TUSB9260

USB 3.0 TO SATA BRIDGE

Data Manual

PRODUCTION DATA information is current as of publication date.

Products conform to specifications per the terms of the Texas

Instruments standard warranty. Production processing does not

necessarily include testing of all parameters.

Literature Number: SLLS962C

December 2009–Revised July 2010

TUSB9260

SLLS962C–DECEMBER 2009–REVISED JULY 2010

www.ti.com

Contents

1 MAIN FEATURES ................................................................................................................ 5

1.1 TUSB9260 Features ........................................................................................................ 5

1.2 Target Applications ......................................................................................................... 5

2 INTRODUCTION .................................................................................................................. 6

2.1 System Overview ........................................................................................................... 6

2.2 Device Block Diagram ...................................................................................................... 6

3 OPERATION ....................................................................................................................... 8

3.1 General Functionality ....................................................................................................... 8

3.2 Firmware Support ........................................................................................................... 9

3.3 GPIO/PWM LED Designations ............................................................................................ 9

3.4 Power Up and Reset Sequence ......................................................................................... 10

4 SIGNAL DESCRIPTIONS ..................................................................................................... 11

5 CLOCK CONNECTIONS ...................................................................................................... 15

5.1 Clock Source Requirements ............................................................................................. 15

5.2 Clock Source Selection Guide ........................................................................................... 15

5.3 Oscillator .................................................................................................................... 16

5.4 Crystal ....................................................................................................................... 16

6 ELECTRICAL SPECIFICATIONS .......................................................................................... 17

6.1 Absolute Maximum Ratings .............................................................................................. 17

6.2 Recommended Operating Conditions .................................................................................. 17

6.3 DC Electrical Characteristics for 3.3-V Digital I/O ..................................................................... 17

7 POWER CONSUMPTION ..................................................................................................... 18

2 Contents Copyright © 2009–2010, Texas Instruments Incorporated

TUSB9260

www.ti.com

SLLS962C–DECEMBER 2009–REVISED JULY 2010

List of Figures

2-1 Device Block Diagram............................................................................................................. 7

5-1 Typical Crystal Connections .................................................................................................... 15

Copyright © 2009–2010, Texas Instruments Incorporated List of Figures 3

TUSB9260

SLLS962C–DECEMBER 2009–REVISED JULY 2010

www.ti.com

List of Tables

3-1 GPIO/PWM LED Designations................................................................................................... 9

4-1 I/O Definitions..................................................................................................................... 11

4-2 Clock and Reset Signals ........................................................................................................ 11

4-3 SATA Interface Signals.......................................................................................................... 11

4-4 USB Interface Signals ........................................................................................................... 12

4-5 Serial Peripheral Interface (SPI) Signals...................................................................................... 12

4-6 JTAG, GPIO, and PWM Signals ............................................................................................... 13

4-7 Power and Ground Signals ..................................................................................................... 14

5-1 Oscillator Specification .......................................................................................................... 16

5-2 Crystal Specification ............................................................................................................. 16

7-1 SuperSpeed USB Power Consumption ....................................................................................... 18

7-2 High Speed USB Power Consumption ........................................................................................ 18

4 List of Tables Copyright © 2009–2010, Texas Instruments Incorporated

TUSB9260

www.ti.com

SLLS962C–DECEMBER 2009–REVISED JULY 2010

USB 3.0 TO SATA BRIDGE

Check for Samples: TUSB9260

1 MAIN FEATURES

1.1 TUSB9260 Features

1

• Universal Serial Bus (USB)

– SuperSpeed USB 3.0 Compliant - TID 340000007

• Integrated Transceiver Supports SS/HS/FS Signaling

– Best in Class Adaptive Equalizer

• Allows for Greater Jitter Tolerance in the Receiver

– USB Class Support

• USB Attached SCSI Protocol (UASP)

• USB Mass Storage Class Bulk-Only Transport (BOT)

• Support for Error Conditions Per the 13 Cases (Defined in the BOT Specification)

• USB Bootability Support

• USB Human Interface Device (HID)

– Supports Firmware Update Via USB, Using a TI Provided Application

• SATA Interface

– Serial ATA Specification Revision 2.6

• gen1i, gen1m, gen2i, and gen2m

– Support for Mass-Storage Devices Compatible With the ATA/ATAPI-8 Specification

• Integrated ARM Cortex M3 Core

– Customizable Application Code Loaded From EEPROM Via SPI Interface

– Two Additional SPI Port Chip Selects for Peripheral Connection

– Up to 12 GPIOs for End-User Configuration

• 2 GPIOs Have PWM Functionality for LED Blink Speed Control

– Serial Communications Interface for Debug (UART)

• General Features

– Can Operate from Either a Single Low Cost Crystal or Clock Oscillator

• Supports 40 MHz

– A JTAG Interface is Used for IEEE1149.1 and IEEE1149.6 Boundary Scan

– Available in a Fully RoHS Compliant Package

1.2 Target Applications

• External HDD/SSD

• External DVD

• External CD

• HDD-Based Portable Media Player

1

Please be aware that an important notice concerning availability, standard warranty, and use in critical applications of Texas

Instruments semiconductor products and disclaimers thereto appears at the end of this data sheet.

PRODUCTION DATA information is current as of publication date.

Products conform to specifications per the terms of the Texas

Instruments standard warranty. Production processing does not

necessarily include testing of all parameters.

