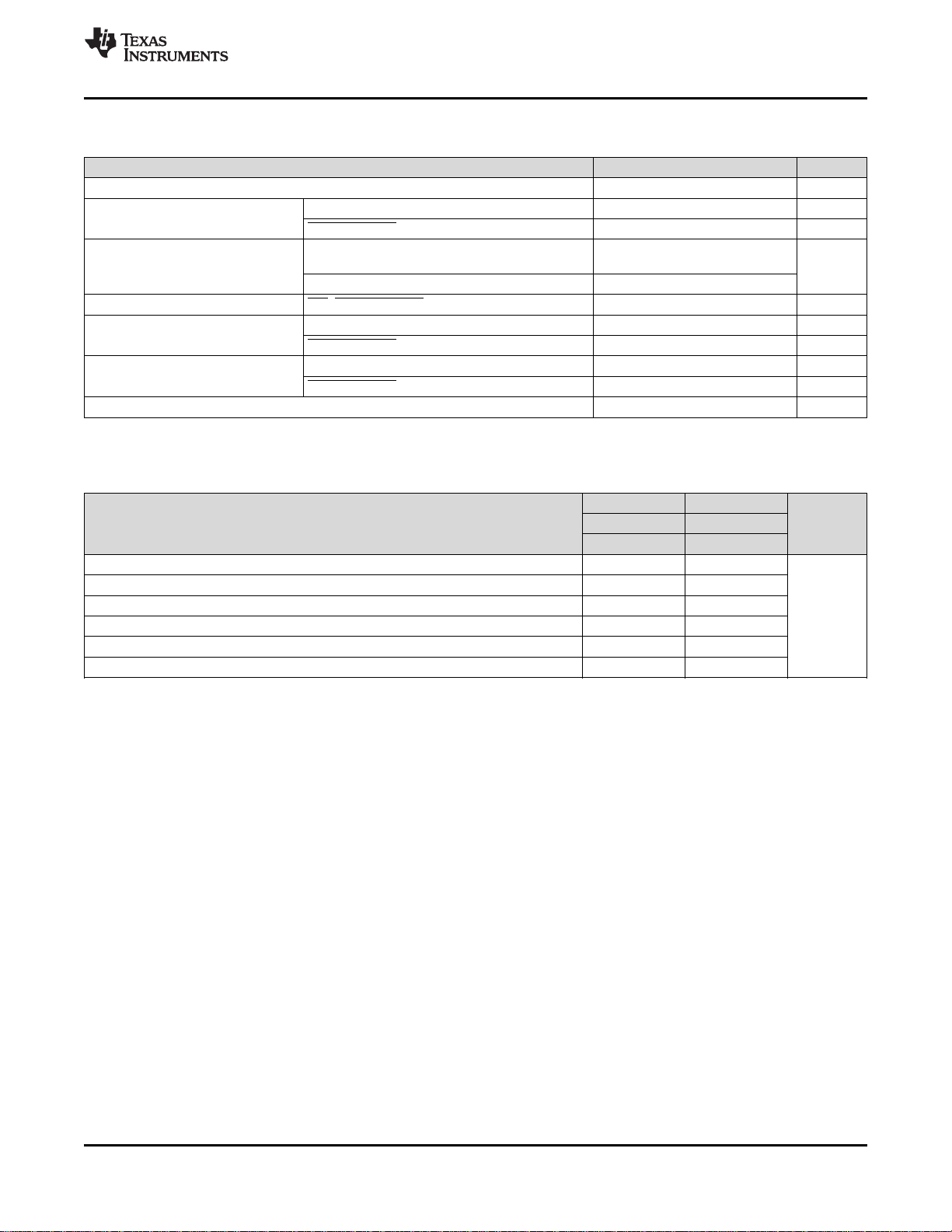

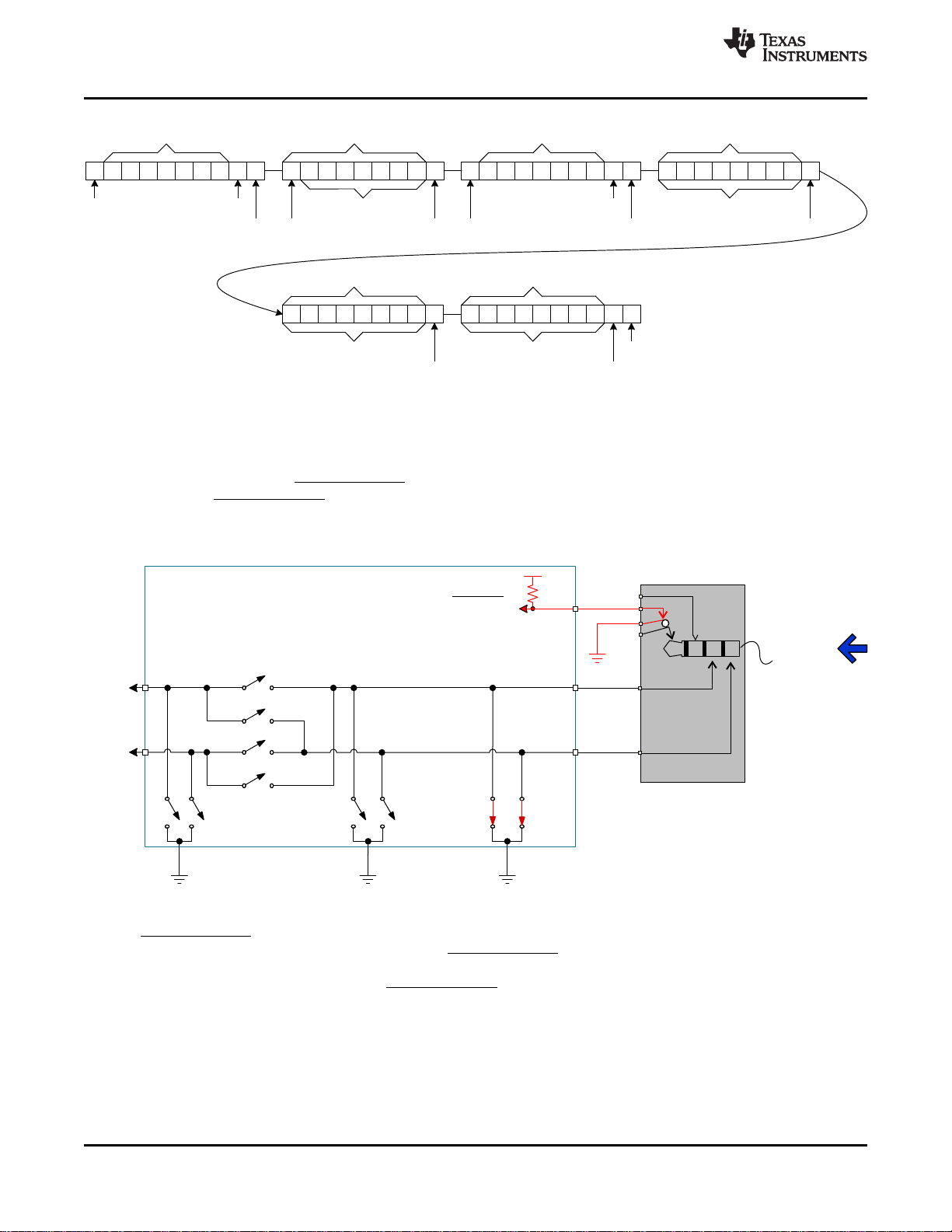

BATTERY

Application

Processor

TS3A227E

Audio Codec

L

R

G

L

R

G M

L

R

GM

Product

Folder

Sample &

Buy

Technical

Documents

Tools &

Software

Support &

Community

SCDS358B –NOVEMBER 2014–REVISED FEBRUARY 2015

TS3A227E Autonomous Audio Accessory Detection and Configuration Switch

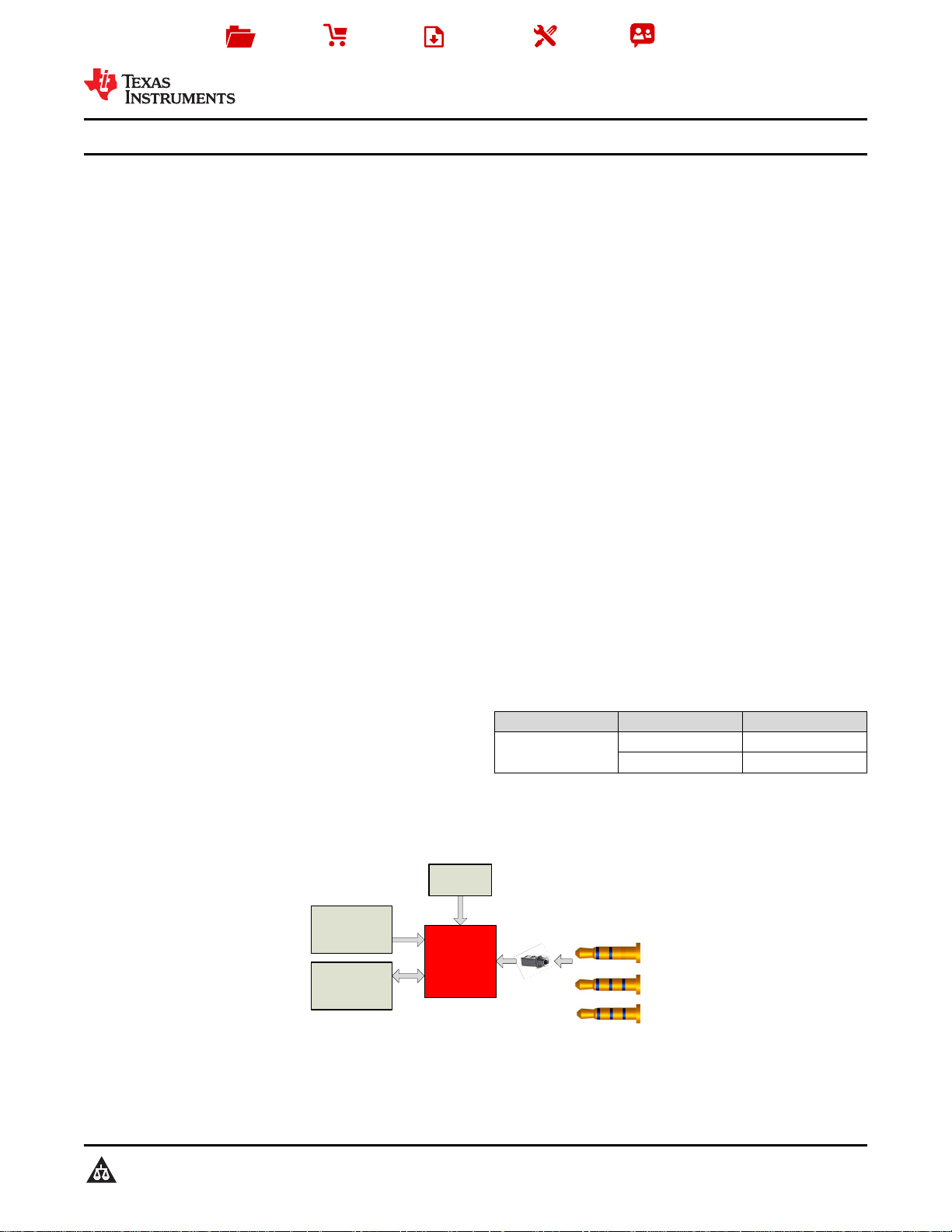

1 Features 3 Description

1

• Supple Range of 2.5 V to 4.5 V

• Accessory Insertion/Removal Detection with

Adjustable De-bounce Timings

• Accessory Configuration Detection:

– Stereo 3-pole Headphone

– 4-pole Standard Headset with MIC on Sleeve

– 4-pole OMTP Headset with MIC on Ring2

• Key Press Detection for Up to 4 Keys

• Ultra Low Ground FET RONof 60 mΩ

• Power Off Noise Removal

• Isolation of MICBIAS From Audio Jack to Remove

Click/Pop Noise

• Integrated Codec Sense Line

• Manual I2C Control

• FM Transmission Capability

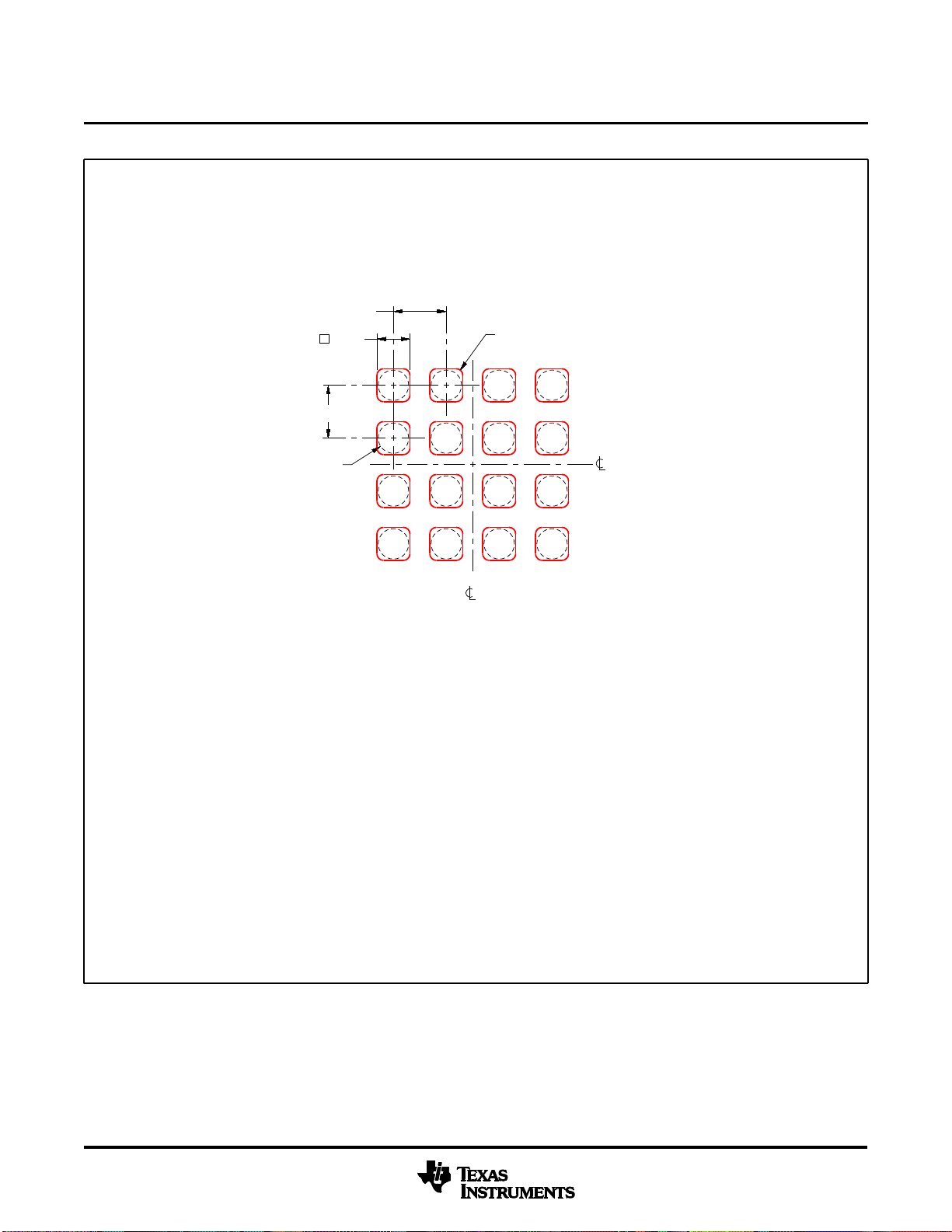

• Dual Small Package Options

– 16 Pin DSBGA

– 16 Pin QFN

2 Applications

• Mobile Phones

• Tablets

• Notebooks and Ultrabooks

• Anywhere a 3.5 mm Audio Jack is Used

The TS3A227E is an autonomous audio accessory

detection and configuration switch that detects 3-pole

or 4-pole audio accessories and configures internal

switches to route the signals accordingly.

The internal ground FETS of the TS3A227E have an

ultra-low RONof 60 mΩ to minimize crosstalk impact.

The ground FETs are also designed to pass FM

signals, making it possible to use the ground line of

the accessory as an FM antenna in mobile audio

applications.

Internal isolation switches allow the TS3A227E to

remove the click/pop noise that can be generated

during and insertion or removal of an audio

accessory. In addition depletion FETs prevent a

floating ground while the device is unpowered,

removing the humming noise present when leaving

accessories plugged into an unpowered system.

A low-power sleep mode is provided which shuts

down internal circuitry to achieve very low quiescent

current draw when no headset is inserted.

The TS3A227E features integrated key press

detection for detecting up to 4 keys with press and

release support.

Manual I2C control allows the TS3A227E to adapt to

application needs by providing control over debounce settings and switch states.

Device Information

PART NUMBER PACKAGE BODY SIZE (NOM)

TS3A227E

(1) For all available packages, see the orderable addendum at

the end of the datasheet.

TS3A227E

(1)

QFN (16) 3.50 mm × 3.50 mm

DSBGA (16) 1.79 mm × 1.79 mm

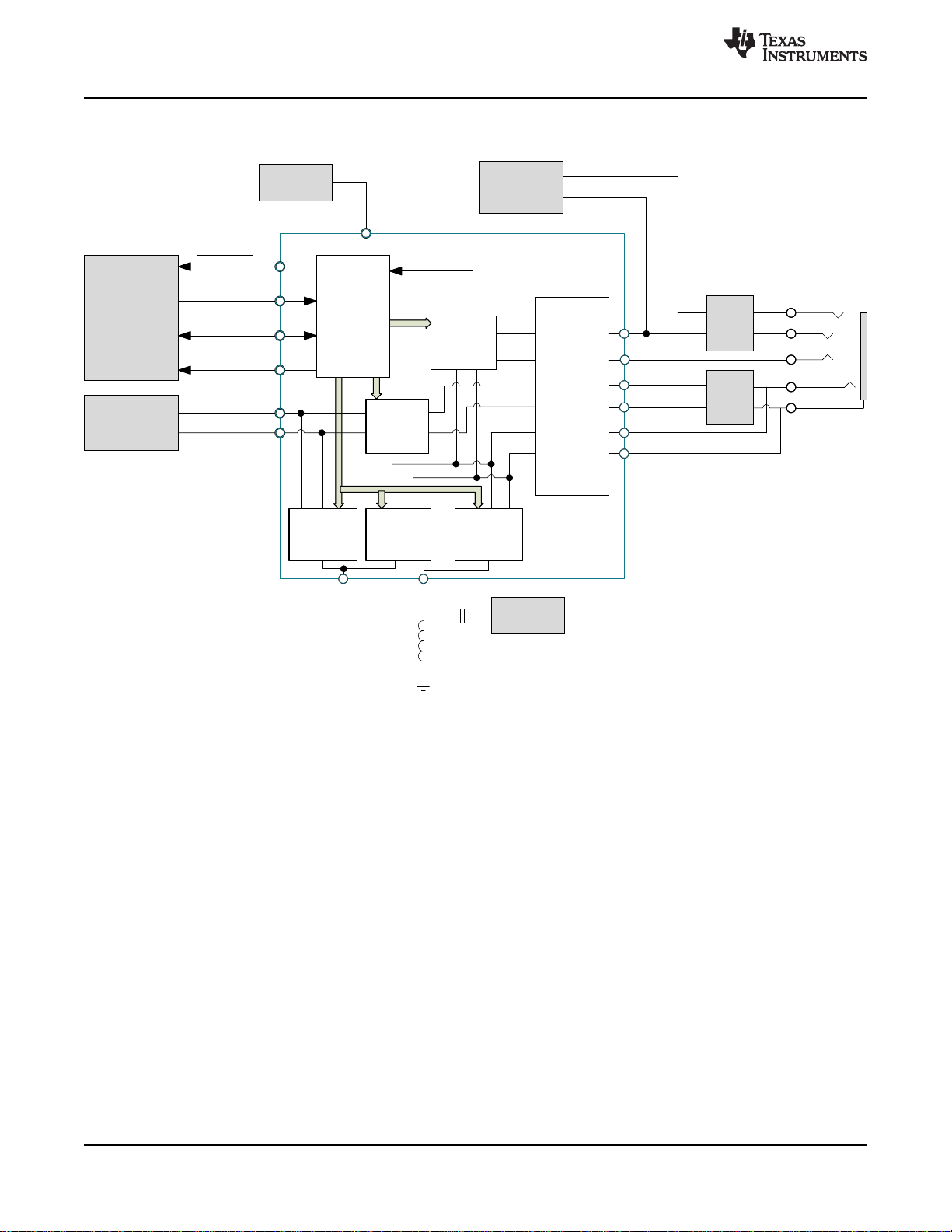

4 Simplified Schematic

1

An IMPORTANT NOTICE at the end of this data sheet addresses availability, warranty, changes, use in safety-critical applications,

intellectual property matters and other important disclaimers. PRODUCTION DATA.

