Page 1

User’s Guide

User’ s Gu ide

1

Page 2

EVM IMPORTANT NOTICE

Texas Instruments (TI) provides the enclosed product(s) under the following conditions:

This evaluation kit being sold by TI is intended for use for ENGINEERING DEVELOPMENT OR EVALUATION

PURPOSES ONLY and is not considered by TI to be fit for commercial use. As such, the goods being provided

may not be complete in terms of required design-, marketing-, and/or manufacturing-related protective

considerations, including product safety measures typically found in the end product incorporating the goods.

As a prototype, this product does not fall within the scope of the European Union directive on electromagnetic

compatibility and therefore may not meet the technical requirements of the directive.

Should this evaluation kit not meet the specifications indicated in the EVM User’s Guide, the kit may be returned

within 30 days from the date of delivery for a full refund. THE FOREGOING WARRANTY IS THE EXCLUSIVE

WARRANTY MADE BY SELLER TO BUYER AND IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESSED,

IMPLIED, OR S TA TUTOR Y, INCLUDING ANY WARRANTY OF MERCHANTABILITY OR FITNESS FOR ANY

PARTICULAR PURPOSE.

The user assumes all responsibility and liability for proper and safe handling of the goods. Further, the user

indemnifies TI from all claims arising from the handling or use of the goods. Please be aware that the products

received may not be regulatory compliant or agency certified (FCC, UL, CE, etc.). Due to the open construction

of the product, it is the user’s responsibility to take any and all appropriate precautions with regard to electrostatic

discharge.

EXCEPT TO THE EXTENT OF THE INDEMNITY SET FORTH ABOVE, NEITHER PARTY SHALL BE LIABLE

TO THE OTHER FOR ANY INDIRECT, SPECIAL, INCIDENTAL, OR CONSEQUENTIAL DAMAGES.

TI currently deals with a variety of customers for products, and therefore our arrangement with the user is not

exclusive.

TI assumes no liability for applications assistance, customer product design, software performance, or

infringement of patents or services described herein.

Please read the EVM User’s Guide and, specifically, the EVM Warnings and Restrictions notice in the EVM

User’s Guide prior to handling the product. This notice contains important safety information about temperatures

and voltages. For further safety concerns, please contact the TI application engineer.

Persons handling the product must have electronics training and observe good laboratory practice standards.

No license is granted under any patent right or other intellectual property right of TI covering or relating to any

machine, process, or combination in which such TI products or services might be or are used.

Mailing Address:

Texas Instruments

Post Office Box 655303

Dallas, Texas 75265

Copyright 2003, Texas Instruments Incorporated

2

Page 3

DYNAMIC WARNINGS AND RESTRICTIONS

It is important to operate this EVM within the input voltage range of 0 Vdc to100 Vdc.

Exceeding the specified input range may cause unexpected operation and/or irreversible damage to the EVM.

If there are questions concerning the input range, please contact a TI field representative prior to connecting

the input power.

Applying loads outside of the specified output range may result in unintended operation and/or possible

permanent damage to the EVM. Please consult the EVM User’s Guide prior to connecting any load to the EVM

output. If there is uncertainty as to the load specification, please contact a TI field representative.

During normal operation, some circuit components may have case temperatures greater than 50°C. The EVM

is designed to operate properly with certain components above 50°C as long as the input and output ranges are

maintained. These components include but are not limited to linear regulators, switching transistors, pass

transistors, and current sense resistors. These types of devices can be identified using the EVM schematic

located in the EVM User’s Guide. When placing measurement probes near these devices during operation,

please be aware that these devices may be very warm to the touch.

Mailing Address:

Texas Instruments

Post Office Box 655303

Dallas, Texas 75265

Copyright 2004, Texas Instruments Incorporated

3

Page 4

SLUU195 − June 2004

r

TPS40090 Multi-Phase Buck Converter and TPS2834

Drivers Steps-Down from 12-V to 1.5-V at 100 A

Systems Powe

Contents

1 Introduction 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 Features 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 Schematic 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4 Component Selection 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5 Test Setup 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6 Test Results/Performance Data 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7 Layout Considerations 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8 EVM Assembly Drawing and PCB Layout 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9 List of Materials 24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1 Introduction

The TPS40090EVM−002 multi-phase dc-to-dc converter utilizes the TPS40090 multi-phase

controller and TPS2834 adaptive driver to step down a 12-V input to 1.5-V at 420 kHz. The

output current can exceed 100 A. The TPS40090 provides fixed-frequency, peak current-mode

control with forced-phase current balancing. Phase currents are sensed by the voltage drop

across the DC resistance (DCR) of inductors. Other features include a single voltage operation,

true differential output voltage sense, user programmable current limit, capacitor-programmable

soft-start and a power good indicator. Device operation is specified in the TPS40090

datasheet

TPS40090EVM-002 can be configured into 2-, 3− or 4-phase operation. For 2-phase operation,

populate R65 and R66 to tie PWM2 and PWM4 up to internal 5-V and leave components in

related phases unpopulated. For 3-phase operation, tie PWM4 to BP5 through R66 only. For

4-phase operation, leave both R65 and R66 unpopulated.

In this user’s guide, all the tests are conducted under 4 phase operation.

[1]

.

4

TPS40090 Multi-Phase Buck Converter and TPS2834 Drivers Steps-Down from 12-V to 1.5-V at 100 A

