Datasheet TPS61006DGST, TPS61006DGSR, TPS61006DGS, TPS61005DGST, TPS61002DGS Datasheet (Texas Instruments)

...

TPS61000, TPS61001, TPS61002, TPS61003, TPS61004, TPS61005, TPS61006

SINGLE-CELL BOOST CONVERTER WITH START-UP INTO FULL LOAD

SLVS279A – MARCH 2000 – REVISED MAY 2000

1

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

D

Start Up Into a Full Load With Supply

Voltages as Low as 0.9 V Over Full

T emperature Range

D

Minimum 100-mA Output Current From

0.8 V Supply Voltage

D

High Power Conversion Efficiency,

up to 90%

D

Power-Save Mode for Improved Efficiency

at Low Output Currents

D

Device Quiescent Current Less Than 50 µA

D

Added System Security With Integrated

Low-Battery Comparator

D

Low-EMI Converter (Integrated Antiringing

Switch Across Inductor)

D

Micro-Size 10-Pin MSOP Package

D

Evaluation Modules Available

(TPS6100xEVM–156)

D

Applications Include:

– Single- and Dual-Cell Battery Operated

Products

– MP3-Players and Wireless Headsets

– Pagers and Cordless Phones

– Portable Medical Diagnostic Equipment

– Remote Controls

·

description

The TPS6100x devices are boost converters intended for systems that are typically operated from a single- or

dual-cell nickel-cadmium (NiCd), nickel-metal hydride (NiMH), or alkaline battery . The converter output voltage

can be adjusted from 1.5 V to a maximum of 3.3 V and provides a minimum output current of 100 mA. The

converter starts up into a full load with a supply voltage of 0.9 V and stays in operation with supply voltages as

low as 0.8 V.

The converter is based on a fixed-frequency , current-mode pulse-width-modulation (PWM) controller that goes

into power-save mode at low load currents. The current through the switch is limited to a maximum of 1 100 mA,

depending on the output voltage. The current sense is integrated to further minimize external component count.

The converter can be disabled to minimize battery drain when the system is put into standby.

A low-EMI mode is implemented to reduce interference and radiated electromagnetic energy that is caused by

the ringing of the inductor when the inductor discharge-current decreases to zero. The device is packaged in

the space saving 10-pin MSOP package.

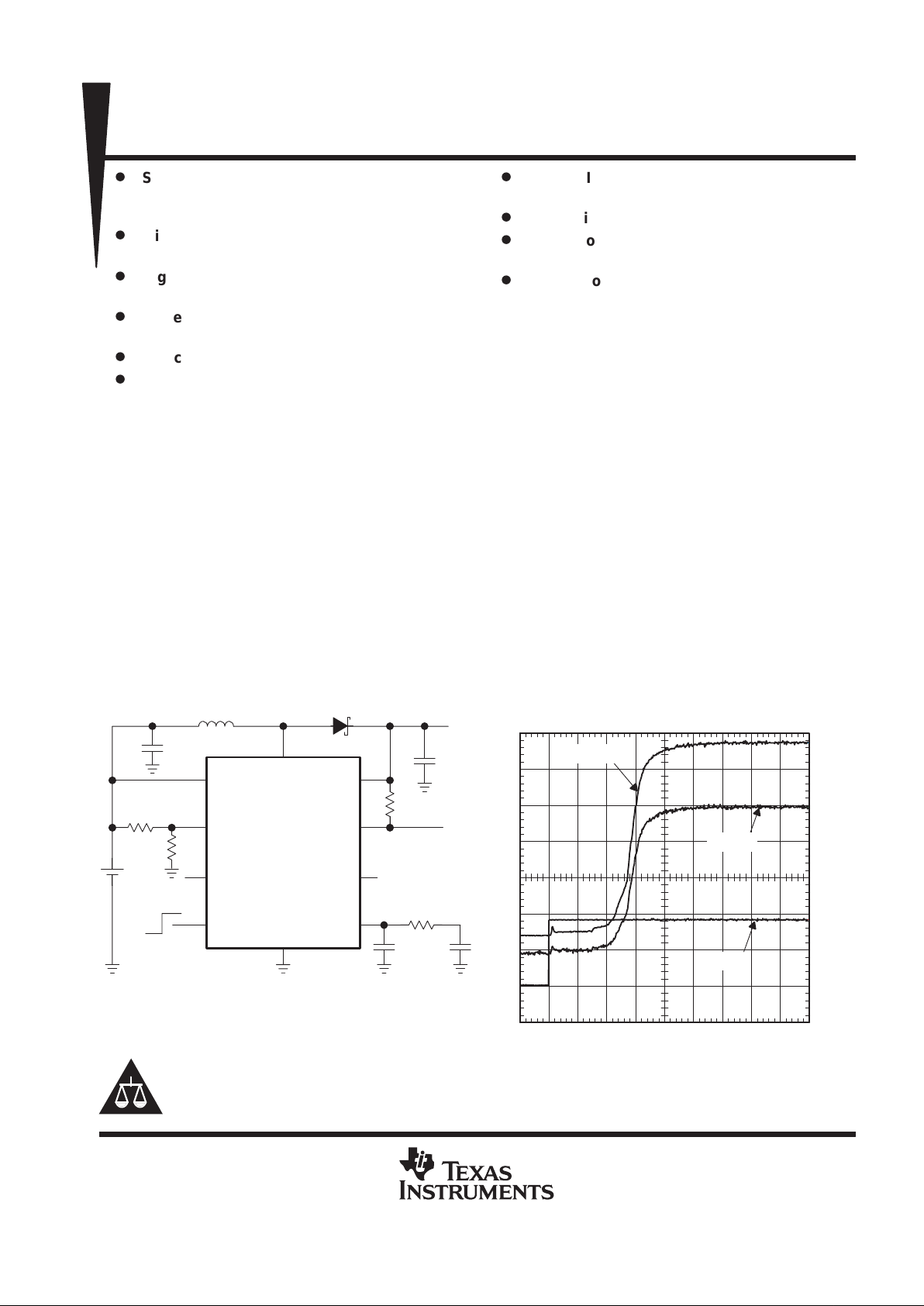

5

6

TPS61006

9

8

1

10

3

2

7

4

SW

V

BAT

LBI

NC

EN

V

OUT

LBO

FB

COMP

GND

Low Battery

Warning

R4

10 kΩ

R3

ON

OFF

R2

R1

C

i

10 µF

L1

D1

VO = 3.3 V

C1

100 pF

C2

33 nF

C

o

22 µF

33 µH

2

024681012

3

TPS61006

START UP TIMING INTO 33 Ω LOAD

14 16 18 20

1

0

– Output Voltage – V

V

O

V

OUT

EN

I

OUT

80

60

20

100

120

140

0

40

– Output Current – mA

I

O

time – ms

TYPICAL APPLICATION CIRCUIT FOR FIXED

OUTPUT VOLTAGE OPTION

Copyright 2000, Texas Instruments Incorporated

Please be aware that an important notice concerning availability, standard warranty, and use in critical applications of

Texas Instruments semiconductor products and disclaimers thereto appears at the end of this data sheet.

PRODUCTION DATA information is current as of publication date.

Products conform to specifications per the terms of Texas Instruments

standard warranty. Production processing does not necessarily include

testing of all parameters.

