www.ti.com

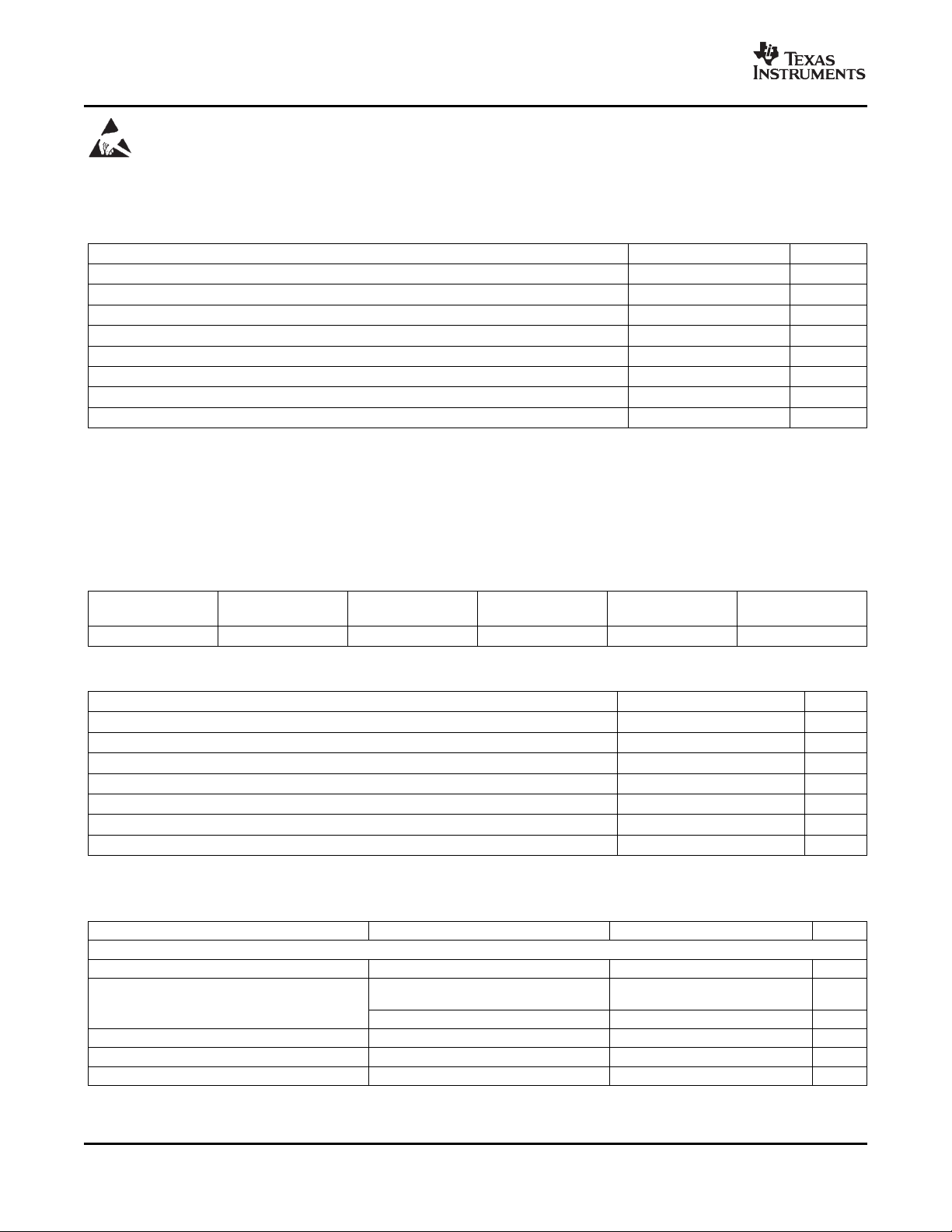

95

90

85

80

75

70

65

60

55

50

3 3.5

4 4.5 5 5.5

6

V -InputVoltage-V

I

Efficiency-%

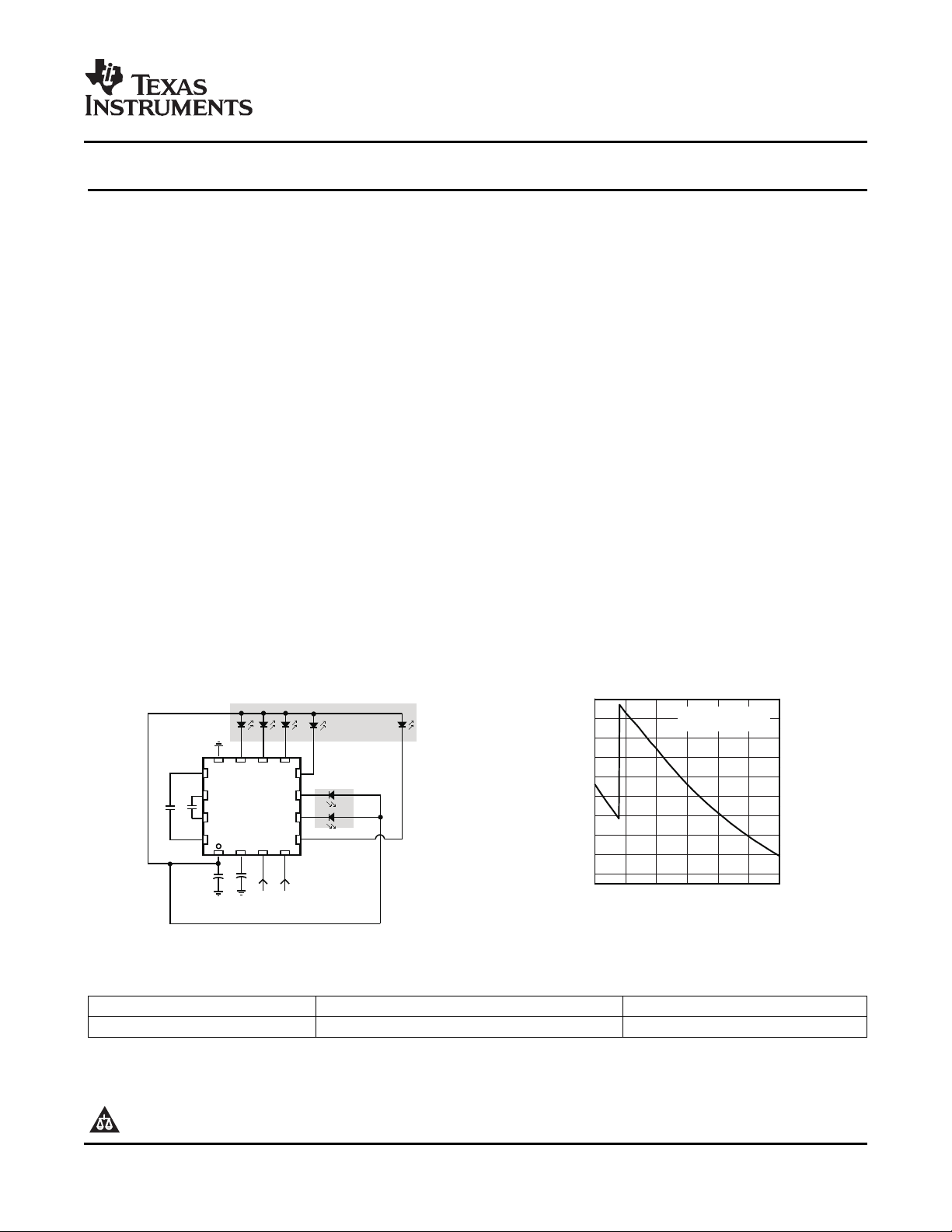

4MainLED-15mA,

V =3.1V

F

C1-

C2+

C2-

C1+

DM1

DM5

DS2

DS1

DM3DM4 DM2

GND

SDAT

SCLKVIN

C1

1mF

C2

1mFC31mF

MainDisplay

C4

4.7mF

SubDisplay

I2CInterface

On/Off, DigitalDimming

VOUT

HIGH EFFICIENCY CHARGE PUMP FOR 7 WLEDs WITH I2C INTERFACE

FEATURES DESCRIPTION

• 3.0-V to 6.0-V Input Voltage Range

• × 1 and × 1.5 Charge Pump

• Fully Programmable Current with I2C

– 64 Dimming Steps with 25mA Maximum

(Sub and Main Display Banks)

– 4 Dimming Steps with 80mA Maximum

(DM5 for Auxiliary Application)

• 2% Current Matching for Sub LEDs at Light

Load Condition (Each 100 µ A)

• 750-kHz Charge Pump Frequency

• Continuous 230-mA Maximum Output Current

• Auto Switching Between × 1 and × 1.5 Mode for

Maximum Efficiency

• Built-in Soft Start and Current Limit

• Open Lamp Detection

• 16-Pin 3mm x 3mm QFN

APPLICATIONS

• Cellular Phones

• PDA, PMP, GPS (Up To 4 Inch LCD Display)

• Multidisplay Handheld Devices

TPS60250

SLVS769 – APRIL 2007

The TPS60250 is a high efficiency, constant

frequency charge pump DC/DC converter that uses a

dual mode 1 × and 1.5 × conversion to maximize

efficiency over the input voltage range. It drives up to

five white LEDs for a main display and up to two

white LEDs for a sub display with regulated constant

current for uniform intensity. By utilizing adaptive

1 × /1.5 × charge pump modes and very low-dropout

current regulators, the TPS60250 achieves high

efficiency over the full 1-cell lithium-battery input

voltage range.

