Page 1

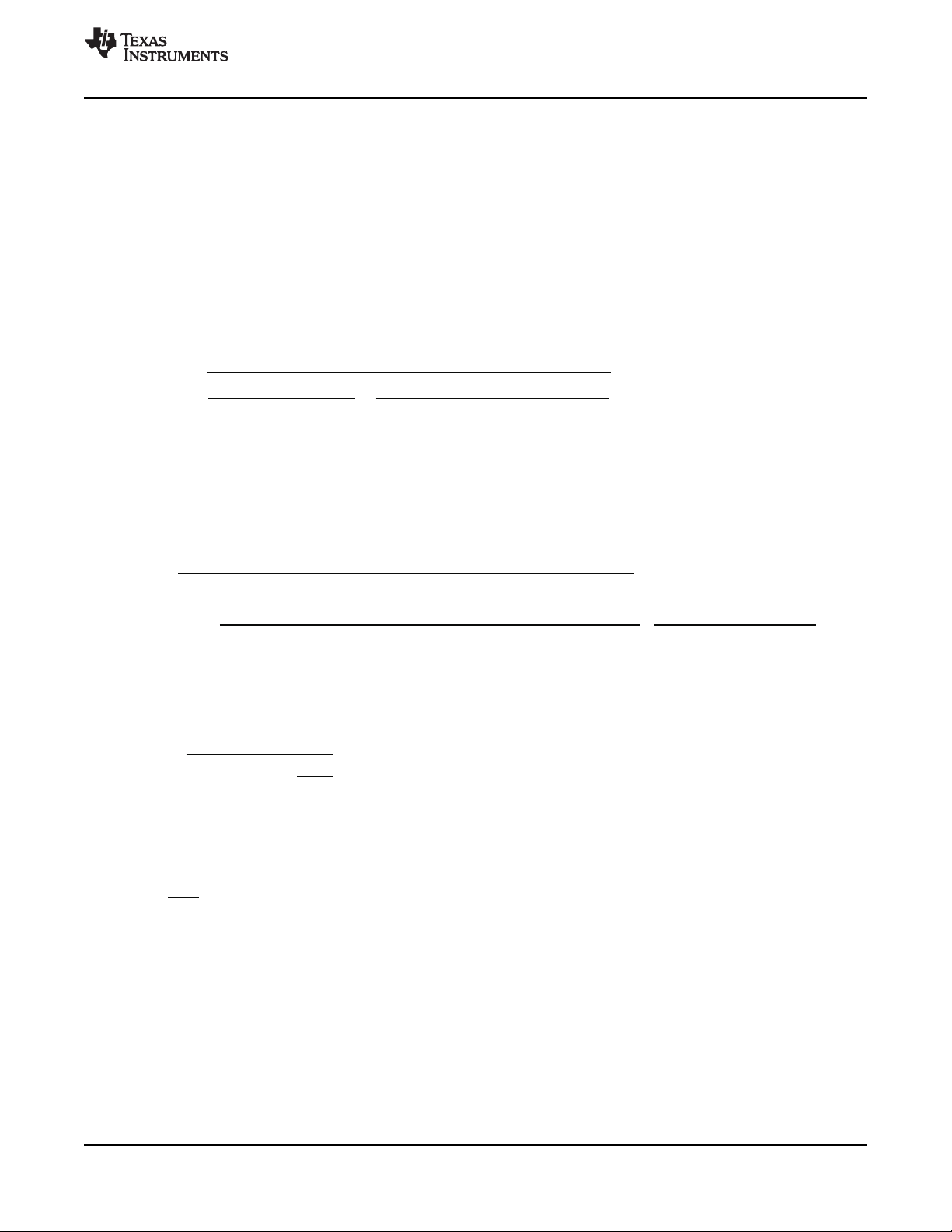

C1

38V MAX

VIN SW

FB

GND

CTRL

COMP

C2

20 mA

TPS61161A

ON/OFF

DIMMING

CONTROL

V 3 V to 18 V

I

L1

22 Hm

1 Fm

C3

220 nF

R

10

set

W

1 Fm

L1: TDK VLCF5020T-220MR75-1

C1: Murata GRM188R61E105K

C2: Murata GRM21BR71H105K

D1: ONsemi MBR0540T1

D1

Product

Folder

Sample &

Buy

Technical

Documents

Tools &

Software

Support &

Community

SLVS937B –MARCH 2009–REVISED NOVEMBER2014

TPS6116xA White LED Driver with PWM Brightness Control in

2-mm x 2-mm WSON Package

1 Features 3 Description

1

• Input Voltage Range: 2.7 V to 18 V

• 26-V Open LED Protection for TPS61160A

38-V Open LED Protection for TPS61161A

• 200mV Reference Voltage With ±2% Accuracy

• PWM Interface for Brightness Control

• Built-in Soft Start

• Up to 90% Efficiency

• 2-mm × 2-mm × 0.8-mm 6-Pin WSON Package

With Thermal Pad

2 Applications

• Cellular Phones

• Portable Media Players

• Ultra Mobile Devices

• GPS Receivers

• White LED Backlighting for Media Form Factor

Display

With a 40-V rated integrated switch FET, the

TPS61160A/61A is a boost converter that drives

LEDs in series. The boost converter runs at 600-kHz

fixed switching frequency to reduce output ripple,

improve conversion efficiency, and allows for the use

of small external components.

The default white LED current is set with the external

sensor resistor Rset, and the feedback voltage is

regulated to 200 mV, as shown in the typical

application. During the operation, the LED current can

be controlled by a pulse width modulation (PWM)

signal applied to the CTRL pin through which the duty

cycle determines the feedback reference voltage. In

PWM dimming mode, the TPS61160A/61A does not

burst the LED current; therefore, it does not generate

audible noises on the output capacitor. For maximum

protection, the device features integrated open LED

protection that disables the TPS61160A/61A to

prevent the output from exceeding the absolute

maximum ratings during open LED conditions.

The TPS61160A/61A is available in a space-saving,

2-mm × 2-mm WSON package with thermal pad.

TPS61160A,TPS61161A

1

An IMPORTANT NOTICE at the end of this data sheet addresses availability, warranty, changes, use in safety-critical applications,

intellectual property matters and other important disclaimers. PRODUCTION DATA.

Device Information

PART NUMBER PACKAGE OPEN LED PROTECTION

TPS61160A TPS61160A use 26 V (typical)

TPS61161A TPS61161A use 38 V (typical)

(1) For all available packages, see the orderable addendum at

the end of the datasheet.

WSON (6)

(1)

Typical Application of TPS61161A

Page 2

TPS61160A,TPS61161A

SLVS937B –MARCH 2009–REVISED NOVEMBER 2014

www.ti.com

Table of Contents

1 Features.................................................................. 1

2 Applications ........................................................... 1

3 Description ............................................................. 1

4 Revision History..................................................... 2

5 Pin Configuration and Functions......................... 3

6 Specifications......................................................... 3

6.1 Absolute Maximum Ratings ...................................... 3

6.2 Handling Ratings....................................................... 4

6.3 Recommended Operating Conditions....................... 4

6.4 Thermal Information.................................................. 4

6.5 Dissipation Ratings ................................................... 4

6.6 Electrical Characteristics........................................... 5

6.7 Typical Characteristics.............................................. 6

7 Detailed Description .............................................. 8

7.1 Overview ................................................................... 8

7.2 Functional Block Diagram......................................... 8

7.3 Feature Description................................................... 8

7.4 Device Functional Modes........................................ 10

8 Application and Implementation ........................ 11

8.1 Application Information............................................ 11

8.2 Typical Applications ................................................ 11

9 Power Supply Recommendations...................... 19

10 Layout................................................................... 20

10.1 Layout Guidelines ................................................. 20

10.2 Layout Example .................................................... 20

10.3 Thermal Considerations........................................ 20

11 Device and Documentation Support................. 21

11.1 Device Support...................................................... 21

11.2 Documentation Support ........................................ 21

11.3 Related Links ........................................................ 21

11.4 Trademarks........................................................... 21

11.5 Electrostatic Discharge Caution............................ 21

11.6 Glossary................................................................ 21

12 Mechanical, Packaging, and Orderable

Information........................................................... 21

4 Revision History

NOTE: Page numbers for previous revisions may differ from page numbers in the current version.

Changes from Revision A (July 2011) to Revision B Page

• Added Device Information and Handling Rating tables, Feature Description, Device Functional Modes, Application

and Implementation, Power Supply Recommendations, Layout, Device and Documentation Support, and

Mechanical, Packaging, and Orderable Information sections; moved some curves to Application Curves section;

change "QFN" to "SON" ......................................................................................................................................................... 1

• Changed (reversed) the Vi=5V and Vi=3.6V characteristic labels in Figure 3....................................................................... 6

Changes from Original (March 2009) to Revision A Page

• Deleted "6 LEDs" and "10 LEDs" from the second feature bullet for TPS61160A and TPS61161A Open-LED

Protection, respectively........................................................................................................................................................... 1

• Deleted "for up to 10 LEDs in Series" from title ..................................................................................................................... 1

• Added "38V Max" to Typical Application of TPS61161A, top of LED string........................................................................... 1

• Changed from "...for driving up to 10 white LED" to "...for driving white LED" in first sentence of OPERATION section. .... 8

• Changed text of last sentence in "OPEN LED PROTECTION" section to clarify circuit description...................................... 9

• Changed Figure 11 to show separate terminals for COMP and FB..................................................................................... 10

• Changed Li-Ion Driver for 6 White LEDs With External PWM Dimming Network to clarify schematic................................ 14

