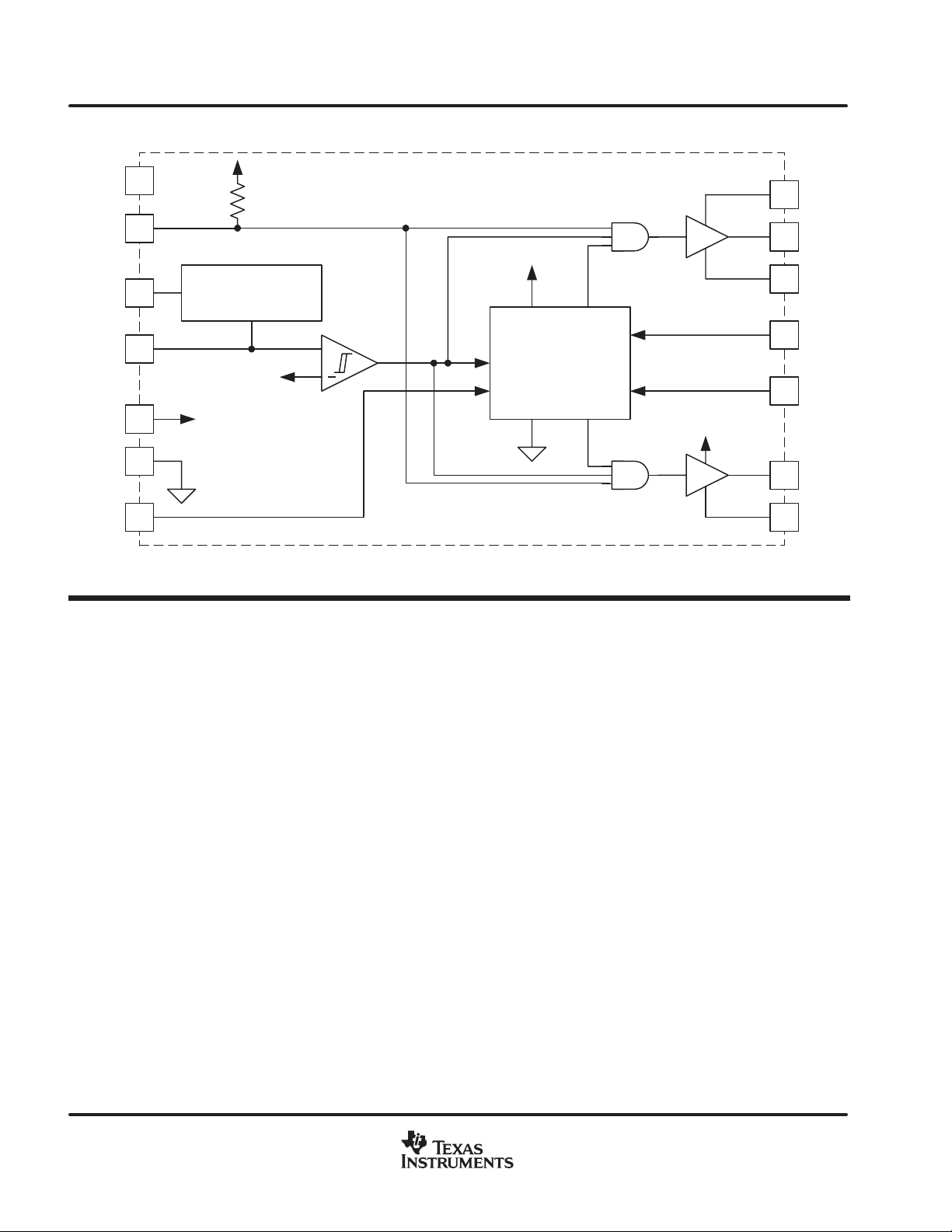

SIMPLIFIED BLOCK DIAGRAM

NC

ENBL

VDD

VLO

PVLO

AGND

1

2

3

4

3.82 V/3.7 V

5

6

IN

7

VLO

110 kΩ

R

ENBL

VLO

REGULATOR

PVLO

+

UVLO

VLO

PREDICTIVE

DELAY

CONTROLLER

PVLO

14

VHI

13

G1

12

SW

11

SWS

10

G2S

9

G2

8 PGND

APPLICATION INFORMATION

predictive gate drive technique

The Predictive Gate Drivet technology utilizes a digital feedback system to detect body-diode conduction, and

then adjusts the deadtime delays to minimize it. This system virtually eliminates the body-diode conduction time

intervals for the synchronous MOSFET, while adjusting for different MOSFETs characteristics, propagation and

load dependent delays. Maximum power stage efficiency is the end result.

Two internal feedback loops in the predictive delay controller continuously adjusts the turn on delays for the two

MOSFET gate drives G1 and G2. As shown in Figure 2, t

body-diode conduction in the synchronous rectifier MOSFET Q

and t

OFF,G2

are fixed by propagation delays internal to the device.

The predictive delay controller is implemented using a digital control technique, and the time delays are

therefore discrete. The turn-on delays, t

ON, G1

and t

ON, G2

switching cycle. The minimum and maximum turn-on delays for G1 and G2 are specified in the electrical

characteristics table.

