UC2578

UC3578

05/99

FEATURES

• Provides Simple Single Inductor Buck

PWM Step-Down Voltage Regulation

• Drives External High Side NMOS

Switch

• 14V to 72V Input Voltage Operating

Range

• Contains 100kHz Internal Oscillator,

2V Reference and UVLO

• Soft Start on Power Up

• Overcurrent Shutdown Followed by

Soft Start

Buck Pulse Width Modulator Stepdown Voltage Regulator

14

16

11 15 10 7 6

2

3

131254

EAINV

EAOUTGNDGND

SRCOUT

SS

CS

VCC

GND GND

DIODE VGG

UC3578

C

SS

2200pF

100k

220pF

50k

R1

1k

5k

C

GG

1µF

15

C

CC

1µF

47µF

10

1N4148

C

S

1000pF

R

S

1k

R

SENSE

0.12

IRFZ34

15-40 V

IN

1µF

C

OUT

220µF

L

OUT

40µH

RECTIFIER

MBR 3100

V

OUT

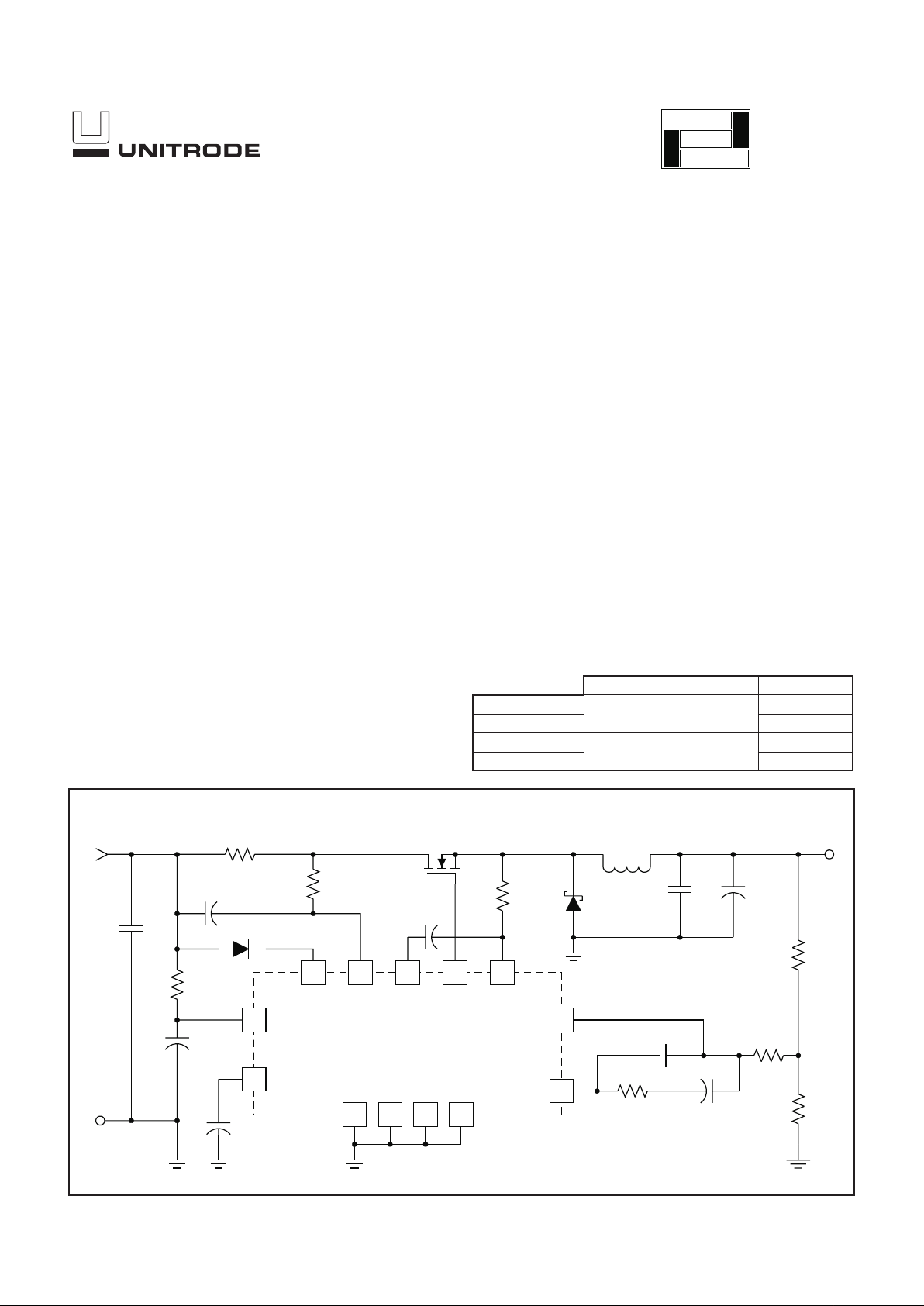

TYPICAL APPLICATION DIAGRAM

UDG-99064

DESCRIPTION

The UC3578 is a PWM controller with an integrated high side floating gate

driver. It is used in buck step down converters and regulates a positive

output voltage. Intended to be used in a distributed power system, the IC

allows operation from 14V to 72V input voltage which range includes the

prevalent telecomm bus voltages. The output duty cycle of the UC3578

can vary between 0% and 90% for operation over the wide input voltage

and load conditions.

The UC3578 simplifies the design of the single switch PWM buck converter

by incorporating a floating high side driver for an external N-channel

MOSFET switch. It also features a 100kHz fixed frequency oscillator, an

internal 2V precision reference, an error amplifier configured for voltage

mode operation, and a PWM comparator with latching logic. Complementing the traditional voltage mode control block, the UC3578 incorporates an overcurrent shutdown circuit with full cycle soft re-start to limit the

input current to a user defined maximum value during overload operation.

Additional functions include an under voltage lockout circuit to insure that

sufficient input supply voltage is present before any switching activity can

occur.

The UC2578 and the UC3578 are both available in surface mount and

thru-hole power packages.

TEMPERATURE RANGE PACKAGE

UC2578DP –40°C to +85°C Power SOIC

UC2578N Power PDIP

UC3578DP 0°C to +70°C Power SOIC

UC3578N Power PDIP

ORDERING INFORMATION

application

INFO

available

2

UC2578

UC3578

ELECTRICAL CHARACTERISTICS:

Unless otherwise specified VCC = 14V, VGG = 14V, TA=TJ.

