7

8

9

10

24

23

22

21

VO1

PGOOD

VBST1

DRVH1

VO2

VREG3

VBST2

DRVH2

TPS51123RGE

(QFN-24)

11

12

20

19

LL1

DRVL1

LL2

DRVL2

13 14 15 16 17 18

EN0

SKIPSEL

GND

VIN

VREG5

ENC

6 5 4 3 2 1

TRIP2

VFB2

TONSEL

VREF

VFB1

TRIP1

PowerPAD

220 nF

20 kW 20 kW 30 kW

100 kW

VREG5

33 mF

5.1 W

0.1 mF

130 kW130 kW

3.3 mF

330 mF

VO1

5 V

VIN

VREG5

ENC

VIN

10 mF x 2

VIN

5.5 V

to

28 V

EN0

5.1 W

0.1 mF

3.3 mF

330 mF

VO2

3.3 V

10 mF x 2

10 mF

13 kW

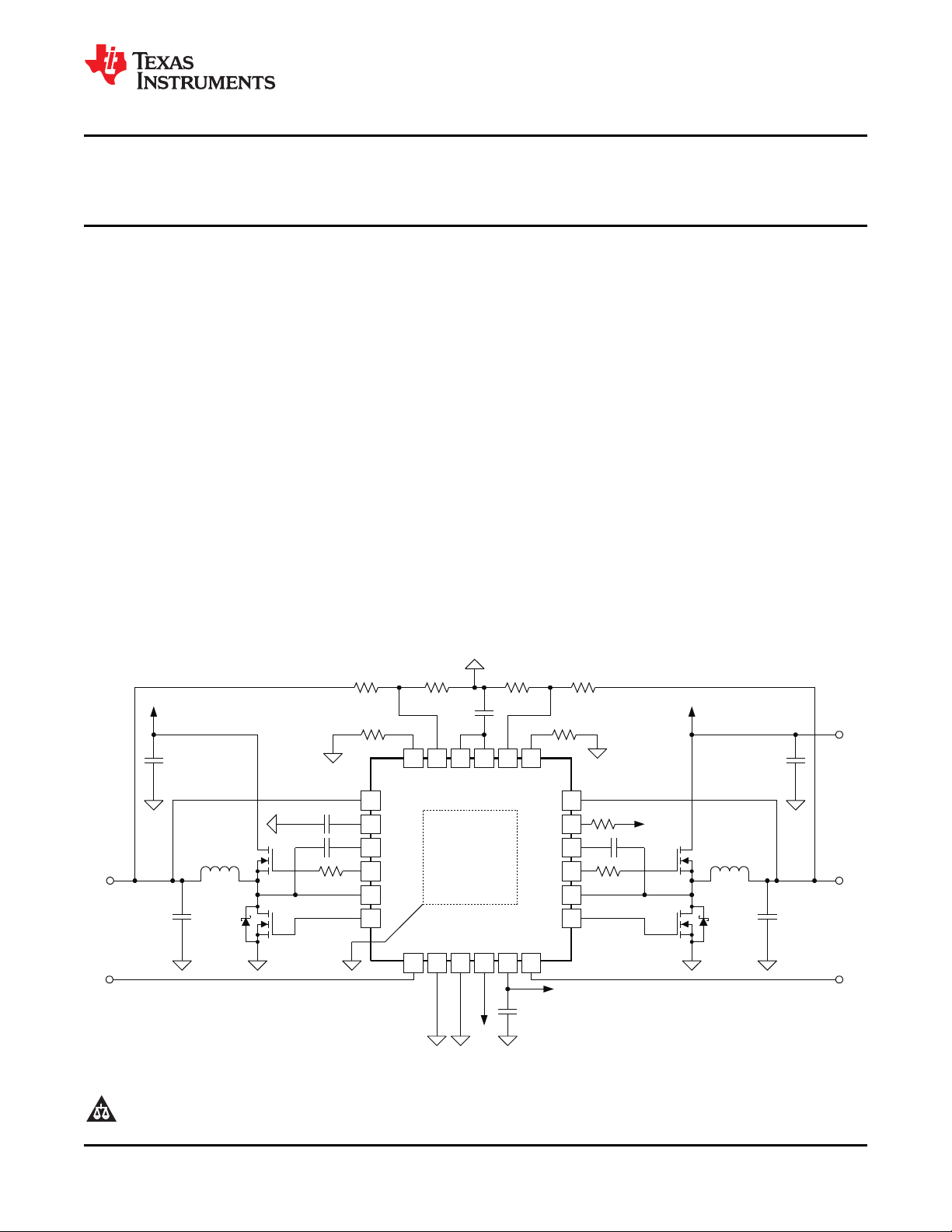

UDG-08167

VIN

TPS51123

www.ti.com

SLUS890E –DECEMBER 2008–REVISED JANUARY 2013

Dual-Synchronous, Step-Down Controller with Out-of-Audio™ Operation and 100-mA

LDOs for Notebook System Power

Check for Samples: TPS51123

1

FEATURES

2

• Wide-Input Voltage Range: 5.5 V to 28 V

• Output Voltage Range: 2 V to 5.5 V • I/O Supplies

• Built-in 100-mA 5-V/3.3-V LDO with Switches • System Power Supplies

• Built-in 1% 2-V Reference Output

• With/Without Out-of-Audio™ Mode Selectable

Light-Load and PWM only Operation

• Internal 1.6-ms Voltage Servo Softstart

• Adaptive On-Time Control Architecture with

Four Selectable Frequency Setting

• 4500 ppm/°C R

• Built-In Output Discharge

• Power Good Output

• Built-in OVP/UVP/OCP

• Thermal Shutdown (Non-latch)

• 24-Pin QFN (RGE) Package

Current Sensing

DS(on)

APPLICATIONS

• Notebook Computers

DESCRIPTION

The TPS51123 is a cost effective, dual-synchronous

buck controller targeted for notebook system power

supply solutions. It provides 5-V and 3.3-V LDOs and

requires few external components. The TPS51123

supports high efficiency, fast transient responses and

provides a combined power-good signal. Out-ofAudio™ mode light-load operation enables low

acoustic noise at much higher efficiency than

conventional forced PWM operation. Adaptive ontime D-CAP™ control provides convenient and

efficient operation. The part operates with supply

input voltages ranging from 5.5 V to 28 V and

supports output voltages from 2 V to 5.5 V. The

TPS51123 is available in a 24-pin QFN package and

is specified from -40°C to 85°C ambient temperature

range.

1

Please be aware that an important notice concerning availability, standard warranty, and use in critical applications of

Texas Instruments semiconductor products and disclaimers thereto appears at the end of this data sheet.

2Out-of-Audio, D-CAP are trademarks of Texas Instruments.

PRODUCTION DATA information is current as of publication date.

Products conform to specifications per the terms of the Texas

Instruments standard warranty. Production processing does not

necessarily include testing of all parameters.

Copyright © 2008–2013, Texas Instruments Incorporated

TPS51123

SLUS890E –DECEMBER 2008–REVISED JANUARY 2013

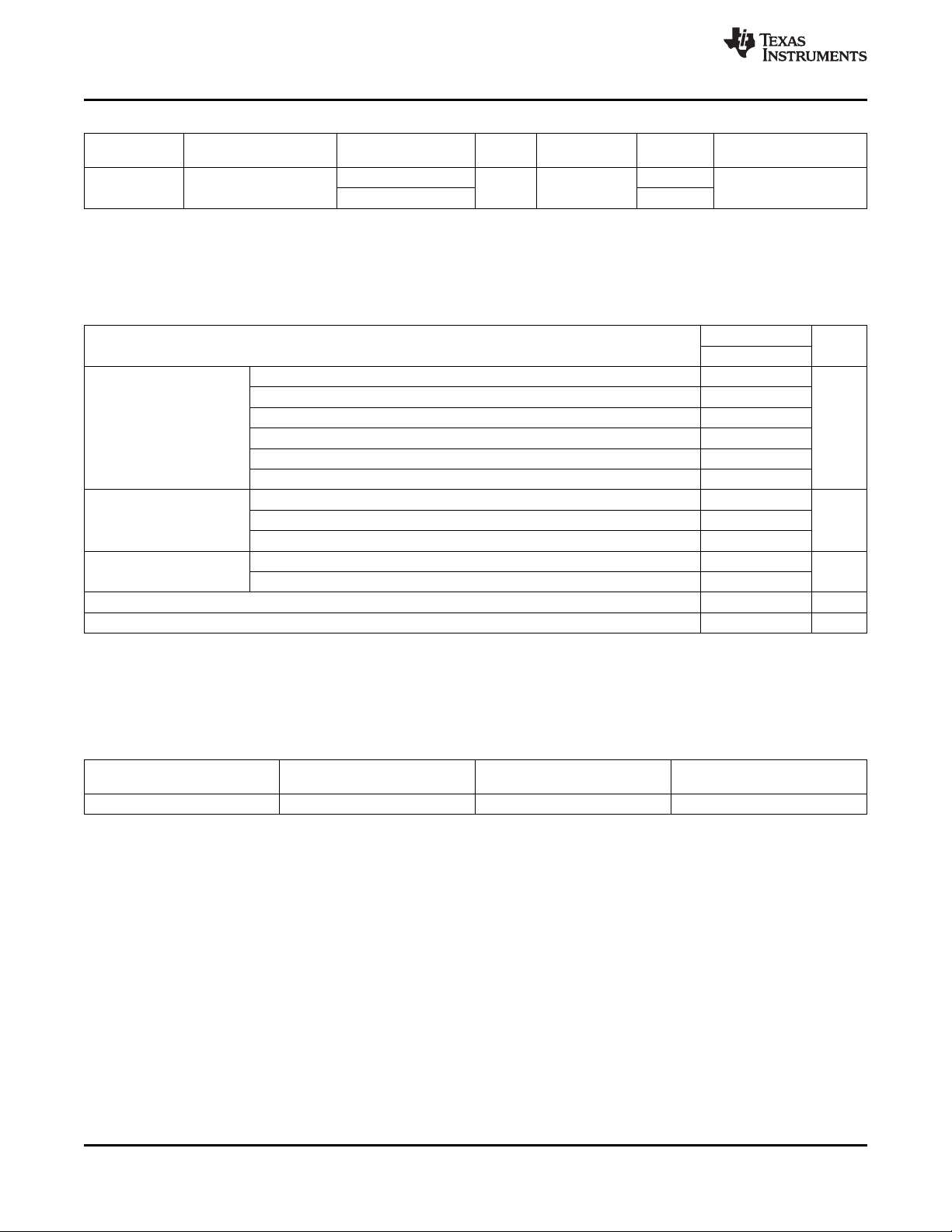

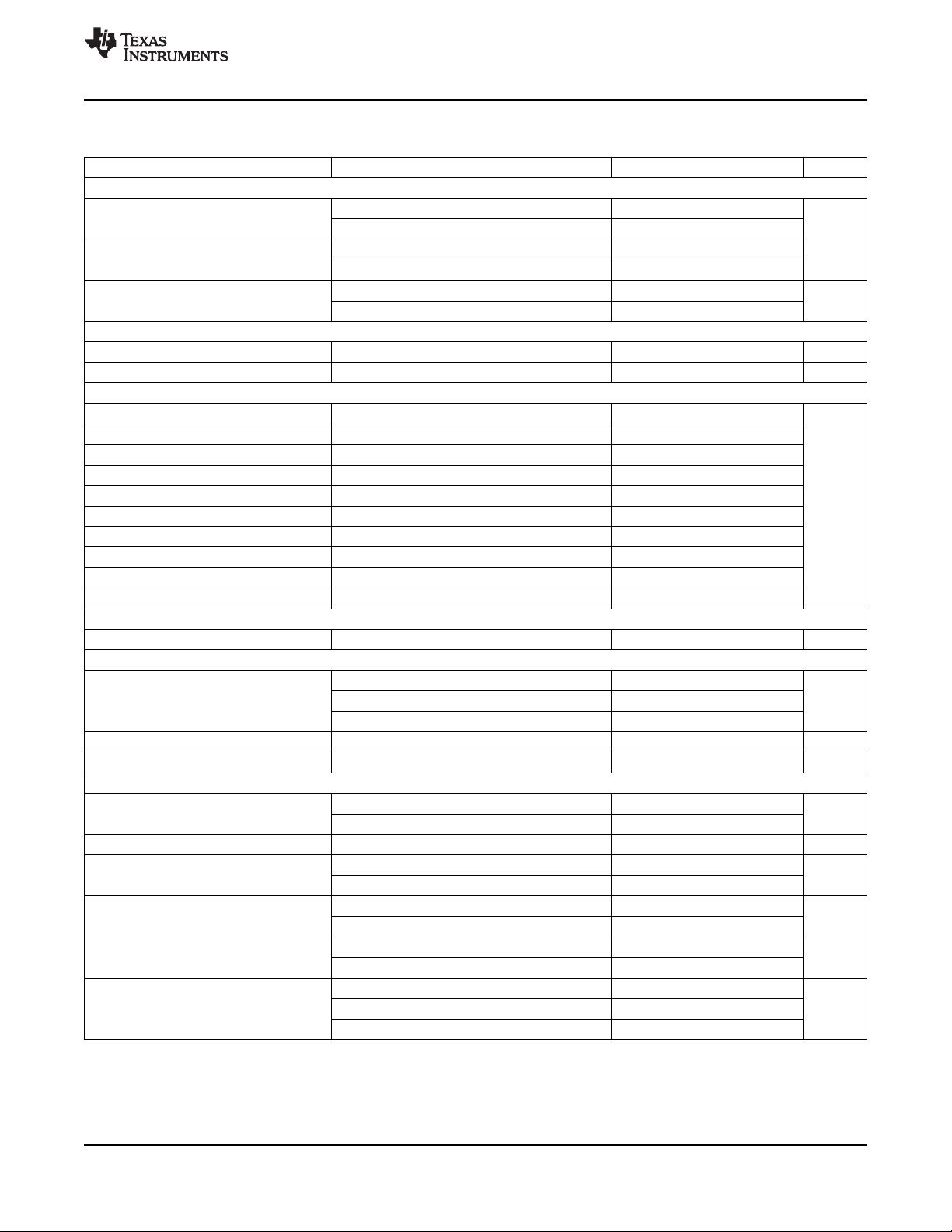

ORDERING INFORMATION

T

A

-40°C to 85°C 24 Tape/Reel

PACKAGE PINS ECO PLAN

Plastic Quad Flat Pack Green (RoHS and no

(QFN) Sb/Br)

ORDERABLE TRANSPORT MINIMUM

DEVICES MEDIA QUANTITY

TPS51123RGET 250

TPS51123RGER 3000

(1)

www.ti.com

(1) For the most current spcifications and package information, see the Package Option Addendum located at the end of this data sheet or

refer to our web site at http://www.ti.com.

ABSOLUTE MAXIMUM RATINGS

(1)

over operating free-air temperature range (unless otherwise noted)

PARAMETER

VBST1, VBST2 –0.3 36

VIN –0.3 30

Input voltage range

(1)

LL1, LL2 –2.0 30

LL1, LL2, pulse width < 20 ns –5.0 30

VBST1, VBST2

(2)

EN0, ENC, TRIP1, TRIP2, VFB1, VFB2, VO1, VO2, TONSEL, SKIPSEL –0.3 6

DRVH1, DRVH2 –1.0 36

Output voltage range

(1)

DRVH1, DRVH2

(2)

PGOOD, VREG3, VREG5, VREF, DRVL1, DRVL2 –0.3 6

Electrostatic discharge kV

Junction temperature range, T

Storage temperature, T

Human body model QSS 009-105 (JESD22-A114A 2

Charged device model QSS 009-147 (JESD22-C101B.01) 1.5

J

stg

(1) Stresses beyond those listed under "absolute maximum ratings" may cause permanent damage to the device. These are stress ratings

only and functional operation of the device at these or any other conditions beyond those indicated under "recommended operating

conditions" is not implied. Exposure to absolute-maximum-rated conditions for extended periods may affect device reliability.

