Datasheet TPS71H50QPWPR, TPS71H50QPWPLE, TPS71H48QPWPR, TPS71H48QPWPLE, TPS71H33QPWPR Datasheet (Texas Instruments)

...

TPS71H01Q, TPS71H33Q, TPS71H48Q, TPS71H50Q

LOW-DROPOUT VOLTAGE REGULATORS

SLVS152A – NOVEMBER 1996 – REVISED JANUAR Y 1997

D

Available in 5-V, 4.85-V, and 3.3-V

Fixed-Output and Adjustable Versions

D

Very Low-Dropout Voltage . . . Maximum of

32 mV at I

D

Very Low Quiescent Current – Independent

= 100 mA (TPS71H50)

O

of Load...285 µA Typ

D

Extremely Low Sleep-State Current

0.5 µA Max

D

2% Tolerance Over Specified Conditions

For Fixed-Output Versions

D

Output Current Range of 0 mA to 500 mA

D

TSSOP Package Option Offers Reduced

Component Height for Space-Critical

Applications

D

Thermally Enhanced Surface-Mount

GND/HEATSINK

GND/HEATSINK

GND

NC

EN

IN

IN

NC

GND/HEATSINK

GND/HEATSINK

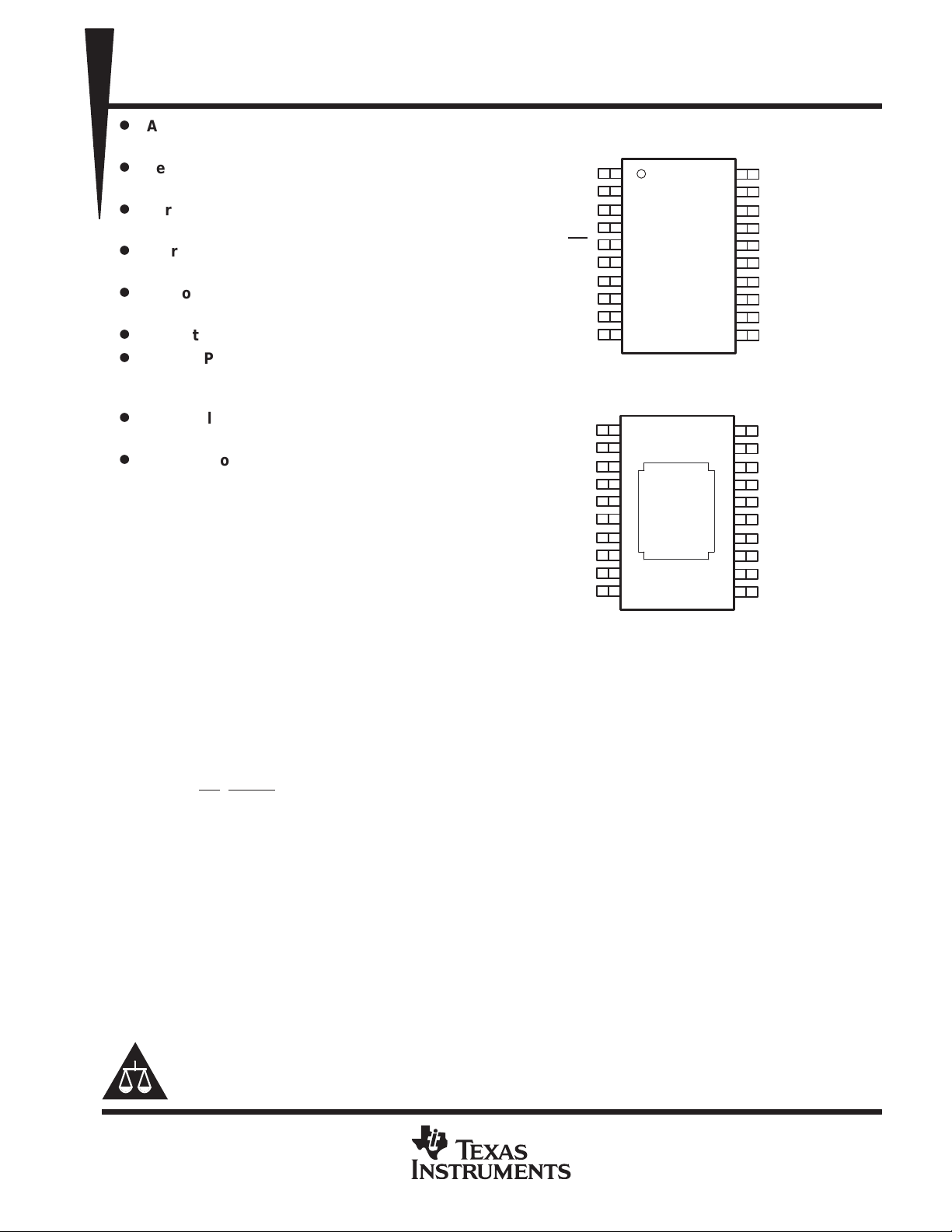

PWP PACKAGE

(TOP VIEW)

1

2

3

4

5

6

7

8

9

10

PWP PACKAGE

(BOTTOM VIEW)

20

19

18

17

16

15

14

13

12

11

GND/HEATSINK

GND/HEATSINK

NC

NC

PG

SENSE†/FB

OUT

OUT

GND/HEATSINK

GND/HEATSINK

Package

D

Power-Good (PG) Status Output

description

The TPS71Hxx integrated circuits are a family of

Thermal

Pad

micropower low-dropout (LDO) voltage regulators. An order of magnitude reduction in dropout

voltage and quiescent current over conventional

LDO performance is achieved by replacing the

typical pnp pass transistor with a PMOS device.

Because the PMOS device behaves as a

low-value resistor, the dropout voltage is very low

(maximum of 32 mV at an output current of

NC – No internal connection

†

SENSE – Fixed voltage options only (TPS71H33,

TPS71H48, and TPS71H50)

‡

FB – Adjustable version only (TPS71H01)

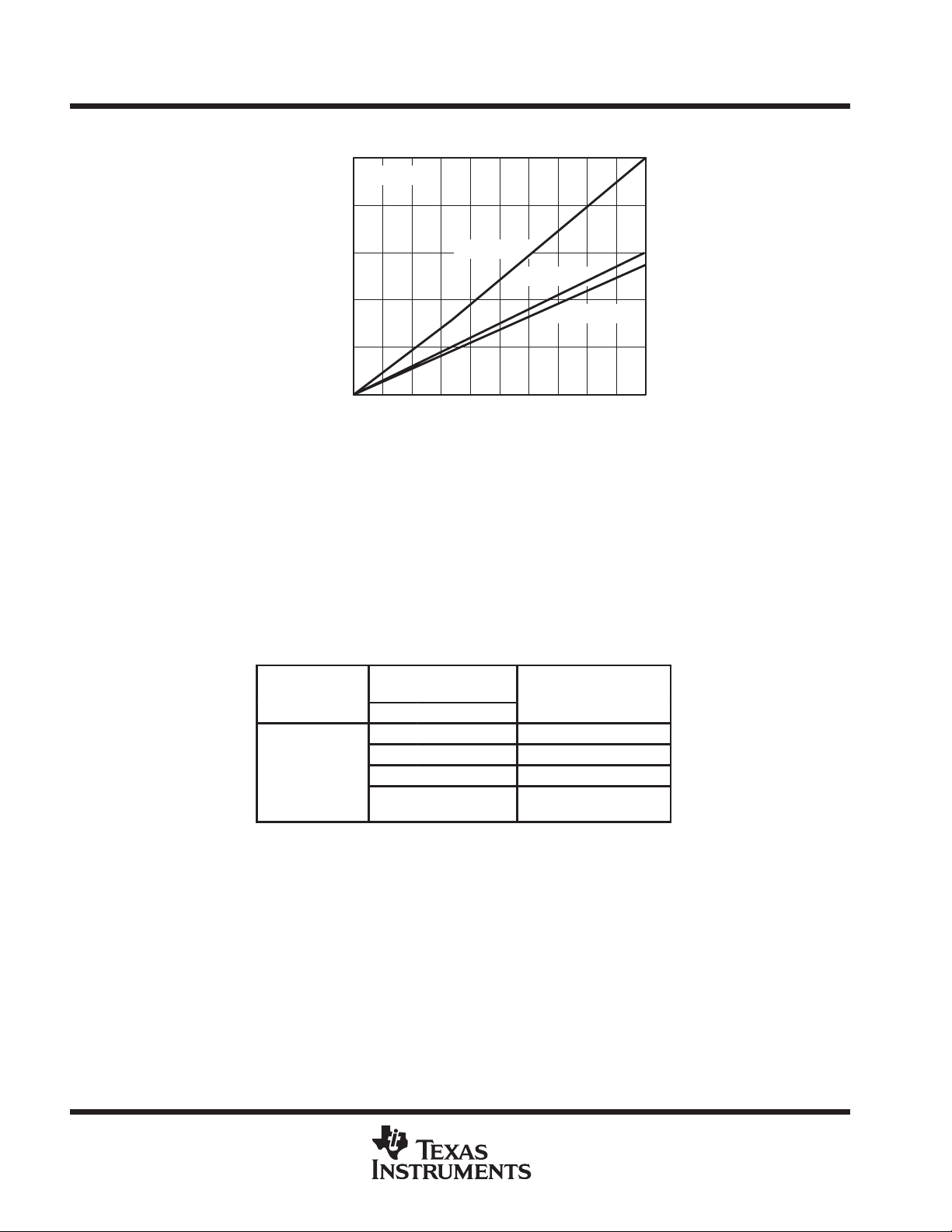

100 mA for the TPS71H50) and is directly

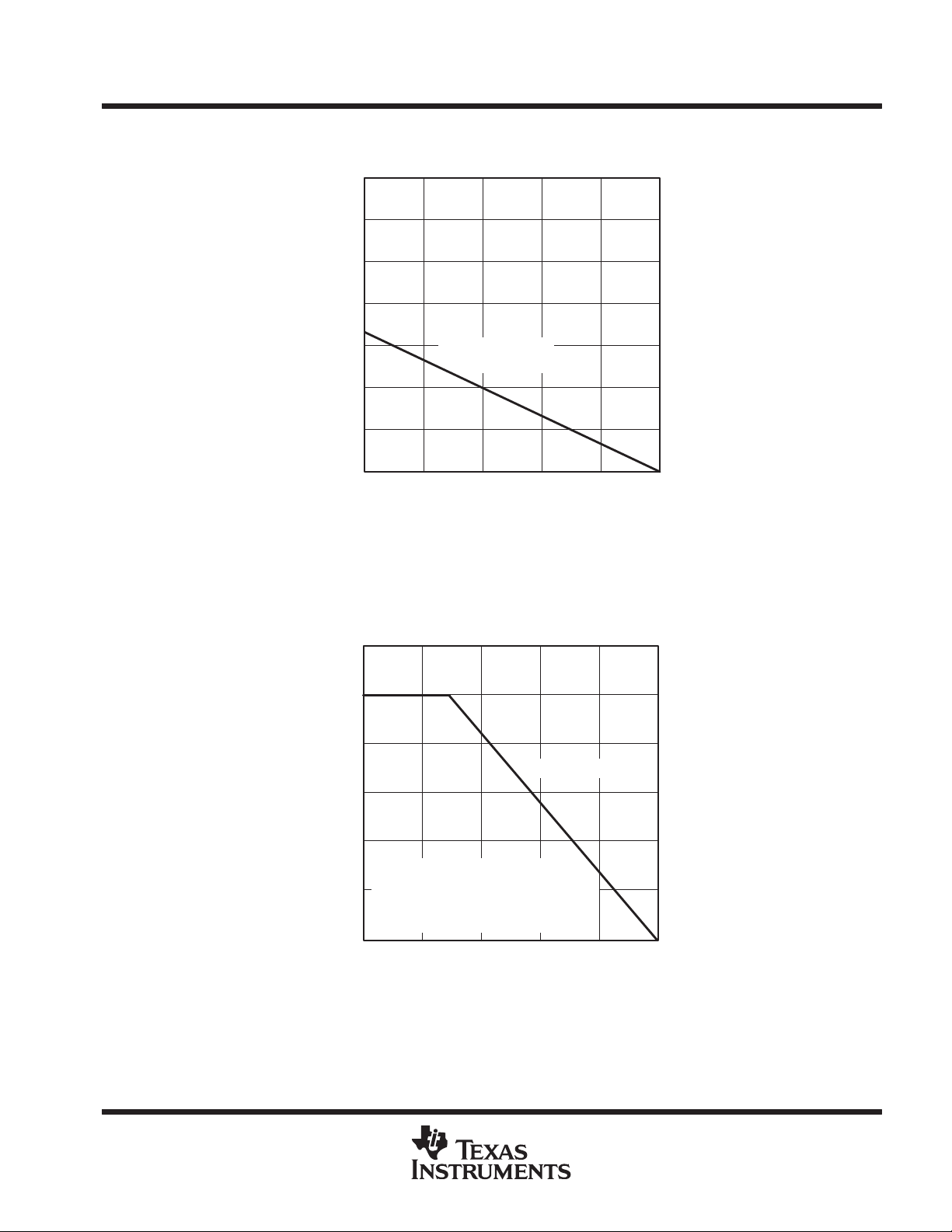

proportional to the output current (see Figure 1). Additionally, since the PMOS pass element is a voltage-driven

device, the quiescent current is very low and remains independent of output loading (typically 285 µA over the

full range of output current, 0 mA to 500 mA). These two key specifications yield a significant improvement in

operating life for battery-powered systems. The LDO family also features a sleep mode; applying a TTL high

signal to EN

(enable) shuts down the regulator, reducing the quiescent current to 0.5 µA maximum at TJ = 25°C.

‡

Please be aware that an important notice concerning availability, standard warranty, and use in critical applications of

Texas Instruments semiconductor products and disclaimers thereto appears at the end of this data sheet.

PRODUCTION DATA information is current as of publication date.

Products conform to specifications per the terms of Texas Instruments

standard warranty. Production processing does not necessarily include

testing of all parameters.