TPS61000, TPS61001, TPS61002, TPS61003, TPS61004, TPS61005, TPS61006

SINGLE-CELL BOOST CONVERTER WITH START-UP INTO FULL LOAD

SLVS279A – MARCH 2000 – REVISED MAY 2000

2

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

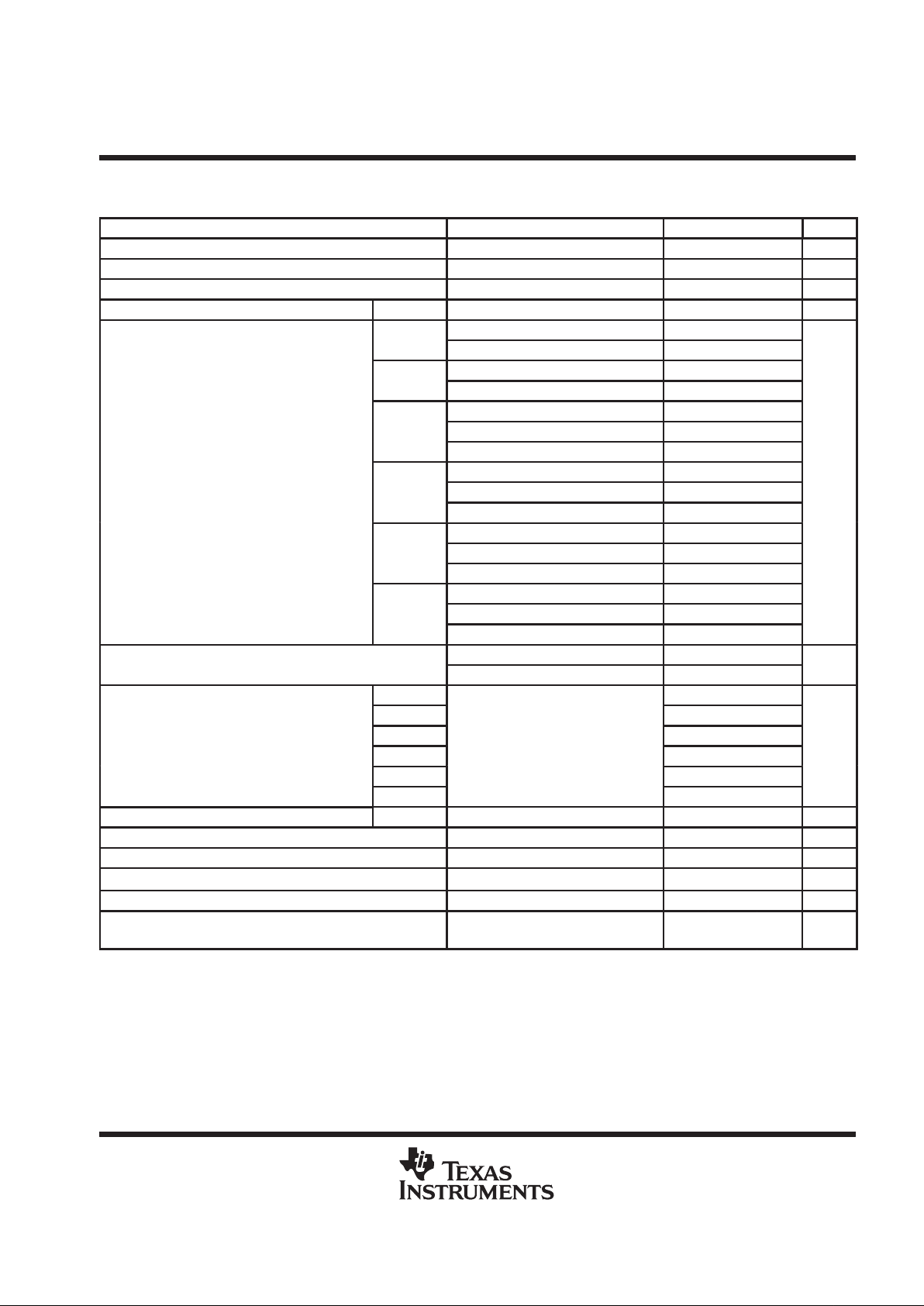

AVAILABLE OPTIONS

T

A

PACKAGE

OUTPUT VOLTAGE

(V)

PART NUMBER

†

MARKING DGS

PACKAGE

Adj. from 1.5 V to 3.3 V TPS61000DGS ADA

1.5 TPS61001DGS ADB

1.8 TPS61002DGS ADC

–40°C to 85°C 10-Pin MSOP DGS 2.5 TPS61003DGS ADD

2.8 TPS61004DGS ADE

3.0 TPS61005DGS ADF

3.3 TPS61006DGS ADG

†

The DGS package is available taped and reeled. Add R suffix to device type (e.g. TPS61000DGSR) to order quantities of

3000 devices per reel.

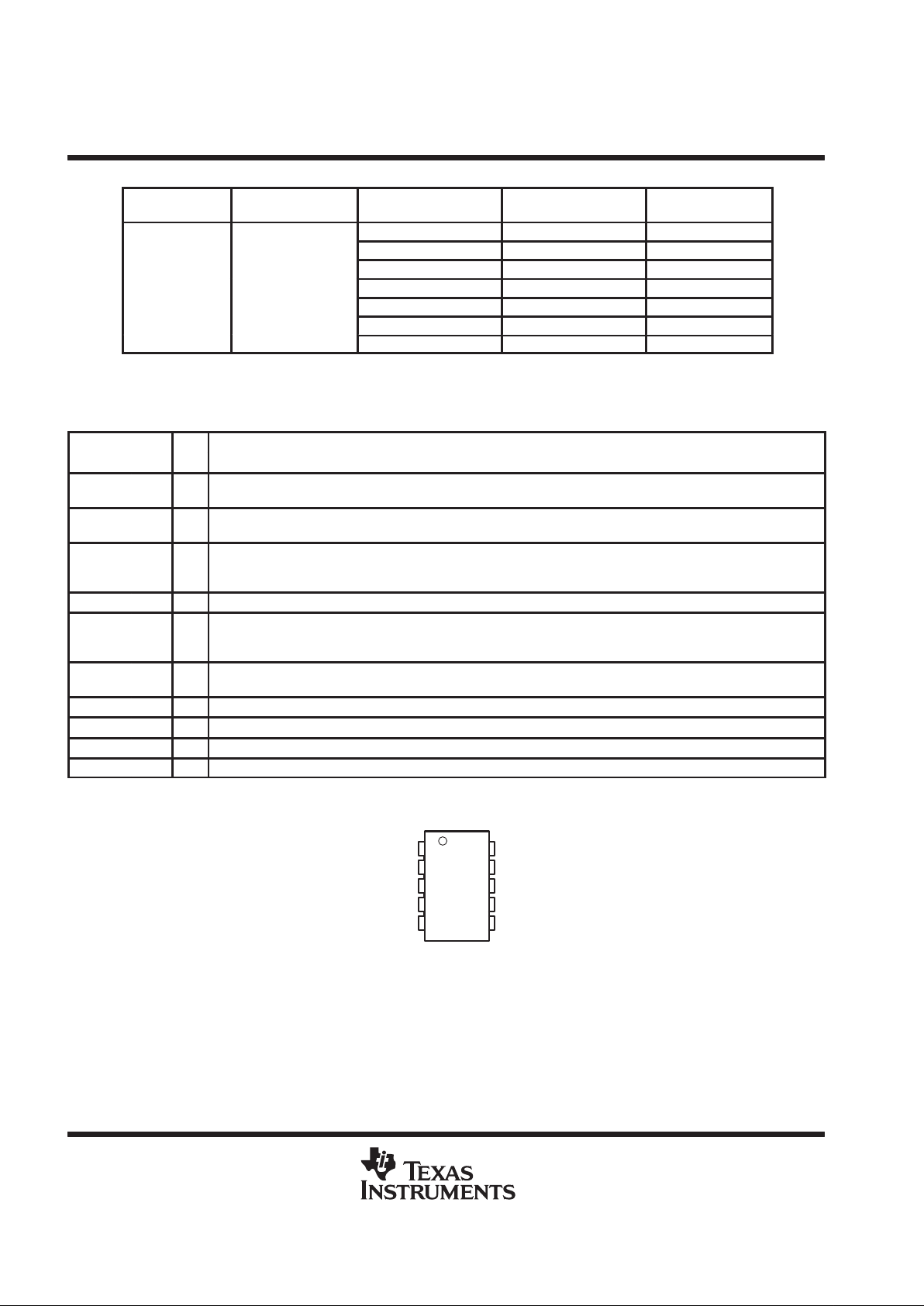

Terminal Functions

TERMINAL

NAME NO.