(2) Voltage values are with respect to the corresponding LLx terminal.

VALUE UNIT

MIN MAX

V

–0.3 6

–0.3 6 V

–40 125

–55 150 °C

DISSIPATION RATINGS

2-oz. trace and copper pad with solder.

PACKAGE TA< 25°C POWER RATING TA= 85°C POWER RATING

24-pin RGE

(1)

1.85 W 18.5 mW/°C 0.74 W

DERATING FACTOR ABOVE T

= 25°C

(1) Enhanced thermal conductance by 3 x 3 thermal vias beneath thermal pad.

2 Submit Documentation Feedback Copyright © 2008–2013, Texas Instruments Incorporated

Product Folder Links: TPS51123

A

TPS51123

www.ti.com

SLUS890E –DECEMBER 2008–REVISED JANUARY 2013

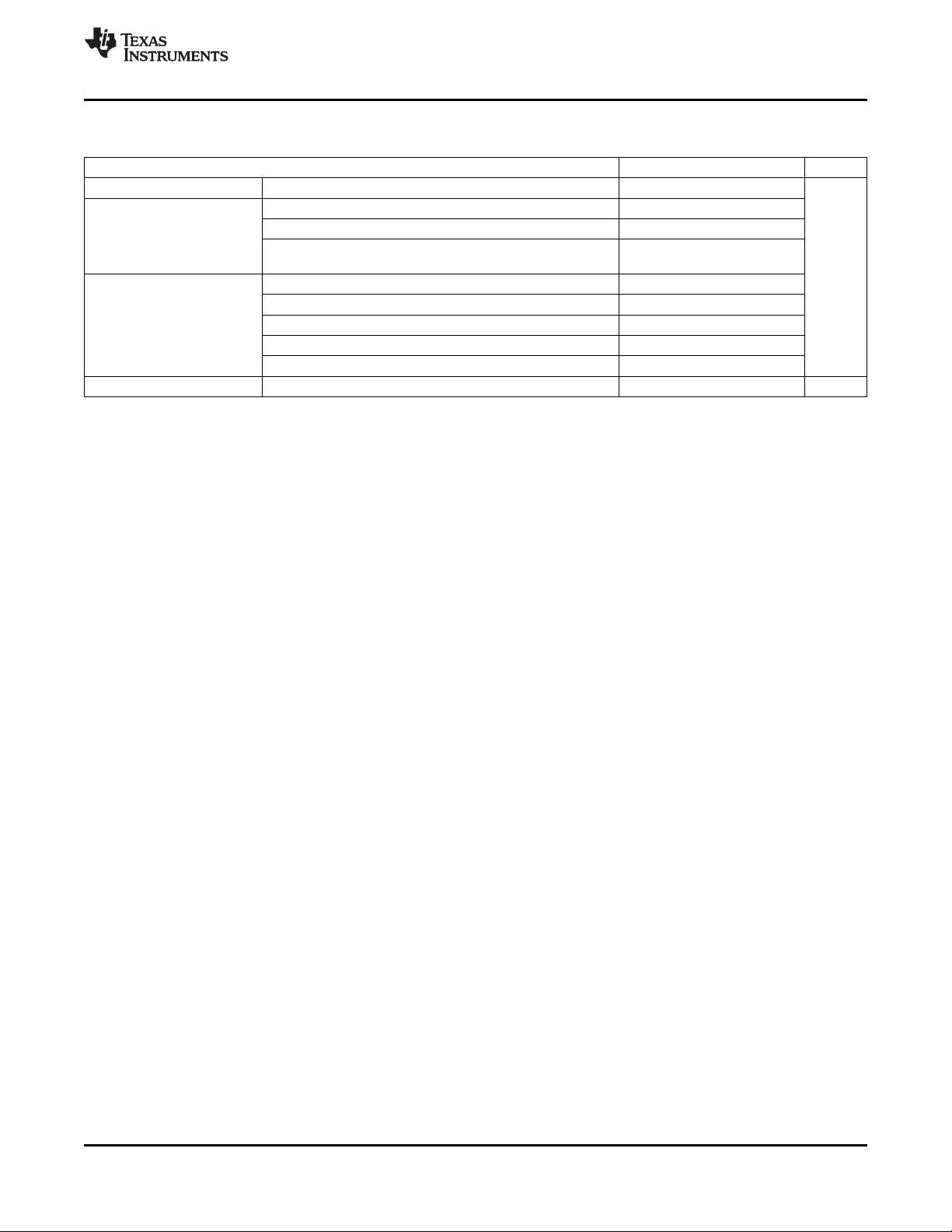

RECOMMENDED OPERATING CONDITIONS

over operating free-air temperature range (unless otherwise noted)

PARAMETER MIN TYP MAX UNIT

Supply voltage VIN 5.5 28

VBST1, VBST2 -0.1 34

Input voltage range

Output voltage range LL1, LL2 -1.8 28

T

A

VBST1, VBST2 (wrt LLx) -0.1 5.5

EN0, ENC, TRIP1, TRIP2, VFB1, VFB2, VO1, VO2, TONSEL,

SKIPSEL

DRVH1, DRVH2 -0.8 34

DRVH1, DRVH2 (wrt LLx) -0.1 5.5

VREF, VREG3, VREG5 -0.1 5.5

PGOOD, DRVL1, DRVL2 -0.1 5.5

Operating free-air temperature -40 85 °C

-0.1 5.5

V

Copyright © 2008–2013, Texas Instruments Incorporated Submit Documentation Feedback 3

Product Folder Links: TPS51123

TPS51123

SLUS890E –DECEMBER 2008–REVISED JANUARY 2013

ELECTRICAL CHARACTERISTICS

over operating free-air temperature range, VIN = 12 V (unless otherwise noted)

PARAMETER CONDITIONS MIN TYP MAX UNIT

SUPPLY CURRENT

I

VIN1

I

VIN2

I

VO1

I

VO2

I

VINSTBY

I

VINSDN

VIN supply current1 VO2 = 0 V, EN0=open, ENC = 5 V, 0.55 1 mA

VIN supply current2 VO2 = 3.3 V, EN0=open, ENC = 5 V, 4 6.5 μA

VO1 current VO2 = 3.3 V, EN0=open, ENC = 5 V, 0.8 1.5 mA

VO2 current VO2 = 3.3 V, EN0=open, ENC = 5 V, 12 100

VIN standby current 95 250

VIN shutdown current 10 25

VREF OUTPUT

V

VREF

VREF output voltage V

VREG5 OUTPUT

V

VREG5

I

VREG5

V

TH5VSW

R

5VSW

VREG5 output voltage 4.75 5 5.25 V

VREG5 output current VO1 = 0 V, VREG5 = 4.5 V 100 175 250 mA

Switch over threshold V

5 V SW R

ON

VREG3 OUTPUT

V

VREG3

I

VREG3

V

TH3VSW

R

3VSW

VREG3 output voltage VO2 = 0 V, I

VREG3 output current VO2 = 0 V, VREG3 = 3 V 100 175 250 mA

Switch over threshold V

3 V SW R

ON

INTERNAL REFERENCE VOLTAGE

V

IREF

V

VFB

I

VFB

OUTPUT VOLTAGE, V

I

Dischg

Internal reference voltage I

VFB regulation voltage

VFB input current VFBx = 2.0 V, TA= 25°C -20 20 nA

DISCHARGE

OUT

VOUT discharge current ENC = 0 V, VOx = 0.5 V 10 60 mA

(1) Ensured by design. Not production tested.

VIN current, TA= 25°C, no load, VO1 = 0 V,

TRIP1 = TRIP2 = 2 V, VFB1 = VFB2 = 2.05 V

VIN current, TA= 25°C, no load, VO1 = 5 V,

TRIP1 = TRIP2 = 2 V, VFB1 = VFB2 = 2.05 V

VO1 current, TA= 25°C, no load, VO1 = 5 V,

TRIP1 = TRIP2 = 2 V, VFB1 = VFB2 = 2.05 V

VO2 current, TA= 25°C, no load, VO1 = 5 V,

TRIP1 = TRIP2 = 2 V, VFB1 = VFB2 = 2.05 V

VIN current, TA= 25°C, no load, μA

EN0 = 1.2 V, ENC = 0 V

VIN current, TA= 25°C, no load,

EN0 = ENC = 0 V

I

= 0 A 1.98 2.00 2.02

VREF

–5 μA < I

VO1 = 0 V, I

VO1 = 0 V, I

6.5 V < VIN < 28 V

VO1 = 0 V, I

< 100 μA 1.97 2.00 2.03

VREF

< 100 mA, TA= 25°C 4.8 5 5.2

VREG5

< 100 mA,

VREG5

< 50 mA, 5.5 V < VIN < 28 V 4. 75 5 5.25

VREG5

Turns on 4.55 4.7 4.85

Hysteresis 0.15 0.25 0.3

VO1 = 5 V, I

VO2 = 0 V, I

VO2 = 0 V, I

= 100 mA 1 3 Ω

VREG5

< 100 mA, TA= 25°C 3.2 3.33 3.46

VREG3

< 100 mA, 6.5 V < VIN < 28 V 3.13 3.33 3.5 V

VREG3

< 50 mA, 5.5 V < VIN < 28 V 3.13 3.33 3.5

VREG3

Turns on 3.05 3.15 3.25

Hysteresis 0.1 0.2 0.25

VO2 = 3.3 V, I

= 0 A, beginning of ON state 1.95 1.98 2.01

VREF

FB voltage, I

FB voltage, I

FB voltage, I

FB voltage, I

(1)

mode

= 100 mA 1.5 4 Ω

VREG3

= 0 A, skip mode 1.98 2.01 2.04

VREF

= 0 A, skip mode, TA= 25°C 1.9849 2.01 2.0351

VREF

= 0 A, OOA mode

VREF

= 0 A, continuous conduction

VREF

(1)

www.ti.com

V

2.00 2.035 2.07

2.00

4 Submit Documentation Feedback Copyright © 2008–2013, Texas Instruments Incorporated

Product Folder Links: TPS51123

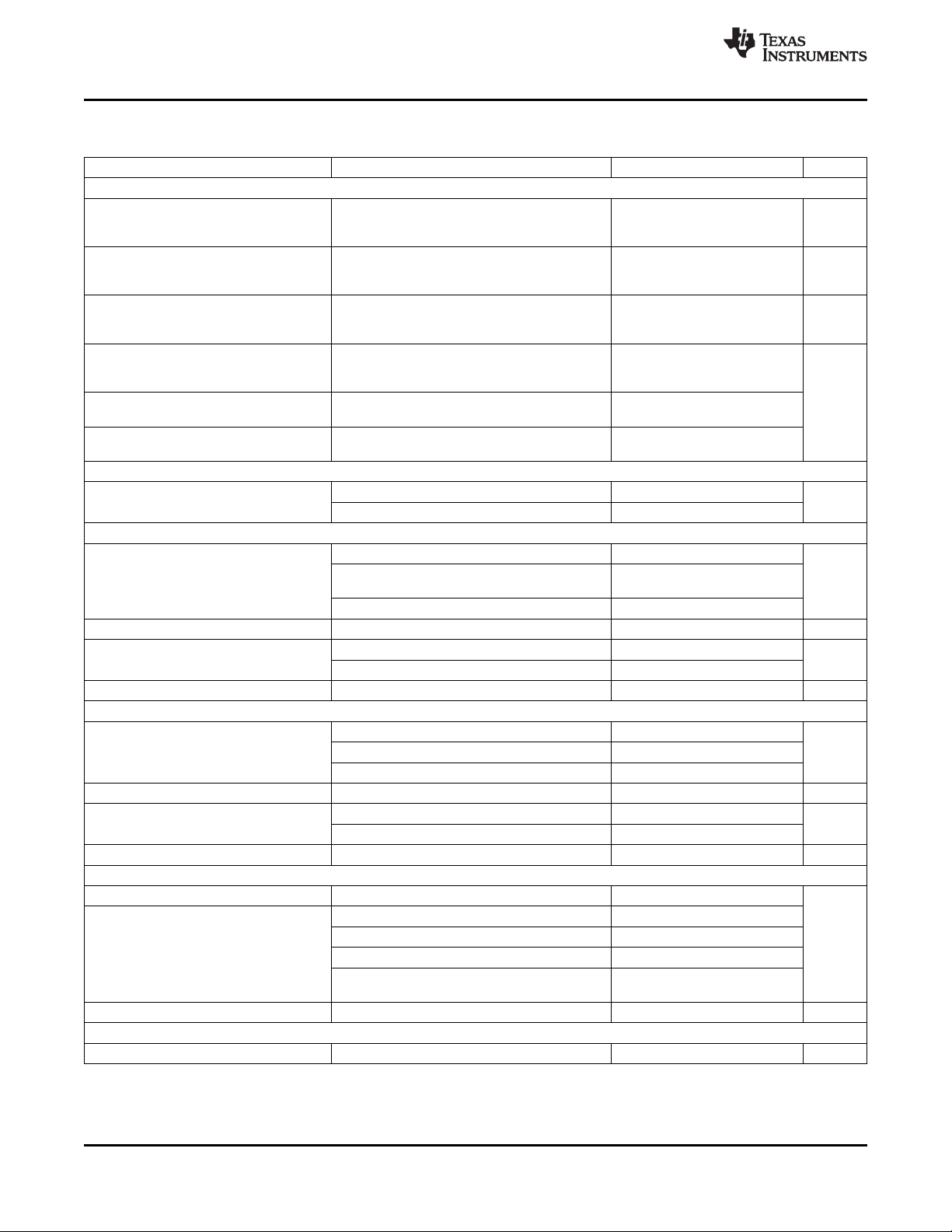

TPS51123

www.ti.com

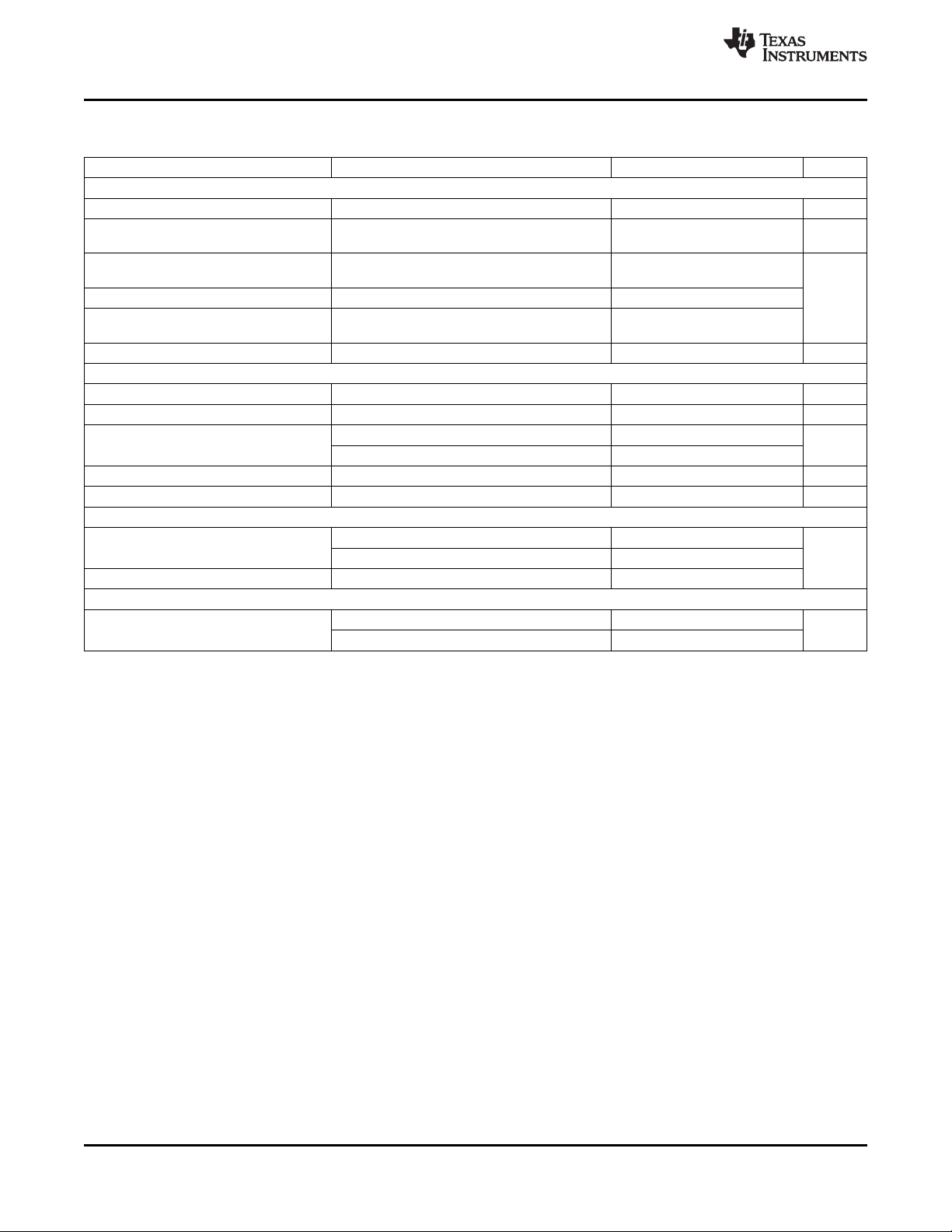

ELECTRICAL CHARACTERISTICS (continued)

over operating free-air temperature range, VIN = 12 V (unless otherwise noted)

