www.ti.com

TPS2120, TPS2121

SLVSEA3F – AUGUST 2018 – REVISED AUGUST 2020

SLVSEA3F – AUGUST 2018 – REVISED AUGUST 2020

TPS2120, TPS2121

TPS212x 2.8-V to 22-V Priority Power MUX with Seamless Switchover

1 Features

• Wide operating range: 2.8 V to 22 V

– Absolute maximum input voltage of 24 V

• Low RON resistance:

– TPS2120: 62 mΩ (typical)

– TPS2121: 56 mΩ (typical)

• Adjustable overvoltage supervisor (OVx):

– Accuracy < ±5%

• Adjustable priority supervisor (PR1):

– Accuracy < ±5%

• TPS2121 Supports external voltage reference

(CP2) with an accuracy of <1%

• Output current limit (ILM):

– TPS2120: 1 A – 3 A

– TPS2121: 1 A – 4.5 A

• Channel status indication (ST)

• Adjustable input settling time (SS)

• Adjustable output soft start time (SS)

• TPS2121 Fast output switchover (tSW): 5 µs

(typical)

• Low Iq from enabled input: 200 µA (typical)

• Low Iq from disabled input: 10 µA (Typical)

• Manual input source selection (OVx)

• Over temperature protection (OTP)

2 Applications

• Backup and standby power

• Input source selection

• Multiple battery management

• EPOS and barcode scanners

• Building automation and surveillance

• Tracking and telematics

3 Description

The TPS212x devices are Dual-Input, Single-Output

(DISO) Power Multiplexer (MUX) that are well suited

for a variety of systems having multiple power

sources. The devices will Automatically Detect,

Select, and Seamlessly Transition between available

inputs.

Priority can be automatically given to the highest

input voltage or manually assigned to a lower voltage

input to support both ORing and Source Selection

operations. A priority voltage supervisor is used to

select an input source.

An Ideal Diode operation is used to seamlessly

transition between input sources. During switchover,

the voltage drop is controlled to block reverse current

before it happens and provide uninterrupted power to

the load with minimal hold-up capacitance.

Current limiting is used during startup and switchover

to protect against overcurrent events, and also

protects the device during normal operation. The

output current limit can be adjusted with a single

external resistor.

The TPS212x devices are available in WCSP and

small VQFN-HR package options characterized for

operation for a temperature range of –40°C to 125°C.

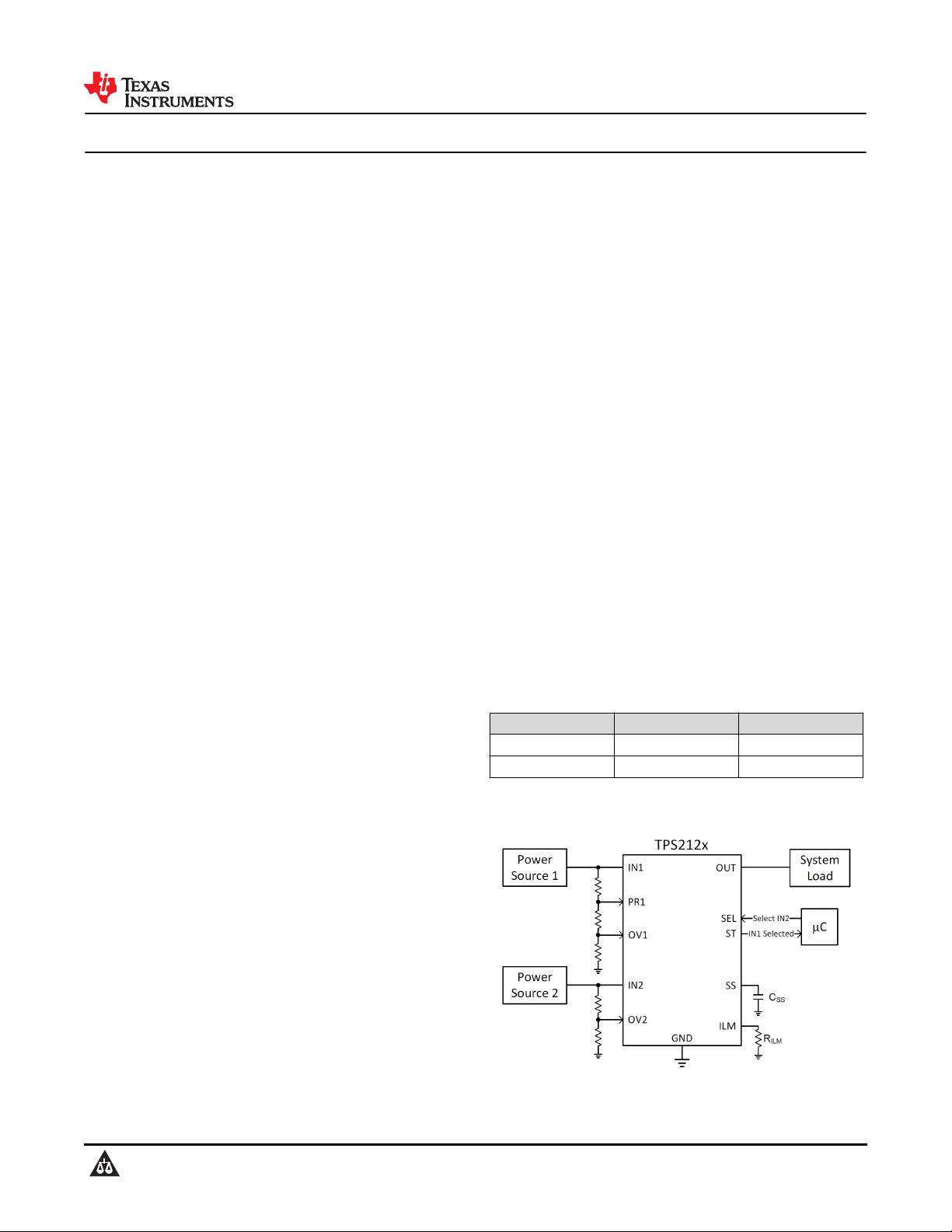

Device Information

PART NUMBER PACKAGE

TPS2120 WCSP (20) 1.5 mm x 2.0 mm

TPS2121 VQFN-HR (12) 2.0 mm x 2.5 mm

(1) For all available packages, see the orderable addendum at

the end of the data sheet.

(1)

BODY SIZE (NOM)

Typical Application

An IMPORTANT NOTICE at the end of this data sheet addresses availability, warranty, changes, use in safety-critical applications,

Copyright © 2020 Texas Instruments Incorporated

intellectual property matters and other important disclaimers. PRODUCTION DATA.

Product Folder Links: TPS2120 TPS2121

Submit Document Feedback

1

TPS2120, TPS2121

SLVSEA3F – AUGUST 2018 – REVISED AUGUST 2020

www.ti.com

Table of Contents

1 Features............................................................................1

2 Applications..................................................................... 1

3 Description.......................................................................1

4 Revision History.............................................................. 2

5 Device Comparison Table...............................................3

6 Pin Configuration and Functions...................................4

7 Specifications.................................................................. 6

7.1 Absolute Maximum Ratings........................................ 6

7.2 ESD Ratings............................................................... 6

7.3 Recommended Operating Conditions.........................6

7.4 Thermal Information....................................................6

7.5 Electrical Characteristics.............................................7

7.6 Typical Characteristics................................................9

8 Parameter Measurement Information.......................... 10

9 Detailed Description...................................................... 11

9.1 Overview................................................................... 11

9.2 Functional Block Diagram......................................... 11

9.3 Feature Description...................................................12

9.4 TPS2120 Device Functional Modes..........................18

9.5 TPS2121 Device Functional Modes..........................18

10 Application and Implementation................................ 19

10.1 Application Information........................................... 19

10.2 Typical Application.................................................. 19

10.3 Automatic Switchover with Priority (XCOMP)......... 25

10.4 Automatic Seamless Switchover with Priority

(XREF)........................................................................ 27

10.5 Highest Voltage Operation (VCOMP)..................... 28

10.6 Reverse Polarity Protection with TPS212x............. 31

10.7 Hotplugging with TPS212x......................................31

11 Power Supply Recommendations..............................33

12 Layout...........................................................................33

12.1 Layout Guidelines................................................... 33

12.2 Layout Example...................................................... 33

13 Device and Documentation Support..........................34

13.1 Documentation Support.......................................... 34

13.2 Receiving Notification of Documentation Updates..34

13.3 Support Resources................................................. 34

13.4 Trademarks.............................................................34

13.5 Electrostatic Discharge Caution..............................34

13.6 Glossary..................................................................34

14 Mechanical, Packaging, and Orderable

Information.................................................................... 34

4 Revision History

NOTE: Page numbers for previous revisions may differ from page numbers in the current version.

Changes from Revision E (February 2020) to Revision F (August 2020) Page

• Updated the numbering format for tables, figures and cross-references throughout the document ..................1

Changes from Revision D (September 2019) to Revision E (February 2020) Page

• Updated the Leakage Current in the Electrical Characteristics table in the Specifications section.................... 6

Changes from Revision C (February 2019) to Revision D (September 2019) Page

• Updated the Reverse Polarity Protection with TPS212x section ..................................................................... 31

• Updated the Hotplugging with TPS212x section ............................................................................................. 31

Changes from Revision B (December 2018) to Revision C (February 2019) Page

• Changed the Adjustable Overvoltage Supervisor (OVx) Accuracy to < ±5% in the Features section................ 1

• Changes made in the Recommended Operating Conditions and Electrical Characteristics table in the

Specifications section......................................................................................................................................... 6

• Changes made in the Active Current Limiting (ILM) section.............................................................................13

• Changed (typical) from 170°C to 160°C in the Thermal Protection (TSD) section............................................ 14

• Changed Equation 8 and Equation 9 ...............................................................................................................23

Changes from Revision A (November 2018) to Revision B (December 2018) Page

• Changed from Advance Information to Production Data.................................................................................... 1

Changes from Revision * (August 2018) to Revision A (November 2018) Page

• Changed Wide Operating Range to 2.7 V to 22 V..............................................................................................1

• Revised the Application and Implementation section....................................................................................... 19