and t

ON,G1

. The turn-off delay for both G1 and G2, t

2

are varied to provide minimum

ON,G2

, are changed by a single step (typically 3 ns) every

OFF,G1

6

www.ti.com

Page 7

2

t

SLUS558 − DECEMBER 2003

APPLICATION INFORMATION

OFF,G1

3.25 V

G1

G2

IN

t

OFF,G2

t

On,G1

PGD

90%

10%

UCC27223

Figure 2. Predictive Gate Drive Timing Diagram

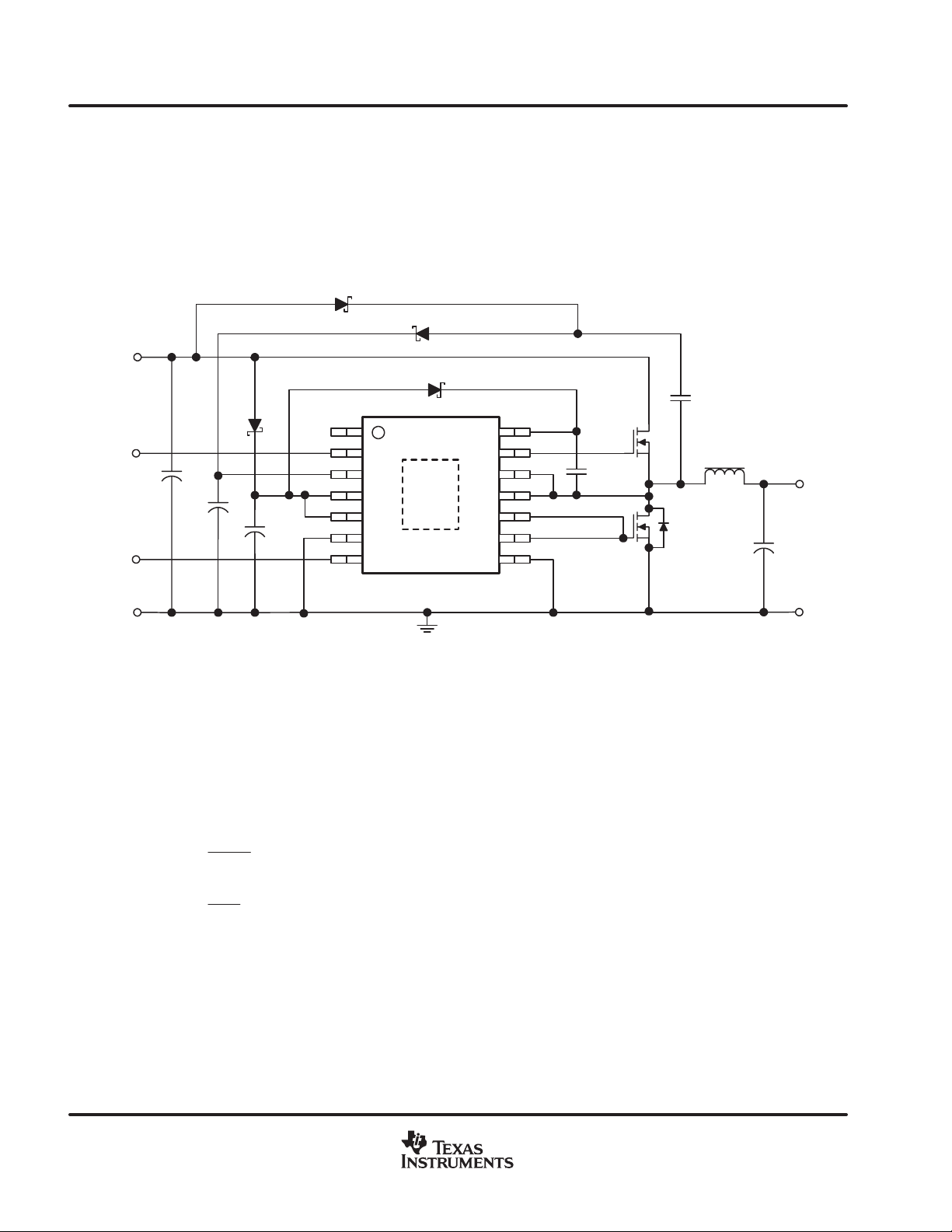

A typical application circuit for systems with 8.5-V to 20-V input is shown in Figure 3.

VIN

D1

R1

Disable

Outputs

PWM

Input

ENBL

VDD

VLO

PVLO

AGND

IN

UCC27223

VHI

G1

SW

SWS

G2S

G2

PGND

N/C

C

IN

C2

t

C1

On,G2

90%

PGD

Q1

10%

Q2

L1

Cout

UDG−0318

V

OUT

GND

Figure 3. System Application: 8.5-V to 20-V Input

www.ti.com

GND

UDG−03183

7

Page 8

SLUS558 − DECEMBER 2003

APPLICATION INFORMATION

selection of VHI series resistor R1 (dV/dt Considerations):

The series resistor R1 may be needed to slowdown the turn-on of the main forward switch to limit the dV/dt which

can inadvertently turn on the synchronous rectifier switch. In nominal 12-V input designs, a R1 value of 4-Ω to

10-Ω can be used depending on the type of MOSFET used and the high-side/low-side MOSFET ratio. In 5-V

or lower input applications however, R1 is not needed.

When the drain-source voltage of a MOSFET quickly rises, inadvertent dV/dt induced turn-on of the device is

possible. This can especially be a problem for input voltages of 12 V or greater. As Q1 rapidly turns on, the

drain-to-source voltage of Q2 rises sharply, resulting in a dV/dt voltage spike appearing on the gate signal of

Q2. If the dV/dt induced voltage spike were to exceed the given threshold voltage, the MOSFET may briefly

turn on when it should otherwise be commanded off. Obviously this undesired event would have a negative

impact on overall efficiency.

Minimizing the dV/dt effect on Q2 can be accomplished by proper MOSFET selection and careful layout

techniques. The details of how to select a MOSFET to minimize dV/dt susceptibility are outlined in SEM−1400,

Topic 2, Appendix A, Section A5. Secondly, the switch node connecting Q1, Q2 and L1 should be laid out as

tight as possible, minimizing any parasitic inductance, which might worsen the dV/dt problem.

If the dV/dt induced voltage spike is still present on the gate Q2, a 4W to 10W value of R1 is recommended to

minimize the possibility of inadvertently turning on Q2. The addition of R1 slows the turn-on of Q1, limiting the

dV/dt rate appearing on the drain-to-source of Q2. Slowing down the turn-on of Q1 will result in slightly higher

switching loss for that device only , but the efficiency gained by preventing dV/dt turn-on of Q2 will far outweigh

the negligible effect of adding R1.

When Q2 is optimally selected for dV/dt robustness and careful attention is paid to the PCB layout of the switch

node, R1 may not be needed at all, and can therefore be replaced with a 0-Ω jumper to maintain high efficiency.

The goal of the designer should not be to completely eliminate the dV/dt turn-on spike but to assure that the

maximum amplitude is less than the MOSFET gate-to-source turn-on threshold voltage under all operating

conditions.

