Page 1

TPS40100

www.ti.com

MIDRANGE INPUT SYNCHRONOUS BUCK CONTROLLER

WITH ADVANCED SEQUENCING AND OUTPUT MARGINING

FEATURES APPLICATIONS

• Operation over 4.5 V to 18 V Input Range

• Adjustable Frequency (Between 100 kHz and

600 kHz) Current Feedback Control

• Output Voltage Range From 0.7 V to 5.5 V

• Simultaneous, Ratiometric and Sequential

Startup Sequencing

• Adaptive Gate Drive

• Remote Sensing (Via Separate GND/PGND)

• Internal Gate Drivers for N-channel MOSFETs

• Internal 5-V Regulator

• 24-Pin QFN Package

• Thermal Shutdown

• Programmable Overcurrent Protection

• Power Good Indicator

• 1%, 690-mV Reference

• Output Margining, 3% and 5%

• Programmable UVLO (with Programmable

Hysteresis)

• Frequency Synchronization

• Servers

• Networking Equipment

• Cable Modems and Routers

• XDSL Modems and Routers

• Set-Top Boxes

• Telecommunications Equipment

• Power Supply Modules

DESCRIPTION

The TPS40100 is a mid voltage, wide-input (between

4.5 V and 18 V), synchronous, step-down controller.

The TPS40100 offers programmable closed loop

soft-start, programmable UVLO (with programmable

hysteresis), programmable inductor sensed current

limit and can be synchronized to other timebases.

The TPS40100 incorporates MOSFET gate drivers

for external N-channel high-side and synchronous

rectifier (SR) MOSFET. Gate drive logic incorporates

adaptive anti-cross conduction circuitry for improved

efficiency, reducing both cross conduction and diode

conduction in the rectifier MOSFET. The externally

programmable current limit provides a hiccup

overcurrent recovery characteristic.

SLUS601–MAY 2005

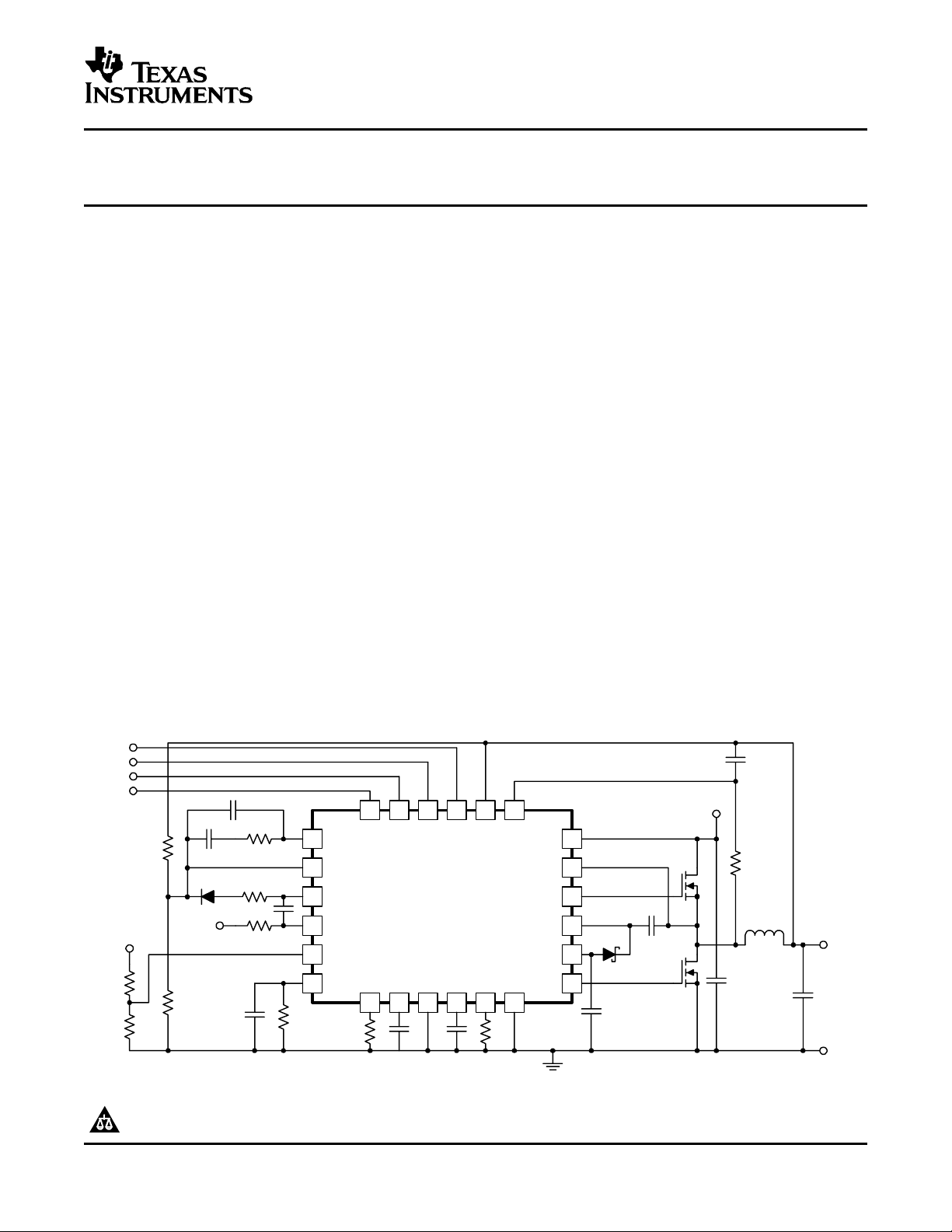

TYPICAL APPLICATION

V

24 2223 21 20 19

PG

SS

VO

GM

VDD

ISNS

HDRV

5VBP

LDRV

PGND

SW

BST

18

17

16

15

14

13

COMP

1

2

3

V

V

IN

TRKIN

Please be aware that an important notice concerning availability, standard warranty, and use in critical applications of Texas

Instruments semiconductor products and disclaimers thereto appears at the end of this data sheet.

4

5

6

MGU

MGD

FB

TRKOUT

TRKIN

UVLO

ILIM

7 98 10 11 12

RT

TPS40100

BIAS

SYNC

GND

IN

UDG−04137

PRODUCTION DATA information is current as of publication date.

Products conform to specifications per the terms of the Texas

Instruments standard warranty. Production processing does not

necessarily include testing of all parameters.

Copyright © 2005, Texas Instruments Incorporated

Page 2

www.ti.com

TPS40100

SLUS601–MAY 2005

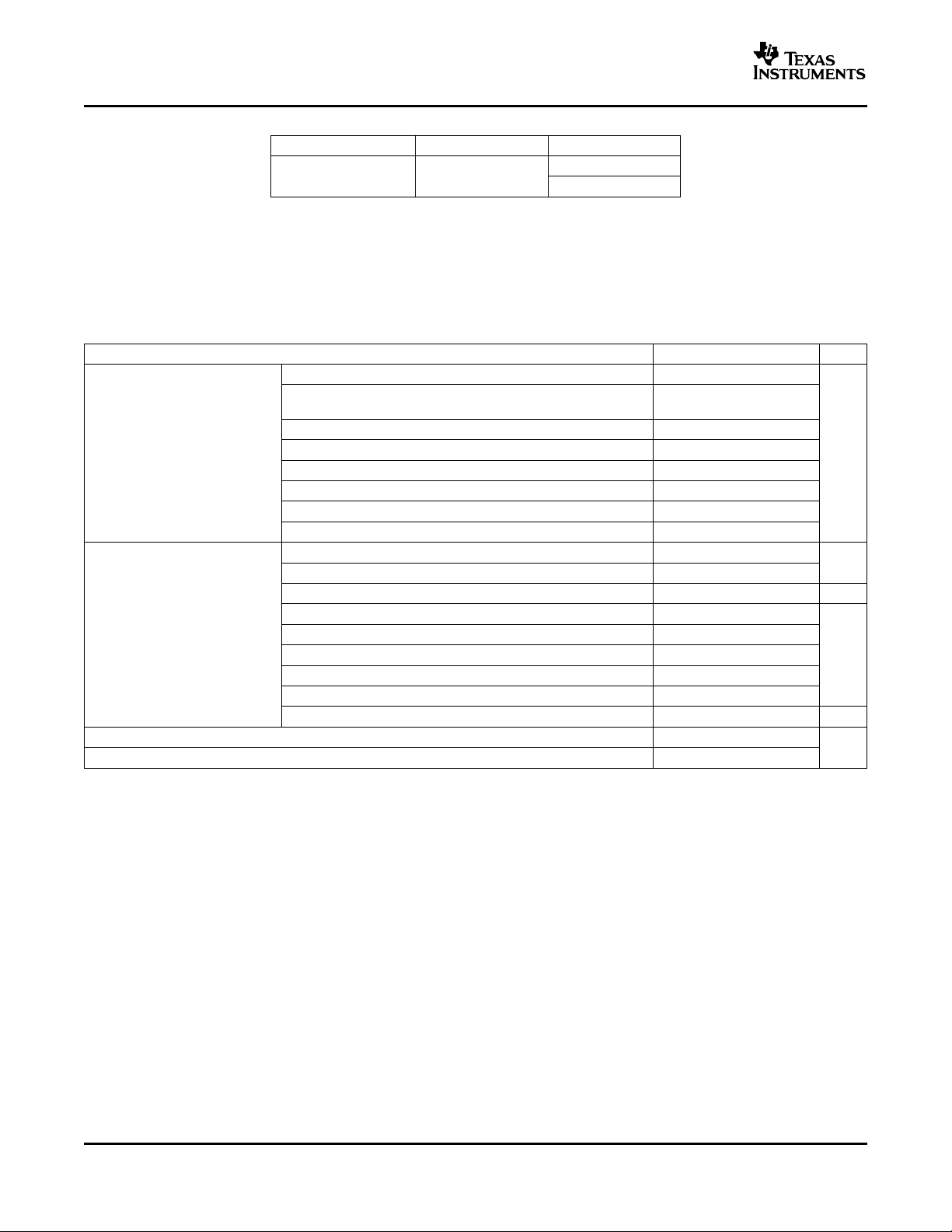

ORDERING INFORMATION

T

A

-40°C to 85°C QFN

PACKAGE PART NUMBER

TPS40100RGER

TPS40100RGET

(1) The QFN package (RGE) is available taped and reeled only. Use

large reel device type R (TPS40100RGER) to order quantities of

3,000 per reel. Use small reel device type T (TPS40100RGET) to

order quantities of 250 per reel.

ABSOLUTE MAXIMUM RATINGS

over operating free-air temperature range unless otherwise noted

VDD -0.3to20

5VBP, BIAS, FB, ILIM, ISNS, LDRV, MGU, MGD, PG, SS,

SYNC, UVLO, VO

BST to SW, HDRV to SW

V

Input voltage range V

IN

SW -1.5 to V

SW (transient) < 100 ns -6 to 30

TRKIN -0.3to20

GNDtoPGND -0.3to0.3

TRKOUT -0.3 to 8.0

HDRV, LDRV (RMS) 0.5

HDRV, LDRV (peak) 2.0

FB, COMP, TRKOUT 10 to -10 mA

SS 20 to -20

I

Input current range PG 20

IN

GM 1mA

RT 10

V5BP 50

RT source 100 µA

T

T

Operating junction temperature range –40 to 125

J

Storage temperature –55 to 150

stg

(1) Stresses beyond those listed under "absolute maximum ratings" may cause permanent damage to the device. These are stress ratings

only, and functional operation of the device at these or any other conditions beyond those indicated under "recommended operating

conditions" is not implied. Exposure to absolute-maximum-rated conditions for extended periods may affect device reliability.

(2) BST to SW and HDRV to SW are relative measurements. BST and HDRV can be this amount of voltage above or below the voltage at

SW.

(3) V5BP current includes gate drive current requirements. Observe maximum TJrating for the device.

