Page 1

TUSB1310

USB 3.0 Transceiver

Data Manual

PRODUCTION DATA information is current as of publication date.

Products conform to specifications per the terms of the Texas

Instruments standard warranty. Production processing does not

necessarily include testing of all parameters.

Literature Number: SLLSE16C

December 2009–Revised August 2010

Page 2

TUSB1310

SLLSE16C–DECEMBER 2009–REVISED AUGUST 2010

www.ti.com

Contents

1 PRODUCT OVERVIEW ......................................................................................................... 7

1.1 Features ...................................................................................................................... 7

1.2 Target Applications ......................................................................................................... 7

1.3 Introduction .................................................................................................................. 8

1.4 Functional Block Diagram .................................................................................................. 8

2 PIN DESCRIPTIONS ........................................................................................................... 10

2.1 Configuration Pins ......................................................................................................... 10

2.2 PIPE ......................................................................................................................... 10

2.3 ULPI ......................................................................................................................... 13

2.3.1 ULPI Modes ..................................................................................................... 13

2.4 Clocking ..................................................................................................................... 14

2.5 JTAG Interface ............................................................................................................. 14

2.6 Reset and Output Control Interface ..................................................................................... 14

2.7 Strap Options .............................................................................................................. 14

2.8 USB Interfaces ............................................................................................................. 15

2.9 Special Connect ........................................................................................................... 15

2.10 Power and Ground ........................................................................................................ 15

3 FUNCTIONAL DESCRIPTION ............................................................................................... 17

3.1 Power On and Reset ...................................................................................................... 17

3.1.1 RESETN and PHY_RESETN – Hardware Reset .......................................................... 17

3.1.2 ULPI Reset – Software Reset ................................................................................. 17

3.1.3 OUT_ENABLE - Output Enable .............................................................................. 17

3.1.4 Power Up Sequence ........................................................................................... 17

3.2 Clocks ....................................................................................................................... 18

3.2.1 Clock Distribution ............................................................................................... 18

3.2.2 Output Clock .................................................................................................... 18

3.3 Power Management ....................................................................................................... 18

3.3.1 USB Power Management ...................................................................................... 19

3.4 Receiver Status ............................................................................................................ 19

3.4.1 Clock Tolerance Compensation .............................................................................. 20

3.4.2 Receiver Detection ............................................................................................. 20

3.4.3 8b/10b Decode Errors .......................................................................................... 20

3.4.4 Elastic Buffer Errors ............................................................................................ 21

3.4.5 Disparity Errors ................................................................................................. 21

3.5 Loopback ................................................................................................................... 21

4 REGISTERS ...................................................................................................................... 22

4.1 Register Definitions ........................................................................................................ 22

4.2 Register Map ............................................................................................................... 22

4.2.1 Vendor ID and Product ID (00h-03h) ........................................................................ 22

4.2.2 Function Control (04h-06h) .................................................................................... 23

4.2.3 Interface Control (07h-09h) .................................................................................... 24

4.2.4 Debug (15h) ..................................................................................................... 24

4.2.5 Scratch Register (16-18h) ..................................................................................... 24

5 DESIGN GUIDELINES ......................................................................................................... 25

5.1 Chip Connection on PCB ................................................................................................. 25

5.1.1 USB Connector Pins Connection ............................................................................. 25

2 Contents Copyright © 2009–2010, Texas Instruments Incorporated

Page 3

TUSB1310

www.ti.com

5.1.2 Clock Connections .............................................................................................. 26

5.2 Clock Source Requirements ............................................................................................. 27

5.2.1 Clock Source Selection Guide ................................................................................ 27

5.2.2 Oscillator ......................................................................................................... 28

5.2.3 Crystal ............................................................................................................ 28

SLLSE16C–DECEMBER 2009–REVISED AUGUST 2010

6 ELECTRICAL SPECIFICATIONS .......................................................................................... 29

6.1 ABSOLUTE MAXIMUM RATINGS ...................................................................................... 29

6.2 RECOMMENDED OPERATING CONDITIONS ....................................................................... 29

6.3 DC CHARACTERISTICS FOR 1.8-V DIGITAL IO .................................................................... 29

6.4 DEVICE POWER CONSUMPTION ..................................................................................... 30

6.5 AC Characteristics ......................................................................................................... 30

6.5.1 Power Up and Reset Timing .................................................................................. 30

6.5.2 PIPE Transmit ................................................................................................... 31

6.5.3 PIPE Receive ................................................................................................... 31

6.5.4 ULPI Parameters ............................................................................................... 32

6.5.5 ULPI Clock ....................................................................................................... 32

6.5.6 ULPI Transmit ................................................................................................... 32

6.5.7 ULPI Receive Timing ........................................................................................... 33

6.5.8 Power State Transition Time .................................................................................. 33

Copyright © 2009–2010, Texas Instruments Incorporated Contents 3

Page 4

TUSB1310

SLLSE16C–DECEMBER 2009–REVISED AUGUST 2010

www.ti.com

List of Figures

1-1 Typical Application................................................................................................................. 8

1-2 Functional Block Diagram ........................................................................................................ 9

3-1 Power Up Sequence............................................................................................................. 18

5-1 Analog Pin Connections......................................................................................................... 25

5-2 USB Standard-A Connector Pin Connection ................................................................................. 26

5-3 USB Standard-B Connector Pin Connection ................................................................................. 26

5-4 Typical Crystal Connections .................................................................................................... 27

6-1 Power Up and Reset Timing.................................................................................................... 30

6-2 PIPE Transmit Timing ........................................................................................................... 31

6-3 PIPE Receive Timing ............................................................................................................ 31

6-4 ULPI Transmit Timing............................................................................................................ 33

6-5 ULPI Receive Timing ............................................................................................................ 33

4 List of Figures Copyright © 2009–2010, Texas Instruments Incorporated

Page 5

TUSB1310

www.ti.com

SLLSE16C–DECEMBER 2009–REVISED AUGUST 2010

List of Tables

2-1 Configuration Pins................................................................................................................ 10

2-2 PIPE Signal Description ......................................................................................................... 10

2-3 ULPI Signal Description ......................................................................................................... 13

2-4 ULPI Synchronous and Low Power Mode Functions........................................................................ 13

2-5 Clock Signal Name Description ................................................................................................ 14

2-6 JTAG Signal Name Description ................................................................................................ 14

2-7 Reset and Output Control Signal Description ................................................................................ 14

2-8 Strapping Options ................................................................................................................ 14

2-9 USB Interface Signal Name Descriptions..................................................................................... 15

2-10 Special Connect Signal Descriptions .......................................................................................... 15

2-11 Power/Ground Signal Descriptions ............................................................................................ 15

3-1 Pin States in Chip Reset ........................................................................................................ 17

3-2 Power States...................................................................................................................... 19

3-3 PIPE Control Pin Matrix ......................................................................................................... 19

3-4 RX_STATUS - SKP .............................................................................................................. 20

3-5 RX_STATUS - Receiver Detection............................................................................................. 20

3-6 8b/10b Decode Errors ........................................................................................................... 21

3-7 Elastic Buffer Errors.............................................................................................................. 21

3-8 Disparity Errors ................................................................................................................... 21

4-1 Register Definitions .............................................................................................................. 22

4-2 Register Map...................................................................................................................... 22

4-3 Vendor ID and Product ID....................................................................................................... 22

4-4 Function Control .................................................................................................................. 23

4-5 Interface Control.................................................................................................................. 24

4-6 Debug.............................................................................................................................. 24

4-7 Scratch Register.................................................................................................................. 24

5-1 Oscillator Specification .......................................................................................................... 28

5-2 Oscillator Specification .......................................................................................................... 28

6-1 Power Up and Reset Timing.................................................................................................... 31

6-2 PIPE Transmit Timing ........................................................................................................... 31

6-3 PIPE Receive Timing ............................................................................................................ 31

6-4 ULPI Parameters ................................................................................................................. 32

6-5 ULPI Clock Parameters ......................................................................................................... 32

6-6 ULPI Transmit Timing............................................................................................................ 33

6-7 ULPI Transmit Timing............................................................................................................ 33

Copyright © 2009–2010, Texas Instruments Incorporated List of Tables 5

Page 6

TUSB1310

SLLSE16C–DECEMBER 2009–REVISED AUGUST 2010

www.ti.com

6 List of Tables Copyright © 2009–2010, Texas Instruments Incorporated

Page 7

TUSB1310

www.ti.com

SLLSE16C–DECEMBER 2009–REVISED AUGUST 2010

USB 3.0 Transceiver

Check for Samples: TUSB1310

1 PRODUCT OVERVIEW

1.1 Features

1

• Universal Serial Bus (USB)

– Single Port 5.0-Gbps USB 3.0 Physical Layer Transceiver

• One 5.0-Gbps SuperSpeed Conneciton

• One 480-Mbps HS/FS/LS Connection

– Fully Compliant with USB 3.0 Specification

– Supports 3+ Meters USB 3.0 Cable Length

– Fully Adaptive Equalizer to Optimize Receiver Sensitivity

– PIPE to Link Layer Controller

• Supports 16-Bit SDR Mode at 250 MHz

• Compliant With PHY Interface for the USB Architectures (PIPE), Version 3.0

– ULPI to Link Layer Controller

• Supports 8-Bit SDR Mode at 60 MHz

• Supports Synchronous Mode and Low Power Mode

• Compliant with UTMI+ Low Pin Interface (ULPI) Specification, Revision 1.1

• General Features

– IEEE 1149.1 JTAG Support

– IEEE 1149.6 JTAG support for the SuperSpeed Port

– Operates on a Single Reference Clock Selectable from 20, 25, 30 or 40 MHz

– 3.3-, 1.8-, and 1.1-V Supply Voltages

– 1.8-V PIPE and ULPI I/O

– Available in Lead-Free 175-Ball 12- x 12-nF BGA Package (175ZAY)

1.2 Target Applications

• Surveillance Cameras

• Multimedia Handset

• Smartphone

• Digital Still Camera

• Portable Media Player

• Personal Navigation Device

• Audio Dock

• Video IP Phone

• Wireless IP Phone

• Software Defined Radio

1

Please be aware that an important notice concerning availability, standard warranty, and use in critical applications of Texas

Instruments semiconductor products and disclaimers thereto appears at the end of this data sheet.

PRODUCTION DATA information is current as of publication date.

Products conform to specifications per the terms of the Texas

Instruments standard warranty. Production processing does not

necessarily include testing of all parameters.