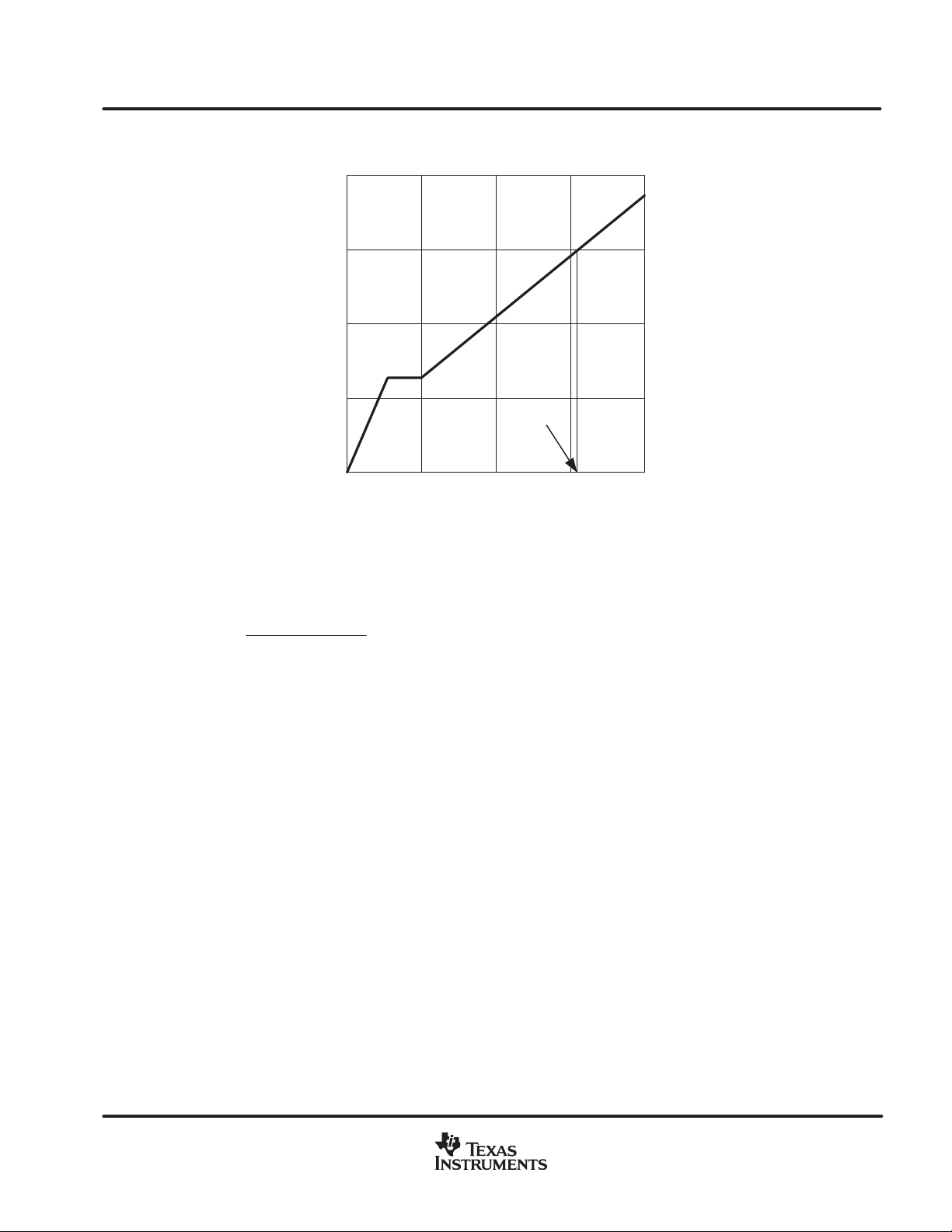

selection of bypass capacitor C1

Bypass capacitors should be selected based upon allowable ripple voltage, usually expressed as a percent of

the regulated power supply rail to be bypassed. In all of the UCC27223 application circuits shown herein, C1

provides the bypass for the main (high-side) gate driver. Every time Q1 is switched on, a packet of charge is

removed from C1 to charge Q1’s gate to approximately 6.0 V. The charge delivered to the gate of Q1 can be

found in the manufacturer’s datasheet curves. An example of a gate charge curve is shown in Figure 4.

8

www.ti.com

Page 9

(1)

SLUS558 − DECEMBER 2003

GATE-TO-SOURCE VOLTAGE

vs

31 nC

8

6

4

2

− Gate-to-Source Voltage − V

GS

V

0

020304010

TOTAL GATE CHARGE

Q6 − Total Gate Charge − nC

Figure 4.

As shown in Figure 4, 31 nC of gate charge is required in order for Q1’s gate to be charged to 6.0 V, relative

to its source. The minimum bypass capacitor value can be found using the following calculation:

Q

C1

MIN

+

k ǒVHI * V

G

Ǔ

SW

where k is the percent ripple on C1, QG is the total gate charge required to drive the gate of Q1 from zero to

the final value of (VHI−VSW). In this example gate charge curve, the value of the quantity (VHI−VSW) is taken

to be 6.0 V. This value represents the nominal VLO regulator output voltage minus the forward voltage drop of

the external Schottky diode, D1. For the MOSFET with the gate charge described in Figure 4, the minimum

capacitance required to maintain a 3% peak-to-peak ripple voltage can be calculated to be 172 nF, so a 180-nF

or a 220-nF capacitor could be used. The maximum peak-to-peak C1 ripple must be kept below 0.4 V for proper

operation.

www.ti.com

9

Page 10

(2)

SLUS558 − DECEMBER 2003

APPLICATION INFORMATION

selection of MOSFETs

The peak current rating of a driver imposes a limit on the maximum gate charge of the external power MOSFET

driven by it. The limit is based on the amount of time needed to deliver or remove the required charge to achieve

the desired switching speed during turn-on and turn-off of the external transistor. Hence, there are the families

of gate driver circuits with different current ratings.

To demonstrate this, assume a constant time interval for the switching transition and a fixed gate drive

amplitude. A larger MOSFET with more gate charge will require higher current capability from the driver to

turn-on or turn-off the device in the same amount of time. Accordingly, there is a practical upper limit on gate

charge which can be driven by the UCC27223. Considering the current capability of the TrueDrive output

stage and the available dynamic range (delay adjust range) of the Predictive Gate Drive circuitry, this limit is

approximately 120 nC of gate charge.

Some higher current applications require several MOSFETs to be connected parallel and driven by the same

gate drive signal. If their combined gate charge exceeds 120 nC, the rise and fall times of the gate drive signals

will extend and limit the delay adjust range of the PGD circuit in the UCC27223. This may limit the benefits of

the PGD technology under certain operating conditions.

Note that there are additional considerations in the gate drive circuit design which influence the maximum gate

charge of the external MOSFETs. The most significant of these is the operating frequency which, together with

the amount of gate charge, will define the power dissipation in the driver. The allowable power dissipation is a

function of the maximum junction and operating temperatures, thermal and reliability considerations.

selection of bypass capacitor C2

C2 supplies the peak current required to turn on the Q2 synchronous rectifier MOSFET, as well as the peak

current to charge the C1 capacitor through the bootstrap diode. Since the synchronous MOSFET is turned on

with 0 V across its drain-to-source, there is no Miller, or gate-to-drain charge. Therefore the synchronous

MOSFET gate can be modeled as a simple linear capacitance. The value of this capacitance can be found from

the datasheet’s gate charge curve. Referring to Figure 5, the slope of the curve past the Miller plateau indicates

the equivalent gate capacitance. Because the Y-axis is described in volts, the capacitance is actually the inverse

of the slope of the curve. For example, the curve in Figure 4 has a slope of approximately 2 V / 12 nC over the

gate charge range of 10 nC to 40 nC. The equivalent capacitance is 12 nC / 2 V = 6 nF. With the equivalent

capacitance, the minimum bypass capacitor value can be calculated as:

C

C2

where

D C

MIN

EQ

EQ

+

k

is the equivalent gate capacitance,

D k is the voltage ripple on C2, expressed as a percentage

For a peak-to-peak ripple of 3%, the minimum C2 capacitor value is calculated to be 200 nF. A 220-nF capacitor

would be used in this case. C2

low ESL by-pass capacitor should be placed as close to the UCC27223 chip as possible. The capacitor provides

the transient currents needed by the drive stage and prevents UVLO shutdown of the driver during turn-on.

should not exceed 4.7 µF. In addition to the calculated capacitance, a 100-nF

MAX

10

www.ti.com

Page 11

+3.3 V or

UT

D

(3)

(4)

SLUS558 − DECEMBER 2003

APPLICATION INFORMATION

regulator current and power dissipation

The regulator current can be calculated from the dc or average current required by the two gate drivers. This

current can be expressed as:

I

REG

+ F

SW

ǒ

CEQ VLO ) Q

Ǔ

G

Assuming all the power dissipation is internal to the device, and the internal bias current is negligible, the power

dissipated by the device is:

P

+ F

DIS

SW

ǒ

CEQ VLO ) Q

Ǔ

VDD

G

For a 500-kHz design, using MOSFETs with the gate charge characteristics shown in Figure 4 for both Q1 and

Q2, the average regulator current would be 35 mA, and, when operated from a 12-V input rail, the resulting

power dissipation is calculated to be 420 mW.

systems using 3.3-V or 5-V power input and 12-V gate drive

Figure 5 shows a schematic for systems where the power bus input is 5 V and 12 V is available for powering

the gate drives. This system provides the 6.5-V gate drive to both MOSFETs, while the power stage operates

off the 3.3-V or 5-V bus.

+5 V

Disable

Outputs

+12 V

PWM

Input

C

C3

IN

N/C

ENBL

VDD

VLO

PVLO

C2

AGND

IN

D1

UCC27223

VHI

G1

SW

SWS

G2S

G2

PGND

R1

Q1

L1

C1

Q2

Cout

V

O

GND

UDG−03184

Figure 5. System Application: 3.3-V or 5-V Power Input with 12 V Available for Gate Drive

Note that the series resistor R1 may be needed to slowdown the turn-on of the main forward switch to limit the

dV/dt which can inadvertently turn on the synchronous rectifier switch. The dV/dt considerations and the

selection of R1 are discussed in the previous section.

www.ti.com

GN

11

Page 12

(5)

(6)

SLUS558 − DECEMBER 2003

APPLICATION INFORMATION

systems with 5-V input only

The circuit pictured in Figure 6 starts up from a 5-V input bus and provides a 6.5-V gate drive to the power

MOSFETs. This circuit uses a charge pump consisting of D

and apply this to the input of the linear regulator. The regulator then regulates the doubled input voltage to the

6.5-V nominal for VLO.

D3

D4

, D4 and C3 to effectively double the input voltage

3

+5V

Disable

Outputs

PWM Input

GND

D2

C

IN

C4

C2

N/C

ENBL

VDD

VLO

PVLO

AGND

IN

D1

UCC27223

VHI

G1

SW

SWS

G2S

G2

PGND

C3

Q1

L1

C1

Q2

Cout

UDG−03185

Figure 6. System Application: 5-V-Only Power Input with 6.5-V Gate Drive Using Charge Pump Circuit

selecting D2, D3, and D

4

Selection of suitable diodes is based upon the conducted peak and average currents. D2 simply provides a path

to charge C2 at converter power-up. Virtually any one of the common BAT54 series of Schottky diodes can be

used. To select D3 and D4, the peak currents of these two diodes need to be taken into account. First, the

average current flowing in both D3 and D4 is the same as the regulator current described in equation (3). The

peak currents in D3 and D4 are described as:

V

OUT

GND

I

+

+

REG

1 * D

I

REG

D

I

D3PK

I

D4PK

For most UCC272223applications, the duty cycle is much less than 50%, and the peak current in D3 is quite

reasonable. However, the peak current in D4 is quite high. This high peak current requires using a diode with

a higher current rating for D4.

To maintain a reasonable charge pump efficiency, BAT54-type diodes can be used for applications where the

peak currents are below approximately 40 mA. For applications where the peak current is greater than 40 mA,

a 350-mA or 500-mA diode should be used. A typical 350-mA diode is SD103CW, SOD−123 package,

manufactured by Diodes Inc. A typical 500-mA diode is the ZHCS500, SOT−23 package, available from Zetex

Inc.

12

www.ti.com

Page 13

(7)

(8)

SLUS558 − DECEMBER 2003

APPLICATION INFORMATION

selection of the flying capacitor C3

The flying capacitor is subjected to large peak currents, and to keep the peak-to-peak ripple voltage low, this

capacitor has to be larger than C1 and C2. Selection of C3 should be done based on allowable peak-to-peak

ripple on C3:

I

C3

MIN

+

FSW k ǒVIN * V

REG

FD3

Ǔ

where I

V

FD2

is the regulator output current, FSW is the switching frequency, k is the percent ripple on C3, and

REG

is the forward drop of D3.

selection of bypass capacitor C4

The bypass capacitor C4 needs to be sized to take the peak current from the charge pump diode D4. The

capacitor is sized based on allowable ripple voltage:

(

C

where V

MIN

FD3

+

FSW k

and V

FD4

I

REG

ǒ

2 VIN * V

are the forward voltages of D3 and D4 and k is the percent ripple allowed on C4.

1 * D)

FD3

* V

FD4

Ǔ

enable pin and driver operation at start-up

In the UCC27223, an active-high ENBL function is implemented on pin 2. This pin when pulled low will shut off

both G1 and G2 outputs regardless of the state of the PWM input signal. The ENBL pin is pull up to VLO internally

with a 110-kΩ resistor so that the chip will be functional if the pin is left open. Enable thresholds are 2.45 V on,

and 1.7 V off. The UCC27223 also includes a logic latch to keep both outputs low at start-up even when V

is past UVLO turn-on threshold. Both outputs will always be low until the first PWM input signal comes in.

DD

www.ti.com

13

Page 14

SLUS558 − DECEMBER 2003

APPLICATION INFORMATION

synchronous rectification and predictive delay

In a normal buck converter, when the main switch turns off, current is flowing to the load in the inductor. This

current cannot be stopped immediately without using infinite voltage. For the current path to flow and maintain

voltage levels at a safe level, a rectifier or catch device is used. This device can be either a conventional diode,

or it can be a controlled active device if a control signal is available to drive it. The UCC27223 provides a signal

to drive an N-channel MOSFET as a rectifier. This control signal is carefully coordinated with the drive signal

for the main switch so that there is minimum delay from the time that the rectifier MOSFET turns off and the main

switch turns on, and minimum delay from when the main switch turns off and the rectifier MOSFET turns on.