Page 5

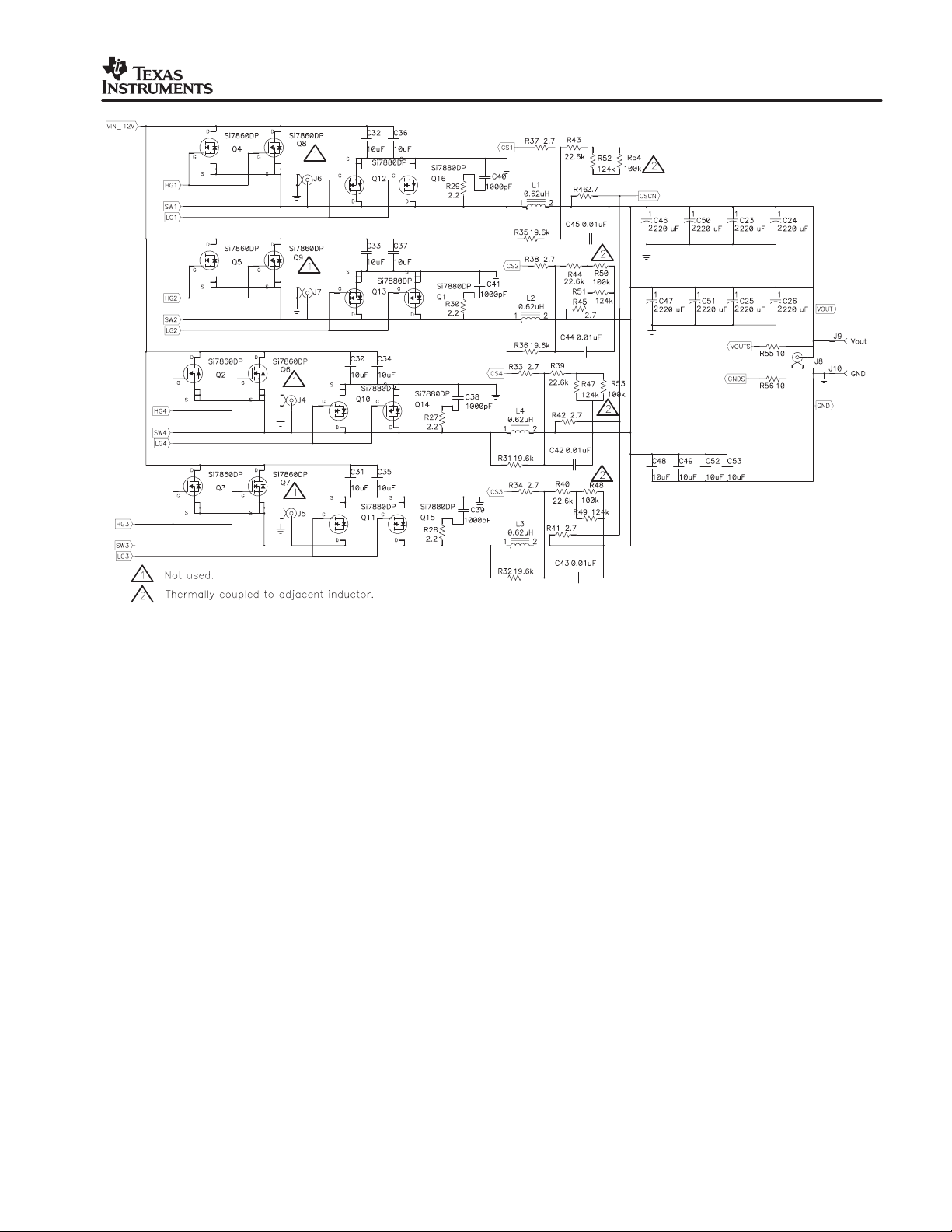

2 Features

Load transient response voltage

Load transient response voltage

Load transient response recovery

Load transient response recovery

PARAMETER TEST CONDITIONS MIN TYP MAX UNITS

Input voltage range 10.5 12.0 14.0

Output voltage set point 1.477 1.508 1.540

Output current range VIN = 12 V 0 100 120 A

Line regulation

Load regulation I

change

time

Loop bandwidth I

Phase margin I

Input ripple voltage 80 200

Output ripple voltage 15 25

Output rise time ms

Operating frequency 370 418 454 kHz

Full load efficiency

Current sharing tolerance

Table 1. TPS40090EVM−002 Performance Summary

I

rising from 10 A to 100 A,

(1)

OUT

10.5 V ≤ VIN ≤ 14 V

rising from 10 A to 100 A ±0.3%

OUT

I

rising from 10 A to 100 A −160

OUT

I

falling from 100 A to 10 A 200

OUT

I

rising from 10 A to 100 A < 10

OUT

I

falling from 100 A to 10 A < 15

OUT

= 100 A, I

OUT

= 100 A 40 °

OUT

VIN = 12 V, V

I

= 100 A

OUT

VIN = 12 V, V

I

= 100 A

OUT

= 10 A 89 kHz

OUT

= 1.5 V,

OUT

= 1.5 V,

OUT

SLUU195 − June 2004

±0.1%

84.3%

±5% ±10%

mV

mV

V

PK

µs

PK

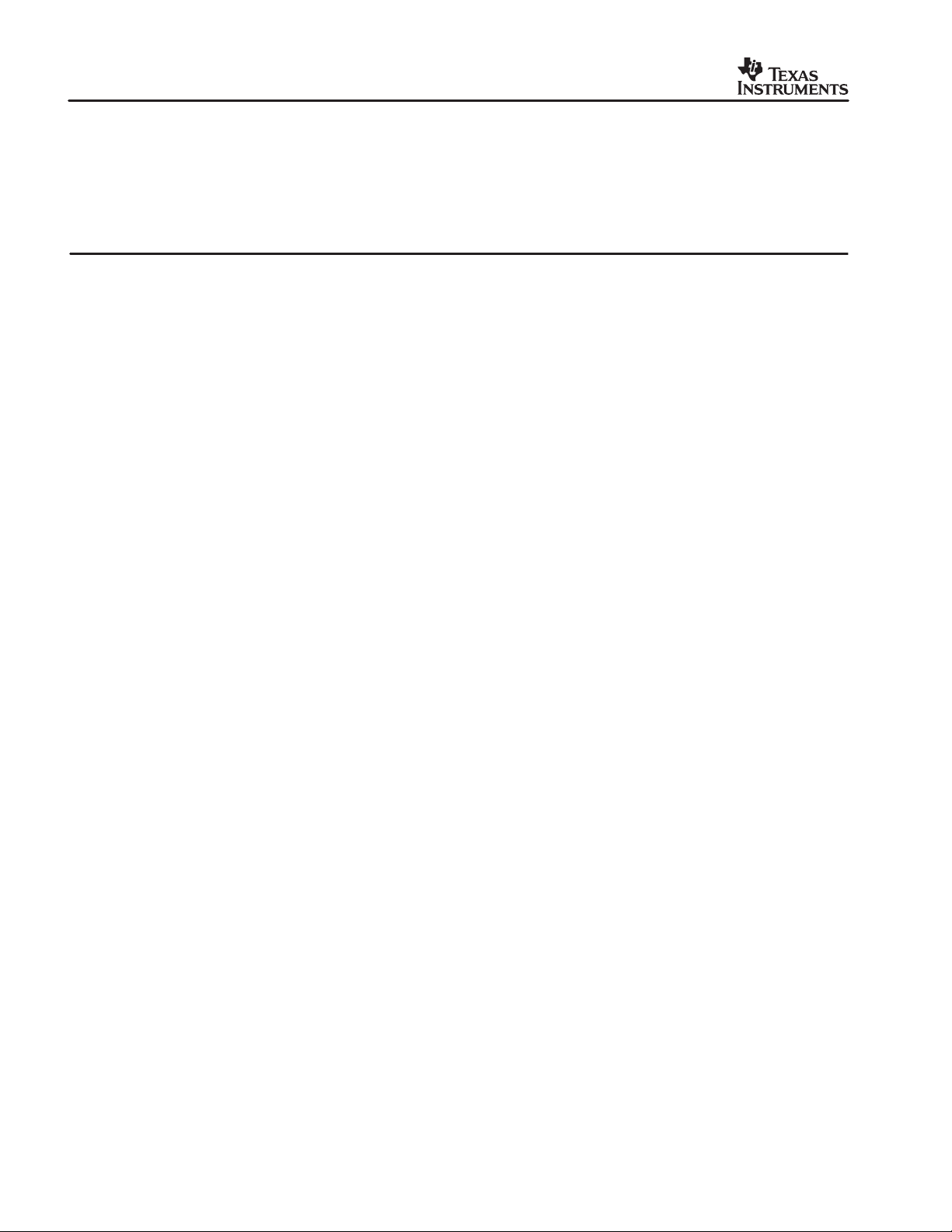

3 Schematic

12V

+

+

Phase Programming

R65 R66

4−phase open open

3−phase open 1k

2−phase 1k 1k

Figure 1. TPS40090EVM−002 Schematic Part 1 − TPS40090 Controller and Pre-Bias Circuit

