Datasheet UC3914N, UC3914DWTR, UC3914DW, UC2914DWTR, UC2914J Datasheet (Texas Instruments)

...

UC1914

UC2914

UC3914

SLUS425A - AUGUST 1999

FEATURES

•

5V to 35V Operation

•

Precision Maximum Current Control

•

Precision Fault Threshold

•

Programmable Average Power

Limiting

•

Programmable Overcurrent Limit

•

Shutdown Control

•

Charge Pump for Low R

DS(on)

High-Side Drive

•

Latch Reset Function Available

•

Output Drive V

GS

Clamping

•

Fault Output Indication

• 18 Pin DIL and SOIC Packages

5V to 35V Hot Swap Power Manager

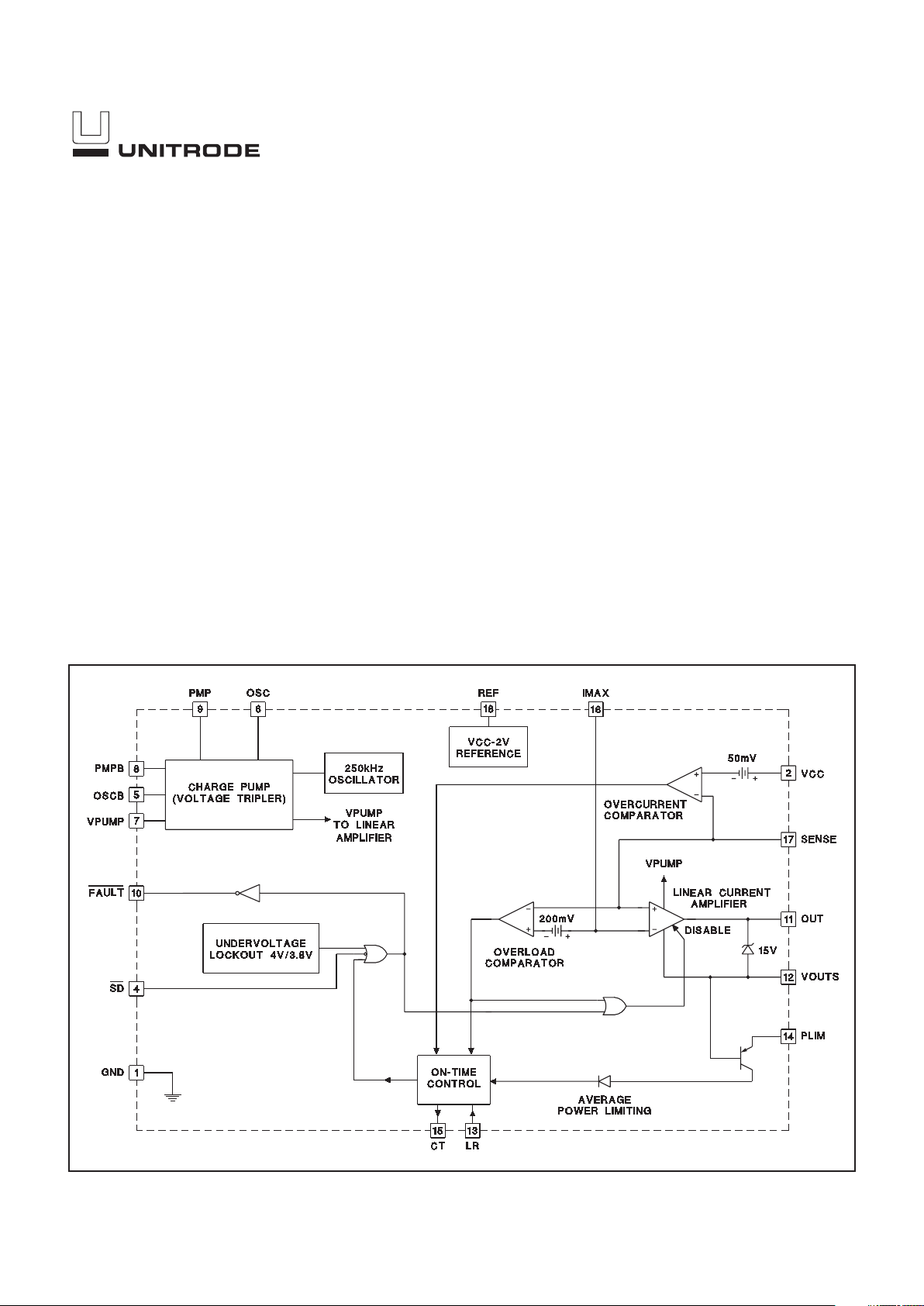

BLOCK DIAGRAM

UDG-95134-2

DESCRIPTION

The UC3914 family of Hot Swap Power Managers provides complete

power management, hot swap and fault handling capability. Integrating this

part and a few external components, allows a board to be swapped in or

out upon failure or system modification without removing power to the hard

-

ware, while maintaining the integrity of the powered system. Complemen

tary output drivers and diodes have been integrated for use with external

capacitors as a charge pump to ensure sufficient gate drive to the external

NMOS transistor for low R

DS(on)

. All control and housekeeping functions

are integrated and externally programmable and include the fault current

level, maximum output sourcing current, maximum fault time and average

power limiting of the external FET. The UC3914 features a duty ratio cur

rent limiting technique, which provides peak load capability while limiting

the average power dissipation of the external pass transistor during fault

conditions. The fault level is fixed at 50mV with respect to VCC to minimize

total dropout. The fault current level is set with an external current sense re

sistor. The maximum allowable sourcing current is programmed by using a

resistor divider from VCC to REF to set the voltage on IMAX. The maximum

current level, when the output appears as a current source is

(VCC – V

IMAX

)/R

SENSE

.