2 Submit Document Feedback

Copyright © 2020 Texas Instruments Incorporated

Product Folder Links: TPS2120 TPS2121

www.ti.com

SLVSEA3F – AUGUST 2018 – REVISED AUGUST 2020

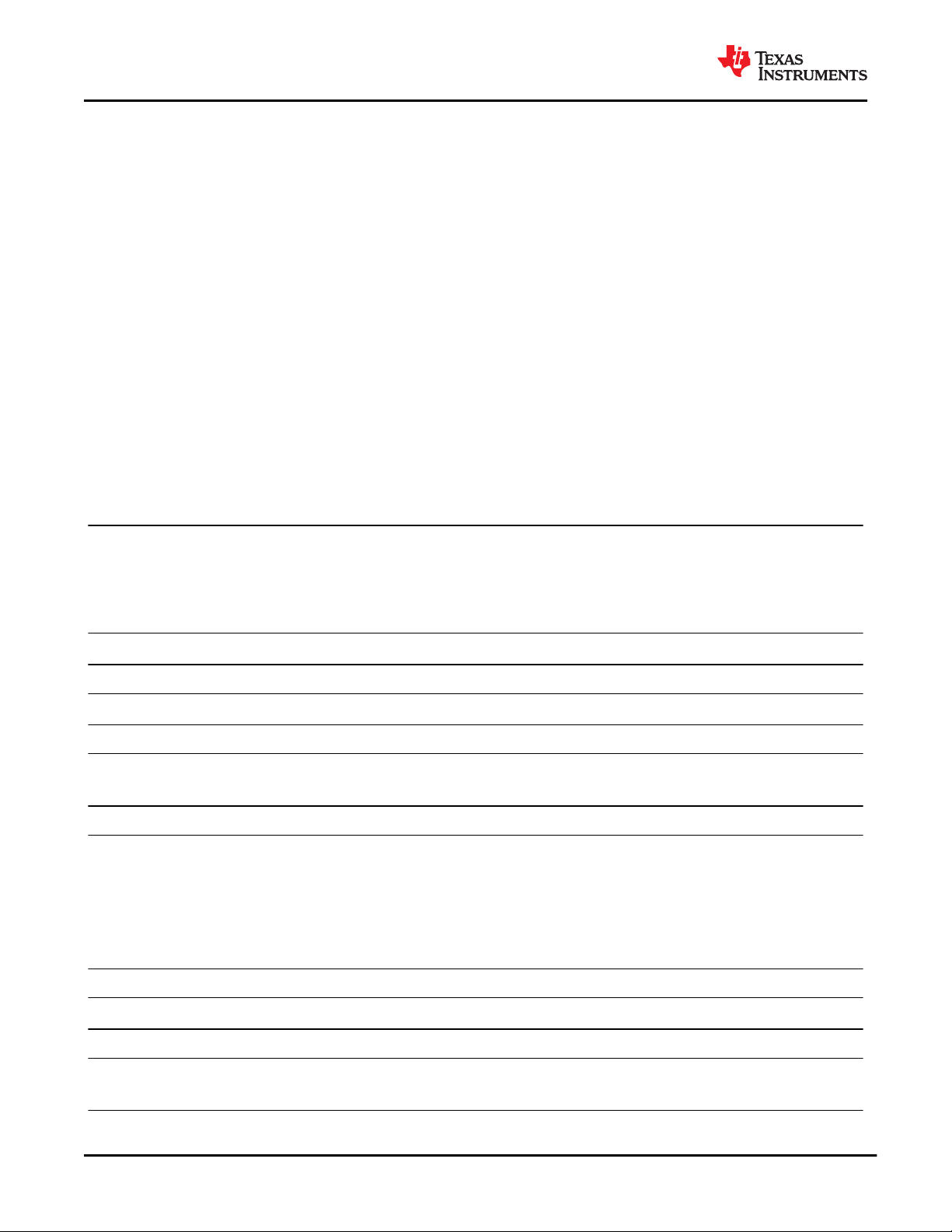

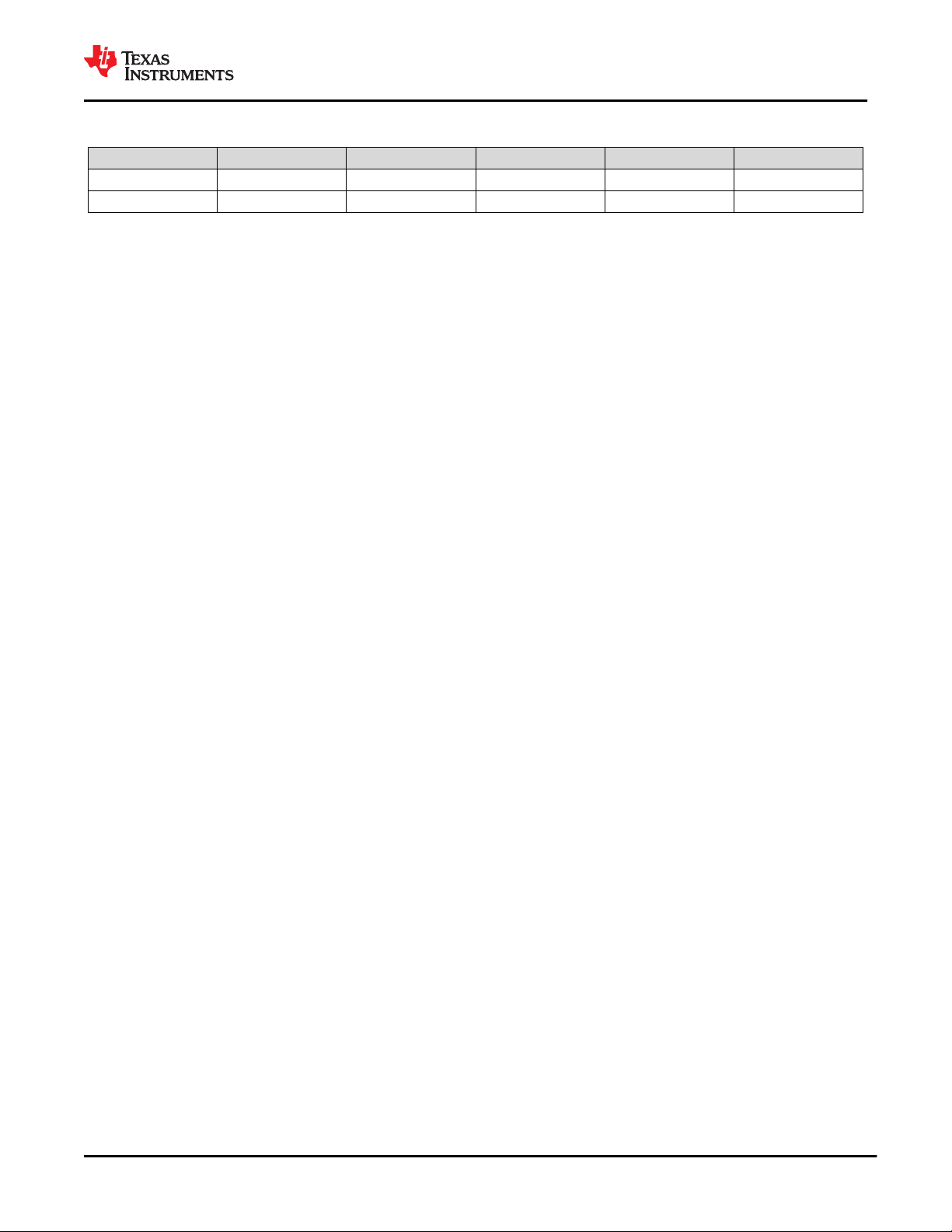

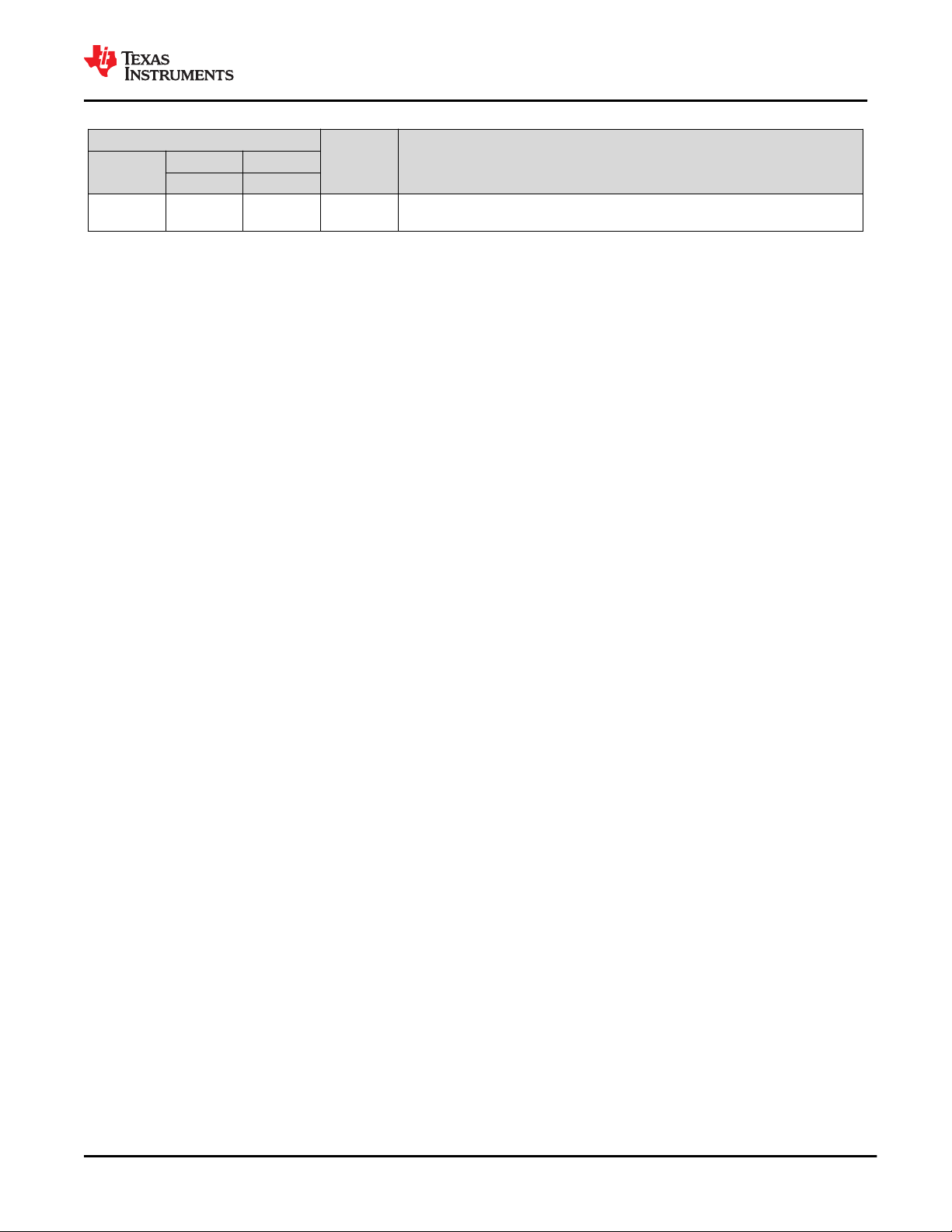

5 Device Comparison Table

Part Number Package On-Resistance Maximum Current Fastest Switchover Unique Pin

TPS2120 WCSP (20) 62 mΩ 3 A 100 us SEL

TPS2121 VQFN-HR (12) 56 mΩ 4.5 A 5 us CP2

TPS2120, TPS2121

Copyright © 2020 Texas Instruments Incorporated

Product Folder Links: TPS2120 TPS2121

Submit Document Feedback

3

TPS2120, TPS2121

SLVSEA3F – AUGUST 2018 – REVISED AUGUST 2020

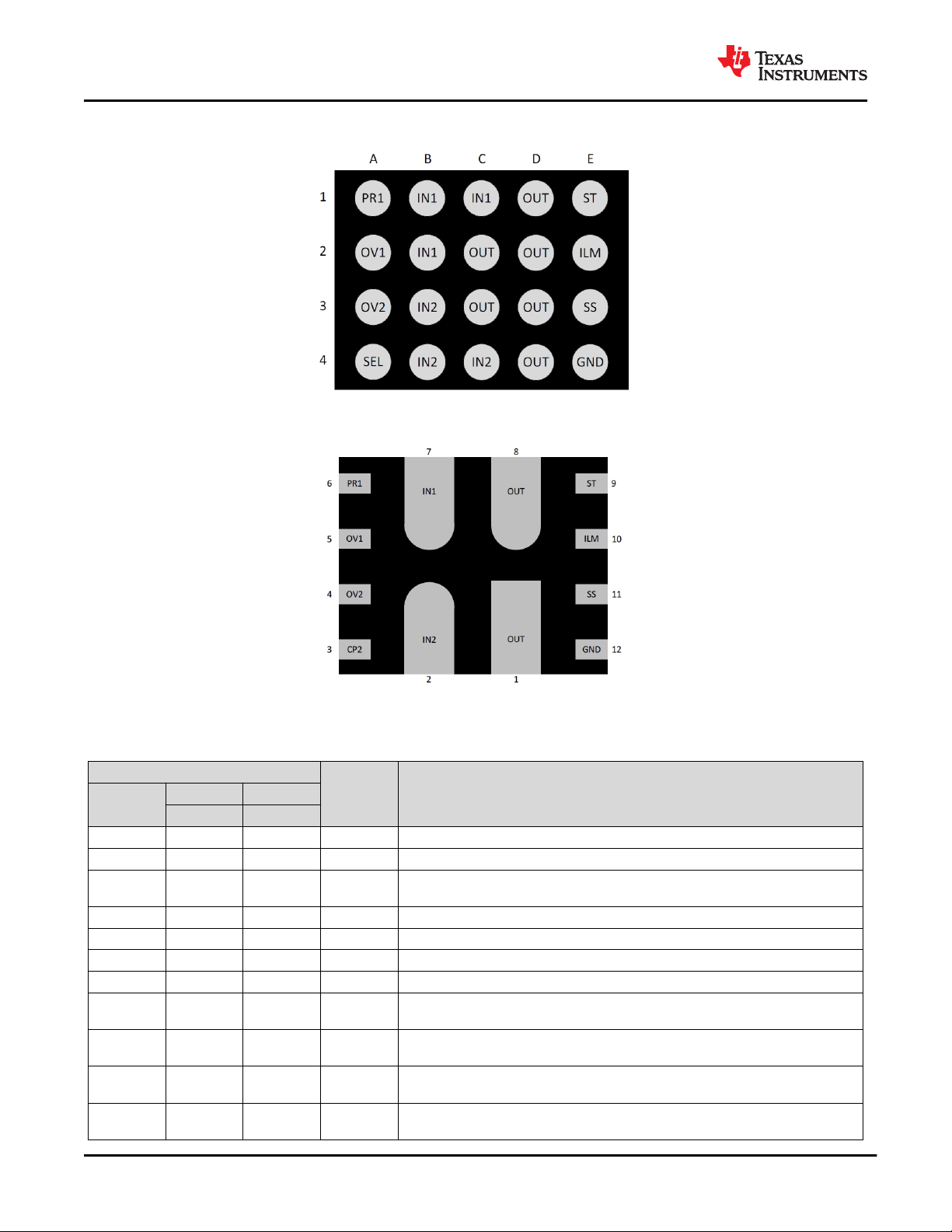

6 Pin Configuration and Functions

Figure 6-1. TPS2120 (YFP) Package 20-Pin WCSP Bottom View

www.ti.com

Figure 6-2. TPS2121 (RUX) Package 12-Pin VQFN-HR Bottom View

Pin Functions

PIN

NAME

IN1 B1, B2, C1 7 I Power Input for Source 1

IN2 B3, B4, C4 2 I Power Input for Source 2

OUT

ST E1 9 O Status output indicating which channel is selected. Connect to GND if not required.

ILIM E2 10 O Output Current Limiting for both channels.

SS E3 11 O Adjusts Input Setting Delay Time and Output Soft Start Time

GND E4 12 — Device Ground

PR1 A1

OV1 A2

OV2 A3

SEL A4

TPS2120 TPS2121

WCSP VQFN-HR

C2, C3, D1,

D2, D3, D4

1, 8

6

5

4

—

I/O DESCRIPTION

I Power Output

Enables Priority Operation. Connect to IN1 to set switchover voltage. Connect to

I

GND if not required.

Active Low Enable Supervisor for IN1 Overvoltage Protection. Connect to GND if

I

not required.

Active Low Enable Supervisor for IN2 Overvoltage Protection. Connect to GND if

I

not required.

Active low Enable for IN1. Allows GPIO to override priority operation and manually

I

select IN2. TPS2120 only.

4 Submit Document Feedback

Copyright © 2020 Texas Instruments Incorporated

Product Folder Links: TPS2120 TPS2121

www.ti.com

NAME

CP2 —

TPS2120 TPS2121

PIN

WCSP VQFN-HR

3

SLVSEA3F – AUGUST 2018 – REVISED AUGUST 2020

Pin Functions (continued)

I/O DESCRIPTION

Enables Comparator Operation and is compared to PR1 to set switchover voltage.

I

Connect to GND if not required. TPS2121 only.

TPS2120, TPS2121

Copyright © 2020 Texas Instruments Incorporated

Product Folder Links: TPS2120 TPS2121

Submit Document Feedback

5

TPS2120, TPS2121

SLVSEA3F – AUGUST 2018 – REVISED AUGUST 2020

www.ti.com

7 Specifications

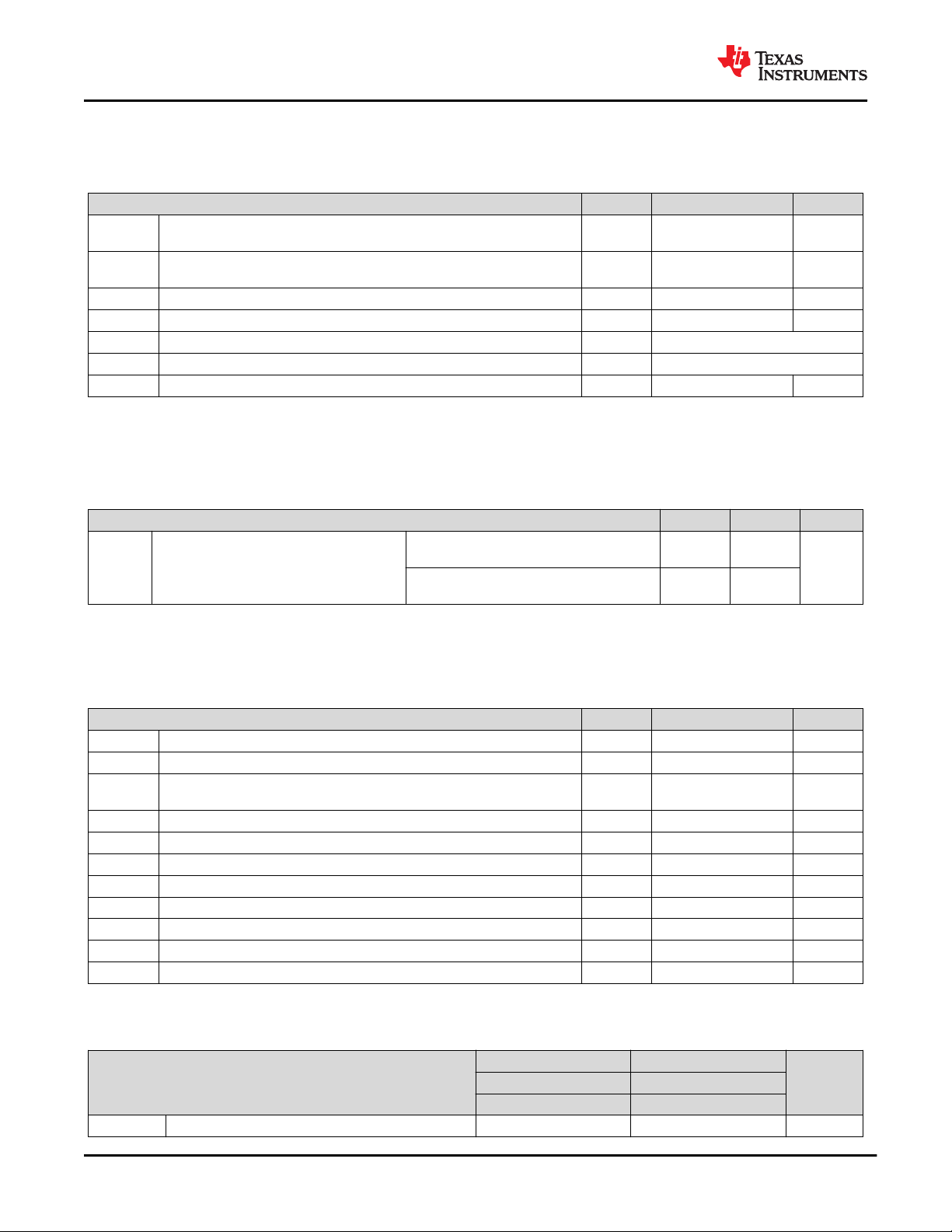

7.1 Absolute Maximum Ratings

over operating free-air temperature range (unless otherwise noted)

V

, V

,

, V

,

IN2

Maximum Power Pin Voltage

Maximum Overvoltage Pin Voltage OV1, OV2 -0.3 6 V

Maximum Control Pin Voltage PRI, SEL -0.3 6 V

SEL

Maximum Control Pin Voltage ST -0.3 6 V

Maximum Output Current OUT Internally Limited

Maximum Junction Temperature Internally Limited

Storage temperature -65 150 °C

IN1

V

OUT

V

OV1

V

OV2

V

PRI

V

ST

I

OUT

T

J, MAX

T

STG

(1) Stresses beyond those listed under Absolute Maximum Rating may cause permanent damage to the device. These are stress ratings

only, which do not imply functional operation of the device at these or any other conditions beyond those indicated under

Recommended Operating Condition. Exposure to absolute-maximum-rated conditions for extended periods may affect device

reliability.