TPS40090 Multi-Phase Buck Converter and TPS2834 Drivers Steps-Down from 12-V to 1.5-V at 100 A

5

Page 6

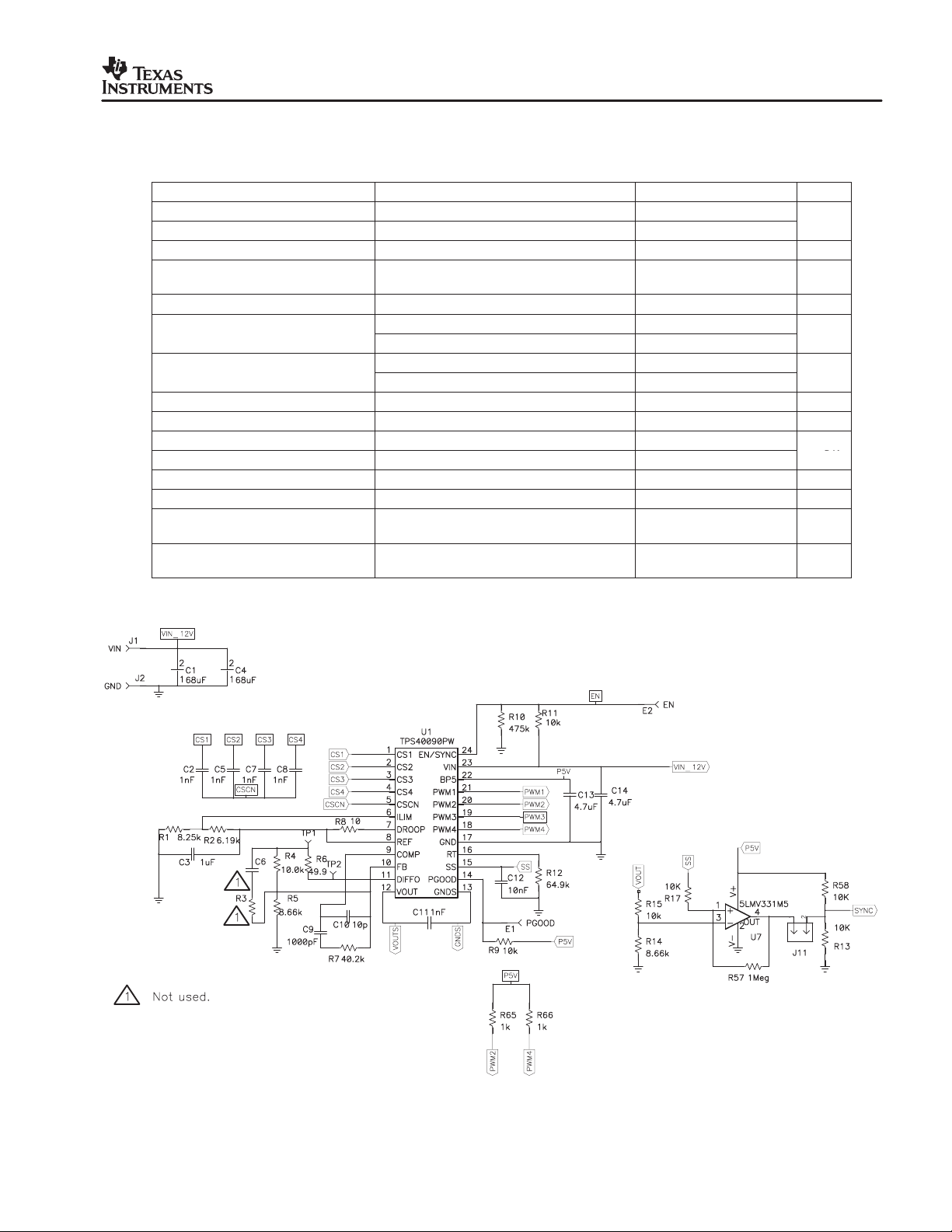

SLUU195 − June 2004

TRANS_EN

Figure 2. TPS40090EVM−002 Schematic Part 2 − Driver Circuit and Load Transient Generator

6

TPS40090 Multi-Phase Buck Converter and TPS2834 Drivers Steps-Down from 12-V to 1.5-V at 100 A

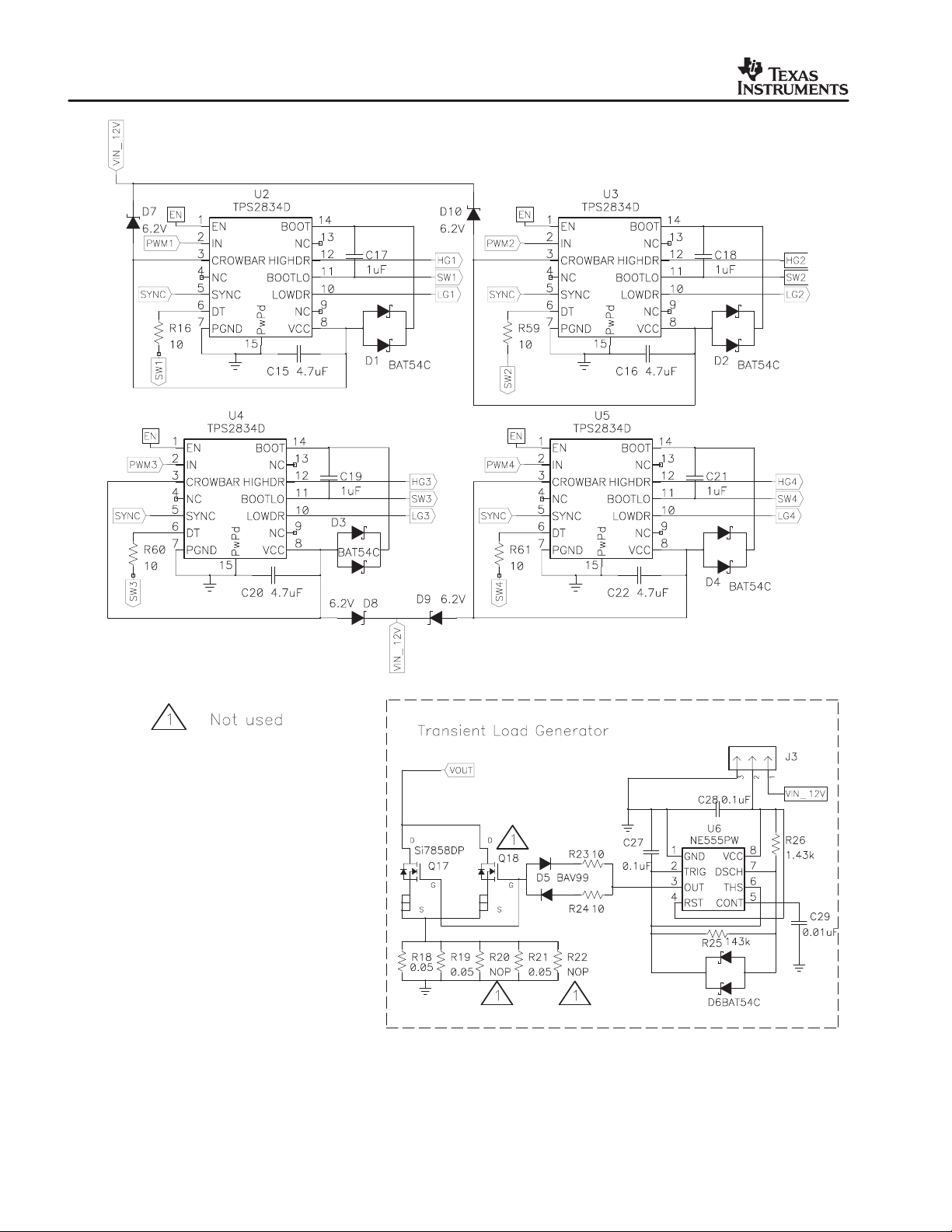

Page 7

SLUU195 − June 2004

(1)

