Page 1

www.ti.com

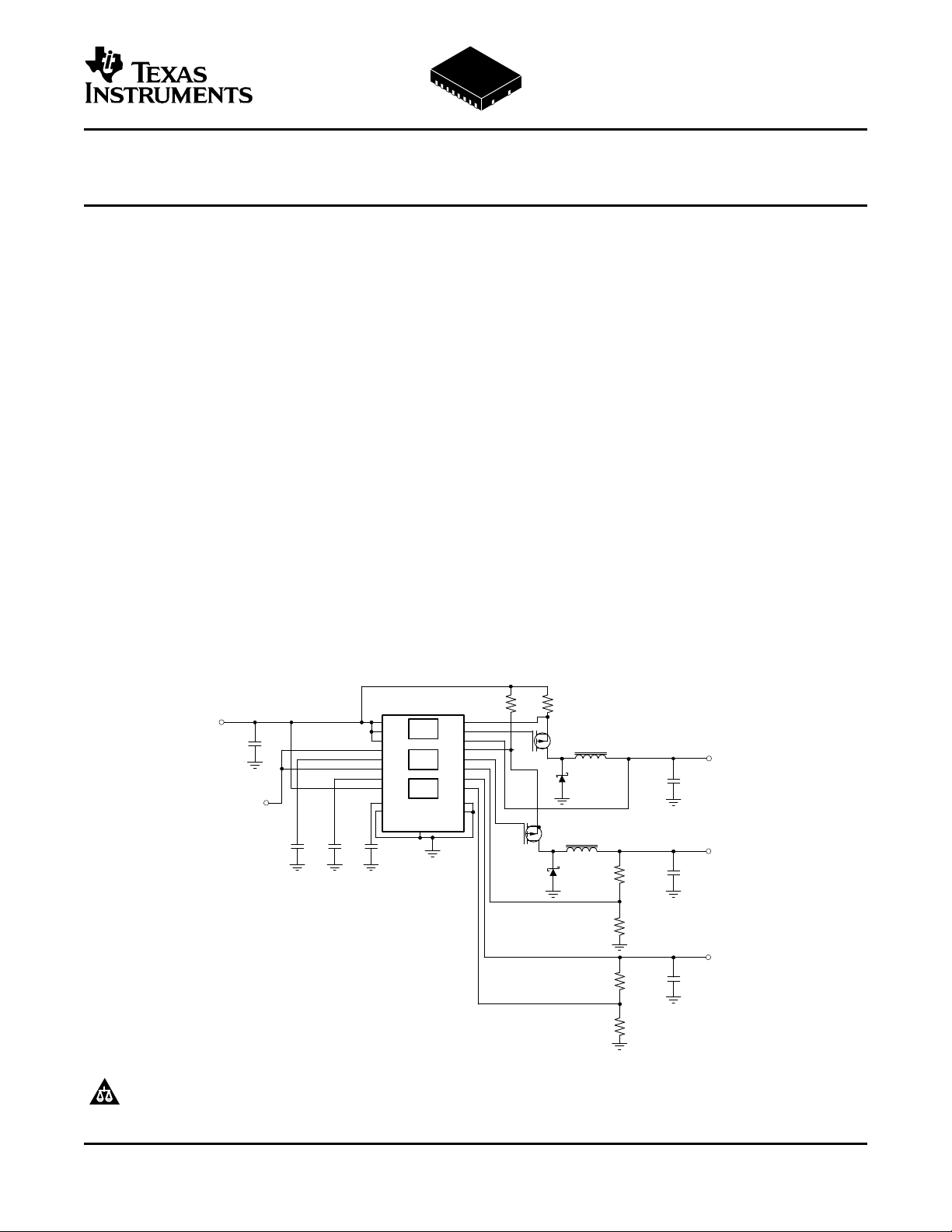

IN1

IN2

IN3

EN1

SS1

EN2

SS2

EN3

IS1

SW 1

FB1

IS2

SW 2

FB2

OUT 3

FB3

DGN D

3A

BUC K1

3A

BUC K2

300mA

LDO

SS3

DGND

AGN D

DGND

TPS75003

+

+

V

CCAUX

2.5V @ 300m A

V

CCO

3.3V @ 3A

V

CCINT

1.2V @ 3A

V

CCAUX

5V_Input

Triple-Supply Power Management IC

for Powering FPGAs and DSPs

FEATURES DESCRIPTION

• Two 95% Efficient, 3A Buck Controllers and

One 300mA LDO

• Tested and Endorsed by Xilinx for Powering

the Spartan™-3, Spartan-3E and Spartan-3L

FPGAs

• Adjustable (1.2V to 6.5V for Bucks, 1.0V to

6.5V for LDO) Output Voltages on All

Channels

• Input Voltage Range: 2.2V to 6.5V

• Independent Soft-Start for Each Supply

• Independent Enable for Each Supply for

Flexible Sequencing

• LDO Stable with 2.2µF Ceramic Output Cap

• Small, Low-Profile 4.5mm x 3.5mm x 0.9mm

QFN Package

APPLICATIONS

• FPGA/DSP/ASIC Supplies

• Set-Top Boxes

• DSL Modems

• Plasma TV Display Panels

TPS75003

SBVS052D – OCTOBER 2004 – REVISED MARCH 2005

The TPS75003 is a complete power management

solution for FPGA, DSP and other multi-supply applications. The device has been tested with and meets

all of the Xilinx Spartan-3, Spartan-3E and

Spartan-3L start-up profile requirements, including

monotonic voltage ramp and minimum voltage rail

rise time. Independent Enables for each output allow

sequencing to minimize demand on the power supply

at start-up. Soft-start on each supply limits inrush

current during start-up. Two integrated buck controllers allow efficient, cost-effective voltage conversion

for both low and high current supplies such as core

and I/O. A 300mA LDO is integrated to provide an

auxiliary rail such as V

FPGA. All three supply voltages are offered in

user-programmable options for maximum flexibility.

The TPS75003 is fully specified from -40 ° C to +85 ° C

and is offered in a QFN package, yielding a highly

compact total solution size with high power dissipation capability.

on the Xilinx Spartan-3

CCAUX

Please be aware that an important notice concerning availability, standard warranty, and use in critical applications of Texas

Instruments semiconductor products and disclaimers thereto appears at the end of this data sheet.

Spartan is a trademark of Xilinx, Inc.

All trademarks are the property of their respective owners.

PRODUCTION DATA information is current as of publication date.

Products conform to specifications per the terms of the Texas

Instruments standard warranty. Production processing does not

necessarily include testing of all parameters.

Copyright © 2004–2005, Texas Instruments Incorporated

Page 2

www.ti.com

TPS75003

SBVS052D – OCTOBER 2004 – REVISED MARCH 2005

This integrated circuit can be damaged by ESD. Texas Instruments recommends that all integrated

circuits be handled with appropriate precautions. Failure to observe proper handling and installation

procedures can cause damage.

ESD damage can range from subtle performance degradation to complete device failure. Precision

integrated circuits may be more susceptible to damage because very small parametric changes could

cause the device not to meet its published specifications.

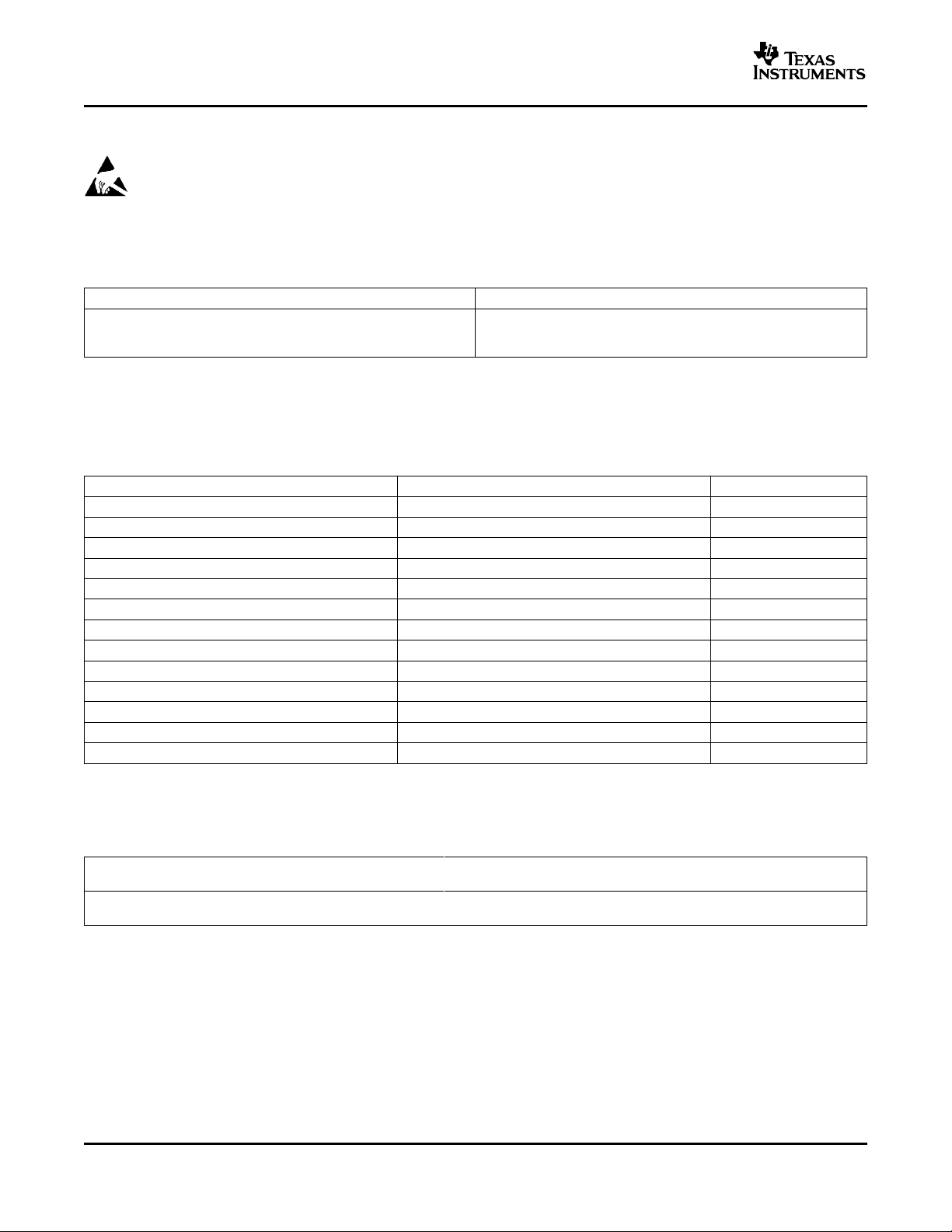

ORDERING INFORMATION

PRODUCT V

(1)

OUT

Buck1: Adjustable

TPS75003 Buck2: Adjustable

LDO: Adjustable

(1) For the most current specifications and package information, see the Package Option Addendum located at the end of this document, or

see the TI website at www.ti.com .

