1

2

3

4

12

11

10

9

SW

DH

DL

V5

VREF

REFIN

GSNS

VSNS

TPS51219RTE

5 6 7 8

PGND

GND

TRIP

COMP

16 15 14 13

BST

EN

MODE

PGOOD

PwrPd

VSNS

GSNS

PGOOD

V5IN

EN

V

OUT

V

IN

UDG-11006

www.ti.com

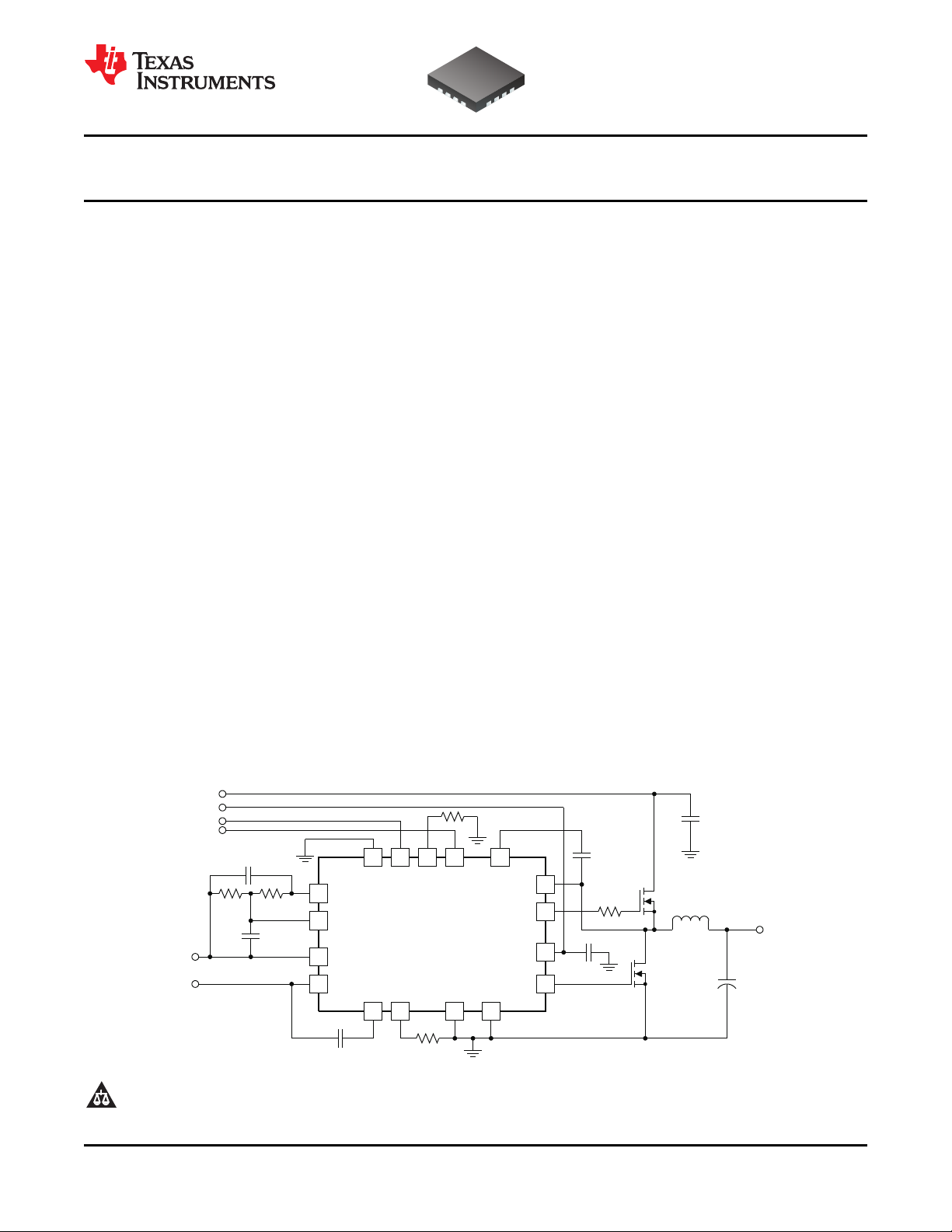

High Performance, Single-Synchronous Step-Down Controller

with Differential Voltage Feedback

1

FEATURES

23

• Differential Voltage Feedback

• DC Compensation for Accurate Regulation

• Wide Input Voltage Range: 3 V to 28 V

• Output Voltage Range: 0.5 V to 2.0 V with

Fixed Options of 1.05 V and 1.00 V

• Wide Output Load Range: 0 A to 20 A+

• Adaptive On-Time Modulation with Selectable

Control Architecture and Frequency

– D-CAP™ Mode at 300 kHz/400 kHz for Fast

Transient Response

– D-CAP2™ Mode at 500 kHz/670 kHz for

Ceramic Output Capacitor

• 4700 ppm/°C, Low-Side R

• R

Accurate Current Sense Option

SENSE

• Internal, 1-ms Voltage Servo Softstart

• Built-In Output Discharge

• Power Good Output

• Integrated Boost Switch

• Built-In OVP/UVP/OCP

• Thermal Shutdown (Non-latched)

• 3 mm × 3 mm, 16-Pin, QFN (RTE) Package

APPLICATIONS

• Notebook Computers

• I/O Supplies

Current Sensing

DS(on)

TPS51219

SLUSAG1B –MARCH 2011– REVISED OCTOBER 2011

DESCRIPTION

The TPS51219 is a small-sized single buck controller

with adaptive on-time control. It provides a choice of

control modes (D-CAP™ or D-CAP2™) to meet a

wide range of system requirements. It is designed for

tight DC regulation requirements such as the VCCIO

application for Intel®notebooks. The performance

and flexibility of the TPS51219 makes it suitable for

low output voltage, high current, PC system power

rails and similar point-of-load (POL) power supplies.

Differential voltage feedback and the voltage

compensation function combine to provide high

precision power to load devices.

A small package, fixed voltage options and minimal

external component count saves cost and space,

while a dedicated EN pin and pre-set frequency

selections minimize design effort. The skip-mode at

light load condition, strong gate drivers, and low-side

FET R

operation over a broad load range. The external

resistor current sense option enables accurate

current sensing. The conversion input voltage (the

high-side FET drain voltage) ranges from 3 V to 28 V

and output voltage ranges from 0.5 V to 2.0 V. The

device requires an external 5-V supply.

The TPS51219 is available in a 16-pin, QFN package

and is specified for ambient temperature from -40°C

to 85°C.

current sensing provides high efficiency

DS(on)

1

2D-CAP, D-CAP2 are trademarks of Texas Instruments.

3Intel is a registered trademark of Intel.

PRODUCTION DATA information is current as of publication date.

Products conform to specifications per the terms of the Texas

Instruments standard warranty. Production processing does not

necessarily include testing of all parameters.

Please be aware that an important notice concerning availability, standard warranty, and use in critical applications of Texas

Instruments semiconductor products and disclaimers thereto appears at the end of this data sheet.

Copyright © 2011, Texas Instruments Incorporated

TPS51219

SLUSAG1B –MARCH 2011– REVISED OCTOBER 2011

These devices have limited built-in ESD protection. The leads should be shorted together or the device placed in conductive foam

during storage or handling to prevent electrostatic damage to the MOS gates.

www.ti.com

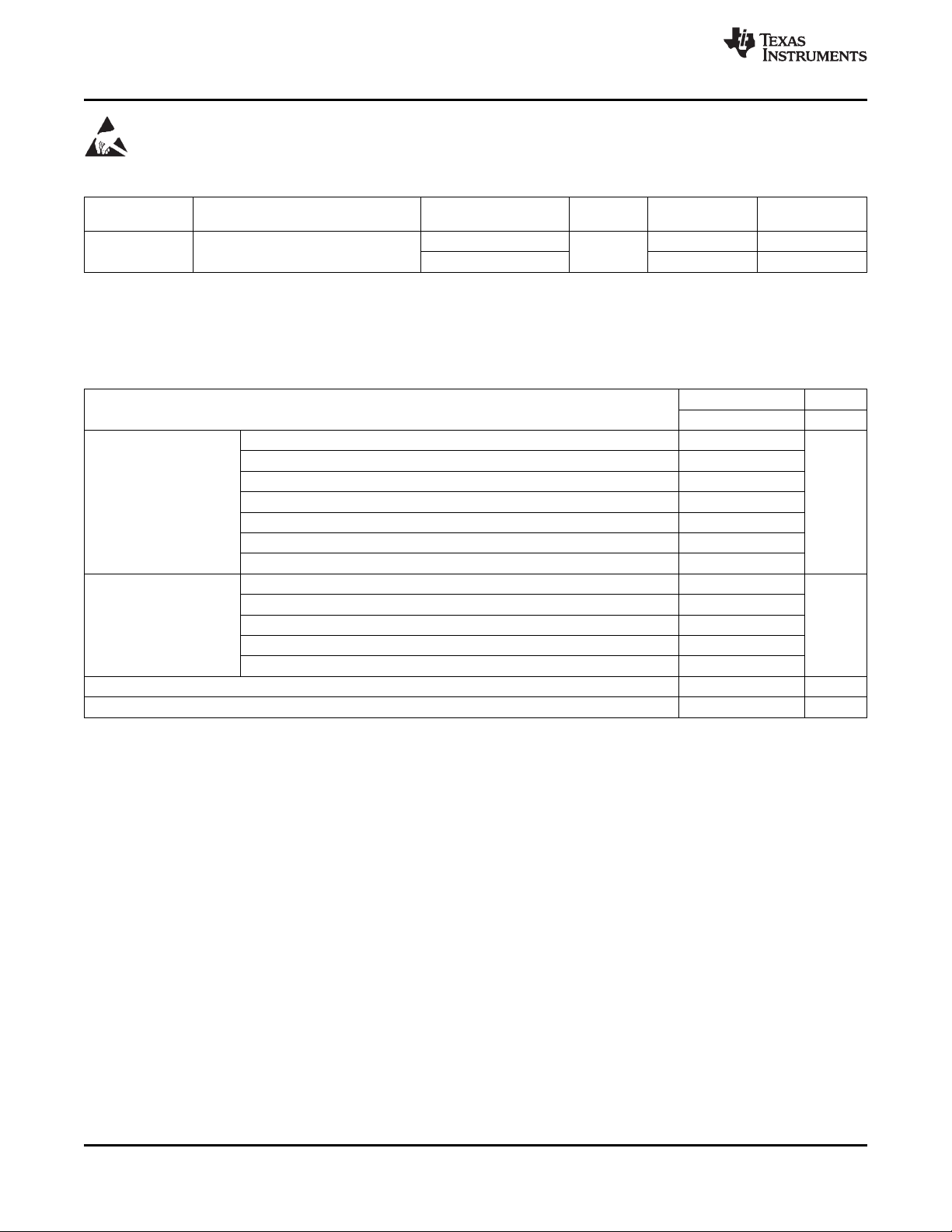

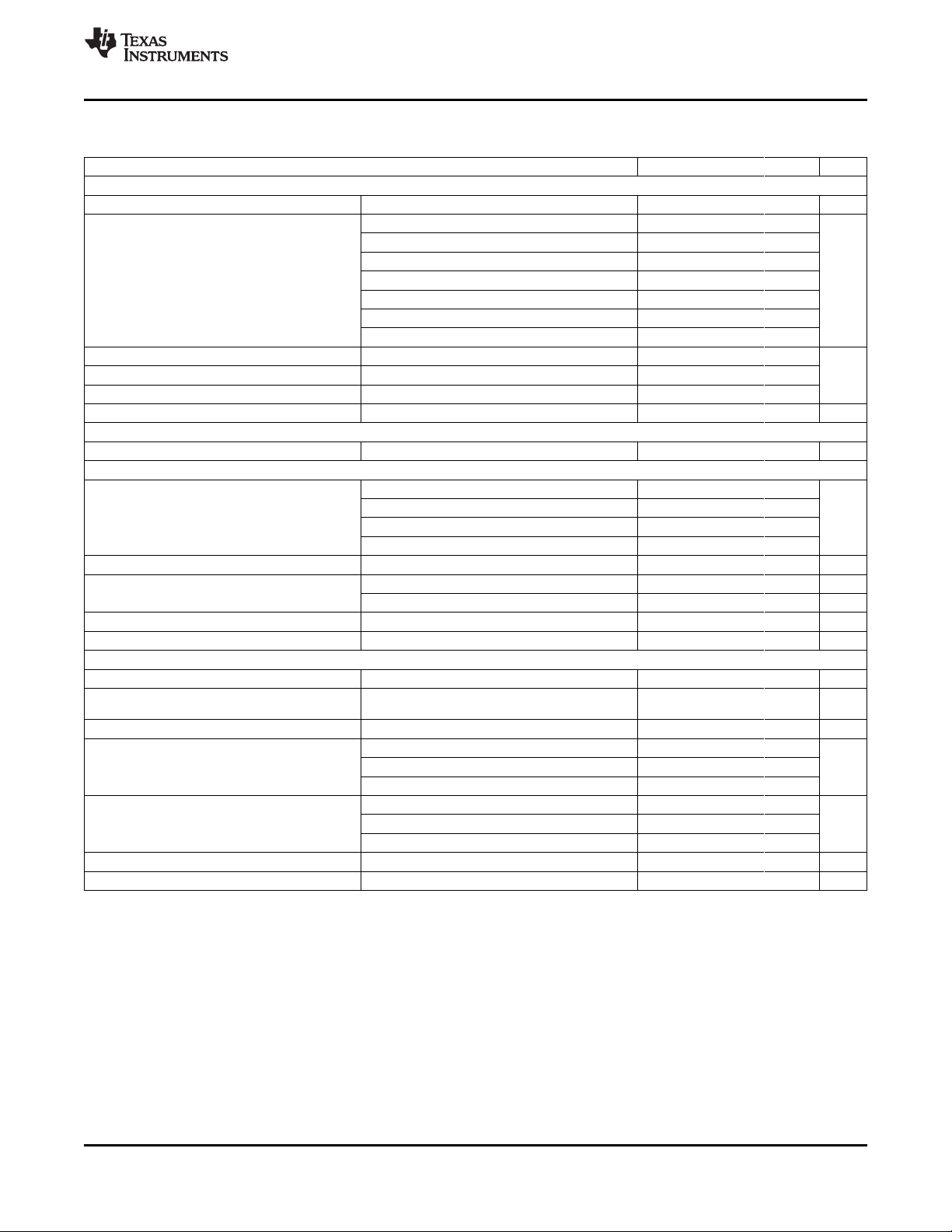

ORDERING INFORMATION

T

A

PACKAGE PINS

–40°C to 85°C Plastic Quad Flat Pack (QFN) 16

ORDERABLE DEVICE OUTPUT MINIMUM

NUMBER SUPPLY QUANTITY

TPS51219RTER Tape and reel 3000

TPS51219RTET Mini-reel 250

(1)

(1) For the most current package and ordering information see the Package Option Addendum at the end of this document, or see the TI

web site at www.ti.com.