(continued)

2

UC1914

UC2914

UC3914

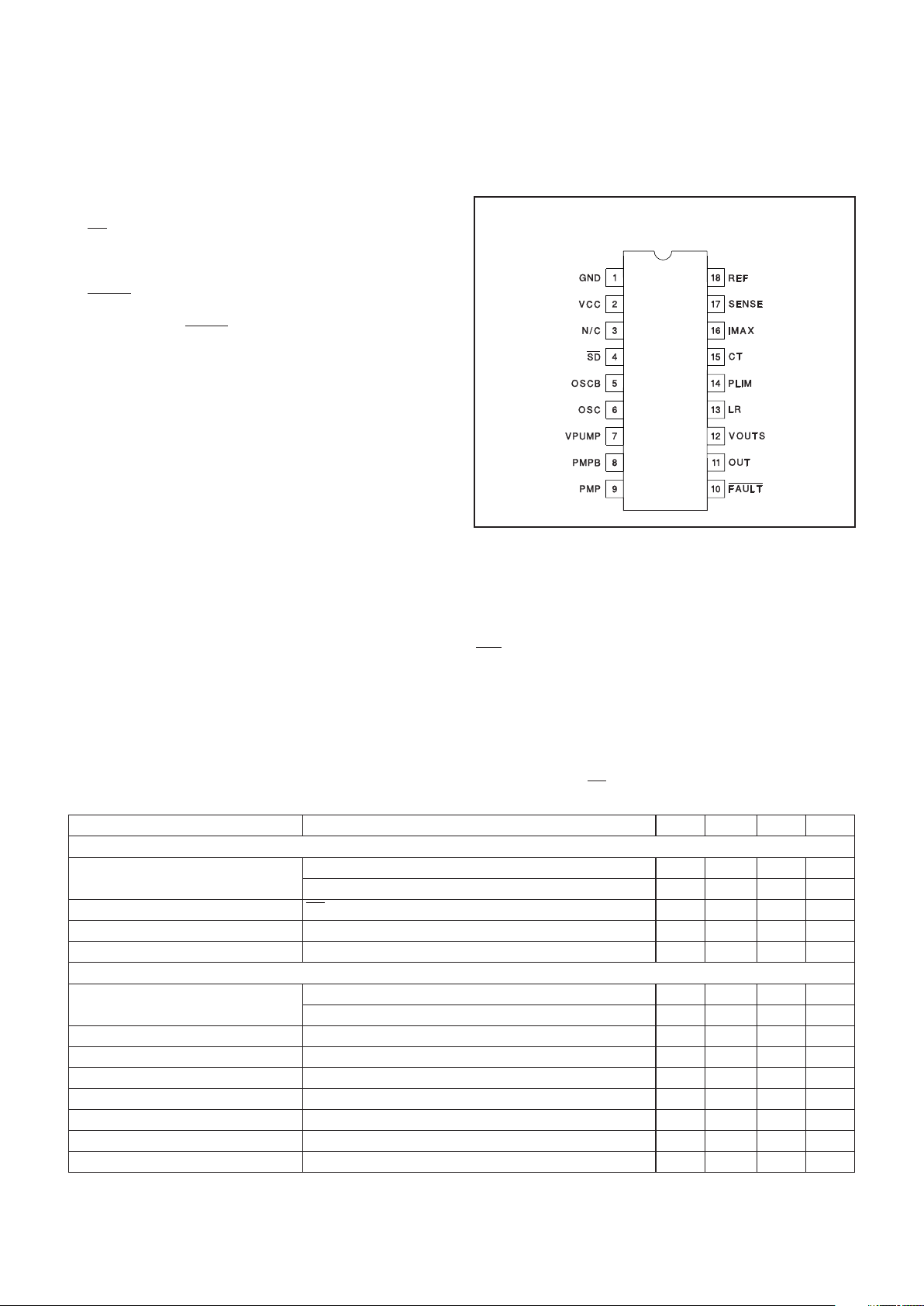

CONNECTION DIAGRAM

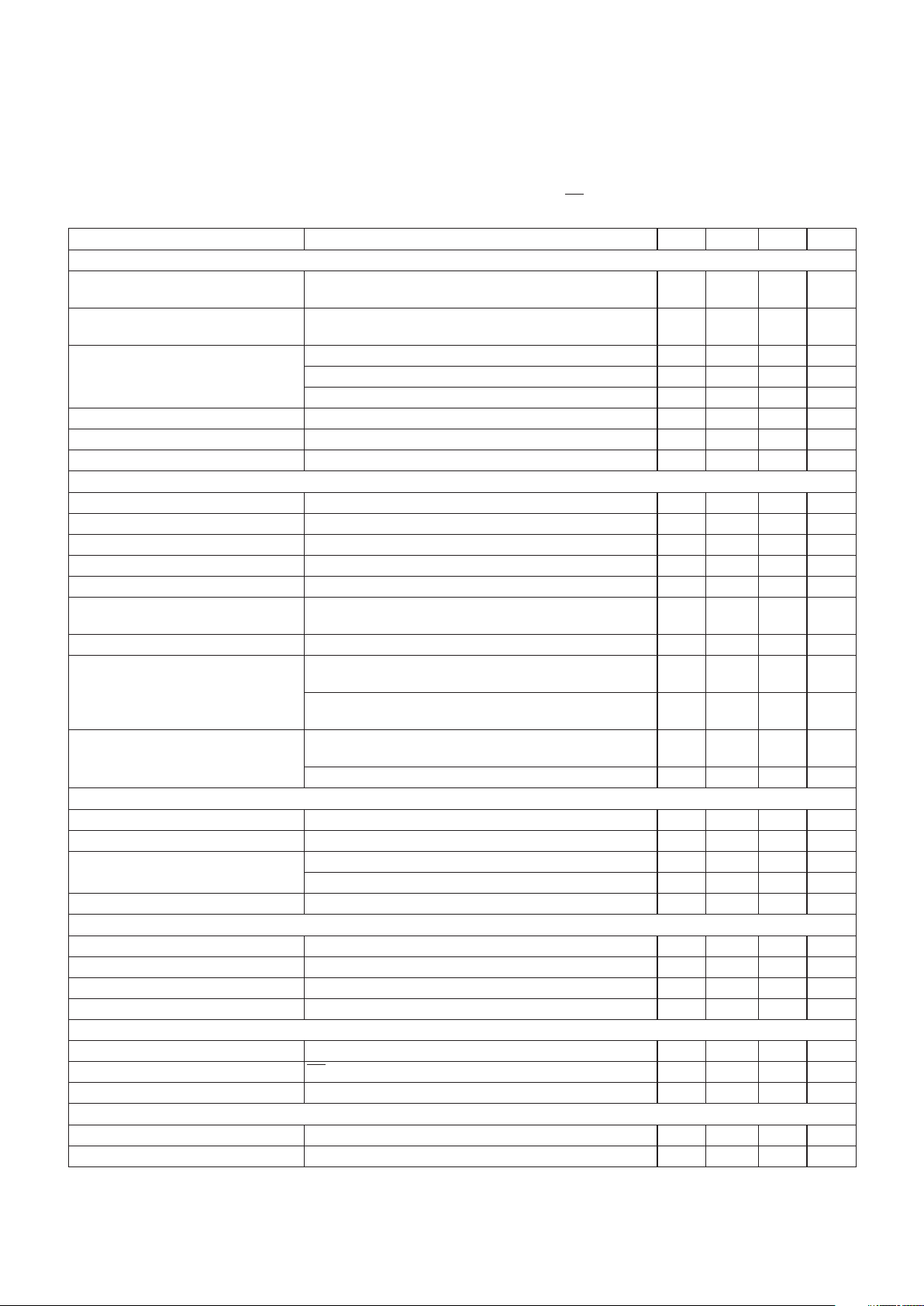

ELECTRICAL CHARACTERISTICS:

Unless otherwise specified, TA= 0°C to 70°C for the UC3914, –40°C to 85°C for

the UC2914, and –55°C to 125°C for the UC1914. VCC = 12V, V

PUMP=VPUMP

(max), SD = 5V, CP1 = CP2 = C

PUMP

= 0.01µF.