ABSOLUTE MAXIMUM RATINGS

over operating free-air temperature range (unless otherwise noted)

V

range (IN1, IN2, IN3) -0.3 to +7.0 V

INX

V

range (EN1, EN2, EN3) -0.3 to V

ENX

V

range (SW1, SW2, SW3) -0.3 to V

SWX

V

range (IS1, IS2, IS3) -0.3 to V

ISX

V

range -0.3 to +7.0 V

OUT3

V

range (SS1, SS2, SS3) -0.3 to V

SSX

V

range (FB1, FB2, FB3) -0.3 to +3.3 V

FBX

Peak LDO output current (I

Continuous total power dissipation See Dissipation Ratings Table —

Junction temperature range, T

Storage temperature range -65 to +150 ° C

ESD rating, HBM 1 kV

ESD rating, CDM 500 V

(1) Stresses beyond those listed under absolute maximum ratings may cause permanent damage to the device. These are stress ratings

only, and functional operation of the device at these or any other conditions beyond those indicated under the Electrical Characteristics

is not implied. Exposure to absolute maximum rated conditions for extended periods may affect device reliability.

) Internally limited —

OUT3

J

(1)

TPS75003 UNIT

+0.3 V

INX

+0.3 V

INX

+0.3 V

INX

+0.3 V

INX

-55 to +150 ° C

DISSIPATION RATINGS

BOARD R

Reference

(1)

Layout

Θ JA

44 22.7mW/ ° C 2.27W 1.25W 0.91W

(1) Refer to PCB Layout section. Internal power dissipation limits are determined by LDO operation: P

2

DERATING FACTOR TA≤ 25 ° C TA= 70 ° C TA= 85 ° C

ABOVE TA= 25 ° C POWER RATING POWER RATING POWER RATING

= (V

– V

) x I

DISS

IN3

OUT3

.

OUT3

Page 3

www.ti.com

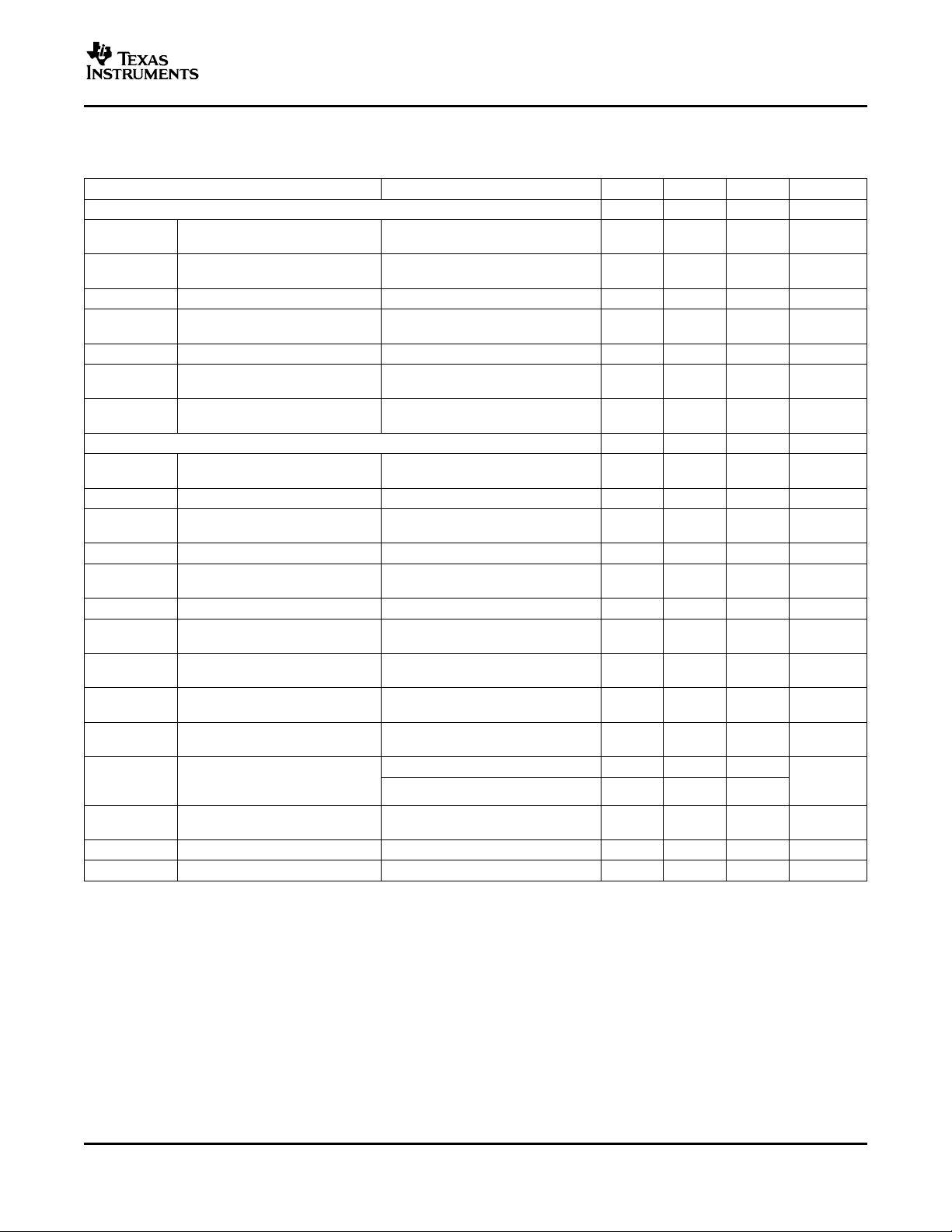

ELECTRICAL CHARACTERISTICS

V

= V

, V

= V

, V

= V

, V

= V

EN1

IN1

EN2

IN2

EN3

IN3

IN1

IN2

= 2.2V, V

TA= -40 ° C to +85 ° C, unless otherwise noted. Typical values are at TA= 25 ° C.

PARAMETER CONDITIONS MIN TYP MAX UNIT

Supply and Logic

V

INX

I

Q

I

SHDN

V

IH1, 2

V

IH3

V

ILX

I

ENX

Buck Controllers 1 and 2

V

OUT1,2

V

FB1,2

I

FB1,2

V

IS1,2

I

IS1,2

∆ V

/ ∆ V

OUT%

∆ V

/ ∆ I

OUT%

n

1,2

t

STR1,2

R

DS,ON1,2

I

SW1,2

t

ON

t

OFF

(1) To be in regulation, minimum V

components. Minimum V

(2) Maximum V

(3) Depends on external components.

Input Voltage Range (IN1, IN2,

(1)

IN3)

Quiescent Current, IQ= I

I

AGND

Shutdown Supply Current V

+

DGND

I

OUT1

EN1

Enable High, enabled

(EN1, EN2)

Enable High, enabled (EN3) 1.14 V

Enable Low, shutdown

(EN1, EN2, EN3)

Enable pin current (EN1, EN2,

EN3)

Adjustable Output Voltage

(2)

Range

Feedback Voltage (FB1, FB2) 1.220 V

Feedback Voltage Accuracy

(1)

(FB1, FB2)

Current into FB1, FB2 pins 0.01 0.5 µA

Reference Voltage for Current

Sense

Current into IS1, IS2 Pins 0.01 0.5 µA

Line Regulation

IN

Load Regulation 0.6 % / A

OUT

Efficiency

Startup Time

(1)

(3)

(3)

Gate Driver P-Channel and V

N-Channel MOSFET Ω

On-Resistance

Measured with the circuit in Figure 1 ,

V

OUT

Measured with the circuit in Figure 1 ,

30mA ≤ I

Measured with the circuit in Figure 1 ,

I

OUT

Measured with the circuit in Figure 1 ,

RL= 6 Ω , C

IN1,2

V

IN1,2

Gate Driver P-Channel and

N-Channel MOSFET Drive Current

Minimum On Time 1.36 1.55 1.84 µs

Minimum Off Time 0.44 0.65 0.86 µs

(or V

IN1

= V

IN3

is dependent on external components and will be less than VIN.

OUT

OUT3

) must be greater than V

IN2

+ V

or 2.2V, whichever is greater.

