Datasheet UC3848N, UC3848DWTR, UC3848DW, UC2848DW, UC2848N Datasheet (Texas Instruments)

...

UC1848

UC2848

UC3848

4/96

FEATURES

• Practical Primary Side Control of

Isolated Power Supplies with DC

Control of Secondary Side Current

• Accurate Programmable Maximum

Duty Cycle Clamp

• Maximum Volt-Second Product Clamp

to Prevent Core Saturation

• Practical Operation Up to 1MHz

• High Current (2A Pk) Totem Pole

Output Driver

• Wide Bandwidth (8MHz) Current Error

Amplifier

• Under Voltage Lockout Monitors VCC,

VIN and VREF

• Output Active Low During UVLO

• Low Startup Current (500µA)

• Precision 5V Reference (1%)

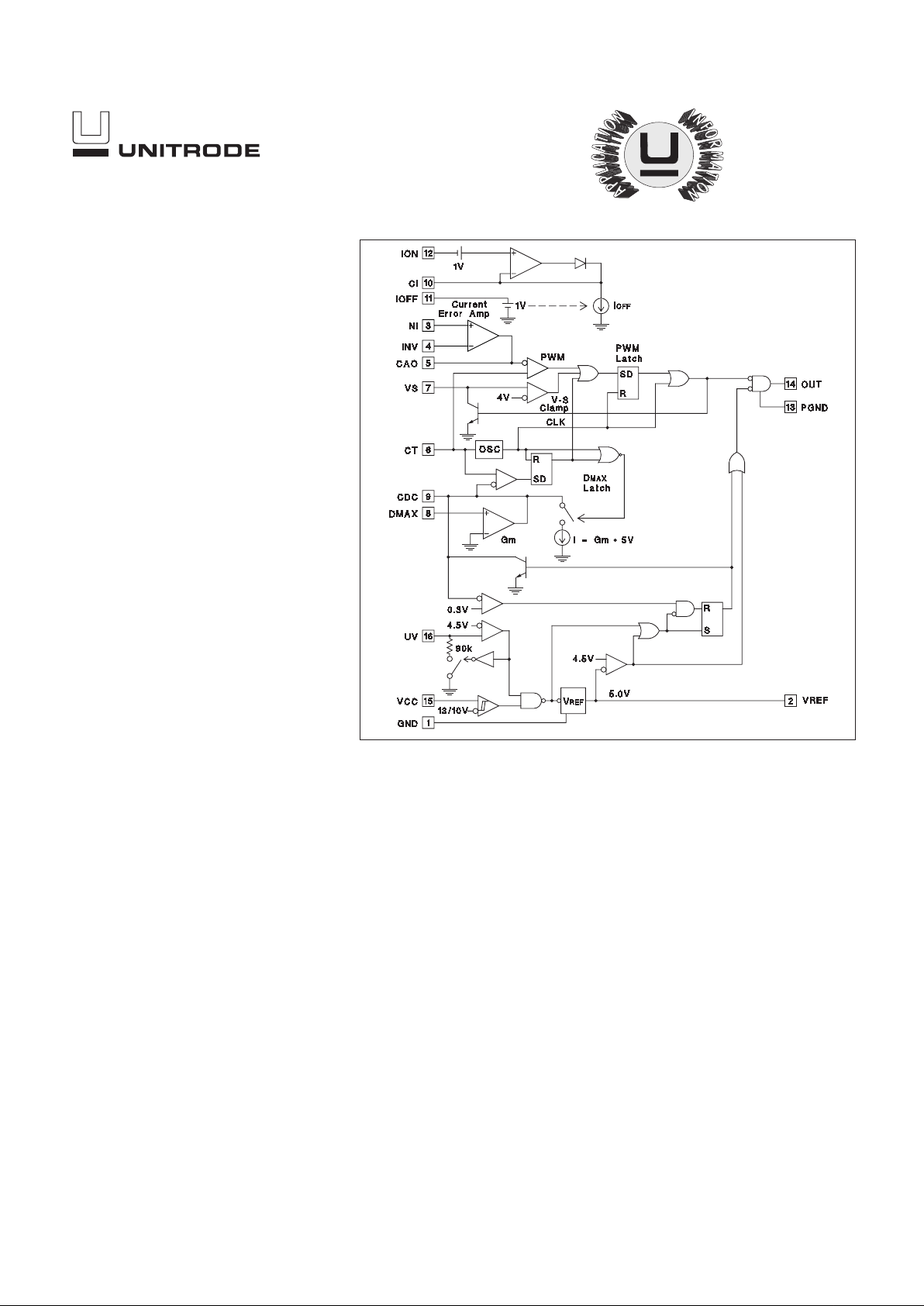

The UC3848 family of PWM control ICs makes primary

side average current mode control practical for isolated

switching converters. Average current mode control insures that both cycle by cycle peak switch current and

maximum average inductor current are well defined and

will not run away in a short circuit situation. The UC3848

can be used to control a wide variety of converter topologies.

