4/97

• Precision Phase Locked Frequency

Control System

• Crystal Oscillator

• Programmable Reference Frequency

Dividers

• Phase Detector with Absolute Frequency

Steering

• Digital Lock Indicator

• Double Edge Option on the Frequency

Feedback Sensing Amplifier

• Two High Current Op-Amps

• 5V Reference Output

Phase Locked Frequency Controller

UC1633

UC2633

UC3633

FEATURES

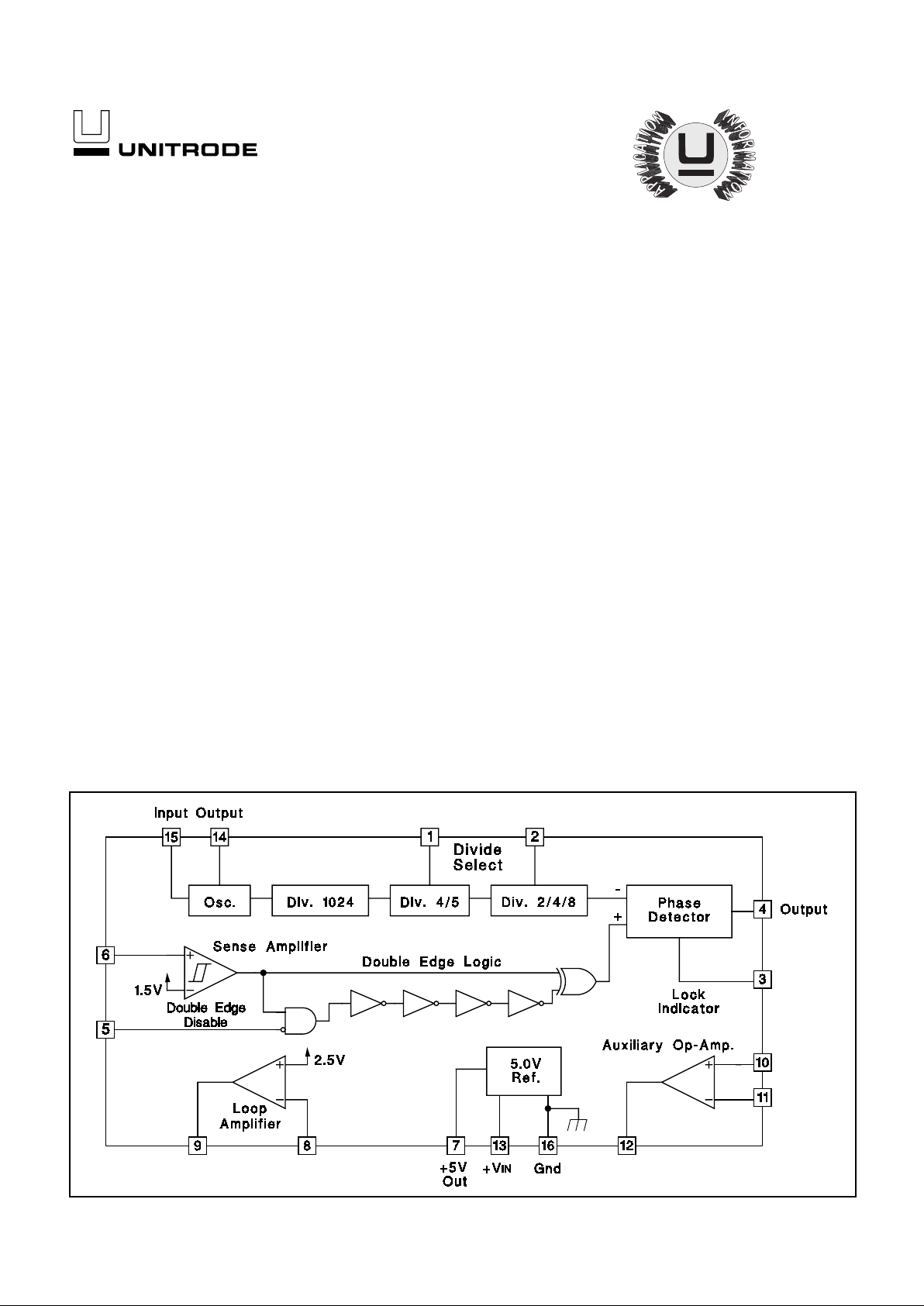

The UC1633 family of integrated circuits was designed for use in phase

locked frequency control loops. While optimized for precision speed

control of DC m ot ors, t hes e devices are u niversal en ough for most applications that require phase locked control. A precise reference frequency can be generated us ing the device’s high frequency oscillator

and programma ble frequency dividers. The oscillator operates using a

broad range of crystals, or, can function as a buffer stage to an external

frequency source.