ABSOLUTE MAXIMUM RATINGS

(1)

over operating free-air temperature range (unless otherwise noted)

VALUE UNIT

MIN MAX

BST –0.3 36

(3)

BST

SW –5 30

Input voltage range

(2)

EN, MODE, TRIP, V5 –0.3 6.0 V

COMP, REFIN, VSNS –0.3 3.6

GSNS –0.35 0.35

PGND –0.3 0.3

DH –5 36

(3)

DH

Output voltage range

(2)

DL –0.3 6 V

PGOOD –0.3 6

VREF –0.3 3.6

Junction temperature range, T

Storage temperature range, T

J

STG

(1) Stresses beyond those listed under absolute maximum ratings may cause permanent damage to the device. These are stress ratings

only and functional operation of the device at these or any other conditions beyond those indicated under recommended operating

conditions is not implied. Exposure to absolute-maximum-rated conditions for extended periods may affect device reliability.

(2) All voltage values are with respect to the network ground terminal unless otherwise noted.

(3) Voltage values are with respect to the SW terminal.

–0.3 6

–0.3 6

125 °C

–55 150 °C

2 Submit Documentation Feedback Copyright © 2011, Texas Instruments Incorporated

TPS51219

www.ti.com

RECOMMENDED OPERATING CONDITIONS

Supply voltage V5 4.5 5.5 V

BST –0.1 33.5

(1)

BST

SW -3 28

(2)

Input voltage range V

Output voltage range V

T

A

(1) Voltage values are with respect to the SW terminal.

(2) This voltage should be applied for less than 30% of the repetitive period.

SW

EN, TRIP, MODE –0.1 5.5

REFIN, VSNS, COMP –0.1 3.5

GSNS –0.3 0.3

PGND –0.1 0.1

DH –3 33.5

(1)

DH

(2)

DH

DL –0.1 5.5

PGOOD –0.1 5.5

VREF –0.1 3.5

Operating free-air temperature –40 85 °C

SLUSAG1B –MARCH 2011– REVISED OCTOBER 2011

MIN TYP MAX UNIT

–0.1 5.5

–4.5 28

–0.1 5.5

–4.5 33.5

THERMAL INFORMATION

TPS51219

THERMAL METRIC

θ

θ

θ

ψ

ψ

θ

JA

JCtop

JB

JT

JB

JCbot

Junction-to-ambient thermal resistance

Junction-to-case (top) thermal resistance

Junction-to-board thermal resistance

Junction-to-top characterization parameter

Junction-to-board characterization parameter

Junction-to-case (bottom) thermal resistance

(1) For more information about traditional and new thermal metrics, see the IC Package Thermal Metrics application report, SPRA953.

(2) The junction-to-ambient thermal resistance under natural convection is obtained in a simulation on a JEDEC-standard, high-K board, as

specified in JESD51-7, in an environment described in JESD51-2a.

(3) The junction-to-case (top) thermal resistance is obtained by simulating a cold plate test on the package top. No specific

JEDEC-standard test exists, but a close description can be found in the ANSI SEMI standard G30-88.

(4) The junction-to-board thermal resistance is obtained by simulating in an environment with a ring cold plate fixture to control the PCB

temperature, as described in JESD51-8.

(5) The junction-to-top characterization parameter, ψJT, estimates the junction temperature of a device in a real system and is extracted

from the simulation data for obtaining θJA, using a procedure described in JESD51-2a (sections 6 and 7).

(6) The junction-to-board characterization parameter, ψJB, estimates the junction temperature of a device in a real system and is extracted

from the simulation data for obtaining θJA, using a procedure described in JESD51-2a (sections 6 and 7).

(7) The junction-to-case (bottom) thermal resistance is obtained by simulating a cold plate test on the exposed (power) pad. No specific

JEDEC standard test exists, but a close description can be found in the ANSI SEMI standard G30-88.

(1)

RTE UNITS

16 PINS

(2)

(3)

(4)

(5)

(6)

(7)

48.5

49.5

22.1

0.7

22.1

7.1

°C/W

Copyright © 2011, Texas Instruments Incorporated Submit Documentation Feedback 3

TPS51219

SLUSAG1B –MARCH 2011– REVISED OCTOBER 2011

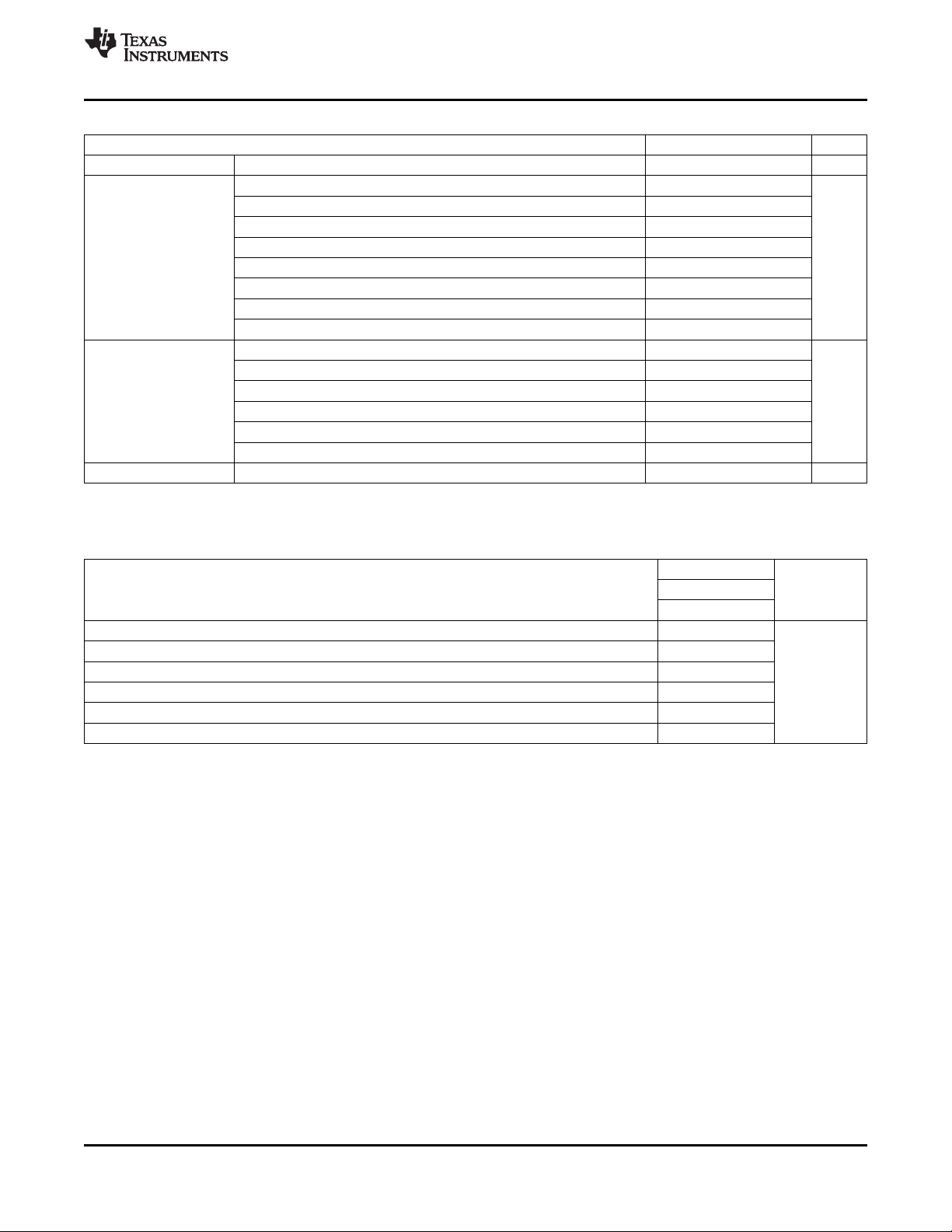

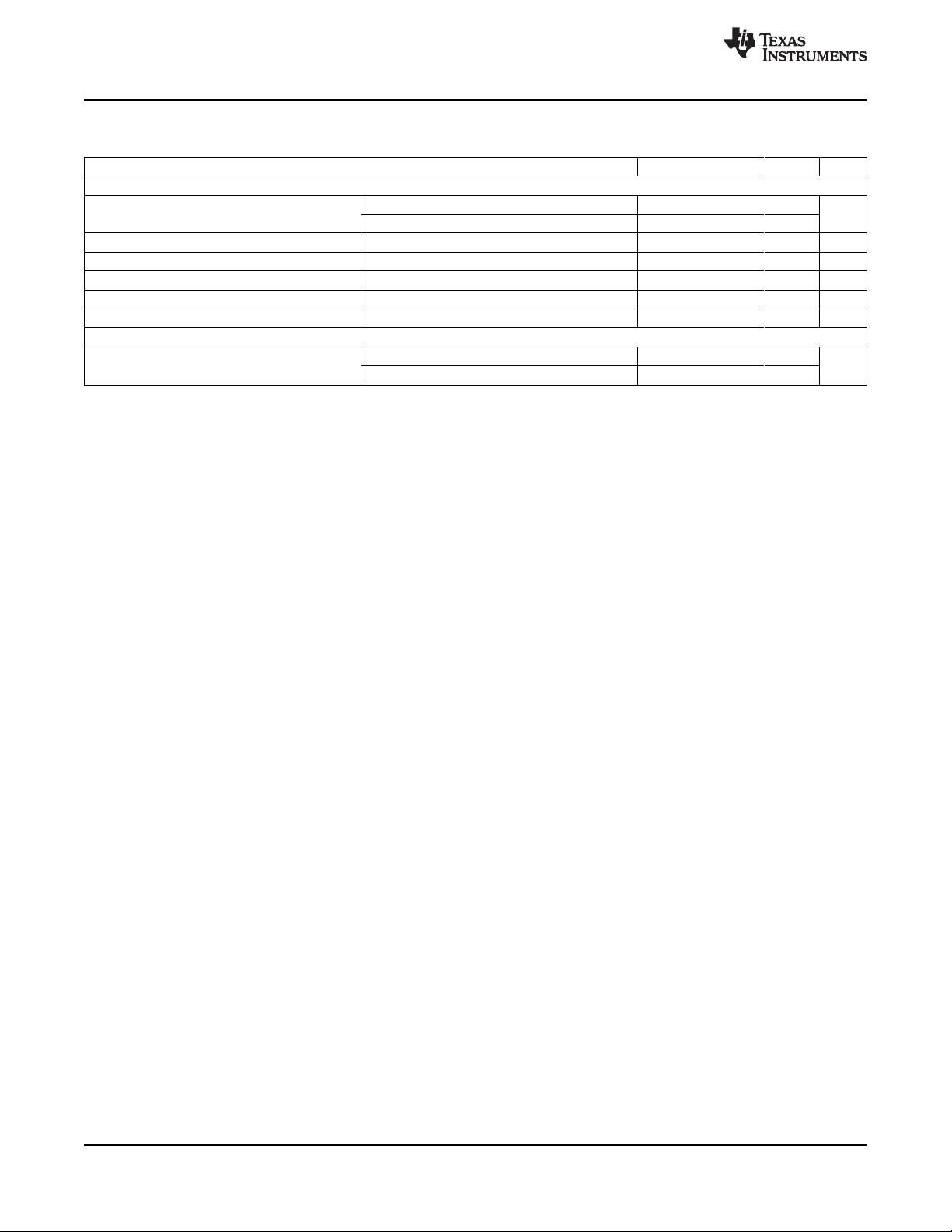

ELECTRICAL CHARACTERISTICS

over operating free-air temperature range, VV5= 5 V, V

PARAMETER TEST CONDITION MIN TYP MAX UNIT

SUPPLY CURRENT

I

V5

I

V5SDN

VREF OUTPUT

V

VREF

V

VREF(tol)

I

VREF(ocl)

OUTPUT VOLTAGE

V

VSNS

V

VSNS(tol)

V

REFIN1

V

REFIN1P05

V

OFF_LPCMP

V

COMPCLP

g

M

I

VSNS

I

REFIN

I

VSNS(dis)

SWITCH MODE POWER SUPPLY (SMPS) FREQUENCY

f

SW

t

ON(min)

t

OFF(min)

MOSFET DRIVERS

R

DH

R

DL

t

DEAD

INTERNAL BOOT STRAP SWITCH

V

FBST

I

BSTLK

(1) Ensured by design. Not production tested.