PARAMETER TEST CONDITIONS MIN TYP MAX UNITS

Oscillator Section

Frequency VCC = 14V to 72V, EAINV = 1.9V, T

J

= 25°C 100 110 120 kHz

VCC = 11V to 14V, Over Temperature 90 120 kHz

Error Amplifier Section

EAINV EAOUT = EAINV 1.97 2 2.03 V

I

EAINV

EAOUT = EAINV 100 300 nA

EAVOL EAOUT/EAINV, 25°C 70 80 dB

EAOUT High EAINV ≤ 1.9V, I

EAOUT

= –100µA 5.5 6.2 V

EAOUT Low EAINV ≥ 2.1V, I

EAOUT

= 100µA 0.8 1.1 V

Unity Gain Bandwidth TJ= 25°C, F = 100kHz 0.85 1 MHz

PSRR, EAOUT EAOUT = EAINV, VCC = 14V 80 90 dB

Current Sense Comparator Section

Threshold (Referred to VCC) 0.4 0.5 0.6 V

Input Bias Current CS = VCC – 0.4V 0.2 1 µA

Propagation Delay V

OVERDRIVE

= 250mV 0.7 1.2 µs

Blanking Time V

OVERDRIVE

= 250mV 75 200 300 ns

Gate Drive Output Section

VOH I

OUT

= –200mA 9.5 11 V

VOL I

OUT

= 20mA 0.2 0.36 V

I

OUT

= 200mA 1.5 2 V

Rise Time TJ= 25°C, C

LOAD

= 1nF 40 70 ns

Fall Time TJ= 25°C, C

LOAD

= 1nF 40 70 ns

Pulse Width Modulator Section

Maximum Duty Cycle EAINV ≤ 1.9V 85 90 %

Minimum Duty Cycle EAINV ≥ 2.1V 0 %

Modulator Gain EAOUT = 2.5V to 3.5V 30 %/V

Undervoltage Lockout Section

Start Threshold OUT – SRC, EAINV ≤ 1.9V, SRC = 0V 10 11 12 V

UVLO Hysteresis 1.5 2 2.5 V

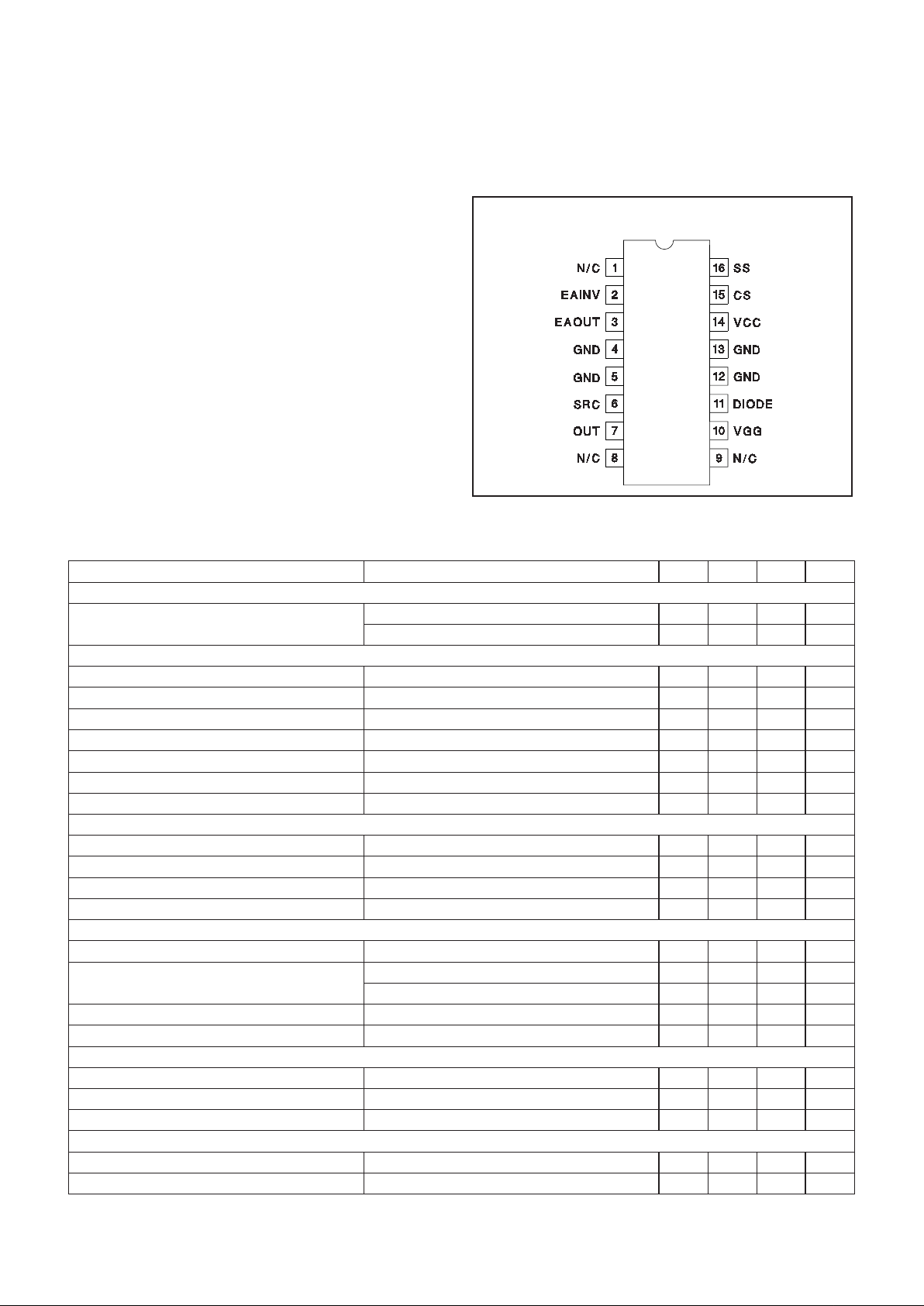

CONNECTION DIAGRAM

Note: The four GND pins are internally connected.

