Page 1

Abstract

This user’s guide provides a detailed account of the TPS65912x Evaluation Module (EVM) including a

general overview, schematic diagram, board layout, setup instructions, graphical user interface (GUI) and

bill of materials (BOM). Use this EVM for integrated circuit (IC) evaluation and also for design reference.

The TPS65912x is a power management unit (PMU) for processor power.

How to Use This Manual

This document is formatted in order of operation; become familiar with the schematic and layout before

proceeding to the setup section.

Notational Conventions

• EVM – Evaluation Module

• PMU – Power Management Unit

• IC – Integrated Circuit

• PMIC – Power Management Integrated Circuit

• BOM – Bill of Materials

• PCB – Printed-circuit board

• GUI – Graphical User Interface

Preface

SLVU750A–July 2012–Revised May 2013

TPS65912xEVM-081 User's Guide

Information About Cautions and Warnings

This book may contain cautions and warnings.

Please read this document thoroughly.

Not following this document in detail could potentially damage your software or

equipment.

Please take all possible safety precautions.

Improper use of this evaluation module could potentially cause

physical harm.

The information in a caution or a warning is provided for protection. Please read each caution and warning

carefully.

CAUTION

WARNING

SLVU750A–July 2012–Revised May 2013 TPS65912xEVM-081 User's Guide

Submit Documentation Feedback

Copyright © 2012–2013, Texas Instruments Incorporated

1

Page 2

Related Documentation From Texas Instruments

Related Documentation From Texas Instruments

Refer to the data sheet, SWCS054, for detailed information on the TPS65912x IC features and operating

specifications.

If You Need Assistance

Visit the TI E2E Forums: http://e2e.ti.com

FCC Warning

This equipment is intended for use in a laboratory test environment only. It generates, uses, and can

radiate radio frequency energy and has not been tested for compliance with the limits of computing

devices pursuant to subpart J of part 15 of FCC rules, which are designed to provide reasonable

protection against radio frequency interference. Operation of this equipment in other environments may

cause interference with radio communications, in which case the user, at his/her own expense, is required

to take whatever measures necessary to correct this interference.

www.ti.com

2

TPS65912xEVM-081 User's Guide SLVU750A–July 2012–Revised May 2013

Copyright © 2012–2013, Texas Instruments Incorporated

Submit Documentation Feedback

Page 3

1 TPS65912xEVM-081 Overview

The TPS65912xEVM-081 allows evaluation of the IC and serves a reference design.

1.1 Introduction to Using the TPS65912xEVM-081

Make a copy of this user’s guide available to the operator of this EVM.

User's Guide

SLVU750A–July 2012–Revised May 2013

TPS65912xEVM-081

SLVU750A–July 2012–Revised May 2013 TPS65912xEVM-081

Submit Documentation Feedback

Copyright © 2012–2013, Texas Instruments Incorporated

3

Page 4

CLOCKS

Components with no values are not installed.

