Page 1

TEXAS ELECTRONICS, INC.

COMPLETE WEATHER STATION

USER’S MANUAL

5529 Redfield St. Dallas, TX 75235 P.O. Box 7225 Dallas, TX 75209

Phone (214) 631-2490 Fax (214) 631-4218 Toll Free (800) 424-5651

Page 2

SERIES 525 RAINFALL SENSORS

DESCRIPTION

The sensor consists of a gold anodized aluminum collector funnel with a knife-edge that diverts the water to a

tipping bucket mechanism. The models TR-525I and TR-525USW are calibrated in inches (.01” per tip) and

model TR-525M is calibrated in millimeters (.1mm per tip). A magnet is attached to the tipping bucket, which,

as the bucket tips, actuates a magnetic switch. Thus, a momentary switch closure takes place with each tip of

the bucket. Connecting the sensor to an event counter on an electronic datalogger or display module will allow

record keeping of accumulated rainfall. If an analog signal representing rainfall accumulation is required,

Texas Electronics, Inc. manufactures a suitable conditioning circuit.

The spent water drains out of the bottom of the housing; hence, the sensor requires no attention or servicing of

any sort. It is completely automatic. The aluminum sensor housing is finished with a white baked enamel paint

to withstand years of exposure to the environment.

SPECIFICATIONS

Resolution: 0.01” or 0.1 mm

Accuracy:

English

Metric

Average Switch Closure Time: 135 ms

Maximum Bounce Settling Time: 0.75 ms

Maximum Switch Rating: 30 VDC @ 2 A, 115 VAC @ 1 A

Temperature Limits: +32°F to +125°F

Humidity Limits: 0 to 100%

Height: 10.125”

Weight: 2.5 pounds

Receiving Orifice Diameter:

Cable: 25 feet, 2-conductor

Installation: Consists of attaching the three sensor support legs to a firm

Maintenance:

Warranty: Three Years

1.0% at 1”/hr or less

1.0% at 10 mm/hr or less

6.060” (English)

9.664” (Metric)

8.000” USW (English)

platform or securing the side bracket to a stable vertical structure

such as the lower end of weather station mast. Sensor cable is then

connected to monitoring equipment.

Occasional cleaning of debris from filter screen may be required.

Page 3

ORDERING INFORMATION

Model # Description

TR-525I Rain Gauge, 6.06” collector, English

(Please specify for calibration of 0.2 mm/tip)

TR-525USW Rain Gauge, 8.00” collector, English

TR-525M Rain Gauge, 25 mm collector, Metric

Optional Parts / Accessories

HOBO Event Datalogger and Software

MB-525 Pole Mounting Base

FC-525 Field Calibration Kit

BB-525 Bird Repellant

HT-525 Heater, 120 VAC

Cable Additional Cable

Page 4

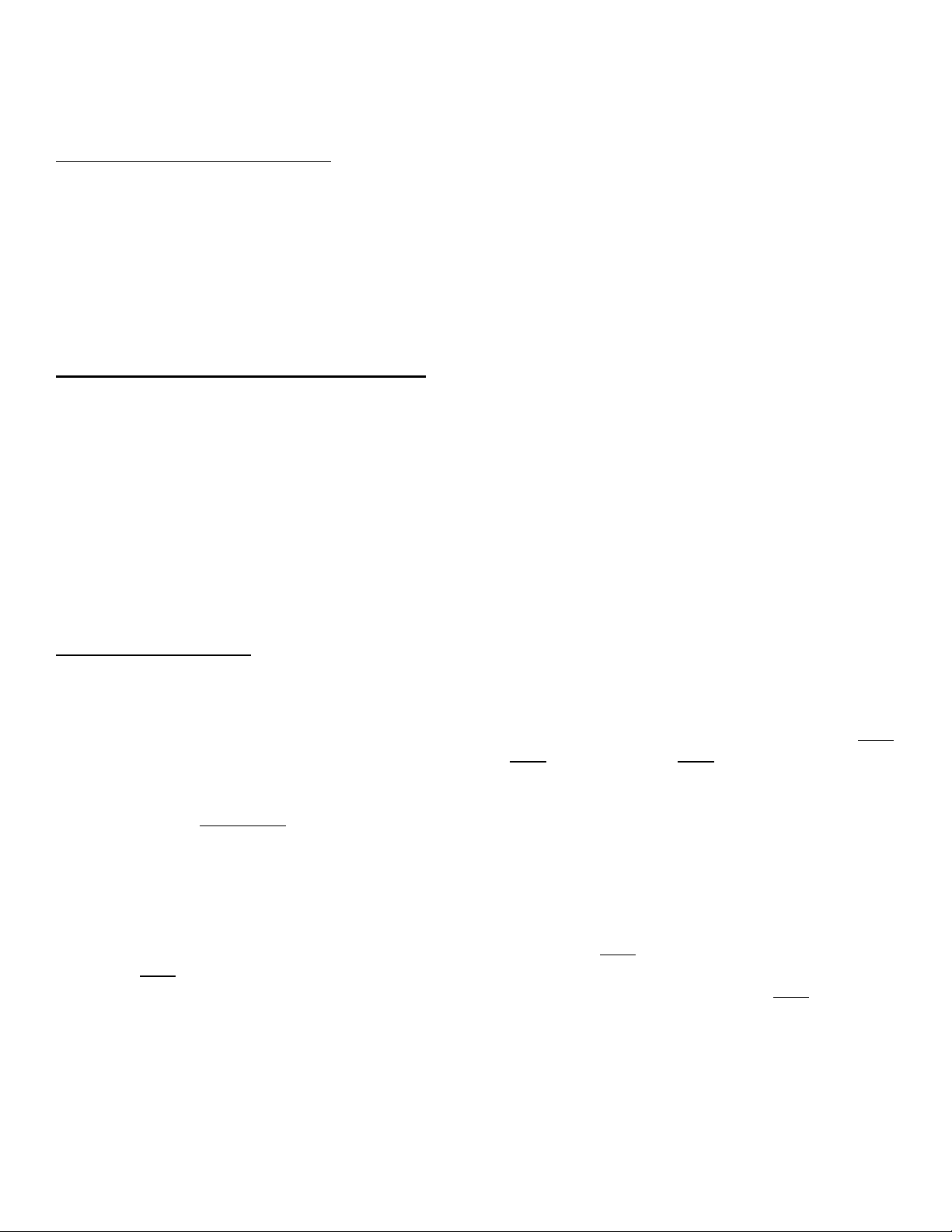

MODEL 525

TIPPING BUCKET RAIN GAUGE TRANSMITTER

INSTALLATION INSTRUCTIONS

A clear and unobstructed mounting location is necessary to obtain accurate rainfall readings.

