Page 1

User’s Guide

February 2002

PMP Portable Power

SLVU065

Page 2

IMPORTANT NOTICE

Texas Instruments Incorporated and its subsidiaries (TI) reserve the right to make corrections, modifications,

enhancements, improvements, and other changes to its products and services at any time and to discontinue

any product or service without notice. Customers should obtain the latest relevant information before placing

orders and should verify that such information is current and complete. All products are sold subject to TI’s terms

and conditions of sale supplied at the time of order acknowledgment.

TI warrants performance of its hardware products to the specifications applicable at the time of sale in

accordance with TI’s standard warranty. Testing and other quality control techniques are used to the extent TI

deems necessary to support this warranty . Except where mandated by government requirements, testing of all

parameters of each product is not necessarily performed.

TI assumes no liability for applications assistance or customer product design. Customers are responsible for

their products and applications using TI components. To minimize the risks associated with customer products

and applications, customers should provide adequate design and operating safeguards.

TI does not warrant or represent that any license, either express or implied, is granted under any TI patent right,

copyright, mask work right, or other TI intellectual property right relating to any combination, machine, or process

in which TI products or services are used. Information published by TI regarding third−party products or services

does not constitute a license from TI to use such products or services or a warranty or endorsement thereof.

Use of such information may require a license from a third party under the patents or other intellectual property

of the third party, or a license from TI under the patents or other intellectual property of TI.

Reproduction of information in TI data books or data sheets is permissible only if reproduction is without

alteration and is accompanied by all associated warranties, conditions, limitations, and notices. Reproduction

of this information with alteration is an unfair and deceptive business practice. TI is not responsible or liable for

such altered documentation.

Resale of TI products or services with statements different from or beyond the parameters stated by TI for that

product or service voids all express and any implied warranties for the associated TI product or service and

is an unfair and deceptive business practice. TI is not responsible or liable for any such statements.

Mailing Address:

Texas Instruments

Post Office Box 655303

Dallas, Texas 75265

Copyright 2002, Texas Instruments Incorporated

Page 3

EVM IMPORTANT NOTICE

Texas Instruments (TI) provides the enclosed product(s) under the following conditions:

This evaluation kit being sold by TI is intended for use for ENGINEERING DEVELOPMENT OR EVALUATION

PURPOSES ONLY and is not considered by TI to be fit for commercial use. As such, the goods being provided

may not be complete in terms of required design-, marketing-, and/or manufacturing-related protective

considerations, including product safety measures typically found in the end product incorporating the goods.

As a prototype, this product does not fall within the scope of the European Union directive on electromagnetic

compatibility and therefore may not meet the technical requirements of the directive.

Should this evaluation kit not meet the specifications indicated in the EVM User’s Guide, the kit may be returned

within 30 days from the date of delivery for a full refund. THE FOREGOING WARRANTY IS THE EXCLUSIVE

WARRANTY MADE BY SELLER TO BUYER AND IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESSED,

IMPLIED, OR S TATUTORY, INCLUDING ANY WARRANTY OF MERCHANTABILITY OR FITNESS FOR ANY

PARTICULAR PURPOSE.

The user assumes all responsibility and liability for proper and safe handling of the goods. Further, the user

indemnifies TI from all claims arising from the handling or use of the goods. Please be aware that the products

received may not be regulatory compliant or agency certified (FCC, UL, CE, etc.). Due to the open construction

of the product, it is the user’s responsibility to take any and all appropriate precautions with regard to electrostatic

discharge.

EXCEPT TO THE EXTENT OF THE INDEMNITY SET FORTH ABOVE, NEITHER PARTY SHALL BE LIABLE

TO THE OTHER FOR ANY INDIRECT, SPECIAL, INCIDENTAL, OR CONSEQUENTIAL DAMAGES.

TI currently deals with a variety of customers for products, and therefore our arrangement with the user is not

exclusive.

TI assumes no liability for applications assistance, customer product design, software performance, or

infringement of patents or services described herein.