The phase detector on these integrated circuits compares the reference freque ncy with a f requenc y/phase feedback signal. In the case of

a motor, feedback is obtained at a hall ou tput of other speed detection

device. This signal is buffered by a sense ampilfier that squares up the

signal as it goes into the digital phase detector. The phase detector responds propor tionally to the phase error between the reference and the

sense amplifier output. This phase detector includes absolute frequency steering to provide maximum drive signals when any frequency

error exists. This feature allows optimum start-up and lock times to be

realized.

Two op-amps are included that can be configured to provide necessary

loop filtering. The outputs of the op-amps will source or sink in excess

of 16mA, so they can provide a low impedence control signal to driving

circuits.

Additional featur es i nc l ud e a do uble edge option on the sense amplifier

that can be use d to double the loop reference frequency for increased

loop bandwidths. A digital lock signal is provided that indicates when

there is zero fr equen cy erro r, and a 5V reference output allows DC operating levels to be accurately set.

DESCRIPTION

BLOCK DIAGRAM

1

PARAMETER TEST CONDITIONS MIN. TYP. MAX. UNITS

Supply Current +VIN = 15V 20 28 mA

Reference

Output Voltage (V

REF

) 4.75 5.0 5.25 V

Load Regulation I

OUT

= 0V to 7mA 5.0 20 mV

Line Regulation +V

IN

= 8V to 15V 2.0 20 mV

Short Circuit Current V

OUT

= 0V 12 30 mA

Oscillator

DC Voltage Gain Oscillator Input to Oscillator Output 12 16 20 dB

Input DC Level (V

IB

) Oscillator Input Pin Open, TJ = 25°C 1.15 1.3 1.45 V

Input Impedance (Not e 3) V

IN

= VIB ±0.5V, TJ = 25°C 1.3 1.6 1.9 k

Ω

Output DC Level Oscillator Input Pin Open, TJ = 25°C 1.2 1.4 1.6 V

Maximum Operating Frequency 10 MHz

Dividers

Maximum Input Frequency Input = 1VPP at Oscillator Input 10 MHz

Div. 4/5 Input Current Input = 5V (Div. by 4) 150 500

µ

A

Input = 0V (Div. by 5) -5.0 0.0 5.0

µ

A

Div. 4/5 Threshold 0.5 1.6 2.2 V