(2)

(1)

(1)

TPS40100 UNIT

-0.3 to 6

-0.3 to 6.0

VIN

A

(3)

°C

2

Page 3

TPS40100

www.ti.com

SLUS601–MAY 2005

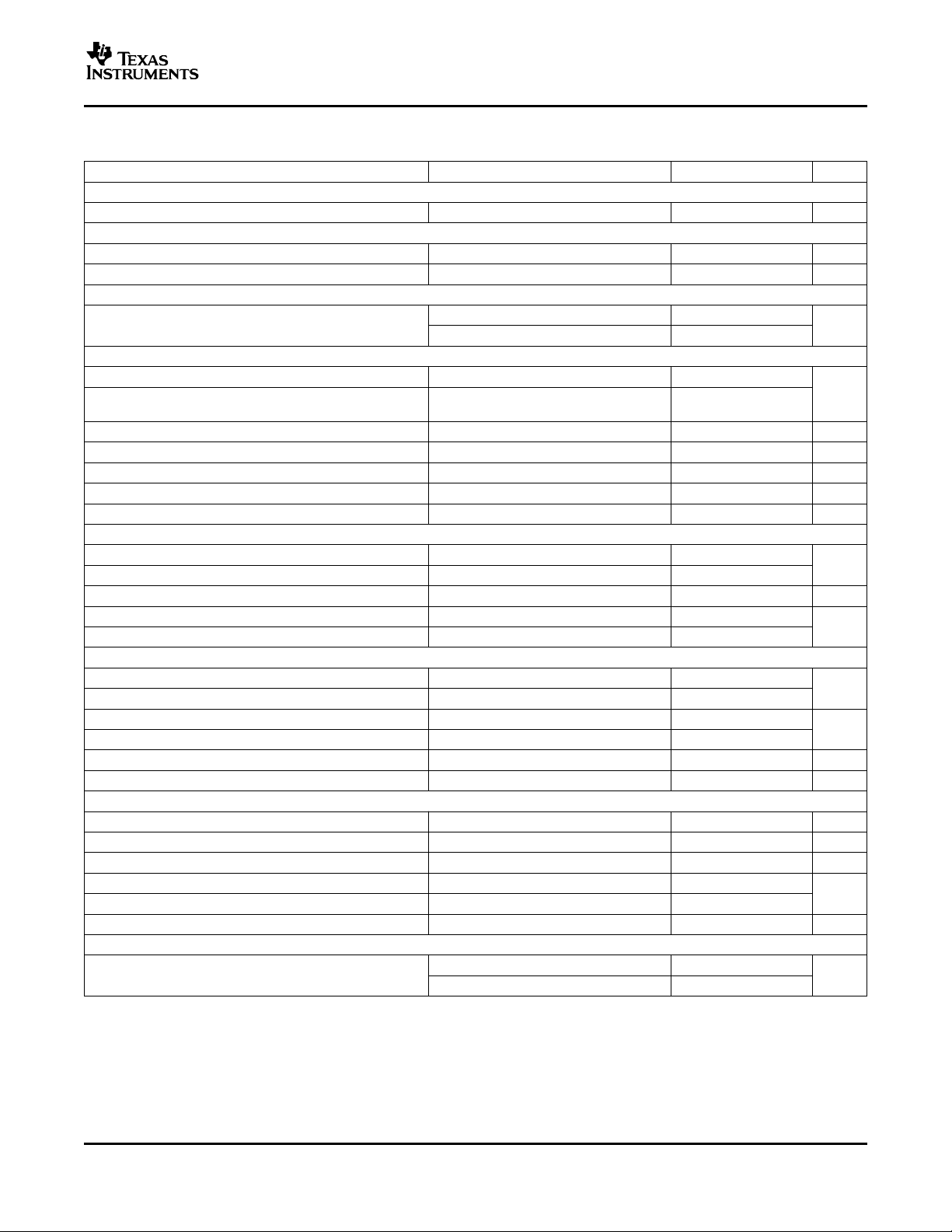

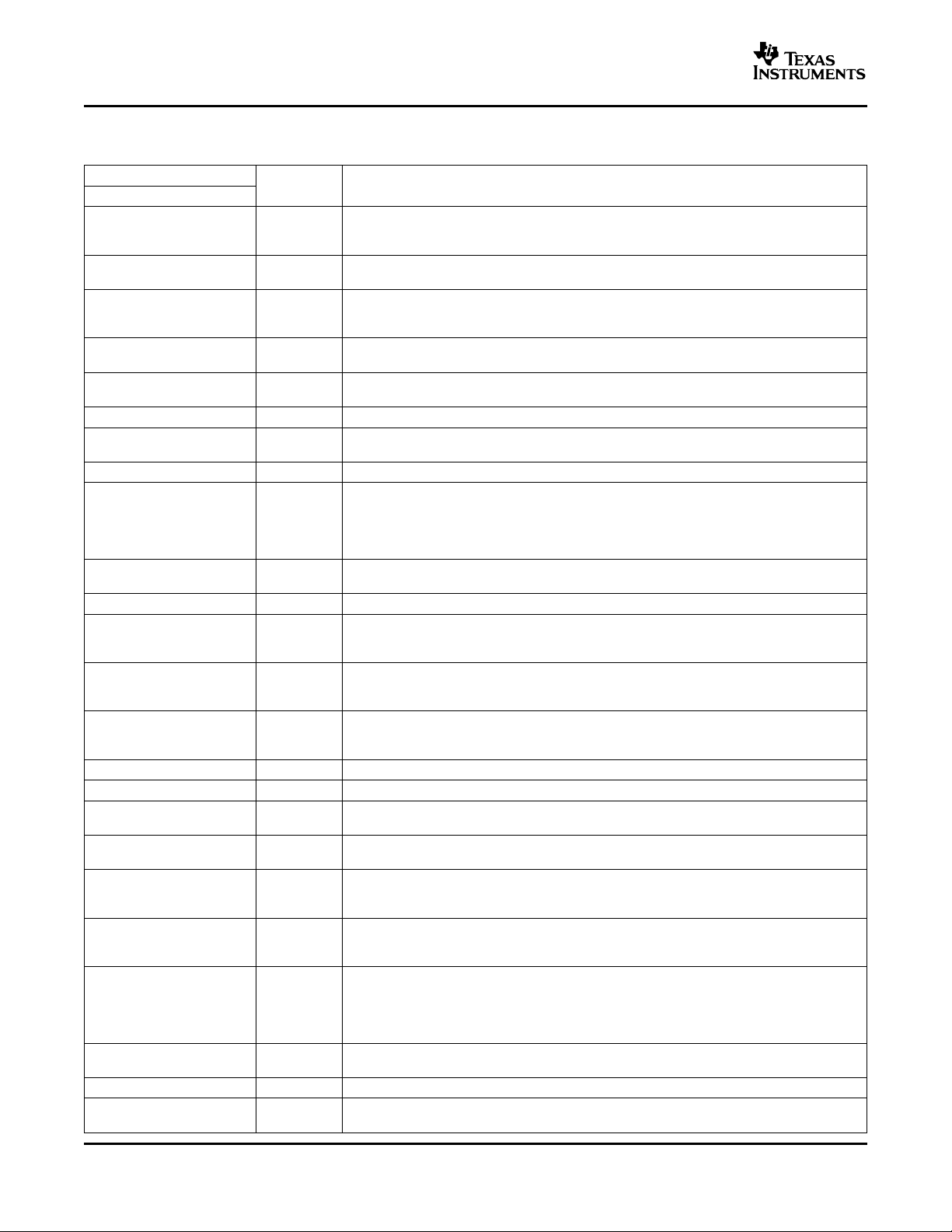

ELECTRICAL CHARACTERISTICS

-40°C ≤ TA=TJ≤ 85°C, V

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

INPUT VOLTAGE

V

VDD

OPERATING CURRENT

I

DD

I

SD

5VPB

OSCILLATOR/RAMP GENERATOR

f

SW

V

RAMP

t

OFF

D

MIN

t

MIN

V

VLY

FREQUENCY SYNCHRONIZATION

V

IH

V

IL

I

SYNC

t

SYNC

t

SYNC_SH

SOFT-START AND FAULT IDLE

I

SS

I

SS_SINK

V

SSC

V

SSD

V

SSOS

ERROR AMPLIFIER

GBWP Gain bandwidth product

AVOL Open loop 60 80 dB

I

BIAS

I

OH

I

OL

FEEDBACK REFERENCE

V

FB

(1) Ensured by design. Not production tested.

(2) To meet set up time requirements for the synchronization circuit, a negative logic pulse must be greater than 100 ns wide.

Operating range 4.5 18.0 V

Quiescent current VFB> 0.8 V, 0% duty cycle 1.3 1.8 2.5 mA

Shutdown current V

Internal regulator V

Programmable oscillator frequency 100 600

Oscillator frequency accuracy 250 275 300

Ramp amplitude

Fixed off-time 100 150 ns

Minimum duty cycle 0%

Minimum controllable pulse width

Valley voltage

High-level input voltage 2

Low-level input voltage 0.8

Input current, SYNC V

Mimimum pulse width, SYNC 50

Minimum set-up/hold time, SYNC

Soft-start source (charge) current 13 20 25

Soft-start sink (discharge) current 3.4 5.0 6.6

Soft-start completed voltage 3.25 3.40 3.75

Soft-start discharged voltage 0.15 0.20 0.25

Retry interval time to SS time ratio

Offset from SS to error amplifier 300 500 800 mV

Input bias current, FB 50 200 nA

High-level output current 23

Low-level output current 23

Slew rate

Feedback voltage reference mV

=12V,RRT= 182 kΩ,RGM= 232 kΩ,R

VDD

(1)

(1)

(1)

(2)

(1)

(1)

(1)

= 121 kΩ (unless otherwise noted)