Please read the EVM User’s Guide and, specifically, the EVM Warnings and Restrictions notice in the EVM

User’s Guide prior to handling the product. This notice contains important safety information about temperatures

and voltages. For further safety concerns, please contact the TI application engineer.

Persons handling the product must have electronics training and observe good laboratory practice standards.

No license is granted under any patent right or other intellectual property right of TI covering or relating to any

machine, process, or combination in which such TI products or services might be or are used.

Mailing Address:

Texas Instruments

Post Office Box 655303

Dallas, Texas 75265

Copyright 2002, Texas Instruments Incorporated

Page 4

EVM WARNINGS AND RESTRICTIONS

It is important to operate this EVM within the supply voltage range of 1.8 V to 6 V.

Exceeding the specified supply range may cause unexpected operation and/or irreversible

damage to the EVM. If there are questions concerning the supply range, please contact a TI

field representative prior to connecting the input power.

Applying loads outside of the specified output range may result in unintended operation and/or

possible permanent damage to the EVM. Please consult the EVM User’s Guide prior to

connecting any load to the EVM output. If there is uncertainty as to the load specification,

please contact a TI field representative.

During normal operation, some circuit components may have case temperatures greater than

125°C. The EVM is designed to operate properly with certain components above 125°C as

long as the input and output ranges are maintained. These components include but are not

limited to linear regulators, switching transistors, pass transistors, and current sense

resistors. These types of devices can be identified using the EVM schematic located in the

EVM User’s Guide. When placing measurement probes near these devices during operation,

please be aware that these devices may be very warm to the touch.

Mailing Address:

Texas Instruments

Post Office Box 655303

Dallas, Texas 75265

Copyright 2002, Texas Instruments Incorporated

Page 5

About This Manual

This users guide describes the characteristics, operation, and use of the

TPS61040EVM LCD bias supply evaluation module (EVM). This EVM is a

Texas Instruments high-efficiency boost converter that is configured to

generate 18 V at 2 0 mA, for LCD bias supply, from a single cell Li−Ion battery.

The users guide includes a schematic diagram, bill of materials (BOM), and

test data.

How to Use This Manual

This document contains the following chapters:

- Chapter 1—Introduction

- Chapter 2—Setup and Test Results

- Chapter 3—Board Layout

- Chapter 4—Schematic and Bill of Materials

Related Documentation From Texas Instruments

- TPS601040/41 data sheet (literature number SLVS413).

FCC Warning

This equipment is intended for use in a laboratory test environment only. It

generates, uses, and can radiate radio frequency energy and has not been

tested for compliance with the limits of computing devices pursuant to subpart

J of part 15 of FCC rules, which are designed to provide reasonable protection

against radio frequency interference. Operation of this equipment in other

environments may cause interference with radio communications, in which

case the user at his own expense will be required to take whatever measures

may be required to correct this interference.

Read This First

v

Page 6

vi

Page 7

Running Title—Attribute Reference

1 Introduction 1-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1 Background 1-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2 Performance Specification Summary 1-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 Setup and Test Results 2-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1 Input/Output Connections 2-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2 EVM Operation 2-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3 Start-Up 2-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4 Output Voltage Ripple 2-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.5 Switching Waveforms 2-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.6 Input Voltage Ripple 2-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.7 Efficiency 2-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.8 Output Adjust 2-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.8.1 Variable Resistor Output Voltage Adjust 2-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.8.2 Variable Control Voltage Output Voltage Adjust 2-6. . . . . . . . . . . . . . . . . . . . . . . . . .