2 Submit Documentation Feedback Copyright © 2009–2014, Texas Instruments Incorporated

Product Folder Links: TPS61160A TPS61161A

Page 3

www.ti.com

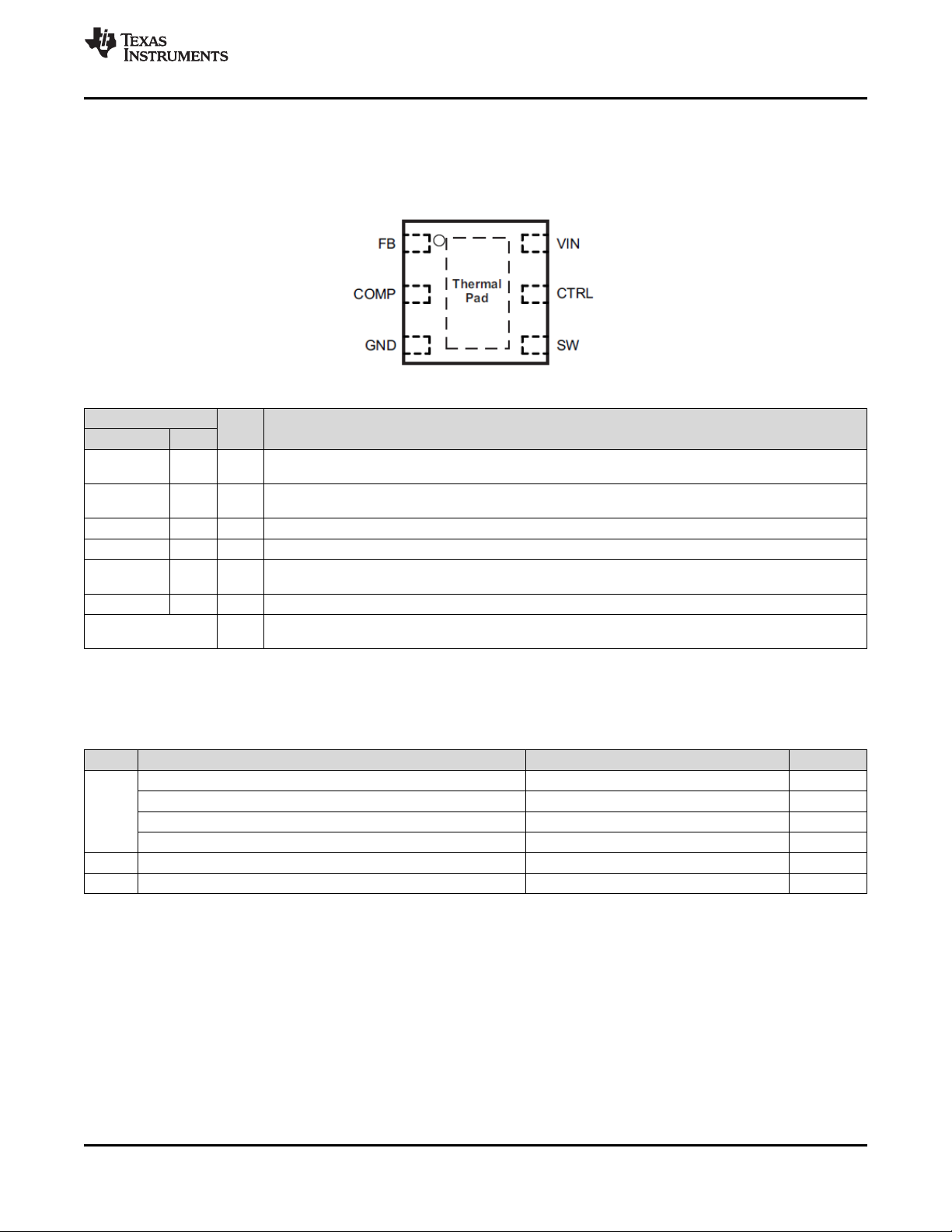

5 Pin Configuration and Functions

TPS61160A,TPS61161A

SLVS937B –MARCH 2009–REVISED NOVEMBER 2014

WSON (DRV) Package

6 Pins

Top View

Pin Functions

PIN

NAME NO.

COMP 2 O

CTRL 5 I

FB 1 I Feedback pin for current. Connect the sense resistor from FB to GND.

GND 3 O Ground

SW 4 I

VIN 6 I The input supply pin for the IC. Connect VIN to a supply voltage between 2.7 V and 18 V.

Thermal Pad

I/O DESCRIPTION

Output of the transconductance error amplifier. Connect an external capacitor to this pin to compensate the

regulator.

Control pin of the boost regulator. Enable and disable IC. PWM signal can be applied to the pin for LED

brightness dimming as well.

This is the switching node of the IC. Connect the inductor between the VIN and SW pin. This pin is also

used to sense the output voltage for open LED protection

The thermal pad should be soldered to the analog ground plane. If possible, use thermal via to connect to

ground plane for ideal power dissipation.

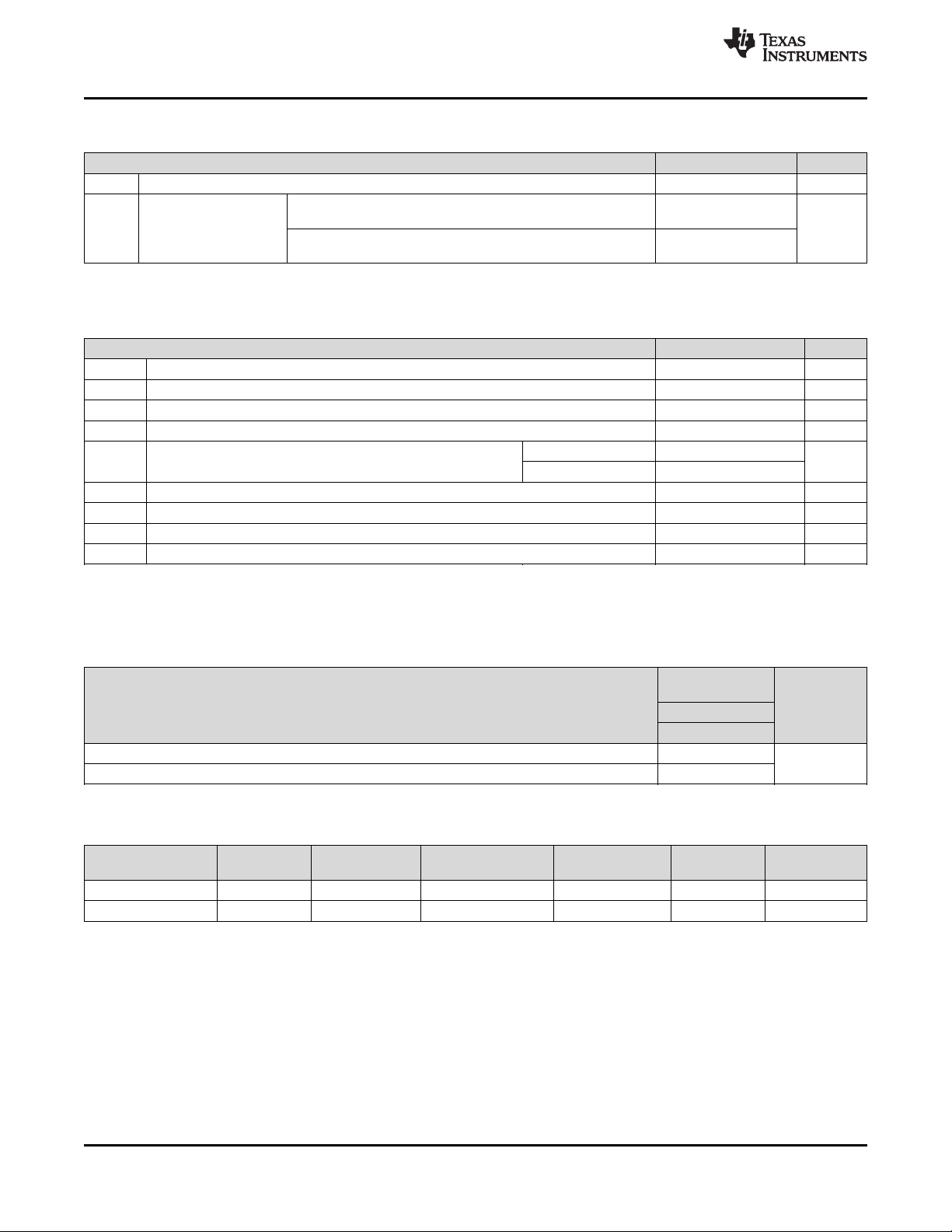

6 Specifications

6.1 Absolute Maximum Ratings

over operating free-air temperature range (unless otherwise noted)

Supply voltages on VIN

V

Voltages on CTRL

I

Voltage on FB and COMP

Voltage on SW

P

T

Continuous power dissipation See Dissipation Ratings

D

Operating junction temperature –40 150 °C

J

(1) Stresses beyond those listed under Absolute Maximum Ratings may cause permanent damage to the device. These are stress ratings

only, and functional operation of the device at these or any other conditions beyond those indicated under Recommended Operating

Conditions is not implied. Exposure to absolute-maximum-rated conditions for extended periods may affect device reliability.

(2) All voltage values are with respect to network ground terminal.

(2)

(2)

(2)

(2)

(1)

MIN MAX UNIT

–0.3 20 V

–0.3 20 V

–0.3 3 V

–0.3 40 V

Copyright © 2009–2014, Texas Instruments Incorporated Submit Documentation Feedback 3

Product Folder Links: TPS61160A TPS61161A

Page 4

TPS61160A,TPS61161A

SLVS937B –MARCH 2009–REVISED NOVEMBER 2014

www.ti.com

6.2 Handling Ratings

MIN MAX UNIT

T

V

Storage temperature range –65 150 °C

stg

Human body model (HBM), per ANSI/ESDA/JEDEC JS-001, all 4000

(1)

Electrostatic discharge V

(ESD)

pins

Charged device model (CDM), per JEDEC specification 1000

JESD22-C101, all pins

(2)

(1) JEDEC document JEP155 states that 500-V HBM allows safe manufacturing with a standard ESD control process.

(2) JEDEC document JEP157 states that 250-V CDM allows safe manufacturing with a standard ESD control process.

6.3 Recommended Operating Conditions

MIN MAX UNIT

V

I

V

O

L Inductor

f

dim

Duty

C

IN

C

O

T

A

T

J

(1) These values are recommended values that have been successfully tested in several applications. Other values may be acceptable in

(2) The device can support the frequency range from 1 kHz to 5 kHz, based on the specification, t

Input voltage, V

IN

Output voltage V

(1)

PWM dimming frequency

(2)

2.7 18 V

IN

10 22 μH

5 100 kHz

PWM duty cycle resolution 10 kHz 0.5%

30 kHz 1.5%

Input capacitor 1 μF

Output capacitor

(1)

0.47 10 μF

Operating ambient temperature –40 85 °C

Operating junction temperature –40 125 °C

other applications but should be fully tested by the user.

. The output ripple needs to be

considered in the range of 1 kHz to 5 kHz.

off

38 V

6.4 Thermal Information

TPS61160A,

THERMAL METRIC

(1)

TPS61161A

DRV

UNIT

6 PINS

R

θJA

R

θJC(top)

Junction-to-ambient thermal resistance 140

Junction-to-case (top) thermal resistance 20

°C/W

(1) For more information about traditional and new thermal metrics, see the IC Package Thermal Metrics application report, SPRA953.