ILIM

< 1 V 500 µA

UVLO

7V≤ V

4.5 V ≤ V

4.5 V ≤ V

-40°C ≤ TA=TJ≤ 125°C

≤ 18 V, 0 mA ≤ I

VDD

< 7 V, 0 mA ≤ I

VDD

<18V,

VDD

≤ 30 mA 4.7 5.0 5.3

LOAD

≤ 30 mA 4.3 5.0 5.3

LOAD

0.5 V

C

= 4.7 nF, -40°C ≤ TA=TJ≤ 125°C 175 ns

LOAD

1.0 1.6 2.0 V

= 2.5 V 4.0 5.5 10.0 µA

SYNC

100

16

3.5 5.0 MHz

2.1 V/µs

TA=25°C 686 690 694

-40°C < TA=TJ≤ 125°C 683 697

kHz

P-P

V

ns

µA

V

mA

3

Page 4

www.ti.com

TPS40100

SLUS601–MAY 2005

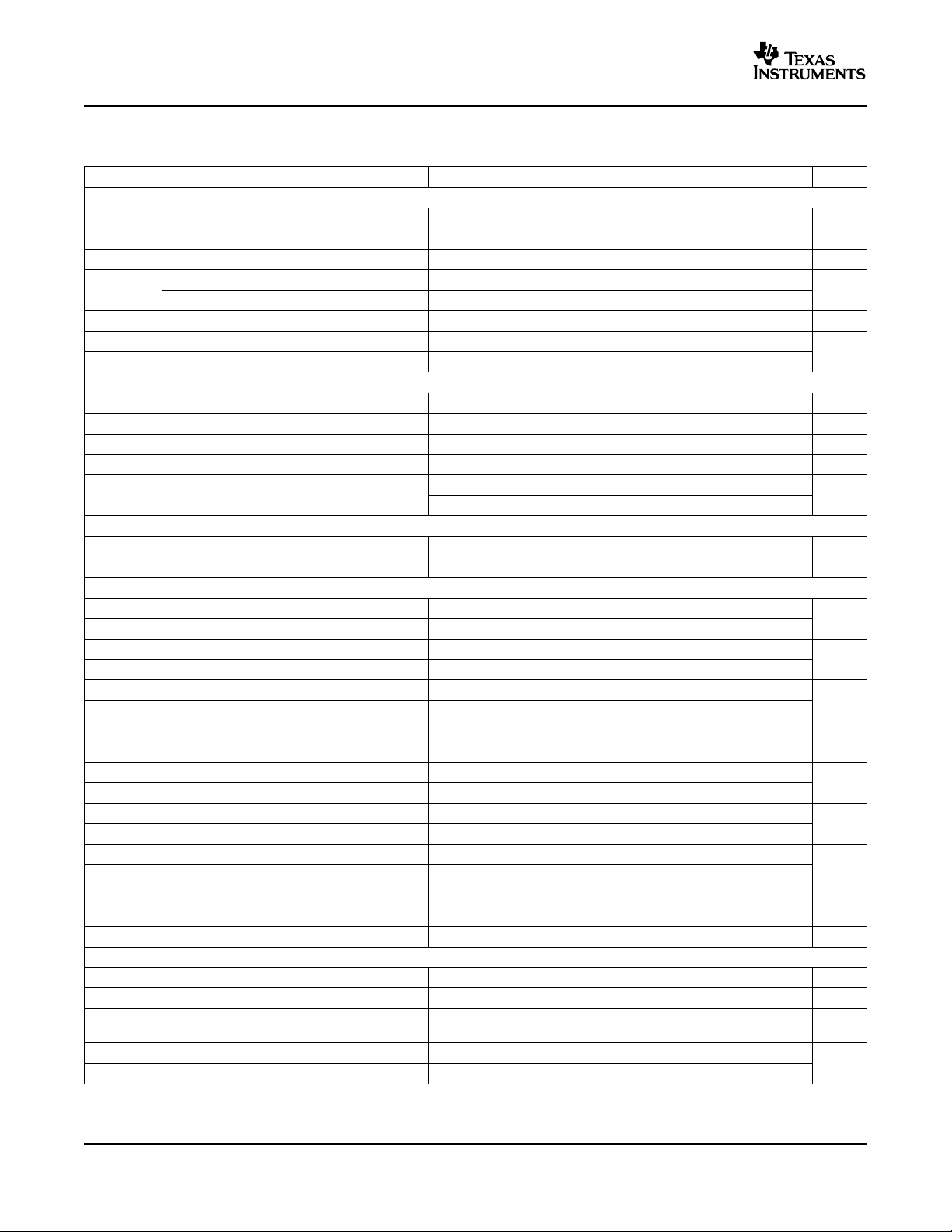

ELECTRICAL CHARACTERISTICS (continued)

-40°C ≤ TA=TJ≤ 85°C, V

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

VOLTAGE MARGINING

V

FBMGU

I

MGUP

V

FBMGD

I

MGDN

t

MGDLY

t

MGTRAN

CURRENT SENSE AMPLIFIER

gm

CSA

TC

GM

V

GMLIN

I

ISNS

V

GMCM

CURRENT LIMIT

V

ILIM

t

ILIMDLY

DRIVER SPECIFICATIONS

t

RHDRV

t

FHDRV

I

HDRVSRPKS

I

HDRVSRMIL

I

HSDVSNPK

I

HDRVSNMIL

R

HDRVUP

R

HDRVDN

t

RLDRV

t

FLDRV

I

LDRVSRPK

I

LDRVSNMIL

I

LSDVSNPK

R

LDRVUP

R

LDRVDN

I

SWLEAK

POWERGOOD

V

LPGD

t

PGD

V

LPGDNP

V

OV

V

UV

(3) Margining delay time is the time delay from an assertion of a margining command until the output voltage begins to transition to the

margined voltage.

(4) Ensured by design. Not production tested.

Feedback voltage margin 5% up V

Feedback voltage margin 3% up 2 V ≤ V

Margin-up bias current 60 80 100 µA

Feedback voltage margin 5% down V

Feedback voltage margin 3% down 2 V ≤ V

Margin-down bias current 60 80 100 µA

Margining delay time

Margining transition time 1.5 7.0

Current sense amplifier gain TJ=25°C 300 333 365 µS

Amplifier gain temperature coefficient -2000 ppm/°C

Gm linear range voltage TJ=25°C -50 50 mV

Bias current at ISNS pin VVO=V

Input voltage common mode V

ILIM pin voltage to trip overcurrent 1.44 1.48 1.52 V

Current limit comparator propagation delay HDRV transition from on to off 70 140 ns

HIgh-side driver rise time

HIgh-side driver fall time

HIgh-side driver peak source current

HIgh-side driver source current at 2.5 V

HIgh-side driver peak sink current

High-side driver sink current at 2.5 V

HIgh-side driver pullup resistance I

HIgh-side driver pulldown resistance I

Low-side driver rise time

Low-side driver fall time

Low-side driver peak source current

Low-side driver source current at 2.5 V

Low-side driver peak sink current

Low-side driver sink current at 2.5 V

Low-side driver pullup resistance I

Low-side driver pulldown resistance I

Leakage current from SW pin -1 1 µA

Powergood low voltage I

Powergood delay time 15 25 35 µs

Powergood low voltage , no device power 1.00 1.25 V

Power good overvoltage threshold, V

Power good undervoltage threshold, V

=12V,RRT= 182 kΩ,RGM= 232 kΩ,R

VDD

MGU

MGD

(3)

4.5 V ≤ VIN≤ 5.5 V 0 3.6

(4)

(4)

(4)

(4)

(4)

(4)

(4)

(4)

(4)

(4)

(4)

FB

FB

C

LOAD

C

LOAD

(4)

V

HDRV-VSW

V

HDRV-VSW

HDRV

HDRV

C

LOAD

C

LOAD

V

LDRV

V

LDRV

LDRV

LDRV

PGD

V

VDD

5-V supply

= 121 kΩ (unless otherwise noted)

ILIM

≤ 500 mV 715 725 735

≤ 3 V 700 711 720

MGU

≤ 500 mV 645 655 665

≤ 3 V 660 669 680

MGD

12 30

= 3.3 V 250 nA

ISNS

06

= 4.7 nF 57

= 4.7 nF 47

800

= 2.5 V 700

1.3

= 2.5 V 1.2

= 300 mA 2.4 4.0

= 300 mA 1.0 1.8

= 4.7 nF 57

= 4.7 nF 47

800

= 2.5 V 700

1.3

= 2.5 V 1.2

= 300 mA 2.0 4.0

= 300 mA 0.8 1.5

= 2 mA 30 100 mV

= OPEN, 10-kΩ pullup to external

765

615

mV

mA

ms

ns

mA

A

Ω

ns

mA

A

Ω

mV

4

Page 5

TPS40100

www.ti.com

ELECTRICAL CHARACTERISTICS (continued)

-40°C ≤ TA=TJ≤ 85°C, V

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

TRACKING AMPLIFIER

V

TRKOS

V

TRKCM

V

TRK

V

HTKROUT

V

LTKROUT

I

SRCTRKOUT

I

SNKTRKOUT

V

TRKDIF

GBWP

AVOL

PROGRAMMABLE UVLO

V

UVLO

I

UVLO

INTERNALLY FIXED UVLO

V

UVLOFON

V

UVLOFOFF

V

UVLOHYST

THERMAL SHUTDOWN

T

SD

T

SDHYST

Tracking amplifier input offset voltage mV

Input common mode, active range 0 6

Tracking amplifier voltage range

High-level output voltage, TRKOUT

Low-level output voltage, TRKOUT 0 0.5

Source current, TRKOUT 0.65 2.00

Sink current, TRKOUT 12

Differential voltage from TRKIN to VO 18 V

Tracking amplifier gain bandwidth product

TRK

Tracking amplifier open loop DC gain

TRK

Undervoltage lockout threshold 1.285 1.332 1.378 V

Hysteresis current 9.0 10.0 10.8 µA

Fixed UVLO turn-on voltage at VDD pin -40°C ≤ TA< 125°C 3.850 4.150 4.425

Fixed UVLO turn-off voltage at VDD pin 3.75 4.06 4.35

UVLO hysteresis at VDD pin 85 mV

Thermal shutdown temerature

Hysteresis

=12V,RRT= 182 kΩ,RGM= 232 kΩ,R

VDD

(6)

(6)

(6)

(6)

V

TRKOS=VTRKIN-VO;VVO

V

TRKOS=VTRKIN-VO

4.5 V ≤ V

5V<V

V

VDD

V

VDD

SLUS601–MAY 2005

= 121 kΩ (unless otherwise noted)

ILIM

≤ 2V 7 25 40

;2V<VVO≤ 6 V -5 25 40

≤ 5.5 V 0 3.6

VDD

VDD

≤ 18 V

(5)

06

= 12 V 5.0 6.5 8.0

= 4.5 V 3.2 3.6

1MHz

60 dB

130 165

25

V

mA

V

°C

(5) Amplifier can track to the lesser of 6 V or (VDD× 0.95)

(6) Ensured by design. Not production tested.

DEVICE INFORMATION

MGU

MGD

SYNC

PG

VO

ISNS

24

23

22

21

20

19

RGE PACKAGE

(BOTTOM VIEW)

COMPFBTRKOUT

TRKIN

UVLO

123456

18 17 16 15 14 13

VDD

SW

BST

HDRV

5VBP

ILIM

7

8

9

10

11

12

LDRV

RT

BIAS

GND

SS

GM

PGND

5

Page 6

www.ti.com

TPS40100

SLUS601–MAY 2005

DEVICE INFORMATION (continued)

TERMINAL FUNCTIONS

TERMINAL

NAME NO.

5VBP 14 O pin to PGND. Power for external circuitry may be drawn from this pin. The total gate drive

BIAS 8 O

BST 15 I connected from 5VBP (A) to BST(K). A schottky diode is recommended for this purpose. A

COMP 1 O

FB 2 I

GM 11 I Connect a resistor from this pin to GND to set the gain of the current sense amplifier.

GND 9 -

HDRV 16 O Floating gate drive for the high side N-channel MOSFET.

ILIM 6 O connected from this pin to GND. When this voltage reaches 1.48 V, an overcurrent condition

ISNS 19 I

LDRV 13 O Gate drive for the N-channel synchronous rectifier.

MGD 23 I 10 kΩ, the output voltage is decreased by 5%. The 3% margin down at the output voltage is

MGU 24 I kΩ, the output voltage is increased by 5%. The 3% margin up at the output voltage is

PG 21 O FB pin is more than 10% higher or lower than 690 mV, a UVLO condition exists, soft-start is

PGND 12 - Power ground for internal drivers

RT 7 I A resistor connected from this pin to GND sets operating frequency.

SS 10 I

SW 17 I

SYNC 22 I synchronize the oscillator frequency to an external master clock. This pin may be left floating

TRKIN 4 I tracks TRKIN voltage with a small controlled offset (typically 25 mV) when the tracking

TRKOUT 3 O the equivalent impedance at the FB node. The diode should be a low leakage type to

UVLO 5 I

VDD 18 I Supply voltage for the device.

VO 20 I

I/O DESCRIPTION

Output of an internal 5-V regulator. A 1-µF bypass capacitor should be connected from this

current and external current draw should not cause the device to exceed thermal capabilities

The bypassed supply for internal device circuitry. Connect a 0.1-µF or greater ceramic

capacitor from this pin to GND.

Gate drive voltage for the high-side N-channel MOSFET. An external diode must be

capacitor must be connected from this pin to the SW pin.

Output of the error amplifier. A feedback network is connected from this pin to the FB pin for

control loop compensation.

Inverting input to the error amplifier. In normal operation the voltage on this pin is equal to

the internal reference voltage (approximately 690 mV).

Low power or signal ground for the device. All signal level circuits should be referenced to

this pin unless otherwise noted.

Current limit pin used to set the overcurrent threshold and transient ride out time. An internal

current source that is proportional to the inductor current sets a voltage on a resistor

is declared by the device. Adding a capacitor in parallel with the resistor to GND sets a time

delay that can be used to help avoid nuisance trips.

Input from the inductor DCR sensing network. This input signal is one of the inputs to the

current sense amplifier for current feedback control and overcurrent protection

Margin down pin used for load stress test. When this pin is pulled to GND through less than

accommodated when this pin is connected to GND through a 30-kΩ resistor.

Margin up pin used for load stress test. When this pin is pulled to GND through less than 10

accommodated when this pin is connected to GND through a 30-kΩ resistor.

Open drain power good output for the device. This pin is pulled low when the voltage at the

active, tracking is active, an overcurrent condition exists or the die is over temperature.

Soft-start programming pin. A capacitor connected from this pin to ground programs the

soft-start time. This pin is also used as a time out function during an overcurrent event.

Connected to the switched node of the converter. This pin is the return line for the flying high

side driver.

Rising edge triggered synchronization input for the device. This pin can be used to

or grounded if the function is not used.