V5 supply current TA= 25°C, No load, VEN= 5 V 560 μA

V5 shutdown current TA= 25°C, No load, VEN= 0 V 0.5 2.0 μA

Output voltage I

Output voltage tolerance

Current limit V

VSNS sense voltage V

VSNS regulation voltage tolerance V

= 0 μA wrt GSNS 2.000 V

VREF

0 μA ≤ I

VREF

0 μA ≤ I

VREF

VREF-GSNS

V

= 0 V 1.000 V

REFIN

= 3.3 V 1.050 V

REFIN

0.5 V ≤ V

REFIN

V

= 0 V, 0°C ≤ TA≤ 85°C –9 9

REFIN

V

= 0 V, -40°C ≤ TA≤ 85°C -14 14

REFIN

= 3.3 V, 0°C ≤ TA≤ 85°C –9 9 mV

REFIN

V

= 3.3 V, -40°C ≤ TA≤ 85°C -14 14

REFIN

V

= 0.5 V and V

REFIN

REFIN voltage for 1.00-V output 0.3 V

REFIN voltage for 1.05-V output 2.2 V

Loop comparator offset voltage V

COMP clamp voltage

Error amplifier transconductance V

VSNS input current V

REFIN input current V

= 1 V, VSNS shorted to COMP -5 5 mV

REFIN

V

= 0 V, V

REFIN

V

= 0 V, V

REFIN

= 0 V 130 μS

REFIN

= 1.05 V -1 1 μA

VSNS

= 0 V –1 1 μA

REFIN

VSNS discharge current VEN= 0 V, V

VIN= 12 V, V

Switching frequency kHz

VIN= 12 V, V

VIN= 12 V, V

VIN= 12 V, V

Minimum on time DH rising to falling

Minimum off time DH falling to rising 320

DH resistance

DL resistance

Dead time ns

Forward voltage V

Source, IDH= –50 mA 1.6 3.0

Sink, IDH= 50 mA 0.6 1.5

Source, IDL= –50 mA 0.9 2.0

Sink, IDL= 50 mA 0.5 1.2

DH-off to DL-on 10

DL-off to DH-on 20

, TA= 25°C, IF= 10 mA 0.1 0.2 V

V5-BST

BST leakage current TA= 25°C, V

www.ti.com

= 0 V, VEN= 5 V (unless otherwise noted)

MODE

< 30 μA, TA= 0°C to 85°C -0.8% 0.8%

< 300 μA, TA= –40°C to 85°C -1.2% 1.2%

= 1.7 V 0.4 1.0 mA

≤ 2 V V

= 2.0 V -5 5

REFIN

= 0.95 V 0.885 V

VSNS

= 1.05 V 1.115 V

VSNS

= 0.5 V 5 12 mA

VSNS

VSNS

VSNS

VSNS

VSNS

= 1.8 V, V

= 1.8 V, V

= 1.8 V, V

= 1.8 V, V

(1)

= 2.5 V 400

MODE

= 1.67 V 300

MODE

= 0.2 V 670

MODE

= 0.033 V 500

MODE

REFIN

60

V

ns

Ω

= 33 V, VSW= 28 V 0.01 1.5 μA

BST

4 Submit Documentation Feedback Copyright © 2011, Texas Instruments Incorporated

www.ti.com

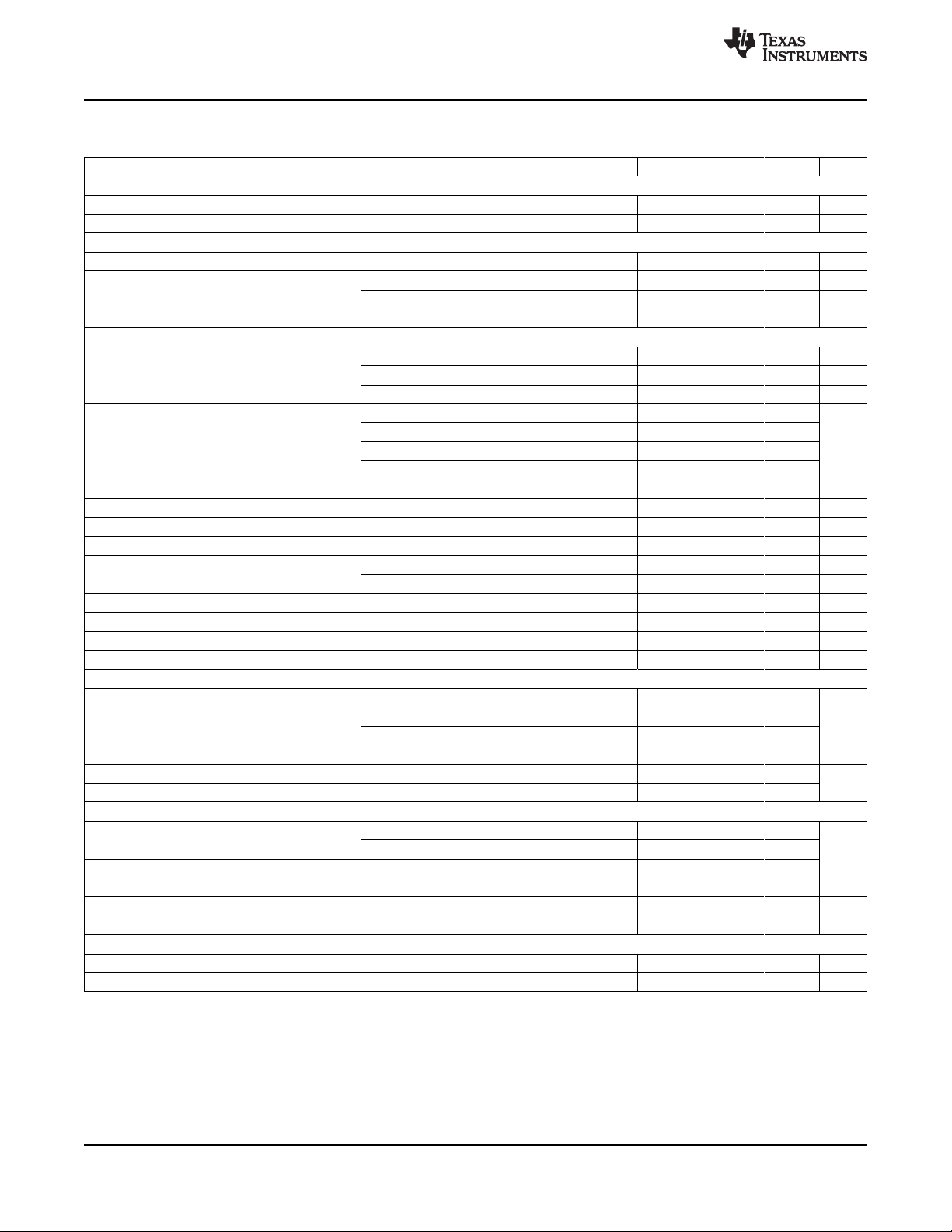

ELECTRICAL CHARACTERISTICS (continued)

over operating free-air temperature range, VV5= 5 V, V

PARAMETER TEST CONDITION MIN TYP MAX UNIT

LOGIC THRESHOLD

I

MODE

V

THMODE

V

LL

V

LH

V

LHYST

I

LLK

SOFT START

t

SS

POWERGOOD COMPARATOR

V

THPG

I

PG

t

PGDLY

t

PGCMPSS

I

PG(leak)

CURRENT DETECTION

I

TRIP

(2)

TC

ITRIP

V

TRIP

V

OCL

V

OCLN

V

RTRIP

V

ZC

(2) Ensured by design. Not production tested.

MODE source current 15.6 16.7 17.8 μA

MODE 0-1 113 143 173

MODE 1-2 253 283 313

MODE 2-3 433 458 483

MODE threshold voltage MODE 3-4 644 667 690 mV

MODE 4-5 914 949 984

MODE 5-6 1329 1369 1409

MODE 6-7 1950 2000 2050

EN low-level voltage 0.5

EN high-level voltage 1.8 V

EN hysteresis voltage 0.25

EN input leakage current –1 0 1 μA

Soft-start time Internal soft-start time 1.1 ms

PGOOD in from higher 106% 108% 110%

PGOOD threshold

PGOOD in from lower 90% 92% 94%

PGOOD out to higher 114% 116% 118%

PGOOD out to lower 82% 84% 86%

PGOOD sink current V

PGOOD delay time

PGOOD

Delay for PGOOD in 0.8 1.0 1.2 ms

Delay for PGOOD out, with 100 mV over drive 0.25 µs

PGOOD start-up delay PGOOD comparator wake-up delay 2.5 ms

PGOOD leakage current -1 0 1 µA

TRIP source current TA= 25°C, V

TRIP source current temperature

coefficient

V

(2)

voltage range R

TRIP

Current limit threshold V

Negative current limit threshold V

R

V

V

V

V

DS(on)

DS(on)

TRIP

TRIP

TRIP

TRIP

TRIP

TRIP

Resistor sense trip voltage Resistor sensing 25 mV

Zero cross detection offset 0 mV

MODE

= 0.5 V 3 6 mA

TRIP

sensing 4700 ppm/°C

sensing 0.2 3 V

= 3.0 V, R

= 1.6 V, R

= 0.2 V, R

= 3.0 V, R

= 1.6 V, R

= 0.2 V, R

DS(on)

DS(on)

DS(on)

DS(on)

DS(on)

DS(on)

TPS51219

SLUSAG1B –MARCH 2011– REVISED OCTOBER 2011

= 0 V, VEN= 5 V (unless otherwise noted)

= 0.4 V, R

sensing 360 375 390

sensing 190 200 210 mV

sensing 20 25 30

sensing –390 –375 –360

sensing –212 –200 –188 mV

sensing –30 –25 –20

sensing 9 10 11 μA

DS(on)

Copyright © 2011, Texas Instruments Incorporated Submit Documentation Feedback 5

TPS51219

SLUSAG1B –MARCH 2011– REVISED OCTOBER 2011

ELECTRICAL CHARACTERISTICS (continued)

over operating free-air temperature range, VV5= 5 V, V

PARAMETER TEST CONDITION MIN TYP MAX UNIT

PROTECTIONS

V

UVLO

V

OVP

t

OVPDLY

V

UVP

t

UVPDLY

t

UVPENDLY

V5 UVLO threshold voltage V

OVP threshold voltage OVP detect voltage 118% 120% 122%

OVP propagation delay With 100 mV over drive 370 ns

UVP threshold voltage UVP detect voltage 66% 68% 70%

UVP delay 1 ms

UVP enable delay 1.4 ms

THERMAL SHUTDOWN

T

SDN

Thermal shutdown threshold °C

(3) Ensured by design. Not production tested.

Wake-up 4.2 4.4 4.5

Shutdown 3.7 3.9 4.1

Shutdown temperature

Hysteresis

MODE

(3)

= 0 V, VEN= 5 V (unless otherwise noted)

(3)

www.ti.com

140

10

6 Submit Documentation Feedback Copyright © 2011, Texas Instruments Incorporated

4

2

3

8

12

11

10

9

VREF

REFIN

GSNS

VSNS

PGOOD

DH

DL

V5

16 15 14 13

1

5 6 7

MODE

EN

BST

SW

PGND

GND

COMP

TRIP

TPS51219

PowerPAD

TM

www.ti.com

TPS51219

SLUSAG1B –MARCH 2011– REVISED OCTOBER 2011

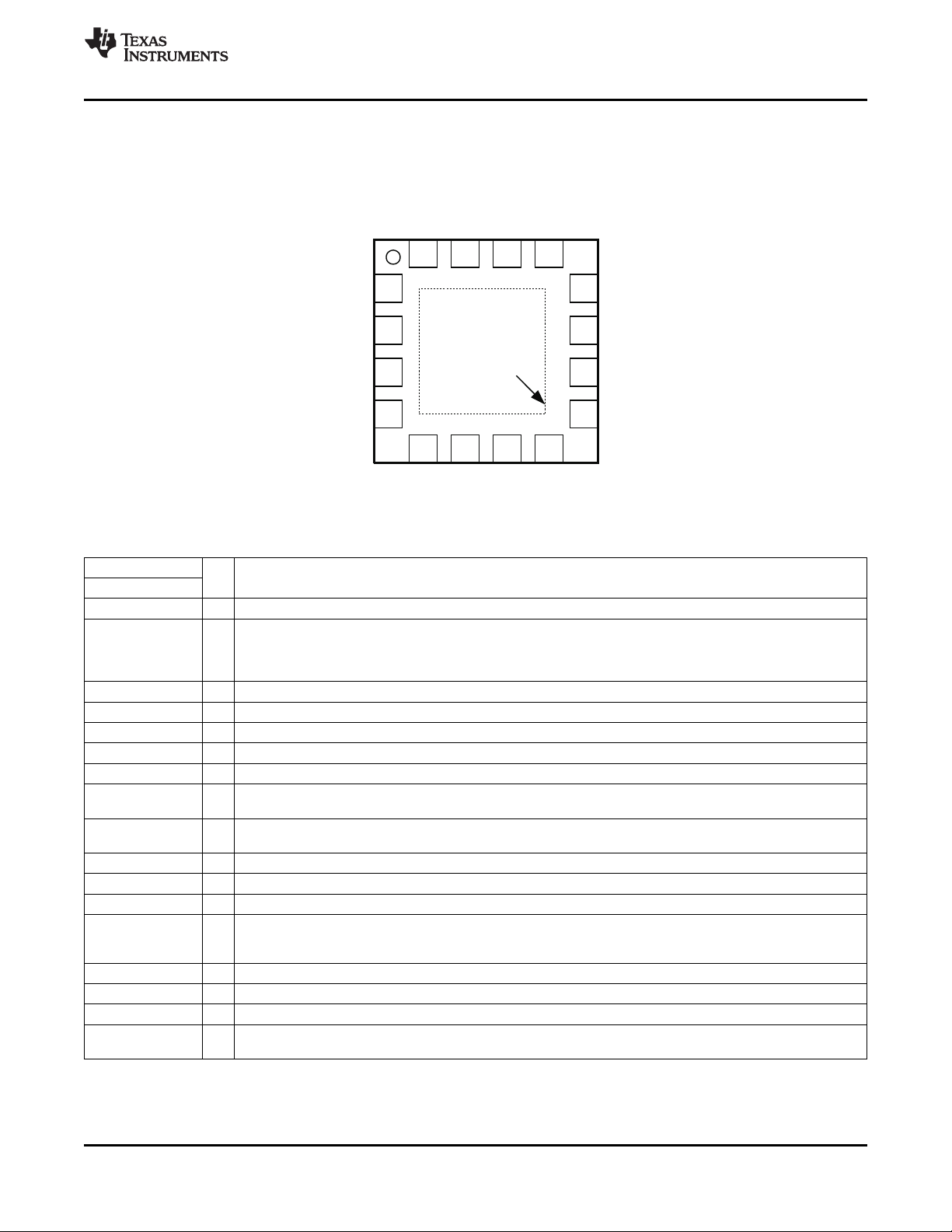

DEVICE INFORMATION

RTE PACKAGE (TOP VIEW)

PIN FUNCTIONS

PIN

NAME NO.

BST 13 I High-side MOSFET gate driver bootstrap voltage input. Connect a capacitor from the BST pin to the SW pin.

COMP 5 I

DH 11 O High-side MOSFET gate driver output.

DL 10 O Low-side MOSFET gate driver output.

EN 14 I Enable pin. 3.3-V I/O level, 100 ns de-bounce. Short to GND to disable the device.

GND 7 – Device analog ground; Connect to a quiet point on the system GND plane

GSNS 3 I Voltage sense return tied directly to the GND sense point of the load. Short to GND if remote sense is not used.

MODE 15 I

PGND 8 –

PGOOD 16 O Powergood signal open drain output. PGOOD goes high when the output voltage is within the target range.

REFIN 2 I Output voltage setting pin. See the VREF and REFIN, Output Voltage section.

SW 12 I/O High-side MOSFET gate driver return. R

TRIP 6 I current sensing if connected to GND through an OCL setting resistor. For R

VSNS 4 I Voltage sense line tied directly to the load voltage sense point.

VREF 1 O 2.0-V ±0.8% voltage reference output.

V5 9 I 5V power supply input for internal circuits and MOSFET gate drivers.

