Datasheet UC3909QTR, UC3909Q, UC3909N, UC3909DWTR, UC3909DW Datasheet (Texas Instruments)

...

UC2909

UC3909

DESCRIPTION

The UC3909 family of Switchmode Lead-Acid Battery Chargers accurately

controls lead acid battery charging with a highly efficient average current

mode control loop. This chip combines charge state logic with average current PWM control circuitry. Charge state logic commands current or voltage

control depending on the charge state. The chip includes undervoltage

lockout circuitry to insure sufficient supply voltage is present before output

switching starts. Additional circuit blocks include a differential current sense

amplifier, a 1.5% voltage reference, a –3.9mV/°C thermistor linearization

circuit, voltage and current error amplifiers, a PWM oscillator, a PWM comparator, a PWM latch, charge state decode bits, and a 100mA open collector output driver.

Switchmode Lead-Acid Battery Charger

FEATURES

• Accurate and Efficient Control of

Battery Charging

• Average Current Mode Control from

Trickle to Overcharge

• Resistor Programmable Charge

Currents

• Thermistor Interface Tracks Battery

Requirements Over Temperature

• Output Status Bits Report on Four

Internal Charge States

• Undervoltage Lockout Monitors VCC

and VREF

1/99

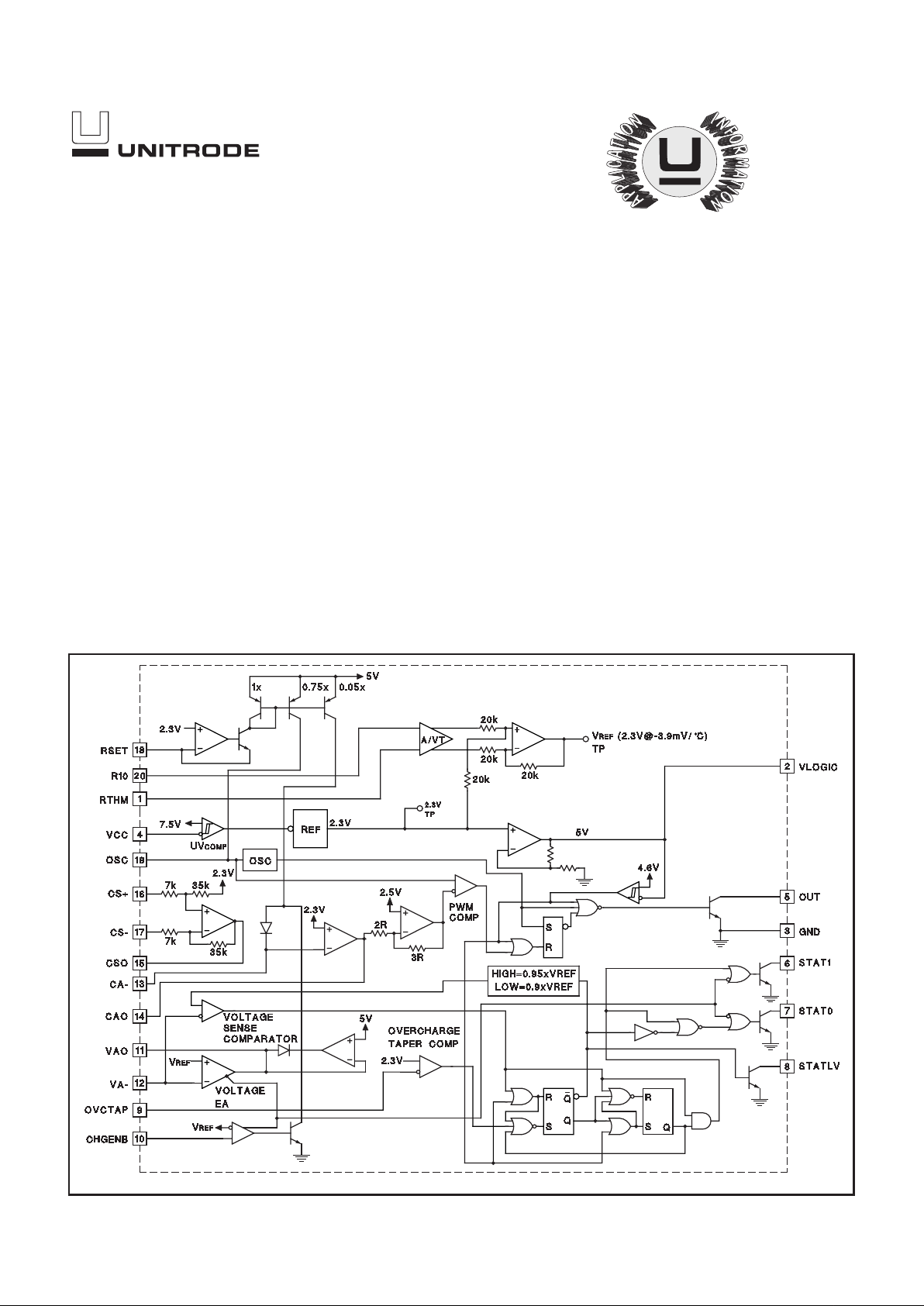

BLOCK DIAGRAM

UDG-95007-1

Pin numbers refer to J, N, DW packages.

