Page 1

12-V Input, 1.5-V Output, 40-A Two Phase Synchronous

Buck Converter Using the TPS40130

The TPS40130EVM-001 evaluation module (EVM) is a high efficiency, two phase

synchronous buck converter providing a fixed 1.5-V output at up to 40 A from a 12-V

input bus. The EVM is designed to start up from a single supply, so no additional bias

voltage is required for start-up. The module uses the TPS40130 high frequency two

phase controller.

Contents

1 Description ........................................................................................... 2

2 TPS40130EVM-001 Electrical Performance Specifications ................................... 3

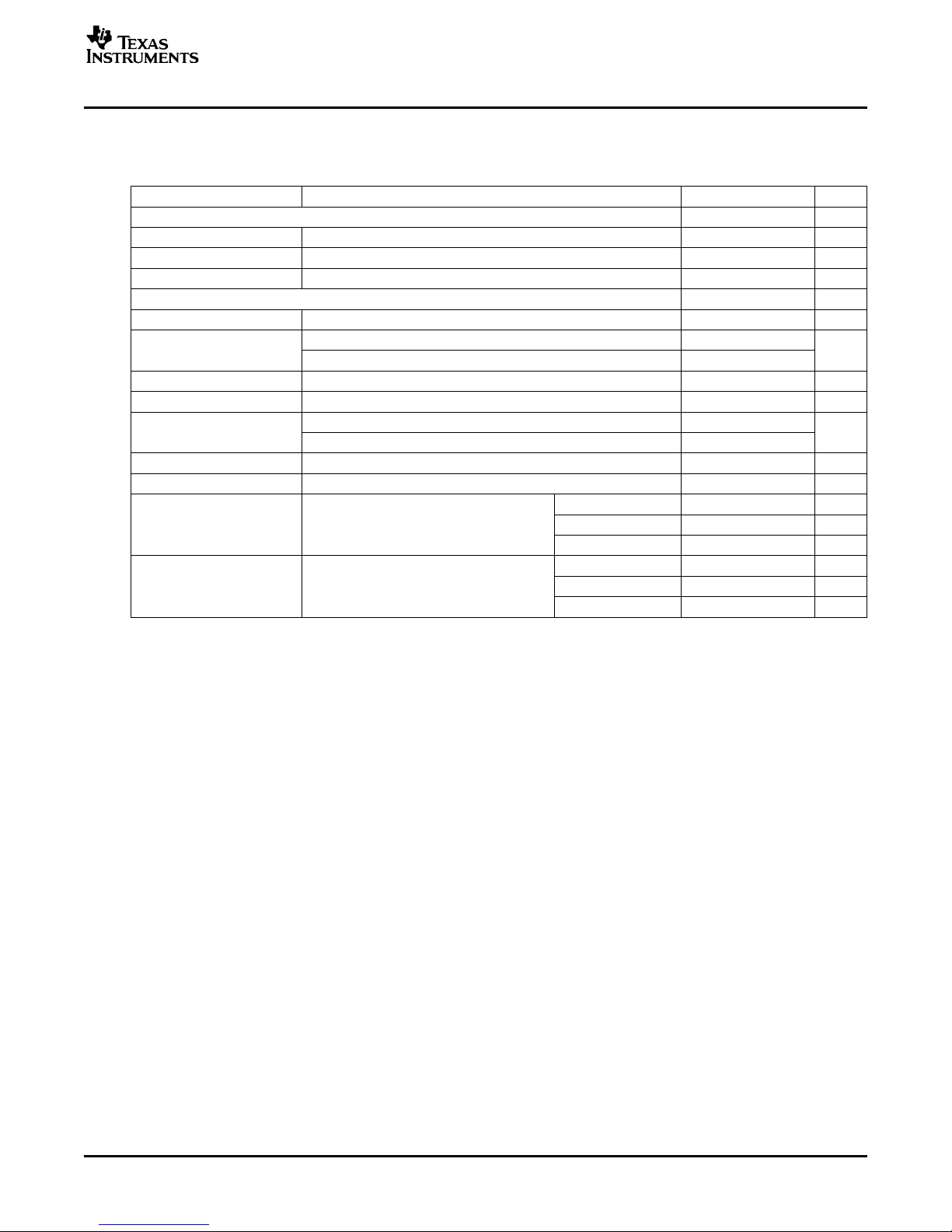

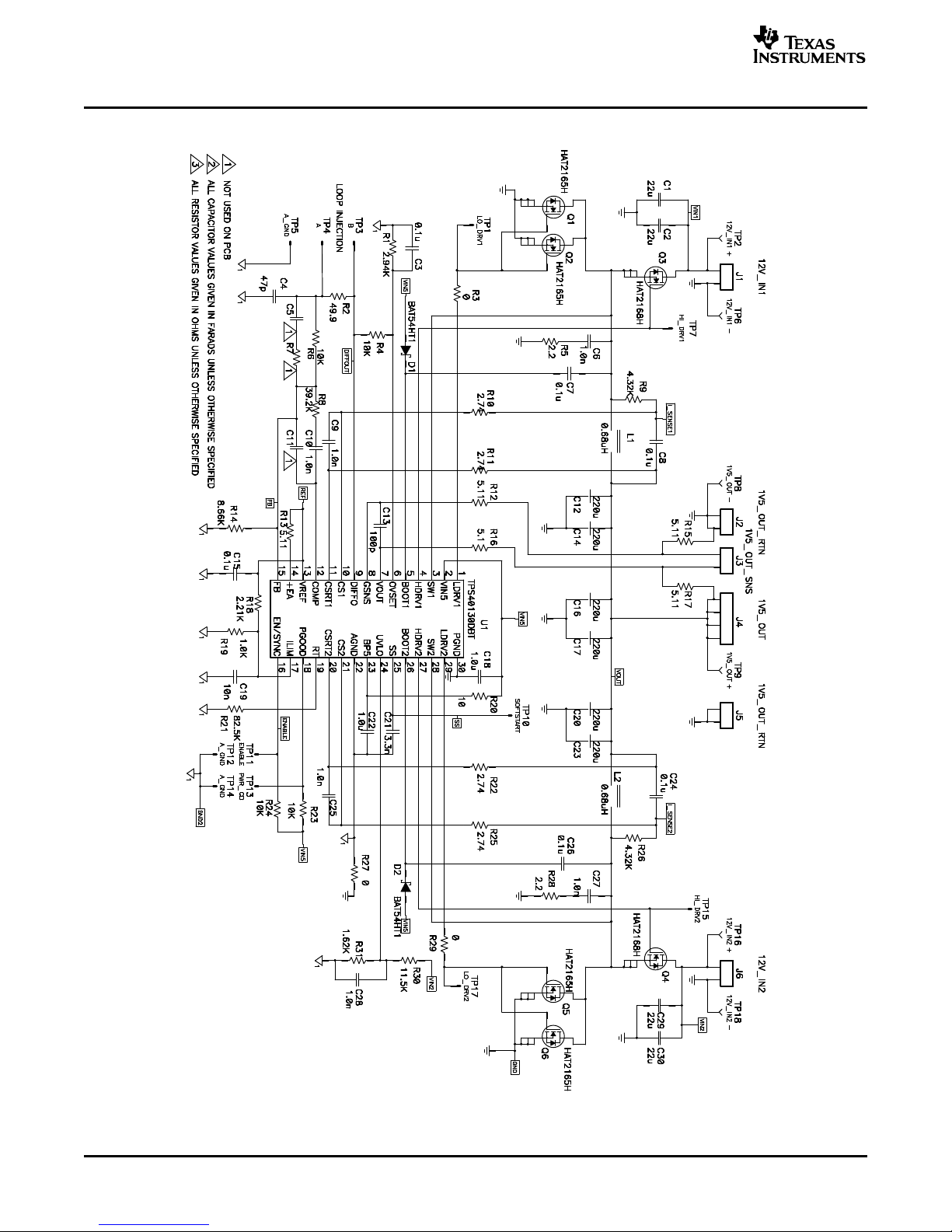

3 Schematics .......................................................................................... 4

4 Test Setup ........................................................................................... 7

5 TPS40130EVM-001 Typical Performance Data and Characteristic Curves............... 10

6 EVM Assembly Drawings and Layout .......................................................... 12

7 List of Materials .................................................................................... 16

User's Guide

SLUU208 – October 2004

List of Figures

1 TPS40130EVM-001 Power Stage/Control Schematic ......................................... 4

2 TPS40130EVM-001 Support Circuitry Schematic .............................................. 5

3 TPS40130EVM-001 Recommended Test Setup ............................................... 9

4 TPS40130EVM-001 Efficiency, V

V

= 1.5 V, I

1V5_OUT

= 4 A to 40 A ........................................................ 10

1V5_OUT

5 TPS40130EVM-001 Line Regulation, I

12V_IN

= 10 V to 14 V,

= 20 A ........................................ 10

1V5_OUT

6 TPS40130EVM-001 Load Regulation .......................................................... 11

7 TPS40130EVM-001 5 A to 55 A Transient Response, 5 A to 55 A at 3 A/µs,

I

1V5_OUT (10A/div)

, V

1V5_OUT(rip)

(20 mv/div), Time 10 µs/div ...................................... 11

8 TPS40130EVM-001 55 A to 5 A Transient Response, 55 A to 5 A at 3 A/µs,

I

1V5_OUT (10A/div)

, V

1V5_OUT(rip)

(20 mV/div), Time 10 µs/div ..................................... 12

9 TPS40130EVM-001 Component Placement (Top View) .................................... 13

10 TPS40130EVM-001 Silkscreen (Top View) ................................................... 13

11 TPS40130EVM-001 Top Copper (Top View) .................................................. 14