This transmitter has provisions for mounting two ways, surface mounting and mast mounting. Surface

mounting is recommended where possible. The transmitter housing MUST be mounted in a LEVEL position

and in a location free from vibration. If mast mounted, make sure that the mast is properly guyed so that

vibration in high winds is kept to a minimum.

THE FOLLOWING IS VERY IMPORTANT:

After the final transmitter installation has been made, remove the top gold funnel portion of the transmitter and

observe the black tipping bucket. It should NOT (repeat NOT) be held in a dead center position by the

magnetic attraction of the bucket magnet and the hermetically sealed magnetic switch. Press either end of the

bucket down against the stop to be sure that it is not centered.

The transmitter to indicator connecting cable may be either shortened or lengthened as required.

The funnel and tipping bucket mechanism should be cleaned periodically. An accumulation of dirt, bugs, etc.

on the tipping bucket will adversely affect the calibration.

FIELD CALIBRATION

TR-525USW

Absolutely accurate calibration can be obtained only with laboratory equipment, but an approximate field check

can be easily made. The tipping bucket mechanism is a simple and highly reliable device. The transmitter must

be located in a clear area, away from trees, buildings, etc. It must also be mounted level. Accurate readings

will not be obtained unless the transmitter is mounted in a level position. The mechanism must be clean. Any

accumulation of foreign material, dust, etc. will alter the calibration of this unit. The transmitter must be

calibrated with the rate of flow of water through the tipping bucket mechanism under control. At least 36

seconds should be allowed to fill one side of the tipping bucket. This represents a maximum flow rate of on

inch of rain per hour. If the flow rate is increased, then the instrument will read low (if properly calibrated).

Decreasing the rate of flow will not materially affect the calibration. The reason for this is obvious if the

tipping bucket assembly is observed when the weight if this water starts to tip the bucket. Some time is

required for the bucket to tip (a few milliseconds). During the first 50% of this time, water flows into the empty

bucket. The amount of water flowing during the first 50% of the time is error, the faster the flow rate, the

greater the error. Now at flow rates of one inch per hour (100 bucket fillings) or less, the water actually drips

into the bucket rather than flowing. Under this condition, the bucket tips between drips, and no error water is

added to a full moving bucket.

TO CHECK CALIBRATION:

A field calibration kit is available from Texas Electronics, Inc. Model No. FC-525 is a kit that consists of a

holding tank, pre-measured beaker, two orifices, cleaning tools and instructions.

Page 5

FIELD CALIBRATION

TR-525I & TR-525M

Absolutely accurate calibration can be obtained only with laboratory equipment, but an approximate field check

can be easily made. The tipping bucket mechanism is a simple and highly reliable device. The transmitter must

be located in a clear area, away from trees, buildings, etc. It must also be mounted level. Accurate readings

will not be obtained unless the transmitter is mounted in a level position. The mechanism must be clean. Any

accumulation of foreign material, dust, etc. will alter the calibration of this unit. The transmitter must be

calibrated with the rate of flow of water through the tipping bucket mechanism under control. At least 36

seconds should be allowed to fill one side of the tipping bucket. This represents a maximum flow rate of on

inch of rain per hour. If the flow rate is increased, then the instrument will read low (if properly calibrated).

Decreasing the rate of flow will not materially affect the calibration. The reason for this is obvious if the

tipping bucket assembly is observed in operation…with water falling into one side of the tipping bucket, there

comes a point when the weight of this water starts to tip the bucket. Some time is required for the bucket to tip

(a few milliseconds). During the first 50% of this tipping time, water continues to flow into the filled bucket;

the last 50% of this tipping time, water flows into the empty bucket. The amount of water flowing during the

first 50% of the time is error, the faster the flow rate the greater the error. Now at flow rates of one inch per

hour (100 bucket fillings) or less, the water actually drips into the bucket rather than flowing. Under this

condition, the bucket tips between drips, and no error water is added to a full moving bucket.

TO CHECK CALIBRATION:

A field calibration kit is available from Texas Electronics, Inc. Model No. FC-525 is a kit that consists of a

holding tank, pre-measured beaker, two orifices, cleaning tools and instructions.

Page 6

04°F / 0.2°C

MODEL TTH-1315 TEMPERATURE HUMIDITY SENSOR

DESCRIPTION

The Texas Electronics, Inc. Model TTH-1315 Sensor utilized a Rotronics HygroClip S3 Humidity Temperature

Probe with interchangeable sensing elements that do not require calibration.

The unit is encased in a corrosive-resistant spun aluminum radiation shield that allows for wind aspiration and

protection from the sun's UV rays. The shield is finished in white baked-enamel to provide for virtual cosmetic

invisibility while reflecting much of the radiant heat from surrounding objects and the sun.

Overcurrent protection is provided in a NEMA 4X enclosure that is mounted to the angled mounting bracket on

the sensor. Tranzorbs are utilized to protect the sensor and signal conditioning units in an overcurrent situation.

With DC voltage applied to the sensor, the unit will return signal voltages that are linear to the range of the

instrument. Signal conditioning is applied to ensure proper voltages are returned and can be amplified or

modified to a current output to connect to any analog signal processing unit.

SPECIFICATIONS

Humidity Sensor: ROTRONIC HygromerÒ C94

(capacitive)

Temperature Sensor:

Sensor Protection: Wire Mesh filter (standard) /

Measuring Range: 0-100 % Relative Humidity

Operating Limits: Same as measuring range

RTD Pt100 Ohm, 1/3 DIN

foam filter (optional)

-40° to +140°F (-40° to +60°C)

Temperature

Accuracy at

73°F / 23°C:

Repeatability: Better than 0.5% RH and 0.1°C/

Analog output signals: 0…100% RH = 0…1V

+/- 1.5% RH and +/- 0.5°F /

0.3°C - standard calibration

+/- 1.0% RH and +/-

- special calibration (optional)

32.18°F

(minimum load >10k ohm)-

40…+140°F = 0…1V (-

40…+60°C)

Analog Signal Resolution 0.02%

RH and 0.1°F

Page 7

Sampling Time: <0.7 sec

Maximum cable length: 5 m / 15 ft. for direct output

Up to 100 m / 325 ft. with signal

amplifier

Connection Type:

Protection grade: IP65 (probe to connector)

Supply voltage: 3.5 … 50VDC

Current consumption: <4 mA

Minimum excitation time: <4 sec

EMC compatibility (CE): EN-50081-2, EN-50082-2

Material: Polycarbonate, white

Dimensions:

Weight: 14 g / 0.5 oz.