Copyright © 2009–2010, Texas Instruments Incorporated

Page 8

TUSB1310

SLLSE16C–DECEMBER 2009–REVISED AUGUST 2010

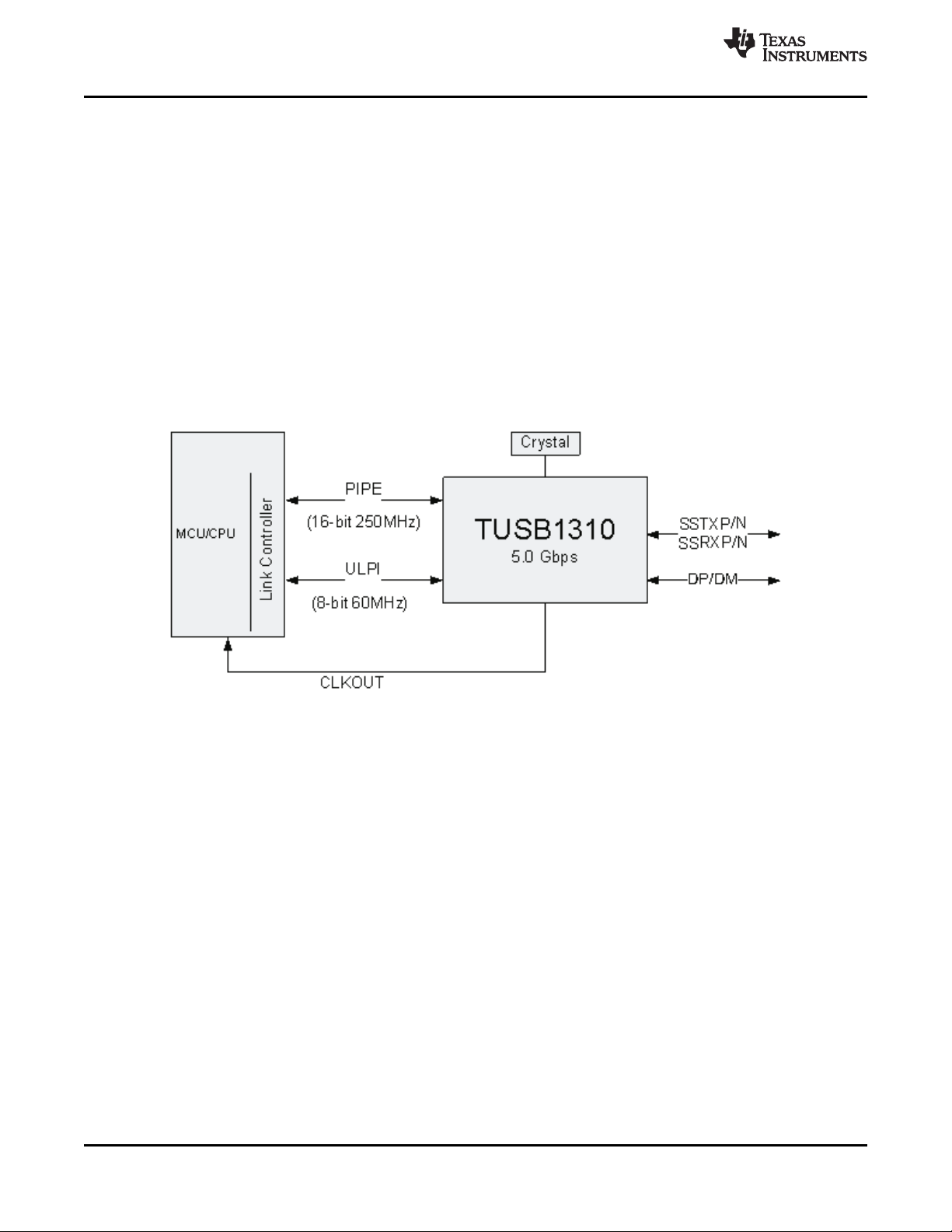

1.3 Introduction

The TUSB1310 is a single port, 5.0-Gbps USB 3.0 physical layer transceiver operating off of a single

crystal or an external reference clock. The reference clock frequencies are selectable from 20, 25, 30, and

40 MHz. The TUSB1310 provides a clock to USB link layer controllers. The single reference clock allows

the TUSB1310 to provide a cost effective USB 3.0 solution with few external components and a minimum

implementation cost.

Link controller interfaces to the TUSB1310 are via a PIPE (SuperSpeed) and a ULPI (USB2.0) interface.

The 16-bit PIPE operates with a 250-MHz interface clock. The ULPI supports 8-bit operations with a

60-MHz interface clock.

USB 3.0 reduces active power and idle power by improving power management. The PIPE interface

controls the TUSB1310 low power states which minimizes power consumption.

SuperSpeed USB leverages existing USB software infrastructure by keeping the existing software

interfaces and software drivers. In addition the SuperSpeed USB retains backward compatibility at the

Type-A connector with USB2.0 based PCs and with USB2.0 cables.

www.ti.com

Figure 1-1. Typical Application

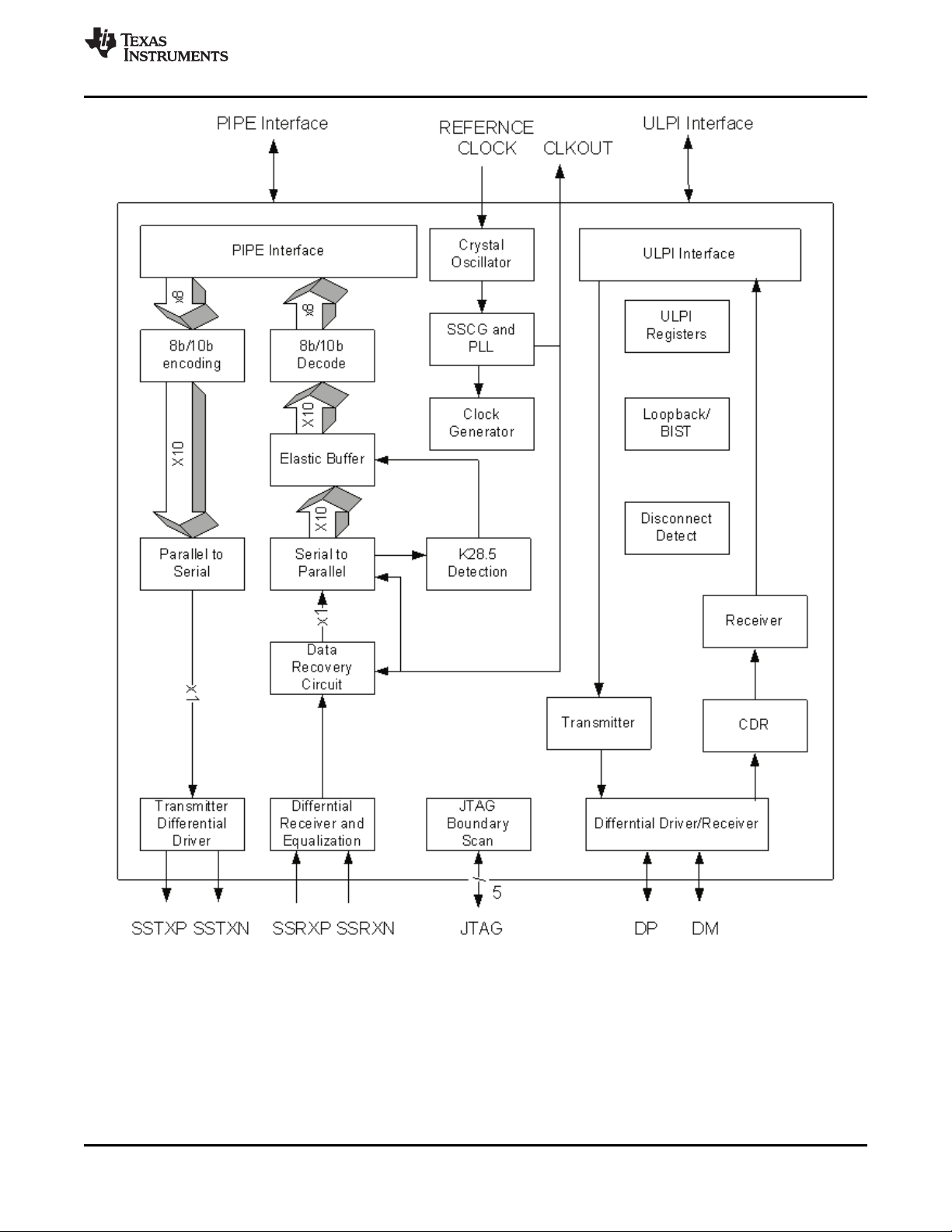

1.4 Functional Block Diagram

The USB physical layer handles the low level USB protocol and signaling. This includes data serialization

and deserialization, 8b/10b encoding, analog buffers, elastic buffers and receiver detection. It shifts the

clock domain of the data from the USB rate to one that is compatible with the link layer controller.

The SuperSpeed USB contains SSTXP/SSTXN and SSRXP/SSRXP differential pairs and uses the PIPE

to communicate with the link layer controller. The Non-SuperSpeed USB has a DP/DM differential pair and

communicates with the link layer controller via the ULPI. The TUSB1310 reference clock is connected to

an internal crystal oscillator, spread spectrum clock and PLL which provides clocks to all blocks and to the

CLKOUT pin for the link layer controller.

A JTAG interface is used for IEEE1149.1 and IEEE1149.6 boundary scan.

8 PRODUCT OVERVIEW Copyright © 2009–2010, Texas Instruments Incorporated

Submit Documentation Feedback

Product Folder Link(s): TUSB1310

Page 9

TUSB1310

www.ti.com

SLLSE16C–DECEMBER 2009–REVISED AUGUST 2010

Figure 1-2. Functional Block Diagram

Copyright © 2009–2010, Texas Instruments Incorporated PRODUCT OVERVIEW 9

Submit Documentation Feedback

Product Folder Link(s): TUSB1310

Page 10

TUSB1310

SLLSE16C–DECEMBER 2009–REVISED AUGUST 2010

2 PIN DESCRIPTIONS

TYPE DESCRIPTION

I Input

O Output

I/O Input/output

PD, PU Internal pull-down / pull-up

S Strapping pin

P Power Supply

G Ground

2.1 Configuration Pins

The configuration pins are not latched by RESETN.

Table 2-1. Configuration Pins

SIGNAL NAME TYPE PIN NO. MODE NAME DESCRIPTION

PHY_MODE1 I, PD H12 USB Must be set to 0. Operates as USB 3.0 transceiver.

PHY_MODE0 I, PU J12 USB Must be set to 1. Operates as USB 3.0 transceiver.

2.2 PIPE

www.ti.com

The TUSB1310 supports 16-bit SDR mode with a 250-MHz clock.

Table 2-2. PIPE Signal Description

SIGNAL NAME TYPE BALL NO. DESCRIPTION

TX_CLK I K1

TX_DATA15 G2

TX_DATA14 H2

TX_DATA13 H1

TX_DATA12 J2

TX_DATA11 L3

TX_DATA10 L2

TX_DATA9 M2

TX_DATA8 M1

TX_DATA7 N1

TX_DATA6 P1

TX_DATA5 N2

TX_DATA4 P2

TX_DATA3 N3

TX_DATA2 P3

TX_DATA1 N4

TX_DATA0 P5

TX_DATAK1 G1

TX_DATAK0 J1

PCLK O A6 to this clock. This clock operates at 250 MHz. The rising edge of the clock is the reference

I The 16 bits represent 2 symbols of transmit data where TX_DATA7-0 is the first symbol to

I

TX_DATA and TX_DATAK clock for source synchronous PIPE. This clock frequency is

the same as PCLK frequency. The rising edge of the clock is the reference for all signals.