12 TPS40130EVM-001 Layer 2 (X-Ray Top View)............................................... 14

13 TPS40130EVM-001 Layer 3 (X-Ray Top View)............................................... 15

14 TPS40130EVM-001 Bottom Copper (X-Ray Bottom View) ................................. 15

List of Tables

1 TPS40130EVM-001 Electrical and Performance Specifications ............................. 3

2 Adjusting V

With R14 ...................................................................... 6

1V5_OUT

3 Adjusting Overcurrent Protection with R19 ...................................................... 6

4 TPS40130EVM-001 Bill of Materials ........................................................... 16

12-V Input, 1.5-V Output, 40-A Two Phase Synchronous Buck Converter Using the TPS40130SLUU208 – October 2004 1

Page 2

www.ti.com

Description

1 Description

The TPS40130EVM-001 is designed to use a regulated 12-V (10-V to 14-V) bus to produce a high current,

regulated 1.5-V output at up to 40 A of load current. The TPS40130EVM-001 uses a number of advanced

technologies to improve its performance. Lossless DCR current sensing eliminates the need for a current

sense resistor, reduces losses, and improves efficiency. A unity gain amplifier provides accurate,

integrated remote sense capabilities for highly accurate, point of load regulated output voltages.

Independent, programmable overvoltage protection (OVP) provides accurate overvoltage protection, even

as the user adjusts the output voltage, or accidentally shorts the feedback pin to ground.

1.1 Applications

• Nonisolated High Current Point of Load and Low Voltage Bus Converters

• Video Graphic Adaptors

• Internet Servers

• Networking Equipment

• Telecommunications Equipment

• DC Power Distributed Systems

1.2 Features

• 91% Peak and 89% Full Load Efficiency at 10-V Input

• 10-V to 14-V Input Range

• 1.5-V Fixed Output, Adjustable with Single Resistor

• 40-Adc Steady State Output Current

• 330-kHz per Phase Operation (660-kHz Output Ripple)

• Single Main Switch MOSFET and Dual Synchronous Rectifier MOSFET for Each Phase

• Single Component Side, Surface Mount Design (4.5" × 4.0”)

• Current Mode Control with Forced Current Sharing

• Four Layer PCB with all Components on Top Side

• Convenient Test Points for Probing Critical Waveforms and Noninvasive Loop Response Testing

• 5-V LDO for Single Supply Operation

• Space for the TPS40120 Digitally Controlled Resistor Network for 6-Bit VID Control (Not Populated)

12-V Input, 1.5-V Output, 40-A Two Phase Synchronous Buck Converter Using the TPS401302 SLUU208 – October 2004