PARAMETER CONDITIONS MIN TYP MAX UNIT

OUTPUT DRIVERS

R

DRVH

R

DRVL

t

DEAD

DRVH resistance

DRVL resistance

Dead time ns

Source, V

Sink, V

Source, V

Sink, V

DRVHx-off to DRVLx-on 10

DRVLx-off to DRVHx-on 30

INTERNAL BST DIODE

V

FBST

I

VBSTLK

Forward voltage V

VREG5-VBSTx

VBST leakage current VBSTx = 34 V, LLx = 28 V, TA= 25 °C 0.1 1 μA

DUTY AND FREQUENCY CONTROL

t

ON11

t

ON12

t

ON13

t

ON14

t

ON21

t

ON22

t

ON23

t

ON24

t

ON(min)

t

OFF(min)

CH1 on-time 1 VIN= 12 V, VO1 = 5 V, 200 kHz setting 2080

CH1 on-time 2 VIN= 12 V, VO1 = 5 V, 245 kHz setting 1700

CH1 on-time 3 VIN= 12 V, VO1 = 5 V, 300 kHz setting 1390

CH1 on-time 4 VIN= 12 V, VO1 = 5 V, 365 kHz setting 1140

CH2 on-time 1 VIN= 12 V, VO2 = 3.3 V, 250 kHz setting 1100

CH2 on-time 2 VIN= 12 V, VO2 = 3.3 V, 305 kHz setting 900

CH2 on-time 3 VIN= 12 V, VO2 = 3.3 V, 375 kHz setting 730

CH2 on-time 4 VIN= 12 V, VO2 = 3.3 V, 460 kHz setting 600

Minimum on-time TA= 25 °C 80

Minimum off -ime TA= 25 °C 300

SOFTSTART

t

SS

Internal SS time Internal soft start 1.1 1.6 2.1 ms

POWERGOOD

PG in from lower 92.50% 95% 97.50%

V

THPG

PG threshold PG in from higher 102.50% 105% 107.50%

PG hysteresis 2.50% 5% 7.50%

I

PGMAX

t

PGDEL

PG sink current PGOOD = 0.5 V 5 12 mA

PG delay time Delay for PG in 350 510 670 μs

LOGIC THRESHOLD AND SETTING CONDITIONS

V

I

V

EN0

EN0

ENC

EN0 setting voltage V

EN0 current V

ENC threshold voltage V

Shutdown 0.4

Enable 2.4

EN0

Shutdown 0.6

Enable 2

200 kHz/250 kHz 1.5

V

TONSEL

TONSEL setting voltage V

245 kHz/305 kHz 1.9 2.1

300 kHz/375 kHz 2.7 3.6

365 kHz/460 kHz 4.7

Auto skip 1.5

V

SKIPSEL

SKIPSEL setting voltage PWM only 1.9 2.1 V

OOA auto skip 2.7

BSTx - DRVHx

DRVHx - LLx

VREG5 - DRVLx

= 100 mV 1.5 4

DRVLx

, IF= 10 mA, TA= 25 °C 0.7 0.8 0.9 V

= 0.2 V 2 3.5 5 μA

= 100 mV 4 8

= 100 mV 1.5 4

= 100 mV 4 8

SLUS890E –DECEMBER 2008–REVISED JANUARY 2013

Ω

ns

Copyright © 2008–2013, Texas Instruments Incorporated Submit Documentation Feedback 5

Product Folder Links: TPS51123

TPS51123

SLUS890E –DECEMBER 2008–REVISED JANUARY 2013

ELECTRICAL CHARACTERISTICS (continued)

over operating free-air temperature range, VIN = 12 V (unless otherwise noted)

PARAMETER CONDITIONS MIN TYP MAX UNIT

PROTECTION: CURRENT SENSE

I

TRIP

TC

ITRIP

V

OCLoff

V

OCL(max)

V

ZC

V

TRIP

PROTECTION: UNDERVOLTAGE AND OVERVOLTAGE PROTECTION

V

OVP

t

OVPDEL

V

UVP

t

UVPDEL

t

UVPEN

UNDERVOLTAGE LOCKOUT (UVLO)

V

UVVREG5

V

UVVREG3

THERMAL SHUTDOWN

T

SDN

TRIPx source current V

TRIPx current temperature

coefficient

OCP comparator offset -8 0 8

Maximum OCL setting V

Zero cross detection

comparator offset

Current limit threshold V

= 920 mV, TA= 25°C 9.4 10 10.6 μA

TRIPx

On the basis of 25°C 4500 ppm/°C

((V

TRIPx-GND

GND

TRIPx

V

GND-LLx

TRIPx-GND

/9)-24 mV -V

= 920 mV

GND-LLx

) voltage, V

= 5 V 185 205 225 mV

voltage -5 0 5

(2)

voltage

OVP trip threshold OVP detect 110% 115% 120%

OVP prop delay 2 μs

Output UVP trip threshold

UVP detect 55% 60% 65%

Hysteresis 10%

Output UVP prop delay 20 32 40 μs

Output UVP enable delay 1.4 2 2.6 ms

VREG5 UVLO threshold

VREG3 UVLO threshold Shutdown

Thermal shutdown threshold °C

Wake up 4.1 4.2 4.3

Hysteresis 0.38 0.43 0.48 V

(2)

Shutdown temperature

Hysteresis

(2)

(2)

www.ti.com

TRIPx-

0.515 2 V

VO2-1

150

10

(2) Ensured by design. Not production tested.

6 Submit Documentation Feedback Copyright © 2008–2013, Texas Instruments Incorporated

Product Folder Links: TPS51123

TPS51123

www.ti.com

SLUS890E –DECEMBER 2008–REVISED JANUARY 2013

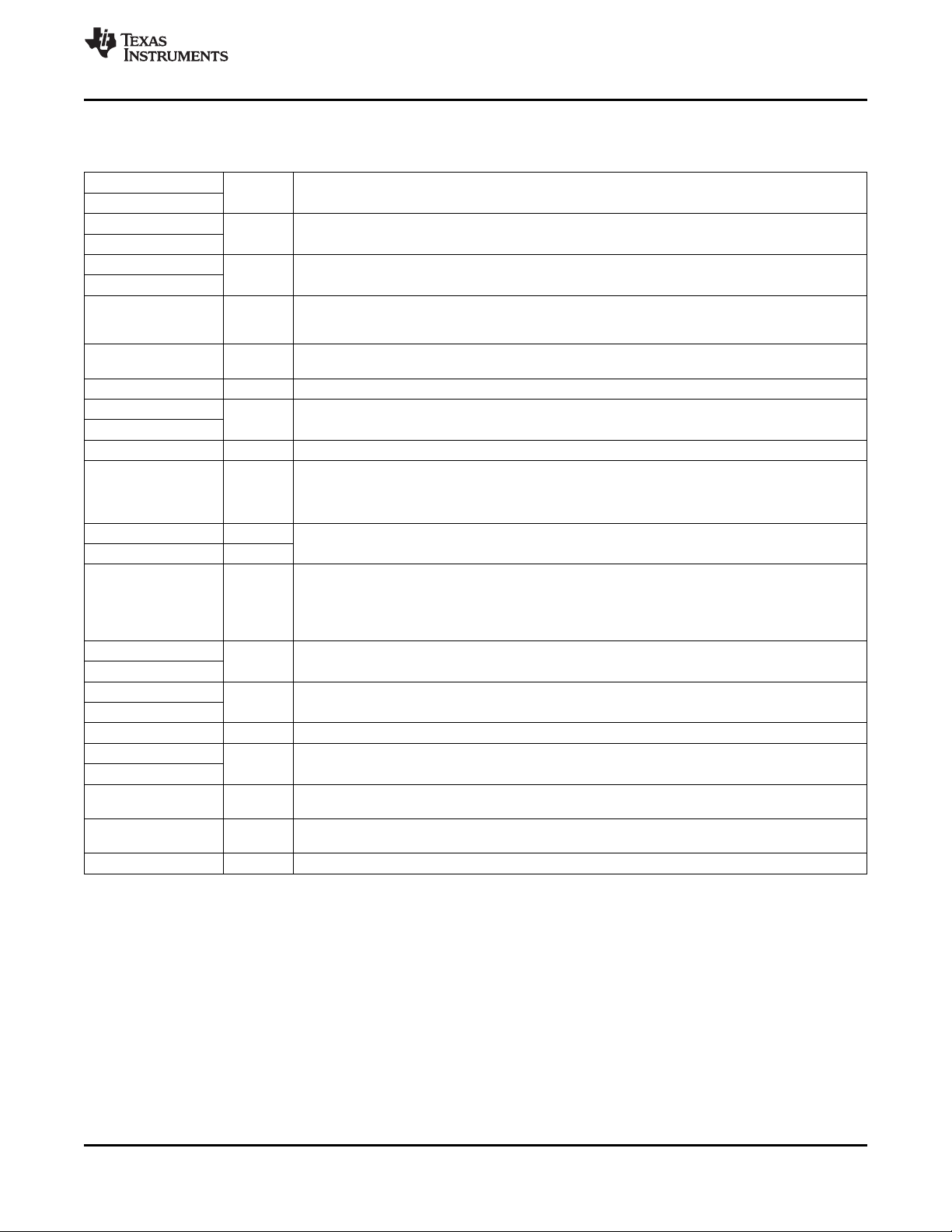

DEVICE INFORMATION

Table 1. TERMINAL FUNCTIONS TABLE

TERMINAL

NAME NO.

DRVH1 21

DRVH2 10

DRVL1 19

DRVL2 12

EN0 13 I/O Open : LDOs on, and ready to turn both switcher channels.

ENC 18 I

GND 15 – Ground.

LL1 20

LL2 11

PGOOD 23 O Powergood window comparator output for channel 1 and 2. (Logical AND)

SKIPSEL 14 I

TRIP1 1 I/O

TRIP2 6

TONSEL 4 I 300 kHz/375 kHz setting: connect to VREG3

VBST1 22

VBST2 9

VFB1 2

VFB2 5

VIN 16 I High voltage power supply input for 5-V/3.3-V LDO.

VO1 24

VO2 7

VREF 3 O

VREG3 8 O

VREG5 17 O 5-V power supply output. Connect a 33-μF ceramic capacitor to Power GND near the device.

I/O DESCRIPTION

O High-side N-channel MOSFET driver outputs. LL referenced drivers.

O Low-side N-channel MOSFET driver outputs. GND referenced drivers.

Master enable input.

GND : disable all circuit

Channel 1 and Channel 2 enable input. Pull up to the voltage ranging 3.3-V to 5-V to turn on both

switcher channels. Short to ground to shutdown them.

I Switch node connections for high-side drivers, current limit and control circuitry.

Selection pin for operation mode:

OOA auto skip : Connect to VREG3 or VREG5

PWM only: Connect to VREF

Auto skip: Connect to GND

OCL trip setting pins. Connect resistor from this pin to GND to set threshold for synchronous R

sense.

On-time adjustment pin.

365 kHz/460 kHz setting: connect to VREG5

245 kHz/305 kHz setting: connect to VREF

200 kHz/250 kHz setting: connect to GND

I Supply input for high-side N-channel MOSFET driver (boost terminal).

I SMPS feedback inputs. Connect with feedback resistor divider.

I/O

Output connection to SMPS. These terminals work as fixed voltage inputs and output discharge

inputs. VO1 and VO2 also work as 5-V and 3.3-V switch over return power input respectively.

2-V reference voltage output. Connect 220-nF to 1-μF ceramic capacitor to Signal GND near the

device.

3.3-V power supply output. Connect a 10-μF ceramic capacitor to Power GND near the device. A 1μF ceramic capacitor is acceptable when not loaded.