Parallel USB SuperSpeed data input bus.

be transmitted, and TX_DATA15-8 is the second symbol.

Data/Control for the symbols of transmit data. TX_DATAK0 corresponds to the low-byte of

TX_DATA, TX_DATAK1 to the upper byte.

Parallel interface data clock. All data movement across the parallel PIPE is synchronous

for all signals.

10 PIN DESCRIPTIONS Copyright © 2009–2010, Texas Instruments Incorporated

Submit Documentation Feedback

Product Folder Link(s): TUSB1310

Page 11

TUSB1310

www.ti.com

SLLSE16C–DECEMBER 2009–REVISED AUGUST 2010

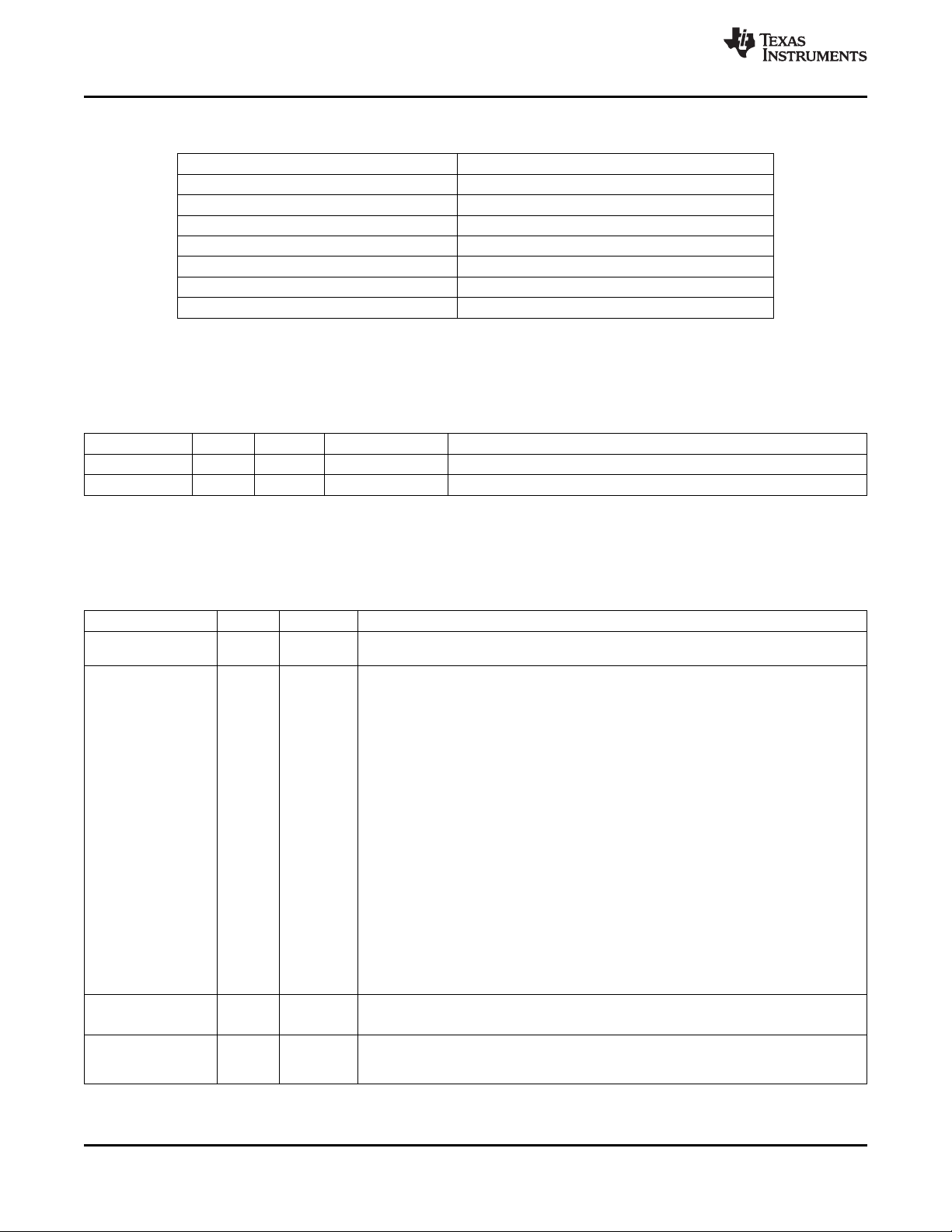

Table 2-2. PIPE Signal Description (continued)

SIGNAL NAME TYPE BALL NO. DESCRIPTION

RX_DATA15 B9

RX_DATA14 A9

RX_DATA13 A8

RX_DATA12 B8

RX_DATA11 B5

RX_DATA10 B4

RX_DATA9 A4

RX_DATA8 B3

RX_DATA7 A3

RX_DATA6 A2

RX_DATA5 B1

RX_DATA4 C2

RX_DATA3 C1

RX_DATA2 D1

RX_DATA1 D2

RX_DATA0 E2

RX_DATAK1 B7 Data/Control for the symbols of receive data. RX_DATAK0 corresponds to the low-byte of

RX_DATAK0 A7

RX_VALID O F1 Active High. Indicates symbol lock and valid data on RX_DATA and RX_DATAK.

CONTROL AND STATUS SIGNALS

PHY_RESETN I, PU J3 Active Low. Resets the transmitter and receiver. This signal is asynchronous.

TX_DETRX_LPBK I, PD M6

TX_ELECIDLE I K3 Active High. Forces TX output to electrical idle depending on the power state.

RX_ELECIDLE F3

RX_STATUS2 C7

RX_STATUS1 C6 BIT 2 BIT 1 BIT 0 DESCRIPTION

RX_STATUS0 C5 0 0 0 Received data OK

POWER_DOWN1 G3 Power up and down the transceiver power states.

POWER_DOWN0 H3 BIT 1 BIT 0 DESCRIPTION

O The 16 bits represent 2 symbols of receive data where RX_DATA7-0 is the first symbol

O RX_DATA, RX_DATAK1 to the upper byte. A value of zero indicates a data byte; a value

S, I/O, Active High. While de-asserted with the PHY in P0, P1, P2, or P3, indicates detection of

PD LFPS.

O

I

Parallel USB SuperSpeed data output bus.

received, and RX_DATA15-8 is the second.

of 1 indicates a control byte.

Active High. Used to tell the PHY to begin a receiver detection operation or to begin

loopback.

Encodes receiver status and error codes for the received data stream when receiving

data.

0 0 1 1 SKP ordered set added

0 1 0 1 SKP ordered set removed

0 1 1 Receiver detected

1 0 0 8B/10B decode error

1 0 1 Elastic buffer overflow

Elastic buffer underflow.

1 1 0 This error code is not used if the elasticity buffer is

operating in the nominal buffer empty mode.

1 1 1 Receive disparity error

0 0 P0, normal operation

0 1 P1, low recovery time latency, power saving state

1 0 P2, longer recovery time latency, low power state

1 1 P3, lowest power state

When transitioning from P3 to P0, the signaling is asynchronous.

Copyright © 2009–2010, Texas Instruments Incorporated PIN DESCRIPTIONS 11

Submit Documentation Feedback

Product Folder Link(s): TUSB1310

Page 12

TUSB1310

SLLSE16C–DECEMBER 2009–REVISED AUGUST 2010

www.ti.com

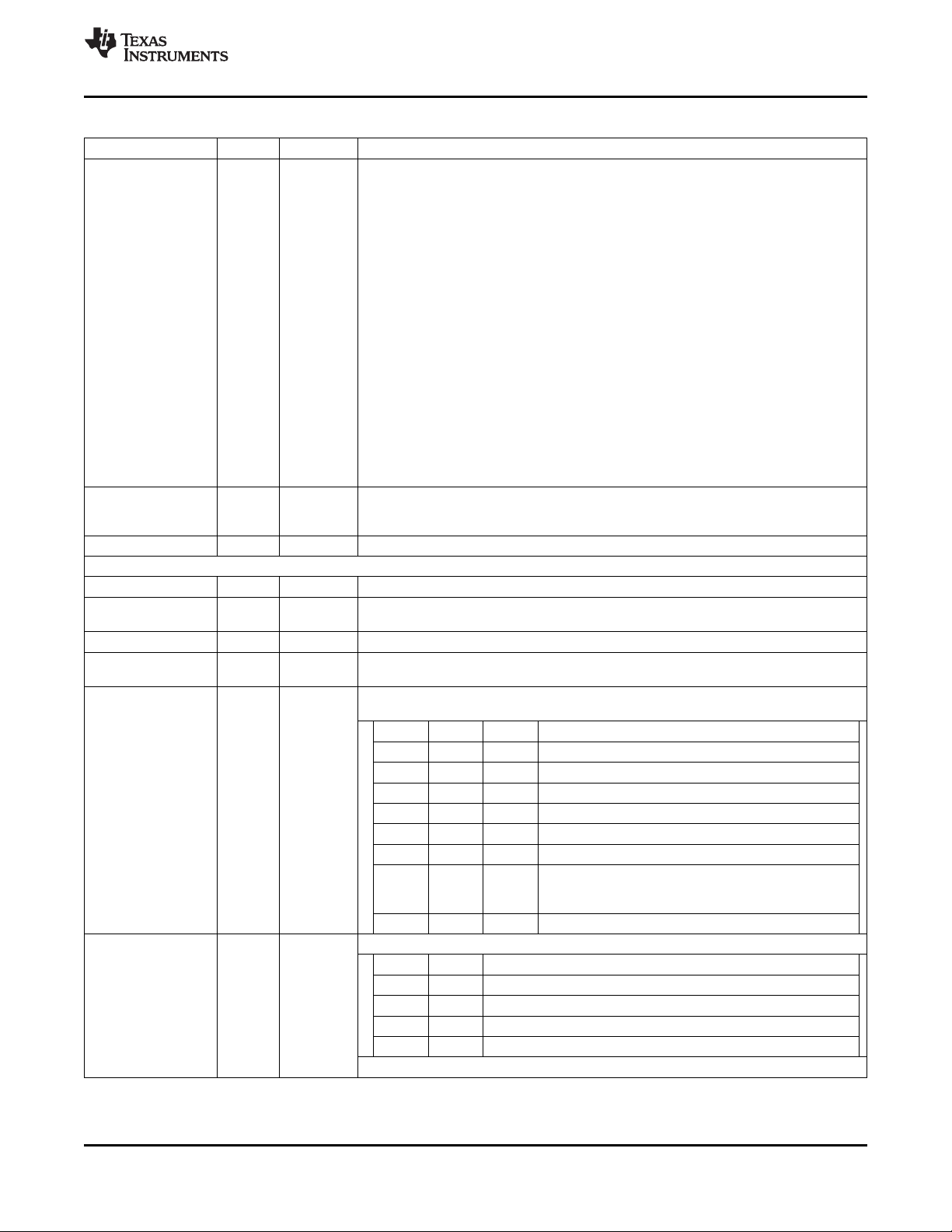

Table 2-2. PIPE Signal Description (continued)

SIGNAL NAME TYPE BALL NO. DESCRIPTION

PHY_STATUS E3

PWRPRESENT O H11 Indicates the presence of VBUS

CONFIGURATION PINS

TX_ONESZEROS I, PD M4 the transmitter to transmit an alternating sequence of 50 - 250 ones and 50 - 250 zeros –

TX_DEEMPH1 K11

TX_DEEMPH0 L11 BIT 1 BIT 0 DESCRIPTION

TX_MARGIN2 M11 Selects transmitter voltage levels

TX_MARGIN1 M10 BIT 2 BIT 1 BIT 0 TX_SWING DESCRIPTION

TX_MARGIN0 M9 0 0 0 0

TX_SWING I, PD M5 0 Full swing

RX_POLARITY I, PD C8

RX_TERMINATION I, PD D3 0 Terminations removed

RATE I, PU L6

ELAS_BUF_MODE I, PD C9 0 Nominal half full buffer mode

S, I/O, management state transitions, rate change, and receiver detection. When this signal

PD transitions during entry and exit from P3 and PCLK is not running, then the signaling is

I, PD, PU

I, PD

Active High. Used to communicate completion of several PHY func-tions including power

asynchronous.