Copyright © 2009–2010, Texas Instruments Incorporated

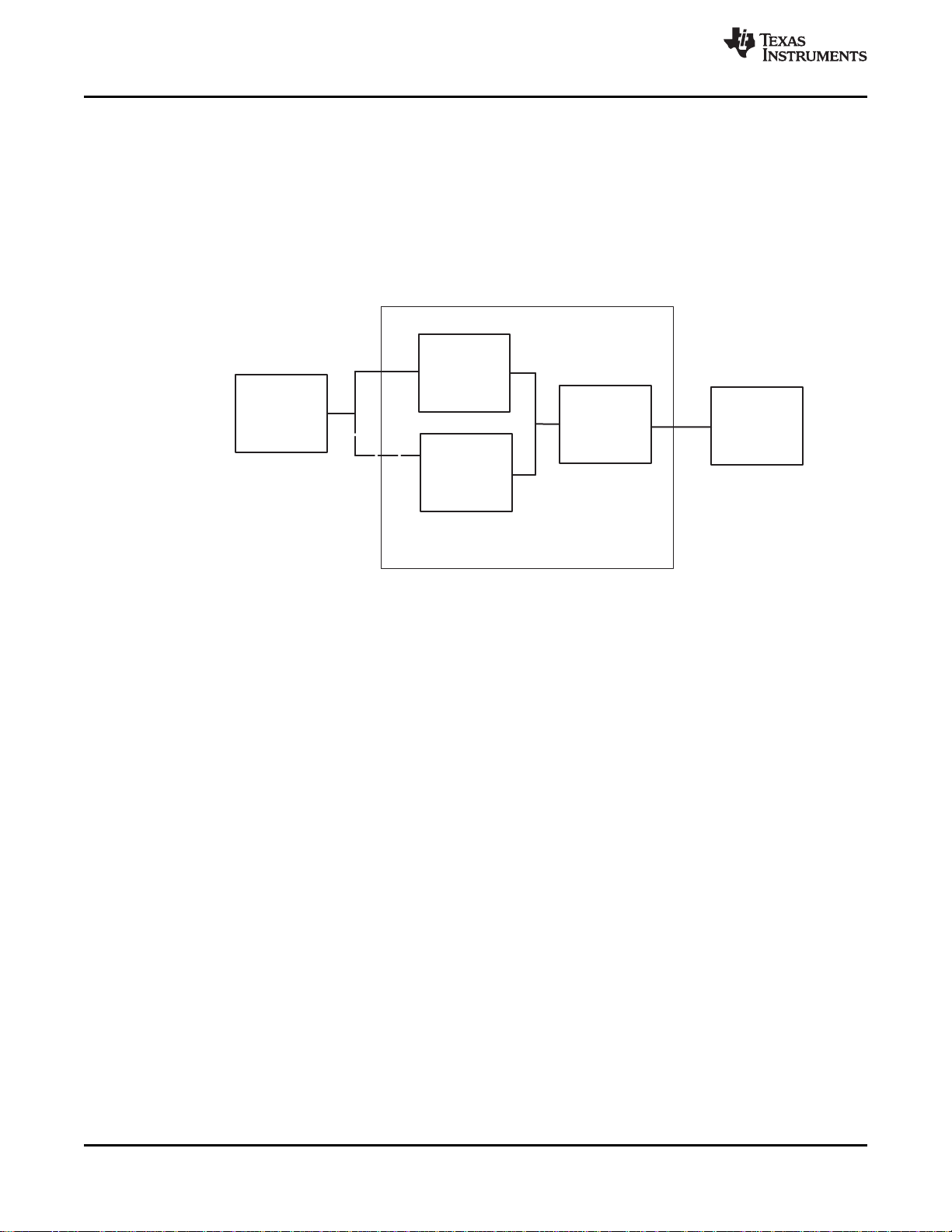

SATA

Gen1/2

TUSB9260

HDD

USB 3.0

SuperSpeed

(1)

USB 2.0

High-speed

(1)

PC

with

USB 3.0

Support

(1) USB connection is made at either SuperSpeed or High-Speed depending on the upstream connection support.