Note 3: These impedence levels will vary with TJ at about 1700ppm/°C

UC1633

UC2633

UC3633

Input Supply Voltage (+VIN) . . . . . . . . . . . . . . . . . . . . . . . . +20V

Reference Output Current . . . . . . . . . . . . . . . . . . . . . . . . -30mA

Op-Amp Output Currents . . . . . . . . . . . . . . . . . . . . . . . . ±30mA

Op-Amp Input Voltages . . . . . . . . . . . . . . . . . . . . . -.3V to +20V

Phase Detector Output Current . . . . . . . . . . . . . . . . . . . ±10mA

Lock Indicator Output Current . . . . . . . . . . . . . . . . . . . . +15mA

Lock Indicator Output Voltage . . . . . . . . . . . . . . . . . . . . . . +20V

Divide Select Input Voltages . . . . . . . . . . . . . . . . . -.3V to +10V

Double Edge Disable Input Voltage . . . . . . . . . . . . -.3V to +10V

Oscillator Input Voltage . . . . . . . . . . . . . . . . . . . . . . -.3V to +5V

Sense Amplifier Input Voltage . . . . . . . . . . . . . . . . .3V to +20V

Power Dissipation at TA = 25°C (Note 2 . . . . . . . . . . . 1000mW

Power dissipation at TC = 25°C (Note 2) . . . . . . . . . . . 2000mW

Operating Junction Temperature . . . . . . . . . . . -55°C to +150°C

Storage Temperature . . . . . . . . . . . . . . . . . . . . -65°C to +150°C

Lead Temperature (Soldering, 10 Seconds) . . . . . . . . . . 300°C

ABSOLUTE MAXIMUM RATINGS

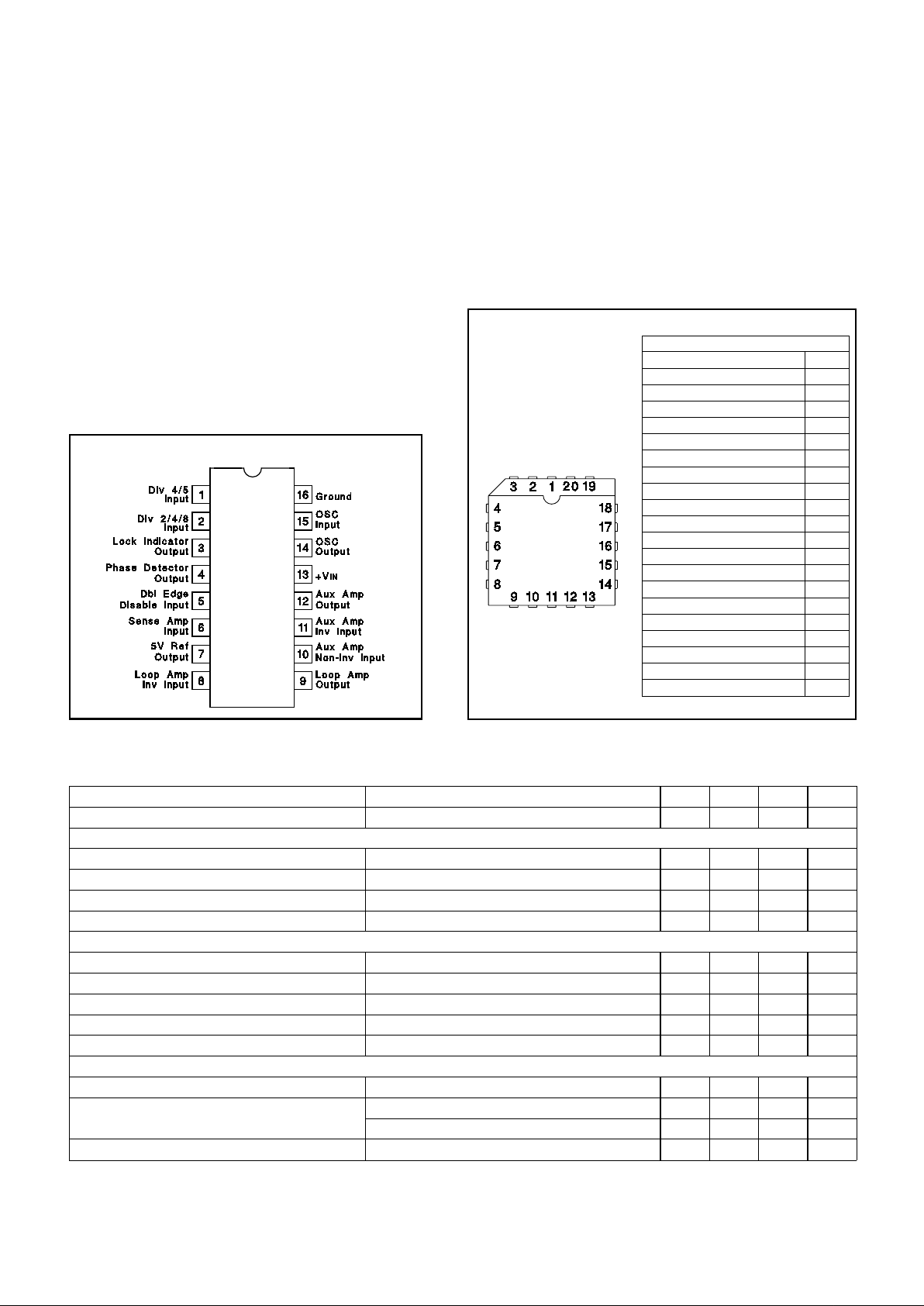

CONNECTION DIAGRAMS

PACKAGE PIN FUNCTION

FUNCTION PIN

N/C

1

Div 4/5 Input

2

Div 2/4/8 Input

3

Lock Indicator Output

4

Phase Detector Output

5

N/C

6

Dbl Edge Disable Input

7

Sense Amp Input

8

5V Ref Output

9

Loop Amp Inv Input

10

N/C

11

Loop Amp Output

12

Aux Amp Non-Inv Input

13

Aux Amp Inv Input

14

Aux Amp Output

15

N/C

16

+V

IN

17

OSC Output

18

OSC Input

19

Ground

20

PLCC-20 (T OP VI EW)

Q Package

Note1: V oltages are referenced to ground, (Pin 16). Currents

are positive into, negative out of, the specified terminals.

Note 2: Consult Packaging Section of Databook for thermal limitations and considerations of package.

DIL-16 (TOP VIEW)