Active High. Used only when transmitting USB compliance pat-terns CP7 or CP8. Causes

regardless of the state of the TX_DATA interface.

Selects transmitter de-emphasis. When the MAC changes, the TUSB1310 starts to

transmit with the new setting within 128 ns.

0 0 -6 dB de-emphasis

0 1 -3.5 dB de-emphasis

1 0 No de-emphasis

1 1 Reserved

Normal operating range

800 mV - 1200 mV

0 0 0 1

0 0 1

0 1 0

0 1 1

1 0 200 mV - 400 mV

1 1 100 mV - 200 mV

Controls transmitter voltage swing level

1 Half swing

Active High. Tells PHY to do a polarity inversion on the received data. Inverted data show

up on RX_DATA15-0 within 20 PCLK clocks after RX_POLARITY is asserted.

0 PHY does no polarity inversion.

1 PHY does polarity inversion.

Controls presence of receiver terminations

1 Terminations present

Controls the link signaling rate

The RATE is always 1.

Selects elasticity buffer operating mode

1 Nominal empty buffer mode

Don't care

0 800 mV - 1200 mV

1 400 mV - 700 mV

0 700 mV - 900 mV

1 300 mV - 500 mV

0 400 mV - 600 mV

1 200 mV - 400 mV

Normal operating range

400 mV - 700 mV

12 PIN DESCRIPTIONS Copyright © 2009–2010, Texas Instruments Incorporated

Submit Documentation Feedback

Product Folder Link(s): TUSB1310

Page 13

TUSB1310

www.ti.com

SLLSE16C–DECEMBER 2009–REVISED AUGUST 2010

2.3 ULPI

The ULPI (ultra low pin count interface) is a low pin count USB PHY to a link layer controller interface. The

ULPI consists of the interface and the ULPI registers. The TUSB1310 is always the master of the ULPI

bus.

Table 2-3. ULPI Signal Description

SIGNAL NAME TYPE BALL NO. DESCRIPTION

ULPI_CLK O P11

ULPI_DATA7 N6

ULPI_DATA6 P6

ULPI_DATA5 N7

ULPI_DATA4 P7

ULPI_DATA3 N8

ULPI_DATA2 P8

ULPI_DATA1 P9

ULPI_DATA0 N9

ULPI_DIR O M7 0 ULPI_DATA lines are inputs

ULPI_STP S, I, PU M8

ULPI_NXT O N11

S, I/O, PD

60-MHz interface clock. All ULPI signals are synchronous to ULPI_CLK. The ULPI_CLK is

always a 60-MHz output of the TUSB1310. In low power mode, the ULPI_CLK is not driven.

Data bus. Driven to 00h by the Link when the ULPI bus is idle.

8-bit data timed on rising edge of ULPI_CLK

Controls the direction of the ULPI_DATA bus

1 ULPI_DATA lines are outputs

Active High. The Link must assert ULPI_STP to signal the end of a USB transmit packet or a

register write operation. The ULPI_STP signal must be asserted in the cycle after the last data

byte is presented on the bus. The ULPI_STP has an internal weak pull-up to safeguard

against false commands on the ULPI_DATA lines.

Active High. The PHY asserts ULPI_NXT to throttle all data types, except register read data

and the RX CMD. The PHY also asserts ULPI_NXT and ULPI_DIR simultaneously to indicate

USB receive activity, if ULPI_DIR was previously low. The PHY is not allowed to assert

ULPI_NXT during the first cycle of the TX CMD driven by the Link.

2.3.1 ULPI Modes

The TUSB1310 supports synchronous mode and low power mode. The default mode is synchronous

mode.

The synchronous mode is a normal operation mode. The ULPI_DATA are synchronous to ULPI_CLK. The

low power mode is used during power down and no ULPI_CLK. The TUSB1310 sets ULPI_DIR to output

and drives LineState signals and interrupts.

Table 2-4. ULPI Synchronous and Low Power Mode Functions

SYNCHRONOUS LOW POWER

ULPI_CLK(OUT)

ULPI_DATA7(I/O)

ULPI_DATA6(I/O)

ULPI_DATA5(I/O)

ULPI_DATA4{I/O}

ULPI_DATA3(I/O) ULPI_INT (OUT)

ULPI_DATA2(I/O)

ULPI_DATA1(I/O) ULPI_LINESTATE1(OUT)

ULPI_DATA0(I/O) ULPI_LINE_STATE0 (OUT)

ULPI_DIR(OUT)

ULPI_STP(IN)

ULPI_NXT(OUT)

Copyright © 2009–2010, Texas Instruments Incorporated PIN DESCRIPTIONS 13

Submit Documentation Feedback

Product Folder Link(s): TUSB1310

Page 14

TUSB1310

SLLSE16C–DECEMBER 2009–REVISED AUGUST 2010

www.ti.com

2.4 Clocking

Table 2-5. Clock Signal Name Description

SIGNAL NAME TYPE BALL NO. DESCRIPTION

XI I A12 supports either a crystal unit, or a 1.8-V clock input. Frequencies supported are 20, 25,

XO O A11 Crystal output. If a 1.8-V clock input is connected to XI, XO must be left open.

CLKOUT O D10 OOBCLK is driven in U3 mode.

Crystal Input. This pin is the clock reference input for the TUSB1310. The TUSB1310

30, or 40 MHz.

2.5 JTAG Interface

The JTAG Interface is used for board-level boundary scan. All digital IO support IEEE1149.1 boundary

scan and SuperSpeed differential pairs support IEEE1149.6 boundary scan.

Table 2-6. JTAG Signal Name Description

SIGNAL NAME TYPE BALL NO. DESCRIPTION

JTAG_TCK I, PU G11 JTAG test clock

JTAG_TMS I, PU D11 JTAG test mode select

JTAG_TDI I, PU E11 JTAG test data input

JTAG_TRSTN I, PD E12 JTAG test asynchronous reset. Active Low.

JTAG_TDO O F11 JTAG test data output

2.6 Reset and Output Control Interface

Table 2-7. Reset and Output Control Signal Description

SIGNAL NAME TYPE BALL NO. DESCRIPTION

RESETN I J11 Active Low. Resets the transmitter and receiver. This signal is asynchronous.

Active High. This can be connected to a 1.8-V power on reset signal on the PCB in

OUT_ENABLE I L10 0: Disable all driver outputs while IO powers are supplied, but internal control circuit

order to avoid static current and signal contention during power up.

powers are not present during power up.

1: Enable all driver outputs during normal operation.

2.7 Strap Options

Strapping pins are latched by reset de-assertion in the TUSB1310.

Table 2-8. Strapping Options

SIGNAL NAME TYPE BALL NO. DESCRIPTION

XTAL_DIS

(RX_ELECIDLE)

PIPE_16BIT

(PHY_STATUS)

ISO_START

(ULPI_DATA7)

S, I/O, PD F3 0 Crystal Input

S, I/O, PD E3 0 16-bit PIPE SDR mode

S, I/O, PD N6 When in the isolate mode, the TUSB1310 will continue to respond to ULPI. Once the

Selects an input clock source

1 Clock Input

Selects PIPE

Must be 0 at reset.

Active High. Puts PIPE into isolate mode. When in the isolate mode, TUSB1310 does

not respond to packet data present at TX_DATA15-0, TXDATAK1-0 inputs and presents

a high imped-ance on the PCLK, RX_DATA15-0, RX_DATAK1-0, RX_VALID outputs.

isolate mode bit in ULPI register is cleared, the USB interfaces will start transmitting

packet data on TX_DATA15-0 and driving PCLK, RX_DATA15-0, RX_DATA1-0, and

RX_VALID.

14 PIN DESCRIPTIONS Copyright © 2009–2010, Texas Instruments Incorporated

Submit Documentation Feedback

Product Folder Link(s): TUSB1310

Page 15

TUSB1310

www.ti.com

SLLSE16C–DECEMBER 2009–REVISED AUGUST 2010

Table 2-8. Strapping Options (continued)

SIGNAL NAME TYPE BALL NO. DESCRIPTION

ULPI_8BIT

(ULPI_DATA6)

REFCLKSEL1,

REFCLKSEL0 N7

(ULPI_DATA5, P7

ULPI_DATA4)

S, I/O, PD P6 0 8-bit ULPI SDR mode

S, I/O, PD 01 25 MHz on XI

Selects ULPI data bus bit width

Must be set to 0.

Select input reference clock frequency for on-chip oscillator

00 20 MHz on XI

10 30 MHz on XI

11 40 MHz on XI

2.8 USB Interfaces

Table 2-9. USB Interface Signal Name Descriptions

SIGNAL NAME TYPE BALL NO. DESCRIPTION

SSTXP H14

SSTXM J14

SSRXP E14

SSRXM F14

DP P14

DM P13

VBUS I N12

O USB SuperSpeed transmitter differential pair

I USB SuperSpeed receiver differential pair

I/O USB non-SuperSpeed differential pair

USB VBUS pin

Connected through an external voltage divider.

2.9 Special Connect

Table 2-10. Special Connect Signal Descriptions

SIGNAL NAME TYPE BALL NO. DESCRIPTION

R1EXT O L14

R1EXTRTN I L13 R1 ground reference. This pin is not connected to board ground.

CEXT O M14 Connected to an external 4.7-nF capacitor

CEXTSS O A14 Connected to an external 4.7-nF capacitor

D6

D5

RSVD I/O Must be left open.

C13

C14

K4

J4

High precision external resistor used for calibration. The R1 value shall be 10 kΩ ±1%

accuracy.