7.2 ESD Ratings

Human body model (HBM), per ANSI/ESDA/

V

ESD

Electrostatic discharge

JEDEC JS-001,

Charged device model (CDM), per JEDEC

specification JESD22-C101,

(1)

(1)

Pins MIN MAX UNIT

IN1, IN2,

OUT

-0.3 24 V

Pins VALUE UNIT

All ±2000

(2)

All ±500

V

(1) JEDEC document JEP155 states that 500-V HBM allows safe manufacturing with a standard ESD control process.

(2) JEDEC document JEP157 states that 250-V CDM allows safe manufacturing with a standard ESD control process.

7.3 Recommended Operating Conditions

over operating free-air temperature range (unless otherwise noted)

Pins MIN MAX UNIT

V

, V

IN1

V

OUT

V

OV1

V

OV2

V

, V

PRI

V

ST

R

ST

R

ILM

V

SS

I

, I

IN1

I

, I

IN1

T

J

Input Voltage Range

IN2

Output Voltage Range OUT 0 22 V

,

Overvoltage Pin Voltage OV1, OV2 0 5.5 V

Control Pin Voltage PRI, SEL 0 5.5 V

SEL

Control Pin Voltage ST 0 5.5 V

Status Pin Pull Up Resistance ST 6 20 kΩ

Current Limit Resistance ILM 18 100 kΩ

SS Pin Output Voltage SS 4 V

TPS2120 Continuous Input Current IN1, IN2 3 A

IN2

TPS2121 Continuous Input Current IN1, IN2 4.5 A

IN2

Junction temperature - -40 125 °C

(1) See Power Supply Recommendations Section for more Details

7.4 Thermal Information

THERMAL METRIC

R

θJA

Junction-to-ambient thermal resistance 72.5 72.2 °C/W

(1)

IN1, IN2 2.8 22 V

TPS2120 TPS2121

(1)

20 PINS 11 PINS

UNITYFP (WCSP) RNW (PKG FAM)

6 Submit Document Feedback

Copyright © 2020 Texas Instruments Incorporated

Product Folder Links: TPS2120 TPS2121

www.ti.com

SLVSEA3F – AUGUST 2018 – REVISED AUGUST 2020

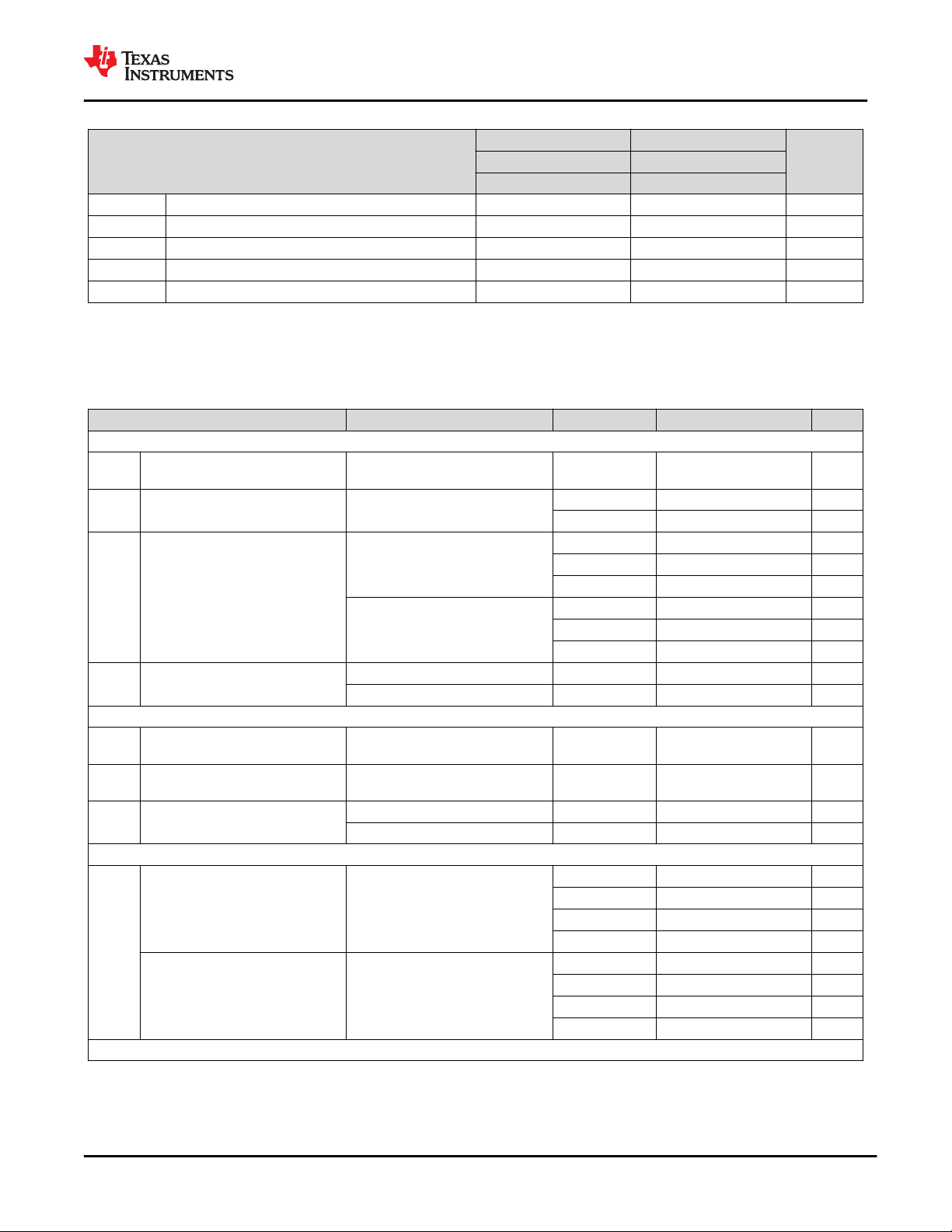

7.4 Thermal Information (continued)

TPS2120, TPS2121

TPS2120 TPS2121

THERMAL METRIC

(1)

UNITYFP (WCSP) RNW (PKG FAM)

20 PINS 11 PINS

R

θJC(top)

R

θJB

Ψ

JT

Ψ

JB

R

θJC(bot)

Junction-to-case (top) thermal resistance 0.5 38.5 °C/W

Junction-to-board thermal resistance 16.4 15.4 °C/W

Junction-to-top characterization parameter 0.3 0.9 °C/W

Junction-to-board characterization parameter 16.6 15.5 °C/W

Junction-to-case (bottom) thermal resistance N/A N/A °C/W

(1) For more information about traditional and new thermal metrics, see the Semiconductor and IC Package Thermal Metrics application

report.

7.5 Electrical Characteristics

over operating free-air temperature range (unless otherwise noted)

PARAMETER TEST CONDITIONS T

INPUT SOURCE (IN1, IN2)

I

Q, INx

I

SBY, INx

I

LK, INx

V

Quiescent Current

(INx Powering OUT)

Standby Current

(INx not powering OUT)

Leakage Current

(INx to OUT)

Undervoltage Lockout

UV, INx

OUTPUT SWITCHOVER (OUT)

t

SW

t

FSW

V

Switchover Time

Fast Switchover Time

(TPS2121 only)

Input Voltage Comparator

COMP

(V

referenced to V

IN2

ON-RESISTANCE (INx to OUT)

ON-State Resistance (TPS2120)

R

ON

ON-State Resistance (TPS2121)

CURRENT LIMIT (ILM)

(1)

IN1

J

OUT = Open -40°C to 125°C 300 400 µA

V

= V

INx

(1)

OUT

25°C 0 15 25 µA

-40°C to 125°C 25 µA

25°C -1 1 µA

|V

- V

INx

OUT

| ≤ 5V

-40°C to 85°C -5 5 µA

-40°C to 125°C -80 80 µA

25°C -1 1 µA

|V

- V

INx

OUT

| ≤ 22V

-40°C to 85°C -35 35 µA

-40°C to 125°C -500 500 µA

V

Rising -40°C to 125°C 2.5 2.65 2.8 V

INx

V

Falling -40°C to 125°C 2.4 2.55 2.7 V

INx

V

< V

OUT

OUT

IN1

IN1

INx

REF

< V

INx

REF

≥ V

IN2

> V

, Falling Hysteresis -40°C to 125°C 2.5 3.5 4.5 %

IN2

CP2 or SEL < V

V

CP2 ≥ V

V

)

V

-40°C to 125°C 100 µs

-40°C to 125°C 5 µs

-40°C to 125°C 0 280 600 mV

25°C 62 75 mΩ

I

= -200 mA

OUT

V

V

PRI

INx

> V

REF

≥ 5.0 V

-40°C to 85°C 90 mΩ

-40°C to 105°C 100 mΩ

-40°C to 125°C 120 mΩ

25°C 56 70 mΩ

I

= -200 mA

OUT

V

V

PRI

INx

> V

REF

≥ 5.0 V

-40°C to 85°C 85 mΩ

-40°C to 105°C 90 mΩ

-40°C to 125°C 100 mΩ

MIN TYP MAX UNIT

Copyright © 2020 Texas Instruments Incorporated

Product Folder Links: TPS2120 TPS2121

Submit Document Feedback

7

TPS2120, TPS2121

SLVSEA3F – AUGUST 2018 – REVISED AUGUST 2020

7.5 Electrical Characteristics (continued)

over operating free-air temperature range (unless otherwise noted)

PARAMETER TEST CONDITIONS T

R

= 31.6kΩ -40°C to 125°C 3 3.5 4 A

ILM

R

= 46.4kΩ -40°C to 125°C 2 2.5 3 A

Output Current Limit (TPS2120)

(2)

I

LM

Output Current Limit (TPS2121)

(3)

t

LM

Current Limit Response Time Output Steady State -40°C to 125°C 250 µs

CONTROL PINS (PRI, SEL, OV1, OV2)

V

V

I

LK, x

Internal Voltage Reference

REF, x

Comparator Offset Voltage

OFST

(TPS2121 only)

Pin Leakage Current

STATUS INDICATION PIN (ST)

I

LK, ST

t

ST

Pin Leakage VST = 0 V to 5.5 V -40°C to 125°C -0.1 0.1 µA

Status Delay L to H -40°C to 125°C 1 µs

FAST REVERSE CURRENT BLOCKING (RCB)

I

RCB

V

t

RCB

Fast Reverse Current Detection

Threshold

RCB Release Voltage V

RCB

Fast Reverse Current Blocking

Response Time

THERMAL SHUTDOWN (TSD)

T

Thermal Shutdown

SD

ILM

R

= 85kΩ -40°C to 125°C 1 1.5 2 A

ILM

R

< 1kΩ -40°C to 125°C 1.5 2.5 3.5 A

ILM

R

= 18.7kΩ -40°C to 125°C 4.6 5.2 5.8 A

ILM

R

= 22.1kΩ -40°C to 125°C 4 4.5 5 A

ILM

R

= 29.8kΩ -40°C to 125°C 3 3.5 4 A

ILM

R

= 44.2kΩ -40°C to 125°C 2 2.5 3 A

ILM

R

= 80kΩ -40°C to 125°C 1 1.5 2 A

ILM

R

< 1kΩ -40°C to 125°C 1.5 2.5 3.5 A

ILM

V

, V

PR1

CP2, VOV1

V

, V

PR1

CP2, VOV1

V

> V

PR1

V

> V

CP2

V

, V

PR1

CP2, VOV1

REF

REF

, V

Rising -40°C to 125°C 1.01 1.06 1.1 V

OV2

, V

Falling -40°C to 125°C 0.99 1.04 1.09 V

OV2

, V

= 0 V to 5.5

OV2

V

V

> V

OUT

INx

> V

OUT

INx

Shutdown Rising 160 °C

Recovery Falling 150 °C

www.ti.com

J

MIN TYP MAX UNIT

-40°C to 125°C 5 20 40 mV

-40°C to 125°C -0.1 0.1 µA

-40°C to 125°C 0.2 1 2 A

-40°C to 125°C 0 25 50 mV

-40°C to 125°C 10 µs

(1) When PR1 < V

not to exceed I

, CP2 < V

REF

Q,INx

, and |V

.

REF

| < 1V, Quiescent current can be drawn from both IN1 and IN2 with combined current

IN1-VIN2

(2) The current limit can be measured by forcing a voltage differential from VIN to VOUT. This value must be at least 200mV greater than

the voltage drop across the device at the current limit threshold (ILM x R

voltage drop of (1.5A x 100mΩ + 200mV) = 350mV from VIN to VOUT for a current limit setting of 1.5A (typical).

). For example, the TPS2121 would need a minimum

ON(MAX)

(3) For more information on device behavior during short circuit conditions, see Section 9.3.3.