6.5 Dissipation Ratings

BOARD PACKAGE R

(1)

Low-K

High-K

DRV 20°C/W 140°C/W 7.1 mW/°C 715 mW 395 mW 285 mW

(2)

DRV 20°C/W 65°C/W 15.4 mW/°C 1540 mW 845 mW 615 mW

θJC

R

θJA

(1) The JEDEC low-K (1s) board used to derive this data was a 3 in × 3 in, two-layer board with 2-ounce copper traces on top of the board.

(2) The JEDEC high-K (2s2p) board used to derive this data was a 3 in × 3 in, multilayer board with 1-ounce internal power and ground

planes and 2-ounce copper traces on top and bottom of the board.

DERATING FACTOR

ABOVE TA= 25°C

TA< 25°C TA= 70°C TA= 85°C

4 Submit Documentation Feedback Copyright © 2009–2014, Texas Instruments Incorporated

Product Folder Links: TPS61160A TPS61161A

Page 5

TPS61160A,TPS61161A

www.ti.com

SLVS937B –MARCH 2009–REVISED NOVEMBER 2014

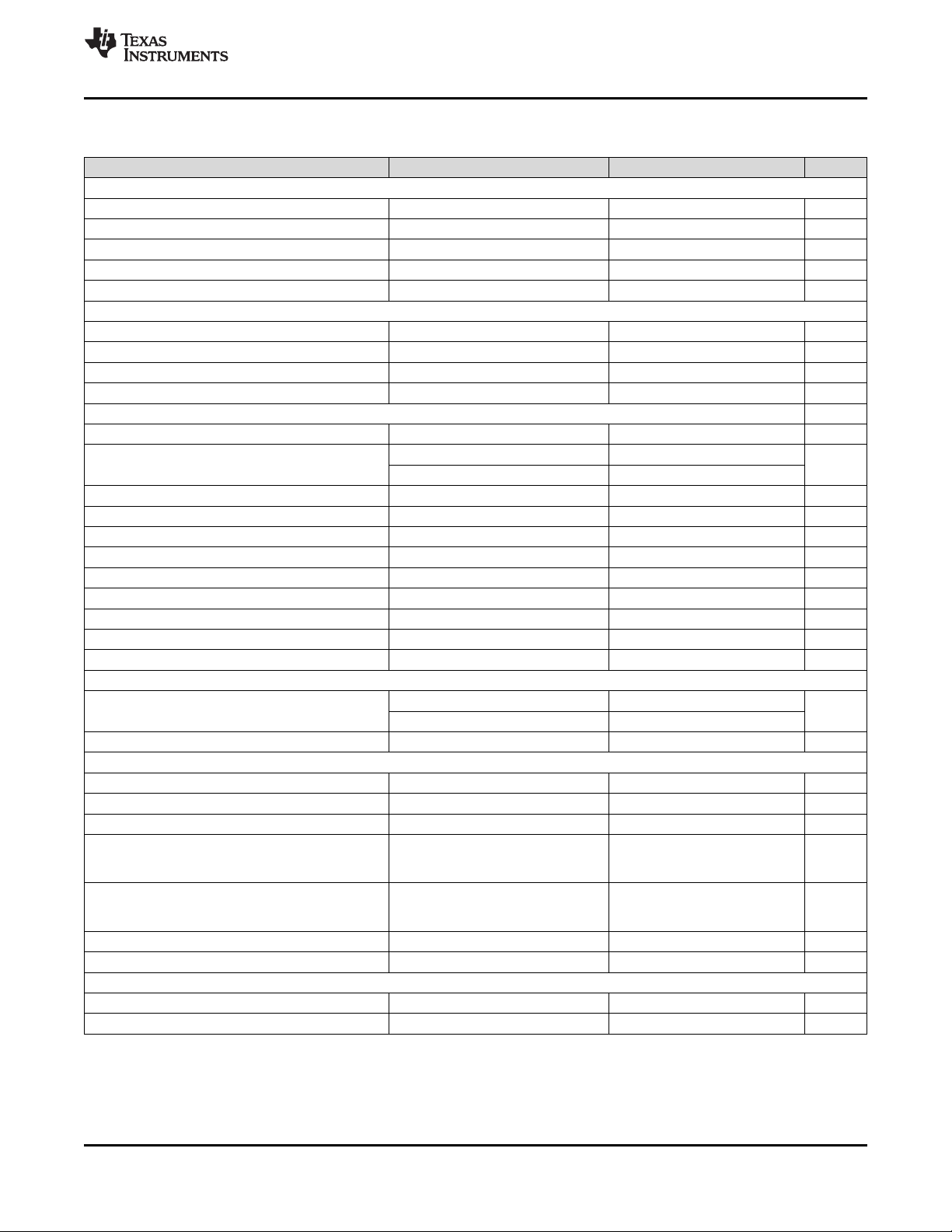

6.6 Electrical Characteristics

VIN= 3.6 V, CTRL = VIN; for Min/Max values TA= –40°C to 85°C, typical values are at TA= 25°C (unless otherwise noted)

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

SUPPLY CURRENT

V

I

I

Q

I

SD

UVLO Undervoltage lockout threshold VIN falling 2.2 2.5 V

V

hys

ENABLE AND REFERENCE CONTROL

V

(CTRLh)

V

(CTRLl)

R

(CTRL)

t

off

VOLTAGE AND CURRENT CONTROL

V

REF

V

(REF_PWM)

I

FB

f

S

D

max

t

min_on

I

sink

I

source

G

ea

R

ea

f

ea

POWER SWITCH

R

DS(on)

I

LN_NFET

OC and OLP

I

LIM

I

LIM_Start

t

Half_LIM

V

ovp

V

(FB_OVP)

t

REF

t

step

THERMAL SHUTDOWN

T

shutdown

T

hysteresis

Input voltage range, V

IN

Operating quiescent current into V

Device PWM switching no load 1.8 mA

IN

2.7 18 V

Shutdown current CRTL = GND, VIN= 4.2 V 1 μA

Undervoltage lockout hysteresis 70 mV

CTRL logic high voltage VIN= 2.7 V to 18 V 1.2 V

CTRL logic low voltage VIN= 2.7 V to 18 V 0.4 V

CTRL pull down resistor 400 800 1600 kΩ

CTRL pulse width to shutdown CTRL high to low 2.5 ms

Voltage feedback regulation voltage 196 200 204 mV

Voltage feedback regulation voltage VFB= 50 mV 47 50 53 mV

under brightness control

VFB= 20 mV 17 20 23

Voltage feedback input bias current VFB= 200 mV 2 μA

Oscillator frequency 500 600 700 kHz

Maximum duty cycle VFB= 100 mV 90% 93%

Minimum on pulse width 40 ns

Comp pin sink current 100 μA

Comp pin source current 100 μA

Error amplifier transconductance 240 320 400 μmho

Error amplifier output resistance 6 MΩ

Error amplifier crossover frequency 5 pF connected to COMP 500 kHz

N-channel MOSFET on-resistance VIN= 3.6 V 0.3 0.6

VIN= 3 V 0.7

N-channel leakage current VSW= 35 V, TA= 25°C 1 μA

N-Channel MOSFET current limit D = D

Start up current limit D = D

max

max

0.56 0.7 0.84 A

0.4 A

Time step for half current limit 5 ms

Open LED protection threshold Measured on the SW pin, 25 26 27 V

TPS61160A 37 38 39

TPS61161A

Open LED protection threshold on FB Measured on the FB pin, percentage

of Vref, 50%

Vref = 200 mV and 20 mV

V

filter time constant 180 μs

REF

V

ramp up time 213 μs

REF

Thermal shutdown threshold 160 °C

Thermal shutdown threshold hysteresis 15 °C

Ω

Copyright © 2009–2014, Texas Instruments Incorporated Submit Documentation Feedback 5