In addition to the basic functions required for pulse width

modulation, the UC3848 implements a patented technique of sensing secondary current in an isolated buck

derived converter from the primary side. A current waveform synthesizer monitors switch current and simulates

the inductor current down slope so that the complete current waveform can be constructed on the primary side

without actual secondary side measurement. This information on the primary side allows for full DC control of

output current.

The UC3848 circuitry includes a precision reference, a

wide bandwidth error amplifier for average current control, an oscillator to generate the system clock, latching

PWM comparator and logic circuits, and a high current

output driver. The current error amplifier easily interfaces

with an optoisolator from a secondary side voltage sensing circuit.

A full featured undervoltage lockout (UVLO) circuit is contained in the UC3848. UVLO monitors the supply voltage

to the controller (VCC), the reference voltage (VREF),

and the input line voltage (VIN). All three must be good

before soft start commences. If either VCC or VIN is low,

the supply current required by the chip is only 500µA and

the output is actively held low.

Two on board protection features set controlled limits to

prevent transformer core saturation. Input voltage is monitored and pulse width is constrained to limit the maximum volt-second product applied to the transformer. A

unique patented technique limits maximum duty cycle

within 3% of a user programmed value.

These two features allow for more optimal use of transformers and switches, resulting in reduced system size

and cost.

Patents embodied in the UC3848 belong to Lambda

Electronics Incorporated and are licensed for use in applications employing these devices.

DESCRIPTION

BLOCK DIAGRAM

Average Current Mode PWM Controller

UDG-93003-1

2

UC1848

UC2848

UC3848

Supply Voltage (Pin 15). . . . . . . . . . . . . . . . . . . . . . . . . . . . 22V

Output Current, Source or Sink (Pin 14)

DC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.5A

Pulse (0.5 s) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.2A

Power Ground to Ground (Pin 1 to Pin 13) . . . . . . . . . . . ± 0.2V

Analog Input Voltages

(Pins 3, 4, 7, 8, 12, 16). . . . . . . . . . . . . . . . . . . . . –0.3 to 7V

Analog Input Currents, Source or Sink

(Pins 3, 4, 7, 8, 11, 12, 16) . . . . . . . . . . . . . . . . . . . . . . 1mA

Analog Output Currents, Source or Sink (Pins 5 & 10) . . . 5mA

Power Dissipation at TA = 60°C. . . . . . . . . . . . . . . . . . . . . . 1W

Storage Temperature Range. . . . . . . . . . . . . . .−65°C to +150°C

Lead Temperature (Soldering 10 seconds) . . . . . . . . . . +300°C

Notes: All voltages are with respect to ground (DIL and SOIC

Pin 1). Currents are positive into the specified terminal. Pin

numbers refer to the 16 pin DIL and SOIC packages. Consult

Packaging Section of Databook for thermal limitations and

considerations of packages.

