Page 1

VIN

POWER MANAGEMENT

VOUT

GND

µC

GPIO

VDD

GND

Rp

GPIO

RSTn

TPL5010-Q1

VDD

GND

RSTn

WAKE

DELAY/

M_RST

DONE

R

EXT

Battery

-+

Product

Folder

Sample &

Buy

Technical

Documents

Tools &

Software

Support &

Community

TPL5010-Q1

SNAS679 –SEPTEMBER 2016

TPL5010-Q1 AEC-Q100 Nano-Power System Timer with Watchdog Function

1 Features

1

• Qualified for Automotive Applications

• AEC-Q100 Qualified with the Following Results:

– Device Temperature Grade 1: –40°C to 125°C

Ambient Operating Temperature Range

– Device HBM ESD Classification Level 2

– Device CDM ESD Classification Level C5

• Current Consumption of 35 nA (typ) at 2.5 V

• Supply Voltage from 1.8 V to 5.5 V

• Selectable Time Intervals 100 ms to 7200 s

• Timer Accuracy 1% (Typical)

• Resistor Selectable Time Interval

• Watchdog Functionality

• Manual Reset

• TPL5x10Q Family of AEC-Q100 Nano-Power

System Timers

• TPL5010-Q1 - Supply Current 35 nA

– Low Power Timer

– Watchdog Function

– Programmable Delay Range

– Manual Reset

• TPL5110-Q1 - Supply Current 35 nA

– Low Power Timer

– MOS-Driver

– Programmable Delay Range

– Manual Reset

– One-Shot Feature

2 Applications

• Electric Vehicles

• Always On Systems

• Battery powered systems

• Clutch Actuator circuit

• Car Door Handle circuit

• Smart Key

• Remote current sensor

• Intruder Detection

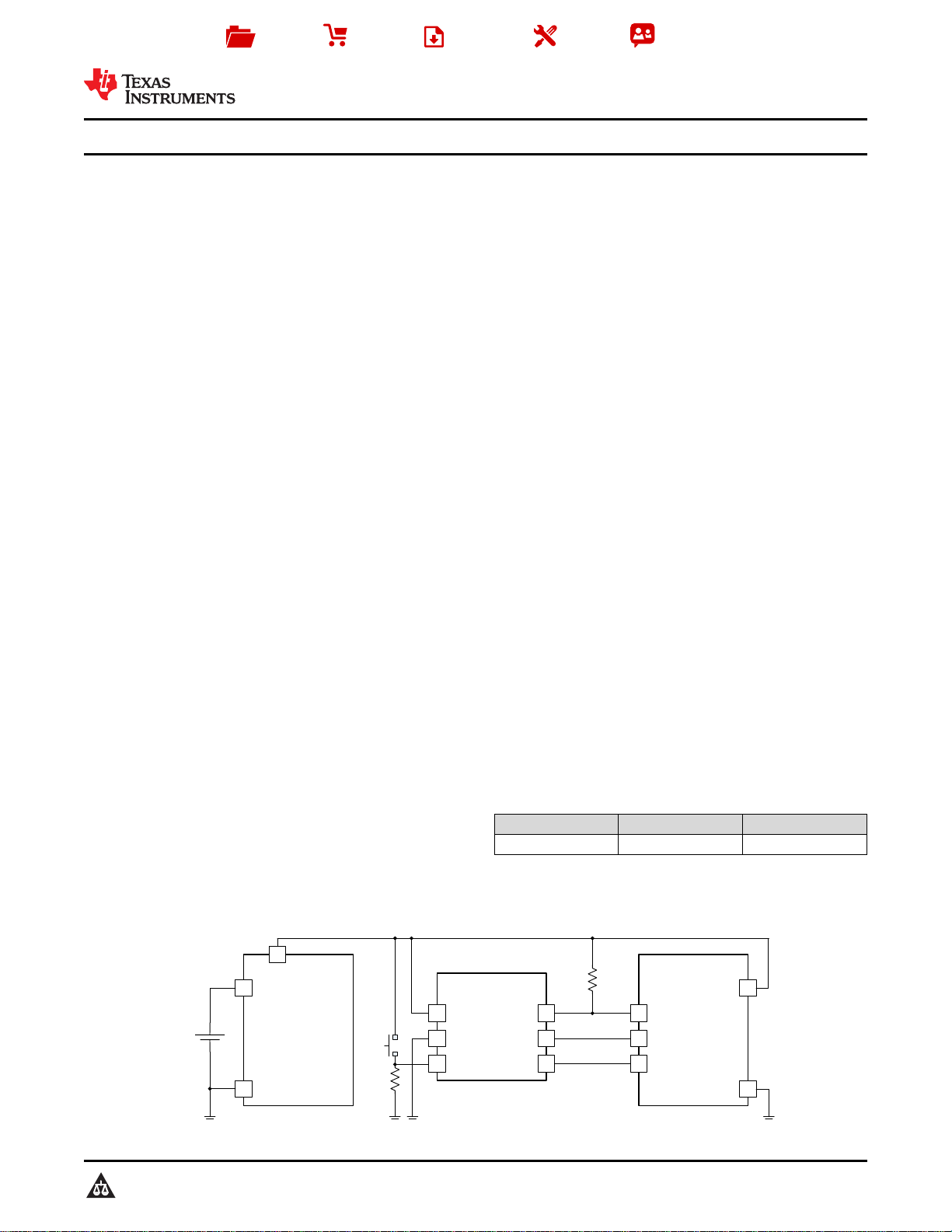

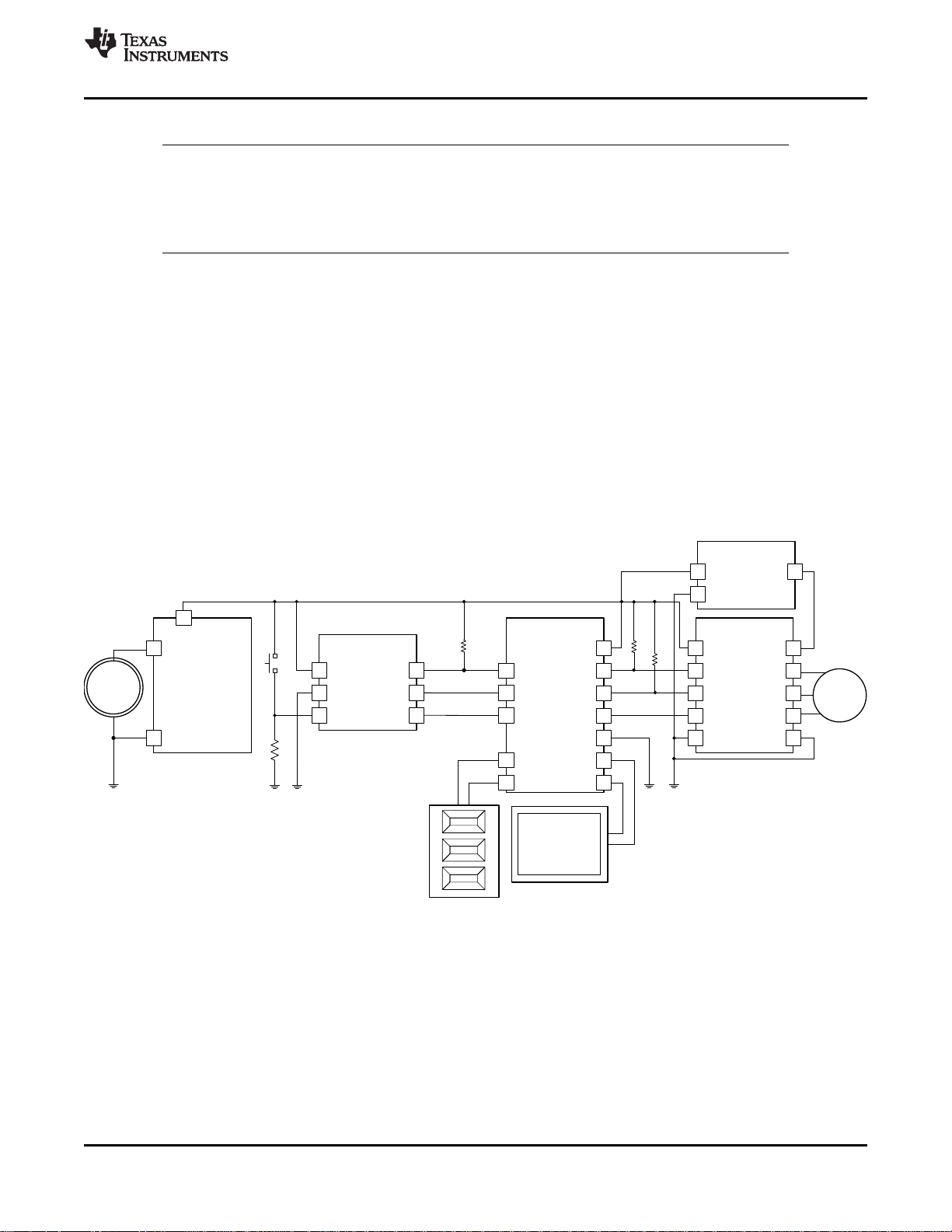

3 Description

The TPL5010-Q1 Nano Timer is a low power, AECQ100 qualified timer with a watchdog feature ideal for

system wake up in duty cycled or battery powered

applications. In such systems the microcontroller

timer can be used for system wake-up, but if the

timer sleep current is high, up to 60-80% of the total

system current can be consumed by the

microcontroller timer in this sleep mode. Consuming

only 35 nA, the TPL5010-Q1 can replace the

functionality of the integrated microcontroller timer

and allow the microcontroller to be placed in a much

lower power mode. Such power savings extend the

operating life of batteries and enable the use of

significantly smaller batteries making the TPL5010Q1 ideal for power sensitive applications.. The