This scheme, Predictive Gate Drivet delay, uses information from the current switching cycle to adjust the

delays that are to be used in the next cycle. Figure 7 shows the switch-node voltage waveform for a

synchronously rectified buck converter. Illustrated are the relative effects of a fixed-delay drive scheme

(constant, pre-set delays for the turnoff to turn on intervals), an adaptive delay drive scheme (variable delays

based upon voltages sensed on the current switching cycle) and the predictive delay drive scheme.

Note that the longer the time spent in body-diode conduction during the rectifier conduction period, the lower

the efficiency. Also, not described in Figure 7 is the fact that the predictive delay circuit can prevent the body

diode from becoming forward biased at all while at the same time avoiding cross conduction or shoot through.

This results in a significant power savings when the main MOSFET turns on, and minimizes reverse recovery

loss in the body diode of the rectifier MOSFET.

The power dissipation on the main (forward) MOSFET is reduced as well, although that savings is not as

significant as the savings in the rectifier MOSFET.

During reverse recovery the body diode is still forward biased, thus the reverse recovery current goes through

the forward MOSFET while the drain−source voltage is still high, causing additional switching losses. Without

PGD during this switching transition, Vds = Vin and Ids = Iload + Irr in the main MOSFET. With PGD however,

Vds = V in and Ids = Iload. The reduction in current accounts for additional power savings in the main MOSFET.

V

IN

0 V

V

D

GND

Channel Conduction

Body Diode Conduction

Fixed Delay

Adaptive Delay

Predictive Delay

UDG−02175

14

Figure 7. Switch Node Waveforms for Synchronous Buck Converter

www.ti.com

Page 15

SLUS558 − DECEMBER 2003

APPLICATION INFORMATION

comparison between predictive and adaptive gate drive techniques

The first synchronous rectifier controllers had a fixed turn-on delay between the two gate drivers. The advantage

of this well-known technique is its simplicity. The drawbacks include the need to make the delay times long

enough to cover the entire application of the device and the temperature and lot-to-lot variation of the time delay.

Since the body-diode of the synchronous rectifier conducts during this deadtime, the efficiency of this technique

varies with different MOSFETs, ambient temperature, and with the lot-to-lot variation of the deadtime delay.

To combat the variability of the internal time delays, second generation controllers used state information from

the power stage to control the turn-on of the two gate drivers. This technique is usually referred to as adaptive

gate drive technique and is pictured in FIgure 8.

V

IN

+

ON

ON

OFF

+

V

OUT

UDG−01031

Figure 8. Adaptive Gate Drive Technique

The main advantage of the adaptive technique is the on-the-fly delay adjustment for different MOSFETs and

temperature-variable time delays. The disadvantages include the body-diode conduction time intervals caused

by delays in the cross-coupling loops and the inability to compensate for the delay to charge the MOSFET gates

to the threshold levels. Additionally, i t i s d i fficult to determine whether the synchronous MOSFET channel is off

by solely monitoring the SR MOSFET gate voltage. Some devices actually add a programmable delay between

the turn-off of the synchronous rectifier and the turn-on of the main MOSFET via an external capacitor. This

added delay directly affects the power stage efficiency through additional body-diode conduction losses. Since

these losses are centralized in the synchronous MOSFET, the stress and temperature rise in this component

becomes a major design headache.

The third-generation predictive control technique is different from the adaptive technique in that it uses

information from the previous switching cycle to set the deadtime for the current cycle. The adaptive technique

on the other hand uses the current state information to set the delay times. The inherent feedback loop

propagation delays cause body-diode conduction.

www.ti.com

15

Page 16

SLUS558 − DECEMBER 2003

APPLICATION INFORMATION

adaptive vs. predictive waveforms

Figures 9 through 11 illustrate the adaptive (left) vs. predictive (right) switching waveforms. Key comparison

regions are denoted with (A), (B), (C), (D), and (E) for the adaptive control waveforms and (A′), (B′), (C′), (D′),

and (E′) for the predictive control waveforms. Figures 10 and 11 are close-ups of each transition edge.

At (A), the propagation delay from sensing the synchronous rectifier gate going low to the high-side gate going

high results in approximately 60 ns of body-diode conduction shown at (B). With the predictive drive, as soon

as the body-diode conduction of the SR MOSFET (B) is sensed, the high-side turn-on delay is adjusted to

minimize the body-diode conduction time (B′).

At (A′), the high side gate-to-source voltage is increasing while the synchronous rectifier gate-to-source voltage

is decreasing. A natural result of the precise timing of the high-side MOSFET turn-on is shown at (C) and (C′).

The overshoot and ringing for the predictive drive (C′) has much smaller amplitude than the adaptive drive (C)

due a reduction in reverse recovery in the SR MOSFET body diode. This reduction in reverse recovery is only

possible with the extremely precise gate timing used in the predictive drive technique.

At (D), the propagation delay from the synchronous rectifier drain-to-source voltage falling to the gate-to-source

voltage rising causes the body diode of the SR MOSFET to conduct for approximately 60 ns (E). When the

predictive drive is enabled (D′), the inherent delay is eliminated and virtually no body-diode conduction is shown

at (E′).

A

C

B

Adaptive Drive

Complementary

D

E

100 ns / div

Gate Drive

Waveforms

2 V / div

VDS of SR

MOSFET

Switch

2 V / div

Figure 9. Adaptive vs. Predictive Switching Waveforms

A4

C4

B4

Predictive Drive

100 ns / div

D4

E4

16

www.ti.com

Page 17

SLUS558 − DECEMBER 2003

APPLICATION INFORMATION

A4

B4

20 ns / div

Adaptive Drive

20 ns / div

Complementary

A

C

B

Gate Drive

Waveforms

2 V / div

VDS of SR

MOSFET

Switch

2 V / div

Predictive Drive

Figure 10. Close-Up: Turn-Off of Synchronous Rectifier Switch to Turn-On of Main Switch

Complementary

Gate Drive

D

E

Waveforms

2 V / div

VDS of SR

MOSFET

Switch

2 V / div

D4

E4

C4

Adaptive Drive

20 ns / div

Predictive Drive

20 ns / div

Figure 11. Close-Up: Turn-Off of Main Switch to Turn-On of Synchronous Rectifier Switch

efficiency comparison

Figures 12 through 15 show a series of efficiency measurements taken at two output voltages (0.9 V and 1.8

V) and two switching frequencies (250 kHz and 500 kHz) for both predictive and adaptive delay techniques.