Four enable inputs, ENmain, ENsub1, ENsub2, and

ENaux, available through I2C, are used for simple

on/off controls for the independent main, sub1, sub2,

and DM5 displays, respectively. To lower operating

current when using one sub display LED, the device

provides completely separate operation in sub

display LEDs.

The TPS60250 is available in a 16-pin 3mmx3mm

thin QFN.

Figure 1. Typical Application for Sub and Main Figure 2. Efficiency vs Input Voltage

ORDERING INFORMATION

(1) For the most current package and ordering information, see the Package Option Addendum at the end of this document, or see the TI

PRODUCTION DATA information is current as of publication date.

Products conform to specifications per the terms of the Texas

Instruments standard warranty. Production processing does not

necessarily include testing of all parameters.

PART NUMBER PACKAGE T

TPS60250RTE 16 Pin 3 mm × 3 mm QFN (RTE) –40 ° C to +85 ° C

web site at www.ti.com.

Please be aware that an important notice concerning availability, standard warranty, and use in critical applications of Texas

Instruments semiconductor products and disclaimers thereto appears at the end of this data sheet.

(1)

A

Copyright © 2007, Texas Instruments Incorporated

www.ti.com

TPS60250

SLVS769 – APRIL 2007

These devices have limited built-in ESD protection. The leads should be shorted together or the device placed in conductive foam

during storage or handling to prevent electrostatic damage to the MOS gates.

ABSOLUTE MAXIMUM RATINGS

over operating free-air temperature range (unless otherwise noted)

V

T

T

T

(1) Stresses beyond those listed under absolute maximum ratings may cause permanent damage to the device. These are stress ratings

(2) The Human body model (HBM) is a 100-pF capacitor discharged through a 1.5-k Ω resistor into each pin. The testing is done according

(3) Charged Device Model

(4) Machine Model (MM) is a 200-pF capacitor discharged through a 500-nH inductor with no series resistor into each pin. The testing is

Input voltage range (all pins) –0.3 to 7 V

I

MAX Output current limit 650 mA

HBM ESD Rating

CDM ESD Rating

MM ESD Rating

Operating temperature range –40 to 85 ° C

A

Maximum operating junction temperature 150 ° C

J

Storage temperature –55 to 150 ° C

ST

(2)

(3)

(4)

only and functional operation of the device at these or any other conditions beyond those indicated under recommended operating

conditions is not implied. Exposure to absolute-maximum-rated conditions for extended periods may affect device reliability.

JEDECs EIA/JESD22-A114.

done according JEDECs EIA/JESD22-A115.

(1)

VALUE UNIT

2 kV

500 V

200 V

DISSIPATION RATINGS

PACKAGE

QFN 3 × 3 RTE 74.6 ° C/W 48.7 ° C/W 2.05 W 1.13 W 0.821 W

THERMAL THERMAL TA≤ 25 ° C POWER DERATING FACTOR TA= 85 ° C POWER

RESISTANCE, R

θ JC

RESISTANCE, R

θ JA

RATING ABOVE TA= 25 ° C RATING

RECOMMENDED OPERATING CONDITIONS

MIN NOM MAX UNIT

V

I

I

O(max)

C

I

C

O

C1, C

T

A

T

J

Input voltage range 3.0 6.0 V

Maximum output current 230 mA

Input capacitor 1.0 µ F

Output capacitor 4.7 µ F

Flying capacitor 1.0 µ F

2

Operating ambient temperature –40 85 ° C

Operating junction temperature –40 125 ° C

ELECTRICAL CHARACTERISTICS

VI= 3.5 V, TA= –40 ° C to 85 ° C, typical values are at TA= 25 ° C (unless otherwise noted)

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

SUPPLY VOLTAGE

V

I

I

Q

I

SD

V

UVLO1

V

UVLO2

Input voltage range 3.0 6.0 V

750-kHz Switching in 1.5 × Mode

Operating quiescent current

Shutdown current Enable Control Register has 0x00 1.3 µ A

UVLO Threshold voltage1

UVLO Threshold voltage2

(1)

(2)

(I

No switching in × 1 mode (IO= 100 µ A) 68 µ A

VIfalling 2.2 2.4 2.6 V

VIfalling 1.2 1.3 1.5 V

MAIN_LED

= 15 mA × 4, IO= 60 mA)

6.7 mA

(1) Shut down charge pump and power stage and keep I2C content

(2) Shut down completely and come up with all 0's after device restart

2

Submit Documentation Feedback

www.ti.com

ELECTRICAL CHARACTERISTICS (continued)

VI= 3.5 V, TA= –40 ° C to 85 ° C, typical values are at TA= 25 ° C (unless otherwise noted)

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

V

hys

T

S

CHARGE PUMP

V

out

F

s

R

O

CURRENT SINK

K

m_sub

K

m_main

K

a

I

D_MS

I

D_DM5

V

DropOut

V

TH_GU

V

TH_GD

SERIAL INTERFACE TIMING REQUIREMENTS

f

max

t

wH(HIGH)

t

wL(LOW)

t

r

t

f

t

h(STA)

t

su(STA)

t

h(DATA)

t

su(DATA)

t

su(STO)

t

(BUF)

I2C COMPATIBLE INTERFACE VOLTAGE SPECIFICATION (SCLK, SDAT, VIO)

V

IL

V

IH

V

OL

Under-voltage lockout hysterisis UVLO1 210 mV

Soft start time

(3)

VI= 3 V, CO= 1 µ F,

I

= 15 mA × 4

MAIN_LED

Overvoltage limit 6.5 V

Switching frequency 750 kHz

× 1 Mode, (VI– VO)/I

Open loop output impedance Ω

× 1.5 Mode, (VI× 1.5 – VO)/IOVI= 3.0V (IO=

O

120mA)

Current matching of sub LEDs at light I

load condition

LED to LED Current matching

(4)

(5)

Current accuracy I

Maximum LED current of DM1-4 and

DS1-2

Maximum LED current of DM5 80 mA

LED Drop out voltage See

1 × Mode to 1.5 × mode transition V

threshold voltage

(7)

Input voltage hysteresis for 1.5 × to 1 × Measured as VI– (VO– V

mode transition mA × 4

= 100 µ A × 2, V

SUB_LED

I

= 15 mA × 4,

MAIN_LED

3.0 V ≤ VI≤ 4.2 V

= 15 mA ± 7%

LED

= 0.4 V

DXX

Main and Sub Display Current Register =

0 × 01&2(111111), 25.5 mA

V

= 0.2 V

DXX

Aux Display Current Register = 0 × 03

(XXXX11), V

(6)

Falling, 15 mA × 4 measured on the

DXX

lowest V

= 0.4 V

DM5

DXX

), I

DXX_MIN

MAIN_LED

Clock frequency 400 kHz

Pulse duration, clock high time 600 ns

Pulse duration, clock low time 1300 ns

DATA and CLK rise time 300 ns

DATA and CLK fall time 300 ns

High time (repeated) START

condition(after this period the first clock 600 ns

pulse is generated)

Setup time for repeated START

condition

Data input hold time 0 ns

Data input setup time 100 ns

STOP condition setup time 600 ns

Bus free time 1300 ns

Low-leveI input voltage 3.0V ≤ VI≤ 6.0V 0 0.5 V

High-level input voltage 3.0V ≤ VI≤ 6.0V 1.1 V

Low-level output voltage I

= 2 mA 0.4 V

LOAD

TPS60250

SLVS769 – APRIL 2007

0.5 ms

1.2

3.5 5.0

0 ± 2%

± 1% ± 5%

80 120 mV

85 100 120 mV

= 15

470 mV

600 ns

(3) Measurement Condition: From enabling the LED driver to 90% output voltage after VIis already up.

(4) LED current matching is defined as: (I

(5) LED to LED Current Matching is defined as: (I

(6) Dropout Voltage is defined as V

V

= 0.2 V, WLED current = 15 mA × 4.