DO

= 3.0V, V

IN3

= I

= 0mA, I

OUT2

= V

= V

EN2

OUT3

OUT3

= 0V 0.05 3.0 µA

EN3

+ 0.5V ≤ VIN≤ 6.5V

≤ 2A

OUT

= 1A

= 100µF, C

OUT

> 2.5V 4

= 2.2V 6

OUT1,NOM

TPS75003

SBVS052D – OCTOBER 2004 – REVISED MARCH 2005

= 2.5V, C

= 1mA 75 150 µA

= 2.2nF

SS

(or V

OUT2,NOM

= C

OUT1

OUT2

= 47µF, C

2.2 6.5 V

1.4 V

0 0.3 V

0.01 0.5 µA

V

FBX

-2 +2 %

80 100 120 mV

0.1 % / V

94 %

5 ms

100 mA

) by an amount determined by external

= 2.2µF,

OUT3

INX

IN3

V

INX

V

V

V

3

Page 4

www.ti.com

TPS75003

SBVS052D – OCTOBER 2004 – REVISED MARCH 2005

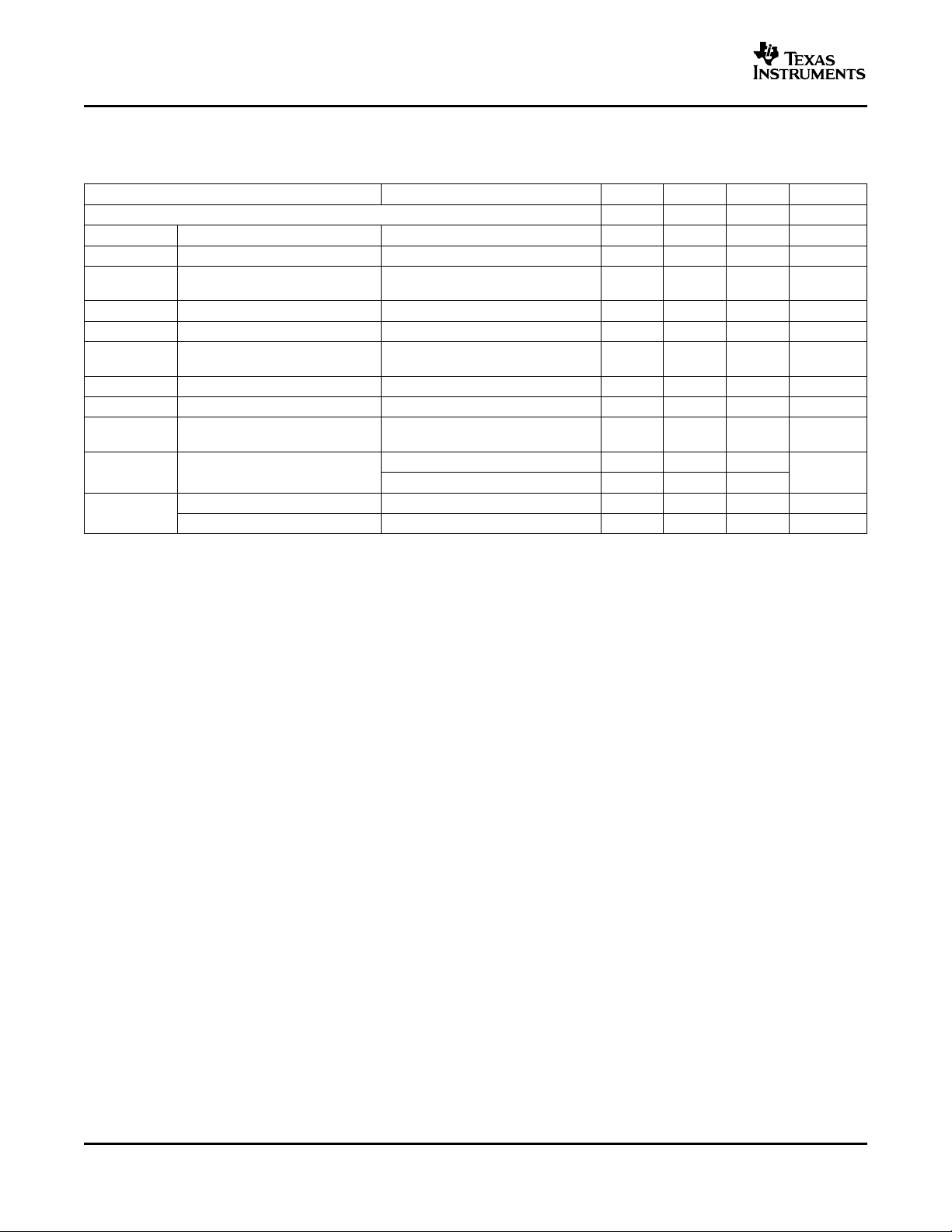

ELECTRICAL CHARACTERISTICS (continued)

V

= V

, V

= V

, V

= V

, V

= V

EN1

IN1

EN2

IN2

EN3

IN3

IN1

IN2

= 2.2V, V

TA= -40 ° C to +85 ° C, unless otherwise noted. Typical values are at TA= 25 ° C.

PARAMETER CONDITIONS MIN TYP MAX UNIT

LDO

V

OUT3

V

FB3

∆ V

/ ∆ V

OUT%

∆ V

/ ∆ I

OUT%

V

DO

I

CL3

I

FB3

V

n

t

SD

UVLO

Output Voltage Range 1.0 6.5 - V

Feedback Pin Voltage 0.507 V

2.95V ≤ V

Feedback Pin Voltage Accuracy

Line Regulation

IN

Load Regulation 10mA ≤ I

OUT

Dropout Voltage

(V

= V

IN

(4)

(5)

OUT(NOM)

- 0.1)

Current Limit V

(4)

1mA ≤ I

V

OUT3

I

OUT3

OUT

Current into FB3 pin 0.03 0.1 µA

Output Noise 400 µV

Thermal Shutdown Temperature

for LDO

BW = 100Hz - 100kHz,

I

OUT3

Shutdown, Temp Increasing 175

Reset, Temp Decreasing 160

Under-Voltage Lockout Threshold VINRising 1.80 V

Under-Voltage Lockout Hysteresis VINFalling 100 mV

= 3.0V, V

IN3

≤ 6.5V

IN3

≤ 300mA

OUT3

+ 0.5V ≤ V

≤ 300mA 0.01 % / mA

OUT3

OUT3

≤ 6.5V 0.075 % / V

IN3

= 300mA 250 350 mV

= 0.9 x V

OUT(NOM)

= 300mA

= 2.5V, C

= C

OUT1

OUT2

= 47µF, C

-4.0 +4.0 %

375 600 1000 mA

= 2.2µF,

OUT3

DO

V

RMS

° C

(4) To be in regulation, minimum V

components. Minimum V

(5) V

does not apply when V

DO

IN3

(or V

IN1

= V

OUT3

+ V

OUT

) must be greater than V

IN2

+ V

or 2.2V, whichever is greater.

DO

< 2.2V.