DS(on)

Copyright © 2008–2013, Texas Instruments Incorporated Submit Documentation Feedback 7

Product Folder Links: TPS51123

TPS51123RGE

(QFN-24)

VO1

PGOOD

VO2

VREG3

VBST1

DRVL1

LL1

DRVH1

VBST2

DRVH2

LL2

DRVL2

EN0

TRIP2

VFB2

VREF

TONSEL

VFB1

TRIP1

SKIPSEL

GND

VIN

ENC

VREG5

2

3

4

5

6

7 8

9 10

11

1

12

13

14

15

16

17

18

24 23

22 21

20 19

TPS51123

SLUS890E –DECEMBER 2008–REVISED JANUARY 2013

www.ti.com

QFN PACKAGE (TOP VIEW)

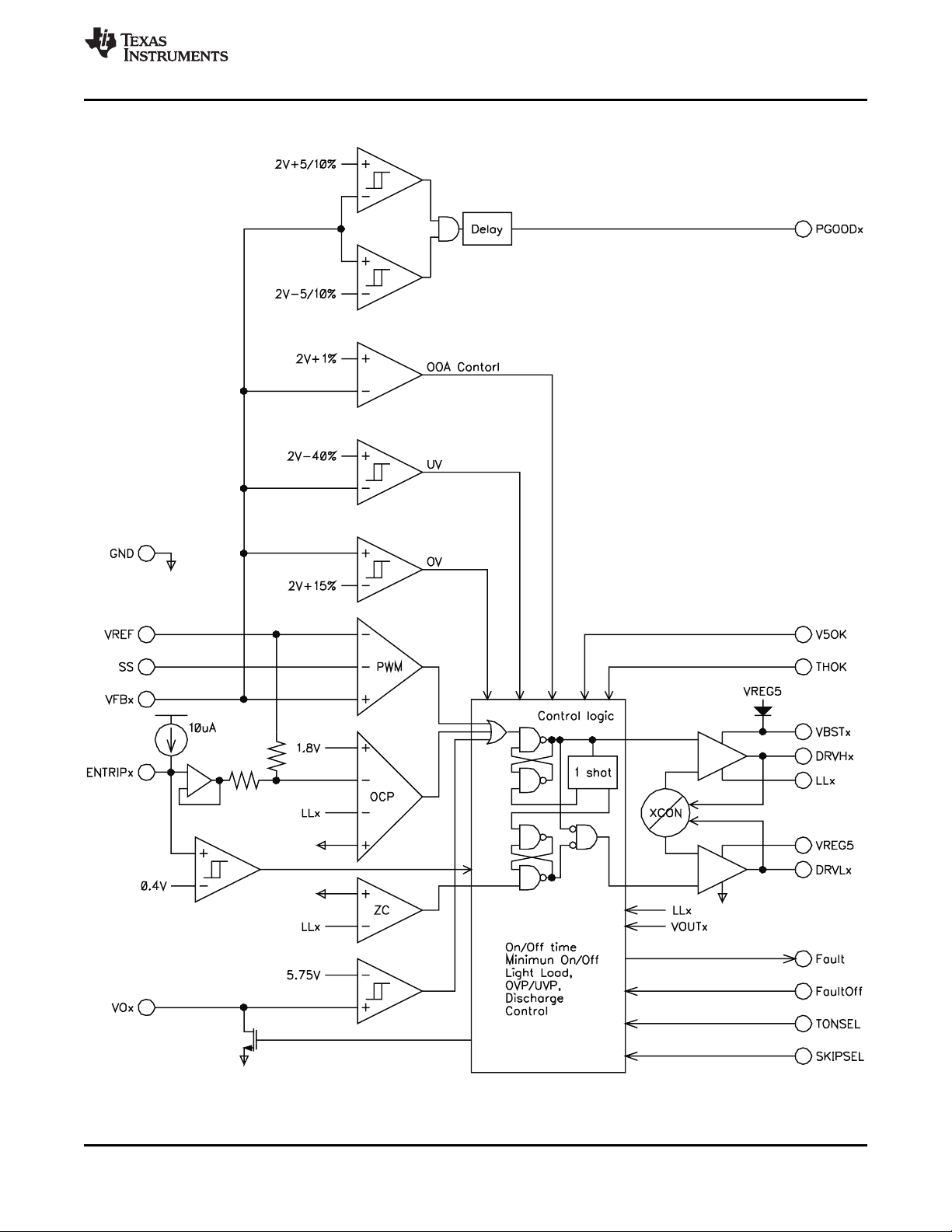

Functional Block Diagram

8 Submit Documentation Feedback Copyright © 2008–2013, Texas Instruments Incorporated

Product Folder Links: TPS51123

TPS51123

www.ti.com

SLUS890E –DECEMBER 2008–REVISED JANUARY 2013

Switcher Controller Block

Copyright © 2008–2013, Texas Instruments Incorporated Submit Documentation Feedback 9

Product Folder Links: TPS51123

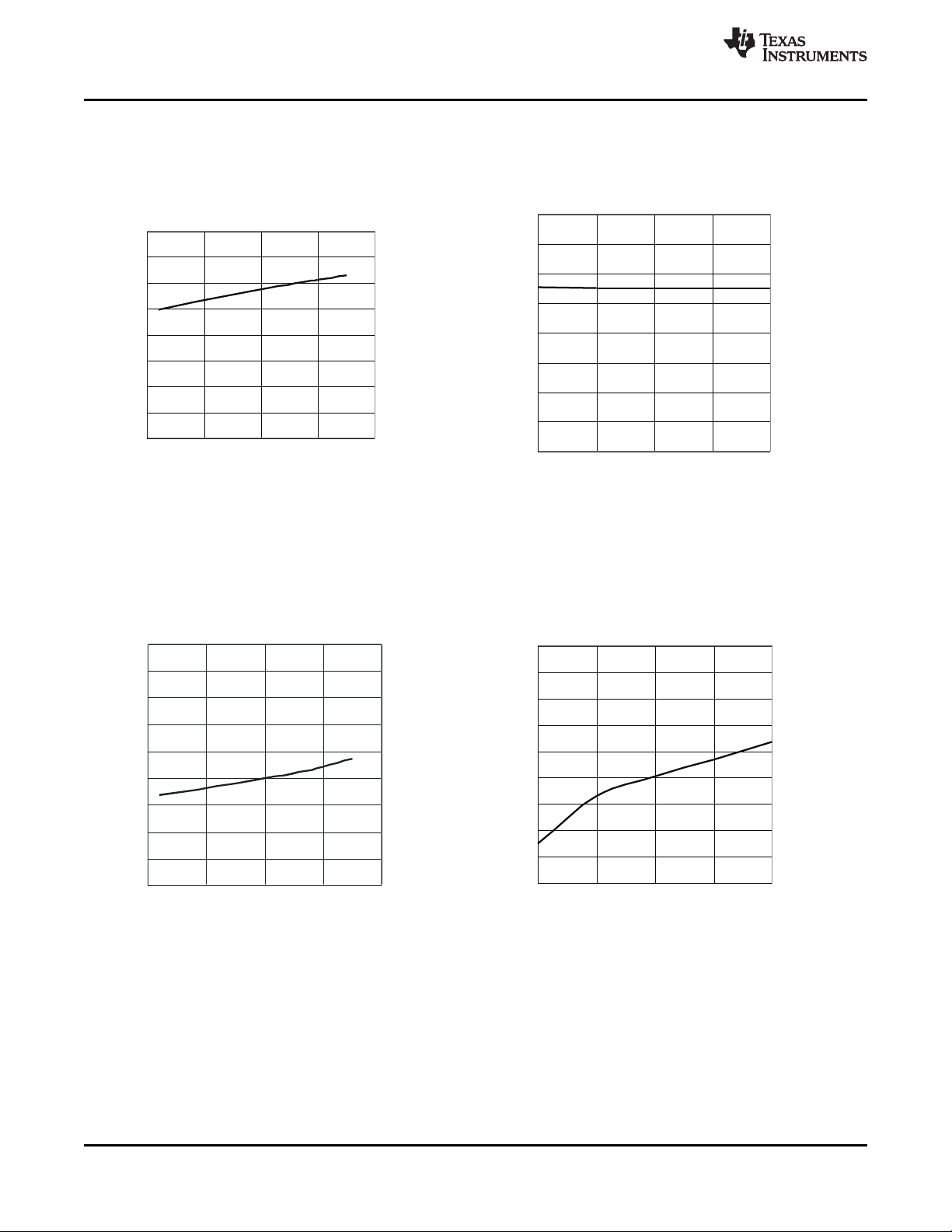

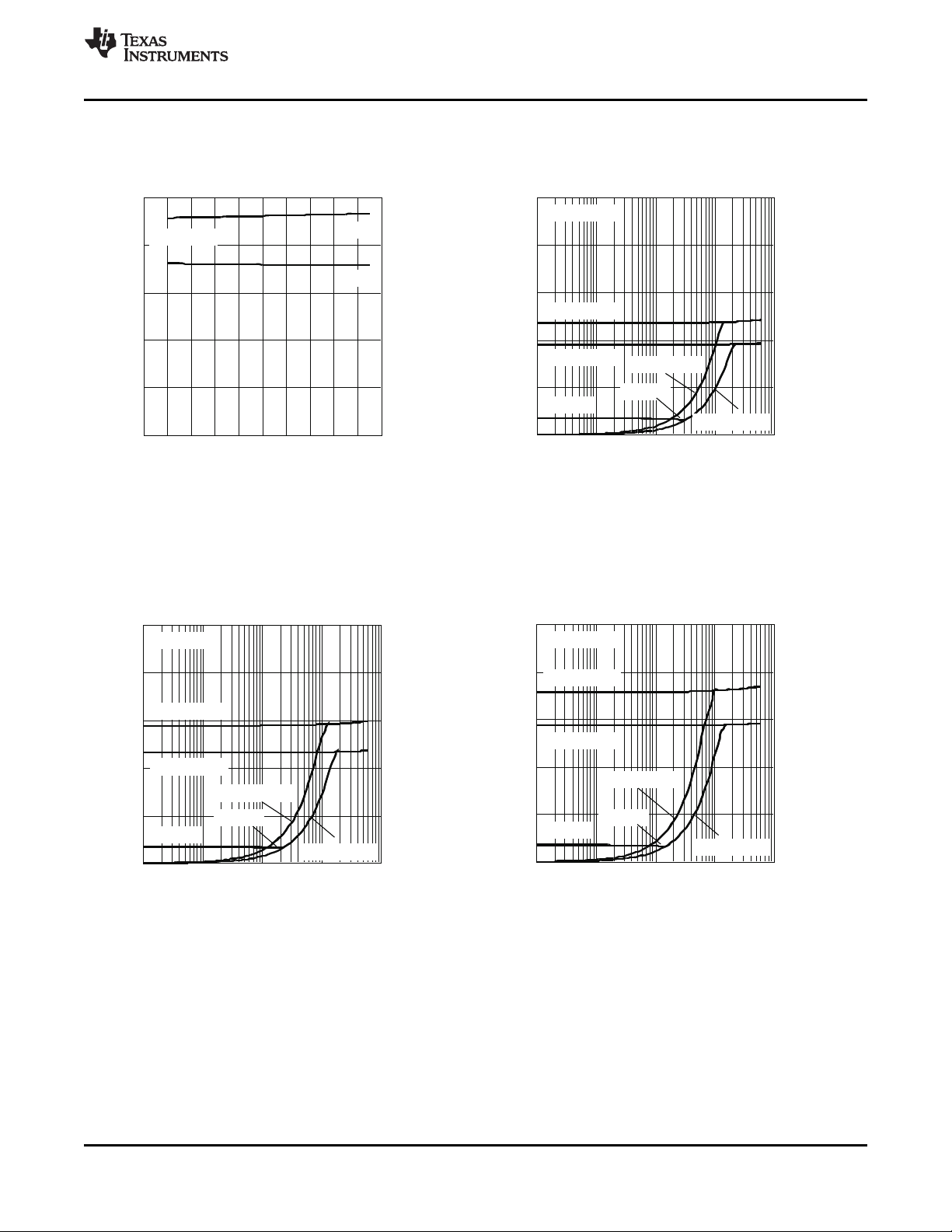

VIN SUPPLY CURRENT2

vs

JUNCTION TEMPERATURE

0

1

2

3

4

5

6

7

8

9

-50 0 50 100 150

TJ- Junction Temperature - °C

I

VIN2

- VIN Supply Current2 - mA

VIN SUPPLY CURRENT2

vs

INPUT VOLTAGE

0

1

2

3

4

5

6

7

8

9

5 10 15 20 25

VIN- Input Voltage - V

I

VIN2

- VIN Supply Current2 - mA

VIN SUPPLY CURRENT1

vs

INPUT VOLTAGE

0

100

200

300

400

500

600

700

800

5 10 15 20 25

VIN- Input Voltage - V

I

VIN1

- VIN Supply Current1 - mA

VIN SUPPLY CURRENT1

vs

JUNCTION TEMPERATURE

0

100

200

300

400

500

600

700

800

-50 0 50 100 150

TJ- Junction Temperature - °C

I

VIN1

- VIN Supply Current1 - mA

TPS51123

SLUS890E –DECEMBER 2008–REVISED JANUARY 2013

TYPICAL CHARACTERISTICS

www.ti.com

10 Submit Documentation Feedback Copyright © 2008–2013, Texas Instruments Incorporated

Figure 1. Figure 2.

Figure 3. Figure 4.

Product Folder Links: TPS51123

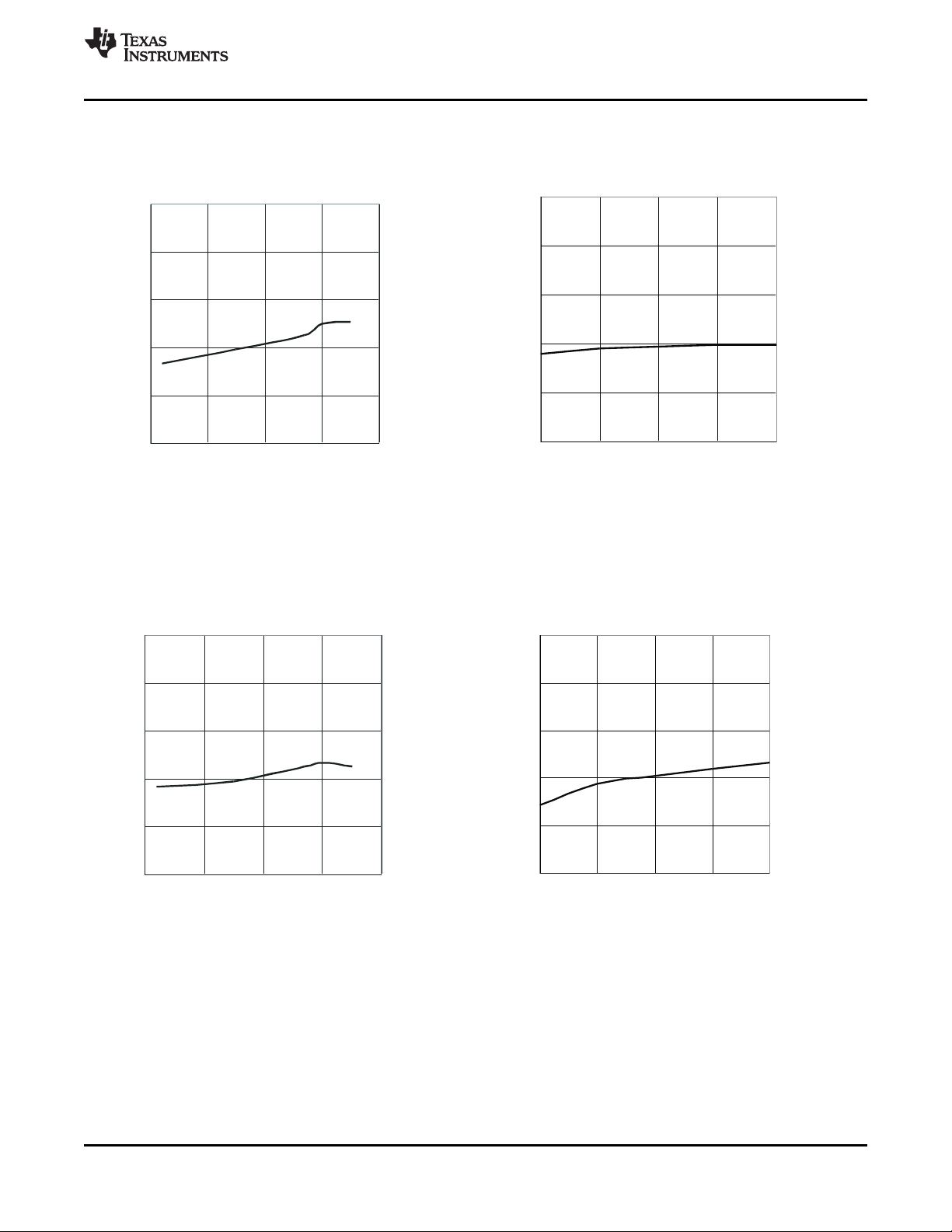

VIN SHUTDOWN CURRENT

vs

INPUT VOLTAGE

0

5

10

15

20

25

5 10 15 20 25

VIN- Input Voltage - V

I

VINSDN

- VIN Shutdown Current - mA

VIN SHUTDOWN CURRENT

vs

JUNCTION TEMPERATURE

0

5

10

15

20

25

-50 0 50 100 150

TJ- Junction Temperature - °C

I

VINS DN

- VIN Shutdown Current - mA

VIN STANDBY CURRENT

vs

JUNCTION TEMPERATURE

0

50

100

150

200

250

-

50

0 50 100 150

TJ- Junction Temperature - °C

I

VINST BY

- VIN Standby Cu rrent - mA

VINSTANDBY CURRENT

vs

INPUTVOLTAGE

0

50

100

150

200

250

5 10 15 20 25

VIN-InputVoltage-V

I

VINST BY

- VIN Standby Current -

nA

TPS51123

www.ti.com

SLUS890E –DECEMBER 2008–REVISED JANUARY 2013

TYPICAL CHARACTERISTICS (continued)

Figure 5. Figure 6.