8 Submit Document Feedback

Copyright © 2020 Texas Instruments Incorporated

Product Folder Links: TPS2120 TPS2121

Input Voltage (V)

Quiescent Current (PA)

2 4 6 8 10 12 14 16 18 20 22

240

248

256

264

272

280

288

296

304

312

320

D001

-40qC

25qC

85qC

125qC

Input Voltage (V)

Quiescent Current (PA)

2 4 6 8 10 12 14 16 18 20 22

160

180

200

220

240

260

D002

-40qC

25qC

85qC

125qC

Input Voltage (V)

Standby Current (PA)

2 4 6 8 10 12 14 16 18 20 22

6

7

8

9

10

11

12

13

14

15

16

D003

-40qC

25qC

85qC

125qC

Input Voltage (V)

Standby Current (PA)

2 4 6 8 10 12 14 16 18 20 22

6

8

10

12

14

16

18

D004

-40qC

25qC

85qC

125qC

Input Voltage (V)

On-Resistance (m:)

2 4 6 8 10 12 14 16 18 20 22

40

48

56

64

72

80

88

96

104

D005

-40qC

25qC

85qC

125qC

CSS Capacitor (nF)

Output Slew Rate (V/ms)

1 2 3 4 5 67 10 20 30 50 70100 200 500 1000

0

3

6

9

12

15

18

D006

5V

12V

20V

www.ti.com

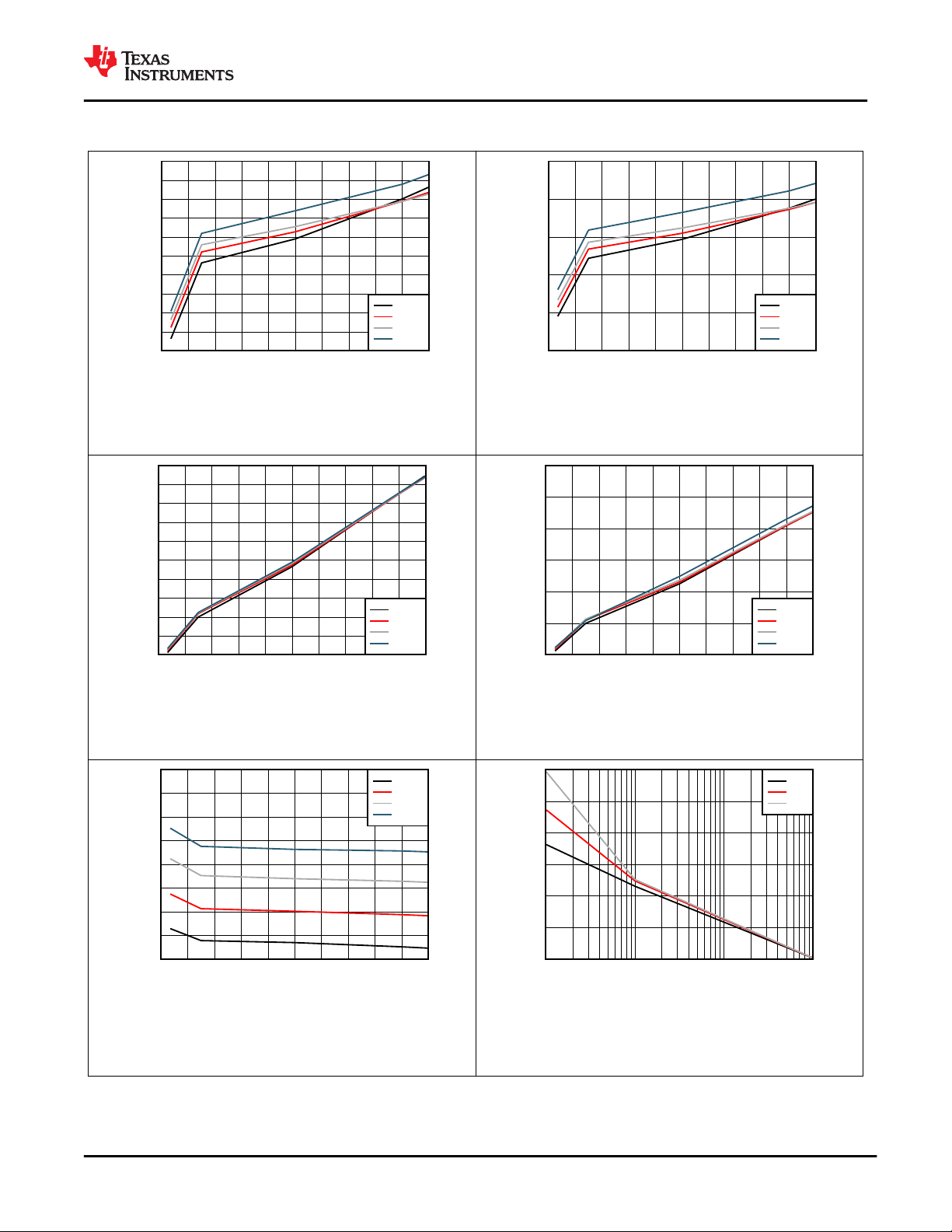

7.6 Typical Characteristics

SLVSEA3F – AUGUST 2018 – REVISED AUGUST 2020

TPS2120, TPS2121

ILM = 5.2A

Figure 7-1. Quiescent Current vs Input Voltage

ILM = 5.2A

Figure 7-3. Standby Current vs Input Voltage

ILM = 1.5A

Figure 7-2. Quiescent Current vs Input Voltage

ILM = 1.5A

Figure 7-4. Standby Current vs Input Voltage

I

= -200 mA

OUT

Figure 7-5. TPS2121 On-Resistance vs Input

Voltage

Copyright © 2020 Texas Instruments Incorporated

V

> UVLO V

IN1

Figure 7-6. Output Slew Rate vs CSS Capacitor

Product Folder Links: TPS2120 TPS2121

= 0V

IN2

Submit Document Feedback

9

TPS2120, TPS2121

SLVSEA3F – AUGUST 2018 – REVISED AUGUST 2020

V

= 12 V V

IN1

IN2

= 0 V

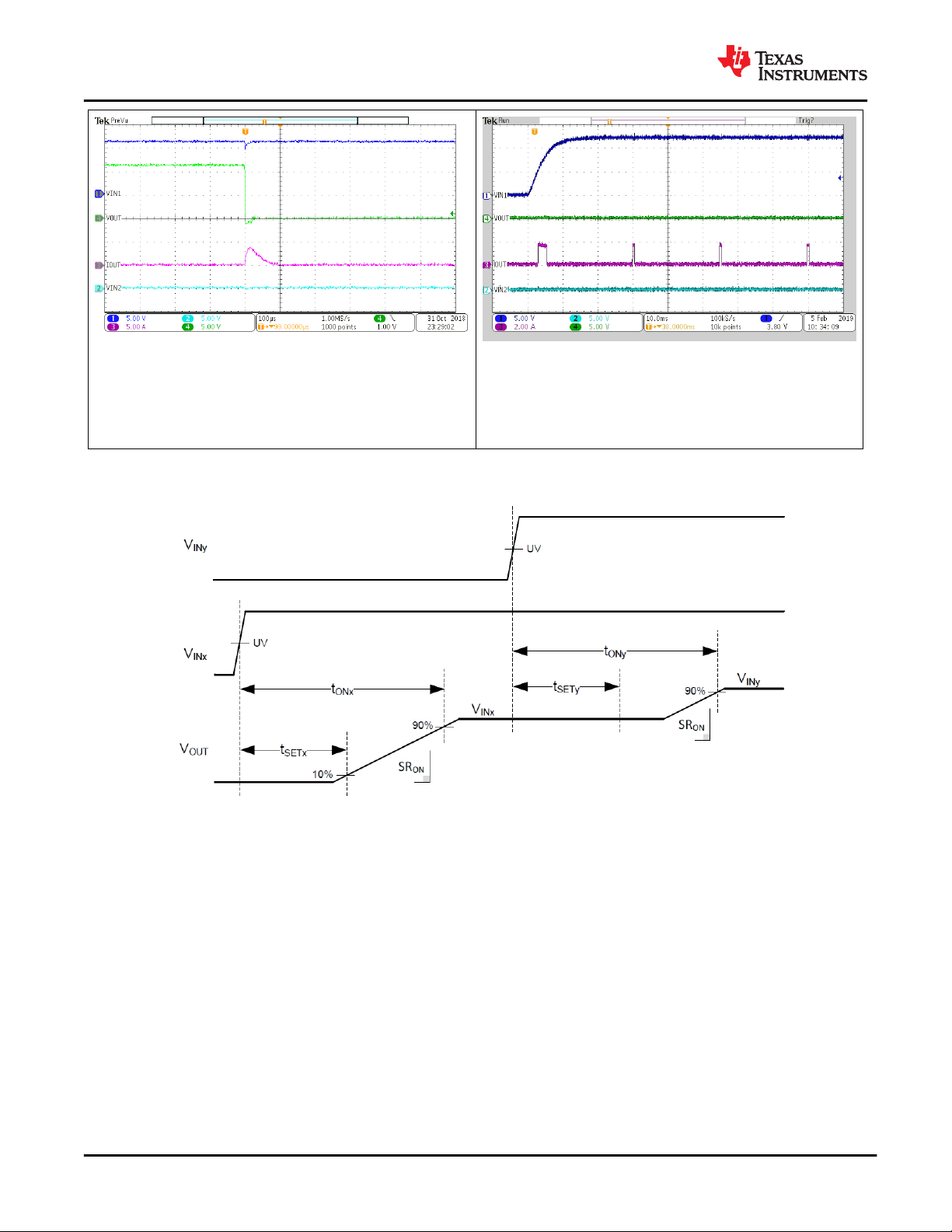

Figure 7-7. TPS2121 Hot Short on OUT while IN1 is

Enabled

8 Parameter Measurement Information

www.ti.com

V

= 12 V V

IN1

R

= 71.5kΩ

ILM

= 0 V V

IN2

OUT

= GND

Figure 7-8. TPS2120 IN1 is Enabled with a Short on

OUT

10 Submit Document Feedback

Figure 8-1. Timing Parameter Diagram

Copyright © 2020 Texas Instruments Incorporated

Product Folder Links: TPS2120 TPS2121

+

±

V

REF

Control Logic

+ Gate Drivers

+

±

+

±

+

±

Temp

SNS

Current

Limit

V

REF

V

REF

V

REF

Temp

SNS

BFET1 HFET1

BFET2 HFET2

IN1

PR1

SEL

OV1

OV2

IN2

ST

GND

SS

OUT

ILM

www.ti.com

SLVSEA3F – AUGUST 2018 – REVISED AUGUST 2020

9 Detailed Description

9.1 Overview

The TPS212x devices are Dual-Input, Single-Output (DISO) Power Multiplexer (MUX) that are well suited for a

variety of systems having multiple power sources. The devices will automatically detect, select, and seamlessly

transition between available inputs. Priority can be automatically given to the highest input voltage or manually

assigned to a lower voltage input to support both ORing and Source Selection operations. A priority voltage

supervisor is used to select an input source.

An Ideal Diode operation is used to seamlessly transition between input sources. During switchover, the voltage

drop is controlled to block reverse current before it happens and provide uninterrupted power to the load with

minimal hold-up capacitance. Active current limiting is used during startup and switchover to protect against

overcurrent, and also protects the device during normal operation. The output current limit can be adjusted with

a single external resistor.