2

UC2909

UC3909

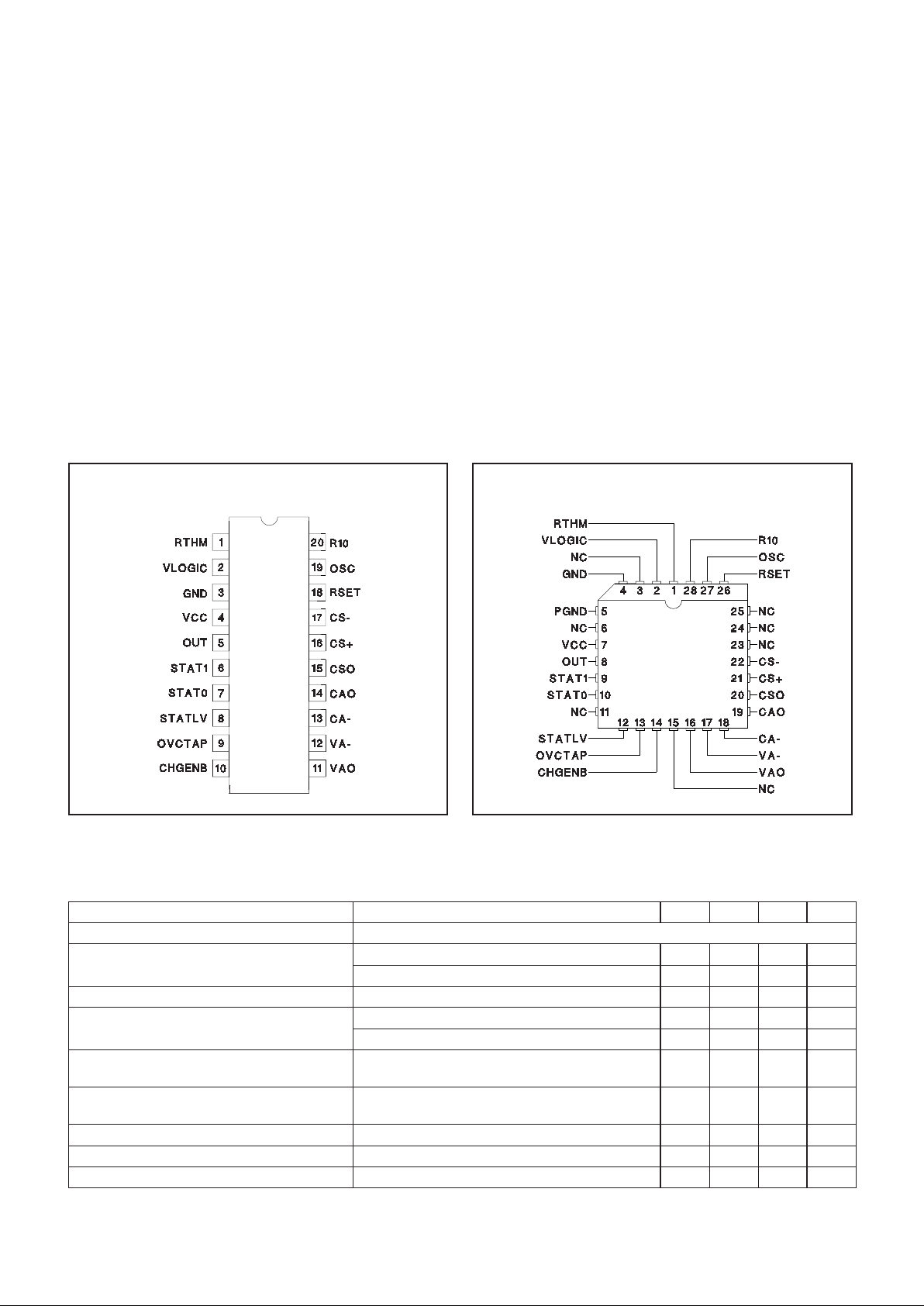

DIL-20, (Top View)

J or N, DW Packages

ABSOLUTE MAXIMUM RATINGS

Supply Voltage (VCC), OUT, STAT0, STAT1 . . . . . . . . . . . 40V

Output Current Sink . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.1A

CS+, CS-. . . . . . . . . . . . . . . . . . . . . . . . . . -0.4 to VCC (Note 1)

Remaining Pin Voltages. . . . . . . . . . . . . . . . . . . . . . -0.3V to 9V

Storage Temperature . . . . . . . . . . . . . . . . . . . -65°C to +150°C

Junction Temperature . . . . . . . . . . . . . . . . . . . -55°C to +150°C

Lead Temperature (Soldering, 10 sec.). . . . . . . . . . . . . +300°C

All currents are positive into, negative out of the specified terminal. Consult Packaging Section of Databook for thermal limitations and considerations of packages.

Note 1: Voltages more negative than -0.4V can be tolerated if

current is limited to 50mA.

CONNECTION DIAGRAMS

ELECTRICAL CHARACTERISTICS:

Unless otherwise stated these specifications apply for TA= –40°C to +85°C for

UC2909; °0C to +70°C for UC3909; CT= 330pF, R

SET

= 11.5k, R10 = 10k, R