DXX

(7) As VIdrops, V

Principle section for details about the mode transition thresholds.

eventually falls below the switchover threshold of 100mV, and TPS60250 switches to 1.5 × mode. See the Operating

DXX

SUB_LED_WORST

(WLED Cathode) to GND voltage at which current into the LED drops 10% from the LED current at

DXX

– I

MAIN_LED_WORST

) / I

AVG_SUB

AVG_SUB

– I

AVG_MAIN

) / I

AVG_MAIN

Submit Documentation Feedback

3

www.ti.com

C1-

C2+

C2-

C1+

DM1

DM

3

DM4

GND

DM2

VOUT VIN SCLK SDAT

DM5

DS2

DS1

1 2

91012 11

7

8

6

5

3 4

13

14

15

16

QFN16-PINRTE

3mmX3mm

(TOP VIEW)

TPS60250

SLVS769 – APRIL 2007

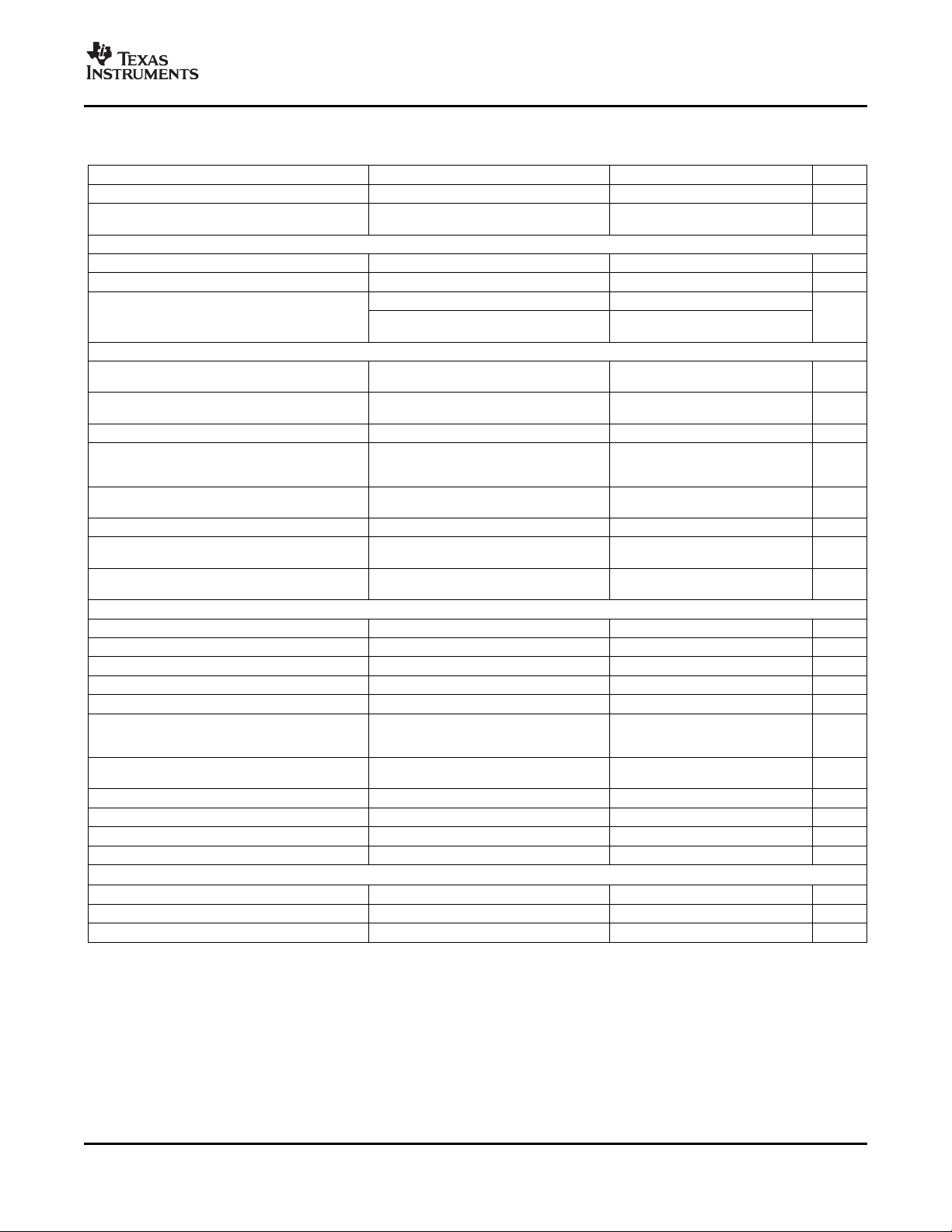

PIN ASSIGNMENTS

TERMINAL FUNCTIONS

TERMINAL

NAME NO.

VOUT 1 O

VIN 2 I

SCLK 3 I I2C Interface

SDAT 4 I/O I2C Interface

DM5 5 I Current sink input. Connect the cathode of the aux display or the 5th main display white LED to this pin.

DS1 6 I

DS2 7 I

DM1 8 I

DM2 9 I

DM3 10 I

DM4 11 I

GND 12 – Ground

C1– 13 – Connect to the flying capacitor C1

C2+ 14 – Connect to the flying capacitor C2

C2– 15 – Connect to the flying capacitor C2

C1+ 16 – Connect to the flying capacitor C1

I/O DESCRIPTION

Connect the anodes of the sub, main, and aux display white LEDs to this pin. Bypass decouple VOUT to

GND with a 4.7- µ F or greater ceramic capacitor.

Supply voltage input. Connect to a 3-V to 6-V input supply source. Bypass VIN to GND with a 1- µ F or

greater ceramic capacitor.

Current sink input. Connect the cathode of one of the sub display white LEDs to this pin.

Current sink input. Connect the cathode of one of the main display white LED to this pin.