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

Copyright 1997, Texas Instruments Incorporated

1

TPS71H01Q, TPS71H33Q, TPS71H48Q, TPS71H50Q

J

(PWP)

LOW-DROPOUT VOLTAGE REGULATORS

SLVS152A – NOVEMBER 1996 – REVISED JANUAR Y 1997

description (continued)

0.25

TA = 25°C

0.2

0.15

0.1

Dropout Voltage – V

0.05

0

0 0.05 0.1 0.15 0.2 0.25 0.3

TPS71H33

TPS71H48

TPS71H50

0.35 0.4 0.45 0.5

IO – Output Current – A

Figure 1. Dropout Voltage Versus Output Current

Power good (PG) reports low output voltage and can be used to implement a power-on reset or a low-battery

indicator.

The TPS71Hxx is offered in 3.3-V, 4.85-V, and 5-V fixed-voltage versions and in an adjustable version

(programmable over the range of 1.2 V to 9.75 V). Output voltage tolerance is specified as a maximum of 2%

over line, load, and temperature ranges (3% for adjustable version). The TPS71Hxx family is available in a

TSSOP (20-pin) thermally enhanced surface-mount power package. The package has an innovative thermal

pad that, when soldered to the printed-wiring board (PWB), enables the device to dissipate several watts of

power (see Thermal Information section). Maximum height of the package is 1.2 mm.

AVAILABLE OPTIONS

OUTPUT VOLTAGE

T

–55°C to 150°C

†

The PWP package is only available left-end taped and reeled, as indicated

by the LE suffix on the device type. The TPS71H01Q is programmable using

an external resistor divider (see application information).

(V)

MIN TYP MAX

4.9 5 5.1 TPS71H50QPWPLE

4.75 4.85 4.95 TPS71H48QPWPLE

3.23 3.3 3.37 TPS71H33QPWPLE

Adjustable

1.2 V to 9.75 V

†

TSSOP

TPS71H01QPWPLE

2

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

TPS71H01Q, TPS71H33Q, TPS71H48Q, TPS71H50Q

LOW-DROPOUT VOLTAGE REGULATORS

SLVS152A – NOVEMBER 1996 – REVISED JANUAR Y 1997

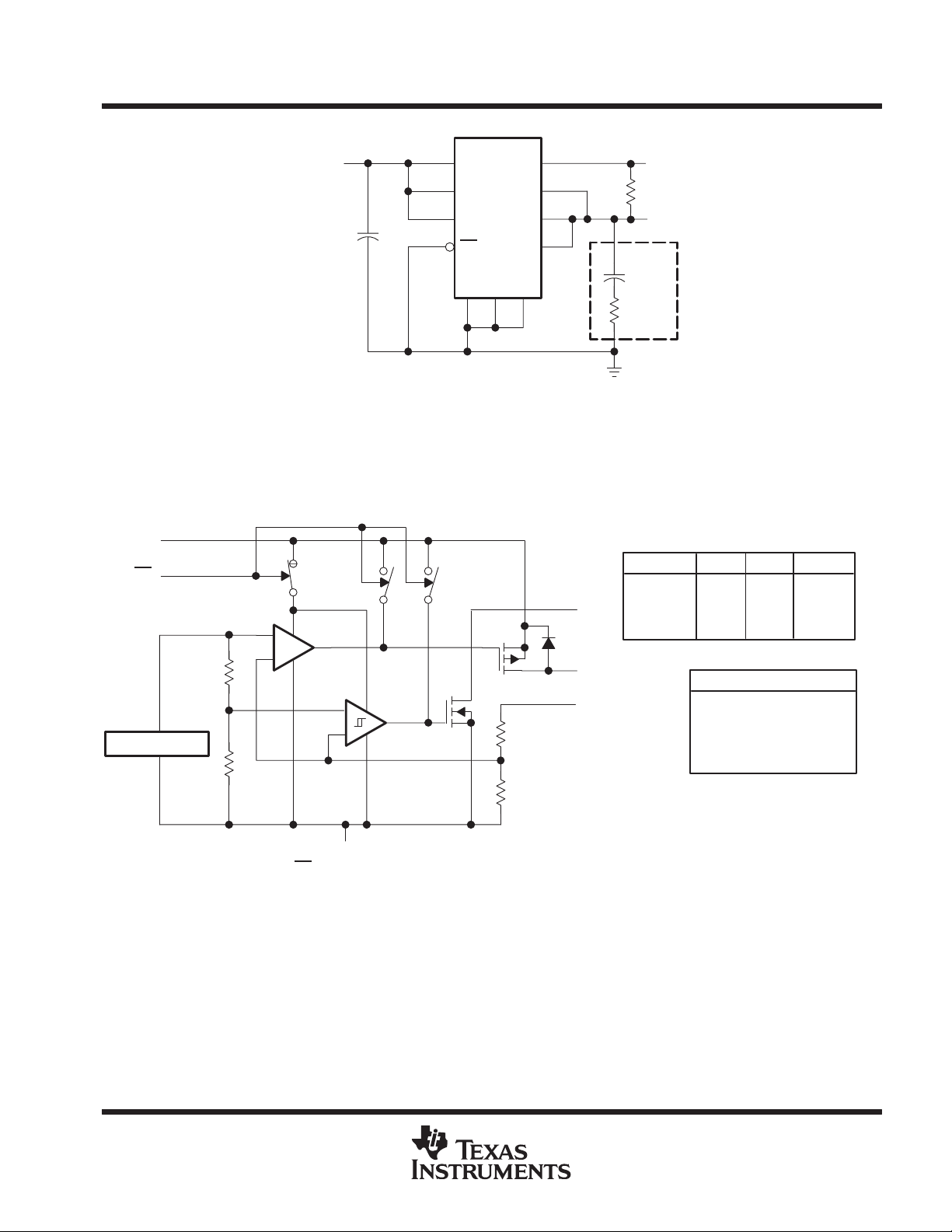

TPS71Hxx

†

functional block diagram

IN

EN

V

ref

= 1.178 V

†

_

+

10

8

IN

9

IN

SENSE

IN

6

EN

GND

V

I

0.1 µF

†

TPS71H33, TPS71H48, TPS71H50 (fixed-voltage options)

‡

Capacitor selection is nontrivial. See application information section

for details.

PG

OUT

OUT

20

15

14

13

+

10 µF

321

CSR

Figure 2. Typical Application Configuration

DEVICE

TPS71H01

TPS71H33

TPS71H48

TPS71H50

NOTE A: Resistors are nominal values only.

1.12 V

††

+

_

PG

OUT

SENSE‡/FB

R1

PG

V

O

‡

C

O

RESISTOR DIVIDER OPTIONS

∞

0

420

726

756

COMPONENT COUNT

MOS transistors

Bilpolar transistors

Diodes

Capacitors

Resistors

233

233

233

UNITR1 R2

Ω

kΩ

kΩ

kΩ

464

41

4

17

76

R2

†

Switch positions are shown with EN

‡

For most applications, SENSE should be externally connected to OUT as close as possible to the device. (For other implementations, refer

to SENSE-pin connection discussion in Applications Information section.)

GND

low (active).

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

3

TPS71H01Q, TPS71H33Q, TPS71H48Q, TPS71H50Q

PACKAGE

A

PACKAGE

C

LOW-DROPOUT VOLTAGE REGULATORS

SLVS152A – NOVEMBER 1996 – REVISED JANUAR Y 1997

absolute maximum ratings over operating free-air temperature range (unless otherwise noted)

‡

Input voltage range

Output current, I

Continuous total power dissipation See Dissipation Rating Tables 1 and 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operating virtual junction temperature range, T

Storage temperature range, T

Lead temperature 1,6 mm (1/16 inch) from case for 10 seconds 260°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

†

Stresses beyond those listed under “absolute maximum ratings” may cause permanent damage to the device. These are stress ratings only, and

functional operation of the device at these or any other conditions beyond those indicated under “recommended operating conditions” is not

implied. Exposure to absolute-maximum-rated conditions for extended periods may affect device reliability.

‡

All voltage values are with respect to network terminal ground.

§

Dissipation rating tables and figures are provided for maintenance of junction temperature at or below

absolute maximum temperature of 150°C. For guidelines on maintaining junction temperature within

recommended operating range, see the Thermal Information section.

¶

Refer to Thermal Information section for detailed power dissipation considerations when using the

TSSOP packages.

, VI, PG, SENSE, EN –0.3 V to 11 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 A. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

O

–55°C to 150°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

–65°C to 150°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

stg

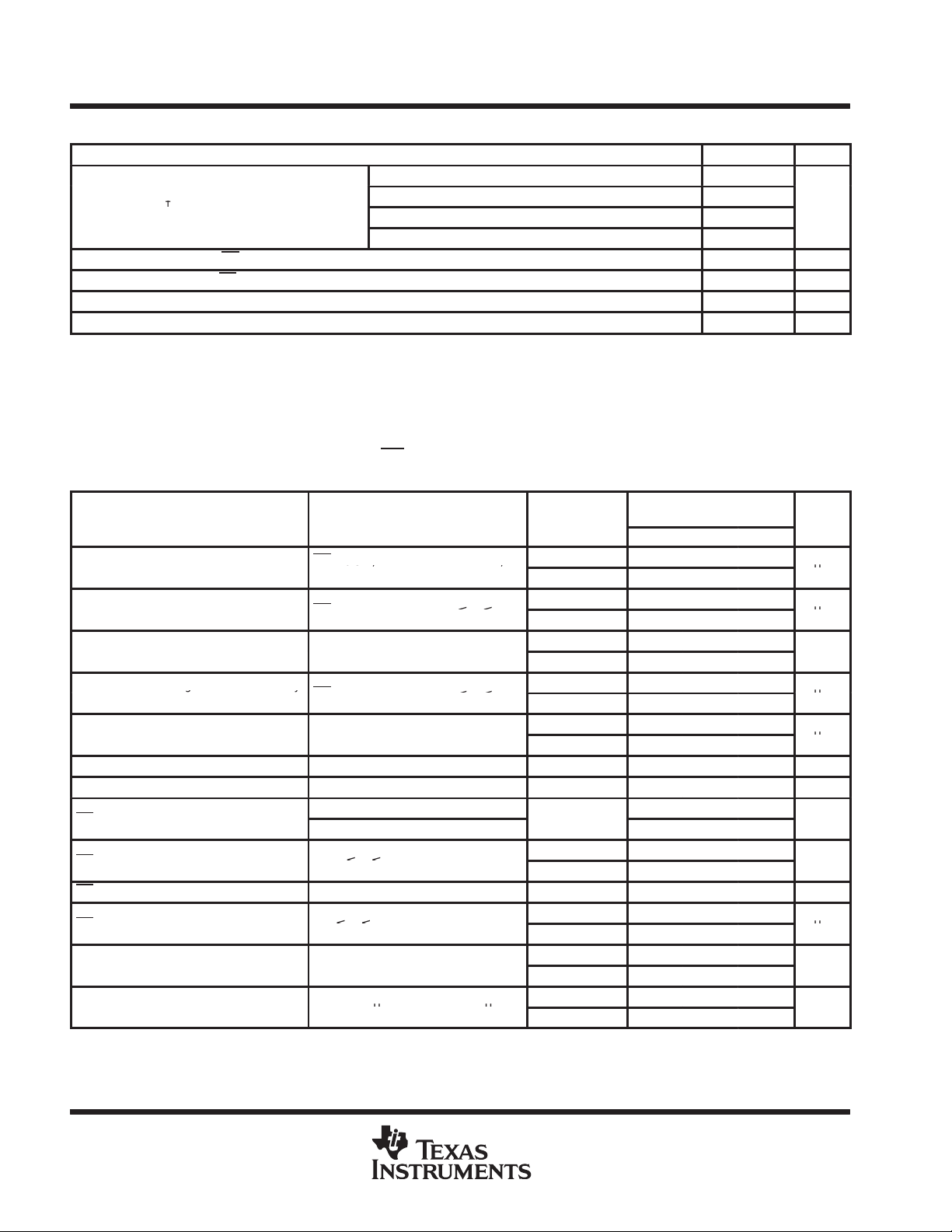

DISSIPATION RA TING TABLE 1 – FREE-AIR TEMPERATURE (see Figure 3)

T

≤ 25°C DERATING FACTOR T

POWER RATING ABOVE TA = 25°CAPOWER RATINGAPOWER RATING

¶

PWP

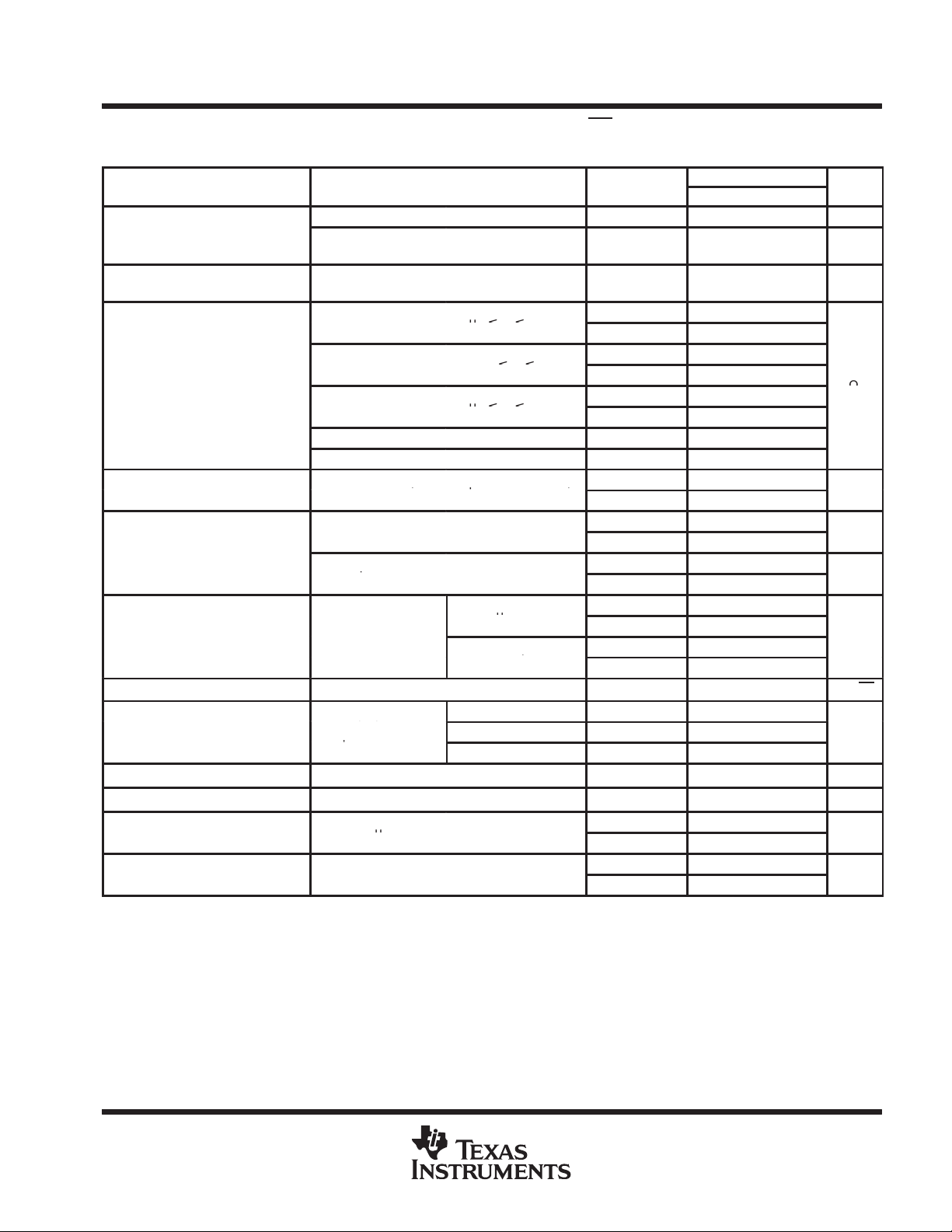

DISSIPATION RA TING TABLE 2 – CASE TEMPERATURE (see Figure 4)