THM

= 10k, VCC= 15V, Output no load, R

STAT0

=

R

STAT1

= 10k, CHGENB = OVCTAP = VLOGIC, TA= TJ.

PARAMETER TEST CONDITIONS MIN TYP MAX UNITS

Current Sense AMP (CSA) Section

V

ID

= CS+ – CS–

DC Gain CS– = 0, CS+ = -50mV; CS+ = –250mV 4.90 5 5.10 V/V

CS+ = 0, CS– = 50mV; CS–- = 250mV 4.90 5 5.10 V/V

V

OFFSET(VCSO

– V

CAO

) CS+ = CS– = 2.3V, CAO = CA– 15 mV

CMRR VCM= –0.25 to VCC – 2, 8.8 < VCC < 14 50 dB

VCM= –0.25 to VCC, 14 < VCC < 35 50 dB

V

OL

VID= –550mV, –0.25V < VCM < VCC–2,

IO= 500µA

0.3 0.6 V

V

OH

VID= +700mV, –0.25V < VCM < VCC–2,

IO= –250µA

5.2 5.7 6.2 V

Output Source Current V

ID

= +700mV, CSO = 4V –1 –0.5 mA

Output Sink Current VID= –550mV, CSO = 1V 3 4.5 mA

3dB Bandwidth VID= 90mV, VCM= 0V 200 kHz

LCC-28, PLCC-28 (Top View)

L, Q Packages

3

UC2909

UC3909

ELECTRICAL CHARACTERISTICS: Unless otherwise stated these specifications apply for T

A

= –40°C to +85°C for

UC2909; °0C to +70°C for UC3909; CT= 330pF, R

SET

= 11.5k, R10 = 10k, R

THM

= 10k, VCC= 15V, Output no load, R

STAT0

=

R

STAT1

= 10k, CHGENB = OVCTAP = VLOGIC, TA= TJ.