DO

OUT1,NOM

(or V

OUT2,NOM

) by an amount determined by external

4

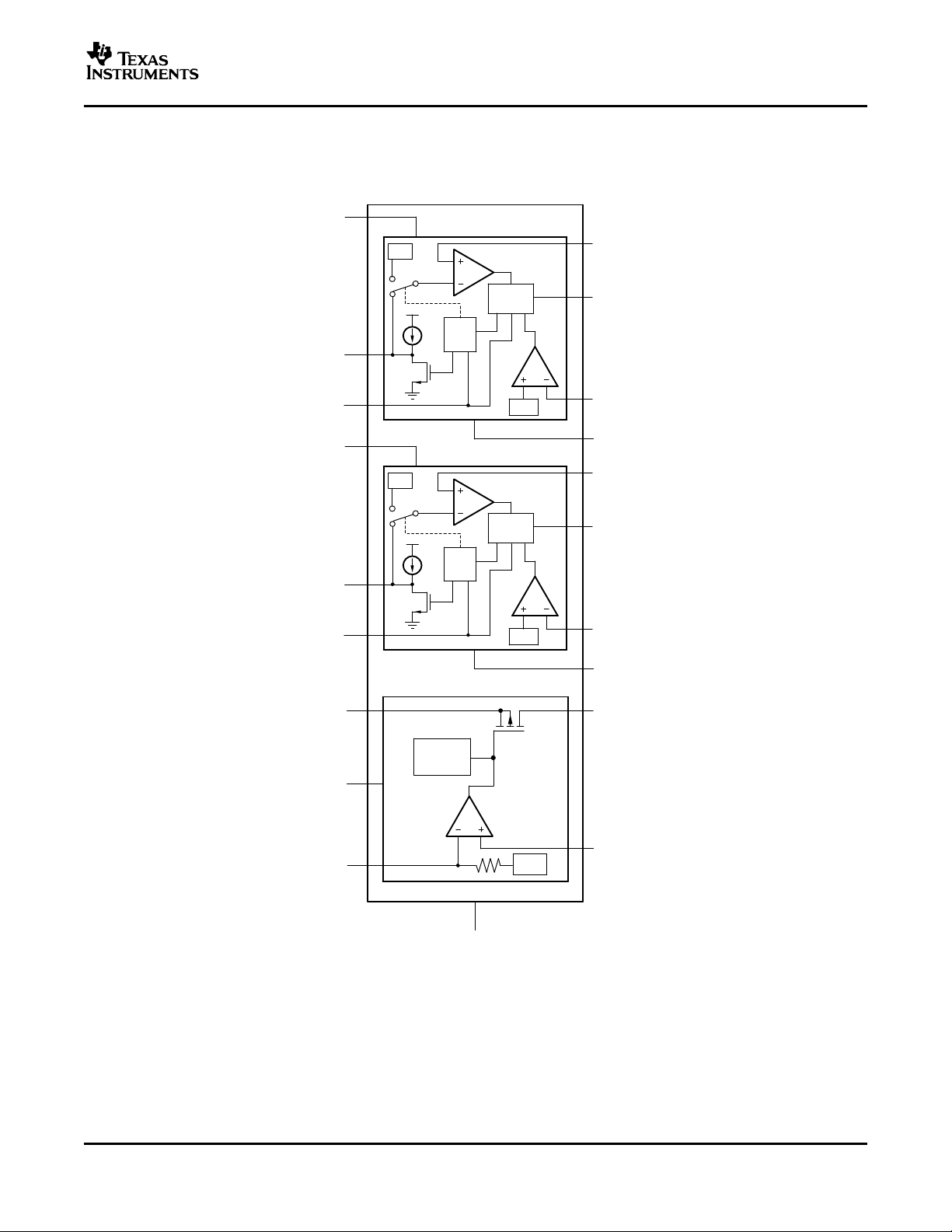

Page 5

www.ti.com

V

RE F1

Soft

Start

Control

Switch

Control

V

IS1

IS1

SW1

FB1

EN1

SS1

IN1

≤

3A Buck Controller

DGND

V

RE F2

Soft

Start

Control

Switch

Control

V

IS2

IS2

SW2

FB2

EN2

SS2

IN2

≤

3A Buck Controller

DGND

FB3

OUT3IN3

EN3

SS3

Thermal/

Current

Limit

300mA LDO

V

REF 3

AGND

TPS75003

TPS75003

SBVS052D – OCTOBER 2004 – REVISED MARCH 2005

DEVICE INFORMATION

Functional Block Diagram

5

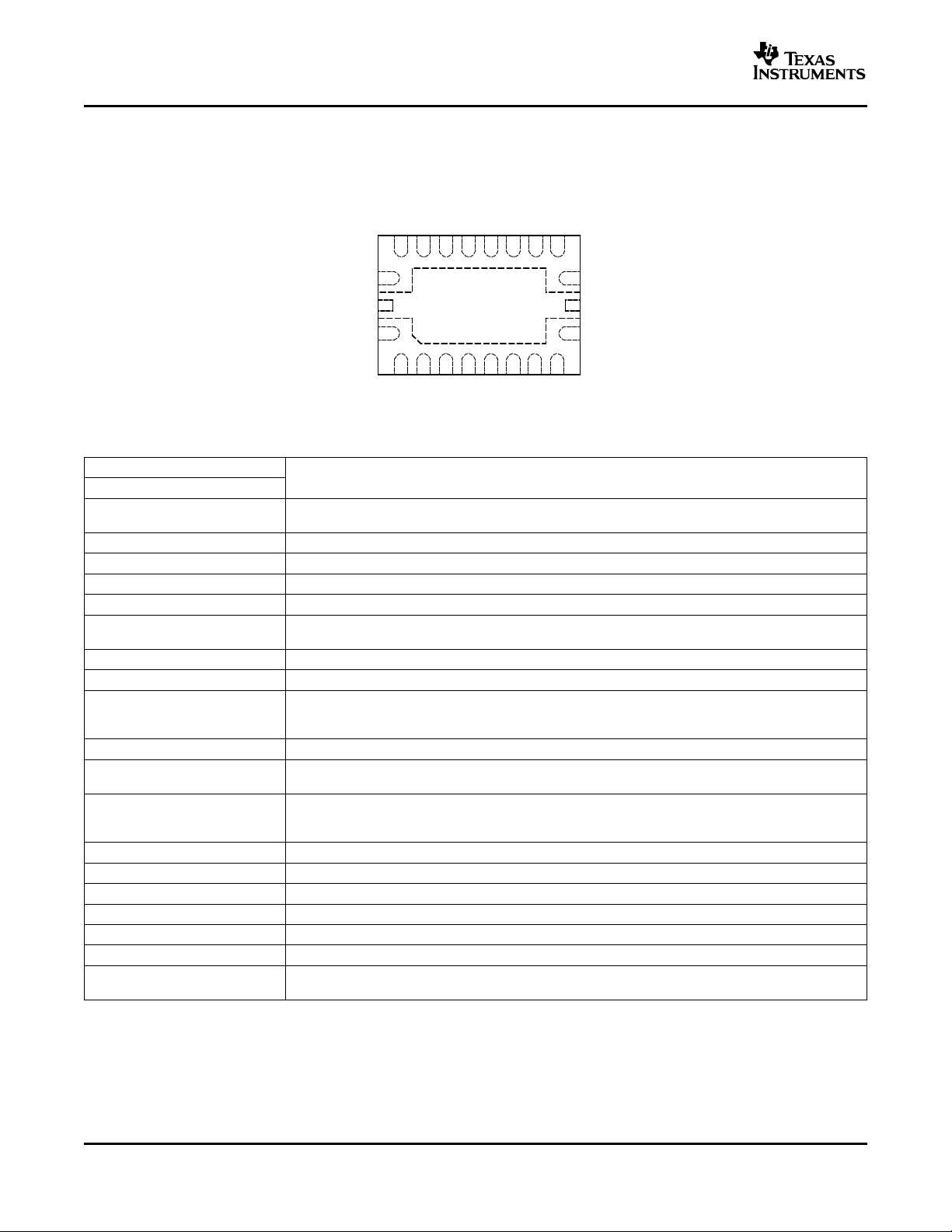

Page 6

www.ti.com

IN3

OUT3

FB1

FB2

20

1

11

10

DGND

SS3

AGND

EN1

SS1

DGND

SW1

IN1

IS1

19

18

17

16

15

14

13

12

FB3

EN3

EN2

SS2

DGND

SW2

IN2

IS2

2

3

4

5

6

7

8

9

RHL PACKAGE

4.5mm x 3.5mm QFN

(TOP VIEW)

TPS75003

SBVS052D – OCTOBER 2004 – REVISED MARCH 2005

DEVICE INFORMATION (continued)

TERMINAL

NAME RHL

DGND 6, 15, PAD

AGND 18 Ground connection for LDO.

IN1 13 Input supply to BUCK1.

IN2 8 Input supply to BUCK2.

IN3 20 Input supply to LDO.

EN1 17

EN2 4 Same as EN1 but for BUCK2 controller.

EN3 3 Same as EN1 but for LDO.

SS1 16 slowing the ramp-up of current limit. This high-impedance pin is noise-sensitive; careful layout is

SS2 5 Same as SS1 but for BUCK2 regulator.

SS3 19

IS1 12 to an internal reference to set current limit. For a robust output start-up ramp, careful layout and

IS2 9 Same as IS1 but compared to IN2 and used for BUCK2 controller.

SW1 14 Gate drive pin for external BUCK1 P-channel MOSFET.

SW2 7 Same as SW1 but for BUCK2 controller.

FB1 11 Feedback pin. Used to set the output voltage of BUCK1 regulator.

FB2 10 Same as FB1 but for BUCK2 controller.

FB3 2 Same as FB1 but for LDO.

OUT3 1

TERMINAL FUNCTIONS

DESCRIPTION

Ground connection for BUCK1 and BUCK2 converters. Pins 6 and 15 should be connected to the back

side exposed pad by a short metal trace as shown in the PCB Layout section of this data sheet.

Driving the enable pin (ENx) high turns on BUCK1 regulator. Driving this pin low puts it into shutdown

mode, reducing operating current. The enable pin does not trigger on fast negative going transients.

Connecting a capacitor between this pin and ground increases start-up time of the BUCK1 regulator by

important. See Typical Characteristics, Applications and PCB Layout sections for details.

Connecting a capacitor from this pin to ground slows the start-up time of the LDO reference, therby

slowing output voltage ramp-up. See Applications section for details.

Current sense input for BUCK1 regulator. The voltage difference between this pin and IN1 is compared

bypassing are required. See Applications section for details.

Regulated LDO output. A small ceramic capacitor ( ≥ 2.2µF) is needed from this pin to ground to ensure

stability.

6

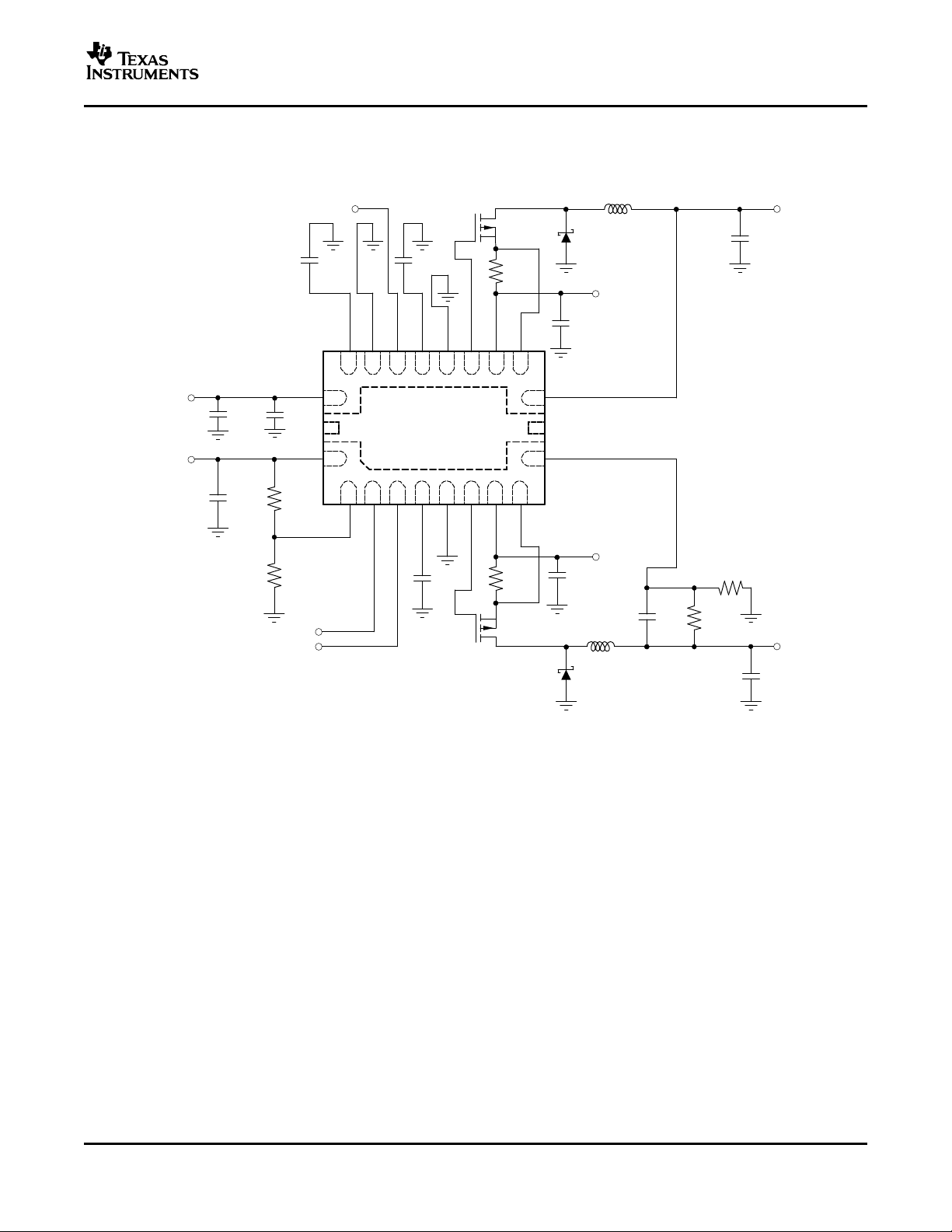

Page 7

www.ti.com

L1

5µH

Sumida

CDRH6D38−5R0

IN3

OUT3

FB1

FB2

20

1

11

10

DGND

SS3

AGND

EN1

SS1

DGND

SW1

IN1

IS1

19

18

17

16

15

14

13

12

FB3

EN3

EN2

SS2

DGND

SW2

IN2

IS2

2

3

4

5

6

7

8

9

R3

61.9k

Ω

R4

15.4k

Ω

EN3

EN2

V

IN

EN1

V

IN

1.5nF

1.5nF

0.01µF

R1

33m

Ω

10pF

100µF

Tantalum

100µF

Tantalum

Siliconix

Si2323DS

Siliconix

Si2323DS

Q2

L2

15µH

Sumida

CDRH8D43−150

V

CCINT

1.2V, 2A

Vishay

SS32

D2

0.1µF

1µF

V

CCAUX

2.5V, 300mA

10µF

0.1µF

R5

61.9k

Ω

ON Semiconductor

MBRM120

R6

36.5k

Ω

V

CCO

3.3V, 2A

R2

33m

Ω

100µF

V

IN

Q1

SBVS052D – OCTOBER 2004 – REVISED MARCH 2005

Typical Application Circuit for Powering the Xilinx Spartan-3 FPGA

TPS75003

Figure 1.