Control input allowing simultaneous startup of multiple controllers. The converter output

amplifier is used. See application secttion for more information.

Output of the tracking amplifier. If the tracking feature is used, this pin should be connected

to FB pin through a resistor in series with a diode. The resistor value can be calculated from

minimize errors due to diode reverse current. For further information on compensation of the

tracking amplifier refer to the application information

Provides for programming the undervoltage lockout level and serves as a shutdown input for

the device.

Output voltage. This is the reference input to the current sense amplifier for current mode

control and overcurrent protection.

6

Page 7

TPS40100

www.ti.com

COMP

FB

MGU

MGD

ISNS

VO

GM

TPS40100

1

2

24

23

19

20

11

SS

Reference

Select

+

Current

Mirror

RT SYNC

7 22

Oscillator

+

0.725 V

0.711 V

0.690 V

0.669 V

0.655 V

+

+

FUNCTIONAL BLOCK DIAGRAM

UVLO

5

CLK

PWM

20 kΩ

+

1.48 V

THERMSD

1.5 V

CLK

OC

1.33 V

10 µA

+

OC/SS

Controller

+

OC

FAULT

CLK

OC

FAULT

UVLO

Adaptive

Drive

Prebias

Control

Reference

Gate

and

Voltages

SLUS601–MAY 2005

15 BST

16 HDRV

17 SW

14 5VBP

13 LDRV

12 PGND

21 PG

TRKOUT

3

4TRKIN

+

6

ILIM

10

SS

9

GND

Housekeeping

8

BIAS

18 VDD

UDG−04142

7

Page 8

www.ti.com

TPS40100

SLUS601–MAY 2005

APPLICATION INFORMATION

Introduction

The TPS40100 is a synchronous buck controller targeted at applications that require sequencing and output

voltage margining features. This controller uses a current feedback mechanism to make loop compensation

easier for loads that can have wide capacitance variations. Current sensing (for both current feedback and

overcurrent) is true differential and can be done using the inductor DC resistance (with a R-C filter) or with a

separate sense resistor in series with the inductor. The overcurrent level is programmable independently from

the amount of current feedback providing greater application flexibility. Likewise, the overcurrent function has

user programmable integration to eliminate nuisance tripping and allow the user to tailor the response to

application requirements. The controller provides an integrated method to margin the output voltage to ± 3% and

± 5% of its nominal value by simply grounding one of two pins directly or through a resistance. Powergood and

clock synchronization functions are provided on dedicated pins. Users can program operating frequency and the

closed loop soft-start time by means of a resistor and capacitor to ground respectively. Output sequencing/tracking can be accomplished in one of three ways: sequential (one output comes up, then a second

comes up), ratiometric (one or more outputs reach regulation at the same time – the voltages all follow a

constant ration while starting) and simultaneous (one or more outputs track together on startup and reach

regulation in order from lowest to highest).

Programming Operating Frequency

Operating frequency is set by connecting a resistor to GND from the RT pin. The relationship is:

ȡ

RT+

where

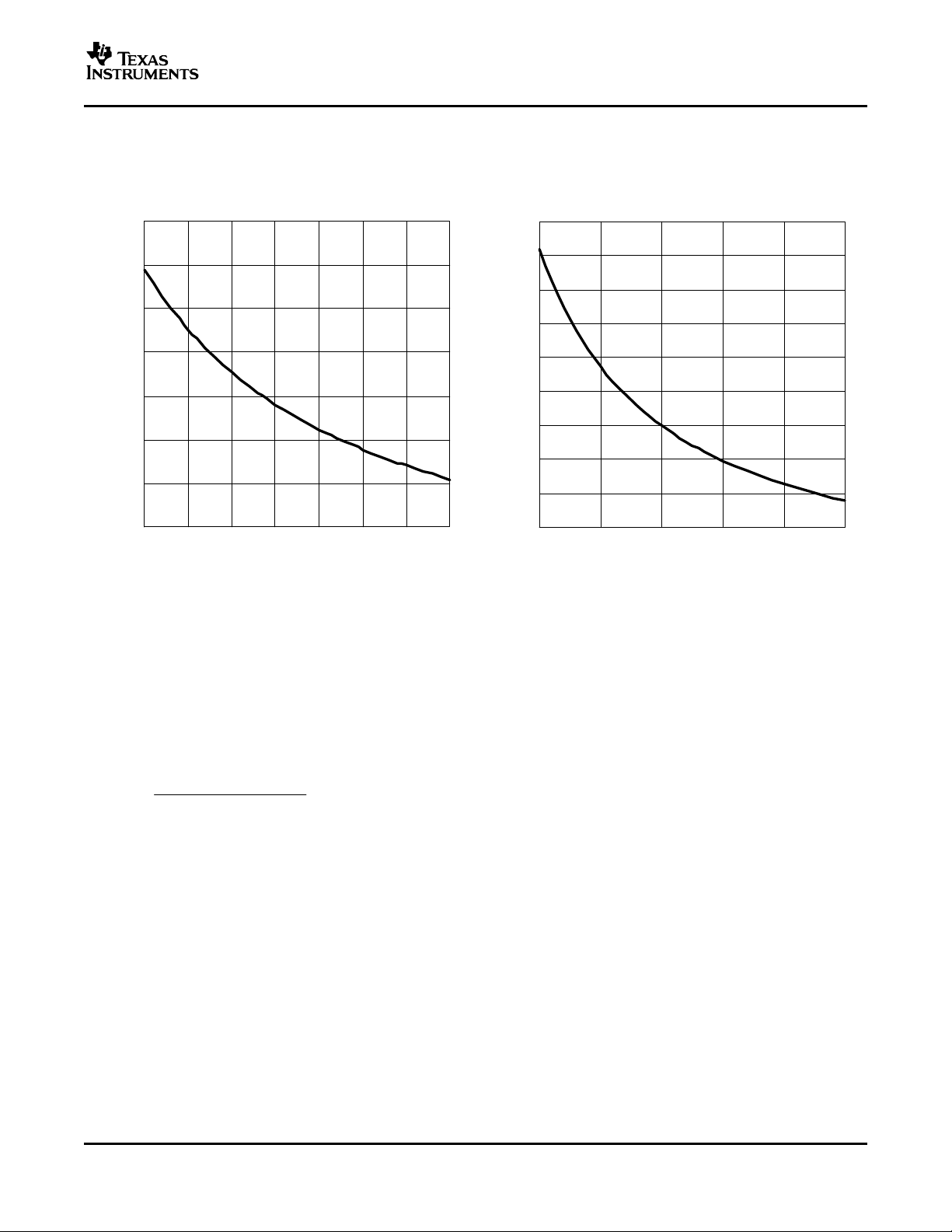

Figure 1 and Figure 2 show the relationship between the switching frequency and the RTresistor as described in

Equation 1. The scaling is different between them to allow the user a more accurate views at both high and low

frequency.

* 3.98 10

ȧ

f

Ȣ

• fSWis the switching frequency in kHz

• R

SW

is in kΩ

T

ȣ

4

2

ȧ

Ȥ

)

5.14 10

ǒ

f

SW

4

Ǔ

* 8.6 (kW)

(1)

8

Page 9

TPS40100

www.ti.com

APPLICATION INFORMATION (continued)

− Timing Resistance − kΩ

R

T

225

200

175

150

125

100

75

50

250

TIMING RESISTOR TIMING RESISTOR

SWITCHING FREQUENCY SWITCHING FREQUENCY

(250 kHz to 600 kHz) (100 kHz to 350 kHz)

350300 400 500450 600550

f

− Switching Frequency − kHz

SW

vs vs

Figure 1. Figure 2.

SLUS601–MAY 2005

550

500

450

400

350

300

250

− Timing Resistance − kΩ

T

200

R

150

100

100

150 200 250 350300

f − Switching Frequency − kHz

Selecting an Inductor Value

The inductor value determines the ripple current in the output capacitors and has an effect on the achievable

transient response. A large inductance decreases ripple current and output voltage ripple, but is physically larger

than a smaller inductance at the same current rating and limits output current slew rate more that a smaller

inductance would. A lower inductance increases ripple current and output voltage ripple, but is physically smaller

than a larger inductance at the same current rating. For most applications, a good compromise is selecting an

inductance value that gives a ripple current between 20% and 30% of the full load current of the converter. The

required inductance for a given ripple current can be found from:

L +

ǒ

VIN* V

VIN fSW DI

OUT

Ǔ

V

OUT

(H)

(2)

where

• L is the inductance value (H)

• V

is the input voltage to the converter (V)

IN

• V

• f

•∆I is the peak-to-peak ripple current in the inductor (A)

is the output voltage of the converter (V)

OUT

is the switching frequency chosen for the converter (Hz)

SW

Selecting the Output Capacitance

The required value for the output capacitance depends on the output ripple voltage requirements and the ripple

current in the inductor, as well as any load transient specifications that may exist.

The output voltage ripple depends directly on the ripple current and is affected by two parameters from the

output capacitor: total capacitance and the capacitors equivalent series resistance (ESR). The output ripple

voltage (worst case) can be found from:

9

Page 10

www.ti.com

TPS40100

SLUS601–MAY 2005

APPLICATION INFORMATION (continued)

DV + DI

ESR ) ǒ

ƪ

8 C

1

OUT

f

SW

Ǔ

(V)

ƫ

(3)

where

•∆V is the peak to peak output ripple voltage (V)

•∆I is the peak-to-peak ripple current in the inductor (A)

• f

is the switching frequency chosen for the converter (Hz)

SW

• C

• ESR is the equivalent series resistance of the capacitor, C

is the capacitance value of the output capacitor (F)

OUT

OUT

(Ω)

For electrolytic capacitors, the output ripple voltage is almost entirely (90% or more) due to the ESR of the

capacitor. When using ceramic output capacitors, the output ripple contribution from ESR is much smaller and

the capacitance value itself becomes more significant. Paralleling output capacitors to achieve a desired output

capacitance generally lowers the effective ESR more effectively than using a single larger capacitor. This

increases performance at the expense of board area.

If there are load transient requirements that must be met, the overshoot and undershoot of the output voltage

must be considered. If the load suddenly increases, the output voltage momentarily dips until the c urrent in the

inductor can ramp up to match the new load requirement. If the feedback loop is designed aggressively, this

undershoot can be minimized. For a given undershoot specification, the required output capacitance can be

found by:

C

O(under)

+

2 V

UNDER

L I

D

STEP

ǒVIN* V

MAX

2

(F)

Ǔ

OUT

(4)

where

• C

• L is the inductor value (H)

• I

STEP

• V

• D

• V

• V

is the output capacitance required to meet the undershoot specification (F)

O(under)

is the change in load current (A)

is the maximum allowable output voltage undershoot

UNDER

is the maximum duty cycle for the converter

MAX

is the input voltage

IN

is the output voltage

OUT

Similarly, if the load current suddenly goes from a high value to a low value, the output voltage overshoots. The

ouput voltage rises until the current in the inductor drops to the new load current. The required capacitance for a

given amount of overshoot can be found by:

C

O(over)

+

2 V

L I

OVER

STEP

V

2

OUT

(F)

(5)

where

• C

• L in the inductor value (H)

• I

• V

• V

The required value of output capacitance is the maximum of C

is the output capacitance required to meet the undershoot specification (F)

O(over)

is the change in load current (A)

STEP

is the maximum allowable output voltage overshoot

OVER

is the output voltage

OUT

O(under)

and C

O(over)

.

Knowing the inductor ripple current, the switching frequency, the required load step and the allowable output

voltage excursion allows calculation of the required output capacitance from a transient response perspective.

The actual value and type of output capacitance is the one that satisfies both the ripple and transient

specifications.