PARAMETER TEST CONDITIONS MIN TYP MAX UNITS

Current Error Amplifier (CEA) Section

I

B

8.8V < VCC < 35V, V

CHGENB

= V

LOGIC

0.1 0.8 µA

V

IO

(Note 2) 8.8V < VCC < 35V, CAO = CA– 10 mV

A

VO

1V < VAO < 4V 60 90 dB

GBW TJ= 25°C, F = 100kHz 1 1.5 MHz

V

OL

IO= 250µA 0.4 0.6 V

V

OH

IO= –5mA 4.5 5 V

Output Source Current CAO = 4V –25 –12 mA

Output Sink Current CAO = 1V 2 3 mA

ICA–, I

TRCK_CONTROL

V

CHGENB

= GND 8.5 10 11.5 µA

Voltage Amplifier (CEA) Section

I

B

Total Bias Current; Regulating Level 0.1 1 µA

VIO(Note 2) 8.8V < VCC < 35V, VCM = 2.3V, VAO = VA– 1.2 mV

A

VO

1V < CAO < 4V 60 90 dB

GBW TJ= 25°C, F = 100kHz 0.25 0.5 MHz

V

OL

IO= 500µA 0.4 0.6 V

V

OH

IO= –500µA 4.75 5 5.25 V

Output Source Current CAO = 4V –2 –1 mA

Output Sink Current CAO = 1V 2 2.5 mA

VAO Leakage: High Impedance State V

CHGENB

= GND, STAT0 = 0 & STAT1 = 0,

VAO = 2.3V

–1 1 µA

Pulse Width Modulator Section

Maximum Duty Cycle CAO = 0.6V 90 95 100 %

Modulator Gain CAO = 2.5V, 3.2V 63 71 80 %/V

OSC Peak 3V

OSC Valley 1V

Oscillator Section

Frequency 8.8V < VCC < 35V 198 220 242 kHz

Thermistor Derived Reference Section

V

ID

= V

RTHM

– V

R10

Initial Accuracy, VAO (RTHM = 10k) VID= 0, R10 = RTHM =10k (Note 3) 2.2655 2.3 2.3345 V

VID= 0, R10 = RTHM =10k, –40°C ≤TA< 0°C

(Note 3)

2.254 2.3 2.346 V

Line Regulation V

CC

= 8.8V to 35V 3 10 mV

VAO RTHM = 138k, R10 = 10k 2.458 2.495 2.532 V

RTHM = 138k, R10 = 10k, -40°C ≤ TA< 0°C 2.445 2.495 2.545 V

RTHM = 33.63k, R10 = 10k 2.362 2.398 2.434 V

RTHM = 33.63k, R10 = 10k, -40°C ≤ T

A

< 0°C 2.350 2.398 2.446 V

RTHM = 1.014k, R10 = 10k 2.035 2.066 2.097 V

RTHM = 1.014k, R10 = 10k, -40°C ≤ TA< 0°C 2.025 2.066 2.107 V

Charge Enable Comparator Section (CEC)

Threshold Voltage As a function of VA– 0.99 1 1.01 V/V

Input Bias Current CHGENB = 2.3V –0.5 –0.1 µA

4

UC2909

UC3909

ELECTRICAL CHARACTERISTICS: Unless otherwise stated these specifications apply for T

A

= –40°C to +85°C for

UC2909; °0C to +70°C for UC3909; CT= 330pF, R

SET

= 11.5k, R10 = 10k, R

THM

= 10k, VCC= 15V, Output no load, R

STAT0

=

R

STAT1

= 10k, CHGENB = OVCTAP = VLOGIC, TA= TJ.

PARAMETER TEST CONDITIONS MIN TYP MAX UNITS

Voltage Sense Comparator Section (VSC)

Threshold Voltage STAT0 = 0, STAT1 = 0, Function of V

REF

0.945 0.95 0.955 V/V

STAT0 = 1, STAT1 = 0, Function of V

REF

0.895 0.9 0.905 V/V

Over Charge Taper Current Comparator Section (OCTIC)

Threshold Voltage Function of 2.3V REF, CA- = CAO 0.99 1 1.01 V/V

Input Bias Current OVCTAP = 2.3V –0.5 –0.1 µA

Logic 5V Reference Section (VLOGIC)