4

Submit Documentation Feedback

www.ti.com

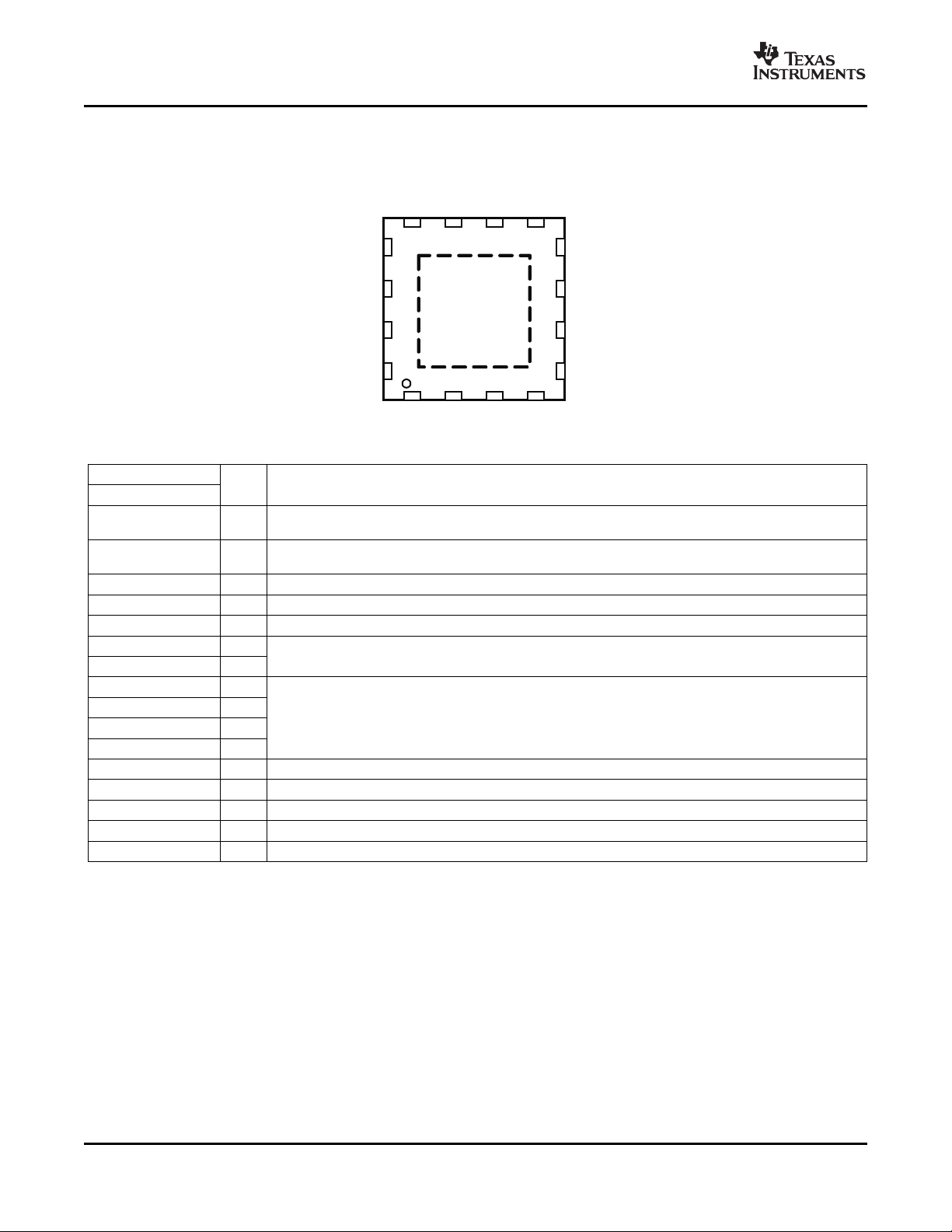

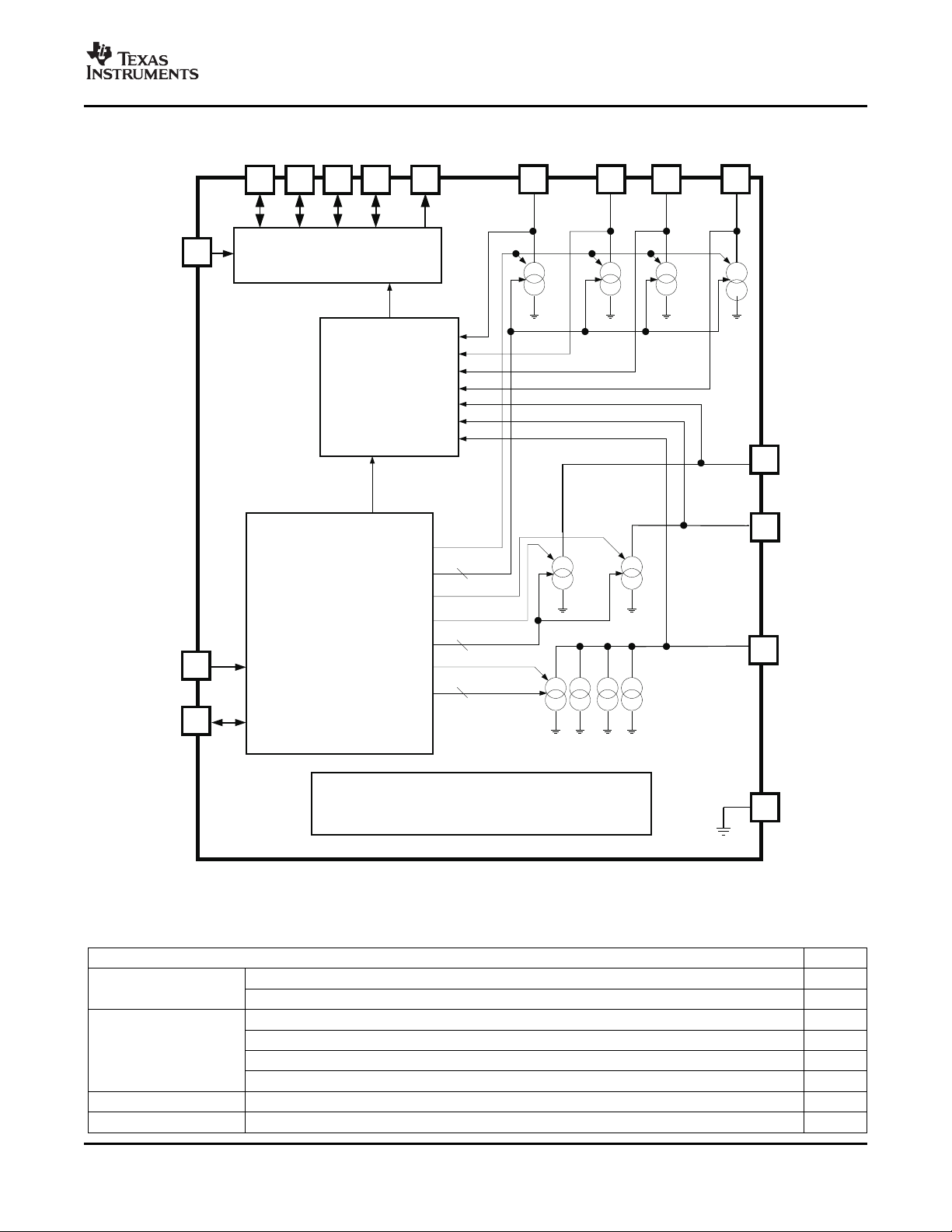

FUNCTIONAL BLOCK DIAGRAM

5

DM5

6

DS1

7 DS2

11 10 9 8

DM 4 DM 3 DM 2 DM 1

GEAR

CONTROL

&

OPENLAMP

DETECTION

1X, 1.5XCHARGEPUMP

1

VOUT

13141516

C

1

-

C

2

+

C

2

-

C

1

+

2

VIN

I2C

INTERFACE

ENmain

MainDimming

ENsub 1

ENsub 2

SubDimming

ENaux

AUXDimming

SCLK

SDAT 4

3

6

6

6

12 GND

BIAS, TEST,& MONITORING

ENold

TPS60250

SLVS769 – APRIL 2007

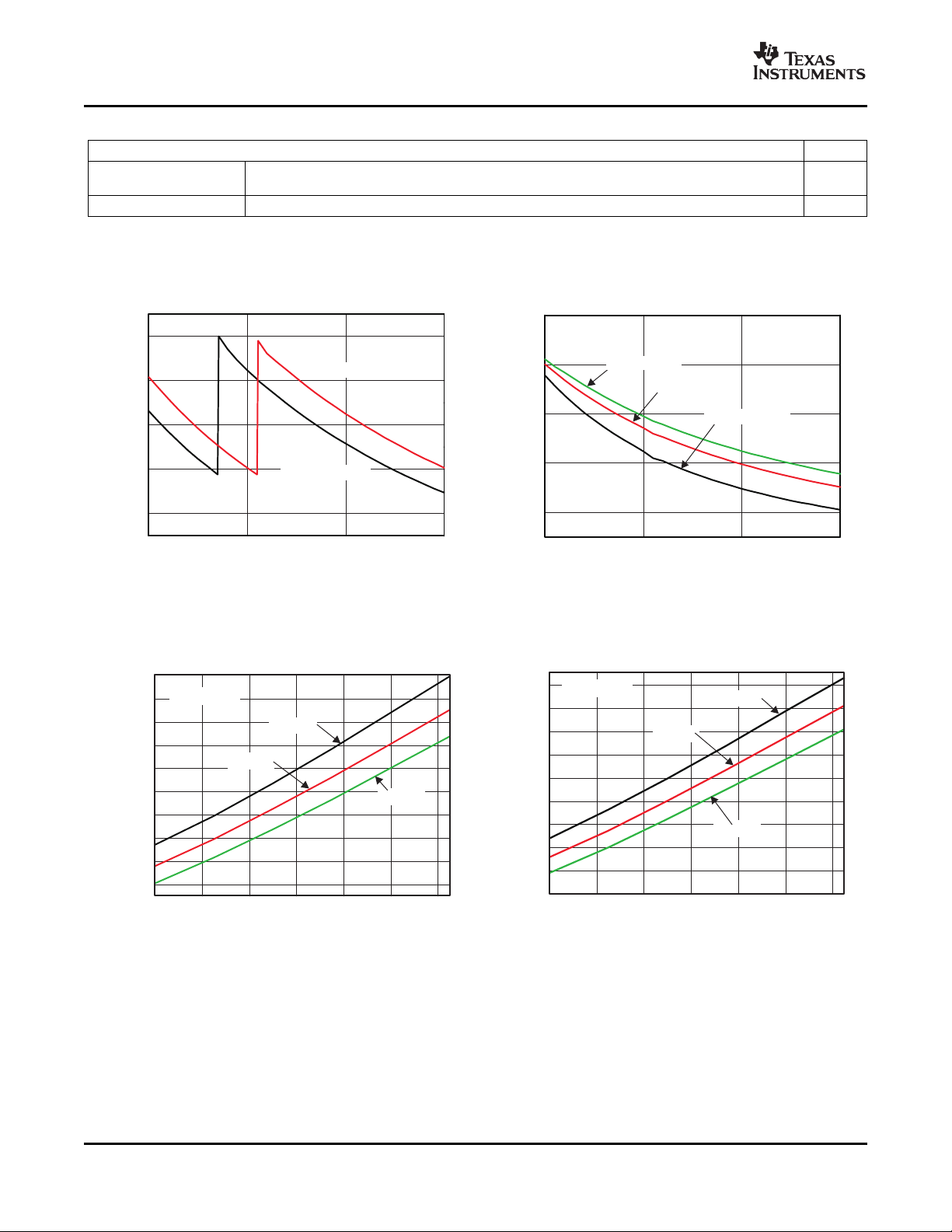

TABLE OF GRAPHS

Efficiency

Output Impedance of × 1

and × 1.5 Mode

Shutdown Current Shutdown Current vs Input Voltage Figure 9

Input Current Input Current vs Supply Voltage, 4 Main LED Figure 10

Efficiency vs Input Voltage, 4 Main LED - 15mA, 25mA Figure 3

Efficiency vs Input Voltage, 2 Sub LED with Light Load Condition, × 1 Mode Operation Figure 4