Page 3

www.ti.com

2 TPS40130EVM-001 Electrical Performance Specifications

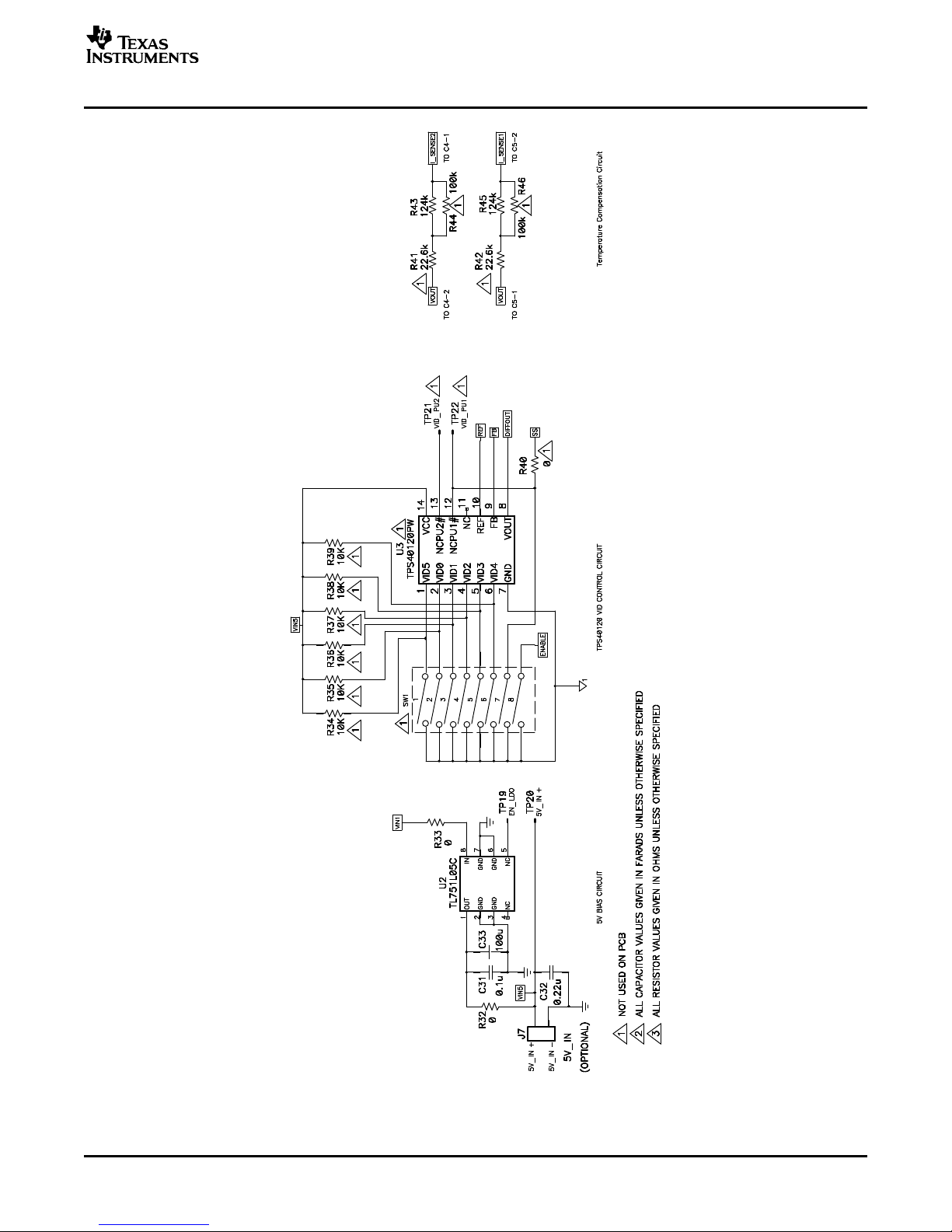

Table 1. TPS40130EVM-001 Electrical and Performance Specifications

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

INPUT CHARACTERISTICS

Input voltage range 10 14 V

Max input current VIN= 10 V, I

No-load input current VIN= 14 V, I

OUTPUT CHARACTERISTICS

Output voltage R14 = 8.66 k Ω 1.45 1.50 1.55 V

Output voltage regulation Line regulation (10 V < VIN< 14 V, I

Load regulation (0 A < I

Output voltage ripple VIN= 14 V, I

Output load current 0 40 A

Output overcurrent Limit source current to 8.5 A none —

Limit load current to 40 A

Output current limit Limit source current to VIN= 12 V 80 A

Switching frequency 300 330 360 kHz

Peak efficiency V

Full load efficiency V

= 1.5 V, 20 A < I

OUT

= 1.5 V, I

OUT

TPS40130EVM-001 Electrical Performance Specifications

= 40 A 6.9 A

OUT

= 0 A 180 mA

OUT

= 20 A) 1%

OUT

< 40 A, VIN= 12 V) 1%

OUT

= 40 A 30 mV

OUT

< 30 A V

OUT

= 40 A V

OUT

= 10 V 91%

12V_IN

V

= 12 V 90%

12V_IN

V

= 14 V 89%

12V_IN

= 10 V 89%

12V_IN

V

= 12 V 88%

12V_IN

V

= 14 V 87%

12V_IN

pp

12-V Input, 1.5-V Output, 40-A Two Phase Synchronous Buck Converter Using the TPS40130SLUU208 – October 2004 3

Page 4

www.ti.com

+ + ++ + +

Schematics

3 Schematics

Figure 1. TPS40130EVM-001 Power Stage/Control Schematic

12-V Input, 1.5-V Output, 40-A Two Phase Synchronous Buck Converter Using the TPS401304 SLUU208 – October 2004

Page 5

www.ti.com

+

Schematics

Figure 2. TPS40130EVM-001 Support Circuitry Schematic

12-V Input, 1.5-V Output, 40-A Two Phase Synchronous Buck Converter Using the TPS40130SLUU208 – October 2004 5

Page 6

www.ti.com

V

VOUT

V

VREF

R14 R6

R14

V

OVP

V

OVSET

R1 R4

R1

Schematics

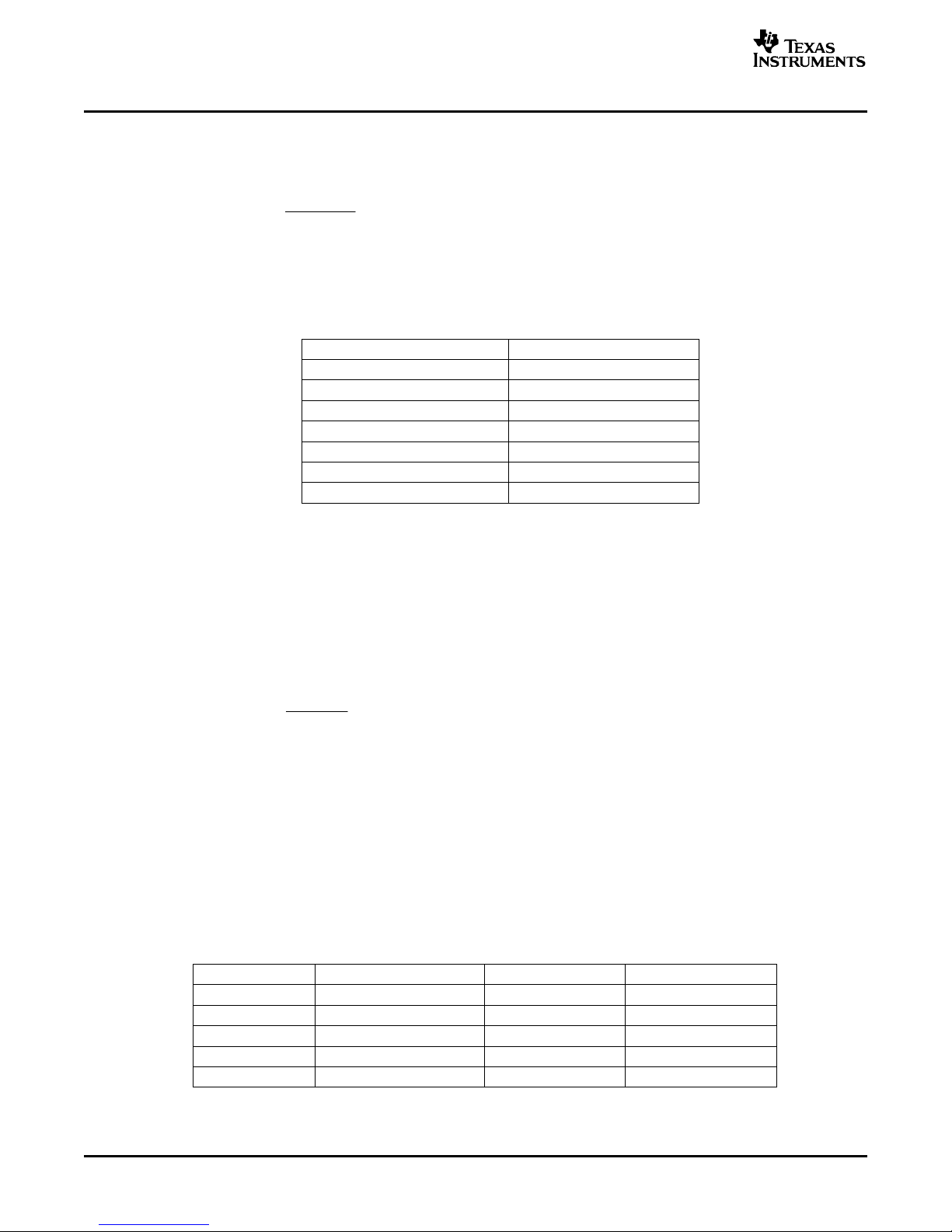

3.1 Adjusting Output Voltage (R14)

The regulated output voltage can be adjusted within a limited range by changing the ground resistor in the

feedback resistor divider (R14). The output voltage is given by Equation 1 , where V

10.0 k Ω .