T

A=TJ

.

PARAMETER TEST CONDITIONS MIN TYP MAX UNITS

VCC Section

I

CC

(Note 2) 8 15 mA

VCC = 35V, (Note 2) 12 20 mA

Shutdown I

CC

SD = 0V 500 900 µA

UVLO Turn on threshold 4.0 4.4 V

UVLO Hysteresis 100 200 350 mV

Fault Timing Section

Overcurrent Threshold T

J

= 25°C, with respect to VCC –55 –50 –45 mV

Over operating temperature, with respect to VCC –57 –50 –42 mV

IMAX Input Bias 13µA

CT Charge Current CT = 1V –140 –100 –60 µA

CT Discharge Current CT = 1V 2.0 3.0 4.5 µA

CT Charge Current CT = 1V, Overload condition –6.0 –3.0 –1.5 mA

CT Fault Threshold 2.25 2.50 2.75 V

CT Reset Threshold 0.45 0.50 0.55 V

Output Duty Cycle Fault condition, I

PL

= 0 1.5 3.0 4.5 %

Input Supply Voltage, VCC . . . . . . . . . . . . . . . . . . . . . . . . . 40V

Maximum Forced Voltage

SD

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12V

IMAX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . VCC

LR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12V

Maximum Current

FAULT

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20mA

PLIM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10mA

Maximum Voltage, FAULT

. . . . . . . . . . . . . . . . . . . . . . . . . 40V

Reference Output Current . . . . . . . . . . . . . . . Internally Limited

Storage Temperature . . . . . . . . . . . . . . . . . . . –65°C to +150°C

Junction Temperature. . . . . . . . . . . . . . . . . . . –55°C to +150°C

Lead Temperature (Soldering, 10 sec.) . . . . . . . . . . . . . +300°C

Unless otherwise indicated, voltages are referenced to ground.

Currents are positive into, negative out of specified terminal.

Consult Packaging Section of Databook for thermal limitations

and considerations of package.

ABSOLUTE MAXIMUM RATINGS

When the output current is less than the fault level, the

external output transistor remains switched on. When the

output current exceeds the fault level, but is less than the

maximum sourcing level programmed by IMAX, the output remains switched on, and the fault timer starts to

charge C

T

, a timing capacitor. Once CTcharges to 2.5V,

the output device is turned off and C

T

is slowly dis-

charged. Once C

T

is discharged to 0.5V, the IC performs

a retry and the output transistor is switched on again.

The UC3914 offers two distinct reset modes. In one

mode with LR left floating or held low, the IC will repeatedly try to reset itself if a fault occurs as described

above. In the second mode with LR held high, once a

fault occurs, the output is latched off until either LR is

toggled low, the part is shutdown then re-enabled using

SD,

or the power to the part is turned off and then on

again.

This part is offered in both 18 pin DW Wide-Body (SOIC)

and Dual-In-Line (DIL) packages.

DESCRIPTION (cont.)

DIL-18, SOIC-18 (Top View)

N or J Package, DW Package

3

UC1914

UC2914

UC3914

ELECTRICAL CHARACTERISTICS:

Unless otherwise specified, TA= 0°C to 70°C for the UC3914, –40°C to 85°C for the

UC2914, and –55°C to 125°C for the UC1914. VCC = 12V, V

PUMP=VPUMP

(max), SD = 5V, CP1 = CP2 = C

PUMP

= 0.01µF.

T

A=TJ

.

PARAMETER TEST CONDITIONS MIN TYP MAX UNITS

Output Section

OUT High Voltage VOUTS = VCC, VPUMP = VPUMP max, with respect to

VPUMP

–1.5 –1.0 V

OUT High Voltage VOUTS = VCC, VPUMP = VPUMP max, IOUT = –2mA,

with respect to VPUMP

–2.0 –1.5 V

OUT Low Voltage I

OUT

= 0 0.8 1.3 V

I

OUT

= 5mA 1 2 V

I

OUT

= 25mA, Overload Condition, VOUTS = 0V 1.2 1.8 V

OUT Clamp Voltage VOUTS = 0V 11.5 13.0 14.5 V

Rise Time C

OUT

= 1nF (Note 1) 750 1250 ns

Fall Time C

OUT

= 1nF (Note 1) 250 500 ns

Charge Pump Section

OSC, OSCB Frequency 60 150 250 kHz

OSC, OSCB Output High I

OSC

= –5mA 10.0 11.0 11.6 V

OSC, OSCB Output Low I

OSC

= 5mA 0.2 0.5 V

OSC, OSCB Output Clamp Voltage VCC = 25 18.5 20.5 22.5 V

OSC, OSCB Output Current Limit High Side Only –20 –10 –3 mA

Pump Diode Voltage Drop I

DIODE

= 10mA, Measured from PMP to PMPB, PMPB to

VPUMP

0.5 0.9 1.3 V

PMP Clamp Voltage VCC = 25 18.5 20.5 22.5 V

VPUMP Maximum Voltage VCC = 12, VOUTS = VCC, Voltage Where Charge Pump

Disabled

20 22 24 V

VCC = 35V, VOUTS = VCC, Voltage Where Charge

Pump Disabled

42 45 48 V

VPUMP Hysteresis VCC = 12, VOUTS = VCC, Voltage Where Charge Pump

Re-enabled

0.3 0.7 1.4 V

VCC = 35V, VOUTS = VCC, Charge Pump Re-enabled 0.25 0.7 1.4 V

Linear Current Section

Input Offset Voltage –15 0 15 mV

Voltage Gain 60 80 dB

IMAX Control Voltage IMAX = OUT, SENSE = VCC, with respect to VCC –20 0 20 mV

IMAX = OUT, SENSE = REF, with respect to REF –20 0 20 mV

SENSE Input Bias 1.5 3.5 µA

Reference Section

REF Output Voltage With respect to VCC –2.25 –2.00 –1.75 V

REF Current Limit 12.5 20.0 50.0 mA

Load Regulation I

VREF

= 1mA to 5mA 25 60 mV

Line Regulation VCC = 5V to 35V 25 100 mV

Shutdown Section

Shutdown Threshold 0.6 1.5 2.0 V

Input Current SD

= 5V 150 300 µA

Delay to Output (Note 1) 0.5 2.0 µs

Fault Section

Fault Output Low I

FAULT

= 1mA 100 200 mV

Fault Output Leakage V

FAULT

= 35V 10 500 nA

4

UC1914

UC2914

UC3914

PIN DESCRIPTIONS

CT: A capacitor is connected to this pin in order to set

the maximum fault time. The minimum fault time must be

more than the time to charge external load capacitance.