Switch Resistance vs Free-Air Temperature, × 1 Mode, I

Switch Resistance vs Free-Air Temperature, × 1 Mode, I

Switch Resistance vs Free-Air Temperature, × 1.5 Mode Charge Pump Open-Loop , I

Switch Resistance vs Free-Air Temperature, × 1.5 Mode Charge Pump Open-Loop, I

TYPICAL CHARACTERISTICS

DESCRIPTION REF

= 230 mA Figure 5

LED

= 100 mA Figure 6

LED

= 230 mA Figure 7

LED

= 100 mA Figure 8

LED

Submit Documentation Feedback

5

www.ti.com

90

80

70

60

50

Efficiency-%

3 4 5 6

V -InputVoltage-V

I

15mA,V =3.43V

F

25mA,V =3.79V

F

100

80

40

60

20

Efficiency-%

3 4 5 6

V -InputVoltage-V

I

0.2mA,V =2.6V

F

1mA,V =2.8V

F

0.5mA,V =2.7V

F

-40 -20 0 20 40 60 80

0.65

0.70

0.75

0.80

0.85

0.90

0.95

1

1.05

1.10

SwitchResistance- W

T -Free-AirTemperature-°C

A

I

LED

=100mA

V =3.6V

I

V =3.9V

I

V =3.3V

I

-40 -20 0 20 40 60 80

0.70

0.75

0.80

0.85

0.90

0.95

1

1.05

1.10

1.15

T -Free-AirTemperature-°C

A

V =3.6V

I

V =3.9V

I

I

LED

=230mA

V =3.3V

I

SwitchResistance- W

TPS60250

SLVS769 – APRIL 2007

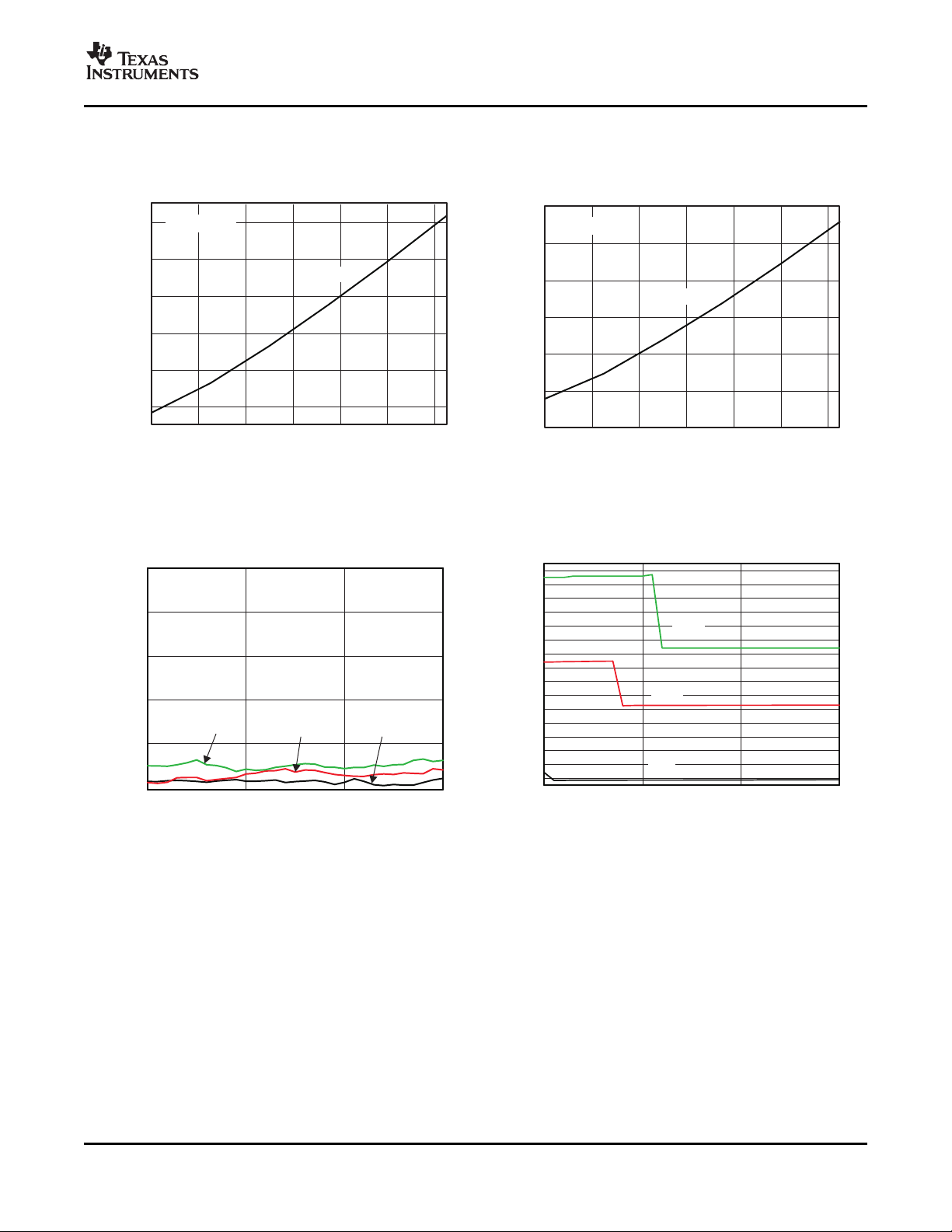

TYPICAL CHARACTERISTICS (continued)

DESCRIPTION REF

DM5 with Maximum 80

mA

Current Accuracy WLED Current vs Input Voltage, 4 Main LED with 15 mA Figure 12

DM5 Current vs Input Voltage, Programmed with 80 mA Figure 11

EFFICIENCY vs

vs INPUT VOLTAGE

INPUT VOLTAGE (2 Sub LED with Light Load Condition,

(4 Main LED - 15mA, 25mA) × 1 Mode Operation)

Figure 3. Figure 4.

SWITCH RESISTANCE SWITCH RESISTANCE

vs vs

FREE-AIR TEMPERATURE FREE-AIR TEMPERATURE

( × 1 Mode) ( × 1 Mode)

EFFICIENCY

6

Figure 5. Figure 6.

Submit Documentation Feedback

www.ti.com

-40

-20

0

20

40 60 80

2.8

3

3.2

3.4

3.6

3.8

I

LED

=230mA

V =3V

I

SwitchResistance- W

T -Free-AirTemperature-°C

A

-40 -20 0 20 40 60 80

2.6

2.8

3

3.2

3.4

3.6

3.8

SwitchResistance-

W

T -Free-AirTemperature-°C

A

I

LED

=100mA

V =3V

I

0.16

0.15

0.14

0.13

0.12

0.11

0.10

0.09

0.08

0.07

0.06

0.05

0.04

0.03

0.02

0.01

I

-InputCurrent- A

CC

3

4

5

6

V -InputVoltage-V

I

25mA

15mA

2mA

10

8

6

4

2

0

ShutdownCurrent- Am

3

4

5

6

V -InputVoltage-V

I

T =85°C

A

T =25°C

A

T =-40°C

A

TPS60250

SLVS769 – APRIL 2007

SWITCH RESISTANCE SWITCH RESISTANCE

vs vs

FREE-AIR TEMPERATURE FREE-AIR TEMPERATURE

( × 1.5 Mode Charge Pump Open-Loop) ( × 1.5 Mode Charge Pump Open-Loop)

Figure 7. Figure 8.

INPUT CURRENT

SHUTDOWN CURRENT vs

vs SUPPLY VOLTAGE

INPUT VOLTAGE (4 Main LED)

Figure 9. Figure 10.

Submit Documentation Feedback

7

www.ti.com

2.5 3 3.5 4

0

0.01

0.02

0.03

0.04

0.05

0.06

0.07

0.08

V -InputVoltage-V

I

0.3V

0.15V

0.1V

0.05V

0.4V

0.35V

0.25V

0.2V

DM5Current- A

0.016

0.014

0.012

0.010

3 4 5 6

V -InputVoltage-V

I

WLEDCurrent-

A

IDM3IDM2

IDM1

IDM4

TPS60250

SLVS769 – APRIL 2007

DM5 CURRENT WLED CURRENT

vs vs

INPUT VOLTAGE INPUT VOLTAGE

(Programmed with 80 mA) (4 Main LED with 15 mA)

Figure 11. Figure 12.