Table 2 contains common values for R14 to generate popular output voltages. The TPS40130EVM-001 is

stable through these output voltages but the efficiency may suffer as the power stage is optimized for the

1.5-V output.

= 0.7 V and R6 =

VREF

(1)

3.2 Adjusting Overvoltage Protection (R1)

The output voltage is protected through an overvoltage protection circuit separate from the feedback loop,

to prevent damaging the 4-V output capacitors. Initially set for 3.5 V to allow the user to adjust the output

voltage from 1.2 V to 3.3 V, the OVP set point can be adjusted to be closer to the output voltage by

changing R1. The output overvoltage set point is given by Equation 2 , where V

10.0 k Ω .

Setting R1 = R14 provides 14% to 18% margin between the voltage set value and the OVP set point.

Narrower overvoltage margins can be obtained, however the tolerance on the OVP reference voltage must

be closely observed.

Table 2. Adjusting V

V

OUT

3.3 V 2.67 k Ω

2.5 V 3.83 k Ω

2.2 V 4.64 k Ω

2.0 V 5.36 k Ω

1.8 V 6.34 k Ω

1.5 V 8.66 k Ω

1.2 V 14.0 k Ω

1V5_OUT

With R14

R14

= 0.816 V and R4 =

OVSET

(2)

3.3 Adjusting Overcurrent Protection (I

The TPS40130EVM-001 is preconfigured with the overcurrent protection (OVP) set very high to allow the

converter to deliver high-current, short duration loads, operate under higher loads with sufficient air flow,

but still provide output short-circuit protection. To set the current limit to a lower value, change R19

according to Table 3 .

Table 3. Adjusting Overcurrent Protection with R19

I

MAX CURRENT LIMIT R18 R19

OUT

30 A 40 A 2.21 k Ω 464 Ω

40 A 50 A 2.21 k Ω 590 Ω

50 A 60 A 2.21 k Ω 715 Ω

60 A 70 A 2.21 k Ω 845 Ω

70 A 80 A 2.21 k Ω 1 k Ω

12-V Input, 1.5-V Output, 40-A Two Phase Synchronous Buck Converter Using the TPS401306 SLUU208 – October 2004

)

lim

Page 7

www.ti.com

Test Setup

For more details on setting V

for specific overcurrent protection levels, see the overcurrent protection

Ilim

equations in the Functional Descriptions section of the TPS40130 data sheet.

3.4 Using an External 5-V Supply (R32 and R33)

The TPS40130EVM-001 is designed to be run from a single 12-V supply by incorporating a TL751 5-V

LDO, however an external supply can be used if a separate 5-V bus is available in the target system. To

use an external 5-V supply, connect it through 5V_IN (J7) and remove R32 and R33 to disconnect the

LDO from the circuit. The TPS40130EVM-001 requires approximately 50 mA of current from the 5-V

supply.

4 Test Setup

4.1 Equipment

4.1.1 Voltage Source

V

: The input voltage source (V

4.1.2 Meters

12V_IN

Connect V

to J1 and J6 as shown in Figure 1 .

12V_IN

A1: 0 Adc to 10 Adc ammeter

V1: V

V2: V

, 0 V to 15 V voltmeter

12V_IN

1V5_OUT

VOUT, 0 V to 5 V voltmeter

12V_IN

) should be a 0-V to 15-V variable dc source capable of 8.5 Adc.

4.1.3 Loads

LOAD1: The output load (LOAD1) should be an electronic constant current mode load capable of 0 Adc to

40 Adc at 1.5 V.

4.1.4 Recommended Wire Gauge

V

to J1 and J6: The connection between the source voltage, V

12V_IN

carry as much as 7 Adc. The minimum recommended wire size is AWG #16 with the total length of wire

less than 4 feet (2 feet input, 2 feet return).

J4 to LOAD1: The connection between J4 of HPA087 and LOAD1 can carry as much as 40 Adc. The

minimum recommended wire size is 4 x AWG #16, with the total length of wire less than 1 foot.

J2 and J5 to LOAD1: The connection between J2 and J5 of HPA087 and LOAD1 can carry as much as

40 Adc. The minimum recommended wire size is 2 x AWG #16 (two wires per connector), with the total

length of wire less than 1 foot.

and J1 and J6 of HPA087 can

12V_IN

12-V Input, 1.5-V Output, 40-A Two Phase Synchronous Buck Converter Using the TPS40130SLUU208 – October 2004 7

Page 8

www.ti.com

Test Setup

4.1.5 Other

FAN: The TPS40130EVM-001 includes components that can get hot to the touch. Because this EVM is

not enclosed to allow probing of circuit nodes, a small fan capable of 200 to 400 lfm is required to reduce

component surface temperatures to prevent user injury. The EVM should not be left unattended while

powered or probed while the fan is not running.

OSCILLOSCOPE: A 60-MHz or faster oscilloscope can be used to determine the ripple voltage on

1V5_OUT. The oscilloscope should be set for 1 M Ω impedance, ac coupling, 1 µs/division horizontal

resolution, 20 mV/division vertical resolution for taking output ripple measurements.