I/O

DESCRIPTION

COMP 2

Compensation of error amplifier. Connect R-C-C network to set frequency response of control loop. See the

Application

section for more details.

EN 1 I

Chip-enable input. The converter is switched on if EN is set high and is switched off when EN is connected to ground

(shutdown mode).

FB 3 I

Feedback input for adjustable output voltage (TPS61000 only). The output voltage is programmed depending on the

values of resistors R1 and R2. For the fixed output voltage versions (TPS61001, 2, 3, 4, 5, 6), leave the FB pin

unconnected.

GND 4 Ground

LBI 9 I

Low-battery detector input. A low-battery signal is generated at the LBO pin when the voltage on LBI drops below the

threshold of 500 mV . Connect LBI to GND or V

BAT

if the low-battery detector function is not used. Do not leave this

pin floating.

LBO 10 O

Open-drain low-battery detector output. This pin is pulled low if the voltage on LBI drops below the threshold of

500 mV. A pull-up resistor should be connected between LBO and V

OUT

.

NC 8 Not connected

SW 7 I Switch input pin. The node between inductor and anode of the rectifier diode is connected to this pin.

V

BAT

6 I Supply pin

V

OUT

5 O Output voltage. For the fixed output voltage versions, the integrated resistive divider is connected to this pin.

1

2

3

4

5

10

9

8

7

6

EN

COMP

FB

GND

V

OUT

LBO

LBI

NC

SW

V

BAT

DGS PACKAGE

(TOP VIEW)

TPS61000, TPS61001, TPS61002, TPS61003, TPS61004, TPS61005, TPS61006

SINGLE-CELL BOOST CONVERTER WITH START-UP INTO FULL LOAD

SLVS279A – MARCH 2000 – REVISED MAY 2000

3

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

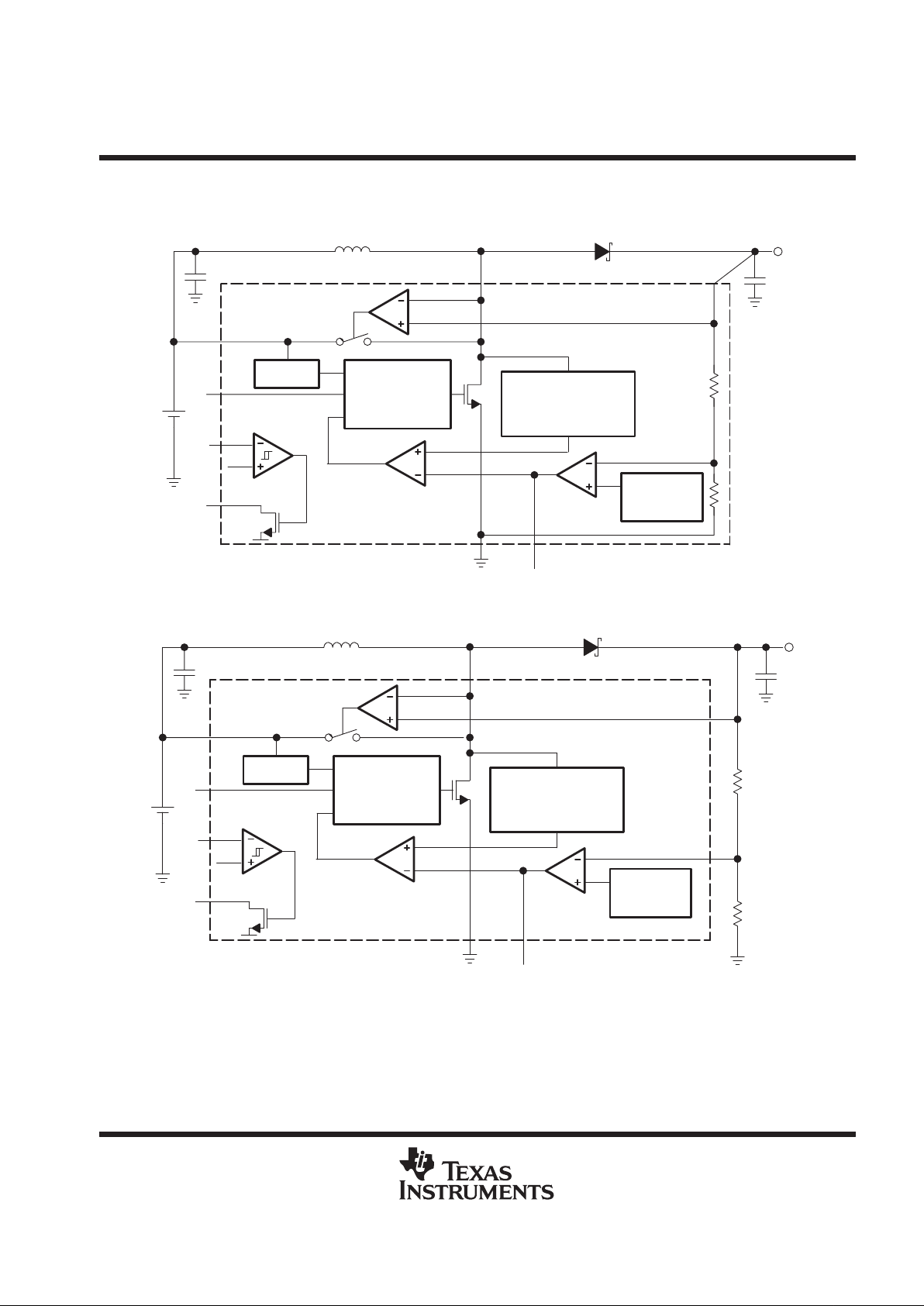

functional block diagram

fixed output-voltage option

V

REF

V

BAT

Control Logic

Oscillator

Gate Drive

UVLO

Current Sense

Current Limit

Slope Compensation

Bandgap

Reference

EN

LBI

LBO

GND COMP

L1 D1

V

OUT

C

O

C

I

SW

Comparator

LBI/LBO

Comparator

Error

Amplifier

Anti-Ringing

Comparator

and Switch

adjustable output-voltage option

V

REF

V

BAT

Control Logic

Oscillator

Gate Drive

UVLO

Current Sense

Current Limit

Slope Compensation

Bandgap

Reference

EN

LBI

LBO

GND COMP

L1 D1

V

OUT

C

O

C

I

SW

Comparator

LBI/LBO

Comparator

Error

Amplifier

Anti-Ringing

Comparator

and Switch

FB

TPS61000, TPS61001, TPS61002, TPS61003, TPS61004, TPS61005, TPS61006

SINGLE-CELL BOOST CONVERTER WITH START-UP INTO FULL LOAD

SLVS279A – MARCH 2000 – REVISED MAY 2000

4

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

detailed description

controller circuit

The device is based on a current-mode control topology using a constant-frequency pulse-width modulator to

regulate the output voltage. It runs at an oscillator frequency of 500 kHz. The current sense is implemented by

measuring the voltage across the switch. The controller also limits the current through the power switch on a

pulse by pulse basis. Care must be taken that the inductor saturation current is higher than the current limit of

the TPS6100x. This prevents the inductor from going into saturation and therefore protects both device and

inductor. The current limit should not become active during normal operating conditions.