DIL-16, SOIC-16 (Top View)

N or DP Packages

VCC. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . +72V

EAINV . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . –0.3V to +10V

EAOUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . –0.3V to +10V

SS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . –0.3V to +10V

DIODE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . –0.3V to VCC

VGG . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . –0.3V to VCC +14V

CS. . . . . . . . . . . . . . . . . . . . . . . . . . . . VCC – 5V to VCC +0.6V

I

OUT

Pulsed . . . . . . . . . . . . . . . . . . . . . . . . . . . . –0.8A to +0.6A

SRC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . –0.6V to VCC

Storage Temperature . . . . . . . . . . . . . . . . . . . −65°C to +150°C

Junction Temperature. . . . . . . . . . . . . . . . . . . –55°C to +150°C

Lead Temperature (Soldering, 10 sec.). . . . . . . . . . . . . +300°C

Currents are positive into, negative out of the specified terminal.

Consult Packaging Section of Databook for thermal limitations

and considerations of packages.

ABSOLUTE MAXIMUM RATINGS

3

UC2578

UC3578

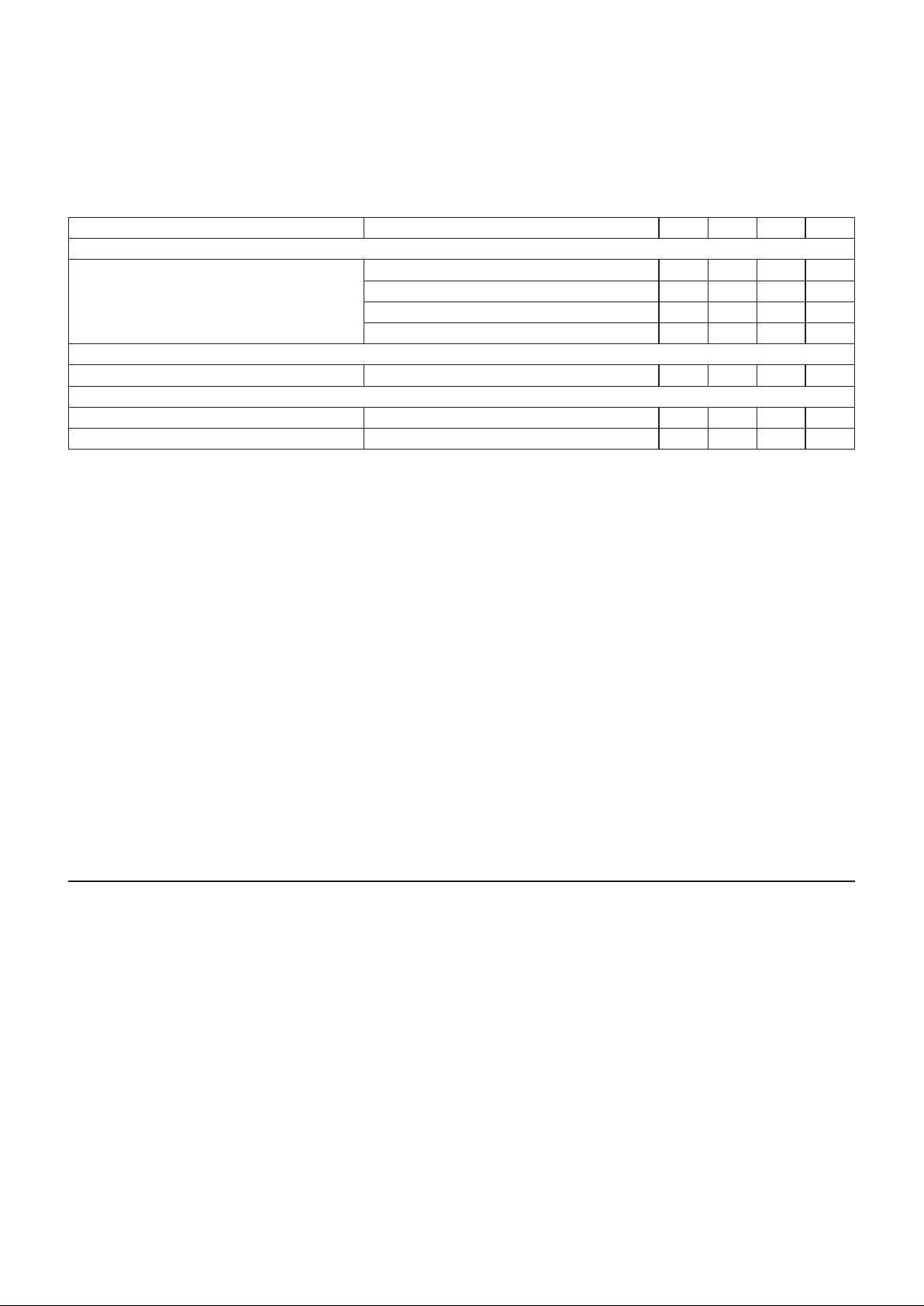

ELECTRICAL CHARACTERISTICS:

Unless otherwise specified VCC = 14V, VGG = 14V, TA=TJ.