1

DEF_SPI_I2C

GPIO1_MISO

GPIO2_CE

LEDA_GPIO3

LEDB_GPIO4

LEDC_GPIO5

GND

A1

VLDO7

A2

VINLDO67

A3

VLDO6

A4

VDCDC4

A5

PGND4

A6

SW4

A7

VINDCDC4

A8

LSO

A9

LSO

B1

LEDC_GPIO5

B2

LEDB_GPIO4

B3

LEDA_GPIO3

B4

VDCDC4_GND

B5

PGND4

B6

SW4

B7

VINDCDC4

B8

LSI

B9

LSI

C1

VINDCDC3

C2

EN_LS1

C3

EN_LS0

C4

GPIO2_CE

C5

EN4_DCDC4_SEL

C6

EN3_DCDC3_SEL

C7

AGND

C8

VINDCDC_ANA

C9

VINDCDC2

D1

SW3

D2

CONFIG2

D3

PWRON

D4

GPIO1_MISO

D5

SCLK_SCK

D6

POWERHOLD_ON

D7

VDCDC2

D8

EN2_DCDC2_SEL

D9

SW2

E1

PGND3

E2

CONFIG1

E3

DGND

E4

SDA_MOSI

E5

SCL_AVS_CLK_REQ1

E6

SDA_AVS_CLK_REQ2

E7

DEF_SPI_I2C-GPIO0

E8

EN1_DCDC1_SEL

E9

PGND2

F1

VINLDO4

F2

VDCDC3

F3

AGND

F4

VCON_PWM

F5

VCON_CLK

F6

OMAP_WDI_32K_OUT

F7

VDDIO

F8

VINLDO3

F9

VLDO3

G1

VLDO4

G2

VCCS_VIN_MON

G3

LDOAO

G4

SLEEP_PWR_REQ

G5

INT1

G6

~RESPWRON_VSUP_OUT

G7

CPCAP_WDI

G8

VINLDO5

G9

VLDO5

H1

VLD02

H2

VCC

H3

VREF1V25

H4

VDCDC1_GND

H5

PGND1

H6

SW1

H7

VINDCDC1

H8

VINLDO8

H9

VLDO8

J1

VLDO10

J2

VINLDO1210

J3

VLDO1

J4

VDCDC1

J5

PGND1

J6

SW1

J7

VINDCDC1

J8

VINLDO9

J9

VLDO9

U1

TPS65912YFF

L3 1.0uH

L4 1.0uH

C1 22uF

C2

10uF

C3

10uF

L1 1.0uH

C5

10uF

C6

10uF

C7 10uF

C8

10uF

C9 10uF

L2 1.0uH

C10

10uF

C11

2.2uF

C12 2.2uF

C13 2.2uF

C14 2.2uF

C15 2.2uF

C16 2.2uF

C17 2.2uF

C18 2.2uF

C19 2.2uF

C20 2.2uF

C21 2.2uF

C22 2.2uF

C23 2.2uF

C24 4.7uF

C25 4.7uF

C26 4.7uF

C27 4.7uF

D1

LTST-C190YKT

D2

LTST-C190GKT

D3

LTST-C190CKT

C28 220nF

C29 2.2uF

C30

2.2uF

R1 0

R13 0

C4 22uF

C31 2.2uF

1

2

3

4

5

6

7

J40

R9

R10

R11

3.30k

R12

R14

3.30k

R15

3.30k

Y1

R19

J1

1

2

3

4 5

6

7

8

U2

Y2

R2

R3

J2

R16

0

R5

0

R6

0

R7 0

R17

0

C53

J8

R8

R20 0

R21

0

R22 0

R24

0

VDCDC4

VDCDC1

VDCDC4_SENSE

VDCDC4_GND_SENSE

VDCDC3

VDCDC2

LSI

LSO

VINLDO3

VLDO3

VINLDO1210

VLDO1

VLDO2

VINLDO4

VLDO4

VINLDO5

VLDO5

VINLDO67

VLDO6

VLDO7

VINLDO8

VLDO8

VINLDO9

VLDO9

VLDO10

VCC

SCL_CLK

SDA_MOSI

GPIO1_MISO

GPIO2_CE

SCL_AVS

SDA_AVS

EN2_DCDC2

EN3_DCDC3

EN4_DCDC4

PWRHOLD

VBAT

VBAT

LDOAO

VREF1V25

LEDA_GPIO3

LEDB_GPIO4

LEDC_GPIO5

VBAT

CONFIG1

CONFIG2

CPCAP_WDI

DEF_SPI_I2C

EN1_DCDC1

EN_LS0

EN_LS1

INT1

NRESPWRON

OMAP_WDI

PWRON

SLEEP

VCCS_VIN_MON

VCON_CLK

VCON_PWM

VDCDC1_GND_SENSE

VDCDC1_SENSE

VDDIO

VDCDC3_SENSE

VDCDC2_SENSE

VBAT

VBAT

VBAT

VBAT

VDDIO

DEF_SPI_I2C

GPIO1_MISO

GPIO2_CE

LEDA_GPIO3

LEDB_GPIO4

LEDC_GPIO5

GND

TXCOUT

SCL_CLK

SDA_MOSI

INTA

INTA

INTA

SQW_INTB

VLDO3

VCLKS

GND

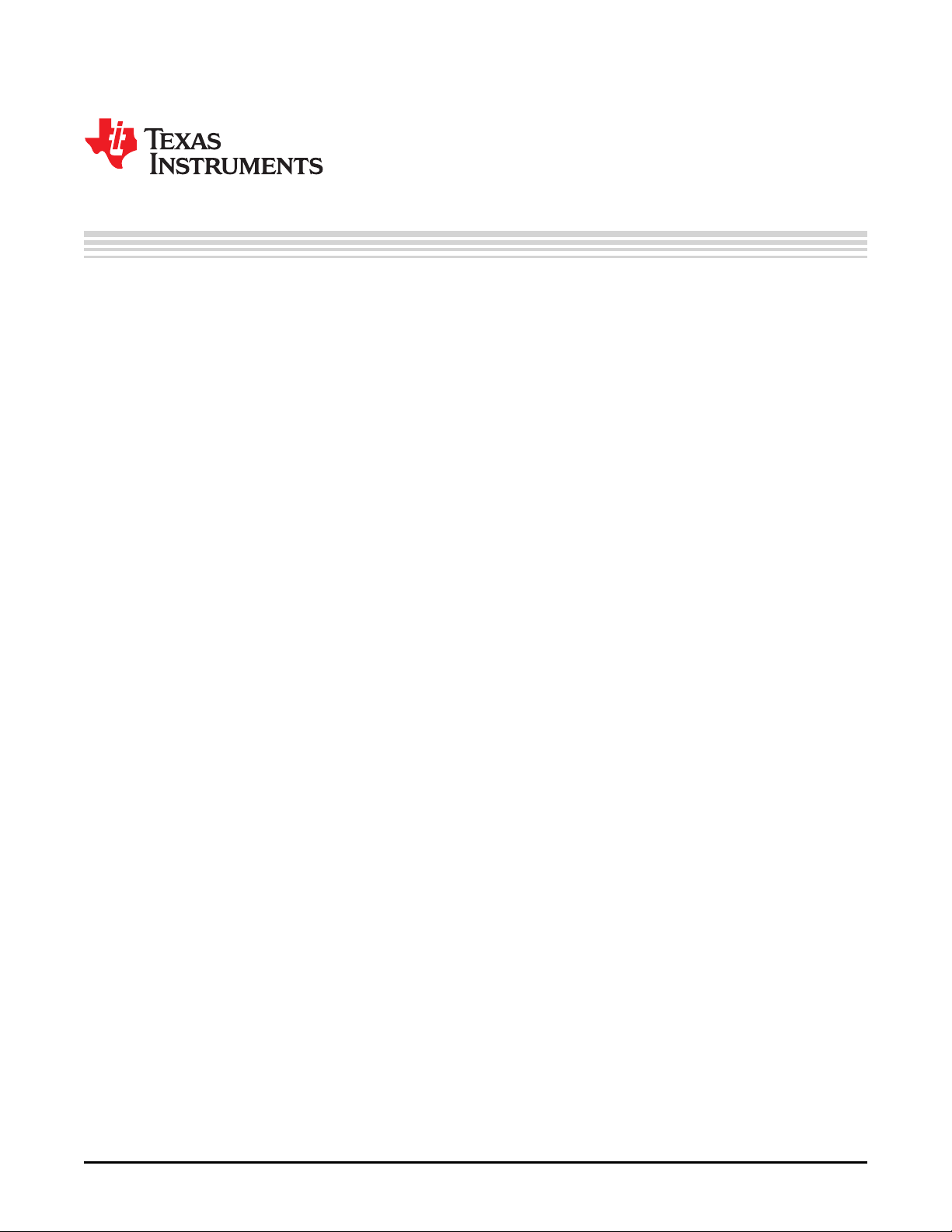

Schematic Diagram

2 Schematic Diagram

The following figures represent the schematic diagram for the EVM:

www.ti.com

4

TPS65912xEVM-081 SLVU750A–July 2012–Revised May 2013

Figure 1. TPS65912xEVM-081 Schematic Page 1/2

Submit Documentation Feedback

Copyright © 2012–2013, Texas Instruments Incorporated

Page 5

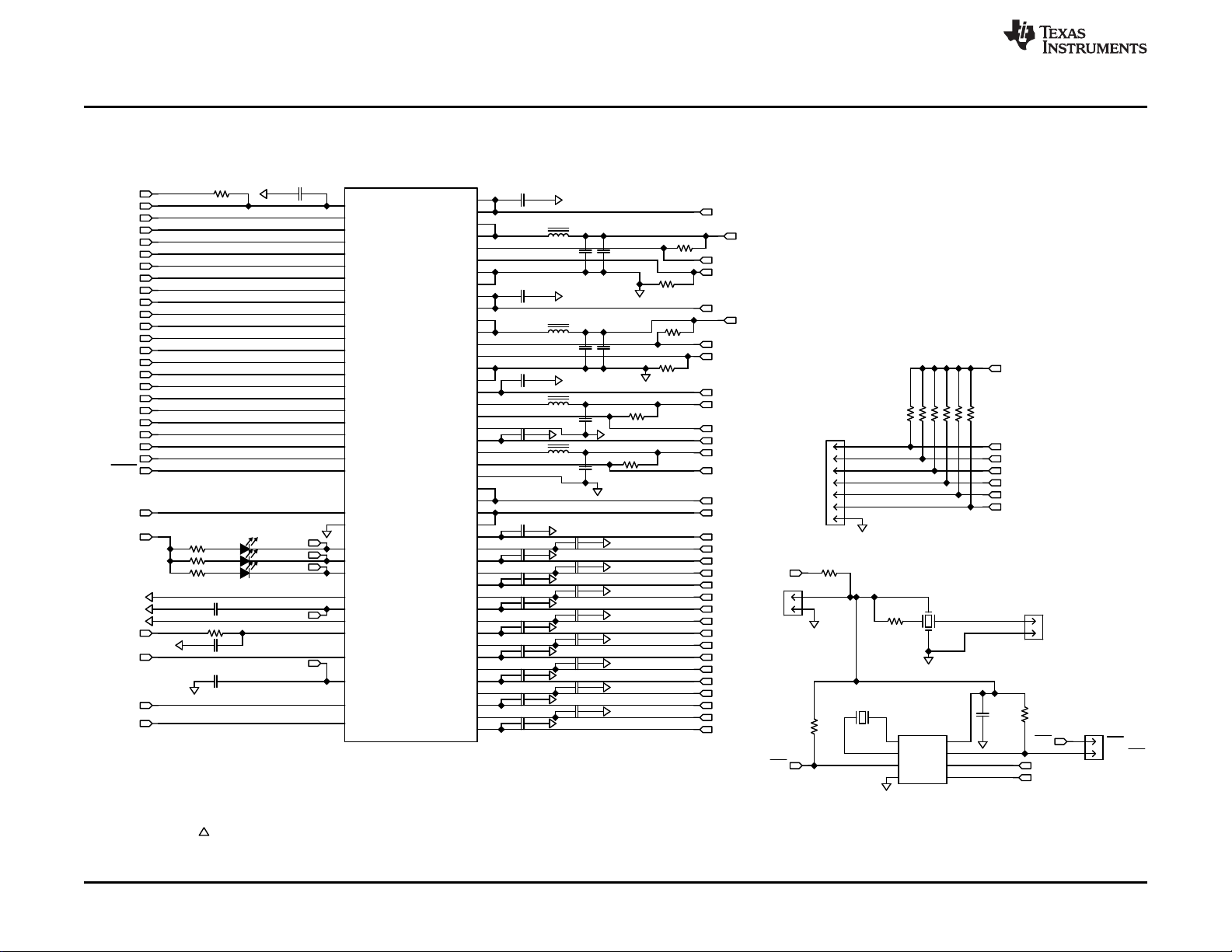

SPI

ENABLE

CONFIG

I2C

AVS-I2C

DCDC OUTPUT

LOAD SWITCH

VDCDC1

VDCDC2

VDCDC3

VDCDC4

LSI

LSO

LDO SUPPLY

VINLDO1210

VINLDO3

VINLDO4

VINLDO5

VINLDO67

VINLDO8

VINLDO9

LDO OUTPUT

VLDO1

VLDO2

VLDO3

VLDO4

VLDO5

VLDO6

VLDO7

VLDO8

VLDO9

VLDO10

SUPPLY INPUT

CLK_REQ1

CLK_REQ2

PWR_REQ

3V to 5V

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

S+

S-

S+

S+

S+

S-

VREF1V25

GND

VDDIO

GND

SLEEP

GND

INT1

GND

NRESPWRON

GND

SCL_AVS

GND

SDA_AVS

GND

VCON_CLK

GND

VCON_PWM

GND

CPCAP_WDI

LDOAO

OMAP_WDI

VDDIO

EN_LS1

GND

VDDIO

EN_LS0

GND

VDDIO

EN4

GND

VDDIO

EN3

GND

VDDIO

EN2

GND

VDDIO

EN1

GND

LDOA0

CONFIG1

GND

LDOA0

CONFIG2

GND

LDOA0

DEF_SPI_I2C

GND

LSI

VCCS_VIN_MON

VBAT

VCCS_VIN_MON

GND

LDOA0

PWRON

VDDIO

(JP12)

PWRHOLD

GND

PWRON

GND

Components with no values are not installed.