The fault time is defined as:

T

CT

I

FAULT

CH

=

•2

where I

CH

= 100µA+IPL, where IPLis the current into the

power limit pin. Once the fault time is reached the output

will shutdown for a time given by:

T

CT

I

SD

DIS

=

•2

where I

DIS

is nominally 3µA.

FAULT:

Open collector output which pulls low upon any

of the following conditions: Timer fault, Shutdown, UVLO.

This pin MUST be pulled up to VCC or another supply

through a suitable impedance.

GND: Ground reference for the IC.

IMAX: This pin programs the maximum allowable

sourcing current. Since REF is a –2V reference (with re

spect to VCC), a voltage divider can be derived from

VCC to REF in order to generate the program level for

the IMAX pin. The current level at which the output ap

pears as a current source is equal to the voltage on the

IMAX pin, with respect to VCC, divided by the current

sense resistor. If desired, a controlled current startup can

be programmed with a capacitor on IMAX to VCC.

LR: If this pin is held high and a fault occurs, the timer

will be prevented from resetting the fault latch when CT is

discharged below the reset comparator threshold. The

part will not retry until this pin is brought to a logic low or

a power-on-reset occurs. Pulling this pin low before the

reset time is reached will not clear the fault until the reset

time is reached. Floating or holding this pin low will result

in the part repeatedly trying to reset itself if a fault occurs.

OUT: Output drive to the MOSFET pass element. Internal clamping ensures that the maximum V

GS drive is

15V.

OSC, OSCB: Complementary output drivers for intermediate charge pump stages. A 0.01µF capacitor should be

placed between OSC and PMP, and OSCB and PMPB.

PLIM: This feature ensures that the average MOSFET

power dissipation is controlled. A resistor is connected

from this pin to VCC. Current will flow into PLIM which

adds to the fault timer charge current, reducing the duty

cycle from the typical 3% level. When I

PL >> 100µA then

the average MOSFET power dissipation is given by:

P

FET_AVG = IMAX • 3 • 10

–6

•RPL.

PMP, PMPB: Complementary pins which couple charge

pump capacitors to internal diodes and are used to pro

-

vide charge to the reservoir capacitor tied to VPUMP.

Typical capacitor values used are 0.01µF.

REF: –2V reference with respect to VCC used to pro

-

gram the IMAX pin voltage. A 0.1µF ceramic or tantalum

capacitor MUST be tied between this pin and VCC to en

-

sure proper operation of the chip.

SD:

When this TTL compatible input is brought to a logic

low, the output of the linear amplifier is driven low,

FAULT

is pulled low and the IC is put into a low power

mode. The ABSOLUTE maximum voltage that can be

placed on this pin is 12V.

ELECTRICAL CHARACTERISTICS: Unless otherwise specified, T

A

= 0°C to 70°C for the UC3914, –40°C to 85°C for the

UC2914, and –55°C to 125°C for the UC1914. VCC = 12V, V

PUMP=VPUMP

(max), SD = 5V, CP1 = CP2 = C

PUMP

= 0.01µF.

T

A=TJ

.

PARAMETER TEST CONDITIONS MIN TYP MAX UNITS

Latch Section

LR Threshold High to Low 0.6 1.4 2.0 V

Input Current LR = 5V 500 750 µA

Power Limiting Section

Duty Cycle Control In Fault, I

PLIM

= 200µA 0.6 1.3 2.0 %

In Fault, I

PLIM

= 3mA 0.05 0.12 0.20 %

Overload Section

Delay to Output (Note 1) 500 1250 ns

Threshold Respect to IMAX –250 –200 –150 mV

Note 1: Guaranteed by design. Not 100% tested in production.

Note 2: A mathematical averaging is used to determine this value. See Application Section for more information.

5

UC1914

UC2914

UC3914

SENSE: Input voltage from current sense resistor. When

there is greater than 50mV across this pin with respect to

VCC, a fault is sensed and C

T

begins to charge.

VCC: Input voltage to the IC. Typical voltages are 4.5V to

35V. The minimum input voltage required for operation is

4.5V.

VOUTS: Source connection of external N-channel MOS

-

FET and sensed output voltage of load.

VPUMP: Charge pump output voltage. A capacitor

should be tied between this pin and VOUTS with a typi

-

cal value being 0.01µF.

PIN DESCRIPTIONS (cont.)

0

0.5

1

1.5

2

2.5

3

3.5

-55 -40 0 25 70 85 125

TEMPERATURE (°C)

V

IO

(mV)

Linear Amp VIOvs. Temperature

-52

-51.5

-51

-50.5

-50

-49.5

-49

-48.5

-48

-55 -40 0 25 70 85 125

TEMPERATURE (°C)

FAULT THRESHOLD (mV)