Product Folder Links: TPS61160A TPS61161A

Page 6

40

50

60

70

80

90

100

0 10 20 30 40 50

10 LEDs - TPS61161A

V = 12 V

I

Output Current - mA

Efficiency - %

V = 5 V

I

V = 3.6 V

I

300

400

500

600

700

800

900

1000

20 30 40 50 60 70 80 90

DutyCycle-%

SwitchCurrentLimit-mA

40

50

60

70

80

90

100

0 10 20 30 40 50

OutputCurrent-mA

4(12.8V),6(19.2V)LEDs

8(25.6V),10(32V)LEDs

6LEDs

V =3.6V

I

4LEDs

8LEDs

10LEDs

Efficiency-%

40

50

60

70

80

90

100

0 10 20 30 40 50

6LEDs- TPS61160A

V =3.6V

I

V =3V

I

V =4.2V

I

OutputCurrent-mA

Efficiency-%

TPS61160A,TPS61161A

SLVS937B –MARCH 2009–REVISED NOVEMBER 2014

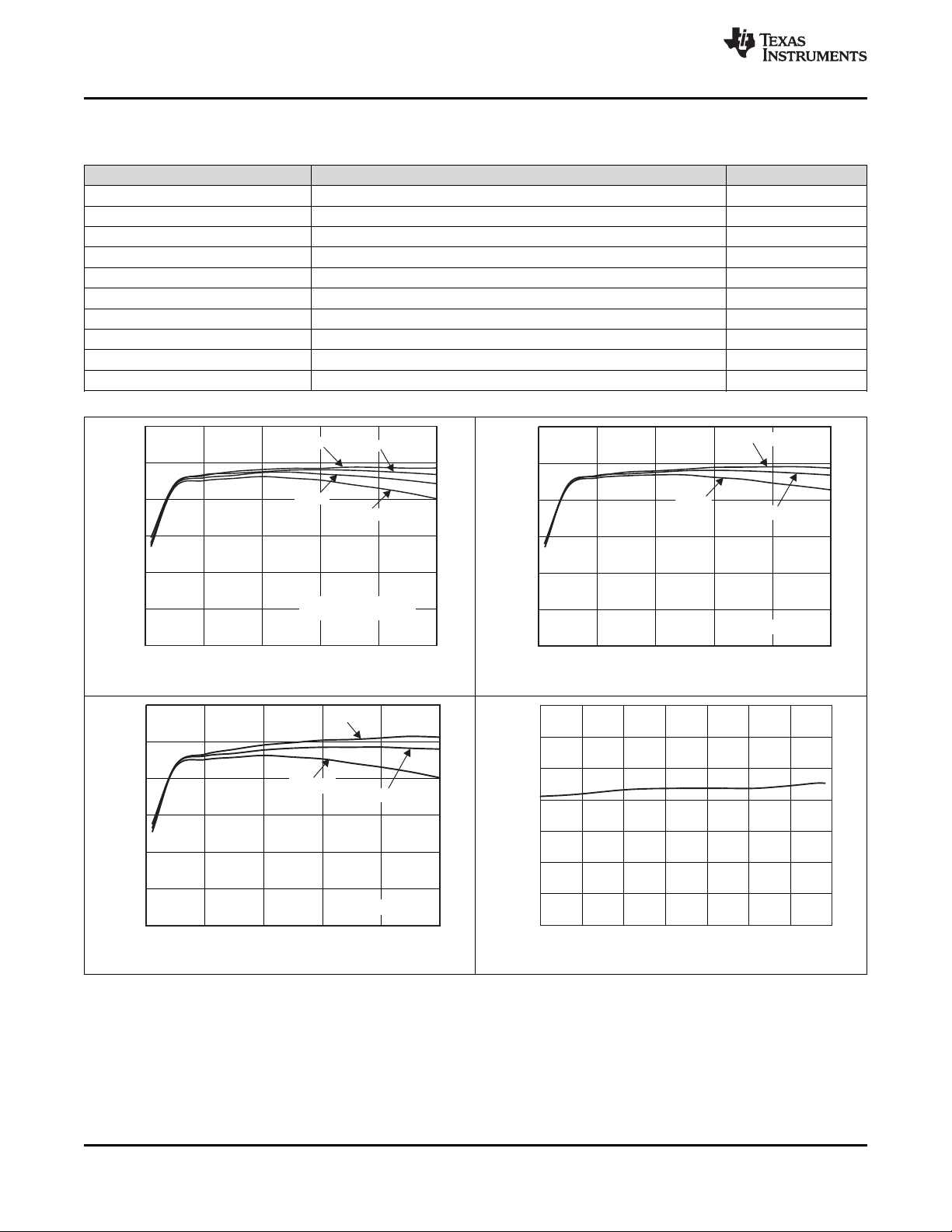

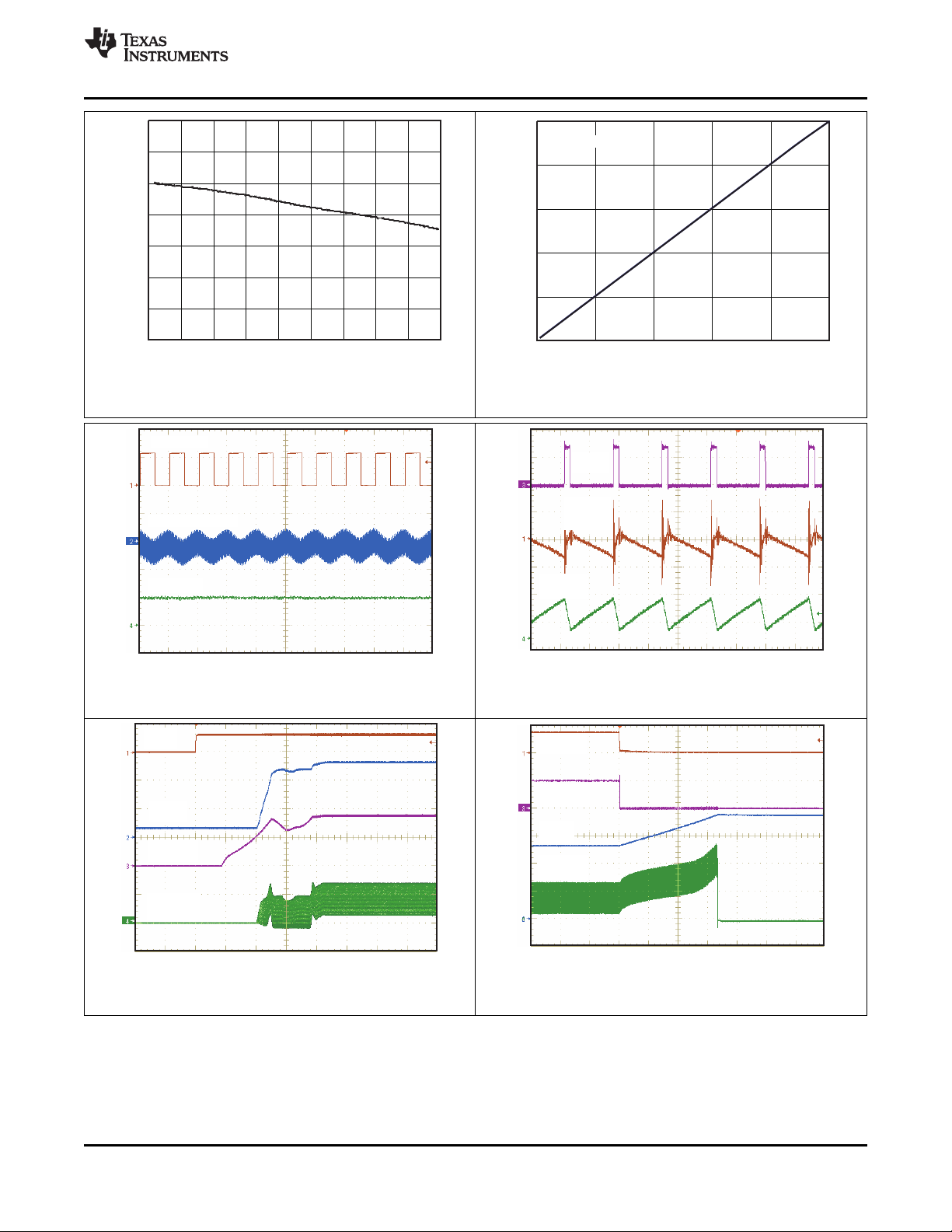

6.7 Typical Characteristics

Table 1. Table of Graphs

FIGURE

Efficiency TPS61160A/61A VIN= 3.6 V; 4, 6, 8, 10 LEDs; L = 22 μH Figure 1

Efficiency TPS61160A Figure 2

Efficiency TPS61161A Figure 3

Current limit TA= 25°C Figure 4

Current limit Figure 5

PWM dimming linearity VIN= 3.6 V; PWM Freq = 10 kHz and 40 kHz Figure 6

Output ripple at PWM dimming 8 LEDs; VIN= 3.6 V; I

Switching waveform 8 LEDs; VIN= 3.6 V; I

Start-up 8 LEDs; VIN= 3.6 V; I

Open LED protection 8 LEDs; VIN= 3.6 V; I

= 20 mA; PWM Freq = 10 kHz Figure 7

LOAD

= 20 mA; L = 22 μH Figure 8

LOAD

= 20 mA; L =22 μH Figure 9

LOAD

= 20 mA; L = 22 μH Figure 10

LOAD

www.ti.com

Figure 1. Efficiency vs Output Current

Figure 3. Efficiency vs Output Current Figure 4. Switch Current Limit vs Duty Cycle

6 Submit Documentation Feedback Copyright © 2009–2014, Texas Instruments Incorporated

Figure 2. Efficiency vs Output Current

Product Folder Links: TPS61160A TPS61161A

Page 7

t-2ms/div

CTRL

5V/div

VOUT

10V/div

COMP

500mV/div

I

200mA/div

L

t-100 s/divm

OPENLED

5V/div

FB

200mV/div

VOUT

10V/div

I

200mA/div

L

t-100 s/divm

PWM2V/div

VOUT 20mV/div AC

I 10mA/div

LED

t-1 s/divm

SW

20V/div

VOUT

20mV/div

AC

I

200mA/div

L

0

40

80

120

160

200

0 20 40 60 80 100

PWMDutyCycle-%

10kHz,40kHz

FBVoltage-mV

300

400

500

600

700

800

900

1000

-40 -20 0 20 40 60 80 100 120 140

Temperature- C°

SwitchCurrentLimit-mA

www.ti.com

TPS61160A,TPS61161A

SLVS937B –MARCH 2009–REVISED NOVEMBER 2014

Figure 5. Switch Current Limit vs Temperature

Figure 7. Output Ripple at PWM Dimming

Figure 6. FB Voltage vs PWM Duty Cycle

Figure 8. Switching Waveform

Copyright © 2009–2014, Texas Instruments Incorporated Submit Documentation Feedback 7