1

VDDIO

VBAT

GND

PWRHOLD

JP8

JP9

JP1

JP2

JP3

JP4

JP5

1

2

J28

1

2

3

4

J29

JP6

JP7

1

2

J30

1

2

J31

1

2

J35

1

2

J36

1

2

3

4

5

6

7

8

9

10

J37

1

2

3

4

5

6

7

8

9

10

J38

1

2

3 4

5

6

J39

1

2

3

4

J32

R30

3.30k

R31

3.30k

R32

3.30k

R33

3.30k

1

2

J34

1

2

3

4

5

6

J3

C32 10uF

R26

0

R27

0

1

2

3

4

5

6

J4

C33 10uF

R28

0

1

2

3

4

5

6

J5

C34 10uF

R29

0

1

2

3

4

5

6

J6

C35 10uF

R34

0

R35

0

1

2

3

4

J26

1

2

3

4

J27

1

2

J9

1

2

J10

1

2

J11

1

2

J12

C36 2.2uF

C37 2.2uF

C38 2.2uF

C39 2.2uF

R36

R37 0

R38

R39

R40

R41 0

R42

R43 0

R44

R45 0

1

2

J13

C40 2.2uF

R46

R47 0

1

2

J14

C41 2.2uF

R48

R49 0

1

2

J15

C42 2.2uF

R50

R51 0

1

2

J16

C43

2.2uF

1

2

J17

C44

2.2uF

1

2

J18

C45

2.2uF

1

2

J19

C46

2.2uF

1

2

J20

C47

2.2uF

1

2

J21

C48

2.2uF

1

2

J22

C49

2.2uF

1

2

J23

C50

2.2uF

1

2

J24

C51

2.2uF

1

2

J25

C52

2.2uF

1

2

3

4

5

6

J7

C54 10uF

R53

0

R54

R56

R57

R58

0

JP11

S1

R18

10.0k

1

2

J33

C55

4.7uF

R23

3.30k

1

2

J41

1

2

J42

R60

R61

C56

22uF

R4 0

JP10

R25

R52

R55

R59

R62

JP12

LDOAO

LDOAO

LDOAO

CONFIG1

CONFIG2

DEF_SPI_I2C

EN1_DCDC1

EN2_DCDC2

EN3_DCDC3

EN4_DCDC4

CPCAP_WDI

NRESPWRON

LDOAO

EN_LS0

EN_LS1

VREF1V25

VDDIO

SLEEP

INT1

SDA_MOSI

SCL_CLK

SDA_AVS

GPIO2_CE

SDA_MOSI SCL_CLK

GPIO1_MISO

VDDIO

OMAP_WDI

VDDIO

VCON_CLK

VCON_PWM

VDDIO

VDDIO

SCL_AVS

VCCS_VIN_MON

VBAT

LSI

VDCDC1

VDCDC1_SENSE

VDCDC1_GND_SENSE

VDCDC2

VDCDC2_SENSE

VDCDC3

VDCDC3_SENSE

VDCDC4

VDCDC4_SENSE

VDCDC4_GND_SENSE

LSI

LSO

VINLDO1210

VINLDO3

VINLDO4

VINLDO5

VDCDC3

VBAT

VDCDC2

VDCDC3

VDCDC2

VBAT

VDCDC2

VBAT

VDCDC3

VBAT

VINLDO67

VDCDC3

VBAT

VINLDO8

VDCDC3

VBAT

VINLDO9

VDCDC3

VBAT

VLDO1

VLDO2

VLDO3

VLDO4

VLDO5

VLDO6

VLDO7

VLDO8

VLDO9

VLDO10