¶

PWP

700 mW 5.6 mW/°C 448 mW 140 mW

T

≤ 62.5°C DERATING FACTOR T

POWER RATING ABOVE TC = 62.5°CCPOWER RATINGCPOWER RATING

25 W 285.7 mW/°C 22.9 W 7.1 W

J

§

= 70°C T

= 70°C T

= 125°C

§

= 125°C

†

4

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

TPS71H01Q, TPS71H33Q, TPS71H48Q, TPS71H50Q

LOW-DROPOUT VOLTAGE REGULATORS

SLVS152A – NOVEMBER 1996 – REVISED JANUAR Y 1997

DISSIPATION DERATING CURVE

vs

FREE-AIR TEMPERATURE

1400

1200

1000

800

600

400

200

– Maximum Continuous Dissipation – mW

D

P

0

25 50 75 100

PWP Package

R

= 178°C/W

θJA

TA – Free-Air Temperature – ° C

Figure 3

†

125 150

MAXIMUM CONTINUOUS DISSIPATION

†

vs

CASE TEMPERATURE

30

25

20

PWP Package

15

10

Measured with the exposed thermal pad

coupled to an infinite heat sink with a

5

– Maximum Continuous Dissipation – W

D

P

thermally conductive compound (the

thermal conductivity of the compound

is 0.815 W/m ⋅°C). The R

0

25 50 75 100

TC – Case Temperature – °C

θJC

is 3.5°C/W.

125 150

Figure 4

†

Dissipation rating tables and figures are provided for maintenance of junction temperature at or below absolute maximum temperature of 150°C.

For guidelines on maintaining junction temperature within recommended operating range, see the Thermal Information section.

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

5

TPS71H01Q, TPS71H33Q, TPS71H48Q, TPS71H50Q

Input voltage, V

†

V

§

J

,

,

Ground current (active mode)

EN ≤ 0.5 V, V

I

V

O

V,

A

Input current (standby mode)

EN

V

2.7 V ≤ V

≤ 10 V

A

Output current limit

V

V

V

A

gy

EN

V

2.7 V ≤ V

V

A

PG leak

t

Normal operation

V

10 V

A

EN logic high (standb

)

40°C to 125°C

V

EN logic l

)

2.7 V ≤ V

V

V

EN i

t

0 V ≤ V

V

A

Minimum V

for active pass element

V

Minimum V

for valid PG

I

300 µA

I

300 µA

V

LOW-DROPOUT VOLTAGE REGULATORS

SLVS152A – NOVEMBER 1996 – REVISED JANUAR Y 1997

recommended operating conditions

MIN MAX UNIT

TPS71H01Q 2.5 10

p

High-level input voltage at EN, V

Low-level input voltage at EN, V

Output current range, I

Operating virtual junction temperature range, T

†

Minimum input voltage defined in the recommended operating conditions is the maximum specified output voltage plus dropout voltage at the

maximum specified load range. Since dropout voltage is a function of output current, the usable range can be extended for lighter loads. To

calculate the minimum input voltage for your maximum output current, use the following equation: V

Because the TPS71H01 is programmable, r

calculating VDO from r

the recommended input voltage range for the TPS71H01.

I

IH

IL

O

is given in Note 2 in the electrical characteristics table. The minimum value of 2.5 V is the absolute lower limit for

DS(on)

DS(on)

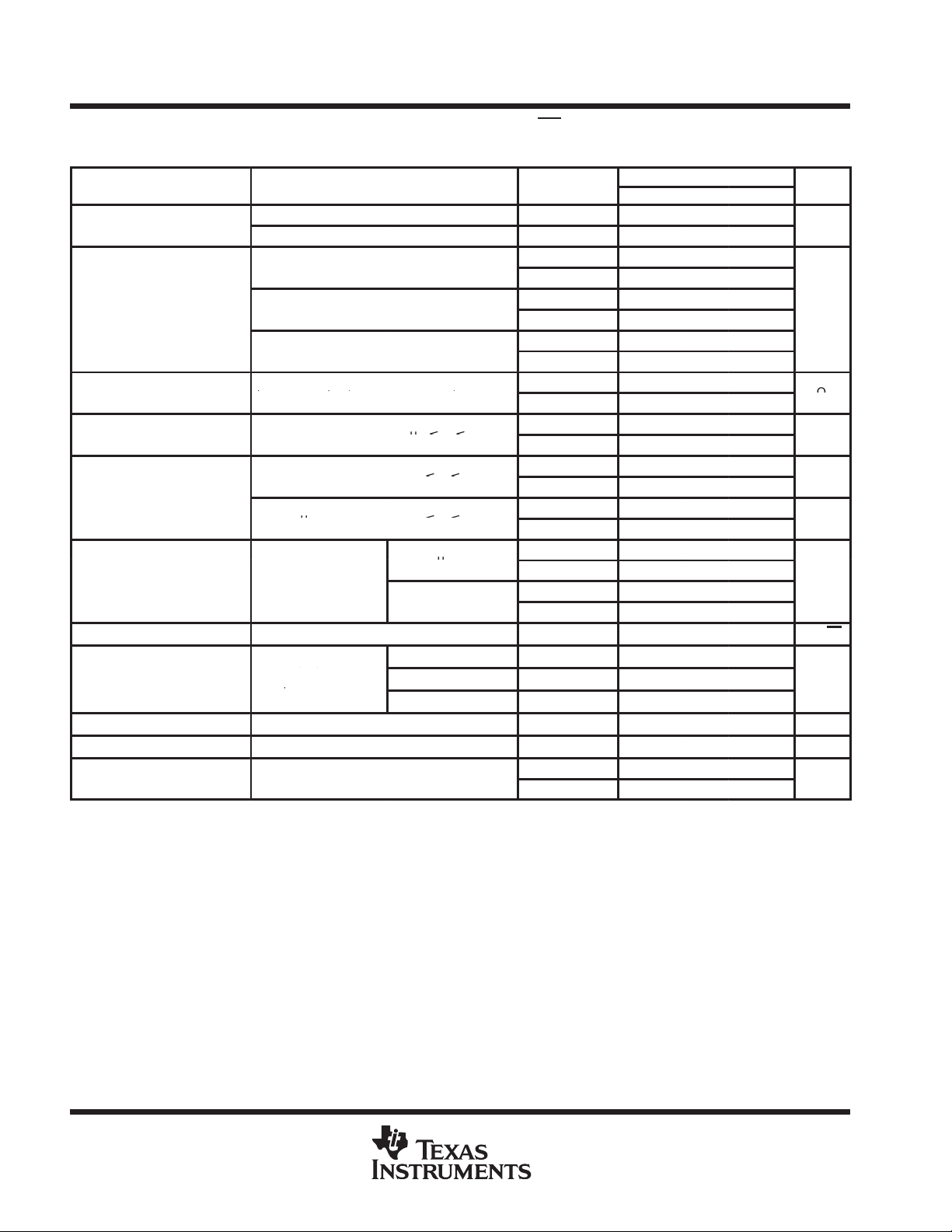

electrical characteristics at IO = 10 mA, EN = 0 V , CO = 4.7 µF/CSR‡ = 1 Ω, SENSE/FB shorted to OUT

(unless otherwise noted)

PARAMETER

EN ≤ 0.5 V

0 mA ≤ IO ≤ 500 mA

p

p

Pass-element leakage current in standby

mode

age curren

Output voltage temperature coefficient –40°C to 125°C 61 75 ppm/°C

Thermal shutdown junction temperature 165 °C

y mode

ow (active mode

EN hysteresis voltage 25°C 50 mV

nput curren

I

I

‡

CSR (compensation series resistance) refers to the total series resistance, including the equivalent series resistance (ESR) of the capacitor, any

series resistance added externally, and PWB trace resistance to CO.

§

Pulse-testing techniques are used to maintain virtual junction temperature as close as possible to ambient temperature; thermal effects must

be taken into account separately.

p

O

2.5 V ≤ VI ≤ 6 V

6 V ≤ VI ≤ 10 V

PG

TPS71H33Q 3.77 10

TPS71H48Q 5.2 10

TPS71H50Q 5.33 10

2 V

0.5 V

0 500 mA

J

= V

should be used to calculate VDO before applying the above equation. The equation for

TEST CONDITIONS

=

,

I

= 0,

=

,

I

p

≤ 10

I

≤ 10

I

=

V

= V

+ 1 V

+ 1

I

= 10

I

≤ 10

I

,

=

PG

=

PG

T

25°C 285 350

–40°C to 125°C 460

25°C 0.5

–40°C to 125°C 2

25°C 1.2 2

–40°C to 125°C 2

25°C 0.5

–40°C to 125°C 1

25°C 0.02 0.5

–40°C to 125°C 0.5

°

–

25°C 0.5

–40°C to 125°C 0.5

25°C –0.5 0.5

–40°C to 125°C –0.5 0.5

25°C 2.05 2.5

–40°C to 125°C 2.5

25°C 1.06 1.5

–40°C to 125°C 1.9

I(min)

TPS71H01Q, TPS71H33Q

TPS71H48Q, TPS71H50Q

MIN TYP MAX

°

2

2.7

–40 125 °C

+ V

O(max)

DO(max load)

UNIT

µ

µ

µ

µ

µ

6

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

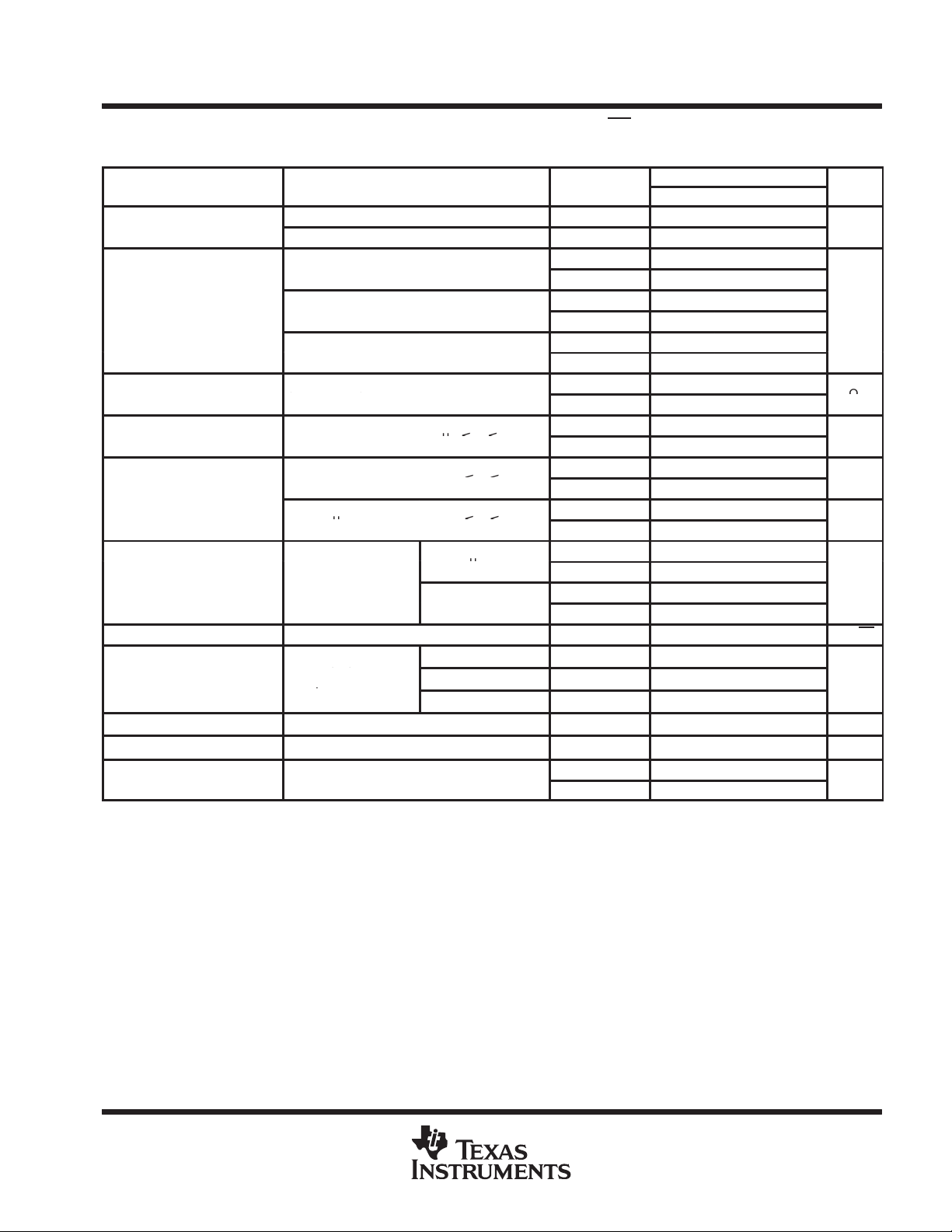

PARAMETER

TEST CONDITIONS

‡

T

UNIT

Reference voltage (measured at

V

50 µA ≤ I

150 mA

V

150 mA ≤ I

500 mA

Ω

V

2.9 V

50 µA ≤ I

≤ 500 mA

Input regulation

I

,

µ

O

,

mV

O

,

I

,

mV

Output regulation

O

µ ,

I

,

mV

I

A

Ripple rejection

f

120 H

dB

O

,

†

CSR

†

Ω

PG

§

I

400 µA

V

V

V

FB input current

nA

TPS71H01Q, TPS71H33Q, TPS71H48Q, TPS71H50Q

LOW-DROPOUT VOLTAGE REGULATORS

SLVS152A – NOVEMBER 1996 – REVISED JANUAR Y 1997

TPS71H01 electrical characteristics at IO = 10 mA, V

= 3.5 V, EN = 0 V, CO = 4.7 µF/CSR† = 1 Ω, FB

I

shorted to OUT at device leads (unless otherwise noted)

J

VI = 3.5 V, IO = 10 mA 25°C 1.178 V

FB with OUT connected to FB)

Reference voltage temperature

coefficient

Pass-element series resistance

(see Note 2)

p

p

pp

Output noise-spectral density f = 120 Hz 25°C 2

Output noise voltage

PG trip-threshold voltage

PG hysteresis voltage

p

output low voltage

p

†

CSR refers to the total series resistance, including the ESR of the capacitor, any series resistance added externally, and PWB trace resistance

to CO.

