Page 1

1 Introduction

The TPS8804EVM is used to evaluate the TPS8804 smoke and CO detector analog front end (AFE) and

power management IC. The EVM allows for easy connection from the TPS8804 to a user-supplied

photoelectric chamber and carbon monoxide sensor. The TPS8804 GUI interfaces with the EVM to quickly

evaluate the photo amplifier, LED driver, and CO amplifier performance, and other blocks with the register

map. For a more thorough evaluation, an external microcontroller can be connected to the TPS8804EVM

to create a smoke detection system.

1.1 Applications

• Smoke and CO detectors

1.2 Features

• Dual LED drivers for blue and IR LEDs

• Wide bandwidth, low offset photodiode amplifier

• Ultra-low power CO transimpedance amplifier

• LDOs for internal analog blocks and external microcontroller

• Single buffered analog output AMUX for CO and photo signals

• Serial interface for configuring amplifiers, drivers, regulators

• SLC interface for power line communication

• Under-voltage, over-temperature fault monitors

• Wide input voltage range for flexible power supply configuration

User's Guide

SLVUBT6–October 2019

Using the TPS8804EVM

1.3 Recommended Equipment

• 4.5-V to 15.5-V power supply capable of 100mA

• USB2ANY™ interface adaptor

• TPS880x GUI software

– Installation files are available in the TPS8804EVM product folder

• Multimeter for measuring regulator voltages and CO amplifier output

• Oscilloscope for measuring photodiode signal pulse shape

2 Setup

Specific connections on the TPS8804EVM board require configuration before starting the evaluation.

2.1 Sensor Connections

TI recommends connecting a photoelectric smoke chamber and CO sensor to the TPS8804EVM for the

evaluation. The TPS8804EVM has a built-in photodiode (D7), blue LED (D8), and IR LED (D6) for

functional testing. These components can be de-soldered in order to connect a photoelectric chamber

photodiode, IR LED, and/or blue LED its place. Ensure the photodiode wires are kept short to preserve

signal integrity.

SLVUBT6–October 2019

Submit Documentation Feedback

Copyright © 2019, Texas Instruments Incorporated

Using the TPS8804EVM

1

Page 2

Setup

The CO sensor is connected to J17 screw terminals with the sensor counter terminal tied to AGND.

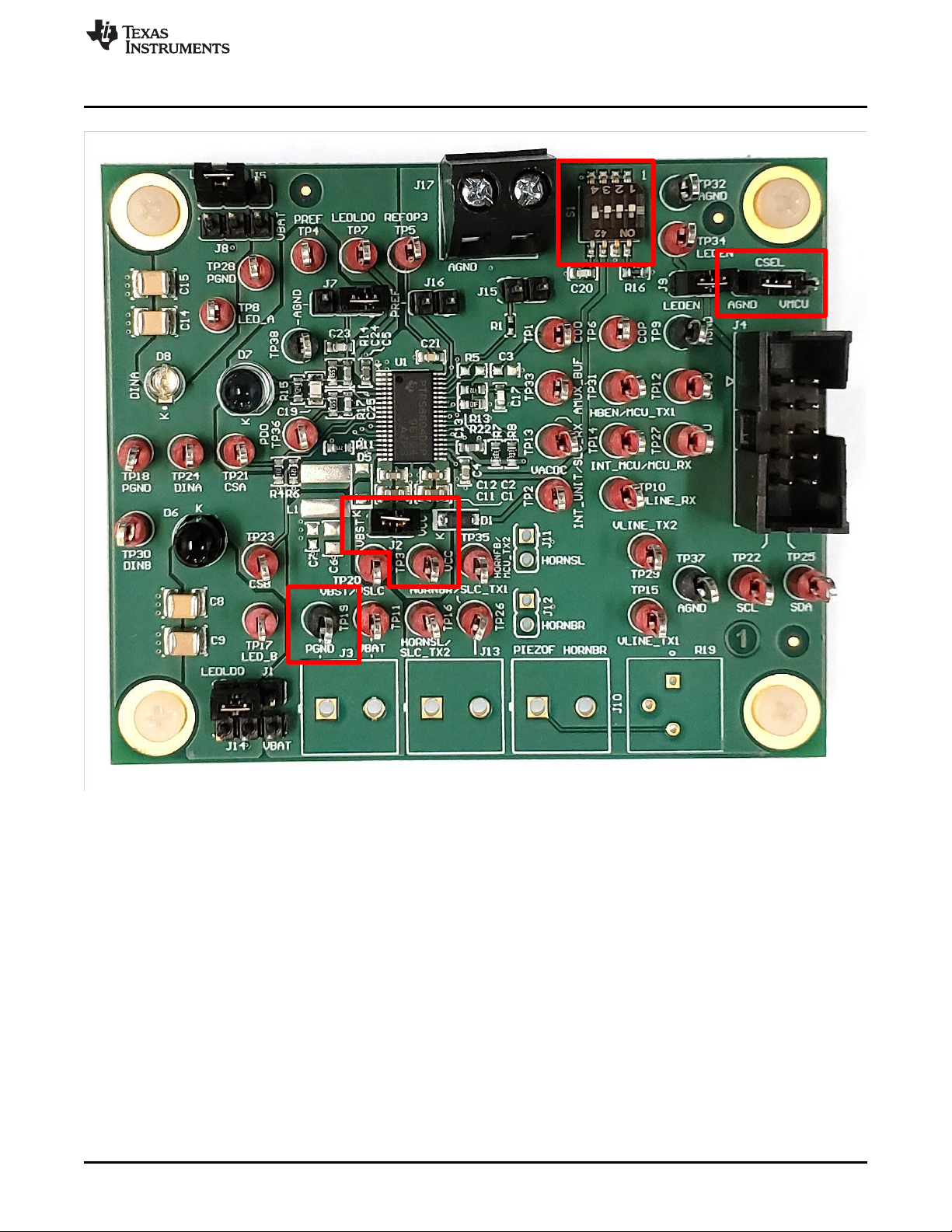

2.2 Jumper and Switch Configurations

The S1 switch position determines the VMCU voltage at power-up. Ensure that only one S1 sub-switch is

in the ON position. Table 1 displays the VMCU voltage corresponding with each S1 switch position. For

proper operation with the USB2ANY adapter, set VMCU to 3.3 V with sub-switch 4.