TS3A227E

SCDS358B –NOVEMBER 2014–REVISED FEBRUARY 2015

www.ti.com

Table of Contents

1 Features.................................................................. 1

2 Applications ........................................................... 1

3 Description ............................................................. 1

4 Simplified Schematic............................................. 1

5 Revision History..................................................... 2

6 Pin Configuration and Functions......................... 3

7 Specifications......................................................... 4

7.1 Absolute Maximum Ratings...................................... 4

7.2 ESD Ratings ............................................................ 4

7.3 Recommended Operating Conditions....................... 5

7.4 Thermal Information.................................................. 5

7.5 Electrical Characteristics........................................... 6

7.6 I2C Interface Timing Characteristics ......................... 8

7.7 Timing Diagrams....................................................... 9

7.8 Typical Characteristics............................................ 12

8 Parameter Measurement Information ................ 12

9 Detailed Description ............................................ 17

9.1 Overview ................................................................. 17

9.2 Functional Block Diagram....................................... 18

9.3 Feature Description................................................. 19

9.4 Device Functional Modes........................................ 20

9.5 Register Maps ........................................................ 24

9.6 Register Field Descriptions..................................... 24

10 Application and Implementation........................ 33

10.1 Application Information.......................................... 33

10.2 Typical Application ............................................... 33

11 Power Supply Recommendations..................... 47

12 Layout................................................................... 48

12.1 Layout Guidelines ................................................. 48

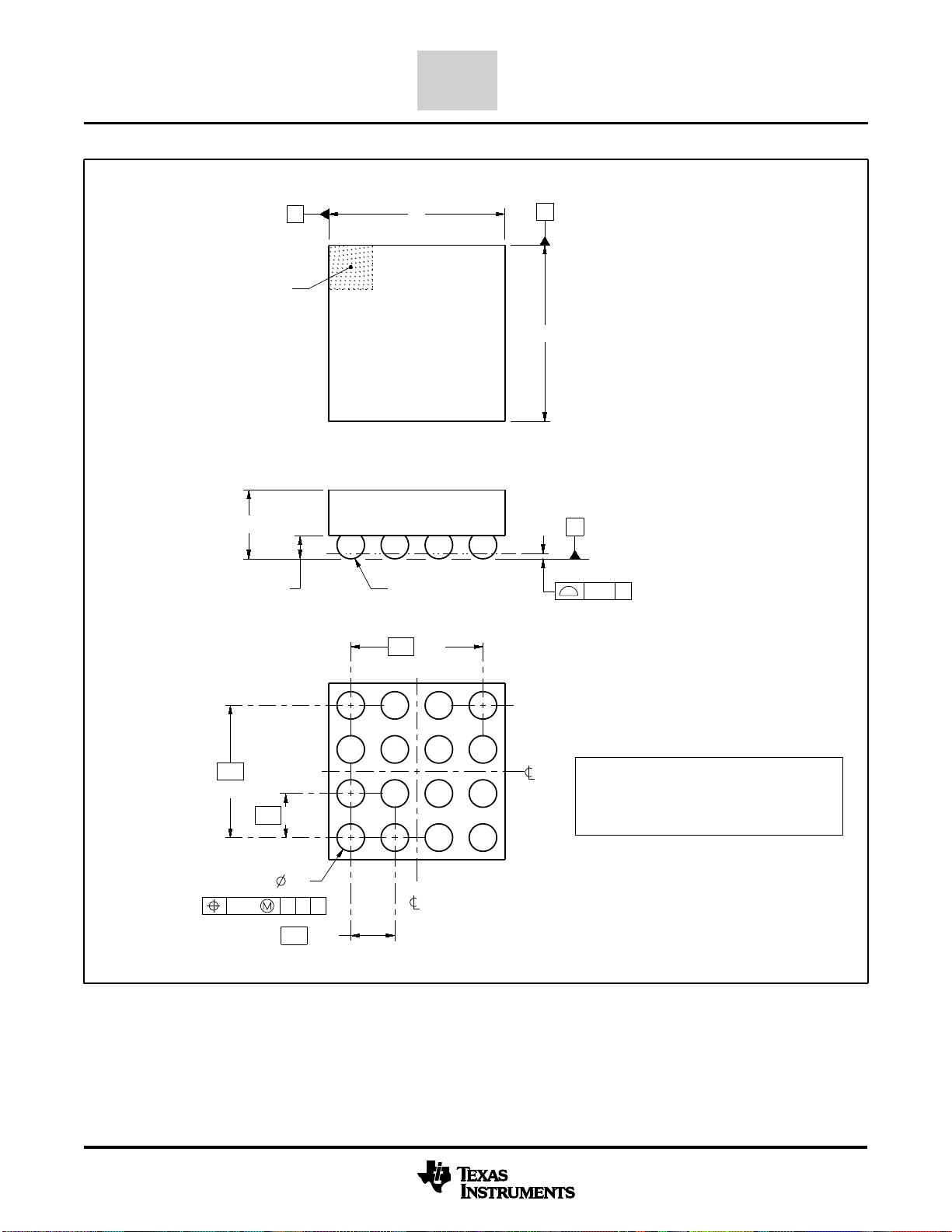

12.2 Layout Example (QFN)......................................... 48

12.3 Layout Example (DSBGA).................................... 49

13 Device and Documentation Support................. 50

13.1 Trademarks........................................................... 50

13.2 Electrostatic Discharge Caution............................ 50

13.3 Glossary................................................................ 50

14 Mechanical, Packaging, and Orderable

Information........................................................... 50

5 Revision History

Changes from Revision A (December 2014) to Revision B Page

• Added DSBGA package to the Thermal Information table. ................................................................................................... 5

• Updated SWITCH RESISTANCE for the DSBGA package. ................................................................................................. 6

Changes from Original (July 2014) to Revision A Page

• Initial release of full version document. ................................................................................................................................. 1

2 Submit Documentation Feedback Copyright © 2014–2015, Texas Instruments Incorporated

Product Folder Links: TS3A227E

GND

TIP

GND

SDA

VDD

MICP

GNDA

RING2

SLEEVE

SCL

THERMALPAD

16 15 14 13

5 6 7 8

1

2

3

4

12

11

10

9

RING2_SENSE

SLEEVE_SENSE

GND_SENSE

DET_TRIGGER

MC_PRESENT

INT

4 3 2 1

D

C

B

A

VDD

SLEEVE_

SENSE

GND

INT

SDA

SCL

GND

TIP

RING2

MICP

RING2_

SENSE

MIC_

PRESENT

GND_

SENSE

DET_

TRIGGER

SLEEVE GNDA

www.ti.com

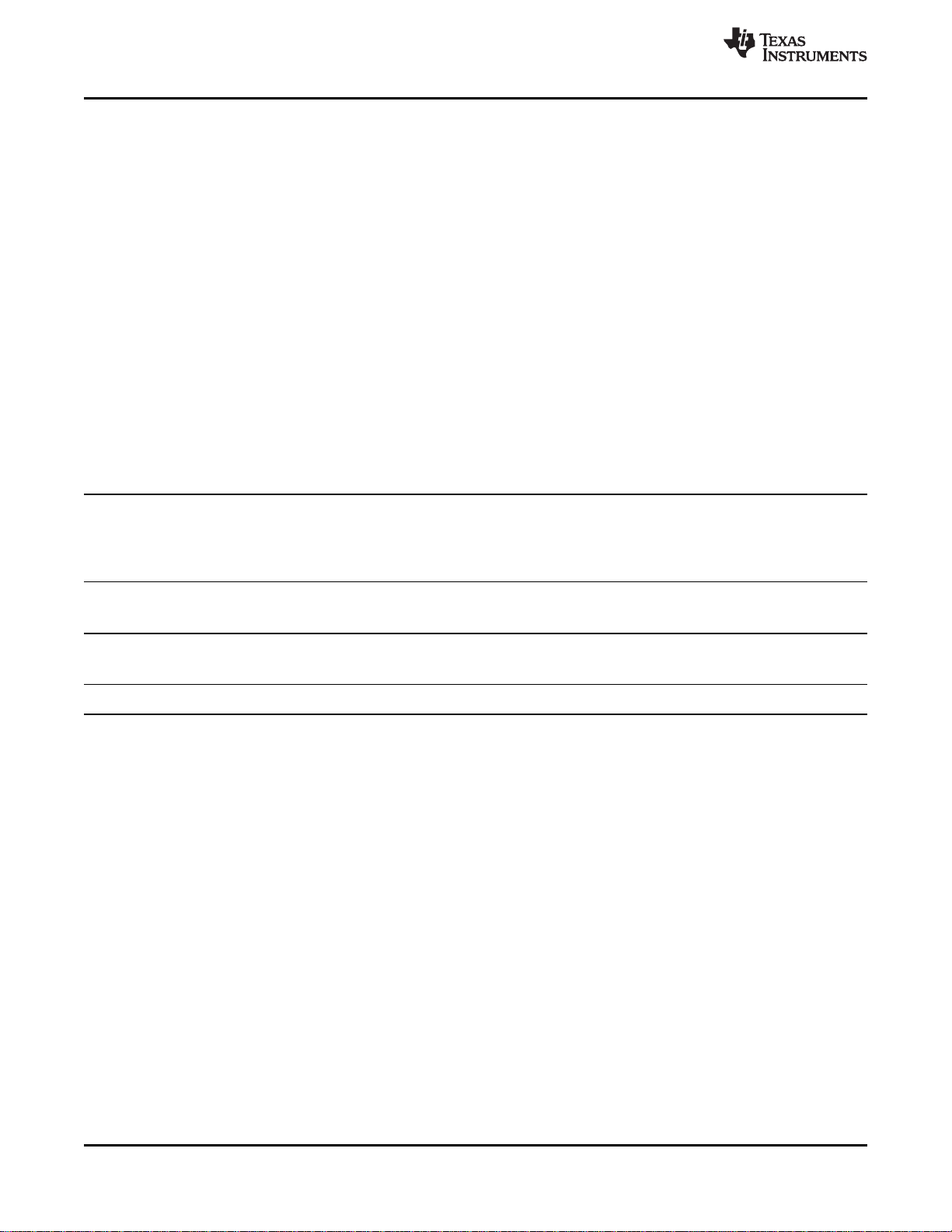

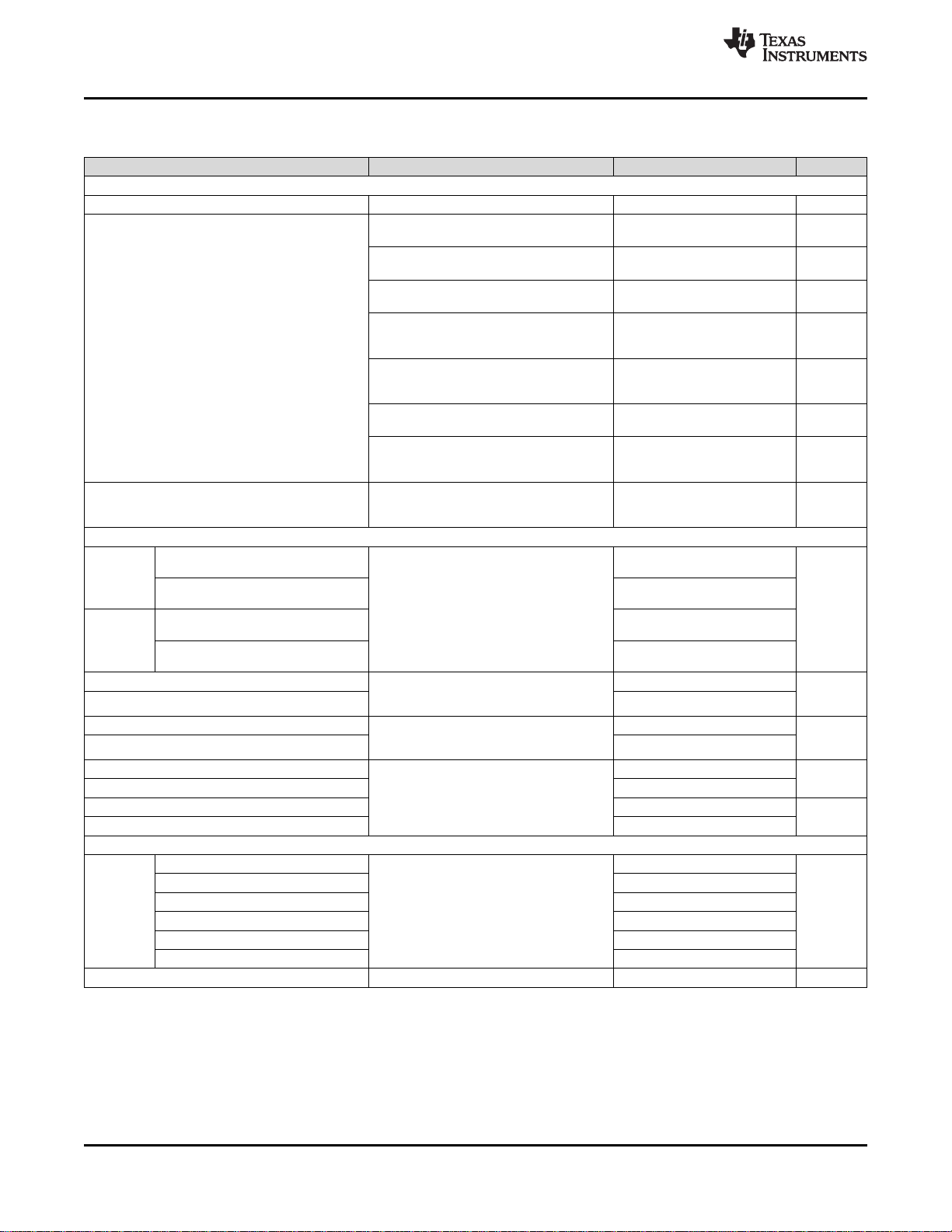

6 Pin Configuration and Functions

TS3A227E

SCDS358B –NOVEMBER 2014–REVISED FEBRUARY 2015

NAME RVA YFF

DET_TRIGGER 15 B1 I/O

GND 1, 2 A2, B2 GND Primary ground connection for the TS3A227E. Must be connected to system ground.

GNDA 11 D2 I/O

GND_SENSE 5 A4 I/O Ground sense line for the codec.

INT 13 C2 GND

MIC_PRESENT 16 A1 I/O Open drain output to indicate to the host that a headset with a microphone is inserted..

MICP 6 B4 I/O Microphone signal connection to the codec. Microphone bias is applied to this pin.

RING2 12 D1 O

RING2_SENSE 7 C4 GND

SCL 9 C3 I

SDA 3 B3 I/O

SLEEVE 10 D3 O

SLEEVE_SENSE 8 D4 GND

THERMAL PAD GND

TIP 14 C1 I/O Connect to the TIP pin of the 3.5 mm jack.

VDD 4 A3 PWR Power input to the TS3A227E. External de-coupling capacitors are required on this pin.

PIN

DSBGA – YFF

Top View

Pin Functions

TYPE DESCRIPTION

A falling edge from high to low on this pin triggers accessory detection. This pin can be connected the

headset jack to allow automatic pull-down to ground after headset insertion to initialize detection.

Ground connection for the internal ground FETs of the TS3A227E. If FM is being supported connect this pin

to the FM matching network. If FM is not being support connect this pin to system ground.

Open drain interrupt output from the TS3A227E to notify the host that an event has occurred. If I2C is not

used this pin must be grounded.

Headset current return path if RING2 is ground for the headset. Connect to 3.5 mm jack RING2 connection

with low DC resistance trace.

Connected to the RING2 pin of the 3.5 mm jack. If RING2 pin on plug in is MIC signal, this is connected to

MICP. If not, this is connected to GND_SENSE and becomes the ground sensing feedback for the accessory

Clock from I2C bus. This can be connected to VDD if I2C is not used.

Bidirectional data from/to I2C bus. This can be connected to VDD if I2C is not used.

Headset current return path if SLEEVE is GND for headset. Connect to 3.5 mm jack SLEEVE connection with

low DC resistance trace.

Connected to the SLEEVE pin of the 3.5 mm jack. If SLEEVE pin on plug in is MIC signal, this is connected to

MICP. If not, this is connected to GND_SENSE and becomes the ground sensing feedback for the accessory

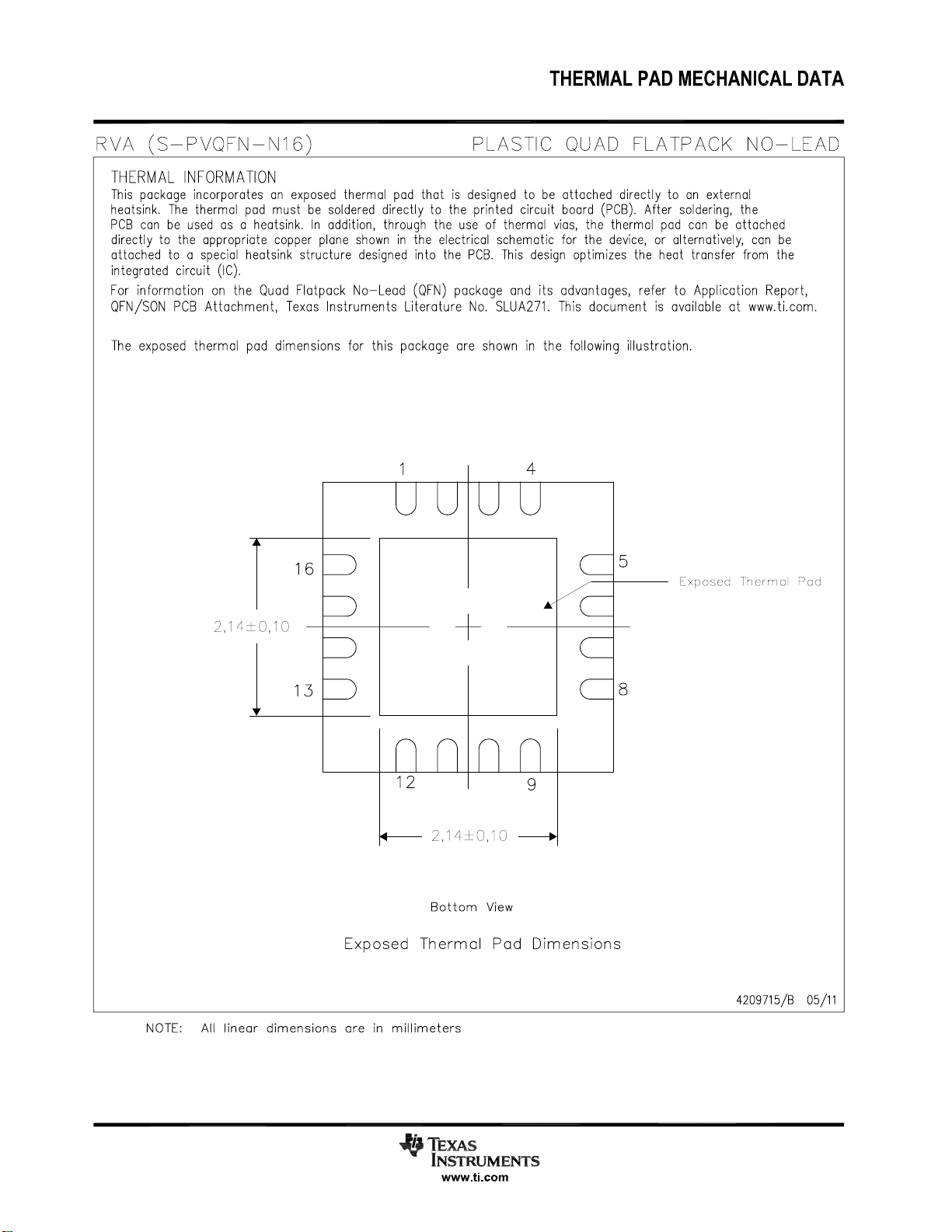

The THERMAL PAD of the RVA – QFN package must be connected to any internal PCB ground plane using

multiple vias for best thermal performance.

QFN – RVA

Top View

Copyright © 2014–2015, Texas Instruments Incorporated Submit Documentation Feedback 3

Product Folder Links: TS3A227E

TS3A227E

SCDS358B –NOVEMBER 2014–REVISED FEBRUARY 2015

www.ti.com

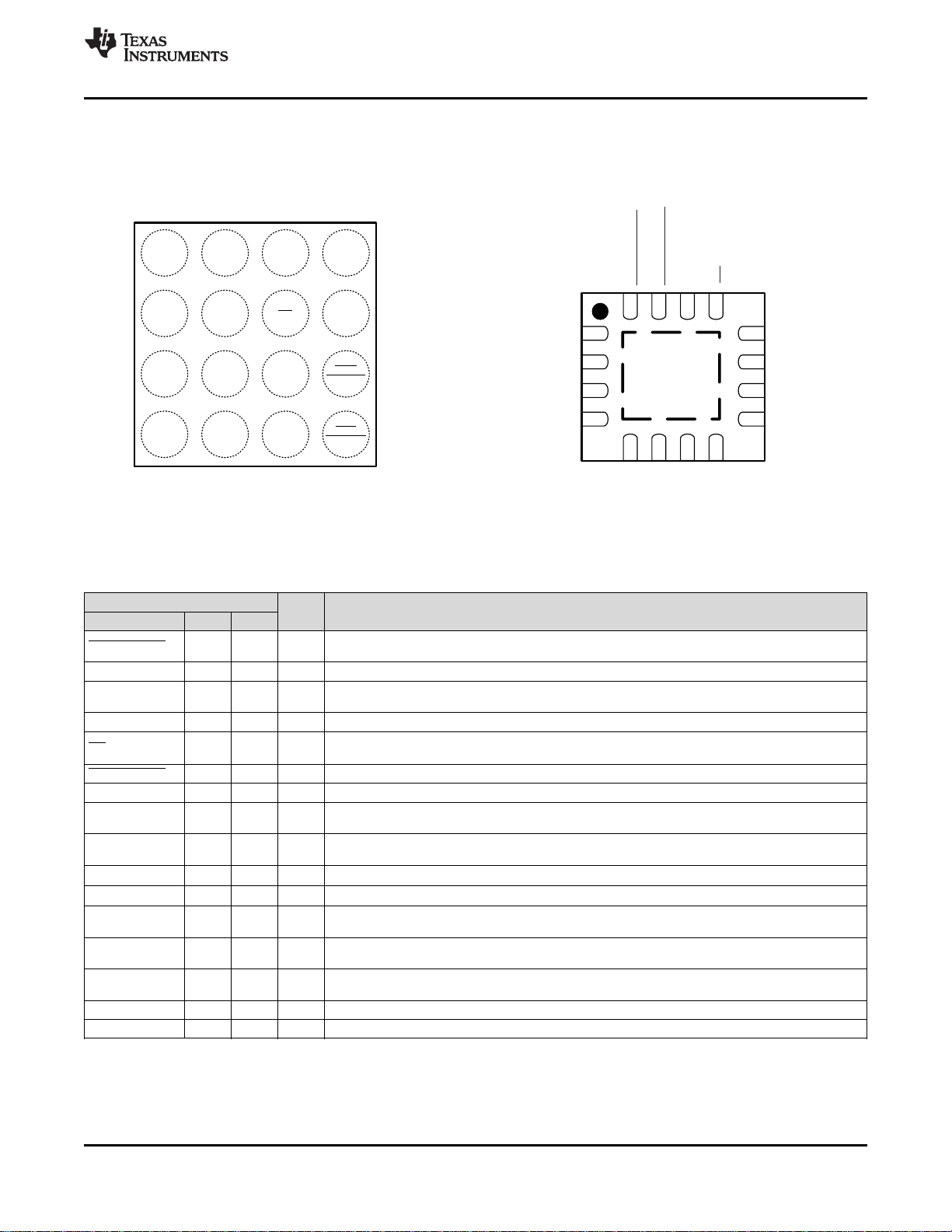

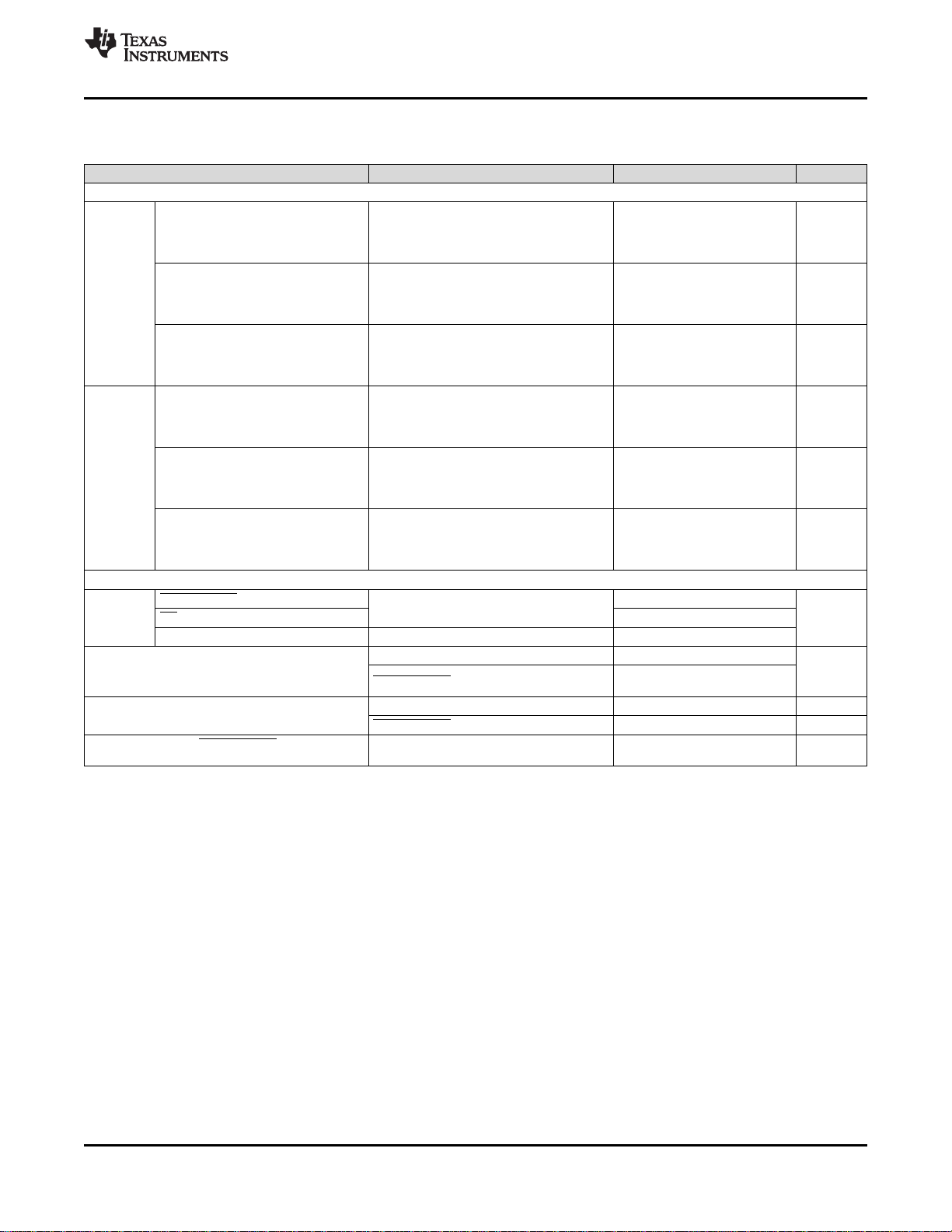

7 Specifications

7.1 Absolute Maximum Ratings

over operating free-air temperature range referenced with respect to GND (unless otherwise noted)

MIN MAX UNIT

Input Voltage VDD –0.3 5 V

SDA, SCL, INT, MIC_PRESENT –0.3 VDD+ 0.5 V

TIP –3.3 VDD+ 0.5 V

DET_TRIGGER –2.2 VDD+ 0.5 V

GND_SENSE, RING2, SLEEVE, RING2_SENSE, SLEEVE_SENSE, –0.3 3.6

MICP, GNDA 0.5

ON-state switch Combined continuous current through R2GNDFET and SLV GNDFET 500 mA

current

Operating ambient temperature range –40 85 °C

T

stg

(1) Stresses beyond those listed under Absolute Maximum Ratings may cause permanent damage to the device. These are stress ratings

only, which do not imply functional operation of the device at these or any other conditions beyond those indicated under Recommended

Operating Conditions. Exposure to absolute-maximum-rated conditions for extended periods may affect device reliability.