3 Board Layout 3-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1 Layout 3-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4 Schematic and Bill of Materials 4-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1 Schematic 4-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2 Bill of Materials 4-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2−1 Start-Up Waveforms 2-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2−2 Output Ripple 2-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2−3 SW Waveform 2-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2−4 Input Ripple Voltage 2-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2−5 Typical Efficiency 2-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3−1 Assembly Layer 3-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3−2 Top Layer Routing 3-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3−3 Bottom Layer Routing 3-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4−1 TPS61040EVM−001 Schematic 4-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Contents

vii

Page 8

Running Title—Attribute Reference

1−1 TPS61040 Performance Specification Summary 1-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2−1 Input/Output Connections 2-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4−1 TPS61040EVM−001 Bill of Materials 4-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

viii

Page 9

Chapter 1

This chapter contains background information for the TPS61040 and support

documentation for the TPS61040EVM−001 evaluation module.

Topic Page

1.1 Background 1-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2 Performance Specification Summary 1-2. . . . . . . . . . . . . . . . . . . . . . . . . . .

Introduction

1-1

Page 10

Background

1.1 Background

This TPS61040EVM uses the TPS61040 boost converter to generate an 18-V

output from a single cell Li-Ion battery (3 V to 4.2 V). This EVM operates over

an input voltage range of 1.8 V to 6 V, but has been optimized over the 3-V to

5-V input range. Operation with an input voltage down to 1.8 V is possible,

depending on the output current and voltage settings. The EVM includes an

adjust pin that allows the user to adjust the LCD bias with either a variable

resistance or an analog voltage.

The output voltage of the TPS61040EVM can be adjusted up to 28 V by

modifying the resistor values used in resistor divider R1 & R2. The EVM can

also be configured for higher or lower output currents. For lower currents, the

TPS61040 may be replaced by the pin for pin compatible TPS61041. More

information about output voltage adjustment and current ratings of

TPS61040/41 devices can be found in the data sheet Literature Number

SLVS413.

1.2 Performance Specification Summary

Table 1−1 provides a summary of the TPS61040EVM−001 performance

specifications. All specifications are given for an ambient temperature of 25°C.

The EVM may be modified to operate over different input and output currents

and voltages, per the TPS61040 data sheet specifications.

Table 1−1.TPS61040 Performance Specification Summary

Specification Test Conditions Min Typ Max Unit

Input voltage range IO = 20 mA 3 5 V

Output voltage 18 V

Output current 5 20 mA

Output voltage ripple 100 mV

Efficiency 88.5%

1-2

Introduction

Page 11

Chapter 2

This chapter describes how to properly connect, setup, and use the

TPS61040EVM−001. This chapter also presents the test results for this EVM.

Topic Page

2.1 Input/Output Connections 2-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2 EVM Operation 2-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3 Start-Up 2-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4 Output Voltage Ripple 2-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.5 Switching Waveforms 2-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.6 Input Voltage Ripple 2-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.7 Efficiency 2-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.8 Output Adjust 2-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setup and Test Results

2-1

Page 12

Input/Output Connections

2.1 Input/Output Connections

The TPS61040EVM−001 PWB has several connections, which are described

in Table 2−1.

Table 2−1.Input/Output Connections

Reference

Designator

J1 Vin

J2 GND This is the return connection to the input power supply.

J3 Adjust

J4 GND This is the return pin for the load.

J5 Vout This is the positive connection for the load.

JP1 Enable

Name Description

This is the positive connection to the input power supply. The leads to the input

supply should be twisted and kept as short as possible.

A variable resistor may be connected between J3−1 and J3−2 to vary the output

voltage of the EVM. J3−1 has a square pad and is connected directly to the FB pin

of the TPS61040. J3−2 has a round pad and is connected directly to ground. The

output voltage may also be adjusted by connecting an analog voltage through a

resistor to J3−1.

Use this connector to enable and disable the power supply. Connect a jumper

between the ON pin and the center pin to enable the supply, and connect a jumper

between the Off pin and the center pin to disable the supply. When the EN pin of the

TPS61040 is left open, its state is undetermined. The jumper must either be

connected to On (Vin) or to Off (GND) for the EVM to operate correctly.

2.2 EVM Operation

Connect an input supply and a load to the appropriate connectors provided on

the EVM. The absolute maximum input voltage is 7 V. The TPS61040 is

designed to operate with a maximum 6-V input voltage. Move the adjust

jumper from the Off position to the On position to enable the supply.