Table 1. VMCU Power-up Voltage

S1 Switch Position VMCU

1 1.5V

2 1.8V

3 2.5V

4 3.3V

The J2 jumper connects VSLC to VCC. A single supply connected to VCC powers the entire EVM with the

jumper connected.

The J6 jumper selects the I2C device address. Connect J6 to the AGND position to set the address to

0x3F. Connect J6 to the VMCU position to set the address to 0x2A. The GUI is compatible with both

options and defaults to 0x2A.

www.ti.com

2

Using the TPS8804EVM

Copyright © 2019, Texas Instruments Incorporated

SLVUBT6–October 2019

Submit Documentation Feedback

Page 3

www.ti.com

Setup

2.3 Power Connection

Connect the power supply to VCC and PGND. Set the power supply to 5 V, 100 mA. Enable the power

supply and measure the voltage on VMCU (TP27) to ensure it is operating at the voltage option selected

by S1:

• 1.5 V

• 1.8 V

• 2.5 V

• 3.3 V

See Table 1 for more information on the initial VMCU voltage.

SLVUBT6–October 2019

Submit Documentation Feedback

Figure 1. Switch, Jumper, and Power Connections

Copyright © 2019, Texas Instruments Incorporated

Using the TPS8804EVM

3

Page 4

Setup

2.4 USB2ANY Connection

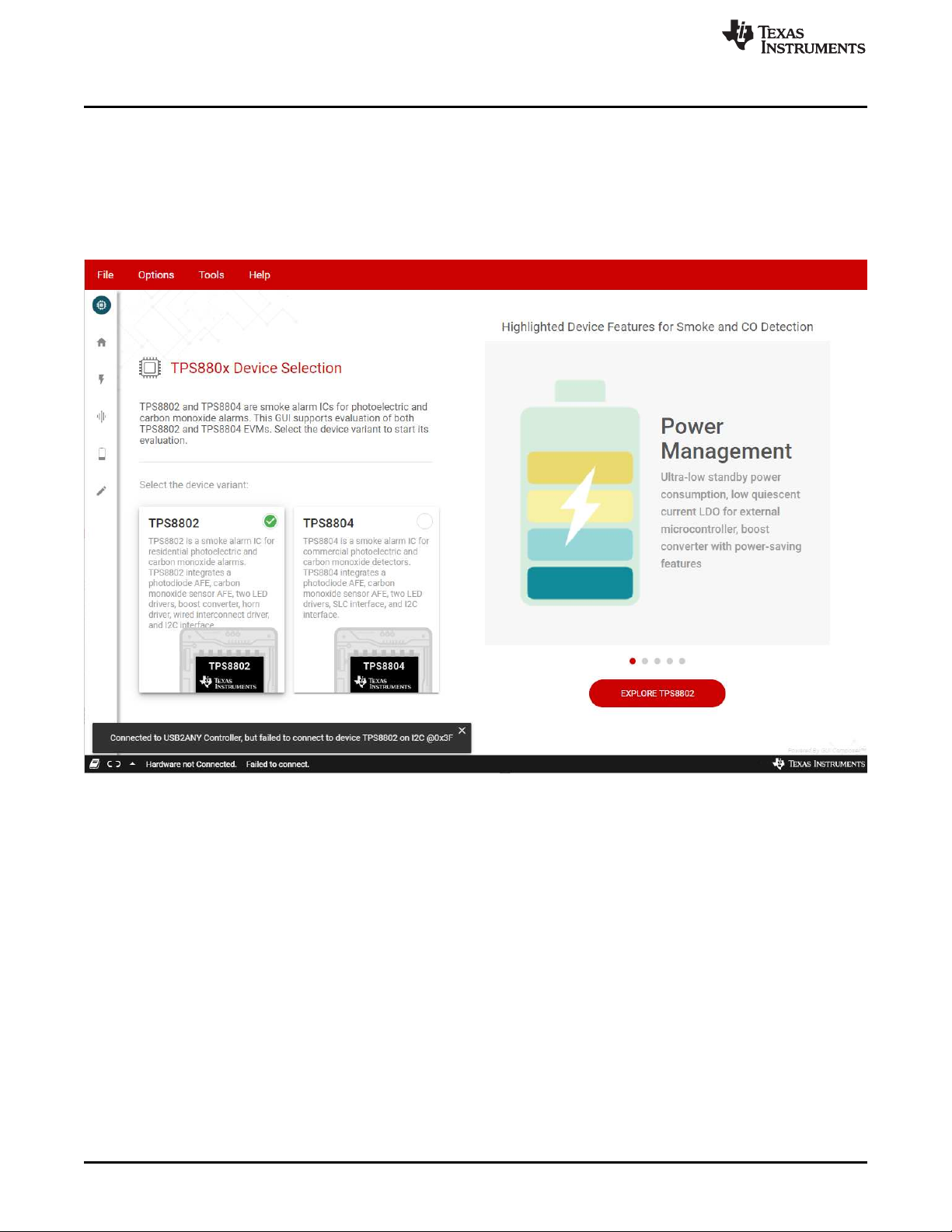

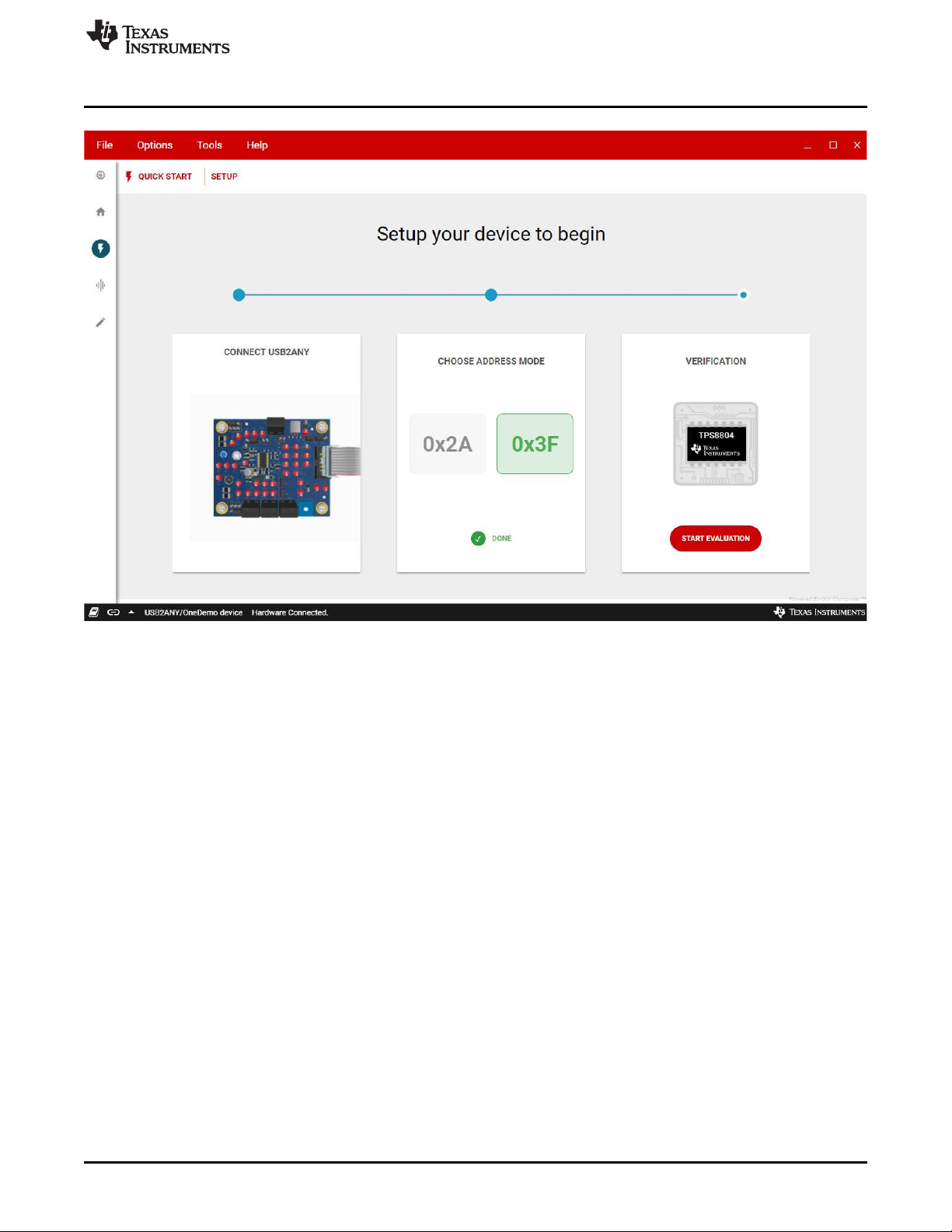

Use a USB cable to connect the USB2ANY adapter to a computer with the TPS880x GUI installed. Open

the TPS880x GUI and verify the USB2ANY adapter is recognized (see Figure 2). With the EVM powered,

connect the USB2ANY adapter to the EVM using the USB2ANY adapter 10-pin ribbon cable. Click

EXPLORE TPS8804EVM then QUICK START and select the device address corresponding to the J6

jumper (see Section 2.2). Send the test command to verify the EVM, USB2ANY adapter, and GUI

software are all connected.

www.ti.com

Figure 2. TPS880x GUI Connected to USB2ANY Adapter

4

Using the TPS8804EVM

Copyright © 2019, Texas Instruments Incorporated

SLVUBT6–October 2019

Submit Documentation Feedback

Page 5

www.ti.com

Analog Evaluation

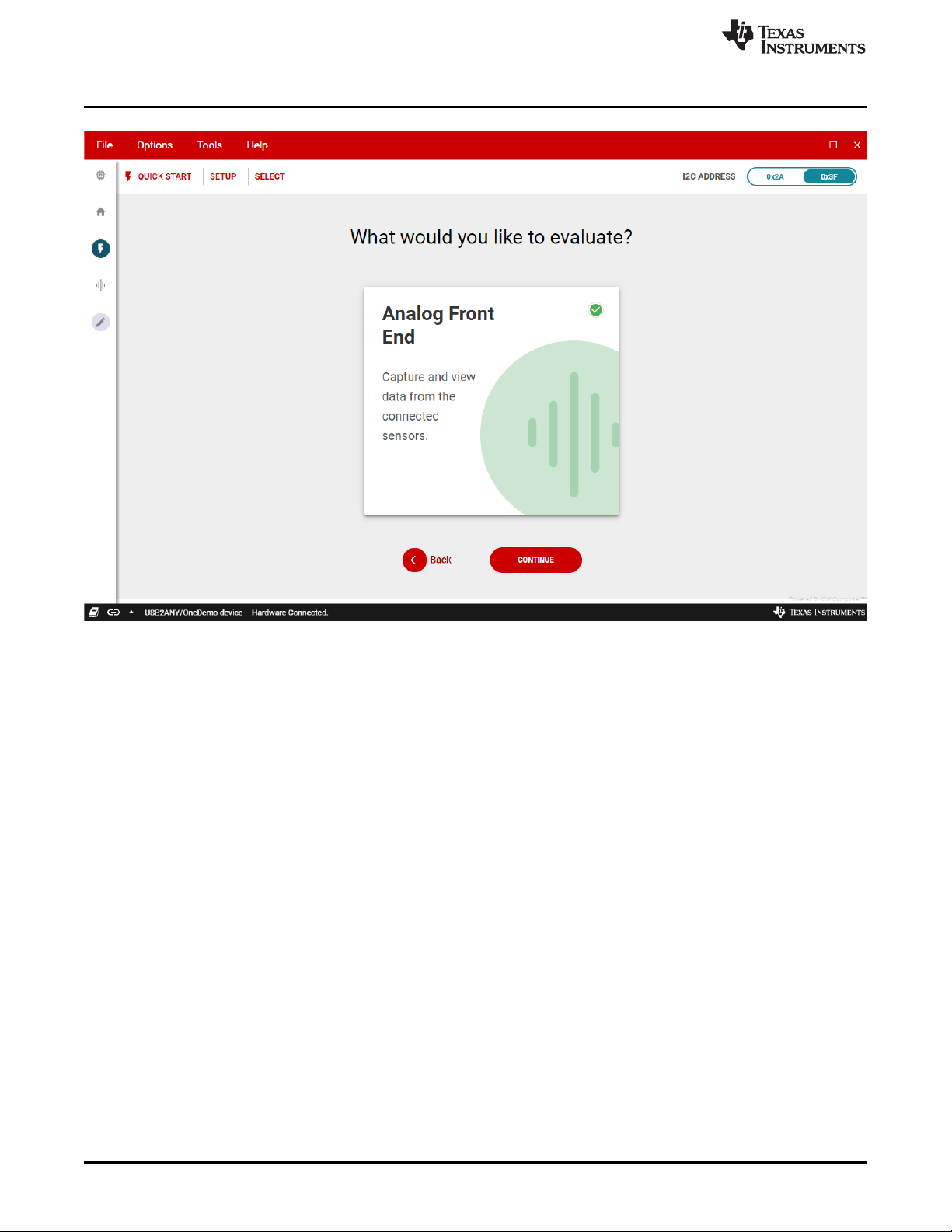

3 Analog Evaluation

Click START EVALUATION and select the feature to evaluate. The Analog Front End section guides the