TPL5010-Q1 provides selectable timing intervals from

100 ms to 7200 s and is designed for interrupt-driven

applications. Some standards (such as EN50271)

require implementation of a watchdog for safety and

the TPL5010-Q1 realizes this watchdog function at

almost no additional power consumption. The

TPL5010-Q1 is available in a 6-pin SOT23 package.

Device Information

PART NUMBER PACKAGE BODY SIZE (NOM)

TPL5010-Q1 SOT23 (6) 3.00 mm x 3.00 mm

(1) For all available packages, see the orderable addendum at

the end of the datasheet.

(1)

Simplified Application

1

An IMPORTANT NOTICE at the end of this data sheet addresses availability, warranty, changes, use in safety-critical applications,

intellectual property matters and other important disclaimers. PRODUCTION DATA.

Page 2

TPL5010-Q1

SNAS679 –SEPTEMBER 2016

www.ti.com

Table of Contents

1 Features.................................................................. 1

2 Applications ........................................................... 1

3 Description ............................................................. 1

4 Revision History..................................................... 2

5 Device Comparison Table..................................... 2

6 Pin Configuration and Functions......................... 3

7 Specifications......................................................... 4

7.1 Absolute Maximum Ratings ...................................... 4

7.2 ESD Ratings.............................................................. 4

7.3 Recommended Operating Conditions ...................... 4

7.4 Thermal Information ................................................. 4

7.5 Electrical Characteristics........................................... 5

7.6 Timing Requirements ............................................... 6

7.7 Typical Characteristics.............................................. 7

8 Detailed Description.............................................. 8

8.1 Overview ................................................................... 8

8.2 Functional Block Diagram......................................... 8

4 Revision History

DATE REVISION NOTES

September 2016 * Initial release.