VBAT

LSI

VBAT

LSI

LSO

VBAT

VDCDC2

LDOAO

VDDIO

PWRHOLD

PWRON

SCL_AVS

SDA_AVS

VDDIO

VDDIO

VDDIO

VCC

VDCDC2

VDCDC2

VDCDC2

VDCDC2

VDCDC3

www.ti.com

Schematic Diagram

SLVU750A–July 2012–Revised May 2013 TPS65912xEVM-081

Submit Documentation Feedback

Figure 2. TPS65912xEVM-081 Schematic Page 2/2

Copyright © 2012–2013, Texas Instruments Incorporated

5

Page 6

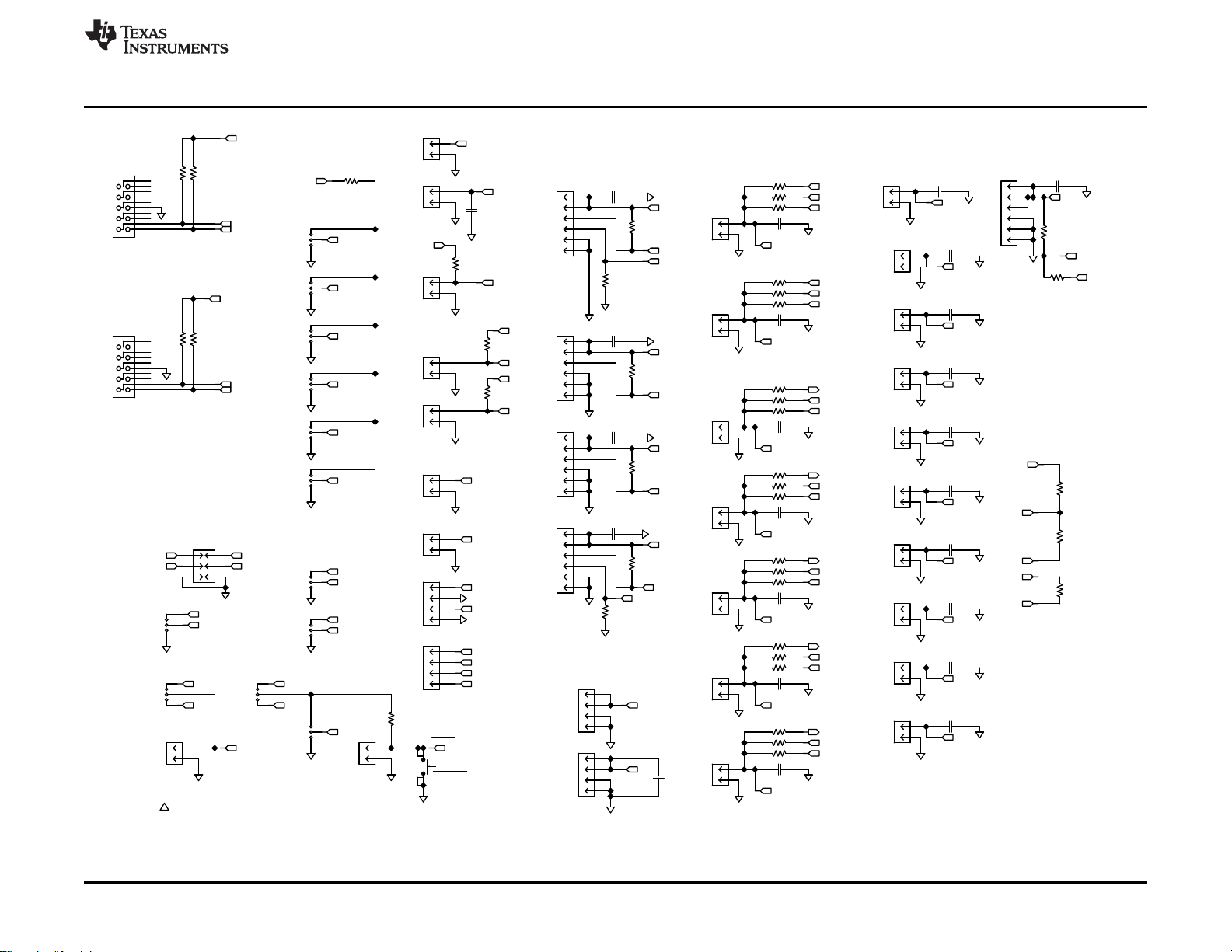

Layout

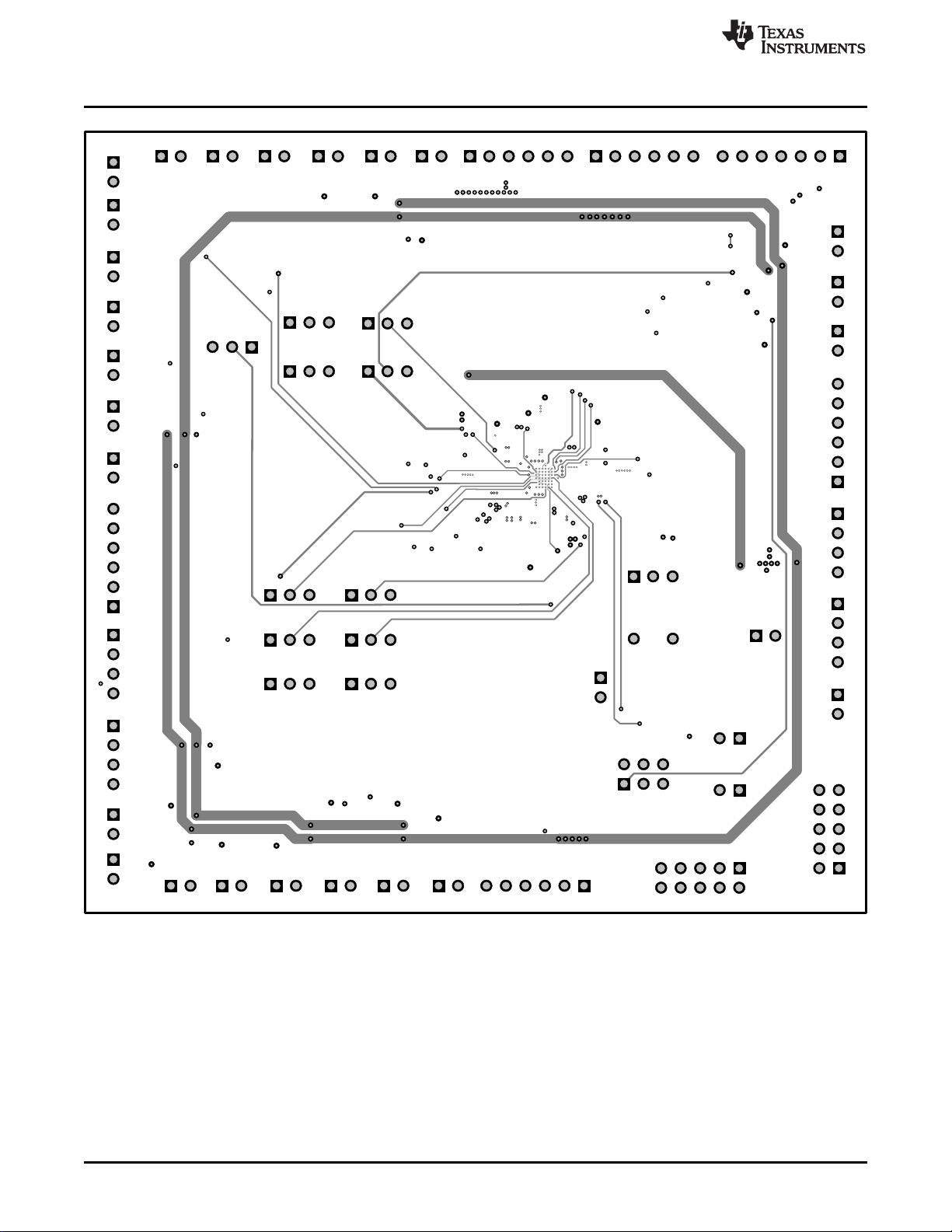

3 Layout

The EVM board layout is detailed in the following images:

www.ti.com

Figure 3. TPS65912xEVM-081 Layout Top

6

TPS65912xEVM-081 SLVU750A–July 2012–Revised May 2013

Copyright © 2012–2013, Texas Instruments Incorporated

Submit Documentation Feedback

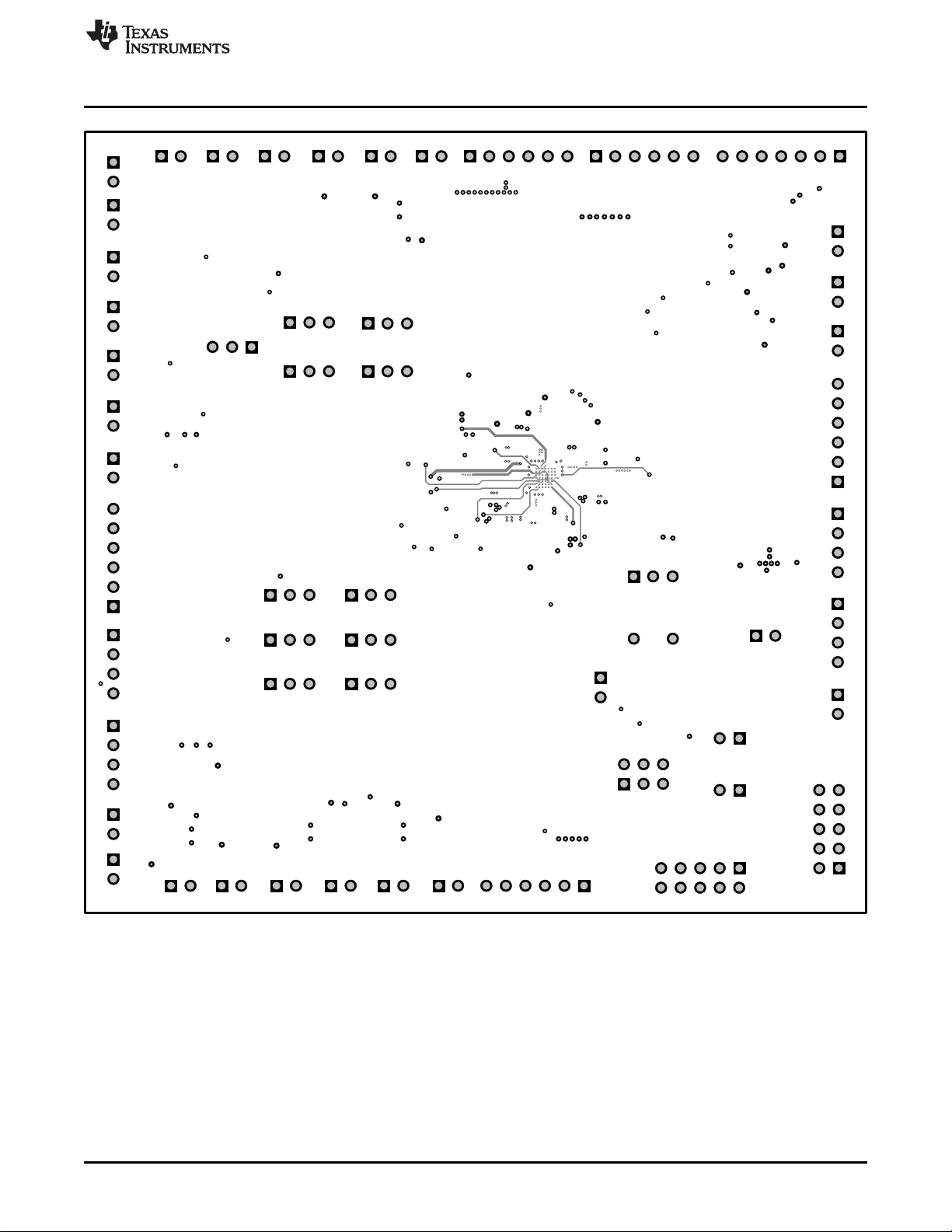

Page 7

www.ti.com

Layout

Figure 4. TPS65912xEVM-081 Layout Layer 2

SLVU750A–July 2012–Revised May 2013 TPS65912xEVM-081

Submit Documentation Feedback

Copyright © 2012–2013, Texas Instruments Incorporated

7

Page 8

Layout

www.ti.com

Figure 5. TPS65912xEVM-081 Layout Layer 3

8

TPS65912xEVM-081 SLVU750A–July 2012–Revised May 2013

Copyright © 2012–2013, Texas Instruments Incorporated

Submit Documentation Feedback

Page 9

www.ti.com

Layout

Figure 6. TPS65912xEVM-081 Layout Layer 4

SLVU750A–July 2012–Revised May 2013 TPS65912xEVM-081

Submit Documentation Feedback

Copyright © 2012–2013, Texas Instruments Incorporated

9

Page 10

Layout

www.ti.com

10

Figure 7. TPS65912xEVM-081 Layout Layer 5

TPS65912xEVM-081 SLVU750A–July 2012–Revised May 2013

Copyright © 2012–2013, Texas Instruments Incorporated

Submit Documentation Feedback

Page 11

www.ti.com

Layout

Figure 8. TPS65912xEVM-081 Layout Bottom

SLVU750A–July 2012–Revised May 2013 TPS65912xEVM-081

Submit Documentation Feedback

Copyright © 2012–2013, Texas Instruments Incorporated

11

Page 12

Setup

4 Setup

This section describes setup of the EVM.