The efficiency gain using the predictive technique is 1% for a V

of 250 kHz (Figure 12). Figures 13 and 14 show the efficiency gain approximately doubles when V

by a factor of two (to 0.9 V), or when the switching frequency is doubled to 500 kHz. With both doubled frequency

and one-half of the output voltage, the efficiency gain of predictive technology is about 4% over the adaptive

technology (Figure 15). Therefore, as the switching frequency increases and output voltages are lowered, the

efficiency gains are higher. This results in lower operational temperatures for increased reliability as well as

smaller size designs for increased frequencies.

level of 1.8 V and at a switching frequency

OUT

OUT

is lowered

www.ti.com

17

Page 18

SLUS558 − DECEMBER 2003

APPLICATION INFORMATION

EFFICIENCY

vs

OUTPUT CURRENT

96

94

92

90

88

86

84

Efficiency − %

82

80

78

76

74

0 5 10 15 20

ADAPTIVE

I

OUT

− Output Current − A

PREDICTIVE

DELTA POWER

DISSIPATION

VIN = 5 V

V

= 1.8 V

OUT

fSW = 250 kHz

Figure 12

EFFICIENCY

vs

OUTPUT CURRENT

96

94

92

90

88

86

84

Efficiency − %

82

80

78

76

74

0 5 10 15 20

ADAPTIVE

DELTA POWER

DISSIPATION

I

OUT

− Output Current − A

PREDICTIVE

VIN = 5 V

V

= 1.8 V

OUT

fSW = 500 kHz

Figure 14

0.5

0.4

0.3

0.2

0.1

0.0

1.2

1.0

0.8

0.6

0.4

0.2

0.0

96

VIN = 5 V

V

94

fSW = 250 kHz

92

90

88

86

84

82

Efficiency − %

80

Delta Power Dissipation − W

78

76

74

0 5 10 15 20

96

VIN = 5 V

94

V

OUT

fSW = 500 kHz

92

90

88

86

84

Efficiency − %

82

80

Delta Power Dissipation − W

78

76

74

0 5 10 15 20

= 0.9 V

OUT

ADAPTIVE

= 0.9 V

ADAPTIVE

EFFICIENCY

vs

OUTPUT CURRENT

PREDICTIVE

DELTA POWER

DISSIPATION

I

− Output Current − A

OUT

Figure 13

EFFICIENCY

vs

OUTPUT CURRENT

PREDICTIVE

DELTA POWER

DISSIPATION

I

− Output Current − A

OUT

Figure 15

0.5

0.4

0.3

0.2

0.1

Delta Power Dissipation − W

0.0

1.2

1.0

0.8

0.6

0.4

Delta Power Dissipation − W

0.2

0.0

18

www.ti.com

Page 19

SLUS558 − DECEMBER 2003

LAYOUT CONSIDERATIONS

packaging

The UCC27223 is only available in TI’s thermally enhanced 14-pin PowerPad package. This package offers

exceptional thermal impedance with a junction-to-case rating of 2_C/W. Shown as the crosshatched region in

Figure 16, PowerPad includes an exposed leadframe die pad located on the bottom side of the package.

Exposed pad dimensions for the PowerPadt TSSOP 14-pin package are 69 mils x 56 mils (1.8 mm x 1.4 mm).

However, the exposed pad tolerances can be + 41 / − 2 mils (+ 1.05 /− .05 mm) due to position and mold flow

variation. Effectively removing the heat from the PowerPAD package requires a thermal land area, shown as

the shaded gray region in Figure 16, designed into the PCB directly beneath the package. A minimum thermal

land area of 5 mm by 3.4 mm is recommended as illustrated in Figure 16. Any tolerance variances of the exposed

PowerPad falls well within the thermal land area when the recommended minimum land area is included on

the printed circuit board. In addition, a 2-by-3 array of 13-mil thermal vias is required within the exposed

PowerPad area, as shown in Figure 16. If additional heat sinking capability is required, larger 25-mil vias can

be added to the thermal land area.

Required Vias on PowerPad Area

2 x 3 Array

0.33mm

(13 mil) dia Vias

0.65mm

(0.0256”)

3.4mm

(0.1339”)

0.3mm

(0.0118”)

1.05mm

(0.0413”)

Exposed

PowerPad

1.4mm (0.056”)

Exposed

PowerPad

1.8mm (0.069”)

Optional Vias on Thermal Land Area

0.635mm

(25 mil) dia Vias

5.0mm

(0.1968”)

Figure 16. TSSOP−14PWP Package Outline and Minimum PowerPADE PCB Thermal Land

www.ti.com

19

Page 20

SLUS558 − DECEMBER 2003

REFERENCE DESIGN AND EVALUATION MODULE

A reference design is discussed in, 5 V to 0.9 V − 1.8 V (adjustable), 20-A High Efficiency Synchronous Buck

Converter Using the UCC27223 with Predictive Gate Drivet, TI Literature Number SLUU181 and

accompanying evaluation module UCC27223EVM. The design highlights UCC27223 and its Predictive Gate

Drivet synchronous buck operation using a simple single ended PWM controller. The schematic is shown in

Figure 17.

+

+

20

Figure 17. Typical Application Diagram

www.ti.com

Page 21

SLUS558 − DECEMBER 2003

TYPICAL CHARACTERISTICS

BIAS CURRENT

vs

TEMPERATURE (NO LOAD)

16

14

12

10

8

− Bias Current − mA

6

SUPPLY

4

I

2

0

IDD: VDD = 12 V, 500 kHz

IDD: VDD = 8.5 V, Static

I

: VLO = 12 V, Static, 5 V Only Systems

VLO

−50 −25 0 25 50 75 100 125

TA − Temperature − °C

Figure 18

UVLO THRESHOLD

vs

TEMPERATURE

4.2

4.1

4.0

3.9

3.8

3.7

3.6

UVLO Threshold − V

3.5

3.4

3.3

3.2

−50 −25 0 25 50 75 100 125

UVLO On

UVLO Off

TA − Temperature − °C

Figure 19

VLO LINE REGULATION

vs

TEMPERATURE (NO LOAD, IVLO = 0 mA)

6.8

6.7

6.6

VDD = 20 V

6.5

− Line Regulation − V

6.4

LO

V

6.3

6.2

−50 −25 0 25 50 75 100 125

TA − Temperature − °C

VDD = 12 V

Figure 20

VLO LOAD REGULATION

vs

TEMPERATURE

6.8

6.7

6.6

I

= 0 mA

VLO

6.5

I

= 100 mA

VLO

6.4

− Load Regulation − V

LO

V

6.3

6.2

−50 −25 0 25 50 75 100 125

TA − Temperature − °C

Figure 21

www.ti.com

21

Page 22

SLUS558 − DECEMBER 2003

TYPICAL CHARACTERISTICS

DROPOUT VOLTAGE (VDD AT VLO = 6.175 V)

vs

OUTPUT CURENT

8.6

8.4

8.2

8.0

7.8

− Dropout Voltage − V

7.6

DD

V

7.4

7.2

7.0

0 50 100

IVLO − VLO Output Current − mA

Figure 22

DROPOUT VOLTAGE (VDD AT VLO = 6.175 V)

vs

TEMPERATURE (I

8.6

8.4

8.2

8.0

7.8

7.6

− Dropout Voltage − V

DD

V

7.4

7.2

7.0

−50 25 125

TA − Temperature − °C

= 100 mA)

VLO

Figure 23

10075500−25

VLO SHORT CIRCUIT CURRENT

vs

TEMPERATURE

300

290

280

270

260

250

240

230

− Short Circuit Current − mA

LO

220

V

210

200

−50 25 125

TA − Temperature − °C

Figure 24

INPUT THRESHOLD

vs

TEMPERATURE (VDD = 10 V TO 20 V)

4.0

Input Threshold Rising

3.5

3.0

Input Threshold Falling

2.5

2.0

1.5

Input Threshold − V

1.0

0.5

0.0

10075500−25

−50 25 125

Input Threshold Hyst.