Placing a variable resistor across the adjust pins of the EVM allows the user

to vary the output voltage. Specific design equations may be found in the

TPS61040 data sheet.

2.3 Start-Up

Figure 2−1 shows the startup voltage and current waveforms of the EVM.

When the EVM is enabled, the TPS61040 goes through its programmed

three-stage soft-start sequence to reduce inrush current at turn on.

2-2

Setup and Test Results

Page 13

Figure 2−1.Start-Up Waveforms

2.4 Output Voltage Ripple

Output Voltage Ripple

Figure 2−2 shows the output voltage ripple with IO = 20 mA. The top trace

shows the ripple with 3.6-V input, and the bottom trace shows the ripple with

a 4.2-V input. The difference in switching frequency between the two traces

is expected and is explained in the data sheet.

Figure 2−2.Output Ripple

Setup and Test Results

2-3

Page 14

Switching Waveforms

2.5 Switching Waveforms

Figure 2−3 shows the switching waveform at the SW pin of the TPS61040.

When the internal FET turns on, the voltage at the SW pin is pulled to ground

until the inductor current reaches 450 mA. When the inductor current reaches

450 mA, the FET turns off and the voltage at the SW pin rises to the output

voltage plus the forward voltage drop of the diode. During this time, the

inductor transfers its stored energy to the load and the output capacitor . When

the inductor current decays to zero, the SW node rings at a frequency

determined by the output inductor and the drain capacitance of the internal

FET . This ringing is indicative of a discontinuous boost power supply topology.

Figure 2−3.SW Waveform

2.6 Input Voltage Ripple

Figure 2−4 shows the input voltage and current ripple of the supply with

Vin = 3.6 V and IO = 20 mA. The input capacitance of the TPS61040 and the

impedance of the input voltage supply largely determine the input voltage and

current ripple. Increasing the input capacitance or lowering the source

impedance reduces the input voltage and current ripple.

2-4

Setup and Test Results

Page 15

Figure 2−4.Input Ripple Voltage

2.7 Efficiency

Efficiency

Input Ripple Voltage

Input Ripple Current

Figure 2−5 shows the measured efficiency of the TPS61040.

Figure 2−5.Typical Efficiency

Efficiency − %

90

89

88

87

86

85

84

83

82

81

80

2.5 5 7.5 10 12.5 15 17.5 20

IO − Output Current − mA

VI = 6 V

VI = 4.2 V

VI = 3.6 V

VI = 2.5 V

Setup and Test Results

2-5

Page 16

Output Adjust

3)

R2

1.233 V R1

2.8 Output Adjust

The TPS61040EMV−001 provides two methods of output voltage adjustment

for LCD contrast control. The first method of output voltage adjustment is

accomplished with a variable resistor, while the second method is

accomplished using a variable control voltage.

2.8.1 Variable Resistor Output Voltage Adjust

This method is accomplished by removing R2 on the EVM and then placing

a variable resistor between J3−1 and ground. The equations provided below

calculate the range of the variable resistor where:

- R

(adjust),min

- R

(adjust),max

- R1 = value for R1

- V

O,max

- V

O,min

R

adjust,min

R

adjust,max

For example, if V

R

(adjust),min

implemented using a 154-kΩ resistor in series with a 20-kΩ potentiometer.

+ 1.233 V

+ 1.233 V

= 153.4 kΩ, and R

= minimum value for R2

= maximum value for R2

= maximum desired output voltage

= minimum desired output voltage

R1

ǒ

O,max

V

O,max

ǒ

V

= 19 V, V

* 1.233 V

R1

* 1.233 V

O,min

O,min

(adjust),max

2.8.2 Variable Control Voltage Output Voltage Adjust

This method is accomplished by connecting a variable control voltage through

a resistor, R

R

(adjust)

where:

, to J3−1. The equations provided below calculate R2 and

(adjust)