TUSB9260

SLLS962C–DECEMBER 2009–REVISED JULY 2010

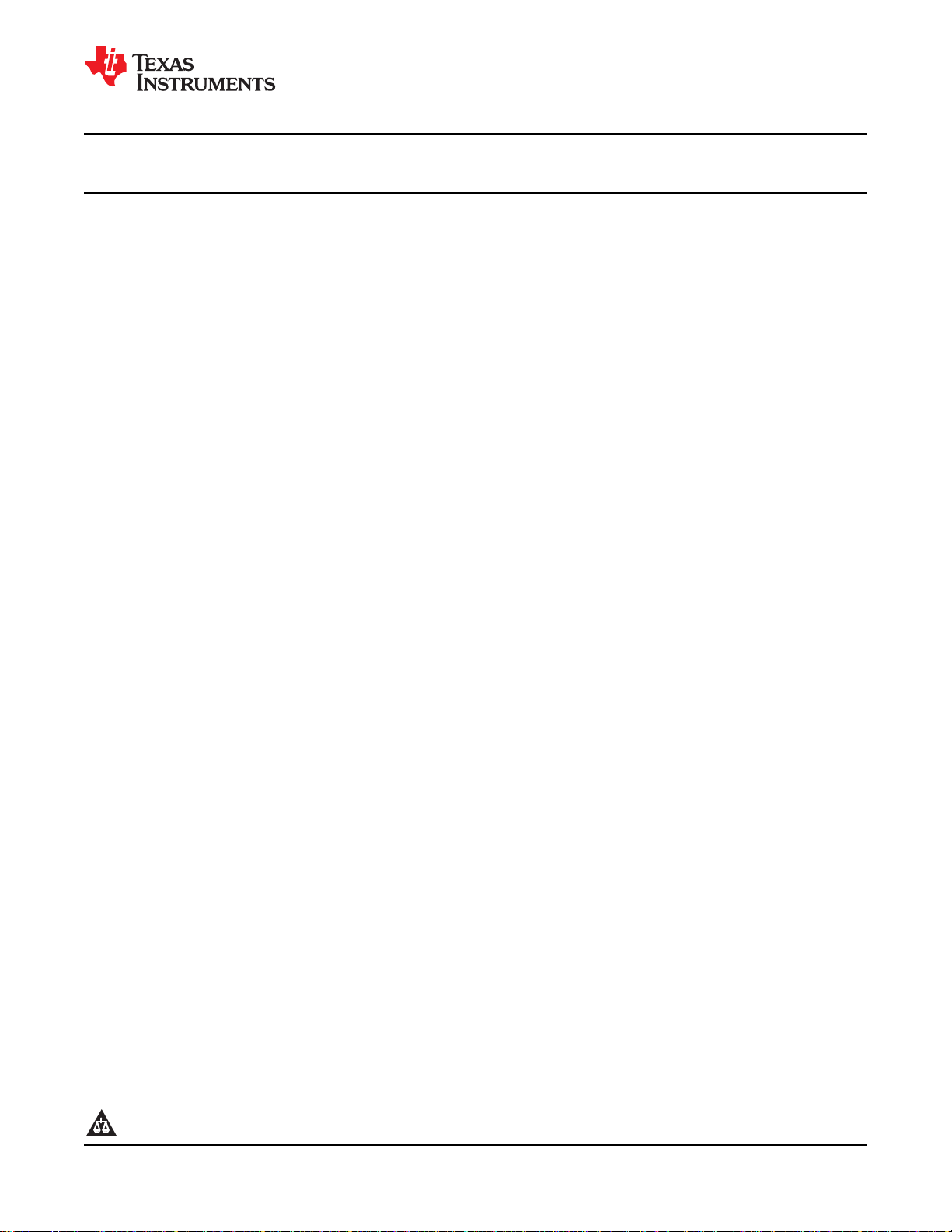

2 INTRODUCTION

2.1 System Overview

The TUSB9260 is an ARM cortex M3 microcontroller based USB 3.0 to serial ATA bridge. It provides the

necessary hardware and firmware to implement a USB attached SCSI protocol (UASP) compliant mass

storage device suitable for bridging hard disk drives (HDD), solid state disk drives (SSD), optical drives

and other compatible SATA 1.5-Gbps or SATA 3.0-Gbps devices to a USB 3.0 bus. In addition to UASP

support, the firmware implements the mass storage class bulk-only transport (BOT), and USB human

in-terface device (HID) interfaces.

www.ti.com

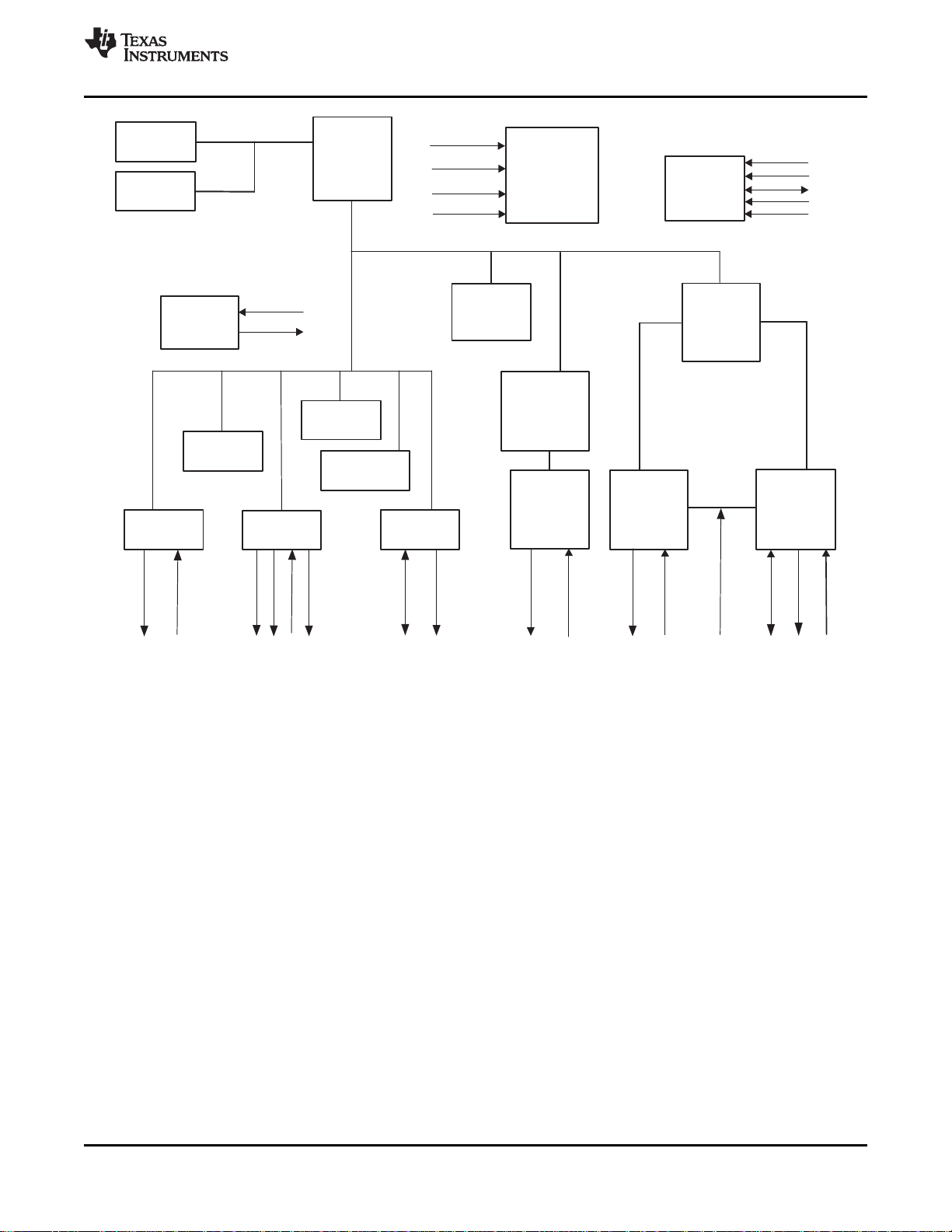

2.2 Device Block Diagram

The major functional blocks are as follows:

• Cortex M3 microcontroller subsystem including the following peripherals:

– Time interrupt modules, including watchdog timer

– Universal asynchronous receive/transmit (SCI)

– Serial peripheral interface (SPI)

– General purpose input/output (GPIO)

– PWM for support of PWM outputs (PWM)

