Page 1

TPS1120, TPS1120Y

DUAL P-CHANNEL ENHANCEMENT-MODE MOSFETS

SLVS080A – MARCH 1994 – REVISED AUGUST 1995

1

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

D

Low r

DS(on)

. . . 0.18 Ω at VGS = –10 V

D

3-V Compatible

D

Requires No External V

CC

D

TTL and CMOS Compatible Inputs

D

V

GS(th)

= –1.5 V Max

D

ESD Protection Up to 2 kV per

MIL-STD-883C, Method 3015

description

The TPS1120 incorporates two independent

p-channel enhancement-mode MOSFETs that

have been optimized, by means of the Texas

Instruments LinBiCMOS process, for 3-V or 5-V

power distribution in battery-powered systems. With a maximum V

GS(th)

of –1.5 V and an I

DSS

of only 0.5 µA,

the TPS1120 is the ideal high-side switch for low-voltage portable battery-management systems, where

maximizing battery life is a primary concern. Because portable equipment is potentially subject to electrostatic

discharge (ESD), the MOSFET s have built-in circuitry for 2-kV ESD protection. End equipment for the TPS1 120

includes notebook computers, personal digital assistants (PDAs), cellular telephones, bar-code scanners, and

PCMCIA cards. For existing designs, the TPS1 120D has a pinout common with other p-channel MOSFETs in

small-outline integrated circuit SOIC packages.

The TPS1120 is characterized for an operating junction temperature range, T

J

, from –40°C to 150°C.

AVAILABLE OPTIONS

PACKAGED DEVICES

†

T

J

SMALL OUTLINE

(D)

CHIP FORM

(Y)

–40°C to 150°C TPS1120D TPS1120Y

†

The D package is available taped and reeled. Add an R suffix to device

type (e.g., TPS1120DR). The chip form is tested at 25°C.

Caution. This device contains circuits to protect its inputs and outputs against damage due to high static voltages or electrostatic

fields. These circuits have been qualified to protect this device against electrostatic discharges (ESD) of up to 2 kV according to

MIL-STD-883C, Method 3015; however, it is advised that precautions be taken to avoid application of any voltage higher than

maximum-rated voltages to these high-impedance circuits.

LinBiCMS is a trademark of Texas Instruments Incorporated.

Copyright 1995, Texas Instruments Incorporated

PRODUCTION DATA information is current as of publication date.

Products conform to specifications per the terms of Texas Instruments

standard warranty. Production processing does not necessarily include

testing of all parameters.

1

2

3

4

8

7

6

5

1SOURCE

1GATE

2SOURCE

2GATE

1DRAIN

1DRAIN

2DRAIN

2DRAIN

D PACKAGE

(TOP VIEW)