8.3 Feature Description................................................... 8

8.4 Device Functional Modes.......................................... 9

8.5 Programming ............................................................ 9

9 Application and Implementation ........................ 15

9.1 Application Information............................................ 15

9.2 Typical Application ................................................. 15

10 Power Supply Recommendations ..................... 17

11 Layout................................................................... 17

11.1 Layout Guidelines ................................................. 17

11.2 Layout Example .................................................... 17

12 Device and Documentation Support................. 18

12.1 Receiving Notification of Documentation Updates 18

12.2 Community Resources.......................................... 18

12.3 Trademarks........................................................... 18

12.4 Electrostatic Discharge Caution............................ 18

12.5 Glossary................................................................ 18

13 Mechanical, Packaging, and Orderable

Information........................................................... 18

5 Device Comparison Table

TPL5x10Q Family of AEC-Q100 Nano- Power System Timers

PART NUMBER SUPPLY CURRENT (Typ) SPECIAL FEATURES

TPL5010-Q1 35 nA

TPL5110-Q1 35 nA

Low Power Timer

Watchdog Function

Programmable Delay Range

Manual Reset

Low Power Timer

MOS-Driver

Programmable Delay Range

Manual Reset

One-Shot Feature

2

Submit Documentation Feedback Copyright © 2016, Texas Instruments Incorporated

Product Folder Links: TPL5010-Q1

Page 3

TPL5010-Q1

VDD

GND

RSTn

WAKE

DELAY/

M_RST

DONE

1

2

3 4

5

6

TPL5010-Q1

www.ti.com

SNAS679 –SEPTEMBER 2016

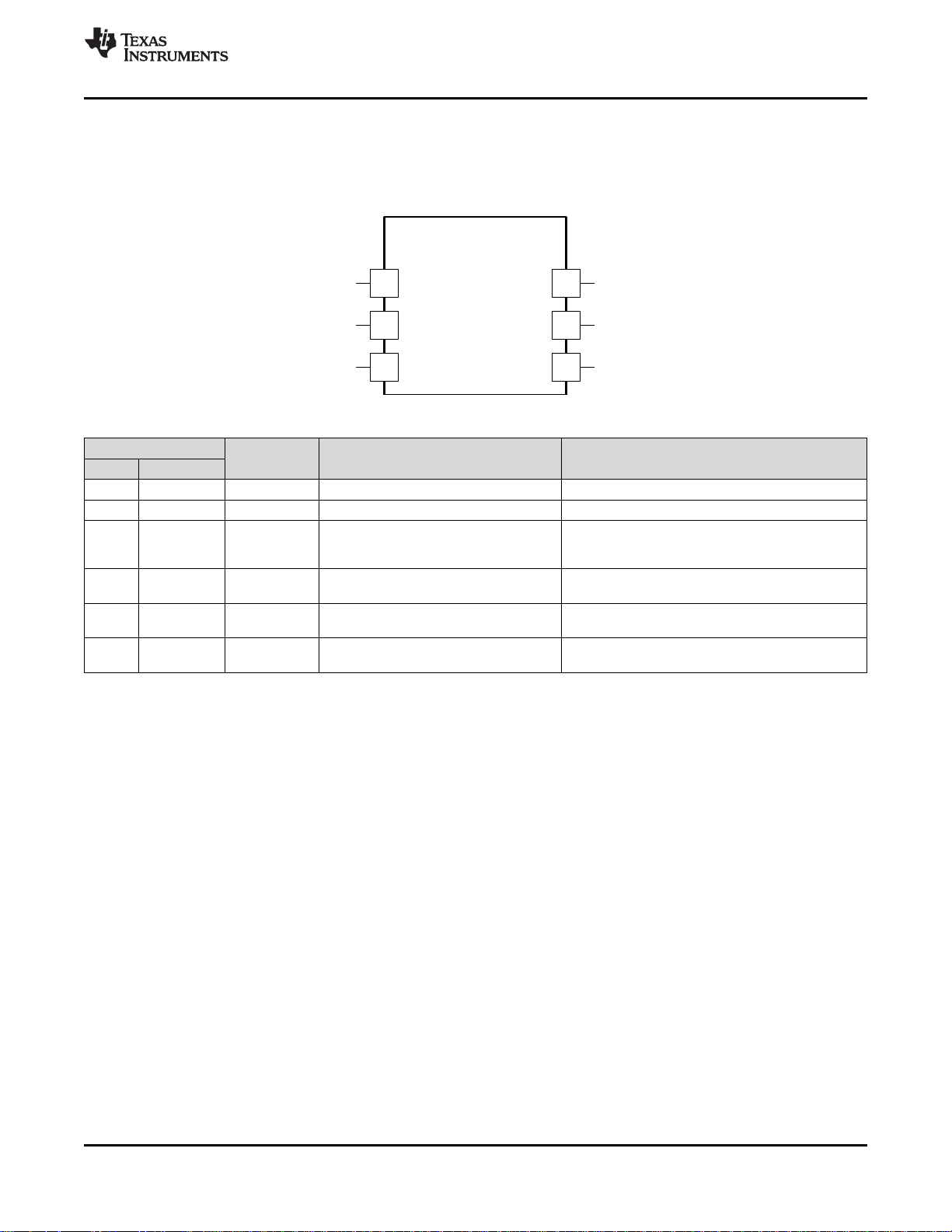

6 Pin Configuration and Functions

SOT23

6-Pin DDC

Top View

Table 1. Pin Functions

PIN

NO. NAME

1 VDD P Supply voltage

2 GND G Ground

3 DELAY/

M_RST

4 DONE I Logic Input for watchdog functionality Digital signal driven by the µC to indicate successful

5 WAKE O Timer output signal generated every t

6 RSTn O Reset Output (open drain output) Digital signal to RESET the µC, pull-up resistance is

(1) G= Ground, P= Power, O= Output, I= Input.

(1)

TYPE

I Time Interval set and Manual Reset Resistance between this pin and GND is used to

period.

DESCRIPTION APPLICATION INFORMATION

select the time interval. The reset switch is also

connected to this pin.

processing of the WAKE signal.