PARAMETER TEST CONDITIONS MIN TYP MAX UNITS

VGG Regulator Section

VGG – SRC VCC = 72V, SRC = 0V, I

VGG

= –7mA 14.5 15.25 17 V

VCC = 50V, SRC = 0V, I

VGG

= –7mA 14 14.75 16 V

VCC = 15V, SRC = 0V, I

VGG

= –7mA 13 13.75 14.5 V

VCC = 11V, SRC = 0V, I

VGG

= –7mA 9.5 10 10.5 V

Soft Start Ramp Section

Soft Start Ramp Current –30 –45 µA

Supply Current Section

I

VCC

EAINV ≥ 2.1V, SRC = 0V 10 14 mA

I

VGG

EAINV ≥ 2.1V, SRC = 0V 7 10.5 mA

CS: Peak current limit sense pin. Senses the current

across a current sense resistor placed between VCC and

the drain of the NMOS buck switch. OUT will be held low

(NMOS buck switch off) if VCC – CS exceeds 0.5V.

DIODE: An external small signal diode (1N4148 typical)

is connected here, anode to VCC and cathode to

DIODE, to implement the VGG regulator function.

EAINV: Inverting input to error amplifier. V

OUT

sense

feedback is connected to this pin. The non-inverting input

of the error amplifier is internally connected to 2V.

EAOUT: Output of the error amplifier. Use EAOUT and

EAINV for loop compensation components.

GND: Circuit Ground. The four ground pins are internally

connected together by the fused leadframe of the

package. They provide the primary thermal conduction

path for dissipating junction heat.

OUT: Gate drive for the external NMOS switch

connected between VCC and the buck inductor.

SRC: This pin is connected to the junction of the external

NMOS switch source, the floating voltage source

capacitor, the free-wheeling diode cathode, and buck

inductor.

SS: The external soft start capacitor is connected to this

pin.

VGG: An external capacitor connected from VGG to

SRC completes the floating voltage source for the

floating gate driver. A1µF capacitor is recommended.

VCC: Input supply voltage. This pin supplies an internal

ground referenced voltage regulator that supplies the IC

and an on-chip regulated floating voltage source (VGG –

SRC) used by the floating driver to drive the external

NMOS buck switch. This pin should be bypassed with a

high quality ceramic capacitor.

PIN DESCRIPTIONS

The UC3578 Floating Buck Controller is a high frequency

switching regulator with a floating driver which provides

PWM control for non-isolated buck converters. The controller operates at a fixed 100 kHz switching frequency,

and in voltage mode control. The duty cycle range of the

PWM output is 0% to 90% allowing for a wide range of

input voltages (14V minimum with transients to 72V).

The regulator features an undervoltage lockout threshold

of 11V with approximately 2V hysterisis as well as soft

start capability. The typical application circuit shown is for

a 15V to 40V input and a 12V at 3A output.

To ensure proper operation of the floating driver, an external capacitor (1µF ceramic) must be connected from

VGG to SRC, and to the source of the external MOSFET

through a small resistor, as shown in the typical application diagram and in Fig 2. This capacitor provides the energy for the high side driver. The gate drive voltage to

the MOSFET is internally regulated to 14V. A diode

(1N4148) is required from the input voltage to DIODE.

This allows the floating drive capacitor to charge during

conduction of the output rectifier but prevents its discharge back into the supply rail. A 1µF ceramic capacitor

is recommended from VCC to ground to provide high frequency decoupling. Additional decoupling of this pin

could be accomplished by a low value resistor between

VCC and V

IN

anda1µF capacitor from VCC to GND as

shown in the schematic.

APPLICATION INFORMATION

4

UC2578

UC3578

Current Limit

The current sense pin provides overcurrent shutdown.