2.10 Power and Ground

Table 2-11. Power/Ground Signal Descriptions

SIGNAL NAME TYPE BALL NO. DESCRIPTION

VDDA3P3 P P12 Analog 3.3-V power supply

N14

VDDA1P8 P A13 Analog 1.8-V power supply

C10

Copyright © 2009–2010, Texas Instruments Incorporated PIN DESCRIPTIONS 15

Submit Documentation Feedback

Product Folder Link(s): TUSB1310

Page 16

TUSB1310

SLLSE16C–DECEMBER 2009–REVISED AUGUST 2010

Table 2-11. Power/Ground Signal Descriptions (continued)

SIGNAL NAME TYPE BALL NO. DESCRIPTION

C12

K14

VDDA1P1 P Analog 1.1-V power supply

VDD1P8 P Digital IO 1.8-V power supply

VDD1P1 P Digital 1.1-V power supply

VSSA G G12 Analog ground

VSSOSC G B12

VSS G J6 J7 Digital ground

G13

G14

D14

C11

B2 C3

D4 D7

D8 D9

E4 F4

G4 H4

L5 L4

M3 L7

L8 L9

A5 A10

B6 B10

E1 F2

K2 L1

N5 P4

N10 P10

K13 D13

C4

B14 B13

J13 H13

F13 E13

K12 L12

D12

N13

M12

M13

Oscillator ground

If using a crystal, this should not be connected to PCB ground plane.

See Chapter 5 for guidelines.

If using an oscillator, this should be connected to PCB ground.

F6 F7

F8 F9

G6 G7

G8 G9

H6 H7

H8 H9

J8 J9

B11 F12

www.ti.com

16 PIN DESCRIPTIONS Copyright © 2009–2010, Texas Instruments Incorporated

Submit Documentation Feedback

Product Folder Link(s): TUSB1310

Page 17

TUSB1310

www.ti.com

3 FUNCTIONAL DESCRIPTION

3.1 Power On and Reset

The TUSB1310 has two hardware reset pins, a chip reset RESETN and a logic reset PHY_RESETN. The

RESETN is used only at Power On. The PHY_RESETN can be used as a functional reset. The ULPI

register also has a software reset.

Until all power sources are supplied, the OUT_ENABLE pin can control the output driver enable. After all

power sources are supplied, the chip reset RESETN and a ULPI soft reset will be asserted by the link

layer. The power up sequence is described in section 3.1.4.

3.1.1 RESETN and PHY_RESETN – Hardware Reset

The RESETN sets all internal states to initial values. The link layer needs to hold the PHY in reset via the

RESETN until all power sources and the reference clock to the TUSB1310 are stable. All pins used for

strapping options must be set before RESETN de-assertion. All strapping option pins have internal pull-up

or pull-down to set default values, but if any non-default values are desired, they need to be controlled

externally by the link layer controller.

Table 3-1. Pin States in Chip Reset

PIPE CONTROL

PIN NAME

TX_DETRX_LPBK Inactive 0

TX_ELECIDLE Active 1

TX_COMPLIANCE Inactive 0

RX_POLARITY Inactive 0

POWER_DOWN U2 10b

TX_MARGIN2-0 Normal operating range 000b

TX_DEEMP -3.5 dB 1

RATE 5.0 Gbps 1

TX_SWING Full swing or half swing 0 or 1

RX_TERMINATION Appropriate state 0 or 1

STATE VALUE

SLLSE16C–DECEMBER 2009–REVISED AUGUST 2010

3.1.2 ULPI Reset – Software Reset

After power-up, the link layer controller must set the Reset bit in ULPI register. It resets the core but does

not reset the ULPI interface or the ULPI registers.

During the ULPI reset, the ULPI_DIR is de-asserted. After the reset, the ULPI_DIR is asserted again and

the TUSB1310 sends an RX CMD update to the link layer. During the reset, the link should ignore signals

on the ULPI_DATA7-0 and must not access the TUSB1310.

3.1.3 OUT_ENABLE - Output Enable

Digital IO buffers use two power supplies, core VDD1P1 and IO VDD1P8. During power up,

OUT_ENABLE must be asserted low for proper operation.

3.1.4 Power Up Sequence

The power up sequence is shown in Figure 3-1.

Copyright © 2009–2010, Texas Instruments Incorporated FUNCTIONAL DESCRIPTION 17

Submit Documentation Feedback

Product Folder Link(s): TUSB1310

Page 18

Power Supplies

XI

RESETN

PCLK

ULPI_CLK

Internal resetn/

PLL_EN/

SUSPENDM

Internal latched

strapping pin states

Latched data

PHY_STATUS/

ULPI_DIR

300ms

TUSB1310

SLLSE16C–DECEMBER 2009–REVISED AUGUST 2010

www.ti.com

Figure 3-1. Power Up Sequence

3.2 Clocks

3.2.1 Clock Distribution

3.2.2 Output Clock

3.3 Power Management

After proper power supply sequencing, the reference clock on XI starts to operate. On the RESETN

de-assertion, REFCLKSEL1-0 is determined depending on the PHY_MODE pins, PLL is locked and the

valid ULPI_CLK and the valid PCLK are driven.

After all stable clocks are provided, the TUSB1310 allows the link layer controller to access by

de-asserting the ULPI_DIR. The link layer controller sets the Reset bit in the ULPI register. At the PIPE

in-terface, the PHY_STATUS changes from high to low in order to indicate the TUSB1310 is in the power

state specified by the POWER_DOWN signal. After the PHY_STATUS change, the TUSB1310 is ready

for PIPE transactions.

A source clock should be provided via XI/XO from an external crystal or from a square wave clock. The

USB3.0 PLL provides a clock to the PIPE which drives 250 MHz. The USB2.0 PLL provides a 60-MHz

clock to the ULPI.

The CLKOUT is used by the link layer controller or the MAC. When ClkoutEn bit at the ULPI SS USB

register is set low, a 120-MHz clock is available via the CLKOUT only in the USB U3 power state. If the

ClkoutEn bit is set high, the 250-MHz clock is driven via CLKOUT in all power states.

The SuperSpeed USB power state transition is controlled by the PIPE POWER_DOWN1-0 and the

non-SuperSpeed USB power state is transitioned by setting suspendM bit in the ULPI Function control

register via the ULPI or by asserting the ULPI_STP.

18 FUNCTIONAL DESCRIPTION Copyright © 2009–2010, Texas Instruments Incorporated

Submit Documentation Feedback

Product Folder Link(s): TUSB1310

Page 19

TUSB1310

www.ti.com

SLLSE16C–DECEMBER 2009–REVISED AUGUST 2010

3.3.1 USB Power Management

The USB 3.0 specification improves power consumption by defining 4 power states, U0, U1, U2, and U3

while the PIPE specification defines P0, P1, P2 and P3. The POWER_DOWN pin states are mapped to

LTSSM states as described in Table 2-10. For all power state transitions, the link layer controller must not

begin any operational sequences or further power state transitions until the TUSB1310 has indicated that

the internal state transition is completed.

Table 3-2. Power States

PIPE

POWER PCLK PLL TRANSMITTING RECEIVING PHY_STATUS

STATE

P0 On On Active or Idle or LFPS Active or Idle

P1 U1 On On Idle or LFPS Idle

P2 On On Idle or LFPS or RxDetect Idle

P3 U3, SS.disabled an Off LFPS or RxDetect Idle

USB POWER

STATE

U0, all other LTSSM A single cycle

states assertion

A single cycle

assertion

U2, RxDetect, A single cycle

SS.Inactive assertion

Off. The

PIPE is in

asynchrono

us mode

PHY_STATUS is

asserted before

PCLK is turned off

and deasserted

when PCLK is fully

off.

When the link layer controller wants to transmit LFPS in P1, P2, or P3 state, it must de-assert

TX_ELECIDLE. The TUSB1310 generates valid LFPS until the TX_ELECIDLE is asserted. The link layer

controller must assert TX_ELECIDLE before transitioning to P0.

When RX_ELECIDLE is de-asserted in P0, P1, P2, or P3, the TUSB1310 receiver monitors for LFPS

except during reset or when RX_TERMINATION is removed for electrical idle.

When the TUSB1310 is in P0 and is actively transmitting; only RX_POLARITY can be asserted.

Table 3-3. PIPE Control Pin Matrix

POWER STATE TX_DETRX_LPBK TX_ELECIDLE DESCRIPTION

0 0 Transmitting data on TX_DATA

P0

P1 Don't care

P2 0 1 Idle

P3 Don't care

0 1 Not transmitting and is in electrical idle.

1 0 Goes into loopback mode

1 1 Transmits LFPS signaling

0 Transmits LFPS signaling

1 Not transmitting and is in electrical idle.

Don't care 0 Transmits LFPS signaling

1 1 Does a receiver detection operation

0 Transmits LFPS signaling

1 Does a receiver detection operation

3.4 Receiver Status

The TUSB1310 has an elastic buffer for clock tolerance compensation, the link partner detection, and

some received data error detections. The receive data status from SSRXP/SSRXN differential pair

presents on RX_STATUS2-0. If an error occurs during a SKP ordered set, the error signaling has

precedence. If more than one error occurs on a received byte, the errors have the priority below.

1. 8B/10B decode error

2. Elastic buffer overflow

Copyright © 2009–2010, Texas Instruments Incorporated FUNCTIONAL DESCRIPTION 19

Submit Documentation Feedback

Product Folder Link(s): TUSB1310

Page 20

TUSB1310

SLLSE16C–DECEMBER 2009–REVISED AUGUST 2010

3. Elastic buffer underflow (can not occur in nominal empty buffer model)

4. Disparity error

3.4.1 Clock Tolerance Compensation

The receiver contains an elastic buffer used to compensate for differences in frequencies between bit

rates at the two ends of a link. The elastic buffer must be capable of holding enough symbols to handle

worst case differences in frequency and worst case intervals between SKP ordered sets. A SKP order set

is a set of symbols transmitted as a group. The SKP ordered sets allows the receiver to adjust the data

stream being received to prevent the elastic buffer from either overflowing or under-flowing due to any

clock tolerance differences.

The TUSB1310 supports two models, nominal half full buffer model and nominal empty buffer mode. For

the nominal half full buffer model, the TUSB1310 monitors the receive data stream. When a Skip ordered

set is received, the TUSB1310 adds or removes one SKP order set from each SKP to manage its elastic

buffer to keep the buffer as close to half full as possible. Only full SKP ordered sets are added or

removed. When a SKP order set is added, the TUSB1310 asserts an “Add SKP” code (001b) on the

RX_STATUS for one clock cycle. When a SKP order set is removed, the RX_STATUS is has a “Remove

SHP” code (010b).