4.1 Additional Hardware

Two external power supplies are required to operate the EVM. One supply must deliver 5 A at 5 V and the

other must deliver 1 A at 1.8 V.

NOTE: I2C™ Bus: A personal computer and USB-TO-GPIO box and cable are required to use the

I2C bus with the GUI.

4.2 Jumper Settings

Verify shorting jumpers are installed per Table 1:

www.ti.com

Table 1. Jumper Settings

Jumper Shunt Location

JP1 Between pin1 and pin2

JP2 Between pin2 and pin3

JP3 Between pin2 and pin3

JP4 Between pin2 and pin3

JP5 Between pin2 and pin3

JP6 Between pin2 and pin3

JP7 Between pin2 and pin3

JP8 Between pin2 and pin3

JP9 Between pin2 and pin3

JP10 Between pin2 and pin3

JP11 Between pin1 and pin2

4.3 Power Supply Connections

Set the 5-V power supply to the off state and connect it to the VBAT input header, J9; positive lead to pin

1 and negative lead to pin 6.

Make sure the 1.8-V power supply is switched off and connect it to the VDDIO input header, J43; positive

lead to pin 1 and negative lead to pin 2.

Switch on the 1.8-V power supply.

Switch on the 5-V power supply.

Neither supply sources more than a few milliamps in this no load condition.

4.4 Operation

If the preceding instructions were followed, the EVM is operating under its default conditions. Refer to the

TPS65912x data sheet (SWCS054) for default converter/LDO state and loading conditions.

12

TPS65912xEVM-081 SLVU750A–July 2012–Revised May 2013

Copyright © 2012–2013, Texas Instruments Incorporated

Submit Documentation Feedback

Page 13

www.ti.com

5 Layout Considerations

This section describes basic layout requirements for the TPS65912x.

5.1 General Layout

As for all switching power supplies, the layout is an important step in the design. Proper function of the

device demands careful attention to PCB layout. Follow board layout instructions carefully to attain the

specified performance. If the layout is not carefully done, the regulators may show poor line and/or load

regulation and stability issues as well as EMI problems. It is critical to provide a low impedance ground

path. Therefore, use wide and short traces for the main current paths. Place input capacitors as close as

possible to the IC pins as well as the inductor and output capacitor. Keep the common path to the GND

pins, which returns the small signal components, and the high current of the output capacitors as short as

possible to avoid ground noise. Connect the VDCDCx trace right to the output capacitor and routed away

from noisy components and traces (for example, the L1, L2, L3 and L4 traces).

5.2 Critical Signals for Layout

As outlined above, a number of signals require careful layout. Item numbers are assigned in Table 2

linking them to the examples in Section 5.3.

Item Signal Name Description Layout Guidelines

1 PGND1, Power-ground connection for DCDC1 to Connect to the GND plane. Ideally, route this signal on the

PGND2, DCDC4. This pin is internally tied to the same layer that the device is placed. Use multiple vias to the

PGND3, PGND4 source of the low side transistor and GND plane if it is on a different layer. As DCDC1 and DCDC4

carries the full output current + inductor are designed (operated) for larger output current, they are

current ripple. more critical than DCDC2 and DCDC3. The GND-terminal of

2 VINDCDC1, Input supply to the power stage for Connect to the supply voltage trace. Place an input capacitor

VINDCDC2,VIN DCDC1 to DCDC4. This pin is connected on each of the VINDCDCx pins with low impedance to GND

DCDC3, to the high-side power switch and carries and low impedance to the VINDCDCx pin. The input capacitor

VINDCDC4 the full output current + inductor current will have to buffer the input current rising within less than

ripple. As there is only an input current 10ns to the average output current (in PWM mode) minus the

when the internal high-side switch is inductor current ripple.

closed, the input current of a step-down

converter is discontinuous. This causes

current spikes on the input and requires

an input capacitor on each of the

VINDCDCx pins.

3 VINDCD-ANA Analog supply input to the DCDC1-to- This pin needs to be powered by the same voltage

DCDC4 converters. It supplies part of the VINDCDC1 to VINDCDC4 are tied to. Its input should be

gate driver and other analog circuitry. properly bypassed with a capacitor and routed to the supply

Layout Considerations

Table 2. Layout Guidelines and Descriptions

the output capacitor requires a low-impedance connection to

the respective PGND pin, as in case where the internal lowside switch is closed, the current flows in the path of output

inductor, output capacitor, PGND pin and L pin. Do not

connect VDCDCx_GND (the GND-SENSE connection for

DCDC1 and DCDC4) directly to the PGND pins. Tie

VDCDCx_GND to the GND-pad of the output capacitor or

directly to the GND plane. Tie AGND directly to the GND

plane. Connect PGND to the GND-plane independently of

other pins, not coupling noise on PGND into other pins.

voltage separately from VINDCDCx in order to avoid noise

generated by the power stages being coupled into

VINDCDC_ANA. Its input current is only a few mA, so the

trace does not have to be very wide.

SLVU750A–July 2012–Revised May 2013 TPS65912xEVM-081

Submit Documentation Feedback

Copyright © 2012–2013, Texas Instruments Incorporated

13

Page 14

Layout Considerations

Item Signal Name Description Layout Guidelines

4 L1, L2, L3, L4 These are the connections to the mid The pin carries the output current including inductor current

5 VDCDC1, Voltage feedback pins for DCDC1 to The pins are high impedance (MR) and sensible to noise from

VDCDC2, DCDC4 the switch node. The trace should not be routed in parallel to

DCDC3,VDCDC the L-traces and should be tied to the V+-pad of the output

4 capacitor directly.

6 VDCDC1_GND, GND-terminal for remote sense The pins are the GND connections for remote sense and can

VDCDC4_GND either be tied to the GND pad of the output capacitor or

7 Vcc Analog supply voltage pin Must be bypassed with a separate input capacitor, does not

8 AGND, DGND Analog and digital GND connection These GND pins need to be tied to the GND plane. The

www.ti.com

Table 2. Layout Guidelines and Descriptions (continued)

point of the power stage consisting of the ripple. It charges the output capacitor through the high side

high- and low-side switch. The output switch and inductor from the input supply and through the

inductor is connected here. inductor and GND while the high side switch is open and low

side switch is closed. As the L pins toggle with the switching

frequency with high slew rates the trace should be routed

apart from sensitive signals such as the feedback connection

to the error amplifier (VDCDCx pins). It is acceptable to

increase the trace length in order to place the input capacitor

close to the device. Having the input capacitor close to

TPS65912x is more critical than having a short connection to

the output inductor as long as the L-trace is shielded to the

feedback trace.

DCDC1 and DCDC4 allow remote sense, so the pin could

alternatively be routed to the input capacitor on the load side.