Thermal

pad

I/O DESCRIPTION

Connection for the DC compensation integrator for improved load-line performance. Connect a capacitor from

this pin to the VSNS pin (when operating in D-CAP2 mode), or to the positive terminal of the output capacitor

(when operating in D-CAP mode). Connect directly to the VSNS pin without capacitor to disable the integrator

function.

Connect a resistor to GND to configure switching frequency, control mode and current sense scheme. (See

Table 2)

Synchronous low-side MOSFET gate driver return. Also serve as the current sensing input (+). Connect to the

GND pin as close as possible to the device.

current sensing input (–) when using R

DS(on)

Current sense comparator input (-) for resistor current sensing. Or overcurrent threshold setting pin for R

μA at room temperature, TC=4700ppm/°C, is sourced to set the trip voltage.

– – Thermal pad. Connect directly to system GND plane with multiple vias.

current sensing.

DS(on)

current sensing operation, 10

DS(on)

DS(on)

Copyright © 2011, Texas Instruments Incorporated Submit Documentation Feedback 7

8

12

PGND

SW

OC

ZC

XCON

13

BST

9 V5

PWM

4

REFIN

TRIP

Delay

16 PGOOD

Control Logic

10 mA

+

+

V

REFIN

+ 20%

+

+

2

VSNS

6

11 DH

10 DL

t

ON

OneShot

UV

OV

V

REFIN

– 32%

14EN

Soft-Start

+

NOC

+

1VREF Reference

7 R

R

Control Mode

On-Time

Current Sense

Selection

16.7 mA

15 MODE

V

REFIN

+8/16%

V

REFIN

– 8/16%

+

+

Discharge

V5OK

+

4.3 V/3.9 V

UVPOVP

COMP 5

+

VBG

5-V UVLO

TPS51219

UDG-11007

EN

3GSNS

7GND

EN

Set_1p05v

Set_adj

Discharge

R

8 R

+

V

REFIN

2.2 V

0.3 V

Set_adj

Set_1p05v

EN

+

+

25 mV

Set_resistor _sensing

Set_resistor _sensing

TPS51219

SLUSAG1B –MARCH 2011– REVISED OCTOBER 2011

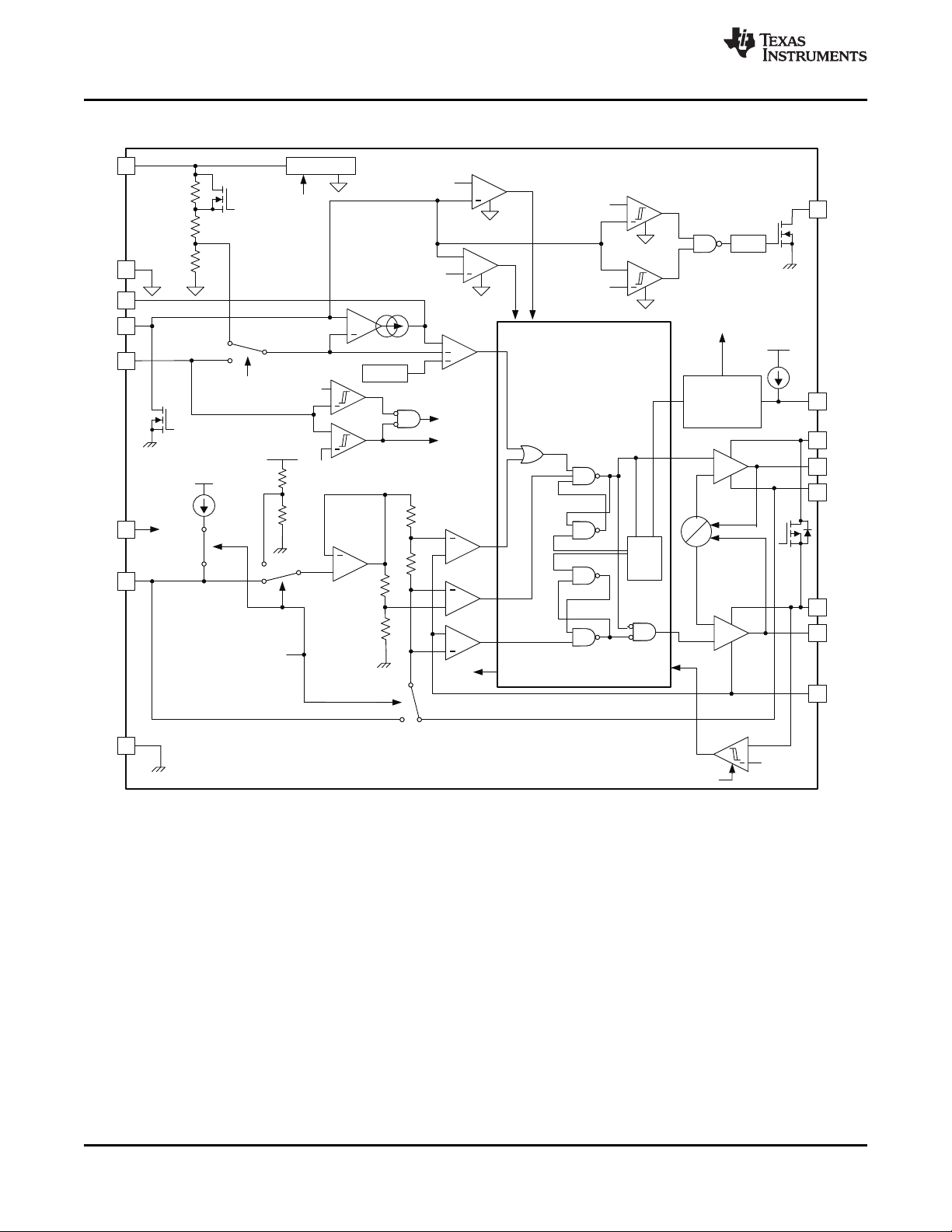

FUNCTIONAL BLOCK DIAGRAM

www.ti.com

8 Submit Documentation Feedback Copyright © 2011, Texas Instruments Incorporated

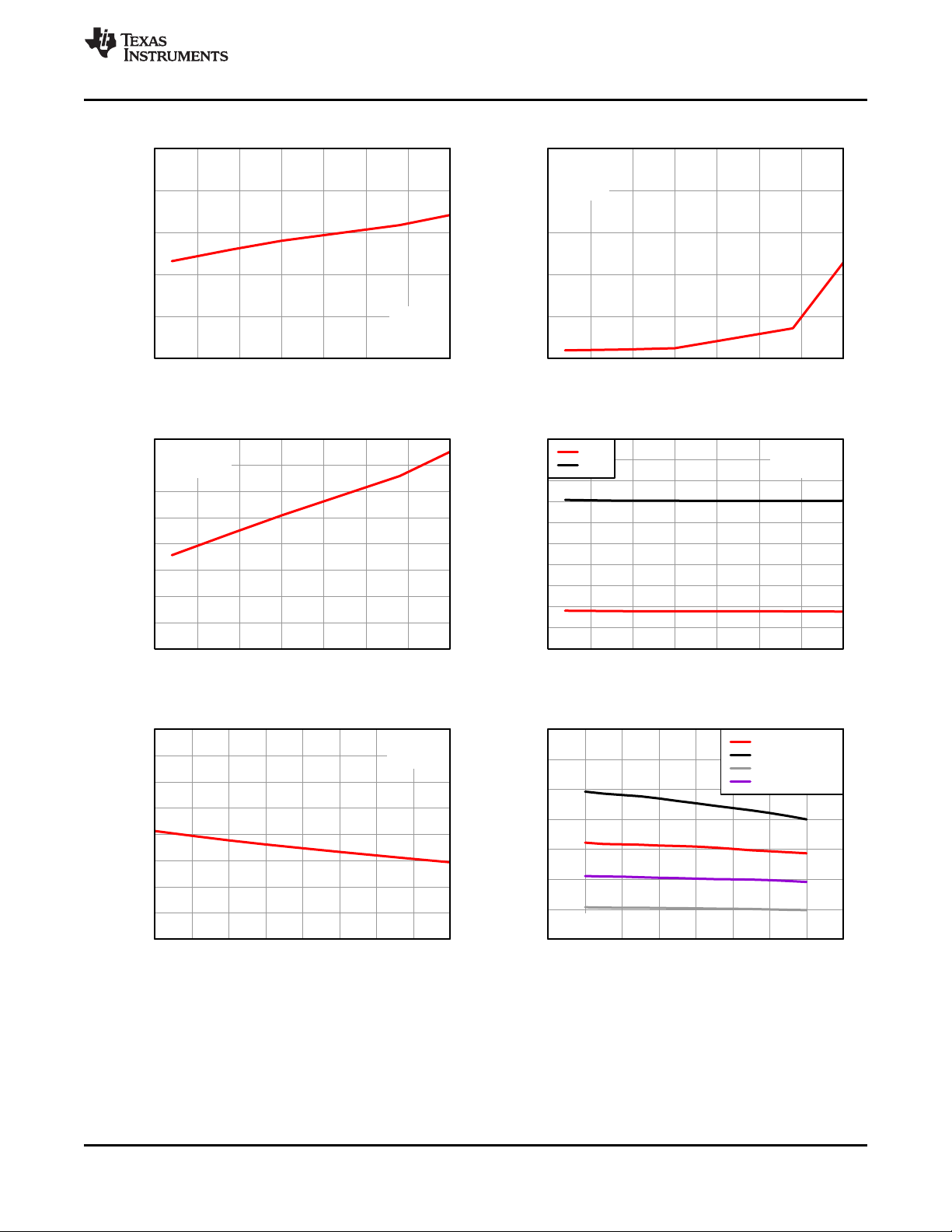

0

200

400

600

800

1000

−50 −25 0 25 50 75 100 125

Junction Temperature (°C)

V5 Supply Current (µA)

VV5 = 5 V

VEN = 5 V

No Load

0

2

4

6

8

10

−50 −25 0 25 50 75 100 125

Junction Temperature (°C)

V5 Shutdown Current (µA)

VV5 = 5 V

VEN = 0 V

No Load

0

2

4

6

8

10

12

14

16

−50 −25 0 25 50 75 100 125

Junction Temperature (°C)

Trip Source Current (µA)

VV5 = 5 V

V

TRIP

= 0.5 V

50

60

70

80

90

100

110

120

130

140

150

−50 −25 0 25 50 75 100 125

Junction Temperature (°C)

UVP/OVP Threshold (%)

UVP

OVP

VV5 = 5 V

V

REFIN

= 0 V

1.980

1.985

1.990

1.995

2.000

2.005

2.010

2.015

2.020

0 50 100 150 200 250 300 350 400

VREF Current (µA)

VREF Voltage (V)

VV5 = 5 V

TA = 27°C

200

300

400

500

600

700

800

900

6 8 10 12 14 16 18 20 22

Input Voltage (V)

Switching Frequency (kHz)

R

MODE

= 1 kΩ

R

MODE

= 12 kΩ

R

MODE

= 100 kΩ

R

MODE

= 200 kΩ

I

OUT

= 10 A

www.ti.com

TPS51219

SLUSAG1B –MARCH 2011– REVISED OCTOBER 2011

TYPICAL CHARACTERISTICS

Figure 1. V5 Supply Current vs Junction Temperature Figure 2. V5 Shutdown Current vs Junction Temperature

Figure 3. Current Sense Current vs Junction Temperature Figure 4. OVP/UVP Threshold vs Junction Temperature

Copyright © 2011, Texas Instruments Incorporated Submit Documentation Feedback 9

Figure 5. VREF Load Regulation Figure 6. Switching Frequency vs Input Voltage

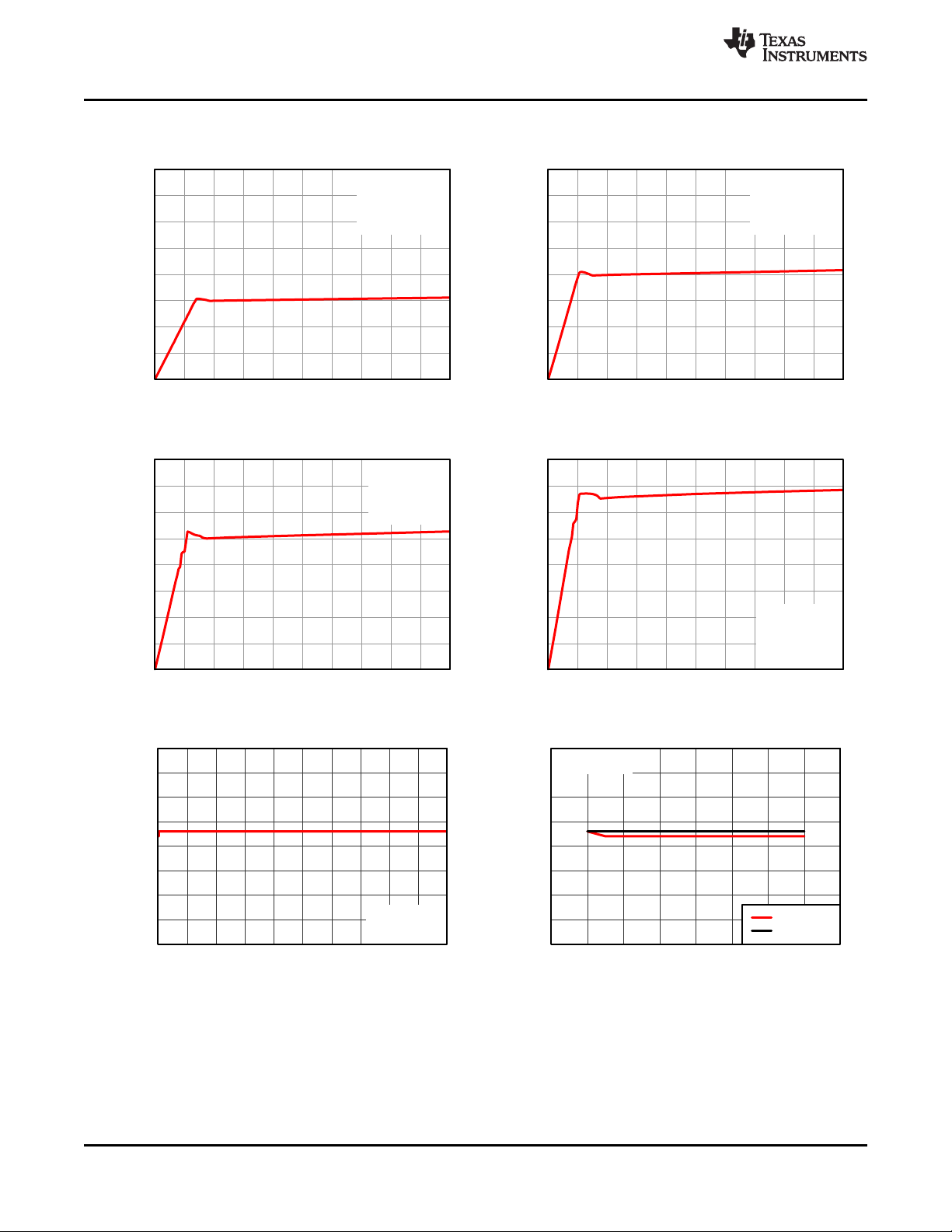

0

100

200

300

400

500

600

700

800

0 2 4 6 8 10 12 14 16 18 20

Output Current (A)