• USB 3.0 core (endpoint controller) and integrated SuperSpeed PHY

• AHCI compliant SATA controller and integrated SATA PHY

– Supporting gen1i, gen1m, gen2i, and gen2m

• Chip level clock generation and distribution

• Support for JTAG 1149.1 and 1149.6

6 INTRODUCTION Copyright © 2009–2010, Texas Instruments Incorporated

Submit Documentation Feedback

Product Folder Link(s): TUSB9260

ROM

RAM

ARM

Cortex M3

Power

and

Reset

Distribution

JTAG

Clock

Generation

TCK

TMS

TDO

TDI

TRST

XI

XO

SCI

(UART)

Watchdog

SPI

Timer

GPIO

PWM

U

a

r

tR

X

U

a

r

TX

S

C

L

K

Timer

Data Path

RAM

80 kB

SA

T

A

TX+

SA

T

A

TX-

SA

T

ARX+

SA

T

ARX-

SATA II

PHY

USB SS

PHY

USB HS/FS

PHY

SATA

AHCI

USB 3.0

Device

Controller

SSTX+

SSTX-

SSRX+

SSRX-

VBUS

VDD3.3

VDD1.8

VDD1.1

DATA_OUT

DATA_IN

CS[2:0]

GPIO[11:0]

PWM[1:0]

DP/DM

USB_R1

USB_R1RTN

GRSTz

TUSB9260

www.ti.com

SLLS962C–DECEMBER 2009–REVISED JULY 2010

Figure 2-1. Device Block Diagram

Copyright © 2009–2010, Texas Instruments Incorporated INTRODUCTION 7

Submit Documentation Feedback

Product Folder Link(s): TUSB9260

TUSB9260

SLLS962C–DECEMBER 2009–REVISED JULY 2010

3 OPERATION

3.1 General Functionality

The TUSB9260 ROM contains boot code that executes after a global reset which performs the initial

con-figuration required to load a firmware image from an attached SPI flash memory to local RAM. In the

ab-sence of an attached SPI flash memory or a valid image in the SPI flash memory, the firmware will idle

and wait for a connection from a USB host through its HID interface which is also configured from the boot

code. The latter can be accomplished using a custom application or driver to load the firmware from a file

resident on the host system.

Once the firmware is loaded it configures the SATA advanced host controller interface host bus adapter

(AHCI) and the USB device controller. In addition, the configuration of the AHCI includes a port reset

which initiates an out of band (OOB) TX sequence from the AHCI link layer to determine if a device is

connected, and if so negotiate the connection speed with the device (3.0 Gbps or 1.5 Gbps).

The configuration of the USB device controller includes creation of the descriptors and configuration of the

device endpoints for support of UASP and USB mass storage class bulk-only transport (BOT). In addition,

the firmware provides any other custom configuration required for application specific implementation, for

example a HID interface for user initiated backup.

After USB device controller configuration is complete, if a SATA device was detected during the AHCI

con-figuration the firmware connects the device to the USB bus when VBUS is detected. According to the

USB 3.0 specification, the TUSB9260 will initially try to connect at SuperSpeed, if successful it will enter

U0; otherwise, after the training time out it will enable the DP pull up and connect as a USB 2.0

high-speed or full-speed device depending on the speed supported by host or hub port.

www.ti.com

When connected, the firmware presents the BOT interface as the primary interface and the UASP

inter-face as the secondary interface. If the host stack is UASP aware, it can enable the UASP interface

using a SET_INTERFACE request for alternate interface 1.

Following speed negotiation, the device should transmit a device to host (D2H) FIS with the device

signature. This first D2H FIS is received by the link layer and copied to the port signature register. When

firmware is notified of the device connection it queries the device for capabilities using the IDENTIFY

DEVICE command. Firmware then configures the device as appropriate for its interface and features

supported, for example an HDD that supports native command queuing (NCQ).

The configuration of the USB device controller includes creation of the descriptors, configuration of the

device endpoints for support of UASP and USB mass storage class bulk-only transport (BOT), allocation

of memory for the transmit request blocks (TRBs), and creation of the TRBs necessary to transmit and

receive packet data over the USB. In addition, the firmware provides any other custom configuration

required for application specific implementation, for example a HID interface for user initiated backup.

After USB device controller configuration is complete, if a SATA device was detected during the AHCI

configuration the firmware connects the device to the USB bus when VBUS is detected. According to the

USB 3.0 specification, the TUSB9260 will initially try to connect at SuperSpeed, if successful it will enter

U0; otherwise, after the training time out it will enable the DP pull up and connect as a USB 2.0

high-speed or full-speed device depending on the speed supported by host or hub port.

When connected as a SuperSpeed device, the firmware presents the UASP interface as the primary

interface, and the BOT interface as a secondary interface. If the host stack is not UASP aware, it can

enable the BOT interface using a SET_INTERFACE request for alternate interface 1.

8 OPERATION Copyright © 2009–2010, Texas Instruments Incorporated

Submit Documentation Feedback

Product Folder Link(s): TUSB9260

TUSB9260

www.ti.com

3.2 Firmware Support

Default firmware support is provided for the following:

• USB 3.0 SuperSpeed and USB 2.0 High-Speed and Full-Speed

• USB Attached SCSI Protocol (UASP)

• USB Mass Storage Class (MSC) Bulk-Only Transport (BOT)

– Including the 13 Error Cases

• USB Mass Storage Specification for Bootability

• USB Device Class Definition for Human Interface Devices (HID)

– Firmware Update and Custom Functionality (e.g. One-Touch Backup)

• Serial ATA Advanced Host Controller Interface (AHCI)

• General Purpose Input/Output (GPIO)

– LED Control and Custom Functions (e.g. One-Touch Backup Control)

• Pulse Width Modulation (PWM)

– LED Dimming Control

• Serial Peripheral Interface (SPI)

– Firmware storage and storing Custom Device Descriptors

• Serial Communications Interface (SCI)

– Debug Output Only

SLLS962C–DECEMBER 2009–REVISED JULY 2010

3.3 GPIO/PWM LED Designations

The default firmware provided by TI drives the GPIO and PWM outputs as listed in the table below.