10

Page 11

TPS40100

www.ti.com

SLUS601–MAY 2005

APPLICATION INFORMATION (continued)

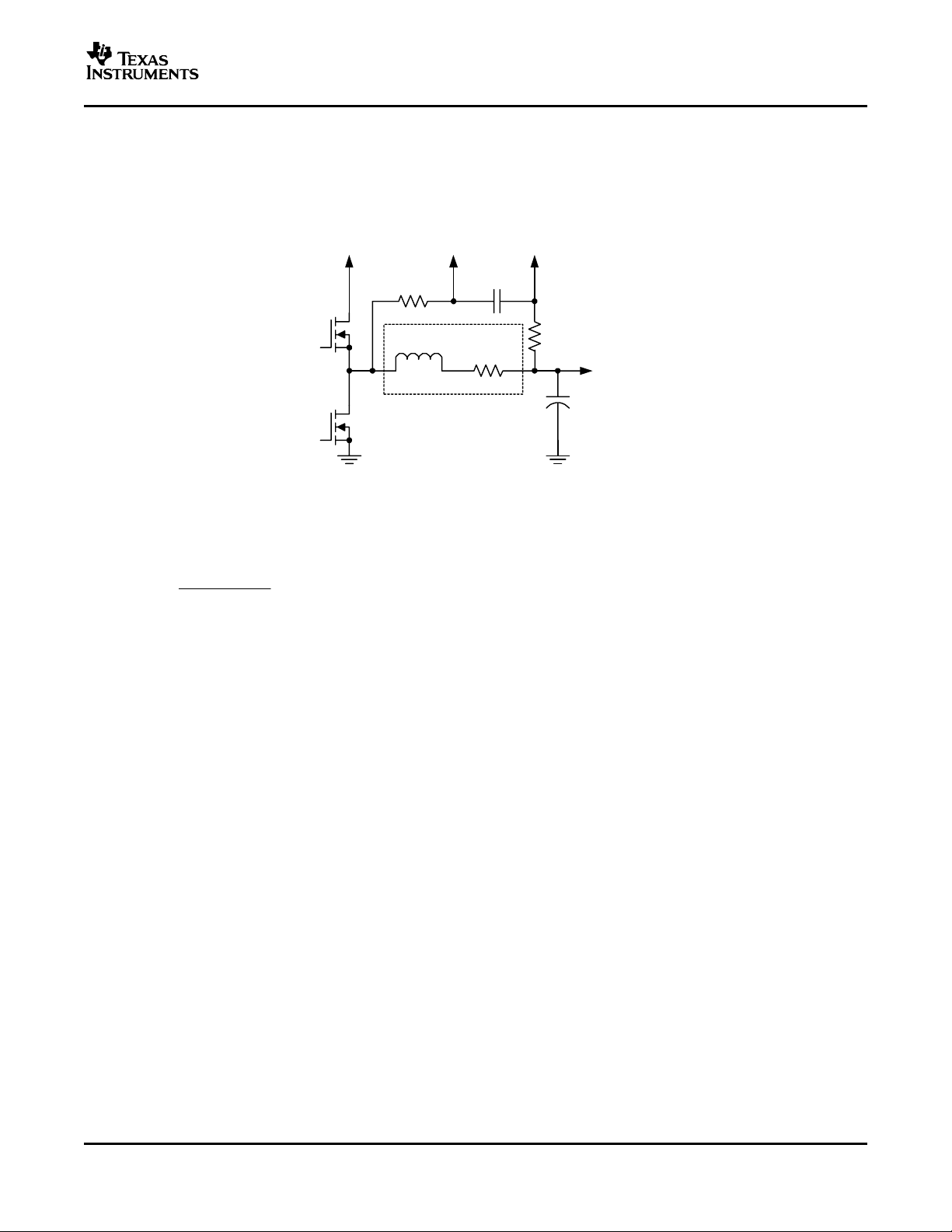

Calculating the Current Sense Filter Network

The TPS 40100 gets current feedback information by sensing the voltage across the inductor resistance, R

order to do this, a filter must be constructed that allows the sensed voltage to be representative of the actual

current in the inductor. This filter is a series R-C network connected across the inductor as shown in Figure 3.

V

IN

To ISNS pin

R

FLT

L

R

C

LDC

FLT

To VO pin

100 Ω

V

O

C

O

UDG−04150

Figure 3. Current Sensing Filter Circuit

If the R

FLT-CFLT

voltage across R

condition (100 nF is suggested). R

R

FLT

time constant is matched to the L/R

. It is recommended to keep R

+

LDC

L

R

C

LDC

* 100 (W)

FLT

can then be calculated.

FLT

time constant, the voltage across C

LDC

10 kΩ or less. C

FLT

can be arbitrarily chosen to meet this

FLT

is equal to the

FLT

where

• R

• C

• L is the output inductance (H)

• R

When laying out the board, better performance can be accomplished by locating C

is the current sense filter resistance (Ω)

FLT

is the current sense filter capacitance (F)

FLT

is the DC resistance of the output inductor (Ω)

LDC

as close as possible to the

FLT

VO and ISNS pins. The closer the two resistors can be brought to the device the better as this reduces the

length of high impedance runs that are susceptible to noise pickup. The 100-Ω resistor from V

to the VO pin

OUT

of the device is to limit current in the event that the output voltage dips below ground when a short is applied to

the output of the converter.

LDC

.In

(6)

Compensation for Inductor Resistance Change Over Temperature

The resistance in the inductor that is sensed is the resistance of the copper winding. This value changes over

temperature and has approximately a 4000 ppm/°C temperature coefficient. The gain of current sense amplifier

in the TPS40100 has a built in temperature coefficient of approximately -2000 ppm/°C. If the circuit is physically

arranged so that there is good thermal coupling between the inductor and the device, the thermal shifts tend to

offset. If the thermal coupling is perfect, the net temperature coefficient is 2000 ppm/°C. If the coupling is not

perfect, the net temperature coefficient lies between 2000 ppm/°C and 4000 ppm/°C. For most applications this is

sufficient. If desired, the temperature drifts can be compensated for. The following compensation scheme

assumes that the temperature rise at the device is directly proportional to the temperature rise at the inductor. If

this is not the case, compensation accuracy suffers. Also, there is generally a time lag in the temperature rise at

the device vs. at the inductor that could introduce transient errors beyond those predicted by the compensation.

Also, the 100-Ω resistor in Figure 3 is not shown. However, it is required if the output voltage can dip below

ground during fault conditions. The calculations are not afffected, other than increasing the effective value of R

by 100-Ω.

F1

11

Page 12

www.ti.com

TPS40100

SLUS601–MAY 2005

APPLICATION INFORMATION (continued)

The relative resistance change in the inductor is given by:

R

+ 1 ) TCL ǒTL* T

REL(L)

where

• R

• TCLis the temperature coefficient of copper, 4000 ppm/°C or 0.004

• T

• T

is the relative resistance of the inductor at TLcompared to the resistance at T

REL(L)

is the inductor copper temperature (°C)

L

is the reference temperature, typically lowest ambient (°C)

BASE

The relative gain of the current sense amplifier is given by a similar equation:

gm

+ 1 ) TCGM ǒTIC* T

(REL)

where

• gm

• TCGMis the temperature coefficient of the amplifier gain, -2000 ppm/°C or -0.002

• T

• T

is the relative gain of the amplifier at TICcompared to the gain at T

REL

is the device junction temperature (°C)

IC

is the reference temperature, typically lowest ambient (°C)

BASE

The temperature rise of the device can usually be related to the temperature rise of the inductor. The relationship

between the two temperature rises can be approximated as a linear relationship in most cases:

TIC* T

BASE

+ǒTL* T

BASE

where

• TICis the device junction temperature (°C)

• T

• T

• k

is the reference temperature, typically lowest ambient (°C)

BASE

is the inductor copper temperature (°C)

L

is the constant that relates device temperature rise to the inductor temperature rise and must be

THM

determined experimentally for any given design

BASE

Ǔ

k

Ǔ

(dimensionless)

Ǔ

BASE

THM

(dimensionless)

(7)

BASE

(8)

BASE

(9)

With these assumptions, the effective inductor resistance over temperature is:

R

REL(eff)

R

REL(eff)

+ R

REL(L)

gm

+ƪ1 ) TC

REL

ǒ

TL* T

L

is the relative effective resistance that must be compensated for when doing the compensation. The

BASE

Ǔƫ

ƪ1 ) k

TCGM ǒTL* T

THM

BASE

Ǔƫ

(dimensionless)

circuit of Figure 4 shows a method of compensating for thermal shifts in current limit. The NTC thermistor (R

must be well coupled to the inductor. C

should be located as close to the device as possible.

FLT

(10)

NTC

)

12

Page 13

TPS40100

www.ti.com

APPLICATION INFORMATION (continued)

ILIM

6

R

ILIM

+

−2000 ppm/°C

V

IN

VO

20

ISNS

19

R

SLUS601–MAY 2005

R

THE

R

F3

R

F2

R

NTC

C

F1

L

FLT

R

LDG

V

OUT

C

OUT

UDG−04148

Figure 4. Compensation for Temperature Coefficient of the Inductor Resistance

The first step is to determine an attenuation ratio α. This ratio should be near to 1 but not too close. I f it is too

close to 1, the circuit requires large impedances and thermistor values too high. If α is too low, the current signal

is attenuated unnecessarily. A suggested value is 0.8.

R

a ^ 0.8

R

is the equivalent resistance of the RF2-RF3-R

THE

R

+ RF2)

THE

The base temperature (T

THE

R

) R

THE

RF3 R

RF3) R

(dimensionless)

F1

network:

NTC

NTC

(W)

NTC

) should be selected to be the lowest temperature of interest for the thermal

BASE

(11)

(12)

matching – the lowest ambient expected. The resistance of the inductor at this base temperature should be used

to calculate effective resistance. The expected current sense amplifier gain at T

calculating over current components (R

ILIM

).

should be used for

BASE

The next step is to decide at what two temperatures the compensation is matched to the response of the

deviceand inductor copper, T1 and T2. Once these are chosen, an NTC thermistor can be chosen and its value

found from its data sheet at these two temperatures: R

NTC(T1)

and R

. The component values in the network

NTC(T2)

can be calculated using the following equations:

13

Page 14

www.ti.com

TPS40100

SLUS601–MAY 2005

APPLICATION INFORMATION (continued)

LDC(Tbase)

LDC(Tbase)

a R

R

LDC(T1)

a R

R

LDC(T2)

NTC(T1)

THE(T1)

) R

R

L

FLT

LDC(Tbase)

* a R

LDC(Tbase)

* a R

* R

* R

NTC(T2)

NTC(T2)

a

R

R

NTC(T2)

THE(T2)

(W)

(W2)

(W)

REL(effT1)

REL(effT2)

R

LDC(Tbase)

R

LDC(Tbase)

(W)

(W)

F1

F1

(dimensionless)

(W)

(W)

Ǹ

2a

ǒRF3) R

is the value of the current sense filter capacitor (F)

is the DC resistance of the inductor at temperature T

(W)

Ǔ

NTC(T1)

RF3) R

are the equivalent resistances of the R

are the inductor resistances at temperatures T1 and T2

, are the relative resistances of the inductor at T1 and T2 vs. Tbase

are the effective resistance of the NTC thermistor at temperatures T1 and T2

* RF3 R

NTC(T1)

RF1+

R

R

R

R

LDC(T1)

LDC(T2)

THE(T1)

THE(T2)

R

LDC(Tbase) C

+ R

+ R

+

+

R

a + 1 *

b + R

c + R

RF3+

RF2+

R

NTC(T1)

NTC(T1)

* b " b2* 4ac

R

THE(T1)

where

• L is the value of the output inductance (H)

• C

FLT

•αis the attenuation ratio chosen from Equation 11

• R

THE(T1),RTHE(T2)

• R

LDC(Tbase)

• R

LDC(T1),RLDC(T2)

• R

REL(effT1),RREL(effT2)

• R

NCT(T1),RNTC(T2)

NTC(T1)

(W)

network at temperatures T1 and T2

THE

in Ω

BASE

(13)

(14)

(15)

(16)

(17)

(18)

(19)

(20)

(21)

(22)

Establishing Current Feedback

The amount of current feedback in a given application is programmable by the user. The amount of current

feedback used is intended to be just enough to reduce the Q of the output filter double pole. This allows design

of a converter control loop that is stable for a very wide range of output capacitance. Setting the current feedback

higher offers little real benefit and can actually degrade load transient response, as well as introduce pulse

skipping in the converter. The current feedback is adjusted by setting the gain of the current sense amplifier. The

amplifier is a transconductance type and its gain is a set by connecting a resistor from the GM pin to GND:

RGM+

43.443 gm

2

) 0.01543 gm

CSA

where

• RGMis the resistor that sets the gain of the amplifier (Ω)

• gm

is the gain of the current sense amplifier (S)

CSA

The value of the sense amplifier gain should be less than 1000 µS, and more than 250 µS, with the resulting

gain setting resistor greater than 50 kΩ. As a suggested starting point, set the gain of the current sense amplifier

to a nominal 280 µS with RGM of 279 kΩ. This value should accommodate most applications adequately.