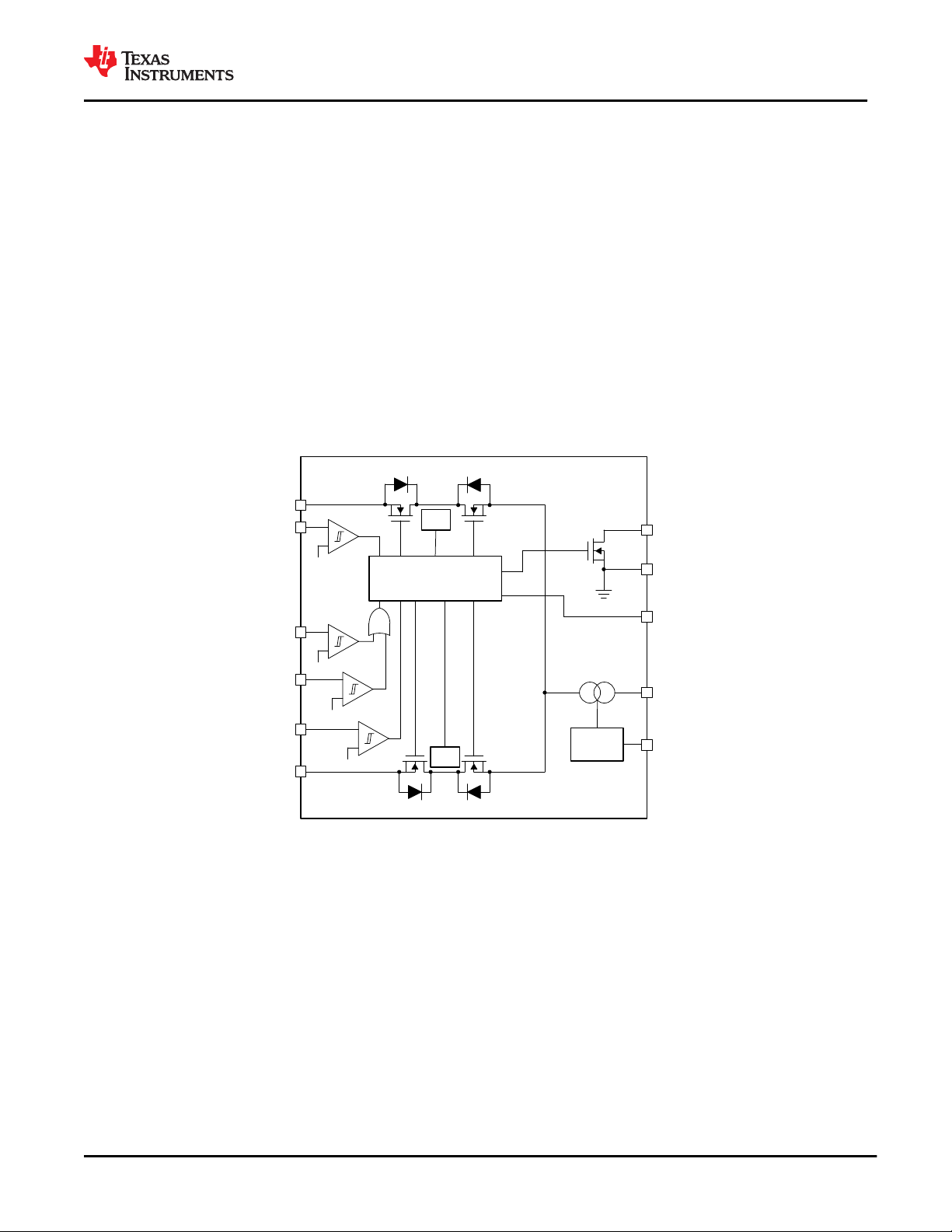

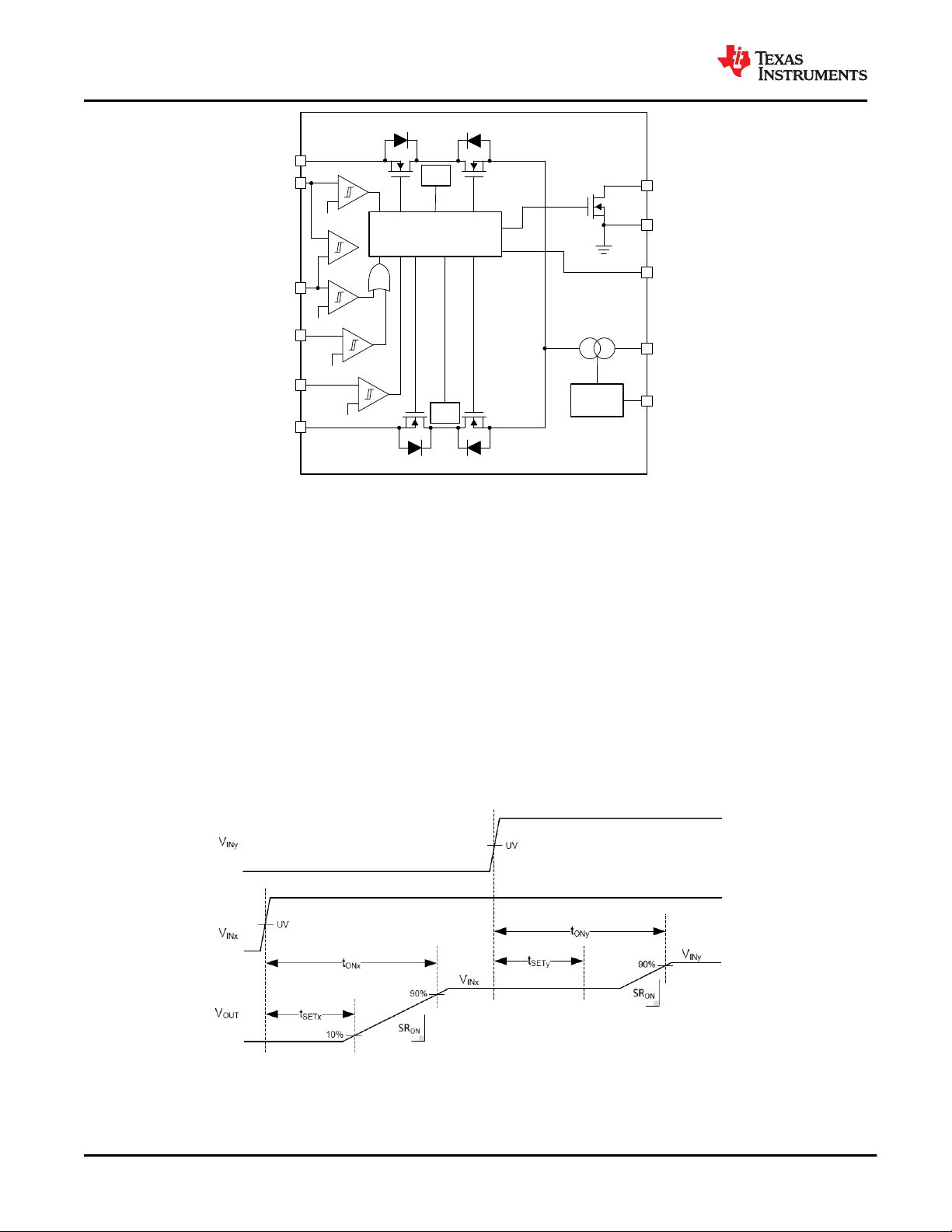

9.2 Functional Block Diagram

The below figures show the block diagrams for the TPS2120 and TPS2121. The TPS2120 has the SEL pin,

while the TPS2121 has the CP2 pin and supports fast switchover.

TPS2120, TPS2121

Figure 9-1. TPS2120 Functional Block Diagram

Copyright © 2020 Texas Instruments Incorporated

Product Folder Links: TPS2120 TPS2121

Submit Document Feedback

11

+

±

V

REF

Control Logic

+ Gate Drivers

+

±

+

±

+

±

Temp

SNS

Current

Limit

V

REF

V

REF

V

REF

Temp

SNS

BFET1 HFET1

BFET2 HFET2

IN1

PR1

CP2

OV1

OV2

IN2

ST

GND

SS

OUT

ILM

+

±

V

OFST

TPS2120, TPS2121

SLVSEA3F – AUGUST 2018 – REVISED AUGUST 2020

Figure 9-2. TPS2121 Functional Block Diagram

www.ti.com

9.3 Feature Description

This section describes the different features of the TPS212x power mux device.

9.3.1 Input Settling Time and Output Soft Start Control (SS)

The TPS212x will automatically select the first source to become valid (INx >UV and INx <OV). The external

capacitor (CSS) will then be used as a timer to wait for the input to finish setting (tSETx). When the settling timer

has expired, CSS will continue to charge and set the output slew rate (SRON) for a soft start. After the total turn

on time (tONx), soft start will not be used again for INx until it ceases to be valid (INx <UV or INx >OV).

When the second source becomes valid (INy >UV and INy <OV), the external capacitor (Css) will be used again

for a second settling time (tSETy). After tSETy, the TPS212x will decide whether to continue sourcing the first

source, or switchover to the second source. If the second source is selected at the end of tSETy, then CSS will

be reused to set the output slew rate (SRON) for a second soft start. After the total turn on time (tONy), soft start

will not be used again for INy until it ceases to be valid (INy <UV or INy >OV).

If INy becomes valid before the end of tONx, tSETy will be delayed and start after tONx has ended.

12 Submit Document Feedback

Figure 9-3. Settling and Soft Start Timing

Product Folder Links: TPS2120 TPS2121

Copyright © 2020 Texas Instruments Incorporated

LM

0.861

ILM

69.1

IR

LM

0.861

ILM

65.2

IR

www.ti.com

SLVSEA3F – AUGUST 2018 – REVISED AUGUST 2020

If INy is not selected during tSETy, a second soft start will not take place, skipping tONy, and CSS will be retired

until one of the inputs ceases to be valid.

9.3.1.1 Slew Rate vs. CSS Capacitor

Table 9-1 shows the estimated slew rate across CSS capacitance and VIN.

Table 9-1. Slew Rate vs. CSS Capacitor

TPS2120, TPS2121

CSS CAPACITOR VIN = 5 V VIN = 12 V VIN = 20 V UNITS

100 nF 780 800 880 V/s

1 uF 88 92 92 V/s

10 uF 8.8 9.6 10.4 V/s

9.3.2 Active Current Limiting (ILM)

The load current is monitored at all times. When the load current exceed the current limit trip point ILM

programmed by RILM resistor, the device regulates the current within t

. The following equations can be used

ILM

to find the RILM value for a desired current limit, where RILM is in kΩ and between 18 kΩ to 100 kΩ.

TPS2120:

TPS2121:

(1)

(2)

During current regulation, the output voltage will drop resulting in increased device power dissipation. If the

device junction temperature (TJ) reaches the thermal shutdown threshold (TSD) the internal FETs are turned off.

After cooling down, the device will automatically restart.

Copyright © 2020 Texas Instruments Incorporated

Product Folder Links: TPS2120 TPS2121

Submit Document Feedback

13

TPS2120, TPS2121

SLVSEA3F – AUGUST 2018 – REVISED AUGUST 2020

www.ti.com

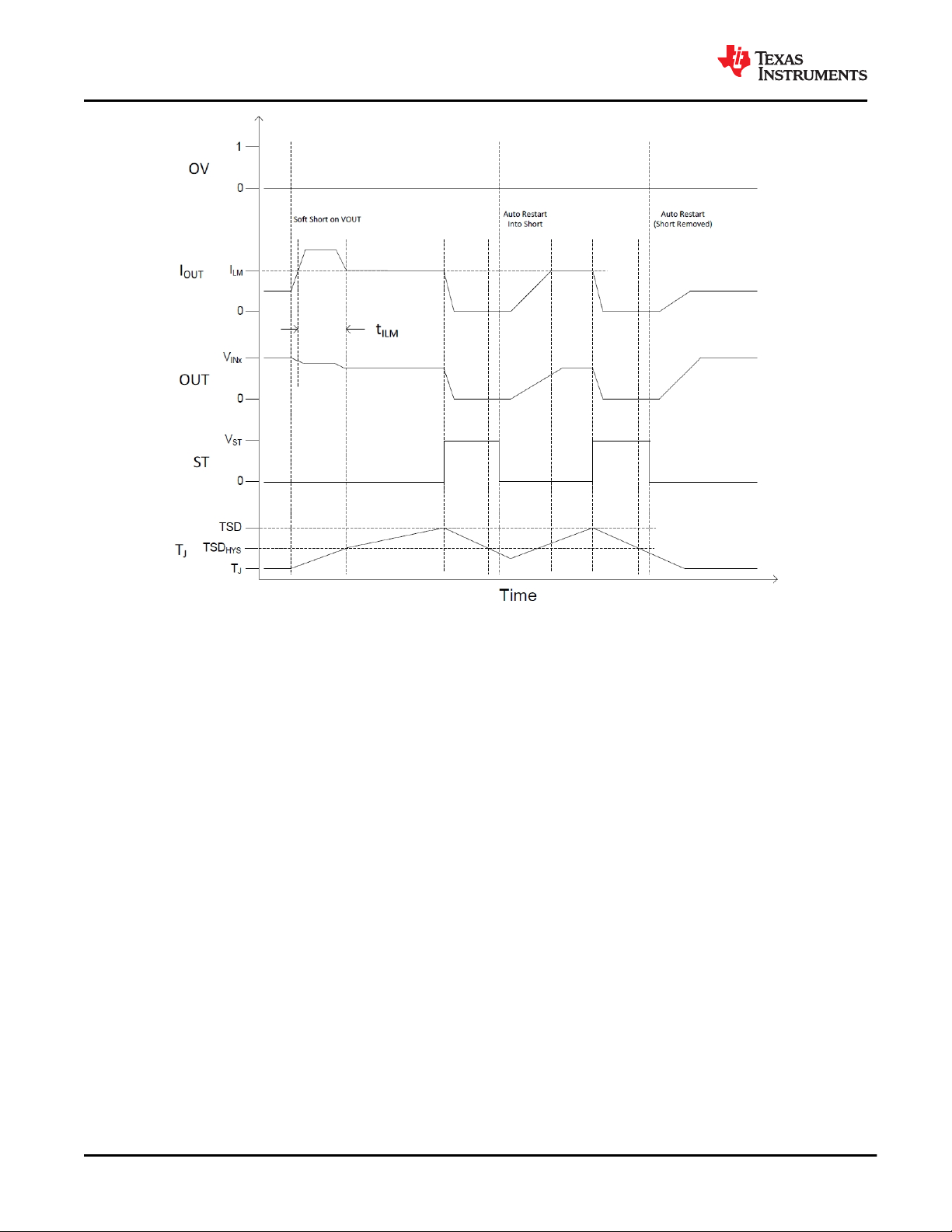

Figure 9-4. Current Limiting Behavior

9.3.3 Short-Circuit Protection

During a transient short circuit event, the current through the device increases very rapidly. As the current-limit

amplifier cannot respond quickly to this event due to its limited bandwidth, the device incorporates a fast-trip

overcurrent protection (OCP) comparator, with a threshold I

within 1 µs, when the current through internal FET IOUT exceeds I

about 2.4x of the programmed current limit I

= 2.4 × ILM. The OCP circuit holds the internal FET off for about

OCP

. This comparator shuts down the pass device

OCP

(I

> I

OCP

OUT

). The trip threshold is set to

OCP

25 ms, after which the device turns back on. If the short is still present then the current-limit loop will regulate the

output current to ILM and behave in a manner similar to a power up into a short.

9.3.4 Thermal Protection (TSD)

The TPS212x devices have built-in absolute thermal shutdown and relative thermal shutdown to ensure

maximum reliability of the power mux. The absolute thermal shutdown is designed to disable the power FETs, if

the junction temperature exceeds 160°C (typical). The device auto recovers about 25 ms after TJ < [T (TSD) –

10°C]. The relative thermal shutdown protects the device by turning off when the temperature of the power FETs

increases sharply such that the FET temperature rises about 60°C above the rest of the die. The device auto

recovers about 25 ms after the FETs cools down by 20°C. The relative thermal shutdown is critical for protecting

the device against faults such as a power up into a short which causes the FET temperature to increase sharply.

9.3.5 Overvoltage Protection (OVx)

Output Overvoltage Protection is available for both IN1 and IN2 in case either applied voltage is greater than the

maximum supported load voltage. The VREF comparator on the OVx pins allow for the Overvoltage Protection

threshold to be adjusted independently for each input. When overvoltage is engaged, the corresponding channel

will turn off immediately. Fast switchover to the other input is supported if it is a valid voltage.

14 Submit Document Feedback

Copyright © 2020 Texas Instruments Incorporated

Product Folder Links: TPS2120 TPS2121

V

SUP PLY

R1

R2

OVx

OUT,MIN SW DIP

V = V - V

OUT

DIP SW

OUT

I

V t

C

§ ·

u

¨ ¸

¨ ¸

© ¹

www.ti.com

SLVSEA3F – AUGUST 2018 – REVISED AUGUST 2020

TPS2120, TPS2121

Figure 9-5. OVP Resistor Configuration

9.3.6 Fast Reverse Current Blocking (RCB)

Each channel has the always on reverse current blocking. If the output is forced above the selected input by

V

, the channel will switch off to stop the reverse current I

IRCB

RCB

within t

. As the output falls to within V

RCB

VIN, the selected channel will quickly turn back on to avoid unnecessary voltage drops during fast switchover

(tSW).

RCB

of

9.3.7 Output Voltage Dip and Fast Switchover Control (TPS2121 only)

After input settling and soft start time, the TPS2121 utilizes a fast switchover to minimize output voltage drop.

Where VSW is the output voltage when the switchover is triggered and tSW is the time until the output voltage

stops dipping. The amount of voltage dip during the switchover time is a function of output load current (IOUT)

and load capacitance (COUT). The minimum output voltage during switchover can be found using the following

equations:

Where:

Copyright © 2020 Texas Instruments Incorporated

Figure 9-6. Reverse Current Blocking Behavior

Product Folder Links: TPS2120 TPS2121

(3)

(4)

Submit Document Feedback

15

V

IN1

I

OUT

V

IN2

V

IN2

V

IN1

0 V

V

SW

t

SW

V

OUT,MIN

Current Limited

0

V

OUT

I

IN2

SR

OUT

Input

Voltages

PRI

V

OUT,MIN

= V

SW

- (tSWxSR

OUT

) where SR

OUT

= I

OUT/COUT

V

OUT,MIN

= 3.5 V - (5µs x 30mV/µs) = 3.35 V

V

OUT,MIN

= 3.5 V - (5µs x 1A/10µF) = 3 V

V

OUT,MIN

= 3.5 V - (5µs x 1A/100µF) = 3.45 V

Time

V

REF

H

L

TPS2120, TPS2121

SLVSEA3F – AUGUST 2018 – REVISED AUGUST 2020

www.ti.com

Figure 9-7. Minimum Output Voltage During Fast Switchover

If switching from a lower to a higher voltage, the selected channel will not detect reverse voltage and shall turn

on immediately using the current monitor to limit the output current to a safe level. If the output current reaches

the current limit during fast switchover, this will increase the total time until the output reaches steady state.