4.2 Equipment Setup

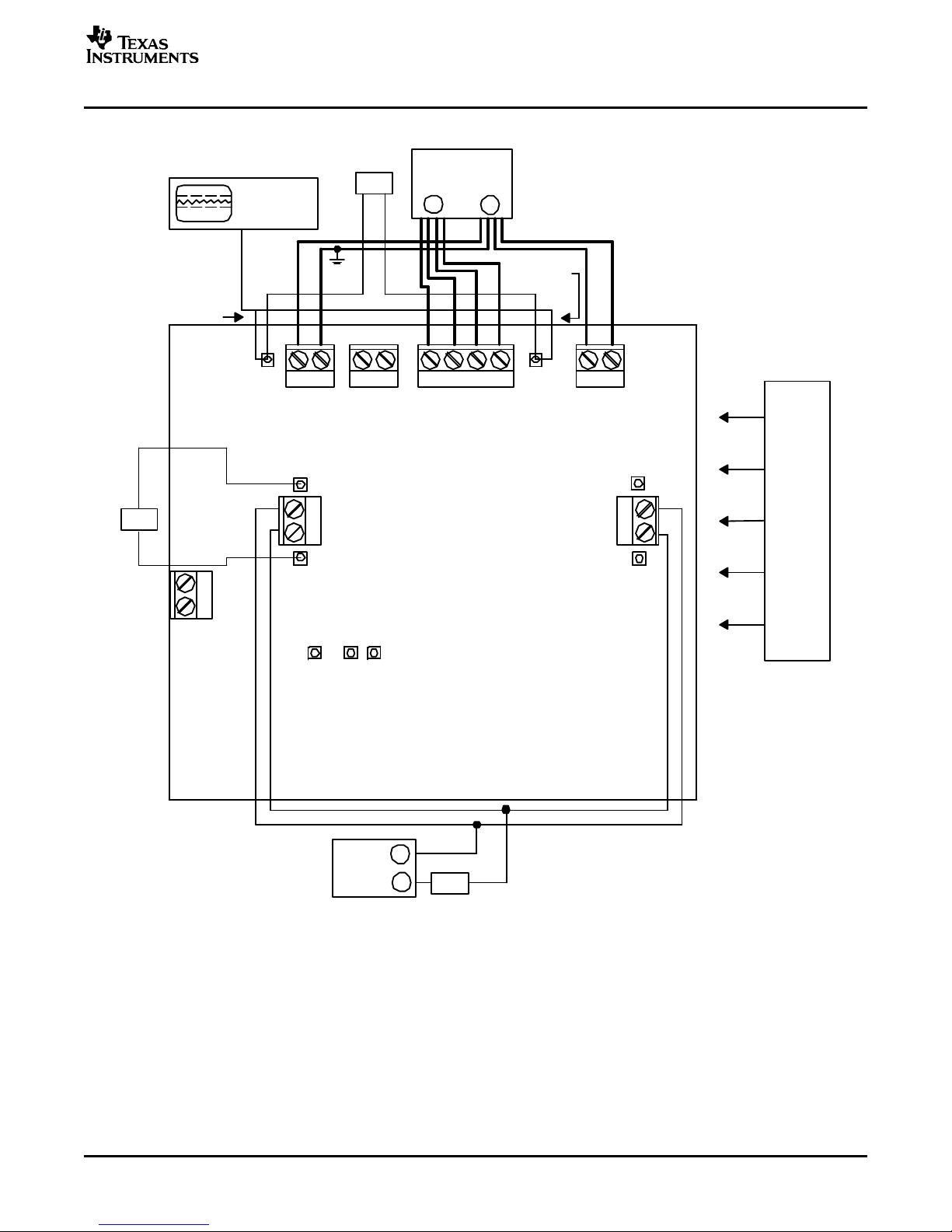

Shown in Figure 3 is the basic test setup recommended to evaluate the TPS40130EVM-001. Note that

although the return for J1, J2, J5, and J6 are all the same, the connections should remain separate as

shown in Figure 3 .

4.2.1 Procedure

1. Working at an ESD workstation, make sure that any wrist straps, bootstraps, or mats are connected

referencing the user to earth ground before power is applied to the EVM. Electrostatic smock and

safety glasses should also be worn.

2. Prior to connecting the dc input source, V

7.0 A maximum. Make sure V

3. Connect the ammeter A1 (0-A to 7-A range) between V

4. Connect voltmeter V1 to 12V_IN + and 12V_IN– as shown in Figure 3 .

5. Connect LOAD1 to J2 as shown in Figure 1 . Set LOAD1 to constant current mode to sink 0 Adc before

V

6. Connect voltmeter, V2 across 1V5_OUT + and 1V5_OUT - as shown in Figure 3 .

7. Place fan as shown in Figure 3 and turn on, making sure air is flowing across the EVM.

, it is advisable to limit the source current from V

12V_IN

is initially set to 0 V and connected as shown in Figure 3 .

12V_IN

and J1 and J2 as shown in Figure 3 .

12V_IN

is applied.

12V_IN

to

12V_IN

12-V Input, 1.5-V Output, 40-A Two Phase Synchronous Buck Converter Using the TPS401308 SLUU208 – October 2004

Page 9

www.ti.com

A1

−

−

+

+

−− −−−

+

++++

−

+

−

+

−

+

V2

1V5_OUT 1V5_OUT_RTN2

12V_IN1

12V_IN2

5V_IN

+

−

−

+

Ground Clip

Oscilloscope

J3 J4 J5

J6

J1

J7

1M, AC

10mV / div

20MHz

LOAD1

1.5V @ 40A

Scope

Probe

1V5_OUT_SNS

1V5_OUT_RTN1

J2

V1

TPS40130EVM−001

Two Phase 12V to 1.5V @ 40A

FAN

V

12V_IN

Test Setup

4.2.2 Diagram

Figure 3. TPS40130EVM-001 Recommended Test Setup

4.3 Startup/Shutdown Procedure

1. Increase V

2. Vary LOAD1 from 0 Adc to 40 Adc

3. Vary V

12V_IN

4. Decrease LOAD1 to 0 A

5. Decrease V

(V1) from 0 Vdc to 10 Vdc

12V_IN

(V1) from 10 Vdc to 14 Vdc

to 0 V

12V_IN

12-V Input, 1.5-V Output, 40-A Two Phase Synchronous Buck Converter Using the TPS40130SLUU208 – October 2004 9

Page 10

www.ti.com

HPA087A Efficiency

80

82

84

86

88

90

92

4 14 24 34

Output Current

Efficiency

Vin 10v

Vin 12v

Vin 14v

Line Regulation

@ 20A Load

1.505

1.507

1.509

1.511

1.513

1.515

10 11 12 13 14

Input Voltage

Output Voltage

Line reg

TPS40130EVM-001 Typical Performance Data and Characteristic Curves

4.4 Equipment Shutdown

1. Shut down oscilloscope

2. Shut down LOAD1

3. Shut down V

12V_IN

4. Shut down fan

5 TPS40130EVM-001 Typical Performance Data and Characteristic Curves

Figure 4 , Figure 5 , Figure 6 , and Figure 7 present typical performance curves for the TPS40130EVM-001.

Since actual performance data can be affected by measurement techniques and environment variables,

these curves are presented for reference and may differ from actual field measurements.

5.1 Efficiency

Figure 4. TPS40130EVM-001 Efficiency, V

5.2 Line Regulation

Figure 5. TPS40130EVM-001 Line Regulation, I

12-V Input, 1.5-V Output, 40-A Two Phase Synchronous Buck Converter Using the TPS4013010 SLUU208 – October 2004

V

1V5_OUT

= 1.5 V, I

= 10 V to 14 V,

12V_IN

1V5_OUT

= 4 A to 40 A

1V5_OUT

= 20 A

Page 11

www.ti.com

5.3 Load Regulation

Load Regulation

1.505

1.507

1.509

1.511

1.513

1.515

0 10 20 30 40

Output Current

OUtput Voltage

10v In

12v In

14v IN

5.4 Transient Response

TPS40130EVM-001 Typical Performance Data and Characteristic Curves

Figure 6. TPS40130EVM-001 Load Regulation

5.4.1 Positive Transient

Figure 7. TPS40130EVM-001 5 A to 55 A Transient Response, 5 A to 55 A at 3 A/µs,

I

1V5_OUT (10A/div)

, V

1V5_OUT(rip)

(20 mv/div), Time 10 µs/div

12-V Input, 1.5-V Output, 40-A Two Phase Synchronous Buck Converter Using the TPS40130SLUU208 – October 2004 11

Page 12

www.ti.com

EVM Assembly Drawings and Layout

5.4.2 Negative Transient

Figure 8. TPS40130EVM-001 55 A to 5 A Transient Response, 55 A to 5 A at 3 A/µs,

I

1V5_OUT (10A/div)

, V

1V5_OUT(rip)