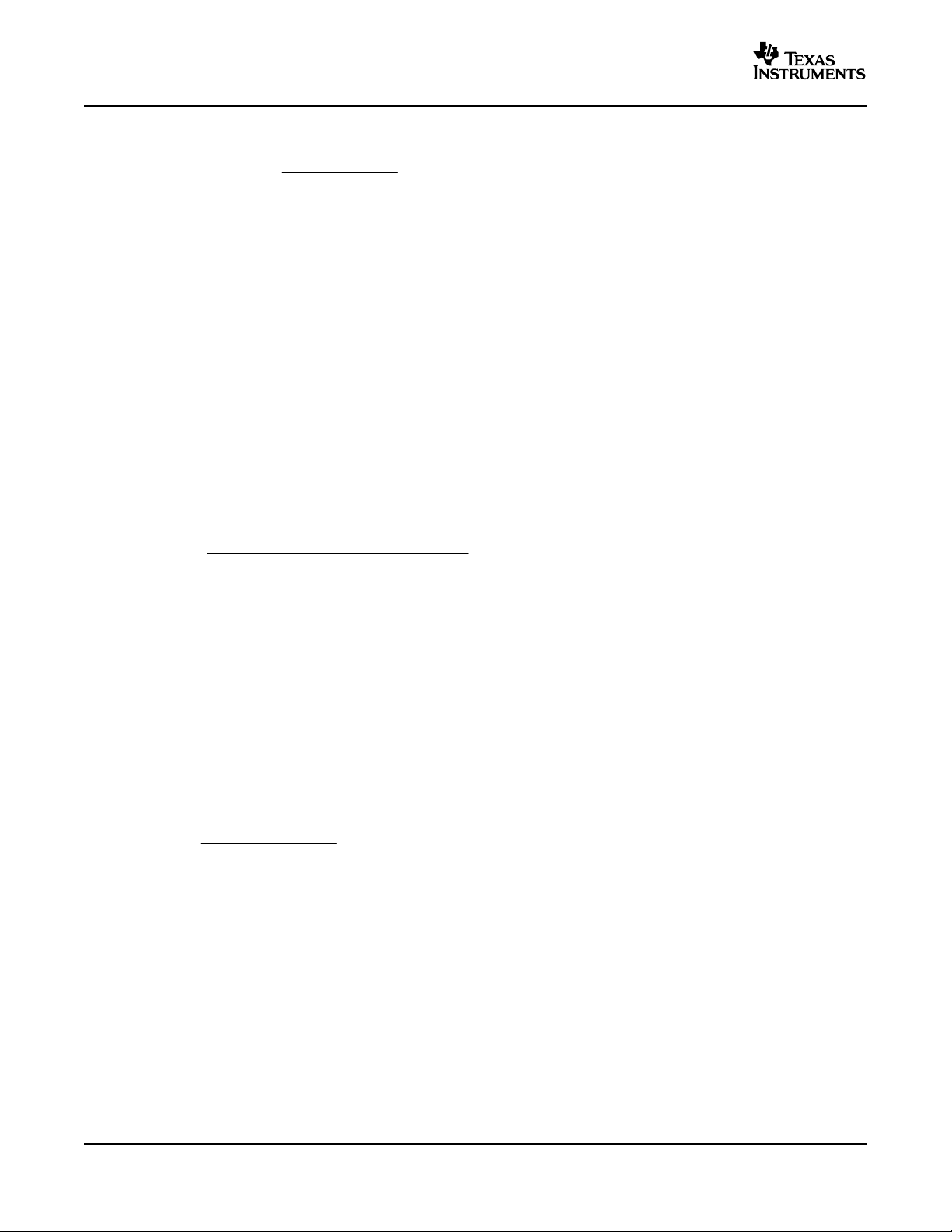

Figure 5 shows the current sense amplifier gain setting resistance vs. the sense amplifier gain.

14

3

) 3.225 10

CSA

*6

(W)

(23)

Page 15

TPS40100

www.ti.com

APPLICATION INFORMATION (continued)

CURRENT SENSE AMPLIFIER GAIN SETTING RESISTANCE

CURRENT SENSE AMPLIFIER GAIN

75

25

250 400 700550 1000850

gm − Sense Amplifier Transconductance − µS

− Gain Setting Resistance − kΩ

R

325

275

225

175

125

GM

SLUS601–MAY 2005

vs

Figure 5.

Control to Output Gain of the Converter

A model that gives a good first order approximation to the control to output gain of a converter based on the

TPS40100 controller is shown in Figure 6. This model can be used in conjunction with a simulator to generate ac

and transient response plots. The block labeled “X2” is a simple gain of 2. The amplifier gm can be a simple

voltage controlled current source with a gain equal to the selected gm for the current sense amplifier (CSA).

Analytically, the control to output gain of this model ( Figure 6) can be expressed as follows:

KCO(s) +

K

(s) is the output filter transfer function:

FILT

K

(s) =

FILT

R

LOAD

R

) R

LDC

VIN K

1 ) Y(s) KCS K

LOAD

L C

R

(dimensionless)

Usually, R

K

FILT

LDC

(s) +

<< R

L C

and the following approximation holds:

LOAD

OUT

Y(s) is the current signal transfer function and assumes that the inductor intrinsic time constant is matched to the

current sense filter network time constant.

K

PWM

PWM

OUT)RLOAD

LDC)RLOAD

s2)

ƪ

(s)

FILT

V

s2)

R

ESR

L)R

LOAD COUT

(dimensionless)

IN

L)C

C

OUT

R

R

ESR

ǒR

OUT

s ) 1

ǒR

LOAD

C

LOAD RESR)RLDC RLOAD)RLDC RESR

ESR)RLDC

OUT

s ) 1

R

LOAD

Ǔ

ƫ

s ) 1

(24)

Ǔ

s ) 1

(25)

(26)

15

Page 16

www.ti.com

TPS40100

SLUS601–MAY 2005

APPLICATION INFORMATION (continued)

Y(s) +

1 * K

L

R

LDC

KCSis the gain of the current sense amplifier in the current feedback loop:

KCS+ gm

CSA

where (for Equation 24 through Equation 28)

• VINis the input voltage (V)

• K

PWM

• R

LOAD

• R

LDC

• L is the output filter inductance (H)

• C

OUT

• R

ESR

• gm

CSA

• 20 kΩ is the impedance the current sense amplifier works against (from block diagram)

A computer aided math tool is highly recommended for use in evaluating these equations.

(s)

FILT

(dimensionless)

s ) 1

20 kW (dimensionless)

is the gain of the pulse width modulator and is equal to 2

is the equivalent load resistance (Ω)

is the DC inductor resistance (Ω)

is the output filter capacitance (F)

is the equivalent series resistance of the output filter capacitor (Ω)

is the gain of the current sense amplifier (S)

(27)

(28)

L

R

LDC

V

IN

+

X2

R

EA

20 kΩ

gm

CSA

+

R

COMP

2

R

ISNS

FLT

C

FLT

VO

C

1

C

2

FB

+

+

690 mV

R

C

OUT

R

ESR

R

BIAS

1

V

X

V

OUT

R

LOAD

1 V AC

UDG−04149

Figure 6. Averaged Model for a Converter Based on the TPS40100

Compensating the Loop (Type II)

The first step is to select a target loop crossover frequency. Choosing the crossover frequency too high

contributes to making the converter pulse skip. A balance of crossover frequency and amount of current

feedback must be maintained to avoid pulse skipping. A suggested maximum loop crossover frequency is one

fifth-of the switching frequency.

f

SW

fCv

where

• fCis the loop crossover frequency

• f

(Hz)

5

is the switching frequency

SW

(29)

16

Page 17

TPS40100

www.ti.com

SLUS601–MAY 2005

APPLICATION INFORMATION (continued)

Using either the analytical model or the simulated model, determine the control to output gain at the chosen loop

crossover frequency. The gain of the compensator is the reciprocal of this gain:

K

COMP(co)

where

• K

COMP(CO)

• K

CO(fC

If simulating the response using the model, the control to output gain is VX/V

over the range of interest and plot VX/V

Depending on the chosen loop crossover frequency and the characteristics of the output capacitor, either a Type

II or a Type III compensator could be required. If the output capacitance has sufficient ESR, phase shift from the

ESR zero may by used to eliminate the need for a Type III compensator. The model in Figure 6 uses a Type II

compensator. In this case the compensator response looks like Figure 7.

1

+

Ť

KCO(fc)

(Hz)

Ť

is the required compensator gain at the crossover frequency

) is the value of the control to output transfer function at the crossover frequency

. Sweep the AC voltage source

OUT

OUT

.

COMPENSATOR GAIN

vs

FREQUENCY

(30)

K

COMP(co)

Gain − dB

f

Z

f − Frequency − kHz

f

C

Figure 7.

f

P

First select R1. The choice is somewhat arbitrary but affects the rest of the components once chosen. The

suggested value is 10 kΩ.

R

is found from the gain required from the compensator at the crossover frequency.

2

R2+ KLF R1(W)

(31)

It is generally recommended to place the pole frequency one decade above the crossover frequency and the

zero frequency one decade below the crossover frequency.

17

Page 18

www.ti.com

TPS40100

SLUS601–MAY 2005

APPLICATION INFORMATION (continued)

fP+ fC 10 +

f

C

fZ+

10

+

2 p R2 C

2 p R

Compensating the Loop (Type III)

If the output capacitor does not have sufficient ESR to use the phase shift from the ESR zero, a Type III

compensator is required. This is the case for most designs with ceramic output capacitors only. A series R-C

circuit is added in parallel to R1as shown in Figure 8.

This is the same compensator as in Figure 6 except for the addition of C3and R3. A typical response of this

circuit is shown in Figure 9.

1

1

C

2

2

1

(Hz)

(Hz)

(32)

(33)

Gain − dB

COMPENSATOR GAIN

K

COMP(co)

K

LF

f

Z

f − Frequency − kHz

vs

FREQUENCY

R

BIAS

C

3

R

1

C

1

C

2

K

HF

f

Z3

Figure 9. Figure 8. Type III Compensator Schematic

f

f

C

f

P3

P

COMP

Error Amplifier

R

2

FB

+

R

3

VX

UDG−04143

The reason for using the Type III compensator is to take advantage of the phase lead associated with the

upward slope of the gain between f

and fP3. The crossover frequency should be located between these two

Z3

frequencies. The amount of phase lead generated is dependent on the separation of the fZ3and fP3. In general, if

f

is one half of fCand fP3is twice fC, the amount of phase lead at fCgenerated is sufficient for most applications.

Z3

Certainly more or less may be used depending on the situation.

As an example of selecting the extra required extra phase lead, suppose that the control to output gain phase

evaluates to -145° at fC. The Type II compensator has approximately 11.5° of phase lag at fCdue to the origin

pole, the zero at f

/10 and the pole at 10xfC. This would give only 23.5° of phase margin, which while stable is

C

not ideal. Placing fZ3and fP3at one half and twice the crossover frequency respectively adds approximately 36°

of phase lead at f

for a new phase margin of 59.5°.

C

To calculate the values for this type of compensator, first select R1. Again the choice is somewhat arbitrary. 10

kΩ is a suggested value.