Digital pulsed signal to wake up the µC at the end of

IP

the programmed time interval.

required

Product Folder Links: TPL5010-Q1

Submit Documentation FeedbackCopyright © 2016, Texas Instruments Incorporated

3

Page 4

TPL5010-Q1

SNAS679 –SEPTEMBER 2016

www.ti.com

7 Specifications

7.1 Absolute Maximum Ratings

over operating free-air temperature range (unless otherwise noted)

Supply voltage (VDD-GND) –0.3 6.0 V

Input voltage at any pin

(2)

Input current on any pin –5 5 mA

T

stg

T

J

Storage temperature –65 150 °C

Junction temperature

(3)

(1) Stresses beyond those listed under Absolute Maximum Ratings may cause permanent damage to the device. These are stress ratings

only, which do not imply functional operation of the device at these or any other conditions beyond those indicated under Recommended

Operating Conditions . Exposure to absolute-maximum-rated conditions for extended periods may affect device reliability.

(2) The voltage between any two pins should not exceed 6V.

(3) The maximum power dissipation is a function of TJ(MAX), θJA, and the ambient temperature, TA. The maximum allowable power

dissipation at any ambient temperature is PDMAX = (TJ(MAX) - TA)/ θJA. All numbers apply for packages soldered directly onto a PC

board.

7.2 ESD Ratings

V

(ESD)

Electrostatic discharge

(1) AEC Q100-002 indicates that HBM stressing shall be in accordance with ANSI/ESDA/JEDEC JS-001 specification.

Human-body model, per AEC Q100-002

Charged-device model (CDM), per AEC Q10-011 ±750

(1)

MIN MAX UNIT

–0.3 VDD + 0.3 V

150 °C

VALUE UNIT

(1)

±2000

V

7.3 Recommended Operating Conditions

over operating free-air temperature range (unless otherwise noted)

MIN NOM MAX UNIT

Supply voltage (VDD-GND) 1.8 5.5 V

Temperature –40 125 °C

7.4 Thermal Information

TPL5010-Q1

THERMAL METRIC

R

θJA

R

θJC(top)

R

θJB

ψ

JT

ψ

JB

Junction-to-ambient thermal resistance 163 °C/W

Junction-to-case (top) thermal resistance 26 °C/W

Junction-to-board thermal resistance 57 °C/W

Junction-to-top characterization parameter 7.5 °C/W

Junction-to-board characterization parameter 57 °C/W

(1) For more information about traditional and new thermal metrics, see the Semiconductor and IC Package Thermal Metrics application

report.

(1)

UNITSOT23

6 PINS

4

Submit Documentation Feedback Copyright © 2016, Texas Instruments Incorporated

Product Folder Links: TPL5010-Q1

Page 5

TPL5010-Q1

www.ti.com

SNAS679 –SEPTEMBER 2016

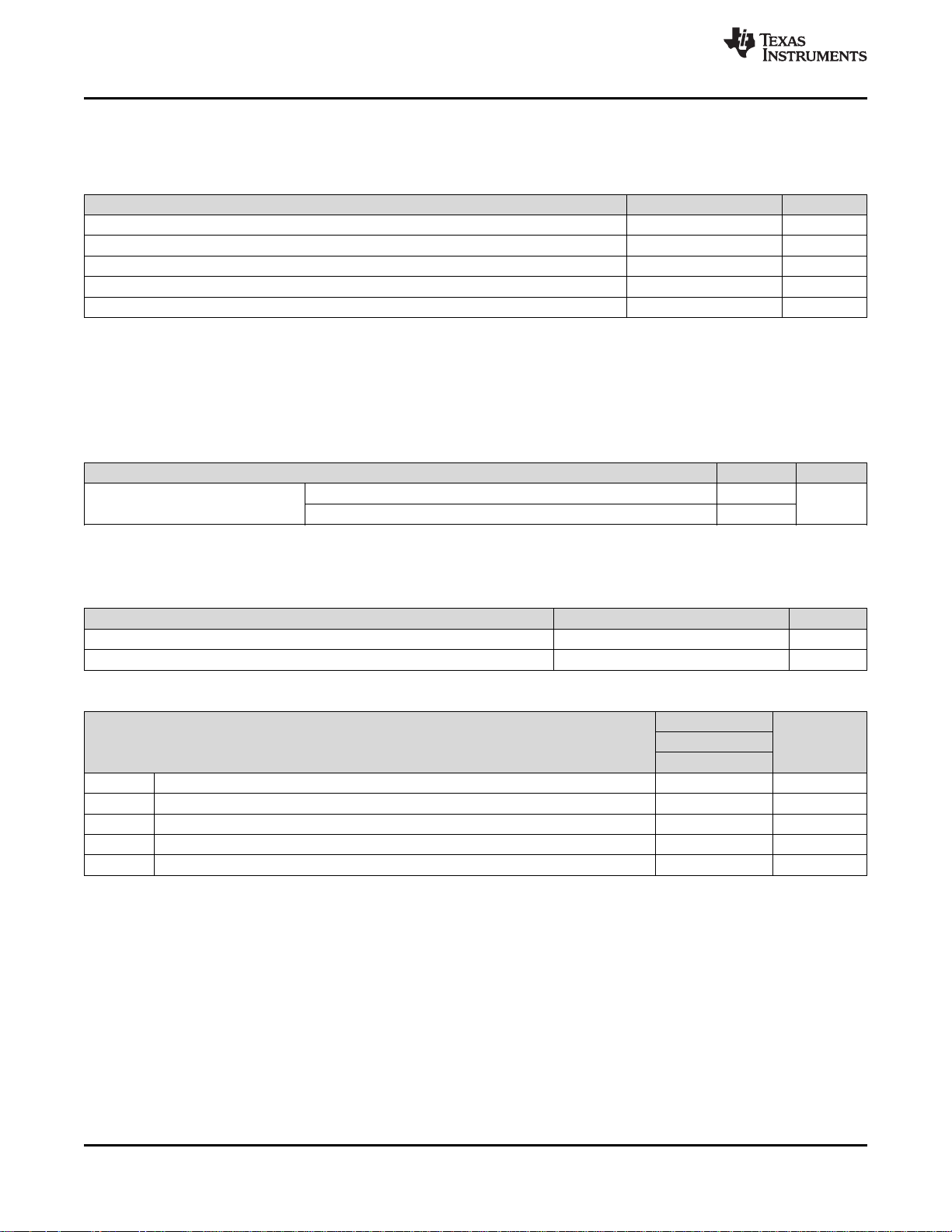

7.5 Electrical Characteristics

TA= 25°C, VDD-GND=2.5 V (unless otherwise stated)