J or N Package

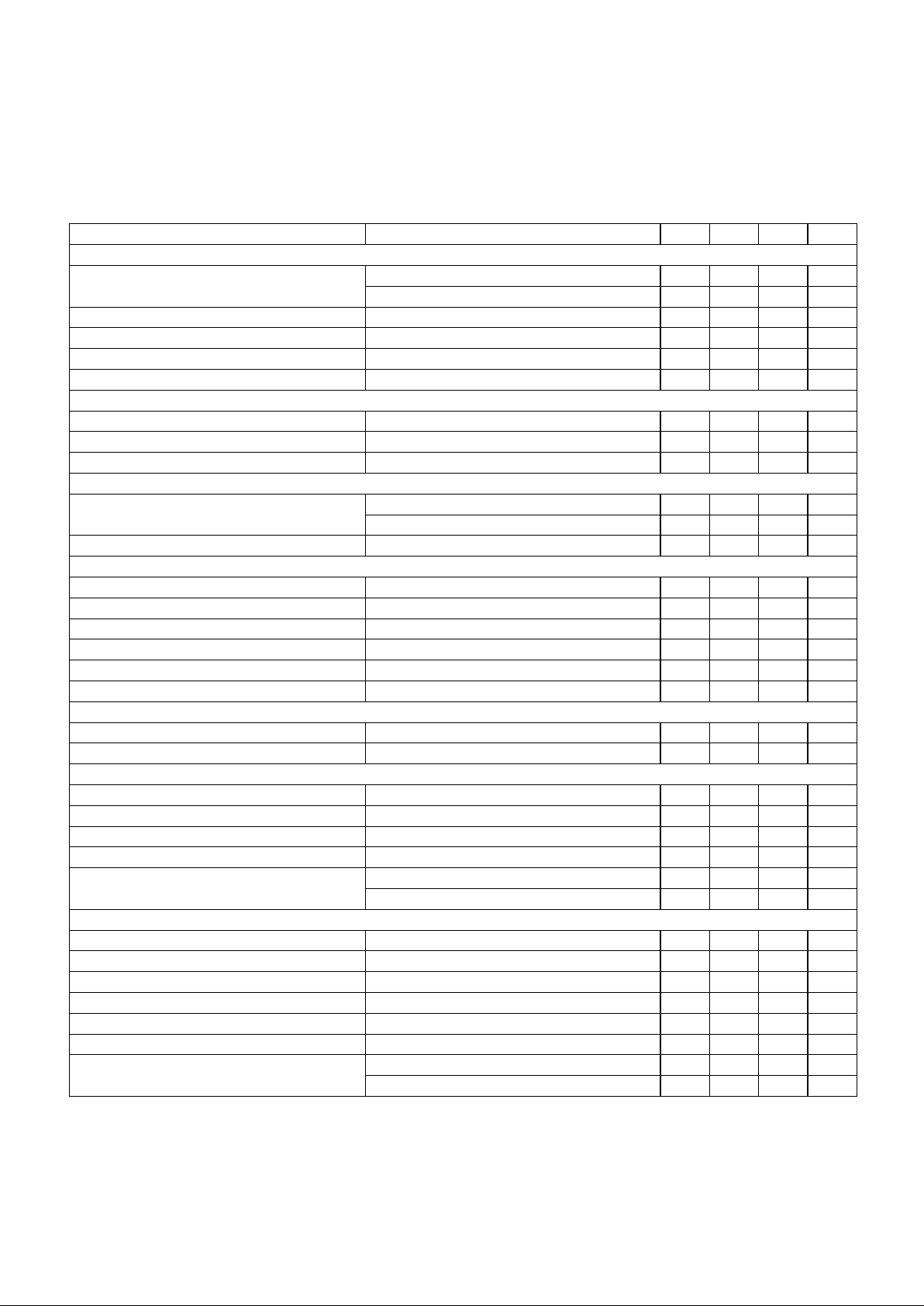

ELECTRICAL CHARACTERISTICS:

(Unless otherwise stated, these specifications apply for TA = 0°C to +70°C for the

UC3633, -25°C to +85°C for the UC2633, -55°C to +125°C for the UC1633, +VIN =

12V; TA=TJ.)

2

PARAMETER TEST CONDITIONS MIN. TYP. MAX. UNITS

Dividers (cont.)

Div. 2/4/8 Input Curre nt Input = 5V (Div. by 8) 150 500

µ

A

Input = 0V (Div. by 2) -500 -150

µ

A

Div. 2/4/8 Open Circui t Vol tage Input Current = 0µA (Div. by 4) 1.5 2.5 3.5 V

Div. by 2 Threshold 0.20 0.8 V

Div. by 4 Threshold 1.5 3.5 V

Div. by 8 Threshold Volts Below V

REF

0.20 0.8 V

Sense Amplifier

Threshold Voltage Percent of V

REF

27 30 33 %

Threshold Hysteresis 10 mV

Input Bias Current Input = 1.5V -1.0 -0.2

µ

A

Double Edge Disable Input

Input Current Input = 5V (Disabled) 150 500

µ

A

Input = 0V (Enabled) -5.0 0.0 5.0

µ

A

Threshold Voltage 0.5 1.6 2.2 v

Phase Detector

High Output Level Positive Phase/Freq. Error, Volts Below V

REF

0.2 0.5 V

Low Output Level Negative Phase/Freq. Error 0.2 0.5 V

Mid Output Level Zero Phase/Freq. Error, Percen t of V

REF

47 50 53 %

High Level Maxi mum Source Current V

OUT