‡

Pulse-testing techniques are used to maintain virtual junction temperature as close as possible to ambient temperature; thermal effects must

be taken into account separately.

§

Output voltage programmed to 2.5 V with closed-loop configuration (see application information).

NOTES: 1. When VI < 2.9 V and IO > 150 mA simultaneously, pass element r

dropout voltage prevents the regulator from maintaining the specified tolerance range.

2. To calculate dropout voltage, use equation:

r

DS(on)

5.9 V , which corresponds to dropout conditions for programmed output voltages of 2.5 V, 3 V, 4 V, and 6 V, respectively. (For other

programmed values, see Figure 26.)

§

§

VDO = IO

⋅ r

is a function of both output current and input voltage. The parametric table lists r

2.5 V ≤ VI ≤ 10 V,

See Note 1

= 2.4 V,

I

= 2.4 V,

I

,

=

I

VI = 3.9 V, 50 µA ≤ IO ≤ 500 mA 25°C 0.32

VI = 5.9 V, 50 µA ≤ IO ≤ 500 mA 25°C 0.23

V

= 2.5 V to 10 V, 50 µA ≤ I

See Note 1

I

= 5 mA to 500 mA, 2.5 V ≤ V

See Note 1

I

= 50 µA to 500 mA, 2.5 V ≤ V

See Note 1

=

10 Hz ≤ f ≤ 100 kHz,

VFB voltage decreasing from above V

Measured at V

PG

DS(on)

=

z

= 1

FB

,

5 mA ≤ IO ≤ 500 mA,

≤

O

≤

O

O

≤ 500 mA,

≤ 10 V,

≤ 10 V,

= 50 µ

O

I

= 500 mA,

See Note 1

CO = 4.7 µF 25°C 95

CO = 10 µF 25°C 89

CO = 100 µF 25°C 74

PG

= 2.13

I

DS(on)

–40°C to 125°C 1.143 1.213 V

–40°C to 125°C 61 75 ppm/°C

25°C 0.7 1

–40°C to 125°C 1

25°C 0.83 1.3

–40°C to 125°C 1.3

25°C 0.52 0.85

–40°C to 125°C 0.85

25°C 18

–40°C to 125°C 25

25°C 14

–40°C to 125°C 25

25°C 22

–40°C to 125°C 54

25°C 48 59

–40°C to 125°C 44

25°C 45 54

–40°C to 125°C 44

–40°C to 125°C 1.101 1.145 V

25°C 12 mV

25°C 0.1 0.4

–40°C to 125°C 0.4

25°C –10 0.1 10

–40°C to 125°C –20 20

increases (see Figure 27) to a point such that the resulting

DS(on)

TPS71H01Q

MIN TYP MAX

µV/√Hz

µVrms

for VI = 2.4 V, 2.9 V, 3.9 V, and

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

7

TPS71H01Q, TPS71H33Q, TPS71H48Q, TPS71H50Q

PARAMETER

TEST CONDITIONS

‡

T

UNIT

Output voltage

V

I

V

V

D

I

100 mA

V

V

mV

I

500 mA

V

3.23 V

(

O)O

,

I

,

Ω

Input regulation

V

50 µA ≤ I

500 mA

mV

I

5 mA to 500 mA

V

≤ 10 V

mV

Output regulation

I

500 mA

V

V

mV

I

A

Ripple rejection

f

120 H

dB

I

500 mA

CSR

†

Ω

PG output low voltage

I

V

V

V

LOW-DROPOUT VOLTAGE REGULATORS

SLVS152A – NOVEMBER 1996 – REVISED JANUAR Y 1997

TPS71H33 electrical characteristics at IO = 10 mA, V

= 4.3 V , EN = 0 V , CO = 4.7 µF/CSR† = 1 Ω, SENSE

I

shorted to OUT (unless otherwise noted)

J

p

ropout voltage

Pass-element series (3.23 V – V

resistance

p

p

pp

Output noise-spectral density f = 120 Hz 25°C 2

Output noise voltage

PG trip-threshold voltage

PG hysteresis voltage

p

†

CSR refers to the total series resistance, including the ESR of the capacitor, any series resistance added externally, and PWB trace resistance

to CO.

‡

Pulse-testing techniques are used to maintain virtual junction temperature as close as possible to ambient temperature; thermal effects must

be taken into account separately.

VI = 4.3 V, IO = 10 mA 25°C 3.3

4.3 V ≤ VI ≤ 10 V, 5 mA ≤ IO ≤ 500 mA –40°C to 125°C 3.23 3.37

= 10 mA,

O

=

O

=

O

IO = 500 mA

= 4.3 V to 10 V,

I

=

O

= 50 µA to

O

=

10 Hz ≤ f ≤ 100 kHz,

VO voltage decreasing from above V

= 1 mA,

PG

†

= 1

=

,

,

)/I

, V

z

= 3.23

I

= 3.23

I

=

I

= 3.23 V,

,4.3 V ≤

,4.3 V ≤

= 50 µ

O

=

O

CO = 4.7 µF

CO = 10 µF

CO = 100 µF

= 2.8

I

O

I

I

≤

≤ 10

PG

25°C 4.5 7

–40°C to 125°C 8

25°C 47 60

–40°C to 125°C 80

25°C 235 300

–40°C to 125°C 400

25°C 0.47 0.6

–40°C to 125°C 0.8

25°C 20

–40°C to 125°C 27

25°C 21 38

–40°C to 125°C 75

25°C 30 60

–40°C to 125°C 120

25°C 43 54

–40°C to 125°C 40

25°C 39 49

–40°C to 125°C 36

25°C 274

25°C 228

25°C 159

–40°C to 125°C 2.868 3 V

25°C 35 mV

25°C 0.22 0.4

–40°C to 125°C 0.4

TPS71H33Q

MIN TYP MAX

µV/√Hz

µVrms

8

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

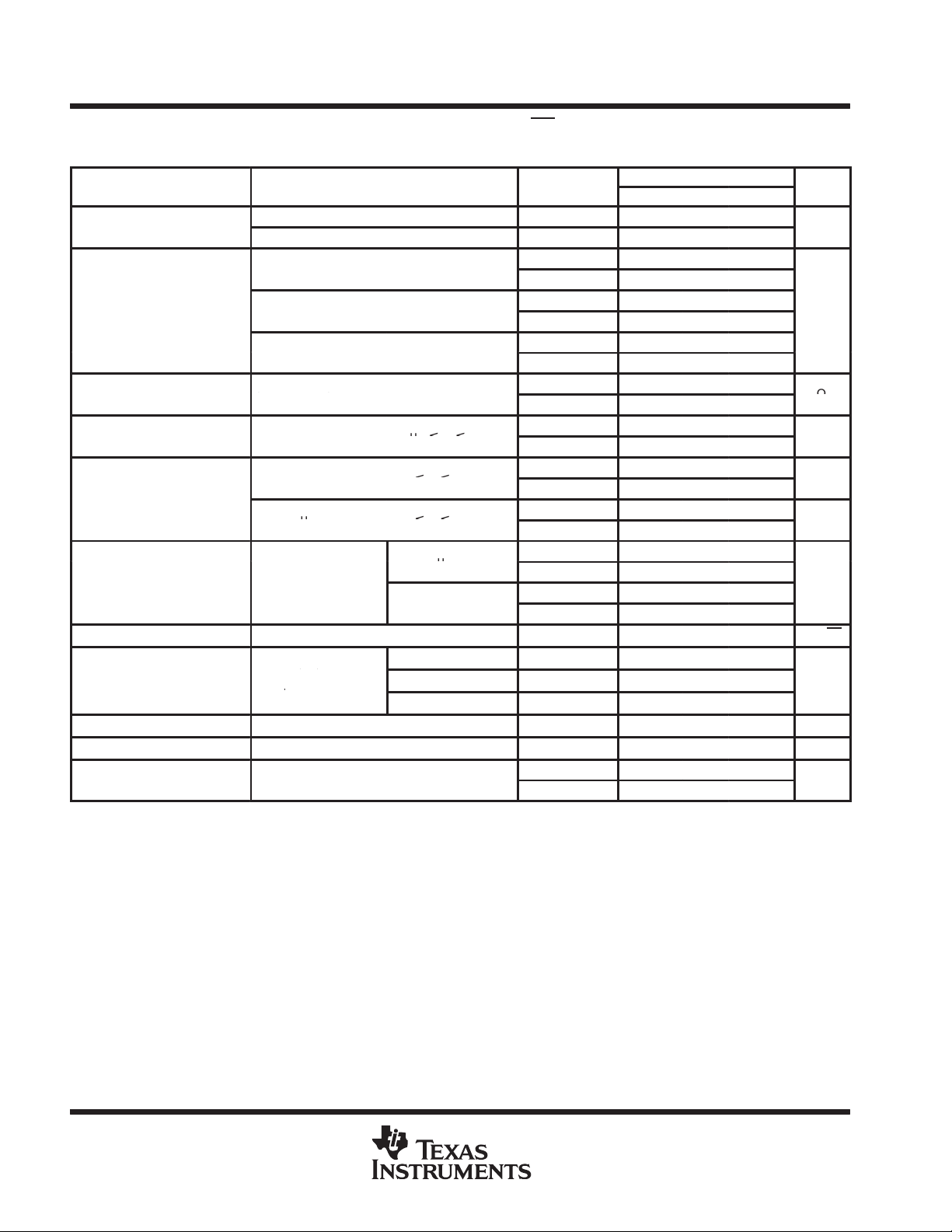

PARAMETER

TEST CONDITIONS

‡

T

UNIT

Output voltage

V

I

V

V

D

I

100 mA

V

V

mV

I

500 mA

V

V

(

O)O

,

I

,

Ω

Input regulation

V

50 µA ≤ I

500 mA

mV

I

500 mA

V

V

mV

Output regulation

I

50 µA to 500 mA

V

≤ 10 V

mV

I

A

Ripple rejection

f

120 H

dB

I

500 mA

CSR

†

Ω

PG

I

V

V

V

TPS71H01Q, TPS71H33Q, TPS71H48Q, TPS71H50Q

LOW-DROPOUT VOLTAGE REGULATORS

SLVS152A – NOVEMBER 1996 – REVISED JANUAR Y 1997

TPS71H48 electrical characteristics at IO = 10 mA, V

= 5.85 V, EN = 0 V, CO = 4.7 µF/CSR† = 1 Ω,

I

SENSE shorted to OUT (unless otherwise noted)

J

p

ropout voltage

Pass-element series (4.75 V – V

resistance

p

p

pp

Output noise-spectral density f = 120 Hz 25°C 2 µV/√Hz

Output noise voltage

PG trip-threshold voltage

PG hysteresis voltage

output low voltage

†

CSR refers to the total series resistance, including the ESR of the capacitor, any series resistance added externally, and PWB trace resistance

to CO.

‡

Pulse-testing techniques are used to maintain virtual junction temperature as close as possible to ambient temperature; thermal effects must

be taken into account separately.

VI = 5.85 V, IO = 10 mA 25°C 4.85

5.85 V ≤ VI ≤ 10 V, 5 mA ≤ IO ≤ 500 mA –40°C to 125°C 4.75 4.95

= 10 mA,

O

=

O

=

O

IO = 500 mA

= 5.85 V to 10 V,

I

= 5 mA to

O

=

O

=

10 Hz ≤ f ≤ 100 kHz,

VO voltage decreasing from above V

= 1.2 mA,

PG

†

= 1

=

,

,

)/I

, V

z

= 4.75

I

= 4.75

I

= 4.75

I

= 4.75 V,

,5.85 V ≤

,5.85 V ≤

= 50 µ

O

=

O

CO = 4.7 µF

CO = 10 µF

CO = 100 µF

= 4.12

I

O

≤

≤ 10

I

I

PG

25°C 2.9 6

–40°C to 125°C 8

25°C 30 37

–40°C to 125°C 54

25°C 150 180

–40°C to 125°C 250

25°C 0.32 0.35

–40°C to 125°C 0.52

25°C 27

–40°C to 125°C 37

25°C 12 42

–40°C to 125°C 80

25°C 42 60

–40°C to 125°C 130

25°C 42 53

–40°C to 125°C 39

25°C 39 50

–40°C to 125°C 35

25°C 410

25°C 328

25°C 212

–40°C to 125°C 4.5 4.7 V

25°C 50 mV

25°C 0.2 0.4

–40°C to 125°C 0.4

TPS71H48Q

MIN TYP MAX

µVrms

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

9

TPS71H01Q, TPS71H33Q, TPS71H48Q, TPS71H50Q

PARAMETER

TEST CONDITIONS

‡

T

UNIT

Output voltage

V

I

V

V

D

I

100 mA

V

V

mV

I

500 mA

V

V

(

O)O

,

I

Ω

Input regulation

V

50 µA ≤ I

500 mA

mV

I

500 mA

V

V

mV

Output regulation

I

50 µA to 500 mA

V

≤ 10 V

mV

I

A

Ripple rejection

f

120 H

dB

I

500 mA

CSR

†

Ω

PG output low voltage

I

V

V

V

LOW-DROPOUT VOLTAGE REGULATORS

SLVS152A – NOVEMBER 1996 – REVISED JANUAR Y 1997

TPS71H50 electrical characteristics at IO = 10 mA, V

= 6 V , EN = 0 V , CO = 4.7 µF/CSR† = 1 Ω, SENSE

I

shorted to OUT (unless otherwise noted)

J

p

ropout voltage

Pass-element series (4.88 V – V

resistance

p

p

pp

Output noise-spectral density f = 120 Hz 25°C 2

Output noise voltage

PG trip-threshold voltage

PG hysteresis voltage

p

†

CSR refers to the total series resistance, including the ESR of the capacitor, any series resistance added externally, and PWB trace resistance

to CO.