10075500−25

TA − Temperature − °C

Figure 25

22

www.ti.com

Page 23

SLUS558 − DECEMBER 2003

TYPICAL CHARACTERISTICS

PREDICTIVE DELAY BIT WEIGHT

vs

TEMPERATURE

4.7

4.5

4.3

4.1

3.9

PGD Step Resolution − ns

3.7

3.5

−50 25 125

TA − Temperature − °C

Figure 26

PROPAGATION DELAYS

vs

TEMPERATURE

120

100

t

, G2

OFF

80

t

, G1

OFF

60

− Propagation Delays − ns

40

PROP

t

20

0

10075500−25

−50 25 125

TA − Temperature − °C

10075500−25

Figure 27

PREDICTIVE DELAY RANGE

vs

60

50

40

30

20

10

− G1 Delay Range − ns

ON

t

−10

−20

−30

tON, G1 Max

0

−50 25 125

TEMPERATURE

tON, G1 Min

TA − Temperature − °C

Figure 28

PREDICTIVE DELAY RANGE

vs

TEMPERATURE

60

50

40

30

20

10

− G2 Delay Range − ns

0

ON

t

−10

−20

−30

10075500−25

−50 25 125

tON, G2 Max

tON, G2 Min

10075500−25

TA − Temperature − °C

Figure 29

www.ti.com

23

Page 24

SLUS558 − DECEMBER 2003

TYPICAL CHARACTERISTICS

G1 RISE AND FALL TIMES

vs

TEMPERATURE (2.2 nF)

30

25

20

− ns

F

, t

15

R

G1 t

10

5

0

Rise Time

Fall Time

−50 25 125

TA − Temperature − °C

Figure 30

G2 RISE AND FALL TIMES

vs

TEMPERATURE (2.2 nF)

30

25

20

− ns

F

, t

15

R

G2 t

10

5

0

10075500−25

−50 25 125

Fall Time

Rise Time

10075500−25

TA − Temperature − °C

Figure 31

G1 SINK RESISTANCE

vs

TEMPERATURE (R

1.5

1.4

1.3

1.2

1.1

− Ω

1.0

SINK

G1 R

0.9

0.8

0.7

0.6

0.5

−50 25 125

TA − Temperature − °C

DS(on)

)

Figure 32

G1 SOURCE RESISTANCE

vs

TEMPERATURE

40

35

30

25

− Ω

20

SOURCE

15

G1 R

10

5

0

10075500−25

−50 25 125

TA − Temperature − °C

10075500−25

Figure 33

24

www.ti.com

Page 25

5

G2 SINK RESISTANCE

SLUS558 − DECEMBER 2003

TYPICAL CHARACTERISTICS

G2 SOURCE RESISTANCE

vs

TEMPERATURE

40

vs

TEMPERATURE (R

DS(on)

)

40

35

30

25

− Ω

20

SINK

G2 R

15

10

5

0

−50 25 12

TA − Temperature − °C

Figure 34

7

10075500−25

VHI CURRENT

vs

FREQUENCY

35

30

25

− Ω

20

SOURCE

15

G2 R

10

5

0

−50 25 125

TA − Ambient Temperature − °C

Figure 35

10075500−25

6

5

4

3

VHI Current − mA

2

1

0

0 200 400 600 800 1000 1200

Frequency − kHz

Figure 36

www.ti.com

25

Page 26

SLUS558 − DECEMBER 2003

RELATED PRODUCTS

PART

NUMBER

TPS40090 High Frequency 2, 3, 4−Phase Multiphase Controller − TSSOP−24

UCC27221/2 High Efficiency Predictive Synchronous Buck ± 3.3 A PowerPADt HTSSOP−14

TPS2830/1 Fast synchronous buck MOSFET drivers with dead-time control ± 2.4 A PowerPADt HTSSOP−14, SOIC−14

TPS2832/3 Fast synchronous buck MOSFET drivers with dead-time control ± 2.4 A SOIC−8

TPS2834/5 Synchronous buck MOSFET drivers with dead-time control ± 2.4 A PowerPADt HTSSOP−14, SOIC−14

TPS2836/7 Synchronous buck MOSFET drivers with dead-time control ± 2.4 A SOIC−8

TPS2838/9 Synchronous buck MOSFET drivers with drive regulator ± 4 A PowerPADt HTSSOP−16

TPS2848/9 Synchronous buck MOSFET drivers with drive regulator ± 4 A PowerPADt HTSSOP−14

DESCRIPTION

GATE

DRIVE

PACKAGE

REFERENCES

1. Power Supply Design Seminar SEM−1400 Topic 2: Design and Application Guide for High Speed MOSFET

Gate Drive Circuits, by Laszlo Balogh, Texas Instruments Literature Number SLUP169.

2. User’s Guide: 5 V to 0.9 V − 1.8 V (adjustable), 20-A High−Efficiency Synchronous Buck Converter using

UCC27223 with Predictive Gate Drivet, TI Literature Number SLUU181.

3. User’s Guide: 12 V to 1.8 V, 20 A High-Efficiency Synchronous Buck Converter Using UCC27222 With

Predictive Gate Drivet Technology, TI Literature Number SLUU140.

4. Application Note: UCC27221/2 Predictive Gate Drivet FAQ, TI Literature Number SLUA280.

5. Application Note: Predictive Gate Drivet Boosts Converter Efficiency, TI Literature Number SLUA281.

6. Application Note: Increasing UCC27221/2 Gate Drive Voltage, TI Literature Number SLUA292.

26

www.ti.com

Page 27

20 PINS SHOWN

SLUS558 − DECEMBER 2003

MECHANICAL DATA

PWP (R-PDSO-G**) PowerPAD PLASTIC SMALL-OUTLINE

0,65

20

1

1,20 MAX

0,30

0,19

11

4,50

4,30

10

A

0,15

0,05

PINS **

DIM

M

0,10

6,60

6,20

Seating Plane

0,10

1614

Thermal Pad

(See Note F)

20

0,15 NOM

0°−ā 8°

Gage Plane

0,25

0,75

0,50

2824

A MAX

A MIN

NOTES: A. All linear dimensions are in millimeters.