As can be seen from the block diagram, the overcurrent

comparator is wire ANDed with the oscillator after an internally set blanking time. The I

LIMIT

threshold level is set

by the current sense resistor from R

SENSE

.

I

V

R

LIMIT

SENSE

=

05.

An optional filter can be added (RSCS) from the current

sense resistor to CS to provide high frequency filtering of

the current sense signal if necessary.

During a current limit condition, the soft start capacitor on

SS is discharged until its voltage level reaches 1.2V. During this time, a duty cycle clamp is activated to approximately 0.6V above the voltage level on the SS capacitor.

This condition persist until the SS capacitor is discharged

to 1.2V, thus disabling the output driver. At this time, the

SS capacitor is allowed to charge to 5V through the 50µA

current source and normal operation resumes when the

SS capacitor reaches 5V. During the condition described,

the regulator enters a hiccup current limit mode of operation which limits the power dissipation in the MOSFET

and output rectifier under a short circuit condition.

Error Amplifier

The onboard error amplifier of the UC3578 is a voltage

amplifier with its non-inverting input tied to an internal 2V

reference. As usual, loop compensation can be added

from the inverting input of EAINV to the error amplifier

output at EAOUT. Consideration must be given when

choosing the values of the compensation components

around the amplifier so that the output swing of the amplifier is not restricted. The output of the amplifier can

source 100µA typically.

General

As in any buck converter, when the switch is off, the

source flies low due to the conduction of the

free-wheeling rectifier. The source (SRC) is pulled below

ground by an amount determined by the forward voltage

drop of the rectifier and by any transient voltage spike

from inductance in this path. The occurrence of this condition could result in erratic operation of the IC during this

period if the negative excursion is not limited. This is because of conduction of current in the substrate of the IC

due to the source pin being pulled below ground and forward biasing the internal substrate PN junction. To limit

this effect, a small resistor (15Ω) can be placed in series

between the MOSFET source and the SRC pin as shown

in Fig. 1. Too large a resistor will limit the drive to the

Figure 1. Block diagram.

APPLICATION INFORMATION (cont.)

UDG-97006

5

UC2578

UC3578

MOSFET and result in startup problems with the regulator. A Schottky rectifier is used for the free-wheeling diode to limit the negative excursion of the source. This will

also limit the reverse recovery current thus limiting the inductive voltage spike.

In applications where transient load excursions may result in a no load condition, it is necessary that the output

of the regulator be loaded with a small load current

(10mA to 15mA). This will prevent the output voltage

from going unregulated at no load. This small load current is necessary for proper operation of the floating

driver since the source must fly low to charge up the

floating driver capacitance.

Thermal Considerations

For proper operation and reliability of the UC3578,

proper thermal management is essential. It is important

that the designer keep in mind that with surface mount

packages, a significant amount of the heat that the device generates is conducted out through the lead frame.

Because of this, the PCB design becomes a critical part

of the thermal management system. Worst case junction-to-ambient thermal resistance for different package

configurations are given in a table in the data book in the

package information section.

The maximum ambient operating temperature is an important factor in determining what the maximum operating voltage can be for a particular application. For

example, if we assume a maximum operating ambient

temperature of 70°C we can determine what the maximum allowable input voltage can be given other parameters such as package thermal impedance and MOSFET

total gate charge by following the procedure outlined below;

()

TTCCC

J

A

max

––=° °=°125 70 55

. (1)

Pd=

55 C

58 C / W

=0.95W

°

°

,

(2)

where 58°C/W is the worst case theta j-a for the 16 pin

DP package and Pd is the package power dissipation.

1

2

3

4

5

6

7

8

16

15

14

13

12

11

10

9

1µF

470pF

0.1µF

0.01µF

1N4148

N/C

EAINV

EAOUT

GND

GND

SRC

OUT

N/C

SS

CS

VCC

GND

GND

DIODE

VGG

N/C

UC3578

330

0.1µF0.1µF

8.25k

5.62k

2200µF2200µF

680pF

51

1

2

10

30µH

470

200

13

1N4148

5

220µF

220µF

VIN(–)

V

IN

(+)

15k

TIP47

1N4745A

47µF

47k

2200pF

100pF

2

3

1

HS3

23

1

HS1

IRF530

V

OUT

(–)

V

OUT

(+)

HS1, HS2, HS3: HEATSINKS

HS2

MBR10100

Figure 2. Detailed application schematic for the UC3578 evaluation board.