For the nominal empty buffer model the TUSB1310 attempts to keep the elasticity buffer as close to empty

as possible. When no SKP ordered sets have been received, the TUSB1310 will be required to insert SKP

ordered sets into the received data stream.

www.ti.com

RX_STATUS2-0 SKP ADDITION or REMOVAL LENGTH

001b 1 SKP ordered set added

010b 1 SKP ordered set removed

3.4.2 Receiver Detection

TX_DETRX_LPBK starts a receiver detection operation to determine if there is a receiver at the other end

of the link. When the receiver detect sequence completes, the PHY_STATUS is asserted for one clock

and drives the RX_STATUS signals to the appropriate code. Once the TX_DETRX_LPBK signal is

asserted, the link layer controller must leave the signal asserted until the PHY_STATUS pulse. When

receiver detection is performed in P3, the PHY_STATUS shows the appropriate receiver detect value until

the TX_DETRX_LPBK is de-asserted.

RX_STATUS2-0 DETECTED CONDITION LENGTH

000b Receiver not present

011b Receiver present

3.4.3 8b/10b Decode Errors

When the TUSB1310 detects an 8b/10b decode error, it will assert an EDB (0xFE) symbol in the data on

the RX_DATA where the bad byte occurred. In the same clock cycle that the EDB symbol is asserted on

the RX_DATA, the 8b/10b decode error code (100b) will be asserted on the RX_STATUS. 8b/10b

decoding error has priority over all other receiver error codes and could mask out a disparity error

occurring on the other byte of data being clocked onto the RX_DATA with the EDB symbol.

Table 3-4. RX_STATUS - SKP

One clock cycle

Table 3-5. RX_STATUS - Receiver Detection

One clock cycle

20 FUNCTIONAL DESCRIPTION Copyright © 2009–2010, Texas Instruments Incorporated

Submit Documentation Feedback

Product Folder Link(s): TUSB1310

Page 21

TUSB1310

www.ti.com

RX_STATUS2-0 DETECTED ERROR LENGTH

100b 8B/10B decode error

3.4.4 Elastic Buffer Errors

When the elastic buffer overflows, data is lost during the reception of the data. The elastic buffer overflow

error code (101b) will be asserted on the RX_STATUS on the PCLK cycle the omitted data would have

been asserted. The data asserted on the RX_DATA is still valid data, the elastic buffer overflow error code

on the RX_STATUS just marks a discontinuity point in the data stream being received.

When the elastic buffer underflows, EDB (0xFE) symbols are inserted into the data stream on the

RX_DATA to fill the holes created by the gaps between valid data. For every PCLK cycle a EDB symbol is

asserted on the RX_DATA, an elastic buffer underflow error code (111b) is asserted on the RX_STATUS.

In nominal empty buffer mode, SKP ordered sets are transferred on RX_DATA and the underflow is not

signaled.

RX_STATUS2-0 DETECTED ERROR LENGTH

101b Elastic buffer overflow

110b Elastic buffer underflow

SLLSE16C–DECEMBER 2009–REVISED AUGUST 2010

Table 3-6. 8b/10b Decode Errors

Clock cycles during the effected byte is

transferred on RX_DATA15-0

Table 3-7. Elastic Buffer Errors

Clock cycles the omitted data would have

appeared

Clock cycles during the EDB symbol

presence on RX_DATA15-0

3.4.5 Disparity Errors

When the TUSB1310 detects a disparity error, it will assert a disparity error code (111b) on the

RX_STATUS in the same PCLK cycle it asserts the erroneous data on the RX_DATA. The disparity code

does not discern which byte on the RX_DATA is the erroneous data.

RX_STATUS2-0 DETECTED ERROR LENGTH

111b Disparity error

3.5 Loopback

The TUSB1310 begins an internal loopback operation from SSRXP/SSRXN differential pairs to

SSTXP/SSTXN differential pairs when the TX_DETRX_LPBK is asserted while holding TX_ELECIDLE

de-asserted. The TUSB1310 will stop transmitting data to the SSTXP/SSTXN signaling pair from the

TX_DATA and begin transmitting on the SSTXP/SSTXN signaling pair the data received at the

SSRXP/SSRXN signaling pair. This data is not routed through the 8b/10b coding/encoding paths. While in

the loopback operation, the received data is still sent to the RX_DATA. The data sent to the RX_DATA is

routed through the 10b/8b decoder.

The TX_DETRX_LPBK de-assertion will terminate the loopback operation and return to transmitting

TX_DATA over the SSTXP/SSTXN signaling pair. The TUSB1310 only transitions out of loopback on

detection of LFPS signaling by transitioning to P2 state and starting the LFPS handshake.

Table 3-8. Disparity Errors

Clock cycles during the ef-fected byte is

transferred on RX_DATA15-0

Copyright © 2009–2010, Texas Instruments Incorporated FUNCTIONAL DESCRIPTION 21

Submit Documentation Feedback

Product Folder Link(s): TUSB1310

Page 22

TUSB1310

SLLSE16C–DECEMBER 2009–REVISED AUGUST 2010

www.ti.com

4 REGISTERS

4.1 Register Definitions

Table 4-1. Register Definitions

ACCESS CODE EXPANDED NAME DESCRIPTION

Rd Read Register can be read. Read only if this is the only mode given.

Wr Write Pattern on the data bus will be written over all bits of the register.

S Set Pattern on the data bus is OR'ed with and written into the register.

C Clear

4.2 Register Map

The TUSB1310 contains the ULPI registers consisting of an immediate register set and an extended

register set.

Table 4-2. Register Map

REGISTER NAME

IMMEDIATE REGISTER SET

Vendor ID low 00h

Vendor ID high 01h

Product ID low 02h

Product ID high 03h

Function control 04h-06h 04h 05h 06h

Interface control 07h-09h 07h 08h 09h

Reserved 10h – 14h

Debug 15h

Scratch register 16h-18h 16h 17h 18h

Reserved 19h-2Eh

Access extended register set 2Fh

NonSS USB 30h-32h 30h 31h 32h

SS USB 33h-35h 33h 34h 35h

Reserved 36h-3Fh

EXTENDED REGISTER SET

Maps to immediate register set above 00h-3Fh

Reserved 40h-7Fh

Vendor specific 80h-FFh

Pattern on the data bus is a mask. If a bit in the mask is set, then the

corresponding register bit will be set to zero(cleared).

ADDRESS (6 BITS)

Rd Wr Set Clr

4.2.1 Vendor ID and Product ID (00h-03h)

Table 4-3. Vendor ID and Product ID

ADDRESS BITS NAME ACCESS RESET DESCRIPTION

00h 7:00 Vendor ID low Rd 51h Lower byte of vendor ID supplied by USB-IF

01h 7:00 Vendor ID high Rd 04h Upper byte of vendor ID supplied by USB-IF

02h 7:00 Product ID low Rd 10h Lower byte of vendor ID supplied by vendor

03h 7:00 Product ID high Rd 13h Upper byte of vendor ID supplied by vendor

22 REGISTERS Copyright © 2009–2010, Texas Instruments Incorporated

Submit Documentation Feedback

Product Folder Link(s): TUSB1310

Page 23

TUSB1310

www.ti.com

SLLSE16C–DECEMBER 2009–REVISED AUGUST 2010

4.2.2 Function Control (04h-06h)

Address: 04h-06h (Read), 04h(Write), 05h(Set), 06h(Clear)

Table 4-4. Function Control

BITS NAME ACCESS RESET DESCRIPTION

Selects the required transceiver speed

00b : Enable HS transceiver

1:00 XcvrSelect Rd/Wr/S/C 1h

2 TermSelect Rd/Wr/S/C 0 OpMode, DpPulldown and DmPulldown. Since low speed peripherals

4:03 OpMode Rd/Wr/S/C 0

5 Reset Rd/Wr/S/C 0

6 SuspendM Rd/Wr/S/C 1h

7 Reserved Rd 0 Reserved

01b: Enable FS transceiver

10b: Enable LS transceiver

11b: Enable FS transceiver for LS packets

(FS preamble is automatically pre-pended)

Controls the internal 1.5-kΩ pullup resister and 45-Ω HS terminations.

Control over bus resistors changes depending on XcvrSelect,

never support full speed or hi-speed, providing the 1.5 kΩ on DM for

low speed is optional.

Selects the required bit encoding style during transmit

00 : Normal operation

01: Non-driving

10: Disable bit-stuff and NRZI encoding

11: Do not automatically add SYNC and EOP when transmitting. Must

be used only for HS packets.

Active High transceiver reset. After the Link sets this bit, the

TUSB1310 must assert the ULPI_DIR and reset the ULPI. When the

reset is completed, the PHY de-asserts the ULPI_DIR and

automatically clears this bit. After de-asserting the ULPI_DIR, the PHY

must re-assert the ULPI_DIR and send an RX CMD update on the link

layer controller. The link layer controller must wait for the ULPI_DIR to

de-assert before using the ULPI bus. Does not reset the ULPI or ULPI

register set.

Active low PHY suspend. Put the TUSB1310 into low power mode.

The PHY can power down all blocks except the full speed receiver,

OTG comparators, and the ULPI pins. The PHY must automatically set

this bit to '1' when low power mode is exited.

0: Low power mode

1: Powered

Copyright © 2009–2010, Texas Instruments Incorporated REGISTERS 23

Submit Documentation Feedback

Product Folder Link(s): TUSB1310

Page 24

TUSB1310

SLLSE16C–DECEMBER 2009–REVISED AUGUST 2010

4.2.3 Interface Control (07h-09h)

Address: 07-09h (Read), 07h (Write), 08h (Set), .09h (Clear)

Table 4-5. Interface Control

BITS NAME ACCESS RESET DESCRIPTION

0 Reserved Rd 0b Reserved, only write a 0 to this bit.

1 Reserved Rd 0b Reserved, only write a 0 to this bit.

2 Reserved Rd 0h Reserved

Active low clock suspend. Valid only in serial mode. Powers down the

internal clock circuitry only. Valid only when SuspendM = 1. The

3 ClockSuspendM Rd/Wr/S/C 0b

6:04 Reserved Rd 0h Reserved

7 Rd/Wr/S/C 0

Interface protect

disable

TUSB1310 must ignore ClockSuspend when SuspendM = 0. By

default, the clock will not be powered in serial mode.

0 : Clock will not be powered in serial mode

1 : Clock will be powered in serial mode

Controls internal pullups and pulldowns on the ULPI_STP and the

ULPI_DATA for protecting the ULPI when the link layer controller

tri-states the signals.

0 enables the pullup and pulldown

1 disables the pullup and pulldown

4.2.4 Debug (15h)

www.ti.com

Address: 15h (Read-only)

Table 4-6. Debug

BITS NAME ACCESS RESET DESCRIPTION

0 LineState0 Rd 0 Contains the current value of LineState0

1 LineState1 Rd 0 Contains the current value of LineState0

07:2 Reserved Rd 0 Reserved

4.2.5 Scratch Register (16-18h)

Address: 16-18h (Read), .16h (Write), .17h (Set), .18h (Clear)

Table 4-7. Scratch Register

BITS NAME ACCESS RESET DESCRIPTION

7:0 Scratch Rd/Wr/S/C 00 and clear this register and the TUSB1310 functionality will not be

Empty register byte for testing purposes. Software can read, write, set,

affected.