CO AFE and photo AFE evaluation. Enter the register map to evaluate the other blocks in the TPS8804

device.

Figure 3. Test Command Successful

SLVUBT6–October 2019

Submit Documentation Feedback

Copyright © 2019, Texas Instruments Incorporated

Using the TPS8804EVM

5

Page 6

Analog Evaluation

www.ti.com

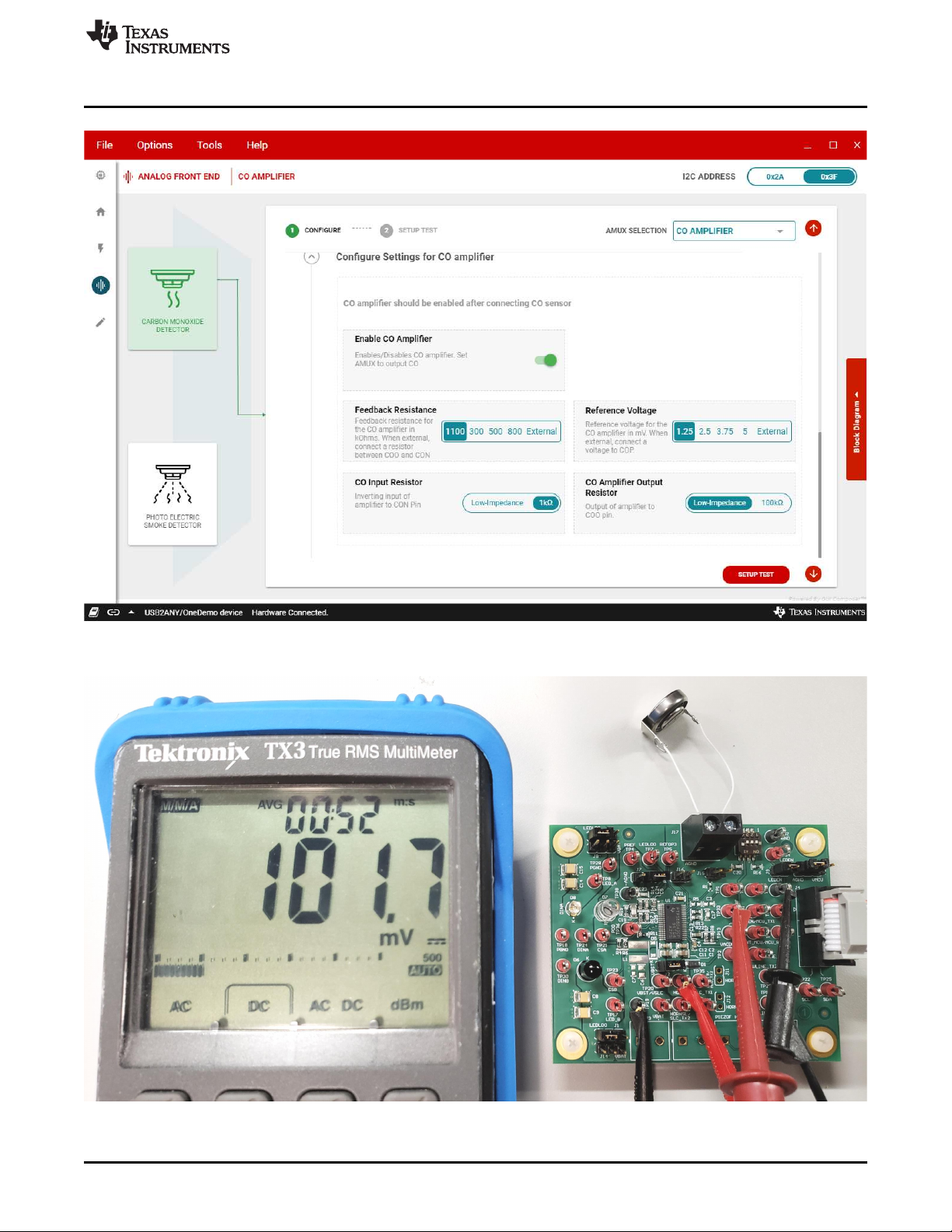

3.1 CO AFE Evaluation

If a CO sensor is available, connect it to the J17 terminal block. Select the feedback resistance and

reference voltage in the GUI software. The TPS8804EVM default configuration uses the internal resistors

and references. To use an external feedback resistor, solder a resistor to R5. To use an external input

resistor, replace the R1 0-Ω resistor with the required input resistance. The output resistor filters the CO

amplifier output when a capacitor is installed on C3.

Set the AMUX SELECTION to CO AMPLIFIER. Enable the CO amplifier and measure the voltage on

AMUX_BUF.