‡

Pulse-testing techniques are used to maintain virtual junction temperature as close as possible to ambient temperature; thermal effects must

be taken into account separately.

VI = 6 V, IO = 10 mA 25°C 5

6 V ≤ VI ≤ 10 V, 5 mA ≤ IO ≤ 500 mA –40°C to 125°C 4.9 5.1

= 10 mA,

O

=

O

=

O

IO = 500 mA

= 6 V to 10 V,

I

= 5 mA to

O

=

O

=

10 Hz ≤ f ≤ 100 kHz,

VO voltage decreasing from above V

= 1.2 mA,

PG

†

= 1

=

,

,

)/I

, V

z

= 4.88

I

= 4.88

I

= 4.88

I

= 4.88 V.

,6 V ≤

,6 V ≤

= 50 µ

O

=

O

CO = 4.7 µF

CO = 10 µF

CO = 100 µF

= 4.25

I

O

≤ 10

I

I

≤

PG

25°C 2.9 6

–40°C to 125°C 8

25°C 27 32

–40°C to 125°C 47

25°C 146 170

–40°C to 125°C 230

25°C 0.29 0.32

–40°C to 125°C 0.47

25°C 25

–40°C to 125°C 32

25°C 30 45

–40°C to 125°C 86

25°C 45 65

–40°C to 125°C 140

25°C 45 55

–40°C to 125°C 40

25°C 42 52

–40°C to 125°C 36

25°C 430

25°C 345

25°C 220

–40°C to 125°C 4.55 4.75 V

25°C 53 mV

25°C 0.2 0.4

–40°C to 125°C 0.4

TPS71H50Q

MIN TYP MAX

µV/√Hz

µVrms

10

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

VOOutput voltage

rrent

Ripple rejection

Frequenc

Output spectral noise densit

s

Freq

enc

V

CSR

Compensation series resistance

rrent

CSR

Compensation series resistance

Ceramic capacitance

CSR

Compensation series resistance

rrent

CSR

Compensation series resistance

Ceramic capacitance

TPS71H01Q, TPS71H33Q, TPS71H48Q, TPS71H50Q

LOW-DROPOUT VOLTAGE REGULATORS

SLVS152A – NOVEMBER 1996 – REVISED JANUAR Y 1997

TYPICAL CHARACTERISTICS

Table of Graphs

FIGURE

vs Output current 5

I

Q

V

DO

∆V

DO

∆V

O

V

O

∆V

O

r

DS(on)

R Divider resistance vs Free-air temperature 26

I

I(SENSE)

I

I

I(EN)

V

PG

Quiescent current

Typical dropout voltage vs Output current 8

Change in dropout voltage vs Free-air temperature 9

Change in output voltage vs Free-air temperature 10

Output voltage vs Input voltage 11

Change in output voltage vs Input voltage 12

p

pp

p

p

Pass-element resistance vs Input voltage 25

SENSE current vs Free-air temperature 27

FB leakage current vs Free-air temperature 28

Minimum input voltage for active-pass element vs Free-air temperature 29

Minimum input voltage for valid PG vs Free-air temperature 30

Input current (EN) vs Free-air temperature 31

Output voltage response from Enable (EN) 32

Power-good (PG) voltage vs Output voltage 33

p

p

p

p

yv

vs Input voltage 6

vs Free-air temperature 7

13

p

vs Output cu

vs

vs Output cu

vs

vs Output cu

vs

y

u

y

p

p

p

p

14

15

16

17

18

19

20

21

22

23

24

34

35

36

37

38

39

40

41

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

11

TPS71H01Q, TPS71H33Q, TPS71H48Q, TPS71H50Q

LOW-DROPOUT VOLTAGE REGULATORS

SLVS152A – NOVEMBER 1996 – REVISED JANUAR Y 1997

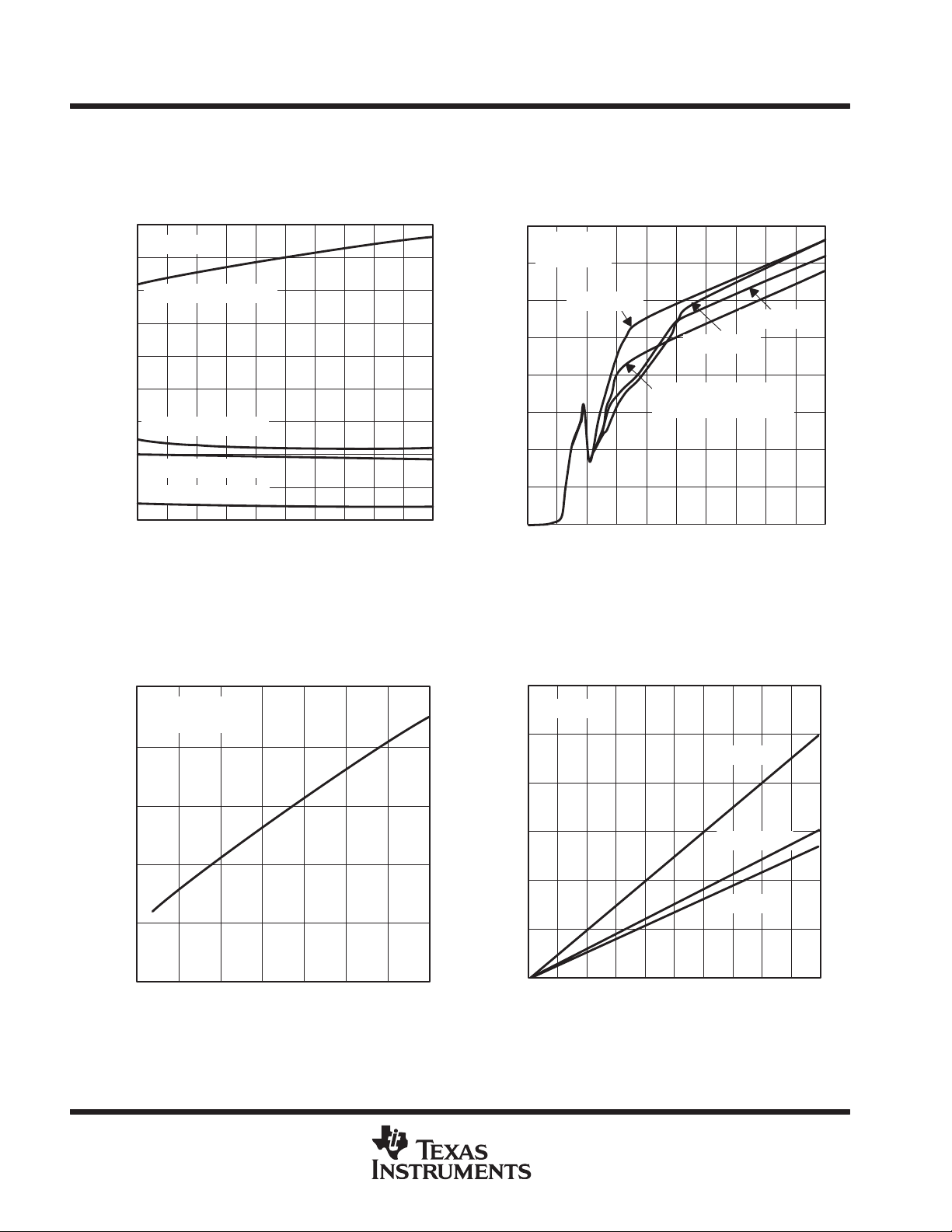

TYPICAL CHARACTERISTICS

355

TA = 25°C

345

335

Aµ

– Quiescent Current –

Q

I

TPS71Hxx, VI = 10 V

325

315

305

295

TPS71H50, VI = 6 V

285

TPS71H48, VI = 5.85 V

275

TPS71H33, VI = 4.3 V

265

0 50 100 150 200 250 300

FREE-AIR TEMPERATURE

400

VI = V

O(nom)

IO = 10 mA

350

Aµ

300

250

– Quiesent Current –

Q

I

200

QUIESCENT CURRENT

vs

OUTPUT CURRENT

350 400 450 500

IO – Output Current – mA

Figure 5

TPS71H48Q

QUIESCENT CURRENT

vs

+ 1 V

QUIESCENT CURRENT

INPUT VOLTAGE

400

TA = 25°C

RL = 10 Ω

350

Aµ

300

250

200

150

– Quiescent Current –

Q

100

I

50

0

0123456

TPS71H33

VI – Input Voltage – V

Figure 6

DROPOUT VOLTAGE

OUTPUT CURRENT

0.3

TA = 25°C

0.25

0.2

0.15

Dropout Voltage – V

0.1

0.05

vs

TPS71H48

TPS71H50

TPS71H01 With V

Programmed to 2.5 V

O

78910

vs

TPS71H33

TPS71H48

TPS71H50

12

150

–50 –25 0 25 50 75 100 125

TA – Free-Air Temperature – ° C

Figure 7

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

0

0 50 100 150 200 250 300

IO – Output Current – mA

Figure 8

350 400 450 500

TPS71H01Q, TPS71H33Q, TPS71H48Q, TPS71H50Q

LOW-DROPOUT VOLTAGE REGULATORS

SLVS152A – NOVEMBER 1996 – REVISED JANUAR Y 1997

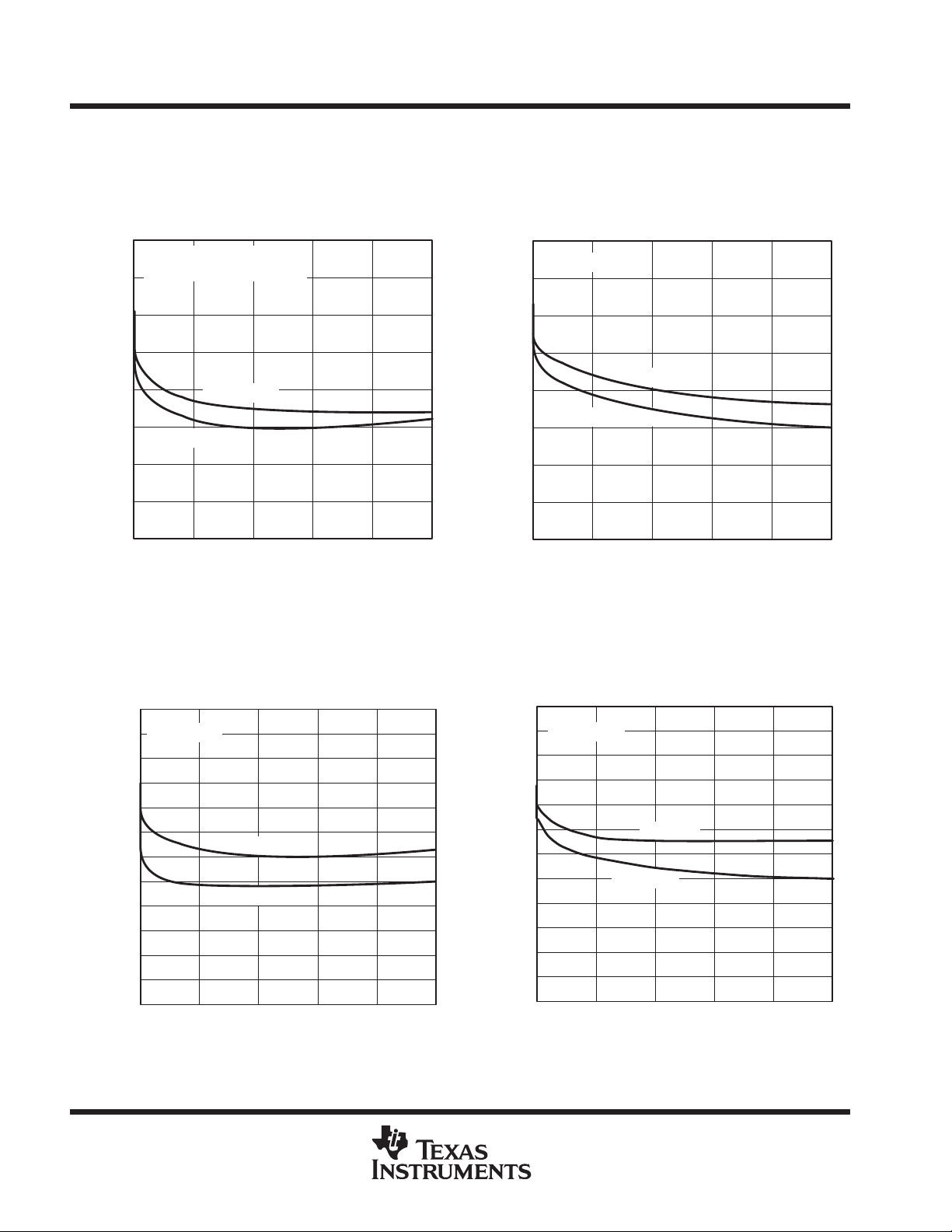

TYPICAL CHARACTERISTICS

CHANGE IN DROPOUT VOLTAGE

vs

FREE-AIR TEMPERATURE

10

IO = 100 mA

8

6

4

2

0

–2

–4

–6

Change in Dropout Voltage – mV

–8

–10

–50 –25 0 25 50 75 100 125

TA – Free-Air Temperature – ° C

Figure 9

OUTPUT VOLTAGE

vs

INPUT VOLTAGE

6

TA = 25°C

RL = 10 Ω

5

4

3

TPS71H50

TPS71H48

TPS71H33

CHANGE IN OUTPUT VOLTAGE

vs

FREE-AIR TEMPERATURE

20

VI = V

IO = 10 mA

15

10

5

0

–5

–10

– Change in Output Voltage – mV

O

V

–15

∆

–20

–50 –25 0 25 50 75 100 125

+ 1 V

O(nom)