Figure 9. Start-Up

Figure 10. Open LED Protection

Product Folder Links: TPS61160A TPS61161A

Page 8

SW

Ramp

Generator

Oscillator

Current

Sensor

OLP

CTRL

GND

C3

L1

+

FB

Reference

Control

D1

Error

Amplifer

2

1

Rset

C2

Vin

C1

PWM Control

4

6

Soft

Start-up

5

3

COMP

TPS61160A,TPS61161A

SLVS937B –MARCH 2009–REVISED NOVEMBER 2014

www.ti.com

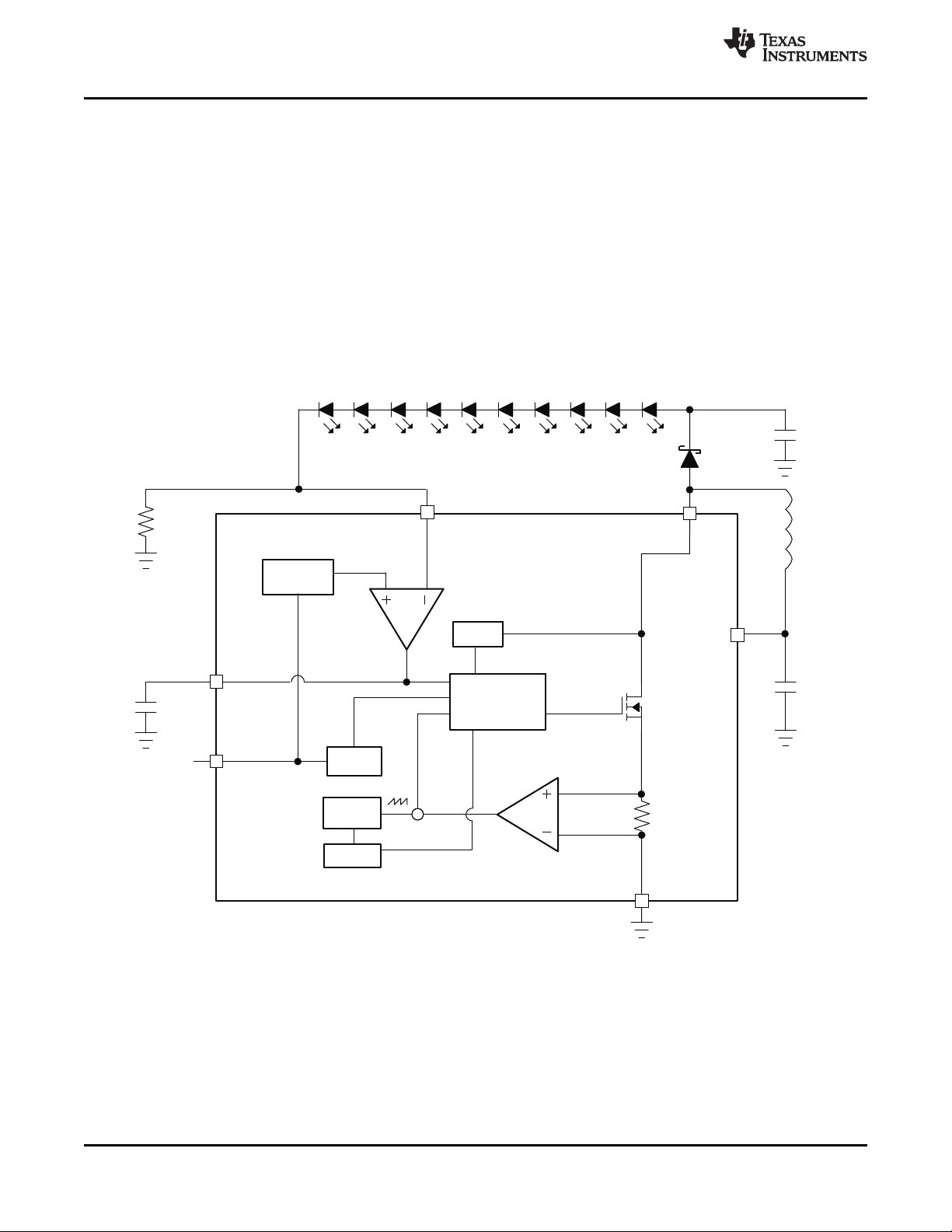

7 Detailed Description

7.1 Overview

The TPS61160A/61A is a high-efficiency, high output voltage boost converter in small package size that is ideal

for driving white LED in series. The serial LED connection provides even illumination by sourcing the same

output current through all LEDs, eliminating the need for expensive factory calibration. The device integrates 40V/0.7-A switch FET and operates in pulse width modulation (PWM) with 600-kHz fixed switching frequency. For

operation see the block diagram. The duty cycle of the converter is set by the error amplifier output and the

current signal applied to the PWM control comparator. The control architecture is based on traditional currentmode control; therefore, a slope compensation is added to the current signal to allow stable operation for duty

cycles larger than 50%. The feedback loop regulates the FB pin to a low reference voltage (200 mV typical),

reducing the power dissipation in the current sense resistor.

7.2 Functional Block Diagram

7.3 Feature Description

7.3.1 Soft Start-Up

Soft-start circuitry is integrated into the IC to avoid a high inrush current during start-up. After the device is

enabled, the voltage at FB pin ramps up to the reference voltage in 32 steps, each step takes 213 μs. This

ensures that the output voltage rises slowly to reduce the input current. Additionally, for the first 5 msec after the

COMP voltage ramps, the current limit of the switch is set to half of the normal current limit spec. During this

period, the input current is kept below 400 mA (typical). See the start-up waveform of a typical example,

Figure 9.

8 Submit Documentation Feedback Copyright © 2009–2014, Texas Instruments Incorporated

Product Folder Links: TPS61160A TPS61161A

Page 9

V Duty 200 mV

u

FB

LED

SET

V

R

TPS61160A,TPS61161A

www.ti.com

SLVS937B –MARCH 2009–REVISED NOVEMBER 2014

Feature Description (continued)

7.3.2 Open LED Protection

Open LED protection circuitry prevents IC damage as the result of white LED disconnection. The

TPS61160A/61A monitors the voltage at the SW pin and FB pin during each switching cycle. The circuitry turns

off the switch FET and shuts down the IC when both of the following conditions persist for 8 switching clock

cycles: (1) the SW voltage exceeds the V

voltage. As a result, the output voltage falls to the level of the input supply. The device remains in shutdown

mode until it is enabled by toggling the CTRL pin logic. To allow the use of inexpensive low-voltage output

capacitor, the TPS61160A/61A has different open lamp protection thresholds. The threshold is set at 26 V for the

TPS61160A and 38 V for the TPS61161A. Select the appropriate device so that the product of the number of

external LEDs and each LED's maximum forward voltage plus the 200 mV reference voltage does not exceed

the minimum OVP threshold or (n

LEDS

X V

7.3.3 Shutdown

The TPS61160A/61A enters shutdown mode when the CTRL voltage is logic low for more than 2.5 ms. During

shutdown, the input supply current for the device is less than 1 μA (max). Although the internal FET does not

switch in shutdown, there is still a DC current path between the input and the LEDs through the inductor and

Schottky diode. The minimum forward voltage of the LED array must exceed the maximum input voltage to

ensure that the LEDs remain off in shutdown; however, in the typical application with two or more LEDs, the

forward voltage is large enough to reverse bias the Schottky and keep leakage current low.

7.3.4 Current Program

The FB voltage is regulated by a low 0.2-V reference voltage. The LED current is programmed externally using a

current-sense resistor in series with the LED string. The value of the RSET is calculated using Equation 1:

threshold and (2) the FB voltage is less than half of regulation

OVP

LED(MAX)

) + 200 mV ≤ V

OVP(MIN).

where

• I

• VFB= regulated voltage of FB

• R

= output current of LEDs

LED

= current sense resistor (1)

SET

The output current tolerance depends on the FB accuracy and the current sensor resistor accuracy.

7.3.5 PWM Brightness Dimming

When the CTRL pin is constantly high, the FB voltage is regulated to 200 mV typically. However, the CTRL pin

allows a PWM signal to reduce this regulation voltage; therefore, it achieves LED brightness dimming. The

relationship between the duty cycle and FB voltage is given by Equation 2.

where

• Duty = duty cycle of the PWM signal

• 200 mV = internal reference voltage (2)

As shown in Figure 11, the IC chops up the internal 200-mV reference voltage at the duty cycle of the PWM

signal. The pulse signal is then filtered by an internal low pass filter. The output of the filter is connected to the

error amplifier as the reference voltage for the FB pin regulation. Therefore, although a PWM signal is used for

brightness dimming, only the WLED DC current is modulated, which is often referred as analog dimming. This

eliminates the audible noise which often occurs when the LED current is pulsed in replica of the frequency and

duty cycle of PWM control. Unlike other scheme which filters the PWM signal for analog dimming,

TPS61160A/61A regulation voltage is independent of the PWM logic voltage level which often has large

variations.

For optimum performance, use the PWM dimming frequency in the range of 5 kHz to 100 kHz. The requirement

of minimum dimming frequency comes from the output ripple. Low frequency causes high output ripple. Since the

CTRL pin is logic only pin, applying an external RC filter to the pin does not work.

Copyright © 2009–2014, Texas Instruments Incorporated Submit Documentation Feedback 9

Product Folder Links: TPS61160A TPS61161A

Page 10

VBG

200 mV

Error

Amplifier

FB

CTRL

COMP

TPS61160A,TPS61161A

SLVS937B –MARCH 2009–REVISED NOVEMBER 2014

www.ti.com

Feature Description (continued)

Figure 11. Block Diagram of Programmable FB Voltage Using PWM Signal

To use lower PWM dimming, add an external RC network connected to the FB pin as shown in Figure 15).

7.3.6 Undervoltage Lockout

An undervoltage lockout prevents operation of the device at input voltages below typical 2.2 V. When the input

voltage is below the undervoltage threshold, the device is shutdown and the internal switch FET is turned off. If

the input voltage rises by undervoltage lockout hysteresis, the IC restarts.

7.3.7 Thermal Shutdown

An internal thermal shutdown turns off the device when the typical junction temperature of 160°C is exceeded.

The device is released from shutdown automatically when the junction temperature decreases by 15°C.

7.4 Device Functional Modes

7.4.1 Operation with CTRL

When the CTRL pin is held below the VIL threshold, the device is disabled, and switching is inhibited. The IC

quiescent current is reduced in this state. When VINis above the UVLO threshold, and the CTRL terminal is

increased above the VIH threshold the soft-start sequence initiates then the device becomes active.

7.4.2 External PWM Dimming

For assistance in selecting the proper values for Rset, R1-R3, RFLTR, CFLTR and D2 for the specific

application, refer to How to Use Analog Dimming With the TPS6116x (SLVA471) and/or Design Tool for Analog

Dimming Using a PWM Signal (http://www.ti.com/lit/zip/slvc366). Also see Choosing Component Values section

below.

10 Submit Documentation Feedback Copyright © 2009–2014, Texas Instruments Incorporated

Product Folder Links: TPS61160A TPS61161A

Page 11

C1

38V MAX

VIN SW

FB

GND

CTRL

COMP

C2

20 mA

TPS61161A

ON/OFF

DIMMING

CONTROL

V 3 V to 18 V

I

L1

22 Hm

1 Fm

C3

220 nF

R

10

set

W

1 Fm

L1: TDK VLCF5020T-220MR75-1

C1: Murata GRM188R61E105K

C2: Murata GRM21BR71H105K

D1: ONsemi MBR0540T1

D1

TPS61160A,TPS61161A

www.ti.com

SLVS937B –MARCH 2009–REVISED NOVEMBER 2014

8 Application and Implementation

NOTE

Information in the following applications sections is not part of the TI component

specification, and TI does not warrant its accuracy or completeness. TI’s customers are

responsible for determining suitability of components for their purposes. Customers should

validate and test their design implementation to confirm system functionality.

8.1 Application Information

The TPS61160A/61A provides a complete high-performance LED lighting solution for mobile devices supporting

a single string of 6 (TPS61160A) or 10 (TPS61161A) white LEDs.

8.2 Typical Applications

8.2.1 Typical Application of TPS61161A

Figure 12. Typical Application of TPS61161A

8.2.1.1 Design Requirements

DESIGN PARAMETER EXAMPLE VALUE

Inductor 22 µH

Minimum input voltage 3 V

Number of series LED 10

LED maximum forward voltage (Vf) 3.3 V

Schottky diode forward voltage (Vf) 0.2 V

Efficiency (η) 85%

Switching frequency (SW) 600 kHz

Copyright © 2009–2014, Texas Instruments Incorporated Submit Documentation Feedback 11

Product Folder Links: TPS61160A TPS61161A

Page 12

_

u

u

in DC

out out

V I

V

K

_

/ 2u u

lim

out max

I

in p

out

V I

V

K

1

1 1

ª º

§ ·

u u

« »

¨ ¸

« »

© ¹

¬ ¼

p

s

out f in in

L F

V V V V

TPS61160A,TPS61161A

SLVS937B –MARCH 2009–REVISED NOVEMBER 2014

www.ti.com

Applying Equation 3 and Equation 4, when VINis 3 V, 10 LEDs output equivalent to V

of 32.2 V, the inductor

OUT

is 22 μH, the Schottky forward voltage is 0.2 V, the maximum output current is 47 mA in typical condition.