7

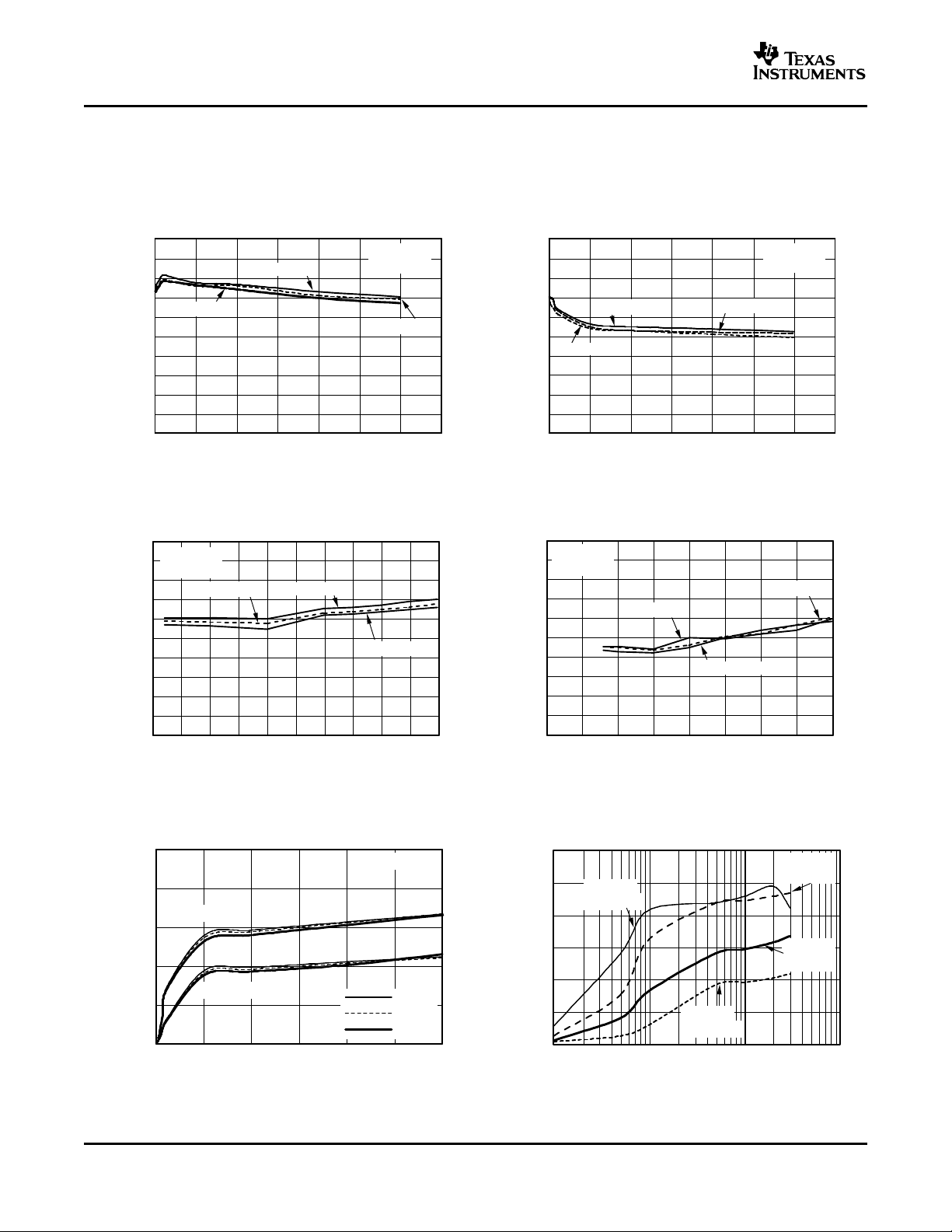

Page 8

www.ti.com

0 0.5 1.0 1.5 2.0 2.5 3.0 3.5

I

OUT

(A)

VIN= 3.3V

V

OUT

= 1.2V

TA= +85C

TA=−40C

TA= +25C

5

4

3

2

1

0

−

1

−

2

−

3

−

4

−

5

∆ V

OUT

(%)

0 0.5 1.0 1.5 2.0 2.5 3.0 3.5

I

OUT

(A)

VIN= 5V

V

OUT

= 3.3V

5

4

3

2

1

0

−

1

−

2

−

3

−

4

−

5

∆

V

OUT

(%)

TA= +85C

TA=−40C

TA= +25C

3.0

V

IN

(V)

5

4

3

2

1

0

−

1

−

2

−

3

−

4

−

5

∆

V

OUT

(

%)

V

OUT

= 3.3V

I

OUT

= 2A

3.5 4.0 4.5 5.0 5.5 6.0 6.5 7.0

TA= +85C

TA= +25C

TA=−40C

2.0

V

IN

(V)

5

4

3

2

1

0

−

1

−

2

−

3

−

4

−

5

∆

V

OUT

(

%)

V

OUT

= 1.2V

I

OUT

= 2A

2.5 3.0 3.5 4.0 4.5 5.0 5.5 6.0 6.5 7.0

TA=−40C

TA= +25C

TA= +85C

0 0.5 1.0 1.5 2.0 2.5 3.0

500

400

300

200

100

0

Switching F

requency(kHz)

I

OUT

(A)

V

OUT

= 1.2V

VIN= 3.3V

VIN= 5.0V

−

40C

+25C

+85C

600

500

400

300

200

100

0

Switching Frequency (kHz)

0.01 0.1 1.0 10

I

OUT

(A)

VIN= 5.0V

V

OUT

= 1.2V

VIN= 3.3V

V

OUT

= 1.2V

VIN= 5.0V

V

OUT

= 3.3V

V

OUT

= 1.2V

VIN= 2.2V

TPS75003

SBVS052D – OCTOBER 2004 – REVISED MARCH 2005

Buck Converter

BUCK LOAD REGULATION BUCK LOAD REGULATION

Figure 2. Figure 3.

TYPICAL CHARACTERISTICS

Measured using circuit in Figure 1

BUCK LINE REGULATION BUCK LINE REGULATION

Figure 4. Figure 5.

BUCK SWITCHING FREQUENCY vs I

, T

OUT

A

BUCK SWITCHING FREQUENCY vs I

OUT

8

Figure 6. Figure 7.

Page 9

www.ti.com

1µs/div

VIN= 5.0V

V

OUT

= 3.3V

I

OUT

= 2A

20mV/div

100

90

80

70

60

50

40

30

20

10

0

Efficiency (%)

0.0001 0.001 0.01 0.1 1 10

I

OUT

(A)

VIN= 5.0V

V

OUT

= 3.3V

VIN= 3.3V

V

OUT

= 1.2V

VIN= 5.0V

V

OUT

= 1.2V

EN

VIN= 5V,C

OUT

= 330µF

VIN= 5V,C

OUT

= 100µF

VIN= 3.3V, C

OUT

= 680µF

VIN= 3.3V,C

OUT

= 100µF

CSS= 0.01µF

V

OUT

= 1.2V

20ms/div

V

OUT

(500mV/div)

EN

VIN= 5V,I

OUT

= 0.5A

VIN= 5V,I

OUT

= 1.0A

VIN= 5V,I

OUT

= 2.0A

VIN= 3.3V, I

OUT

= 1.0A

CSS= 0.01µF

V

OUT

= 1.2V

20ms/div

V

OUT

(500mV/div)

VIN= 3.3V,I

OUT

= 2.0A

EN

VIN= 3.3V,CSS= 0.001µF

VIN= 5V, CSS= 0.001µF

VIN= 5V, CSS= 0.01µF

VIN= 3.3V,CSS= 0.01µF

I

OUT

= 1A

V

OUT

= 1.2V

20ms/div

V

OUT

(500mV/div)

EN

I

OUT

= 2A,

CSS= 560pF

I

OUT

= 0.5A,

CSS= 560pF

I

OUT

= 0.5A, CSS= 1500pF

I

OUT

= 2A, CSS= 1500pF

VIN= 5V

V

OUT

= 3.3V

5ms/div

V

OUT

(2V/div)

TYPICAL CHARACTERISTICS (continued)

Measured using circuit in Figure 1

TPS75003

SBVS052D – OCTOBER 2004 – REVISED MARCH 2005

BUCK OUTPUT VOLTAGE RIPPLE EFFICIENCY vs I

Figure 8. Figure 9.

BUCK START-UP BUCK START-UP

vs vs

VINand I

OUT

VINand C

OUT

OUT

BUCK START-UP BUCK START-UP

Figure 10. Figure 11.

vs vs

VINand C

SS

Figure 12. Figure 13.

I

and C

OUT

SS

9

Page 10

www.ti.com

EN

VIN= 3.3V,

I

OUT

= 1A,

R

S

= 0.020

VIN=5V, I

OUT

= 1A,

RS= 0.033

VIN= 3.3V,

I

OUT

= 1A,

RS= 0.033

V

IN

= 5V,

I

OUT

= 1A,

RS= 0.020

V

OUT

= 1.2V, CSS= 0.01µF

20ms/div

V

OUT

(1V/div)

∆V

OUT

(%)

0 0.05 0.1 0.15 0.2 0.25 0.3 0.35 0.4

5

4

3

2

1

0

−

1

−

2

−

3

−

4

−

5

I

OUT

(A)

VIN= 3.3V

V

OUT

= 2.5V

TA= +25C

TA= +85C

TA=−40C

∆V

OUT

(%)

3.0 3.5 4.0 4.5 5.0 5.5 6.0 6.5 7.0

VIN(V)

V

OUT

= 2.5V

I

OUT

= 1mA

TA= +85C

5

4

3

2

1

0

−

1

−

2

−

3

−

4

−

5

TA= +25C

TA=−40C

450

400

350

300

250

200

150

100

50

0

V

D

O

(mV

)

Ambient Temperature (C)

−40−25−

10 5 20 35 50 65 8580

V

OUT

= 2.5V

I

OUT

= 300mA

500

400

300

200

100

0

V

DO

(mV)

0 50 100 150 200 250 300 350 400 450

I

OUT

(mA)

TA=−40C

TA= +25C

TA= +85C

VIN= 3.3V

V

OUT

= 2.5V

TPS75003

SBVS052D – OCTOBER 2004 – REVISED MARCH 2005

TYPICAL CHARACTERISTICS (continued)

Measured using circuit in Figure 1

LDO Converter

BUCK START-UP

VINand R

vs

SENSE

Figure 14.