24 REGISTERS Copyright © 2009–2010, Texas Instruments Incorporated

Submit Documentation Feedback

Product Folder Link(s): TUSB1310

Page 25

CEXTSS

CEXT

4 .7nF

VSSA

VSSA

4.7 nF

R1EXT

R1EXTRTN

10KW ± 1 %

SSRXP

VBUS

SSRXN

SSTXP

SSTXN

DP

DM

USB Connector

XI

VSSOSC

XO

Crystal

Connection

ULPIPIPE RX

PIPE TX

Link Controller

JTAGJTAG

10KW ± 1%

90.9KW ± 1 %

TUSB1310

www.ti.com

5 DESIGN GUIDELINES

5.1 Chip Connection on PCB

Components should be placed close to the TUSB1310 to reduce the trace length of the interface between

the components and the TUSB1310. If external capacitors can not accommodate a close placement,

shielding to ground is recommended.

SLLSE16C–DECEMBER 2009–REVISED AUGUST 2010

5.1.1 USB Connector Pins Connection

Figure 5-1. Analog Pin Connections

Differential pair signals, DP/DM, SSTXP/SSTXN, SSRXP/SSRXN, should be kept as short as possible.

The differential pair traces should be trace-length matched and parallelism should be maintained. They

also need to minimize vias and corners and should avoid crossing plane splits and stubs.

Figure 5-2 and Figure 5-3 are for visual reference only.

Copyright © 2009–2010, Texas Instruments Incorporated DESIGN GUIDELINES 25

Submit Documentation Feedback

Product Folder Link(s): TUSB1310

Page 26

SSRXP

VBUS

5

6

7

8

9

4

1

3

2

Pin# Signal Name

1

2

3

4

5

6

7

8

9

VBUS

DM

DP

GND

SSRXN

SSRXP

GND_DRAIN

SSTXN

SSTXP

SSRXN

SSTXP

SSTXN

DPDM

90.9kW ± 1%

10kW ± 1%

SSRXP

VBUS

9

8

7

6

5

4

3

1

2

Pin# Signal Name

1

2

3

4

5

6

7

8

9

VBUS

DM

DP

GND

SSTXN

SSTXP

GND_DRAIN

SSRXN

SSRXP

SSRXN

SSTXP

SSTXN

DPDM

90.9kW ± 1%

10kW ± 1%

TUSB1310

SLLSE16C–DECEMBER 2009–REVISED AUGUST 2010

Figure 5-2. USB Standard-A Connector Pin Connection

www.ti.com

Figure 5-3. USB Standard-B Connector Pin Connection

5.1.2 Clock Connections

The TUSB1310 supports an external oscillator source or a crystal unit. If a clock is provided to XI instead

of a crystal, XO is left open. Otherwise, if a crystal is used, the connection needs to follow the guidelines

below.

Since XI and XO are coupled to other leads and supplies on the PCB, it is important to keep them as short

as possible and away from any switching leads. It is also recommended to minimize the capacitance

between XI and XO. This can be accomplished by connecting the VSSOSC lead to the two external

capacitors CL1 and CL2 and shielding them with the clean ground lines. The VSSOSC should not be

connected to PCB ground.

26 DESIGN GUIDELINES Copyright © 2009–2010, Texas Instruments Incorporated

Submit Documentation Feedback

Product Folder Link(s): TUSB1310

Page 27

TUSB1310

www.ti.com

Load capacitance (Cload) of the crystal varying with the crystal vendors is the total capacitance value of

the entire oscillation circuit system as seen from the crystal. It includes two external capacitors CL1 and

CL2 in Figure 5-4. CVSS below is optional, but recommended for minimum jitter implementation. The

trace length between the decoupling capacitors and the corresponding power pins on the TUSB1310

needs to be minimized. It is also recommended that the trace length from the capacitor pad to the power

or ground plane be minimized.

SLLSE16C–DECEMBER 2009–REVISED AUGUST 2010

Figure 5-4. Typical Crystal Connections

5.2 Clock Source Requirements

5.2.1 Clock Source Selection Guide

Reference clock jitter is an important parameter. Jitter on the reference clock will degrade both the

transmit eye and receiver jitter tolerance no matter how clean the rest of the PLL is, thereby impairing

sys-tem performance. Additionally, a particularly jittery reference clock may interfere with PLL lock

detection mechanism, forcing the lock detector to issue an unlock signal. A good quality, low jitter

reference clock is required to achieve compliance with supported USB3.0 standards. For example,

USB3.0 specification requires the random jitter (RJ) component of either RX or TX to be 2.42 ps (random

phase jitter calculated after applying jitter transfer function - JTF). As the PLL typically has a number of

additional jitter components, the reference clock jitter must be considerably below the overall jitter budget.

Copyright © 2009–2010, Texas Instruments Incorporated DESIGN GUIDELINES 27

Submit Documentation Feedback

Product Folder Link(s): TUSB1310

Page 28

TUSB1310

SLLSE16C–DECEMBER 2009–REVISED AUGUST 2010

www.ti.com

5.2.2 Oscillator

If an external clock source is used, XI should be tied to the clock source and XO should be left floating.

Table 5-1. Oscillator Specification

PARAMETER CONDITION MIN TYP MAX UNIT

Frequency tolerance Operational temperature ±50 ppm

Frequency stability 1 year aging ±50 ppm

Rise / Fall time 20% - 80% 6 ns

Reference clock RJwith JTF (1 sigma)

Reference clock TJwith JTF (total p-p)

Reference clock jitter (absolute p-p)

(1) Sigma value assuming Gaussian distribution

(2) After application of JTF

(3) Calculated as 14.1 x RJ+ D

(4) Absolute phase jitter (p-p)

(1)(2)

(2)(3)

(4)

J

0.8 ps

25 ps

50 ps

5.2.3 Crystal

Either a 20-MHz, 25-MHz, 30-MHz, or 40-MHz crystal can be selected. A parallel, 20-pF load crystal

should be used if a crystal source is used.

Table 5-2. Oscillator Specification

PARAMETER CONDITION MIN TYP MAX UNIT

Frequency tolerance Operational temperature ±50 ppm

Frequency stability 1 year aging ±50 ppm

Load capacitance 12 20 24 pF

28 DESIGN GUIDELINES Copyright © 2009–2010, Texas Instruments Incorporated

Submit Documentation Feedback

Product Folder Link(s): TUSB1310

Page 29

TUSB1310

www.ti.com

6 ELECTRICAL SPECIFICATIONS

6.1 ABSOLUTE MAXIMUM RATINGS

over operating free-air temperature range (unless otherwise noted)

V

DD1P1

V

DD1P8

V

DDA1P1

V

DDA1P8

V

DDA3P3

6.2 RECOMMENDED OPERATING CONDITIONS

over operating free-air temperature range (unless otherwise noted)

V

DDA3P3

V

DDA1P8

V

DDA1P1

V

DD1P8

V

DD1P1

V

BUS

T

A

T

J

Digital 1.1 steady-state supply voltage -0.3 to 1.4 V

Digital IO 1.8 steady-state supply voltage -0.3 to 2.45 V

Analog 1.1 steady-state supply voltage -0.3 to 1.4 V

Analog 1.8 steady-state supply voltage -0.3 to 2.45 V

Analog 3.3 steady-state supply voltage -0.3 to 3.8 V

Analog 3.3 supply voltage 2.97 3.3 3.63 V

Analog 1.8 supply voltage 1.71 1.8 1.98 V

Analog 1.1 supply voltage 1.045 1.1 1.155 V

Digital IO 1.8 supply voltage 1.62 1.8 1.98 V

Digital 1.1 supply voltage 1.045 1.1 1.155 V

Voltage at VBUS PAD 0 1.21 V

Operating free-air temperature range -40 85 °C

Operating junction temperature range -40 105 °C

Human Body Model (HBM) 500

ESD V

Charged Device Model

(CDM)

SLLSE16C–DECEMBER 2009–REVISED AUGUST 2010

VALUE UNIT

MIN NOM MAX UNIT

500

6.3 DC CHARACTERISTICS FOR 1.8-V DIGITAL IO

over operating free-air temperature range (unless otherwise noted)

PARAMETER MIN TYP MAX UNIT

V

IH

V

IL

V

OH

V

OL

V

hys

I

I

I

I(PUon)

I

OZ

(1)

I

Z

V

TX_DIFF_SS

High-level input voltage V

Low-level input voltage V

IO = -2 mA, V

pulldown disabled 0.45

IO = -2 mA, V

pulldown disabled VDDS

IO = 2 mA, driver enabled, V

pulldown disabled

IO = 2 mA, V

pulldown disabled VDDS

= 1.62 V to 1.98 V, driver enabled, pullup or VDDS -

DDS

= 1.4 V to 1.6 V, driver enabled, pullup or 0.75 x

DDS

= 1.62 V to 1.98 V, pullup or

DDS

= 1.4 V to 1.6 V, driver enabled, pullup or 0.25 x

DDS

Input hysteresis 100 270 mV

Any receiver, including those with a pullup or pulldown. The

pullup or pulldown must be disabled.

Receiver/pullup only, pullup enabled (not inhibited), V

= 0 V -47 to -169

PAD

Receiver/pullup only, pullup enabled (not inhibited) -100

Driver only, driver disabled ±20 µA

SSTXP/SSTXN Differential p-p Tx voltage swing 0.8 1.2 V

(1) IZis the total leakage current through the PAD connection of a driver/receiver combination that may include a pullup or pulldown. The

driver output is disabled and the pullup or pulldown is inhibited.

Copyright © 2009–2010, Texas Instruments Incorporated ELECTRICAL SPECIFICATIONS 29

Submit Documentation Feedback

Product Folder Link(s): TUSB1310

0.65 x

VDDS

0.35 x

VDDS

V

0.45

V

±1 µA

µA

±20 µA

Page 30

VDD

1 P 1

VDD

1P 8 and

Analog Power Supplies

OUT

_ ENABLE

XI

RESETN

Latch

-In of Hardware

Strapping Pins

ULPI

_ DIR

Tcfgin 1

Drive Output

Strapping pins

Tcfgin 2

TUSB1310

SLLSE16C–DECEMBER 2009–REVISED AUGUST 2010

www.ti.com

DC CHARACTERISTICS FOR 1.8-V DIGITAL IO (continued)

over operating free-air temperature range (unless otherwise noted)

PARAMETER MIN TYP MAX UNIT

R

TX_DIFF_DC

V

TX_RCV_DET

C

AC_COUPLING

R

RX_DC

R

RX_DIFF_DC

V

RX_LFPS_DET

V

CM_AC_LFPS

V

CM_LFPS_active

V

TX_DIFF_PP_LFPS

6.4 DEVICE POWER CONSUMPTION

over operating free-air temperature range (unless otherwise noted)

VDDA3P3 power consumption 13 mW

VDDA1P8 power consumption 77 mW

VDDA1P1 power consumption 118 mW

VDD1P1 power consumption 98 mW

VDD1P8 power consumption 128 mW

(1) Power consumption condition is transmitting and/or receiving (in U0) at 25°C and nominal voltages.