(20 mV/div), Time 10 µs/div

6 EVM Assembly Drawings and Layout

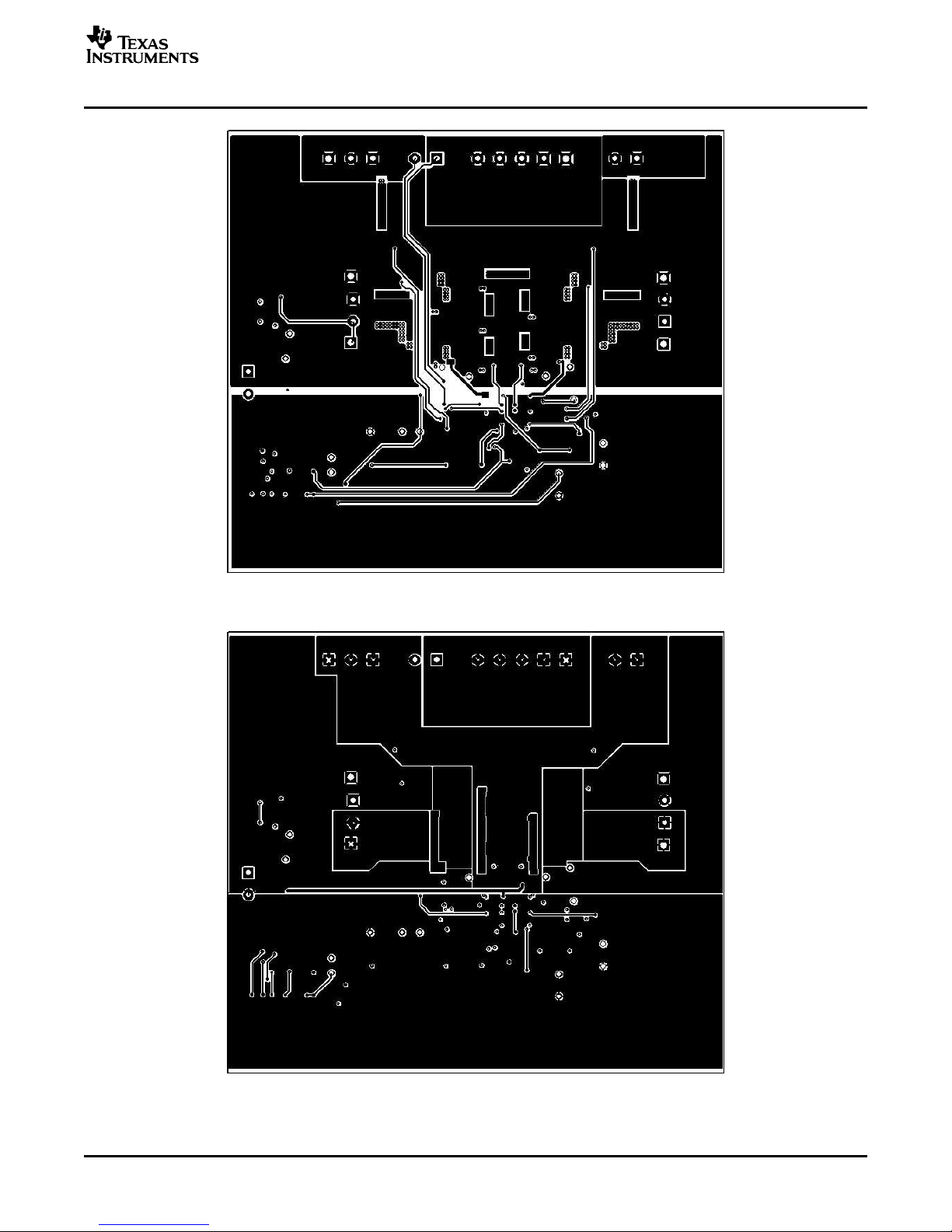

Figure 9 through Figure 14 show the design of the TPS40130EVM-001 printed circuit board. The EVM has

been designed using a 4-layer, 2-oz copper-clad circuit board 4.5" × 4.0” with all components on the top

side to allow the user to easily view, probe, and evaluate the TPS40130 control IC in a practical

application. Moving components to both sides of the PCB or using additional internal layers can offer

additional size reduction for space constrained systems.

12-V Input, 1.5-V Output, 40-A Two Phase Synchronous Buck Converter Using the TPS4013012 SLUU208 – October 2004

Page 13

www.ti.com

EVM Assembly Drawings and Layout

Figure 9. TPS40130EVM-001 Component Placement (Top View)

Figure 10. TPS40130EVM-001 Silkscreen (Top View)

12-V Input, 1.5-V Output, 40-A Two Phase Synchronous Buck Converter Using the TPS40130SLUU208 – October 2004 13

Page 14

www.ti.com

EVM Assembly Drawings and Layout

Figure 11. TPS40130EVM-001 Top Copper (Top View)

Figure 12. TPS40130EVM-001 Layer 2 (X-Ray Top View)

12-V Input, 1.5-V Output, 40-A Two Phase Synchronous Buck Converter Using the TPS4013014 SLUU208 – October 2004

Page 15

www.ti.com

EVM Assembly Drawings and Layout

Figure 13. TPS40130EVM-001 Layer 3 (X-Ray Top View)

Figure 14. TPS40130EVM-001 Bottom Copper (X-Ray Bottom View)

12-V Input, 1.5-V Output, 40-A Two Phase Synchronous Buck Converter Using the TPS40130SLUU208 – October 2004 15