(2) This rating is exclusive and the voltage on the pins must not exceed either 3.6 and VDD. E.g. if VDD= 4.5 V the voltage on the pin must

not exceed 3.6 V and if VDDis = 2.5 V the voltage on the pin must not exceed 3.0 V.

Continuous current through R2DFET and SLV DFET 50

Continuous current through S1 20

Continuous current through S2 20

Continuous current through S3PR 50

Continuous current through S3PS 50

Continuous current through S3GR 100

Continuous current through S3GS 100

Storage temperature range –65 150 °C

(1)

(2)

and VDD+ V

7.2 ESD Ratings

VALUE UNIT

V

Human body model (HBM), ESD stress voltagenew note #1 to the ESD

Ratings table and combined MIN MAX column to VALUE

Electrostatic discharge Charged device model (CDM), ESD stress voltage

(ESD)

Contact discharge model (IEC) ESD stress voltage on TIP,

DET_TRIGGER, RING2_SENSE, SLEEVE_SENSE, RING2, SLEEVE

(1) (2)

(1) (3)

(1)

(1) Electrostatic Discharge (ESD) to measure device sensitivity and immunity to damage caused by assembly line electrostatic discharges

into the device

(2) JEDEC document JEP155 states that 500-V HBM allows safe manufacturing with a standard ESD control process.

(3) JEDEC document JEP157 states that 250-V CDM allows safe manufacturing with a standard ESD control process.

±2000 V

±500 V

±8000 V

4 Submit Documentation Feedback Copyright © 2014–2015, Texas Instruments Incorporated

Product Folder Links: TS3A227E

TS3A227E

www.ti.com

SCDS358B –NOVEMBER 2014–REVISED FEBRUARY 2015

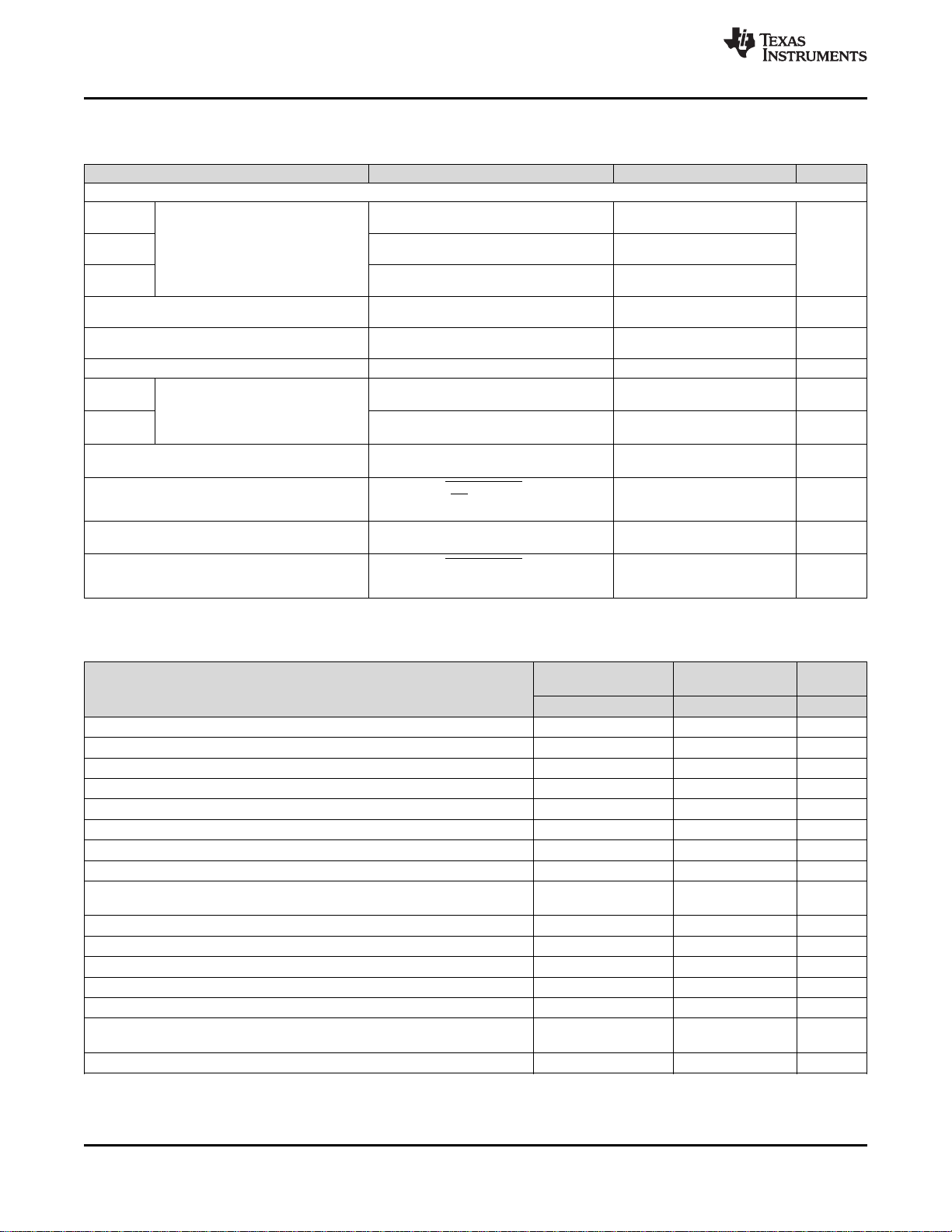

7.3 Recommended Operating Conditions

over operating free-air temperature range (unless otherwise noted)

MIN MAX UNIT

VDD Power supply voltage range 2.5 4.5 V

VIDigital input voltage range

VIOInput/output voltage range V

SDA, SCL 0 V

DET_TRIGGER –2.2 V

RING2_SENSE, SLEEVE_SENSE, RING2,

SLEEVE, GND_SENSE, MICP

0 3.3

(1)

TIP –3 V

VOOutput voltage range INT, MIC_PRESENT 0 V

VIHInput logic high

VILInput logic low

T

Operating ambient temperature –40 85 °C

A

SDA, SCL 1.2 V

DET_TRIGGER 0.65 × V

DD

SDA, SCL 0 0.4 V

DET_TRIGGER 0 0.4 × V

DD

DD

and VDD

DD

DD

DD

V

DD

DD

(1) This rating is exclusive and the voltage on the pins must not exceed either 3.3 and VDD. E.g. if VDD= 4.5 V the voltage on the pin must

not exceed 3.3 V and if VDDis = 2.5 V the voltage on the pin must not exceed 2.5 V.

V

V

V

V

V

V

7.4 Thermal Information

TS3A227E TS3A227E

THERMAL METRIC

R

θJA

R

θJC(top)

R

θJB

ψ

JT

ψ

JB

R

θJC(bot)

Junction-to-ambient thermal resistance 45.9 77.9

Junction-to-case (top) thermal resistance 52.6 0.6

Junction-to-board thermal resistance 21.2 12.5

Junction-to-top characterization parameter 0.9 2.3

Junction-to-board characterization parameter 21.2 12.5

Junction-to-case (bottom) thermal resistance 4.3 -

(1) For more information about traditional and new thermal metrics, see the IC Package Thermal Metrics application report, SPRA953.

(1)

RTE YFF UNIT

16 PINS 16 PINS

°C/W

Copyright © 2014–2015, Texas Instruments Incorporated Submit Documentation Feedback 5

Product Folder Links: TS3A227E

TS3A227E

SCDS358B –NOVEMBER 2014–REVISED FEBRUARY 2015

www.ti.com

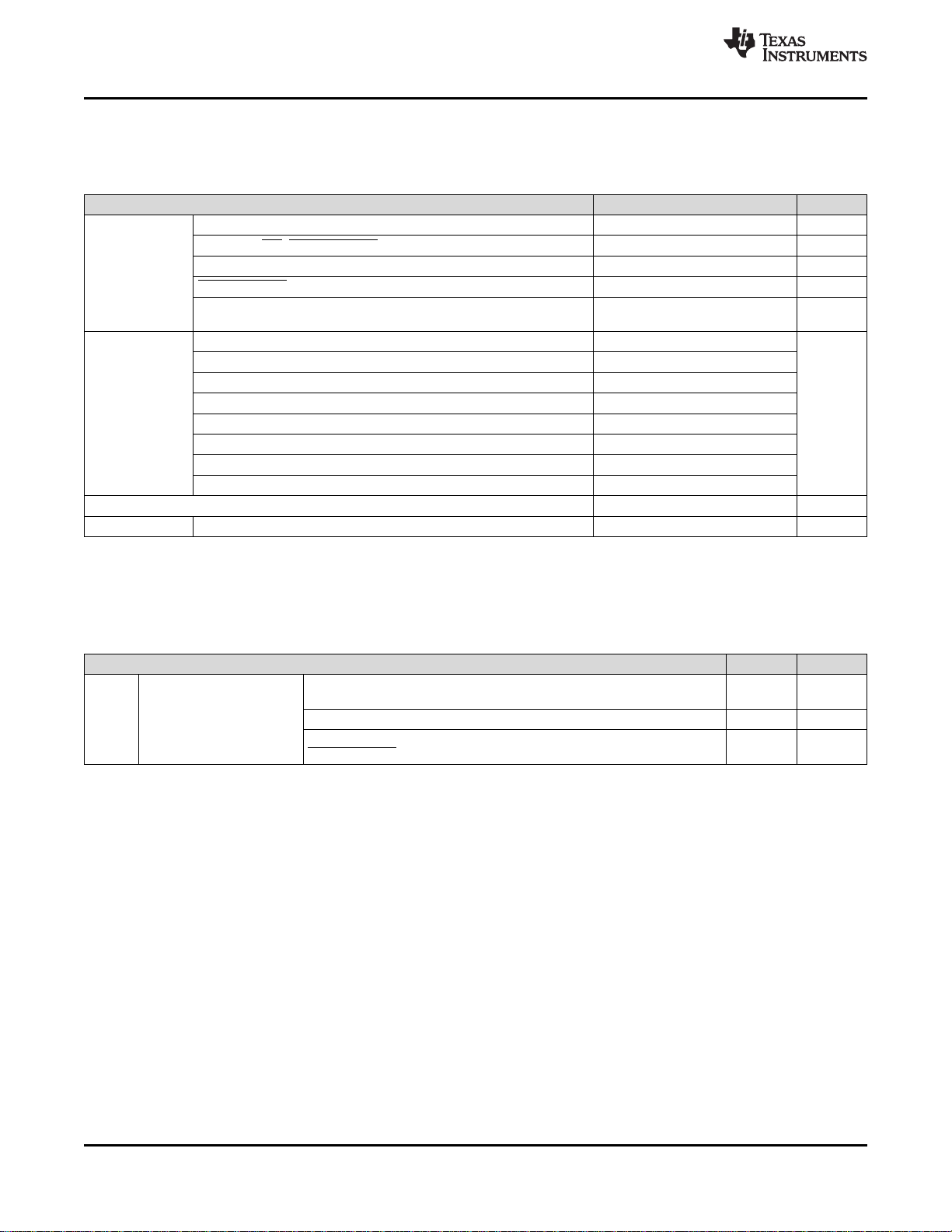

7.5 Electrical Characteristics

Unless otherwise noted the specification applies over the VDD and ambient operating temperature range.

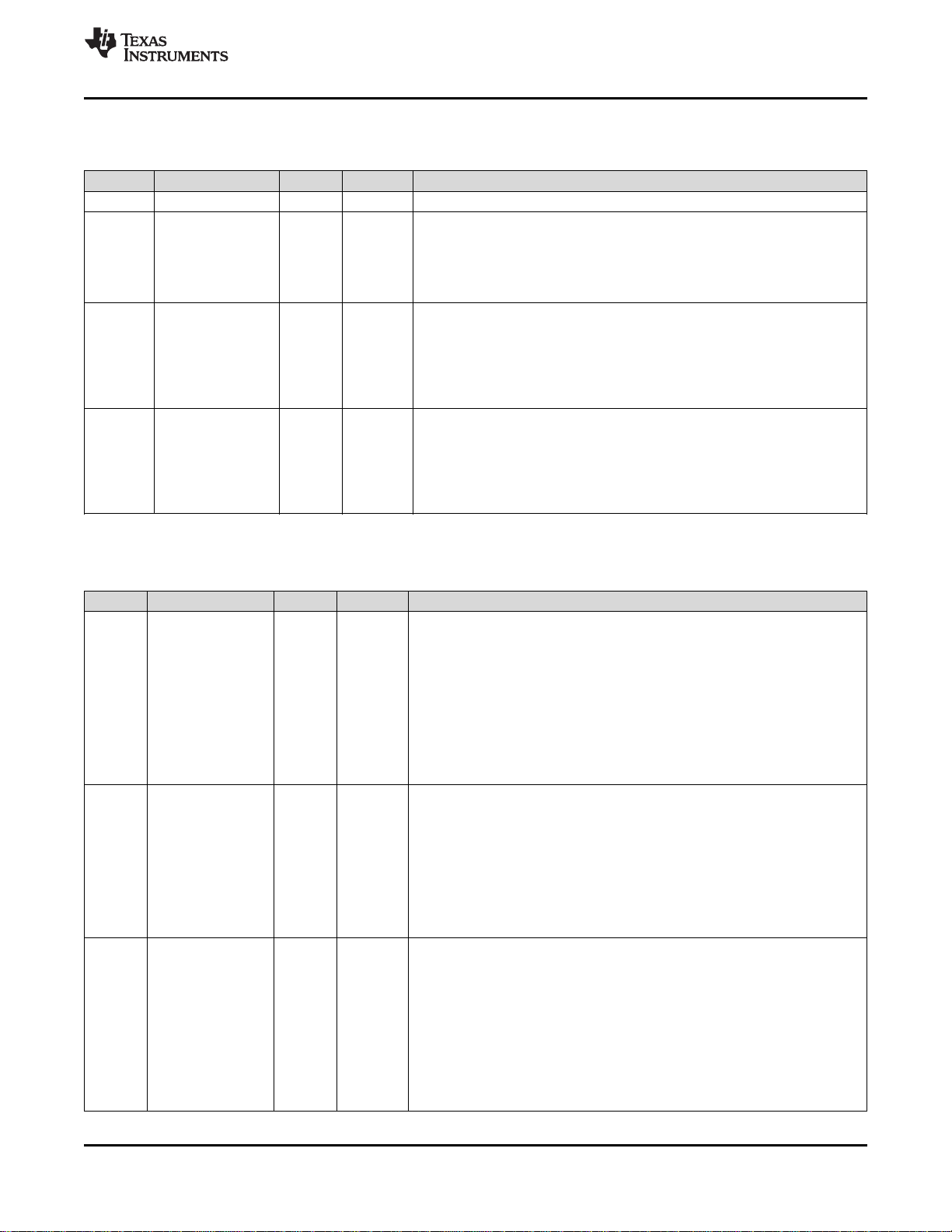

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

SUPPLY VOLTAGE

VDD Supplyvoltage 2.5 3.3 4.5 V

No accessory inserted. I2C bus inactive

VDD= 2.5 V to 4.5 V

Manual switch control = ’1’ , I2C bus inactive,

VDD= 2.5 V to 4.5 V, Depletion FETs on

Manual switch control = ’1’ , I2C bus inactive,

VDD= 2.5 V to 4.5 V Depletion FETs off

3-pole accessory inserted.

I

DD

Quiescent current

I2C bus inactive

VDD= 2.5 V to 4.5 V

3-pole accessory inserted.

I2C bus inactive,

(1)

, FM Support = ’0’

(1)

FM Support = ’1’

VDD= 2.5 V to 4.5 V

4-pole Accessory inserted.

I2C bus inactive,

(1)

VDD= 2.5 V to 4.5 V

4-pole Accessory inserted.

I

DD_1.8

Quiescent current addition from using a

1.8 V I2C bus.

(2)

KP detection enabled

I2C bus inactive,

No accessory inserted.

I2C bus inactive at 1.8 V,

VDD= 2.5 V to 4.5 V

(1)

VDD= 2.5 V to 4.5 V

SWITCH RESISTANCE

RING2 GNDFET on resistance (DSBGA

R

R2GNDFT

R

SLVGNDFT

Package)

RING2 GNDFET on resistance (QFN

Package)

SLEEVE GNDFET on resistance (DSBGA

Package)

SLEEVE GNDFET on resistance (QFN

VDD= 3.3 V, V

I

= 75 mA

GNDA

GND

= 0V,

Package)

R

S3PS

R

S3PR

R

S3GS

R

S3GR

R

S1

R

S2

R

R2DFET

R

SLVDFET

S3PS on resistance VDD= 3.3 V, 3 6.5

V

S3PR on resistance 3 6.5

SLEEVE_SENSE/RING2_SENSE

I

= ±10 mA

MICP

S3GS on resistance VDD= 3.3 V, 0.5 1

V

S3GR on resistance 0.5 1

SLEEVE_SENSE/RING2_SENSE

I

GND_SENSE

= ±75 mA

Switch 1 on resistance 15 30

Switch 2 on resistance 15 30

RING2 depletion FET on resistance 75 150

VDD= 3.3 V, I

GND

= 10 mA

SLEEVE depletion FET on resistance 75 150

SWITCH LEAKAGE CURRENT

RING2 pin off leakage 1

SLEEVE pin off leakage 1

I

OFF

RING2_SENSE pin off leakage 1

SLEEVE_SENSE pin off leakage 1

VIN= 0 V to 3.3 V, VDD= 3.3 V µA

MICP pin off leakage 1

GND_SENSE pin off leakage 1

I

ON

S2PS, S3PR, S3GS, S3GR on leakage V

SLEEVE/RING2

= 0V, VDD= 3.3 V 1 µA

(1) The I2C bus is inactive if both the SDA and SCL lines are tied to VDD.

(2) If the I2C bus is operating at 1.8 V the I

(3) The I2C bus is inactive if both the SDA and SCL lines are tied to 1.8 V.

current number will be in addition to the other current consumption numbers specified.

DD_1.8

(3)

= 0 V to 2.7 V, Ω

= 0 V to 2.7 V, Ω

(1)

(1)

0.5 10 µA

7 15 µA

20 40 µA

11 20 µA

25 45 µA

25 40 µA

30 45 µA

1 8 µA

40 85

60 95

40 85

60 95

mΩ

Ω

Ω

6 Submit Documentation Feedback Copyright © 2014–2015, Texas Instruments Incorporated

Product Folder Links: TS3A227E

www.ti.com

SCDS358B –NOVEMBER 2014–REVISED FEBRUARY 2015

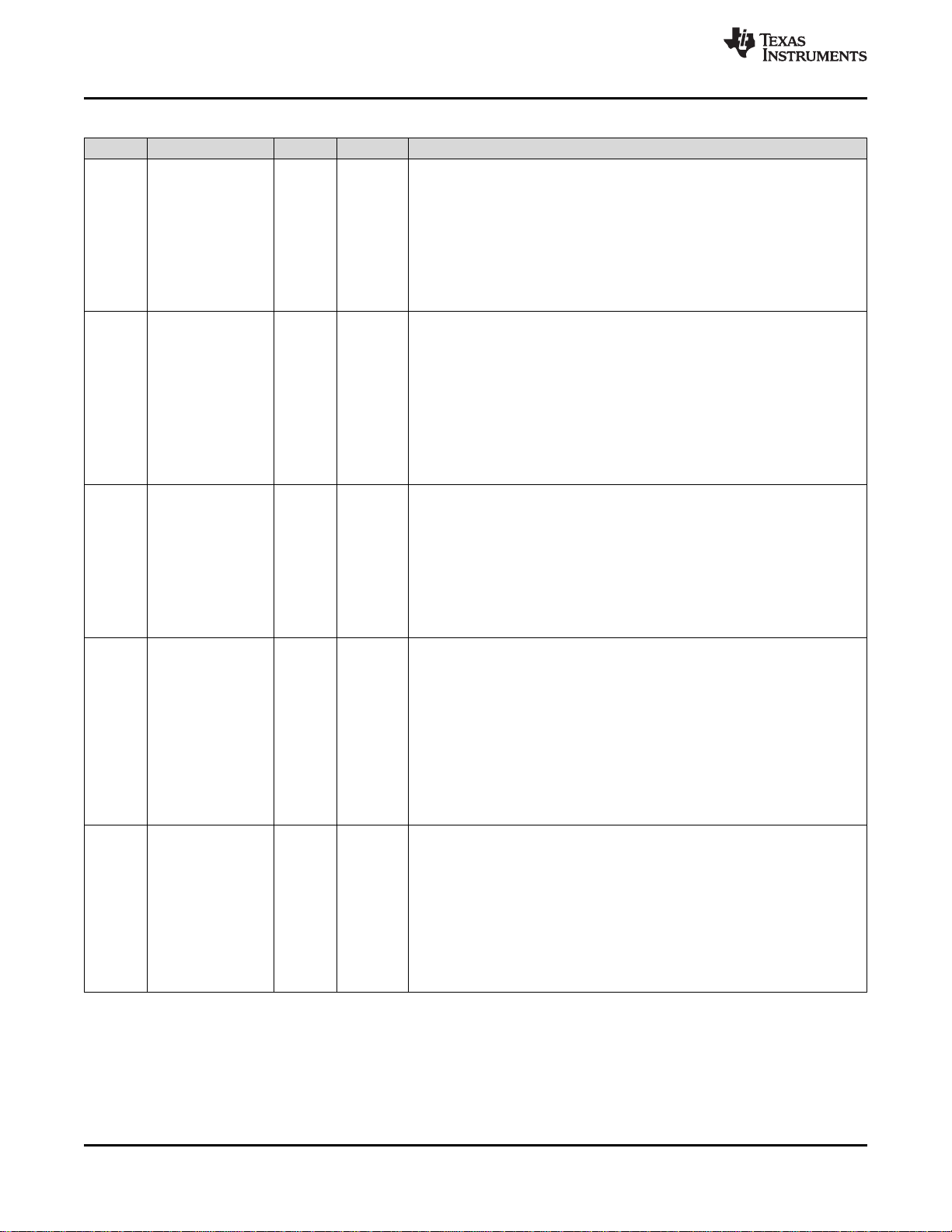

Electrical Characteristics (continued)

Unless otherwise noted the specification applies over the VDD and ambient operating temperature range.