DC differential impedance 72 120 Ω

The amount of voltage change allowed during receiver detection 0.6 V

AC coupling capacitor 75 200 nF

Receiver DC common mode impedance 18 30 Ω

DC differential impedance 72 120 Ω

LFPS detect threshold 100 300 mV

100 mV

10 mV

800 1200 mV

(1)

PARAMETER MIN TYP MAX UNIT

6.5 AC Characteristics

6.5.1 Power Up and Reset Timing

The TUSB1310 does not drive signals on any strapping pins before they are latched internally.

Figure 6-1. Power Up and Reset Timing

30 ELECTRICAL SPECIFICATIONS Copyright © 2009–2010, Texas Instruments Incorporated

Submit Documentation Feedback

Product Folder Link(s): TUSB1310

Page 31

TX _ CLK

TX _ DATA 15 -0

TX _ DATAK 1 - 0

Valid Data

Thd 2

Tcyc 2

Tsu 2

PCLK

RX _ DATA 15 -0

RX _ DATAK 1 -0

RX _ VALID

RX _STATUS 2- 0

PHY _ STATUS

Valid Data

Tcyc 3

Tdly 3

TUSB1310

www.ti.com

SLLSE16C–DECEMBER 2009–REVISED AUGUST 2010

Table 6-1. Power Up and Reset Timing

SYMBOL DESCRIPTION MIN TYP MAX UNIT

Tcfgin1 Hardware configuration latch-in time from RESETN 0 ns

Tcfgin2 Time from RESETN to dDriver outputs on strapping pins 0 ns

RESETN pulse width 1 µs

RESETN to PHY_STATUS de-assertion 300 µs

6.5.2 PIPE Transmit

Figure 6-2. PIPE Transmit Timing

Table 6-2. PIPE Transmit Timing

SYMBOL DESCRIPTION MIN TYP MAX UNIT

Tcyc2 TX_CLK Period 4 ns

Tdty2 TX_CLK Period 50 %

Tsu2 Data Setup to TX_CLK rise and TX_CLK fall

Thd2 Data Hold to TX_CLK rise and TX_CLK fall

(1) This includes TX_DATA15-0, TX_DATAK1-0, TX_ONESZEROS, RATE, TX_DEEMPTH, TX_DETRX_LPBK, TX_ELECIDLE,

TX_MARGIN, TX_SWING, RX_POLARITY, POWER_DOWN1-0.

(1)

(1)

1 ns

0 ns

6.5.3 PIPE Receive

Figure 6-3. PIPE Receive Timing

Table 6-3. PIPE Receive Timing

SYMBOL DESCRIPTION MIN TYP MAX UNIT

Tcyc3 PCLK Period 4 ns

Tdty3 PCLK Duty Cycle 50 %

Tdly3 1 2 ns

(1) Output Load max = 10 pF, min = 5 pF

(2) Timing is relative to the 50% transition point, not VIH/VIL.

Copyright © 2009–2010, Texas Instruments Incorporated ELECTRICAL SPECIFICATIONS 31

PCLK rise and fall to RX_DATA15-0, RX_DATAK1-0, RX_VALID,

RX_STATUS2-0, PHY_STATUS Delay

(1)(2)

Submit Documentation Feedback

Product Folder Link(s): TUSB1310

Page 32

TUSB1310

SLLSE16C–DECEMBER 2009–REVISED AUGUST 2010

www.ti.com

6.5.4 ULPI Parameters

Table 6-4. ULPI Parameters

DESCRIPTION NOTES HS FS LS UNIT

RX CMD delay 2-4 2-4 2-4 clocks

TX start delay 1-2 1-10 1-10 clocks

TX end delay PHY pipeline delays 2-5 clocks

RX start delay 3-8 clocks

RX end delay 3-8 17-18 122-123 clocks

Transmit-Transmit (host only) 15-24 7-18 77-247 clocks

Receive-Transmit (host or peripheral) 1-14 7-18 77-247 clocks

Link decision times

6.5.5 ULPI Clock

Table 6-5. ULPI Clock Parameters

SYMBOL DESCRIPTION MIN TYP MAX UNIT

Fstart_8bit Frequency (first transition) ±10% 54 60 66 MHz

Fsteady Frequency (steady state) ±500 ppm 59.97 60 60.03 MHz

Dstart_8bit Duty cycle (first transition) ±10% 40 50 60 %

Dsteady Duty cycle (steady state) ±500 ppm 49.975 50 50.025 %

Tsteady Time to reach steady state frequency and duty cycle after first transition 1.4 ms

Tstart_dev Clock startup time after deassertion of SuspemdM – Peripheral 5.6 ms

Tstart_host Clock startup time after deassertion of SuspemdM – Hold ms

Tprep PHY preparation time after first transition of input clock µs

Tjitter Jitter ps

Trise/Tfall Rise and fall time ns

6.5.6 ULPI Transmit

Figure 6-4. ULPI Transmit Timing

32 ELECTRICAL SPECIFICATIONS Copyright © 2009–2010, Texas Instruments Incorporated

Submit Documentation Feedback

Product Folder Link(s): TUSB1310

Page 33

TUSB1310

www.ti.com

SLLSE16C–DECEMBER 2009–REVISED AUGUST 2010

Table 6-6. ULPI Transmit Timing

SYMBOL DESCRIPTION MIN TYP MAX UNIT

Tsc8, Tsd8 ULPI_STP setup time 6 ns

Thc8, Thd8 ULPI_STP hold time 0 ns

6.5.7 ULPI Receive Timing

Figure 6-5. ULPI Receive Timing

Table 6-7. ULPI Transmit Timing

SYMBOL DESCRIPTION MIN TYP MAX UNIT

Tdc9, Tdd9 ULPI_DIR/ULPI_NXT/ULPI_DATA7-0

(1) Output Load max = 10 pF, min = 5 pF

(1)

9 ns

6.5.8 Power State Transition Time

The P1 to P0 transition time is the amount of time for the TUSB1310 to return to P0 state, after having

been in the P1 state. This time is measured from when the MAC sets the POWER_DOWN signals to P0

until the TUSB1310 asserts PHY_STATUS. The TUSB1310 asserts PHY_STATUS when it is ready to

begin data transmission and reception.

The P2 to P0 transition time is the amount of time for the TUSB1310 to return to the P0 state, after having

been in the P2 state. This time is measured from when the MAC sets the POWER_DOWN signals to P0

until the TUSB1310 asserts PHY_STATUS. The TUSB1310 asserts PHY_STATUS when it is ready to

begin data transmission and reception.

The P3 to P0 transition time is the amount of time for the TUSB1310 to go to P0 state, after having been

in the P3 state. Time is measured from when the MAC sets the POWER_DOWN signals to P0 until the

TUSB1310 deasserts PHY_STATUS. The TUSB1310 asserts PHY_STATUS when it is ready to begin

data transmission and reception.

Copyright © 2009–2010, Texas Instruments Incorporated ELECTRICAL SPECIFICATIONS 33

Submit Documentation Feedback

Product Folder Link(s): TUSB1310

Page 34

PACKAGE OPTION ADDENDUM

www.ti.com

27-Aug-2010

PACKAGING INFORMATION

Orderable Device

TUSB1310IZAYR PREVIEW NFBGA ZAY 175 1000 TBD Call TI Call TI Samples Not Available

TUSB1310ZAY ACTIVE NFBGA ZAY 175 160 Green (RoHS

TUSB1310ZAYR PREVIEW NFBGA ZAY 175 1000 TBD Call TI Call TI Samples Not Available

(1)

The marketing status values are defined as follows:

ACTIVE: Product device recommended for new designs.

LIFEBUY: TI has announced that the device will be discontinued, and a lifetime-buy period is in effect.

NRND: Not recommended for new designs. Device is in production to support existing customers, but TI does not recommend using this part in a new design.

PREVIEW: Device has been announced but is not in production. Samples may or may not be available.

OBSOLETE: TI has discontinued the production of the device.

Status

(1)

Package Type Package

Drawing

Pins Package Qty

Eco Plan

& no Sb/Br)

(2)

Lead/

Ball Finish

SNAGCU Level-3-260C-168 HR Request Free Samples

MSL Peak Temp

(3)

Samples

(Requires Login)

(2)

Eco Plan - The planned eco-friendly classification: Pb-Free (RoHS), Pb-Free (RoHS Exempt), or Green (RoHS & no Sb/Br) - please check http://www.ti.com/productcontent for the latest availability

information and additional product content details.

TBD: The Pb-Free/Green conversion plan has not been defined.

Pb-Free (RoHS): TI's terms "Lead-Free" or "Pb-Free" mean semiconductor products that are compatible with the current RoHS requirements for all 6 substances, including the requirement that

lead not exceed 0.1% by weight in homogeneous materials. Where designed to be soldered at high temperatures, TI Pb-Free products are suitable for use in specified lead-free processes.

Pb-Free (RoHS Exempt): This component has a RoHS exemption for either 1) lead-based flip-chip solder bumps used between the die and package, or 2) lead-based die adhesive used between

the die and leadframe. The component is otherwise considered Pb-Free (RoHS compatible) as defined above.

Green (RoHS & no Sb/Br): TI defines "Green" to mean Pb-Free (RoHS compatible), and free of Bromine (Br) and Antimony (Sb) based flame retardants (Br or Sb do not exceed 0.1% by weight

in homogeneous material)

(3)

MSL, Peak Temp. -- The Moisture Sensitivity Level rating according to the JEDEC industry standard classifications, and peak solder temperature.

Important Information and Disclaimer:The information provided on this page represents TI's knowledge and belief as of the date that it is provided. TI bases its knowledge and belief on information

provided by third parties, and makes no representation or warranty as to the accuracy of such information. Efforts are underway to better integrate information from third parties. TI has taken and

continues to take reasonable steps to provide representative and accurate information but may not have conducted destructive testing or chemical analysis on incoming materials and chemicals.

TI and TI suppliers consider certain information to be proprietary, and thus CAS numbers and other limited information may not be available for release.

In no event shall TI's liability arising out of such information exceed the total purchase price of the TI part(s) at issue in this document sold by TI to Customer on an annual basis.

Addendum-Page 1

Page 35

Page 36

IMPORTANT NOTICE

Texas Instruments Incorporated and its subsidiaries (TI) reserve the right to make corrections, modifications, enhancements, improvements,

and other changes to its products and services at any time and to discontinue any product or service without notice. Customers should

obtain the latest relevant information before placing orders and should verify that such information is current and complete. All products are

sold subject to TI’s terms and conditions of sale supplied at the time of order acknowledgment.

TI warrants performance of its hardware products to the specifications applicable at the time of sale in accordance with TI’s standard

warranty. Testing and other quality control techniques are used to the extent TI deems necessary to support this warranty. Except where

mandated by government requirements, testing of all parameters of each product is not necessarily performed.

TI assumes no liability for applications assistance or customer product design. Customers are responsible for their products and