Figure 9-8. Fast Switchover from Lower to Higher Voltage

If an input is selected while the output voltage is still a higher voltage, that channel will continue to block reverse

current by waiting to fast turn on until the output drops below the V

16 Submit Document Feedback

Product Folder Links: TPS2120 TPS2121

threshold.

RCB

Copyright © 2020 Texas Instruments Incorporated

V

OUT,MIN

= V

IN1

+ V

RCB

- (t

SW

x SR

OUT

) where SR

OUT

= I

OUT/COUT

V

OUT,MIN

= 4.25 V + 50 mV - (5µs x 30mV/µs) = 4.15 V

V

OUT,MIN

= 4.25 V + 50 mV - (5µs x 1A/10µF) = 3.8 V

V

OUT,MIN

= 4.25 V + 50 mV (5µs x 1A/100µF) = 4.25 V

SR

OUT

V

RCB

t

SW

V

OUT,MIN

No Spikes

Input

Voltages

OV2

V

OUT

I

IN1

Time

V

IN1

I

OUT

V

IN2

V

IN2

V

IN1

0 V

0

1

0

www.ti.com

SLVSEA3F – AUGUST 2018 – REVISED AUGUST 2020

TPS2120, TPS2121

Figure 9-9. Fast Switchover from Higher to Lower Voltage

9.3.8 Input Voltage Comparator (VCOMP)

If both PR1 and CP2 are < VREF, the device will use an internal comparator between the two inputs to

determine the priority source. V

If IN2 falls below the V

Hysteresis, then IN1 will have priority.

COMP

is configured to ensure IN2 will take priority if the input voltages are equal.

COMP

Figure 9-10. VCOMP Priority Source Selection

Copyright © 2020 Texas Instruments Incorporated

Product Folder Links: TPS2120 TPS2121

Submit Document Feedback

17

TPS2120, TPS2121

SLVSEA3F – AUGUST 2018 – REVISED AUGUST 2020

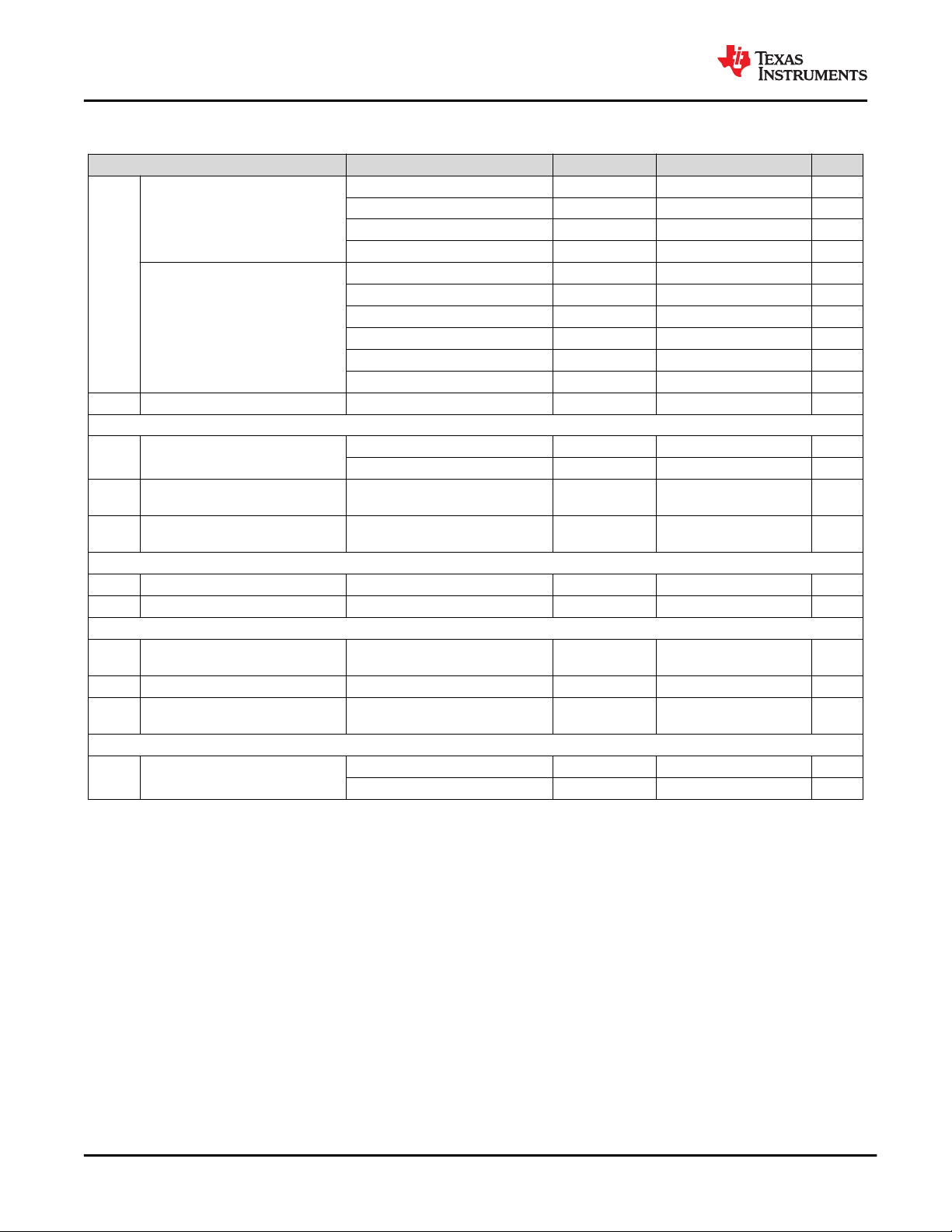

9.4 TPS2120 Device Functional Modes

Table 9-2 shows the TPS2120 functional behavior.

Table 9-2. TPS2120 Output Source Selection Table

DEVICE INPUTS DEVICE OUTPUTS

IN1 ≤ UV OR

OV1 ≥ VREF OR

SEL ≥VREF

0 0 0 IN2 < IN1 IN1 H VCOMP

0 0 0 IN2 ≥ IN1 IN2 L VCOMP

0 0 1 X IN1 H VREF

0 1 X X IN1 H Invalid Input

1 0 X X IN2 L SEL / Invalid Input

1 1 X X Hi-Z H Invalid Inputs

IN2 ≤ UV OR

OV2 ≥ VREF

PR1 ≥ VREF VCOMP OUT ST MODE

A summary of the operation of the TPS2120 device can be found below:

• If only one input voltage is valid (above UV and below OV) then that input will power the output.

• If both inputs are not valid, then the output is Hi-Z.

• ST is pulled high when the output is Hi-Z or IN1. It is pulled low when IN2 is powering the output.

• If both inputs are valid and PR1 is pulled high (higher than VREF, 1.06-V typical), then IN1 is used.

• If both inputs are valid and PR1 is pulled low, then the highest voltage input is used.

OPERATION

www.ti.com

MODE OF

9.5 TPS2121 Device Functional Modes

Table 9-3 shows the TPS2121 functional behavior.

Table 9-3. TPS2121 Output Source Selection Table

DEVICE INPUTS DEVICE OUTPUTS

IN1 ≤ UV OR

OV1 ≥ VREF

0 X 0 0 IN2 < IN1 X IN1 H VCOMP

X 0 0 0 IN2 ≥ IN1 X IN2 L VCOMP

0 X 0 1 X X IN1 H VREF

X 0 1 0 X X IN2 L VREF

0 X 1 1 X PR1 > CP2 IN1 H XCOMP / XREF

X 0 1 1 X PR1 ≤ CP2 IN2 L XCOMP / XREF

0 1 X X X X IN1 H Invalid Input

1 0 X X X X IN2 L Invalid Input

1 1 X X X X Hi-Z H Invalid Inputs

IN2 ≤ UV OR

OV2 ≥ VREF

CP2 ≥

VREF

PR1 ≥

VREF

VCOMP XCOMP OUT ST MODE

A summary of the operation of the TPS2121 device can be found below:

• If only one input voltage is valid (above UV and below OV) then that input will power the output.

• If both inputs are not valid, then the output is Hi-Z.

• ST is pulled high when the output is Hi-Z or IN1. It is pulled low when IN2 is powering the output.

• If CP2 is pulled low, then the TPS2121 ignores this pin.

• When CP2 is pulled high, this enables fast switchover and is compared to PR1. If PR1 > CP2 then IN1 is

used, and if PR1 < CP2 then IN2 is used.

• If both inputs are valid, CP2 is low, and PR1 is pulled high, (higher than VREF, 1.06-V typical), then IN1 is

used.

• If both inputs are valid, CP2 is low, and PR1 is pulled low, then the highest voltage input is used.

MODE OF

OPERATION

18 Submit Document Feedback

Copyright © 2020 Texas Instruments Incorporated

Product Folder Links: TPS2120 TPS2121

www.ti.com

SLVSEA3F – AUGUST 2018 – REVISED AUGUST 2020

10 Application and Implementation

Note

Information in the following applications sections is not part of the TI component specification, and TI

does not warrant its accuracy or completeness. TI’s customers are responsible for determining

suitability of components for their purposes. Customers should validate and test their design

implementation to confirm system functionality.

10.1 Application Information

The TPS212x device is a highly configurable power mux that can be designed to meet various application

requirements. When designing the TPS212x for a power mux configuration, 3 key factors should be considered:

• VOUT voltage dip

• Manual and Automatic Switchover

• Switchover Time

The TPS212x device can be configured in various modes to meet these considerations and provides a general

table that describes each mode of operation. This application section will highlight 3 common modes of

operation that address these factors.

10.2 Typical Application

Table 10-1 summarizes the applications highlighted in the following sections.

TPS2120, TPS2121

Table 10-1. TPS212x Application Summary Table

MODE DEVICE(S) DESCRIPTION SECTION

Manual Switchover TPS2120 / TPS2121

Automatic Switchover with

Priority (XCOMP)

Automatic Switchover with

Priority (XREF)

Highest Voltage Operation

(VCOMP)

TPS2121

TPS2121

TPS2120 / TPS2121

An external controller (such as an MCU) can be used

to manually select between the two input sources.

Prioritizes Supply 1 when present, and quickly

switches to Supply 2 when Supply 1 drops.

Prioritizes Supply 1 when present, and quickly

switches to Supply 2 when Supply 1 drops. An external

supply is used to increase the accuracy of the

comparator for switchover.

The device automatically selects the highest voltage

supply to power the output.

11.2.1

11.3

11.4

11.5

Copyright © 2020 Texas Instruments Incorporated

Product Folder Links: TPS2120 TPS2121

Submit Document Feedback

19

TPS2120, TPS2121

SLVSEA3F – AUGUST 2018 – REVISED AUGUST 2020

10.2.1 Manual Switchover Schematic

Figure 10-1 and Figure 10-2 show the application schematic for manual switchover on the TPS2120 and

TPS2121.

www.ti.com

Figure 10-1. TPS2120 Manual Switchover

Figure 10-2. TPS2121 Manual Switchover

10.2.2 Design Requirements

In certain power architectures, an external MCU or controller monitors the downstream load. If the controller

needs to select between multiple supplies, the controller can manually switch between inputs through a single

GPIO. In this configuration, an external signal will switch between two input supplies, a 5-V supply (IN1) and a

3.3-V supply (IN2). Table 10-2 summarizes the design parameters for this example.

20 Submit Document Feedback

Copyright © 2020 Texas Instruments Incorporated

Product Folder Links: TPS2120 TPS2121

www.ti.com

SLVSEA3F – AUGUST 2018 – REVISED AUGUST 2020

Table 10-2. Manual Switchover Design Requirements

TPS2120, TPS2121

DESIGN PARAMETER SPECIFICATION DETAILS

IN1 Voltage V

IN2 Voltage V

Load Current I

Load Capacitance C

Maximum Inrush Current I

Current Limit 2 A

Switchover Time t

Mode of Operation Manual Switchover TPS2120: VREF

External MCU Signal V

Overvoltage Protection V

IN1

IN1

OUT

L

INRUSH

SW

MCU

OV1

V

OV2

5 V

3.3 V

500 mA

100 µF

100 mA

TPS2121: 5 µs

TPS2120: 100 µs

TPS2121: XREF

3.3 V

OV1 : 6.1 V

OV2: 4 V

10.2.3 Detailed Design Description

The TPS212x devices can be configured to manually switch between IN1 and IN2 through an external GPIO. In

this example, an external MCU signal is selecting between main power and auxiliary power to power a

downstream load. By manually toggling the TPS212x, the device will switch between both sources, even if one

supply is higher than the other supply. Ultimately, the main factor that will determine the switchover time between

IN1 (5 V) and IN2 (3.3 V) is the output load.

Manual switchover can be enabled by configuring the TPS212x for internal voltage reference control scheme

(VREF). In the VREF scheme, if the voltage on PR1 is higher than the internal VREF voltage, 1.06 V (typical),

the device will select IN1 as the output. If the voltage on PR1 drops below VREF, then the device will switch to

IN2, as long as IN2 is presenting a valid input voltage. IN1 is commonly connected to PR1 with an external

resistor divider. OV1 and OV2 can be configured to provide overvoltage protection. The ST pin can be pulled

high with a resistor to provide feedback on the status of the system. If the status pin is high, IN1 is the output. If

the pin is low, IN2 is the output. If this feature is not required, the ST pin can be connected to GND.

On the TPS2120, by connecting an external signal to the select pin (SEL), the device can override the PR1/

VREF comparison. If the voltage on SEL is higher than VREF at approximately (1.06 V), then the device will

select IN2, as shown on Table 9-2. If the voltage on SEL drops below VREF, then the device will switch to IN1 as

long as PR1 >= VREF. Otherwise, the highest voltage input will be chosen between IN1 and IN2. In this

example, since the IN1 is higher than IN2, at 5 V, it will be selected.

Copyright © 2020 Texas Instruments Incorporated

Product Folder Links: TPS2120 TPS2121

Submit Document Feedback

21

TPS2120, TPS2121

SLVSEA3F – AUGUST 2018 – REVISED AUGUST 2020

Figure 10-3 shows the application schematic for this design example on the TPS2120.

Figure 10-3. TPS2120 Manual Switchover

www.ti.com

On the TPS2121, fast switchover can be enabled to minimize the voltage drop on VOUT. The internal

comparator will detect and seamlessly switch between IN1 and IN2 as long as a reverse voltage condition does

not exist on that channel. To enable fast switchover on the TPS2121, CP2 needs to be higher than VREF, 1.06-V

(typical). By using the external voltage reference control scheme (XREF), the voltages on PR1 and CP2 pins are

compared to determine whether IN1 or IN2 is powering the output. If the voltage on PR1 is higher than CP2,

then IN1 is powering the output. If the voltage on PR1 is lower than CP2, then IN2 is powering the output.

Manual switchover on the TPS2121 is configured by connecting PR1 to IN1 with a resistor divider, and

connecting CP2 to the external 3.3-V MCU signal. If the voltage on CP2 is higher than the voltage on PR1, then

IN2 will power the output. However, if CP2 is toggled low, then IN1 will power the output, assuming IN1 has a

valid input voltage.