Page 2

TPS1120, TPS1120Y

DUAL P-CHANNEL ENHANCEMENT-MODE MOSFETS

SLVS080A – MARCH 1994 – REVISED AUGUST 1995

2

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

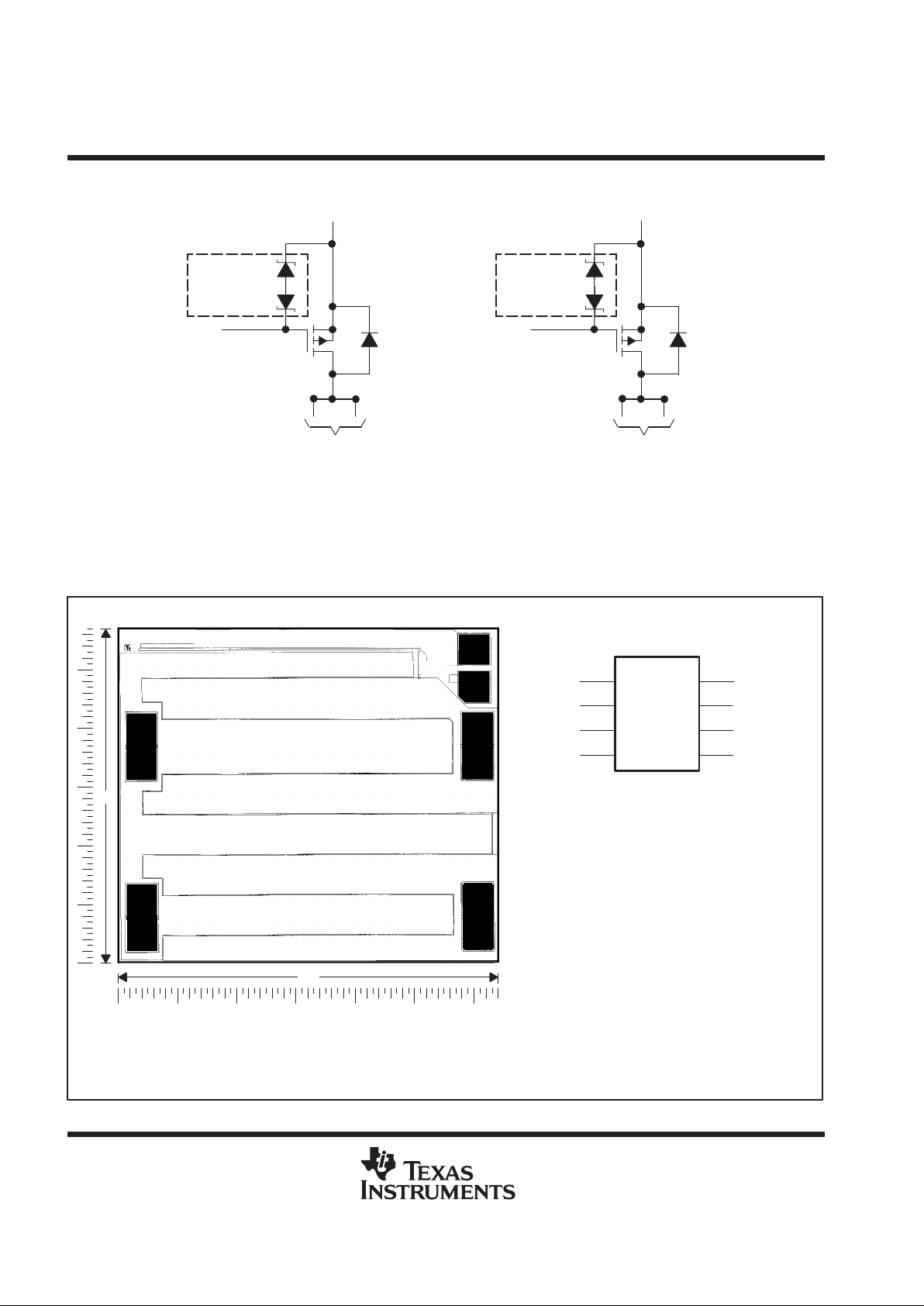

schematic

1GATE

1SOURCE

1DRAIN

†

ESD-

Protection

Circuitry

2GATE

2SOURCE

2DRAIN

†

ESD-

Protection

Circuitry

†

For all applications, both drain pins for each device should be connected.

TPS1120Y chip information

This chip, when properly assembled, displays characteristics similar to the TPS1 120C. Thermal compression

or ultrasonic bonding may be used on the doped aluminum bonding pads. The chip may be mounted with

conductive epoxy or a gold-silicon preform.

BONDING PAD ASSIGNMENTS

CHIP THICKNESS: 15 MILS TYPICAL

BONDING PADS: 4 × 4 MILS MINIMUM

TJmax = 150°C

TOLERANCES ARE ±10%

ALL DIMENSIONS ARE IN MILS

TPS1120Y

(2)

(6)

(1)

(3)

(7)

(8)

(5)(4)

1DRAIN1SOURCE

1GATE

2SOURCE

2GATE

1DRAIN

2DRAIN

2DRAIN

57

64

(2)

(1)

(3)

(4)

(6)

(7)

(8)

(5)