Figure 4. Evaluation Selection Menu

6

Using the TPS8804EVM

Copyright © 2019, Texas Instruments Incorporated

SLVUBT6–October 2019

Submit Documentation Feedback

Page 7

www.ti.com

Analog Evaluation

Figure 5. CO Amplifier Settings

SLVUBT6–October 2019

Submit Documentation Feedback

Figure 6. Clean Air CO Amplifier Output

Copyright © 2019, Texas Instruments Incorporated

Using the TPS8804EVM

7

Page 8

Analog Evaluation

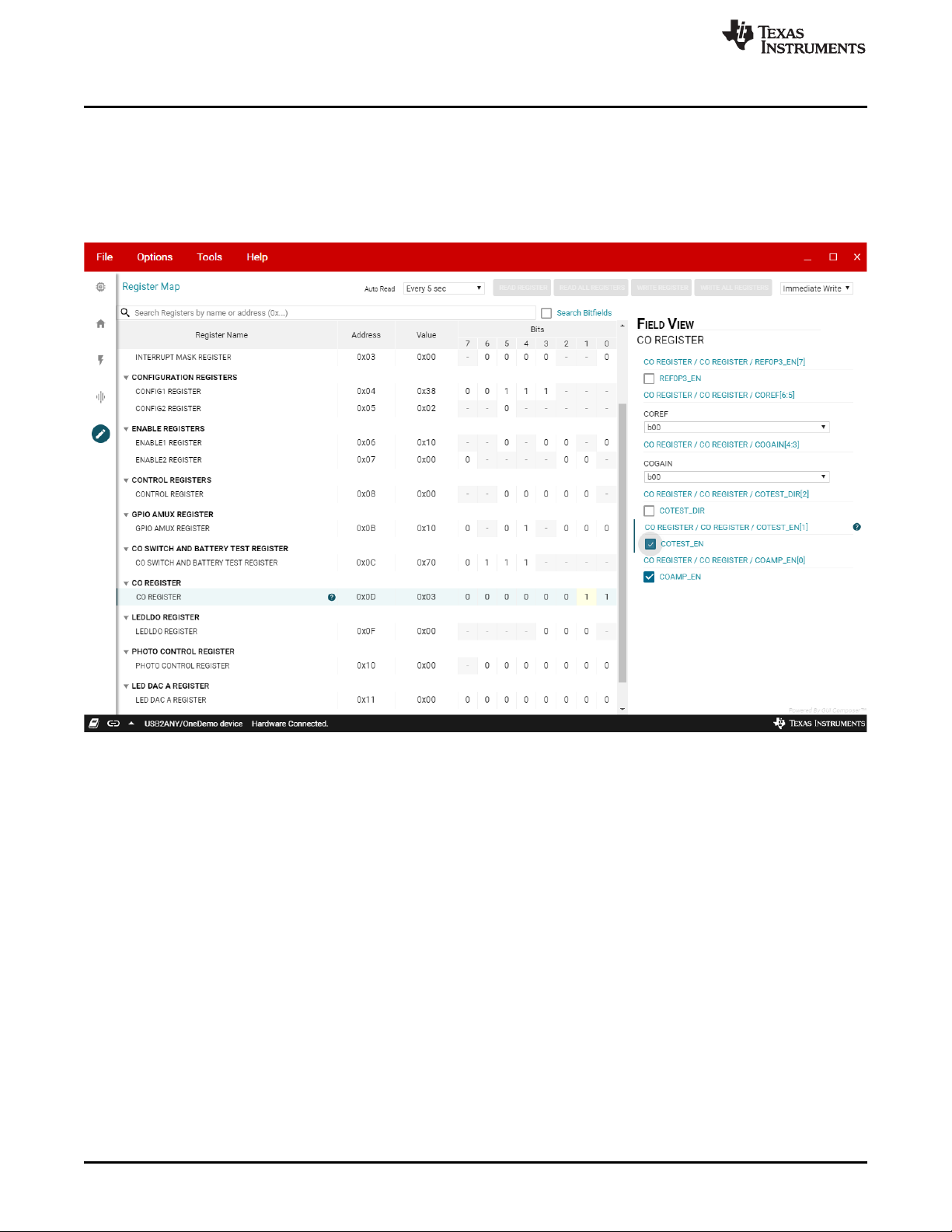

3.1.1 CO Connectivity Test

A simple test confirms that the CO sensor is connected to the EVM. Remove the shunt connected to J7

and connect a shunt to J15 and J16. Write COTEST_EN = 1 and measure the pulse shape on

AMUX_BUF using an oscilloscope. When COTEST_EN = 1, the PREF pin is pulled low and injects charge

into the CO sensor and amplifier. The AMUX pulse shape is different if the CO sensor is disconnected.

Write COTEST_EN = 0, remove the J15 and J16 shunts, and connect the J7 shunt when finished.