TA – Free-Air Temperature – ° C

Figure 10

CHANGE IN OUTPUT VOLTAGE

vs

INPUT VOLTAGE

20

TA = 25°C

RL = 10 Ω

15

10

5

0

TPS71H50

TPS71H48

2

– Output Voltage – V

O

V

1

0

TPS71H01 With V

Programmed to 2.5 V

0123456

VI – Input Voltage – V

Figure 11

O

78910

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

–5

–10

– Change In Output Voltage – mV

O

∆V

–15

–20

TPS71H33

4567

VI – Input Voltage – V

Figure 12

8910

13

TPS71H01Q, TPS71H33Q, TPS71H48Q, TPS71H50Q

LOW-DROPOUT VOLTAGE REGULATORS

SLVS152A – NOVEMBER 1996 – REVISED JANUAR Y 1997

TYPICAL CHARACTERISTICS

OUTPUT VOLTAGE

OUTPUT CURRENT

2.52

TA = 25°C

2.515

2.505

2.495

– Output Voltage – V

O

V

2.485

VO Programmed to 2.5 V

2.51

2.5

VI = 10 V

2.49

2.48

0 100 200 300

VI = 3.5 V

IO – Output Current – mA

TPS71H01Q

vs

Figure 13

400 500

OUTPUT VOLTAGE

OUTPUT CURRENT

3.34

TA = 25°C

3.33

3.32

3.31

3.3

3.29

– Output Voltage – V

O

V

3.28

3.27

3.26

0 100 200 300

VI = 4.3 V

IO – Output Current – mA

Figure 14

TPS71H33Q

vs

VI = 10 V

400 500

OUTPUT VOLTAGE

OUTPUT CURRENT

4.92

TA = 25°C

4.91

4.9

4.89

4.88

4.87

4.86

4.85

– Output Voltage – V

4.84

O

V

4.83

4.82

4.81

4.8

0 100 300

IO – Output Current – mA

TPS71H48Q

vs

VI = 5.85 V

VI = 10 V

200 400

Figure 15

500

OUTPUT VOLTAGE

OUTPUT CURRENT

5.06

5.05

5.04

5.03

5.02

5.01

4.99

– Output Voltage – V

4.98

O

V

4.97

4.96

4.95

4.94

TA = 25°C

5

VI = 10 V

0 100 300

IO – Output Current – mA

Figure 16

TPS71H50Q

vs

VI = 6 V

200

400 500

14

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

TPS71H01Q, TPS71H33Q, TPS71H48Q, TPS71H50Q

LOW-DROPOUT VOLTAGE REGULATORS

SLVS152A – NOVEMBER 1996 – REVISED JANUAR Y 1997

TYPICAL CHARACTERISTICS

TPS71H01Q

RIPPLE REJECTION

vs

FREQUENCY

70

60

50

40

30

TA = 25°C

Ripple Rejection – dB

VI = 3.5 V

20

CO = 4.7 µF (CSR = 1 Ω)

No Input Capacitance

VO Programmed to 2.5 V

10

0

10 100 1K 10K 100K 1M 10M

RL = 10 Ω

f – Frequency – Hz

RL = 100 kΩ

RL = 500 Ω

Figure 17

70

60

50

40

30

20

Ripple Rejection – dB

TA = 25°C

10

VI = 3.5 V

CO = 4.7 µF (CSR = 1 Ω)

0

No Input Capacitance

–10

10

TPS71H33Q

RIPPLE REJECTION

vs

FREQUENCY

RL = 100 kΩ

RL = 500 Ω

RL = 10 Ω

10 M1 M100 k10 k1 k100

f – Frequency – Hz

Figure 18

70

60

50

40

30

20

Ripple Rejection – dB

10

–10

RL = 10 Ω

TA = 25°C

VI = 3.5 V

0

CO = 4.7 µF (CSR = 1 Ω)

No Input Capacitance

10

TPS71H48Q

RIPPLE REJECTION

vs

FREQUENCY

RL = 100 kΩ

RL = 500 Ω

f – Frequency – Hz

Figure 19

TPS71H50Q

RIPPLE REJECTION

vs

FREQUENCY

70

60

50

RL = 10 Ω

40

30

Ripple Rejection – dB

20

TA = 25°C

VI = 3.5 V

10

CO = 4.7 µF (CSR = 1 Ω)

No Input Capacitance

10 M1 M100 k10 k1 k100

0

10

f – Frequency – Hz

RL = 100 kΩ

RL = 500 Ω

10 M1 M100 k10 k1 k100

Figure 20

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

15

TPS71H01Q, TPS71H33Q, TPS71H48Q, TPS71H50Q

LOW-DROPOUT VOLTAGE REGULATORS

SLVS152A – NOVEMBER 1996 – REVISED JANUAR Y 1997

TYPICAL CHARACTERISTICS

TPS71H01Q

OUTPUT SPECTRAL NOISE DENSITY

FREQUENCY

10

Hzµ

V/

1

0.1

Output Spectral Noise Density –

CO = 100 µF (CSR = 1 Ω)

0.01

10 10

2

f – Frequency – Hz

Figure 21

vs

TA = 25°C

No Input Capacitance

VI = 3.5 V

VO Programmed to 2.5 V

CO = 4.7 µF (CSR = 1 Ω)

CO = 10 µF (CSR = 1 Ω)

10

3

10

4

10

TPS71H33Q

OUTPUT SPECTRAL NOISE DENSITY

vs

FREQUENCY

10

Hzµ

V/

1

0.1

Output Spectral Noise Density –

5

0.01

10

2

10

f – Frequency – Hz

TA = 25°C

No Input Capacitance

VI = 4.3 V

CO = 10 µF (CSR = 1 Ω)

CO = 4.7 µF (CSR = 1 Ω)

CO = 100 µF (CSR = 1 Ω)

10

3

10

4

10

5

Figure 22

TPS71H48Q

OUTPUT SPECTRAL NOISE DENSITY

vs

FREQUENCY

10

V/ Hzµ

1

0.1

CO = 100 µF (CSR = 1 Ω)

Output Spectral Noise Density –

0.01

10 100 1 k 10 k 100 k

f – Frequency – Hz

TA = 25°C

No Input Capacitance

VI = 5.85 V

CO = 10 µF (CSR = 1 Ω)

CO = 4.7 µF (CSR = 1 Ω)

Figure 23

TPS71H50Q

OUTPUT SPECTRAL NOISE DENSITY

vs

FREQUENCY

10

Hzµ

V/

1

0.1

Output Spectral Noise Density –

CO = 100 µF (CSR = 1 Ω)

0.01

10 100 1 k 10 k 100 k

CO = 10 µF (CSR = 1 Ω)

CO = 4.7 µF (CSR = 1 Ω)

TA = 25°C

No Input Capacitance

VI = 6 V

f – Frequency – Hz

Figure 24

16

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

TPS71H01Q, TPS71H33Q, TPS71H48Q, TPS71H50Q

LOW-DROPOUT VOLTAGE REGULATORS

SLVS152A – NOVEMBER 1996 – REVISED JANUAR Y 1997

TYPICAL CHARACTERISTICS

PASS-ELEMENT RESISTANCE

vs

INPUT VOLTAGE

1.1

1

Ω

0.9

0.8

0.7

0.6

0.5

0.4

– Pass-Element Resistance –

0.3

DS(on)

r

0.2

0.1

2457

368

IO = 500 mA

IO = 100 mA

VI – Input Voltage – V

Figure 25

FIXED-OUTPUT VERSIONS

SENSE PIN CURRENT

vs

FREE-AIR TEMPERATURE

6

VI = V

V

I(sense)

5.8

Aµ

5.6

O(nom)

= V

+ 1 V

O(nom)

T

= 25°C

A

V

= 1.12 V

I(FB)

910

DIVIDER RESISTANCE

vs

FREE-AIR TEMPERATURE

1.2

1.1

Ω

1

0.9

0.8

0.7

0.6

R – Divider Resistance – M

0.5

0.4

–50 –25 0 25 50 75 100 125

TPS71H50

TPS71H48

TPS71H33

TA – Free-Air Temperature – ° C

VI = V

V

I(sense)

O(nom)

= V

Figure 26

ADJUSTABLE VERSION

FB LEAKAGE CURRENT

vs

FREE-AIR TEMPERATURE

0.6

VFB = 2.5 V

0.5

+ 1 V

O(nom)

5.4

5.2

5

– Sense Pin Current –

4.8

I(sense)

I

4.6

4.4

–50 –25 0 25 50 75 100 125

TA – Free-Air Temperature – ° C

Figure 27

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

0.4

0.3

0.2

FB Leakage Current – nA

0.1

0

–50 –25 0 25 50 75 100 125

TA – Free-Air Temperature – ° C

Figure 28

17

TPS71H01Q, TPS71H33Q, TPS71H48Q, TPS71H50Q

LOW-DROPOUT VOLTAGE REGULATORS

SLVS152A – NOVEMBER 1996 – REVISED JANUAR Y 1997

TYPICAL CHARACTERISTICS

MINIMUM INPUT VOLTAGE FOR ACTIVE

PASS ELEMENT

vs

FREE-AIR TEMPERATURE

2.1

RL = 500 Ω

2.09

2.08

2.07

2.06

2.05

2.04

2.03

– Minimum Input Voltage – V

I

2.02

V

2.01

2

–50 –25 0 25 50 75 100 125

TA – Free-Air Temperature – ° C

Figure 29

MINIMUM INPUT VOLTAGE FOR VALID

POWER GOOD (PG)

vs

FREE-AIR TEMPERATURE

1.1

1.09

1.08

1.07

– Minimum Input Voltage – V

I

V

1.06

1.05

–50 –25 0 25 50 75 100 125

TA – Free-Air Temperature – ° C

Figure 30

EN INPUT CURRENT

vs

FREE-AIR TEMPERATURE

100

VI = V

90

80

70

60

50

40

– Input Current – nA

30

I(EN)

I

20

10

0

–40 –20 0 20 40 60 80 100 120 140

= 10 V

I(EN)

TA – Free-Air Temperature – ° C

Figure 31

18

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

TPS71H01Q, TPS71H33Q, TPS71H48Q, TPS71H50Q

LOW-DROPOUT VOLTAGE REGULATORS

SLVS152A – NOVEMBER 1996 – REVISED JANUAR Y 1997

TYPICAL CHARACTERISTICS

OUTPUT VOLTAGE RESPONSE FROM

– Output Voltage – V

O

V

ENABLE (EN

V

O(nom)

TA = 25°C

RL = 500 Ω

CO = 4.7 µF (ESR = 1Ω)

No Input Capacitance

)

6

4

2

EN Voltage – V

0

0 20 40 60 80 100 120 140

Time – µs

Figure 32

POWER-GOOD (PG) VOLTAGE

vs

OUTPUT VOLTAGE

6

TA = 25°C

PG Pulled Up to 5 V With 5 kΩ

5

4

3

2

– Power-Good (PG) Voltage – V

PG

1

V

0

93 94 95 96

VO – Output Voltage (VO as a percent of V

Figure 33

97 98

) – %

O(nom)

–2

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

19

TPS71H01Q, TPS71H33Q, TPS71H48Q, TPS71H50Q

LOW-DROPOUT VOLTAGE REGULATORS

SLVS152A – NOVEMBER 1996 – REVISED JANUAR Y 1997

TYPICAL CHARACTERISTICS

TYPICAL REGIONS OF STABILITY

COMPENSATION SERIES RESISTANCE

OUTPUT CURRENT

100

Compensation Series Resistance – Ω

CSR –

0.1

VI = V

O(nom)

No Input Capacitance

CO = 4.7 µF

No Added Ceramic Capacitance

TA = 25°C

10

1

0 50 100 150 200 250 300

IO – Output Current – mA

Figure 34

+ 1 V

vs

Region of Instability

Region of Instability

350 400 450 500

TYPICAL REGIONS OF STABILITY

COMPENSATION SERIES RESISTANCE

vs

OUTPUT CURRENT

100

VI = V

No Input Capacitance

CO = 4.7 µF + 0.5 µF of

Ceramic Capacitance

TA = 25°C

10

1

Compensation Series Resistance – ΩCSR –

0.1

0 50 100 150 200 250 300 350 400 450 500

+ 1 V

O(nom)

Region of Instability

Region of Instability

IO – Output Current – mA

Figure 35

TYPICAL REGIONS OF STABILITY

COMPENSATION SERIES RESISTANCE

vs

ADDED CERAMIC CAPACITANCE

100

VI = V

No Input Capacitance

IO= 100 mA

CO = 4.7 µF

TA = 25°C

10

1

Compensation Series Resistance – ΩCSR –

0.1

0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1

+ 1 V

O(nom)

Region of Instability

Region of Instability

Ceramic Capacitance – µF

Figure 36

TYPICAL REGIONS OF STABILITY

COMPENSATION SERIES RESISTANCE

vs

ADDED CERAMIC CAPACITANCE

100

VI = V

No Input Capacitance

IO= 500 mA

CO = 4.7 µF

TA = 25°C

10

1

Compensation Series Resistance – ΩCSR –

0.1

0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1

+ 1 V

O(nom)

Region of Instability

Region of Instability

Ceramic Capacitance – µF

Figure 37

20

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

TPS71H01Q, TPS71H33Q, TPS71H48Q, TPS71H50Q

LOW-DROPOUT VOLTAGE REGULATORS

SLVS152A – NOVEMBER 1996 – REVISED JANUAR Y 1997

TYPICAL CHARACTERISTICS

TYPICAL REGIONS OF STABILITY

COMPENSATION SERIES RESISTANCE

OUTPUT CURRENT

100

Region of Instability

10

1

Compensation Series Resistance – ΩCSR –

0.1

0 50 100 150 200 250 300

IO – Output Current – mA

vs

VI = V

O(nom)

No Input Capacitance

CO = 10 µF

No Ceramic Capacitance

TA = 25°C

Figure 38

†

+ 1 V

350 400 450 500

TYPICAL REGIONS OF STABILITY

COMPENSATION SERIES RESISTANCE

OUTPUT CURRENT

100

VI = V

No Input Capacitance

CO = 10 µF + 0.5 µF of

Added Ceramic Capacitance

TA = 25°C

10

1

Compensation Series Resistance – ΩCSR –

0.1

0 50 100 150 200 250 300

+ 1 V

O(nom)

Region of Instability

IO – Output Current – mA

Figure 39

†

vs

350 400 450 500

TYPICAL REGIONS OF STABILITY

COMPENSATION SERIES RESISTANCE

ADDED CERAMIC CAPACITANCE

100

VI = V

No Input Capacitance

CO = 10 µF

IO = 100 mA

TA = 25°C

10

1

Compensation Series Resistance – ΩCSR –

0.1

0 0.1 0.2 0.3 0.4 0.5 0.6

+ 1 V

O(nom)

Region of Instability

Ceramic Capacitance – µF

vs

Figure 40

†

0.7 0.8 0.9 1

TYPICAL REGIONS OF STABILITY

COMPENSATION SERIES RESISTANCE

ADDED CERAMIC CAPACITANCE

100

VI = V

No Input Capacitance

CO = 10 µF

IO = 500 mA

TA = 25°C

10

1

Compensation Series Resistance – ΩCSR –

0.1

0 0.1 0.2 0.3 0.4 0.5 0.6

+ 1 V

O(nom)

Region of Instability

Ceramic Capacitance – µF

Figure 41

†

vs

0.7 0.8 0.9 1

†CSR values below 0.1 Ω are not recommended.