PARAMETER TEST CONDITIONS MIN

POWER SUPPLY

IDD Supply current

TIMER

t

IP

Time interval period

Time interval setting accuracy

Timer interval setting accuracy over

supply voltage

t

OSC

Oscillator accuracy –0.5% 0.5%

Oscillator accuracy over

temperature

Oscillator accuracy over supply

voltage

Oscillator accuracy over life time

t

DONE

t

RSTn

t

WAKE

Minimum DONE pulse width

RSTn pulse width 320 ms

WAKE pulse width 20 ms

t_Rext Time to convert Rext

DIGITAL LOGIC LEVELS

VIH Minimum logic high threshold DONE

pin

VIL Maximum logic low threshold DONE

pin

VOH Logic output high-level WAKE pin

VOL Logic output low-level WAKE pin

VOL

IOH

VIH

RSTn

RSTn

M_RST

RSTn logic output low-level IOL= –1 mA 0.3 V

RSTn high-level output current VOH

Minimum logic high threshold

DELAY/M_RST pin

(1) Values apply only for factory testing conditions at the temperature indicated. Factory testing conditions result in very limited self-heating

of the device such that TJ= TA.No specification of parametric performance is indicated in the electrical tables under conditions of

internal self-heating where TJ> TA. Absolute Maximum Ratings indicate junction temperature limits beyond which the device may be

permanently degraded, either mechanically or electrically.

(2) Limits are specified by testing, design, or statistical analysis at 25°C. Limits over the operating temperature range are specified through

correlations using statistical quality control (SQC) method.

(3) Typical values represent the most likely parametric norm as determined at the time of characterization. Actual typical values may vary

over time and will also depend on the application and configuration. The typical values are not tested and are not specified on shipped

production material.

(4) The supply current excludes load and pull-up resistor current. Input pins are at GND or VDD.

(5) This parameter is specified by design and/or characterization and is not tested in production.

(6) The accuracy for time interval settings below 1 second is ±100 ms.

(7) Operational life time test procedure equivalent to 10 years.

(4)

(5)

(6)

(5)

(5)

(7)

(5)

(5)

(5)

(1)

(2)

TYP

(3)

MAX

(2)

UNIT

Operation mode 35 50 nA

Digital conversion of external

200 400 µA

resistance (Rext)