Bayonet cap on mounting

connector

Length: 100 mm (3.94")

Diameter: 15 mm (0.59")

FEATURES & BENEFITS

• Combines Temperature and Humidity onto one sensing unit

• Rotronics HygroClip S3 has interchangeable sensing elements requiring no calibration

• Stacked plate construction of shelter provides natural ventilation

• Quick-Release mounting bracket allows for easy installation and maintenance

• Aluminum radiation shield is lightweight and extremely durable

• White baked-enamel finish reflects most radiant heat from sun and surrounding objects

INSTALLATION & MAINTENANCE

The radiation shield with sensing element can be pole or mast mounted. Whenever possible, sensors should be

installed at a height of 4 ft. (1.2 meters) or greater over earth or sod at least 100 ft. (30.48 meters) away from

any concrete or other hard-surfaced area and not closer to any other object than four times the height of the

object above the instrument shelter or remote sensors. Avoid roof installations if possible. If it is necessary to

roof-mount shelters and sensors, they should not be closer than 30 ft. (9.14 meters) to any large, vertical

reflecting surface (walls, etc.), exhaust fans, or cooling towers. Electronic remote sensors when roof-mounted

should be at least 9 ft. (2.74 meters) or greater above the roof surface. To minimize radiation effects from the

roof, they can also be mounted on a horizontal boom so that they will extend from the side of the building roof

or tower assembly.

ORDERING INFORMATION

Model # Description

TTH-1315 Temperature & Humidity Sensor

TTH-1315A Temperature & Humidity Sensor, 4-20 Ma

Optional Parts / Accessories

H50 Interior Humidity Sensing element only

Cable Additional Cable

Page 8

MODEL TD-4 WIND DIRECTION SENSOR

DESCRIPTION

The Texas Electronics, Inc. TD-4 Wind Direction Sensor is a mechanical style wind meter that measures the

horizontal wind azimuth. This unit combines small physical size with superior bearings to meet the EPA's

Prevention of Significant Deterioration (PSD) starting threshold requirements.

The TD-4 wind direction sensor is a freestanding device for measuring the direction of wind. The sensor

consists of a vane and counterweight assembly, which is mechanically coupled to a potentiometer (variable

resistor). As the vane rotates in the wind, the potentiometer changes resistance proportionally to the direction of

wind.

SPECIFICATIONS

Operating Range: 0-360° mechanical

Signal Presentation: 5000 ohm potentiometer,

10000 ohm potentiometer, or

Analog 4-20 mA

5000 ohm output:

10000 ohm output: 0-357° electrical range

Analog 4-20 mA output: 0-355° electrical range

Performance:

Accuracy: +/- 3.0°

Starting Threshold: 0.6 mph (0.27 m/s)

Resolution: 1°

Potentiometer Linearity: +/- 1.0%

Environmental:

Operational Envelope: 0-135 mph (0 to 60 m/s)

Temperature: -40 to 160° F (-40 to 70° C)

Relative Humidity: 0-100%

Physical:

Vane Overall Length: 8.5" (21.6 cm)

Overall Height: 6.75" (17.2 cm)

Turning Radius: 13" (33 cm)

Weight: 0.5 lbs (0.23 kg) less cable

Bearings: APEC 3 or better

Mounting Base: Screw attachment, 10-32 machine

Cable: 60' (18.3 m) 3 conductor 22 gauge

Warranty: 3 year

0-355° electrical range

3 VDC excitation minimum

3 VDC excitation minimum

10-30 VDC

screw

Page 9

FEATURES & BENEFITS

• Superior low starting threshold

• Long life hybrid dual wiper potentiometer

• No plastic parts for extremely long life

• Precision stainless steel bearings for stability and repeatability

• Crossarm included with purchase of matching wind speed sensor

• Easy installation and maintenance

• Over 25 years in production

• Lightweight and rugged anodized aluminum exterior

INSTALLATION & MAINTENANCE

Installation consists of threading the 10-32 mounting base into our crossarm or any other suitable beam. If a

crossarm is used, the entire unit can be bolted to a mast or attached via U-bolts.

The sensor is dynamically calibrated at the factory and due to the nature of its operation should not require field

calibration. Calibration is a matter of proper orientation during installation. A magnetic compass is

recommended for proper orientation. Field maintenance should include occasional cleaning of the vane

assembly and inspection of the internal mechanism to make sure it is free from insects and debris. In some

applications users may need to occasionally verify and document sensor accuracy with a calibration dial/vane.

Possible bearing and potentiometer replacement every three to five years to maintain low starting threshold.

ORDERING INFORMATION

Model # Description

TD-4 Wind Direction Sensor, Light Industrial

TD-410 Wind Direction Sensor, Light, 10K

TD-4A Wind Direction Sensor, Light, 4-20 mA

*

Sensor is designed to work with TV-4 series wind speed sensors.

Optional Parts / Accessories

Cable Additional Cable

Page 10

MODEL TV-4 WIND SPEED SENSOR

DESCRIPTION

The Texas Electronics, Inc. TV-4 Wind Speed Sensor is a mechanical style anemometer that measures the

horizontal velocity of wind. This unit combines small physical size with superior bearings to meet the EPA's

Prevention of Significant Deterioration (PSD) starting threshold requirements.

The TV-4 wind speed sensor is a freestanding device for measuring air velocity. The sensor consists of a

lightweight 3-cup anemometer, which electromechanically converts wind speed into a measurable electronic

signal.

The output signal can be presented in 3 optional forms: a pulsed DC signal, an AC frequency, or a conditioned

analog signal. Each output has a specific application. The pulsed DC signal is used where high-accuracy is

needed and continuous power is not a problem. The AC frequency output is used in situations where power

consumption is critical. And finally, the conditioned analog signal is used to easily and quickly communicate

with virtually all digital control systems such as PLC's or SCADA systems.