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

SWITCH TIMING

VDD= 2.5 V, 3.3 V, 4.5 V,

RL= 300 Ω, CL= 50 pF

V

SLEEVE_SENSE/RING2_SENSE

3.3 V (VDD= 3.3 V, VDD= 4.5 V)

= 2.5 V (VDD= 2.5 V),

VDD= 2.5 V, 3.3 V, 4.5 V

RPU= 1500 Ω, CL= 50 pF

VPU= 2.5 V (VDD= 2.5 V),

3.3 V (VDD= 3.3 V, VDD= 4.5 V)

VDD= 2.5 V, 3.3 V, 4.5 V

RPU= 1500 Ω, CL= 50 pF

VPU= 2.5 V (VDD= 2.5 V),

3.3 V (VDD= 3.3 V, VDD= 4.5 V)

VDD= 2.5 V, 3.3 V, 4.5 V

RL= 300 Ω, CL= 50 pF

V

SLEEVE_SENSE/RING2_SENSE

3.3 V (VDD= 3.3 V, VDD= 4.5 V)

= 2.5 V (VDD= 2.5 V),

VDD= 2.5 V, 3.3 V, 4.5 V

RPU= 1500 Ω, CL= 50 pF

VPU= 2.5 V (VDD= 2.5 V),

3.3 V (VDD= 3.3 V, VDD= 4.5 V)

VDD= 2.5 V, 3.3 V, 4.5 V

RPU= 1500 Ω, CL= 50 pF

VPU= 2.5 V (VDD= 2.5 V),

3.3 V (VDD= 3.3 V, VDD= 4.5 V)

VDD= 3.3 V, IOL= 10 mA

= 3 mA 0 0.4

OLMAX

SDA, SCL 1.2 V

DET_TRIGGER V

VDDx

0.65

SDA, SCL 0 0.4

DET_TRIGGER 0 VDDx 0.4

VDD= 3.3 V, I

/DET_TRIGGER

= 1 µA 0.5 1 1.85 MΩ

t

OFF

t

ON

DIGITAL I/O

V

OL

V

IH

V

IL

R

PU/DT

Turn off time for S3PS, S3PR, S3GS,

S3GR

Turn off time for S1, S2, RING2 GNDFET,

SLEEVE GNDFET

Turn off time for RING2 DFET and

SLEEVE DFET

Turn on time for S3PS, S3PR, S3GS,

S3GR

Turn on time for S1, S2, RING2 GNDFET,

SLEEVE GNDFET

Turn on time for RING2 DFET and

SLEEVE DFET

MIC_PRESENT low level output voltage 0 0.4

INT low level output voltage 0 0.4 V

SDA low level output voltage VDD= 3.3 V, I

Input logic high V

Input logic low

Internal DET_TRIGGER pull-up

resistance

TS3A227E

5 µs

5 µs

500 µs

1 µs

35 µs

1 µs

DD

DD

Copyright © 2014–2015, Texas Instruments Incorporated Submit Documentation Feedback 7

Product Folder Links: TS3A227E

TS3A227E

SCDS358B –NOVEMBER 2014–REVISED FEBRUARY 2015

www.ti.com

Electrical Characteristics (continued)

Unless otherwise noted the specification applies over the VDD and ambient operating temperature range.

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

DYNAMIC CHARACTERISTICS

PSR

217

PSR

1k

PSR

20k

ISO

S3

SEP

S3

BW Bandwidth through GNDFETs VIN= 60 mVPP, I

THD

200

THD

500

SNR –90 –110 dB

t

DET

T

power-up

t

REMOVAL

Power supply rejection –85 –110 dB

SLEEVE_SENSE or RING2_SENSE to

MICP Isolation

SLEEVE_SENSE to RING2_SENSE

Separation

MICP to RING2_SENSE or

SLEEVE_SENSE total harmonic

distortion

MICP to RING2_SENSE or

SLEEVE_SENSE signal to noise ratio

Detection sequence duration high to low and INT transition from high to low. 175 210 ms

Power up time Power-up time 20 25 ms

Removal wait period low to high and RING2/SLEEVE DFETs turning 50 65 ms

VDD= 3.3 V ± 200 mVPP, f = 217 Hz, RLat

RING2= 50 Ω

VDD= 3.3 V ± 200 mVPP, f = 1 kHz, RLat

RING2= 50 Ω

VDD= 3.3 V ± 200 mVPP, f = 20 kHz, RLat

RING2= 50 Ω

VIN= 200 mVPP, f = 20 Hz – 20 kHz, RL= 50 Ω –90 dB

VIN= 200 mVPP, f = 20 Hz – 20 kHz, RL= 50 Ω –75 dB

= 10 mA 120 150 MHz

BIAS

VIN= 1.5 V + 200 mVPP, f = 20 Hz – 20 kHz,

RS= 600 Ω, RL= 600 Ω

VIN= 1.5 V + 500 mVPP, f = 20 Hz – 20 kHz,

RS= 600 Ω, RL= 600 Ω

VIN= 1 V

RS= 600 Ω, RL= 600 Ω

Time between DET_TRIGGER transition from

Default 90 ms insertion debounce.

Time from VDD> 2.5 V till I2C communication is

ready

Time between DET_TRIGGER transition from

on

, f = 20 Hz – 20 kHz,

RMS

–95 –120

–70 –90

0.003 %

0.002%

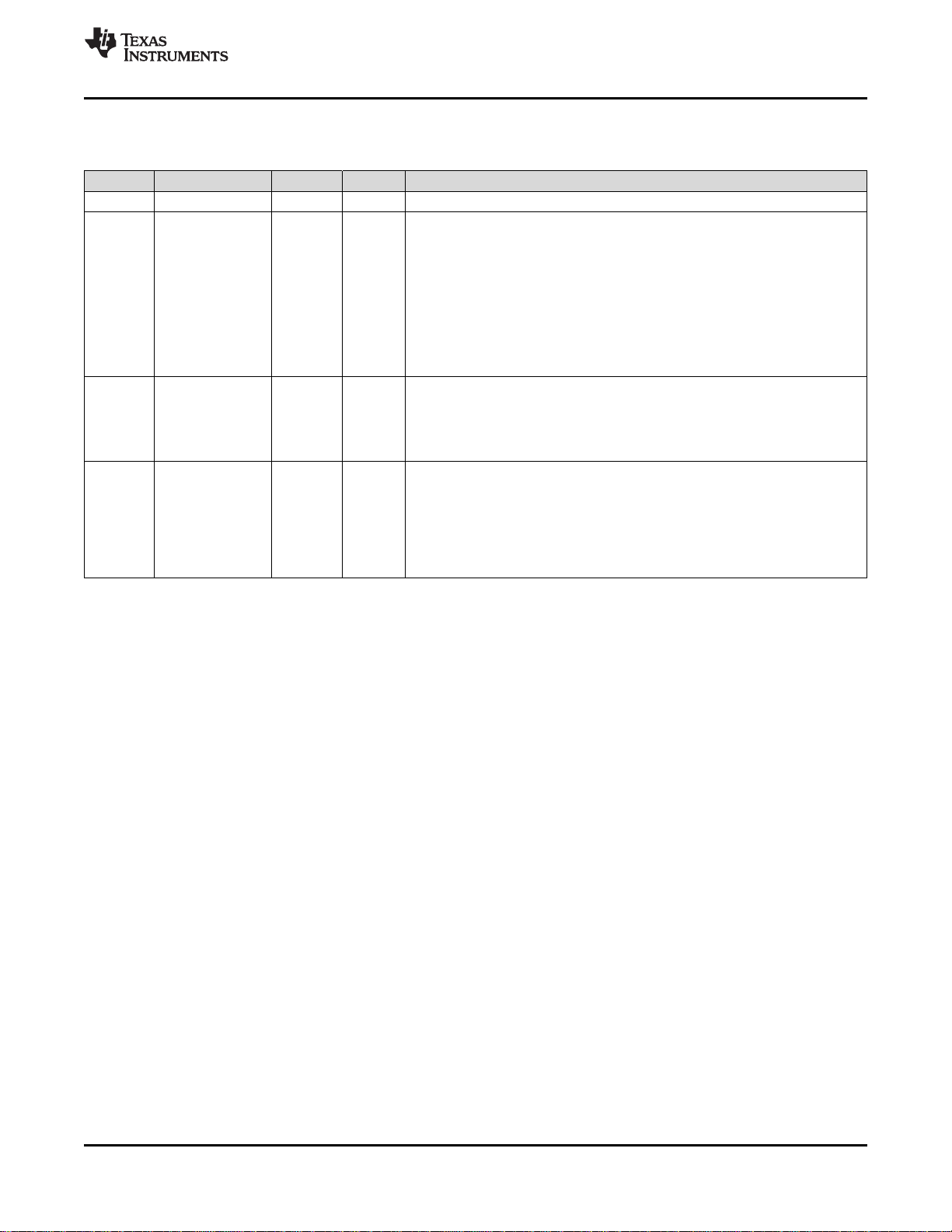

7.6 I2C Interface Timing Characteristics

Unless otherwise noted the specification applies over the VDD and ambient operating temperature range

STANDARD MODE FAST MODE I2C

I2C BUS BUS

MIN MAX MIN MAX

20 + 0.1

Cb

3.45 0.3 0.9 µs

f

scl

t

sch

t

scl

t

sp

t

sds

t

sdh

t

icr

t

icf

t

ocf

t

buf

t

sts

t

sth

t

sps

t

vd(data)

t

vd(ack)

C

b

PARAMETER

I2C clock frequency 0 100 0 400 kHz

I2C clock high time 4 0.6 µs

I2C clock low time 4.7 1.3 µs

I2C spike time 50 50 ns

I2C serial data setup time 250 100 ns

I2C serial data hold time 0 0 ns

I2C input rise time 1000 21 300 ns

I2C input fall time 300 21 300 ns

I2C output fall time; 10 pF to 400 pF bus 300 300 µs

I2C bus free time between Stop and Start 4.7 1.3 µs

I2C Start or repeater Start condition setup time 4.7 0.6 µs

I2C Start or repeater Start condition hold time 4 0.6 µs

I2C Stop condition setup time 4 0.6 µs

Valid data time; SCL low to SDA output valid 3.45 0.3 0.9 µs

Valid data time of ACK condition; ACK signal from SCL low to SDA

(out) low

I2C bus capacitive loading 0 400 0 400 pF

UNIT

8 Submit Documentation Feedback Copyright © 2014–2015, Texas Instruments Incorporated

Product Folder Links: TS3A227E

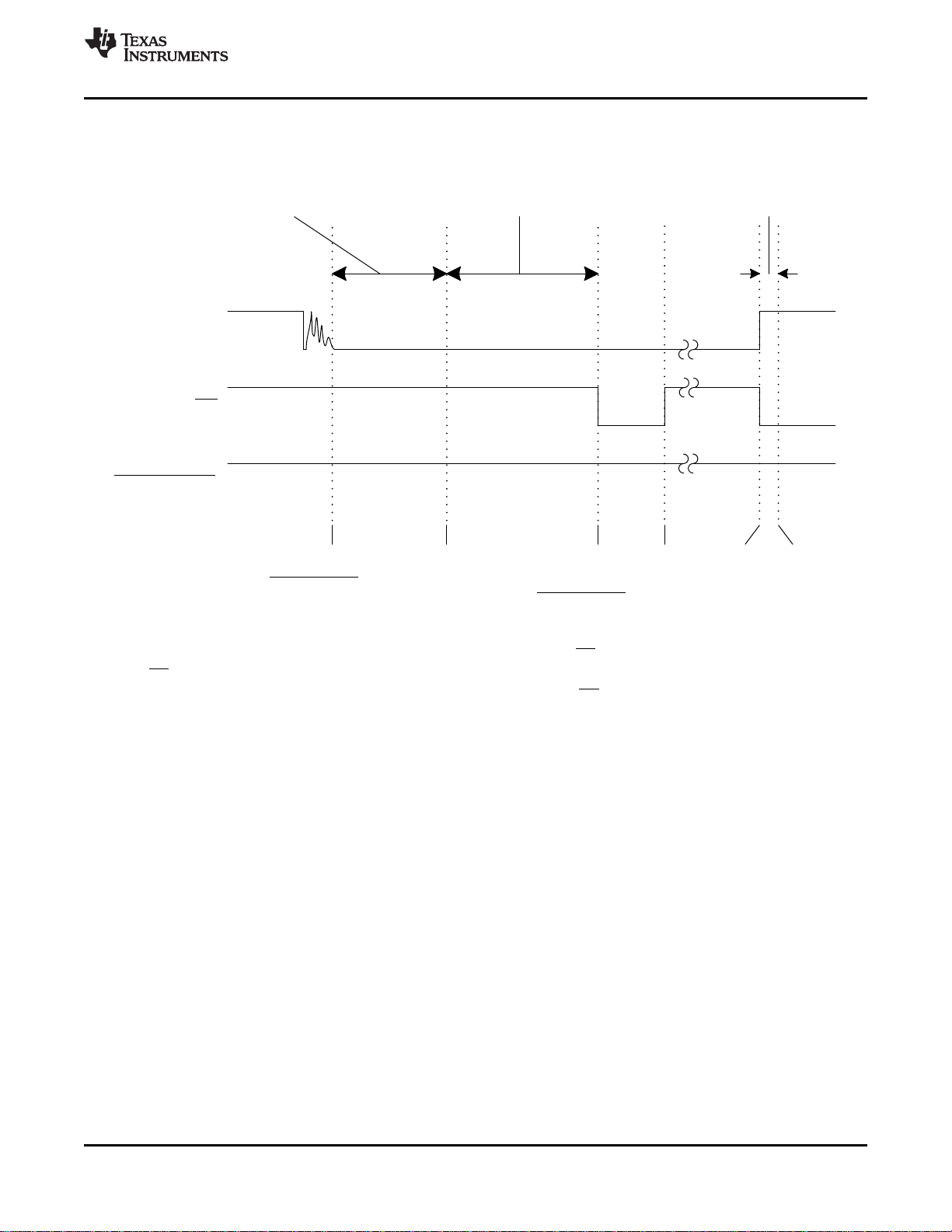

DET_TRIGGER

INT

Insertion

de-bounce time

(90 ms default )

Accessory detection time

(A) (B) (D) (E) (F)

Removal

wait time

MIC_PRESENT

High

(C)

www.ti.com

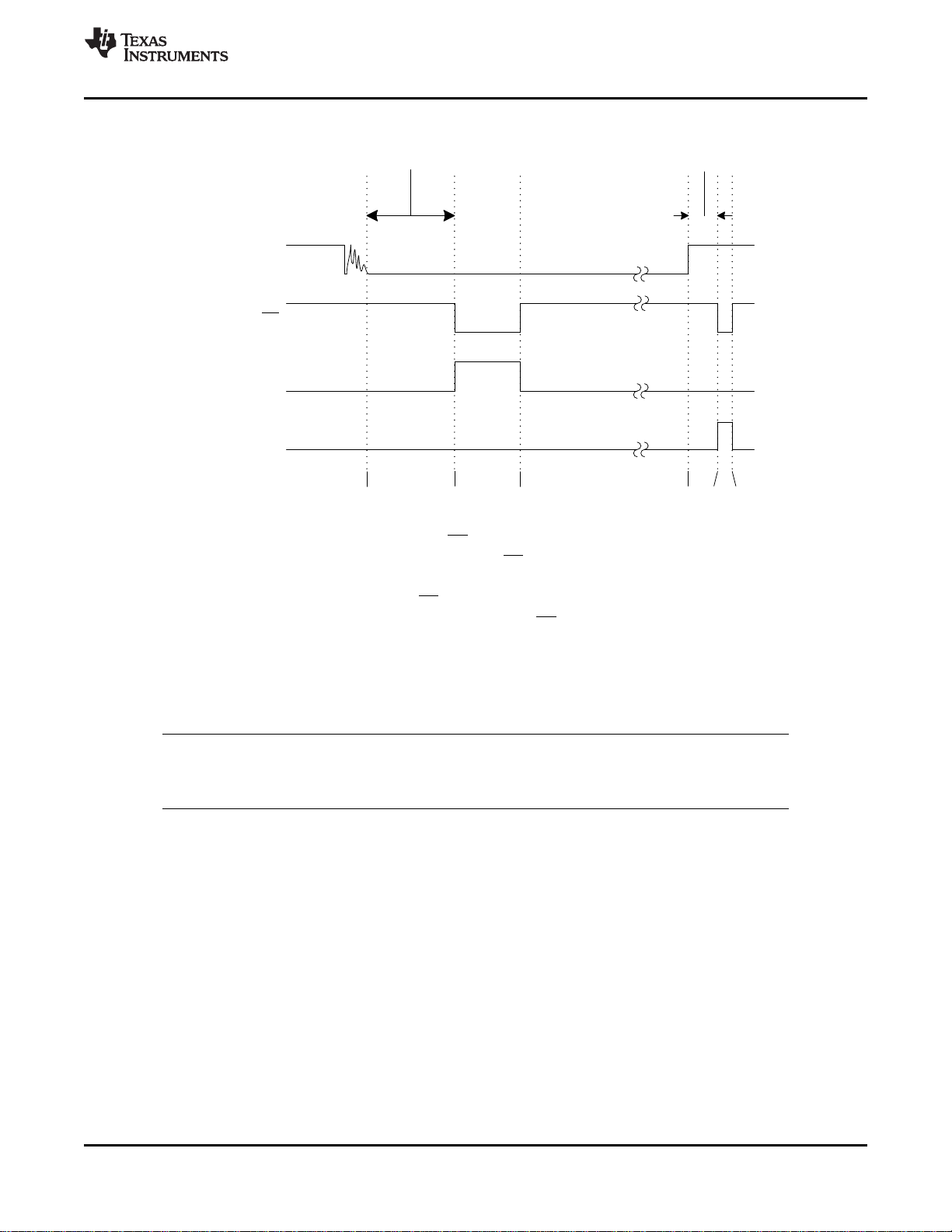

7.7 Timing Diagrams

TS3A227E

SCDS358B –NOVEMBER 2014–REVISED FEBRUARY 2015

A. (This is the point that DET_TRIGGER has stopped glitching and is fully low. The de-bounce time of 90 ms starts from

the point that the pin is constantly below the VILlevel. Any time the DET_TRIGGER pin cross the VIHlevel the de-

bounce timer will restart.

B. Point B is the end of the insertion de-bounce time and the beginning of accessory detection.

C. Detection has completed at this point. The switches will be routed before the INT pin is pulled low.

D. INT is cleared after the host reads the interrupt register.

E. The headset is removed here. The switch states will change immediately and INT will be pulled low.

F. After a 50 ms removal de-bounce timer the TS3A227E will go back into sleep mode if manual switch control is not

enabled

Figure 1. 3-Pole Accessory

Copyright © 2014–2015, Texas Instruments Incorporated Submit Documentation Feedback 9

Product Folder Links: TS3A227E

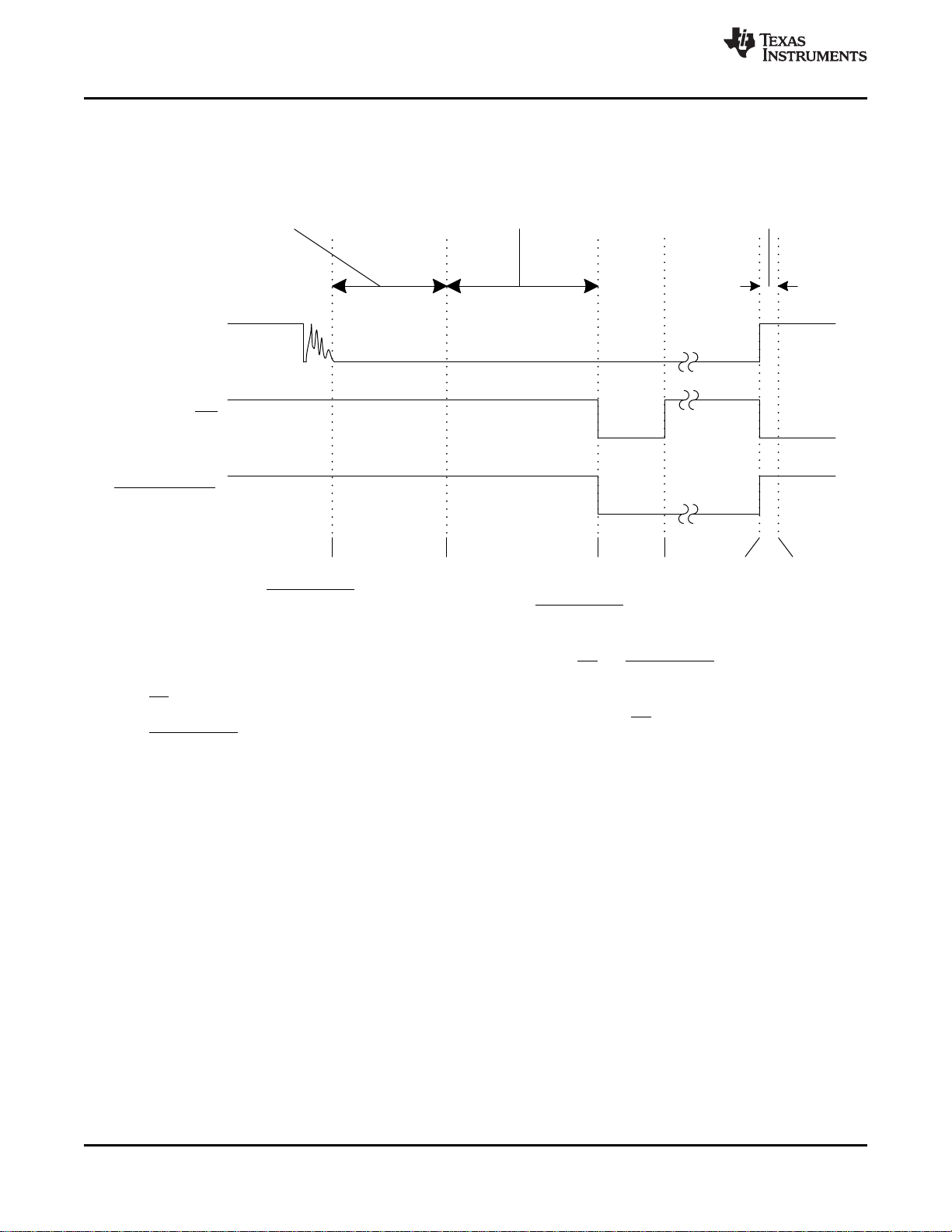

DET_TRIGGER

INT

Insertion

de-bounce time

(90 ms default )

Accessory detection time

(A) (B) (D) (E) (F)

Removal

wait time

MIC_PRESENT

High

(C)

TS3A227E

SCDS358B –NOVEMBER 2014–REVISED FEBRUARY 2015

Timing Diagrams (continued)

www.ti.com

A. This is the point that DET_TRIGGER has stopped glitching and is fully low. The de-bounce time of 90 ms starts from

the point that the pin is constantly below the VILlevel. Any time the DET_TRIGGER pin cross the VIH level the de-

bounce timer will restart.