www.ti.com

Figure 7. COTEST_EN Register Bit

8

Using the TPS8804EVM

Copyright © 2019, Texas Instruments Incorporated

SLVUBT6–October 2019

Submit Documentation Feedback

Page 9

www.ti.com

Analog Evaluation

Figure 8. CO Connectivity Test without Sensor

SLVUBT6–October 2019

Submit Documentation Feedback

Copyright © 2019, Texas Instruments Incorporated

Using the TPS8804EVM

9

Page 10

Analog Evaluation

www.ti.com

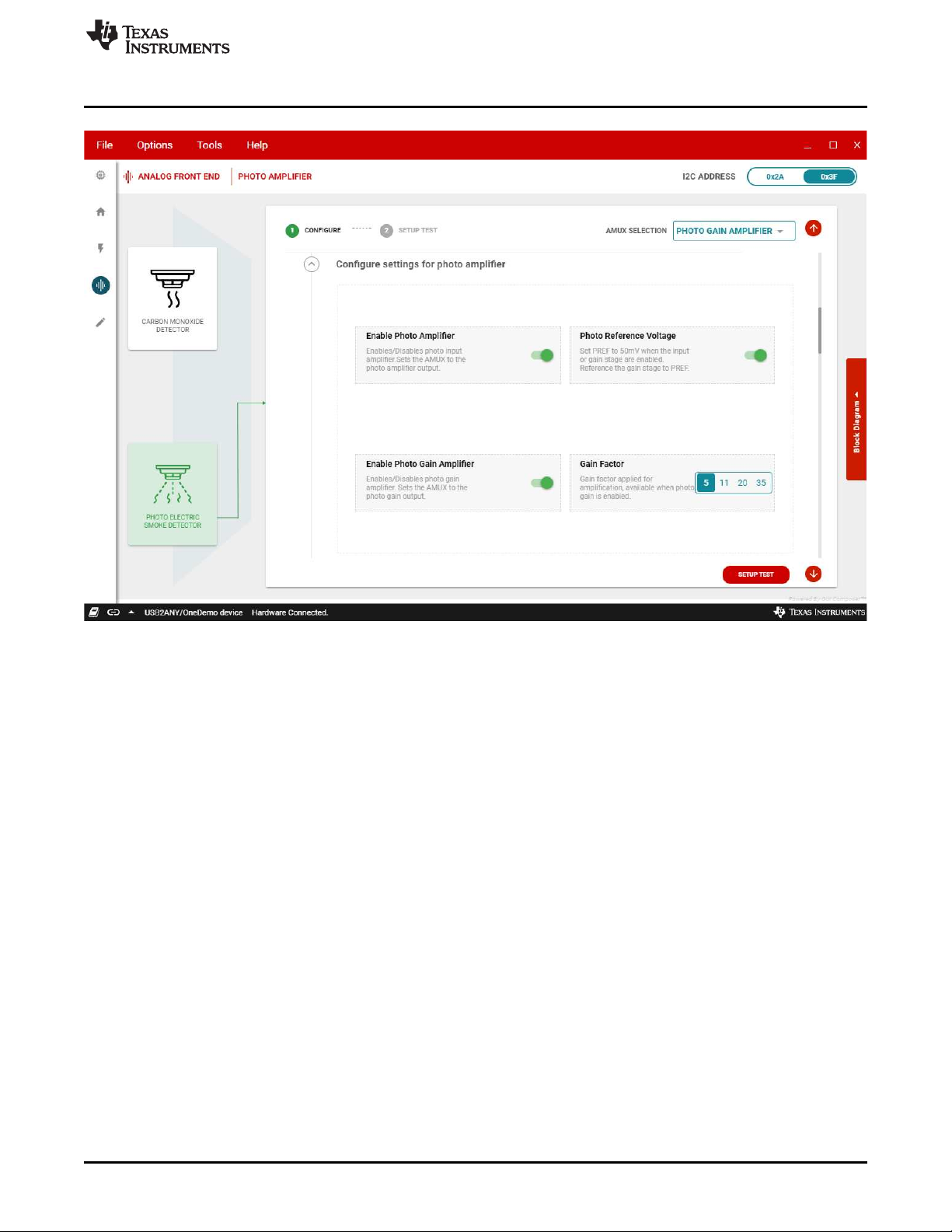

3.2 Photo AFE Evaluation

Connect the photoelectric chamber to the EVM. If a photoelectric chamber is not available, place a box

over the EVM to block ambient light and reflect the EVM LED light into the photodiode when testing the

photo AFE.

Enable the photo amplifier, photo gain amplifier, and set the AMUX SELECTION to PHOTO GAIN

AMPLIFIER. Select the photo reference on the EVM with jumper J7 and enable the photo reference

voltage if the reference is set to PREF. Set the gain factor to the required value. If no extra gain is

required, set the AMUX SELECTION to PHOTO AMPLIFIER.

Figure 9. CO Connectivity Test with Sensor

10

Using the TPS8804EVM

Copyright © 2019, Texas Instruments Incorporated

SLVUBT6–October 2019

Submit Documentation Feedback

Page 11

www.ti.com

Analog Evaluation

Figure 10. Photo Amplifier Settings

Configure the power to the LEDs. By default, LED A and LED B are connected to LEDLDO. Use the J1,

J5, J8, and J14 jumpers to select which supply powers each LED. Enable the LEDLDO if it powers either

LED.

SLVUBT6–October 2019

Submit Documentation Feedback

Copyright © 2019, Texas Instruments Incorporated

Using the TPS8804EVM

11

Page 12

Analog Evaluation

www.ti.com

Figure 11. LED Power Supply Settings

Configure the PWM pulse settings for the LED driver. The default setting 201 ms pulse rate and 1 ms

pulse width sufficiently tests the LED driver. This setting controls the PWM signal from the USB2ANY

adapter to the EVM.

Configure the LED current for each driver. The default EVM CSA resistance is 10 Ω and the default EVM

CSB resistance is 1.3 Ω. These resistors can be switched on the EVM to change the LED current and

temperature compensation. Set the DAC voltage to fine tune the LED current. Set the temperature

coefficient to the required setting. Click SETUP TEST after configuring the photo amplifier, LED power

supply, and LED driver.

12

Using the TPS8804EVM

Copyright © 2019, Texas Instruments Incorporated

SLVUBT6–October 2019

Submit Documentation Feedback

Page 13

www.ti.com

Analog Evaluation

Figure 12. LED Driver Settings

Select the LED to be tested. Enable the LED PWM to send the PWM signal to the LEDEN pin. Enable

LEDPIN_EN to control the LED driver using the LEDEN pin. Place a box over the EVM if the EVM LEDs

and photodiode are used to block ambient light and reflect the LED light into the photodiode.

Use an oscilloscope to measure the LED current, photo input amplifier, and photo gain amplifier signals.

Probe LEDEN to measure the LED control signal. Probe CSA or CSB to measure the LED driver current.

Probe PDO to measure the photo input stage amplifier. Probe AMUX_BUF to measure the photo gain

stage amplifier.

SLVUBT6–October 2019

Submit Documentation Feedback

Copyright © 2019, Texas Instruments Incorporated

Using the TPS8804EVM

13

Page 14

Analog Evaluation

www.ti.com

14

Using the TPS8804EVM

Figure 13. EVM Photo Measurement Probe Configuration

Copyright © 2019, Texas Instruments Incorporated

SLVUBT6–October 2019

Submit Documentation Feedback

Page 15

www.ti.com

Analog Evaluation

Figure 14. LED A Signals

SLVUBT6–October 2019

Submit Documentation Feedback

Copyright © 2019, Texas Instruments Incorporated

Using the TPS8804EVM

15

Page 16

Analog Evaluation

www.ti.com

Figure 15. LED B Signals

16

Using the TPS8804EVM

Copyright © 2019, Texas Instruments Incorporated

SLVUBT6–October 2019

Submit Documentation Feedback

Page 17

www.ti.com

Analog Evaluation

3.3 Register Map

Use the register map to evaluate other blocks in the TPS8804. Use the search to find register bits that

correspond to a certain block or function. Load and save register map configurations in the File menu.

Click the question mark icon (?) to display more information about the selected register or bits.