1650 selectable time

Intervals

Min time interval 100 ms

Max time

7200

interval

s

Excluding the precision of Rext ±0.6%

1.8 V ≤ VDD ≤ 5.5 V ±25 ppm/V

-40°C ≤ TA≤ 125°C 150 ppm/°C

1.8 V ≤ VDD ≤ 5.5 V ±0.4 %/V

0.24%

100 ns

100 ms

0.7 ×

V

VDD

0.3 ×

V

VDD

Iout = 100 µA VDD – 0.3 V

Iout = 1 mA VDD – 0.7 V

Iout = –100 µA 0.3 V

Iout = –1 mA 0.7 V

= VDD 1 nA

RSTn

1.5 V

Product Folder Links: TPL5010-Q1

Submit Documentation FeedbackCopyright © 2016, Texas Instruments Incorporated

5

Page 6

WAKE

VDD

DONE

RSTn

t

t

IP

t

tt

R_EXT

+ t

RSTn

t

t

tD

DONE

t

t

DONE

tr

RSTn

tf

RSTn

tr

WAKE

tf

WAKE

tt

RSTn+tDB

t

tt

RSTn

+ tIPt

DELAY/

M_RST

tt

WAKE

t

tt

M_RST

tt

RSTn

t

TPL5010-Q1

SNAS679 –SEPTEMBER 2016

www.ti.com

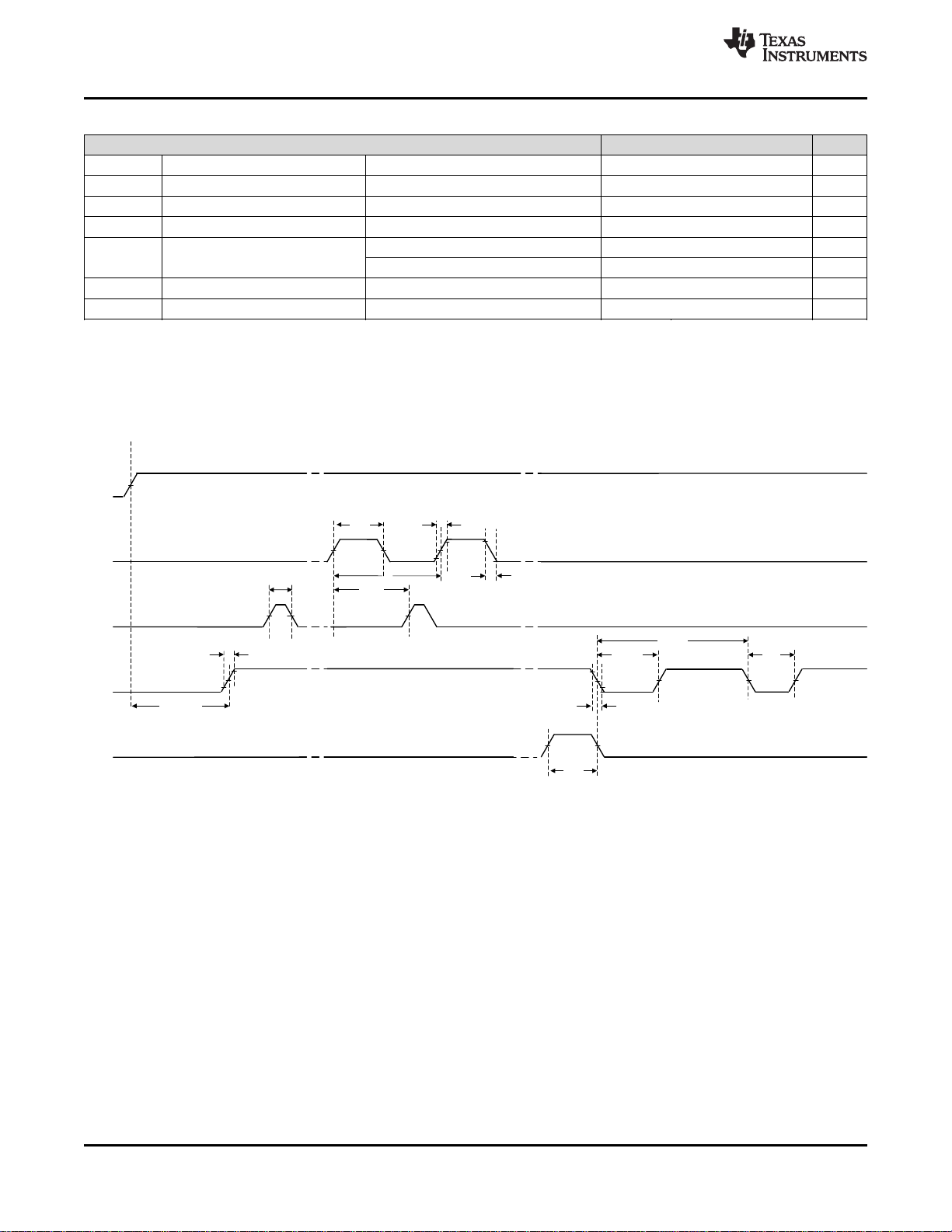

7.6 Timing Requirements

(1)

MIN

tr

RSTn

tf

RSTn

tr

WAKE

tf

WAKE

tD

DONE

t

M_RST

t

DB

Rise Time RSTn

Fall time RSTn

Rise time WAKE

Fall time WAKE

DONE to RSTn or WAKE to

DONE delay

Minimum valid manual reset

De-bounce manual reset 20 ms

(3)

(3)

(3)

(3)

Capacitive load 50 pF, Rpull-up 100 kΩ 11 µs

Capacitive load 50 pF, Rpull-up 100 kΩ 50 ns

Capacitive load 50 pF 50 ns

Capacitive load 50 pF 50 ns

Min delay

Max delay

(3)

Observation time 30 ms 20 ms

(4)

(4)

(1) Limits are specified by testing, design, or statistical analysis at 25°C. Limits over the operating temperature range are specified through

correlations using statistical quality control (SQC) method.

(2) Typical values represent the most likely parametric norm as determined at the time of characterization. Actual typical values may vary

over time and will also depend on the application and configuration. The typical values are not tested and are not specified on shipped

production material.

(3) This parameter is specified by design and/or characterization and is not tested in production.

(4) In case of RSTn from its falling edge, in case of WAKE, from its rising edge.

NOM

(2)

MAX

(1)

UNIT

100 ns

tIP–20 ms

Figure 1. TPL5010-Q1 Timing

6

Submit Documentation Feedback Copyright © 2016, Texas Instruments Incorporated

Product Folder Links: TPL5010-Q1

Page 7

Accuracy (%)

Frequency

0

5%

10%

15%

20%

25%

30%

35%

40%

-1 -0.8 -0.6 -0.4 -0.2 0 0.2 0.4 0.6 0.8

Time (s)

Supply current (PA)

0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1

0.01

0.1

1

10

100

1000

POR

R

EXT

READING

TIMER MODE

Supply Voltage (V)

Oscillator accuracy (%)

1.5 1.9 2.3 2.7 3.1 3.5 3.9 4.3 4.7 5.1 5.5

-1

-0.5

0

0.5

1

1.5

2

TA= -40°C

TA= 25°C

TA= 70°C

TA= 105°C

TA= 125°C

Temperature (°C)

Oscillator accuracy (%)

-40 -25 -10 5 20 35 50 65 80 95 110 125

-1

-0.5

0

0.5

1

1.5

2

VDD= 1.8V

VDD= 2.5V

VDD= 3.3V

VDD= 5.5V

Temperature (°C)

Supply current (nA)

-40 -25 -10 5 20 35 50 65 80 95 110 125

20

30

40

50

60

70

80

90

100

VDD= 1.8V

VDD= 2.5V

VDD= 3.3V

VDD= 5.5V

Supply Voltage (V)

Supply current (nA)