Page 3

TPS1120, TPS1120Y

DUAL P-CHANNEL ENHANCEMENT-MODE MOSFETS

SLVS080A – MARCH 1994 – REVISED AUGUST 1995

3

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

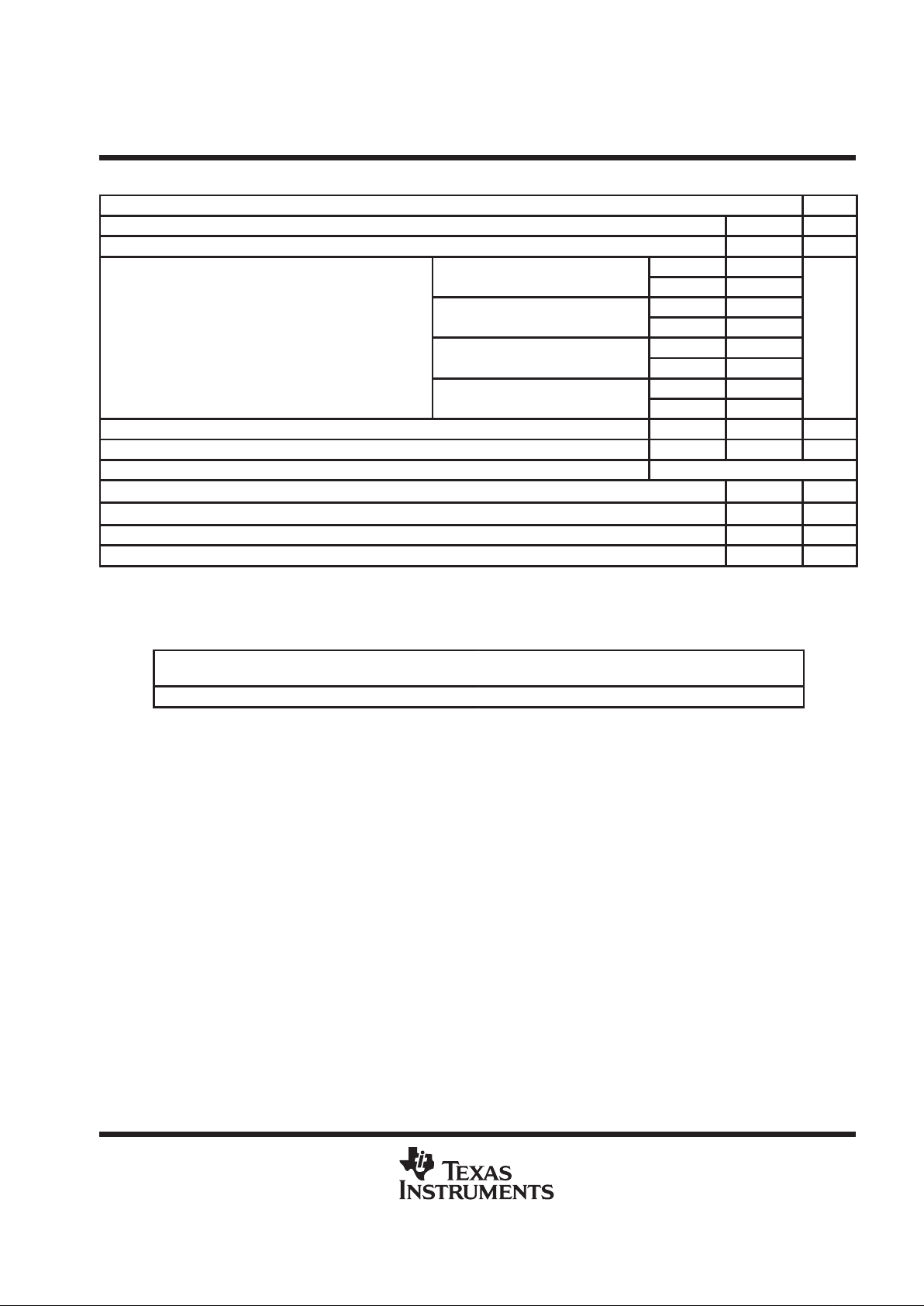

absolute maximum ratings over operating free-air temperature (unless otherwise noted)