LDO LOAD REGULATION LDO LINE REGULATION

LDO DROPOUT vs I

10

Figure 15. Figure 16.

LDO DROPOUT vs T

OUT

Figure 17. Figure 18.

A

Page 11

www.ti.com

2.0 2.5 3.0 3.5 4.0 4.5 5.0 5.5 6.0 6.5 7.0

12

10

8

6

4

2

0

R

DS,ON

( Ω)

VIN(V)

TA=−40C

TA= +25C

TA= +85C

2.0 2.5 3.0 3.5 4.0 4.5 5.0 5.5 6.0 6.5 7.0

12

10

8

6

4

2

0

R

DS, ON

( Ω)

VIN(V)

TA=−40C

TA= +25C

TA= +85C

2.525

2.520

2.515

2.510

2.505

2.500

2.495

2.490

2.485

2.480

2.475

V

OUT

(V)

−

40

−

15 10 35 60 85

Ambient Temperature (C)

VIN= 3.3V

TYPICAL CHARACTERISTICS (continued)

Measured using circuit in Figure 1

R

DS,ON

SBVS052D – OCTOBER 2004 – REVISED MARCH 2005

PMOSvs V

IN

R

NMOSvs V

DS,ON

Figure 19. Figure 20.

TPS75003

IN

LDO V

Figure 21.

vs T

OUT

A

11

Page 12

www.ti.com

TPS75003

SBVS052D – OCTOBER 2004 – REVISED MARCH 2005

APPLICATION INFORMATION

The TPS75003 is an integrated power management IC designed specifically to power DSPs and FPGAs such as

the Xilinx Spartan-3, Spartan-3E and Spartan-3L. Two non-synchronous buck controllers can be configured to

supply up to 3A for both CORE and I/O rails. A low dropout linear regulator powers auxiliary rails up to 300mA.

All channels have independent enable and soft-start, allowing control of inrush current and output voltage ramp

time as required by the application.

Figure 1 shows a typical application circuit for powering the Xilinx Spartan-3 FPGA. Table 1 through Table 4

show component values that have been tested for use with 2A and 3A load currents. Other similar external

components can be substituted as desired; however, in all cases the circuits that are used should be tested for

compliance to application requirements.

Table 1. Inductors Tested with the TPS75003

PART NUMBER MANUFACTURER INDUCTANCE DC RESISTANCE SATURATION CURRENT

SLF7032T–100M1R4 TDK 10µH ± 20% 53m Ω ± 20% 1.4A

SLF6025–150MR88 TDK 15µH ± 20% 85m Ω ± 20% 0.88A

CDRH6D28–5R0 Sumida 5µH 23m Ω 2.4A

CDRH6D38-5R0 Sumida 5µH 18m Ω 2.9A

CDRH103R–100 Sumida 10µH 45m Ω 2.4A

CDRH4D28–100 Sumida 10µH 96m Ω 1.0A

CDRH8D43-150 Sumida 15µH 42m Ω 2.9A

CDRH5D18–6R2 Sumida 6.2µH 71m Ω 1.4A

DO3316P–472 Coilcraft 4.7µH 18m Ω 5.4A

DT3316P–153 Coilcraft 15µH 60m Ω 1.8A

DT3316P–223 Coilcraft 22µH 84m Ω 1.5A

744052006 Würth 6.2µH 80m Ω 1.45A

74451115 Würth 15µH 90m Ω 0.8A

Table 2. PMOS Transistors Tested with the TPS75003

PART NUMBER MANUFACTURER R

Si5447DC Vishay Siliconix 0.11 Ω at VGS = –2.5V –20V –3.5A at +25 ° C 1206

Si5475DC Vishay Siliconix 0.041 Ω at VGS = –2.5V –12V –6.6A at +25 ° C 1206

Si2323DS Vishay Siliconix 0.052 Ω at VGS = –2.5V –20V –4.1A at +25 ° C SOT23

Si2301ADS Vishay Siliconix 0.19 Ω at VGS = –2.5V –20V –1.4A at +25 ° C SOT23

Si2323DS Vishay Siliconix 0.41 Ω at VGS = –2.5V –20V –4.1A at +25 ° C SOT23

FDG326P Fairchild 0.17 Ω at VGS = –2.5V –20V –1.5A SC70

(TYP) V

DS,ON

DS

I

D

PACKAGE

Table 3. Diodes Tested with the TPS75003

PART NUMBER MANUFACTURER V

MBRM120LT3 ON Semiconductor 20V 1.0A DO216AA

MBR0530T1 ON Semiconductor 30V 1.5A SOD123

ZHCS2000TA Zetex 40V 2.0A SOT23–6

B320 Diodes Inc. 20V 3.0A SMA

SS32 Fairchild 20V 3.0A DO214AB

R

I

F

PACKAGE

12

Page 13

www.ti.com

0.1µF

R

D

Q L

f = measured resonant

frequency at switch node

R = 2πfL

TPS75003

SBVS052D – OCTOBER 2004 – REVISED MARCH 2005

Table 4. Capacitors Tested with the TPS75003

PART NUMBER MANUFACTURER CAPACITANCE ESR VOLTAGE RATING

6TPB47M (PosCap) Sanyo 47µF 0.1 Ω 6.3V

T491D476M010AS Kemet 47µF 0.8 Ω 10V

B45197A Epco 47µF 0.175 Ω 16V

B45294–R1107–M40 Epco 100µF 0.045 Ω 6.3V

594D476X0016C2 Vishay 47µF 0.11 Ω 16V

594D127X96R3C2 Vishay 120µF 0.085 Ω 6.3V

TPSC107K006R0150 AVX 100µF 0.15 Ω 6.3V

6TPS100MC Sanyo 100µF 0.45 Ω 6.3V

OPERATION (BUCK CONTROLLERS)

Channels 1 and 2 contain two identical non-synchronous buck controllers that use minimum on-time/minimum

off-time hysteretic control. (Refer to Figure 1 .) For clarity, BUCK1 is used throughout the discussion of device

operation. When V

increasing current through the inductor (L1) until V

reached. Once either of these conditions is met, the PMOS is switched off for at least the minimum off-time of

the device. After the minimum off-time has passed, the output voltage is monitored and the switch is turned on

again when necessary.

When output current is low, the buck controllers operate in discontinuous mode. In this mode, each switching

cycle begins at zero inductor current, rises to a maximum value, then falls back to zero current. When current

reaches zero on the falling edge, ringing occurs at the resonant frequency of the inductor and stray switch node

capacitance. This is normal operation; it does not affect circuit performance, and can be minimized if desired by

using an RC snubber and/or a resistor in series with the gate of the PMOS, as shown in Figure 22 .

is below its target, an external PMOS (Q1) is turned on for at least the minimum on-time,

OUT1

reaches its target value or the current limit (set by R1) is

OUT1

At higher output currents, the TPS75003 operates in continuous mode. In continuous mode, there is no ringing at

the switch node and V

When V

the external PMOS to allow regulation at lower dropout than would otherwise be possible.

Enable (Buck Controllers)

The enable pins (EN1 and EN2) for the buck controllers are active high. When the enable pin is driven low and

input voltage is present at IN1 or IN2, an on-chip FET is turned on to discharge the soft-start pin SS1 or SS2,

respectively. If the soft-start feature is being used, enable should be driven high at least 10 µ s after V

to ensure this discharge cycle occurs.

UVLO (Buck Controllers)

An under-voltage lockout circuit is present to prevent turning on the external PMOS (Q1 or Q2) until a reliable

operating voltage is reached on the appropriate regulator (IN1 or IN2). This prevents the buck controllers from

mis-operation at low input voltages.

Figure 22. RC Snubber and Series Gate Resistor Used to Minimize Ringing

is equal to V

OUT

approaches or falls below V

IN

times the duty cycle of the switching waveform.

IN

, the buck controllers operate in 100% duty cycle mode, fully turning on

OUT

is applied

IN

13

Page 14

www.ti.com

I

LIMIT

V

IS1,2

R

1,2

I

RMS

I

OUT

D I

OUT

V

OUT

V

IN

P

DISS

I

RMS

2

R

TPS75003

SBVS052D – OCTOBER 2004 – REVISED MARCH 2005

Current Limit (Buck Controllers)

An external resistor (R1 or R2) is used to set the current limit for the external PMOS transistor (Q1 or Q2). These

resistors are connected between IN1 and IS1 (or IN2 and IS2) to provide a reference voltage across these pins

that is proportional to the current flowing through the PMOS transistor. This reference voltage is compared to an

internal reference to determine if an over-current condition exists. When current limit is exceeded, the external

PMOS is turned off for the minimum off-time. Current limit detection is disabled for 10ns any time the PMOS is

turned on to avoid triggering on switching noise. In 100% duty cycle mode, current limit is always enabled.

Current limit is calculated using the V

Equation 1 :

The current limit resistor must be appropriately rated for the dissipated power determined by its RMS current

calculated by Equation 2 :

For low-cost applications the I

pin can be connected to the drain of the PMOS, using R

S1,2

R2 to set current limit. Variations in the PMOS R

protect external components such as the inductor, the diode, and the switch itself from damage as a result of

over-current.

or V

IS1

specification in the Electrical Characteristics section, shown in

IS2

instead of R1 or

must be taken into account to ensure that current limit will

DS,ON

DS,ON

(1)

(2)

Short-Circuit Protection (Buck Controllers)

In an overload condition, the current rating of the external components (PMOS, diode, and inductor) can be

exceeded. To help guard against this, the TPS75003 increases its minimum off-time when the voltage at the

feedback pin is lower than the reference voltage. When the output is shorted (V

is zero), minimum off-time is

FB

increased to approximately 4 µ s. The increase in off-time is proportional to the difference between the voltage at

the feedback pin and the internal reference.