B. Point B is the end of the insertion de-bounce time and the beginning of accessory detection.

C. Detection has completed at this point. The switches will be routed before the INT and MIC_PRESENT pins are pulled

low.

D. INT is cleared after the host reads the interrupt register.

E. The headset is removed here. The switch states will change immediately and INT will be pulled low. The

MIC_PRESENT pin will be released.

F. After a 50 ms removal de-bounce timer the TS3A227E will go back into sleep mode if manual switch control is not

enabled

Figure 2. 4-Pole Accessory

10 Submit Documentation Feedback Copyright © 2014–2015, Texas Instruments Incorporated

Product Folder Links: TS3A227E

DET_TRIGGER

INT

Insertion

de-bounce time

(90 ms default )

Accessory detection time

(A) (B) (C) (D) (E) ( F)

Removal

wait time

MIC_PRESENT

High

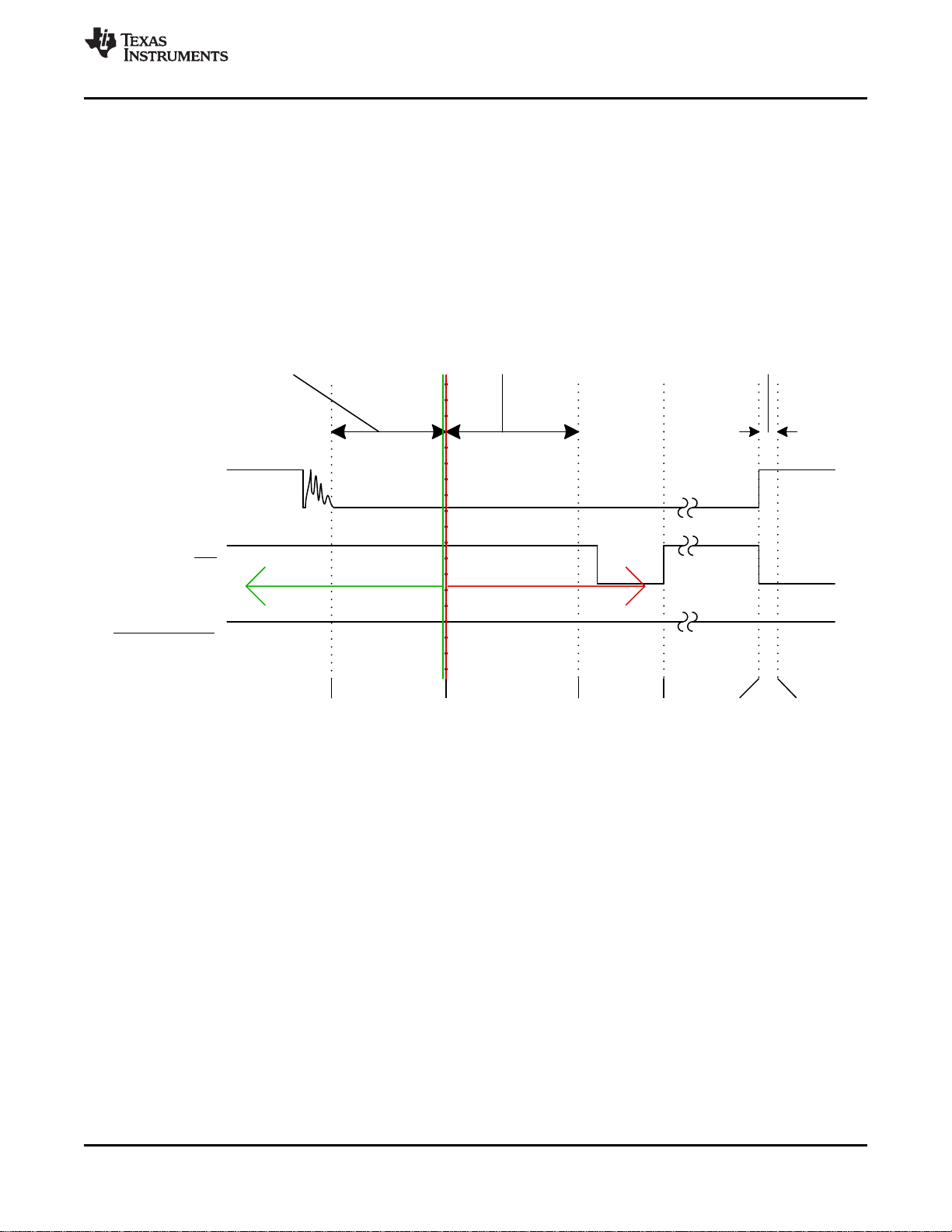

TS3A227E

www.ti.com

SCDS358B –NOVEMBER 2014–REVISED FEBRUARY 2015

Timing Diagrams (continued)

7.7.1 Removal

A removal event will interrupt any on-going process in the TS3A227E. The following diagram depicts how the

device “jumps” during a removal.

If the removal event occurs during the insertion de-bounce period the TS3A227E will jump to the (A) point of the

diagram depicted by the green arrow and line.

Any time after point (B) has been reached and the accessory is removed the device jumps to point (E), which

includes key press detection. Under Manual Switch Control the switch states will not change.

Copyright © 2014–2015, Texas Instruments Incorporated Submit Documentation Feedback 11

Figure 3. Removal Timing During Insertion

Product Folder Links: TS3A227E

I

GND

R2/SLV DFET

V

SLEEVE/RING2

Channel ON

RON= V

SLEEVE/RING2

/ I

GND

I

GNDA

R2/SLV GNDFET

V

SLEEVE/RING2

Channel ON

RON= V

SLEEVE/RING2

/ I

GNDA

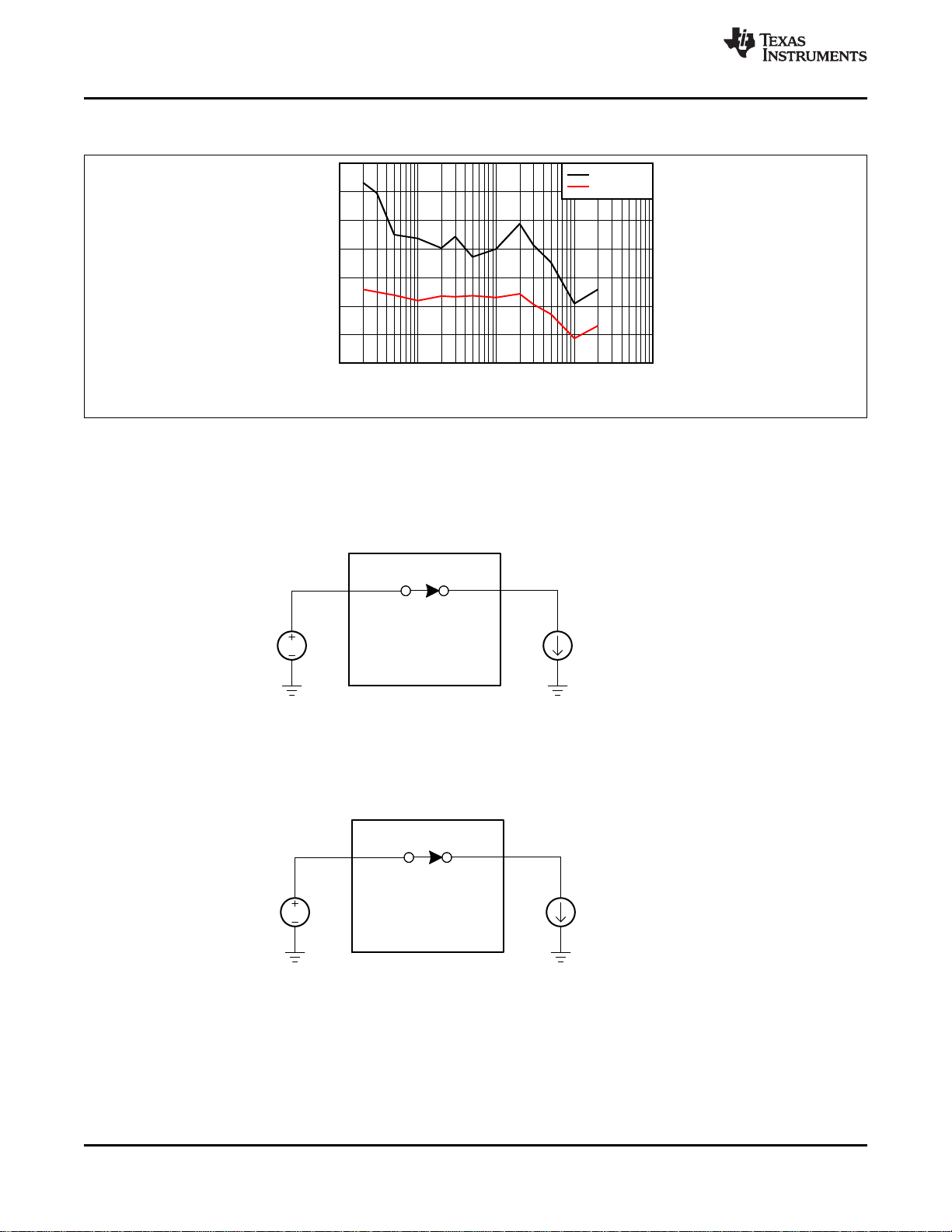

Frequency (Hz)

THD (%)

10 2030 50 100 200 5001000 10000 100000

0

0.0005

0.001

0.0015

0.002

0.0025

0.003

0.0035

D001

200 mVpp

500 mVpp

TS3A227E

SCDS358B –NOVEMBER 2014–REVISED FEBRUARY 2015

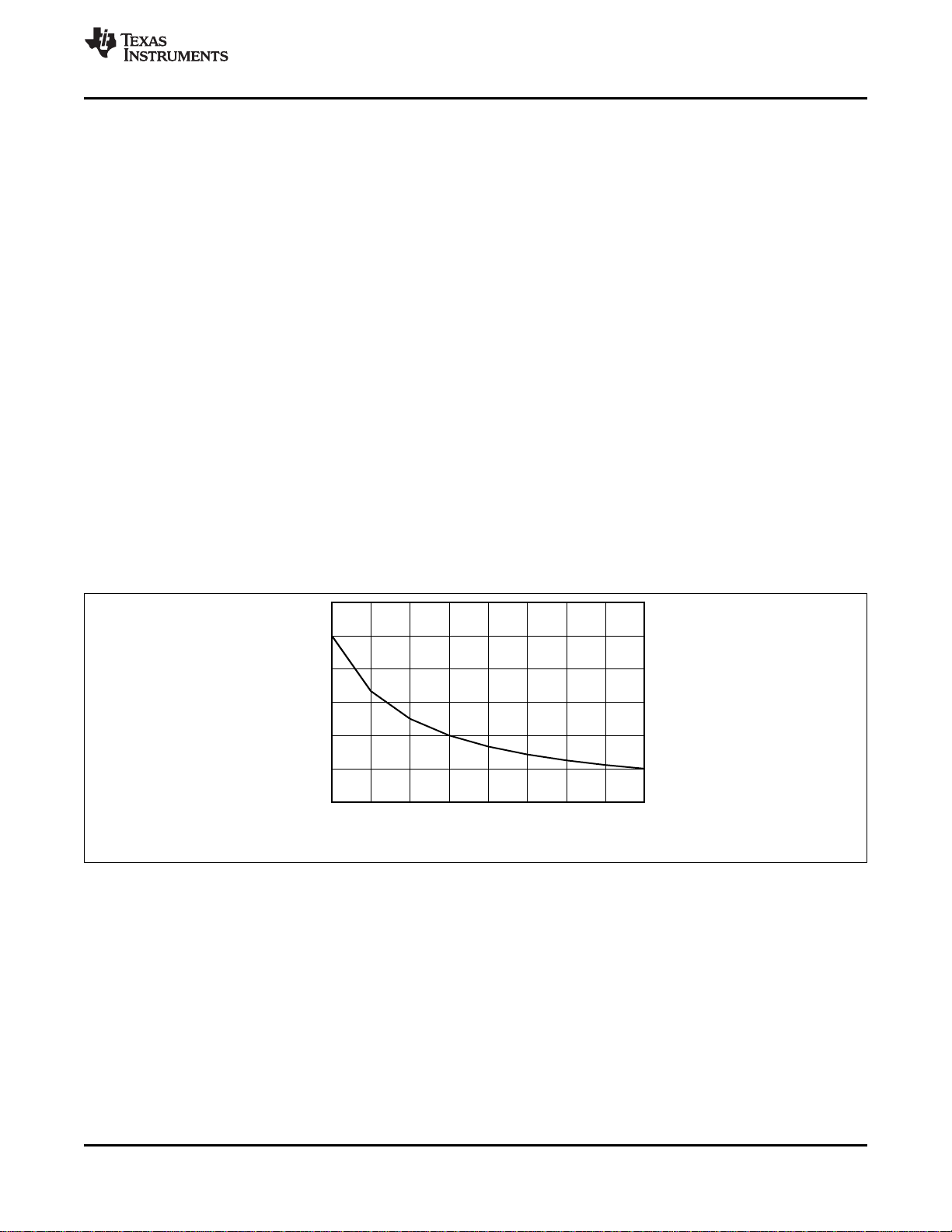

7.8 Typical Characteristics

8 Parameter Measurement Information

www.ti.com

Figure 4. S3PX THD

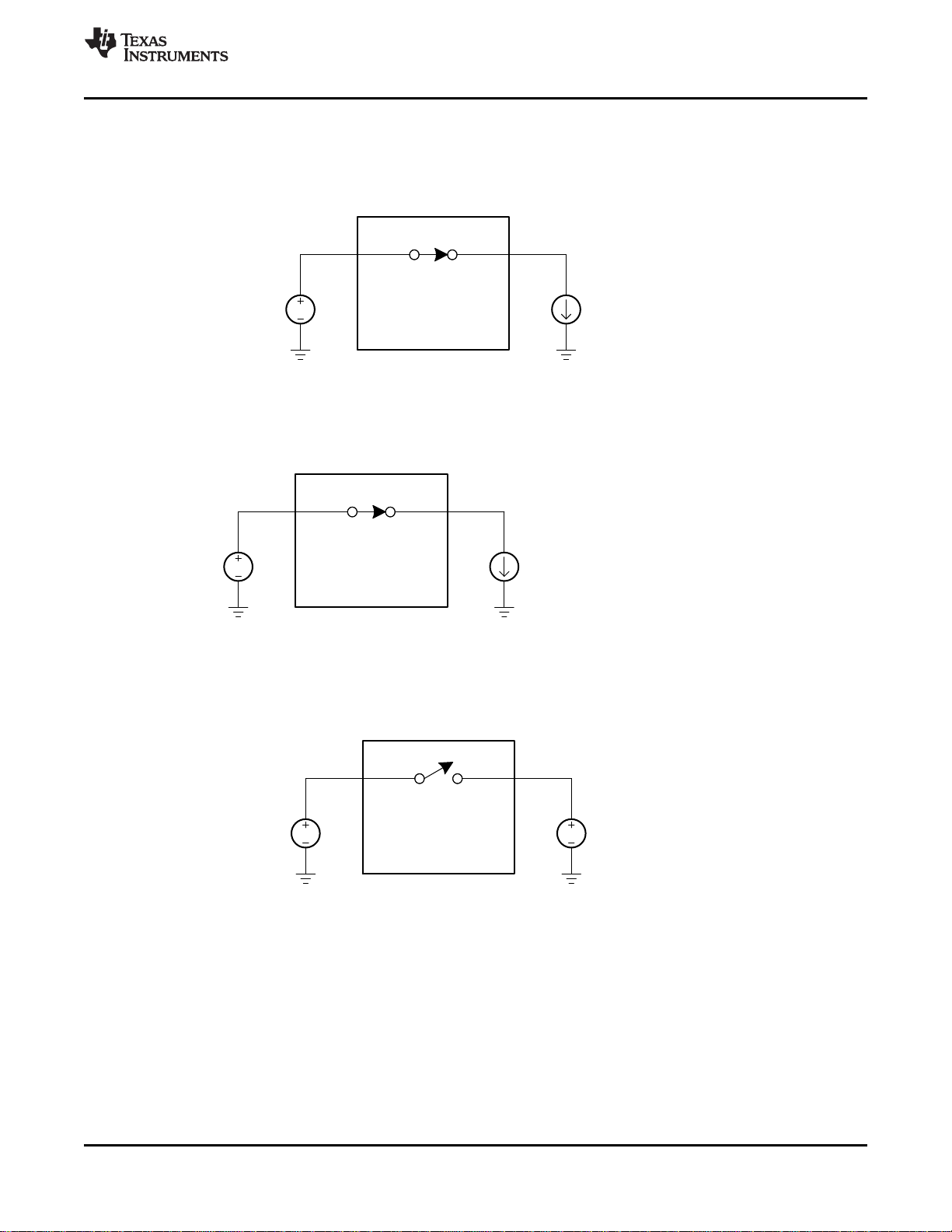

Figure 5. RING2/SLEEVE GNDFET On Resistance Measurement

Figure 6. RING2/SLEEVE DFET On Resistance Measurement

12 Submit Documentation Feedback Copyright © 2014–2015, Texas Instruments Incorporated

Product Folder Links: TS3A227E

V

OUT

Switch

V

IN

Channel OFF

I

RING 2_SENSE/SLEEVE_ SENSE

S3PS/R

S3GS/R

V

MICP/GND_SENSE

Channel ON

RON= V

MICP/GND_SENSE

/ I

RING2_SENSE /SLEEVE_SENSE

I

GND

S1/S2

V

MICP/GND_SENSE

Channel ON

RON= V

MICP/GND_SENSE

/ I

GND

www.ti.com

TS3A227E

SCDS358B –NOVEMBER 2014–REVISED FEBRUARY 2015

Parameter Measurement Information (continued)

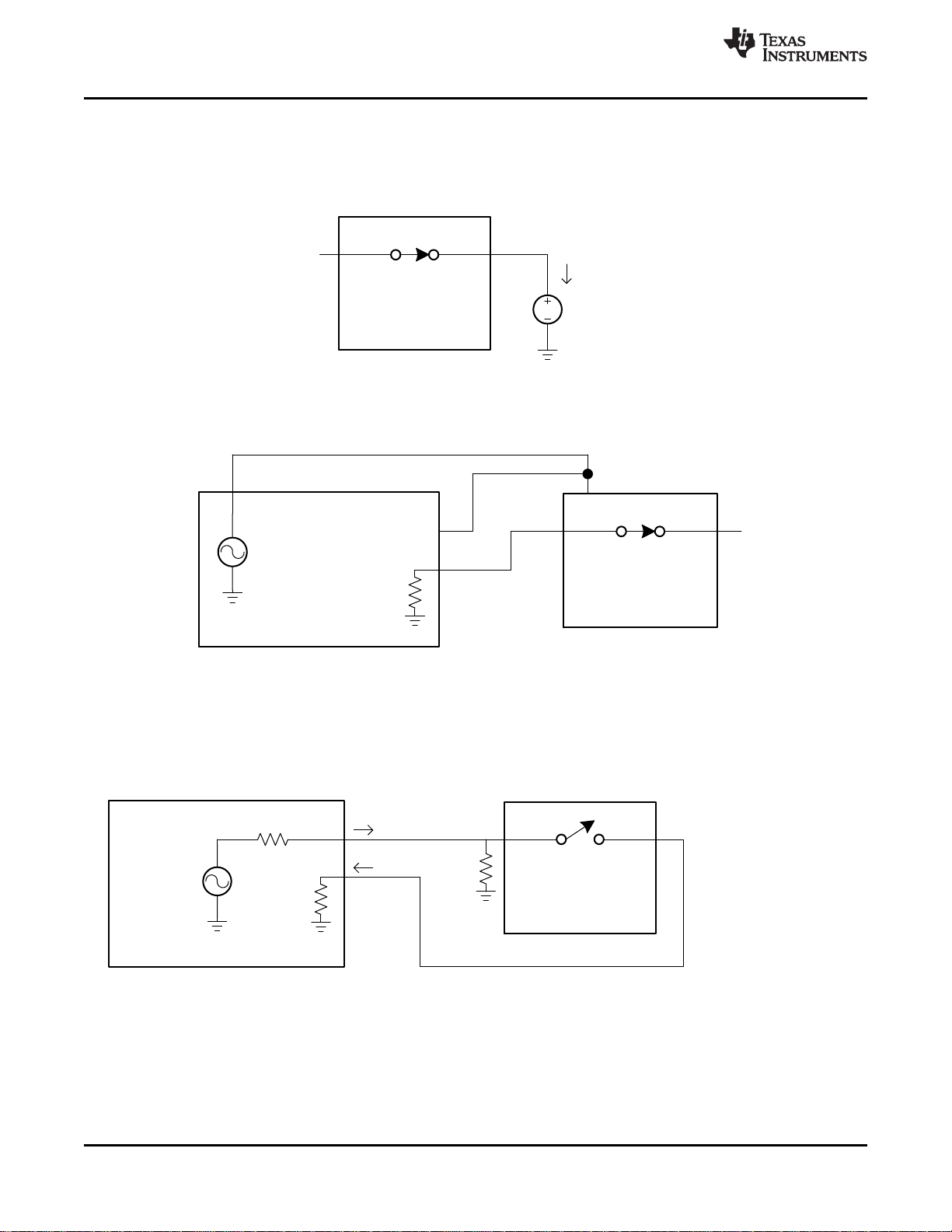

Figure 7. S1/S2 On Resistance Measurement

Figure 8. S3PS, S3PR, S3GS, S3GR On Resistance Measurement

Figure 9. Switch Off Leakage Current

Copyright © 2014–2015, Texas Instruments Incorporated Submit Documentation Feedback 13

Product Folder Links: TS3A227E

Switch

Network Analyzer

Source

Signal

50 Ω

50 Ω

Channel Off

V

MICP/GND_SENSE

V

SLEEVE_SENSE/RING2 _SENSE

50 Ω

Switch

Channel ON

V

DD

3.3 V ± 200 mV

PP

Reference

Test

Source Generator

Source

Signal

50 Ω

V

OUT

Switch

Channel ON

I

Leakage

TS3A227E

SCDS358B –NOVEMBER 2014–REVISED FEBRUARY 2015

Parameter Measurement Information (continued)