†

UNIT

Drain-to-source voltage, V

DS

–15 V

Gate-to-source voltage, V

GS

2 or –15 V

TA = 25°C ±0.39

V

GS

= –2.7

V

TA = 125°C ±0.21

TA = 25°C ±0.5

°

V

GS

= –3

V

TA = 125°C ±0.25

Continuous drain current, each device (T

J

=

150°C), I

D

TA = 25°C ±0.74

A

V

GS

= –4.5

V

TA = 125°C ±0.34

TA = 25°C ±1.17

V

GS

= –10

V

TA = 125°C ±0.53

Pulse drain current, I

D

TA = 25°C ±7 A

Continuous source current (diode conduction), I

S

TA = 25°C –1 A

Continuous total power dissipation See Dissipation Rating Table

Storage temperature range, T

stg

–55 to 150 °C

Operating junction temperature range, T

J

–40 to 150 °C

Operating free-air temperature range, T

A

–40 to 125 °C

Lead temperature 1,6 mm (1/16 inch) from case for 10 seconds 260 °C

†

Stresses beyond those listed under “absolute maximum ratings” may cause permanent damage to the device. These are stress ratings only, and

functional operation of the device at these or any other conditions beyond those indicated under “recommended operating conditions” is not

implied. Exposure to absolute-maximum-rated conditions for extended periods may affect device reliability.

DISSIPATION RATING TABLE

PACKAGE

TA ≤ 25°C

POWER RATING

DERATING FACTOR

‡

ABOVE TA = 25°C

TA = 70°C

POWER RATING

TA = 85°C

POWER RATING

TA = 125°C

POWER RATING

D 840 mW 6.71 mW/°C 538 mW 437 mW 169 mW

‡

Maximum values are calculated using a derating factor based on R

θJA

= 149°C/W for the package. These devices are

mounted on an FR4 board with no special thermal considerations.