Soft-Start (Buck Controllers)

The buck controllers each have independent soft-start capability to limit inrush during start-up and to meet timing

requirements of the Xilinx Spartan-3 FPGA. Limiting inrush current by using soft-start, or by staggering the

turn-on of power rails, also guards against voltage drops at the input source due to its output impedance. Refer

to the soft-start circuitry shown in Figure 23 and the soft-start timing diagram shown in Figure 24 . BUCK 1 will be

discussed in this section; it is identical to BUCK2. Note that pins SS1 and SS2 are very high-impedance and

cannot be probed using a typical oscilloscope setup. When input voltage is applied at IN1 and EN1 is driven low,

any charge on the SS pin is discharged by an on-chip pull-down transistor. When EN1 is driven high, an on-chip

current source starts charging the external soft-start capacitor C

. The voltage on the capacitor is compared to

SS1

the voltage across the current sense resistor R1 to determine if an over-current condition exists. If the voltage

drop across the sense resistor goes above the reference voltage, then the external PMOS is shut off for the

minimum off-time. This implementation provides a cycle-by-cycle current limit and allows the user to program the

soft-start time over a wide range for most applications. For detailed information on choosing C

and C

SS1

SS2

the section, Selecting the Soft-Start Cap.

, see

14

Page 15

www.ti.com

Soft

Start

Control

Switch

Control

V

IS1

EN1

SW1

IS1

IN1

SS1

V

IN

Current

Limit

V

SS1

V

EN1

Time

CIN, MIN

(12)L (I

L

)

2

V

(

RIPPLE

)

V

IN

(12)L 0.3 I

OUT

2

V

(

RIPPLE

)

V

IN

Figure 23. Soft-Start Circuitry

TPS75003

SBVS052D – OCTOBER 2004 – REVISED MARCH 2005

Figure 24. Soft-Start Timing Diagram

Input Capacitor C

, C

IN1

Selection (Buck Controllers)

IN2

It is good analog design practice to place input capacitors near the inputs of the device in order to ensure a low

impedance input supply. 10 µ F to 22 µ F of capacitance for each buck converter is adequate for most applications,

and should be placed within 100mils (0.001in) of the IN1 and IN2 pins to minimize the effects of pulsed current

switching noise on the soft-start circuitry during the first ~1V of output voltage ramp. Low ESR capacitors also

help to minimize noise on the supply line. The minimum value of capacitance can be estimated using Equation 3 :

(3)

15

Page 16

www.ti.com

I

C,IN(RMS)

I

OUT

V

OUT

V

IN,

MIN

VINV

OUTIOUT

r

DS(on)

RL I

OUT

t

(OFF,min)

V

OUTVSCHOTTKY

RL I

OUT

t

ON,

MIN

L

MIN

V

IN

V

OUTIOUT

r

DS(on)

RL I

OUT

t

ON,

MIN

I

L

MIN

V

OUTVSCHOTTKY

RL I

OUT

t

OFF,

MIN

I

I

PMOS(RMS)

I

OUT

D I

OUT

V

OUT

V

IN

P

(cond)

I

OUT

D

2

r

DS(on)

1TC TJ25C

I

OUT

D

r

DS(on)

TPS75003

SBVS052D – OCTOBER 2004 – REVISED MARCH 2005

Note that the capacitors must be able to handle the RMS current in continuous conduction mode, which can be

calculated using Equation 4 :

Inductor Value Selection (Buck Controllers)

The inductor is chosen based on inductance value and maximum current rating. Larger inductors reduce current

ripple (and therefore, output voltage ripple) but are physically larger and more expensive. Inductors with lower

DC resistance typically improve efficiency, but also have higher cost and larger physical size. The buck

converters work well with inductor values between 4.7 µ H and 47 µ H in most applications. When selecting an

inductor, the current rating should exceed the current limit set by R

determine the minimum inductor size, first determine if the device will operate in minimum on-time or minimum

off-time mode. The device will operate in minimum on-time mode if Equation 5 is satisfied:

where R

= the inductor's DC resistance.

L

Minimum inductor size needed when operating in minimum on-time mode is given by Equation 6 :

or R

IS

(see Current Limit section). To

DS,ON

(4)

(5)

Minimum inductor size needed when operating in minimum off-time mode is given by Equation 7 :

External PMOS Transistor Selection (Buck Controllers)

The external PMOS transistor is selected based on threshold voltage (V

capacitance (C

IN1 or IN2 that will be used. A V

) and voltage rating. The PMOS V

G

magnitude that is 0.5V less than the lowest input voltage is normally sufficient.

T

magnitude must be much lower than the lowest voltage at

T

), on-resistance (R

T

), gate

DS,ON

The PMOS gate will see voltages from 0V to the maximum input voltage, so gate-to-source breakdown should be

a few volts higher than the maximum input supply. The drain-to-source of the device will also see this full voltage

swing, and should therefore be a few volts higher than the maximum input supply. The RMS current in the PMOS

can be estimated by using Equation 8 :

The power dissipated in the PMOS is comprised of both conduction and switching losses. Switching losses are

typically insignificant. The conduction losses are a function of the RMS current and the R

DS,ON

of the PMOS, and

are calculated by Equation 9 :

(6)

(7)

(8)

(9)

16

Page 17

www.ti.com

I

(

diode)(RMS)

I

OUT

1D I

OUT

1

V

OUT

V

IN

V

PP

I ESR

1

8 C

OUT

f

1.1I ESR

C

OUT

L I

OUT

2

VINV

OUT

V

R1

1

1

R1

A

1

R1

B

and R1

B

1

1

R1

1

R1

A

R1

A

5

4

R1

TPS75003

SBVS052D – OCTOBER 2004 – REVISED MARCH 2005

Diode Selection (Buck Controllers)

The diode is off when the PMOS is on, and on when the PMOS is off. Since it will be turned on and off at a

relatively high frequency, a Schottky diode is recommended for good performance. The peak current rating of the

diode should exceed the peak current limit set by the sense resistor R

current and low forward voltage at operating current will optimize efficiency. Equation 10 calculates the estimated

average power dissipation:

Output Capacitor Selection (Buck Controllers)

The output capacitor is selected based on output voltage ripple and transient response requirements. As a result

of the nature of the hysteretic control loop, a minimum ESR of a few tens of m Ω should be maintained for good

operation unless a feed-forward resistor is used. Low ESR bulk tantalum or PosCap capacitors work best in most

applications. A 1.0 µ F ceramic capacitor can be used in parallel with this capacitor to filter higher frequency

spikes. The output voltage ripple can be estimated by Equation 11 :

To calculate the capacitance needed to achieve a given voltage ripple as a result of a load transient from zero

output to full current, use Equation 12 :

. A diode with low reverse leakage

IS1,2

(10)

(11)

If only ceramic or other very low ESR output capacitor configurations are desired, additional voltage ripple must

be passed to the feedback pin. This can be accomplished by using the application circuit in Figure 1 . Resistor

R

adds additional control signal to the feedback loop. This circuit works best with R

1B

too low, the output shows worse load regulation. R

Use Equation 14 to calculate R1

Output Voltage Ripple Effect on V

Output voltage ripple causes V

if R1

A

OUT

= (4)(R1

B

(Buck Controllers)

OUT

to be higher or lower than the target value by half of the peak-to-peak voltage

and R

1A

):

A

can be calculated using Equation 13 :

1B

= 2 to 4 x R

1B

. If R

1A

ripple. For minimum on-time, the ripple adds to the voltage; for minimum off-time, it subtracts from the voltage.

Soft-Start Capacitor Selection (Buck Controllers)

BUCK1 is discussed in this section; it is identical to BUCK2. Soft-start is implemented on the buck controllers by

ramping current limit from 0 to its target value (set by R1) over a user-defined time. This time is set by the

external soft-start cap connected to pin SS1. If SS1 is left open, a small on-chip capacitor will provide a current

limit ramp time of approximately 250µs. Figure 25 shows the effects of R1 and SS1 on the current limit start-up

ramp.

(12)

is

1B

(13)

(14)

17

Page 18

www.ti.com

3.0A

Current

Limit

0.7A

Time

R1 = 33mΩ

R1 = 143mΩ

C

SS1

= 0.022µF

C

SS1

= 0.022µF

C

SS1

= 0.01µF

C

SS1

= 0.01µF

V

OUT

V

FB

R

5

R

6

1

TPS75003

SBVS052D – OCTOBER 2004 – REVISED MARCH 2005

Figure 25. Effects of C

and R

SS1

on Current Ramp Limit

1

This soft-start current limit ramo can be used to provide inrush current control or output voltage ramp control.

While the current limit ramp can be easily understood by looking at Figure 25 , the output voltage ramp is a

complex function of many variables. The dominant variables in this process are V

important variables are V

IN1

and L1.

, C

, I

OUT1

SS1

, and R1. Less

OUT1

The best way to set a target start-up time is through bench measurement under target conditions, adjusting C

to get the desired startup profile. To stay above a minimum start-up time, set the nominal start-up time to

approximately five times the minimum. To stay below a maximum time, set the nominal start-up time at one-fifth

of the maximum. Fastest start-up times occur at maximum V

, with minimum V

IN1

, L1, C

OUT1

, C

OUT1

SS1

, and I

Slowest start-up times occur under opposite conditions.

Refer to Figure 10 to Figure 14 for characterization curves showing how the start-up profile is affected by these

critical parameters.

Output Voltage Setting Selection (Buck Controllers)

Output voltage is set using two resistors as shown for Buck2 in Figure 1 . Output voltage is then calculated using

Equation 15 :

where V

= 1.24V.

FB

LDO OPERATION

The TPS75003 LDO uses a PMOS pass element and is offered in an adjustable version for ease of

programming to any output voltage. When used to power V

output voltages to power other circuitry. The LDO has integrated soft-start, independent enable, and short-circuit

and thermal protection. The LDO can be used to power V

signals are used as described in Application Note SLVA159 (available for download from www.ti.com ).

CC,AUX

it is set to 2.5V; it can optionally be set to other

CC,AUX

on the Xilinx Spartan-3 FPGA when 3.3V JTAG

SS1

.

OUT1

(15)

Input Capacitor Selection (LDO)

Although an input capacitor is not required, it is good analog design practice to connect a 0.1 µ F to 10 µ F low ESR

capacitor across the input supply near the regulator. This capacitor counteracts reactive input sources and

improves transient response, stability, and ripple rejection. A higher value capacitor may be needed if large, fast

rise-time load transients are anticipated, or if the device is located far from its power source.