Copyright © 2008–2013, Texas Instruments Incorporated Submit Documentation Feedback 11

Figure 7. Figure 8.

Product Folder Links: TPS51123

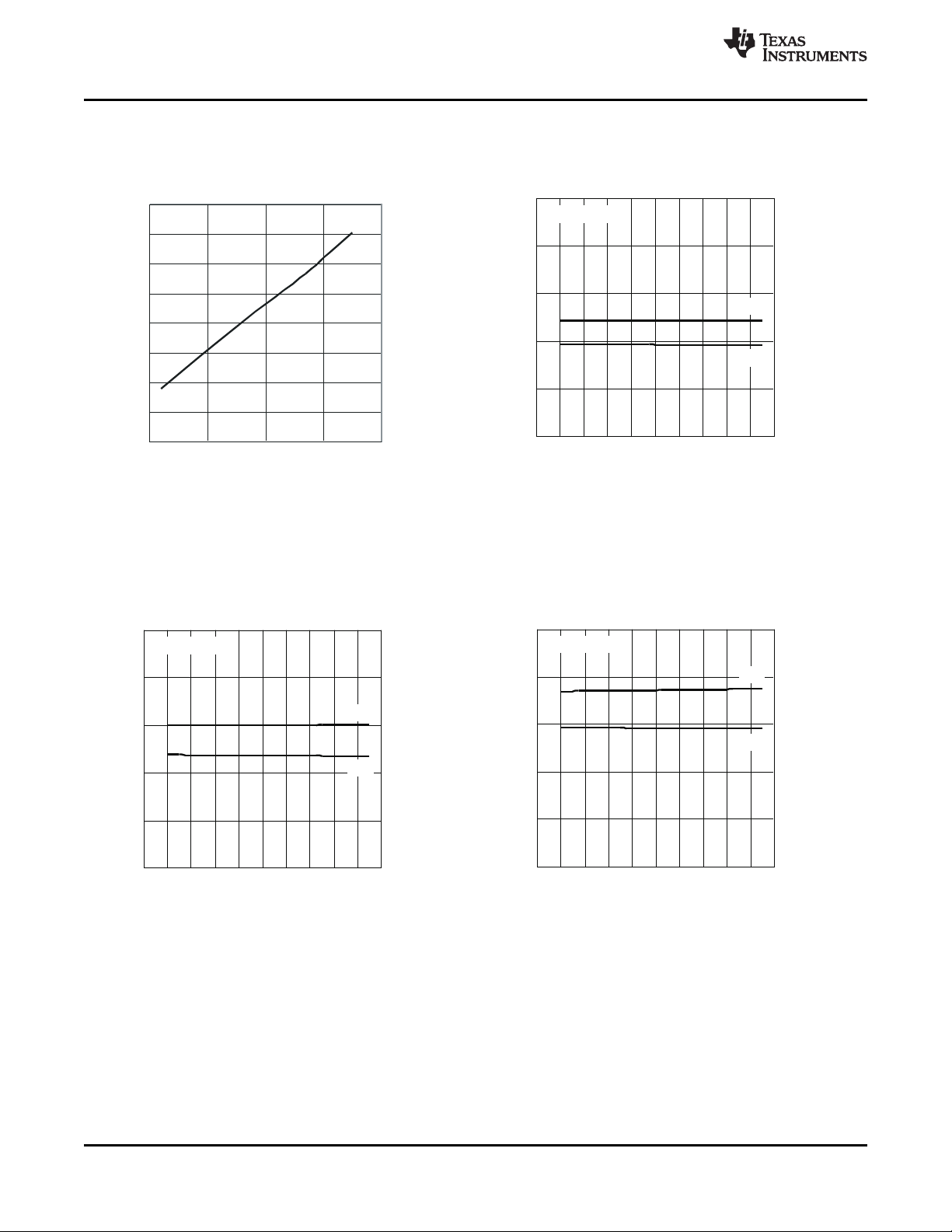

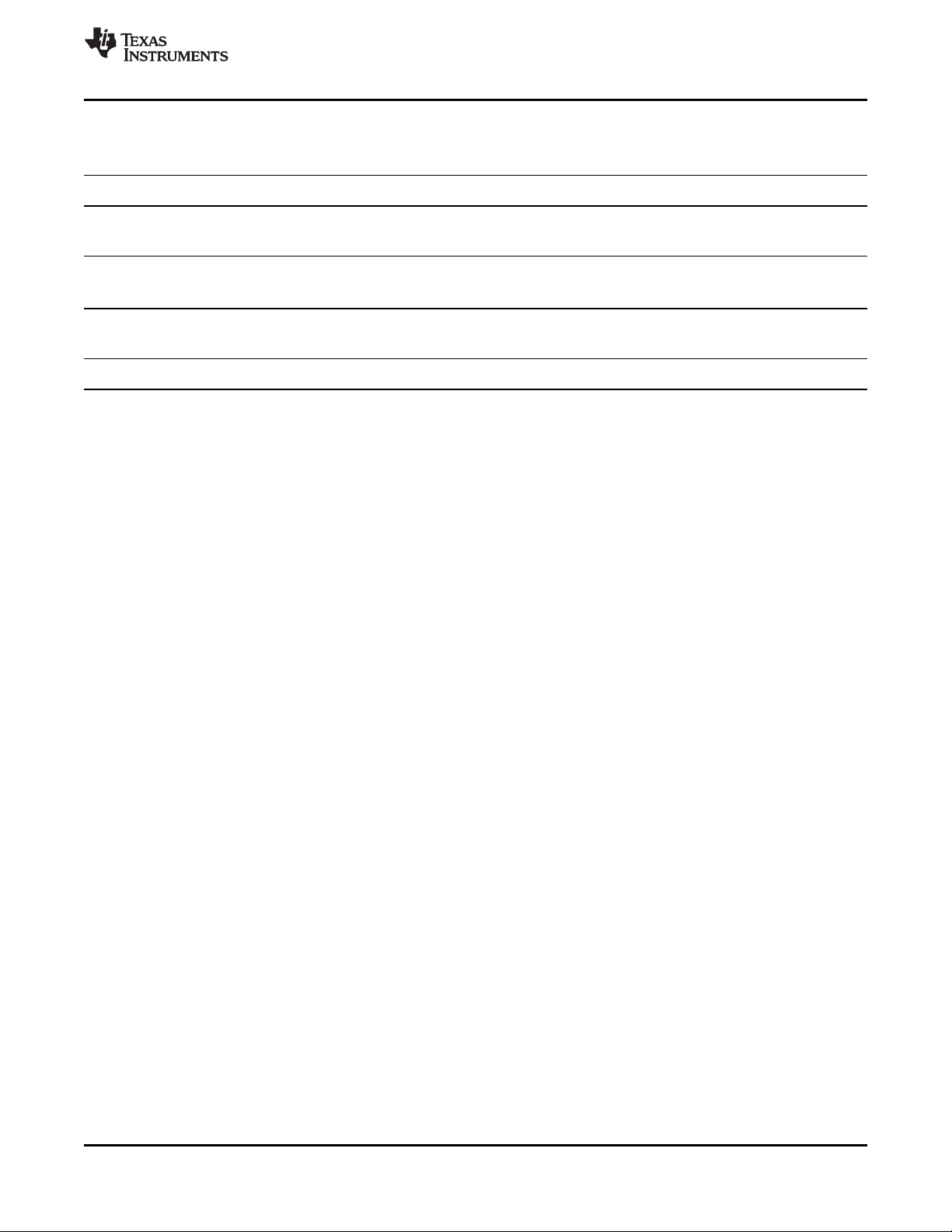

SWITCHINGFREQUENCY

vs

INPUTVOLTAGE

0

100

200

300

400

500

6 8 10 12 14 16 18 20 22 24 26

VIN-InputVoltage-V

f

SW

- Swithching Frequency - kHz

TONSEL =2V

CH1

CH2

SWITCHINGFREQUENCY

vs

INPUTVOLTAGE

0

100

200

300

400

500

6 8 10 12 14 16 18 20 22 24 26

VIN-InputVoltage-V

f

SW

- Swithching Frequency - kHz

TONSEL =3.3V

CH1

CH2

CURRENT SENSE CURRENT

vs

JUNCTION TEMPERATURE

6

7

8

9

10

11

12

13

14

-

50

0 50 100 150

TJ- Junction Temperature - °C

- Current Sense Current - mA

I

TRIP

SWITCHINGFREQUENCY

vs

INPUTVOLTAGE

0

100

200

300

400

500

6 8 10 12 14 16 18 20 22 24 26

VIN-InputVoltage-V

f

SW

- Swithching Frequency - kHz

TONSEL =GND

CH1

CH2

TPS51123

SLUS890E –DECEMBER 2008–REVISED JANUARY 2013

TYPICAL CHARACTERISTICS (continued)

Figure 9. Figure 10.

www.ti.com

12 Submit Documentation Feedback Copyright © 2008–2013, Texas Instruments Incorporated

Figure 11. Figure 12.

Product Folder Links: TPS51123

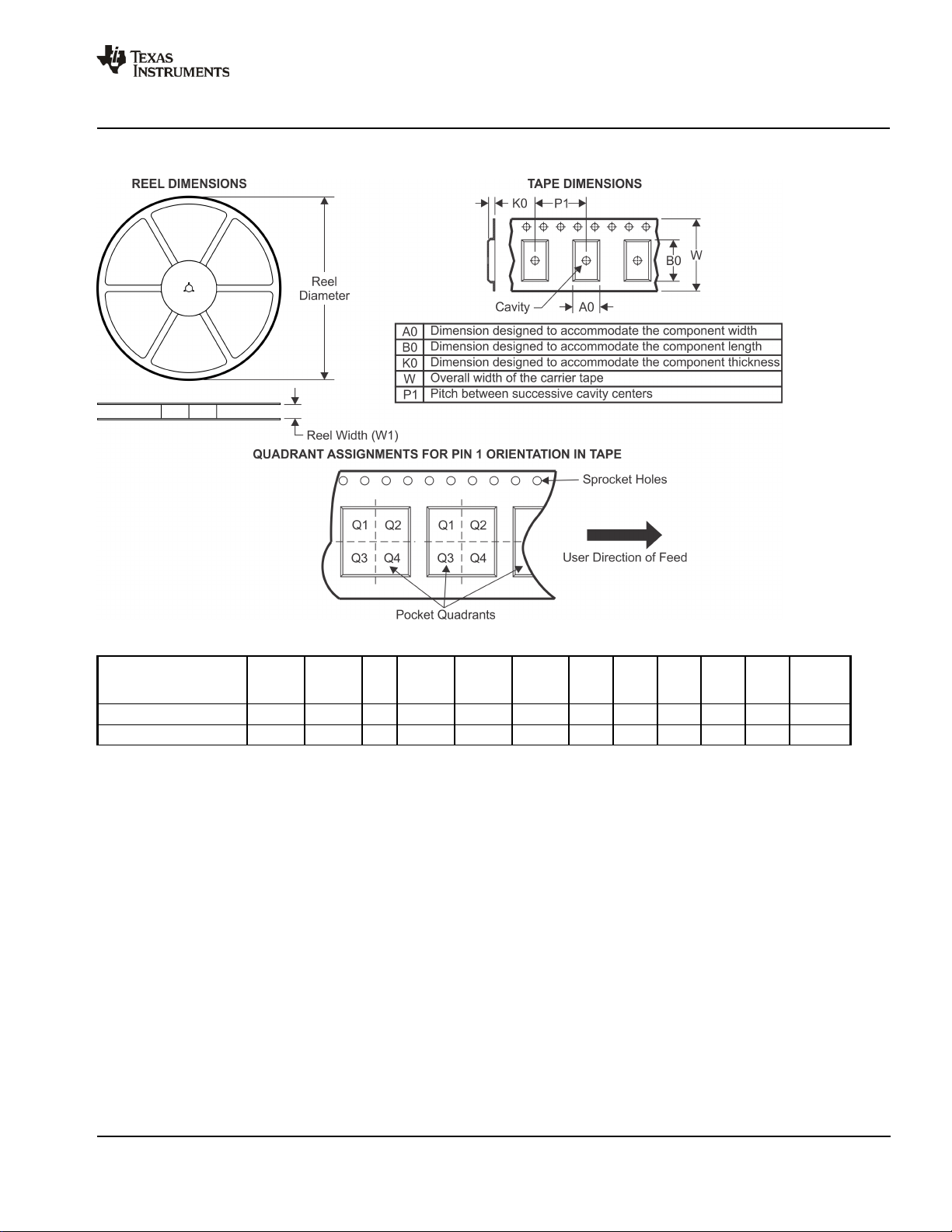

SWITCHINGFREQUENCY

vs

OUTPUTCURRENT

0

100

200

300

400

500

0.001 0.01 0.1 1 10

I

OUT

-OutputCurrent- A

f

SW

- Swithching Frequency - kHz

TONSEL =2V

CH2 Auto-skip

CH2OOA

CH2PWMOnly

CH1PWMOnly

CH1 Auto-skip

CH1OOA

SWITCHINGFREQUENCY

vs

OUTPUTCURRENT

0

100

200

300

400

500

0.001 0.01 0.1 1 10

I

OUT

-OutputCurrent- A

f

SW

- Swithching Frequency - kHz

TONSEL =3.3V

CH2 Auto-skip

CH2OOA

CH2PWMOnly

CH1PWMOnly

CH1 Auto-skip

CH1OOA

SWITCHINGFREQUENCY

vs

INPUTVOLTAGE

0

100

200

300

400

500

6 8 10 12 14 16 18 20 22 24 26

VIN-InputVoltage-V

f

SW

- Swithching Frequency - kHz

TONSEL =5V

CH1

CH2

SWITCHINGFREQUENCY

vs

OUTPUTCURRENT

0

100

200

300

400

500

0.001 0.01 0.1 1 10

I

OUT

-OutputCurrent- A

f

SW

- Swithching Frequency - kHz

TONSEL =GND

CH2 Auto-skip

CH2OOA

CH2PWMOnly

CH1PWMOnly

CH1 Auto-skip

CH1OOA

TPS51123

www.ti.com

SLUS890E –DECEMBER 2008–REVISED JANUARY 2013

TYPICAL CHARACTERISTICS (continued)

Figure 13. Figure 14.

Copyright © 2008–2013, Texas Instruments Incorporated Submit Documentation Feedback 13

Figure 15. Figure 16.