Page 16

www.ti.com

List of Materials

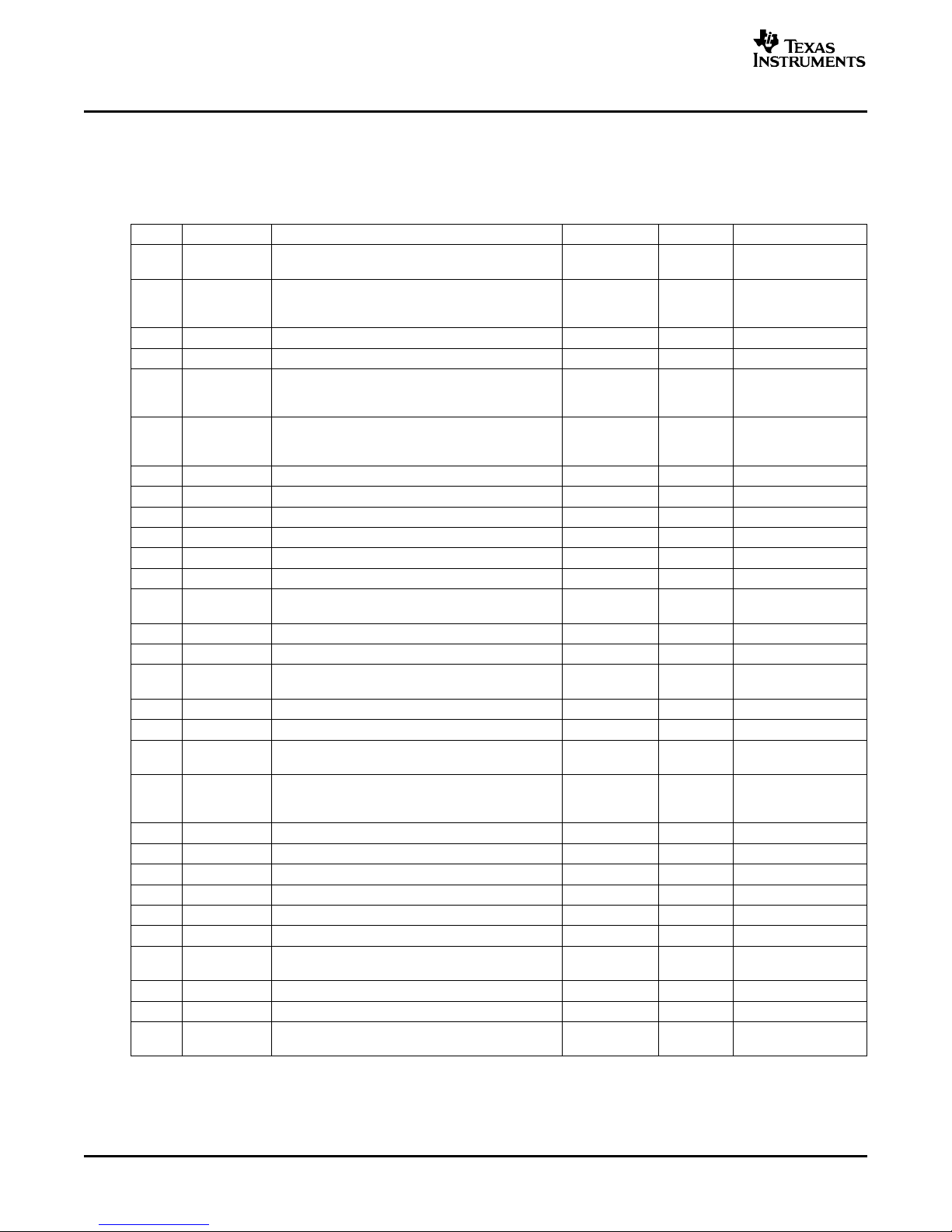

7 List of Materials

Table 4 lists the EVM components as configured according to the schematic shown in Figure 1 and

Figure 2 .

Table 4. TPS40130EVM-001 Bill of Materials

Count RefDes Description Size MFR Part Number

4 C1, C2, C29, Capacitor, ceramic, 22-µF, 16-V, X7R, 15% 1210 TDK C3225X7R1C226M

C30

7 C3, C7, C8, Capacitor, ceramic, 0.1-µF, 25-V, X7R, 10% 805 Std Std

C15, C24,

C26, C31

1 C4 Capacitor, ceramic, 47-pF, 50-V, NPO, 10% 805 Std Std

0 C5, C11 Capacitor, ceramic, pF, 50-V, X7R, 10% 805 Std Std

7 C6, C9, C10, Capacitor, ceramic, 1000-pF, 50-V, X7R, 10% 805 Std Std

C19, C25,

C27, C28

6 C12, C14, Capacitor, aluminum, 220-µF, 5-m Ω , 4-V, 20% 7343 Panasonic EEF-UEOG221R

C16, C17, (UE Series)

C20, C23

1 C13 Capacitor, ceramic, 100-pF, 50-V, NPO, 10% 805 Std Std

2 C18, C22 Capacitor, ceramic, 1-µF, 16-V, X5R, 10% 805 Std Std

1 C21 Capacitor, ceramic, 3300-pF, 50-V, X7R, 10% 805 Std Std

1 C32 Capacitor, ceramic, 0.22-µF, 16-V, X7R, 10% 805 Panasonic ECJ-2VB1C224K

1 C33 Capacitor, POSCAP, 100-µF, 10-V, 40-m Ω , 20% 7343(D) Sanyo 10TPB100ML

2 D1, D2 Diode, Schottky, 200-mA, 30-V SOD323 On Semi BAT54HT1

6 J1, J2, J3, J5, Terminal block, 2-pin, 15-A, 5,1-mm 0.40 x 0.35 OST ED1609

J6, J7

1 J4 Terminal block, 4-pin, 15-A, 5,1-mm 0.80 x 0.35 OST ED2227

2 L1, L2 Inductor, SMT, 0.68-µH, 30-A, 0.9-m Ω 0.524 x 0.492 Wurth S0410124A

4 Q1, Q2, Q5, MOSFET, N-channel, 30-V, 55-A, 2.5-m Ω LFPAK Renesas HAT2165H

Q6

2 Q3, Q4 MOSFET, N-channel, 30-V, 20-A, 6-m Ω LFPAK Renesas HAT2168H

1 R1 Resistor, chip, 2.94-k Ω , 1/10-W, 1% 805 Std Std

4 R10, R11, Resistor, chip, 2.74- Ω , 1/10-W, 1% 805 Std Std

R22, R25

5 R12, R13, Resistor, chip, 5.11- Ω , 1/10-W, 1% 805 Std Std

R15, R16,

R17

1 R14 Resistor, chip, 8.66-k Ω , 1/10-W, 1% 805 Std Std

1 R18 Resistor, chip, 2.21-k Ω , 1/10-W, 1% 805 Std Std

1 R19 Resistor, chip, 1.0-k Ω , 1/10-W, 1% 805 Std Std

1 R2 Resistor, chip, 49.9- Ω , 1/10-W, 1% 805 Std Std

1 R20 Resistor, chip, 10- Ω , 1/10-W, 1% 805 Std Std

1 R21 Resistor, chip, 82.5-k Ω , 1/10-W, 1% 805 Std Std

5 R3, R27, R29, Resistor, chip, 0- Ω jumper, 1/10-W, 5% 805 Std Std

R32, R33

1 R30 Resistor, chip, 11.5-k Ω , 1/10-W, 1% 805 Std Std

1 R31 Resistor, chip, 1.62-k Ω , 1/10-W, 1% 805 Std Std

4 R4, R6, R23, Resistor, chip, 10-k Ω , 1/10-W, 1% 805 Std Std

R24

(1) (2) (3) (4)

(1)

These assemblies are ESD sensitive, ESD precautions shall be observed.

(2)

These assemblies must be clean and free from flux and all contaminants. Use of no clean flux is not acceptable.

(3)

These assemblies must comply with workmanship standards IPC-A-610 Class 2.

(4)

Ref designators marked with an asterik " * " cannot be substituted. All other components can be substituted with equivalent

manufacturers components.

12-V Input, 1.5-V Output, 40-A Two Phase Synchronous Buck Converter Using the TPS4013016 SLUU208 – October 2004