SPECIFICATIONS

Operating Range: 0-100 mph

Signal Presentation: Pulsed DC output - light chopper

AC Frequency, or Analog, 4-20 mA

(Please specify)

Pulsed DC output: 20-slot disc

1 MPH = 520 pulses/min.

100 MPH = 52000 pulses/min.

AC Frequency output: 26 mV/MPH (typical)

0.133 Hz/MPH

Analog 4-20 mA out: 4 mA = 0 MPH

20 mA = 100 MPH

Performance:

Accuracy: +/- 2.0 mph (0.89 m/s)

Distance Constant: > 21.7' (6.6 m)

Starting Threshold: 0.6 mph (0.27 m/s)

Environmental:

Operational Envelope: 0-135 mph (0 to 60 m/s)

Temperature: -40 to 160° F (-40 to 70° C)

Relative Humidity: 0-100%

Input Power: +5.0 VDC @ 5mA (typical)

(Other voltages available upon request)

Input Power: None (self-generating)

Input Power: 10-36 VDC

Page 11

Physical:

Cup Wheel Diameter: 6.0" (15.3 cm)

Overall Height: 4.75" (12.1 cm)

Turning Radius: 3.0" (7.6 cm)

Cup Diameter: 2.0" (5.1 cm)

Bearings: APEC 3 or better

Mounting Base: Screw attachment, 10-32 machine screw

Weight: 0.5 lbs (0.23 kg) less cable

Cable: 60' (18.3 m) 3 conductor 22 gauge

Warranty: 3 year

FEATURES & BENEFITS

• Superior low starting threshold due to small physical size

• No plastic parts for extremely long life

• Precision stainless steel bearings for stability and repeatability

• Crossarm included with purchase of matching wind direction sensor

• Easy installation and maintenance

• Over 5 years in production

• Lightweight and rugged anodized aluminum exterior

INSTALLATION & MAINTENANCE

Installation consists of threading the 10-32 mounting base into our crossarm or any other suitable beam. If a

crossarm is used, the entire unit can be bolted to a mast or attached via U-bolts.

The sensor is dynamically calibrated at the factory and due to the nature of its operation should not require field

calibration. Field maintenance should include occasional cleaning of the cup assembly and inspection of the

internal mechanism to make sure it is free from insects and debris. In some applications users may need to

occasionally verify and document sensor accuracy with a synchronous test motor. Other possible routine

maintenance is to replace the bearing housing assembly every three to five years to maintain low starting

threshold.

ORDERING INFORMATION

Model # Description

TV-4 Wind Speed Sensor, Light Industrial

(Specify supply voltages other than 5 VDC)

TV-4AC Wind Speed Sensor, AC Generator

TV-4A Wind Speed Sensor, Analog 4-20 mA

*Sensor is designed to work with TD-4 wind direction sensor.

Optional Parts / Accessories

Cable Additional Cable

Page 12

Non

MODEL SP-LITE SOLAR RADIATION SENSOR

DESCRIPTION

The Texas Electronics, Inc. SP-Lite Solar Radiation Sensor utilizes a Kipp & Zonen Silicon pyranometer

mounted in a white baked-enamel finished aluminum bracket that provides a stable upward-facing installation.

It measures the solar energy that is received from the entire hemisphere (180 degrees field of view). The output

is expressed in Watts per square meter.

The pyranometer is designed for continuous outdoor use. Its calibration is valid for natural sunlight only, but

not for artificial light. In its most frequent application, the pyranometer is used for measuring the solar radiation

emitting on the horizontal surface.

The sensor consists of a photodiode; housing, mounting bracket with cable junction box attached, and cable. A

resistance shunts the photodiode. This is done to generate a voltage output. The photodiode and the material on

top of it determine most electrical specifications. It is encapsulated in the housing in such a way that it has a

field of view of 180 degrees and that its angular characteristics fulfill the "Cosine Response".

The nominal output resistance of the pyranometer is 50 Watts. This implies that the input impedance of the

readout equipment should be at least 5000 Ohms in order to make an error of less than 0.1%.

Cable can be extended without problems to a length of 328 ft. or 100 meters, provided that cable resistance is

less than 0.1% of the input impedance of the readout equipment.

The electrical sensitivity of the photodiode changes with the temperature. A nominal value for this is 0.2%

change per degree Celsius. Calibration is done at 20°C (68°F).

SPECIFICATIONS

Electrical: Impedance (nominal): 50 Ohms

Response time: < 1 sec.

Sensitivity (nominal): 100 uV/W/m2

Expected signal range under atmospheric conditions: 0 to 0.2V

Stability: <+/- 2% per year

-linearity: < 1% up to 1000 W/m2

Temperature dependence of sensitivity: +/- 0.15%/°C

Spectral: Spectral range: 0.4 to 1.1 nm

Detector type: SILICON photo diode

Directional: Cosine corrected between 80° angle of incidence, error: within +/- 10%

Cosine errors averaged over opposite azimuth error (at 60° angle of

incidence): within +/- 10%

Tilt response: no error

Page 13

Mechanical: Material of housing: Anodized aluminum contained in white baked-

enamel finished aluminum mounting bracket

Cable length: 60 ft.

Dimensions: Height from surface to top of level Pyranometer - - 6.25"

(15.87 cm)

Width - 2.75 " (6.98 cm)

Length - 8.25 " (20.95 cm)

Weight: 3 lbs. (1.36 kg.) with 60 ft. cable

Environmental:

Cable:

Warranty:

Working temperature range - -30° to +70°C (-22° to +158°F)

60 ft. (18.28 meters)

3 year

FEATURES & BENEFITS

• SP-Lite is an all-weather instrument

• Designed for continuous outdoor use

• Complies with "Cosine Response"

• Full 180-degree field of view for complete hemispheric measurement

• Contained in lightweight and rugged white baked-enamel finished aluminum mounting bracket

INSTALLATION & MAINTENANCE

Installation:

The site for an upward-facing pyranometer should be free from any significant obstructions above the plane of

the sensing element and should be readily accessible. If practicable, instrument should be located so that (1.) a

shadow will not be cast on it at any time (e.g. by radio masts, etc.); (2.) it is not close to light-colored walls or

other objects likely to reflect sunlight onto it; and (3.) it is not exposed to artificial radiation sources. A flat roof

provides the best location, or a rigid stand with a horizontal upper surface some distance from building

structures or other obstructions. The stand should be sufficiently rigid that the horizontal position of the

receiving surface does not change, especially during high winds. Precautions should be taken to avoid

subjecting the instrument to severe shocks or vibration.

Calibration / Cleaning Frequency:

Recalibration is suggested every two years, preferably by letting a higher standard run parallel during two sunny

days and comparing daily totals.

The sensor should be kept clean, using water or alcohol.

ORDERING INFORMATION

Model # Description

SP-Lite Solar Radiation Sensor

SP-Lite-A Solar Radiation Sensor, 4-20 mA

Optional Parts / Accessories

Cable Additional Cable available upon request

Page 14

Texas Electronics, Inc.

Texas Electronics, Inc.

Texas Electronics, Inc.Texas Electronics, Inc.