ABSOLUTE MAXIMUM RATINGS

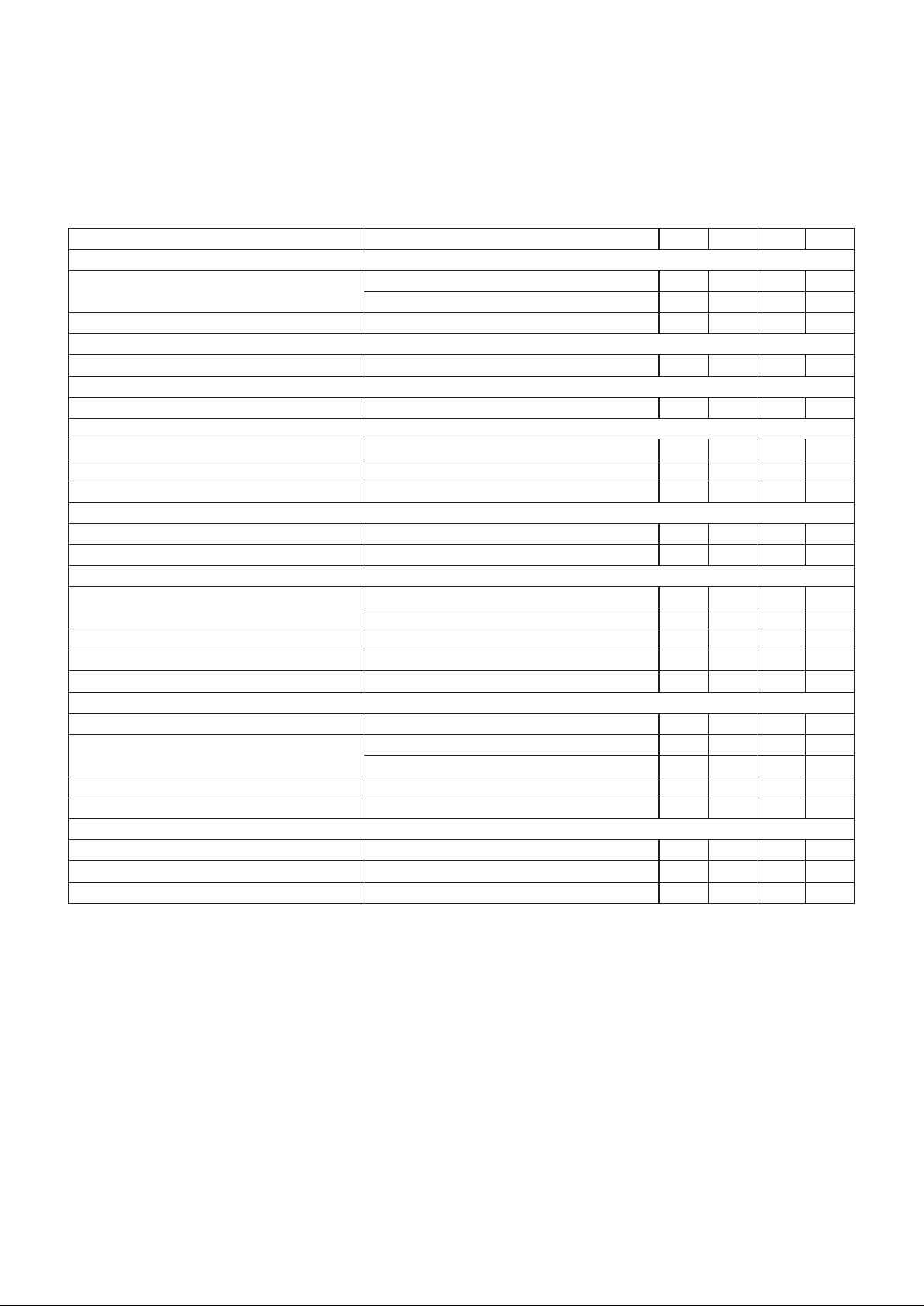

ELECTRICAL CHARACTERISTICS:

Unless otherwise stated, all specifications are over the junction temperature range

of −55°C to +125°C for the UC1848, −40°C to +85°C for the UC2848, and 0°C to +70°C for the UC3848. Test conditions are: VCC

= 12V, CT = 400pF, CI = 100pF, IOFF = 100µA, CDC = 100nF, Cvs = 100pF, and Ivs = 400µA, TA = TJ.