8.2.1.2 Detailed Design Procedure

8.2.1.2.1 Maximum Output Current

The overcurrent limit in a boost converter limits the maximum input current, and thus maximum input power for a

given input voltage. Maximum output power is less than maximum input power due to power conversion losses.

Therefore, the current limit setting, input voltage, output voltage and efficiency can all change maximum current

output. The current limit clamps the peak inductor current; therefore, the ripple has to be subtracted to derive

maximum DC current. The ripple current is a function of switching frequency, inductor value and duty cycle.

Equation 3 and Equation 4 take into account of all the above factors for maximum output current calculation.

where

• Ip= inductor peak to peak ripple

• L = inductor value

• Vf= Schottky diode forward voltage

• Fs = switching frequency

• V

= output voltage of the boost converter. It is equal to the sum of VFB and the voltage drop across LEDs

out

(3)

where

• I

• I

• η = efficiency (4)

8.2.1.2.2 Inductor Selection

= maximum output current of the boost converter

out_max

= over current limit

lim

The selection of the inductor affects steady state operation as well as transient behavior and loop stability. These

factors make it the most important component in power regulator design. There are three important inductor

specifications, inductor value, DC resistance and saturation current. Considering inductor value alone is not

enough.

The inductor value determines the inductor ripple current. Choose an inductor that can handle the necessary

peak current without saturating, according to half of the peak-to-peak ripple current given by Equation 3, pause

the inductor DC current given by:

(5)

Inductor values can have ±20% tolerance with no current bias. When the inductor current approaches saturation

level, its inductance can decrease 20% to 35% from the 0A value depending on how the inductor vendor defines

saturation current. Using an inductor with a smaller inductance value forces discontinuous PWM when the

inductor current ramps down to zero before the end of each switching cycle. This reduces the boost converter’s

maximum output current, causes large input voltage ripple and reduces efficiency. Large inductance value

provides much more output current and higher conversion efficiency. For these reasons, a 10 μH to 22 μH

inductor value range is recommended. A 22 μH inductor optimized the efficiency for most application while

maintaining low inductor peak to peak ripple. Table 2 lists the recommended inductor for the TPS61160A/61A.

When recommending inductor value, the factory has considered –40% and +20% tolerance from its nominal

value.

12 Submit Documentation Feedback Copyright © 2009–2014, Texas Instruments Incorporated

Product Folder Links: TPS61160A TPS61161A

Page 13

_

u

ripple ESR

ESR out

R I

( ) u

u u

out in

out

out s ripple

V V

V F V

out

I

TPS61160A,TPS61161A

www.ti.com

SLVS937B –MARCH 2009–REVISED NOVEMBER 2014

TPS61160A/61A has built-in slope compensation to avoid sub-harmonic oscillation associated with current mode

control. If the inductor value is lower than 10 μH, the slope compensation may not be adequate, and the loop can

be unstable. Therefore, customers need to verify the inductor in their application if it is different from the

recommended values.

Table 2. Recommended Inductors for TPS61160A/61A

PART NUMBER VENDOR

LQH3NPN100NM0 10 0.3 750 3 × 3 × 1.5 Murata

VLCF5020T-220MR75-1 22 0.4 750 5 × 5 × 2.0 TDK

CDH3809/SLD 10 0.3 570 4 × 4 × 1.0 Sumida

A997AS-220M 22 0.4 510 4 × 4 × 1.8 TOKO

8.2.1.2.3 Schottky Diode Selection

L DCR MAX SATURATION CURRENT SIZE

(μH) (Ω) (mA) (L × W × H mm)

The high switching frequency of the TPS61160A/61A demands a high-speed rectification for optimum efficiency.

Ensure that the diode average and peak current rating exceeds the average output current and peak inductor

current. In addition, the diode’s reverse breakdown voltage must exceed the open LED protection voltage. The

ONSemi MBR0540 and the ZETEX ZHCS400 are recommended for TPS61160A/61A.

8.2.1.2.4 Compensation Capacitor Selection

The compensation capacitor C3 (see Functional Block Diagram), connected from COMP pin to GND, is used to

stabilize the feedback loop of the TPS61160A/61A. Use a 220-nF ceramic capacitor for C3.

8.2.1.2.5 Input and Output Capacitor Selection

The output capacitor is mainly selected to meet the requirements for the output ripple and loop stability. This

ripple voltage is related to the capacitor’s capacitance and its equivalent series resistance (ESR). Assuming a

capacitor with zero ESR, the minimum capacitance needed for a given ripple can be calculated by

where

• V

= peak-to-peak output ripple (6)

ripple

The additional output ripple component caused by ESR is calculated using:

(7)

Due to its low ESR, Vripple_ESR can be neglected for ceramic capacitors, but must be considered if tantalum or

electrolytic capacitors are used.

Care must be taken when evaluating a ceramic capacitor’s derating under dc bias, aging and AC signal. For

example, larger form factor capacitors (in 1206 size) have a resonant frequencies in the range of the switching

frequency. So the effective capacitance is significantly lower. The DC bias can also significantly reduce

capacitance. Ceramic capacitors can loss as much as 50% of its capacitance at its rated voltage. Therefore,

leave the margin on the voltage rating to ensure adequate capacitance at the required output voltage.

The capacitor in the range of 1 μF to 4.7 μF is recommended for input side. The output requires a capacitor in

the range of 0.47 μF to 10 μF. The output capacitor affects the loop stability of the boost regulator. If the output

capacitor is below the range, the boost regulator can potentially become unstable. For example, if use the output

capacitor of 0.1 μF, a 470 nF compensation capacitor has to be used for the loop stable.

The popular vendors for high value ceramic capacitors are:

TDK (http://www.component.tdk.com/components.php)

Murata (http://www.murata.com/cap/index.html)

Copyright © 2009–2014, Texas Instruments Incorporated Submit Documentation Feedback 13

Product Folder Links: TPS61160A TPS61161A

Page 14

L1

10 Hm

C1

D1

Rset

10 W

VIN SW

FB

GND

CTRL

COMP

C2

220nF

TPS61160A

ON/OFF

DIMMING

CONTROL

R1

100Ω

R

FLTR

C

FLTR

C3

L1:

C1: Murata GRM188R61A105K

C2: Murata GRM188R61E474K

D1:

Murata LQH3NPN100NM0

ONsemi MBR0540T1

D2: ONsemi MMSZ4711

D2

R2

0

10

20

30

40

50

60

70

80

90

100

0 10 20 30 40 50 60 70 80 90 100

EFFICIENCY (%)

DIMMING DUTY CYCLE (%)

VIN = 3.0 V

VIN = 3.6 V

VIN = 4.2 V

VIN = 5.0 V

C002

TPS61160A,TPS61161A

SLVS937B –MARCH 2009–REVISED NOVEMBER 2014

8.2.1.3 Application Curves

www.ti.com

8.2.2 Li-Ion Driver for 6 White LEDs

8.2.2.1 Design Requirements

14 Submit Documentation Feedback Copyright © 2009–2014, Texas Instruments Incorporated

Figure 13. Efficiency vs Dimming Duty Cycle

Figure 14. Start-Up with 10 Series LEDs (DPWM = 100%)

Figure 15. Li-Ion Driver for 6 White LEDs With External PWM Dimming Network

DESIGN PARAMETER EXAMPLE VALUE

Inductor 22 µH

Minimum input voltage 3 V

Number of series LED 6

LED maximum forward voltage (Vf) 3.2 V

Schottky diode forward voltage (Vf) 0.2 V

Switching frequency (fSW) 600 kHz

External PWM output voltage 3 V

External PWM frequency 20 kHz

Efficiency 82%

Product Folder Links: TPS61160A TPS61161A

Page 15

FLTR

FLTR 1 RC

1

C =

2 (R // R ) fp

RC

r

0.35

=

t

f

FLTR

pwm

FLTR 1

1

C =

2 (R // R )

10

f

p

2 L ED(ma x) PWM(max) F B LED (min) PW M(min) FB PWM (max) PWM(min)

1 FLTR

FB LED (max ) LED(min) LED(max) LED(m in)

R (I (V V ) I (V V )) V V

R + R = +

V (I I ) I I

- - - -

- -

( )

FB PW M(m ax) PWM(m in)

SET

P WM(max) LE D(max ) FB LED (max) F B LED(min) PWM(m in) LED(min )

V V V

R =

V I V I + V I V I

-

-

PWM(max) (max) PWM(H ) (max) PWM(L)

V = D V + (1 D )V-

PWM(min) (min) P WM(H) (min) PWM(L)

V = D V + (1 D )V-

FLTR

)L(PW M)H(P W M

FLTR

FB

FB

RR

V)D(VD

R//)RR(

V

I

error%

+

-+´

-

+

=

121

1

www.ti.com

TPS61160A,TPS61161A

SLVS937B –MARCH 2009–REVISED NOVEMBER 2014

Applying Equation 3 and Equation 4, when VINis 3 V, 6 LEDs output equivalent to V

of 19.4 V, the inductor is

OUT

22 μH, the Schottky forward voltage is 0.2 V, the maximum output current is 76 mA in typical condition.

8.2.2.2 Detailed Design Procedure

8.2.2.2.1 Choosing Component Values

As per SLVA471, the values of R

FLTR

, C

, R1, R2, and R

FLTR

are determined by the system parameters and

SET

error tolerance. The main source of LED current error is leakage current from the FB pin. The error gets worse

as the LED current decreases. The error due to leakage current is given by Functional Block Diagram, where the

impedance seen by the FB pin has a major impact. To reduce error due to the leakage current, the impedance

seen by the FB pin needs to be small. Because R2is much smaller than R1+ R

, R2must be chosen to be

FLTR

small to minimize the impedance seen by the FB pin. In general, R2must be chosen to be 1 kΩ or less. If greater

accuracy at smaller currents is needed, then R2must be chosen to be even smaller.

(8)

Once R2has been chosen, the value of R

Equation 11, and Equation 12. The individual values of R1and R

+ R

. In general, choosing R1and R

FLTR

FLTR

and R1+ R

SET

can be calculated using Equation 9, Equation 10,

FLTR

can be any combination that sums up to R

FLTR

to be the same value gives a minimum requirement for C

FLTR

.

(9)

(10)

1

(11)

(12)

Finally, C

is popular in many lighting products. At a minimum, C

can be chosen based on the amount of filtering desired or to provide a gradual dimming effect that

FLTR

must be chosen to provide at least 20 dB of

FLTR

attenuation at the PWM frequency. Equation 13 can be used to calculate the minimum capacitor value to provide

this attenuation.