Product Folder Links: TPS51123

VREG5 OUTPUT VOLTAGE

vs

OUTPUT CURRENT

4.90

4.95

5.00

5.05

0 20 40 60 80 100

I

VREG5

- VREG5 Output Cur re nt - m A

V

VREG5

- VREG5 Outp ut Voltage - V

VREG3 OUTPUT VOLTAGE

vs

OUTPUT CURRENT

3.2

3.25

3.3

3.35

0 20 40 60 80 100

I

VREG3

- VREG3 Output Cur re nt - m A

VVR EG3 - VREG3 Output Voltage - V

SWITCHINGFREQUENCY

vs

OUTPUTCURRENT

0

100

200

300

400

500

0.001 0.01 0.1 1 10

I

OUT

-OutputCurrent- A

f

SW

- Swithching Frequency - kHz

TONSEL =5V

CH2 Auto-skip

CH2OOA

CH2PWMOnly

CH1PWMOnly

CH1 Auto-skip

CH1OOA

OVP/UVP THRESHOLD VOLTAGE

vs

JUNCTION TEMPERATURE

40

50

60

70

80

90

100

110

120

130

140

150

-50 0 50 100 150

TJ- Junction Temperature - °C

V

OVP/VUV P

- OVP/UVP Threshold - %

TPS51123

SLUS890E –DECEMBER 2008–REVISED JANUARY 2013

TYPICAL CHARACTERISTICS (continued)

Figure 17. Figure 18.

www.ti.com

14 Submit Documentation Feedback Copyright © 2008–2013, Texas Instruments Incorporated

Figure 19. Figure 20.

Product Folder Links: TPS51123

3.3-VOUTPUTVOLTAGE

vs

OUTPUTCURRENT

3.240

3.270

3.300

3.330

3.360

0.001 0.01 0.1 1 10

I

OUT2

-3.3-VOutputCurrent- A

V

OUT2

- 3.3-V Outp ut Voltage - V

PWMOnly

Auto-skip

OOA

5-VOUTPUTVOLTAGE

vs

INPUTVOLTAGE

4.950

4.975

5.000

5.025

5.050

5.075

6 8 10 12 14 16 18 20 22 24 26

VIN-InputVoltage-V

V

OUT1

- 5-V Out put Voltag e - V

IO=0A

IO=6A

VREF OUTPUT VOLTAGE

vs

OUTPUT CURRENT

1.980

1.985

1.990

1.995

2.000

2.005

2.010

2.015

2.020

0 20 40 60 80 100

I

VREF

- VREF Output Current - mA

V

VREF

- VREF Output Voltage - V

5-V OUTPUT VOLTAGE

vs

OUTPUT CURRENT

4.950

4.975

5.000

5.025

5.050

5.075

0.001 0.01 0.1 1 10

I

OUT1

- 5-V Output Current - A

V

OUT1

- 5-V Output Voltage - V

PWM Only

Auto-skip

OOA

TPS51123

www.ti.com

SLUS890E –DECEMBER 2008–REVISED JANUARY 2013

TYPICAL CHARACTERISTICS (continued)

Copyright © 2008–2013, Texas Instruments Incorporated Submit Documentation Feedback 15

Figure 21. Figure 22.

Figure 23. Figure 24.

Product Folder Links: TPS51123

3.3-V EFFICIENCY

vs

OUTPUT CURRENT

0

20

40

60

80

100

0.001 0.01 0.1 1 10

I

OUT2

- 3.3-V Output Current - A

h - Efficiency - %

Auto-skip

PWM Only

OOA

5-V Switcher ON

VIN=8V

VIN=12V

VIN=20V

3.3-VOUTPUTVOLTAGE

vs

INPUTVOLTAGE

3.240

3.270

3.300

3.330

3.360

6 8 10 12 14 16 18 20 22 24 26

VIN-InputVoltage-V

V

OUT2

- 3.3-V Outp ut Voltage - V

IO=0A

IO=6A

0

20

40

60

80

100

0.001 0.01 0.1 1 10

h – Efficiency – %

VIN= 20 V

VIN= 12 V

VIN= 8 V

OOA

Auto-Skip

PWM Only

I

OUT1

– 5-V Output Current – A

5-V EFFICIENCY

vs

OUTPUT CURRENT

TPS51123

SLUS890E –DECEMBER 2008–REVISED JANUARY 2013

TYPICAL CHARACTERISTICS (continued)

Figure 25. Figure 26.

www.ti.com

16 Submit Documentation Feedback Copyright © 2008–2013, Texas Instruments Incorporated

Figure 27.

Product Folder Links: TPS51123

ENC (5 V/div)

V

OUT1

(2 V/div)

PGOOD (5 V/div)

ENC (5 V/div)

V

OUT2

(2 V/div)

PGOOD (5 V/div)

V

OUT1

(100mV/div)

I

IND

(5A/div)

I

OUT1

(5A/div)

V

OUT2

(100mV/div)

I

IND

(5A/div)

I

OUT2

(5A/div)

TPS51123

www.ti.com

SLUS890E –DECEMBER 2008–REVISED JANUARY 2013

TYPICAL CHARACTERISTICS (continued)

5-V Load Transient Response 3.3-V Load Transient Response

Figure 28. Figure 29.

5-V Startup Waveforms 3.3-V Startup Waveforms

Figure 30. Figure 31.

Copyright © 2008–2013, Texas Instruments Incorporated Submit Documentation Feedback 17

Product Folder Links: TPS51123

ENC (10 V/div)

V

OUT1

(2 V/div)

PGOOD (5 V/div)

DRVL1 (5 V/div)

ENC (10 V/div)

V

OUT2

(2 V/div)

PGOOD (5 V/div)

DRVL2 (5 V/div)

V

OUT1

(200mV/div)

VREG5 (200mV/div)

V

OUT2

(200mV/div)

VREG3 (200mV/div)

TPS51123

SLUS890E –DECEMBER 2008–REVISED JANUARY 2013

TYPICAL CHARACTERISTICS (continued)

5-V Switchover Waveforms 3.3-V Switchover Waveforms

Figure 32. Figure 33.

5-V Soft-stop Waveforms 3.3-V Soft-stop Waveforms

www.ti.com

18 Submit Documentation Feedback Copyright © 2008–2013, Texas Instruments Incorporated

Figure 34. Figure 35.

Product Folder Links: TPS51123

TPS51123

www.ti.com

SLUS890E –DECEMBER 2008–REVISED JANUARY 2013

APPLICATION INFORMATION

PWM Operations

The main control loop of the switch mode power supply (SMPS) is designed as an adaptive on-time pulse width

modulation (PWM) controller. It supports a proprietary D-CAP™ mode. D-CAP™ mode does not require external

compensation circuit and is suitable for low external component count configuration when used with appropriate

amount of ESR at the output capacitor(s).

At the beginning of each cycle, the synchronous top MOSFET is turned on, or becomes ‘ON’ state. This

MOSFET is turned off, or becomes ‘OFF’ state, after internal one shot timer expires. This one shot is determined

by VINand V

to keep frequency fairly constant over input voltage range, hence it is called adaptive on-time

OUT

control. The MOSFET is turned on again when the feedback point voltage, VFB, decreased to match with internal

2-V reference. The inductor current information is also monitored and should be below the over current threshold

to initiate this new cycle. Repeating operation in this manner, the controller regulates the output voltage. The

synchronous bottom or the “rectifying” MOSFET is turned on at the beginning of each ‘OFF’ state to keep the

conduction loss minimum.The rectifying MOSFET is turned off before the top MOSFET turns on at next switching

cycle or when inductor current information detects zero level. In the auto-skip mode or the OOA skip mode, this

enables seamless transition to the reduced frequency operation at light load condition so that high efficiency is

kept over broad range of load current.

Adaptive On-Time Control and PWM Frequency

TPS51123 does not have a dedicated oscillator on board. However, the part runs with pseudo-constant

frequency by feed-forwarding the input and output voltage into the on-time, one-shot timer. The on-time is

controlled inverse proportional to the input voltage and proportional to the output voltage so that the duty ratio will

be kept as VOUT/VIN technically with the same cycle time. The frequencies are set by TONSEL terminal

connection as Table 2.

Table 2. TONSEL Connection and Switching Frequency

TONSEL CONNECTION

GND 200 250

VREF 245 305

VREG3 300 375

VREG5 365 460

SWITCHING FREQUENCY (kHz)

CH1 CH2

Copyright © 2008–2013, Texas Instruments Incorporated Submit Documentation Feedback 19

Product Folder Links: TPS51123

f

SW

0

O

1

f

2 ESR C 4

= £

p ´ ´

ESR

R1

Co

+

2V

+

Lx

R2

Control

logic

&

Driver

RL

VIN

VFB

DRVH

DRVL

PWM

Switching ModulatorVoltage Divider

IoIc

I

L

Vc

Output Capacitor

TPS51123

SLUS890E –DECEMBER 2008–REVISED JANUARY 2013

Loop Compensation

From small-signal loop analysis, a buck converter using D-CAPTMmode can be simplified as below.

Figure 36. Simplifying the Modulator

www.ti.com

The output voltage is compared with internal reference voltage after divider resistors, R1 and R2. The PWM

comparator determines the timing to turn on high-side MOSFET. The gain and speed of the comparator is high

enough to keep the voltage at the beginning of each on cycle substantially constant. For the loop stability, the

0dB frequency, f0, defined below need to be lower than 1/4 of the switching frequency.

As f0is determined solely by the output capacitor's characteristics, loop stability of D-CAPTMmode is determined

by the capacitor's chemistry. For example, specialty polymer capacitors (SP-CAP) have Co in the order of

several 100 μF and ESR in range of 10 mΩ. These make f0on the order of 100 kHz or less and the loop will be

stable. However, ceramic capacitors have f0at more than 700 kHz, which is not suitable for this operational

mode.

Ramp Signal

The TPS51123 adds a ramp signal to the 2-V reference in order to improve its jitter performance. As described in

the previous section, the feedback voltage is compared with the reference information to keep the output voltage

in regulation. By adding a small ramp signal to the reference, the S/N ratio at the onset of a new switching cycle

is improved. Therefore the operation becomes less jitter and stable. The ramp signal is controlled to start with 20mV at the beginning of ON-cycle and to become 0 mV at the end of OFF-cycle in steady state. By using this

scheme, the TPS51123 improve jitter performance without sacrificing the reference accuracy.

(1)

20 Submit Documentation Feedback Copyright © 2008–2013, Texas Instruments Incorporated

Product Folder Links: TPS51123

( )

f

IN OUT OUT

OUT(LL)

IN

1

I

2 L

V V V

V

´

´ ´

- ´

=

TPS51123

www.ti.com

SLUS890E –DECEMBER 2008–REVISED JANUARY 2013

Light Load Condition in Auto-Skip Operation

The TPS51123 automatically reduces switching frequency at light load conditions to maintain high efficiency.

This reduction of frequency is achieved smoothly and without increase of V

ripple. Detail operation is

OUT

described as follows. As the output current decreases from heavy load condition, the inductor current is also

reduced and eventually comes to the point that its ‘valley’ touches zero current, which is the boundary between

continuous conduction and discontinuous conduction modes. The rectifying MOSFET is turned off when this zero

inductor current is detected. As the load current further decreased, the converter runs in discontinuous

conduction mode and it takes longer and longer to discharge the output capacitor to the level that requires next

‘ON’ cycle. The ON time is kept the same as that in the heavy load condition. In reverse, when the output current

increase from light load to heavy load, switching frequency increases to the preset value as the inductor current

reaches to the continuous conduction. The transition load point to the light load operation I

OUT(LL)

(i.e. the

threshold between continuous and discontinuous conduction mode) can be calculated as follows;

(2)

where f is the PWM switching frequency.

Switching frequency versus output current in the light load condition is a function of L, VINand V

decreases almost proportional to the output current from the I

kHz at I

/5 if the frequency setting is 300 kHz.

OUT(LL)

shown in Equation 2. For example, it ise 60

OUT(LL)

OUT

, but it

Out-of-Audio™ Light-Load Operation

Out-of-Audio™ (OOA) light-load mode is a unique control feature that keeps the switching frequency above

acoustic audible frequencies toward virtually no load condition while maintaining best of the art high conversion

efficiency. When the Out-of-Audio™ operation is selected, OOA control circuit monitors the states of both

MOSFET and force to change into the ‘ON’ state if both of MOSFETs are off for more than 32 μs. This means

that the top MOSFET is turned on even if the output voltage is higher than the target value so that the output

capacitor is tends to be overcharged.

The OOA control circuit detects the over-voltage condition and begins to modulate the on time to keep the output

voltage regulated. As a result, the output voltage becomes 0.5% higher than normal light-load operation.

Enable and Soft Start

EN0 is the control pin of VREG5, VREG3 and VREF regulators. Bring this node down to GND disables those

three regulators and minimize the shutdown supply current to 10 μA. Pulling this node up to 3.3 V or 5 V will turn

the three regulators on to standby mode. The two switch mode power supplies (channel-1, channel-2) become

ready to enable at this standby mode. The TPS51123 has an internal, 1.6 ms, voltage servo softstart for each

channel. When the ENC pin becomes higher than the enable threshold voltage, which is typically 1.26 V, an

internal DAC begins ramping up the reference voltage to both of the PWM comparators at the same time.

Smooth control of the output voltage is maintained during start up.

Table 3. Enabling State

EN0 ENC VREF VREG5 VREG3 CH1 CH2

GND Don’t Care Off Off Off Off Off

Open Off On On On Off Off

Open On On On On On On

VREG5/VREG3 Linear Regulators

There are two sets of 100-mA standby linear regulators which outputs 5 V and 3.3 V, respectively. The VREG5

serves as the main power supply for the analog circuitry of the device and provides the current for gate drivers.

The VREG3 is intended mainly for auxiliary 3.3-V supply for the notebook system during standby mode.

Add a ceramic capacitor with a value of at least 33 μF and place it close to the VREG5 pin, and add at most

10 μF to the VREG3 pin. Total capacitance connected to the VREG3 pin should not exceed 10 μF .

Copyright © 2008–2013, Texas Instruments Incorporated Submit Documentation Feedback 21

Product Folder Links: TPS51123

TPS51123

SLUS890E –DECEMBER 2008–REVISED JANUARY 2013

www.ti.com

VREG5 Switch Over

When the VO1 voltage becomes higher than 4.7 V AND channel-1 internal powergood flag is generated, internal

5-V LDO regulator is shut off and the VREG5 output is connected to VO1 by internal switch over MOSFET. The

510-μs powergood delay helps a switch over without glitch.

VREG3 Switch Over

When the VO2 voltage becomes higher than 3.15 V AND channel-2 internal powergood flag is generated,

internal 3.3-V LDO regulator is shut off and the VREG3 output is connected to VO2 by internal switch over

MOSFET. The 510-μs powergood delay helps a switch over without glitch.

Powergood

The TPS51123 has one powergood output that indicates 'high' when both switcher outputs are within the targets

(AND gated). The powergood function is activated with 2-ms internal delay after ENC goes high. If the output

voltage becomes within ±5% of the target value, internal comparators detect power good state and the

powergood signal becomes high after 510-μs internal delay. Therefore PGOOD goes high around 2.5 ms after

ENC goes high. If the output voltage goes outside of ±10% of the target value, the powergood signal becomes

low after 2-μs internal delay. The powergood output is an open drain output and is needed to be pulled up

outside.

Also note that, in the case of Auto-skip or Out-of-Audio™ mode, if the output voltage goes +10% above the

target value and the power-good signal flags low, then the loop attempts to correct the output by turning on the

low-side driver (forced PWM mode). After the feedback voltage returns to be within +5% of the target value and

the power-good signal goes high, the controller returns back to auto-skip mode or Out-of-Audio™ mode.

Output Discharge Control

When ENC is low, the TPS51123 discharges outputs using internal MOSFET which is connected to VOx and

GND. The current capability of these MOSFETs is limited to discharge slowly.

Low-Side Driver

The low-side driver is designed to drive high current low R

represented by its internal resistance, which are 4 Ω for VREG5 to DRVLx and 1.5 Ω for DRVLx to GND. A dead

time to prevent shoot through is internally generated between top MOSFET off to bottom MOSFET on, and

bottom MOSFET off to top MOSFET on. 5-V bias voltage is delivered from VREG5 supply. The instantaneous

drive current is supplied by an input capacitor connected between VREG5 and GND. The average drive current

is equal to the gate charge at Vgs = 5 V times switching frequency. This gate drive current as well as the highside gate drive current times 5 V makes the driving power which need to be dissipated from TPS51123 package.