Ǔ

Ǔ

= 17 V, and R1 = 2.21 MΩ, then

= 172.8 kΩ. This scenario is best

(1)

(2)

+

ƪ

1.233 VǒV

2-6

O,min

* V

O,max

R

adjust

For example, if V

3.3 V, and R1 = 1 MΩ, then R2

V

(adjust)

ǒ

V

adjust,max

) V

adjust,min

+ R2 R1

= 0 V then VO = 19 V. When V

* V

O,max

* V

adjust,min

Ǔ

adjust,max

* V

ǒ

V

adjust,max

ƪ

1.233 V(R2 ) R1)* V

= 19 V, V

O,min

= 72.4 kΩ, and R

Ǔ

adjust,min

= 17 V , V

xV

O,min

* 1.233 V

(adjust)

) V

adjust,max

xV

O,max

Ǔ

ƫ

R2

O,min

(adjust),min

= 3.3 V then VO = 17 V.

= 0 V , V

(adjust)

Setup and Test Results

(adjust),max

= 1.65 MΩ. When

(

ƫ

(4)

=

Page 17

3.1 Layout

Chapter 3

This chapter provides the TPS61040EVM−001 board layout and illustrations.

Topic Page

3.1 Layout 3-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Board layout is critical for all switch mode power supplies. Figures 3−1, 3−2

and 3−3 show the board layout for the TPS61040EVM−001 PWB. The nodes

with high-switching frequency are short and isolated from the noise-sensitive

feedback circuitry. Careful attention has been given to the routing of

high-frequency current loops. Refer to the data sheet for specific layout

guidelines.