Table 3-1. GPIO/PWM LED Designations

GPIO0 SW heartbeat

GPIO1/GPIO5 USB3 power state (U0-U3)

GPIO2 HS/FS suspend

GPIO3 Push button input on customer board

GPIO4 Not used

GPIO6 FS/HS connected

GPIO7 SS connected

PWM0 Disk activity

PWM1 U3 or HS/FS suspend state (fades high and low)

GPIO10

(SPICS1)

GPIO11

(SPICS2)

The LED’s on the TUSB9260 Product Development Kit (PDK) board are connected as in the table above.

Please see the TUSB9260 PDK Guide (SLLA303) for more information on GPIO LED connection and

usage. This EVM is available for purchase, contact TI for ordering information.

Not used

Not used

00: U3 state or default

01: U2 state

10: U1 state

11: U0 state

Copyright © 2009–2010, Texas Instruments Incorporated OPERATION 9

Submit Documentation Feedback

Product Folder Link(s): TUSB9260

TUSB9260

SLLS962C–DECEMBER 2009–REVISED JULY 2010

3.4 Power Up and Reset Sequence

The TUSB9260 does not have specific power sequencing requirements with respect to the core power

(VDD), I/O power (VDD33), or analog power (VDDA11, VDDA33, VDDA18, and VDDR18). The core

power (VDD) or IO power (VDD33) may be powered up for an indefinite period of time while others are not

powered up if all of these constraints are met:

• All maximum ratings and recommended operating conditions are observed.

• All warnings about exposure to maximum rated and recommended conditions are observed,

par-ticularly junction temperature. These apply to power transitions as well as normal operation.

• Bus contention while VDD33 is powered up must be limited to 100 hours over the projected life-time of

the device.

• Bus contention while VDD33 is powered down may violate the absolute maximum ratings.

A supply bus is powered up when the voltage is within the recommended operating range. It is powered

down when it is below that range, either stable or in transition.

A minimum reset duration of 1 ms is required. This is defined as the time when the power supplies are in

the recommended operating range to the de-assertion of GRSTz.

www.ti.com

10 OPERATION Copyright © 2009–2010, Texas Instruments Incorporated

Submit Documentation Feedback

Product Folder Link(s): TUSB9260

TUSB9260

www.ti.com

SLLS962C–DECEMBER 2009–REVISED JULY 2010

4 SIGNAL DESCRIPTIONS

Table 4-1. I/O Definitions

I/O TYPE DESCRIPTION

I Input

O Output

I/O Input - Output

PU Internal pull-up resistor

PD Internal pull-down resistor

PWR Power signal

Table 4-2. Clock and Reset Signals

TERMINAL

NAME

GRSTz 4

XI 52 I be driven by the output of an external oscillator. When using a crystal a 1-MΩ feedback resistor

XO 54 O external oscillator this pin may be left unconnected. When using a crystal a 1-MΩ feedback

FREQSEL[1:0] 31, 30

PIN

NO.

I/O DESCRIPTION

I Global power reset. This reset brings all of the TUSB9260 internal registers to their default

PU states. When GRSTz is asserted, the device is completely nonfunctional.

Crystal input. This terminal is the crystal input for the internal oscillator. The input may alternately

is required between X1 and XO.

Crystal output. This terminal is the crystal output for the internal oscillator. If XI is driven by an

resistor is required between X1 and XO.

Frequency select. These terminals indicate the oscillator input frequency and are used to

configure the correct PLL multiplier. The field encoding is as follows:

FREQSEL[1] FREQSEL[0] INPUT CLOCK FREQUENCY

I

PU

0 0 Reserved

0 1 Reserved

1 0 Reserved

1 1 40 MHz

Table 4-3. SATA Interface Signals

TERMINAL

NAME

SATA_TXP 57 O Serial ATA transmitter differential pair (positive)

SATA_TXM 56 O Serial ATA transmitter differential pair (negative)

SATA_RXP 60 I Serial ATA receiver differential pair (positive)

SATA_RXM 59 I Serial ATA receiver differential pair (negative)

Copyright © 2009–2010, Texas Instruments Incorporated SIGNAL DESCRIPTIONS 11

PIN

NO.

I/O DESCRIPTION

Submit Documentation Feedback

Product Folder Link(s): TUSB9260

TUSB9260

SLLS962C–DECEMBER 2009–REVISED JULY 2010

www.ti.com

Table 4-4. USB Interface Signals

TERMINAL

NAME

USB_SSTXP 43 O USB SuperSpeed transmitter differential pair (positive)

USB_SSTXM 42 O USB SuperSpeed transmitter differential pair (negative)

USB_SSRXP 46 I USB SuperSpeed receiver differential pair (positive)

USB_SSRXM 45 I USB SuperSpeed receiver differential pair (negative)

USB_DP 36 I/O USB High-speed differential transceiver (positive)

USB_DM 35 I/O USB High-speed differential transceiver (negative)

USB_VBUS 33 I USB bus power

USB_R1 39 O Precision resistor reference. A 10-kΩ ±1% resistor should be connected between R1 and R1RTN.

USB_R1RTN 40 I Precision resistor reference return

PIN

NO.

I/O DESCRIPTION

Table 4-5. Serial Peripheral Interface (SPI) Signals

TERMINAL

NAME

SPI_SCLK 17 SPI clock

SPI_DATA_IN 18 SPI master data in

SPI_DATA_OUT 20 SPI master data out

SPI_CS0 21 Primary SPI chip select for Flash RAM

SPI_CS2/

GPIO11

SPI_CS1/

GPIO10

PIN

NO.

23

22

I/O DESCRIPTION

O

PU

I

PU

O

PU

O

PU

I/O SPCI chip select for additional peripherals. When not used for SPI chip select this pin may be

PU used as general purpose I/O.

I/O SPCI chip select for additional peripherals. When not used for SPI chip select this pin may be

PU used as general purpose I/O.