8

Submit Documentation Feedback

www.ti.com

TPS60250

SLVS769 – APRIL 2007

APPLICATION INFORMATION

APPLICATION OVERVIEW

Most of the current handsets fall into one of three categories. First is the clamshell design, with a main display

on the inside, a secondary display on the outside and a keypad backlight. Second is the bar design, with a main

display and a keypad backlight. Third is the slide type (slide-up and slide-down) design, with a main display and

two keypad banks (inside and outside). The TPS60250 is well suited for use in these three major phone designs

because it has 7 individually regulated white LED current paths and that drive up to five white LEDs in main

display and up to two white LEDs in sub display with regulated constant current for uniform intensity. The main

and sub display LED channels drive up to 25mA and an auxiliary LED output (DM5) drives up to 80mA that can

be assigned for keypad backlight, torch light or low cost/weak camera flash application using I2C interface.

The TPS60250 circuit uses only 4 external components: the input/output capacitors and 2 chargepump flying

capacitors. The few external components combined with the small 3mm × 3mm QFN package provide for a small

total solution size. By combining independent control of three separate banks of backlight LEDs with low cost

and weak flash capability, the TPS60250 helps designers minimize power consumption especially in case of

light load condition while reducing component count and package size.

OPERATING PRINCIPLE

Charge pumps are becoming increasingly attractive in battery-operated applications where board space and

maximum height of the converter are critical constraints. The major advantage of a charge pump is the use of

only capacitors as storage elements. The TPS60250 chargepump provides regulated LED current from a 3-V to

6-V input source. It operates in two modes. The 1 × mode, where the input is connected to the output through a

pass element, and a high efficiency 1.5 × charge pump mode. The IC maximizes power efficiency by operating in

1 × and 1.5 × modes as input voltage and LED current conditions require. The mode of operation is automatically

selected by comparing the forward voltage of the WLED plus the voltage of current sink for each LED with the

input voltage. The IC starts up in 1 × mode, and automatically transitions to 1.5 × if the voltage at any current sink

input (DM_or DS_) falls below the 100-mV transition voltage. The IC returns to 1 × mode as the input rises.

Figure 13 provides a visual explanation of the 1 × to 1.5 × transition.

In 1.5 × mode, the internal oscillator determines the charge/discharge cycles for the flying capacitors. During a

charge cycle, the flying capacitors are connected in series and charged up to the input voltage. After the on-time

of the internal oscillator expires, the flying capacitors are reconfigured to be in parallel and then connected in

series to the input voltage. This provides an output of 1.5 × the input voltage. After the off-time of the internal

oscillator expires, another charge cycle initiates and the process repeats.

Submit Documentation Feedback

9

www.ti.com

x1Operating

Area

x1.5

Operating

Area

V

I

V

I

V

O

V

A

V

F

V

DX

CP WLEDDriver

V

B

V

C

V

HYS

TPS60250

SLVS769 – APRIL 2007

APPLICATION INFORMATION (continued)

Figure 13. Input Voltage Hysteresis Between × 1 and × 1.5 Mode

As shown in Figure 13 , there is input voltage hysteresis voltage between 1 × and 1.5 × mode to ensure stable

operation during mode transition. For the 1 cell Li-Ion battery input voltage range, the TPS60250 operates in 1 ×

mode when a fully charged battery is installed. Once the battery voltage drops below the V

level, which is the

B

mode transition voltage from 1 × to 1.5 × , the WLED driver operates in 1.5 × mode. Once in 1.5 × mode, the battery

voltage must rise to the V

level in order to transition from 1.5 × to 1 × . This hysteresis ensures stable operation

C

when there is some input voltage fluctuation at the 1 × /1.5 × mode transition. The WLED driver provides a typical

280mV hysteresis voltage (V

The transition voltage, VB, depends on V

drop) and V

V

B

V

A

Where R

impedance specifications.

The TPS60250 switches up to 1.5 × mode when the input voltage is below V

(the drop out voltage of the charge pump stage) and is calculated as follows:

A

= V

+ V

A

= R

OUT1X

OUT1X

+ V

F

DX

× I

LEDTOTAL

is the 1 × mode output impedance of the IC. See the Electrical Characteristics table for output

as the input is lower than VC. 1.5 × Mode is exited when the input voltage rises above VC. V

V

= V

C

+ 470 mV

F

The input voltage mode transition hysteresis voltage (V

) that changes based on LED current, to prevent oscillating between modes.

HYS

(the mode transition threshold voltage), V

DX

and remains in 1.5 × mode as long

B

) between 1 × and 1.5 × is calculated using the

HYS

(WLED forward voltage

F

is calculated as:

C

following equation.

V

HYS

Note that V

= VC– V

A

= 520 mV – V

B

– VA, where V

DX

is the key factor in determining V

= 100mV

DX

and is dependant on the 1 × mode charge pump output

HYS

impedance and WLED current.

10

Submit Documentation Feedback

www.ti.com

TPS60250

SLVS769 – APRIL 2007

APPLICATION INFORMATION (continued)

LED CURRENT SINKS (DM_, DS_)

The TPS60250 has constant current sinks which drive seven individual LED current paths. Each current sink

regulates the LED current to a constant value determined by the I2C interface. The internal register addressing

allows the LED main channels DM1~DM5 to be controlled independently from the LED sub channels DS1~DS2.

All the LED channels sink up to 25mA of current except DM5 which has an 80-mA maximum current when

configured as an auxiliary output. Using the I2C interface, the user may assign DM5 to the main display bank

with up to 25-mA current or as an auxiliary output for torch or keypad light or low/weak camera flash with 80-mA

current. DM5 has 64 dimming steps same as main and sub display banks when assigned to the main display.

However, it has its own current programming register and enable control. When assigned as an auxiliary, DM5

has 4 dimming steps (full scale, 70%, 40%, 20%).

These optimized current sinks minimize the voltage headroom required to drive each LED and maximize power

efficiency by increasing the amount of time the controller stays in 1 × mode before transitioning to 1.5 × mode.

OPEN LAMP DETECTION

In system production it is often necessary to leave LED current paths open depending on the phone model. For

example, one phone may use 2 LEDs to backlight the main display while another uses 4 LEDs. Rather than use

two different ICs for these different phone applications, the TPS60250 may be used in both applications with no

additional efficiency loss in the 2 LED applications. In traditional LED driver applications when an LED current

path is open, the current sink voltage falls to ground and the current regulation circuitry drives the output to a

maximum voltage in an attempt to regulate the current for the missing LED path. This severely reduces the

system efficiency. The TPS60250 uses 7 internal comparators to detect when one or more open LED condition

occurs and shut down prevent it from forcing the device to gear up the open current sink. The open lamp

detection is enabled/disabled using the I2C interface.

CAPACITOR SELECTION

The TPS60250 is optimized to work with ceramic capacitors with a dielectric of X5R or better. The two flying

capacitors must be the same value for proper operation. The 750-kHz switching frequency requires that the

flying capacitor be less than 4.7 µ F. Use of 1- µ F ceramic capacitors for both chargepump flying capacitors is

recommended.

For good input voltage filtering, low ESR ceramic capacitors are recommended. A 1- µ F ceramic input capacitor

is sufficient for most of the applications. For better input voltage filtering this value can be increased.

The output capacitor controls the amount of ripple on the output. Since small ripple is undetectable by the

human eye, a 4.7- µ F output capacitor works well. If better output filtering and lower ripple is desired, a larger

output capacitor may be used.

SETTING THE LED CURRENT

Figure 14. Dimming Steps for Sub, Main, and Keypad Backlight

Submit Documentation Feedback

11

www.ti.com

Dataline

stable;

datavalid

DATA

CLK

Change

ofdata

allowed

STARTCondition

DATA

CLK

STOP Condition

S P

CE

TPS60250

SLVS769 – APRIL 2007

APPLICATION INFORMATION (continued)

Figure 14 shows the dimming steps for sub, main, and auxiliary display banks in the 25mA maximum current

application. In order to satisfy today's requirement on LED current, the TPS60250 covers low LED current area

from 100 µ A to 1.5mA with 100- µ A dimming step (total 16 steps for 25-mA maximum current) for the new LCD

panels which have improved transparency rates. For LED currents in the range from 2mA to 25mA, the device

uses 48 dimming steps with 0.5mA step. Also, DM5 has 4 dimming steps once the current path is assigned for

auxiliary applications with maximum 80-mA current.