1.5 1.9 2.3 2.7 3.1 3.5 3.9 4.3 4.7 5.1 5.5

20

30

40

50

60

70

80

90

100

TA= -40°C

TA= 25°C

TA= 70°C

TA= 105°C

TA = 125°C

www.ti.com

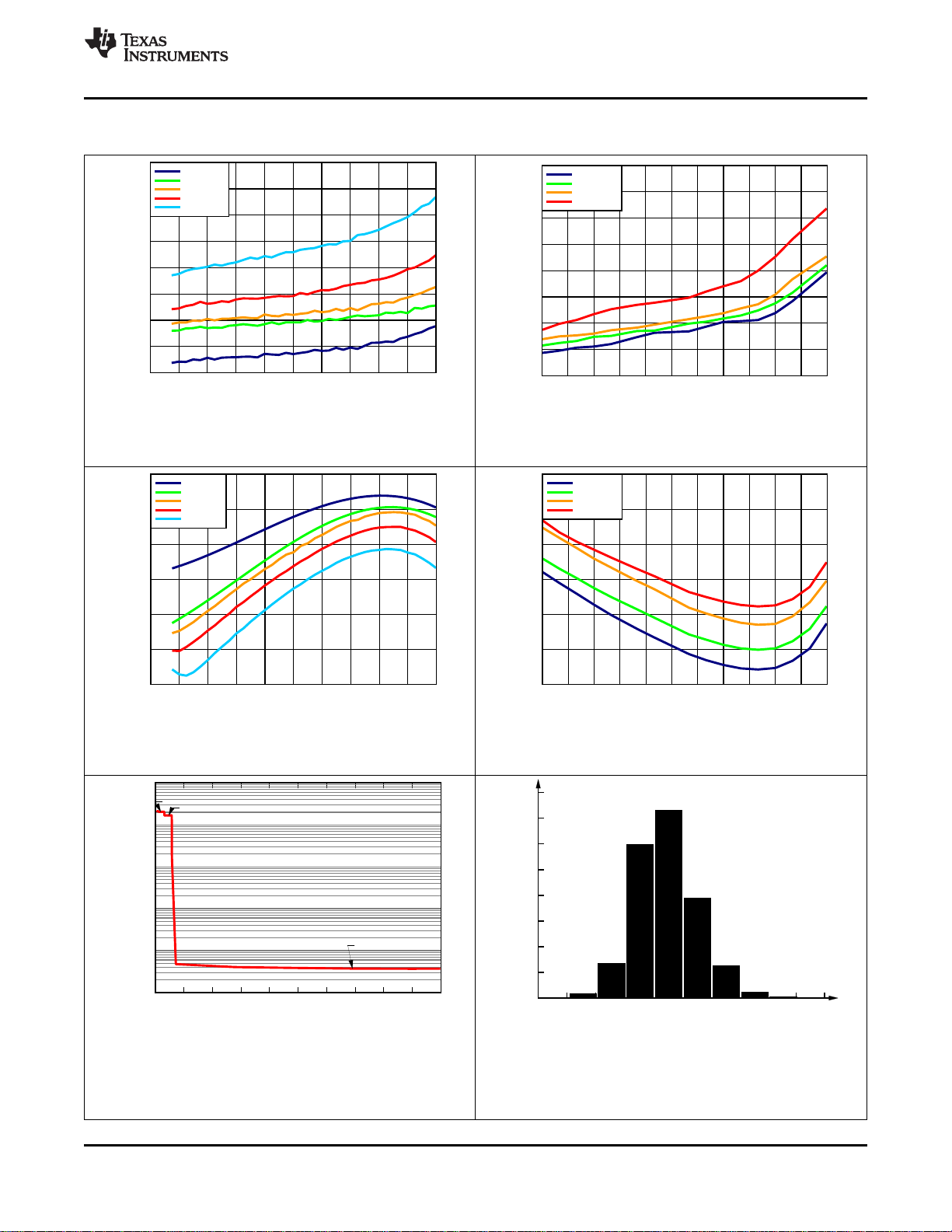

7.7 Typical Characteristics

TPL5010-Q1

SNAS679 –SEPTEMBER 2016

Figure 2. IDDvs V

DD

Figure 4. Oscillator Accuracy vs V

DD

Figure 3. IDDvs Temperature

Figure 5. Oscillator Accuracy vs Temperature

Figure 6. IDDvs Time

number of

observations >

Product Folder Links: TPL5010-Q1

1 s < tIP≤ 7200 s

20000

Figure 7. Time Interval Setting Accuracy

Submit Documentation FeedbackCopyright © 2016, Texas Instruments Incorporated

7

Page 8

WAKE

DONE

RSTn

DELAY/

M_RST

t

t

IP

t

t

t

IP

t

tt

RSTn

+ tIPt

MISSED

DONE

LOW FREQUENCY

OSCILLATOR

FREQUENCY

DIVIDER

RSTn

WAKE

VDD

GND

DELAY/

M_RST

DECODER

&

MANUAL RESET

DETECTOR

LOGIC

CONTROL

DONE

TPL5010-Q1

SNAS679 –SEPTEMBER 2016

www.ti.com

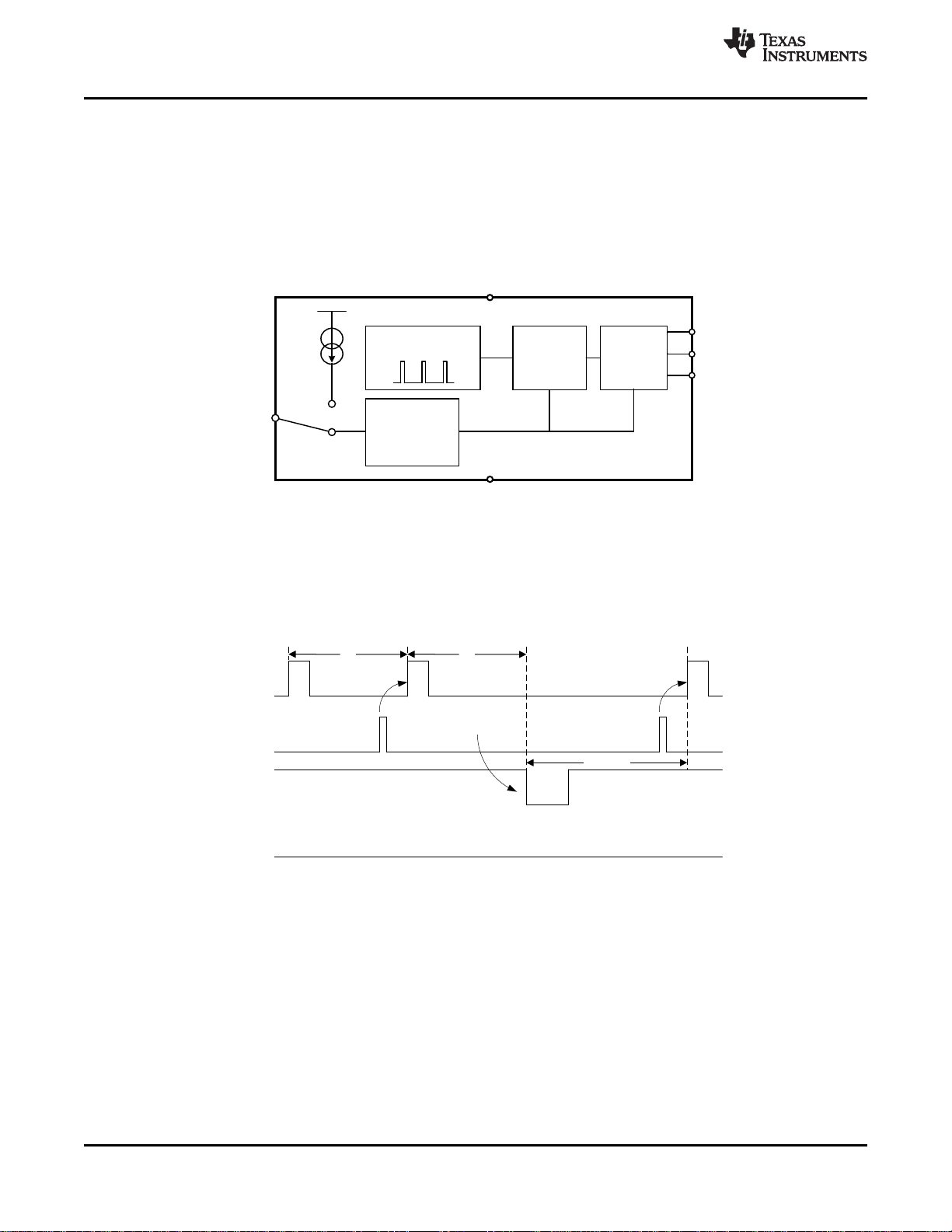

8 Detailed Description

8.1 Overview

The TPL5010-Q1 is a system wakeup timer with a watchdog feature, ideal for low power applications. TPL5010Q1 is ideal for use in interrupt-driven applications and provides selectable timing from 100 ms to 7200 s.

8.2 Functional Block Diagram

8.3 Feature Description

The DONE, WAKE and RSTn signals are used to implement the watchdog function. The TPL5010-Q1 is

programmed to issue a periodic WAKE pulse to a µC which is in sleep or standby mode. After receiving the

WAKE pulse, the µC must issue a DONE signal to the TPL5010-Q1 at least 20 ms before the rising edge of the

next WAKE pulse. If the DONE signal is not asserted, the TPL5010-Q1 asserts the RSTn signal to reset the µC.

A manual reset function is realized by momentarily pulling the DELAY/M_RST pin to VDD.

Figure 8. Watchdog

8.3.1 WAKE

The WAKE pulse is sent out from the TPL5010-Q1 when the programmed time interval starts (except at the

beginning of the first cycle or if in the previous interval the DONE has not been received).

This signal is normally low.

8.3.2 DONE

The DONE pin is driven by a µC to signal successful processing of the WAKE signal. The TPL5010-Q1

recognizes a valid DONE signal as a low to high transition; if two or more DONE signals are received within the

time interval, only the first DONE signal is processed.

The DONE signal resets the counter of the watchdog only. If the DONE signal is received when the WAKE is still