Switching Frequency (kHz)

R

MODE

= 100 kΩ

VIN = 12 V

V

OUT

= 1.05 V

L = 0.56 µH

0

100

200

300

400

500

600

700

800

0 2 4 6 8 10 12 14 16 18 20

Output Current (A)

Switching Frequency (kHz)

R

MODE

= 200 kΩ

VIN = 12 V

V

OUT

= 1.05 V

L = 0.56 µH

0

100

200

300

400

500

600

700

800

0 2 4 6 8 10 12 14 16 18 20

Output Current (A)

Switching Frequency (kHz)

R

MODE

= 1 kΩ

VIN = 12 V

V

OUT

= 1.05 V

L = 0.45 µH

0

100

200

300

400

500

600

700

800

0 2 4 6 8 10 12 14 16 18 20

Output Current (A)

Switching Frequency (kHz)

R

MODE

= 12 kΩ

VIN = 12 V

V

OUT

= 1.05 V

L = 0.36 µH

1.030

1.035

1.040

1.045

1.050

1.055

1.060

1.065

1.070

0 2 4 6 8 10 12 14 16 18 20

1.05−V Output Current (A)

VSNS−GSNS − 1.05−V Output Voltage (V)

R

MODE

= 1 kΩ

VIN = 12 V

G001

1.030

1.035

1.040

1.045

1.050

1.055

1.060

1.065

1.070

6 8 10 12 14 16 18 20 22

Input Voltage (V)

VSNS−GSNS − 1.05−V Output Voltage (V)

I

OUT

= 0 A

I

OUT

= 10 A

R

MODE

= 1 kΩ

G001

TPS51219

SLUSAG1B –MARCH 2011– REVISED OCTOBER 2011

Figure 11 and Figure 12 refer to the application schematic in Figure 33.

Figure 7. Switching Frequency vs Load Current Figure 8. Switching Frequency vs Load Current

www.ti.com

TYPICAL CHARACTERISTICS

Figure 9. Switching Frequency vs Load Current Figure 10. Switching Frequency vs Load Current

10 Submit Documentation Feedback Copyright © 2011, Texas Instruments Incorporated

Figure 11. 1.05-V Output Load Regulation Figure 12. 1.05-V Output Line Regulation

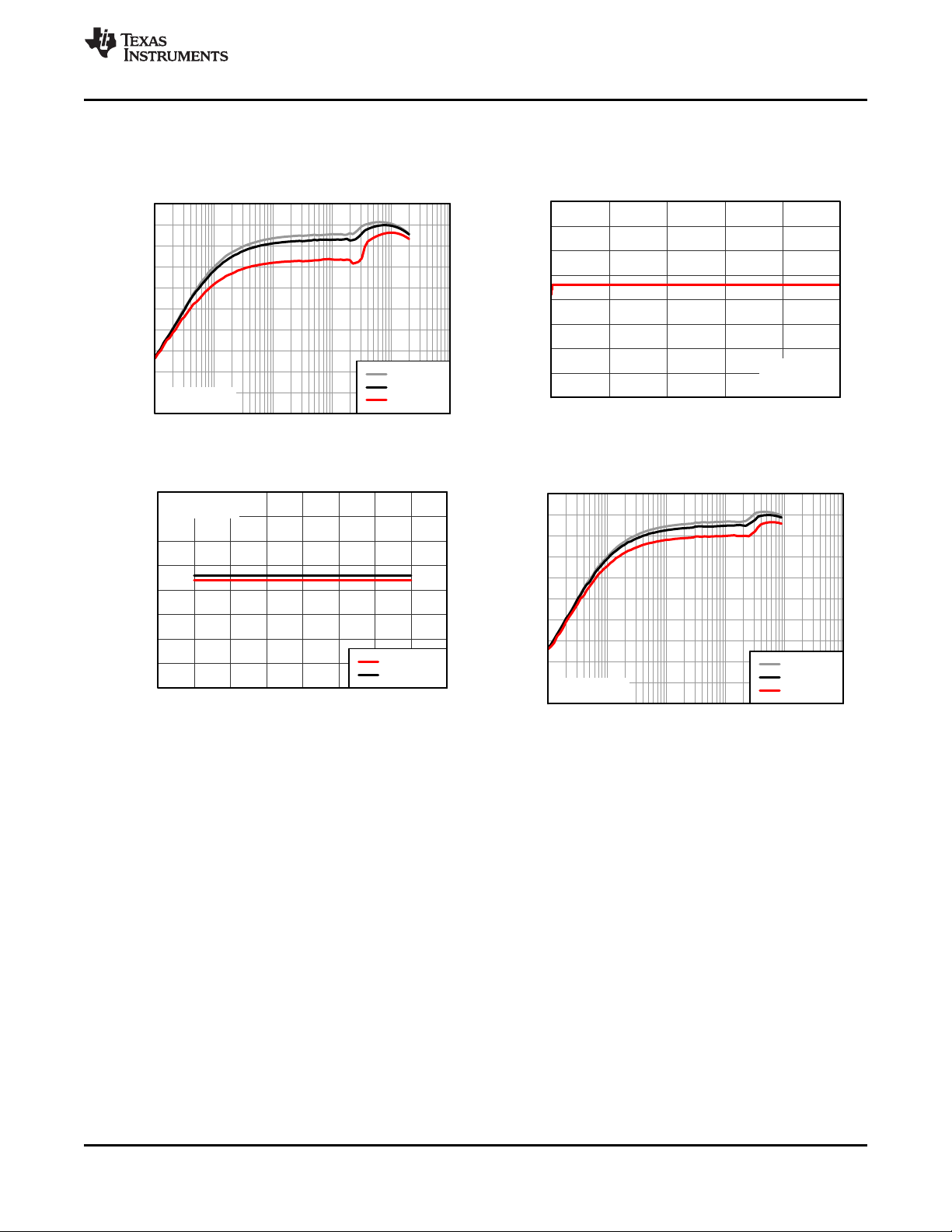

0.980

0.985

0.990

0.995

1.000

1.005

1.010

1.015

1.020

0 2 4 6 8 10

1.00−V Output Current (A)

VSNS−GSNS − 1.00−V Output Voltage (V)

R

MODE

= 1 kΩ

VIN = 12 V

G001

0

10

20

30

40

50

60

70

80

90

100

0.001 0.01 0.1 1 10 100

1.05−V Output Current (A)

Efficiency (%)

VIN = 8 V

VIN = 12 V

VIN = 20 V

R

MODE

= 1 kΩ

0.980

0.985

0.990

0.995

1.000

1.005

1.010

1.015

1.020

6 8 10 12 14 16 18 20 22

Input Voltage (V)

VSNS−GSNS − 1.00−V Output Voltage (V)

I

OUT

= 0 A

I

OUT

= 10 A

R

MODE

= 1 kΩ

G001

0

10

20

30

40

50

60

70

80

90

100

0.001 0.01 0.1 1 10 100

1.00−V Output Current (A)

Efficiency (%)

VIN = 8 V

VIN = 12 V

VIN = 20 V

R

MODE

= 1 kΩ

www.ti.com

TPS51219

SLUSAG1B –MARCH 2011– REVISED OCTOBER 2011

TYPICAL CHARACTERISTICS

Figure 11, Figure 12, and Figure 13 refer to the application schematic in Figure 33.

Figure 14, Figure 15 and Figure 16, refer to the application schematic in Figure 33 except the parameters

of L1 (0.56 µH), C7 (2 × 330 µF) and Q3 (not used).

Figure 13. 1.05-V Output Efficiency Figure 14. 1.00-V Output Load Regulation

Figure 15. 1.00-V Output Line Regulation Figure 16. 1.00-V Output Efficiency

Copyright © 2011, Texas Instruments Incorporated Submit Documentation Feedback 11

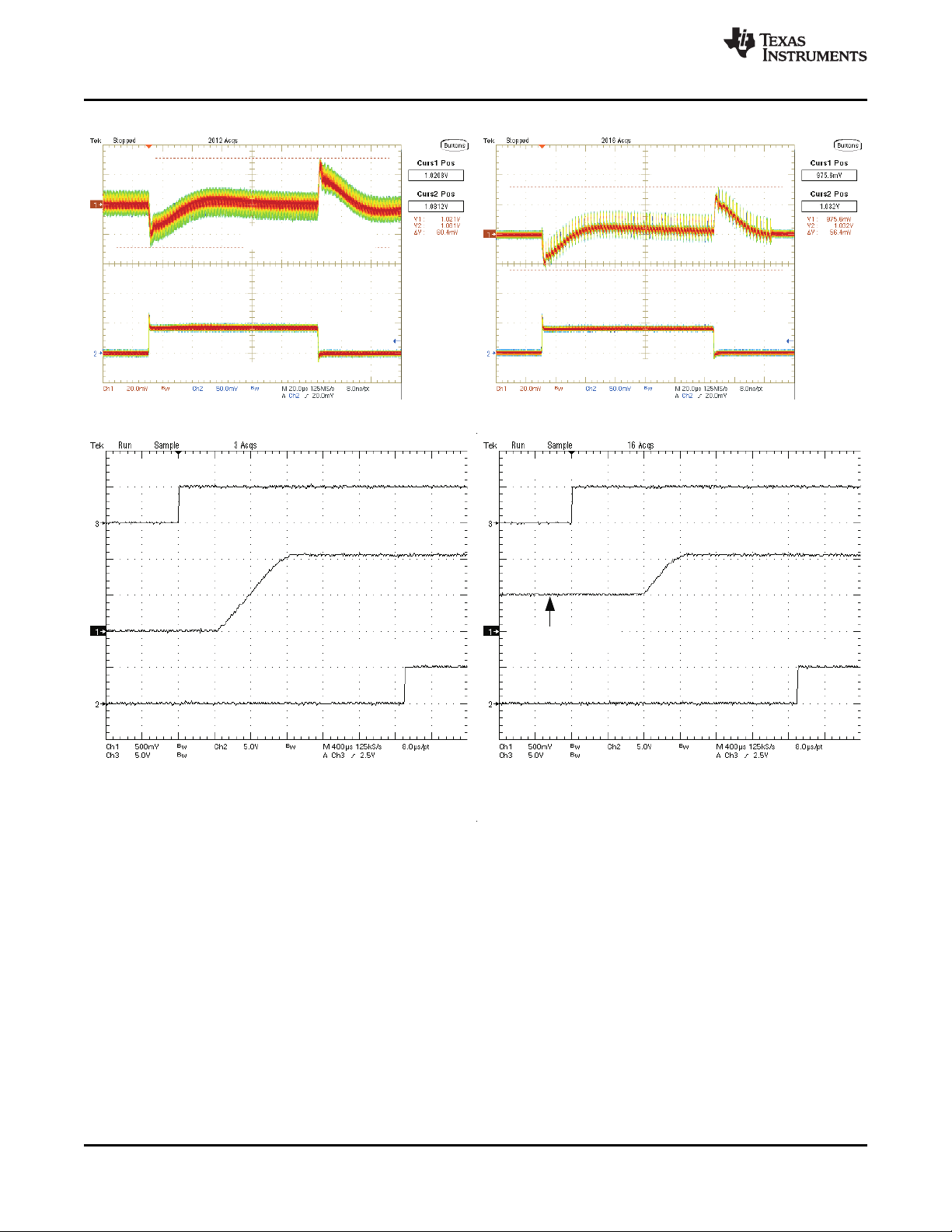

VIN=20 V

VSNS-GSNS (20 mV/div)

offset: 1.05 V

I

OUT

(8 A/div)

offset: 6 A

C

OUT

= 5 x 330 µF(Bulk) + 12 x 22 µF(MLCC)

VIN=20 V

VSNS-GSNS (20 mV/div)

offset: 1.00 V

I

OUT

(8 A/div)

C

OUT

= 2 x 330 µF(Bulk) + 12 x 22 µF(MLCC)

EN (5 V/div)

VSNS-GSNS

(500mV/div)

PGOOD (5V/div)

Time (400 µs/div)

I

OUT

= 15A

Time (400 µs/div)

EN (5 V/div)

VSNS-GSNS

(500mV/div)

PGOOD (5V/div)

I

OUT

= 0 A

0.5-V Pre-biased

TPS51219

SLUSAG1B –MARCH 2011– REVISED OCTOBER 2011

Figure 17. 1.05-V Load Transient Response Figure 18. 1.00-V Load Transient Response

www.ti.com

TYPICAL CHARACTERISTICS

12 Submit Documentation Feedback Copyright © 2011, Texas Instruments Incorporated

Figure 19. 1.05-V Startup Waveforms Figure 20. 1.05-V Startup Waveforms (0.5-V Pre-Biased)

Time (100 ms/div)

EN (5 V/div)

VSNS-GSNS

(500mV/div)

PGOOD (5V/div)

I

OUT

= 0 A

100 1000 10000 100000 1000000

−80

−60

−40

−20

0

20

40

60

80

−180

−135

−90

−45

0

45

90

135

180

Frequency (Hz)

Gain (dB)

Phase (°)

Gain

Phase

VIN =12 V

I

OUT

=15 A

R

MODE

=1 kΩ

www.ti.com

TPS51219

SLUSAG1B –MARCH 2011– REVISED OCTOBER 2011

TYPICAL CHARACTERISTICS

Figure 22 refers to application schematic of Figure 33.

Figure 21. 1.05-V Soft-stop Waveforms

Figure 22. Bode Plot, V

OUT

=1.05 V

Copyright © 2011, Texas Instruments Incorporated Submit Documentation Feedback 13

TPS51219

1

2

3

VREF

GSNS

REFIN

R1

10 nF

R2

0,1 mF

UDG-11042

TPS51219

SLUSAG1B –MARCH 2011– REVISED OCTOBER 2011

APPLICATION INFORMATION

Swtich Mode Power Supply Control

The TPS51219 is a high performance, single-synchronous step-down controller with differential voltage feedback.

The TPS51219 realizes accurate regulation at the specific load point over wide load range with the combination

of three functions.