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

21

TPS71H01Q, TPS71H33Q, TPS71H48Q, TPS71H50Q

LOW-DROPOUT VOLTAGE REGULATORS

SLVS152A – NOVEMBER 1996 – REVISED JANUAR Y 1997

TYPICAL CHARACTERISTICS

+

C

CSR

To Load

O

†

C

cer

R

L

V

I

†

Ceramic capacitor

IN

EN

OUT

SENSE

GND

Figure 42. Test Circuit for Typical Regions of Stability (see Figures 34 through 41)

22

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

TPS71H01Q, TPS71H33Q, TPS71H48Q, TPS71H50Q

LOW-DROPOUT VOLTAGE REGULATORS

SLVS152A – NOVEMBER 1996 – REVISED JANUAR Y 1997

THERMAL INFORMATION

standard TSSOP-20

In response to system-miniaturization trends, integrated circuits are being offered in low-profile and fine-pitch

surface-mount packages. Implementation of many of today’s high-performance devices in these packages

requires special attention to power dissipation. Many system-dependent issues such as thermal coupling,

airflow, added heat sinks and convection surfaces, and the presence of other heat-generating components

affect the power-dissipation limits of a given component.

Three basic approaches for enhancing thermal performance are illustrated in this discussion:

D

Improving the power-dissipation capability of the PWB design

D

Improving the thermal coupling of the component to the PWB

D

Introducing airflow in the system

Figure 43 is an example of a thermally enhanced PWB layout for the 20-lead TSSOP package. This layout

involves adding copper on the PWB to conduct heat away from the device. The R

system is illustrated in Figure 44. The family of curves illustrates the effect of increasing the size of the

copper-heat-sink surface area. The PWB is a standard FR4 board (L × W × H = 3.2 inch × 3.2 inch × 0.062 inch);

the board traces and heat sink area are 1-oz (per square foot) copper.

for this component/board

θJA

Copper Heat Sink

1 oz Copper

Figure 43. Thermally Enhanced PWB Layout (not to scale) for the 20-Pin TSSOP

Figure 45 shows the thermal resistance for the same system with the addition of a thermally conductive

compound between the body of the TSSOP package and the PWB copper routed directly beneath the device.

The thermal conductivity for the compound used in this analysis is 0.815 W/m × °C.

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

23

TPS71H01Q, TPS71H33Q, TPS71H48Q, TPS71H50Q

LOW-DROPOUT VOLTAGE REGULATORS

SLVS152A – NOVEMBER 1996 – REVISED JANUAR Y 1997

THERMAL INFORMATION

standard TSSOP-20 (continued)

THERMAL RESISTANCE, JUNCTION-TO-AMBIENT

vs

AIR FLOW

190

C/W

°

170

2

1 cm

150

130

110

90

70

50

JAθ

0 50 100 150 200 250

R – Thermal Resistance, Junction-to-Ambient –

4 cm

Component/Board System

20-Lead TSSOP

2

0 cm

2

2 cm

2

Air Flow – ft/min

8 cm

2

Figure 44

Using these figures to determine the system R

with the equation:

THERMAL RESISTANCE, JUNCTION-TO-AMBIENT

vs

AIR FLOW

190

C/W

Component/Board System

20-Lead TSSOP

170

Includes Thermally Conductive

Compound Between Body and Board

150

130

2

110

90

70

50

JAθ

8 cm

0 50 100 150 200 250

Air Flow – ft/min

4 cm

2

2 cm

2

0 cm

1 cm

2

2

300

°

R – Thermal Resistance, Junction-to-Ambient –

Figure 45

allows the maximum power-dissipation limit to be calculated

θJA

300

P

D(max)

+

T

J(max)

R

q

*

T

JA(system)

A

Where

T

is the maximum allowable junction temperature (i.e., 150°C absolute maximum and

J(max)

125°C maximum recommended operating temperature for specified operation).

This limit should then be applied to the internal power dissipated by the TPS71Hxx regulator. The equation for

calculating total internal power dissipation of the TPS71Hxx is:

P

D(total)

+

ǒ

VI*

Ǔ

V

@

IO)

V

@

I

O

I

Q

Because the quiescent current of the TPS71Hxx family is very low, the second term is negligible, further

simplifying the equation to:

P

D(total)

+

ǒ

VI*

Ǔ

V

@

I

O

O

24

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

TPS71H01Q, TPS71H33Q, TPS71H48Q, TPS71H50Q

LOW-DROPOUT VOLTAGE REGULATORS

SLVS152A – NOVEMBER 1996 – REVISED JANUAR Y 1997

THERMAL INFORMATION

standard TSSOP-20 (continued)

For a 20-lead TSSOP /FR4 board system with thermally conductive compound between the board and the

device body, where T

power-dissipation limit can be calculated. As indicated in Figure 45, the system R

maximum power-dissipation limit is:

= 55°C, airflow = 100 ft/min, copper heat sink area = 1 cm2, the maximum

A

is 94°C/W; therefore, the

θJA

T

P

D(max)

If the system implements a TPS71H48 regulator where V

is:

P

D(total)

Comparing P

maximum limit. When it does, one of two corrective actions can be taken. The power-dissipation limit can be

raised by increasing the airflow or the heat-sink area. Alternatively , the internal power dissipation of the regulator

can be lowered by reducing the input voltage or the load current. In either case, the above calculations should

be repeated with the new system parameters.

+

ǒ

+

D(total)

J(max)

R

q

VI*

with P

*

T

JA(system)

Ǔ

V

@

IO+(6*

O

D(max)

A

°°

125 C*55 C

+

reveals that the power dissipation in this example does not exceed the

°

94 CńW

4.85)@0.385+443 mW

+

745 mW

= 6 V and IO = 385 mA, the internal power dissipation

I

thermally enhanced TSSOP-20

The thermally enhanced PWP package is based on the 20-pin TSSOP, but includes a thermal pad [see

Figure 46(c)] to provide an effective thermal contact between the IC and the PWB.

Traditionally, surface mount and power have been mutually exclusive terms. A variety of scaled-down

TO220-type packages have leads formed as gull wings to make them applicable for surface-mount applications.

These packages, however, suffer from several shortcomings: they do not address the very low profile

requirements (<2 mm) of many of today’s advanced systems, and they do not offer a pin-count high enough

to accommodate increasing integration. On the other hand, traditional low-power surface-mount packages

require power-dissipation derating that severely limits the usable range of many high-performance analog

circuits.

The PWP package (thermally enhanced TSSOP) combines fine-pitch surface-mount technology with thermal

performance comparable to much larger power packages.

The PWP package is designed to optimize the heat transfer to the PWB. Because of the very small size and

limited mass of a TSSOP package, thermal enhancement is achieved by improving the thermal conduction

paths that remove heat from the component. The thermal pad is formed using a lead-frame design (patent

pending) and manufacturing technique to provide the user with direct connection to the heat-generating IC.

When this pad is soldered or otherwise coupled to an external heat dissipator, high power dissipation in the

ultrathin, fine-pitch, surface-mount package can be reliably achieved.

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

25

TPS71H01Q, TPS71H33Q, TPS71H48Q, TPS71H50Q

LOW-DROPOUT VOLTAGE REGULATORS

SLVS152A – NOVEMBER 1996 – REVISED JANUAR Y 1997

THERMAL INFORMATION

thermally enhanced TSSOP-20 (continued)

DIE

Side View (a)

DIE

End View (b)

Thermal

Pad

Bottom View (c)

Figure 46. Views of Thermally Enhanced PWP Package

Because the conduction path has been enhanced, power-dissipation capability is determined by the thermal

considerations in the PWB design. For example, simply adding a localized copper plane (heat-sink surface),

which is coupled to the thermal pad, enables the PWP package to dissipate 2.5 W in free air (reference

Figure 48(a), 8 cm

2

of copper heat sink and natural convection). Increasing the heat-sink size increases the

power dissipation range for the component. The power dissipation limit can be further improved by adding

airflow to a PWB/IC assembly (see Figures 47 and 48). The line drawn at 0.3 cm

2

in Figures 47 and 48 indicates

performance at the minimum recommended heat-sink size, illustrated in Figure 50.

The thermal pad is directly connected to the substrate of the IC, which for the TPS71HxxQPWP series is a

secondary electrical connection to device ground. The heat-sink surface that is added to the PWB can be a

ground plane or left electrically isolated. In other TO220-type surface-mount packages, the thermal connection

is also the primary electrical connection for a given terminal which is not always ground. The PWP package

provides up to 12 independent leads that can be used as inputs and outputs (Note: leads 1, 2, 9, 10, 11, 12,

19, and 20 are internally connected to the thermal pad and the IC substrate).

26

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

THERMAL INFORMATION

thermally enhanced TSSOP-20 (continued)

COPPER HEAT-SINK AREA

150

TPS71H01Q, TPS71H33Q, TPS71H48Q, TPS71H50Q

LOW-DROPOUT VOLTAGE REGULATORS

SLVS152A – NOVEMBER 1996 – REVISED JANUAR Y 1997

THERMAL RESISTANCE

vs

125

C/W

°

100

75

– Thermal Resistance –

JA

θ

R

50

25

Natural Convection

50 ft/min

250 ft/min

0235

1460.3

100 ft/min

150 ft/min

200 ft/min

300 ft/min

Copper Heat-Sink Area – cm

Figure 47

78

2

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

27

TPS71H01Q, TPS71H33Q, TPS71H48Q, TPS71H50Q

LOW-DROPOUT VOLTAGE REGULATORS

SLVS152A – NOVEMBER 1996 – REVISED JANUAR Y 1997

THERMAL INFORMATION

thermally enhanced TSSOP-20 (continued)

3.5

TA = 25°C

3

2.5

2

1.5

1

– Power Dissipation Limit – W

D

P

0.5

0

0246

0.3

300 ft/min

Natural Convection

Copper Heat-Sink Size – cm

(a)

3.5

150 ft/min

2

3

TA = 105°C

3.5

TA = 55°C

3

2.5

2

1.5

1

– Power Dissipation Limit – W

D

P

0.5

8

0

0246

0.3

Copper Heat-Sink Size – cm

300 ft/min

150 ft/min

Natural Convection

8

2

(b)

2.5

2

1.5

300 ft/min

1

– Power Dissipation Limit – W

D

P

0.5

0

0246

0.3

Copper Heat-Sink Size – cm

150 ft/min

Natural Convection

8

2

(c)

Figure 48. Power Ratings of the PWP Package at Ambient Temperatures of 25°C, 55°C, and 105°C

28

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

TPS71H01Q, TPS71H33Q, TPS71H48Q, TPS71H50Q

LOW-DROPOUT VOLTAGE REGULATORS

SLVS152A – NOVEMBER 1996 – REVISED JANUAR Y 1997

THERMAL INFORMATION

thermally enhanced TSSOP-20 (continued)

Figure 49 is an example of a thermally enhanced PWB layout for use with the new PWP package. This board

configuration was used in the thermal experiments that generated the power ratings shown in Figures 47 and

48. As discussed earlier, copper has been added on the PWB to conduct heat away from the device. R

this assembly is illustrated in Figure 47 as a function of heat-sink area. A family of curves is included to illustrate

the effect of airflow introduced into the system.

Heat-Sink Area

1 oz Copper

Board thickness 62 mils

Board size 3.2 in. × 3.2 in.

Board material FR4

Copper trace/heat sink 1 oz

Exposed pad mounting 63/67 tin/lead solder

θJA

for

Figure 49. PWB Layout (Including Copper Heatsink Area) for Thermally Enhanced PWP Package

From Figure 47, R

power-dissipation limit for the component/PWB assembly, with the equation:

P

D(max)

Where

T

max is the maximum specified junction temperature (150°C absolute maximum limit, 125°C recommended

J

operating limit) and T

P

for calculating total internal power dissipation of the TPS71H33QPWP is:

Since the quiescent current of the TPS71H33QPWP is very low, the second term is negligible, further simplifying

the equation to:

For the case where T

power-dissipation limit can be calculated. First, from Figure 47, we find the system R

the maximum power-dissipation limit is:

should then be applied to the internal power dissipated by the TPS71H33QPWP regulator. The equation

D(max)

P

D(total)

P

D(total)

+

+

+

for a PWB assembly can be determined and used to calculate the maximum

θJA

TJmax*T

R

q

JA(system)

is the ambient temperature.

A

ǒ

VI*

ǒ

VI*

A

A

Ǔ

V

IO)

VI

O

Ǔ

V

I

O

= 55°C, airflow = 200 ft/min, copper heat-sink area = 4 cm2, the maximum

O

I

Q

is 50°C/W; therefore,

θJA

P

D(max)

TJmax*T

+

R

q

JA(system)

A

+

°°

125 C*55 C

°

50 CńW

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

+

1.4 W

29

TPS71H01Q, TPS71H33Q, TPS71H48Q, TPS71H50Q

LOW-DROPOUT VOLTAGE REGULATORS

SLVS152A – NOVEMBER 1996 – REVISED JANUAR Y 1997

THERMAL INFORMATION

thermally enhanced TSSOP-20 (continued)

If the system implements a TPS71H33QPWP regulator, where VI = 6 V and IO = 500 mA, the internal power

dissipation is:

P

D(total)

Comparing P

calculated limit. When it does, one of two corrective actions should be made: raising the power-dissipation limit

by increasing the airflow or the heat-sink area, or lowering the internal power dissipation of the regulator by

reducing the input voltage or the load current. In either case, the above calculations should be repeated with

the new system parameters.