12 SIGNAL DESCRIPTIONS Copyright © 2009–2010, Texas Instruments Incorporated

Submit Documentation Feedback

Product Folder Link(s): TUSB9260

TUSB9260

www.ti.com

SLLS962C–DECEMBER 2009–REVISED JULY 2010

Table 4-6. JTAG, GPIO, and PWM Signals

TERMINAL

NAME

JTAG_TCK 25 JTAG test clock

JTAG_TDI 26 JTAG test data in

JTAG_TDO 27 JTAG test data out

JTAG_TMS 28 JTAG test mode select

JTAG_TRSTz 29 JTAG test reset

GPIO9/UART_TX 6

GPIO8/UART_RX 5

GPIO7 16

GPIO6 15

GPIO5 14

GPIO4 13

GPIO3 11

GPIO2 10

GPIO1 9

GPIO0 8

PWM0 2

PWM1 3

(1) PWM pull down resistors are disabled by default. A firmware modification is required to turn them on. All other internal pull up/down

resistors are enabled by default.

PIN

NO.

I/O DESCRIPTION

I

PD

I

PU

O

PD

I

PU

I

PD

I/O GPIO/UART transmitter. This terminal can be configured as a GPIO or as the transmitter for a

PU UART channel. This pin defaults to a general purpose output.

I/O GPIO/UART receiver. This terminal can be configured as a GPIO or as the receiver for a UART

PU channel. This pin defaults to a general purpose output.

I/O

PD

I/O

PD

I/O

PD

I/O

PD

Configurable as general purpose input/outputs

I/O

PD

I/O

PD

I/O

PD

I/O

PD

O

(1)

PD

Pulse Width Modulation (PWM). Can be used to drive status LED's.

O

(1)

PD

Copyright © 2009–2010, Texas Instruments Incorporated SIGNAL DESCRIPTIONS 13

Submit Documentation Feedback

Product Folder Link(s): TUSB9260

TUSB9260

SLLS962C–DECEMBER 2009–REVISED JULY 2010

Table 4-7. Power and Ground Signals

TERMINAL

NAME

VDDR18 48, 62 PWR 1.8-V power rail

VDDA18 37 PWR 1.8-V analog power rail

VDD 44, 47, PWR 1.1-V power rail

VDD33 PWR 3.3-V power rail

VDDA33 34 PWR 3.3-V analog power rail

VSSOSC 53 PWR using an oscillator, this should be connected to PCB ground. See the Clock Source

VSS 65 PWR Ground - Thermal Pad

PIN

NO.

1, 12,

19, 32,

38, 41,

49, 55,

58, 61,

63, 64

7, 24,

50, 51

I/O DESCRIPTION

Oscillator ground. If using a crystal, this should not be connected to PCB ground plane. If

Requirements section for more details.

www.ti.com

14 SIGNAL DESCRIPTIONS Copyright © 2009–2010, Texas Instruments Incorporated

Submit Documentation Feedback

Product Folder Link(s): TUSB9260

TUSB9260

www.ti.com

5 CLOCK CONNECTIONS

5.1 Clock Source Requirements

The TUSB9260 supports an external oscillator source or a crystal unit. If a clock is provided to XI instead

of a crystal, XO is left open and VSSOSC should be connected to the PCB ground plane. Otherwise, if a

crystal is used, the connection needs to follow the guidelines below.

Since XI and XO are coupled to other leads and supplies on the PCB, it is important to keep them as short

as possible and away from any switching leads. It is also recommended to minimize the capacitance

be-tween XI and XO. This can be accomplished by connecting the VSSOSC lead to the two external

capaci-tors CL1 and CL2 and shielding them with the clean ground lines. The VSSOSC should not be

connected to PCB ground when using a crystal.

Load capacitance (C

entire oscillation circuit system as seen from the crystal. It includes two external capacitors CL1 and CL2

in Figure 5-1. The trace length between the decoupling capacitors and the corresponding power pins on

the TUSB9260 needs to be minimized. It is also recommended that the trace length from the capacitor

pad to the power or ground plane be minimized.

) of the crystal varying with the crystal vendors is the total capacitance value of the

load

SLLS962C–DECEMBER 2009–REVISED JULY 2010

Figure 5-1. Typical Crystal Connections

5.2 Clock Source Selection Guide

Reference clock jitter is an important parameter. Jitter on the reference clock will degrade both the

trans-mit eye and receiver jitter tolerance no matter how clean the rest of the PLL is, thereby impairing

system performance. Additionally, a particularly jittery reference clock may interfere with PLL lock

detection mechanism, forcing the Lock Detector to issue an Unlock signal. A good quality, low jitter

reference clock is required to achieve compliance with supported USB3.0 standards. For example,

USB3.0 specification requires the random jitter (RJ) component of either RX or TX to be 2.42 ps (random

phase jitter calculated after applying jitter transfer function - JTF). As the PLL typically has a number of

additional jitter compo-nents, the Reference Clock jitter must be considerably below the overall jitter

budget.

Copyright © 2009–2010, Texas Instruments Incorporated CLOCK CONNECTIONS 15

Submit Documentation Feedback

Product Folder Link(s): TUSB9260

TUSB9260

SLLS962C–DECEMBER 2009–REVISED JULY 2010

5.3 Oscillator

XI should be tied to the 1.8-V clock source and XO should be left floating.

VSSOSC should be connected to the PCB ground plane.

A 40-MHz clock can be used.

PARAMETER CONDITIONS MIN TYP MAX UNIT

C

XI

V

IL

V

IH

T

tosc_i

T

duty

TR/T

R

J

T

J

T

p-p

(1) Sigma value assuming Gaussian distribution

(2) After application of JTF

(3) Calculated as 14.1 x RJ+ D

(4) Absolute phase jitter (p-p)

XI input capacitance 0.414 pF

Low-level input voltage 0.35 x VDDR18 V

High-level input voltage 0.65 x VDDR18 V

Frequency tolerance Operational temperature –50 50 ppm

Duty cycle 45 50 55 %

Rise/Fall time 20% - 80 % 6 ns

F

Reference clock R

Reference clock T

J

J

Reference clock jitter (absolute p-p)

J

Table 5-1. Oscillator Specification

VDDIO = 1.8 V,

TJ= 25°C

JTF (1 sigma)

JTF (total p-p)

(1)(2)

(2)(3)

(4)

www.ti.com

0.8 ps

25 ps

50 ps

5.4 Crystal

A parallel, 20-pF load capacitor should be used if a crystal source is used.