The diagram below shows the application schematic for this design example on the TPS2121.

22 Submit Document Feedback

Figure 10-4. TPS2121 Manual Switchover

Copyright © 2020 Texas Instruments Incorporated

Product Folder Links: TPS2120 TPS2121

PR1 IN1

5 k

V V

5 k 10.2 k

:

u

: :

IN1

5 k

5 k 10.2 k

:

u

: :

IN1

5 k

5 k 23.7 k

§ ·

:

u

¨ ¸

: :

© ¹

IN2

5 k

5 k 13.7 k

§ ·

:

u

¨ ¸

: :

© ¹

LM

0.861

69.1

I 2.06 A

59

www.ti.com

10.2.4 Design Procedure

10.2.4.1 Selecting PR1 and CP2 Resistors

The TPS2120 does not contain a CP2 pin. Instead, a select pin (SEL), enables override of the PR1 / VREF

comparison. Once the voltage on SEL is greater than VREF, the device will select IN2 as the output. For manual

switchover, an external signal can be connected to the SEL pin. For this example, the external MCU signal is a

3.3-V enable.

The TPS2121 can be configured for manual switchover in a similar manner as the TPS2120. Instead of a SEL

pin, the 3.3-V external MCU signal can be connected to CP2. As long as the voltage on CP2 is higher than PR1,

the device will select IN2 as the output. When the voltage on CP2 drops below PR1, the device will switch back

to IN1. Therefore, the resistor divider on PR1 is configured the same as above, with the 5 kΩ and 10.2 kΩ.

For additional precautions, the voltage on PR1 can also be configured. If the voltage on IN1 were to drop, the

device can automatically switchover to IN2. In this example, if voltage on IN1 drops below IN2 (3.3 V) then the

device will switch to IN2. Therefore, the resistor divider on PR1 should be configured such that the voltage on

PR1 will drop below VREF, when IN1 dips below 3.3 V. The bottom resistor is chosen to be 5 kΩ due to it's

commonality and minimal current leakage. If a smaller leakage is desired, a larger resistor can be used. With this

configuration, the top resistor was selected to be 10.2 kΩ. With this resistor configuration, the device will switch

to IN2 when the voltage on IN1 dips to 3.22 V. Refer to Table 9-2 for additional information regarding the

switchover configuration.

See Equation 5 for the VPR1 Calculation

SLVSEA3F – AUGUST 2018 – REVISED AUGUST 2020

TPS2120, TPS2121

(5)

10.2.4.2 Selecting OVx Resistors

Independent output overvoltage protection is available for both IN1 and IN2. The VREF comparator on the OV1

and OV2 pins allows for the overvoltage protection thresholds to be adjusted independently, allowing for different

overvoltage thresholds on each channel. When overvoltage is engaged, the corresponding channel will turn off

immediately if the pin reaches VREF, 1.06 V (typical). On this design, the overvoltage thresholds are triggered at

roughly 1-V higher than the nominal input voltages. On IN1, the overvoltage resistor divider was programmed to

be 6.08 V, where as the divider on IN2 was programmed to be 3.96 V. The OV resistor calculations are shown in

Equation 6 and Equation 7.

(6)

(7)

10.2.4.3 Selecting Soft-Start Capacitor and Current Limit Resistors

Equation 1 can be used to determine the RLIM values for this application. In this example, the DC load current is

1 A. Setting the current limit to 2 A will limit potential inrush current events and protect downstream loads. See

Equation 8 for the TPS2120 ILM Calculation:

Copyright © 2020 Texas Instruments Incorporated

Product Folder Links: TPS2120 TPS2121

(8)

Submit Document Feedback

23

LM

0.861

65.2

I 1.95 A

59

INRUSH

ON

I

SRC

ON

100 mA

SR 1000 V / S

100 F

P

TPS2120, TPS2121

SLVSEA3F – AUGUST 2018 – REVISED AUGUST 2020

www.ti.com

See Equation 9 for the TPS2121 ILM Calculation:

(9)

To calculate the slew rate needed to limit the inrush current to 100 mA, the Slew Rate Calculation can be used in

Equation 10:

(10)

(11)

Using this equation, the slew rate must be limited to 1000V/S or below to keep the inrush current below 100 mA.

According to Table 9-1, at 5 V a CSS capacitance of 100 nF will provide a slew rate of 780V/S (typical), which is

below the calculated threshold of 1000V/S. Therefore, a 100 nF capacitor will limit the inrush below 100 mA in a

typical application.

10.2.5 Application Curves

Figure 10-5. TPS2120 Switchover from IN1 to IN2 Figure 10-6. TPS2120 Switchover from IN2 to IN1

Figure 10-7. TPS2121 Switchover from IN1 to IN2 Figure 10-8. TPS2121 Switchover from IN2 to IN1

24 Submit Document Feedback

Copyright © 2020 Texas Instruments Incorporated

Product Folder Links: TPS2120 TPS2121

TPS2121

IN1

OUT

IN1

(12V)

PRI

System Load

(2A, 200µF)

OV1

GND

SS

ILM

ST

IN2

IN2

(5V)

5kO

63.4kO

5kO

18.2kO

21.5kO

1µF

5kO

10.2kO

5kO

CP2

OV2

23.7kO

www.ti.com

SLVSEA3F – AUGUST 2018 – REVISED AUGUST 2020

10.3 Automatic Switchover with Priority (XCOMP)

In certain applications, the system needs to provide uninterrupted sources of power. If one of the input power

supplies were to fail, the system needs to automatically switchover to a backup power source without interrupting

normal operation. In this example, two scenarios will be demonstrated. The first example will prioritize a 12-V

main supply, and switchover to a 5-V auxiliary supply whenever the 12 V is not present. The second example will

showcase power redundancy with two 12-V supplies. If one 12-V supply were to fail, the device will seamlessly

switchover to the backup supply.

10.3.1 Application Schematic

Figure 10-9 shows the application schematic for automatic switchover on the TPS2121 between a 12-V and 5-V

supply.

TPS2120, TPS2121

Figure 10-9. Automatic Switchover Between 12 V and 5 V

10.3.2 Design Requirements

Table 10-3. Automatic Switchover Design Requirements

DESIGN PARAMETER SPECIFICATION DETAILS

IN1 Voltage V

IN2 Voltage V

Load Current I

Load Capacitance C

Maximum Inrush Current I

Mode of Operation Automatic Switchover TPS2121: XCOMP

Switchover Time t

IN1

IN1

OUT

L

INRUSH

SW

12 V

5 V

2 A

200 µF

100 mA

TPS2120: 5 µs

10.3.3 Detailed Design Description

The first example demonstrates automatic switchover from main power (IN1) to standby power (IN2). This

architecture is commonly found on applications that require a secondary/auxiliary input to conserve power while

keeping downstream loads on. When switching between main and auxiliary power, the voltage drop on the

output should also be minimal to prevent the downstream load from resetting or entering a lockout condition.

In this first example, the system is prioritizing the 12-V main supply on IN1. When the 12-V supply drops below

7.6 V, the device will automatically switch to the 5-V auxiliary supply on IN2. When the 12-V supply returns, it will

Copyright © 2020 Texas Instruments Incorporated

Product Folder Links: TPS2120 TPS2121

Submit Document Feedback

25

CP2

5 k

V 5 V 1.64 V

5 k 10.2 k

:

u

: :

PR1

5 k

V 12 V 2.59 V

5 k 18.2 k

:

u

: :

5 k

5 k 18.2 k

:

u

: :

TPS2120, TPS2121

SLVSEA3F – AUGUST 2018 – REVISED AUGUST 2020

become the output supply again. Furthermore, the voltage drop on the output should be minimal, providing the

output with uninterrupted redundant power.

To minimize the voltage dip on the output, the TPS2121 will be used in fast switchover mode. By configuring the

device in external comparator control scheme (XCOMP), the voltages on PR1 and CP2 are compared to

determine whether IN1 or IN2 is powering the output. However, unlike the XREF mode, described above in the

manual switchover configuration, XCOMP does not connect an external GPIO signal to the CP2 pin. Instead,

PR1 and CP2 are connected to IN1 and IN2 respectively, allowing a direct voltage comparison between the two

input channels. PR1 and CP2 are connected to IN1 and IN2 with a resistor divider. If the voltage on CP2 is

higher than the voltage on PR1, then IN2 will power the output. If the voltage on PR1 is higher than the voltage

on CP2, then IN1 will power the output.

10.3.4 Design Procedure

10.3.4.1 Selecting PR1 and CP2 Resistors

In this example, the device will switch from IN1 to IN2 when the voltage on IN1 drops below 7.6 V. Therefore, the

voltage on PR1 needs to remain higher than the voltage on CP2 until this condition exists.

Since this example was tested on the TPS2121EVM, the resistor divider configured the voltage on CP2 to be

1.644 V.

See Equation 12 for the VCP2 Calculation

www.ti.com

(12)

Since the voltage on CP2 is higher than VREF, fast switchover mode is enabled.

Next, to calculate the necessary resistor divider on PR1, the voltage on PR1 needs to drop below 1.64 V when

IN1 reaches 7.6 V. On the EVM, the PR1 resistors were configured as followed:

See Equation 13 for the VPR1 Caculation

(13)

10.3.5 Application Curves

Figure 10-10. Automatic Switchover from IN1 to

IN2

26 Submit Document Feedback

Figure 10-11. Automatic Switchover from IN2 to IN1

Copyright © 2020 Texas Instruments Incorporated

Product Folder Links: TPS2120 TPS2121

TPS2121

IN1

OUT

IN1

(12V)

PRI

System Load

(2.5A, 320µF)

OV1

GND

SS

ILM

ST

IN2

IN2

(12V)

5kO

57.6kO

3.24k

12kO

21.5kO

1µF

Hyst

1MO

OV2

5kO

57.6kO

CP2

XREF

3V

www.ti.com

SLVSEA3F – AUGUST 2018 – REVISED AUGUST 2020

10.4 Automatic Seamless Switchover with Priority (XREF)

In this second automatic switchover example, the application design will showcase power redundancy with two

12-V supplies. If one 12-V supply were to fail, the device will seamlessly switchover to the backup supply.

10.4.1 Application Schematic

Figure 10-12 shows the application schematic for automatic switchover with redundant supplies on the

TPS2121.

TPS2120, TPS2121

Figure 10-12. Automatic Switchover Between Two 12-V Supplies

10.4.2 Design Requirements

Table 10-4. Automatic Switchover Design Requirements

DESIGN PARAMETER SPECIFICATION DETAILS

Input Voltage Range V

Output Voltage Range V

Load Current I

Load Capacitance C

Switchover Time t

Mode of Operation Automatic Switchover TPS2121: XREF

IN1

, V

OUT

OUT

SW

IN2

L

12.1 V ± 3%

12 V ± 5%

2.5 A

320 µF

TPS2120: 5 µs

10.4.3 Detailed Design Description

In the second example, the system seamlessly switches between two 12-V supplies, providing uninterrupted

power to a downstream load. Priority is given to IN1, the main 12-V power rail, and switches over to IN2, the

backup 12-V power rail, whenever IN1 dips. When the main power rail returns, the device will switch back to the

main supply. Redundant power is critical in systems that require uninterrupted sources of power. If the output

voltage were to dip on these systems, this could cause the downstream load to reset to enter an undervoltage

lockout condition. Therefore, the TPS2121 will be used in fast switchover mode to minimize the output voltage

dip.

Similar to the automatic switchover example shown above, the TPS2121 can be configured in XCOMP mode.

However, to minimize the voltage switchover error for a more seamless switchover, an external precision

regulator can be connected to CP2 in XREF mode. In this configuration, a REF3325 provides an external

reference voltage on 2.5 V ± 0.15% (2.50375V). If the voltage on PR1 is higher than this external reference,

priority will be given to IN1. If the voltage on PR1 drops below 2.50375V, then the device will switchover to IN2.

Copyright © 2020 Texas Instruments Incorporated

Product Folder Links: TPS2120 TPS2121

Submit Document Feedback

27

TPS2121

IN1

OUT

IN1

(5V)

System Load

(0.5A, 100µF)

OV1

GND

SS

ILM

ST

IN2

IN2

(5V)

51.1kO

0.01uF

5kO

23.7kO

OV2

5k

23.7kO

PR1

CP2

TPS2120, TPS2121

SLVSEA3F – AUGUST 2018 – REVISED AUGUST 2020

www.ti.com

The design specifications detail the input voltage range for 12.1 ± 3%. Therefore, the resistor divider on PR1 is

configured such that the voltage on the pin dips below 2.50375V before IN1 crosses 11.73 V (12.1 V – 3%).

Once this occurs, the design will start fast switchover to IN2 within 5 us.

For additional information regarding this configuration, including full design procedures, schematics, and layout,

please refer to TIDA-01638: Seamless Switchover for Backup Power Reference Design.

10.4.4 Application Curves

Figure 10-13. Seamless Switchover Between Two

Figure 10-14. Fast Switchover Demonstration

12-V Supplies

10.5 Highest Voltage Operation (VCOMP)

10.5.1 Application Schematic

Figure 10-15 shows the application schematic for highest voltage operation on the TPS2121. The same

configuration can be completed on the TPS2120, with the SEL pin connected to GND instead of the CP2 pin.

28 Submit Document Feedback

Figure 10-15. Highest Voltage Operation

Product Folder Links: TPS2120 TPS2121

Copyright © 2020 Texas Instruments Incorporated

www.ti.com

10.5.2 Design Requirements

SLVSEA3F – AUGUST 2018 – REVISED AUGUST 2020

TPS2120, TPS2121

Copyright © 2020 Texas Instruments Incorporated

Product Folder Links: TPS2120 TPS2121

Submit Document Feedback

29

TPS2120, TPS2121

SLVSEA3F – AUGUST 2018 – REVISED AUGUST 2020

www.ti.com

Table 10-5. Highest Voltage Design Requirements

DESIGN PARAMETER SPECIFICATION DETAILS

Input Voltage V

Output Voltage V

Load Current I

Load Capacitance C

Switchover Time t

Mode of Operation Automatic Switchover TPS2121: VCOMP

IN1

, V

OUT

OUT

SW

IN2

L

5 V

5 V

0.5 A

100 µF

TPS2121: 100 µs

10.5.3 Detailed Design Description

In this mode of operation, the device will use an internal comparator between the two inputs to determine the

priority source. If both PR1 and CP2 are below VREF, priority is given to the highest input voltage. If both of the

inputs voltages are equal, V

hysteresis, then IN1 will have priority. If IN2 gets reapplied, it will take priority when it falls within V

and hysteresis ensures that IN2 takes priority. If IN2 falls below the V

COMP

COMP

COMP

of IN1.

In this example, the TPS2120 is configured with two 5-V inputs. When IN2 is applied to the system, it takes

priority over IN1. Once it gets removed, priority returns to IN1.