= 4.3V 2.0 8.0 mA

Low Level Maximum Sink Current V

OUT

= 0.7V 2.0 5.0 mA

Mid Level Output Im pe da nc e (Note 3) I

OUT

= -200 to +200µA, TJ = 25°C 4.5 6.0 7.5 k

Ω

Lock Indicator Output

Saturation Voltage Freq. Error, I

OUT

= 5mA 0.3 0.45 V

Leakage Current Zero Freq. Error, V

OUT

= 15V 0.1 1.0

µ

A

Loop Amplifier

NON INV. Reference Voltage Percent of V

REF

47 50 53 %

Input Bias Current Input = 2.5V -0.8 -0.2

µ

A

AVOL 60 75 dB

PSRR +V

IN

= 8V to 15V 70 100 dB

Short Circuit Current Source, V

OUT

= 0V 16 35 mA

Sink, V

OUT

= 5V 16 30 mA

Auxiliary Op-Amp

Input Offset Voltage V

CM

= 2.5V 8 mV

Input Bias Current VCM = 2.5V -0.8 -0.2

µ

A

Input Offset Current V

CM

= 2.5V .01 0.1

µ

A

AVOL 70 120 dB

PSRR +V

IN

= 8V to 15V 70 100 dB

CMRR VCM = 0V to 10V 70 100 dB

Short Circuit Current Source, V

OUT

= 0V 16 35 mA

Sink, V

OUT

= 5V 16 30 mA

Note 3: These impedence levels will vary with TJ at about 1700pp m/ °C

UC1633

UC2633

UC3633

ELECTRICAL

CHARACTERISTICS (cont.):

(Unless otherwise stated, these specifications apply for TA = 0°C to +70°C for t he UC3 633,

-25°C to +85°C for the UC2633, -55°C to +125°C for the UC1633, +VIN = 12V; TA=TJ.)