+ +

+ +

Figure 3. TPS40090EVM−002 Schematic Part 3 − Power Stage

4 Component Selection

4.1 Frequency of Operation

+ + +

+

1.5V/100A

The clock oscillator frequency for the TPS40090 is programmed with a single resistor from RT

(pin 16) to signal ground. Equation (1) from the datasheet allows selection of the R

resistor in

T

kΩ for a given switching frequency in kHz.

+ R12 + K

R

T

PH

ǒ

39.2 103 f

*1.024

PH

* 7

Ǔ

(kW)

where

• K

• f

• for 2-phase and 3-phase configurations K

• for 4-phase K

The R

T

is the coefficient that depends on the number of active phases

PH

is the single phase frequency, in kHz

PH

=1.333

PH

=1.0 is a single phase frequency, kHz.

PH

resistor value is returned by the last expression in kΩ. For 420 kHz, RT is calculated as

65.8 kΩ and a resistor with a 64.9-kΩ standard value is used.

TPS40090 Multi-Phase Buck Converter and TPS2834 Drivers Steps-Down from 12-V to 1.5-V at 100 A

7

Page 8

SLUU195 − June 2004

(2)

(3)

4.2 Inductance Value

The output inductor value for each phase can be calculated from the volt-second during off time,

shown in equation (2).

V

L +

where

• I

RIPPLE

With I

RIPPLE

to be 0.63 µH. Using SPM12550−R62M300 inductors from TDK, each had inductance of 0.6µH

and resistance of 1.75-mΩ.

In multi-phase high current buck converter design, due to the ripple cancellation factor from

interleaving, the inductor value could be smaller than that in a single phase operation. But from

conduction loss point of view, the inductor value tends to be big to reduce the ripple current, thus

losses.

4.3 Input Capacitor Selection

The bulk input capacitor selection is based on the input voltage ripple requirements. Due to the

interleaving of multi phase, the input RMS current is reduced. The input ripple current RMS

value over load current is calculated in equation (3).

D I

IN(nom)

OUT

f I

RIPPLE

is usually chosen to be between 10% and 40% of maximum phase current I

= 20% of I

ǒ

NPH,D

ǒ1*

PH(max)

Ǔ

+

V

OUT

V

IN(max)

Ǔ

PH(max)

, there is a ripple current of 5 A, and the inductance value is found

.

2

D *

ǒ

NPH,D

k

ȱ

ȧ

ǒ

Ȳ

ȱ

ǒ

kǒNPH,DǓ) 1

ȧ

Ȳ

where

ǒ

• k

NPH,DǓ+ floorǒNPH D

• floor(x) is the function to return the greatest integer less than N

• N

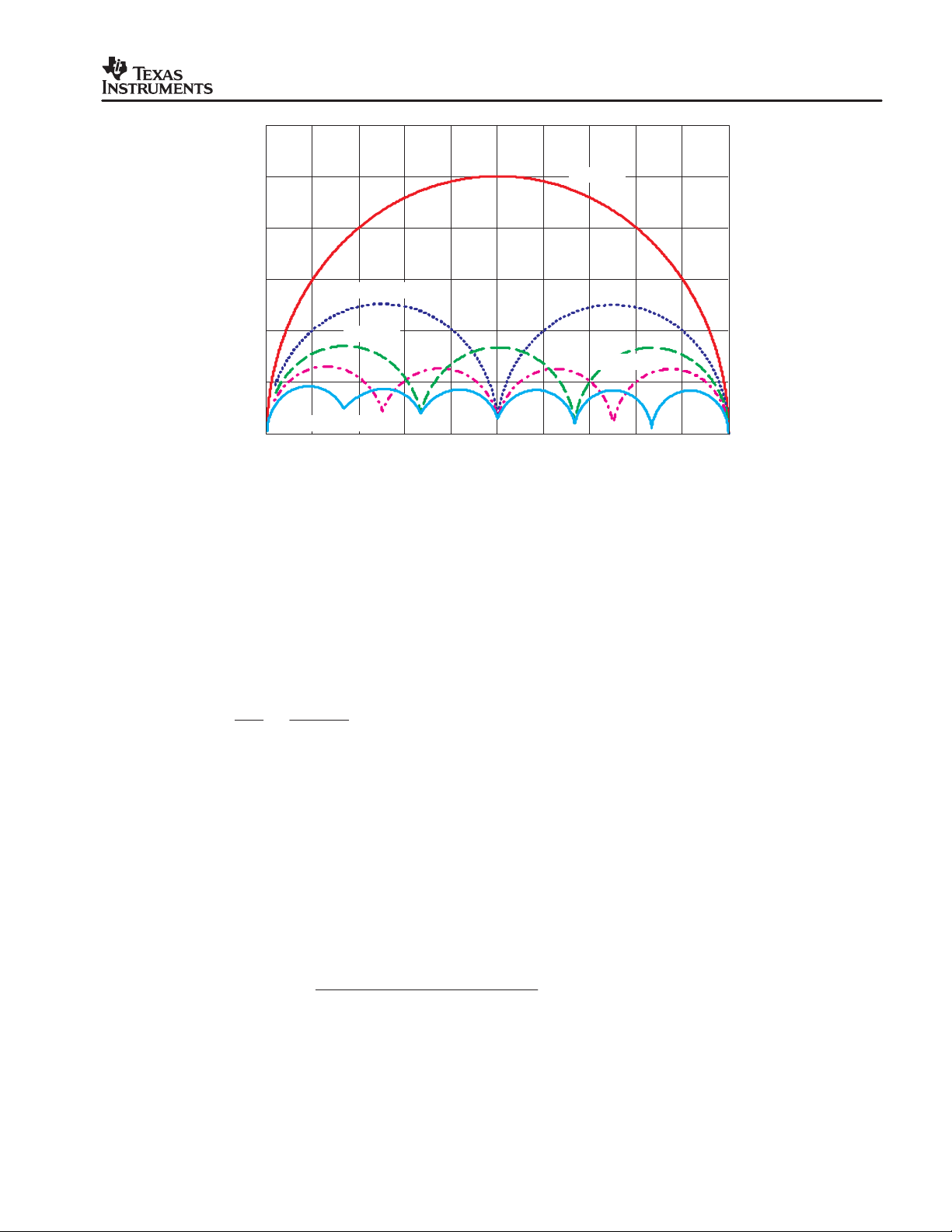

Figure 4 shows the input ripple current RMS value over the load current versus duty cycle with

different number of active phases.