10.5.4 Detailed Design Procedure

See Table 9-2 to summarize the priority between IN1 and IN2. Once IN2 reaches within VCOMP of IN1, the

TPS2120 will switchover to IN2. Since IN1 is 5 V, once IN2 reaches 4.7 V (5 V – 300 mV), typically, the device

will switch over to IN2. On the falling transition, once IN2 drops below VCOMP of IN1, the added hysteresis will

prevent the device from switching back to IN1. Once IN2 drops below VCOMP and the hysteresis (3.5% typical) ,

the device will switch. Therefore, the device will switch back to IN1 once IN1 reaches (5 V – 300 mV – 175 mV),

4.525 V.

10.5.5 Application Curves

Figure 10-16. Switchover from IN1 to IN2 Figure 10-17. Timing from IN1 to IN2

30 Submit Document Feedback

Copyright © 2020 Texas Instruments Incorporated

Product Folder Links: TPS2120 TPS2121

µC

IN1

OUT

PR1

IN2

OV2

SEL

OV1

GND

SS

ILM

R

ILM

C

SS

ST

Supply 1

Supply 2

Device GND

Device GND

System Load

System G ND

ESD Diode

ESD Diode

ESD Diode

Diode

System G ND

www.ti.com

SLVSEA3F – AUGUST 2018 – REVISED AUGUST 2020

TPS2120, TPS2121

Figure 10-18. Switchover from IN2 to IN1

10.6 Reverse Polarity Protection with TPS212x

For applications that require reverse polarity protection, the TPS212x can be configured to protect against miswiring input power supplies and block reverse current that could potentially damage the system. By connecting a

diode on the GND pin of the TPS212x, this prevents reverse current from flowing back into the device when VIN

is below system ground.

Since the TPS212x has an absolute maximum rating of 24 V when referenced to device ground, the GND diode

should be rated to standoff voltages up to the maximum reverse voltage. Furthermore, since the control pin

voltages (PR1, OV1, OV2, etc.) are in reference to system GND, the voltage thresholds will need to be

recalculated based on the voltage drop across the diode. To reduce the voltage drop, a resistor in parallel with

the diode can also be used.

Figure 10-19. TPS212x Reverse Polarity Configuration

10.7 Hotplugging with TPS212x

Some applications require power muxing between hotplugged inputs, such as USB applications or systems with

secondary supplies coming from a long cable. During a hot plug event, the inherent inductance in the cable and

input traces can cause a voltage spike on the input pin (V = L

the input of the TPS212x that could potentially exceed the absolute maximum rating.

Copyright © 2020 Texas Instruments Incorporated

* dI / dT). This can cause a voltage spike on

CABLE

Product Folder Links: TPS2120 TPS2121

Submit Document Feedback

31

IN1

OUT

Supply 1

System Load

PR1

GND

SS

ILM

IN2

CP2

Supply 2

-

+

VIN1

-

+

VIN2

TPS2120, TPS2121

SLVSEA3F – AUGUST 2018 – REVISED AUGUST 2020

Figure 10-20. TPS212x Hotplug Configuration

www.ti.com

Figure 10-21 shows a hotplug event where a 12-V supply is connected to the TPS212x through a 15ft cable.

Without an external TVS, the input voltage spikes to over 30 V. To protect against this voltage transient, a

clamping device such as a TVS (Transient Voltage Suppression) diode can be used. As shown in Figure 10-22 ,

by using the TVS1800, the same voltage spike was clamped to 19.3 V.

Figure 10-21. TPS2121 Hotplug Event without TVS Figure 10-22. TPS2121 Hotplug Event with

TVS1800

32 Submit Document Feedback

Product Folder Links: TPS2120 TPS2121

Copyright © 2020 Texas Instruments Incorporated

www.ti.com

SLVSEA3F – AUGUST 2018 – REVISED AUGUST 2020

TPS2120, TPS2121

11 Power Supply Recommendations

IN1, IN2, and OUT traces should all be wide enough to accomodate the amount of current passing through the

device. Bypass capacitors on these pins should be placed as close to the device as possible. Low ESR ceramic

capacitors with X5R or X7R dielectric are recommended.

To avoid output voltage drop, the capacitance on OUT can be increased. If the power supply cannot handle the

inrush current transients due to the output capacitance, a higher input capacitance can be used. In the case

where there are long cables or wires connected to the input of the device, there may be ringing on the supply,

especially during the fast switchover of the TPS2121. To help nullify the inductance of the cables and prevent

ringing, a large capacitance can be used near the input of the device.

12 Layout

12.1 Layout Guidelines

Use short wide traces for input and output planes. For high current applications place vias under input and

output pins to avoid current density and thermal resistance bottlenecks.

12.2 Layout Example

The example layout for the TPS2121 shows where to place vias for better thermal dissipation. This can improve

the junction-to-ambient thermal resistance (R

θJA

).

Copyright © 2020 Texas Instruments Incorporated

Product Folder Links: TPS2120 TPS2121

Submit Document Feedback

33

TPS2120, TPS2121

SLVSEA3F – AUGUST 2018 – REVISED AUGUST 2020

www.ti.com

13 Device and Documentation Support

13.1 Documentation Support

13.1.1 Related Links

The table below lists quick access links. Categories include technical documents, support and community

resources, tools and software, and quick access to order now.

Table 13-1. Related Links

PARTS PRODUCT FOLDER ORDER NOW

TPS2120 Click here Click here Click here Click here Click here

TPS2121 Click here Click here Click here Click here Click here

TECHNICAL

DOCUMENTS

13.2 Receiving Notification of Documentation Updates

To receive notification of documentation updates, navigate to the device product folder on ti.com. Click on

Subscribe to updates to register and receive a weekly digest of any product information that has changed. For

change details, review the revision history included in any revised document.

13.3 Support Resources

TI E2E™ support forums are an engineer's go-to source for fast, verified answers and design help — straight

from the experts. Search existing answers or ask your own question to get the quick design help you need.

TOOLS &

SOFTWARE

SUPPORT &

COMMUNITY

Linked content is provided "AS IS" by the respective contributors. They do not constitute TI specifications and do

not necessarily reflect TI's views; see TI's Terms of Use.

13.4 Trademarks

TI E2E™ is a trademark of Texas Instruments.

All other trademarks are the property of their respective owners.

13.5 Electrostatic Discharge Caution

This integrated circuit can be damaged by ESD. Texas Instruments recommends that all integrated circuits be handled

with appropriate precautions. Failure to observe proper handling and installation procedures can cause damage.

ESD damage can range from subtle performance degradation to complete device failure. Precision integrated circuits may

be more susceptible to damage because very small parametric changes could cause the device not to meet its published

specifications.

13.6 Glossary

TI Glossary This glossary lists and explains terms, acronyms, and definitions.

14 Mechanical, Packaging, and Orderable Information

The following pages include mechanical, packaging, and orderable information. This information is the most

current data available for the designated devices. This data is subject to change without notice and revision of

this document. For browser-based versions of this data sheet, refer to the left-hand navigation.

34 Submit Document Feedback

Copyright © 2020 Texas Instruments Incorporated

Product Folder Links: TPS2120 TPS2121

www.ti.com

SLVSEA3F – AUGUST 2018 – REVISED AUGUST 2020

TPS2120, TPS2121

Copyright © 2020 Texas Instruments Incorporated

Product Folder Links: TPS2120 TPS2121

Submit Document Feedback

35

www.ti.com

EXAMPLE BOARD LAYOUT

20X (

0.23)

(0.4) TYP

(0.4) TYP

( 0.23)

METAL

0.05 MAX

SOLDER MASK

OPENING

METAL UNDER

SOLDER MASK

( 0.23)

SOLDER MASK

OPENING

0.05 MIN

4226007/A 06/2020

DSBGA - 0.5 mm max height

YFP0020-C01

DIE SIZE BALL GRID ARRAY

NOTES: (continued)

3. Final dimensions may vary due to manufacturing tolerance considerations and also routing constraints.

For more information, see Texas Instruments literature number SNVA009 (www.ti.com/lit/snva009).

SOLDER MASK DETAILS

NOT TO SCALE

SYMM

SYMM

LAND PATTERN EXAMPLE

SCALE:25X

A

B

C

D

1

2

3

4

E

NON-SOLDER MASK

DEFINED

(PREFERRED)

SOLDER MASK

DEFINED

TPS2120, TPS2121

SLVSEA3F – AUGUST 2018 – REVISED AUGUST 2020

www.ti.com

36 Submit Document Feedback

Product Folder Links: TPS2120 TPS2121

Copyright © 2020 Texas Instruments Incorporated

www.ti.com

EXAMPLE STENCIL DESIGN

(0.4) TYP

(0.4) TYP

20X ( 0.25)

(R0.05) TYP

METAL

TYP

4226007/A 06/2020

DSBGA - 0.5 mm max height

YFP0020-C01

DIE SIZE BALL GRID ARRAY

NOTES: (continued)

4. Laser cutting apertures with trapezoidal walls and rounded corners may offer better paste release.

SYMM

SYMM

SOLDER PASTE EXAMPLE

BASED ON 0.1 mm THICK STENCIL

SCALE:30X

A

B

C

D

1

2

3

E

4

www.ti.com

SLVSEA3F – AUGUST 2018 – REVISED AUGUST 2020

TPS2120, TPS2121

Copyright © 2020 Texas Instruments Incorporated

Product Folder Links: TPS2120 TPS2121

Submit Document Feedback

37

NOTES:

1. All linear dimensions are in millimeters. Any dimensions in parenthesis are for reference only. Dimensioning and tolerancing

per ASME Y14.5M.

2. This drawing is subject to change without notice.

PACKAGE OUTLINE

4224010/A 11/2017

www.ti.com

VQFN-HR - 1 mm max height

PLASTIC QUAD FLAT-NO LEAD

RUX0012A

A

0.08

C

0.1 C A B

0.05 C

B

SYMM

SYMM

2.1

1.9

2.6

2.4

PIN 1 INDEX AREA

(0.1) TYP

1 MAX

0.05

0.00

SEATING PLANE

C

8X

0.5

0.3

8X

0.25

0.15

2X 1.5

6X 0.5

4X

0.45

0.25

0.1 C A B

0.05 C

4X

0.95

0.75

2X 0.7

1

2

3

6

7

8

9

12

TPS2120, TPS2121

SLVSEA3F – AUGUST 2018 – REVISED AUGUST 2020

www.ti.com

38 Submit Document Feedback

Product Folder Links: TPS2120 TPS2121

Copyright © 2020 Texas Instruments Incorporated

NOTES: (continued)

3. For more information, see Texas Instruments literature number SLUA271 (www.ti.com/lit/slua271)

.

EXAMPLE BOARD LAYOUT

4224010/A 11/2017

www.ti.com

VQFN-HR - 1 mm max height

RUX0012A

PLASTIC QUAD FLAT-NO LEAD

SYMM

SYMM

LAND PATTERN EXAMPLE

SCALE: 25X

4X (0.4)

4X (1.05)

8X (0.6)

8X (0.2)

2X

(0.7)

(2.3)

6X 0.5

1.35

1

2

3

6

7

8

9

12

NON- SOLDER MASK

DEFINED

METAL

SOLDER MASK

OPENING

EXPOSED METAL

0.05 MAX

ALL AROUND

(R0.05) TYP

VIA TYP

2X (0.8)

www.ti.com

SLVSEA3F – AUGUST 2018 – REVISED AUGUST 2020

TPS2120, TPS2121

Copyright © 2020 Texas Instruments Incorporated

Product Folder Links: TPS2120 TPS2121

Submit Document Feedback

39

NOTES: (continued)

4. Laser cutting apertures with trapezoidal walls and rounded corners may offer better paste release. IPC-7525 may have alternate

design recommendations.

EXAMPLE STENCIL DESIGN

4224010/A 11/2017

www.ti.com

VQFN-HR - 1 mm max height

RUX0012A

PLASTIC QUAD FLAT-NO LEAD

SYMM

SOLDER PASTE EXAMPLE

BASED ON 0.1mm THICK STENCIL

EXPOSED PAD

100% PRINTED COVERAGE BY AREA

SCALE: 25X

SYMM

4X (0.4)

4X (1.05)

8X (0.6)

8X (0.2)

2X

(0.7)

(2.3)

6X 0.5

1.35

1

2

3

6

7

8

9

12

(R0.05) TYP

TPS2120, TPS2121

SLVSEA3F – AUGUST 2018 – REVISED AUGUST 2020

www.ti.com

40 Submit Document Feedback

Product Folder Links: TPS2120 TPS2121

Copyright © 2020 Texas Instruments Incorporated

PACKAGE OPTION ADDENDUM

www.ti.com

10-Dec-2020

PACKAGING INFORMATION

Orderable Device Status

TPS2120YFPR ACTIVE DSBGA YFP 20 3000 RoHS & Green SAC396 | SNAGCU Level-1-260C-UNLIM -40 to 125 20

TPS2120YFPT ACTIVE DSBGA YFP 20 250 RoHS & Green SAC396 | SNAGCU Level-1-260C-UNLIM -40 to 125 20

TPS2121RUXR ACTIVE VQFN-HR RUX 12 3000 RoHS & Green NIPDAU Level-1-260C-UNLIM -40 to 125 2121

TPS2121RUXT ACTIVE VQFN-HR RUX 12 250 RoHS & Green NIPDAU Level-1-260C-UNLIM -40 to 125 2121

(1)

The marketing status values are defined as follows:

ACTIVE: Product device recommended for new designs.

LIFEBUY: TI has announced that the device will be discontinued, and a lifetime-buy period is in effect.

NRND: Not recommended for new designs. Device is in production to support existing customers, but TI does not recommend using this part in a new design.

PREVIEW: Device has been announced but is not in production. Samples may or may not be available.

OBSOLETE: TI has discontinued the production of the device.

Package Type Package

(1)

Drawing

Pins Package

Qty

Eco Plan

(2)

Lead finish/

Ball material

(6)

MSL Peak Temp

(3)

Op Temp (°C) Device Marking

(4/5)

(2)

RoHS: TI defines "RoHS" to mean semiconductor products that are compliant with the current EU RoHS requirements for all 10 RoHS substances, including the requirement that RoHS substance

do not exceed 0.1% by weight in homogeneous materials. Where designed to be soldered at high temperatures, "RoHS" products are suitable for use in specified lead-free processes. TI may

reference these types of products as "Pb-Free".

RoHS Exempt: TI defines "RoHS Exempt" to mean products that contain lead but are compliant with EU RoHS pursuant to a specific EU RoHS exemption.

Green: TI defines "Green" to mean the content of Chlorine (Cl) and Bromine (Br) based flame retardants meet JS709B low halogen requirements of <=1000ppm threshold. Antimony trioxide based

flame retardants must also meet the <=1000ppm threshold requirement.

(3)

MSL, Peak Temp. - The Moisture Sensitivity Level rating according to the JEDEC industry standard classifications, and peak solder temperature.

(4)

There may be additional marking, which relates to the logo, the lot trace code information, or the environmental category on the device.

(5)

Multiple Device Markings will be inside parentheses. Only one Device Marking contained in parentheses and separated by a "~" will appear on a device. If a line is indented then it is a continuation

of the previous line and the two combined represent the entire Device Marking for that device.

(6)