18

Page 19

TPS40100

www.ti.com

SLUS601–MAY 2005

APPLICATION INFORMATION (continued)

Select the required extra phase lead beyond the Type II compensation to obtain the required phase margin and

calculate the required multiple for the additional pole and zero:

K3+ tanǒQ

LEAD

Ǔ

) tanǒQ

where

•Θ

• K

is the required extra phase lead to be generated by the addition of the extra pole and zero

LEAD

is the multiplier applied to fCto get the new pole and zero locations

3

The locations of fZ3and fP3are:

f

fZ3+

C

(Hz)

K

3

fP3+ fC K3(Hz)

where

• K3is the multiplier applied to fCto get the new pole and zero locations

• f

is the zero created by the addition of R3and C

Z3

• fP3is the pole created by the addition of R3and C

The required gain, K

COMP(co)

, from the compensator at fC, is the same as for the Type II compensation, found in

Equation 30. The gain KLF(see Figure 9) is found by:

K

KLF+

COMP(co)

K

3

(dimensionless)

R2can then be found:

R2+ KLF R1(W)

The high-frequency gain is:

KHF+ K

COMP(co)

K3(dimensionless)

Ǔ

) 1Ǹ(dimensionless)

LEAD

(34)

(35)

(36)

3

3

(37)

(38)

(39)

Now:

R3+

KHF R1* R

C3+

2 p R3 f

R1 R

2

1

P3

(W)

2

(40)

(F)

(41)

The remaining pole and zero are located a decade above and below fCas before. Equation 31 and Equation 32

canbeusedtosolveforC1and C2as before.

19

Page 20

www.ti.com

TPS40100

SLUS601–MAY 2005

APPLICATION INFORMATION (continued)

Establishing Tracking and Designing a Tracking Control Loop

The tracking startup feature of the TPS40100 is a separate control loop that controls the output voltage to a

reference applied to the TRKIN pin. This reference voltage is typically a ramp generated by an external R-C

circuit. Connecting the junction of R5, C5 and R6 (see Figure 10) of multiple converters together allows the

converters output voltages to track together during start up. A controlled power down is accomplished by pulling

down the common junction in a controlled manner and then removing power to the converters or turning them off

by grounding the UVLO pin.The relevant circuit fragment is shown in Figure 10.

V

OUT

A

R

3

R

1

V

IN

R

6

R

C

5

VO

20

TRKIN

5

4

TRKOUT

+

C

4

3

C

3

R

D

4

1

R

A

BIAS

C

2

FB

2

690 mV

C

1

R

2

COMP

+

1

To PWM

UDG−04145

Figure 10. Tracking Loop Control Schematic

First, select a value for R4. In order for this circuit to work properly, the output of the tracking amplifier must be

able to cause the FB pin to reach at least 690 mV with the output voltage at zero volts. This is so that the output

voltage can be forced to zero by the tracking amplifier. This places a maximum value on R4:

R4t

ƪ

V

HTRKOUT(min)

* V

V

FB

DIODE

* V

FB

ƫ

R1 R

R1) R

BIAS

BIAS

W

(42)

where

• V

HTRKOUT(min)

• V

DIODE

• VFBis the value of the reference voltage (690 mV)

is the minimum output voltage of the tracking amplifier (see Electrical Characteristics table)

is the forward voltage of the device selected for D

1

R4should not be chosen much lower than this value since that unnecessarily increases tracking loop gain,

making compensation more difficult and opening the door to potential non-linear control issues. D1 could be a

schottky if the impedance of the R

1-RBIAS

string is low enough that the leakage current is not a consequence. Be

aware that schottky diode leakage currents rise significantly at elevated temperature. If elevated temperature

operation and increased accuracy are important, use a standard or low leakage junction diode or the

base-emitter junction of a transistor for D1.

Once R4is selected, the gain of the closed loop power supply looking into “A” is known. That gain is the ratio of

R1and R4:

dV

dV

OUT

TRKOUT

+*

R

1

(dimensionless)

R

4

(43)

The tracking loop itself should have a crossover frequency much less that the crossover frequency of the voltage

control loop. Typically, the tracking loop crossover frequency is 1/10th or less of the voltage loop crossover

frequency to avoid loop interactions. Note that the presence of the diode in the circuit gives a non-linear control

mechanism for the tracking loop. The presence of this non-linearity makes designing a control loop more

challenging. The simplest approach is to simply limit the bandwidth of this loop to no more than necessary.

20

Page 21

TPS40100

www.ti.com

SLUS601–MAY 2005

APPLICATION INFORMATION (continued)

Knowing the gain of the voltage loop looking into R4and the desired tracking loop crossover frequency, R5and

C4can be found:

R

R5 C4+

2 p R1 f

where

• f

is the desired tracking loop crossover frequency

CTRK

The actual values of R5and C4are a balance between impedance level and component size. Any of a range of

values is applicable. In general, R5should be no more than 20% of R6, and less than 10 kΩ. If this is done, then

R6can safely be ignored for purposes of tracking loop gain calculations. For general usage, R6should probably

be between 100 kΩ and 500 kΩ.

If an overshoot bump is present on the output at the beginning a tracking controlled startup, the tracking loop

bandwidth is likely too high. Reducing the bandwidth helps reduce the initial overshoot. See Figure 11 and

Figure 12.

4

cTRK

(s)

(44)

(200 mV/div)

t − Time − 1 ms/div

Figure 11. Excessive Tracking Loop Bandwidth Figure 12. Limited Tracking Loop Bandwidth

The tracking ramp time is the time required for C5to charge to the same voltage as the output voltage of the

converter.

V

OUT

t

+*R6 C5 lnǒ1 *

TRK

Ǔ

V

(s)

IN

(45)

where

• V

• V

• t

is the output voltage of the converter

OUT

is the voltage applied to the top of R

IN

is the desired tracking ramp time

TRK

6

With these equations, it is possible to design the tracking loop so that the impedance level of the loop and the

component size are balanced for the particular application. Note that higher impedances make the loop more

susceptible to noise issues while lower impedances require increased capacitor size.

Figure 13 shows the spice model for the voltage loop expanded for use with the tracking loop.

21

Page 22

www.ti.com

TPS40100

SLUS601–MAY 2005

APPLICATION INFORMATION (continued)

V

+

IN

X2

gm

CSA

ISNS

+

R

C

SFLT

1

L

R

C

LDC

SFLT

R

C

OUT

CESR

R

V

OUT

LOAD

R

EA

20 kΩ

R

R

3

BIAS

R

C

2

2

+

+

R

4

C4

C

3

R

1

V

X

+

R

5

+

UDG−04147

Figure 13. AC Behavioral Model for Tracking Control Loop

To use the model, the AC voltage source is swept over the frequency range of interest. The open loop ac

response is VX/V

OUT

.

Programming Soft-Start Time

The soft-start time of the TPS40100 is fully user programmable by selecting a single capacitor. The SS pin

sources 20 µA to charge this capacitor. The actual output ramp-up time is the amount of time that it takes for the

20 µA to charge the capacitor through a 690 mV range. There is some initial lag due to an offset from the actual

SS pin voltage to the voltage applied to the error amplifier. See Figure 15. The soft-start is done in a closed loop

fashion, meaning that the error amplifier controls the output voltage at all times during the soft start period and

the feedback loop is never open as occurs in duty cycle limit soft-start schemes. The error amplifier has two

non-inverting inputs, one connected to the 690 mV reference voltage, and one connected to the offset SS pin

voltage. The lower of these two voltages is what the error amplifier controls the FB pin to. As the voltage on the

SS pin ramps up past approximately 1.04 V (resulting in 690 mV at the SS “+” input – See Figure 15), the 690

mV reference voltage becomes the dominant input and the converter has reached its final regulation voltage.

The capacitor required for a given soft-start ramp time for the output voltage is given by:

CSS+ TSS

where

• TSSis the desired soft-start ramp time (s)

• C

• V

20 mA

is the required capacitance on the SS pin (F)

SS

is the reference voltage feedback loop (690 mV)

FB

F

V

FB

(46)

22

Page 23

TPS40100

www.ti.com

APPLICATION INFORMATION (continued)

COMP

1

FB

2

SS

10

C

SS

Figure 14. Error Amplifier and Soft-Start Functional Diagram

20 µA

350 mV

+

5 µA

690 mV

+

+

Error Amplifier

SLUS601–MAY 2005

COMP

CHARGE

From UVLO circuits,

Fault controller

UDG−04138

UVLO

(Internal Logic State)

4.8 V

3.5 V

1.04 V

0.35 V

SS

Tss

Tss Delay

VOUT

PDG

Figure 15. Relationship Between UVLO (Internal Logic State), SS, VOUT and PGD at Startup

Interaction Between Soft-Start and Tracking Startup

Since the TPS40100 provides two means of controlling the startup (closed loop soft-start and tracking) care must

be taken to ensure that the two methods do not interfere with each other. The two methods should not be

allowed to try and control the output at the same time. If tracking is to be used, the reference input to the tracking

amplifier (TRKIN) should be held low until soft-start completes, or the voltage at the SS pin is at least above 1.04

V. This ensures that the soft-start circuit is not trying to control the startup at the same time as tracking circuit. If

it is desired to have soft-start control the startup, then there are two options:

23

Page 24

www.ti.com

TPS40100

SLUS601–MAY 2005

APPLICATION INFORMATION (continued)

• Disconnect the tracking amplifier output from the FB node (this is the recommended solution. The tracking

amplifier can then be used for other system purposes if desired)

• Maintain the tracking amplifier output connection to the FB circuit - the reference to the tracking amplifier

should be tied to VDD pin in this case. This places the tracking amplifier output (TRKOUT) in a low state

continuously and therefore removes any influence the tracking circuit has on the converter startup.

Additionally, when tracking is allowed to control the startup, soft-start should not be set to an arbitrarily short

time. This causes the output voltage to bump up when power is applied to the converter as soft-start ramps up

quickly and the tracking loop (which is necessarily low bandwidth) cannot respond fast enough to control the

output to zero voltage. In other words, the soft start ramp rate must be within the capability of the tracking loop to

override.

Overcurrent Protection

Overcurrent characteristics are determined by connecting a parallel R-C network from the ILIM pin to GND. The

ILIM pin sources a current that is proportional to the current sense amplifier transconductance and the voltage

between ISNS and VO. This current produces a voltage on the R-C network at ILIM. If the voltage at the ILIM pin

reaches 1.48 V, an overcurrent condition is declared and the outputs stop switching for a period of time. This

time period is determined by the time is takes to discharge the soft-start capacitor with a controlled current sink.

To set the overcurrent level:

V

R

+

ILIM

gm

CSA

where

• V

ILIM

• I

is the overcurrent level to be set

OC

• gm

CSA

• R

LDC

• R

ILIM

The response time of the overcurrent circuit is determined by the R-C time constant at the ILIM pin and the level

of the overcurrent. The response time is given by:

tOC+*R

ILIM

where

• tOCis the response time before declaring an overcurrent

• R

ILIM

• n is the multiplier of the overcurrent. If the overcurrent is 2 times the programmed level, then n is 2.

ILIM

R

is the overcurrent comparator threshold (1.48 V typically)

is the transconductance of the current sensing amplifier

is the equivalent series resistance of the inductor (or the sense resistor value)

is the value of the resistor from ILIM to GND

C

(Ω) and C

I

LDC

lnǒ1 *

ILIM

(F) are the components connected to the ILIM pin

ILIM

OC

W

1

Ǔ

(s)

n

(47)

(48)

By suitable manipulation of the time constant at ILIM, the overcurrent response can be tailored to ride out short

term transients and still provide protection for overloads and short circuits. The gm of the current sense amplifier

has a temperature coefficient of approximately -2000 ppm/°C. This is to help offset the temperature coefficient of

resistance of the copper in the inductor, about +4000 ppm/°C. The net is a +2000 ppm/°C temperature

coefficient. So, for a 100°C increase in temperature, the overcurrent threshold decreases by 20%, assuming

good thermal coupling between the controller and the inductor. Temperature compensation can be done as

described earlier if desired.

When an overcurrent condition is declared, the controller stops switching and turns off both the high-side

MOSFET and the low-side MOSFET. The soft-start capacitor is then discharged at 25% of the charge rate during

an overcurrent condition and the converter remains idle until the soft start pin reaches 200 mV, at which point the

soft-start circuit starts charging again and the converter attempts to restart. In normal operation, the soft-start

capacitor is charged to approximately 3.5 V when an initial fault is applied to the output. This means that the

minimum time before the first restart attempt is:

24

Page 25

TPS40100

www.ti.com

SLUS601–MAY 2005

APPLICATION INFORMATION (continued)

t

RESTART

+

where

3.3 C

• t

RESTART

• C

• I

is soft start capacitance (F)

SS

is the soft start discharge current – 5 µA

SSDIS

If the output fault is persistent, and an overcurrent is declared on the restart, both of the MOSFETs are turned off

and the soft-start capacitor continues to charge to 3.5 V and then discharge to 200 mV before another restart is

attempted.