Page 4

TPS1120, TPS1120Y

DUAL P-CHANNEL ENHANCEMENT-MODE MOSFETS

SLVS080A – MARCH 1994 – REVISED AUGUST 1995

4

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

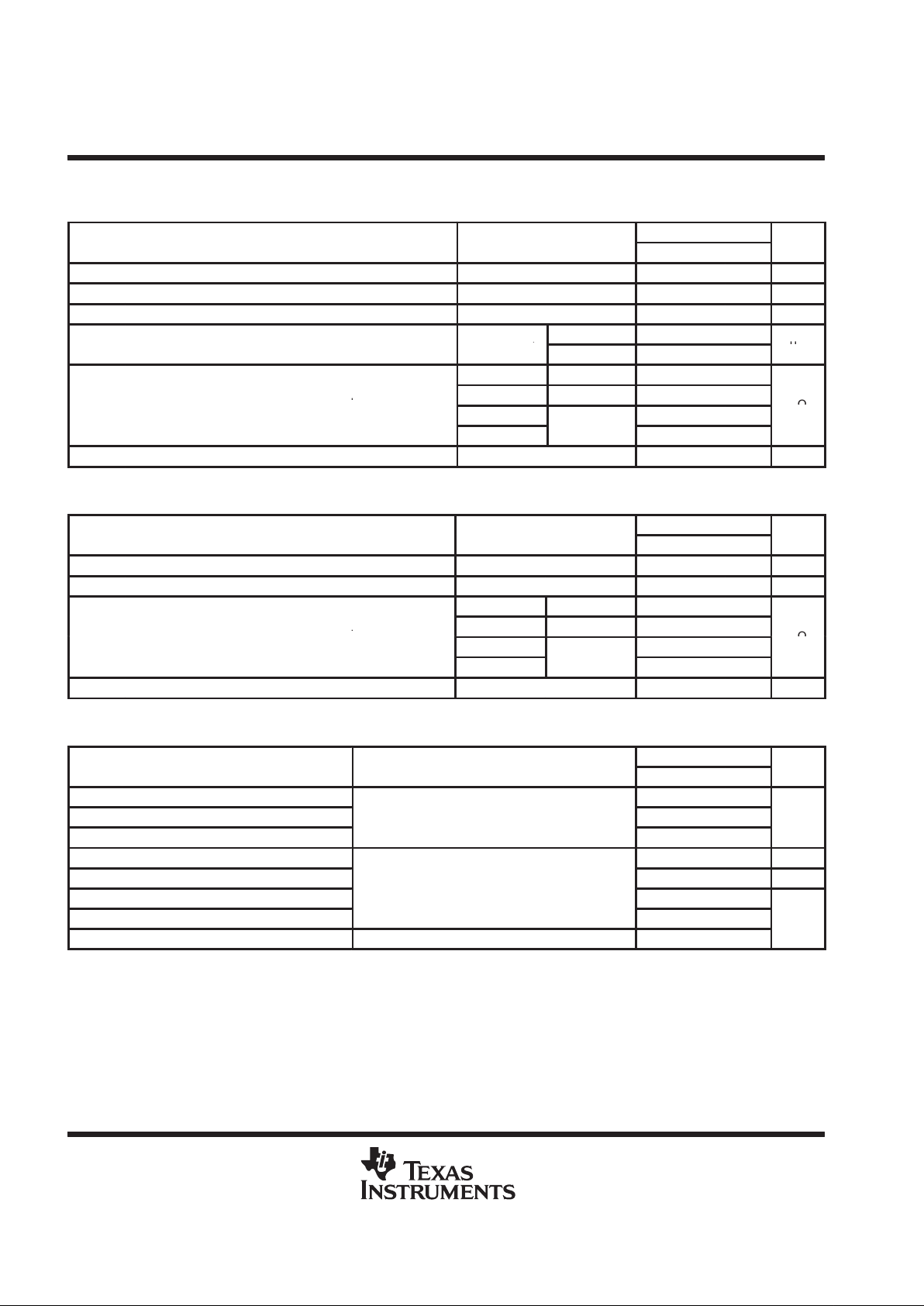

electrical characteristics at TJ = 25°C (unless otherwise noted)

static

TPS1120

PARAMETER

TEST CONDITIONS

MIN TYP MAX

UNIT

V

GS(th)

Gate-to-source threshold voltage VDS = VGS, ID = –250 µA –1 –1.25 –1.50 V

V

SD

Source-to-drain voltage (diode forward voltage)

†

IS = –1 A, VGS = 0 V –0.9 V

I

GSS

Reverse gate current, drain short circuited to source VDS = 0 V, VGS = –12 V ±100 nA

V

= –12 V ,

TJ = 25°C –0.5

I

DSS

Zero-gate-voltage drain current

DS

,

VGS = 0 V

TJ = 125°C –10

µ

A

VGS = –10 V ID = –1.5 A 180

VGS = –4.5 V ID = –0.5 A 291 400

r

DS(on)

Static drain-t

o-source on-state resistance

†

VGS = –3 V

476 700

mΩ

VGS = –2.7 V

I

D

= –0.2

A

606 850

g

fs

Forward transconductance

†

VDS = –10 V , ID = –2 A 2.5 S

†

Pulse test: pulse width ≤ 300 µs, duty cycle ≤ 2%

static

TPS1120Y

PARAMETER

TEST CONDITIONS

MIN TYP MAX

UNIT

V

GS(th)

Gate-to-source threshold voltage VDS = VGS, ID = –250 µA –1.25 V

V

SD

Source-to-drain voltage (diode forward voltage)

†

IS = –1 A, VGS = 0 V –0.9 V

VGS = –10 V ID = –1.5 A 180

VGS = –4.5 V ID = –0.5 A 291

r

DS(on)

Static drain-t

o-source on-state resistance

†

VGS = –3 V

476

mΩ

VGS = –2.7 V

I

D

= –0.2

A

606

g

fs

Forward transconductance

†

VDS = –10 V , ID = –2 A 2.5 S

†

Pulse test: pulse width ≤ 300 µs, duty cycle ≤ 2%

dynamic

TPS1120, TPS1120Y

PARAMETER

TEST CONDITIONS

MIN TYP MAX

UNIT

Q

g

Total gate charge 5.45

Q

gs

Gate-to-source charge

VDS = –10 V , VGS = –10 V , ID = –1 A

0.87

nC

Q

gd

Gate-to-drain charge 1.4

t

d(on)

Turn-on delay time 4.5 ns

t

d(off)

Turn-off delay time

V

= –10 V , R

= 10 Ω,I

= –1 A,

13 ns

t

r

Rise time

DD

,

RG = 6 Ω,

L

,

See Figures 1 and 2

D

,

10

t

f

Fall time 2

ns

t

rr(SD)