The TPS6100x is designed for high efficiency over a wide output current range. Even at light loads the efficiency

stays high because the controller enters a power-save

mode, minimizing switching losses of the converter. In

this mode, the controller only switches if the output voltage trips below a set threshold voltage. It ramps up the

output voltage with one or several pulses, and again goes into the power-save mode once the output voltage

exceeds the threshold voltage. The controller enters the power-save mode when the output current drops to

levels that force the discontinuous current mode. It calculates a minimum duty cycle based on input and output

voltage and uses the calculation for the transition out of the

power-save mode into continuous current mode.

The control loop must be externally compensated with an R/C/C network connected to the COMP pin. See the

application section for more details on the design of the compensation network.

device enable

The device is put into operation when EN is set high. During start-up of the converter the input current from the

battery is limited until the voltage on COMP reaches its operating point. The device is put into a shutdown mode

when EN is set to GND. In this mode, the regulator stops switching and all internal control circuitry including

the low-battery comparator is switched off. The output voltage drops to one diode drop below the input voltage

in shutdown.

under-voltage lockout

An under-voltage lockout function prevents the device start-up if the supply voltage on V

BAT

is lower than

approximately 0.7 V . This under-voltage lockout function is implemented in order to prevent the malfunctioning

of the converter. When in operation and the battery is being discharged, the device will automatically enter the

shutdown mode if the voltage on V

BAT

drops below approximately 0.7 V.

If the EN pin is hardwired to V

BAT

and if the voltage at V

BAT

drops temporarily below the UVLO threshold voltage,

the device will switch off and will not start up again automatically , even if the supply voltage rises above 0.9 V.

The device will start up again only after a signal change from low to high on EN or if the battery voltage is

completely removed.

TPS61000, TPS61001, TPS61002, TPS61003, TPS61004, TPS61005, TPS61006

SINGLE-CELL BOOST CONVERTER WITH START-UP INTO FULL LOAD

SLVS279A – MARCH 2000 – REVISED MAY 2000

5

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

detailed description (continued)

low Battery detector circuit (LBI and LBO)

The low-battery detector circuit is typically used to supervise the battery voltage and to generate an error flag

when the battery voltage drops below a user-set threshold voltage. The function is active only when the device

is enabled. When the device is disabled, the LBO pin is high impedance. The LBO pin goes active low when

the voltage on the LBI pin decreases below the set threshold voltage of 500 mV ±15 mV , which is equal to the

internal reference voltage. The battery voltage, at which the detection circuit switches, can be programmed with

a resistive divider connected to the LBI pin. The resistive divider scales down the battery voltage to a voltage

level of 500 mV, which is then compared to the LBI threshold voltage. The LBI pin has a build-in hysteresis of

10 mV. Please see the application section for more details about the programming of the LBI threshold.

If the low-battery detection circuit is not used, the LBI pin should be connected to GND (or to V

BAT

) and the LBO

pin can be left unconnected. Do not let the LBI pin float.

low-EMI switch

The device integrates a circuit which removes the ringing that typically appears on the SW-node when the converter enters the discontinuous current mode. In this case, the current through the inductor ramps to zero and

the Schottky diode stops conducting. Due to remaining energy that is stored in parasitic components of diode,

inductor and switch, a ringing on the SW pin is induced. The integrated anti-ringing switch clamps this voltage

internally to V

BAT

and therefore dampens this ringing.

The anti-ringing switch is turned on by a comparator that monitors the voltage between SW and V

OUT

. This

voltage indicates when the diode is reverse biased. The ringing on the SW-node is damped to a large degree,

reducing the electromagnetic interference generated by the switching regulator to a very great extends.

adjustable output voltage

The accuracy of the internal voltage reference, the controller topology , and the accuracy of the external resistor

divider determine the accuracy of the adjustable output voltage version of the TPS61000. The reference voltage

has an accuracy of ±4% over line, load, and temperature. The controller switches between fixed frequency and

pulse-skip mode, depending on load current. This adds an offset to the output voltage that is equivalent to 1%

of VO. Using 1% accurate resistors for the feedback divider, a total accuracy of ±6% can be achieved over the

complete output current range.

TPS61000, TPS61001, TPS61002, TPS61003, TPS61004, TPS61005, TPS61006

SINGLE-CELL BOOST CONVERTER WITH START-UP INTO FULL LOAD

SLVS279A – MARCH 2000 – REVISED MAY 2000

6

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

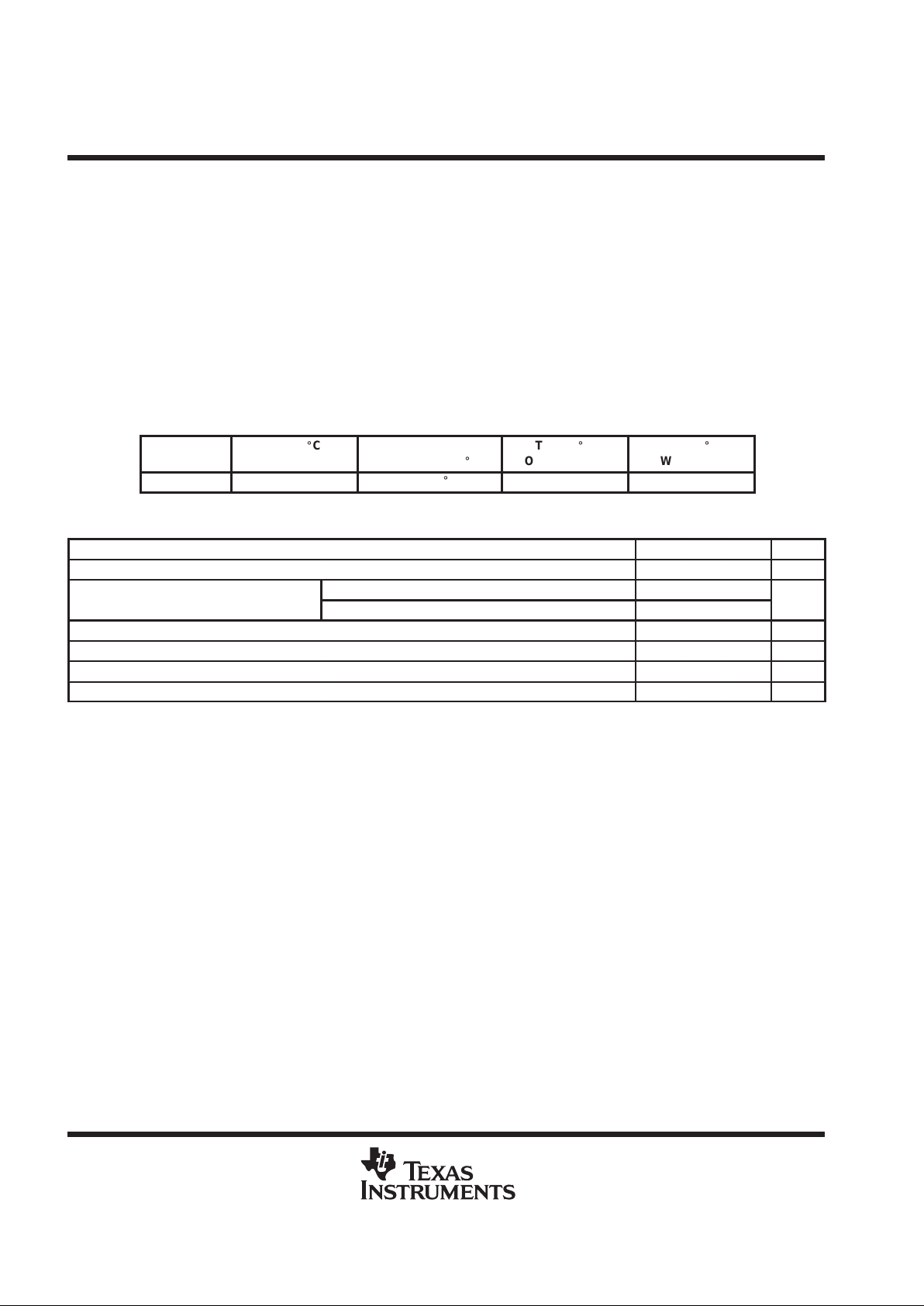

absolute maximum ratings

†

Input voltage range, VI (V

BAT

, V

OUT

, COMP, FB, LBO, EN, LBI) –0.3 V to 3.6 V. . . . . . . . . . . . . . . . . . . . . . . . .