SERIAL INTERFACE

The serial interface is compatible with the standard and fast mode I2C specifications, allowing transfers at up to

400 kHz. The interface adds flexibility to the WLED driver solution, enabling most functions to be programmed to

new values depending on the instantaneous application requirements. Register contents remain intact as long

as V

For normal data transfer, DATA is allowed to change only when CLK is low. Changes when CLK is high are

reserved for indicating the start and stop conditions. During data transfer, the data line must remain stable

whenever the clock line is high. There is one clock pulse per bit of data. Each data transfer is initiated with a

start condition and terminated with a stop condition. When addressed, the TPS60250 device generates an

acknowledge bit after the reception of each byte. The master device (microprocessor) must generate an extra

clock pulse that is associated with the acknowledge bit. The TPS60250 device must pull down the DATA line

during the acknowledge clock pulse so that the DATA line is a stable low during the high period of the

acknowledge clock pulse. Setup and hold times must be taken into account. During read operations, a master

must signal the end of data to the slave by not generating an acknowledge bit on the last byte that was clocked

out of the slave. In this case, the slave TPS60250 device must leave the data line high to enable the master to

generate the stop condition.

remains above UVLO2 (typical 1.3V).

CC

Figure 15. Bit Transfer on the Serial Interface

Figure 16. START and STOP Conditions

12

Submit Documentation Feedback

www.ti.com

SCLK

... ......

SDAT

Slave Address DataRegister Address

.........

A6 R6 R5 R0

AC

K

D7 D6 D5 D0

AC

K

R7

AC

K

R/WA0A4A5

0 0 0 0

StopStart

NOTE: SLAVE=TPS60250

SCLK

... ......

SDAT

Slave Address Slave Address

Register

Address

....

A6 R0

AC

K

R7

AC

K

R/WA0

0 0 0 0

Stop

Start

NOTE: SLAVE=TPS60250

...

..

AC

K

D0D7

AC

K

R/WA0A6

1

Slave

Drives

theData

Master

Drives

ACKandStop

Repeated

Start

..

APPLICATION INFORMATION (continued)

Figure 17. Serial I/F READ From TPS60250: Protocol A

TPS60250

SLVS769 – APRIL 2007

Figure 18. Serial I/F READ From TPS60250: Protocol B

Figure 19. Serial I/F Timing Diagram

The I2C interface uses a combined protocol in which the START condition and the Slave Address are both

repeated. The TPS60250 provides 2 I2C Slave Address using internal EEPROM in case more than 1 device is

used in the system. The primary I2C Slave Address is 1110111. For alternative I2C address, contact the factory.

Submit Documentation Feedback

13

www.ti.com

TPS60250

SLVS769 – APRIL 2007

APPLICATION INFORMATION (continued)

Enable Control Register (Address: 0x00h)

ENABLE B7 B6 B5 B4 B3 B2 B1 B0

BIT NAME X ENold ENmain ENsub2 ENsub1 ENaux DM5H DM5L

Bit 6 ENold (Enable Open Lamp Detection)

1: Open Lamp Detection Enabled

0: Open Lamp Detection Disabled

Bit 5 ENmain

1: Enable Main Display LEDs (DM1-DM4)

0: Disable Main Display LEDs

Bit 4 ENsub2

1: Enable Sub Display LED 2 (DS2)

0: Disable Sub Display LED 2

Bit 3 ENsub1

1: Enable Sub Display LED 1 (DS1)

0: Disable Sub Display LED 1

Bit 2 ENaux

1: Enable Aux Display LED (DM5)

0: Disable Aux Display LED

Bits 1,0 DM5H, DM5L

DM5H DM5L

(B1) (B0)

0 0 Shutdown mode. All outputs disabled, all internal registers set to 0x00h

0 1 Enable the IC and Group DM5 as main display with maximum current of 25mA

1 0 Enable the IC and set DM5 as Aux output with maximum current of 80mA.

Dimming steps determined by Iaux0 and Iaux1 bits.

1 1 Shutdown mode. All outputs disabled, all internal registers set to 0x00h

DM5 Mode and Shutdown Mode

Sub Display Current Control Register (Address: 0x01h)

SUB DISP

CURRENT

BIT NAME X X Isub5 Isub4 Isub3 Isub2 Isub1 Isub0

B7 B6 B5 B4 B3 B2 B1 B0

Bits 5 - 0 Isub5 - Isub0 (total 64 steps)

6-Bit command (64 steps) to these bits sets the current for DS1 and DS2.

For LED currents between 0 and 1.5mA, one step = 0.1mA increment

For LED currents between 1.5 and 25.5mA, one step = 0.5mA increment

Main Display Current Control Register (Address: 0x02h)

MAIN DISP

CURRENT

BIT NAME X X Imain5 Imain4 Imain3 Imain2 Imain1 Imain0

B7 B6 B5 B4 B3 B2 B1 B0

Bits 5 - 0 Imain5 - Imain0 (total 64 steps)

6-Bit command (64 steps) to these bits sets the current for DM1-DM4.

For LED currents between 0 and 1.5mA, one step = 0.1mA increment

For LED currents between 1.5 and 25.5mA, one step = 0.5mA increment

14

Submit Documentation Feedback

www.ti.com

Aux Output Brightness and Operation Mode Control Register (Address: 0x03h)

AUX DISP

CURRENT

BIT NAME Iaux5 Iaux4 Iaux3 Iaux2 Iaux1 Iaux0 Mode1 Mode0

B7 B6 B5 B4 B3 B2 B1 B0

Bits 7 - 2 (DM5 set to Main Display Mode)

Iaux5 - Iaux0 (total 64 steps)

6-Bit command (64 steps) to these bits sets the current for DM5.

For LED currents between 0 and 1.5mA, one step = 0.1mA increment

For LED currents between 1.5 and 25.5mA, one step = 0.5mA increment

Bits 7 - 2 (DM5 set to Aux Display Mode)

Iaux5 Iaux4 Iaux3 Iaux2 Iaux1 Iaux0 Aux Dimming

(B7) (B6) (B5) (B4) (B3) (B2) Step

X X X X 0 0 20%

X X X X 0 1 40%

X X X X 1 0 70%

X X X X 1 1 100%

TPS60250

SLVS769 – APRIL 2007

Bits 1,0 Mode1, Mode0

Mode1 Mode0

(B1) (B0)

TPS60250 Mode

0 0 Auto-Switchover Mode. The TPS60250 selects

1 × /1.5 × mode as described in the Operating Principle

section.

0 1 1 × Mode. TPS60250 remains in 1 × mode regardless

of the input voltage. LED current may not regulate at

lower input voltages when in this mode.

1 0 1.5 × Mode. TPS60250 remains in 1.5 × mode

regardless of the input voltage.

1 1 Auto-Switchover Mode. The TPS60250 selects

1 × /1.5 × mode as described in the Operating Principle

section.

Submit Documentation Feedback

15

www.ti.com

C1-

C2+

C2-

C1+

DM1

DM5

DS2

DS1

DM3DM4 DM2GND

SDATSCLKVIN

C1

1

mF

C2

1

mF

C3

1

mF

MainDisplay

C4

4.7

mF

SubDisplay

I2CInterface

On/Off, DigitalDimming

VOUT

h

Light

+

IO V

F

V

in

ǒ

IO) I

op

Ǔ

TPS60250

SLVS769 – APRIL 2007

APPLICATION CIRCUITS

Figure 20. The Typical Application Circuit for Sub and Main Display

As shown in Figure 20 , this is a typical application circuit for a clam shell phone with 5 main LEDs and 2 sub

LEDs. Recently, the LCD panel makers have developed a new panel that has improved the transparency rate

which makes the system efficiency with a 100- µ A LED current a critical load point. To meet system efficiency

requirements with the light load conditions for the new LCD operating panel, the TPS60250 has a maximum

55- µ A operating current with the 100- µ A output load condition. In this application, the controller always operates

in 1 × mode due to the WLED's low forward voltage drop (about 2.6V

with a 100- µ A WLED current). Thus, the

F

total efficiency at a light load condition is determined using Equation 1 :

Where:

IO: Output Load (WLED) Current

VF: Forward Voltage Drop of WLED

Vin: Input Voltage

Iop: Operating Current of LED Driver

(1)

16

Submit Documentation Feedback

www.ti.com

C1-

C2+

C2-

C1+

DM1

DM5

DS2

DS1

DM3DM 4 DM2GND

SDATSCLKVIN

C1

1uF

C2

1mFC31mF

MainDisplay

C4

4.7mF

SubDisplay

I2CInterface

On/Off, DigitalDimming

VOUT

AuxiliaryPortforKeyPad

orFlashLight

TPS60250

SLVS769 – APRIL 2007

Figure 21. The Typical Application Circuit for Sub, Main, and Keypad Backlight

Figure 21 shows the typical application circuit for sub, main, and keypad backlight. In this application, DM5 is

assigned as the auxiliary input for the keypad lighting application.