Fault Threshold vs. Temperature

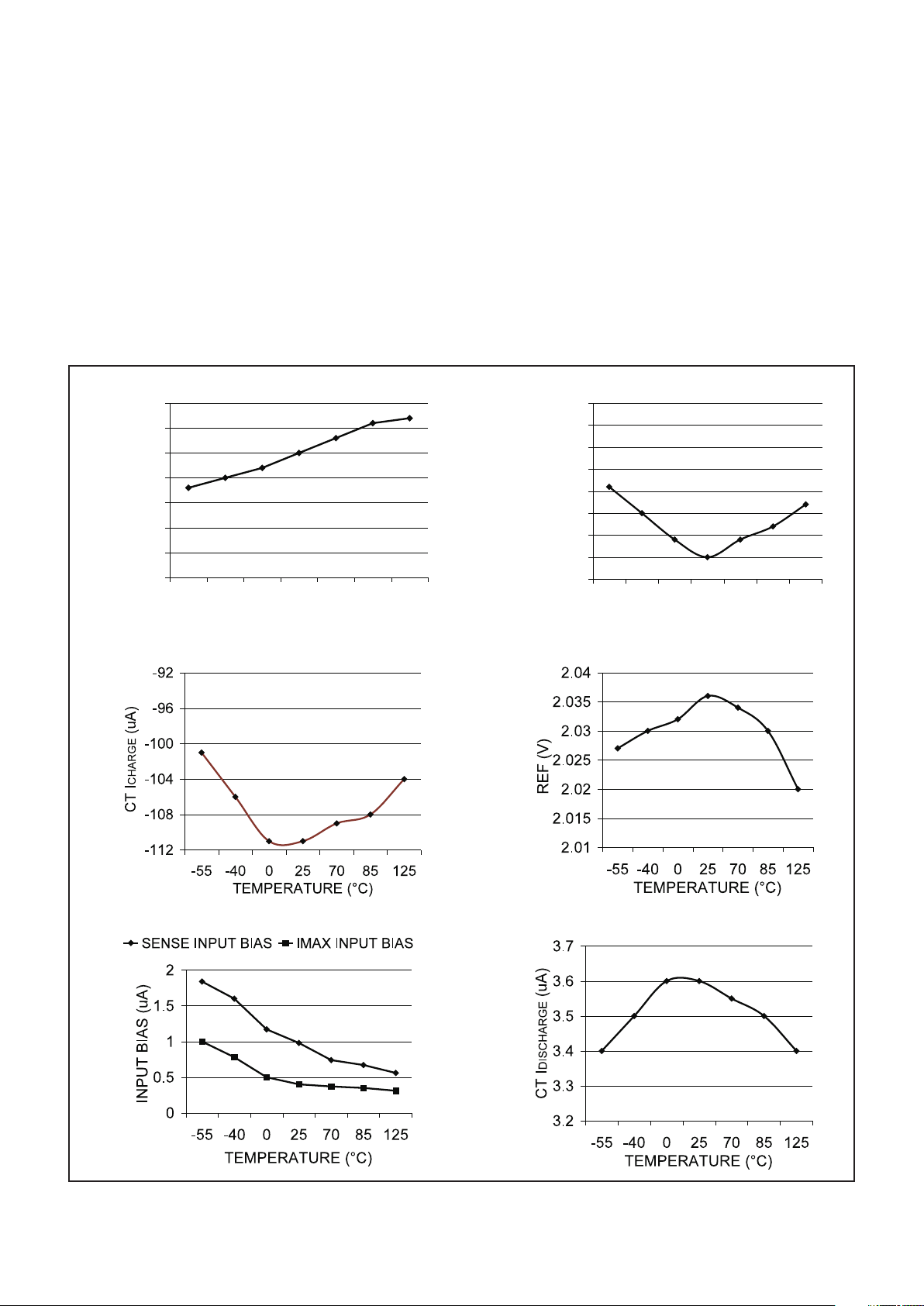

CT I

CHARGE

vs. Temperature VCC - REF vs Temperature

I

MAX

& SENSE Input Bias vs. Temperature

CT I

DISCHARGE

vs. Temperature

Figure 1. Typical characteristic curves.

TYPICAL CHARACTERISTIC CURVES

6

UC1914

UC2914

UC3914

Figure 2. Fault timing circuitry for the UC3914, including power limit and overcurrent.

UDG-97052

The UC3914 is to be used in conjunction with external

passive components and an N-channel MOSFET

(NMOS) to facilitate hot swap capability of application

modules. A typical application set-up is given in Fig. 9.

The term hot swap refers to the system requirement that

submodules be swapped in or out upon failure or system

modification without removing power to the operating

hardware. The integrity of the power bus must not be

compromised due to the addition of an unpowered mod

ule. Significant power bus glitches can occur due to the

substantial initial charging current of on-board module

bypass capacitance and other load conditions (for more

information on hot swapping and power management ap

plications, see Application Note U-151). The UC3914

provides protection by monitoring and controlling the out

put current of an external NMOS to charge this capaci

tance and provide load current. The addition of the

NMOS, a sense resistor, R

SENSE,

and two other resis

tors, R1 and R2, sets the programmed maximum current

level the NMOS can source to charge the load in a controlled manner. The equation for this current, I

MAX

, is:

I

VV

R

MAX

CC IMAX

SENSE

=

−

where V

IMAX

is the voltage generated at the IMAX pin.

Analysis of the application circuit shows that V

IMAX

(with

respect to GND) can be defined as:

()

VV

VV R

RR

VR

RR

V

IMAX REF

CC REF

REF

=+

−•

+

=

•

+

+

1

12

21

12

where V

REF

is the voltage on the REF pin and whose in

ternally generated potential is two volts below VCC. The

UC3914 also has an internal overcurrent comparator

which monitors the voltage between SENSE and VCC. If

this voltage exceeds 50mV, the comparator determines

that a fault has occurred, and a timing capacitor, C

T,

will

begin to charge. This can be rewritten as a current which

causes a fault, I

FAULT

:

I

mV

R

FAULT

SENSE

=

50

Fault Timing

Fig. 2 shows the circuitry associated with the fault timing

function of the UC3914. A typical fault mode, where the

overload comparator and current source I3 do not factor

into operation (switch S2 is open), will first be considered. Once the voltage across R

SENSE

exceeds 50mV, a

fault has occurred. This causes the timing capacitor, C

T

,

to charge with a combination of 100µA (I1) plus the current from the power limiting circuitry (I

PL

).

APPLICATION INFORMATION

7

UC1914

UC2914

UC3914

Figure 3a: Typical timing diagram.

UDG-97054

t0: Normal conditions - output current is nominal, output

voltage is at positive rail, VCC

t1: Fault control reached - output current rises above the

programmed fault value, C

T

begins to charge with ≅

100µA + I

PL

.

t2: Maximum current reached - output current reaches

the programmed maximum level and becomes a con

-

stant current with value IMAX.

t3: Fault occurs - C

T

has charged to 2.5V, fault output

goes low, the FET turns off allowing no output current

to flow, VOUT discharge to GND.

t4: Retry - C

T

has discharged to 0.5V, but fault current

is still exceeded, C

T

begins charging again, FET is on,

VOUT increases.

t5 = t3: Illustrates <3% duty cycle depending upon

R

PL

selected.

t6 = t4

t7 = t0: Fault released, normal condition - return to

normal operation of the hot swap power manager.