SS

I

SSDIS

(s)

is the initial restart time (s)

(49)

UVLO Programming

The TPS40100 provides the user with programmable UVLO level and programmable hysteresis. The UVLO

detection circuit schematic is described in Figure 16 from a functional perspective.

R

1

UVLO 1.33 V

5

R

2

10 µA

+

UVLO

TPS40100

UDG−04139

Figure 16. UVLO Circuit Functional Diagram

To program this circuit, first select the amount of hysteresis (the difference between the startup voltage and the

shutdown voltage) desired:

V

R1+

HYST

I

UVLO

W

(50)

Then select the turn-on voltage and solve for R2.

R2+

V

VON* V

UVLO

UVLO

R

1

* R1 I

UVLO

W

(51)

where

• V

• I

• V

is the desired level of hysteresis in the programmable UVLO circuit

HYST

is the undervoltage lockout circuit hysteresis current (10 µA typ)

UVLO

is the UVLO comparator threshold voltage (1.33 V typ)

UVLO

25

Page 26

www.ti.com

TPS40100

SLUS601–MAY 2005

APPLICATION INFORMATION (continued)

Voltage Margining

The TPS40100 allows the user to make the output voltage temporarily be 3% above or below the nominal output,

or 5% above or below the nominal output. This is accomplished by connecting the MGU or MGD pins to GND

directly or through a resistance. See Table 1.

Table 1. Output Voltage Margining States

RESISTANCE TO GND (kΩ)

R

MGU

OPEN OPEN Nominal

<10 OPEN +5%

OPEN < 10 -5%

25 to 37 OPEN +3%

OPEN 25 to 37 -3%

R

MGD

There are some important considerations when adjusting the output voltage.

• Only one of these pins should be anything other than an open circuit at any given time. States not listed in

the table are invalid states and the behavior of the circuit may be erratic if this is tried.

• When changing the output voltage using the margin pins, it is very important to let the margin transition

complete before altering the state of the margin pins again.

• Do not use mechanical means (switches, non-wetted relay contacts, etc) to alter the margining state. The

contact bounce causes erratic behavior.

OUTPUT VOLTAGE

Synchronization

The TPS40100 may be synchronized to an external clock source that is faster than the free running frequency of

the circuit. The SYNC pin is a rising edge sensitive trigger to the oscillator that causes the current cycle to

terminate and starts the next switching cycle. It is recommended that the synchronization frequency be no more

than 120% of the free running frequency. Following this guideline leads to fewer noise and jitter problems with

the pulse width modulator in the device. The circuit can be synchronized to higher multiples of the free running

frequency, but be aware that this results in a proportional decrease in the amplitude of the ramp from the

oscillator applied to the PWM, leading to increased noise sensitivity and increased PWM gain, possibly affecting

control loop stability.

The pulse applied to the SYNC pin can be any duty ratio as long as the pulse either high or low is at least 100 ns

wide. Levels are logic compatible with any voltage under 1 V considered a low and any voltage over 2 V

considered a high.

Power Good Indication

The PGD pin is an open drain output that actively pulls to GND if any of the following conditions are met

(assuming that the input voltage is above 4.5V)

• Soft-start is active (VSS<3.5V)

• Tracking is active (V

TRKOUT

• VFB<0.61V

• VFB>0.77V

• V

UVLO

<1.33V

• Overcurrent condition exists

• Die temperature is greater than 165°C

A short filter (20 µs) must be overcome before PGD pulls to GND from a high state to allow for short transient

conditions and noise and not indicate a power NOT good condition.

The PGD pin attempts to pull low in the absence of input power. If the VDD pin is open circuited, the voltage on

PGD typically behaves as shown in Figure 17.

>0.7V)

26

Page 27

TPS40100

www.ti.com

POWERGOOD VOLTAGE

vs

2.5

2.0

1.5

1.0

− Powergood Voltage − V

PGD

0.5

V

0

012345

POWERGOOD CURRENT

V

= 0 V

VDD

I

− Powergood Current − mA

PGD

Figure 17.

SLUS601–MAY 2005

Pre-Bias Operation

Some applications require that the converter not sink current during startup if a pre-existing voltage exists at the

output. Since synchronous buck converters inherently sink current some method of overcoming this characteristic

must be employed. Applications that require this operation are typically power rails for a multiple supply

processor or ASIC. The method used in this controller, is to not allow the low side or rectifier FET to turn on until

there the output voltage commanded by the start up ramp is higher than the pre-existing output voltage. This is

detected by monitoring the internal pulse width modulator (PWM) for its first output pulse. Since this controller

uses a closed loop startup, the first output pulse from the PWM does not occur until the output voltage is

commanded to be higher than the pre-existing voltage. This effectively limits the controller to sourcing current

only during the startup sequence. If the pre-existing voltage is higher that the intended regulation point for the

output of the converter, the converter starts and sinks current when the soft-start time has completed.

Remote Sense

The TPS 40100 is capable of remotely sensing the load voltage to improve load regulation. This is accomplished

by connecting the GND pin of the device and the feedback voltage divider as near to the load as possible.

CAUTION:

Long distance runs for the GND pin will cause erratic controller behavior.

This begins to appear as increased pulse width jitter. As a starting point, the GND pin connection should be no

further than six inches from the PGND connection. The actual distance that starts causing erratic behavior is

application and layout dependent and must be evaluated on an individual basis. If the controller exhibits output

pulse jitter in excess of 25 ns and the GND pin is tied to the load ground, connecting the GND pin closer to the

PGND pin (and thereby sacrificing some load regulation) may improve performance. In either case, connecting

the feedback voltage divider at the point of load should not cause any problems. For layout, the voltage divider

components should be close to the device and a trace can be run from there to the load point.

27

Page 28

www.ti.com

TPS40100

SLUS601–MAY 2005

Application Schematics

2

Margin up 3%

2N7002

12 V

100 kΩ

1 µF

Margin down 3% Power Good Indication

27 kΩ

2N7002

V

OUT

Connect at load

10 kΩ

200 kΩ

40.2 kΩ

13.7 kΩ

27 kΩ

47 pF

300 pF

30 kΩ

MMBD1501A

4.99 kΩ

100 pF

14.3 kΩ

158 kΩ

24 2223 21 20 19

MGU

MGD

1

COMP

2

FB

3

TRKOUT

47 nF

4

TRKIN

5

UVLO

6

ILIM

RT

BIAS

7 98 10 11 12

TPS40100

SYNC

GND

PG

SS

3.3 V to 5 V logic supply or 5VBP pin

VO

ISNS

18

VDD

SW

HDRV

BST

5VBP

LDRV

GM

17

16

15

14

13

PGND

270 kΩ

Si73444DP

100 nF

BAT54

Si7868DP

1 µF

5.9 kΩ

100 nF

1.0 µH

COEV

DXM1306−1R0

1.7 mΩ (typ)

470 µF

Panasonic

EEF−SEOD471R

1 1

V

OUT

1.2 V

15 A

12 V

1 µF

162 kΩ

22 µF TDK C4532X7R1C226M

1

Open switch after input power is stable and SS capacitor had finished charging.

2

150 nF

10 nF

(if required)

10 Ω

BAT54S

(if required)

Figure 18. 300-kHz, 12-V to 1.2-V Converter With Tracking Startup Capability and Remote Sensing

Remote

GND Sense

Connect at

Load

UDG−04140

28

Page 29

TPS40100

www.ti.com

3

Margin down 5%

Margin up 5%

2N7002

3.32 kΩ

12 V

330 pF

100 kΩ

1 µF 2.67 kΩ

V

OUT

Connect at load

200 kΩ

40.2 kΩ

2N7002

10 kΩ

47 pF

3.9 nF

15 kΩ

MMBD1501A

4.99 kΩ

100 pF

Power Good Indication

6.2 kΩ

1

2

3

47 nF

4

5

6

158 kΩ

24 2223 21 20 19

PG

SS

VO

VDD

SW

HDRV

BST

5VBP

LDRV

GM

MGU

MGD

SYNC

COMP

FB

TRKOUT

TPS40100

TRKIN

UVLO

ILIM

RT

BIAS

GND

7 98 10 11 12

3.3 V to 5 V logic supply or 5VBP pin

ISNS

18

17

16

15

14

13

PGND

Si7344DP

100 nF

BAT54

Si7868DP

1 µF

5.9 kΩ

100 nF

1.0 µH

COEV

DXM1306−1R0

1.7 mΩ (typ)

1

SLUS601–MAY 2005

12 V

2

2 2

1

V

OUT

3.3 V

15 A

1

22 µF TDK C4532X7R1C226M

100 µF TDK C3225X5ROJ107M

2

Open switch after input power is stable and SS capacitor had finished charging.

3

120 kΩ 1 µF 270 kΩ

150 nF

Figure 19. 400-kHz, 12-V to 3.3-V Converter With Tracking Capability and 5% Margining

UDG−04141

29

Page 30

www.ti.com

TPS40100

SLUS601–MAY 2005

12 V

200 kΩ

40.2 kΩ

10 kΩ

13.7 kΩ

300 pF

100 pF

47 pF

14.3 kΩ

NC

NC

158 kΩ

NC NC NC NC

24 2223 21 20 19

MGU

MGD

1

COMP

2

FB

3

TRKOUT

TPS40100

4

TRKIN

5

UVLO

6

ILIM

RT

BIAS

7 98 10 11 12

SYNC

GND

PG

SS

VO

VDD

SW

HDRV

BST

5VBP

LDRV

GM

ISNS

18

17

16

15

14

13

PGND

270 kΩ

Si73444DP

100 nF

BAT54

Si7868DP

1 µF

5.9 kΩ

DXM1306−1R0

100 nF

1 µH

COEV

1.7 mΩ (typ)

Panasonic

EEF−SEOD471R

11

470 µF

12 V

V

OUT

1.2 V

15 A

187 kΩ 1 µF

150 nF

1

Figure 20. Minimal Application for 12-V to 1-V Converter

22 µF TDK C4532X7R1C226M

UDG−05063

30

Page 31

TPS40100

www.ti.com

12 V

10 kΩ

300 pF

200 kΩ

40.2 kΩ 13.7 kΩ

47 pF

100 pF

14.3 kΩ

NC

NC

NC NC

24 2223 21 20 19

MGU

MGD

1

COMP

2

FB

3

TRKOUT

TPS40100

4

TRKIN

5

UVLO

6

ILIM

RT

BIAS

7 98 10 11 12

158 kΩ

187 kΩ

1 µF

SYNC

GND

150 nF

PG

SS

VO

VDD

SW

HDRV

BST

5VBP

LDRV

GM

ISNS

18

17

16

15

14

13

PGND

270 kΩ

Si73444DP

100 nF

BAT54

Si7868DP

1 µF

100 nF

5.9 kΩ

1 µH

COEV

DXM1306−1R0

1.7 mΩ (typ)

1

1

12 V

470 µF

Panasonic

EEF−SEOD471R

External 5 V

SLUS601–MAY 2005

V

OUT

1.2 V

15 A

10 kΩ

External

Clock

50%

Duty

NC NC

24 2223 21 20 19

MGU

MGD

COMP

1

FB

2

TRKOUT

3

TRKIN

4

UVLO

5

ILIM

6

RT

BIAS

7 98 10 11 12

120 kΩ

1 µF

SYNC

TPS40100

GND

150 nF

PG

SS

VO

VDD

SW

HDRV

BST

5VBP

LDRV

GM

270 kΩ

ISNS

18

17

16

15

14

13

PGND

Si7344DP

100 nF

BAT54

Si7868DP

1 µF

22 µF TDK C4532X7R1C226M

1

100 µF TDK C3225X5ROJ107M

2

5.9 kΩ

DZM1306−1R

1

3.32 kΩ

330 pF

12 V

200 kΩ

40.2 kΩ

10 kΩ

2.67 kΩ

3.9 nF

100 pF

470 pF

6.2 kΩ

NC

NC

158 kΩ

Figure 21. Sequenced Supplies, With Oscillators 180 Degrees Out of Phase

100 nF

1 µH

COEV

3 mΩ (typ)

1

2

12 V