is the number of active phases

PH

Ǔ

N

Ǔ ǒ

PH

2

Ǔ

kǒNPH,DǓ) 1

D *

ǒ

N

PH

ǒ

NPH,D

k

N

Ǔ

Ǔ

Ǔ

PH

ȳ

* D

Ǔ

ȧ

)

ȴ

3

) kǒNPH,D

N

ǒ

12 D

Ǔ

PH

Ǔ

2

kǒNPH,DǓ) 1

2

ǒ

V

ƪ

L f

N

OUT

PH

PH

× D

(

1 * D

ǒ

I

OUT

* D

Ǔ

Ǔ

)

ƫ

3

ȳ

ȧ

ȴ

8

TPS40090 Multi-Phase Buck Converter and TPS2834 Drivers Steps-Down from 12-V to 1.5-V at 100 A

Page 9

0.6

(4)

(5)

(6)

SLUU195 − June 2004

0.5

0.4

0.3

− Normalized RMS Input − A

0.2

0.1

RMS_CIN(nom)

I

0

0 10 20304050 60708090100

The maximum input ripple RMS current can be estimated as shown in (4).

I ^ I

OUT

D I

NPH = 6

Figure 4. Input Ripple Current RMS Value Overload Current

IN(nom)

NPH = 3

ǒ

4, D

NPH = 2

Ǔ

min

Duty Cycle − %

+ 3.18 A

NPH = 1

NPH = 4

It is also important to consider a minimum capacitance value which limits the voltage ripple to a

specified value if all the current is supplied by the onboard capacitor. For a typical ripple voltage

of 150 mV the maximum ESR is calculated in (5) as:

ESR +

Two 68-µF, 20-V Oscon capacitors (20SVP68M) from Sanyo are placed on the input side of the

board. The ESR is 40 mΩ for each capacitor.

D V

D I

150 mV

+

3.18 A

+ 47 mW

4.4 Output Ripple Cancellation and Capacitor Selection

Due to the interleaving of channels, the total output ripple current is smaller than the ripple

current from a single phase. The ripple cancellation factor is expressed in equation (6).

N

PH

P

ǒ

i + 1

ǒ

OUT

NPH,D

DI

kǒNPH,DǓ+ ifǒNPHv 1, DI

Ǔ

+

N

ƪ

i + 1

PH

P

*1

Ť

ǒ

Ť

i * NPH D

i * NPH DŤ) 1

(D), DI

OUT

OUT

Ť

Ǔ

Ǔ

ƫ

ǒ

NPH,D

Ǔ

Ǔ

TPS40090 Multi-Phase Buck Converter and TPS2834 Drivers Steps-Down from 12-V to 1.5-V at 100 A

9

Page 10

SLUU195 − June 2004

(7)

(8)

(9)

where

• D is the duty cycle for a single phase

• N

• K (N

In this case, N

is the number of active phases

PH

) is the intermediate function for calculation

PH

=4 and D

PH

=0.107 which yields k=0.573.

min

The actual output ripple is calculated in equation (7)

I

RIPPLE

V

OUT

+

1.0

0.8

0.6

− Normalized RMS Input − A

0.4

0.2

KǒNPH,D

L f

Ǔ

+

0.6m H 420 kHz

NPH = 4

NPH = 3

1.5 V

NPH = 2

0.573 + 3.41 A

NPH = 1

RMS_Cout(nom)

I

NPH = 6

0

0 10 20304050 60708090100

Duty Cycle − %

Figure 5. Output Ripple Current Cancellation

Selection of the output capacitor is based on many application variables, including function, cost,

size, and availability. There are three ways to calculate the output capacitance.

1. The minimum allowable output capacitance is determined by the amount of inductor ripple

current and the allowable output ripple, as given in equation (8).

C

OUT(min)

+

In this design, C

I

RIPPLE

8 f V

OUT(min)

+

RIPPLE

8 420 kHz 10 mV

is 101-µF with V

3.41 A

RIPPLE

+ 101 mF

=10 mV. However, this affects only the

capacitive component of the ripple voltage, and the final value of capacitance is generally

influenced by ESR and transient considerations.

2. ESR limitation. (To limit the ripple voltage to 10 mV, the capacitor ESR should be less than

the value calculated in equation (9)).

V

t+

R

C

RIPPLE

I

RIPPLE

+

10 mV

3.41 A

+ 2.93 mW

10

TPS40090 Multi-Phase Buck Converter and TPS2834 Drivers Steps-Down from 12-V to 1.5-V at 100 A

Page 11

SLUU195 − June 2004

(10)

3. Transient consideration. An additional consideration in the selection of the output inductor

and capacitance value can be derived from examining the transient voltage overshoot

which can be initiated with a load step from full load to no load. By equating the inductive

energy with the capacitive energy the equation (10) can be derived.

C

where

• I

• I

• V

• V

In this 100-A design the capacitance required for limiting the transient is significantly larger than

the capacitance required to keep the ripple acceptably low. Eight 220-µF POSCAP capacitors

are in parallel with four 22-µF ceramic capacitors. The ESR of each POSCAP is 15mΩ.

+

OUT

is full load

OH

is no load

OL

OUT2

OUT1

is the the allowed transient voltage rise

is the initial voltage

+

2

V

2

L I

4.5 MOSFET Selection

There are different requirements for switching FET(s) and rectifier FET(s) in the high-ratio step

down application. The duty cycle is around 12%. So the rectifier FET(s) is on for most of the

cycle. The conduction loss is dominant. Low-R

turn on of the rectifier FET(s) and cross conduction, choose a rectifier FET with Qgs > Qgd.

When the switch node is falling, the Qgd can pull the gate of the lower FET below GND, which

upsets the driver. Two Si7880DP from Siliconix are in parallel for the rectifier FET. The R

this FET is 3 mΩ and Qgs=18nC, and Qgd=10.5nC.

2

ǒ

Ǔ

EQ

ǒ

V

OUT2

ǒ

I

*

OH

2

Ǔ

ǒ

*

V

L

ǒ

I

OL

OUT1

2

Ǔ

2

Ǔ

Ǔ

+

DS(on)

0.6mH

4

ǒ

(

1.75 V

FET(s) are preferred. Also due to the dV/dt

)

2

(

100 A

*

(

1.5 V

2

)

+ 1846 mF

2

Ǔ

)

DS(on)

of

The switching FET switches at high voltage and high current, the switching loss is dominant.

One single Si7860DP is selected for its low total gate charge.

Both types of FET(s) are offered in the Powerpak SO−8 package.

The PCB is layed out for two FETs in parallel, for both switching FET(s) and rectifier FET(s), to

give the feasibility to modify the board for different applications.

4.6 Current Sensing

TPS40090 supports both resistor current sensing and DCR current sensing approach. DCRs of

the output inductors are used in this design as the current sensing components. The DCR

current sensing circuit is shown in Figure 5. The idea is to parallel a R-C network to the inductor.