N-channel MOSFET(s). The drive capability is

DS(on)

High-Side Driver

The high-side driver is designed to drive high current, low R

floating driver, 5-V bias voltage is delivered from VREG5 supply. The average drive current is also calculated by

the gate charge at Vgs = 5 V times switching frequency. The instantaneous drive current is supplied by the flying

capacitor between VBSTx and LLx pins. The drive capability is represented by its internal resistance, which are 4

Ω for VBSTx to DRVHx and 1.5Ω for DRVHx to LLx.

N-channel MOSFET(s). When configured as a

DS(on)

22 Submit Documentation Feedback Copyright © 2008–2013, Texas Instruments Incorporated

Product Folder Links: TPS51123

( ) ( )

( )

f

IN OUT OUT

TRIP RIPPLE TRIP

OCP

IN

DS on DS on

V V V

V I V

1

I

R 2 R 2 L V

- ´

= + = + ´

´ ´

( )

( ) ( )

( )

TRIP TRIP

TRIP

R k I A

V mV 24 mV

9

W ´ m

= -

TPS51123

www.ti.com

SLUS890E –DECEMBER 2008–REVISED JANUARY 2013

Current Protection

TPS51123 has cycle-by-cycle over current limiting control. The inductor current is monitored during the ‘OFF’

state and the controller keeps the ‘OFF’ state during the inductor current is larger than the over current trip level.

In order to provide both good accuracy and cost effective solution, TPS51123 supports temperature

compensated MOSFET R

setting resistor, R

. TRIPx terminal sources I

TRIP

trip level is set to the OCL trip voltage V

internally.

Note that when TRIPx voltage is under a certain thershould (typically 0.4V), the switcher channel concerned is

shut down. The inductor current is monitored by the voltage between GND pin and LLx pin so that LLx pin should

be connected to the drain terminal of the bottom MOSFET properly. Itrip has 4500 ppm/°C temperature slope to

compensate the temperature dependency of the R

that GND should be connected to the proper current sensing device, i.e. the source terminal of the bottom

MOSFET.

As the comparison is done during the ‘OFF’ state, V

current at over current threshold, I

In an over current condition, the current to the load exceeds the current to the output capacitor thus the output

voltage tends to fall down. Eventually, it ends up with crossing the under voltage protection threshold and

shutdown both channels.

sensing. The TRIPx pin should be connected to GND through the trip voltage

DS(on)

TRIP

, can be calculated as follows;

OCP

current, which is 10 μA typically at room temperature, and the

TRIP

as below. Note that the V

. GND is used as the positive current sensing node so

DS(on)

sets valley level of the inductor current. Thus, the load

TRIP

is limited up to about 205 mV

TRIP

(3)

(4)

Overvoltage and Undervoltage Protection

TPS51123 monitors a resistor divided feedback voltage to detect over and under voltage. When the feedback

voltage becomes higher than 115% of the target voltage, the OVP comparator output goes high and the circuit

latches as the top MOSFET driver OFF and the bottom MOSFET driver ON.

Also, TPS51123 monitors VOx voltage directly and if it becomes greater than 5.75 V the TPS51123 turns off the

top MOSFET driver.

When the feedback voltage becomes lower than 60% of the target voltage, the UVP comparator output goes

high and an internal UVP delay counter begins counting. After 32 μs, TPS51123 latches OFF both top and

bottom MOSFETs drivers, and shut off both drivers of another channel. This function is enabled after 2 ms

following ENC has become high.

Copyright © 2008–2013, Texas Instruments Incorporated Submit Documentation Feedback 23

Product Folder Links: TPS51123

( ) ( )

( )

( )

( )

f

OUT

RIPPLE

V 20 mV 1 D 20 mV L

ESR

2 V I 2 V

´ ´ - ´ ´

= -

´

( )

( )

( )

(

)

( )

f

OUT OUT

IN m ax

TRIP

IND peak

DS on IN m ax

V

1

R L

V V V

I

V´

- ´

= + ´

( )

( )

(

)

( )

( )

( )

(

)

( )

f f

OUT OUT OUT OUT

IN max IN max

IND ripple IN max OUT max IN max

1 3

I I

V V V V V V

L

V V

´

´ ´

- ´ - ´

= = ´

( )

OUT

V 2.0

R1 R2

2.0

-

= ´

TPS51123

SLUS890E –DECEMBER 2008–REVISED JANUARY 2013

www.ti.com

UVLO Protection

TPS51123 has VREG5 under voltage lock out protection (UVLO). When the VREG5 voltage is lower than UVLO

threshold voltage both switch mode power supplies are shut off. This is non-latch protection. When the VREG3

voltage is lower than (VO2 - 1 V), both switch mode power supplies are also shut off

Thermal Shutdown

TPS51123 monitors the temperature of itself. If the temperature exceeds the threshold value (typically 150°C),

TPS51123 is shut off including LDOs. This is non-latch protection.

External Parts Selection

The external components selection is much simple in D-CAP™ Mode.

1. Determine output voltage

The output voltage is programmed by the voltage-divider resistor, R1 and R2, as shown in Figure 36. R1 is

connected between VFBx pin and the output, and R2 is connected betwen the VFBx pin and GND.

Recommended R2 value is from 10 kΩ to 20 kΩ. Determine R1 using equation as below.

(5)

2. Choose the Inductor

The inductance value should be determined to give the ripple current of approximately 1/4 to 1/2 of maximum

output current. Larger ripple current increases output ripple voltage and improves S/N ratio and helps stable

operation.

(6)

The inductor also needs to have low DCR to achieve good efficiency, as well as enough room above peak

inductor current before saturation. The peak inductor current can be estimated as follows.

(7)

3. Choose the Output Capacitor(s)

Organic semiconductor capacitor(s) or specialty polymer capacitor(s) are recommended. Determine ESR to meet

required ripple voltage. A quick approximation is as shown in Equation 8. This equation is based on that required

output ripple slope is approximately 20 mV per TSW(switching period) in terms of VFB terminal voltage.

where

• D is the duty cycle

• the required output ripple slope is approximately 20 mV per tSW(switching period) in terms of VFB terminal

voltage (8)

4. Choose the Low-Side MOSFET

It is highly recommended that the low-side MOSFET should have an integrated Schottky barrier diode, or an

external Schottky barrier diode in parallel to achieve stable operation.

24 Submit Documentation Feedback Copyright © 2008–2013, Texas Instruments Incorporated

Product Folder Links: TPS51123

TPS51123

www.ti.com

SLUS890E –DECEMBER 2008–REVISED JANUARY 2013

Layout Considerations

Certain points must be considered before starting a layout work using the TPS51123.

• TPS51123 has only one GND pin and special care of GND trace design makes operation stable, especially

when both channels operate. Group GND terminals of output voltage divider of both channels and the VREF

capacitor as close as possible, and connect them to an inner GND plane with PowerPad and the overcurrent

setting resistor, as shown in the thin GND line of Figure 37. This trace is named Signal Ground (SGND).

Group ground terminals of VIN capacitor(s), VOUT capacitor(s) and source of low-side MOSFETs as close as

possible, and connect them to another inner GND plane with GND pin of the device and the GND terminal of

VREG3 and VREG5 capacitors, as shown in the bold GND line of Figure 37. This trace is named Power

Ground (PGND). SGND should be connected to PGND at the middle point between ground terminal of VOUT

capacitors.

• Inductor, VOUT capacitor(s), VIN capacitor(s) and MOSFETs are the power components and should be

placed on one side of the PCB (solder side). Power components of each channel should be at the same

distance from the TPS51123. Other small signal parts should be placed on another side (component side).

Inner GND planes should shield and isolate the small signal traces from noisy power lines.

• PCB trace defined as LLx node, which connects to source of high-side MOSFET, drain of low-side MOSFET

and high-voltage side of the inductor, should be as short and wide as possible.

• VREG5 requires capacitance of at least 33-μF and VREG3 requires capacitance of at most 10-μF. VREF

requires a 220-nF ceramic bypass capacitor which should be placed close to the device and traces should be

no longer than 10 mm.

• Connect the overcurrent setting resistors from TRIPx to SGND and close to the device, right next to the

device if possible.

• The discharge path (VOx) should have a dedicated trace to the output capacitor; separate from the output

voltage sensing trace. When LDO5 is switched over Vo1 trace should be 1.5 mm with no loops. When LDO3

is switched over and loaded Vo2 trace should also be 1.5 mm with no loops. There is no restriction for just

monitoring Vox. Make the feedback current setting resistor (the resistor between VFBx to SGND) close to the

device. Place on the component side and avoid vias between this resistor and the device.

• Connections from the drivers to the respective gate of the high-side or the low-side MOSFET should be as

short as possible to reduce stray inductance. Use 0.65-mm (25 mils) or wider trace and via(s) of at least 0.5

mm (20 mils) diameter along this trace.

• All sensitive analog traces and components such as VOx, VFBx, VREF, GND, EN0, TRIPx, PGOOD,

TONSEL and SKIPSEL should be placed away from high-voltage switching nodes such as LLx, DRVLx, and

DRVHx nodes to avoid coupling.

• Traces for VFB1 and VFB2 should be short and laid apart each other to avoid channel to channel

interference.

• In order to effectively remove heat from the package, prepare thermal land and solder to the package’s

thermal pad. Three by three or more vias with a 0.33-mm (13 mils) diameter connected from the thermal land

to the internal ground plane should be used to help dissipation. This thermal land underneath the package

should be connected to SGND, and should NOT be connected to PGND.

Copyright © 2008–2013, Texas Instruments Incorporated Submit Documentation Feedback 25

Product Folder Links: TPS51123

TPS51123

DRVL1DRVL2

PowerPAD

VFB1VFB2 VREF

GND

VREG5

VREG3

220 nF

SGND

SGND

UDG-08166

5 3 2

5 19

15

33 mF

817

10 mF

V

IN

V

IN

V

OUT1

V

OUT2

PGND PGND

TPS51123

SLUS890E –DECEMBER 2008–REVISED JANUARY 2013

www.ti.com

Figure 37. Ground System

26 Submit Documentation Feedback Copyright © 2008–2013, Texas Instruments Incorporated

Product Folder Links: TPS51123

Driver and switch node traces are shown for CH1 only.

*

Cin

Cin

L

L

Vout1

HS-MOSFET

LS-MOSFET

HS-MOSFET

Vout2

Cout

To CH1 Vout divider

To CH2 Vout divider

To VO2

To VO1

LS-MOSFET

Bottom Layer

VIN

GND

Connection to GND island

Connection to GND

Connection of Vout

Top Layer

TPS51123

C

VREF

CH1 Vout divider

C

VREG5

DRVH1*

LL1*

DRVL1*

Through hole

CH2 Vout divider

Connection to

GND island

GND

Inner Layer

C

VREG3

Cout

GND island

TPS51123

www.ti.com

SLUS890E –DECEMBER 2008–REVISED JANUARY 2013

Figure 38. PCB Layout

Copyright © 2008–2013, Texas Instruments Incorporated Submit Documentation Feedback 27

Product Folder Links: TPS51123

9

10

11

12

VO1

PGOOD

VO2

VREG3

TPS51123RGE

(QFN24)

13 14 15 16

VBST1

DRVL1

LL1

DRVH1

VBST2

DRVH2

LL2

DRVL2

17

E

N

0

8

T

R

I

P

2

7

6

V

F

B

2

5

V

R

E

F

4

T

O

N

S

E

L

3

V

F

B

1

2 1

T

R

I

P

1

18

S

K

I

P

S

E

L

19

20

G

N

D

21

V

I

N

22

23

24

E

N

C

VO1

5V/8A

L2

3.3mH

Q3

IRF7821

VO1_GND

PGND

C9

10mF

C7

0.1mF

VIN

VO2

3.3V/8A

L1

3.3mH

Q1

IRF7821

VO2_GND

C4

0.1mF

VIN

PowerPAD

C11

33mF

V

R

E

G

5

C10

POSCAP

330mF

PGND

R9

5.1W

VIN

5.5 ~ 28V

R7

5.1W

C2

10mF

C1

10mF

PGND

C5

POSCAP

330mF

5V/100mA

PGND

R4

30kW

R2

20kW

R1

13kW

SGND

VREG5

VREG5

R8

100kW

PGND

R3

20kW

C6

0.22mF

PGND

SGND

R6

130kW

SGND

R5

130kW

ENC

C3

10mF

PGND

3.3V/100mA

C8

10mF

EN0

PGND

PGND

SGND

Q2

FDS6690AS

Q4

FDS6690AS

UDG-08165

SGND

TPS51123

SLUS890E –DECEMBER 2008–REVISED JANUARY 2013

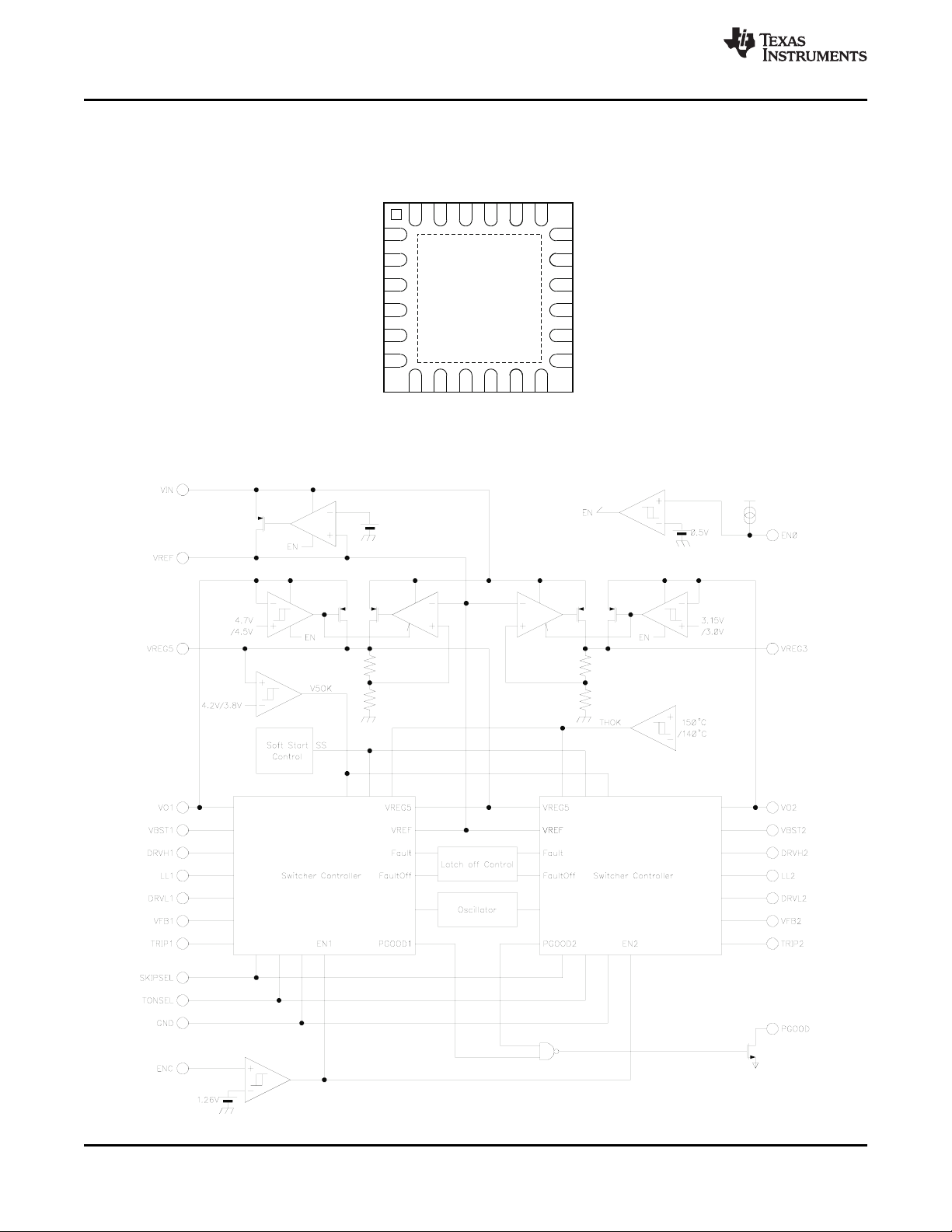

Application Circuit

www.ti.com

Figure 39. 5-V/8-A, 3.3-V/8-A Application Circuit (245-kHz/305-kHz Setting)

Table 4. List of Materials for 5-V/8-A, 3.3-V/8-A Application Circuit

REFERENCE SPECIFICATION MANUFACTURER PART NUMBER

DESIGNATOR

C1, C2, C8, C9 10 μF/25 V Taiyo Yuden TMK325BJ106MM

C3 10 μF/6.3 V TDK C2012X5R0J106K

C11 33 μF/6.3V TDK C3216X5RBJ336M

C5, C10 330 μF/6.3 V/25 mΩ Sanyo 6TPE330ML

L1, L2 3.3 μH, 15.6 A, 5.92 mΩ TOKO FDA1055-3R3M

Q1, Q3 30 V, 9.5 mΩ IR IRF7821

(1)

Q2, Q4

(1) Use a MOSFET with an integrated Schottky barrier diode (SBD) for the low-side, or add an SBD in parallel with a normal MOSFET.