PARAMETER TEST CONDITIONS MIN TYP MAX UNITS

Real Time Current Waveform Synthesizer

Ion Amplifier

Offset Voltage 0.95 1 1.05 V

Slew Rate (Note 1) 20 25 V/µs

lib -2 -20 µA

IOFF Current Mirror

Input Voltage 0.95 1 1.05 V

Current Gain 0.9 1 1.1 A/A

Current Error Amplifier

A

VOL 60 100 dB

Vio 12V ≤ VCC 20V, 0V VCM 5V 10 mV

lib -0.5 -3 µA

Voh IO = −200µA 3 3.3 V

Vol I

O = 200µA 0.3 0.6 V

Source Current VO = 1V 1.4 1.6 2.0 mA

GBW Product f = 200kHz 5 8 MHz

Slew Rate (Note 1) 810 V/µs

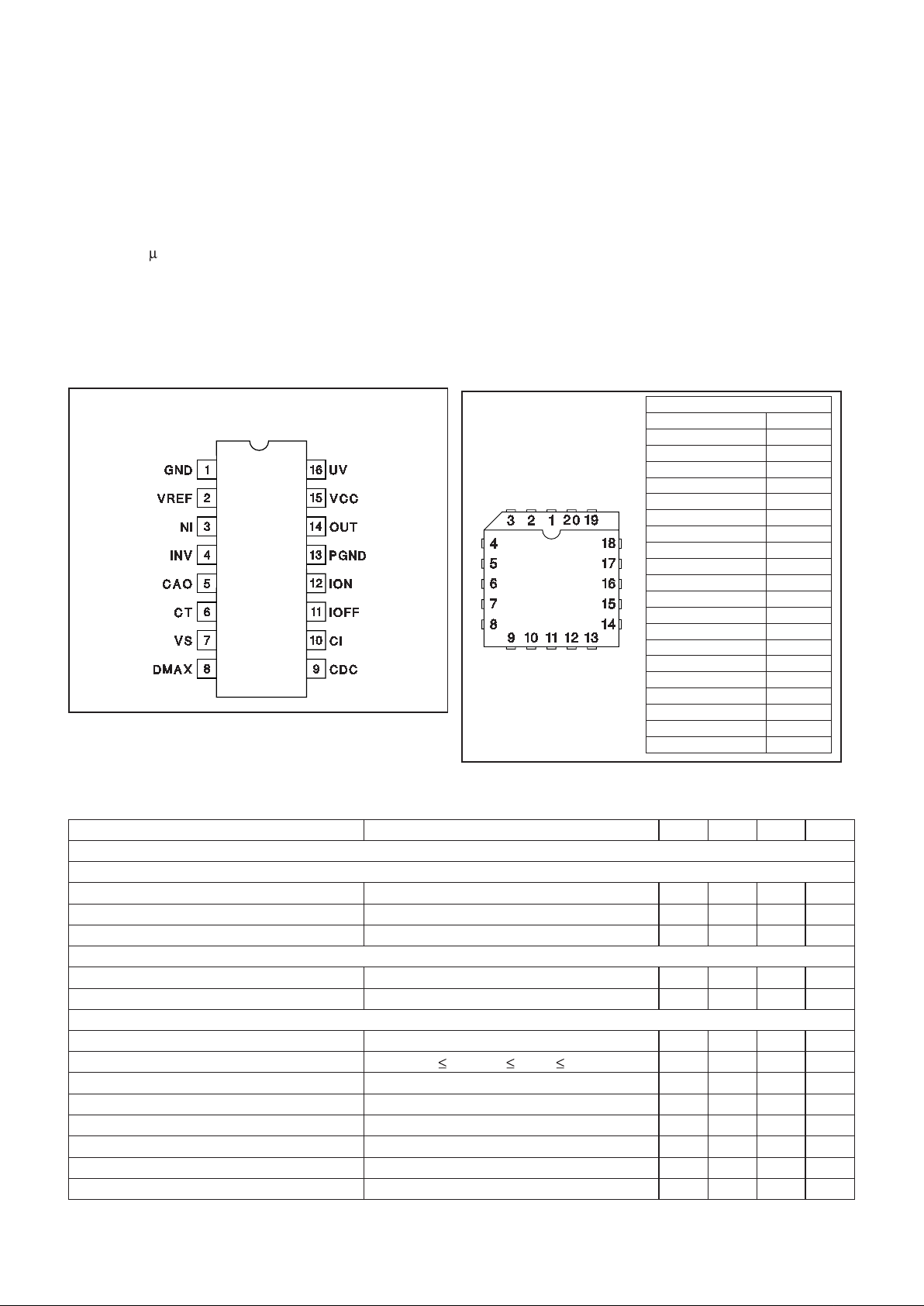

PACKAGE PIN FUNCTION

FUNCTION PIN

N/C 1

GND 2

VREF 3

NI 4

INV 5

N/C 6

CAO 7

CT 8

VS 9

DMAX 10

N/C 11

CDC 12

CI 13

IOFF 14

ION 15

N/C 16

PGND 17

OUT 18

VCC 19

UV 20

PLCC-20 & LCC-20

(Top View)

Q & L Packages

CONNECTION DIAGRAMS

DIL-16, SOIC-16 (Top View)

J, N, or DW Packages

3

UC1848

UC2848

UC3848

ELECTRICAL CHARACTERISTICS:

Unless otherwise stated, all specifications are over the junction temperature range

of −55°C to +125°C for the UC1848, −40°C to +85°C for the UC2848, and 0°C to +70°C for the UC3848. Test conditions are: VCC

= 12V, CT = 400pF, CI = 100pF, IOFF = 100µA, CDC = 100nF, Cvs = 100pF, and Ivs = 400µA, TA = TJ.