Page 17

www.ti.com

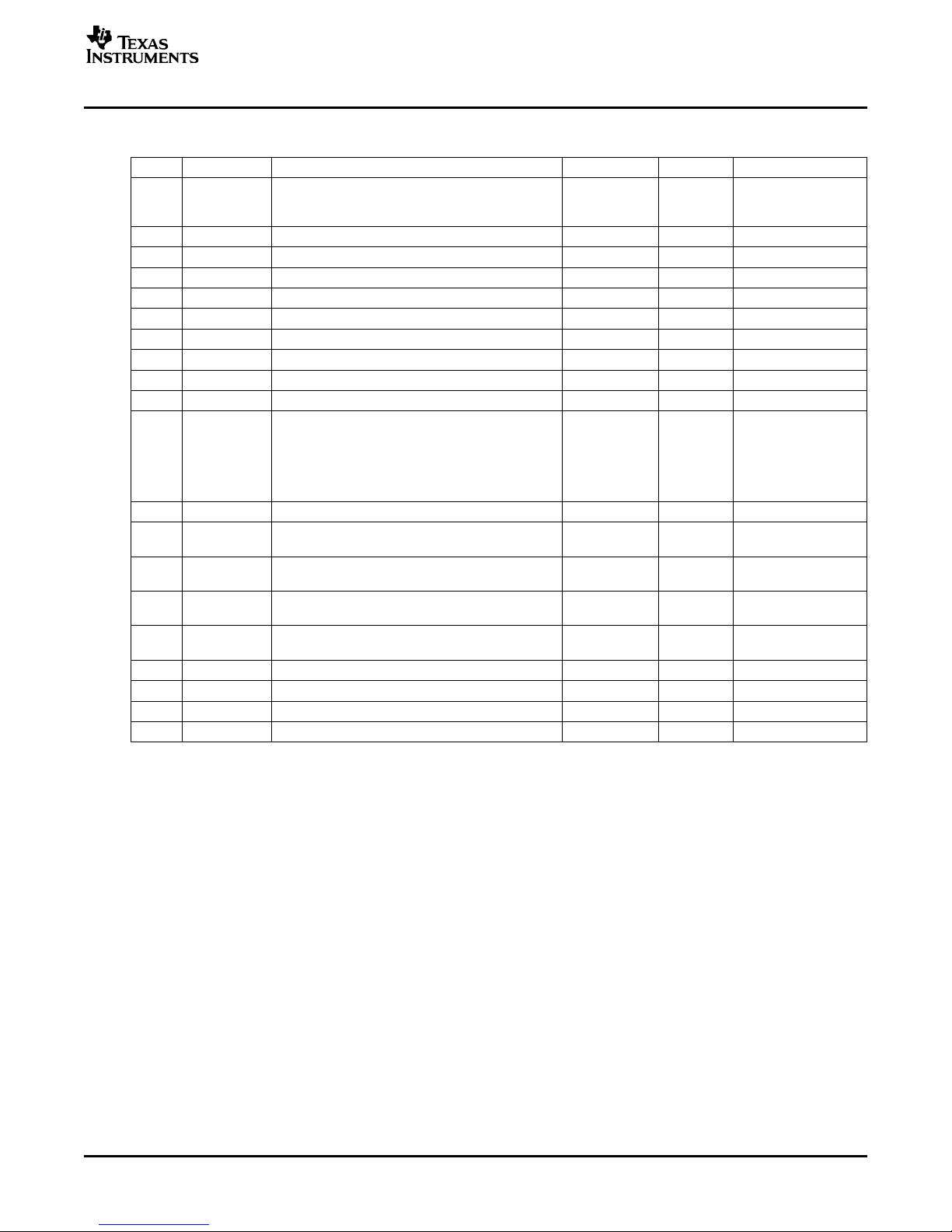

Table 4. TPS40130EVM-001 Bill of Materials (continued)

Count RefDes Description Size MFR Part Number

0 R34, R35, Resistor, chip, 10-k Ω , 1/10-W, 1% 805 Std Std

R36, R37,

R38, R39

0 R40 Resistor, chip, 0- Ω Jumper, 1/10-W, 5% 805 Std Std

0 R41, R42 Resistor, chip, 22.6-k Ω , 1/10-W, 1% 805 Std Std

2 R43, R45 Resistor, chip, 124-k Ω , 1/10-W, 1% 805 Std Std

0 R44, R46 Thermister, chip, NTC, 100-k Ω , -4250 ppm/ ° C 3% 805 Murata NCP21WF104J03RA

2 R5, R28 Resistor, chip, 2.2- Ω , 1/10-W, 1% 805 Std Std

0 R7 Resistor, chip, Ω , 1/10-W, 1% 805 Std Std

1 R8 Resistor, chip, 39.2-k Ω , 1/10-W, 1% 805 Std Std

2 R9, R26 Resistor, chip, 4.32-k Ω , 1/10-W, 1% 805 Std Std

0 SW1 Switch, 8-pos, SPST, low profile, SMT SD08H0SK

11 TP1, TP3, Test point, white, 0.40 hole, 0.050 loop 0.100 Keystone 5002

TP4, TP7,

TP10, TP11,

TP13, TP15,

TP17, TP19,

TP20

0 TP21, TP22 Test point, white, 0.40 hole, 0.050 loop 0.100 Keystone 5002

3 TP2, TP9, Test point, red, thru hole 0.125 Keystone 5010

TP16

3 TP5, TP12, Test point, black, 0.40 hole, 0.050 loop 0.100 Keystone 5001

TP14

3 TP6, TP8, Test point, black, thru hole 0.125 Keystone 5011

TP18

1 U1 IC, High-speed 2-phase synchronous BUCK con- TSSOP-30 TI TPS40130DBT

1 U2 IC, Low drop-out regulator, 5-V to 12-V options SOIC8 TI TL751L05C

0 U3 IC, 6-Bit VID controller SO14 TI TPS40120PW

1 — PCB, 4-Layer FR4, 4.0" x 4.5" x 0.062" 2.4" x 2.1" Any HPA087A

4 — Bumpon

troller

(5)

, transparent 0.44" x 0.2" 3M SJ5303

List of Materials

(5)

Install Bumpons on back side (unpopulated side) of PCB. Install one in each corner after cleaning.

12-V Input, 1.5-V Output, 40-A Two Phase Synchronous Buck Converter Using the TPS40130SLUU208 – October 2004 17

Page 18

IMPORTANT NOTICE

Texas Instruments Incorporated and its subsidiaries (TI) reserve the right to make corrections, modifications,

enhancements, improvements, and other changes to its products and services at any time and to discontinue

any product or service without notice. Customers should obtain the latest relevant information before placing

orders and should verify that such information is current and complete. All products are sold subject to TI’s terms

and conditions of sale supplied at the time of order acknowledgment.

TI warrants performance of its hardware products to the specifications applicable at the time of sale in

accordance with TI’s standard warranty. Testing and other quality control techniques are used to the extent TI

deems necessary to support this warranty . Except where mandated by government requirements, testing of all

parameters of each product is not necessarily performed.

TI assumes no liability for applications assistance or customer product design. Customers are responsible for

their products and applications using TI components. To minimize the risks associated with customer products

and applications, customers should provide adequate design and operating safeguards.

TI does not warrant or represent that any license, either express or implied, is granted under any TI patent right,

copyright, mask work right, or other TI intellectual property right relating to any combination, machine, or process

in which TI products or services are used. Information published by TI regarding third-party products or services

does not constitute a license from TI to use such products or services or a warranty or endorsement thereof.

Use of such information may require a license from a third party under the patents or other intellectual property

of the third party, or a license from TI under the patents or other intellectual property of TI.

Reproduction of information in TI data books or data sheets is permissible only if reproduction is without

alteration and is accompanied by all associated warranties, conditions, limitations, and notices. Reproduction

of this information with alteration is an unfair and deceptive business practice. TI is not responsible or liable for

such altered documentation.

Resale of TI products or services with statements different from or beyond the parameters stated by TI for that

product or service voids all express and any implied warranties for the associated TI product or service and

is an unfair and deceptive business practice. TI is not responsible or liable for any such statements.

Following are URLs where you can obtain information on other Texas Instruments products and application

solutions:

Products Applications

Amplifiers amplifier.ti.com Audio www.ti.com/audio

Data Converters dataconverter.ti.com Automotive www.ti.com/automotive

DSP dsp.ti.com Broadband www.ti.com/broadband

Interface interface.ti.com Digital Control www.ti.com/digitalcontrol

Logic logic.ti.com Military www.ti.com/military

Power Mgmt power.ti.com Optical Networking www.ti.com/opticalnetwork

Microcontrollers microcontroller.ti.com Security www.ti.com/security

Telephony www.ti.com/telephony

Video & Imaging www.ti.com/video

Wireless www.ti.com/wireless

Mailing Address: Texas Instruments

Post Office Box 655303 Dallas, Texas 75265

Copyright 2004, Texas Instruments Incorporated

Loading...

Loading...