5529 Redfield St.

5529 Redfield St.

5529 Redfield St.5529 Redfield St.

Dallas, Tx 75235

Dallas, Tx 75235

Dallas, Tx 75235Dallas, Tx 75235

Model TB-2012M Barometer

Model TB-2012M Barometer

Model TB-2012M BarometerModel TB-2012M Barometer

Remove cover of TB-2012M and adjust

Remove cover of TB-2012M and adjust

Remove cover of TB-2012M and adjustRemove cover of TB-2012M and adjust

for local pressure.

for local pressure.

for local pressure.for local pressure.

Refer to Pressure vs Voltage/Current

Refer to Pressure vs Voltage/Current

Refer to Pressure vs Voltage/CurrentRefer to Pressure vs Voltage/Current

Table under the Barometer section of

Table under the Barometer section of

Table under the Barometer section ofTable under the Barometer section of

the service manual.

the service manual.

the service manual.the service manual.

U1

TB1

COM.

COM.

COM.

COM.

COM.

COM.

COM.

COM.

+12V

+12V

+12V

+12V

SIG.

SIG.

SIG.

SIG.

ELECTRIC BAROMETER

MODEL NO. TB-2012M

S/N 102795

MICRO

SWITCH

USA

P1 P2

C99

C3

D3

D2

R21

D4

D1

C1

R11

R12

R8

R9

R13

R14

R16

U2

C98

C7

C6

U3

C4

R3

R4

R2

R1

R22

R18

R19

R20

REF

C5

R17

SPAN

C2

R15

NULL

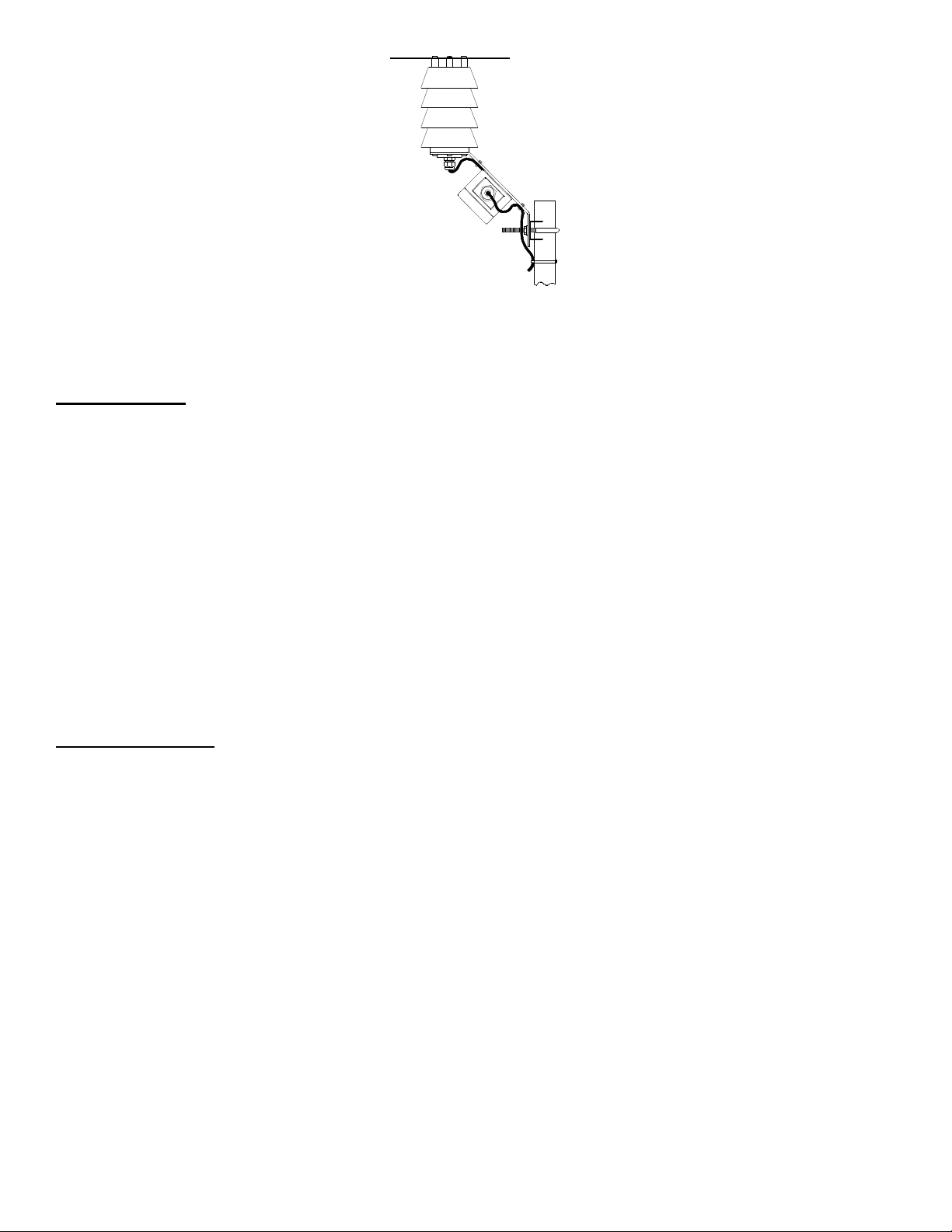

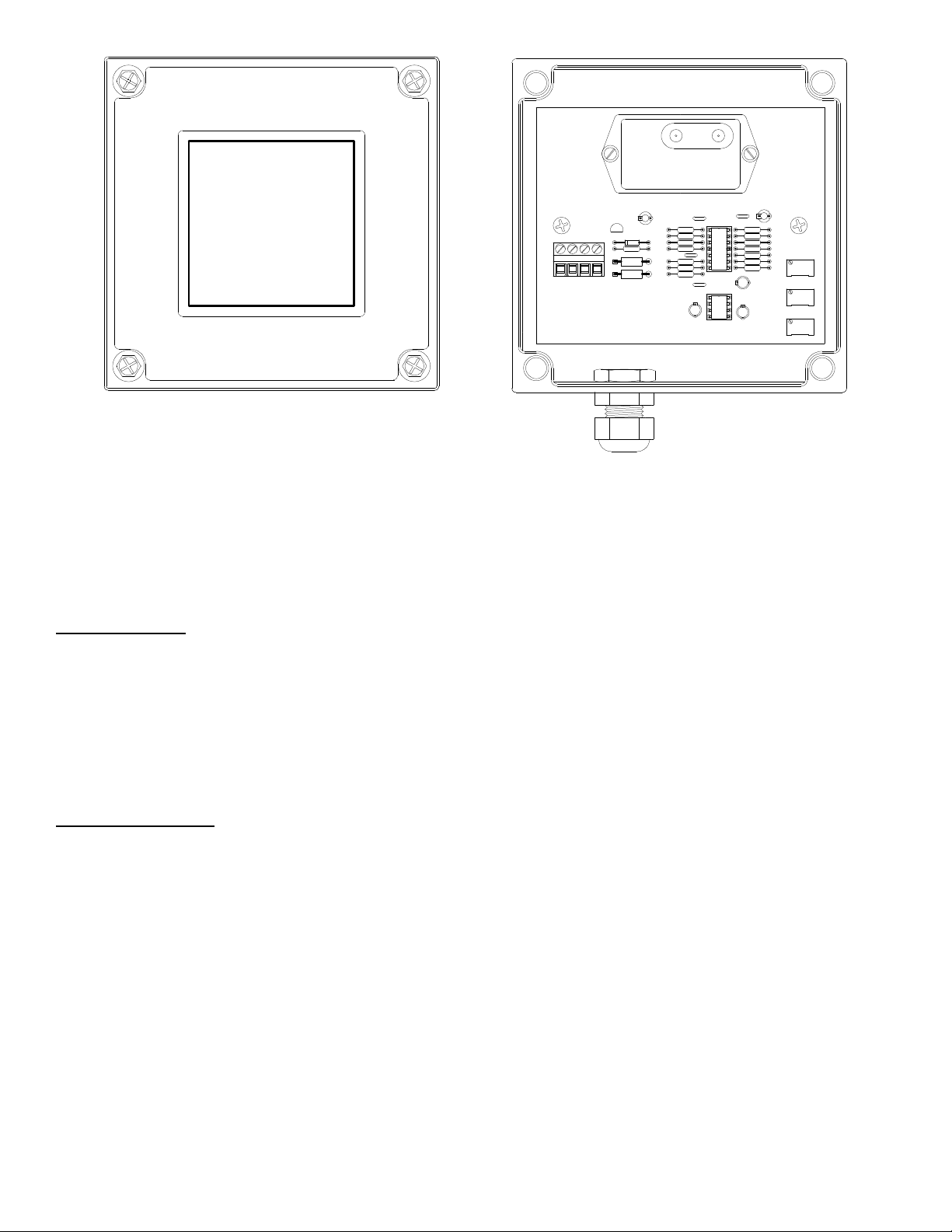

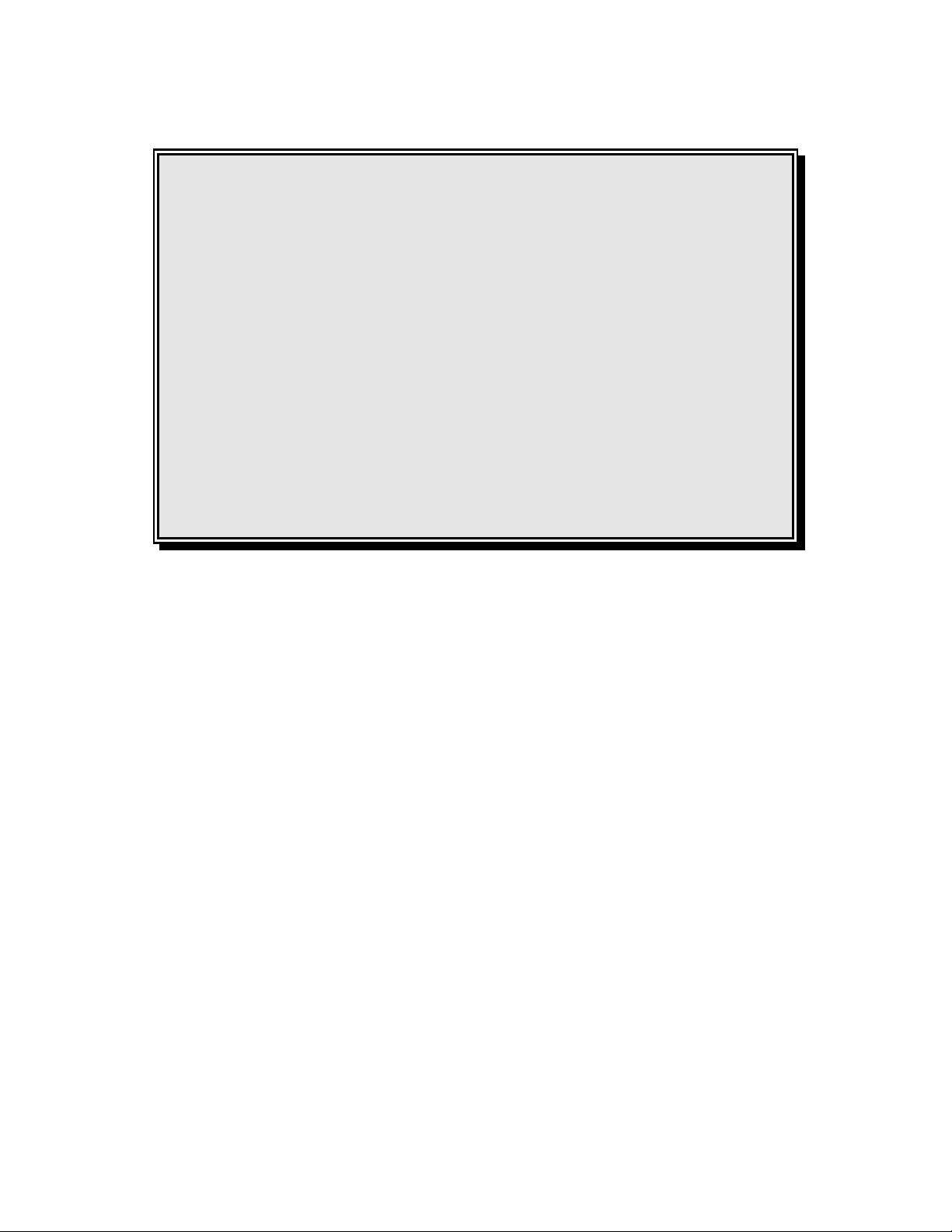

MODEL TB-2012M BAROMETRIC PRESSURE SENSOR

(Shown with cover removed)

DESCRIPTION

The Texas Electronics, Inc. TB-2012M Barometric Pressure Sensor uses an active solid-state device to sense

barometric pressure. Self-contained electronics provide a regulated voltage to the solid-state sensor and

amplification for the signal output. The unit's range of 26" to 32" or 878 mb to 1080 mb of mercury allows it to

be used at elevations up to 1800 feet or 548.64 meters above sea level. The unit is temperature compensated

from -18° to +50°C. if elevations above 1800 feet or 548.64 meters are required, contact the factory for higher

elevation calibration.