B. This drawing is subject to change without notice.

C. Body dimensions do not include mold flash or protrusions.

D. The package thermal performance may be enhanced by attaching an external heat sink to the thermal pad.

This pad is electrically and thermally connected to the backside of the die.

E. Falls within JEDEC MO-153

F. The PowerPAD

substrate which is the ground of the device. The exposed pad dimension is 1.4 mm x 1.8 mm. However, the tolerances can be

+1.05/−0.05 mm (+ 41 / −2 mils) due to position and mold flow variation.

G. For additional information on the PowerPADt package and how to take advantage of its heat dissipating abilities, refer to Technical

Brief, PowerPad Thermally Enhanced Package, Texas Instrument s Literature No. SLMA002 and Application Brief, PowerPad Made

Easy, Texas Instruments Literature No. SLMA004. Both documents are available at www.ti.com.

is not directly connected to any leads of the package. However, it is electrically and thermally connected to the

5,10

4,90

5,10

4,90

6,60

6,40

7,90

7,70

9,80

9,60

4073225/F 10/98

www.ti.com

27

Page 28

PACKAGE OPTION ADDENDUM

www.ti.com

16-May-2005

PACKAGING INFORMATION

Orderable Device Status

(1)

Package

Type

Package

Drawing

Pins Package

Qty

Eco Plan

UCC27223PWP ACTIVE HTSSOP PWP 14 90 Green (RoHS &

no Sb/Br)

UCC27223PWPG4 ACTIVE HTSSOP PWP 14 90 Green (RoHS &

no Sb/Br)

UCC27223PWPR ACTIVE HTSSOP PWP 14 2000 Green (RoHS &

no Sb/Br)

UCC27223PWPRG4 ACTIVE HTSSOP PWP 14 2000 Green (RoHS &

no Sb/Br)

(1)

The marketing status values are defined as follows:

ACTIVE: Product device recommended for new designs.

LIFEBUY: TI has announced that the device will be discontinued, and a lifetime-buy period is in effect.

NRND: Not recommended for new designs. Device is in production to support existing customers, but TI does not recommend using this part in

a new design.

PREVIEW: Device has been announced but is not in production. Samples may or may not be available.

OBSOLETE: TI has discontinued the production of the device.

(2)

Eco Plan - The planned eco-friendly classification: Pb-Free (RoHS) or Green (RoHS & no Sb/Br) - please check

http://www.ti.com/productcontent for the latest availability information and additional product content details.

TBD: The Pb-Free/Green conversion plan has not been defined.

Pb-Free (RoHS): TI's terms "Lead-Free" or "Pb-Free" mean semiconductor products that are compatible with the current RoHS requirements

for all 6 substances, including the requirement that lead not exceed 0.1% by weight in homogeneous materials. Where designed to be soldered

at high temperatures, TI Pb-Free products are suitable for use in specified lead-free processes.

Green (RoHS & no Sb/Br): TI defines "Green" to mean Pb-Free (RoHS compatible), and free of Bromine (Br) and Antimony (Sb) based flame

retardants (Br or Sb do not exceed 0.1% by weight in homogeneous material)

(2)

Lead/Ball Finish MSL Peak Temp

CU NIPDAU Level-2-260C-1 YEAR

CU NIPDAU Level-2-260C-1 YEAR

CU NIPDAU Level-2-260C-1 YEAR

CU NIPDAU Level-2-260C-1 YEAR

(3)

(3)

MSL, Peak Temp. -- The Moisture Sensitivity Level rating according to the JEDEC industry standard classifications, and peak solder

temperature.

Important Information and Disclaimer:The information provided on this page represents TI's knowledge and belief as of the date that it is

provided. TI bases its knowledge and belief on information provided by third parties, and makes no representation or warranty as to the

accuracy of such information. Efforts are underway to better integrate information from third parties. TI has taken and continues to take

reasonable steps to provide representative and accurate information but may not have conducted destructive testing or chemical analysis on

incoming materials and chemicals. TI and TI suppliers consider certain information to be proprietary, and thus CAS numbers and other limited

information may not be available for release.

In no event shall TI's liability arising out of such information exceed the total purchase price of the TI part(s) at issue in this document sold by TI

to Customer on an annual basis.

Addendum-Page 1

Page 29

Page 30

IMPORTANT NOTICE

Texas Instruments Incorporated and its subsidiaries (TI) reserve the right to make corrections, modifications,

enhancements, improvements, and other changes to its products and services at any time and to discontinue

any product or service without notice. Customers should obtain the latest relevant information before placing

orders and should verify that such information is current and complete. All products are sold subject to TI’s terms

and conditions of sale supplied at the time of order acknowledgment.

TI warrants performance of its hardware products to the specifications applicable at the time of sale in

accordance with TI’s standard warranty. Testing and other quality control techniques are used to the extent TI

deems necessary to support this warranty . Except where mandated by government requirements, testing of all

parameters of each product is not necessarily performed.

TI assumes no liability for applications assistance or customer product design. Customers are responsible for

their products and applications using TI components. To minimize the risks associated with customer products

and applications, customers should provide adequate design and operating safeguards.

TI does not warrant or represent that any license, either express or implied, is granted under any TI patent right,

copyright, mask work right, or other TI intellectual property right relating to any combination, machine, or process

in which TI products or services are used. Information published by TI regarding third-party products or services

does not constitute a license from TI to use such products or services or a warranty or endorsement thereof.

Use of such information may require a license from a third party under the patents or other intellectual property

of the third party, or a license from TI under the patents or other intellectual property of TI.

Reproduction of information in TI data books or data sheets is permissible only if reproduction is without

alteration and is accompanied by all associated warranties, conditions, limitations, and notices. Reproduction

of this information with alteration is an unfair and deceptive business practice. TI is not responsible or liable for

such altered documentation.

Resale of TI products or services with statements different from or beyond the parameters stated by TI for that

product or service voids all express and any implied warranties for the associated TI product or service and

is an unfair and deceptive business practice. TI is not responsible or liable for any such statements.

Following are URLs where you can obtain information on other Texas Instruments products and application

solutions:

Products Applications

Amplifiers amplifier.ti.com Audio www.ti.com/audio

Data Converters dataconverter.ti.com Automotive www.ti.com/automotive

DSP dsp.ti.com Broadband www.ti.com/broadband

Interface interface.ti.com Digital Control www.ti.com/digitalcontrol

Logic logic.ti.com Military www.ti.com/military

Power Mgmt power.ti.com Optical Networking www.ti.com/opticalnetwork

Microcontrollers microcontroller.ti.com Security www.ti.com/security

Telephony www.ti.com/telephony

Video & Imaging www.ti.com/video

Wireless www.ti.com/wireless

Mailing Address: Texas Instruments

Post Office Box 655303 Dallas, Texas 75265

Copyright 2005, Texas Instruments Incorporated

Loading...

Loading...