Input voltage, VI (SW) –0.3 V to 7 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Peak current into SW 1300 mA. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Continuous total power dissipation See dissipation rating table. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operating free-air temperature range, T

A

–40°C to 85°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Maximum junction temperature, T

J

150°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Storage temperature range, T

stg

–65°C to 150°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Lead temperature 260°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

†

Stresses beyond those listed under “absolute maximum ratings” may cause permanent damage to the device. These are stress ratings only, and

functional operation of the device at these or any other conditions beyond those indicated under “recommended operating conditions” is not

implied. Exposure to absolute-maximum-rated conditions for extended periods may affect device reliability.

DISSIPATION RATING TABLE

PACKAGE

TA ≤ 25_C

POWER RATING

DERATING FACTOR

ABOVE TA = 25_C

TA = 70_C

POWER RATING

TA = 85_C

POWER RATING

DGS 424 mW 3.4 mW/_C 271 mW 220 mW

recommended operating conditions

MIN NOM MAX UNIT

Supply voltage at V

BAT

0.8 V

O

V

p

V

BAT

= 1.2 V 100

Output current

V

BAT

= 2.4 V 250

mA

Inductor 10 33 µH

Input capacitor 10 µF

Output capacitor 22 µF

Operating junction temperature, T

J

–40 125 °C

TPS61000, TPS61001, TPS61002, TPS61003, TPS61004, TPS61005, TPS61006

SINGLE-CELL BOOST CONVERTER WITH START-UP INTO FULL LOAD

SLVS279A – MARCH 2000 – REVISED MAY 2000

7

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

electrical characteristics over recommended operating free-air temperature range, V

BA T

= 1.2 V , EN

= V

BAT

(unless otherwise noted)

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

V

I

Input voltage for start-up RL = 33 Ω 0.9 V

V

I

Input voltage for start-up RL = 3 kΩ, TA = 25 °C 0.8 V

V

I

Input voltage once started IO = 100 mA 0.8 V

V

O

Programmable output voltage range TPS61000 IO = 100 mA 1.5 3.3 V

1.2 V IO = 1 mA 1.44 1.5 1.55

TPS61001

0.8 V < VI < VO, IO = 100 mA 1.45 1.5 1.55

1.2 V IO = 1 mA 1.72 1.8 1.86

TPS61002

0.8 V < VI < VO, IO = 100 mA 1.74 1.8 1.86

1.2 V IO = 1 mA 2.40 2.5 2.58

TPS61003

0.8 V < VI < VO, IO = 100 mA 2.42 2.5 2.58

1.6 V < VI < VO, IO = 200 mA 2.42 2.5 2.58

p

1.2 V IO = 1 mA 2.68 2.8 2.89

VOOutput voltage

TPS61004

0.8 V < VI < VO, IO = 100 mA 2.72 2.8 2.89

V

1.6 V < VI < VO, IO = 200 mA 2.72 2.8 2.89

1.2 V IO = 1 mA 2.88 3.0 3.1

TPS61005

0.8 V < VI < VO, IO = 100 mA 2.9 3.0 3.1

1.6 V < VI < VO, IO = 200 mA 2.9 3.0 3.1

1.2 V IO = 1 mA 3.16 3.3 3.4

TPS61006

0.8 V < VI < VO, IO = 100 mA 3.2 3.3 3.4

1.6 V < VI < VO, IO = 200 mA 3.2 3.3 3.4

p

VI = 0.8 V 100

IOMaximum continuous output current

VI = 1.8 V 250

mA

TPS61001 0.5

TPS61002 0.65

TPS61003

0.9

ISWSwitch current limit

TPS61004

0.8 V

<

V

I

<

V

O

0.95

A

TPS61005 1

TPS61006 1.1

V

FB

Feedback voltage TPS61006 468 500 515 mV

f Oscillator frequency 360 500 840 kHz

D

MAX

Maximum duty cycle 85%

r

DS(on)

Switch-on resistance VO = 3.3 V 0.18 0.27 Ω

Line regulation (see Note 1) VI = 0.8V to 1.25V , IO = 50 mA 0.3 %/V

Load regulation fixed output voltage versions

(see Note 1)

VI = 1.2 V; IO = 10 mA to 90 mA 0.25%

NOTE 1: Line and load regulation is measured as a percentage deviation from the nominal value (i.e. as percentage deviation from the nominal

output voltage). For line regulation, x %/V stands for ±x% change of the nominal output voltage per 1-V change on the input/supply

voltage. For load regulation, y% stands for ±y% change of the nominal output voltage per the specified current change.

TPS61000, TPS61001, TPS61002, TPS61003, TPS61004, TPS61005, TPS61006

SINGLE-CELL BOOST CONVERTER WITH START-UP INTO FULL LOAD

SLVS279A – MARCH 2000 – REVISED MAY 2000

8

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

electrical characteristics over recommended operating free-air temperature range, V

BA T

= 1.2 V , EN

= V

BAT

(unless otherwise noted) (continued)

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

Quiescent current drawn from power source IO = 0 mA

V

BAT

44

I

Q

(current into V

BAT

and into V

OUT

)

O

VEN = VI, VO = 3.4 V

V

OUT

6

µ

A

I

SD

Shutdown current from power source

(current into V

BAT

and into V

OUT

)

VEN = 0 V 0.2 5 µA

V

IL

EN low-level input voltage

0.2 ×

V

BAT

V

V

IH

EN high-level input voltage

0.8 ×

V

BAT

V

EN input current EN = GND or V

BAT

0.1 1 µA

V

IL

LBI low-level input voltage threshold V

LBI

voltage decreasing 470 500 530 mV

LBI input hysteresis 10 mV

I

I

LBI input current 0.01 0.1 µA

V

OL

LBO low-level output voltage V

LBI

= 0 V, VO = 3.3 V, IOL = 50 µA 0.04 0.2 V

LBO output leakage current V

LBI

= 650 mV , V

LBO

= 3.3 V 0.01 1 µA

I

FB

FB input bias current (TPS61000 only) VFB = 500 mV 0.01 0.1 µA

PARAMETER MEASUREMENT INFORMATION

List of Components:

IC1: Only fixed output versions

(unless otherwise noted)

L1: Coilcraft DO3308P–333

D1: Motorola Schottky Diode

MBRM120L T3

CI: Ceramic

CO:

Ceramic

5

6

TPS6100x

9

8

1

10

3

2

7

4

SW

V

BAT

LBI

NC

EN

V

OUT

LBO

FB

COMP

GND

Low Battery

Warning

R4

10 kΩ

R3

ON

OFF

R2

R1

C

i

10 µF

L1

D1

C1

100 pF

C2

33 nF

C

o

22 µF

33 µH

Figure 1. Circuit Used For Typical Characteristics Measurements

TPS61000, TPS61001, TPS61002, TPS61003, TPS61004, TPS61005, TPS61006

SINGLE-CELL BOOST CONVERTER WITH START-UP INTO FULL LOAD

SLVS279A – MARCH 2000 – REVISED MAY 2000

9

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

TYPICAL CHARACTERISTICS

Table of Graphs

FIGURE

vs Output Current 2, 3

η Efficiency

vs Inductor Type 4

vs Input Voltage 5

I

O

Maximum Output Current vs Input Voltage 6

V

O

Output Voltage vs Output Current 7

V

O

TPS61000 Output Voltage vs Output Current 8

I

Q

No-Load Supply Current vs Input Voltage 9

I

SD

Shutdown Current vs Input Voltage 10

V

I

Minimum Start-Up Input Voltage vs Load Current 11

I

LIM

Switch current limit vs Output Voltage 12

Output Voltage Ripple Amplitude 13

Output Voltage Ripple Amplitude 14

Load Transient Response 15

Line Transient Response 16

Start-Up Timing 17

Figure 2

50

40

20

0

110

Efficiency – %

80

90

EFFICIENCY

vs

OUTPUT CURRENT

100

100

70

60

30

10

VO = 3.3 V

VO = 1.5 V

VI = 1.2 V

IO – Output Current – mA

1000

Figure 3

0

10

20

30

40

50

60

70

80

90

100

1 10 100 1000

VO = 3.3 V

VO = 2.8 V

VI = 2.4 V

Efficiency – %

EFFICIENCY

vs

OUTPUT CURRENT

IO – Output Current – mA

TPS61000, TPS61001, TPS61002, TPS61003, TPS61004, TPS61005, TPS61006

SINGLE-CELL BOOST CONVERTER WITH START-UP INTO FULL LOAD

SLVS279A – MARCH 2000 – REVISED MAY 2000

10

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

TYPICAL CHARACTERISTICS

50

55

60

65

70

75

80

85

90

95

100

Coilcraft

DO1608C

Coilcraft

DS1608C

Coiltronics

UP1B

Coiltronics

UP2B

Sumida

CD43

Sumida

CD54

Efficiency – %

EFFICIENCY

vs

INDUCTOR TYPE

Inductor Type

VI = 1.2 V

VO = 3.3 V

IO = 100 mA

Figure 4

60

65

70

75

80

85

90

95

0.80 1.30 1.80 2.30 2.80 3.30

Efficiency – %

EFFICIENCY

vs

INPUT VOLTAGE

VI – Input Voltage – V

IO = 50 mA

IO = 100 mA

Figure 5

0

0.10

0.20

0.30

0.40

0.50

0.60

0.70

0.80

0.90

1

0.8 1 1.2 1.4 1.6 1.8 2 2.2 2.4 2.6 2.8 3

– Output Current –

MAXIMUM OUTPUT CURRENT

vs

INPUT VOLTAGE

A

VI – Input Voltage – V

VO = 1.45 V

VO = 1.75 V

Figure 6

I

O

VO = 2.42 V

VO = 3.2 V

TPS61000, TPS61001, TPS61002, TPS61003, TPS61004, TPS61005, TPS61006

SINGLE-CELL BOOST CONVERTER WITH START-UP INTO FULL LOAD

SLVS279A – MARCH 2000 – REVISED MAY 2000

11

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

TYPICAL CHARACTERISTICS

1.60

1.80

2.00

2

2.40

2.60

2.80

3

3.20

3.40

3.60

1 10 100 1000

VI = 1.2 V

3.3 V

2.5 V

1.8 V

– Output Voltage – V

TPS61002/3/6

OUTPUT VOLTAGE

vs

OUTPUT CURRENT

V

O

IO – Output Current – mA

Figure 7

Figure 8

1.60

1.80

2

2.20

2.40

2.60

2.80

3

3.20

3.40

3.60

0.1 1 10 100 1000

VO = 3.3 V

– Output Voltage – V

TPS61000

OUTPUT VOLTAGE

vs

OUTPUT CURRENT

V

O

IO – Output Current – mA

VO = 2.5 V

VO = 1.8 V

Figure 9

0

5

10

15

20

25

30

35

40

45

0.80 1.30 1.80 2.30 2.80 3.30 3.80

TA = 85°C

TA = 25°C

TA = –40°C

– Supply Current –

NO-LOAD SUPPLY CURRENT

vs

INPUT VOLTAGE

Aµ

VI – Input Voltage – V

I

Q

Figure 10

0

200

400

600

800

1000

1200

1400

1600

1800

0.80 1.30 1.80 2.30 2.80 3.30 3.80

Supply Current – nA

SHUTDOWN CURRENT

vs

INPUT VOLTAGE

VI – Input Voltage – V

TA = 85°C

TA = 25°C

TA = –40°C

TPS61000, TPS61001, TPS61002, TPS61003, TPS61004, TPS61005, TPS61006

SINGLE-CELL BOOST CONVERTER WITH START-UP INTO FULL LOAD

SLVS279A – MARCH 2000 – REVISED MAY 2000

12

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

TYPICAL CHARACTERISTICS

Figure 11

0.60

0.65

0.70

0.75

0.80

0.85

0.90

010

20

100

VO = min 3.2 V

– Input Voltage – V

MINIMUM START-UP INPUT VOLTAGE

vs

LOAD CURRENT

V

I

IO – Output Current – mA

30 40 50 60 70 80 90

Figure 12

0

0.5

1

1.5

1.5 1.7 1.9 2.1 2.3 2.5 2.7 2.9 3.1 3.3 3.5

VI = 1.2 V

Switch Current Limit – A

TPS61000

SWITCH CURRENT LIMIT

vs

OUTPUT VOLTAGE

VO – Output Voltage – V

Figure 13

3.28

3.26

3.22

3.18

3.30

3.32

TPS61006

OUTPUT VOLTAGE RIPPLE AMPLITUDE

3.34

3.24

3.20

IO = 2 mA

time – ms

– Output Voltage – VV

O

01 5432

Figure 14

3.30

0123

3.32

3.34

3.36

45

TPS61006

OUTPUT VOLTAGE RIPPLE AMPLITUDE

2

0

time – µs

VI = 1.2 V

– Output Voltage – V

V

SW

V

OUT

V

O

V

SW

TPS61000, TPS61001, TPS61002, TPS61003, TPS61004, TPS61005, TPS61006

SINGLE-CELL BOOST CONVERTER WITH START-UP INTO FULL LOAD

SLVS279A – MARCH 2000 – REVISED MAY 2000

13

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

TYPICAL CHARACTERISTICS

Figure 15

3.2

20

0

0123456

3.3

3.4

TPS61006

LOAD TRANSIENT RESPONSE

78910

60

40

– Output Voltage – V

V

O

VI = 1.2 V

RC = 33 kΩ

50 mA

5 mA

– Output Current – mA

I

O

time – ms

Figure 16

3.25

1.2

1

0123456

3.35

3.45

TPS61006

LINE TRANSIENT RESPONSE

3.55

78910

0.8

– Output Voltage – V

V

O

– Input Voltage – V

V

I

V

OUT

V

BAT

time – ms

IO = 50 mA

RC = 33 kΩ

2

024681012

3

TPS61006

START-UP TIMING INTO 33 Ω LOAD

14 16 18 20

1

0

– Output Voltage – V

V

O

V

OUT

EN

I

OUT

80

60

20

100

120

140

0

40

– Output Current – mA

I

O

time – ms

Figure 17

TPS61000, TPS61001, TPS61002, TPS61003, TPS61004, TPS61005, TPS61006

SINGLE-CELL BOOST CONVERTER WITH START-UP INTO FULL LOAD

SLVS279A – MARCH 2000 – REVISED MAY 2000

14

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

APPLICATION INFORMATION

The TPS6100x boost converter family is intended for systems that are powered by a single-cell NiCd or NiMH

battery with a typical terminal voltage between 0.9 V to 1.6 V . It can also be used in systems that are powered

by two-cell NiCd or NiMH batteries with a typical stack voltage between 1.8 V and 3.2 V. Additionally, singleor dual-cell, primary and secondary alkaline battery cells can be the power source in systems where the

TPS6100x is used.

programming the TPS61000 adjustable output voltage device

The output voltage of the TPS61000 can be adjusted with an external resistor divider. The typical value of the

voltage on the FB pin is 500 mV in fixed frequency operation and 485 mV in the power-save operation mode.