Fig. 3a shows typical fault timing waveforms for the ex

ternal NMOS output current, the voltage on the CT pin,

and the output load voltage, V

OUT

, with LR left floating or

grounded. The output voltage waveforms have assumed

an RC characteristic load and time constants will vary de

-

pending upon the component values. Prior to time t

0, the

load is fully charged to almost VCC and the NMOS is

supplying the current, I

O

, to the load. At t0, the current

begins to ramp up due to a change in the load conditions

until, at t

1, the fault current level, I

FAULT,

has been

reached to cause switch S1 to close. This results in C

T

being charged with the current sources I1 and IPL. Dur

-

ing this time, V

OUT

is still almost equal to VCC except for

small losses from voltage drops across the sense resis

-

tor and the NMOS. The output current reaches the pro

-

grammed maximum level, I

MAX,

at t2. The CTvoltage

continues to rise since I

MAX

is still greater than I

FAULT

.

The load output voltage drops because the current load

requirements have become greater than the controlled

maximum sourcing current. The C

T

voltage reaches the

upper comparator threshold (Fig. 2) of 2.5V at t

3, which

promptly shuts off the gate drive to the NMOS (not

APPLICATION INFORMATION (cont.)

8

UC1914

UC2914

UC3914

shown but can be inferred from the fact that no output

current is provided to the load), latches in the fault and

opens switch S1 disconnecting the charging currents I1

and I

PL

from CT. Since no output current is supplied, the

load voltage decays at a rate determined by the load

characteristics and the capacitance. The 3µA current

source, I2, discharges CT to the 0.5V reset comparator

threshold. This time is significantly longer than the charg

ing time and is the basis for the duty cycle current limiting

technique. When the C

T

voltage reaches 0.5V at t4, the

part performs a retry, allowing the NMOS to again source

current to the load and cause V

OUT to rise. In this partic

-

ular example, I

MAX

is still sourced by the NMOS at each

attempted retry and the fault timing sequence is repeated

until time t7 when the load requirements change to I

O.

Since IOis less than the fault current level at this time,

switch S1 is opened, I2 discharges C

T

and V

OUT

rises to

almost VCC.

Fig. 3b shows fault timing waveforms similar to those depicted in Fig. 3a except that the latch reset (LR) function

is utilized. Operation is the same as described above until t4 when the voltage on C

T

reaches the reset threshold.

Holding LR high prevents the latch from being reset, preventing the IC from performing a retry (sourcing current

to the load). The UC3914 is latched off until either LR is

pulled to a logic low, or the chip is forced into an under

voltage lockout (UVLO) condition and back out of UVLO

causing the latch to automatically perform a power on reset. Fig. 3b illustrates LR being toggled low at t5, causing

the part to perform a retry. Time t

6 again illustrates what

happens when a fault is detected. The LR pin is toggled

low and back high at time t7, prior to the voltage on the

CT pin hitting the reset threshold. This information tells

the UC3914 to allow the part to perform a retry when the

lower reset threshold is reached, which occurs at t8.

Time t9 corresponds to when load conditions change to

where a fault is not present as described for Fig. 3a.

Power Limiting

The power limiting circuitry is designed to only source

current into the CT pin. To implement this feature, a re

-

sistor, R

PL

, should be placed between VCC and PLIM.

The current, I

PL

(show in Fig. 2) is given by the following

expression:

I

VV

R

for V V V

PL

CC OUTS

PL

OUTS CT

=

−

>+,1

where V

CT

is the voltage on the CT pin. For V

OUTS

<1V

+V

CT

the common mode range of the power limiting cir

-

cuitry causes I

PL

= 0 leaving only the 100µA current

source to charge C

T.VCC–VOUTS

represents the volt

-

age across the NMOS pass device.

Later it will be shown how this feature will limit average

power dissipation in the pass device. Note that under a

fault condition where the output current is just above the

fault level, but less than the maximum level, V

OUTS

~

VCC, I

PL

= 0 and the CTcharging current is 100µA.

During a fault, the CT pin will charge at a rate deter

mined by the internal charging current and the external

timing capacitor, C

T.

Once CTcharges to 2.5V, the fault

comparator trips and sets the fault latch. When this oc

curs, OUT is pulled down to VOUTS, causing the exter

nal NMOS to shut off and the charging switch, S1, to

open. C

T

will be discharged with I2 until the CTpotential

reaches 0.5V. Once this occurs, the fault latch will reset

(unless LR is being held high, whereby a fault can only

be cleared by pulling this pin low or going through a

power-on-reset cycle), which re-enables the output of the

linear amplifier and allows the fault circuitry to regain

control of the charging switch. If a fault is still present,

the overcurrent comparator will close the charging switch

causing the cycle to repeat. Under a constant fault the

duty cycle is given by:

Duty Cycle

A

IA

PL

=

+3100µµ

Average power dissipation can be limited using the PLIM

pin. Average power dissipation in the pass element is

given by:

()

()

PFETavg VCC V I Duty Cycle

VCC V I

OUTS MAX

OUTS MAX

=− ••

=− ••

3 µ

A

IA

PL

+ 100 µ

VCC – VOUTS is the drain to source voltage across the

FET. When IPL >> 100µA, the duty cycle equation given

above can be rewritten as:

()

Duty Cycle

RPL A

VCC VOUTS

=

•−3µ

and the average power dissipation of the MOSFET is

given by:

()

()

PFETavg

VCC VOUTS IMAX

RPL A

VCC VOUTS

IMAX RPL

=− ••

•

−

=••

33µ

µ

A

The average power is limited by the programmed IMAX

current and the appropriate value for R

PL

.

APPLICATION INFORMATION (cont.)

9

UC1914

UC2914

UC3914

Figure 3b. Typical timing diagram utilizing LR (Latch Reset) function.

APPLICATION INFORMATION (cont.)

t0: Normal conditions - output current is nominal, output

voltage is at positive rail, VCC

t1: Fault control reached - output current rises above the

programmed fault value, C

T begins to charge with ≅

100µA + I

PL.

t2: Maximum current reached - output current reaches

the programmed maximum level and becomes a con

-

stant current with value IMAX.

t3: Fault occurs - C

T has charged to 2.5V, fault output

goes low, the FET turns off allowing no output current to

flow, VOUT discharge to GND.

t4: Reset comparator threshold reached but no retry

since LR pin held high.

t5: LR toggled low, NMOS turned on and sources cur

-

rent to load.

t6 = t3

t7: LR toggled low before V

CT reaches reset compara

-

tor threshold, causing retry.

t8: Since LR toggled low during present cycle, NMOS

turned on and sources current to load.

t9 = t0: Fault released, normal condition - return to

normal operation of the hot swap power manager.