Coupling from fast switching signals must be avoided.

simply to the GND plane. DO NOT CONNECT TO PGND

PINS DIRECTLY.

carry high currents.

current is quite small but they are the GND connection of the

analog and digital circuitry such as the control loop, so the

connection to a solid GND plane needs to be done without

using long traces- preferably by a via to the GND plane.

14

TPS65912xEVM-081 SLVU750A–July 2012–Revised May 2013

Copyright © 2012–2013, Texas Instruments Incorporated

Submit Documentation Feedback

Page 15

www.ti.com

5.3 Detailed Layout Example

Note that the top view is shown here for the device, while the data sheet of TPS65912 shows its pinout as

bottom view.

5.3.1 Connection to Power GND

Layout Considerations

Figure 9. Example for Item1: GND Connections for Elements in DCDC1.

Figure 10. Example for Item 1. GND Plane

SLVU750A–July 2012–Revised May 2013 TPS65912xEVM-081

Submit Documentation Feedback

Copyright © 2012–2013, Texas Instruments Incorporated

15

Page 16

Layout Considerations

5.3.2 Input Capacitor

www.ti.com

Figure 11. Example for Item 2: GND Connections for Elements in DCDC1.

5.3.3 Analog Supply

16

Figure 12. Example for Item 3: Analog Supply

TPS65912xEVM-081 SLVU750A–July 2012–Revised May 2013

Copyright © 2012–2013, Texas Instruments Incorporated

Submit Documentation Feedback

Page 17

www.ti.com

5.3.4 Inductor

Layout Considerations

Figure 13. Example for Item 4: Inductor Location and Routing

SLVU750A–July 2012–Revised May 2013 TPS65912xEVM-081

Submit Documentation Feedback

Copyright © 2012–2013, Texas Instruments Incorporated

17

Page 18

Layout Considerations

5.3.5 DCDC Output Voltage Feedback and Remote Sensing

www.ti.com

18

Figure 14. Example for Items 5 and 6: DCDC Feedback and Remote Sensing

TPS65912xEVM-081 SLVU750A–July 2012–Revised May 2013

Copyright © 2012–2013, Texas Instruments Incorporated

Submit Documentation Feedback

Page 19

www.ti.com

5.3.6 Analog Supply Voltage Pin

Layout Considerations

Figure 15. Example for Item 7: Vcc, Analog Supply Voltage

5.3.7 Analog, Digital and Power GND Connections

Figure 16. Example for Item 8: Connection of PGND to GND

SLVU750A–July 2012–Revised May 2013 TPS65912xEVM-081

Submit Documentation Feedback

Copyright © 2012–2013, Texas Instruments Incorporated

19

Page 20

Layout Considerations

www.ti.com

20

Figure 17. Example for Item 8: Connection of AGND and DGND to GND

TPS65912xEVM-081 SLVU750A–July 2012–Revised May 2013

Copyright © 2012–2013, Texas Instruments Incorporated

Submit Documentation Feedback

Page 21

www.ti.com

6 Graphical User Interface

The provided GUI facilitates PC to IC communication though the I2C bus using the USB-TO-GPIO box and

USB cable. Please refer to USB Interface Adapter Evaluation Module User's Guide, SLLU093, for detailed

operating instructions of the USB-TO-GPIO interface. Connect the 10-pin ribbon cable to J60 of the EVM.

Connect the USB cable of the USB-TO-GPIO to the PC. An overview of the GUI is shown in Figure 18.

Graphical User Interface

Figure 18. Graphical User Interface Screen Shot

SLVU750A–July 2012–Revised May 2013 TPS65912xEVM-081

Submit Documentation Feedback

Copyright © 2012–2013, Texas Instruments Incorporated

21

Page 22

Bill of Materials

7 Bill of Materials

Table 3. PWR081A BOM

Count

-001 -002 RefDes Value Description Size Part Number MFR

3 3 C1, C4, C56 22 µF Capacitor, ceramic, 6.3 V, X5R, 20% 0805 GRM21BR60J226ME39 Murata

33 33 C16-23, C29-31, C11-14, 2.2 µF Capacitor, ceramic, 10 V, X7R, 10% 0603 GRM188R71A225KE15 Murata

C36-52, C15

13 13 C2-3, C5-10, C32-35, C54 10 µF Capacitor, ceramic, 6.3 V, X5R, 20% 0603 GRM188R60J106ME47 Murata

5 5 C24-27, C55 4.7 µF Capacitor, ceramic, 6.3 V, X5R, 10% 0603 GRM188R60J475KE19 Murata

1 1 C28 220 nF Capacitor, ceramic, 6.3 V, X5R, 20% 0603 std std

0 0 C53 Open Capacitor, ceramic, 10 V, X5, 20% 0603 STD STD

1 1 D1 LTST-C190YKT Diode, LED, yellow, 2.1 V, 20 mA, 6 mcd 0603 LTST-C190YKT Lite On

1 1 D2 LTST-C190GKT Diode, LED, green, 2.1 V, 20 mA, 6 mcd 0603 LTST-C190GKT Lite On

1 1 D3 LTST-C190CKT Diode, LED, red, 2.1 V, 20 mA, 6 mcd 0603 LTST-C190CKT Lite On

0 0 J1-2, J8 Open Header, male 2-pin, 100-mil spacing 0.100 in × 2 PEC02SAAN Sullins

4 4 J26-27, J29, J32 PEC04SAAN Header, male 4-pin, 100-mil spacing 0.100 in × 4 PEC04SAAN Sullins

5 5 J3-7 PEC06SAAN Header, male 6-pin, 100-mil spacing 0.100 in × 6 PEC06SAAN Sullins

2 2 J37-38 N2510-6002RB Connector, male straight 2 × 5 pin, 100-mil spacing, 4 wall 0.338 × 0.788 in N2510-6002RB 3M

1 1 J39 30306-6002HB Connector, male right angle 2 × 3 pin, 100-mil spacing, 0.100 in × 2X3 30306-6002HB 3M

shrouded

1 1 J40 PEC07SAAN Header, male 7-pin, 100-mil spacing 0.100 in × 7 PEC07SAAN Sullins

26 26 J9-25, J28, J30-31, J33-36, PEC02SAAN Header, male 2-pin, 100-mil spacing 0.100 in × 2 PEC02SAAN Sullins

J41-42

12 12 JP1-12 PEC03SAAN Header, male 3-pin, 100-mil spacing 0.100 in × 3 PEC03SAAN Sullins