If the two time constants are same (L/DCR=R × C), then V

used to compensate the positive temperature coefficient of copper specific resistance, which is

0.385%/°C. See detail explanation in the datasheet.

TPS40090 Multi-Phase Buck Converter and TPS2834 Drivers Steps-Down from 12-V to 1.5-V at 100 A

C=VDCR

. Extra circuit, shown in (b), is

11

Page 12

SLUU195 − June 2004

(11)

With the chosen inductor described in Inductance Value, (section 4.2, of this document) the

following values are used.

• R=19.6 kΩ

• C=10 nF

• R

NTC

=100 kΩ

• R1=124 kΩ

• R2=22.6 kΩ

V

DCR

L

V

IN

R

DCR

C

V

C

Figure 6. DCR Current Sensing Circuit with Copper Temperature Compensation

4.7 Overcurrent Limit Protection

V

OUT

L

V

IN

R

R

THE

R2

DCR

C

R1

R

NTC

UDG−03136

12

The overcurrent function monitors the voltage level separately on each current sense input and

compares it to the voltage on ILIM pin set by the divider from the controller’s reference.

If the threshold of V

/2.7 is exceeded, the PWM cycle on the respected phase is terminated.

ILIM

Voltage level on the ILIM pin is determined by (11).

V

ILIM

+ 2.7 I

PH(max)

RCS;I

PH(max)

+ I

OUT

)

ǒ

VIN* V

2 L

OUT

Ǔ

V

OUT

fSW V

OUT

IN

where

• I

PH(max)

• R

CS

TPS40090 Multi-Phase Buck Converter and TPS2834 Drivers Steps-Down from 12-V to 1.5-V at 100 A

is the maximum allowable value of the phase current

is the value of the current sense resistor

Page 13

4.8 Compensation Components

(12)

(13)

(14)

The TPS40090 uses peak current mode control. Type II network is used here, which is

implemented to provide one zero and two poles. The first pole is placed at the origin to improve

DC regulation.

The ESR zero of the power stage is:

SLUU195 − June 2004

f

The zero is placed near 3.96 kHz to produce a reasonable time constant.

f

The second pole is placed at ESR zero (354 kHz).

f

The resulting values selected for this design are:

+

ESRZ

+

Z

P1

2p R

2p R11 C11

+

2p R11

1

C

C

1

1

ǒ

+ 354 kHz

OUT

ǒ

C11 C12

ǒ

C11)C12

Ǔ

Ǔ

Ǔ

• R11 = 40.2 kΩ

• C11 = 1000 pF

• C12 = 10 pF

TPS40090 Multi-Phase Buck Converter and TPS2834 Drivers Steps-Down from 12-V to 1.5-V at 100 A

13

Page 14

SLUU195 − June 2004

5 Test Setup

The HPA072 has the following input/output connections: 12-V input J1 (VIN) and J2 (GND),

1.5-V output J9 (VOUT) and J10 (GND). A diagram showing the connection points is shown in

Figure 5. A power supply capable of supplying 18 A should be connected to VIN and GND

through a pair of 10 AWG wires. The 1.5-V load should be connected respectively to J9 and J10

through pairs of 0 AWG wires. Wire lengths should be minimized to reduce losses in the wires.

A 5-inch fan with 200-cfm air flow is recommended to operate this board at full load.

12 V/ 20 A

Power

Supply

Oscilloscope

CH1

J8

J1

TPS40090EVM−002

Board

J2

J9

J10

Figure 7. Connections for the Test

Fluke 45

V

DC

OUT

Electronic

Load

UDG−04063

14

TPS40090 Multi-Phase Buck Converter and TPS2834 Drivers Steps-Down from 12-V to 1.5-V at 100 A

Page 15

6 Test Results and Performance Data

6.1 Efficiency and Power Loss

Figure 8 shows the efficiency as the load varies from 10 A to over 100 A. The efficiency at full

load is about 84.3%.

Figure 7 shows the total loss versus the load current, which is approximately 28.3W at 100 A.

SLUU195 − June 2004

OVERALL EFFICIENCY

90

VIN = 12 V

fSW = 420 kHz

85

80

75

Percent Efficiency − %

70

65

0

20

I

OUTPUT CURRENT

vs

40 60 80 100 120

− Output Current − A

OUT

Figure 8.

TOTAL POWER LOSS

vs

40

35

30

25

20

− Power Loss − W

15

LOSS

P

10

VIN = 12 V

fSW = 420 kHz

5

0

0 20 40 60 80 100 120

OUTPUT CURRENT

I

− Output Current − A

OUT

Figure 9.

TPS40090 Multi-Phase Buck Converter and TPS2834 Drivers Steps-Down from 12-V to 1.5-V at 100 A

15

Page 16

SLUU195 − June 2004

6.2 Closed-Loop Performance

The TPS40090 uses peak current-mode control. Figure 10 shows the bode plots at 100 A of

load current, where no droop function is implemented. The crossover frequency is at 89 kHz with

phase margin of 40°.

80

GAIN AND PHASE

vs

OSCILLATOR FREQUENCY

180

60

40

Gain − dB

20

0

−20

VIN = 12 V

V

= 1.5 V

OUT

I

= 10 A

OUT

−40

100

6.3 Output Ripple and Noise

Figure 11 shows typical output noise where VIN=12 V, and I

than 10 mV.

PHASE

GAIN

1 k 10 k 100 k 1 M

f

− Oscillator Frequency − kHz

OSC

Figure 10. Bode Plot

=100A. The output ripple is less

OUT

I

= 100 A

OUT

135

90

45

0

−45

−90

−135

−180

Phase − 5

16

Output Voltage Ripple

(10 mV/div)

t − Time − 500 ns / div

Figure 11. Output Noise

TPS40090 Multi-Phase Buck Converter and TPS2834 Drivers Steps-Down from 12-V to 1.5-V at 100 A

Page 17

6.4 Transient Response

The on-board load transient circuit enables to check the step load transient response on the

same board. Simply by putting a jumper to connect Pin1 and 2 of J3, a 90-A step load is created

by three 50-mΩ resistors placed on the board. The slew rates of the transient are 200 A/µs for

the load step-down and 160 A/µs for the load step-up.

The transient response is shown in Figure 6 as the load is stepped from 10 to 100 A. The output

deviation is approximately 200 mV and the settling time is within 15 µs.

SLUU195 − June 2004

Load Step = 90 A

Something Voltage

(10 mV/div)

Something Voltage

(10 mV/div)

t − Time − 20 µs / div

Figure 12. Transient Response

TPS40090 Multi-Phase Buck Converter and TPS2834 Drivers Steps-Down from 12-V to 1.5-V at 100 A

17

Page 18

SLUU195 − June 2004

6.5 Start up with Pre-Biased Output

In synchronous buck converter, the bottom FET discharges the pre-biased output during

start-up. To avoid this, a comparator U9 and surround components are used to pull the SYNC

pin of the drivers low, which keeps the bottom FET off during startup. So the output can rise

smoothly. After the SS pin comes up, SYNC is pulled up high and enable the bottom FET’s

driving signal. The converter goes back to normal synchronization mode. This function can be

enabled by shorting J11 on the board.