APPLICATION INFORMATION (cont.)

UDG-99100

6

UC2578

UC3578

UNITRODE CORPORATION

7 CONTINENTALBLVD. • MERRIMACK, NH 03054

TEL. (603) 424-2410 FAX (603) 424-3460

0

5

10

15

20

25

30

0 1020304050607080

VCC (V)

ICC (mA)

-55°C

-25°C

25°C

85°C

125°C

Figure 3. ICCvs. VCC vs. temperature.

()

Pd Qg kHz mA V

IN

=• + •100 19

,

(3)

where Qg is the total MOSFET gate charge and 19mA is

the maximum quiescent current for the UC3578 (I

CC

+

I

GG

) from the data sheet. The switching frequency of the

buck converter is 100kHz.

The gate charge can be determined from the MOSFET

data sheet. As an example, for a IRFZ34 which has a total gate charge of 46nC, substituting for Pd in equation 3:

()

0 95 46 100 19.

WnCkHzmAV

IN

=• +•

, and

()

V=

0.95W

0.0236A

= 40V

IN

max

.

Therefore, at 70°C using a IRFZ34 MOSFET the maximum input voltage is limited to 40V to maintain a maximum junction temperature of 125°C in the 16 pin DP

package.

Higher input voltages can be achieved by choosing a

MOSFET with a lower total gate charge or by a reduced

ambient operating temperature or by reducing the theta

j-a of the package by improving the PCB mounting

method. It is recommended that the four GND pins (4, 5,

12 and 13) be connected to a ground plane to provide a

low resistance thermal path. If a ground plane is not

available, a heat spreader on a double sided PC board is

recommended.

Note: Thermal impedance number is based on device

mounted to 5 square inch FR4 PC board with one ounce

copper. From Unitrode 95-96 data book Table 1, page

9-8, when resistance range is given, lower thermal impedance values are for 5 square inch aluminum PC

board.

ADDITIONAL INFORMATION

Please refer to the following Unitrode topic for additional

application information.

[1] Application Note U-167,

Design and Evaluation of a

48V to 5V Telecom Buck Converter using the UC3578

Control IC

by Mark Dennis.

APPLICATION INFORMATION (cont.)

IMPORTANT NOTICE

T exas Instruments and its subsidiaries (TI) reserve the right to make changes to their products or to discontinue

any product or service without notice, and advise customers to obtain the latest version of relevant information

to verify, before placing orders, that information being relied on is current and complete. All products are sold

subject to the terms and conditions of sale supplied at the time of order acknowledgement, including those

pertaining to warranty, patent infringement, and limitation of liability.

TI warrants performance of its semiconductor products to the specifications applicable at the time of sale in

accordance with TI’s standard warranty. Testing and other quality control techniques are utilized to the extent

TI deems necessary to support this warranty. Specific testing of all parameters of each device is not necessarily

performed, except those mandated by government requirements.

CERT AIN APPLICATIONS USING SEMICONDUCT OR PRODUCTS MAY INVOLVE POTENTIAL RISKS OF

DEATH, PERSONAL INJURY, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE (“CRITICAL

APPLICATIONS”). TI SEMICONDUCTOR PRODUCTS ARE NOT DESIGNED, AUTHORIZED, OR

WARRANTED TO BE SUITABLE FOR USE IN LIFE-SUPPORT DEVICES OR SYSTEMS OR OTHER

CRITICAL APPLICATIONS. INCLUSION OF TI PRODUCTS IN SUCH APPLICA TIONS IS UNDERSTOOD T O

BE FULLY AT THE CUSTOMER’S RISK.

In order to minimize risks associated with the customer’s applications, adequate design and operating

safeguards must be provided by the customer to minimize inherent or procedural hazards.

TI assumes no liability for applications assistance or customer product design. TI does not warrant or represent

that any license, either express or implied, is granted under any patent right, copyright, mask work right, or other

intellectual property right of TI covering or relating to any combination, machine, or process in which such

semiconductor products or services might be or are used. TI’s publication of information regarding any third

party’s products or services does not constitute TI’s approval, warranty or endorsement thereof.

Copyright 1999, Texas Instruments Incorporated

Loading...

Loading...