VSSOSC should not be connected to the PCB ground plane.

A 40-MHz crystal can be used.

T

C

tosc_i

L

Frequency tolerance Operational temperature –50 50 ppm

Frequency stability 1 year aging –50 50 ppm

Load capacitance 12 20 24 pF

Table 5-2. Crystal Specification

PARAMETER CONDITIONS MIN TYP MAX UNIT

16 CLOCK CONNECTIONS Copyright © 2009–2010, Texas Instruments Incorporated

Submit Documentation Feedback

Product Folder Link(s): TUSB9260

TUSB9260

www.ti.com

SLLS962C–DECEMBER 2009–REVISED JULY 2010

6 ELECTRICAL SPECIFICATIONS

6.1 Absolute Maximum Ratings

over operating free-air temperature range (unless otherwise noted)

VALUE UNIT

VDDR18/

VDDA18

VDD Steady-state supply voltage –0.3 to 1.4 V

VDD33/

VDDA33

6.2 Recommended Operating Conditions

over operating free-air temperature range (unless otherwise noted)

VDDR18 Digital 1.8 supply voltage 1.71 1.8 1.89 V

VDDA18 Analog 1.8 supply voltage 1.62 1.8 1.89 V

VDD Digital 1.1 supply voltage 1.045 1.1 1.155 V

VDD33 Digital 3.3 supply voltage 3 3.3 3.6 V

VDDA33 Analog 3.3 supply voltage 3 3.3 3.6 V

VBUS Voltage at VBUS PAD 0 1.155 V

T

A

T

J

Steady-state supply voltage –0.3 to 2.45 V

Steady-state supply voltage –0.3 to 3.8 V

MIN NOM MAX UNIT

Operating free-air temperature range 0 70 °C

Operating junction temperature range 0 105 °C

HBM ESD 1000 V

CDM ESD 500 V

6.3 DC Electrical Characteristics for 3.3-V Digital I/O

over operating free-air temperature range (unless otherwise noted)

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

DRIVER

T

R

T

F

I

OL

I

OH

V

OL

V

OH

V

O

RECEIVER

V

I

V

IL

V

IH

V

hys

t

T

I

I

C

I

Rise time 5 pF 1.5 ns

Fall time 5 pF 1.53 ns

Low-level output current VDD33 = 3.3 V, TJ= 25°C 6 mA

High-level output current VDD33 = 3.3 V, TJ= 25°C –6 mA

Low-level output voltage IOL= 2 mA 0.4 V

High-level output voltage IOL= –2 mA 2.4 V

Output voltage 0 VDD33 V

Input voltage 0 VDD33 V

Low-level input voltage 0 0.8 V

High-level input voltage 2 V

Input hysteresis 200 mV

Input transition time (TRand TF) 10 ns

Input current VI= 0 V to VDD33 12 µA

Input capacitance VDD33 = 3.3 V, TJ= 25°C 0.384 pF

Copyright © 2009–2010, Texas Instruments Incorporated ELECTRICAL SPECIFICATIONS 17

Submit Documentation Feedback

Product Folder Link(s): TUSB9260

TUSB9260

SLLS962C–DECEMBER 2009–REVISED JULY 2010

7 POWER CONSUMPTION

All transfers are to a SATA Gen II SSD. A SATA Gen I target yields an approximate 10-mA power savings

on the 1.1-V rail.

Table 7-1. SuperSpeed USB Power Consumption

POWER RAIL TYPICAL ACTIVE CURRENT (mA)

(3)

VDD11

VDD18

VDD33

(4)

(5)

319 308

58 58

6 6

(1) Transferring data via SS USB to a SSD SATA Gen II device. No SATA power management, U0 only.

(2) SATA Gen II SSD attached no active transfer. No SATA power management, U0 only.

(3) All 1.1-V power rails connected together.

(4) All 1.8-V power rails connected together.

(5) All 3.3-V power rails connected together.

Table 7-2. High Speed USB Power Consumption

POWER RAIL TYPICAL ACTIVE CURRENT (mA)

(3)

VDD11

(4)

VDD18

(5)

VDD33

(1) Transferring data via HS USB to a SSD SATA Gen II device. No SATA power management.

(2) SATA Gen II SSD attached no active transfer. No SATA power management.

(3) All 1.1-V power rails connected together.

(4) All 1.8-V power rails connected together.

(5) All 3.3-V power rails connected together.

197 193

45 36

14 14

(1)

(1)

www.ti.com

TYPICAL IDLE CURRENT

TYPICAL IDLE CURRENT

(mA)

(mA)

(2)

(2)

18 POWER CONSUMPTION Copyright © 2009–2010, Texas Instruments Incorporated

Submit Documentation Feedback

Product Folder Link(s): TUSB9260

PACKAGE OPTION ADDENDUM

www.ti.com

26-Jul-2010

PACKAGING INFORMATION

Orderable Device

TUSB9260PAP PREVIEW HTQFP PAP 64 160 TBD Call TI Call TI Samples Not Available

TUSB9260PVP PREVIEW HTQFP PVP 64 250 TBD Call TI Call TI Samples Not Available

(1)

The marketing status values are defined as follows:

ACTIVE: Product device recommended for new designs.

LIFEBUY: TI has announced that the device will be discontinued, and a lifetime-buy period is in effect.

NRND: Not recommended for new designs. Device is in production to support existing customers, but TI does not recommend using this part in a new design.

PREVIEW: Device has been announced but is not in production. Samples may or may not be available.

OBSOLETE: TI has discontinued the production of the device.

Status

(1)

Package Type Package

Drawing

Pins Package Qty

Eco Plan

(2)

Lead/

Ball Finish

MSL Peak Temp

(3)

Samples

(Requires Login)

(2)

Eco Plan - The planned eco-friendly classification: Pb-Free (RoHS), Pb-Free (RoHS Exempt), or Green (RoHS & no Sb/Br) - please check http://www.ti.com/productcontent for the latest availability

information and additional product content details.