UDG-97055

10

UC1914

UC2914

UC3914

Overload Comparator

The linear amplifier in the UC3914 ensures that the ex

ternal NMOS does not source more than the current

I

MAX, defined above as:

I

VCC V

R

MAX

IMAX

SENSE

=

−

In the event that output current exceeds the programmed

I

MAX

by more than 200mV/R

SENSE,

the output of the lin

ear amplifier will immediately be pulled low (with respect

to VOUTS) providing no gate drive to the NMOS, and

preventing current from being delivered to the load. This

situation could occur if the external NMOS is not re

sponding to a command from the IC or output load condi

tions change quickly to cause an overload condition

before the linear amplifier can respond. For example, if

the NMOS is sourcing current into a load and the load

suddenly becomes short circuited, an overload condition

may occur. The short circuit will cause the V

GS

of the

NMOS to immediately increase, resulting in increased

load current and voltage drop across R

SENSE.

If this drop

exceeds the overload comparator threshold, the amplifier

output will be quickly pulled low. It will also cause the CT

pin to begin charging with I3, a 3mA current source (refer

to Fig. 2) and continue to charge until approximately one

volt below VCC, where it is clamped. This allows a constant fault to show up on FAULT

and since the voltage on

CT will only charge past 2.5V in an overload fault condition, it can be used for detection of output NMOS failure

or to build redundancy into the system.

Estimating Minimum Timing Capacitance

The startup time of the IC may not exceed the fault time

for the application. Since the timing capacitor, C

T

, deter

-

mines the fault time, its minimum value can be deter

mined by calculating the startup time of the IC. The

startup time is dependent upon several external compo

nents. A load capacitor, C

LOAD

, should be tied between

VOUTS and GND. Its value should be greater than that

of C

PUMP,

the reservoir capacitor tied from V

PUMP

to

V

OUTS

(see Fig. 4). Given values of C

LOAD,

Load,

R

SENSE

, VCC and the resistors determining the voltage

on I

MAX

, the user can calculate the approximate startup

time of the node V

OUT.

This time must be less than the

time it takes for C

T

to charge to 2.5V. Assuming the user

has determined the fault current, R

SENSE

can be calcu

-

lated by:

R

mV

I

SENSE

FAULT

=

50

I

MAX

is the maximum current the UC3914 will allow

through the transistor M1. During startup with an output

capacitor, M1 can be modeled as a constant current

source of value I

MAX

where:

I

VCC V

R

MAX

IMAX

SENSE

=

−

Given this information, calculation of startup time is now

possible via the following:

Current Source Load:

T

CVCC

II

START

LOAD

MAX LOAD

=

•

–

Resistive Load:

TRCn

VCC

IR

START LOAD LOAD

MAX LOAD

=− • • −

•

l 1

The only remaining external component which may af

fect the minimum timing capacitor is the optional power

limiting resistor, R

PL

. If the addition of RPLis desirable,

its value can be determined from the “Fault Timing” section above. The minimum timing capacitor values are

now given by

Current Source Load:

CT T

R

VCC

R

START

PL

PL

min =•

•+

•

−

10

2

2

4

APPLICATION INFORMATION (cont.)

Figure 4. Estimating minimum timing capacitor.

UDG-97056

11

UC1914

UC2914

Resistive Load:

()

()

CT

RV I R T

R

V

R

PL CC MAX LOAD START

PL

CC

PL

min =

•+− • •

•

+•

−

10

2

2

4

RC

LOAD LOAD

•

Output Current Softstart

The external MOSFET output current can be increased

at a user-defined rate to ensure that the output voltage

comes up in a controlled fashion by adding capacitor

C

SS

, as shown in Fig. 5. The chip does place one con

straint on the soft start time and that is that the charge

pump time constant has to be much less than the

softstart time constant to ensure proper soft start opera

tion. The time constant determining the startup time of

the charge pump is given by:

τ

CP OUT PUMP

RC

=•

R

OUT

is the output impedance of the charge pump given

by:

R

fCP

OUT

PUMP

=

•

1

where f

PUMP

is the charge pump frequency (125kHz) and

CP = CP1 = CP2 are the charge pump flying capacitors.

For typical values of CP1, CP2 and C

PUMP

(0.01µF) and

a switching frequency of 125kHz, the output impedance

is 800Ω and the charge pump time constant is 8µs. The

charge pump should be close to being fully charged in 3

time constants or 24µs. By placing a capacitor from VCC

to IMAX, the voltage at IMAX, which sets the maximum

output current of the FET, will exponentially decay from

VCC to the desired value set by R1 and R2. The output

current of the MOSFET will be controlled via soft start as

long as the soft start time constant (τ

SS

) is much greater

than the charge pump time constant τ

CP

, given by

()

τ

SS SS

RR C

=•12

Minimizing Total Dropout Under Low Voltage

Operation

In a typical application, the UC3914 will be used to con

trol the output current of an external NMOS during hot

swapping situations. Once the load has been fully

charged, the desired output voltage on the load, V

OUT

,

will be required to be as close to VCC as possible to

minimize total dropout. For a resistive load, R

LOAD,

the

output voltage is given by:

V

R

RR R

VCC

OUT

LOAD

LOAD SENSE DS on

=

++

•

()

R

SENSE

was picked to set the fault current, I

FAULT

.

R

DS(on)

, the on-resistance of the NMOS, should be made

as small as possible to ensure V

OUT

is as close to VCC

as possible. For a given NMOS, the manufacturer will

specify the R

DS(on)

for a certain VGS(maybe 7V to 10V).

The source potential of the NMOS is V

OUT.

In order to

ensure sufficient VGS, this requires the gate of the

NMOS, which is the output of the linear amplifier, to be

many volts higher than VCC. The UC3914 provides the

capability to generate this voltage through the addition of

3 capacitors, CP1, CP2 and C

PUMP

as shown in Fig. 6.

These capacitors should be used in conjunction with the

complementary output drivers and internal diodes in

cluded on-chip to create a charge pump or voltage

tripler. The circuit boosts VCC by utilizing capacitors

CP1, CP2 and C

PUMP

in such a way that the voltage at

V

PUMP

approximately equals (3 • VCC)–(5•V

DIODE

), al

most tripling the input supply voltage to the chip.

APPLICATION INFORMATION (cont.)

6 11

129

8

7

C

PUMP

L

O

A

D

C

LOAD

V

OUT

M1

2

OUT

VOUTS

VPUMP

VCC

R2

18 16

C

SS

R1

C1

IMAXREF

OSC

PMP

5

OSCB

PMPB

CP2

CP1

Figure 5. MOSFET soft start diagram.

UDG-98160

Figure 6. Charge pump block diagram.