SPECIFICATIONS

Calibration Range: 26" to 32" or 878 mb to 1080 mb

Supply Voltage:

12 to 15 VDC

Current Draw: <15 mA

Accuracy: +/- 1.3mb

Operating Temperature Range: -40° to +50°C

Calibrated Temperature Range:

Output:

-18° to +50°C

0-1 VDC

Optional Output: 4-20 mA

Weight:

Dimensions:

2 lb. or 8.9 N or .907 kg. w/ 60 ft. or 18.3 meters cable

6" or 15.24 cm H x 5" or 12.7 cm W x 3" or 7.62 cm D

(Single enclosure: double enclosure also available)

Warranty:

3 year

Page 15

FEATURES & BENEFITS

• Interfaces to virtually all data acquisition systems

• Can be used up to 1800 ft. elevation without factory modification

• Over 1800 ft. elevation applications available

• Easy installation and maintenance

• Over 5 years in production

• Weatherproof Nema Enclosure for superior outdoor protection

• Wide range of 26" to 32" Hg. or 878 to 1080 mb

INSTALLATION & MAINTENANCE

Select a site where the instrument will not be subject to rapid fluctuations of temperature or to jarring and

continuous vibration. Avoid exposing the instrument to direct sunlight or radiant heaters and to direct drafts

such as open windows and doors. A mounting bracket with hardware is attached to the Nema enclosure of the

sensor.

ORDERING INFORMATION

Model # Description

TB-2012M Barometric Pressure Sensor

TB-2012MA Barometric Pressure Sensor, 4-20 mA

Optional Parts / Accessories

Cable Additional Cable

High Elevation: Applications of higher than 1800 ft. or 548.64 meters above sea-level require factory

modification.

Page 16

PROPER EXPOSURE OF METEOROLOGICAL INSTRUMENTS

Generally recognized guidelines follow which depict "ideal" sensor mounting locations. These guidelines or

"rules of thumb" are only suggestive in nature in an attempt to aid the user to selecting optimum representative

sampling locations for a particular sensor.

Reference was made to US Weather Bureau Installation criteria in preparing this data (See Reference 1).

WIND EQUIPMENT:

So far as available sites permit, wind sensors should be placed above the ground on a freely-exposed tower (20

feet or higher) and over terrain that is relatively level and free from obstructions to wind flow. When a

compromise must be made, sensing units should be exposed at least 12 feet above any obstruction within 100

feet and at least as high as any obstruction within 100 to 200 feet of the wind equipment. Support towers or

masts should not be of such bulk or shape as to create an appreciable obstruction to wind flow. Avoid sites

where local obstructions may create up-or-down drafts, eddy currents or jet-flow effects. When sensors are

roof-mounted, they should be installed at least 10 feet (or greater) from the roof surface depending upon the

particular installation site. Turbulence and other local effects can be reduced somewhat by mounting sensors on

the upwind and of the building (that end of the building exposed to the most common local prevailing winds).

Horizontal-mount booms which extend from existing towers should be fabricated so that sensors will extend a

distance of 5 to 10 feet from the tower assembly (dependent on tower thickness).

Wind direction sensors are oriented upon installation in reference to either true north or magnetic north. True

north is obtained by applying a local magnetic variation correction factor to a magnetic north compass

indication (magnetic variation for a particular locality is obtainable from the nearest Weather Bureau Branch

Office). Indicator readings for a true north sensor orientation will then be in terms of true geographic compass

points. All U.S. Weather Bureau surface wind data used for observational network reporting purposes and

general public use is given in reference to this true north format. Indicator readings for a magnetic north sensor

orientation will be in terms of actual readings as would be obtained from directly viewing a magnetic compass

instrument. Wind direction data at Federal Aviation Agency and other aircraft reporting facilities (for direct

control tower-to-pilot utilization) is always made in reference to this magnetic north format.

REMOTE TEMPERATURE/HUMIDITY SENSORS AND INSTRUMENT SHELTERS:

Whenever possible, instrument shelters* as well as remote temperature and/or humidity sensors should be

installed at a height of 4 feet (or greater) over earth or sod at least 100 feet from any concrete or other hardsurfaced area and not closer to any other object than four times the height of the object above the instrument

shelter or remote sensors. Avoid roof installations if possible. If it is necessary to roof-mount shelters and

sensors, they should not be closer than 30 feet to any large, vertical reflecting surface (walls, etc.), exhaust fans,

or cooling towers. Electronic remote sensors when roof-mounted should be at least 9 feet (or greater) above the

roof surface. To minimize radiation effects from the roof, they can also be mounted on a horizontal boom so

that they will extend from the side of a building roof or existing tower. Horizontal booms should extend

approximately 5 to 10 feet from the side of the building roof or tower assembly.

*

Standard U.S. Weather Bureau cotton-region shelter (Spec. No. 450.0615, Rev. 8/67)

Page 17

PRECIPITATION GAUGES:

Rain gauges should be installed on a level plot of ground, at a distance from any object of at least two and

preferably four times the height of the object above the top of the gauge. All types of gauges must be exposed

with the rim of the receiver in a horizontal plane and at a level well above the average level of snow surfaces.

Roof-mounting of rain gauges should be avoided when possible. Air currents at heights other than at ground

level have been observed to cause an apparent decrease in rainfall catch commensurate with the increase in

mounting height above ground level.

Objects which individually or in small groups constitute a "windbreak" reduce prevailing wind speed in the

vicinity of the gauge. This reduction of wind speed will, as a consequence, also reduce possible eddy currents

and turbulence around the gauge. The presence of such objects is usually beneficial in providing a more

accurate rainfall catch. Ideally, the "windbreak" objects (fences, bushes, etc.) should be generally uniform in

height and distance from the gauge. Height above the gauge should not exceed about twice their distance from

the gauge.

ANEROID BAROMETERS - SELF-CONTAINED MECHANICAL INSTRUMENTS AND

ELECTRONIC REMOTE BAROMETRIC PRESSURE SENSORS:

Select a site where the instrument will not be subject to rapid fluctuations of temperature or to jarring and

continuous vibration. Avoid exposing the instrument to direct sunlight or radiant heaters and to direct drafts

such as open windows and doors.

Reference 1:

U.S. Department of Commerce - National Weather Service Bulletin

LS 5927 Revised, 0-4.12, January, 1963.