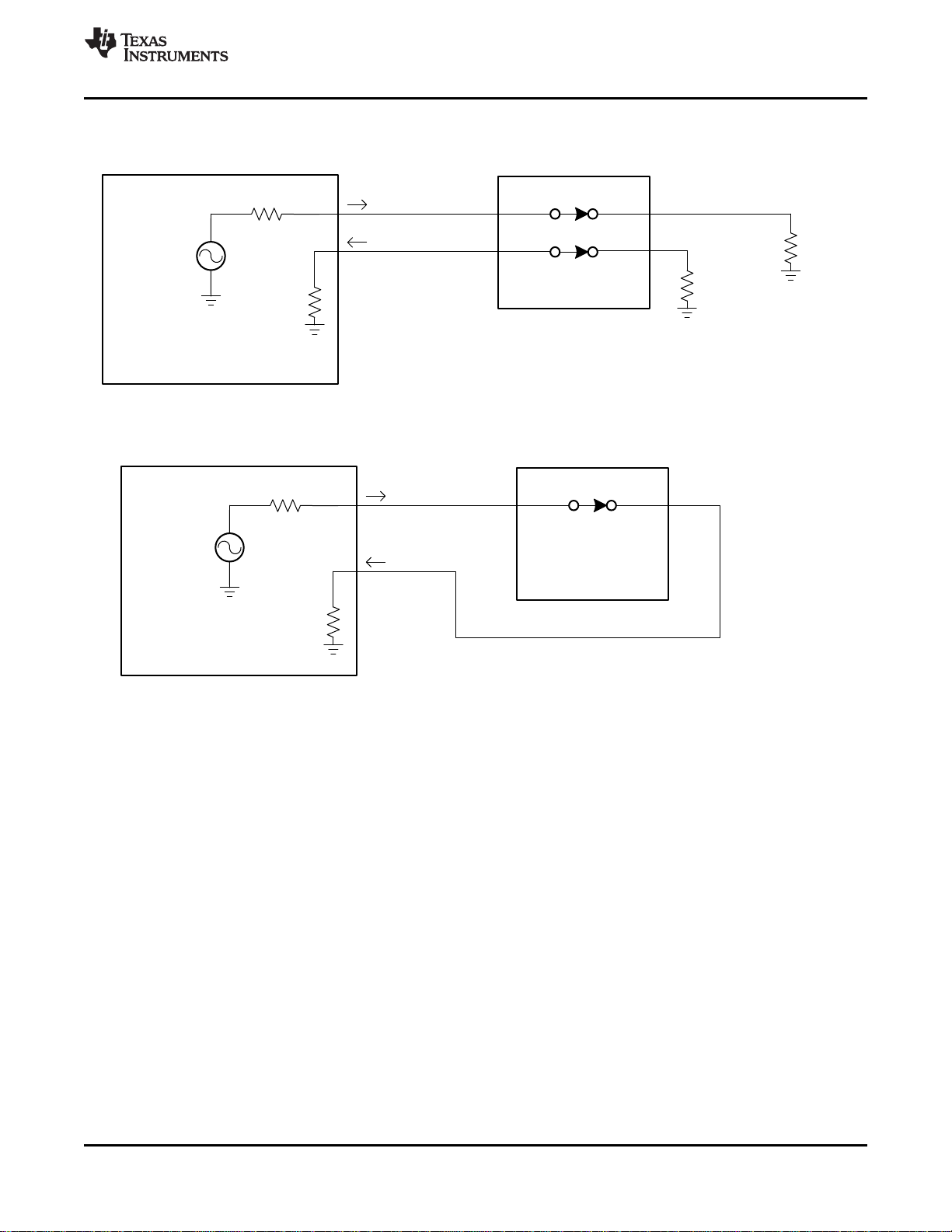

Figure 10. Switch On Leakage Current

www.ti.com

Figure 11. Power Supply Rejection Ratio (PSRR)

Figure 12. Switch Off Isolation

14 Submit Documentation Feedback Copyright © 2014–2015, Texas Instruments Incorporated

Product Folder Links: TS3A227E

Audio Analyzer

Source

Signal

600 Ω

600 Ω

V

MICP

V

SLEEVE_SENSE/RING2_SENSE

Switch

Network Analyzer

Source

Signal

50 Ω

50 Ω

V

MICP

V

SLEEVE_SENSE

50 Ω

50 Ω

V

GND_SENSE V

RING2_SENSE

Switches

www.ti.com

TS3A227E

SCDS358B –NOVEMBER 2014–REVISED FEBRUARY 2015

Parameter Measurement Information (continued)

Figure 13. Channel Separation

Figure 14. Total Harmonic Distortion (THD) and SNR

Copyright © 2014–2015, Texas Instruments Incorporated Submit Documentation Feedback 15

Product Folder Links: TS3A227E

Digital

Core

SDA

SCL

R

PU

C

L

V

PU

V

TEST

V

TEST

SCL

V

TEST

70

%

30

%

t

OFF

t

ON

V

TEST

SCL

V

TEST

90

%

10

%

t

ON

t

OFF

V

MICP/GND _SENSE

Digital

Core

SDA

SCL

R

L

C

L

V

TEST

TS3A227E

SCDS358B –NOVEMBER 2014–REVISED FEBRUARY 2015

Parameter Measurement Information (continued)

www.ti.com

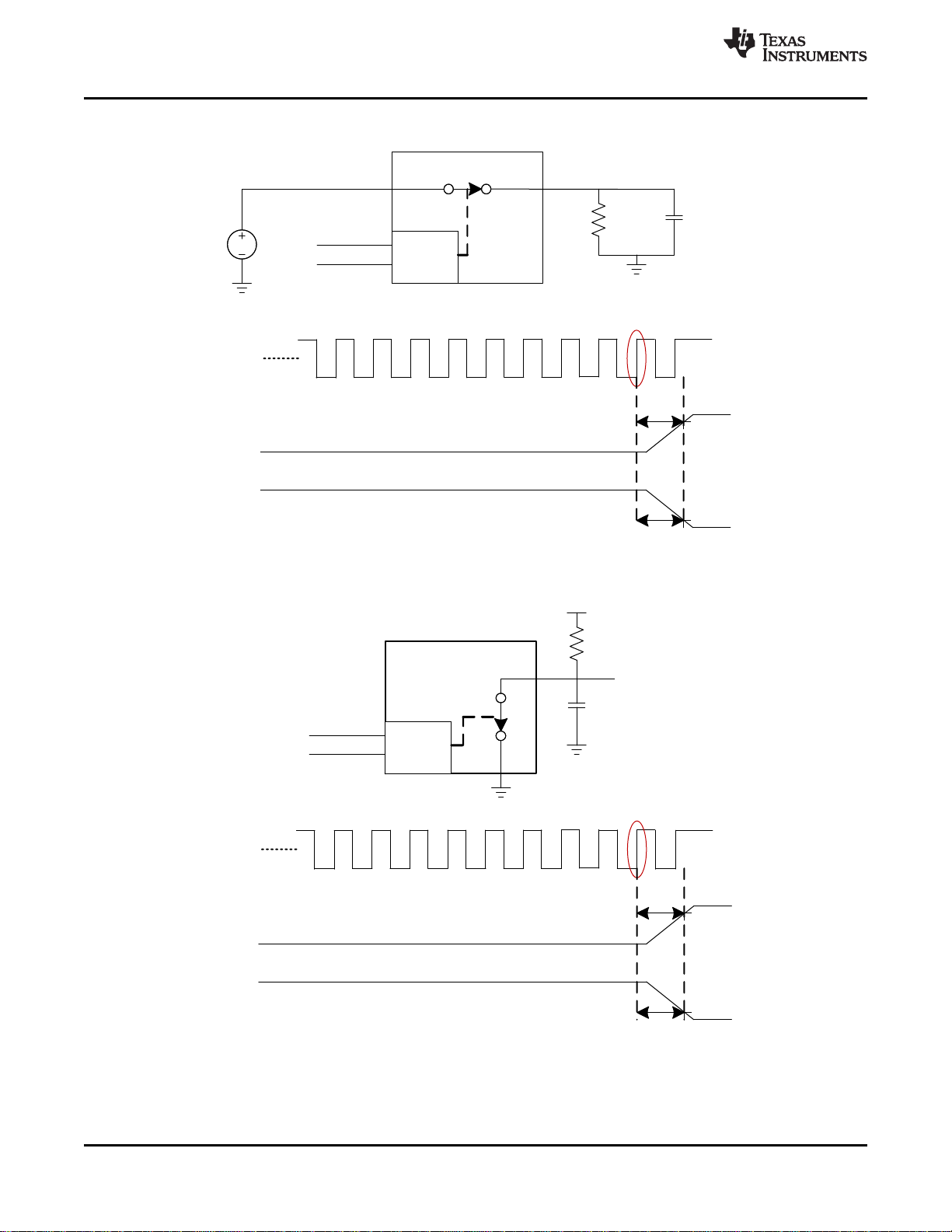

Figure 15. S3 t

N

OFF/tO

Figure 16. S1, S2, GNDFET and DFET tON/t

16 Submit Documentation Feedback Copyright © 2014–2015, Texas Instruments Incorporated

Product Folder Links: TS3A227E

OFF

TS3A227E

www.ti.com

SCDS358B –NOVEMBER 2014–REVISED FEBRUARY 2015

9 Detailed Description

9.1 Overview

The TS3A227E is an autonomous audio accessory switch with adjustable de-bounce settings, ultra-low RON

ground FETs, depletion FETs and manual I2C control.

The detection sequence is initiated via the external DET_TRIGGER pin or via I2C command. The device

incorporates internal de-bounce timings that remove the need for external RC circuits, reducing cost and overall

PCB footprint. Additionally all switches of the TS3A227E and the internal de-bounce timings can be controlled

through I2C.

Before an insertion, TS3A227E isolates the MICBIAS voltage output from the audio jack to remove click/pop

noise that can be created during an insertion event. In addition the device also includes depletion FETs to

ground the accessory SLEEVE and RING2 pins when VDD is not powered. This removes the humming noise

that can be created when plugging an accessory into and unpowered system.

The TS3A227E detects the presence and configuration of the microphone in an attached headset upon insertion.

Upon detection of a microphone the TS3A227E automatically connects a system analog microphone pin (MICP)

to the appropriate audio jack connection. The device also automatically routes the device GNDA pin to the

headset ground. After a 4-pole headset insertion the host can enable the Key Press detection feature of the

TS3A227E.

The device also features an ultra-low power sleep mode to conserve battery life when an accessory is not

inserted.

For FM transmission the ground FETs of the device can be used as an FM transmission path by placing the FM

receiver and matching network on the GNDA pin. The FM support bit must be set to ‘1’ through I2C for FM

transmission to pass.

Copyright © 2014–2015, Texas Instruments Incorporated Submit Documentation Feedback 17

Product Folder Links: TS3A227E

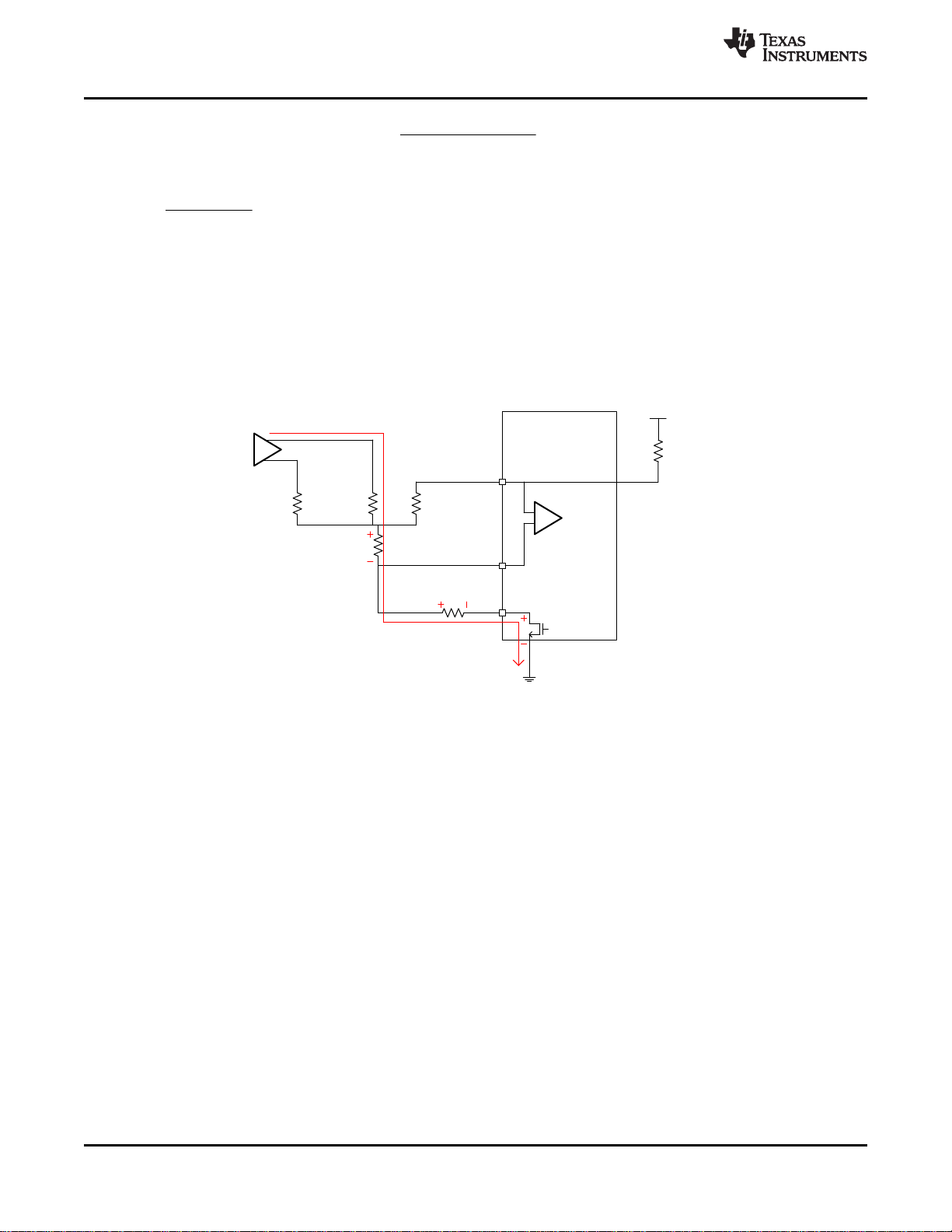

BATTERY

DIGITAL BASEBAND

MIC_PRESENT

SCL

SDA

INTB

VDD

MICROPHONE

AMPLIFIER

EMI

FILTER

EMI

FILTER

RING2_SENSE

SLEEVE_SENSE

TIP

DET_TRIGGER

RING2

SLEEVE

MICP

GND_SENSE

AUDIO

AMPLIFIER

Mic Switch

Matrix

ESD Protection

Depletion FETs

GND Switch

Matrix

TS3A227 E

Detection

Circuitry

Digital interface

control

GND GNDA

FM

Receiver

S1 and S2

TS3A227E

SCDS358B –NOVEMBER 2014–REVISED FEBRUARY 2015

9.2 Functional Block Diagram

www.ti.com

18 Submit Documentation Feedback Copyright © 2014–2015, Texas Instruments Incorporated

Product Folder Links: TS3A227E

R M GL

16-2 kΩ

16- 2 kΩ

600-4kΩ

OMTP

4-pole TRRS

Tip Ring1 SleeveRing2

R G ML

16-2 kΩ

16- 2 kΩ

600-4kΩ

Standard

Tip Ring Sleeve

3-pole TRS

R GL

16-2 kΩ

16- 2 kΩ

TRS

TS3A227E

www.ti.com

SCDS358B –NOVEMBER 2014–REVISED FEBRUARY 2015

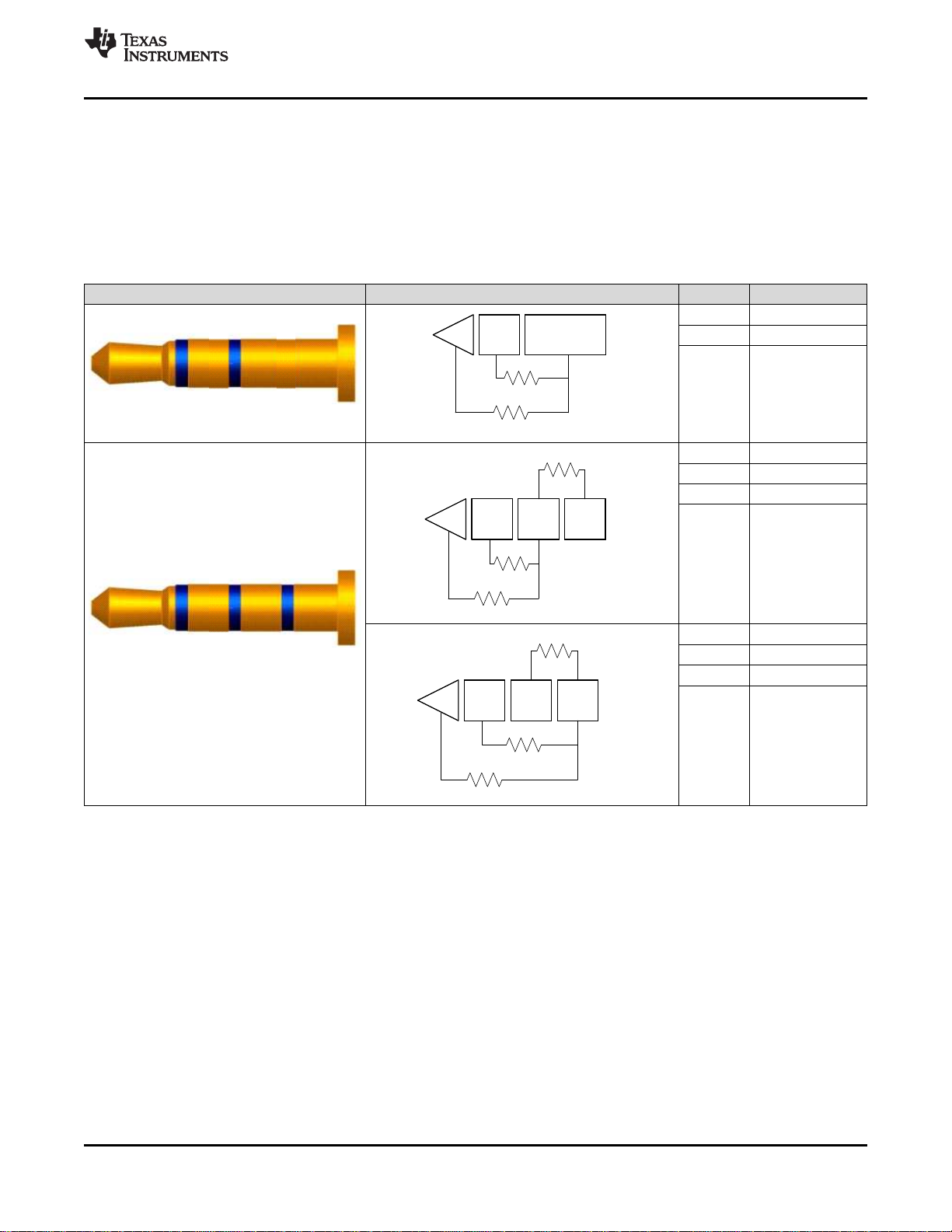

9.3 Feature Description

9.3.1 Accessory Configuration Detection

There are currently two difference configurations for headsets with microphones as shown in Table 1. Many

codecs requires that the system designer make a tough decision via a hardware connection which headset they

would like to support. This is done by directly connecting the microphone bias and the ground connections to the

sleeve and ring2 pins of the audio jack. For the end user this leaves a headset standard as fully unsupported.

Table 1. Two Difference Configurations for Headsets

PHYSICAL CONNECTOR INTERNAL IMPEDANCE NETWORK PIN NAME CONFIGURATION

Tip Audio Left

Ring Audio Right

Sleeve Ground

Tip Audio Left

Ring1 Audio Right

Ring2 Ground

Sleeve Microphone

Tip Audio Left

Ring1 Audio Right

Ring2 Microphone

Sleeve Ground

The TS3A227E fills this system gap by detecting the presence and location of the microphone and automatically

routing the MICBIAS and ground lines to support each headset. This enhances the overall user experience by

allowing headsets from all manufacturers.

9.3.2 Optional Manual I2C Control

The TS3227E also features optional manual I2C control for enhanced system flexibility. This allows the system

designer to manually control the switches and de-bounce settings at their discretion enabling the TS3A227E to

adapt to unique use cases.

This is an optional feature that does not need to be used for the device to operate autonomously.

9.3.3 Adjustable De-bounce Timings

The TS3A227E features manual control of the insertion de-bounce timer with selectable values. The default

insertion de-bounce timer is 90 ms.

This eliminates the need for external RC components which reduces BOM cost, the PCB footprint of the external

RC components. Further information on how to select an appropriate de-bounce timer can be found in the

application and implementation section.

Copyright © 2014–2015, Texas Instruments Incorporated Submit Documentation Feedback 19

Product Folder Links: TS3A227E

TS3A227E

SCDS358B –NOVEMBER 2014–REVISED FEBRUARY 2015

www.ti.com

9.3.4 Key Press Detection

After a headset is inserted, the host can enable Key Press detection through the I2C registers. This will configure

the TS3A227E to detect up to 4 different keys and report when the key is pressed and released.

9.3.5 Click Pop Noise Reduction

During an accessory insertion and removal event the TS3A227E use special techniques to remove the click/pop

noise that can occur with a traditional implementation creating a better user experience.

9.3.6 Power off Noise Removal

In a system that intends to support both headset types, the end user can place the system into sleep mode and

leave a headset/speaker plugged into the audio jack. If the audio jack switch is turned off to conserve power in

the sleep mode this would typically mean the headset/speaker ground would not be connected because there is

no power to turn on the ground FETs. This creates an audible humming noise at the speaker/headset output that

can be discomforting to listen to.

By utilizing always on depletion FETs this issue can be removed and the headset/speaker can be connected to

ground even with the device unpowered.

9.3.7 Sleep Mode

The TS3A227E will automatically enter a low power sleep when no accessory is inserted and manual switch

control is not enabled. After an accessory is inserted the device will wake, run detection, and configure the

switches as necessary.

9.3.8 Codec Sense Line

In the complex systems of today, there is an increasing amount of ICs on any given board. The issue this creates

is that a codec can be far away from the audio jack and there is a potential difference between the grounding of

the codec and the grounding of the headset.

By incorporating a ground sense line into the TS3A227E the codec can compensate for this offset and create a

higher quality audio experience.

9.3.9 FM Support

FM can be picked up using the headset ground line and passed through the ground FETs of the TS3A227E. By

having a bandwidth of 200 MHz the full FM band can be passed through these FETs to a FM matching network

and the FM receiver.

9.4 Device Functional Modes

9.4.1 Sleep Mode

The device will realize a sleep mode of 1 µA if the following are true:

• No accessory is inserted

• Manual Switch Control = ‘0’

The TS3A227E will respond to I2C communication and insertion events while in sleep mode. The user can set

the de-bounce settings and device configuration as desired while in the sleep mode. If the user sets the Manual

Switch Control bit to ‘1’ the device will turn on all blocks and come out of sleep mode.

If there is no accessory inserted and the users exits manual switch control, the switches will revert to the noinsertion state and all unnecessary blocks of the TS3A227E will turn off and enter the sleep mode.