3

UC1633

UC2633

UC3633

Determining the Oscillator Frequency

The frequency at the oscillator is deter mined by the desired RPM of the motor, the divide ratio selected, the

number of poles in the motor, and the state of the double

edge select pin.

f

OSC

(Hz) = (Divide Rati o) • (Motor RPM ) • (1/60 SEC/MIN) •

(No. of Rotor Poles/2) • (x 2 if Pin 5 Low)

The resulting referen ce frequency appearing at the phase

detector inputs is equal to the oscillator frequency divided

by the selected divide ratio. If the double edge option is

used, (Pin 5 low), the f requency of the sense amplifier input signal is do ubled by responding to both the rising and

falling edges of the input signal. Using this option, the loop

reference frequency can be doubled for a given motor

RPM.

APPLICATION AND OPERATING INFORMATION

Recommended Oscillator Configuration Using AT Cut Quartz Crystal

External Reference Frequency Input

Method for Deriving Rotation Feedback Signal from Analog Hall Effect Device

*This signal may require filtering if chopped mode drive scheme is used.

4

Phase Detector Operation

The phase detector on these devices is a digital circuit

that responds to the rising edges of the detector’s two inputs. The phase detector output has three states: a high,

5V state, a low, 0V state, and a middle, 2.5V state. In the

high and low states the output impedance of the detector

is low and the middle state output impedence is high, typically 6.0kΩ. When there is any static frequency difference

between the inputs, the detector output is fixed at its high

level if the +input (the sen se ampl ifier signal) is greater in

frequency, and fixed at its low level if the -input (the reference frequency signal) is greater in frequency.

When the frequencies of the two inputs to the detector

are equal, the phase detector switches between its middle

state and either the high or low st ates, dep ending on the

relative phase of the two signals. If the +input is leading in

phase then, during each period of the input fr equency, the

detector output will be high for a time equal to the time difference between the rising edges of the inputs, and will

be at its middle level for the remainder of the period. If the

phase relationship is reversed, then the detector will go

low for a time proportional to the phase difference of the

inputs. The resulting gain of the phase detector. kø, is

5V/4π radians or about 0.4V/radian. The dynamic range of

the detector is ±2π radians.

The operation of the phase detector is illustrated in the

figures below. The upper figure shows typical voltage

waveforms seen at the detector output for leading and

lagging phase conditions. The lower figure is a state diagram of the phas e det ect or log ic. In this figure, the circles

represent the 10 possible states of the logic, and the connecting arrows represent the transition events/paths to

and from these states. Transition arrows that have a clockwise rotation are the result of a rising edge on the +input,

and conversely, those with counter-clockwise rotation are

tied to the rising edge of the -input signal.

The normal operational states of the logic are 6 and 7 for

positive phase er ror, 1 and 2 for a negative phase error.

States 8 and 9 occur during positive frequency error, 3

and 4 during negative frequency error. States 5 and 10

occur only as the inputs cross over from the frequency error to a normal phase error only condition. The lev el of the

phase detector output is determined by the logic state as

defined in th e state diagram figure. The lock indicator output is high, off, when the detector is in states 1, 2, 6, or 7.

UC1633

UC2633

UC3633

Ty pical Phase Detector Output Waveforms

Phase Detector State Diagram

APPLICATION AND OPERATION INFORMATION

5

UC1633

UC2633

UC3633

APPLICATION AND OPERATION INFORMATION

ν

OUT

ν

IN

(

s

) =

R

3

R

1

•

1 +

s

⁄

ω

z

1 +

s

⁄

ω

p

ω

p

=

1

R

2

C

1

ω

z

=

1

(R

1

+ R

2

)

C

1

Where: |∆V

OUT

| = |V

OUT

- 2.5V|

and V

OUT

= DC Operating Voltage At

Loop Amplifier Output During Phase Lock

If: (V

OUT

- 2.5) > 0, R4 Goes to 0V

(V

OUT

- 2.5) < 0, R4 Goes to 5.0V

* The static phase error of the loop is easily adjusted by

adding resistor, R

4

, as shown. To lock at zero phase error

R

4

is determined by:

R

4

=

2.5V

•

R

3

| ∆

V

OUT

|

ν

OUT

ν

IN

(

s

) =

1

1

+

s 2

ζ

ω

N

+

s

2

ω

N

2

ω

N

=

1

√

R

1R2C1C2

ζ

=

1

2

Q

=

1

2

√

C

2

C

1

R

1

+

R

2

√

R1R

2

Note: with R1 = R2,

ζ =

√

C

2

C

1

Reference Filter Design Aid - Gain Response

Reference Filter Design Aid - Phase Response

Reference Filter Configuration

Suggested Loop Filter Configuration

6

Design Example

UC1633

UC2633

UC3633

Bode Plots - Design Example Open Loop Response

1.)

KLF(s) • KRF(s)

2.*)

N

•

K

φ

•

G

PD

•

K

T

s

2

•

J

3.) Combined Overall Open Loop Response

Where:

K

LF

(s) = Loop Filter Response

K

RF

(s) = Reference Filter Response

N = 4 (Using Double Edge Sensing With 4 Pole

Motor)

Kφ = Phase Detector Gain (.4V/RAD)

G

PD

= Power Stage Transductance (1A/V)

K

T

= Motor Torque Constant (.022NM/A)

J = Motor Moment of Inertia (.0015NM/A - SEC

2

)

s = 2πjf

*Note: For a current mode driver the electrical time constant, LM / RM, of the motor does n ot en te r in to th e s ma ll si gn al res po ns e .

If a voltage mode drive sc heme is used, then the asymptote, plot ted as

2

above, can be approximated by:

N

• K φ

•

K

PD

•

K

T

s

2 • J •

R

M

if: R

M

>

K

T

√

L

M

J

and,

K

T

2

2π • J •

R

M

< f <

R

M

2π

•

L

M

Here: KPD = Voltage gain of Driver Stage

R

M

= Motor Win di ng R e sistance

LM = Motor Wind in g Inductance

APPLICATION AND OPERATION INFORMATION

UNITRODE CORPORATION

7 CONTINENTAL BLVD. • MERRIMACK, NH 03054

TEL. (603) 424-2410 • FAX (603) 424-3460

7

IMPORTANT NOTICE

T exas Instruments and its subsidiaries (TI) reserve the right to make changes to their products or to discontinue

any product or service without notice, and advise customers to obtain the latest version of relevant information

to verify, before placing orders, that information being relied on is current and complete. All products are sold

subject to the terms and conditions of sale supplied at the time of order acknowledgement, including those

pertaining to warranty, patent infringement, and limitation of liability.

TI warrants performance of its semiconductor products to the specifications applicable at the time of sale in

accordance with TI’s standard warranty. Testing and other quality control techniques are utilized to the extent

TI deems necessary to support this warranty. Specific testing of all parameters of each device is not necessarily

performed, except those mandated by government requirements.

CERT AIN APPLICATIONS USING SEMICONDUCTOR PRODUCTS MAY INVOLVE POTENTIAL RISKS OF

DEATH, PERSONAL INJURY, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE (“CRITICAL

APPLICATIONS”). TI SEMICONDUCTOR PRODUCTS ARE NOT DESIGNED, AUTHORIZED, OR

WARRANTED TO BE SUITABLE FOR USE IN LIFE-SUPPORT DEVICES OR SYSTEMS OR OTHER

CRITICAL APPLICATIONS. INCLUSION OF TI PRODUCTS IN SUCH APPLICA TIONS IS UNDERSTOOD T O

BE FULLY AT THE CUSTOMER’S RISK.

In order to minimize risks associated with the customer’s applications, adequate design and operating

safeguards must be provided by the customer to minimize inherent or procedural hazards.

TI assumes no liability for applications assistance or customer product design. TI does not warrant or represent

that any license, either express or implied, is granted under any patent right, copyright, mask work right, or other

intellectual property right of TI covering or relating to any combination, machine, or process in which such

semiconductor products or services might be or are used. TI’s publication of information regarding any third

party’s products or services does not constitute TI’s approval, warranty or endorsement thereof.

Copyright 1999, Texas Instruments Incorporated

Loading...

Loading...