Figure 16. Photo Signal with Photo Chamber

SLVUBT6–October 2019

Submit Documentation Feedback

Copyright © 2019, Texas Instruments Incorporated

Using the TPS8804EVM

17

Page 18

Analog Evaluation

www.ti.com

Figure 17. Register Map Search Function

18

Using the TPS8804EVM

Copyright © 2019, Texas Instruments Incorporated

SLVUBT6–October 2019

Submit Documentation Feedback

Page 19

www.ti.com

4 Board Layout

Board Layout

SLVUBT6–October 2019

Submit Documentation Feedback

Figure 18. TPS8804EVM Top Layer Board Layout

Copyright © 2019, Texas Instruments Incorporated

Using the TPS8804EVM

19

Page 20

Board Layout

www.ti.com

20

Using the TPS8804EVM

Figure 19. TPS8804EVM Bottom Layer Board Layout

Copyright © 2019, Texas Instruments Incorporated

SLVUBT6–October 2019

Submit Documentation Feedback

Page 21

www.ti.com

5 Schematic and Bill of Materials

5.1 Schematic

Schematic and Bill of Materials

5.2 Bill of Materials

REF DES QTY VALUE DESCRIPTION SIZE PART NUMBER

PCB1 1 Printed Circuit Board TPS880x

C1, C11 2 4.7 µF Capacitor, ceramic, 4.7 µF, 25 V, ±10%, X7R, 0805 0805

C2, C12 2 0.1 µF Capacitor, ceramic, 0.1 µF, 25 V, ±5%, X7R, 0603 0603 06033C104JAT2A

C4, C13, C16,

C18

C5 1 1 µF Capacitor, ceramic, 1 µF, 16 V, ±10%, X7R, 0603 0603 EMK107B7105KA-T

C8, C9, C14,

C15

C10 1 100 pF Capacitor, ceramic, 100 pF, 16 V, ±10%, X7R, 0402 0402 0402YC101KAT2A

C17, C20 2 330 pF Capacitor, ceramic, 330 pF, 50 V, ±10%, X7R, 0603 0603

C19 1 7 pF Capacitor, ceramic, 7 pF, 50 V, ±7%, C0G/NP0, 0805 0805

C21 1 1000 pF Capacitor, ceramic, 1000 pF, 50 V, ±10%, X7R, 0603 0603

Figure 20. TPS8804EVM Schematic

Table 2. Bill of Materials

4 1 µF Capacitor, ceramic, 1 µF, 16 V, ±10%, X5R, 0603 0603

4 47 µF Capacitor, ceramic, 47 µF, 16 V, ±20%, X6S, 1210 1210

C2012X7R1E475K1

25AB

C0603C105K4PAC

TU

GRM32EC81C476M

E15L

C0603C331K5RAC

TU

CC0805DRNP09BN

7R0

C0603X102K5RAC

TU

SLVUBT6–October 2019

Submit Documentation Feedback

Copyright © 2019, Texas Instruments Incorporated

Using the TPS8804EVM

21

Page 22

Schematic and Bill of Materials

REF DES QTY VALUE DESCRIPTION SIZE PART NUMBER

C23 1 100 pF

C24, C25 2 10 pF

D1, D2, D3 3 100 V Diode, Switching, 100 V, 0.15 A, SOD-123 SOD-123 1N4148W-TP

D4 1 18 V Diode, Zener, 18 V, 225 mW, SOT-23 SOT-23 BZX84C18LT1G

D6 1 Infrared LED, Infrared, TH D5.5 mm SFH 4556

D7 1 Silicon PIN Photodiode, TH D5.7×H9 mm SFH 213

D8 1 Blue LED, Blue, TH D3.1 mm LTL1CHTBK4

H1, H2, H3, H4 4

H5, H6, H7, H8 4 Standoff, Hex, 0.5"L #4-40 Nylon Standoff 1902C

J1, J5, J6, J7,

J8, J14

J2, J9, J15,

J16

J4 1 Header (shrouded), 100mil, 5×2, Gold, TH

J17 1 Terminal Block, 5.08 mm, 2×1, TH

LBL1 1

Q1, Q2 2 65 V Transistor, NPN, 65 V, 0.1 A, SOT-23 SOT-23 BC846BLT1G

R1 1 0 Resistor, 0, 5%, 0.063 W, 0402 0402 RC0402JR-070RL

R2 1 10.0 kΩ Resistor, 10.0 k, .1%, .0625 W, 0402 0402 RT0402BRD0710KL

R3 1 100 kΩ Resistor, 100 k, 0.1%, 0.1 W, 0603 0603 RG1608P-104-B-T5

R4 1 10.0 Ω Resistor, 10.0, 0.5%, 0.1 W, 0603 0603 RT0603DRE0710RL

R6 1 1.30 Ω Resistor, 1.30, 0.5%, 0.1 W, 0603 0603 RT0603DRE071R3L

R7, R8 2 33 kΩ Resistor, 33 k, 5%, 0.1 W, AEC-Q200 Grade 0, 0603 0603

R9, R10 2 1.0 kΩ

R11 1 2.4 MΩ

R12, R21 2 470 Ω

R13 1 4.7 kΩ Resistor, 4.7 k, 5%, 0.1 W, AEC-Q200 Grade 0, 0603 0603

R14, R17 2 1.5 MΩ

R15 1 470 kΩ Resistor, 470 k, 0.5%, 0.1 W, 0603 0603

R16 1 620 Ω Resistor, 620, 1%, 0.1 W, 0603 0603

R22, R23 2 10MΩ Resistor, 10 M, 5%, 0.1 W, AEC-Q200 Grade 0, 0603 0603

S1 1 Switch, Slide, SPST 4 poles, SMT

SH-J1, SH-J2,

SH-J3, SH-J4,

SH-J7, SH-J8

6 Header, 2.54 mm, 3×1, Tin, TH

4 Header, 2.54 mm, 2×1, Tin, TH

6 1×2 Shunt, 100mil, Flash Gold, Black

Table 2. Bill of Materials (continued)