Figure 3−1.Assembly Layer

Board Layout

3-1

Page 18

Layout

Figure 3−2.Top Layer Routing

Figure 3−3.Bottom Layer Routing

3-2

Board Layout

Page 19

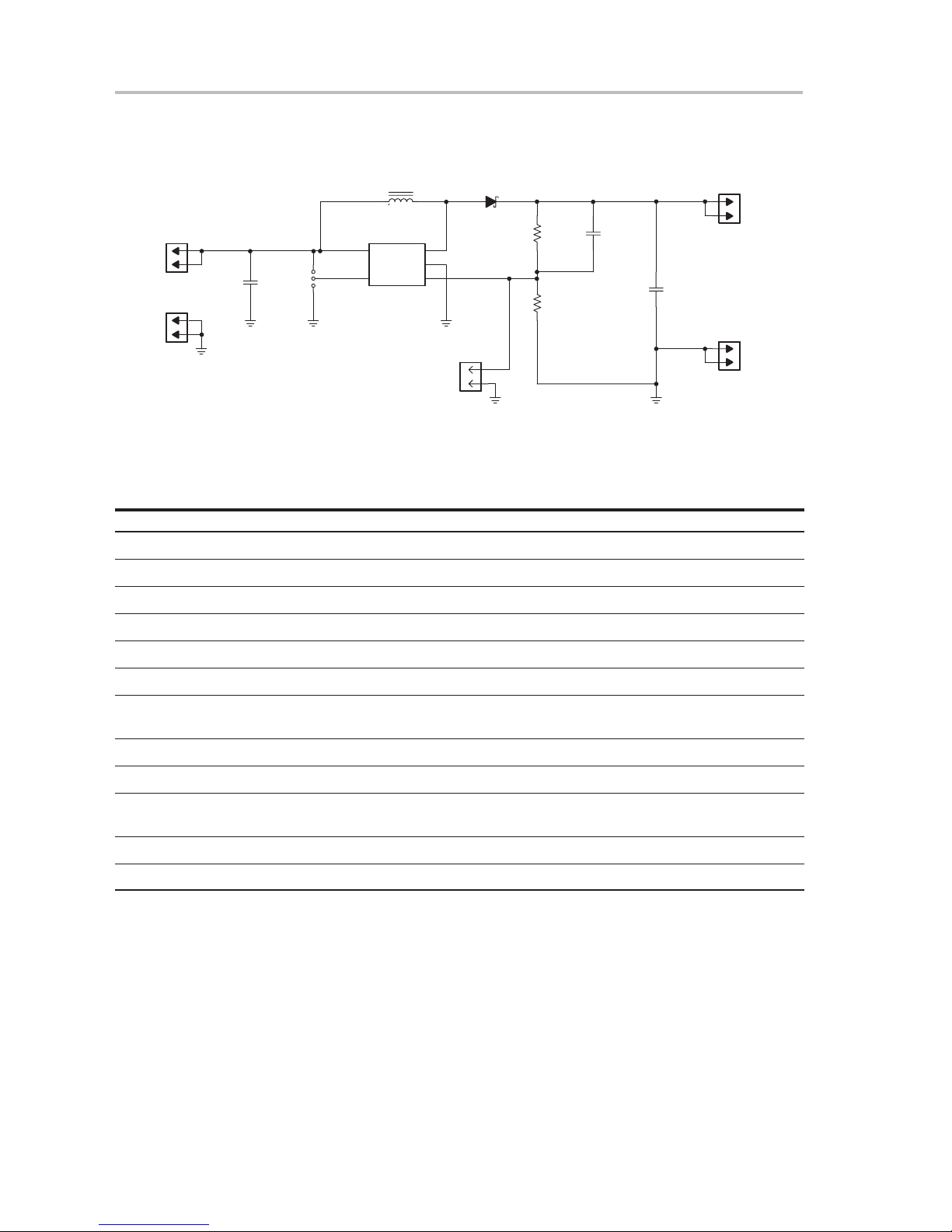

Chapter 4

This chapter provides the TPS61040EVM−001 schematic and bill of materials.

Topic Page

4.1 Schematic 4-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2 Bill of Material 4-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Schematic and Bill of Materials

4-1

Page 20

Schematic

4.1 Schematic

Figure 4−1.TPS61040EVM−001 Schematic

GND

L1

10 µH

U1

1

TPS61040DBV

5

VIN

GND

4

EN

SW

1

2

3

FB

Adjust

J1

1

V

I

2

JP1

C1

J2

1

2

4.7 µF

D1

MBR0530

J3

1

2

R1

2.21 MΩ

R2

162 kΩ

C2

22 pF

C3

1 µF

J5

1

V

O

2

J4

1

GND

2

4.2 Bill of Materials

Table 4−1.TPS61040EVM−001 Bill of Materials

Reference Description Size Qty. MFG Part #

C1 Capacitor, ceramic, 4.7 µF, 6.3 V, X5R, 15% 0805 1 Murata GRM21B60J475KA11

C2 Capacitor, ceramic, 22 pF, 50 V, C0G, 5% 0603 1 Murata GRM1885C1H220JZ01

C3 Capacitor, ceramic, 1 µF, 25 V, X7R, 10% 1206 1 Murata GRM31MR7E105KC01

D1 Diode, Schottky 0.5 A 30 V SOD−123 1 On Semi MBR0530T1

J1 − J5 Header, 2-pin, 100-mil spacing (36-pin strip) 0.1 x 2” 5 Sullins PTC36SAAN

JP1 Header, 3-pin, 100-mil spacing (36-pin strip) 0.1 x 3” 1 Sullins PTC36SAAN

L1 Inductor, SMT, 10 µH, 0.76 A, 0.23 Ω 0.15 x

1 Sumida CR32−100

0.162

R1 Resistor, chip, 2.21 MΩ, 1/16 W, 1% 0603 1 Standard Standard

R2 Resistor, chip, 162 kΩ, 1/16 W, 1% 0603 1 Standard Standard

U1 IC, high efficiency boost converter SOT23−5

1 TI TPS61040DBV

(DBV)

PCB, 1.5’ x 1” x 0.062” 1 Any SLVP209

Shunts, 100-mil, black 0.1 mm 1 3M 929950-00

4-2

Schematic and Bill of Materials

Loading...

Loading...