VLOGIC VCC = 15V 4.875 5.0 5.125 V

Line Regulation 8.8V < V

CC

< 35V 3 15 mV

Load Regulation 0 < IO< 10mA 3 15 mV

Reference Comparator Turn-on Threshold 4.3 4.8 V

Short Circuit Current V

REF

= 0V 30 50 80 mA

Output Stage Section

I

SINK

Continuous 50 mA

I

PEAK

100 mA

V

OL

IO=50mA 1 1.3 V

Leakage Current V

OUT

=35V 25 µA

STAT0 & STAT1 Open Collector Outputs Section

Maximum Sink Current V

OUT

= 8.8V 6 10 mA

Saturation Voltage I

OUT

= 5mA 0.1 0.45 V

Leakage Current V

OUT

= 35V 25 µA

STATLV Open Collector Outputs Section

Maximum Sink Current V

OUT

= 5V 2.5 5 mA

Saturation Voltage I

OUT

= 2mA 0.1 0.45 V

Leakage current V

OUT

= 5V 3 µA

UVLO Section

Turn-on Threshold 6.8 7.8 8.8 V

Hysteresis 100 300 500 mV

I

CC

Section

I

CC

(run) (See Fig. 1) 13 19 mA

ICC(off) VCC = 6.5V 2 mA

Note 2: VIO is measured prior to packaging with internal probe pad.

Note 3: Thermistor initial accuracy is measured and trimmed with respect to VAO; VAO = VA–.

CA–: The inverting input to the current error amplifier.

CAO: The output of the current error amplifier which is

internally clamped to approximately 4V. It is internally

connected to the inverting input of the PWM comparator.

CS–, CS+: The inverting and non-inverting inputs to the

current sense amplifier. This amplifier has a fixed gain of

five and a common-mode voltage range of from –250mV

to +VCC.

CSO: The output of the current sense amplifier which is

internally clamped to approximately 5.7V.

CHGENB: The input to a comparator that detects when

battery voltage is low and places the charger in a trickle

charge state. The charge enable comparator makes the

output of the voltage error amplifier a high impedance

while forcing a fixed 10µA into CA– to set the trickle

charge current.

PIN DESCRIPTIONS

5

UC2909

UC3909

GND: The reference point for the internal reference, all

thresholds, and the return for the remainder of the device. The output sink transistor is wired directly to this

pin.

OVCTAP: The overcharge current taper pin detects

when the output current has tapered to the float threshold in the overcharge state.

OSC: The oscillator ramp pin which has a capacitor (C

T

)

to ground. The ramp oscillates between approximately

1.0V to 3.0V and the frequency is approximated by:

frequency

CR

TSET

=

••

1

12.

OUT: The output of the PWM driver which consists of an

open collector output transistor with 100mA sink capability.

R10: Input used to establish a differential voltage corresponding to the temperature of the thermistor. Connect

a 10k resistor to ground from this point.

RSET: A resistor to ground programs the oscillator

charge current and the trickle control current for the oscillator ramp.

The oscillator charge current is approximately

175.

R

SET

.

The trickle control current (I

TRCK_CONTROL

) is approxi-

mately

0115.

R

SET

.

RTHM: A 10k thermistor is connected to ground and is

thermally connected to the battery. The resistance will

vary exponentially over temperature and its change is

used to vary the internal 2.3V reference by –3.9mV/°C.

The recommended thermistor for this function is part

number L1005-5744-103-D1, Keystone Carbon Company, St. Marys, PA.

STAT0: This open collector pin is the first decode bit

used to decode the charge states.

STAT1: This open collector pin is the second decode bit

used to decode the charge states.

STATLV: This bit is high when the charger is in the float

state.

VA–: The inverting input to the voltage error amplifier.

VAO: The output of the voltage error amplifier. The up-

per output clamp voltage of this amplifier is 5V.

VCC: The input voltage to the chip. The chip is opera-

tional between 7.5V and 40V and should be bypassed

with a 1µF capacitor. A typical I

CC

vs. temperature is

shown in Figure 1.

VLOGIC: The precision reference voltage. It should be

bypassed with a 0.1µF capacitor.

Charge State Decode Chart

STAT0 and STAT1 are open collector outputs. The output is approximately 0.2V for a logic 0.

STAT1 STAT0

Trickle Charge 0 0

Bulk Charge 0 1

Over Charge 1 0

Float Charge 1 1

PIN DESCRIPTIONS (cont.)