PARAMETER TEST CONDITIONS MIN TYP MAX UNITS

Oscillator

Frequency T

A = 25°C 240 250 260 kHz

235 265 kHz

Ramp Amplitude 1.5 1.65 1.8 V

Duty Cycle Clamp

Max Duty Cycle V(D

MAX) = 0.75 • VREF 73.5 76.5 79.5 %

Volt Second Clamp

Max On Time 900 1100 ns

VCC Comparator

Turn-on Threshold 13 14 V

Turn-off Threshold 910 V

Hysteresis 2.5 3 3.5 V

UV Comparator

Turn-on Threshold 4.1 4.35 4.6 V

R

HYSTERESIS Vuv = 4.2V 77 90 103 kΩ

Reference

VREF T

A = 25°C 4.95 5 5.05 V

0 < IO < 10mA, 12 < VCC < 20 4.93 5.07 V

Line Regulation 12 < VCC < 20V 4 15 mV

Load Regulation 0 < IO < 10mA 3 15 mV

Short Circuit Current V

REF = 0V 30 50 70 mA

Output Stage

Rise & Fall Time (Note 1) Cl = 1nF 20 45 ns

Output Low Saturation I

O = 20mA 0.25 0.4 V

IO = 200mA 1.2 2.2 V

Output High Saturation IO = -200mA 2.0 3.0 V

UVLO Output Low Saturation IO = 20mA 0.8 1.2 V

I

CC

ISTART VCC = 12V 0.2 0.4 mA

ICC (pre-start) VCC = 15V, V(UV) = 0 0.5 1 mA

ICC (run) 22 26 mA

Note 1: Guaranteed by design.

Under Voltage Lockout

The Under Voltage Lockout block diagram is shown in

Fig 1. The VCC comparator monitors chip supply voltage.

Hysteretic thresholds are set at 13V and 10V to facilitate

off-line applications. If the VCC comparator is low, ICC is

low (<500µA) and the output is low.

The UV comparator monitors input line voltage (V

IN

). A

pair of resistors divides the input line to UV. Hysteretic in-

put line thresholds are programmed by Rv1 and Rv2.

The thresholds are

VIN(on) = 4.35V • (1 + Rv1/Rv2′) and

VIN(off) = 4.35V • (1 + Rv1/Rv2) where

Rv2′= Rv2||90k.

The resulting hysteresis is

V

IN

(hys) = 4.35V • Rv1 / 90k.

When the UV comparator is low, ICCis low (500µA) and

the output is low.

APPLICATION INFORMATION

4

UC1848

UC2848

UC3848

Figure 1: Under voltage lockout.

UDG-93004

Figure 2: Oscillator frequency.

10

100

1000

10000

10 100 1000 10000

C (pF)

FREQUENCY (kHz)

Oscillator Frequency as a Function of CT

Frequency Decrease as a Function of RT

RT = Open

UDG-93006

UDG-93005

When both the UV and VCC comparators are high, the

internal bias circuitry for the rest of the chip is activated.

The CDC pin (see discussion on Maximum Duty Cycle

Control and Soft Start) and the Output are held low until

VREF exceeds the 4.5V threshold of the VREF comparator. When VREF is good, control of the output driver

is transferred to the PWM circuitry and CDC is allowed to

charge.

If any of the three UVLO comparators go low, the UVLO

latch is set, the output is held low, and CDC is discharged. This state will be maintained until all three comparators are high and the CDC pin is fully discharged.

APPLICATION INFORMATION (cont.)

5

UC1848

UC2848

UC3848

Oscillator

A capacitor from the CT pin to GND programs oscillator

frequency, as shown in Fig. 2. Frequency is determined

by:

F = 1 / (10k • CT).

The sawtooth wave shape is generated by a charging

current of 200

A and a discharge current of 1800 A. The

discharge time of the sawtooth is guaranteed dead time

for the output driver. If the maximum duty cycle control is

defeated by connecting DMAX to VREF, the maximum

duty cycle is limited by the oscillator to 90%. If an adjustment is required, an additional trim resistor RT from CT to

Ground can be used to adjust the oscillator frequency. RT

should not be less than 40k

. This will allow up to a 22%

decrease in frequency.