TBD: The Pb-Free/Green conversion plan has not been defined.

Pb-Free (RoHS): TI's terms "Lead-Free" or "Pb-Free" mean semiconductor products that are compatible with the current RoHS requirements for all 6 substances, including the requirement that

lead not exceed 0.1% by weight in homogeneous materials. Where designed to be soldered at high temperatures, TI Pb-Free products are suitable for use in specified lead-free processes.

Pb-Free (RoHS Exempt): This component has a RoHS exemption for either 1) lead-based flip-chip solder bumps used between the die and package, or 2) lead-based die adhesive used between

the die and leadframe. The component is otherwise considered Pb-Free (RoHS compatible) as defined above.

Green (RoHS & no Sb/Br): TI defines "Green" to mean Pb-Free (RoHS compatible), and free of Bromine (Br) and Antimony (Sb) based flame retardants (Br or Sb do not exceed 0.1% by weight

in homogeneous material)

(3)

MSL, Peak Temp. -- The Moisture Sensitivity Level rating according to the JEDEC industry standard classifications, and peak solder temperature.

Important Information and Disclaimer:The information provided on this page represents TI's knowledge and belief as of the date that it is provided. TI bases its knowledge and belief on information

provided by third parties, and makes no representation or warranty as to the accuracy of such information. Efforts are underway to better integrate information from third parties. TI has taken and

continues to take reasonable steps to provide representative and accurate information but may not have conducted destructive testing or chemical analysis on incoming materials and chemicals.

TI and TI suppliers consider certain information to be proprietary, and thus CAS numbers and other limited information may not be available for release.

In no event shall TI's liability arising out of such information exceed the total purchase price of the TI part(s) at issue in this document sold by TI to Customer on an annual basis.

Addendum-Page 1

IMPORTANT NOTICE

Texas Instruments Incorporated and its subsidiaries (TI) reserve the right to make corrections, modifications, enhancements, improvements,

and other changes to its products and services at any time and to discontinue any product or service without notice. Customers should

obtain the latest relevant information before placing orders and should verify that such information is current and complete. All products are

sold subject to TI’s terms and conditions of sale supplied at the time of order acknowledgment.

TI warrants performance of its hardware products to the specifications applicable at the time of sale in accordance with TI’s standard

warranty. Testing and other quality control techniques are used to the extent TI deems necessary to support this warranty. Except where

mandated by government requirements, testing of all parameters of each product is not necessarily performed.

TI assumes no liability for applications assistance or customer product design. Customers are responsible for their products and

applications using TI components. To minimize the risks associated with customer products and applications, customers should provide

adequate design and operating safeguards.

TI does not warrant or represent that any license, either express or implied, is granted under any TI patent right, copyright, mask work right,

or other TI intellectual property right relating to any combination, machine, or process in which TI products or services are used. Information

published by TI regarding third-party products or services does not constitute a license from TI to use such products or services or a

warranty or endorsement thereof. Use of such information may require a license from a third party under the patents or other intellectual

property of the third party, or a license from TI under the patents or other intellectual property of TI.

Reproduction of TI information in TI data books or data sheets is permissible only if reproduction is without alteration and is accompanied

by all associated warranties, conditions, limitations, and notices. Reproduction of this information with alteration is an unfair and deceptive

business practice. TI is not responsible or liable for such altered documentation. Information of third parties may be subject to additional

restrictions.

Resale of TI products or services with statements different from or beyond the parameters stated by TI for that product or service voids all

express and any implied warranties for the associated TI product or service and is an unfair and deceptive business practice. TI is not

responsible or liable for any such statements.

TI products are not authorized for use in safety-critical applications (such as life support) where a failure of the TI product would reasonably

be expected to cause severe personal injury or death, unless officers of the parties have executed an agreement specifically governing

such use. Buyers represent that they have all necessary expertise in the safety and regulatory ramifications of their applications, and

acknowledge and agree that they are solely responsible for all legal, regulatory and safety-related requirements concerning their products

and any use of TI products in such safety-critical applications, notwithstanding any applications-related information or support that may be

provided by TI. Further, Buyers must fully indemnify TI and its representatives against any damages arising out of the use of TI products in

such safety-critical applications.

TI products are neither designed nor intended for use in military/aerospace applications or environments unless the TI products are

specifically designated by TI as military-grade or "enhanced plastic." Only products designated by TI as military-grade meet military

specifications. Buyers acknowledge and agree that any such use of TI products which TI has not designated as military-grade is solely at

the Buyer's risk, and that they are solely responsible for compliance with all legal and regulatory requirements in connection with such use.

TI products are neither designed nor intended for use in automotive applications or environments unless the specific TI products are

designated by TI as compliant with ISO/TS 16949 requirements. Buyers acknowledge and agree that, if they use any non-designated

products in automotive applications, TI will not be responsible for any failure to meet such requirements.

Following are URLs where you can obtain information on other Texas Instruments products and application solutions:

Products Applications

Amplifiers amplifier.ti.com Audio www.ti.com/audio

Data Converters dataconverter.ti.com Automotive www.ti.com/automotive

DLP® Products www.dlp.com Communications and www.ti.com/communications

DSP dsp.ti.com Computers and www.ti.com/computers

Clocks and Timers www.ti.com/clocks Consumer Electronics www.ti.com/consumer-apps

Interface interface.ti.com Energy www.ti.com/energy

Logic logic.ti.com Industrial www.ti.com/industrial

Power Mgmt power.ti.com Medical www.ti.com/medical

Microcontrollers microcontroller.ti.com Security www.ti.com/security

RFID www.ti-rfid.com Space, Avionics & www.ti.com/space-avionics-defense

RF/IF and ZigBee® Solutions www.ti.com/lprf Video and Imaging www.ti.com/video

Mailing Address: Texas Instruments, Post Office Box 655303, Dallas, Texas 75265

Copyright © 2010, Texas Instruments Incorporated

Telecom

Peripherals

Defense

Wireless www.ti.com/wireless-apps

Loading...

Loading...