Source-to-drain reverse recovery time IF = 5.3 A, di/dt = 100 A/µs 16

Page 5

TPS1120, TPS1120Y

DUAL P-CHANNEL ENHANCEMENT-MODE MOSFETS

SLVS080A – MARCH 1994 – REVISED AUGUST 1995

5

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

PARAMETER MEASUREMENT INFORMATION

Figure 1. Switching-Time Test Circuit

R

G

R

L

V

DD

–

+

V

GS

DUT

V

DS

Figure 2. Switching-Time Waveforms

t

d(on)

t

r

V

DS

t

d(off)

t

f

90%

10%

0 V

–10 V

V

GS

Page 6

TPS1120, TPS1120Y

DUAL P-CHANNEL ENHANCEMENT-MODE MOSFETS

SLVS080A – MARCH 1994 – REVISED AUGUST 1995

6

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

TYPICAL CHARACTERISTICS

†

Table of Graphs

FIGURE

Drain current vs Drain-to-source voltage 3

Drain current vs Gate-to-source voltage 4

Static drain-to-source on-state resistance vs Drain current 5

Capacitance vs Drain-to-source voltage 6

Static drain-to-source on-state resistance (normalized) vs Junction temperature 7

Source-to-drain diode current vs Source-to-drain voltage 8

Static drain-to-source on-state resistance vs Gate-to-source voltage 9

Gate-to-source threshold voltage vs Junction temperature 10

Gate-to-source voltage vs Gate charge 11

– 5

– 4

– 2

– 1

0

– 3

0 – 1– 2– 3– 4– 5– 6

– Drain Current – A

– 7

– 6

DRAIN CURRENT

vs

DRAIN-TO-SOURCE VOLTAGE

– 7 – 8 – 9 – 10

VGS = –6 V

I

D

VDS – Drain-to-Source Voltage – V

VGS = –8 V

VGS = –7 V

VGS = –3 V

VGS = –4 V

VGS = –2 V

VGS = –5 V

TJ = 25°C

Figure 3 Figure 4

0 – 2 – 3 – 5

DRAIN CURRENT

vs

GATE-TO-SOURCE VOLTAGE

– 7– 1 – 4 – 6

– Drain Current – A

I

D

VGS – Gate-to-Source Voltage – V

TJ = 150°C

TJ = 25°C

TJ = –40°C

VDS = –10 V

0

– 5

– 4

– 2

– 1

– 3

– 7

– 6

†

All characteristics data applies for each independent MOSFET incorporated on the TPS1120.

Page 7

TPS1120, TPS1120Y

DUAL P-CHANNEL ENHANCEMENT-MODE MOSFETS

SLVS080A – MARCH 1994 – REVISED AUGUST 1995

7

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

TYPICAL CHARACTERISTICS

0.3

0.2

0.1

0

– 0.1 – 1

0.4

0.5

STATIC DRAIN-TO-SOURCE ON-STATE RESISTANCE

vs

DRAIN CURRENT

0.6

– 10

ID – Drain Current – A

0.7

VGS = –2.7 V

VGS = –3 V

VGS = –4.5 V

VGS = –10 V

TJ = 25°C

– Static Drain-to-Source

r

DS(on)

ΩOn-State Resistance –

Figure 5

200

150

50

0

0 – 1 – 2 – 3 – 4 – 5 – 6

C – Capacitance – pF

250

300

CAPACITANCE

vs

DRAIN-TO-SOURCE VOLTAGE

350

– 7 – 8 – 9 –12

100

–10 –11

C

oss

VDS – Drain-to-Source Voltage – V

C

iss

†

C

rss

‡

VGS = 0

f = 1 MHz

TJ = 25°C

†

C

rss

+

Cgd,C

oss

+

Cds)

CgsC

gd

Cgs)

C

gd

≈ Cds)

C

gd

‡

C

iss

+

Cgs)

Cgd,C

ds(shorted)