18

Page 19

www.ti.com

V

OUT

V

FB

R

3

R

4

1

TPS75003

SBVS052D – OCTOBER 2004 – REVISED MARCH 2005

Output Capacitor Selection (LDO)

A 2.2 µ F or greater capacitor is required near the output of the device to ensure stability. The LDO is stable with

any capacitor type, including ceramic. If improved transient response or ripple rejection is required, larger and/or

lower ESR output capacitors can be used.

Soft-Start (LDO)

The LDO uses an external soft-start capacitor, C

loop. (See the Functional Block Diagram.) This is a voltage-controlled soft-start, as compared to the

current-controlled soft-start used by the buck controllers.

Setting Output Voltage (LDO)

Output voltage is set using two resistors as shown in Figure 1 . Output voltage is then calculated using

Equation 16 :

where V

= 0.507V.

FB

Internal Current Limit (LDO)

The internal current limit of the LDO helps protect the regulator during fault conditions. When an over-current

condition is detected, the output voltage will be reduced until the current falls to a level that will not damage the

device. For good device reliability, the LDO should not operate at current limit.

, to provide an RC-ramped reference voltage to the control

SS3

(16)

Enable Pin (LDO)

The active high enable pin (EN3) can be used to put the device into shutdown mode. If shutdown and soft-start

capability are not required, EN3 can be tied to IN3.

Dropout Voltage (LDO)

The LDO uses a PMOS transistor to achieve low dropout. When (V

(V

), the pass device is in its linear region of operation, and the input-output resistance is the R

DO

– V

IN

) is less than the dropout voltage

OUT

of the pass

DS,ON

transistor. In this region, the regulator is said to be out of regulation; ripple rejection, line regulation, and load

regulation degrade as (V

– V

IN

) falls much below 0.5V.

OUT

Transient Response (LDO)

The LDO does not have an on-chip pull-down circuit for output is over-voltage conditions. This feature permits

applications that connect higher voltage sources such as an alternate power supply to the output. This design

also results in an output overshoot of several percent if the load current quickly drops to zero. The amplitude of

overshoot can be reduced by increasing C

; the duration of overshoot can be reduced by adding a load

OUT

resistor.

Thermal Protection (LDO)

Thermal protection disables the output when the junction temperature, TJ, reaches unsafe levels. When the

junction cools, the output is again enabled. Depending on power dissipation, thermal resistance, and ambient

temperature, the thermal protection circuit may cycle on and off. This cycling limits the dissipation of the

regulator, protecting it from damage. For good long term reliability, the device should not be continuously

operated at or near thermal shutdown.

19

Page 20

www.ti.com

P

D

V

IN3

V

OUT3

I

OUT3

L1

IN3

OUT3

FB1

FB2

20

1

11

10

DGND

SS3

AGND

EN1

SS1

DGND

SW1

IN1

IS1

19

18

17

16

15

14

13

12

FB3

EN3

EN2

SS2

DGND

SW2

IN2

IS2

2

3

4

5

6

7

8

9

R6

R7

EN3

EN2

V

IN

EN1

V

IN

C5,

C18

C3,

C17

C7

R5

C10

C12, C16

C13, C15

Q1

Q2

L2

V

OUT1

D2

C9

C6

V

OUT3

C14

C8

R9

D1

R8

V

OUT2

R4

C1

V

IN

TPS75003

SBVS052D – OCTOBER 2004 – REVISED MARCH 2005

Power Dissipation (LDO)

The TPS75003 comes in a QFN-style package with an exposed lead frame on the package underside. The

exposed lead frame is the primary path for removing heat and should be soldered to a PC board that is

configured to remove the amount of power dissipated by the LDO, as calculated by Equation 17 :

Power dissipation can be minimized by using the lowest possible input voltage necessary to assure the required

output voltage. The two buck converters do not contribute a significant amount of dissipated power. Using

heavier copper will increase the overall effectiveness of removing heat from the device. The addition of plated

through-holes to heat-dissipating layers will also improve the heatsink effectiveness.

PCB Layout Considerations

As with any switching regulators, careful attention must be paid to board layout. A typical application circuit and

corresponding recommended printed circuit board (PCB) layout with emphasis on the most sensitive areas are

shown in Figure 26 through Figure 28 .

(17)

Note: Most sensitive areas are highlighted by bold lines.

20

Figure 26. Typical Application Circuit

Page 21

www.ti.com

TPS75003

SBVS052D – OCTOBER 2004 – REVISED MARCH 2005

Note: Most sensitive areas are highlighted in green.

Figure 27. Recommended PCB Layout, Component Side, Top View

21

Page 22

www.ti.com

TPS75003

SBVS052D – OCTOBER 2004 – REVISED MARCH 2005

Note: Most sensitive areas are highlighted in green.

Figure 28. Recommended PCB Layout, Bottom Side, Top View

22

Page 23

Page 24

PACKAGE OPTION ADDENDUM

www.ti.com

16-May-2005

PACKAGING INFORMATION

Orderable Device Status

(1)

Package

Type

Package

Drawing

Pins Package

Qty

Eco Plan

TPS75003RHLR ACTIVE QFN RHL 20 3000 Green (RoHS &

no Sb/Br)

TPS75003RHLRG4 ACTIVE QFN RHL 20 3000 Green (RoHS &

no Sb/Br)

TPS75003RHLT ACTIVE QFN RHL 20 250 Green (RoHS &

no Sb/Br)

TPS75003RHLTG4 ACTIVE QFN RHL 20 250 Green (RoHS &

no Sb/Br)

(1)

The marketing status values are defined as follows:

ACTIVE: Product device recommended for new designs.

LIFEBUY: TI has announced that the device will be discontinued, and a lifetime-buy period is in effect.

NRND: Not recommended for new designs. Device is in production to support existing customers, but TI does not recommend using this part in

a new design.

PREVIEW: Device has been announced but is not in production. Samples may or may not be available.

OBSOLETE: TI has discontinued the production of the device.

(2)

Eco Plan - The planned eco-friendly classification: Pb-Free (RoHS) or Green (RoHS & no Sb/Br) - please check

http://www.ti.com/productcontent for the latest availability information and additional product content details.

TBD: The Pb-Free/Green conversion plan has not been defined.

Pb-Free (RoHS): TI's terms "Lead-Free" or "Pb-Free" mean semiconductor products that are compatible with the current RoHS requirements

for all 6 substances, including the requirement that lead not exceed 0.1% by weight in homogeneous materials. Where designed to be soldered

at high temperatures, TI Pb-Free products are suitable for use in specified lead-free processes.

Green (RoHS & no Sb/Br): TI defines "Green" to mean Pb-Free (RoHS compatible), and free of Bromine (Br) and Antimony (Sb) based flame

retardants (Br or Sb do not exceed 0.1% by weight in homogeneous material)

(2)

Lead/Ball Finish MSL Peak Temp

CU NIPDAU Level-1-260C-UNLIM

CU NIPDAU Level-1-260C-UNLIM

CU NIPDAU Level-1-260C-UNLIM

CU NIPDAU Level-1-260C-UNLIM

(3)

(3)

MSL, Peak Temp. -- The Moisture Sensitivity Level rating according to the JEDEC industry standard classifications, and peak solder

temperature.

Important Information and Disclaimer:The information provided on this page represents TI's knowledge and belief as of the date that it is

provided. TI bases its knowledge and belief on information provided by third parties, and makes no representation or warranty as to the

accuracy of such information. Efforts are underway to better integrate information from third parties. TI has taken and continues to take

reasonable steps to provide representative and accurate information but may not have conducted destructive testing or chemical analysis on

incoming materials and chemicals. TI and TI suppliers consider certain information to be proprietary, and thus CAS numbers and other limited

information may not be available for release.

In no event shall TI's liability arising out of such information exceed the total purchase price of the TI part(s) at issue in this document sold by TI

to Customer on an annual basis.

Addendum-Page 1

Page 25

IMPORTANT NOTICE

Texas Instruments Incorporated and its subsidiaries (TI) reserve the right to make corrections, modifications,

enhancements, improvements, and other changes to its products and services at any time and to discontinue

any product or service without notice. Customers should obtain the latest relevant information before placing

orders and should verify that such information is current and complete. All products are sold subject to TI’s terms

and conditions of sale supplied at the time of order acknowledgment.

TI warrants performance of its hardware products to the specifications applicable at the time of sale in

accordance with TI’s standard warranty. Testing and other quality control techniques are used to the extent TI

deems necessary to support this warranty . Except where mandated by government requirements, testing of all

parameters of each product is not necessarily performed.

TI assumes no liability for applications assistance or customer product design. Customers are responsible for

their products and applications using TI components. To minimize the risks associated with customer products

and applications, customers should provide adequate design and operating safeguards.

TI does not warrant or represent that any license, either express or implied, is granted under any TI patent right,

copyright, mask work right, or other TI intellectual property right relating to any combination, machine, or process

in which TI products or services are used. Information published by TI regarding third-party products or services

does not constitute a license from TI to use such products or services or a warranty or endorsement thereof.

Use of such information may require a license from a third party under the patents or other intellectual property

of the third party, or a license from TI under the patents or other intellectual property of TI.

Reproduction of information in TI data books or data sheets is permissible only if reproduction is without

alteration and is accompanied by all associated warranties, conditions, limitations, and notices. Reproduction

of this information with alteration is an unfair and deceptive business practice. TI is not responsible or liable for

such altered documentation.

Resale of TI products or services with statements different from or beyond the parameters stated by TI for that

product or service voids all express and any implied warranties for the associated TI product or service and

is an unfair and deceptive business practice. TI is not responsible or liable for any such statements.

Following are URLs where you can obtain information on other Texas Instruments products and application

solutions:

Products Applications

Amplifiers amplifier.ti.com Audio www.ti.com/audio

Data Converters dataconverter.ti.com Automotive www.ti.com/automotive

DSP dsp.ti.com Broadband www.ti.com/broadband

Interface interface.ti.com Digital Control www.ti.com/digitalcontrol

Logic logic.ti.com Military www.ti.com/military

Power Mgmt power.ti.com Optical Networking www.ti.com/opticalnetwork

Microcontrollers microcontroller.ti.com Security www.ti.com/security

Telephony www.ti.com/telephony

Video & Imaging www.ti.com/video

Wireless www.ti.com/wireless

Mailing Address: Texas Instruments

Post Office Box 655303 Dallas, Texas 75265

Copyright 2005, Texas Instruments Incorporated

Loading...

Loading...