Inductor Current Waveform Synthesizer

Average current mode control is a very useful technique

to control the value of any current within a switching converter. Input current, output inductor current, switch current, diode current or almost any other current can be

controlled. In order to implement average current mode

control, the value of the current must be explicitly known

at all times. To control output inductor current (IL) in a

buck derived isolated converter, switch current provides

inductor current information, but only during the on time

of the switch. During the off time, switch current drops

abruptly to zero, but the inductor current actually diminishes with a slope dIL/dt = –V

O

/L. This down slope must

be synthesized in some manner on the primary side to

provide the entire inductor current waveform for the control circuit.

The patented current waveform synthesizer (Fig. 4) consists of a unidirectional voltage follower which forces the

voltage on capacitor CI to follow the on time switch current waveform. A programmable discharge current synthesizes the off time portion of the waveform. ION is the

input to the follower. The discharge current is programmed at IOFF.

The follower has a one volt offset, so that zero current

corresponds to one volt at CI. The best utilization of the

UC3848 is to translate maximum average inductor current to a 4V signal level. Given N and Ns (the turns ratio

of the power and current sense transformers), proper

scaling of IL to V(CI) requires a sense resistor Rs as calculated from:

Rs = 4V • Ns • N / IL(max).

Restated, the maximum average inductor current will be

limited to:

IL(max) = 4V • Ns • N/Rs.

IOFF and CI need to be chosen so that the ratio of

dV(CI)/dt to dIL/dt is the same during switch off time as

on time. Recommended nominal off current is 100

A.

This requires

CI = (100µA • N • Ns • L) / (Rs • V

O

(nom))

where L is the output inductor value and V

O

(nom) is the

converter regulated output voltage.

There are several methods to program IOFF. If accurate

average current control is required during short circuit operation, IOFF must track output voltage. The method

shown in Fig. 4 derives a voltage proportional to V

IN

• D

(Duty Cycle). (In a buck converter, output voltage is proportional to VIN • D.) A resistively loaded diode connection to the bootstrap winding yields a square wave whose

amplitude is proportional to VIN and is duty cycle modulated by the control circuit. Averaging this waveform with

a filter generates a primary side replica of secondary regulated V

O

. A single pole filter is shown, but in practice a

two or three pole filter provides better transient response.

Filtered voltage is converted by ROFF to a current to the

IOFF pin to control CI down slope.

Figure 3: Error amplifier gain and phase response

over frequency.

APPLICATION INFORMATION (cont.)

UDG-93008-1

6

UC1848

UC2848

If the system is not sensitive to short circuit requirements,

Figure 5 shows the simplest method of downslope generation: a single resistor (ROFF = 40k) from IOFF to VREF.

The discharge current is then 100µA. The disadvantage

to this approach is that the synthesizer continues to generate a down slope when the switch is off even during

short circuit conditions. Actual inductor down slope is

closer to zero during a short circuit. The penalty is that

the average current is understated by an amount approximately equal to the nominal inductor ripple current. Output short circuit is therefore higher than the designed

maximum output current.

A third method of generating IOFF is to add a second

winding to the output inductor core (Fig. 6). When the

power switch is off and inductor current flows in the free

wheeling diode, the voltage across the inductor is equal

to the output voltage plus the diode drop. This voltage is

then transformed by the second winding to the primary

side of the converter. The advantages to this approach

are its inherent accuracy and bandwidth. Winding the

second coil on the output inductor core while maintaining

the required isolation makes this a more costly solution.

In the example, ROFF = V

O

/ 100µA. The 4 • ROFF resistor is added to compensate the one volt input level of

the IOFF pin. Without this compensation, a minor current

foldback behavior will be observed.

APPLICATION INFORMATION (cont.)

Figure 5: Fixed IOFF. Figure 6: Second inductor winding generation of

IOFF.

UDG-93010

UDG-93011

Figure 4: Inductor current waveform synthesizer.

UDG-93009

7

UC1848

UC2848

UC3848

Figure 7: Duty cycle control.