28 Submit Documentation Feedback Copyright © 2008–2013, Texas Instruments Incorporated

30 V, 12 mΩ Fairchild FDS6690AS

Product Folder Links: TPS51123

TPS51123

www.ti.com

SLUS890E –DECEMBER 2008–REVISED JANUARY 2013

REVISION HISTORY

Changes from Revision B (March 2010) to Revision C Page

• Added LL1, LL2, pulse width < 20 ns parameter with a value of -5.0 V to 30 V. ................................................................. 2

Changes from Revision C (March 2012) to Revision D Page

• Added ESD ratings to the ABSOLUTE MAXIMUM RATINGS table .................................................................................... 2

• Added clarity to Switcher Controller Block diagram .............................................................................................................. 9

Changes from Revision D (SEPTEMBER 2012) to Revision E Page

• Added specification for VFB regulation voltage in ELECTRICAL CHARACTERISTICS table ............................................. 4

Copyright © 2008–2013, Texas Instruments Incorporated Submit Documentation Feedback 29

Product Folder Links: TPS51123

PACKAGE OPTION ADDENDUM

www.ti.com

21-Mar-2014

PACKAGING INFORMATION

Orderable Device Status

TPS51123RGER ACTIVE VQFN RGE 24 3000 Green (RoHS

TPS51123RGET ACTIVE VQFN RGE 24 250 Green (RoHS

(1)

The marketing status values are defined as follows:

ACTIVE: Product device recommended for new designs.

LIFEBUY: TI has announced that the device will be discontinued, and a lifetime-buy period is in effect.

NRND: Not recommended for new designs. Device is in production to support existing customers, but TI does not recommend using this part in a new design.

PREVIEW: Device has been announced but is not in production. Samples may or may not be available.

OBSOLETE: TI has discontinued the production of the device.

Package Type Package

(1)

Drawing

Pins Package

Qty

Eco Plan

(2)

& no Sb/Br)

& no Sb/Br)

Lead/Ball Finish

(6)

CU NIPDAU Level-2-260C-1 YEAR -40 to 85 (51123 ~ 51123A)

CU NIPDAU Level-2-260C-1 YEAR -40 to 85 51123

MSL Peak Temp

(3)

Op Temp (°C) Device Marking

(4/5)

(2)

Eco Plan - The planned eco-friendly classification: Pb-Free (RoHS), Pb-Free (RoHS Exempt), or Green (RoHS & no Sb/Br) - please check http://www.ti.com/productcontent for the latest availability

information and additional product content details.

TBD: The Pb-Free/Green conversion plan has not been defined.

Pb-Free (RoHS): TI's terms "Lead-Free" or "Pb-Free" mean semiconductor products that are compatible with the current RoHS requirements for all 6 substances, including the requirement that

lead not exceed 0.1% by weight in homogeneous materials. Where designed to be soldered at high temperatures, TI Pb-Free products are suitable for use in specified lead-free processes.

Pb-Free (RoHS Exempt): This component has a RoHS exemption for either 1) lead-based flip-chip solder bumps used between the die and package, or 2) lead-based die adhesive used between

the die and leadframe. The component is otherwise considered Pb-Free (RoHS compatible) as defined above.

Green (RoHS & no Sb/Br): TI defines "Green" to mean Pb-Free (RoHS compatible), and free of Bromine (Br) and Antimony (Sb) based flame retardants (Br or Sb do not exceed 0.1% by weight

in homogeneous material)

(3)

MSL, Peak Temp. - The Moisture Sensitivity Level rating according to the JEDEC industry standard classifications, and peak solder temperature.

(4)

There may be additional marking, which relates to the logo, the lot trace code information, or the environmental category on the device.

(5)

Multiple Device Markings will be inside parentheses. Only one Device Marking contained in parentheses and separated by a "~" will appear on a device. If a line is indented then it is a continuation

of the previous line and the two combined represent the entire Device Marking for that device.

(6)

Lead/Ball Finish - Orderable Devices may have multiple material finish options. Finish options are separated by a vertical ruled line. Lead/Ball Finish values may wrap to two lines if the finish

value exceeds the maximum column width.

Important Information and Disclaimer:The information provided on this page represents TI's knowledge and belief as of the date that it is provided. TI bases its knowledge and belief on information

provided by third parties, and makes no representation or warranty as to the accuracy of such information. Efforts are underway to better integrate information from third parties. TI has taken and

continues to take reasonable steps to provide representative and accurate information but may not have conducted destructive testing or chemical analysis on incoming materials and chemicals.

TI and TI suppliers consider certain information to be proprietary, and thus CAS numbers and other limited information may not be available for release.

Samples

Addendum-Page 1

PACKAGE OPTION ADDENDUM

www.ti.com

In no event shall TI's liability arising out of such information exceed the total purchase price of the TI part(s) at issue in this document sold by TI to Customer on an annual basis.

21-Mar-2014

Addendum-Page 2

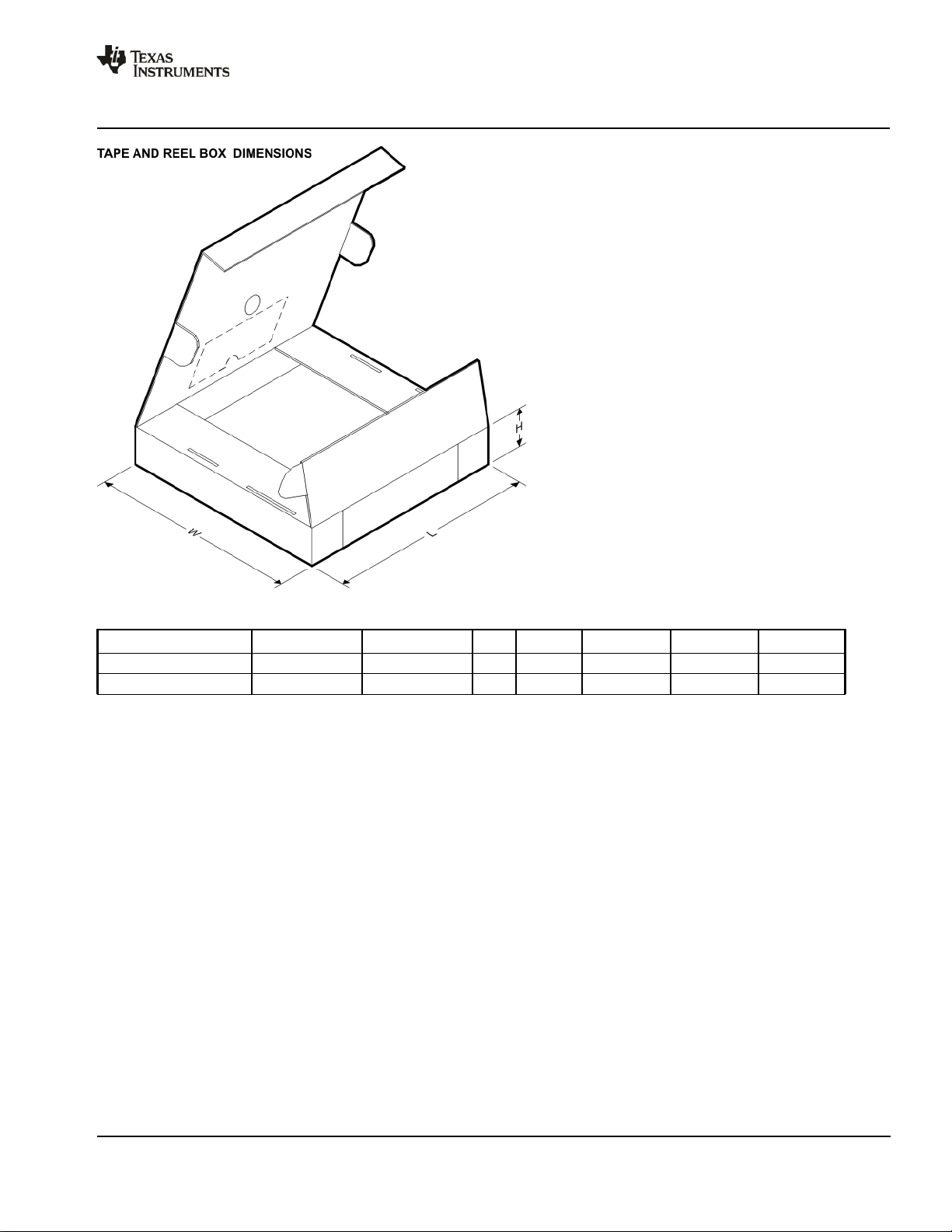

PACKAGE MATERIALS INFORMATION

www.ti.com 12-Aug-2015

TAPE AND REEL INFORMATION

*All dimensions are nominal

Device Package

TPS51123RGER VQFN RGE 24 3000 330.0 12.4 4.25 4.25 1.15 8.0 12.0 Q2

TPS51123RGET VQFN RGE 24 250 180.0 12.4 4.25 4.25 1.15 8.0 12.0 Q2

Type

Package

Drawing

Pins SPQ Reel

Diameter

(mm)

Reel

Width

W1 (mm)

A0

(mm)B0(mm)K0(mm)P1(mm)W(mm)

Pin1

Quadrant

Pack Materials-Page 1

PACKAGE MATERIALS INFORMATION

www.ti.com 12-Aug-2015

*All dimensions are nominal

Device Package Type Package Drawing Pins SPQ Length (mm) Width (mm) Height (mm)

TPS51123RGER VQFN RGE 24 3000 367.0 367.0 35.0

TPS51123RGET VQFN RGE 24 250 210.0 185.0 35.0

Pack Materials-Page 2

IMPORTANT NOTICE

Texas Instruments Incorporated and its subsidiaries (TI) reserve the right to make corrections, enhancements, improvements and other

changes to its semiconductor products and services per JESD46, latest issue, and to discontinue any product or service per JESD48, latest

issue. Buyers should obtain the latest relevant information before placing orders and should verify that such information is current and

complete. All semiconductor products (also referred to herein as “components”) are sold subject to TI’s terms and conditions of sale

supplied at the time of order acknowledgment.

TI warrants performance of its components to the specifications applicable at the time of sale, in accordance with the warranty in TI’s terms

and conditions of sale of semiconductor products. Testing and other quality control techniques are used to the extent TI deems necessary

to support this warranty. Except where mandated by applicable law, testing of all parameters of each component is not necessarily

performed.

TI assumes no liability for applications assistance or the design of Buyers’ products. Buyers are responsible for their products and

applications using TI components. To minimize the risks associated with Buyers’ products and applications, Buyers should provide

adequate design and operating safeguards.

TI does not warrant or represent that any license, either express or implied, is granted under any patent right, copyright, mask work right, or

other intellectual property right relating to any combination, machine, or process in which TI components or services are used. Information

published by TI regarding third-party products or services does not constitute a license to use such products or services or a warranty or

endorsement thereof. Use of such information may require a license from a third party under the patents or other intellectual property of the

third party, or a license from TI under the patents or other intellectual property of TI.

Reproduction of significant portions of TI information in TI data books or data sheets is permissible only if reproduction is without alteration

and is accompanied by all associated warranties, conditions, limitations, and notices. TI is not responsible or liable for such altered

documentation. Information of third parties may be subject to additional restrictions.

Resale of TI components or services with statements different from or beyond the parameters stated by TI for that component or service

voids all express and any implied warranties for the associated TI component or service and is an unfair and deceptive business practice.

TI is not responsible or liable for any such statements.

Buyer acknowledges and agrees that it is solely responsible for compliance with all legal, regulatory and safety-related requirements

concerning its products, and any use of TI components in its applications, notwithstanding any applications-related information or support

that may be provided by TI. Buyer represents and agrees that it has all the necessary expertise to create and implement safeguards which

anticipate dangerous consequences of failures, monitor failures and their consequences, lessen the likelihood of failures that might cause

harm and take appropriate remedial actions. Buyer will fully indemnify TI and its representatives against any damages arising out of the use

of any TI components in safety-critical applications.

In some cases, TI components may be promoted specifically to facilitate safety-related applications. With such components, TI’s goal is to

help enable customers to design and create their own end-product solutions that meet applicable functional safety standards and

requirements. Nonetheless, such components are subject to these terms.

No TI components are authorized for use in FDA Class III (or similar life-critical medical equipment) unless authorized officers of the parties

have executed a special agreement specifically governing such use.

Only those TI components which TI has specifically designated as military grade or “enhanced plastic” are designed and intended for use in

military/aerospace applications or environments. Buyer acknowledges and agrees that any military or aerospace use of TI components

which have not been so designated is solely at the Buyer's risk, and that Buyer is solely responsible for compliance with all legal and

regulatory requirements in connection with such use.

TI has specifically designated certain components as meeting ISO/TS16949 requirements, mainly for automotive use. In any case of use of

non-designated products, TI will not be responsible for any failure to meet ISO/TS16949.

Products Applications

Audio www.ti.com/audio Automotive and Transportation www.ti.com/automotive

Amplifiers amplifier.ti.com Communications and Telecom www.ti.com/communications

Data Converters dataconverter.ti.com Computers and Peripherals www.ti.com/computers

DLP® Products www.dlp.com Consumer Electronics www.ti.com/consumer-apps

DSP dsp.ti.com Energy and Lighting www.ti.com/energy

Clocks and Timers www.ti.com/clocks Industrial www.ti.com/industrial

Interface interface.ti.com Medical www.ti.com/medical

Logic logic.ti.com Security www.ti.com/security

Power Mgmt power.ti.com Space, Avionics and Defense www.ti.com/space-avionics-defense

Microcontrollers microcontroller.ti.com Video and Imaging www.ti.com/video

RFID www.ti-rfid.com

OMAP Applications Processors www.ti.com/omap TI E2E Community e2e.ti.com

Wireless Connectivity www.ti.com/wirelessconnectivity

Mailing Address: Texas Instruments, Post Office Box 655303, Dallas, Texas 75265

Copyright © 2015, Texas Instruments Incorporated

Loading...

Loading...