Figure 6

Figure 7

1.2

0.9

0.8

0.6

1.3

1.4

STATIC DRAIN-TO-SOURCE

ON-STATE RESISTANCE (NORMALIZED)

vs

JUNCTION TEMPERATURE

1.5

1.1

1

0.7

–50 0 50 100 150

TJ – Junction Temperature – °C

VGS = –10 V

ID = –1A

– Static Drain-to-Source

r

DS(on)

On-State Resistance (Normalized)

– 0.1

0 – 0.6 –1.2 –1.8

– Source-to-Drain Diode Current – A

SOURCE-TO-DRAIN DIODE CURRENT

vs

SOURCE-TO-DRAIN VOLTAGE

–1

–10

– 0.2 – 0.4 – 0.8 – 1 –1.4 –1.6

I

SD

VSD – Source-to-Drain Voltage – V

Pulse Test

TJ = 150°C

TJ = 25°C

TJ = –40°C

Figure 8

Page 8

TPS1120, TPS1120Y

DUAL P-CHANNEL ENHANCEMENT-MODE MOSFETS

SLVS080A – MARCH 1994 – REVISED AUGUST 1995

8

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

TYPICAL CHARACTERISTICS

0.2

0.1

0

– 1 – 3 – 5 – 7

0.3

0.4

STATIC DRAIN-TO-SOURCE ON-STATE RESISTANCE

vs

GATE-TO-SOURCE VOLTAGE

0.5

– 9 – 11

– 13 – 15

VGS – Gate-to-Source Voltage – V

0.6

0.7

ID = –1 A

TJ = 25°C

– Static Drain-to-Source On-State

r

DS(on)

Ω

Resistance –

Figure 9 Figure 10

– 1.2

– 1.1

– Gate-to-Source Threshold Voltage – V

– 1.3

– 1.4

GATE-TO-SOURCE THRESHOLD VOLTAGE

vs

JUNCTION TEMPERATURE

– 1.5

–50 0 50 100 150

– 1

– 0.9

TJ – Junction Temperature – °C

V

GS(th)

ID = –250 µA

– 6

– 4

– 2

0

0235

– 8

GATE-TO-SOURCE VOLTAGE

vs

GATE CHARGE

– 10

146

– Gate-to-Source Voltage – V

Qg – Gate Charge – nC

V

GS

VDS = –10 V

ID = –1 A

TJ = 25°C

Figure 11

Page 9

TPS1120, TPS1120Y

DUAL P-CHANNEL ENHANCEMENT-MODE MOSFETS

SLVS080A – MARCH 1994 – REVISED AUGUST 1995

9

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

THERMAL INFORMATION

NOTE A: FR4-board-mounted only

– 1

– 0.1

– 0.001

– 10

– 0.1 – 1 – 10 – 100

– Drain Current – A

DRAIN CURRENT

vs

DRAIN-TO-SOURCE VOLTAGE

I

D

VDS – Drain-to-Source Voltage – V

0.001 s

0.01 s

0.1 s

1 s

10 s

DC

TJ = 150°C

TA = 25°C

Single Pulse

See Note A

Figure 12

10

1

0.1

100

0.001 0.01 0.1 1 10

TRANSIENT JUNCTION-TO-AMBIENT

THERMAL IMPEDANCE

vs

PULSE DURATION

tw – Pulse Duration – s

– Transient Junction-to-AmbientZ

C/W

°

θJA

Single Pulse

See Note A

Thermal Impedance –

Figure 13

NOTE A: FR4-board-mounted only

Page 10

TPS1120, TPS1120Y

DUAL P-CHANNEL ENHANCEMENT-MODE MOSFETS

SLVS080A – MARCH 1994 – REVISED AUGUST 1995

10

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

THERMAL INFORMATION

The profile of the heat sinks used for thermal measurements is shown in Figure 14. Board type is FR4 with 1-oz copper

and 1-oz tin/lead (63/37) plate. Use of vias or through-holes to enhance thermal conduction was avoided.

Figure 15 shows a family of R

θJA

curves. The R

θJA

was obtained for various areas of heat sinks while subject to air

flow. Power remained fixed at 0.25 W per device or 0.50 W per package. This testing was done at 25°C.