LAYOUT GUIDELINES

There are several points to consider when laying out a PCB for charge pump based solutions. In general, all

capacitors should be as close as possible to the device. This is especially important when placing the flying

capacitors (C2, C3 in Figure 20 and Figure 21 ). In cases where DM5 is assigned for torch/flash applications,

with a maximum 80-mA WLED current, this current path must be kept wide to reduce the trace resistance.

Submit Documentation Feedback

17

PACKAGE OPTION ADDENDUM

www.ti.com

7-May-2007

PACKAGING INFORMATION

Orderable Device Status

(1)

Package

Type

Package

Drawing

Pins Package

Qty

Eco Plan

TPS60250RTER ACTIVE QFN RTE 16 3000 Green (RoHS &

no Sb/Br)

TPS60250RTET ACTIVE QFN RTE 16 250 Green (RoHS &

no Sb/Br)

(1)

The marketing status values are defined as follows:

ACTIVE: Product device recommended for new designs.

LIFEBUY: TI has announced that the device will be discontinued, and a lifetime-buy period is in effect.

NRND: Not recommended for new designs. Device is in production to support existing customers, but TI does not recommend using this part in

a new design.

PREVIEW: Device has been announced but is not in production. Samples may or may not be available.

OBSOLETE: TI has discontinued the production of the device.

(2)

Eco Plan - The planned eco-friendly classification: Pb-Free (RoHS), Pb-Free (RoHS Exempt), or Green (RoHS & no Sb/Br) - please check

http://www.ti.com/productcontent for the latest availability information and additional product content details.

TBD: The Pb-Free/Green conversion plan has not been defined.

Pb-Free (RoHS): TI's terms "Lead-Free" or "Pb-Free" mean semiconductor products that are compatible with the current RoHS requirements

for all 6 substances, including the requirement that lead not exceed 0.1% by weight in homogeneous materials. Where designed to be soldered

at high temperatures, TI Pb-Free products are suitable for use in specified lead-free processes.

Pb-Free (RoHS Exempt): This component has a RoHS exemption for either 1) lead-based flip-chip solder bumps used between the die and

package, or 2) lead-based die adhesive used between the die and leadframe. The component is otherwise considered Pb-Free (RoHS

compatible) as defined above.

Green (RoHS & no Sb/Br): TI defines "Green" to mean Pb-Free (RoHS compatible), and free of Bromine (Br) and Antimony (Sb) based flame

retardants (Br or Sb do not exceed 0.1% by weight in homogeneous material)

(2)

Lead/Ball Finish MSL Peak Temp

CU NIPDAU Level-2-260C-1 YEAR

CU NIPDAU Level-2-260C-1 YEAR

(3)

(3)

MSL, Peak Temp. -- The Moisture Sensitivity Level rating according to the JEDEC industry standard classifications, and peak solder

temperature.

Important Information and Disclaimer:The information provided on this page represents TI's knowledge and belief as of the date that it is

provided. TI bases its knowledge and belief on information provided by third parties, and makes no representation or warranty as to the

accuracy of such information. Efforts are underway to better integrate information from third parties. TI has taken and continues to take

reasonable steps to provide representative and accurate information but may not have conducted destructive testing or chemical analysis on

incoming materials and chemicals. TI and TI suppliers consider certain information to be proprietary, and thus CAS numbers and other limited

information may not be available for release.

In no event shall TI's liability arising out of such information exceed the total purchase price of the TI part(s) at issue in this document sold by TI

to Customer on an annual basis.

Addendum-Page 1

PACKAGE MATERIALS INFORMATION

www.ti.com

2-Jul-2007

TAPE AND REEL INFORMATION

Pack Materials-Page 1

PACKAGE MATERIALS INFORMATION

www.ti.com

Device Package Pins Site Reel

Diameter

(mm)

TPS60250RTER RTE 16 MLA 330 12 3.3 3.3 1.1 8 12 Q2

TPS60250RTET RTE 16 MLA 180 12 3.3 3.3 1.1 8 12 Q2

Reel

Width

(mm)

A0 (mm) B0 (mm) K0 (mm) P1

(mm)W(mm)

2-Jul-2007

Pin1

Quadrant

TAPE AND REEL BOX INFORMATION

Device Package Pins Site Length (mm) Width (mm) Height (mm)

TPS60250RTER RTE 16 MLA 346.0 346.0 29.0

TPS60250RTET RTE 16 MLA 190.0 212.7 31.75

Pack Materials-Page 2

IMPORTANT NOTICE

Texas Instruments Incorporated and its subsidiaries (TI) reserve the right to make corrections, modifications, enhancements,

improvements, and other changes to its products and services at any time and to discontinue any product or service without notice.

Customers should obtain the latest relevant information before placing orders and should verify that such information is current and

complete. All products are sold subject to TI’s terms and conditions of sale supplied at the time of order acknowledgment.

TI warrants performance of its hardware products to the specifications applicable at the time of sale in accordance with TI’s

standard warranty. Testing and other quality control techniques are used to the extent TI deems necessary to support this

warranty. Except where mandated by government requirements, testing of all parameters of each product is not necessarily

performed.

TI assumes no liability for applications assistance or customer product design. Customers are responsible for their products and

applications using TI components. To minimize the risks associated with customer products and applications, customers should

provide adequate design and operating safeguards.

TI does not warrant or represent that any license, either express or implied, is granted under any TI patent right, copyright, mask

work right, or other TI intellectual property right relating to any combination, machine, or process in which TI products or services

are used. Information published by TI regarding third-party products or services does not constitute a license from TI to use such

products or services or a warranty or endorsement thereof. Use of such information may require a license from a third party under

the patents or other intellectual property of the third party, or a license from TI under the patents or other intellectual property of TI.

Reproduction of TI information in TI data books or data sheets is permissible only if reproduction is without alteration and is

accompanied by all associated warranties, conditions, limitations, and notices. Reproduction of this information with alteration is an

unfair and deceptive business practice. TI is not responsible or liable for such altered documentation. Information of third parties

may be subject to additional restrictions.

Resale of TI products or services with statements different from or beyond the parameters stated by TI for that product or service

voids all express and any implied warranties for the associated TI product or service and is an unfair and deceptive business

practice. TI is not responsible or liable for any such statements.

TI products are not authorized for use in safety-critical applications (such as life support) where a failure of the TI product would

reasonably be expected to cause severe personal injury or death, unless officers of the parties have executed an agreement

specifically governing such use. Buyers represent that they have all necessary expertise in the safety and regulatory ramifications

of their applications, and acknowledge and agree that they are solely responsible for all legal, regulatory and safety-related

requirements concerning their products and any use of TI products in such safety-critical applications, notwithstanding any

applications-related information or support that may be provided by TI. Further, Buyers must fully indemnify TI and its

representatives against any damages arising out of the use of TI products in such safety-critical applications.

TI products are neither designed nor intended for use in military/aerospace applications or environments unless the TI products are

specifically designated by TI as military-grade or "enhanced plastic." Only products designated by TI as military-grade meet military

specifications. Buyers acknowledge and agree that any such use of TI products which TI has not designated as military-grade is

solely at the Buyer's risk, and that they are solely responsible for compliance with all legal and regulatory requirements in

connection with such use.

TI products are neither designed nor intended for use in automotive applications or environments unless the specific TI products

are designated by TI as compliant with ISO/TS 16949 requirements. Buyers acknowledge and agree that, if they use any

non-designated products in automotive applications, TI will not be responsible for any failure to meet such requirements.

Following are URLs where you can obtain information on other Texas Instruments products and application solutions:

Products Applications

Amplifiers amplifier.ti.com Audio www.ti.com/audio

Data Converters dataconverter.ti.com Automotive www.ti.com/automotive

DSP dsp.ti.com Broadband www.ti.com/broadband

Interface interface.ti.com Digital Control www.ti.com/digitalcontrol

Logic logic.ti.com Military www.ti.com/military

Power Mgmt power.ti.com Optical Networking www.ti.com/opticalnetwork

Microcontrollers microcontroller.ti.com Security www.ti.com/security

RFID www.ti-rfid.com Telephony www.ti.com/telephony

Low Power www.ti.com/lpw Video & Imaging www.ti.com/video

Wireless

Wireless www.ti.com/wireless

Mailing Address: Texas Instruments, Post Office Box 655303, Dallas, Texas 75265

Copyright © 2007, Texas Instruments Incorporated

Loading...

Loading...