UDG-93012-1

UDG-93013-1

Maximum Volt-Second Circuit

A maximum volt-second product can be programmed by

a resistor (Rvs) from VS to VIN and a capacitor (Cvs)

from VS to ground (Figure 7). VS is discharged while the

switch is off. When the output turns on, VS is allowed to

charge. Since the threshold of the VS comparator is

much less than VIN, the charging profile at Vs will be essentially linear. If VS crosses the 4.0V threshold before

the PWM turns the output off, the VS comparator will turn

the output off for the remainder of the cycle. The maximum volt-second product is

V

IN

• TON(max) = 4.0V • Rvs • Cvs.

Maximum Duty Cycle And Soft Start

A patented technique is used to accurately program maximum duty cycle. Programming is accomplished by a divider from VREF to DMAX (Fig. 7). The value

programmed is:

D(max) = Rd1 / (Rd1 + Rd2).

For proper operation, the integrating capacitor, C

DC

,

should be larger than C

DC

(min) >T(osc) / 80k, where

T(osc) is the oscillator period. CDCalso sets the soft start

time constant, so values of C

DC

larger than minimum

may be desired. The soft start time constant is approximately:

T(ss) = 20k • C

DC

.

Ground Planes

The output driver on the UC3848 is capable of 2A peak

currents. Careful layout is essential for correct operation

of the chip. A ground plane must be employed (Fig. 8). A

unique section of the ground plane must be designated

for high di/dt currents associated with the output stage.

This point is the power ground to which to PGND pin is

connected. Power ground can be separated from the rest

of the ground plane and connected at a single point, although this is not strictly necessary if the high di/dt paths

are well understood and accounted for. VCC should be

bypassed directly to power ground with a good high frequency capacitor. The sources of the power MOSFET

should connect to power ground as should the return

connection for input power to the system and the bulk input capacitor. The output should be clamped with a high

current Schottky diode to both VCC and PGND. Nothing

else should be connected to power ground.

VREF should be bypassed directly to the signal portion of

the ground plane with a good high frequency capacitor.

Low esr/esl ceramic 1

F capacitors are recommended

for both VCC and VREF. The capacitors from CT, CDC,

and CI should likewise be connected to the signal ground

plane.

APPLICATION INFORMATION (cont.)

8

UC1848

UC2848

UC3848

UNITRODE CORPORATION

7 CONTINENTALBLVD. • MERRIMACK, NH 03054

TEL. (603) 424-2410 FAX (603) 424-3460

Figure 8: Ground plane considerations.

Figure 9: Typical application - an average current-mode isolated forward converter.

UDG-93014

UDG-93015

IMPORTANT NOTICE

T exas Instruments and its subsidiaries (TI) reserve the right to make changes to their products or to discontinue

any product or service without notice, and advise customers to obtain the latest version of relevant information

to verify, before placing orders, that information being relied on is current and complete. All products are sold

subject to the terms and conditions of sale supplied at the time of order acknowledgement, including those

pertaining to warranty, patent infringement, and limitation of liability.

TI warrants performance of its semiconductor products to the specifications applicable at the time of sale in

accordance with TI’s standard warranty. Testing and other quality control techniques are utilized to the extent

TI deems necessary to support this warranty. Specific testing of all parameters of each device is not necessarily

performed, except those mandated by government requirements.

CERT AIN APPLICATIONS USING SEMICONDUCTOR PRODUCTS MAY INVOLVE POTENTIAL RISKS OF

DEATH, PERSONAL INJURY, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE (“CRITICAL

APPLICATIONS”). TI SEMICONDUCTOR PRODUCTS ARE NOT DESIGNED, AUTHORIZED, OR

WARRANTED TO BE SUITABLE FOR USE IN LIFE-SUPPORT DEVICES OR SYSTEMS OR OTHER

CRITICAL APPLICATIONS. INCLUSION OF TI PRODUCTS IN SUCH APPLICA TIONS IS UNDERSTOOD T O

BE FULLY AT THE CUSTOMER’S RISK.

In order to minimize risks associated with the customer’s applications, adequate design and operating

safeguards must be provided by the customer to minimize inherent or procedural hazards.

TI assumes no liability for applications assistance or customer product design. TI does not warrant or represent

that any license, either express or implied, is granted under any patent right, copyright, mask work right, or other

intellectual property right of TI covering or relating to any combination, machine, or process in which such

semiconductor products or services might be or are used. TI’s publication of information regarding any third

party’s products or services does not constitute TI’s approval, warranty or endorsement thereof.

Copyright 1999, Texas Instruments Incorporated

Loading...

Loading...