4 4 L1-4 1.0 µH Inductor, SMT ±30% 2 × 2.5 mm 1239AS-H-1R0N=P2 Toko

24 24 R1, R4-7, R13, R16-17, 0 Ω Resistor, chip, 1/16W, 1% 0603 STD STD

R20-22, R24, R26-29, R3435, R37, R40, R45, R47,

R49, R51

8 8 R14, R31-32, R15, R33, 3.30 kΩ Resistor, chip, 1/16W, 1% 0603 STD STD

R11, R23, R30

1 1 R18 10.0 kΩ Resistor, chip, 1/16W, 1% 0603 STD STD

0 0 R19, R8, R2-3 Open Resistor, chip, 1/16W, 1% 0603 std std

1 1 R53 0 Ω Resistor, chip, 1/10W, ±1% 0805 STD STD

0 0 R54 open Resistor, chip, 1/10W, ±1% 0805 STD STD

0 0 R56-57 open Resistor, metal film, 1/4W, ± 1% 1206 STD Vishay

1 1 R58 0 Ω Resistor, metal film, 1/4W, ± 1% 1206 STD Vishay

20 20 R9-10, R36, R12, R38-39, open Resistor, chip, 1/16W, 1% 0603 STD STD

R41-44, R46, R48, R25,

R50, R52, R55, R59-62

1 1 S1 KT11P2JM34LFS Switch, SPST, PB momentary, sealed tactile 0.245 × 0.251 in KT11P2JM34LFS C & K

www.ti.com

22

TPS65912xEVM-081 SLVU750A–July 2012–Revised May 2013

Submit Documentation Feedback

Copyright © 2012–2013, Texas Instruments Incorporated

Page 23

www.ti.com

Table 3. PWR081A BOM (continued)

Count

-001 -002 RefDes Value Description Size Part Number MFR

1 0 U1 TPS659121YFF IC, PMU FOR PROCESSOR POWER BGA TPS659121YFF TI

0 1 U1 TPS659122YFF IC, PMU FOR PROCESSOR POWER BGA TPS659122YFF TI

0 0 U2 Open IC, REAL-TIME CLOCK WITH I2C SERIAL INTERFACE SO IDT1337DCGI IDT

0 0 Y1 Open Oscillator, SMT, xxMHz, ±3ppm per year 3.2 × 5 mm CXO-7CxxMHz TXC

0 0 Y2 Open Clock oscillator HC-49 MPxxx CTS

12 12 – – Shunt, 100-mil, black 0.100 929950-00 3M

1 1 – – PCB PWR081 Any

Bill of Materials

SLVU750A–July 2012–Revised May 2013 TPS65912xEVM-081

Submit Documentation Feedback

Copyright © 2012–2013, Texas Instruments Incorporated

23

Page 24

IMPORTANT NOTICE

Texas Instruments Incorporated and its subsidiaries (TI) reserve the right to make corrections, enhancements, improvements and other

changes to its semiconductor products and services per JESD46, latest issue, and to discontinue any product or service per JESD48, latest

issue. Buyers should obtain the latest relevant information before placing orders and should verify that such information is current and

complete. All semiconductor products (also referred to herein as “components”) are sold subject to TI’s terms and conditions of sale

supplied at the time of order acknowledgment.

TI warrants performance of its components to the specifications applicable at the time of sale, in accordance with the warranty in TI’s terms

and conditions of sale of semiconductor products. Testing and other quality control techniques are used to the extent TI deems necessary

to support this warranty. Except where mandated by applicable law, testing of all parameters of each component is not necessarily

performed.

TI assumes no liability for applications assistance or the design of Buyers’ products. Buyers are responsible for their products and

applications using TI components. To minimize the risks associated with Buyers’ products and applications, Buyers should provide

adequate design and operating safeguards.

TI does not warrant or represent that any license, either express or implied, is granted under any patent right, copyright, mask work right, or

other intellectual property right relating to any combination, machine, or process in which TI components or services are used. Information

published by TI regarding third-party products or services does not constitute a license to use such products or services or a warranty or

endorsement thereof. Use of such information may require a license from a third party under the patents or other intellectual property of the

third party, or a license from TI under the patents or other intellectual property of TI.

Reproduction of significant portions of TI information in TI data books or data sheets is permissible only if reproduction is without alteration

and is accompanied by all associated warranties, conditions, limitations, and notices. TI is not responsible or liable for such altered

documentation. Information of third parties may be subject to additional restrictions.

Resale of TI components or services with statements different from or beyond the parameters stated by TI for that component or service

voids all express and any implied warranties for the associated TI component or service and is an unfair and deceptive business practice.

TI is not responsible or liable for any such statements.

Buyer acknowledges and agrees that it is solely responsible for compliance with all legal, regulatory and safety-related requirements

concerning its products, and any use of TI components in its applications, notwithstanding any applications-related information or support

that may be provided by TI. Buyer represents and agrees that it has all the necessary expertise to create and implement safeguards which

anticipate dangerous consequences of failures, monitor failures and their consequences, lessen the likelihood of failures that might cause

harm and take appropriate remedial actions. Buyer will fully indemnify TI and its representatives against any damages arising out of the use

of any TI components in safety-critical applications.

In some cases, TI components may be promoted specifically to facilitate safety-related applications. With such components, TI’s goal is to

help enable customers to design and create their own end-product solutions that meet applicable functional safety standards and

requirements. Nonetheless, such components are subject to these terms.

No TI components are authorized for use in FDA Class III (or similar life-critical medical equipment) unless authorized officers of the parties

have executed a special agreement specifically governing such use.

Only those TI components which TI has specifically designated as military grade or “enhanced plastic” are designed and intended for use in

military/aerospace applications or environments. Buyer acknowledges and agrees that any military or aerospace use of TI components

which have not been so designated is solely at the Buyer's risk, and that Buyer is solely responsible for compliance with all legal and

regulatory requirements in connection with such use.

TI has specifically designated certain components as meeting ISO/TS16949 requirements, mainly for automotive use. In any case of use of

non-designated products, TI will not be responsible for any failure to meet ISO/TS16949.

Products Applications

Audio www.ti.com/audio Automotive and Transportation www.ti.com/automotive

Amplifiers amplifier.ti.com Communications and Telecom www.ti.com/communications

Data Converters dataconverter.ti.com Computers and Peripherals www.ti.com/computers

DLP® Products www.dlp.com Consumer Electronics www.ti.com/consumer-apps

DSP dsp.ti.com Energy and Lighting www.ti.com/energy

Clocks and Timers www.ti.com/clocks Industrial www.ti.com/industrial

Interface interface.ti.com Medical www.ti.com/medical

Logic logic.ti.com Security www.ti.com/security

Power Mgmt power.ti.com Space, Avionics and Defense www.ti.com/space-avionics-defense

Microcontrollers microcontroller.ti.com Video and Imaging www.ti.com/video

RFID www.ti-rfid.com

OMAP Applications Processors www.ti.com/omap TI E2E Community e2e.ti.com

Wireless Connectivity www.ti.com/wirelessconnectivity

Mailing Address: Texas Instruments, Post Office Box 655303, Dallas, Texas 75265

Copyright © 2015, Texas Instruments Incorporated

Page 25

Mouser Electronics

Authorized Distributor

Click to View Pricing, Inventory, Delivery & Lifecycle Information:

Texas Instruments:

TPS659122EVM-081 TPS659121EVM-081

Loading...

Loading...