Figure 1. ICCvs. temperature.

6

UC2909

UC3909

APPLICATION INFORMATION

A Block Diagram of the UC3909 is shown on the first

page, while a Typical Application Circuit is shown in Figure 2. The circuit in Figure 2 requires a DC input voltage

between 12V and 40V.

The UC3909 uses a voltage control loop with average

current limiting to precisely control the charge rate of a

lead-acid battery. The small increase in complexity of

average current limiting is offset by the relative simplicity

of the control loop design.

CONTROL LOOP

Current Sense Amplifier

This amplifier measures the voltage across the sense resistor RS with a fixed gain of five and an offset voltage of

2.3V. This voltage is proportional to the battery current.

The most positive voltage end of RS is connected to CSensuring the correct polarity going into the PWM comparator.

CSO = 2.3V when there is zero battery current.

RS is chosen by dividing 350mV by the maximum allow-

able load current. A smaller value for RS can be chosen

to reduce power dissipation.

Maximum Charge Current, Ibulk, is set by knowing the

maximum voltage error amplifier output, V

OH

= 5V, the

maximum allowable drop across RS, and setting the resistors RG1 and RG2 such that;

(1)

RG

RGVVLOGIC CA

V

VV

V

V

RS RS

RS

1

2

55

523

5

27

185

=

•

=

•

=

•

=

–– –.

.

.2••

IRS

BULK

The maximum allowable drop across RS is specified to

limit the maximum swing at CSO to approximately 2.0V

to keep the CSO amplifier output from saturating.

No charge/load current: V

CSO

= 2.3V,

Max charge/load current: V

max(CSO)

= 2.3V–2.0V = 0.3V

Voltage Error Amplifier:

The voltage error amplifier (VEA) senses the battery

voltage and compares it to the 2.3V – 3.9mV/°C thermis-

tor generated reference. Its output becomes the current

command signal and is summed with the current sense

amplifier output. A 5.0V voltage error amplifier upper

clamp limits maximum load current. During the trickle

charge state, the voltage amplifier output is opened (high

impedance output) by the charge enable comparator. A

trickle bias current is summed into the CA– input which

sets the maximum trickle charge current.

The VEA, VOH= 5V clamp saturates the voltage loop

and consequently limits the charge current as stated in

Equation 1.

During the trickle bias state the maximum allowable

charge current (ITC) is similarly determined:

(2)

ITC

IRG

RS

TRICK CONTROL

=

•

•

_

1

5

I

TRCK_CONTROL

is the fixed control current into CA–.

I

TRCK_CONTROL

is 10µA when R

SET

= 11.5k. See RSET

pin description for equation.

Current Error Amplifier

The current error amplifier (CA) compares the output of

the current sense amplifier to the output of the voltage

error amplifier. The output of the CA forces a PWM duty

cycle which results in the correct average battery current.

With integral compensation, the CA will have a very high

DC current gain, resulting in effectively no average DC

current error. For stability purposes, the high frequency

gain of the CA must be designed such that the magnitude of the down slope of the CA output signal is less

than or equal to the magnitude of the up slope of the

PWM ramp.

CHARGE ALGORITHM

Refer to Figure 3 in UC3906 Data Sheet in the data

book.

A) Trickle Charge State

STAT0 = STAT1 = STATLV = logic 0

When CHGNB is less than VREF (2.3V – 3.9mV/°C),

STATLV is forced low. This decreases the sense voltage

divider ratio, forcing the battery to overcharge (VOC).

(3)

()

VOC VREF

RS RS RS RS

RS RS

=•

++

()

()

||

123 4

34

||

During the trickle charge state, the output of the voltage

error amplifier is high impedance. The trickle control current is directed into the CA– pin setting the maximum

trickle charge current. The trickle charge current is defined in Equation 2.

B) Bulk Charge State

STAT1 = STATLV = logic 0, STAT0 = logic 1

As the battery charges, the UC3909 will transition from

trickle to bulk charge when CHGENB becomes greater

than 2.3V. The transition equation is

(4)

VT VREF

RS RS RS RS

RS RS RS

=•

++

+

(||)

(||)

1234

234

STATLV is still driven low.