(13)

To provide gradual dimming, a large capacitor must be chosen to provide a long transient time when changing

the PWM duty cycle. Equation 14 shows how to calculate the recommended corner frequency of the RC filter

based on the 10% to 90% rise time. Once the corner frequency is known, it can be used to calculate the required

capacitor using Equation 15.

(14)

(15)

For example, a design with R

and R1equal to 10 kΩ and a desired rise time of 500 ms requires a corner

FLTR

frequency of 0.7 Hz and a capacitor of 47 μF.

Copyright © 2009–2014, Texas Instruments Incorporated Submit Documentation Feedback 15

Product Folder Links: TPS61160A TPS61161A

Page 16

0

10

20

30

40

50

60

70

80

90

100

0 10 20 30 40 50 60 70 80 90 100

EFFICIENCY (%)

DIMMING DUTY CYCLE (%)

VIN = 3.0 V

VIN = 3.6 V

VIN = 4.2 V

VIN = 5.0 V

C002

TPS61160A,TPS61161A

SLVS937B –MARCH 2009–REVISED NOVEMBER 2014

8.2.2.3 Application Curves

www.ti.com

Figure 16. Efficiency vs Dimming Duty Cycle

Figure 18. Start-Up with 6 Series LEDs (External PWM,

DPWM = 50%)

Figure 17. Start-Up with 6 series LEDs (External PWM,

DPWM = 10%)

Figure 19. Start-Up with 6 Series LEDs (External PWM,

DPWM = 100%)

16 Submit Documentation Feedback Copyright © 2009–2014, Texas Instruments Incorporated

Product Folder Links: TPS61160A TPS61161A

Page 17

0

10

20

30

40

50

60

70

80

90

100

0 10 20 30 40 50 60 70 80 90 100

EFFICIENCY (%)

DIMMING DUTY CYCLE (%)

VIN = 3.0 V

VIN = 3.6 V

VIN = 4.2 V

VIN = 5.0 V

C002

Vin 3 V to 5 V

L1

10 Hm

C1

1 Fm

D1

Rset

10 W

VIN SW

FB

GND

CTRL

COMP

C2

0.47 Fm

20mA

C3

220 nF

TPS61160A

ON/ OFF

DIMMING

CONTROL

L1:

C1: Murata GRM188R61A105K

C2: Murata GRM188R61E474K

D1:

Murata LQH3NPN100NM0

ONsemi MBR0540T1

www.ti.com

SLVS937B –MARCH 2009–REVISED NOVEMBER 2014

8.2.3 Li-Ion Driver for 6 White LEDs With External PWM Dimming Network

Figure 20. Li-Ion Driver for 6 White LEDs

8.2.3.1 Design Requirements

DESIGN PARAMETER EXAMPLE VALUE

Inductor 22 µH

Minimum input voltage 3 V

Number of series LED 6

LED maximum forward voltage (Vf) 3.2 V

Schottky diode forward voltage (Vf) 0.2 V

Efficiency (η) 82%

Switching frequency 600 kHz

TPS61160A,TPS61161A

Applying Equation 3 and Equation 4, when VINis 3 V, 6 LEDs output equivalent to V

of 19.4 V, the inductor is

OUT

22 μH, the Schottky forward voltage is 0.2 V, the maximum output current is 76 mA in typical condition.

8.2.3.2 Detailed Design Procedure

See Detailed Design Procedure.

8.2.3.3 Application Curves

Copyright © 2009–2014, Texas Instruments Incorporated Submit Documentation Feedback 17

Figure 21. Efficiency vs Duty Cycle

Figure 22. Start-Up with 6 Series LEDs (DPWM = 50%)

Product Folder Links: TPS61160A TPS61161A

Page 18

Vin 3 V to 5 V

L1

22 Hm

D1

Rset

10 W

VIN SW

FB

GND

CTRL

COMP

C2

20mA

C3

220 nF

TPS61161A

ON/OFF

DIMMING

CONTROL

C1

L1: TDK VLCF5020T-220MR75-1

C1: Murata GRM188R61A105K

C2: Murata GRM21BR71H105K

D1: ONsemi MBR0540T1

TPS61160A,TPS61161A

SLVS937B –MARCH 2009–REVISED NOVEMBER 2014

Figure 23. Start-Up with 6 Series LEDs (DPWM = 100%)

www.ti.com

8.2.4 Li-Ion Driver for 8 White LEDs

Figure 24. Li-Ion Driver for 8 White LEDs

18 Submit Documentation Feedback Copyright © 2009–2014, Texas Instruments Incorporated

Product Folder Links: TPS61160A TPS61161A

Page 19

0

10

20

30

40

50

60

70

80

90

100

0 10 20 30 40 50 60 70 80 90 100

EFFICIENCY (%)

DIMMING DUTY CYCLE (%)

VIN = 3.0 V

VIN = 3.6 V

VIN = 4.2 V

VIN = 5.0 V

C002

www.ti.com

8.2.4.1 Design Requirements

DESIGN PARAMETER EXAMPLE VALUE

LED current 0.02 A

Minimum input voltage 3 V

Number of series LED 8

LED maximum forward voltage (Vf) 3.3 V

Schottky diode forward voltage 0.2 V

Efficiency (η) 86%

Switching frequency 600 kHz

TPS61160A,TPS61161A

SLVS937B –MARCH 2009–REVISED NOVEMBER 2014

Applying Equation 3 and Equation 4, when VINis 3 V, 8 LEDs output equivalent to V

of 25.8 V, the inductor is

OUT

22 μH, the Schottky forward voltage is 0.2 V, the maximum output current is 60 mA in typical condition.

8.2.4.2 Detailed Design Procedure

See Detailed Design Procedure.

8.2.4.3 Application Curves

Figure 25. Efficiency vs. Dimming Duty Cycle

Figure 26. Start-Up with 8 Series LEDs (DPWM = 100%)

9 Power Supply Recommendations

The TPS61160A/61A is designed to operate from an input supply range of 2.7 V to 18 V. This input supply

should be well regulated and provide the peak current required by the number of series LEDs and inductor

selected.

Copyright © 2009–2014, Texas Instruments Incorporated Submit Documentation Feedback 19

Product Folder Links: TPS61160A TPS61161A

Page 20

A

D(max)

JA

125 C-T

R

T

q

CTRL

GND

C3

L1

Rset

Vin

CTRL

SW

FB

COMP

GND

C1 Vin

C2

LEDs IN

LEDs Out

Minimize the

area of this

trace

Place enough

VIAs around

thermal pad to

enhance thermal

performance

TPS61160A,TPS61161A

SLVS937B –MARCH 2009–REVISED NOVEMBER 2014

www.ti.com

10 Layout

10.1 Layout Guidelines

As for all switching power supplies, especially those high frequency and high current ones, layout is an important

design step. If layout is not carefully done, the regulator could suffer from instability as well as noise problems.

To reduce switching losses, the SW pin rise and fall times are made as short as possible. To prevent radiation of

high frequency resonance problems, proper layout of the high frequency switching path is essential. Minimize the

length and area of all traces connected to the SW pin and always use a ground plane under the switching

regulator to minimize inter-plane coupling. The loop including the PWM switch, Schottky diode, and output

capacitor, contains high current rising and falling in nanosecond and should be kept as short as possible. The

input capacitor needs not only to be close to the VIN pin, but also to the GND pin in order to reduce the IC

supply ripple. Figure 27 shows a sample layout.

10.2 Layout Example

Figure 27. Sample Layout

10.3 Thermal Considerations

The maximum IC junction temperature should be restricted to 125°C under normal operating conditions. This

restriction limits the power dissipation of the TPS61160A/61A. Calculate the maximum allowable dissipation,

P

, and keep the actual dissipation less than or equal to P

D(max)

determined using Equation 16:

where

• TAis the maximum ambient temperature for the application.

• R

The TPS61160A/61A comes in a thermally enhanced QFN package. This package includes a thermal pad that

improves the thermal capabilities of the package. The R

layout and thermal pad connection. The thermal pad must be soldered to the analog ground on the PCB. Using

thermal vias underneath the thermal pad as illustrated in the layout example. Also see the QFN/SON PCB

Attachment application report (SLUA271).

20 Submit Documentation Feedback Copyright © 2009–2014, Texas Instruments Incorporated

is the thermal resistance junction-to-ambient given in Dissipation Ratings . (16)

θJA

Product Folder Links: TPS61160A TPS61161A

of the QFN package greatly depends on the PCB

θJA

. The maximum-power-dissipation limit is

D(max)

Page 21

TPS61160A,TPS61161A

www.ti.com

SLVS937B –MARCH 2009–REVISED NOVEMBER 2014

11 Device and Documentation Support

11.1 Device Support

11.1.1 Third-Party Products Disclaimer

TI'S PUBLICATION OF INFORMATION REGARDING THIRD-PARTY PRODUCTS OR SERVICES DOES NOT

CONSTITUTE AN ENDORSEMENT REGARDING THE SUITABILITY OF SUCH PRODUCTS OR SERVICES

OR A WARRANTY, REPRESENTATION OR ENDORSEMENT OF SUCH PRODUCTS OR SERVICES, EITHER

ALONE OR IN COMBINATION WITH ANY TI PRODUCT OR SERVICE.

11.2 Documentation Support

11.2.1 Related Documentation

For related documentation, see the following application reports:

QFN/SON PCB Attachment (SLUA271).

How to Use Analog Dimming With the TPS6116x (SLVA471).

Design Tool for Analog Dimming Using a PWM Signal (http://www.ti.com/lit/zip/slvc366).

11.3 Related Links

Table 3 below lists quick access links. Categories include technical documents, support and community

resources, tools and software, and quick access to sample or buy.

Table 3. Related Links

PARTS PRODUCT FOLDER SAMPLE & BUY

TPS61160A Click here Click here Click here Click here Click here

TPS61161A Click here Click here Click here Click here Click here

TECHNICAL TOOLS & SUPPORT &

DOCUMENTS SOFTWARE COMMUNITY

11.4 Trademarks

All trademarks are the property of their respective owners.

11.5 Electrostatic Discharge Caution

These devices have limited built-in ESD protection. The leads should be shorted together or the device placed in conductive foam

during storage or handling to prevent electrostatic damage to the MOS gates.

11.6 Glossary

SLYZ022 — TI Glossary.

This glossary lists and explains terms, acronyms, and definitions.

12 Mechanical, Packaging, and Orderable Information

The following pages include mechanical, packaging, and orderable information. This information is the most

current data available for the designated devices. This data is subject to change without notice and revision of

this document. For browser-based versions of this data sheet, refer to the left-hand navigation.