UDG-97058

12

UC1914

On each complete cycle, CP1 is charged to approxi

-

mately V

CC

–V

DIODE

(unless VCCis greater than 15V

causing internal clamping to limit this charging voltage to

about 13V) when the output Q of the toggle flip flop is

low. When Q

is transitioned low (and Q correspondingly

is brought high), the negative side of CP2 is pulled to

ground, and CP1 charges CP2 up to about (2 • V

CC

–3•

V

DIODE

). When Q is toggled high, the negative side of

CP2 is brought to (V

CC–VDIODE

). Since the voltage

across a capacitor cannot change instantaneously with

time, the positive side of the capacitor swings up to (3 •

V

CC

–4•V

DIODE

). This charges C

PUMP

up to (3 • VCC–

5 • V

DIODE

).

The maximum output voltage of the linear amplifier is ac

tually less than this because of the ability of the amplifier

to swing to within approximately 1V of V

PUMP

. Due to in

efficiencies of the charge pump, the UC3914 may not

have sufficient gate drive to fully enhance a standard

power MOSFET when operating at input voltages below

7V. Logic Level MOSFETs could be used depending on

the application but are limited by their lower current capability. For applications requiring operation below 7V there

are two ways to increase the charge pump output voltage. Fig. 7 shows the typical tripler of Fig. 6 enhanced

with three external schottky diodes. Placing the schottky

diodes in parallel with the internal charge pump diodes

decreases the voltage drop across each diode thereby

increasing the overall efficiency and output voltage of the

charge pump.

Fig. 8 shows a way to use the existing drivers with exter

nal diodes (or Schottky diodes for even higher pump

voltages but with additional cost) and capacitors to make

a voltage quadrupler. The additional charge pump stage

will provide a sufficient pump voltage (V

PUMP

=4•VCC–

7•V

DIODE

) to generate the maximum VGS. Operation is

similar to the case described above. This additional cir

cuitry is not necessary for higher input voltages because

the UC3914 has internal clamping which only allows

V

PUMP

to be 10V greater than V

OUTS

.

Input

Voltage

(VCC)

Internal

Diodes

(V

GS

)

External

Schottky

Diodes (VGS)

Quadrupler

(VGS)

4.5 4.57 6.8 8.7

5 5.8 7.9 8.8

5.5 6.6 8.6 8.9

6 7.6 8.8 9

6.5 8.7 8.8 9

7 8.8 9 9

9 9.2 9.4 9.1

10 9.3 9.4 9.3

Table 1. UC3914 charge pump characteristics.

Table 1 characterizes the UC3914 charge pump in its

standard configuration, with external schottky diodes,

and configured as a voltage quadrupler. Please note:

The voltage quadrupler is unnecessary for input voltages

above 7.0V due the internal clamping action.

ICC Specification

The ICC operating measurement is actually a mathe

-

matical calculation. The charge pump voltage is con

-

stantly being monitored with respect to both V

CC

and

V

OUTS

to determine whether the pump requires servic

ing. If there is insufficient voltage on this pin, the charge

pump drivers are alternately switched to raise the volt

age of the pump (see Fig. 9). Once the voltage on the

pump is high enough, the drivers and other charge pump

related circuitry are shutdown to conserve current. The

pump voltage will decay due to internal loading until it

reaches a low enough level to turn the drivers back on.

The chip requires significantly different amounts of cur

rent during these two modes of operation and the follow

ing mathematical calculation is used to figure out the

average current:

ICC

ICC T ICC T

TT

DRIVERS on ON DRIVERS off OFF

ON OF

=

•+ •

+

() ( )

F

APPLICATION INFORMATION (cont.)

8

7

5

6

CP2

Q

Q

250kHz

OSCILLATOR

TOGGLE

FLIP FLOP

9 2

D1

D2

D3

C

PUMP

TO VOUT

VPUMP

OSCB

CP1

OSC

T

VCCPMP

PMPB

Figure 7. Enhanced charge pump block diagram.

UDG-98204

13

UC1914

UC2914

UC3914

PUMP

PUMP UPPER LEVEL

PUMP LOWER LEVEL

"PUMP"

SERVICING FREQUENCY

OSCILLATOR FREQUENCY

T

ON

T

OFF

OSC

OSCB

TIME

Figure 9. Charge pump waveforms.

UDG-98144

Since the charge pump does not always require servic

ing, the user may think that the charge pump frequency

is much less than the datasheet specification. This is not

the case as the free-running frequency is guaranteed to

be within the datasheet limits. The charge pump servic

ing frequency can make it appear as though the drivers

are operating at a much lower frequency.

APPLICATION INFORMATION (cont.)

Figure 8. Low voltage operation to produce higher

pump voltage.

UDG-97059

14

UC1914

UC2914

UC3914

UNITRODE CORPORATION

7 CONTINENTAL BLVD. • MERRIMACK, NH 03054

TEL. (603) 424-2410 FAX (603) 424-3460

14

12

11

17

2

10

4

5

9 18

1

8

7

166

1513

15V

+

–

VPUMP

PLIM

VOUTS

OUT

+

–

+

–

++

+

–

1.4V

+

–

+

–

2.5V

0.5V

SQ

QR

FAULT

TIMING

CIRCUITRY

FAULT

LATCH

3m

A

H=CLOSE

3mA 103mA

UNDERVOLTAGE

LOCKOUT

4.0V / 3.8V

TO LINEAR

AMPLIFIER

VOUT +10V

(45V

MAX

)

VCC – 2V

REFERENCE

250kHz

OSCILLATOR

T

TOGGLE

VCC

+

–

C

T

CTLR

GND

R

FAULT

TO VCC

C

PUMP

TO V

OUT

VPUMP

CP2

PMPB

OSCB

CP1

PMP OSC

R1 R2

C1

C2

SENSE

R

SENSE

VCC

V

OUT

R

PL

VCC

LINEAR

AMPLIFIER

FAULT=

50mV

H=CLOSE

OVERCURRENT

COMPARATOR

OVERLOAD

COMPARATOR

200mV

50mV

IMAXREF

SD

FAULT

Figure 10. Typical application.

APPLICATION INFORMATION (cont.)

UDG-98194

SAFETY RECOMMENDATIONS

Although the UC3914 is designed to provide system pro

tection for all fault conditions, all integrated circuits can

ultimately fail short. For this reason, if the UC3914 is in

tended for use in safety critical applications where UL or

some other safety rating is required, a redundant safety

device such as a fuse should be placed in series with

the device. The UC3914 will prevent the fuse from blow

-

ing in virtually all fault conditions, increasing system reli

ability and reducing maintainence cost, in addition to

providing the hot swap benefits of the device.

Loading...

Loading...