As Figure 14 illustrates, there are two separated heat sinks for each package. Each heat sink is coupled to the lead

that is internally tied to a single MOSFET source and is half the total area, as shown in Figure 15. For example, if the

total area shown in Figure 15 is 4 cm

2

, each heat sink is 2 cm2.

1DRAIN

2DRAIN

1SOURCE

1GATE

2GATE

The Combined Area

of These Two Heat

Sinks Is 4 cm

2

TPS1120D IC

HS: 4 cm

2

8P SOIC Thermal Analysis

≅ 2 cm

2SOURCE

Figure 14. Profile of Heat Sinks

70

60

50

0 50 100 150

80

90

THERMAL RESISTANCE, JUNCTION-TO-AMBIENT

vs

AIRFLOW, 25°C

100

200 250 300

Airflow, 25°C – ft/min

110

120

– Thermal Resistance, Junction-to-Ambient – C/W

R

θ

130

140

150

TJ = 25°C

P = 0.5 W

Heat Sink Areas

as Shown

°

JA

0.5 cm

2

1 cm

2

2 cm

2

4 cm

2

0 cm

2

8 cm

2

Figure 15

Page 11

TPS1120, TPS1120Y

DUAL P-CHANNEL ENHANCEMENT-MODE MOSFETS

SLVS080A – MARCH 1994 – REVISED AUGUST 1995

11

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

THERMAL INFORMATION

Figure 16 illustrates the thermally enhanced (SO) lead frame. Attaching the two MOSFET dies directly to the source

terminals allows maximum heat transfer into a power plane.

Lead 8

Lead 7

Lead 6

Lead 5

Lead 1

Lead 2

Lead 3

Lead 4

1GATE

1SOURCE

2GATE

2SOURCE

1DRAIN

1DRAIN

2DRAIN

2DRAIN

MOSFET 2

MOSFET 1

Pad 1

Pad 1

Figure 16. TPS1120 Dual MOSFET SO-8 Lead Frame

APPLICATION INFORMATION

Load

3 V or 5 V

Microcontroller

Figure 17. Notebook Load Management

Microcontroller

Charge

Pump

5 V

–4 V

GaAs FET

Amplifier

Driver

Figure 18. Cellular Phone Output Drive

Page 12

IMPORTANT NOTICE

T exas Instruments and its subsidiaries (TI) reserve the right to make changes to their products or to discontinue

any product or service without notice, and advise customers to obtain the latest version of relevant information

to verify, before placing orders, that information being relied on is current and complete. All products are sold

subject to the terms and conditions of sale supplied at the time of order acknowledgement, including those

pertaining to warranty, patent infringement, and limitation of liability.

TI warrants performance of its semiconductor products to the specifications applicable at the time of sale in

accordance with TI’s standard warranty. Testing and other quality control techniques are utilized to the extent

TI deems necessary to support this warranty. Specific testing of all parameters of each device is not necessarily

performed, except those mandated by government requirements.

CERT AIN APPLICATIONS USING SEMICONDUCTOR PRODUCTS MA Y INVOLVE POTENTIAL RISKS OF

DEATH, PERSONAL INJURY, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE (“CRITICAL

APPLICATIONS”). TI SEMICONDUCTOR PRODUCTS ARE NOT DESIGNED, AUTHORIZED, OR

WARRANTED TO BE SUITABLE FOR USE IN LIFE-SUPPORT DEVICES OR SYSTEMS OR OTHER

CRITICAL APPLICATIONS. INCLUSION OF TI PRODUCTS IN SUCH APPLICA TIONS IS UNDERST OOD TO

BE FULLY AT THE CUSTOMER’S RISK.

In order to minimize risks associated with the customer’s applications, adequate design and operating

safeguards must be provided by the customer to minimize inherent or procedural hazards.

TI assumes no liability for applications assistance or customer product design. TI does not warrant or represent

that any license, either express or implied, is granted under any patent right, copyright, mask work right, or other

intellectual property right of TI covering or relating to any combination, machine, or process in which such

semiconductor products or services might be or are used. TI’s publication of information regarding any third

party’s products or services does not constitute TI’s approval, warranty or endorsement thereof.

Copyright 1998, Texas Instruments Incorporated

Loading...

Loading...