Figure 8 shows the start-up waveform with pre−biased output with J11 short and open

respectively. In Figure 12, there are two glitches of SYNC waveform. The first one is cause by

P5V from TPS40090. When TPS40090 is enabled, P5V comes up first. SYNC is connected to

P5V through a divider. The second one happens when the driver is ready and turns on the

bottom FET when PWM signal is low. So the pre-biased output is pulled low which causes the

SYNC signal high to turn off the bottom FET. Then output voltage goes back and rises up

smoothly.

V

OUT

(2 V/div)

V

(2 V/div)

SYNC

V

OUT

(2 V/div)

V

SYNC

(5 V/div)

V

SS

(5 V/div)

t − Time − 1 ms / div

Figure 13. J11 Short Circuit

V

EN

(2 V/div)

V

SS

(5 V/div)

t − Time − 2.5 ms / div

Figure 14. J11 Open Circuit

V

EN

(2 V/div)

18

TPS40090 Multi-Phase Buck Converter and TPS2834 Drivers Steps-Down from 12-V to 1.5-V at 100 A

Page 19

7 Layout Considerations

The PCB layout plays a critical role in the performance in a high frequency switching power

supply design. Following the suggestions listed below will help to improve the performance and

expedite the design.

• To take full advantage of the ripple cancellation factor from interleaving, place the input

capacitors before the junction where the input voltage is distributed to each phase. Place the

output capacitors after the junction where all the inductors are connected;

• Place the external drivers right next to the FETs and use at least 25 mil trace for gate drive

signal to improve noise immunity

• Place some ceramic capacitors in the input of each channel to filter the current spikes

• Place the NTC resistor right next to its related inductor for better thermal coupling

• 2 oz. or thicker copper is recommended to reduce the trace impedance

• Place enough vias along pads of the power components to increase thermal conduction

• Keep the current sensing traces as short as possible to avoid excessive noise pick up

SLUU195 − June 2004

• Place the output inductors as symmetric as possible in relation to the output connectors to

obtain similar voltage drop from the trace impedance

TPS40090 Multi-Phase Buck Converter and TPS2834 Drivers Steps-Down from 12-V to 1.5-V at 100 A

19

Page 20

SLUU195 − June 2004

8 EVM Assembly Drawing and PCB Layout

Figure 15. Top Side Component Assembly

20

Figure 16. Bottom Assembly

TPS40090 Multi-Phase Buck Converter and TPS2834 Drivers Steps-Down from 12-V to 1.5-V at 100 A

Page 21

SLUU195 − June 2004

Figure 17. Top Side Copper

Figure 18. Internal 1 (Ground Plane)

TPS40090 Multi-Phase Buck Converter and TPS2834 Drivers Steps-Down from 12-V to 1.5-V at 100 A

21

Page 22

SLUU195 − June 2004

Figure 19. Internal 2 (Power Plane)

22

Figure 20. Internal 3

TPS40090 Multi-Phase Buck Converter and TPS2834 Drivers Steps-Down from 12-V to 1.5-V at 100 A

Page 23

SLUU195 − June 2004

Figure 21. Internal 4

Figure 22. Bottom Layer Copper

TPS40090 Multi-Phase Buck Converter and TPS2834 Drivers Steps-Down from 12-V to 1.5-V at 100 A

23

Page 24

SLUU195 − June 2004

9 List of Materials

The following table lists the TPS40090EVM−002 components corresponding to the schematic

shown in Figure 1.

Table 2. List of Materials

Reference

Designator

C1, C4 2 Capacitor, OS−CON, 68 µF, 20 V, 40 mΩ, 20% 10.3mm (F8) Sanyo 20SVP68M

C2, C5, C7,

C8,C9, C10,

C11

C3,C17, C18,

C19, C21

C6 0 603 Std Std

C12 1 Capacitor, ceramic, 0.01 µF, 50 V, X7R, ±5% 805 muRata GRM40UJ103J50

C13, C14, C15,

C16, C20, C22

C30, C31, C32,

C33, C34, C35,

C36, C37

C38, C39, C40,

C41

C42, C43, C44,

C45

C23, C24, C25,

C26,C46,

C47,C50, C51

C48, C49, C52,

C53

D1, D2, D3, D4,

D6

D7, D8, D9,

D10

J1, J2, J9, J10 1 Lug, Solderless, #2 − #8 AWG, 1/4 Copper 524600 ILSCO

J4, J5, J6, J7,

J8

L1, L2, L3, L4 4 Inductor, SMT, 0.62 µH, 30 A, 1.75 mΩ 0.524 x 0.492 TDK SPM12550−R62M300

Q2, Q3, Q4, Q5 4 MOSFET, N-channel, 30 V, 18 A, 8.0 mΩ

Q6, Q7, Q8, Q9 0 MOSFET, N-channel, 30 V, 18 A, 8.0 mΩ

Q1, Q10, Q11,

Q12, Q13, Q14,

Q15, Q16

R1 1 Resistor, chip, 8.25 kΩ, 1/16−W, 1% 603 Std Std

R2 1 Resistor, chip, 6.19 kΩ,, 1/16−W, 1% 603 Std Std

R3 0 603 Std Std

R4, R9, R11 3 Resistor, chip, 10 kΩ, 1/16−W, 1% 603 Std Std

R5 1 Resistor, chip, 8.66 kΩ, 1/16−W, 1% 603 Std Std

R6 1 Resistor, chip, 49.9 Ω, 1/16−W, 1% 603 Std Std

R7 1 Resistor, chip, 40.2 kΩ, 1/16−W, 1% 603 Std Std

R8, R16, R55,

R56, R59, R60,

R61

R10 1 Resistor, chip, 475 kΩ, 1/16−W, 5% 603 Std Std

R12 1 Resistor, chip, 64.9 kΩ, 1/16−W, 1% 603 Std Std

QTY Description Size Manufacturer Part Number

7 Capacitor, ceramic, 1000−pF, 25 V, X7R, ±5% 603 muRata GRM39SL102J25

5 Capacitor, dielectric, 1.0 µF, 16 V, X7R, ±10% 805 muRata GRM40B105K16

6 Capacitor, dielectric, 4.7 µF, 16 V, X5R, ±10% 1206 muRata

8 Capacitor, dielectric, 10 µF, 25 V, X5R 1210 TDK C3225X5R1E106M

4 Capacitor, ceramic, 1000−pF, 50 V, X7R, ±5% 805 muRata GRM40TH102J50

4 Capacitor, ceramic, 0.01 µF, 50 V, COG 805 TDK C2012COG1H103JT

8 Capacitor, POSCAP, 220 µF, 2.5 V, 15 mΩ, 20% 7343 (D) Sanyo 2R5TPE220M

4 Capacitor, Ceramic, 10 µF, 6.3 V, X5R 1206 TDK C3216X5R0J106M

5 Diode, dual schottky, 200 mA, 30 V SOT-23 Vishay−Liteon BAT54C

4 Diode, zener, 6.2 V, 350 mW SOT−23 Diodes, Inc. BZX84C6V2

5 Connector, shielded, test jack, vertical 0.0125 DIA

PWRPAK

S0−8

PWRPAK

S0−8

8 MOSFET, N-channel, 30 V, 29 A, 3 mΩ

7 Resistor, chip, 10−Ohms, 1/16−W, 1% 603 Std Std

PWRPAK

S0−8

Johnson

Components

Vishay−Siliconix Si7860DP

Vishay−Siliconix Si7860DP

Vishay−Siliconix Si7880DP

GRM42−

65X5R475K16

129−0701−202

24

TPS40090 Multi-Phase Buck Converter and TPS2834 Drivers Steps-Down from 12-V to 1.5-V at 100 A