Capacitor, ceramic, 100 pF, 50 V, ±5%, C0G/NP0,

0603

Capacitor, ceramic, 10 pF, 50 V, ±5%, C0G/NP0,

0603

Machine Screw, Round, #4-40 × 1/4, Nylon, Philips

panhead

Thermal Transfer Printable Labels, 0.650" W ×

0.200" H - 10,000 per roll

Resistor, 1.0 k, 5%, 0.063 W, AEC-Q200 Grade 0,

0402

Resistor, 2.4 M, 5%, 0.1 W, AEC-Q200 Grade 0,

0603

Resistor, 470, 5%, 0.063 W, AEC-Q200 Grade 0,

0402

Resistor, 1.5 M, 5%, 0.1 W, AEC-Q200 Grade 0,

0603

0603

0603

Screw

Header, 2.54

mm, 3×1, TH

Header, 2.54

mm, 2×1, TH

5×2 Shrouded

header

Terminal

Block, 5.08

mm, 2×1, TH

PCB Label

0.650 × 0.200

inch

0402

0603

0402

0603

SW, SMT Half

Pitch 4SPST,

5.8×2.7×6.25

mm

Closed Top

100mil Shunt

www.ti.com

885012006057

06035A100JAT2A

NY PMS 440 0025

PH

22284033

22284023

5103308-1

039544-3002

THT-14-423-10

CRCW060333K0JN

EA

CRCW04021K00JN

ED

CRCW06032M40JN

EA

CRCW0402470RJN

ED

CRCW06034K70JN

EA

CRCW06031M50JN

EA

RT0603DRE07470K

L

RC0603FR07620RL

CRCW060310M0JN

EA

218-4LPST

SPC02SYAN

22

Using the TPS8804EVM

SLVUBT6–October 2019

Submit Documentation Feedback

Copyright © 2019, Texas Instruments Incorporated

Page 23

www.ti.com

Schematic and Bill of Materials

Table 2. Bill of Materials (continued)

REF DES QTY VALUE DESCRIPTION SIZE PART NUMBER

TP1, TP2,

TP3, TP4,

TP5, TP6,

TP7, TP8,

TP10, TP12,

TP13, TP14,

TP15, TP16,

TP17, TP18,

TP20, TP21,

TP22, TP23,

TP24, TP25,

TP26, TP27,

TP28, TP29,

TP30, TP31,

TP33, TP34,

TP35, TP36

TP9, TP19,

TP32, TP37,

TP38

U1 1 TPS8804DCP, DCP0038A (HTSSOP-38) DCP0038A TPS8804DCP

C3 0 0.22 µF Capacitor, ceramic, 0.22 µF, 16 V, ±10%, X7R, 0603 0603 885012206048

C6 0 4.7 µF Capacitor, ceramic, 4.7 µF, 25 V, ±10%, X7R, 0805 0805

C7 0 0.1 µF Capacitor, ceramic, 0.1 µF, 25 V, ±5%, X7R, 0603 0603 06033C104JAT2A

C22 0 1000 pF Capacitor, ceramic, 1000 pF, 50 V, ±10%, X7R, 0603 0603

D5 0 20 V Diode, Schottky, 20 V, 0.5 A, SOD-123 SOD-123 MBR0520LT1G

FID1, FID2,

FID3, FID4,

FID5, FID6

J3, J10, J13 0 Terminal Block, 5.08 mm, 2×1, TH

J11, J12 0 Header, 2.54 mm, 2×1, Tin, TH

L1 0 33 µH

R5, R20 0 1.00 MΩ

R18 0 5.6 MΩ

R19 0 500 kΩ Trimmer, 500k ohm, 0.5W, TH

SH-J5, SH-J6 0 1 × 2 Shunt, 100mil, Flash Gold, Black

TP11 0 Test Point, Multipurpose, Red, TH

32 Test Point, Multipurpose, Red, TH

5 Test Point, Multipurpose, Black, TH

0 Fiducial mark. There is nothing to buy or mount. N/A

Inductor, Drum Core, Ferrite, 33 uH, 0.7 A, 0.38 ohm,

SMD

Resistor, 1.00 M, 1%, 0.1 W, AEC-Q200 Grade 0,

0603

Resistor, 5.6 M, 5%, 0.1 W, AEC-Q200 Grade 0,

0603

Red

Multipurpose

Testpoint

Black

Multipurpose

Testpoint

Terminal

Block, 5.08

mm, 2×1, TH

Header, 2.54

mm, 2 × 1, TH

5×3×4.8 mm

0603

0603

375×190×375

mil

Closed Top

100mil Shunt

Red

Multipurpose

Testpoint

5010

5011

C2012X7R1E475K1

25AB

C0603X102K5RAC

TU

N/A

039544-3002

22284023

SDR0503-330KL

CRCW06031M00FK

EA

CRCW06035M60JN

EA

3386P-1-504LF

SPC02SYAN

5010

SLVUBT6–October 2019

Submit Documentation Feedback

Copyright © 2019, Texas Instruments Incorporated

Using the TPS8804EVM

23

Page 24

IMPORTANT NOTICE AND DISCLAIMER

TI PROVIDES TECHNICAL AND RELIABILITY DATA (INCLUDING DATASHEETS), DESIGN RESOURCES (INCLUDING REFERENCE

DESIGNS), APPLICATION OR OTHER DESIGN ADVICE, WEB TOOLS, SAFETY INFORMATION, AND OTHER RESOURCES “AS IS”

AND WITH ALL FAULTS, AND DISCLAIMS ALL WARRANTIES, EXPRESS AND IMPLIED, INCLUDING WITHOUT LIMITATION ANY

IMPLIED WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE OR NON-INFRINGEMENT OF THIRD

PARTY INTELLECTUAL PROPERTY RIGHTS.

These resources are intended for skilled developers designing with TI products. You are solely responsible for (1) selecting the appropriate

TI products for your application, (2) designing, validating and testing your application, and (3) ensuring your application meets applicable

standards, and any other safety, security, or other requirements. These resources are subject to change without notice. TI grants you

permission to use these resources only for development of an application that uses the TI products described in the resource. Other

reproduction and display of these resources is prohibited. No license is granted to any other TI intellectual property right or to any third

party intellectual property right. TI disclaims responsibility for, and you will fully indemnify TI and its representatives against, any claims,

damages, costs, losses, and liabilities arising out of your use of these resources.

TI’s products are provided subject to TI’s Terms of Sale (www.ti.com/legal/termsofsale.html) or other applicable terms available either on

ti.com or provided in conjunction with such TI products. TI’s provision of these resources does not expand or otherwise alter TI’s applicable

warranties or warranty disclaimers for TI products.

Mailing Address: Texas Instruments, Post Office Box 655303, Dallas, Texas 75265

Copyright © 2019, Texas Instruments Incorporated

Loading...

Loading...