• 2-V Reference with 0.8% Tolerance. Internal voltage divider provides precise reference (See Table 1 in the

VREF and REFIN, Output Voltage section). A value of 0.1µF is recommended as the decoupling capacitance

between VREF and GSNS pins.

• Integrator. Feedback capacitance connected from the output (COMP pin) to the input (VSNS pin) of the error

amplifier comprises integrator, which increases gain at DC to low frequency region and improves load

regulation of the output voltage. 10nF is recommended as the capacitance between VSNS and COMP pins.

• Differential remote sensing. Differential feedback provides precise output voltage control at the point of

load. Connect VSNS and GSNS directly to output voltage sense point and ground return point at the load

device, respectively. Short GSNS to GND if remote sense is not used.

The TPS51219 supports two control architectures, D-CAP™ mode and D-CAP2™ mode. Both control modes do

not require complex external compensation networks and are suitable for designs with small external

components counts. The D-CAP™ mode provides fast transient response with appropriate amount of equivalent

series resistance (ESR) on the output capacitors. The D-CAP2™ mode is dedicated for a configuration with very

low ESR output capacitors such as multi-layer ceramic capacitors (MLCC). For the both modes, an adaptive

on-time control scheme is used to achieve pseudo-constant frequency. The TPS51219 adjusts the on-time (tON)

to be inversely proportional to the input voltage (VIN) and proportional to the SMPS output voltage (V

switching frequency remains nearly constant over the variation of input voltage at the steady-state condition.

Control modes and switching frequency are selected by the MODE pin described in Table 2.

www.ti.com

). The

OUT

VREF and REFIN, Output Voltage

The device provides a 2.0-V, ±0.8% accurate, voltage reference from VREF. This output has a 300-µA current

capability to drive the REFIN input voltage through a voltage divider circuit. A capacitor with a value of 0.1-µF or

larger should be attached close to the VREF terminal.

The SMPS output voltage is defined by REFIN voltage, within the range between 0.5 V and 2.0 V, programmed

by the resister-divider connected between VREF and GSNS. (See Figure 23 and External Components Selection

section.) A few nano-farads of capacitance from REFIN to GSNS is recommended for stable operation. A voltage

divider and a filter capacitor to this pin should be referenced to GSNS. Fixed output voltage can be set as shown

in Table 1.

XXXX

Table 1. Output Voltage Selection

REFIN VOLTAGE (V) OUTPUT VOLTAGE (V)

3.3 1.05

GSNS 1.00

Resistor Divider Adjustable

XXXX

XXXX

XXXX

Figure 23. Voltage Reference Connections

XXXX

XXXX

14 Submit Documentation Feedback Copyright © 2011, Texas Instruments Incorporated

700 ms400 ms 1.4 ms

EN

VREF

V

OUT

PGOOD

UDG-11008

TPS51219

www.ti.com

Soft-Start and Powergood

Provide a voltage supply to VIN and V5 before asserting EN to high. TPS51219 provides integrated soft-start

functions to suppress in-rush current at start-up. The soft-start is achieved by controlling internal reference

voltage ramping up. Figure 24 shows the start-up waveforms. The switching regulator waits for 400μs after EN

assertion. The MODE pin voltage is read in this period. A typical V

THe TPS51219 has a powergood open-drain output that indicates the V

The target voltage window and transition delay times of the PGOOD comparator are ±8% (typ) and 1-ms delay

for assertion (low to high), and ±16% (typ) and 2-µs delay for de-assertion (high to low) during running. The

PGOOD start-up delay is 2.5 ms after EN is asserted to high. The time constant, which is composed of the

REFIN capacitor and a resistor divider, needs to be short enough to reach the target value before PGOOD

comparator enabled.

OUT

SLUSAG1B –MARCH 2011– REVISED OCTOBER 2011

ramp up duration is 700 μs.

voltage is within the target range.

OUT

Figure 24. Typical Start-up Waveforms

MODE Pin Configuration

The TPS51219 reads the MODE pin voltage when the EN signal is raised high and stores the status in a

register. A 16.7-μA current is sourced from the MODE pin during this time to read the voltage across the resistor

connected between the pin and GND. Table 2 shows resistor values, corresponding control mode, switching

frequency and current sense operation configurations.

Table 2. MODE Selection

MODE NO.

7 200 400

6 100 300

5 68 300

4 47 400

3 33 500

2 22 670

1 12 670

0 1 500

Copyright © 2011, Texas Instruments Incorporated Submit Documentation Feedback 15

RESISTANCE BETWEEN CONTROL SWITCHING CURRENT SENSE

MODE AND GND (kΩ ) MODE FREQUENCY (kHz) OPERATION

R

DS(on)

D-CAP™

Resistor

Resistor

D-CAP2™

R

DS(on)

4

+

2

gM=130 mS

VSNS

REFIN

1

VREF

Control

Logic

and

Driver

R1

R2

11

10

DH

DL

+

2.0 V

V

IN

Lx

ESR

C

OUT

R

LOAD

UDG-11009

V

OUT

5

COMP

C1

+

PWM

= £

p´ ´

SW

0

OUT

f

1

f

2 ESR C 3

£

p´

f

0

M

g

2 C1 10

TPS51219

SLUSAG1B –MARCH 2011– REVISED OCTOBER 2011

D-CAP™ Mode

Figure 25 shows a simplified model of D-CAP™ mode architecture in the TPS51219.

Figure 25. Simplified D-CAP™ Model

www.ti.com

The transconductance amplifier and the capacitance C1 configure an integrator. The VSNS voltage is compared

with REFIN voltage. Ripple voltage generated by ESR of the output capacitance is fed back through the C1 so

that C1 should be properly connected to the positive terminal of output capacitor, not at the remote point of load.

The PWM comparator creates a set signal to turn on the high-side MOSFET each cycle. The D-CAP™ mode

offers flexibility on output inductance and capacitance selections with ease-of-use without complex feedback loop

calculation and external components. However, it does require sufficient amount of ESR that represents inductor

current information for stable operation and good jitter performance. Organic semiconductor capacitor(s) or

specialty polymer capacitor(s) are recommended.

The requirement for loop stability is simple and is described in Equation 1. The 0-dB frequency, f0, is

recommended to be lower than 1/3 of the switching frequency to secure proper phase margin. The integrator

time constant should be long enough compared to f0, for example one decade low, as described in Equation 2.

where

• ESR is the effective series resistance of the output capacitor

• C

• fSWis the switching frequency (1)

where

• gMis transconductance of the error amplifier (typically 130 µS) (2)

16 Submit Documentation Feedback Copyright © 2011, Texas Instruments Incorporated

is the capacitance of the output capacitor

OUT

V

VSNS

V

REFIN

(1)

(2)

t

ON

t

OFF

Slope (2)

Jitter

20 mV

Slope (1)

Jitter

UDG-11010

V

REFIN

+Noise

Time

´

³

´

OUT

SW X

V ESR

20mV

f L

TPS51219

www.ti.com

Jitter is another attribute caused by signal-to-noise ratio of the feedback signal. One of the major factors that

determine jitter performance in D-CAP™ mode is the down-slope angle of the VSNS ripple voltage. Figure 26

shows, in the same noise condition, that jitter is improved by making the slope angle larger.

SLUSAG1B –MARCH 2011– REVISED OCTOBER 2011

Figure 26. Ripple Voltage Slope and Jitter Performance

For a good jitter performance, use the recommended down slope of approximately 20 mV per switching period as

shown in Figure 26 and Equation 3.

where

• V

• LXis the inductance (3)

is the SMPS output voltage

OUT

Copyright © 2011, Texas Instruments Incorporated Submit Documentation Feedback 17

PWM

Comparator

Control

Logic

and

Driver

L

X

R

LOAD

UDG-11011

4

C

C1

V

IN

11

10

DH

DL

VSNS

G

2

REFIN

1

VREF

+

2.0 V

+

–

+

R

C1

C

C2

R

C2

R1

R2

TPS51219

V

OUT

ESR

C

OUT

12

SW

+

5

COMP

C1

´

= £

p´ ´ ´

C C SW

0

X OUT

R C f

f

2 G L C 3

£

p´

f

0

M

g

2 C1 10

TPS51219

SLUSAG1B –MARCH 2011– REVISED OCTOBER 2011

D-CAP2™ Mode Operation

Figure 27 shows simplified model of D-CAP2™ architecture.

Figure 27. Simplified Modulator Using D-CAP2™ Mode

www.ti.com

When the TPS51219 operates in D-CAP2™ mode, connect the COMP and VSNS pins as shown in Figure 27.

The transconductance amplifier and the capacitance C1 configures the integrator. The D-CAP2™ mode in the

TPS51219 includes an internal feedback network enabling the use of very low ESR output capacitor(s) such as

multi-layer ceramic capacitors (MLCC). The role of the internal network is to sense the ripple component of the

inductor current information and then combine it with the voltage feedback signal.

Using RC1=RC2≡RCand CC1=CC2≡CC, 0-dB frequency of the D-CAP2™ mode is given by Equation 4. f0is

recommended to be lower than 1/3 of the switching frequency to secure proper phase margin. The integrator

time constant should be long enough compared to f0, for example one decade low, as described in Equation 5.

where

The typical G value is 0.25, and typical RCCCtime constant values for 500 kHz and 670 kHz operation are 32 μs

and 23 μs, respectively.

For example, when fSW= 500 kHz and LX=0.45 μH, C

capacitor, pay attention to its characteristics. For MLCC use X5R or better dielectric and take into account

derating of the capacitance by both DC bias and AC bias. When derating by DC bias and AC bias are 80% and

50%, respectively, the effective derating is 40% because 0.8 x 0.5 = 0.4. The capacitance of specialty polymer

capacitors may change depending on the operating frequency. Consult capacitor manufacturers for specific

characteristics.

18 Submit Documentation Feedback Copyright © 2011, Texas Instruments Incorporated

• G is gain of the amplifier which amplifies the ripple current information generated by the compensation

circuit (4)

should be larger than 272 μF. At the selection of

OUT

(5)

( )

-

= ´ ´

´

IN OUT

OUT

LOAD(LL)

X IN SW

V V

V

1

I

2 L V f

æ ö

= ´

ç ÷

è ø

TRIP

OCTRIP TRIP

I

V R

8

( ) ( )

æ ö æ ö

-

ç ÷ ç ÷

= + = + ´ ´

ç ÷ ç ÷

´

è ø è ø

IND(ripple)

OCTRIP OCTRIP IN OUT OUT

OCL

X SW IN

DS on DS on

I

V V V V V

1

I

R 2 R 2 L f V

TPS51219

www.ti.com

Light-Load Operation

In auto-skip mode, the TPS51219 SMPS control logic automatically reduces its switching frequency to improve

light-load efficiency. To achieve this intelligence, a zero cross detection comparator is used to prevent negative

inductor current by turning off the low-side MOSFET. Equation 6 shows the boundary load condition of this skip

mode and continuous conduction operation.

Current Sensing

In order to provide both cost effective solution and good accuracy, TPS51219 supports both of MOSFET R

sensing and external resistor sensing. For R

through the trip voltage setting resistor, R

. In this scheme, TRIP terminal sources 10µA of I

TRIP

the trip level is set to 1/8 of the voltage across the R

between the PGND pin and the SW pin so that the SW pin is connected to the drain terminal of the low-side

MOSFET. I

has a 4700ppm/°C temperature slope to compensate the temperature dependency of the R

TRIP

For resistor sensing scheme, an appropriate current sensing resistor should be connected between the source

terminal of the low-side MOSFET and PGND. The TRIP pin is connected to the MOSFET source terminal node.

The inductor current is monitored by the voltage between PGND pin and TRIP pin. In either scheme, PGND is

used as the positive current sensing node so that PGND should be connected to the proper current sensing

device, i.e. the sense resistor or the source terminal of the low-side MOSFET.

sensing scheme, TRIP pin should be connected to GND

DS(on)

. The inductor current is monitored by the voltage

TRIP

SLUSAG1B –MARCH 2011– REVISED OCTOBER 2011

(6)

DS(on)

current and

TRIP

DS(on)

.

Overcurrent Protection

TPS51219 has cycle-by-cycle overcurrent limiting protection. The inductor current is monitored during the

off-state and the controller maintains the off-state when the inductor current is larger than the overcurrent trip

level. The trip level and current sense operation are determined by the MODE pin setting and TRIP pin

connection (See Table 2 and Current Sensing section). For R

10 µA and the trip level is set to 1/8 of the voltage across this R

is determined by Equation 7.

For a resistor sensing scheme, the trip level, V

Because the comparison is made during the off-state, V

load current OCL level, I

Overcurrent limiting using R

, can be calculated by considering the inductor ripple current.

OCL

sensing is shown in Equation 8.

DS(on)

, is a fixed value of 25 mV.

OCTRIP

OCTRIP

where

• I

IND(ripple)

is inductor ripple current (8)

TRIP

sets the valley level of the inductor current. The

sensing scheme, TRIP terminal sources

DS(on)

resistor. The overcurrent trip level, V

OCTRIP

(7)

,

Copyright © 2011, Texas Instruments Incorporated Submit Documentation Feedback 19

æ ö æ ö

-

= + = + ´ ´

ç ÷ ç ÷

´

è ø è ø

IND(ripple)

IN OUT OUT

OCL

EXT EXT X SW IN

I

V V V

25mV 25mV 1

I

R 2 R 2 L f V

TPS51219

SLUSAG1B –MARCH 2011– REVISED OCTOBER 2011

Overcurrent limiting using resistor sensing is shown in Equation 9.

where

• I

• R

IND(ripple)

is inductor ripple current

is the external current sense resistance (9)

EXT

In an overcurrent condition, the current to the load exceeds the current to the output capacitor, thus the output

voltage tends to fall down. Eventually, it crosses the undervoltage protection threshold and shuts down.

Overvoltage and Undervoltage Protection

The TPS51219 sets the overvoltage protection (OVP) when VSNS voltage reaches a level 20% (typ) higher than

the REFIN voltage. When an OV event is detected, the controller changes the output target voltage to 0 V. This

usually turns off DH and forces DL to be on. When the inductor current begins to flow through the low-side

MOSFET and reaches the negative OCL, DL is turned off and DH is turned on, for a minimum on-time.

After the minimum on-time expires, DH is turned off and DL is turned on again. This action minimizes the output

node undershoot due to LC resonance. When the VSNS reaches 0 V, the driver output is latched as DH off, DL

on.

The undervoltage protection (UVP) latch is set when the VSNS voltage remains lower than 68% (typ) of the

REFIN voltage for 1 ms or longer. In this fault condition, the controller latches DH low and DL low and discharges

the V

To release the OVP and UVP latches, toggle EN or adjust the V5 voltage down and up beyond the undervoltage

lockout threshold.