Page 25

SLUU195 − June 2004

Reference

Designator

R27, R28, R29,

R30

R31, R32,R35,

R36

R33, R34, R37,

R38, R41, R42,

R45, R46

R39, R40, R43,

R44

R47, R49, R51,

R52

R48, R50, R53,

R54

R65, R66 2 Resistor, chip, 1.0 kΩ, 1/10-W, 1% 805 Std Std

TP1 1 Test point, 0.062 Hole, Red 0.25 Keystone 5011

TP2 1 Test point, 0.062 Hole, Black 0.25 Keystone 5010

U1 1 IC, high-frequency, multiphase controller 108,800 TI TPS40090PW

U2, U3, U4, U5 4 IC, MOSFET driver, fast synchronous buck with DTC PWP14 TI TPS2834PWP

U6 1 IC, Precision timer TSSOP 8 TI NE555PW

E1, E2 2 Test point, black, 1 mm 0.038 Farnell 240−333

LOAD TRANSIENT CIRCUIT

Q17 1 MOSFET, N-channel, 12 V, 29 A, 3.0 mΩ,

Q18 0 MOSFET, N-channel, 12 V, 29 A, 3.0 mΩ,

R18, R19, R21 3 Resistor, chip, 0.050 Ω,, 1-W, 0.5% 2512 Vishay

R20, R22 0 Resistor, chip, 0.050 Ω,, 1-W, 0.5% 2512 Vishay

R23, R24 2 Resistor, chip, 10 Ω, 1/16−W, 1% 603 Std Std

R25 1 Resistor, chip, 143 kΩ, 1/10−W, 1% 805 Std Std

R26 1 Resistor, chip, 1.43 kΩ, 1/10−W, 1% 805 Std Std

C27, C28 2 Capacitor, ceramic, 0.1 µF, 25 V, X7R, ±10% 805 TDK C2012X7R1E104K

C29 1 Capacitor, ceramic, 0.01 µF, 50 V, X7R, ±5% 805 muRata GRM40UJ103J50

D5 1 Diode, dual ultra fast, series, 200 mA, 70 V SOT23 Fairchild BAV99

D6 1 Diode, dual schottky, 200 mA, 30 V SOT23 Vishay−Liteon BAT54C

J3 1 Header, 3-pin, 100 mil spacing, (36-pin strip) 0.100 x 3 Sullins PTC36SAAN

PRE-BIAS CIRCUIT

U7 1 IC, Single GP comparator, low voltage SOT23−5 National LMV331M5

J11 1 Header, 2-pin, 100 mil spacing, (36-pin strip) 0.100 x 2 Sullins PTC36SAAN

R13, R15, R17,

R58

R57 1 Resistor, chip, 1 MΩ, 1/10−W, 1% 805 Std Std

R14 1 Resistor, chip, 8.66 kΩ, 1/16−W, 1% 603 Std Std

QTY Description Size Manufacturer Part Number

4 Resistor, chip, 2.2 Ω, 1/10−W, 1% 805 Std Std

4 Resistor, chip, 19.6 kΩ, 1/10−W, 1% 805 Std Std

8 Resistor, chip, 2.7 Ω, 1/16−W, 1% 603 Std Std

4 Resistor, chip, 22.6 kΩ, 1/10−W, 1% 805 Std Std

4 Resistor, chip, 124 kΩ, 1/10−W, 1% 805 Std Std

4 NTC Resistor, chip, 100 kΩ, 1/10-W, 1% 805 Vishay

PWRPAK

S0−8

PWRPAK

S0−8

4 Resistor, chip, 10 kΩ, 1/16−W, 1% 603 Std Std

Si7858DP

Si7858DP

NTHS0603N01N1003

J

WSL−2512−R050

0.5% R86

WSL−2512−R050

0.5% R86

TPS40090 Multi-Phase Buck Converter and TPS2834 Drivers Steps-Down from 12-V to 1.5-V at 100 A

25

Page 26

IMPORTANT NOTICE

Texas Instruments Incorporated and its subsidiaries (TI) reserve the right to make corrections, modifications,

enhancements, improvements, and other changes to its products and services at any time and to discontinue

any product or service without notice. Customers should obtain the latest relevant information before placing

orders and should verify that such information is current and complete. All products are sold subject to TI’s terms

and conditions of sale supplied at the time of order acknowledgment.

TI warrants performance of its hardware products to the specifications applicable at the time of sale in

accordance with TI’s standard warranty. Testing and other quality control techniques are used to the extent TI

deems necessary to support this warranty . Except where mandated by government requirements, testing of all

parameters of each product is not necessarily performed.

TI assumes no liability for applications assistance or customer product design. Customers are responsible for

their products and applications using TI components. To minimize the risks associated with customer products

and applications, customers should provide adequate design and operating safeguards.

TI does not warrant or represent that any license, either express or implied, is granted under any TI patent right,

copyright, mask work right, or other TI intellectual property right relating to any combination, machine, or process

in which TI products or services are used. Information published by TI regarding third-party products or services

does not constitute a license from TI to use such products or services or a warranty or endorsement thereof.

Use of such information may require a license from a third party under the patents or other intellectual property

of the third party, or a license from TI under the patents or other intellectual property of TI.

Reproduction of information in TI data books or data sheets is permissible only if reproduction is without

alteration and is accompanied by all associated warranties, conditions, limitations, and notices. Reproduction

of this information with alteration is an unfair and deceptive business practice. TI is not responsible or liable for

such altered documentation.

Resale of TI products or services with statements different from or beyond the parameters stated by TI for that

product or service voids all express and any implied warranties for the associated TI product or service and

is an unfair and deceptive business practice. TI is not responsible or liable for any such statements.

Following are URLs where you can obtain information on other Texas Instruments products and application

solutions:

Products Applications

Amplifiers amplifier.ti.com Audio www.ti.com/audio

Data Converters dataconverter.ti.com Automotive www.ti.com/automotive

DSP dsp.ti.com Broadband www.ti.com/broadband

Interface interface.ti.com Digital Control www.ti.com/digitalcontrol

Logic logic.ti.com Military www.ti.com/military

Power Mgmt power.ti.com Optical Networking www.ti.com/opticalnetwork

Microcontrollers microcontroller.ti.com Security www.ti.com/security

Telephony www.ti.com/telephony

Video & Imaging www.ti.com/video

Wireless www.ti.com/wireless

Mailing Address: Texas Instruments

Post Office Box 655303 Dallas, Texas 75265

Copyright 2004, Texas Instruments Incorporated

Loading...

Loading...