7

UC2909

UC3909

UDG-95008-1

APPLICATION INFORMATION (cont.)

Figure 2. Typical application circuit

Pin numbers refer to J, N, DW packages.

8

UC2909

UC3909

During the bulk charge state, the voltage error amplifier

is now operational and is commanding maximum charge

current (I

BULK

) set by Equation 1. The voltage loop at-

tempts to force the battery to VOC.

C) Overcharge State

STAT0 = STATLV = logic 0, STAT1 = logic 1

The battery voltage surpasses 95% of VOC indicating

the UC3909 is in its overcharge state.

During the overcharge charge state, the voltage loop becomes stable and the charge current begins to taper off.

As the charge current tapers off, the voltage at CSO increases toward its null point of 2.3V. The center connection of the two resistors between CSO and VLOGIC sets

the overcurrent taper threshold (OVCTAP). Knowing the

desired overcharge terminate current (I

OCT

), the resistors

R

OVC1

and R

OVC2

can be calculated by choosing a value

of R

OVC2

and using the following equation:

(5)

()

RIRSR

OVC OCT OVC

12

18518=•••.

D) Float State

STAT0 = STAT1 = STATLV = logic 1

The battery charge current tapers below its OVCTAP

threshold, and forces STATLV high increasing the voltage sense divider ratio. The voltage loop now forces the

battery charger to regulate at its float state voltage (V

F

).

(6)

()

()

VV

RS RS RS

RS

FREF

=

++123

3

If the load drains the battery to less than 90% of VF, the

charger goes back to the bulk charge state, STATE 1.

OFF LINE APPLICATIONS

For off line charge applications, either Figure 3 or Figure

4 can be used as a baseline. Figure 3 has the advantage of high frequency operation resulting in a small isolation transformer. Figure 4 is a simpler design, but at

the expense of larger magnetics.

APPLICATION INFORMATION (cont.)

Figure 3. Off line charger with primary side PWM

UDG-95009

9

UC2909

UC3909

Figure 4. Isolated off line charger

APPLICATION INFORMATION (cont.)

UNITRODE CORPORATION

7 CONTINENTALBLVD. • MERRIMACK, NH 03054

TEL. (603) 424-2410 • FAX (603) 424-3460

UDG-95010

IMPORTANT NOTICE

T exas Instruments and its subsidiaries (TI) reserve the right to make changes to their products or to discontinue

any product or service without notice, and advise customers to obtain the latest version of relevant information

to verify, before placing orders, that information being relied on is current and complete. All products are sold

subject to the terms and conditions of sale supplied at the time of order acknowledgement, including those

pertaining to warranty, patent infringement, and limitation of liability.

TI warrants performance of its semiconductor products to the specifications applicable at the time of sale in

accordance with TI’s standard warranty. Testing and other quality control techniques are utilized to the extent

TI deems necessary to support this warranty. Specific testing of all parameters of each device is not necessarily

performed, except those mandated by government requirements.

CERT AIN APPLICATIONS USING SEMICONDUCT OR PRODUCTS MAY INVOLVE POTENTIAL RISKS OF

DEATH, PERSONAL INJURY, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE (“CRITICAL

APPLICATIONS”). TI SEMICONDUCTOR PRODUCTS ARE NOT DESIGNED, AUTHORIZED, OR

WARRANTED TO BE SUITABLE FOR USE IN LIFE-SUPPORT DEVICES OR SYSTEMS OR OTHER

CRITICAL APPLICATIONS. INCLUSION OF TI PRODUCTS IN SUCH APPLICA TIONS IS UNDERSTOOD T O

BE FULLY AT THE CUSTOMER’S RISK.

In order to minimize risks associated with the customer’s applications, adequate design and operating

safeguards must be provided by the customer to minimize inherent or procedural hazards.

TI assumes no liability for applications assistance or customer product design. TI does not warrant or represent

that any license, either express or implied, is granted under any patent right, copyright, mask work right, or other

intellectual property right of TI covering or relating to any combination, machine, or process in which such

semiconductor products or services might be or are used. TI’s publication of information regarding any third

party’s products or services does not constitute TI’s approval, warranty or endorsement thereof.

Copyright 1999, Texas Instruments Incorporated

Loading...

Loading...