SOLAR RADIATION SENSORS:

The Solar Radiation Sensor is normally mounted on a level surface totally remote from trees, poles, or power

lines that might cast a shadow on the sensor at any time of the day. However, there may be occasions, because

of extreme latitudes, when it is desired to mount the sensor at some angle other than level.

The sensors may also be mounted on a sun tracking mechanism or behind a shadow band if diffuse sky

radiation is to be measured.

WIND DIRECTION & SPEED SENSORS

INSTALLATION

These instructions apply to roof-top installation. We advise that you first read over these instructions before

beginning assembly as several referenced items are not supplied with your weather equipment (this is because

most every installation is unique thus these parts are best obtained by the installer). Reference to the "U-Tube

Cross-Bar Installation" figure and ".Sensor Installation" figure may be helpful.

Step 1: Attach the three anemometer cups to the speed sensor head.

Loosen the three set screws on the top of the anemometer (lower unit).

Insert the anemometer cup arms into the holes. Be sure to press the arms all the way in and make

sure that the flat areas on the arms face toward the set screws.

Tighten the set screws.

Page 18

Step 2: Attach wind vane and counter-weight to the direction sensor head.

Loosen the two set screws on the top of the wind vane (upper unit).

Insert the vane and counter-weight into the holes. Be sure to press both parts all the way in and

make sure the flat areas on each arm face the set-screws.

Tighten the set screws.

Note: For optimum performance and maximum bearing longevity you may wish to fine-tune the

balance of both wind sensors. Place the U-tube flat on a table such that the sensors hang over the

edge. Rotate the vane and the cup in 10 degree increments. After positioning the vane and cups

verify that there is no movement after releasing your hold (this must be done in a wind-free

environment). Balance adjustments are made by loosening the set screw to the lighter cup,

counter-weight or fin and shifting it slightly away from the sensor head.

Step 3: Attach cross-bar to U-tube.

Spread end clamps and slide over the U-tube.

Insert cross-bar into the ends of both clamps.

Fasten cross-bar in a level position with screws, nuts and washers.

Step 4: Attach U-bolts to cross-bar and U-tube.

Remove the two nuts and reinforcing plate from both U-bolts (do not remove the toothed bracket).

Insert one U-bolt through the two holes in the cross-bar and the other through the two holes in the

bottom of the U-arm (be careful not to damage the wires inside the U-arm).

Replace the tube reinforcing plate on the U-bolt and replace the U-bolt nuts.

Step 5: Slip the U-bolts over the mast and tighten.

Make certain that the anemometer cups do not hit the mast.

Step 6: Attach guy wire clamp just below the U-tube assembly.

Step 7: Attach base mount to the roof or side wall.

Note that the base mount U-bolt will rotate to fit any angle.

Step 8: Install guy wire anchors (not included) or locate secure points for guy wire attachment.

Step 9: Erect mast and install guy wires (not included) and turn-buckles (not-included).

Step 10: Ground the mast to help protect the sensors and structure from lightning hits.

Supplies needed: mast wire clamp, grounding wire, wire supports and grounding rod.

Step 11: Run the sensor wire inside to the console.

Lead in wire is permanently attached to the sensor unit.

Attach to console according to wire color code.

If necessary the cable may be cut down in length or wire may be added with negligible effect on the

calibration. If changing cable lengths more than a few hundred feet you may wish contact the

factory to determine the severity of the effect on calibration.

Additional cable lengths are available from Texas Electronics if needed.

Step 12: Calibrate the Wind Vane.

Be sure console is operating properly first.

This is normally a two man job with one individual watching the direction indicated by the weather

station and the other adjusting the sensor while watching a compass.

Page 19

Two methods of aligning the vane are available. The first method involves loosening the large set

screw at the bottom of the wind direction sensor so that it will rotate on the U-arm. Turn the bottom

half of the sensor until the compass readings and the indication match then retighten the set screw.

The second method involves rotating the entire mast assembly until proper orientation is achieved;

this technique is usually easier because of the heights involved but will usually necessitate

repositioning (rotating) of the guy-wire clamp.

If winds are creating rapid fluctuations in the vane making calibration difficult, the vane can be

temporarily secured in a fixed position by carefully wedging a thickly folded piece of paper or

cardboard into the gap between the upper and lower halves of the direction sensor. An alternative

technique is to lap a string over the vane and carefully hold it in position (be careful not to bend the

vane when using this approach).

Page 20

Warranty

Texas Electronics, Inc. (hereafter TEI) warrants the equipment manufactured by it

to be free from defects in material and workmanship. Upon return, transportation

charges prepaid to TEI, within three (3) years of original shipment of sensors and

one (1) year of original shipment of electronics, recorders and indicators, TEI will

repair or replace, at its option, any equipment which it determines to contain

defective material or workmanship, and will return said equipment to purchaser,

F.O.B., TEI. Texas Electronics shall not be obligated however to repair or replace

equipment which has been repaired by others, abused, improperly installed,

altered or otherwise misused or damaged in any way. TEI will not be responsible

for any dismantling, re-assembly, or reinstallation charges.

This warranty is in lieu of all other warranties, expressed or implied. TEI shall

not be liable for any special, indirect, incidental or consequential damages

claimed in connection with any rescission of this agreement by purchaser.

For a list of specific items covered by the extended warranty, see the Three-Year

Warranty Equipment List.

Page 21

Three-Year Warranty Equipment List

Effective February 1, 1992 all of Texas Electronics, Inc. sensors will carry a Three-Year warranty instead of the previous

One-Year. The remainder of terms and conditions of the warranty remains unchanged. A specific list of items follows.

Sensors Covered by Three-Year Warranty

Parameter Model No.

Wind Direction TD-105 (Synchro)

TD-104D (Potentiometer)

TD-110-L2 (Photo-Chopper)

TD-106 (Potentiometer)

Wind Speed TV-110-L2 (Photo-Chopper)

TV-110-L3 (Photo-Chopper)

TV-114 (A.C. Generator)

Barometric Pressure TB-2012

Relative Humidity TH-2013

TH-2013V

Rainfall TR-525

TR-6118

Temperature TT-101 (Outdoor)

TT-103R (Surface Mount)

TT-103R-W (Water Probe)

TT-309I (Indoor)

Solar Radiation TS-100

Systems Covered by Three-Year Warranty

Model No. Description

WSC-5-S Wind Speed Controller

Single Set Point

WSC-5-ST Wind Speed Controller

Single Set Point with Time Delay

WSC-5-D Wind Speed Controller

Dual Set Point

WSC-5-DT Wind Speed Controller

Dual Set Point with Time Delay

WDC-2 Wind Direction Controller

Loading...

Loading...