The maximum allowed value for the output voltage is 3.3 V . The current through the resistive divider should be

about 100 times greater than the current into the FB pin. The typical current into the FB pin is 0.01 µA, the voltage

across R4 is typically 500 mV. Based on those two values, the recommended value for R4 is in the range of

500 kΩ in order to set the divider current at 1 µA. From that, the value of resistor R3, depending on the needed

output voltage V

OUT

, can be calculated using the following equation:

R3+R4

ǒ

V

O

V

FB

*

1

Ǔ +

500 kΩ

ǒ

V

O

500 mV

*

1

Ǔ

(1)

If, as an example, an output voltage of 2.5 V is needed, a 2 MΩ resistor should be chosen for R3.

V

BAT

V

OUT

LBO

5

10

3

R5 R3

R4

6

TPS61000

LBI

9

FB

COMP

2

C

C1

100 pF

C

C2

33 nF

R

C

10 kΩ

EN

NC

R2

R1

1

8

GND

SW

7

4

C

i

10 µF

10 V

C

o

22 µF

10 V

Low Battery

Warning

L1

33 µH

D1

Figure 18. Typical Application Circuit for Adjustable Output Voltage Option

The output voltage of the adjustable output voltage version changes with the output current. Due to

device-internal ground shift, which is caused by the high switch current, the internal reference voltage and hence

the voltage on the FB pin increases with increasing output current. Since the output voltage follows the voltage

on the FB pin, the output voltage rises as well with a rate of 1 mV per 1 mA output current increase. Additionally ,

when the converter goes into pulse-skip mode at output currents around 5 mA and lower, the output voltage

drops due to the hysteresis of the controller. This hysteresis is about 15 mV measured on the FB pin.

TPS61000, TPS61001, TPS61002, TPS61003, TPS61004, TPS61005, TPS61006

SINGLE-CELL BOOST CONVERTER WITH START-UP INTO FULL LOAD

SLVS279A – MARCH 2000 – REVISED MAY 2000

15

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

APPLICATION INFORMATION

programming the low battery comparator threshold voltage

The current through the resistive divider should be about 100 times greater than the current into the LBI pin.

The typical current into the LBI pin is 0.01 µA, the voltage across R2 is equal to the reference voltage that is

generated on chip, which has a value of 500 mV ±15 mV. The recommended value for R2 is therefore in the

range of 500 kΩ. From that, the value of resistor R1 depending on the desired minimum battery voltage V

BAT

,

can be calculated using below equation:

R1+R2

ǒ

V

TRIP

V

REF

*

1Ǔ+

500 kΩ

ǒ

V

BAT

0.5 V

*

1

Ǔ

(2)

For example, if the low-battery detection circuit should flag an error condition on the LBO output pin at a battery

voltage of 1.0 V, a resistor in the range of 500 kΩ should be chosen for R1.

The output of the low battery comparator is a simple open-drain output that goes active low if the battery voltage

drops below the programmed threshold voltage on LBI. The output requires a pullup resistor with a

recommended value of 1MΩ, and should only be pulled up to the V

OUT

. If not used, the LBO pin can be left

floating.

inductor selection

The output filter of inductive switching regulators is a low pass filter of second order. It consists of an inductor and

a capacitor, often referred to as storage inductor and output capacitor.

To select an inductor, keep the possible peak inductor current below the current limit threshold of the power

switch in your chosen configuration. For example, the current limit threshold of the TPS61000’s switch is

1 100 mA at an output voltage of 3.3 V . The highest peak current through the inductor and the switch depends on

the output load, the input (V

BAT

) and the output voltage (V

OUT

). Estimation of the maximum average inductor

current can be done using the following equation:

IL+

I

OUT

x

V

OUT

V

BAT

x0.8

(3)

For example, for an output current of 100 mA at 3.3 V , at least 515 mA current will flow through the inductor at a

minimum input voltage of 0.8 V.

The second parameter for choosing the inductor is the desired current ripple in the inductor. Normally it is advisable to work with a ripple of less than 20% of the average inductor current. A smaller ripple will reduce the magnetic hysteresis losses in the inductor as well as output voltage ripple and EMI. But in the same way , regulation

time at load changes will rise. In addition, a larger inductor will increase the total system costs.

TPS61000, TPS61001, TPS61002, TPS61003, TPS61004, TPS61005, TPS61006

SINGLE-CELL BOOST CONVERTER WITH START-UP INTO FULL LOAD

SLVS279A – MARCH 2000 – REVISED MAY 2000

16

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

APPLICATION INFORMATION

With those parameters it is possible to calculate the value for the inductor:

L

+

V

BAT

xǒV

OUT

–V

BAT

Ǔ

∆ILxfxV

OUT

(4)

Parameter f is the switching frequency and ∆IL is the ripple current in the inductor, i.e. 20% x IL.

In this example, the desired inductor will have the value of 12 µH. With this calculated value and the calculated

currents, it is possible to chose a suitable inductor. Care has to be taken that load transients and losses in the

circuit can lead to higher currents as estimated in equation 3. Also, the losses in the inductor caused by magnetic

hysteresis losses and copper losses are a major parameter for total circuit efficiency.

The following inductors from different suppliers were tested. All will work with the TPS6100x converter within

their specified parameters:

Table 1. Recommended Inductors

VENDOR PART NUMBER

Coilcraft DO1608P Series

DS1608P Series

DO3308 Series

Coiltronics UP1B Series

UP2B Series

Murata LQH3N Series

Sumida CD43 Series

CD54 Series

CDR74B Series

TDK NLC453232T Series

capacitor selection

The major parameter necessary to define the output capacitor is the maximum allowed output voltage ripple of

the converter. This ripple is determined by two parameters of the capacitor, the capacitance and the ESR. It is

possible to calculate the minimum capacitance needed for the defined ripple, supposing that the ESR is zero.

C

min

+

I

OUT

xǒV

OUT

–V

BAT

Ǔ

fx∆VxV

OUT

(5)

Parameter f is the switching frequency and ∆V is the maximum allowed ripple.

With a chosen ripple voltage of 15 mV , a minimum capacitance of 10 µF is needed. The total ripple will be larger

due to the ESR of the output capacitor. This additional component of the ripple can be calculated using the following equation:

∆V

ESR

+

I

OUT

xR

ESR

(6)

TPS61000, TPS61001, TPS61002, TPS61003, TPS61004, TPS61005, TPS61006

SINGLE-CELL BOOST CONVERTER WITH START-UP INTO FULL LOAD

SLVS279A – MARCH 2000 – REVISED MAY 2000

17

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

APPLICATION INFORMATION

An additional ripple of 30 mV is the result of using a tantalum capacitor with a low ESR of 300 mΩ. The total ripple

is the sum of the ripple caused by the capacitance and the ripple caused by the ESR of the capacitor. In this

example, the total ripple will be 45 mV. It is possible to improve the design by enlarging the capacitor or using

smaller capacitors in parallel to reduce the ESR or by using better capacitors with lower ESR, like ceramics. For

example, a 10 µF ceramic capacitor with an ESR of 50 mΩ is used on the evaluation module (EVM). Tradeoffs

have to be made between performance and costs of the converter circuit.