20 Submit Documentation Feedback Copyright © 2014–2015, Texas Instruments Incorporated

Product Folder Links: TS3A227E

TS3A227E

www.ti.com

SCDS358B –NOVEMBER 2014–REVISED FEBRUARY 2015

Device Functional Modes (continued)

9.4.2 Manual Switch Control

The TS3A227E supports manual switch control that can be utilized by setting Bit6 of the Device Settings 1

register to ‘1’.

Key operational characteristics of manual switch control are below.

1. Enabling the manual switch control does not disable automatic insertion and accessory type detection.

2. Manual Switch Control is blocked during accessory type detection which includes an automatic detection

sequence or a manual SW triggered detection sequence. Any changes to the switch control registers, or

setting the device to manual switch control will not update the switches until after the accessory type

detection has completed.

3. Manual Switch Control is also blocked during de-bounce periods.

4. Excluding items 2 and 3 above, immediately after the system enables manual switch control the switch states

will change to reflect the switch control registers. It is advised to set the desired state of the switches before

enabling manual switch control.

5. Turning off the depletion FETs of the device will result in increased power consumption as defined in the

electrical characteristics table.

6. Immediately upon setting Manual Switch Control = ‘0’ the device will automatically configure the switches to

the latest detection state. If an accessory is inserted but the TS3A227E has not run detection due to

Auto_Det_EN = ‘0’, the switch status will revert to the no insertion state.

7. The device cannot be in sleep mode and utilize manual switch control at the same time.

9.4.3 Manual Switch Control Use Cases

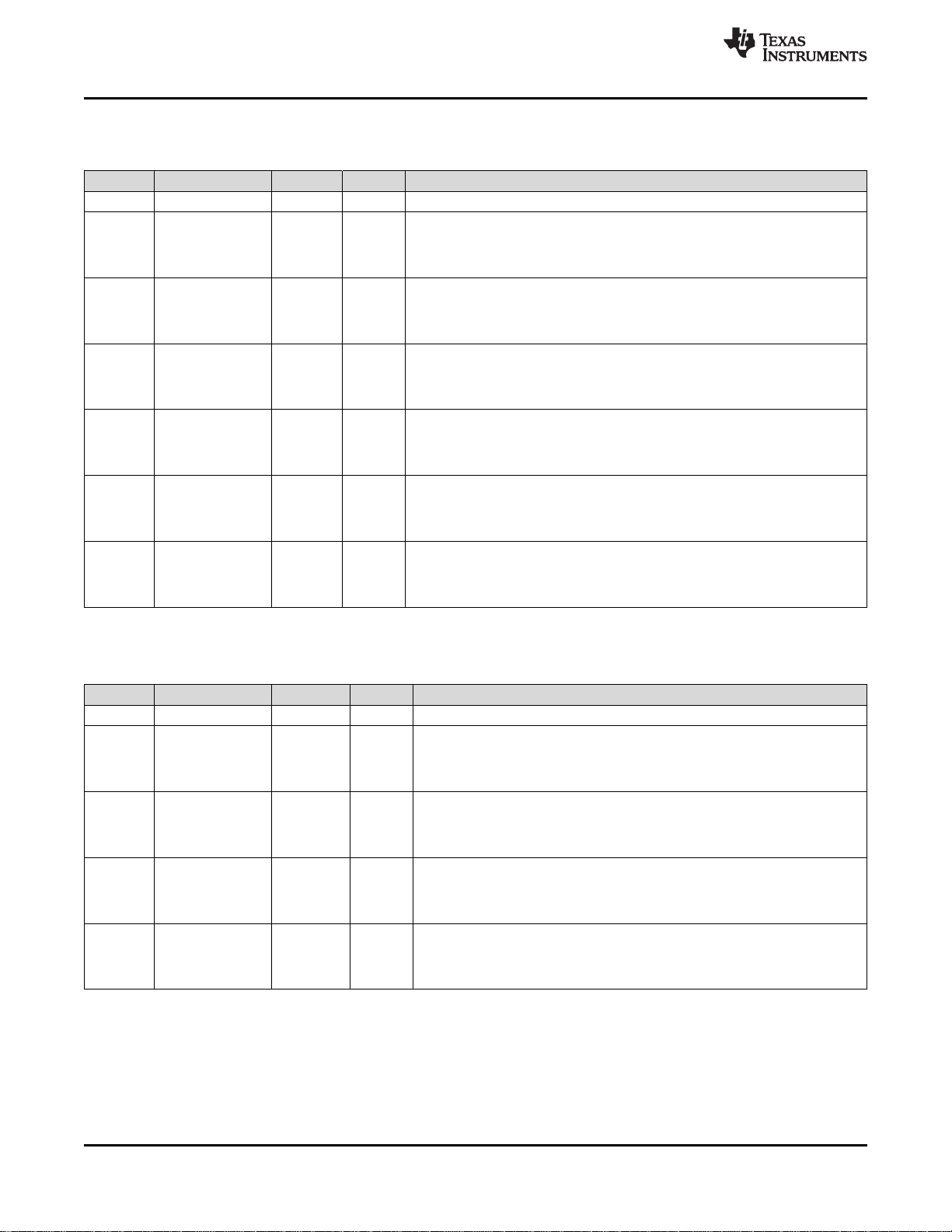

The table below captures what occurs after a 3-pole insertion with the Manual Switch Control, Auto DET Enable,

and DET Trigger bits set to the following before an insertion.

MANUAL DOES TYPE

SWITCH DETECTION

CONTROL RUN

0 0 0 no No-insertion 0

0 0 1 yes 3-pole config 0

0 1 0 yes 3-pole config 0

0 1 1 yes 3-pole config 0

1 0 0 no Switch control registers 0

1 0 1 yes Switch control registers 0

1 1 0 yes Switch control registers 0

1 1 1 yes Switch control registers 0

AUTO DET DET TRIGGER SWITCH STATUS AFTER DET TRIGGER (SW) AFTER

EN (SW) INSERTION INSERTION

The table below captures the switch and relevant register outputs for sequence 1.

EVENT 3-POLE 4-POLE

NO. BIT OMTP BIT

1 Device powers up No-insertion 0 0 0

2 User sets Auto DET Enable = ‘0’ No-insertion 0 0 0

3 3-pole accessory is inserted No-insertion 0 0 0

4 System sets Manual Switch Control = ‘1’ System controlled 0 0 0

5 System sets switch control registers = 0xFF System controlled 0 0 0

6 System sets Manual Switch Control = ‘0’ No-insertion 0 0 0

EVENT DESCRIPTION SWITCH STATUS

4-POLE

STANDARD BIT

Copyright © 2014–2015, Texas Instruments Incorporated Submit Documentation Feedback 21

Product Folder Links: TS3A227E

TS3A227E

SCDS358B –NOVEMBER 2014–REVISED FEBRUARY 2015

www.ti.com

In sequence 1 at event 3 the switch status does not change because the system set the Auto DET Enable = ‘0’.

When the accessory is inserted we will not run detection and not change the switches because of this.

At event 6 the system turns off manual switch control, the switch state reverts back to the No-insertion state

because the TS3A227E has not ran detection.

The table below captures the switch and relevant register outputs for sequence 2.

EVENT SWITCH STATUS 3-POLE 4-POLE 4-POLE

NO. AFTER EVENT BIT STANDARD BIT OMTP BIT

1 Device powers up No-insertion 0 0 0

2 User sets Auto DET Enable = ‘0’ No-insertion 0 0 0

3 3-pole accessory is inserted No-insertion 0 0 0

4 System sets Manual Switch Control = ‘1’ System controlled 0 0 0

5 System sets switch control registers = 0xFF System controlled 0 0 0

6 System sets DET Trigger = ‘1’ System controlled 1 0 0

7 System sets Manual Switch Control = '0' 3-pole configuration 1 0 0

EVENT DESCRIPTION

In sequence 2 at event 3 the switch status does not change because the system set the Auto DET Enable = ‘0’.

When the accessory is inserted we will not run detection and not change the switches because of this.

At event 6 the system turns triggers a manual type detection and the TS3A227E detects a 3-pole accessory. The

switch state will remain in the system controlled state.

At event 7 the system exits manual switch control. The switch status will then change back to the last detection

state. Because detection was ran at event 6 and a 3-pole was detected, the switch state will reflect that of the 3pole switch configuration.

22 Submit Documentation Feedback Copyright © 2014–2015, Texas Instruments Incorporated

Product Folder Links: TS3A227E

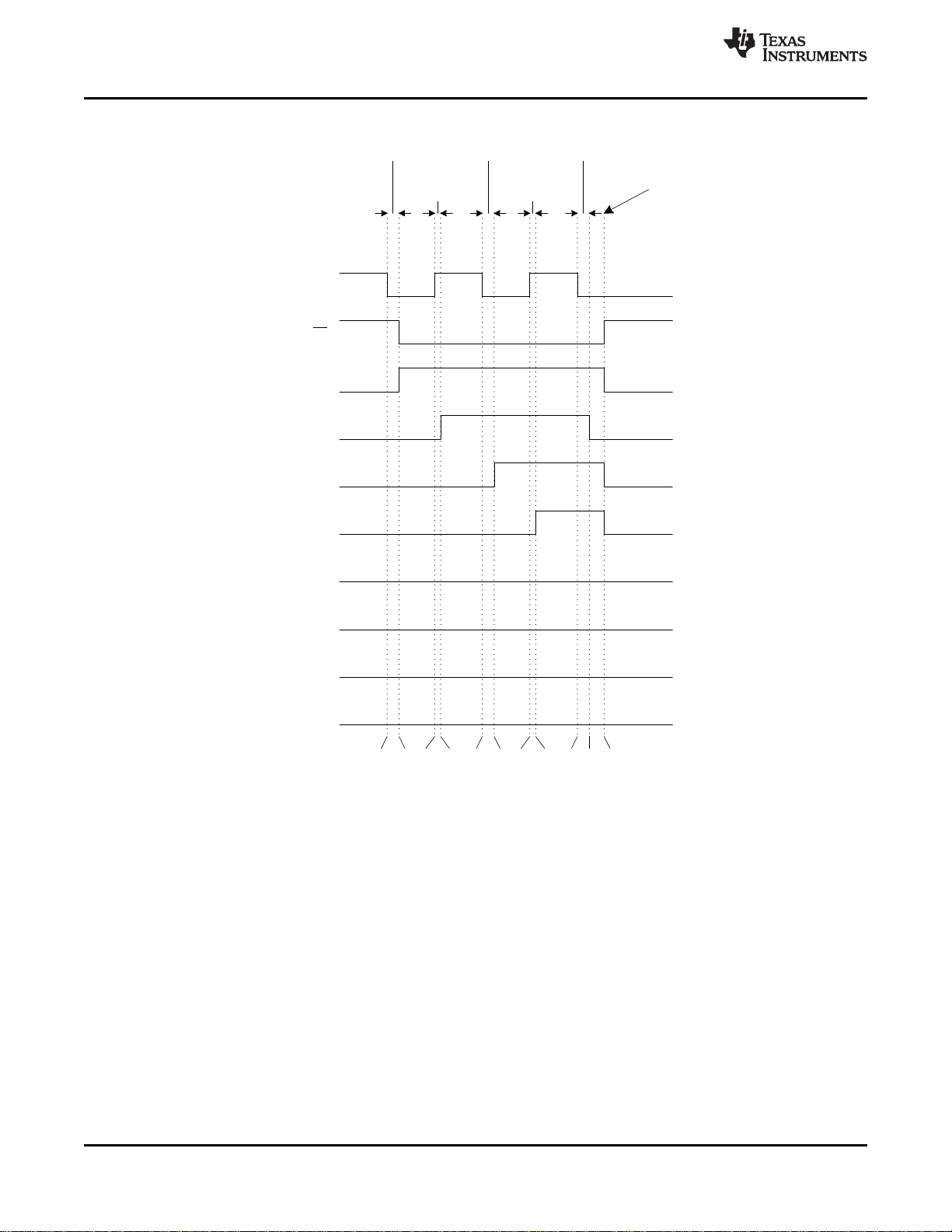

TS3 A227E

MICP

GND_SENSE

S3PR

SLEEVE

S3PS

S3GS

S3GR

S1 S 2

RING2

GNDFET

SLEEVE

GNDFET

RING2

DFET

SLEEVE

DFET

RING2

SLEEVE_SENSE

RING 2_SENSE

GND GNDGNDA

Audio Jack

L R G M

FM

Receiver

TS3A227E

www.ti.com

SCDS358B –NOVEMBER 2014–REVISED FEBRUARY 2015

9.4.4 FM Support Mode

FM support mode needs to be entered via I2C through the Device Settings register. This will turn off the

depletion switches when an accessory is inserted, eliminating the extra ground path. The ground line of the

headset/headphone is used for FM transmission. This signal must pass through the TS3A227E ground FETs as

shown in Figure 17 where the red line indicates the transmission path.

Figure 17. FM Support Transmission Path

NOTE

FM support should be enabled before an accessory is inserted. Toggling the FM

support bit after a headset is inserted can cause a pop noise to be heard by the end

user.

Copyright © 2014–2015, Texas Instruments Incorporated Submit Documentation Feedback 23

Product Folder Links: TS3A227E

TS3A227E

SCDS358B –NOVEMBER 2014–REVISED FEBRUARY 2015

9.5 Register Maps

The I2C address of the TS3A227E is b’0111011X or 77h read and 76h write.

www.ti.com

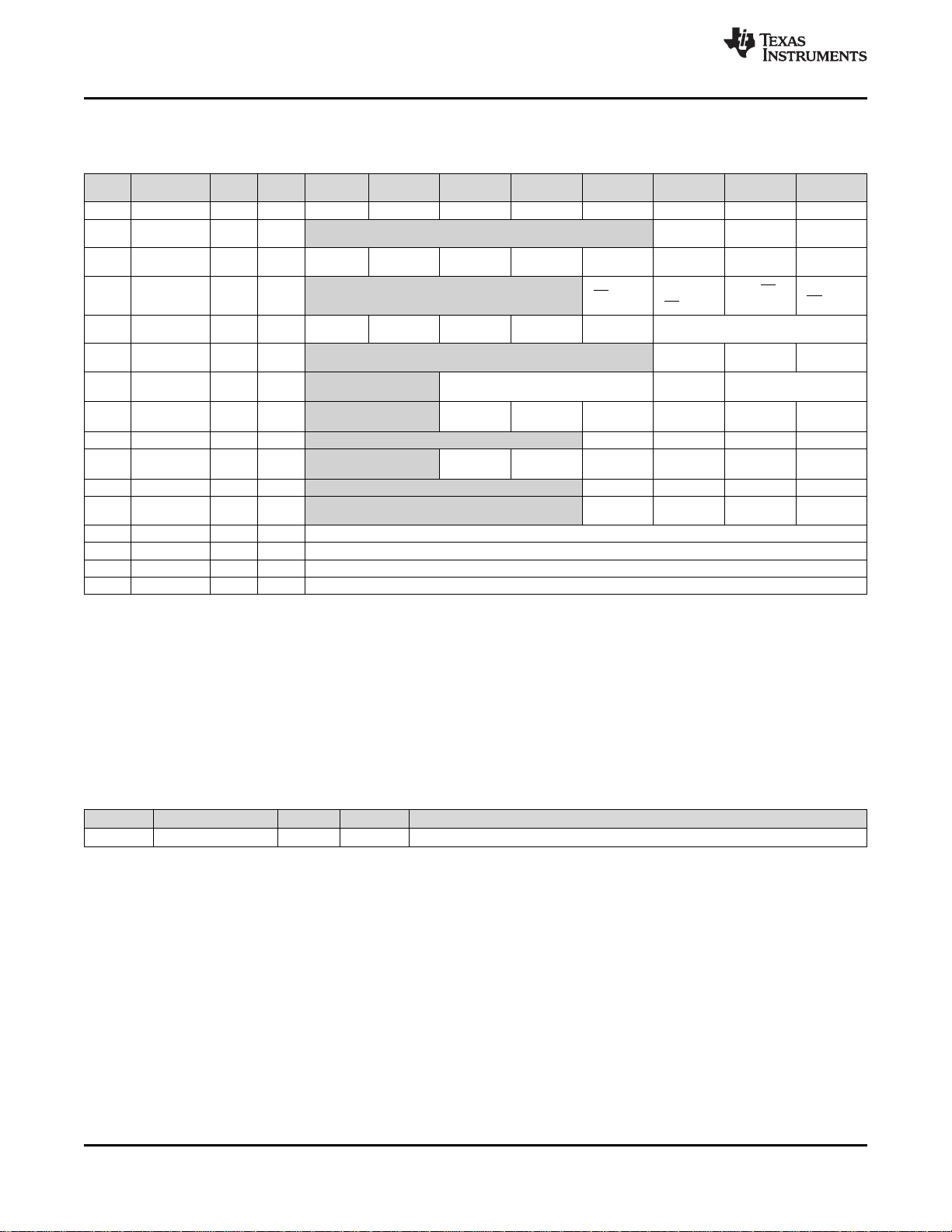

Addr

(xxh)

00h Device ID R 11h 0 0 0 1 0 0 0 1

01h Interrupt R 00h Reserved DC Ins/Rem Event

02h R 00h Key 4 Press Key 3 Release Key 3 Press Key 2 Release Key 2 Press Key 1 Release Key 1 Press

03h Interrupt Disable R/W 08h Reserved INT Disable Conversion

04h Device Settings R/W 23h Reset DET Trigger FM Support Insertion De-bounce Time

05h Device Setting 1 R/W 00h Reserved Raw Data En ADC Trigger

06h Device Setting 2 R/W 0Eh Reserved MICBIAS Setting Key Press De-bounce

07h Switch Control 1 R/W 00h Reserved RING2 DFET Switch 2 Switch 1

08h Switch Control 2 R/W 00h Reserved S3PS S3PR S3GS S3GR

09h Switch Status 1 R 0Ch Reserved RING2DFET Switch 2 Switch 1

0Ah Switch Status 2 R 00h Reserved S3PS S3PR S3GS S3GR

0Bh R 00h Reserved 4-pole OMTP 3-pole

0Ch ADC Output R 00h ADC

0Dh Threshold 1 R/W 20h KP Threshold 1

0Eh Threshold 2 R/W 40h KP Threshold 2

0Fh Threshold 3 R/W 68h KP Threshold 3

Name Type Reset Bit7 Bit6 Bit5 Bit4 Bit3 Bit2 Bit1 Bit0

ADC

Conversion

Key Press Key 4

Interrupts Release

ADC

INT Disable

Manual Switch Auto DET

Control Enable

Key Press

Enable

Key Release

De-bounce

SLEEVE SLEEVE

GNDFET DFET

SLEEVE SLEEVE

GNDFET DFET

Accessory Insertion 4-Pole

Status Status Standard

RING2

GNDFET

RING2

GNDFET

DC INT Ins/Rem Event

Disable INT Disable

Interrupt and Key Press Interrupt register notes:

• The device will continue to automatically run type detection and key press detection even if the host has not

serviced the interrupts.

• Consecutive reads of an interrupt register at 400 kHz will not allow time for the internal registers to clear and

will appear. The internal digital core requires 200 µs to clear the register after it has been read.

9.6 Register Field Descriptions

9.6.1 Device ID Register Field Descriptions (Address 00h)

Figure 18. Device ID Register Field Descriptions (Address 00h)

Bit Field Type Reset Description

7-0 Device ID R 11h Unique Revision number

24 Submit Documentation Feedback Copyright © 2014–2015, Texas Instruments Incorporated

Product Folder Links: TS3A227E

www.ti.com

SCDS358B –NOVEMBER 2014–REVISED FEBRUARY 2015

9.6.2 Interrupt Register Field Descriptions (Address 01h)

Table 2. Interrupt Register Field Descriptions (Address 01h)

Bit Field Type Reset Description

7-3 Reserved R 0h

2 ADC Conversion R 0h ADC Conversion complete Interrupt. Flagged after a manual ADC conversion is

1 DC R 0h Detection Complete interrupt. Flagged after detection is completed for an

0 Ins/Rem Event R 0h Insertion or removal interrupt indicator. This bit is set if there is an insertion or

complete.

Interrupt bit is cleared after being read through I2C or after a removal event.

0h = Default state

1h = ADC Conversion Complete

insertion sequence. This bit is also flagged after completion of a manually

triggered detection.

Interrupt bit is cleared after being read through I2C or after a removal event.

0h = Default state

1h = Detection Completed

removal event. The Insertion status bit of the Accessory Status register (0Bh)

must be checked if this bit is set.

Interrupt bit is cleared after being read through I2C

0h = Default state

1h = Accessory has been inserted or removed

TS3A227E

9.6.3 Key Press Interrupt Register Field Descriptions (Address 02h)

Table 3. Key Press Interrupt Register Field Descriptions (Address 02h)

Bit Field Type Reset Description

7 Key 4 Release R 0h This interrupt bit is set after the user has released key 4 on the accessory for a

6 Key 4 Press R 0h This interrupt bit is set after the user has pressed key 4 on the accessory for a

5 Key 3 Release R 0h This interrupt bit is set after the user has pressed Key 3 on the accessory for a

duration longer than the Key Release De-bounce timer.

This bit will auto-clear on the following conditions:

● Host reads the register through I2C

● The KP Enable bit is set to ‘0’

— The KP Enable bit is set to ‘0’ automatically after a removal

● The Key 4 press bit is set ot '1'

0h = Default State

1h = Key 4 was released

duration longer than the Key Press De-bounce timer.

This bit will auto-clear on the following conditions:

● Host reads the register through I2C

● The KP Enable bit is set to ‘0’

— The KP Enable bit is set to ‘0’ automatically after a removal

0h = Default State

1h = Key 4 was released

duration longer than the Key Release De-bounce timer.

This bit will auto-clear on the following conditions:

● Host reads the register through I2C

● The KP Enable bit is set to ‘0’

— The KP Enable bit is set to ‘0’ automatically after a removal

● The Key 3 Press bit is set to ‘1’

0h = Default State

1h = Key 3 was released

Copyright © 2014–2015, Texas Instruments Incorporated Submit Documentation Feedback 25

Product Folder Links: TS3A227E

TS3A227E

SCDS358B –NOVEMBER 2014–REVISED FEBRUARY 2015

Table 3. Key Press Interrupt Register Field Descriptions (Address 02h) (continued)

Bit Field Type Reset Description

4 Key 3 Press R 0h This interrupt bit is set after the user has pressed Key 3 on the accessory for a

duration longer than the Key Press De-bounce timer.

This bit will auto-clear on the following conditions:

● Host reads the register through I2C

● The KP Enable bit is set to ‘0’

— The KP Enable bit is set to ‘0’ automatically after a removal

0h = Default State

1h = Key 3 was released

3 Key 2 Release R 0h This interrupt bit is set after the user has pressed Key 2 on the accessory for a

duration longer than the Key Release De-bounce timer.

This bit will auto-clear on the following conditions:

● Host reads the register through I2C

● The KP Enable bit is set to ‘0’

— The KP Enable bit is set to ‘0’ automatically after a removal

● The Key 2 Press bit is set to ‘1’

0h = Default State

1h = Key 2 was released

2 Key 2 Press R 0h This interrupt bit is set after the user has pressed Key 2 on the accessory for a

duration longer than the Key Press De-bounce timer.