Copyright © 2009–2014, Texas Instruments Incorporated Submit Documentation Feedback 21

Product Folder Links: TPS61160A TPS61161A

Page 22

PACKAGE OPTION ADDENDUM

www.ti.com

PACKAGING INFORMATION

Orderable Device Status

TPS61160ADRVR ACTIVE WSON DRV 6 3000 Green (RoHS

TPS61160ADRVT ACTIVE WSON DRV 6 250 Green (RoHS

TPS61161ADRVR ACTIVE WSON DRV 6 3000 Green (RoHS

TPS61161ADRVT ACTIVE WSON DRV 6 250 Green (RoHS

(1)

The marketing status values are defined as follows:

ACTIVE: Product device recommended for new designs.

LIFEBUY: TI has announced that the device will be discontinued, and a lifetime-buy period is in effect.

NRND: Not recommended for new designs. Device is in production to support existing customers, but TI does not recommend using this part in a new design.

PREVIEW: Device has been announced but is not in production. Samples may or may not be available.

OBSOLETE: TI has discontinued the production of the device.

Package Type Package

(1)

Drawing

Pins Package

Qty

Eco Plan

(2)

& no Sb/Br)

& no Sb/Br)

& no Sb/Br)

& no Sb/Br)

Lead/Ball Finish

(6)

CU NIPDAU Level-2-260C-1 YEAR -40 to 85 OBV

CU NIPDAU Level-2-260C-1 YEAR -40 to 85 OBV

CU NIPDAU Level-2-260C-1 YEAR -40 to 85 OBT

CU NIPDAU Level-2-260C-1 YEAR -40 to 85 OBT

MSL Peak Temp

(3)

Op Temp (°C) Device Marking

(4/5)

(2)

Eco Plan - The planned eco-friendly classification: Pb-Free (RoHS), Pb-Free (RoHS Exempt), or Green (RoHS & no Sb/Br) - please check http://www.ti.com/productcontent for the latest availability

information and additional product content details.

TBD: The Pb-Free/Green conversion plan has not been defined.

Pb-Free (RoHS): TI's terms "Lead-Free" or "Pb-Free" mean semiconductor products that are compatible with the current RoHS requirements for all 6 substances, including the requirement that

lead not exceed 0.1% by weight in homogeneous materials. Where designed to be soldered at high temperatures, TI Pb-Free products are suitable for use in specified lead-free processes.

Pb-Free (RoHS Exempt): This component has a RoHS exemption for either 1) lead-based flip-chip solder bumps used between the die and package, or 2) lead-based die adhesive used between

the die and leadframe. The component is otherwise considered Pb-Free (RoHS compatible) as defined above.

Green (RoHS & no Sb/Br): TI defines "Green" to mean Pb-Free (RoHS compatible), and free of Bromine (Br) and Antimony (Sb) based flame retardants (Br or Sb do not exceed 0.1% by weight

in homogeneous material)

(3)

MSL, Peak Temp. - The Moisture Sensitivity Level rating according to the JEDEC industry standard classifications, and peak solder temperature.

(4)

There may be additional marking, which relates to the logo, the lot trace code information, or the environmental category on the device.

(5)

Multiple Device Markings will be inside parentheses. Only one Device Marking contained in parentheses and separated by a "~" will appear on a device. If a line is indented then it is a continuation

of the previous line and the two combined represent the entire Device Marking for that device.

(6)

Lead/Ball Finish - Orderable Devices may have multiple material finish options. Finish options are separated by a vertical ruled line. Lead/Ball Finish values may wrap to two lines if the finish

value exceeds the maximum column width.

2-Jun-2016

Samples

Addendum-Page 1

Page 23

PACKAGE OPTION ADDENDUM

www.ti.com

Important Information and Disclaimer:The information provided on this page represents TI's knowledge and belief as of the date that it is provided. TI bases its knowledge and belief on information

provided by third parties, and makes no representation or warranty as to the accuracy of such information. Efforts are underway to better integrate information from third parties. TI has taken and

continues to take reasonable steps to provide representative and accurate information but may not have conducted destructive testing or chemical analysis on incoming materials and chemicals.

TI and TI suppliers consider certain information to be proprietary, and thus CAS numbers and other limited information may not be available for release.

In no event shall TI's liability arising out of such information exceed the total purchase price of the TI part(s) at issue in this document sold by TI to Customer on an annual basis.

2-Jun-2016

Addendum-Page 2

Page 24

PACKAGE MATERIALS INFORMATION

www.ti.com 2-Jun-2016

TAPE AND REEL INFORMATION

*All dimensions are nominal

Device Package

Type

TPS61160ADRVR WSON DRV 6 3000 180.0 8.4 2.3 2.3 1.15 4.0 8.0 Q2

TPS61160ADRVT WSON DRV 6 250 180.0 8.4 2.3 2.3 1.15 4.0 8.0 Q2

TPS61161ADRVR WSON DRV 6 3000 180.0 8.4 2.3 2.3 1.15 4.0 8.0 Q2

TPS61161ADRVT WSON DRV 6 250 180.0 8.4 2.3 2.3 1.15 4.0 8.0 Q2

TPS61161ADRVT WSON DRV 6 250 179.0 8.4 2.2 2.2 1.2 4.0 8.0 Q2

Package

Drawing

Pins SPQ Reel

Diameter

(mm)

Reel

Width

W1 (mm)

A0

(mm)B0(mm)K0(mm)P1(mm)W(mm)

Pin1

Quadrant

Pack Materials-Page 1

Page 25

PACKAGE MATERIALS INFORMATION

www.ti.com 2-Jun-2016

*All dimensions are nominal

Device Package Type Package Drawing Pins SPQ Length (mm) Width (mm) Height (mm)

TPS61160ADRVR WSON DRV 6 3000 210.0 185.0 35.0

TPS61160ADRVT WSON DRV 6 250 210.0 185.0 35.0

TPS61161ADRVR WSON DRV 6 3000 210.0 185.0 35.0

TPS61161ADRVT WSON DRV 6 250 210.0 185.0 35.0

TPS61161ADRVT WSON DRV 6 250 195.0 200.0 45.0

Pack Materials-Page 2

Page 26

Page 27

Page 28

Page 29

IMPORTANT NOTICE

Texas Instruments Incorporated and its subsidiaries (TI) reserve the right to make corrections, enhancements, improvements and other

changes to its semiconductor products and services per JESD46, latest issue, and to discontinue any product or service per JESD48, latest

issue. Buyers should obtain the latest relevant information before placing orders and should verify that such information is current and

complete. All semiconductor products (also referred to herein as “components”) are sold subject to TI’s terms and conditions of sale

supplied at the time of order acknowledgment.

TI warrants performance of its components to the specifications applicable at the time of sale, in accordance with the warranty in TI’s terms

and conditions of sale of semiconductor products. Testing and other quality control techniques are used to the extent TI deems necessary

to support this warranty. Except where mandated by applicable law, testing of all parameters of each component is not necessarily

performed.

TI assumes no liability for applications assistance or the design of Buyers’ products. Buyers are responsible for their products and

applications using TI components. To minimize the risks associated with Buyers’ products and applications, Buyers should provide

adequate design and operating safeguards.

TI does not warrant or represent that any license, either express or implied, is granted under any patent right, copyright, mask work right, or

other intellectual property right relating to any combination, machine, or process in which TI components or services are used. Information

published by TI regarding third-party products or services does not constitute a license to use such products or services or a warranty or

endorsement thereof. Use of such information may require a license from a third party under the patents or other intellectual property of the

third party, or a license from TI under the patents or other intellectual property of TI.

Reproduction of significant portions of TI information in TI data books or data sheets is permissible only if reproduction is without alteration

and is accompanied by all associated warranties, conditions, limitations, and notices. TI is not responsible or liable for such altered

documentation. Information of third parties may be subject to additional restrictions.

Resale of TI components or services with statements different from or beyond the parameters stated by TI for that component or service

voids all express and any implied warranties for the associated TI component or service and is an unfair and deceptive business practice.

TI is not responsible or liable for any such statements.

Buyer acknowledges and agrees that it is solely responsible for compliance with all legal, regulatory and safety-related requirements

concerning its products, and any use of TI components in its applications, notwithstanding any applications-related information or support

that may be provided by TI. Buyer represents and agrees that it has all the necessary expertise to create and implement safeguards which

anticipate dangerous consequences of failures, monitor failures and their consequences, lessen the likelihood of failures that might cause

harm and take appropriate remedial actions. Buyer will fully indemnify TI and its representatives against any damages arising out of the use

of any TI components in safety-critical applications.

In some cases, TI components may be promoted specifically to facilitate safety-related applications. With such components, TI’s goal is to

help enable customers to design and create their own end-product solutions that meet applicable functional safety standards and

requirements. Nonetheless, such components are subject to these terms.

No TI components are authorized for use in FDA Class III (or similar life-critical medical equipment) unless authorized officers of the parties

have executed a special agreement specifically governing such use.

Only those TI components which TI has specifically designated as military grade or “enhanced plastic” are designed and intended for use in

military/aerospace applications or environments. Buyer acknowledges and agrees that any military or aerospace use of TI components

which have not been so designated is solely at the Buyer's risk, and that Buyer is solely responsible for compliance with all legal and

regulatory requirements in connection with such use.

TI has specifically designated certain components as meeting ISO/TS16949 requirements, mainly for automotive use. In any case of use of

non-designated products, TI will not be responsible for any failure to meet ISO/TS16949.

Products Applications

Audio www.ti.com/audio Automotive and Transportation www.ti.com/automotive

Amplifiers amplifier.ti.com Communications and Telecom www.ti.com/communications

Data Converters dataconverter.ti.com Computers and Peripherals www.ti.com/computers

DLP® Products www.dlp.com Consumer Electronics www.ti.com/consumer-apps

DSP dsp.ti.com Energy and Lighting www.ti.com/energy

Clocks and Timers www.ti.com/clocks Industrial www.ti.com/industrial

Interface interface.ti.com Medical www.ti.com/medical

Logic logic.ti.com Security www.ti.com/security

Power Mgmt power.ti.com Space, Avionics and Defense www.ti.com/space-avionics-defense

Microcontrollers microcontroller.ti.com Video and Imaging www.ti.com/video

RFID www.ti-rfid.com

OMAP Applications Processors www.ti.com/omap TI E2E Community e2e.ti.com

Wireless Connectivity www.ti.com/wirelessconnectivity

Mailing Address: Texas Instruments, Post Office Box 655303, Dallas, Texas 75265

Copyright © 2016, Texas Instruments Incorporated

Page 30

Loading...

Loading...