A 10 µF input capacitor is recommended to improve transient behavior of the regulator. A ceramic capacitor or a

tantalum capacitor with a 100 nF ceramic capacitor in parallel placed close to the IC is recommended.

rectifier selection

The rectifier diode has a major impact on the overall converter efficiency. Standard diodes are not suitable for

low-voltage switched mode power supplies. A Schottky diode with low forward voltage and fast reverse recovery

should be used as rectifier to minimize overall losses of the dc-dc converter. The maximum current rating of the

diode must be high enough for the application. The maximum diode current is equal to the maximum current in

the inductor that was calculated in equation 3. The maximum reverse voltage is the output voltage. The chosen

diode should therefore have a reverse voltage rating higher than the output voltage.

Table 2. Recommended Diodes

VENDOR PART NUMBER

Motorola Surface Mount MBRM120LT3

MBR0520L T1

Motorola Axial Lead 1N1517

ROHM RB520S-30

RB160L–40

The typical forward voltage of those diodes is in the range of 0.35 to 0.45 V assuming a peak diode current of

600 mA.

compensation of the control loop

An R/C/C network must be connected to the COMP pin in order to stabilize the control loop of the converter. Both

the pole generated by the inductor L1 and the zero caused by the ESR and capacitance of the output capacitor

must be compensated. The network shown in Figure 19 will satisfy these requirements.

C

C2

33 nF

C

C1

100 pF

R

C

10 kΩ

COMP

Figure 19. Compensation of the Control Loop

TPS61000, TPS61001, TPS61002, TPS61003, TPS61004, TPS61005, TPS61006

SINGLE-CELL BOOST CONVERTER WITH START-UP INTO FULL LOAD

SLVS279A – MARCH 2000 – REVISED MAY 2000

18

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

APPLICATION INFORMATION

Resistor RC and capacitor CC2 depend on the chosen inductance. For a 33 µH inductor, the capacitance of C

C2

should be chosen to 33 nF , or in other words, if the inductor is xx µH, the chosen compensation capacitor should

be xx nF , the same number value. The value of the compensation resistor is then chosen based on the requirement to have a time constant of 0.3 ms for the R/C network of RC and CC2; hence for a 33-nF capacitor, a 10-kΩ

resistor should be chosen for RC.

Capacitor CC1 is depending on the ESR and capacitance value of the output capacitor, and on the value chosen

for RC. Its value is calculated using following equation:

CC1+

COx ESR

COUT

3 R

C

(7)

For a selected output capacitor of 22 µF with an ESR of 0.2 Ω, and RC of 33 kΩ, the value of CC1 is in the range of

100 pF.

Table 3. Recommended Compensation Components

OUTPUT CAPACITOR

INDUCTOR

[µH]

CAPACITANCE

[µF]

ESR

[Ω]

R

C

[kΩ]

C

C1

[pF]

C

C2

[nF]

33 22 0.2 10 100 33

22 22 0.3 15 100 22

10 22 0.4 33 100 10

10 10 0.1 33 100 10

schematic of TPS6100x evaluation modules (TPS6100xEVM–156)

LBO

LBI

NC

SW

V

BAT

EN

COMP

FB

GND

V

OUT

R6

LP1

D1

L1

C1 C3

R2 R1

IN

J1

C6

R5

C5

R3

C2

R4

OUT

TPS6100x

TPS61000, TPS61001, TPS61002, TPS61003, TPS61004, TPS61005, TPS61006

SINGLE-CELL BOOST CONVERTER WITH START-UP INTO FULL LOAD

SLVS279A – MARCH 2000 – REVISED MAY 2000

19

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

APPLICATION INFORMATION

suggested board layout and component placement (21 mm x 21 mm board size)

Figure 20. Top Layer Layout and Component Placement

Figure 21. Bottom Layer Layout and Component Placement

device family products

Other devices in this family are:

PART NUMBER DESCRIPTION

UCC2941-3/-5/-ADJ

p

UCC3941-3/-5/-ADJ

1-V synchronous boost converter with secondary output

UCC29411/2/3

p

p

UCC39411/2/3

1-V low power synchronous boost converter with secondary output

TPS61000, TPS61001, TPS61002, TPS61003, TPS61004, TPS61005, TPS61006

SINGLE-CELL BOOST CONVERTER WITH START-UP INTO FULL LOAD

SLVS279A – MARCH 2000 – REVISED MAY 2000

20

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

THERMAL INFORMATION

Implementation of integrated circuits in low-profile and fine-pitch surface-mount packages typically requires

special attention to power dissipation. Many system-dependent issues such as thermal coupling, airflow, added

heat sinks and convection surfaces, and the presence of other heat-generating components affect the powerdissipation limits of a given component.

Three basic approaches for enhancing thermal performance are listed below:

• Improving the power dissipation capability of the PWB design

• Improving the thermal coupling of the component to the PWB

• Introducing airflow in the system

The maximum junction temperature (TJ) of the TPS6100x devices is 125°C. The thermal resistance of the

10-pin MSOP package (DSG) is R

θJA

= 294°C/W. Specified regulator operation is assured to a maximum

ambient temperature T

A

of 85 °C. Therefore, the maximum power dissipation is about 130 mW. More power can

be dissipated if the maximum ambient temperature of the application is lower.

mW

WC

CC

JA

R

A

MAXJ

T

MAXD

P 136

/294

85125)(

)(

=

°

°–°

=

Θ

=

(8)

–

Under normal operating conditions, the sum of all losses generated inside the converter IC is less than 50 mW,

which is well below the maximum allowed power dissipation of 136 mW as calculated in equation 8. Therefore,

power dissipation is given no special attention.

Table 4 shows where the losses inside the converter are generated.

Table 4. Losses Inside the Converter

LOSSES AMOUNTS

Conduction losses in the switch 36 mW

Switching losses 8 mW

Gate drive losses 2.3 mW

Quiescent current losses < 1 mW

TOTAL < 50 mW

TPS61000, TPS61001, TPS61002, TPS61003, TPS61004, TPS61005, TPS61006

SINGLE-CELL BOOST CONVERTER WITH START-UP INTO FULL LOAD

SLVS279A – MARCH 2000 – REVISED MAY 2000

21

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

MECHANICAL DATA

DGS (S-PDSO-G10) PLASTIC SMALL-OUTLINE PACKAGE

0,69

0,41

0,25

0,15 NOM

Gage Plane

4073272/A 03/98

4,98

0,17

6

3,05

4,78

2,95

10

5

3,05

2,95

1

0,27

0,15

0,05

1,07 MAX

Seating Plane

0,10

0,50

M

0,25

0°–6°

NOTES: A. All linear dimensions are in millimeters.

B. This drawing is subject to change without notice.

C. Body dimensions do not include mold flash or protrusion.

IMPORTANT NOTICE

T exas Instruments and its subsidiaries (TI) reserve the right to make changes to their products or to discontinue

any product or service without notice, and advise customers to obtain the latest version of relevant information

to verify, before placing orders, that information being relied on is current and complete. All products are sold

subject to the terms and conditions of sale supplied at the time of order acknowledgment, including those

pertaining to warranty, patent infringement, and limitation of liability.

TI warrants performance of its semiconductor products to the specifications applicable at the time of sale in

accordance with TI’s standard warranty. Testing and other quality control techniques are utilized to the extent

TI deems necessary to support this warranty. Specific testing of all parameters of each device is not necessarily

performed, except those mandated by government requirements.

Customers are responsible for their applications using TI components.

In order to minimize risks associated with the customer’s applications, adequate design and operating

safeguards must be provided by the customer to minimize inherent or procedural hazards.

TI assumes no liability for applications assistance or customer product design. TI does not warrant or represent

that any license, either express or implied, is granted under any patent right, copyright, mask work right, or other

intellectual property right of TI covering or relating to any combination, machine, or process in which such

semiconductor products or services might be or are used. TI’s publication of information regarding any third

party’s products or services does not constitute TI’s approval, warranty or endorsement thereof.

Copyright 2000, Texas Instruments Incorporated

Loading...

Loading...