This bit will auto-clear on the following conditions:

● Host reads the register through I2C

● The KP Enable bit is set to ‘0’

— The KP Enable bit is set to ‘0’ automatically after a removal

0h = Default State

1h = Key 2 was released

1 Key 1 Release R 0h This interrupt bit is set after the user has pressed Key 1 on the accessory for a

duration longer than the Key Release De-bounce timer. This bit is used for raw

data release events.

This bit will auto-clear on the following conditions:

● Host reads the register through I2C

● The KP Enable bit is set to ‘0’

— The KP Enable bit is set to ‘0’ automatically after a removal

● The Key 1 Press bit is set to ‘1’

0h = Default State

1h = Key 1 was released

0 Key 1 Press R 0h This interrupt bit is set after the user has pressed Key 1 on the accessory for a

duration longer than the Key Press De-bounce timer. This bit is used for raw data

press events.

This bit will auto-clear on the following conditions:

● Host reads the register through I2C

● The KP Enable bit is set to ‘0’

— The KP Enable bit is set to ‘0’ automatically after a removal

0h = Default State

1h = Key 1 was released

www.ti.com

26 Submit Documentation Feedback Copyright © 2014–2015, Texas Instruments Incorporated

Product Folder Links: TS3A227E

www.ti.com

SCDS358B –NOVEMBER 2014–REVISED FEBRUARY 2015

9.6.4 Interrupt Disable Register Field Descriptions (Address 03h)

Table 4. Interrupt Disable Register Field Descriptions (Address 03h)

Bit Field Type Reset Description

7-3 Reserved R 0h

+3 INT Disable R/W 1h Enables or disables all interrupts. Disabling the interrupts will cause the INT to

2 ADC Conversion R/W 0h Enables or disables the ADC conversion interrupt. Disabling the interrupt will

INT Disable cause INT to not assert but the interrupt bit will still be set .

1 DC INT Disable R/W 0h Enables or disables the DC interrupt. Disabling the interrupt will cause INT to

0 Ins/Rem Event INT R/W 0h Enables or disables the Ins/Rem Event interrupt. Disabling the interrupt will

Disable cause INT to not assert but the interrupt bit will still be set.

not assert but the bits will still populate.

0h = interrupts are enabled

1h = interrupts are disabled

In the use case that this bit is == ‘1’ and a key is pressed, the Key Press

interrupt will still assert the INT pin. If the host issues a software ADC trigger

after the key has been pressed, the interrupt will not assert as that ADC

conversion is the only interrupt present.

0h = ADC Conversion interrupt is enabled

1h = ADC Conversion interrupt is disabled

not assert but the interrupt bit will still be set.

0h = DC interrupt is enabled

1h = DC interrupt is disabled

0h = Ins/Rem Event interrupt is enabled

1h = Ins/Rem Event interrupt is disabled

TS3A227E

9.6.5 Device Settings Field Descriptions (Address 04h)

Table 5. Device Settings Field Descriptions (Address 04h)

Bit Field Type Reset Description

7 Reset R/W 0h Initiates software reset of the TS3A227E. This will interrupt any on-going

6 Manual Switch R/W 0h Enables Manual control of the TS3A227E switches. After enabling manual switch

Control control the switch status will immediately reflect the values in the switch control

5 Auto DET Enable R/W 1h Controls whether detection is automatically ran after an insertion.

4 DET Trigger R/W 0h Manually triggers detection. This bit is auto cleared after detection is completed.

3 FM Support R/W 0h Turns on FM support. This will turn off the depletion FETs if any accessory is

operation internal to the device.

0h = Default state

1h = Initiates a reset

registers provided accessory type.

0h = Manual switch control disabled

1h = Manual switch control enabled

0h = Auto accessory detection is disabled

1h = Auto accessory detection is enabled

A DET Trigger request will be ignored in the following cases:

● A detection event is currently being service.

● The interrupt register is not cleared (Register 02h must be = 00h)

● There is no accessory inserted (/DET_TRIGGER is high)

0h = Default value

1h = Manually trigger detection

inserted allowing FM transmission through the ground FETs at the cost of

increased current consumption.

0h = FM not supported and depletion FETs are on after an insertion

1h = FM supported and depletion FETs are off after an insertion

Copyright © 2014–2015, Texas Instruments Incorporated Submit Documentation Feedback 27

Product Folder Links: TS3A227E

TS3A227E

SCDS358B –NOVEMBER 2014–REVISED FEBRUARY 2015

www.ti.com

Table 5. Device Settings Field Descriptions (Address 04h) (continued)

Bit Field Type Reset Description

2.0 Insertion De-bounce R/W 3h Controls the insertion de-bounce timer. Values below are typical values that have

Time ±30% variation. Values in addition have a ±1 ms variation though this will only

really affect the 2 ms timer.

0h = 2 ms

1h = 30 ms

2h = 60 ms

3h = 90 ms

4h = 120 ms

5h = 150 ms

6h = 1 s

7h = 2 s

9.6.6 Key Press Settings 1 Field Descriptions (Address 05h) Table 6. Device Settings 1 Field Descriptions (Address 05h)

Bit Field Type Reset Description

7-3 Reserved R 0h

2 Key Press Enable R/W 0h Enables the Key Press detection of the TSA227E. This bit auto clears after a

1 Raw Data En R/W 0h Enables the Raw data mode for Key Press Detection. This bit auto clears if the

0 ADC Trigger R/W 0h Causes a manual ADC trigger if the Key Press Enable and Raw Data EN bits are

removal event.

If the Key Press Enable bit is set ‘1’ and the Manual Switch Control bit is set to

‘1’, the S3 matrix must be in one of the two correct position as described in the

Key Press Detection section for the TS3A227E to run key press detection.

0h = Default state

1h = Enables Key Press detection

Key Press Enable bit is set to ‘0’.

Enabling raw data mode will not clear the KP interrupt register. After enabling

Raw Data any key press and release event is recorded using the Key 1 Press

and Key 2 Press Release event. The ADC conversion will be recorded in the

ADC output register.

0h = Raw Data is not enabled

1h = Raw Data is enabled

both set to ‘1’. After the ADC conversion is complete the ADC Conversion

interrupt will be set and the ADC Output register will be populated.

This bit auto clears after the ADC Conversion is complete. A new ADC

Conversion can be initiated even if the ADC Conversion interrupt has not been

serviced.

0h = Default State

1h = Triggers ADC conversion

28 Submit Documentation Feedback Copyright © 2014–2015, Texas Instruments Incorporated

Product Folder Links: TS3A227E

www.ti.com

SCDS358B –NOVEMBER 2014–REVISED FEBRUARY 2015

9.6.7 Key Press Settings 2 Field Descriptions (Address 06h) Table 7. Device Settings 2 Field Descriptions (Address 06h)

Bit Field Type Reset Description

7-6 Reserved R 0h

5-3 MICBIAS Setting R/W 1h This controls the key press threshold. Set this setting closest to the intended

2 Key Release De- R/W 1h Controls the Key-Release de-bounce timer. Values below are typical values that

bounce have ±30% variation. Values in addition have a ±1 ms variation though this will

1-0 Key Press De- R/W 2h Controls the key press de-bounce timer. Values below are typical values that

bounce have ±30% variation. Values in addition have a ±1 ms variation though this will

MICBIAS voltage

0h = 2.1 V

1h = 2.2 V (Default)

2h = 2.3 V

3h = 2.4 V

4h = 2.5 V

5h = 2.6 V

6h = 2.7 V

7h = 2.8 V

only really affect the 2 ms timer.

0h = 2 ms

1h = 20 ms (Default)

only really affect the 2 ms timer.

0h = 2 ms

1h = 40 ms

2h = 80 ms (Default)

3h = 120 ms

TS3A227E

Copyright © 2014–2015, Texas Instruments Incorporated Submit Documentation Feedback 29

Product Folder Links: TS3A227E

TS3A227E

SCDS358B –NOVEMBER 2014–REVISED FEBRUARY 2015

9.6.8 Switch Control 1 Field Descriptions (Address 07h)

Table 8. Switch Control 1 Field Descriptions (Address 07h)

Bit Field Type Reset Description

7-6 Reserved R 0h

5 SLEEVE GNDFET R/W 0h Configures the state of the SLEEVE GNDFET if manual switch control is enabled.

If manual switch control is not enabled this bit is ignored.

0h = SLEEVE GNDFET switch off

1h = SLEEVE GNDFET switch on

4 RING2 DFET R/W 0h Configures the state of the RING2 GNDFET if manual switch control is enabled. If

manual switch control is not enabled this bit is ignored.

0h = RING2 GNDFET switch off

1h = RING2 GNDFET switch on

3 SLEEVE DFET R/W 0h Configures the state of the SLEEVE DFET if manual switch control is enabled. If

manual switch control is not enabled this bit is ignored.

0h = SLEEVE DFET switch off

1h = SLEEVE DFET switch on

2 RING2 DFET R/W 0h Configures the state of the RING2 DFET if manual switch control is enabled. If

manual switch control is not enabled this bit is ignored.

0h = RING2 DFET switch off

1h = RING2 DFET switch on

1 Switch 2 R/W 0h Configures the state of the Switch 2 if manual switch control is enabled. If manual

switch control is not enabled this bit is ignored.

0h = Switch 2 off

1h = Switch 2 on

0 Switch 1 R/W 0h Configures the state of the Switch 1 if manual switch control is enabled. If manual

switch control is not enabled this bit is ignored.

0h = Switch 1 off

1h = Switch 1 on

www.ti.com

9.6.9 Switch Control 2 Field Descriptions (Address 08h)

Table 9. Switch Control 2 Field Descriptions (Address 08h)

Bit Field Type Reset Description

7-4 Reserved R 0h

3 S3PS R/W 0h Configures the state of the S3PS if manual switch control is enabled. If manual

2 S3PR R/W 0h Configures the state of the S3PR if manual switch control is enabled. If manual

1 S3GS R/W 0h Configures the state of the S3GS if manual switch control is enabled. If manual

0 S3GR R/W 0h Configures the state of the S3GR if manual switch control is enabled. If manual

switch control is not enabled this bit is ignored.

0h = S3PS switch off

1h = S3PS switch on

switch control is not enabled this bit is ignored.

0h = S3PR switch off

1h = S3PR switch on

switch control is not enabled this bit is ignored.

0h = S3GS off

1h = S3GS on

switch control is not enabled this bit is ignored.

0h = S3GR off

1h = S3GR on

30 Submit Documentation Feedback Copyright © 2014–2015, Texas Instruments Incorporated

Product Folder Links: TS3A227E

www.ti.com

SCDS358B –NOVEMBER 2014–REVISED FEBRUARY 2015

9.6.10 Switch Status 1 Field Descriptions (Address 09h)

Table 10. Switch Status 1 Field Descriptions (Address 09h)

Bit Field Type Reset Description

7-6 Reserved R 0h

5 SLEEVE GNDFET R 0h Indicates the status of SLEEVE GNDFET

0h = SLEEVE GNDFET switch is off

1h = SLEEVE GNDFET switch is on

4 RING2 GNDFET R 0h Indicates the status of RING2 GNDFET

0h = RING2 GNDFET switch is off

1h = RING2 GNDFET switch is on

3 SLEEVE DFET R 1h Indicates the status of SLEEVE DFET

0h = SLEEVE DFET switch is off

1h = SLEEVE DFET switch is on

2 RING2 DFET R 1h Indicates the status of RING2 DFET

0h = RING2 DFET switch is off

1h = RING2 DFET switch is on

1 Switch 2 R 0h Indicates the status of Switch 2

0h = Switch 2 is off

1h = Switch 2 is on

0 Switch 1 R 0h Indicates the status of Switch 1

0h = Switch 1 is off

1h = Switch 1 is on

TS3A227E

9.6.11 Switch Status 2 Field Descriptions (Address 0Ah)

Table 11. Switch Status 2 Field Descriptions (Address 0Ah)

Bit Field Type Reset Description

7-4 Reserved R 0h

3 S3PS R 0h Indicates the status of S3PS

0h = S3PS switch is off

1h = S3PS switch is on

2 S3PR R 0h Indicates the status of S3PR

0h = S3PR switch is off

1h = S3PR switch is on

1 S3GS R 0h Indicates the status of S3GS

0h = S3GS is off

1h = S3GS is on

0 S3GR R 0h Indicates the status of S3GR

0h = S3GR is off

1h = S3GR is on

Copyright © 2014–2015, Texas Instruments Incorporated Submit Documentation Feedback 31

Product Folder Links: TS3A227E

TS3A227E

SCDS358B –NOVEMBER 2014–REVISED FEBRUARY 2015

9.6.12 Detection Results Field Descriptions (Address 0Bh)

Table 12. Detection Results Field Descriptions (Address 0Bh)

Bit Field Type Reset Description

7-4 Reserved R 0h

3 Insertion Status R 0h Indicates if an accessory is inserted the jack or not. This bit is set to the

corresponding state after an accessory is inserted or removed and should be

read after the Ins/Rem Event interrupt has been set to ‘1’.

0h = An accessory is not in the jack

1h = An accessory is in the jack

2 4-pole Standard R 0h Indicates if a 4-pole Standard headset is detected. Bit is set after a completed

detection sequence.

0h = Default state

1h = 4-pole standard headset detected

1 4-pole OMTP R 0h Indicates if a 4-pole OMTP headset is detected. Bit is set after a completed

detection sequence.

0h = Default state

1h = 4-pole OMTP headset detected

0 3-pole R 0h Indicates if a 3-pole headphone is detected. Bit is set after a completed

detection sequence.

0h = Default state

1h = 3-pole headphone detected

9.6.13 ADC Output Field Descriptions (Address 0Ch)

www.ti.com

Table 13. ADC Output Field Descriptions (Address 0Ch)

Bit Field Type Reset Description

7-1 ADC R/W 00h

0 Reserved R 0h

This field contains the output of the key press detection ADC as described in

the key press detection register

9.6.14 Threshold 1 Field Descriptions (Address 0Dh)

Table 14. Threshold 1 Field Descriptions (Address 0Dh)

Bit Field Type Reset Description

7-01 KP Threshold 1 R/W 20h

0 Reserved R 0h

This field sets the key 1 and key 2 boundary threshold. This value must always

be lower than the Threshold 2 register for proper operation.

9.6.15 Threshold 2 Field Descriptions (Address 0Eh)

Table 15. Threshold 2 Field Descriptions (Address 0Eh)

Bit Field Type Reset Description

7-1 KP Threshold 2 R/W 40h always be lower than the Threshold 3 register and higher than the threshold 2

0 Reserved R 0h

This field sets the key 2 and key 3 boundary threshold. This value must

register for proper operation.

9.6.16 Threshold 3 Field Descriptions (Address 0Fh)

Table 16. Threshold 3 Field Descriptions (Address 0Fh)

Bit Field Type Reset Description

7-1 KP Threshold 3 R/W 68h

0 Reserved R 0h

32 Submit Documentation Feedback Copyright © 2014–2015, Texas Instruments Incorporated

Product Folder Links: TS3A227E

This field sets the key 3 and key 4 boundary threshold. This value must

always be higher than the Threshold 2 register for proper operation.

4

16

9

3

13

6

5

1 2

11

10

12

8

7

14

15

MIC_PRESENT

SCL

SDA

INT

MICP

GND_SENSE

VDD

RING 2_SENSE

SLEEVE_SENSE

TIP

DET_TRIGGER

RING2

SLEEVE

GND

GNDA

GND

L1

C4

FM Network

R5

R6

C3

GND_SENSE

MICI

MICBIAS

Application

Processor

C1 C2

3.3 V

R4

R1

R2

R3

TS3A227ERVAR

TS3A227E

www.ti.com

SCDS358B –NOVEMBER 2014–REVISED FEBRUARY 2015

10 Application and Implementation

10.1 Application Information

Figure 19 shows how a standard application schematic for the TS3A227E. The DSBGA package pin connections

will be the same except for the lack of thermal pad. The following sections discuss how the TS3A227E works

with different headsets and how the key press detection operates.

10.2 Typical Application

Figure 19. Typical Application Schematic

Table 17. Component List

COMPONENT VALUE NOTES

R1 4.7 kΩ Pullup resistor must be sized to not exceed max IOL specification for INT pin

R2 4.7 kΩ Pullup resistor must be sized to not exceed max IOL specification for INT pin

R3 4.7 kΩ Pullup resistor must be sized to not exceed max IOL specification for INT pin

R4 4.7 kΩ Pullup resistor must be sized to not exceed max IOL specification for INT pin

R5 10 kΩ Pulldown resistor for high to low transition on DET_TRIGGER

R6 2.2 kΩ ±1% MICBIAS pullup resistor must be ±1% for Key Press Detection to function properly

C1 10 µF De-coupling capacitor for V

C2 100 nF De-coupling capacitor for V

C3 1 µF Value can vary depending on codec needs

C4 47 nF

L1 180 nF

10.2.1 Design Requirements

10.2.1.1 Standard I2C Interface Details

The bi-directional I2C bus consists of the serial clock (SCL) and serial data (SDA) lines. Both lines must be

connected to a positive supply via a pull-up resistor when connected to the output stages of a device. Data

transfer may be initiated only when the bus is not busy.

Copyright © 2014–2015, Texas Instruments Incorporated Submit Documentation Feedback 33

Value can vary depending on FM matching network needs. If FM transmission is not being

supported by the application this capacitor is not needed

Value can vary depending on FM matching network needs. If FM transmission is not being

supported by the application this inductor is not needed and GNDA must be shorted to GND

Product Folder Links: TS3A227E

DD

DD

ST A6 A5 A4 A3 A2 A1 A0 0

START R/W

ACK From slave

A 0 0 0 0 0 0 0 0 A

Auto Increment

Register Address N

Slave Address Sub Address

ACK From slave

D7 D6 D5 D4 D3 D2 D1 D0 A

Data to Register N

Data Byte

ACK From slave

D7 D6 D5 D4 D3 D2 D1 D0 A

Data to Register N

Data Byte

ACK From slave

SP

STOP

1 2 8 9

Clock pulse for

acknowledgment

SCL

ST

Start

Condition

SDA Output

by

Transmitter

SDA Output

by Receiver

NACK

ACK

TS3A227E

SCDS358B –NOVEMBER 2014–REVISED FEBRUARY 2015

www.ti.com

I2C communication with this device is initiated by the master sending a START condition, a high-to-low transition

on the SDA line while the SCL line is high. After the start condition, the device address byte is send, MSB first,

including the data direction bit (R/W). This device does not respond to the general call address. After receiving

the valid address byte (0x77 read, 0x76 write), this device responds with an ACK, a low on the SDA line during

the high of the ACK-related clock pulse.

The data byte follows the address ACK. The R/W bit is kept low for transfer from the master to the slave. The

data byte is followed by an ACK sent from this device. Data are output only if complete bytes are received and

acknowledged. The output data is valid at time (tpv) after the low-to-high transition of SCL, during the clock cycle

for the ACK.

On the I2C bus, only one data bit is transferred during each clock pulse. The data on the SDA line must remain

stable during the high pulse of the clock period, as changes in the data line at this time are interpreted as control

commands (START or STOP).

A Stop condition, a low-to-high transition on the SDA line while the SCL line is high, is sent by the master. The

number of data bytes transferred between the start and the stop conditions from the transmitter to receiver is not

limited. Each byte of eight bits is followed by one ACK bit. The transmitter must release the SDA line before the

receiver can send an ACK bit.

A slave receiver that is addressed must generate an ACK after the reception of each byte. The device that

acknowledges has to pull down the SDA line during the ACK clock pulse so that the SDA line is stable low during

the high pulse of the ACK-related clock period. Setup and fold times must be taken into account.

10.2.1.2 Write Operations

Data is transmitted to the TS3A227E by send the device salve address and setting the LSB to a logic 0. The

command byte is sent after the address and determines which register receives the data that follows the

command byte. The next byte is written to the specified register on the rising edge of the ACK clock pulse. See

Figure 2 and Figure 3 for different modes of write operations.

34 Submit Documentation Feedback Copyright © 2014–2015, Texas Instruments Incorporated

Figure 20. Acknowledgment on the I2C Bus

Figure 21. Repeated Data Write to a Single Register

Product Folder Links: TS3A227E

ST A6 A5 A4 A3 A2 A1 A0 0

START

R/W

ACK From slave

A 0 0 0 0 0 0 0 0 A

Auto Increment

Register Address N

Slave Address Sub Address

ACK From slave

RS

Re-start

A6 A5 A4 A3 A2 A1 A0 1

R/W

ACK From slave

A

Slave Address

D7 D6 D5 D 4 D 3 D 2 D 1 D 0 A

Data from Register N

Data Byte

ACK From master

D7 D6 D5 D 4 D 3 D 2 D 1 D 0 A

Data from Register N

Data Byte

ACK From master

D7 D6 D5 D 4 D 3 D 2 D 1 D 0 NA

Data from Register N

Data Byte

NACK From master

SP

Stop

TS3A227E

www.ti.com

SCDS358B –NOVEMBER 2014–REVISED FEBRUARY 2015

Figure 22. Burst Data Write to Multiple Registers

10.2.1.3 Read Operations

The bus master must send the TS3A227E slave address with the LSB set to logic 0. The command byte is sent

after the address and determines which register is accessed. After a restart, the device slave address is sent

again but this time the LSB is set to logic 1. Data from the register defined by the command byte then is sent

back to the host by the TS3A227E. Data is clicked into the SDA output shift register on the rising edge of the

ACK clock pulse. Figure 23 and Figure 24 show read operations that use a restart between the sub-address

write and the read operation. A Stop and start condition between the sub-address write and the read operation is

also acceptable.

Notes:

1. SDA is pulled low on ACK from the slave or master.

2. Register write always a require sub-address write before writing the first data.

3. Repeated data writes to a single register continue indefinitely until n I2C Stop or Re-start.

4. Repeated data reads from a single register continue indefinitely until an I2C NACK is received from the

master

5. Burst data writes start at the specified register address, then advance to the next register address, even

to the read-only registers and continue until the Stop or Re-start. For the read-only registers, data write

appears to occur, although the register contents are not changed by the write operations.

6. Burst data reads start at the specified register address, then advance to the next register address and

continues until an I2C NACK is received from the master.

Copyright © 2014–2015, Texas Instruments Incorporated Submit Documentation Feedback 35

Figure 23. Repeated Data Read From a Single Register

Product Folder Links: TS3A227E

TS3A227 E

MICP

GND_SENSE

S3PR

RING 2

SLEEVE

S3PS

S3GS

S3GR

S1 S2

RING2

GNDFET

SLEEVE

GNDFET

RING2

DFET

SLEEVE

DFET

GND GNDGNDA

Audio Jack

RING1

TIP

L R ? ?

DET_TRIGGER

High to Low

VDD

ST A6 A5 A4 A3 A2 A1 A0 0

START

R/W

ACK From slave

A 0 0 0 0 0 0 0 0 A

Auto Increment

Register Address N

Slave Address Sub Address

ACK From slave

RS

Re-start

A6 A5 A4 A3 A2 A1 A0 1

R/W

ACK From slave

A

Slave Address

D7 D6 D5 D 4 D 3 D 2 D 1 D 0 A

Data from Register N

Data Byte

ACK From master

D7 D6 D5 D 4 D 3 D 2 D 1 D 0 A

Data from Register N

Data Byte

ACK From master

D7 D6 D5 D 4 D 3 D 2 D 1 D 0 NA

Data from Register N

Data Byte

NACK From master

SP

Stop

TS3A227E

SCDS358B –NOVEMBER 2014–REVISED FEBRUARY 2015