. UVP detection function is enabled after 1.2 ms of SMPS operation to ensure startup.

OUT

www.ti.com

V5 Undervoltage Lockout Protection

TPS51219 has a 5-V supply undervoltage lockout protection (UVLO) threshold. When the V5 voltage is lower

than UVLO threshold voltage, typically 3.9 V, V

is shut off. This is a non-latch protection.

OUT

Thermal Shutdown

TPS51219 includes an internal temperature monitor. If the temperature exceeds the threshold value, 140°C (typ),

V

is shut off. The state of V

OUT

is restarted with soft-start sequence when the device temperature is reduced by 10°C (typ).

is open at thermal shutdown. This is a non-latch protection and the operation

OUT

20 Submit Documentation Feedback Copyright © 2011, Texas Instruments Incorporated

( )

=

æ ö

ç ÷

ç ÷

ç ÷

-

´

æ ö

ç ÷

ç ÷

-

ç ÷

ç ÷

ç ÷

è ø

è ø

IND ripple

OUT

R1

R2

2.0

1

I ESR

V

2

( )

( )

(

)

( ) ( )

( )

(

)

( )

- ´ - ´

= ´ = ´

´ ´

IN OUT OUT IN OUT OUT

max max

X

SW IN O SW IN

IND ripple max max max

V V V V V V

1 3

L

I f V I f V

( )

( )

( )

(

)

( )

- ´

= + ´

´ ´

IN OUT OUT

max

TRIP

IND peak

X SW IN

DS on max

V V V

V

1

I

8 R L f V

( )

( )

( )

æ ö

æ ö

-

ç ÷

´ - ´ ´

ç ÷

ç ÷

ç ÷

´

´

è ø

è ø

=

IN OUT

OUT

OCL DS(on)

X

SW IN

TRIP

TRIP

V V

V

8 I R

2 L

f V

R

I

=

æ ö

-

- ´

ç ÷

´ ´

è ø

EXT

IN OUT OUT

OCL

X SW IN

25mV

R

V V V

I

2 L f V

´ =

X X

EXT

ESL

C R

R

TPS51219

www.ti.com

External Components Selection

The external components selection is simple in D-CAP™ mode.

1. DETERMINE THE VALUE OF R1 AND R2

The output voltage is determined by the value of the voltage-divider resistor, R1 and R2 as shown in Figure 25.

R1 is connected between VREF and REFIN pins, and R2 is connected between the REFIN pin and GSNS.

Setting R1 as 10-kΩ is a good starting point. Determine R2 using Equation 10.

2. CHOOSE THE INDUCTOR

The inductance value should be determined to yield a ripple current of approximately ¼ to ½ of maximum output

current. Larger ripple current increases output ripple voltage and improves the signal-to-noise ratio and helps

stable operation.

SLUSAG1B –MARCH 2011– REVISED OCTOBER 2011

(10)

(11)

The inductor needs a low direct current resistance (DCR) to achieve good efficiency, as well as enough room

above peak inductor current before saturation. The peak inductor current can be estimated in Equation 12.

(12)

3. CHOOSE THE OCL SETTING RESISTANCE

R

for R

TRIP

Combining Equation 7 and Equation 8, R

R

for Resistor Setting

EXT

Combining Equation 7 and Equation 9, R

For more accurate current sensing with an external resistor, the following technique is recommended. Adding an

RC filter to cancel the parasitic inductance (ESL) of resistor, this filter value is calculated using Equation 15.

DS(on)

Sensing

can be obtained using Equation 13.

TRIP

can be obtained using Equation 14.

EXT

(13)

(14)

The time-constant of CXand RXshould match the one of ESL and R

100 Ω is recommended for noise suppression.

Copyright © 2011, Texas Instruments Incorporated Submit Documentation Feedback 21

. Even when CXis not used, an RXof

EXT

(15)

TPS51219

10

6

DL

TRIP

UDG-11043

R

EXT

Cx

ESL

Rx

+

+

25 mV

(typ)

Lx

I

OUT

TPS51219

10

6

DL

TRIP

UDG-11044

R

EXT

Cx

ESL

R

X

+

+

25 mV

(typ)

Lx

I

OUT

R

XC

( )

´ =

X X XC

EXT

ESL

C R R

R

æ ö æ ö

+ -

= + + ´

ç ÷ ç ÷

´ ´

è ø è ø

X XC IN OUT OUT

OCL

EXT XC X SW IN

R R V V V

25mV

I

R R 2 L f V

( )

( )

æ ö

+

= ´

ç ÷

ç ÷

æ ö

-

è ø

- ´

ç ÷

ç ÷

´ ´

è ø

X XC

EXT

XC

IN OUT

OUT

OCL

X SW IN

R R

25mV

R

R

V V

V

I

2 L f V

= £

p´ ´

SW

0

OUT

f

1

f

2 ESR C 3

£

p´

f

0

M

g

2 C1 10

´

³

´

OUT

SW

V ESR

20mV

f Lx

TPS51219

SLUSAG1B –MARCH 2011– REVISED OCTOBER 2011

Figure 28. Resistor Sensing with Compensation Figure 29. Adjustment of Overcurrent Limitation in

Resistor Sensing

www.ti.com

A voltage divider can be configured to adjust for overcurrent limitation, as described in Figure 29. For RX, R

and CXcan be calculated as shown in Equation 16, and the overcurrent limitation value can be calculated as

shown in Equation 17.

Therefore, R

can be obtained using Equation 18.

EXT

4. CHOOSE THE OUTPUT CAPACITORS

D-CAP™ Mode

Organic semiconductor capacitor(s) or specialty polymer capacitor(s) are recommended. Determine the ESR

value to meet small signal stability and recommended ripple voltage. A quick reference is shown in Equation 19

and Equation 20.

where

• gMis 130 µS (typ)

• C1 is the capacitance connected between the VSNS and COMP pins (20)

22 Submit Documentation Feedback Copyright © 2011, Texas Instruments Incorporated

XC

(16)

(17)

(18)

(19)

(21)

( )

´

£

p´ ´ ´

C C

SW

X OUT

R C

f

2 G L C 3

£

p´

f

0

M

g

2 C1 10

www.ti.com

SLUSAG1B –MARCH 2011– REVISED OCTOBER 2011

D-CAP2™ Mode

Determine output capacitance to meet small signal stability as shown in Equation 22 and Equation 23.

where

• G = 0.25 (22)

where

• the RC× CCtime constant is 32 µs for operation at 500 kHz. (23 µs for operation at 670 kHz) (23)

TPS51219

Copyright © 2011, Texas Instruments Incorporated Submit Documentation Feedback 23

TPS51219

DL

10

VIN

MODE GND

V5

9

V

OUT

VSNS

8

7

PGND

COMP

4

2

1

VREF

UDG-11012

REFIN

3

GSNS

155

10 nF

2.2 mF

#1

#2

#3

PwrPad

6

TRIP

VSNS

GSNS

0.1 mF

10 nF

TPS51219

SLUSAG1B –MARCH 2011– REVISED OCTOBER 2011

Layout Considerations

Certain issues must be considered before designing a layout using the TPS51219.

Figure 30. DC/DC Converter Ground System

www.ti.com

• VINcapacitor(s), V

capacitor(s) and MOSFETs are the power components and should be placed on one

OUT

side of the PCB (solder side). Other small signal components should be placed on another side (component

side). At least one inner plane should be inserted, connected to ground, in order to shield and isolate the

small signal traces from noisy power lines.

• All sensitive analog traces and components such as VSNS, COMP, MODE, REFIN, VREF and TRIP should

be placed away from high-voltage switching nodes such as SW, DH, DL or BST to avoid coupling. Use

internal layer(s) as ground plane(s) and shield feedback trace from power traces and components.

• The DC/DC converter has several high-current loops. The area of these loops should be minimized in order to

suppress generating switching noise.

– Loop #1. The most important loop to minimize the area of is the path from the VINcapacitor(s) through the

high and low-side MOSFETs, and back to the capacitor(s) through ground. Connect the negative node of

the VINcapacitor(s) and the source of the low-side MOSFET at ground as close as possible. (Refer to loop

#1 of Figure 30)

– Loop #2. The second important loop is the path from the low-side MOSFET through inductor and V

capacitor(s), and back to source of the low-side MOSFET through ground. Connect source of the low-side

MOSFET and negative node of V

capacitor(s) at ground as close as possible. (Refer to loop #2 of

OUT

Figure 30)

– Loop #3. The third important loop is of gate driving system for the low-side MOSFET. To turn on the

low-side MOSFET, high current flows from V5 capacitor through gate driver and the low-side MOSFET,

and back to negative node of the capacitor through ground. To turn off the low-side MOSFET, high current

flows from gate of the low-side MOSFET through the gate driver and PGND, and back to source of the

low-side MOSFET through ground. Connect negative node of V5 capacitor, source of the low-side

MOSFET and PGND at ground as close as possible. (Refer to loop #3 of Figure 30)

• Connect the PGND and GND pins directly at the device.

24 Submit Documentation Feedback Copyright © 2011, Texas Instruments Incorporated

OUT

C

TPS51219

SW

DH

V5

DL

PGND

GND

BST

5V

GND

VSNS

GSNS

C

R

VIAs to inner

ground layer

C

COMP

C

TPS51219

SW

DH

V5

DL

PGND

GND

BST

5V

GND

VSNS

GSNS

C

R

VIAs to inner

ground layer

COMP

C

C

R

To output bulk

capacitance

TPS51219

www.ti.com

• Connect VSNS directly to the output voltage sense point at the load device. Connect GSNS to ground return

points at the load device. Insert a 10-Ω, 1-nF, R-C filter between the sense point and the VSNS pin where the

COMP capacitance is connected as shown in Case 1 (Figure 31). When the COMP pin capacitance is

connected to output bulk capacitance, connect the R-C filter in series to both the VSNS pin and the COMP

capacitance as shown in Case 2 (Figure 32).

SLUSAG1B –MARCH 2011– REVISED OCTOBER 2011

Figure 31. Case 1: COMP Pin Capacitance Connected to VSNS

Figure 32. Case 2: COMP Pin Capacitance Connected to Output Bulk Capacitance

• Connect the overcurrent setting resistors from TRIP pin to ground and make the connections as close as

possible to the device. The trace from TRIP pin to resistor and from resistor to ground should avoid coupling

to a high-voltage switching node.

• Connect the frequency and mode setting resistor from MODE pin to ground, and make the connections as

close as possible to the device. The trace from the MODE pin to the resistor and from the resistor to ground

should avoid coupling to a high-voltage switching node.

Copyright © 2011, Texas Instruments Incorporated Submit Documentation Feedback 25

C1

0.1uF

R1

100k

C4

2.2uF

C3

0.1uF

Q1

4

5

1 - 3

4

5

1 - 3

FDMS8680

Q2

FDMS8670AS

4

5

1 - 3

Q3

FDMS8670AS

L1

0.45uH

C7

5x330uF

C8

12x22uF

C5

C6

4x10uF

/25V

0.1uF

/50V

R4

0

R3

0

R2

1k

C2

0.01uF

VSNS

GSNS

REFIN

V5

DL

DH

2

3

4

12

9

10

1

VREF SW

11U1

TPS51219

PGND

GND

TR IP

COM P

EN

MODE

PGOOD

PwP d

17

161514

13

567

8

BS T

R5

36k

VIN

Vout

EN

V5IN

8V to 20V

1.05V/20A

4.5V to 5.5V

Vout_GND

3.3V

R6

10

C9

1nF

TPS51219

SLUSAG1B –MARCH 2011– REVISED OCTOBER 2011

•

Connections from gate drivers to the respective gate of the high-side or the low-side MOSFET should be as

short as possible to reduce stray inductance. Use 0.65 mm (25 mils) or wider trace and via(s) of at least 0.5

mm (20 mils) diameter along this trace.

• The PCB trace defined as SW node, which connects to the source of the switching MOSFET, the drain of the

rectifying MOSFET and the high-voltage side of the inductor, should be as short and wide as possible.

• In order to effectively remove heat from the package, prepare the thermal land and solder to the package

thermal pad. Wide trace of the component-side copper, connected to this thermal land, helps to dissipate

heat. Numerous vias with a 0.3-mm diameter connected from the thermal land to the internal/solder-side

ground plane(s) should be used to help dissipation.

www.ti.com

TPS51219 1.05-V/20-A, D-CAP2™ 500-kHz, R

Figure 33. 1.05-V/20-A, D-CAP2™ 500-kHz, R

Sensing Application Circuit

DS(on)

DS(on)

Sensing

REFERENCE

DESIGNATOR

Table 3. 1.05-V/20-A, D-CAP2™ 500-kHz, R

QTY SPECIFICATION MANUFACTURE PART NUMBER

Sensing, List of Materials

DS(on)

C6 4 10 µF, 25 V Taiyo Yuden TMK325BJ106MM

C7 5 330 µF, 2 V, 6 mΩ Panasonic EEFSX0D331XE

C8 12 22 µF, 6.3 V Murata GRM21BB30J226ME38

L1 1 0.45 µH, 17 A, 1.1 mΩ Panasonic ETQP4LR45XFC

Q1 1 30 V, 35 A, 8.5 mΩ Fairchild FDMS8680

Q2, Q3 2 30 V, 42 A, 3.5 mΩ Fairchild FDMS8670AS

26 Submit Documentation Feedback Copyright © 2011, Texas Instruments Incorporated

C1

0.1uF

R1

100k

C4

2.2uF

C3

0.1uF

Q1

4

5

1 - 3

4

5

1 - 3

FDMS8680

Q2

FDMS8670AS

4

5

1 - 3

Q3

FDMS8670AS

L1

0.45uH

C7

5x330uF

C8

12x22uF

C5

C6

4x10uF

/25V

0.1uF

/50V

R4

0

R3

0

R2

200k

C2

0.01uF

VSNS

GSNS

REFIN

V5

DL

DH

2

3

4

12

9

10

1

VREF SW

11

U1

TPS51219

PGND

GND

TRIP

COMP

EN

MODE

PGOOD

PwPd

17

161514

13

567

8

BST

R5

36k

VIN

Vout

EN

V5IN

8V to 20V

1.05V/20A

4.5V to 5.5V

Vout_GND

3.3V

R6

10

C9

1nF

R7

10

C10

1nF

www.ti.com

TPS51219

SLUSAG1B –MARCH 2011– REVISED OCTOBER 2011

1.05-V/20-A, D-CAP™ 400-kHz, R

Figure 34. 1.05-V/20-A, D-CAP™ 400-kHz, R

Sensing Application Circuit

DS(on)