ǒ

+

D(total)

VI*

with P

V

O

Ǔ

IO+(6*

reveals that the power dissipation in this example does not exceed the

D(max)

3.3) 0.5+1.35 W

mounting information

Since the thermal pad is not a primary connection for an electrical signal, the importance of the electrical

connection is not significant. The primary requirement is to complete the thermal contact between the thermal

pad and the PWB metal. The thermal pad is a solderable surface and is fully intended to be soldered at the time

the component is mounted. Although voiding in the thermal-pad solder-connection is not desirable, up to 50%

voiding is acceptable. The data included in Figures 47 and 48 is for soldered connections with voiding between

20% and 50%. The thermal analysis shows no significant difference resulting from the variation in voiding

percentage.

Figure 50 shows the solder-mask land pattern for

the PWP package. The minimum recommended

heat-sink area is also illustrated. This is simply a

copper plane under the body extent of the

package, including metal routed under terminals

1, 2, 9, 10, 11, 12, 19, and 20.

Minimum Recommended

Heat-Sink Area

0.27 mm

Location of Exposed

Thermal Pad on

PWP Package

1.2 mm

reliability information

This section includes demonstrated reliability test

results obtained from the qualification program.

Accelerated tests are performed at high-stress

conditions so that product reliability can be

established during a relatively short test duration.

Specific stress conditions are chosen to represent

accelerated versions of various deviceapplication environments and allow meaningful

extrapolation to normal operating conditions.

component level reliability test results

preconditioning

Preconditioning of components prior to reliability testing is employed to simulate the actual board assembly

process used by the customer. This ensures that reliability test results are more representative of those that

would be seen in the final application. The general form of the preconditioning sequence includes a moisture

soak followed by multiple vapor-phase-reflow or infrared-reflow solder exposures. All components used in the

following reliability tests were preconditioned in accordance with JEDEC Test Method A113 for Level 1 (not

moisture-sensitive) products.

0.65 mm

5.72 mm

Figure 50. PWP Package Land Pattern

30

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

TPS71H01Q, TPS71H33Q, TPS71H48Q, TPS71H50Q

LOW-DROPOUT VOLTAGE REGULATORS

SLVS152A – NOVEMBER 1996 – REVISED JANUAR Y 1997

THERMAL INFORMATION

high-temperature life test

High-temperature life testing is used to demonstrate long-term reliability of the product under bias. The potential

failure mechanisms evaluated with this stress are those associated with dielectric integrity and design or

process sensitivity to mobile-ion phenomena. Components are tested at an elevated ambient temperature of

155°C for an extended period. Results are derated using the Arrhenius equation to an equivalent number of unit

hours at a representative application temperature. The corresponding predicted failure rate is expressed in

FITs, or failures per billion device-hours. The failure rate shown in this case is data-limited since no actual

failures were experienced during qualification testing.

PREDICTED LONG-TERM FAILURE RATE

Number of Units

325 24,468,090 36.2

biased humidity test

Biased humidity testing is used to evaluate the effects of moisture penetration on plastic-encapsulated devices

under bias. This stress verifies the integrity of the package construction and the die passivation system. The

primary potential failure mechanism is electrolytic corrosion. Components are biased in a low power state to

reduce heat dissipation and are subjected to a 120°C, 85%-relative-humidity environment for 100 hours.

Equivalent Unit Hours at 55°C and 0.7 eV FITs at 50% CL

BIASED HUMIDITY TEST RESULTS

Equivalent Unit Hours at 85°C and 85% RH

357,000 0

Failures

autoclave test

The autoclave stress is used to assess the capabilities of the die and package construction materials with

respect to moisture ingress and extended exposure. Predominant failure mechanisms include leakage currents

that result from internal moisture accumulation and galvanic corrosion resulting from reactions with any present

ionic contaminants. Components are subjected to a 121°C, 15 PSIG, 100%-relative-humidity environment for

240 hours.

AUTOCLAVE TEST RESULTS

Total Unit Hours

54,720 0

Failures

thermal shock test

Thermal shock testing is used to evaluate the capability of the component to withstand mechanical stress

resulting from differences in thermal coefficients of expansion among the die and package construction

materials. Failure mechanisms are typically related to physical damage at interface locations between different

materials. Components are cycled between –65°C and 150°C in liquid mediums for a total duration of 1000

cycles.

THERMAL SHOCK TEST RESULTS

Total Unit Cycles

345,000 0

Failures

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

31

TPS71H01Q, TPS71H33Q, TPS71H48Q, TPS71H50Q

LOW-DROPOUT VOLTAGE REGULATORS

SLVS152A – NOVEMBER 1996 – REVISED JANUAR Y 1997

THERMAL INFORMATION

PWB assembly level reliability results

temperature cycle test

T emperature cycle testing of the PWB assembly is used to evaluate the capability of the assembly to withstand

mechanical stress resulting from the differences in thermal coefficients of expansion among die, package, and

PWB board materials. This testing is also used to sufficiently age the soldered thermal connection between the

thermal pad and the Cu trace on the FR4 board and evaluate the degradation of the thermal resistance for a

board-mounted test unit. The assemblies were cycled between temperature extremes of –40°C and 125°C for

a total duration of 730 cycles.

TEMPERATURE CYCLE TEST RESULTS

Total Unit

Cycles

36,500 0 –0.41%

solderability test

Solderability testing is used to simulate actual board-mount performance in a reflow process.

Solderability testing is conducted as follows: The test devices are first steam-aged for 8 hours. A stencil is used

to apply a solder-paste terminal pattern on a ceramic substrate (nominal stencil thickness is 0.005 inch). The

test units are manually placed on the solder-paste footprint with proper implements to avoid contamination. The

ceramic substrate and components are subjected to the IR reflow process as follows:

Failures Average Change

in R

θJA(system)

IR REFLOW PROCESS

PREHEAT SOAK

Temperature 150°C to 170°C 215°C to 230°C

Time 60 sec 60 sec

REFLOW

After cooling to room temperature, the component is removed from the ceramic substrate and the component

terminals are subjected to visual inspection at 10X magnification.

Test results are acceptable if all terminations exhibit a continuous solder coating free of defects for a minimum

95% of the critical surface area of any individual termination. Causes for rejection include: dewetting,

nonwetting, and pin holes. The component leads and the exposed thermal pad were evaluated against this

criteria.

SOLDERABILITY TEST RESULTS

Number of Test Units

22 0

Failures

X-ray test

X-ray testing is used to examine and quantify the voiding of the soldered attachment between the thermal pad

and the PWB copper trace. Voiding between 20% and 50% was observed on a 49-piece sample.

32

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

TPS71H01Q, TPS71H33Q, TPS71H48Q, TPS71H50Q

LOW-DROPOUT VOLTAGE REGULATORS

SLVS152A – NOVEMBER 1996 – REVISED JANUAR Y 1997

APPLICATION INFORMATION

The TPS71Hxx series of low-dropout (LDO) regulators is designed to overcome many of the shortcomings of

earlier-generation LDOs, while adding features such as a power-saving shutdown mode and a power-good

indicator. The TPS71Hxx family includes three fixed-output voltage regulators: the TPS71H33 (3.3 V), the

TPS71H48 (4.85 V), and the TPS71H50 (5 V). The family also offers an adjustable device, the TPS71H01

(adjustable from 1.2 V to 9.75 V).

device operation

The TPS71Hxx, unlike many other LDOs, features very low quiescent currents that remain virtually constant

even with varying loads. Conventional LDO regulators use a pnp-pass element, the base current of which is

directly proportional to the load current through the regulator (I

reveals that those devices are typically specified under near no-load conditions; actual operating currents are

much higher as evidenced by typical quiescent current versus load current curves. The TPS71Hxx uses a

PMOS transistor to pass current; because the gate of the PMOS element is voltage driven, operating currents

are low and invariable over the full load range. The TPS71Hxx specifications reflect actual performance under

load.

Another pitfall associated with the pnp-pass element is its tendency to saturate when the device goes into

dropout. The resulting drop in β forces an increase in I

to large start-up currents. Systems with limited supply current may fail to start up. In battery-powered systems,

it means rapid battery discharge when the voltage decays below the minimum required for regulation. The

TPS71Hxx quiescent current remains low even when the regulator drops out, eliminating both problems.

to maintain the load. During power up, this translates

B

= IC/β). Close examination of the data sheets

B

Included in the TPS71Hxx family is a 4.85-V regulator, the TPS71H48. Designed specifically for 5-V cellular

systems, its 4.85-V output, regulated to within ± 2%, allows for operation within the low-end limit of 5-V systems

specified to ± 5% tolerance; therefore, maximum regulated operating lifetime is obtained from a battery pack

before the device drops out, adding crucial talk minutes between charges.

The TPS71Hxx family also features a shutdown mode that places the output in the high-impedance state

(essentially equal to the feedback-divider resistance) and reduces quiescent current to under 2 µA. If the

shutdown feature is not used, EN

output voltage is reestablished in typically 120 µs.

should be tied to ground. Response to an enable transition is quick; regulated

minimum load requirements

The TPS71Hxx family is stable even at zero load; no minimum load is required for operation.

SENSE-pin connection

The SENSE pin of fixed-output devices must be connected to the regulator output for proper functioning of the

regulator. Normally , this connection should be as short as possible; however , the connection can be made near

a critical circuit (remote sense) to improve performance at that point. Internally, SENSE connects to a

high-impedance wide-bandwidth amplifier through a resistor-divider network and noise pickup feeds through

to the regulator output. Routing the SENSE connection to minimize/avoid noise pickup is essential. Adding an

RC network between SENSE and OUT to filter noise is not recommended because it can cause the regulator

to oscillate.

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

33

TPS71H01Q, TPS71H33Q, TPS71H48Q, TPS71H50Q

LOW-DROPOUT VOLTAGE REGULATORS

SLVS152A – NOVEMBER 1996 – REVISED JANUAR Y 1997

APPLICATION INFORMATION

external capacitor requirements

An input capacitor is not required; however, a ceramic bypass capacitor (0.047 pF to 0.1 µF) improves load

transient response and noise rejection if the TPS71Hxx is located more than a few inches from the power supply .

A higher-capacitance electrolytic capacitor may be necessary if large (hundreds of milliamps) load transients

with fast rise times are anticipated.

As with most LDO regulators, the TPS71Hxx family requires an output capacitor for stability . A low-ESR 10-µ F

solid-tantalum capacitor connected from the regulator output to ground is sufficient to ensure stability over the

full load range (see Figure 51). Adding high-frequency ceramic or film capacitors (such as power-supply bypass

capacitors for digital or analog ICs) can cause the regulator to become unstable unless the ESR of the tantalum

capacitor is less than 1.2 Ω over temperature. Capacitors with published ESR specifications such as the

AVX TPSD106K035R0300 and the Sprague 593D106X0035D2W work well because the maximum ESR at

25°C is 300 mΩ (typically, the ESR in solid-tantalum capacitors increases by a factor of 2 or less when the

temperature drops from 25°C to –40°C). Where component height and/or mounting area is a problem,

physically smaller, 10-µ F devices can be screened for ESR. Figures 34 through 41 show the stable regions of

operation using different values of output capacitance with various values of ceramic load capacitance.

In applications with little or no high-frequency bypass capacitance (< 0.2 µF), the output capacitance can be

reduced to 4.7 µF, provided ESR is maintained between 0.7 and 2.5 Ω. Because minimum capacitor ESR is

seldom if ever specified, it may be necessary to add a 0.5-Ω to 1-Ω resistor in series with the capacitor and limit

ESR to 1.5 Ω maximum. As show in the ESR graphs (Figures 34 through 41), minimum ESR is not a problem

when using 10-µF or larger output capacitors.

The following is a partial listing of surface-mount capacitors usable with the TPS71Hxx family . This information

(along with the ESR graphs, Figures 34 through 41) is included to assist in selection of suitable capacitance

for the user’s application. When necessary to achieve low height requirements along with high output current

and/or high ceramic load capacitance, several higher ESR capacitors can be used in parallel to meet the

guidelines above.

34

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

TPS71H01Q, TPS71H33Q, TPS71H48Q, TPS71H50Q

LOW-DROPOUT VOLTAGE REGULATORS

SLVS152A – NOVEMBER 1996 – REVISED JANUAR Y 1997

APPLICATION INFORMATION

external capacitor requirements (continued)

All load and temperature conditions with up to 1 µF of added ceramic load capacitance:

PART NO. MFR. VALUE MAX ESR

T421C226M010AS Kemet 22 µF, 10 V 0.5 2.8 × 6 × 3.2

593D156X0025D2W Sprague 15 µF, 25 V 0.3 2.8 × 7.3 × 4.3

593D106X0035D2W Sprague 10 µF, 35 V 0.3 2.8 × 7.3 × 4.3

TPSD106M035R0300 AVX 10 µF, 35 V 0.3 2.8 × 7.3 × 4.3

Load < 200 mA, ceramic load capacitance < 0.2 µF, full temperature range:

PART NO. MFR. VALUE MAX ESR

592D156X0020R2T Sprague 15 µF, 20 V 1.1 1.2 × 7.2 × 6

595D156X0025C2T Sprague 15 µF, 25 V 1 2.5 × 7.1 × 3.2

595D106X0025C2T Sprague 10 µF, 25 V 1.2 2.5 × 7.1 × 3.2

293D226X0016D2W Sprague 22 µF, 16 V 1.1 2.8 × 7.3 × 4.3

Load < 100 mA, ceramic load capacitance < 0.2 µF, full temperature range:

PART NO. MFR. VALUE MAX ESR

195D106X06R3V2T Sprague 10 µF, 6.3 V 1.5 1.3 × 3.5 × 2.7

195D106X0016X2T Sprague 10 µF, 16 V 1.5 1.3 × 7 × 2.7

595D156X0016B2T Sprague 15 µF, 16 V 1.8 1.6 × 3.8 × 2.6

695D226X0015F2T Sprague 22 µF, 15 V 1.4 1.8 × 6.5 × 3.4