DS(on)

Sensing

REFERENCE

DESIGNATOR

Table 4. 1.05-V/20-A, D-CAP™ 400-kHz, R

QTY SPECIFICATION MANUFACTURE PART NUMBER

Sensing, List of Materials

DS(on)

C6 4 10 µF, 25 V Taiyo Yuden TMK325BJ106MM

C7 5 330 µF, 2.5 V, 18 mΩ Sanyo 2R5TPE330MI

C8 12 22 µF, 6.3 V Murata GRM21BB30J226ME38

L1 1 0.45 µH, 17 A, 1.1 mΩ Panasonic ETQP4LR45XFC

Q1 1 30 V, 35 A, 8.5 mΩ Fairchild FDMS8680

Q2,Q3 2 30 V, 42 A, 3.5 mΩ Fairchild FDMS8670AS

Copyright © 2011, Texas Instruments Incorporated Submit Documentation Feedback 27

C1

0.1uF

R1

100k

C4

2.2uF

C3

0.1uF

Q1

Q2

4

5

1 - 3

4

5

1 - 3

FDMS8680

FDMS8670AS

L1

0.45uH

C8

C7

2x330uF

12x22uF

C5 C6

4x10uF

/25V

0.1uF

/50V

R4

0

R3

0

R2

33k

C2

0.01uF

VSNS

GSNS

REFIN

V5

DL

DH

2

3

4

12

9

10

1

VREF SW

11

U1

TPS51219

PGND

GND

TRIP

COMP

EN

MODE

PGOOD

PwPd

17

161514

13

567

8

BST

VIN

Vout

EN

V5IN

8V to 20V

1.00V/10.4A

4.5V to 5.5V

Vout_GND

R5

3 m

R6

10

C9

1nF

C10

0.01uF

R7

100

TPS51219

SLUSAG1B –MARCH 2011– REVISED OCTOBER 2011

TPS51219 1.00-V/10.4-A, D-CAP2™ 500-kHz, Resistor Sensing Application Circuit

www.ti.com

Figure 35. 1.00-V/10.4-A, D-CAP2™ 500-kHz, Resistor Sensing

Table 5. 1.00-V/10.4-A, D-CAP2™ 500-kHz, Resistor Sensing, List of Materials

REFERENCE

DESIGNATOR

C6 4 10 µF, 25 V Taiyo Yuden TMK325BJ106MM

C7 2 330 µF, 2 V, 6 mΩ Panasonic EEFSX0D331XE

C8 12 22 µF, 6.3 V Murata GRM21BB30J226ME38

L1 1 0.45 µH, 17 A, 1.1 mΩ Panasonic ETQP4LR45XFC

Q1 1 30 V, 35 A, 8.5 mΩ Fairchild FDMS8680

Q2 1 30 V, 42 A, 3.5 mΩ Fairchild FDMS8670AS

R5 1 3 mΩ, 1 W KOA TLR2HDTD3L00F

28 Submit Documentation Feedback Copyright © 2011, Texas Instruments Incorporated

QTY SPECIFICATION MANUFACTURE PART NUMBER

C1

0.1uF

R1

100k

C4

2.2uF

C3

0.1uF

Q1

Q2

4

5

1 - 3

4

5

1 - 3

FDMS8680

FDMS8670AS

L1

0.45uH

C8

C7

2x330uF

12x22uF

C5 C6

4x10uF

/25V

0.1uF

/50V

R4

0

R3

0

R2

47k

VSNS

GSNS

REFIN

V5

DL

DH

2

3

4

12

9

10

1

VREF SW

11U1

TPS51219

PGND

GND

TRIP

COMP

EN

MODE

PGOOD

PwPd

17

16

15

14

13

5

6

7

8

BST

VIN

Vout

EN

V5IN

8V to 20V

1.00V/10.4A

4.5V to 5.5V

Vout_GND

R5

3m

C2

0.01uF

C9

0.01uF

R6

100

R7

10

C10

1nF

R8

10

C11

1nF

www.ti.com

SLUSAG1B –MARCH 2011– REVISED OCTOBER 2011

TPS51219 1.00-V/10.4-A, D-CAP™ 400-kHz, Resistor Sensing Application Circuit

TPS51219

Figure 36. 1.00-V/10.4-A, D-CAP™ 400-kHz, Resistor Sensing

Table 6. 1.00-V/10.4-A, D-CAP™ 400-kHz, Resistor Sensing, List of Materials

REFERENCE

DESIGNATOR

C6 4 10 µF, 25 V Taiyo Yuden TMK325BJ106MM

C7 2 330 µF, 2 V, 9 mΩ Panasonic EEFSX0D331ER

C8 12 22 µF, 6.3 V Murata GRM21BB30J226ME38

L1 1 0.45 µH, 17 A, 1.1 mΩ Panasonic ETQP4LR45XFC

Q1 1 30 V, 35 A, 8.5 mΩ Fairchild FDMS8680

Q2 1 30 V, 42 A, 3.5 mΩ Fairchild FDMS8670AS

R5 1 3 mΩ, 1 W KOA TLR2HDTD3L00F

Copyright © 2011, Texas Instruments Incorporated Submit Documentation Feedback 29

QTY SPECIFICATION MANUFACTURE PART NUMBER

PACKAGE OPTION ADDENDUM

www.ti.com

23-Feb-2014

PACKAGING INFORMATION

Orderable Device Status

TPS51219RTER ACTIVE WQFN RTE 16 3000 Green (RoHS

TPS51219RTET ACTIVE WQFN RTE 16 250 Green (RoHS

(1)

The marketing status values are defined as follows:

ACTIVE: Product device recommended for new designs.

LIFEBUY: TI has announced that the device will be discontinued, and a lifetime-buy period is in effect.

NRND: Not recommended for new designs. Device is in production to support existing customers, but TI does not recommend using this part in a new design.

PREVIEW: Device has been announced but is not in production. Samples may or may not be available.

OBSOLETE: TI has discontinued the production of the device.

Package Type Package

(1)

Drawing

Pins Package

Qty

Eco Plan

(2)

& no Sb/Br)

& no Sb/Br)

Lead/Ball Finish

(6)

CU NIPDAU Level-2-260C-1 YEAR -40 to 85 51219

CU NIPDAU Level-2-260C-1 YEAR -40 to 85 51219

MSL Peak Temp

(3)

Op Temp (°C) Device Marking

(4/5)

(2)

Eco Plan - The planned eco-friendly classification: Pb-Free (RoHS), Pb-Free (RoHS Exempt), or Green (RoHS & no Sb/Br) - please check http://www.ti.com/productcontent for the latest availability

information and additional product content details.

TBD: The Pb-Free/Green conversion plan has not been defined.

Pb-Free (RoHS): TI's terms "Lead-Free" or "Pb-Free" mean semiconductor products that are compatible with the current RoHS requirements for all 6 substances, including the requirement that

lead not exceed 0.1% by weight in homogeneous materials. Where designed to be soldered at high temperatures, TI Pb-Free products are suitable for use in specified lead-free processes.

Pb-Free (RoHS Exempt): This component has a RoHS exemption for either 1) lead-based flip-chip solder bumps used between the die and package, or 2) lead-based die adhesive used between

the die and leadframe. The component is otherwise considered Pb-Free (RoHS compatible) as defined above.

Green (RoHS & no Sb/Br): TI defines "Green" to mean Pb-Free (RoHS compatible), and free of Bromine (Br) and Antimony (Sb) based flame retardants (Br or Sb do not exceed 0.1% by weight

in homogeneous material)

(3)

MSL, Peak Temp. - The Moisture Sensitivity Level rating according to the JEDEC industry standard classifications, and peak solder temperature.

(4)

There may be additional marking, which relates to the logo, the lot trace code information, or the environmental category on the device.

(5)

Multiple Device Markings will be inside parentheses. Only one Device Marking contained in parentheses and separated by a "~" will appear on a device. If a line is indented then it is a continuation

of the previous line and the two combined represent the entire Device Marking for that device.

(6)

Lead/Ball Finish - Orderable Devices may have multiple material finish options. Finish options are separated by a vertical ruled line. Lead/Ball Finish values may wrap to two lines if the finish

value exceeds the maximum column width.

Important Information and Disclaimer:The information provided on this page represents TI's knowledge and belief as of the date that it is provided. TI bases its knowledge and belief on information

provided by third parties, and makes no representation or warranty as to the accuracy of such information. Efforts are underway to better integrate information from third parties. TI has taken and

continues to take reasonable steps to provide representative and accurate information but may not have conducted destructive testing or chemical analysis on incoming materials and chemicals.

TI and TI suppliers consider certain information to be proprietary, and thus CAS numbers and other limited information may not be available for release.

Samples

Addendum-Page 1

PACKAGE OPTION ADDENDUM

www.ti.com

In no event shall TI's liability arising out of such information exceed the total purchase price of the TI part(s) at issue in this document sold by TI to Customer on an annual basis.

23-Feb-2014

Addendum-Page 2

PACKAGE MATERIALS INFORMATION

www.ti.com 10-Jun-2013

TAPE AND REEL INFORMATION

*All dimensions are nominal

Device Package

TPS51219RTER WQFN RTE 16 3000 330.0 12.4 3.3 3.3 1.1 8.0 12.0 Q2

TPS51219RTER WQFN RTE 16 3000 330.0 12.4 3.3 3.3 1.1 8.0 12.0 Q2

TPS51219RTET WQFN RTE 16 250 330.0 12.4 3.3 3.3 1.1 8.0 12.0 Q2

Type

Package

Drawing

Pins SPQ Reel

Diameter

(mm)

Reel

Width

W1 (mm)

A0

(mm)B0(mm)K0(mm)P1(mm)W(mm)

Pin1

Quadrant

Pack Materials-Page 1

PACKAGE MATERIALS INFORMATION

www.ti.com 10-Jun-2013

*All dimensions are nominal

Device Package Type Package Drawing Pins SPQ Length (mm) Width (mm) Height (mm)

TPS51219RTER WQFN RTE 16 3000 367.0 367.0 35.0

TPS51219RTER WQFN RTE 16 3000 338.0 355.0 50.0

TPS51219RTET WQFN RTE 16 250 338.0 355.0 50.0

Pack Materials-Page 2

IMPORTANT NOTICE

Texas Instruments Incorporated and its subsidiaries (TI) reserve the right to make corrections, enhancements, improvements and other

changes to its semiconductor products and services per JESD46, latest issue, and to discontinue any product or service per JESD48, latest

issue. Buyers should obtain the latest relevant information before placing orders and should verify that such information is current and

complete. All semiconductor products (also referred to herein as “components”) are sold subject to TI’s terms and conditions of sale

supplied at the time of order acknowledgment.

TI warrants performance of its components to the specifications applicable at the time of sale, in accordance with the warranty in TI’s terms

and conditions of sale of semiconductor products. Testing and other quality control techniques are used to the extent TI deems necessary

to support this warranty. Except where mandated by applicable law, testing of all parameters of each component is not necessarily

performed.

TI assumes no liability for applications assistance or the design of Buyers’ products. Buyers are responsible for their products and

applications using TI components. To minimize the risks associated with Buyers’ products and applications, Buyers should provide

adequate design and operating safeguards.

TI does not warrant or represent that any license, either express or implied, is granted under any patent right, copyright, mask work right, or

other intellectual property right relating to any combination, machine, or process in which TI components or services are used. Information

published by TI regarding third-party products or services does not constitute a license to use such products or services or a warranty or

endorsement thereof. Use of such information may require a license from a third party under the patents or other intellectual property of the

third party, or a license from TI under the patents or other intellectual property of TI.

Reproduction of significant portions of TI information in TI data books or data sheets is permissible only if reproduction is without alteration

and is accompanied by all associated warranties, conditions, limitations, and notices. TI is not responsible or liable for such altered

documentation. Information of third parties may be subject to additional restrictions.

Resale of TI components or services with statements different from or beyond the parameters stated by TI for that component or service

voids all express and any implied warranties for the associated TI component or service and is an unfair and deceptive business practice.

TI is not responsible or liable for any such statements.

Buyer acknowledges and agrees that it is solely responsible for compliance with all legal, regulatory and safety-related requirements

concerning its products, and any use of TI components in its applications, notwithstanding any applications-related information or support

that may be provided by TI. Buyer represents and agrees that it has all the necessary expertise to create and implement safeguards which

anticipate dangerous consequences of failures, monitor failures and their consequences, lessen the likelihood of failures that might cause

harm and take appropriate remedial actions. Buyer will fully indemnify TI and its representatives against any damages arising out of the use

of any TI components in safety-critical applications.

In some cases, TI components may be promoted specifically to facilitate safety-related applications. With such components, TI’s goal is to

help enable customers to design and create their own end-product solutions that meet applicable functional safety standards and

requirements. Nonetheless, such components are subject to these terms.

No TI components are authorized for use in FDA Class III (or similar life-critical medical equipment) unless authorized officers of the parties

have executed a special agreement specifically governing such use.

Only those TI components which TI has specifically designated as military grade or “enhanced plastic” are designed and intended for use in

military/aerospace applications or environments. Buyer acknowledges and agrees that any military or aerospace use of TI components

which have not been so designated is solely at the Buyer's risk, and that Buyer is solely responsible for compliance with all legal and

regulatory requirements in connection with such use.

TI has specifically designated certain components as meeting ISO/TS16949 requirements, mainly for automotive use. In any case of use of

non-designated products, TI will not be responsible for any failure to meet ISO/TS16949.

Products Applications

Audio www.ti.com/audio Automotive and Transportation www.ti.com/automotive

Amplifiers amplifier.ti.com Communications and Telecom www.ti.com/communications

Data Converters dataconverter.ti.com Computers and Peripherals www.ti.com/computers

DLP® Products www.dlp.com Consumer Electronics www.ti.com/consumer-apps

DSP dsp.ti.com Energy and Lighting www.ti.com/energy

Clocks and Timers www.ti.com/clocks Industrial www.ti.com/industrial

Interface interface.ti.com Medical www.ti.com/medical

Logic logic.ti.com Security www.ti.com/security

Power Mgmt power.ti.com Space, Avionics and Defense www.ti.com/space-avionics-defense

Microcontrollers microcontroller.ti.com Video and Imaging www.ti.com/video

RFID www.ti-rfid.com

OMAP Applications Processors www.ti.com/omap TI E2E Community e2e.ti.com

Wireless Connectivity www.ti.com/wirelessconnectivity

Mailing Address: Texas Instruments, Post Office Box 655303, Dallas, Texas 75265

Copyright © 2014, Texas Instruments Incorporated

Loading...

Loading...