high, the WAKE will go low as soon as the DONE is recognized.

8

Submit Documentation Feedback Copyright © 2016, Texas Instruments Incorporated

Product Folder Links: TPL5010-Q1

Page 9

WAKE

DONE

RSTn

DELAY/

M_RST

POR

RESISTANCE

READING

t

t

IP

t

tt

R_EXT

+ t

RSTn

+ tIPt

TPL5010-Q1

www.ti.com

SNAS679 –SEPTEMBER 2016

Feature Description (continued)

8.3.3 RSTn

To implement the reset interface between the TPL5010-Q1 and the µC a pull-up resistance is required. 100 kΩ is

recommended, to minimize current.

During the POR and the reading of the REXT the RSTn signal is LOW.

RSTn is asserted (LOW) for either one of the following conditions:

• 1. If the DELAY/M_RST pin is high for at least two consecutive cycles of the internal oscillator (approximately

20 ms).

• 2. At the beginning of a new time interval if DONE is not received at least 20 ms before the next WAKE rising

edge (see Figure 8).

8.4 Device Functional Modes

8.4.1 Startup

During startup, after POR, the TPL5010-Q1 executes a one-time measurement of the resistance attached to the

DELAY/M_RST pin in order to determine the desired time interval for WAKE. This measurement interval is

t

. During this measurement a constant current is temporarily flowing into R

R_EXT

EXT

.

Figure 9. Startup

8.4.2 Normal Operating Mode

During normal operating mode, the TPL5010-Q1 asserts periodic WAKE pulses in response to valid DONE

pulses from the µC. If either a manual reset is applied (logic HIGH on DELAY/M_RST pin) or the µC does not

issue a DONE pulse within the required time, the TPL5010-Q1 asserts the RSTn signal to the µC and restarts its

internal counters. See Figure 8 and Figure 10 .

8.5 Programming

8.5.1 Configuring the WAKE Interval with the DELAY/M_RST Pin

The time interval between 2 adjacent WAKE pulses (rising edges) is selectable through an external resistance

(R

) between the DELAY/M_RST pin and ground. The value of the resistance R

EXT

POR. The allowable range of R

Timer Interval Selection Using External Resistance for how to set the WAKE pulse interval using R

is 500 Ω to 170 kΩ. At least a 1% precision resistance is recommended. See

EXT

The time between 2 adjacent RESET signals (falling edges) or between a RESET (falling edge) and a WAKE

(rising edge) is given by the sum of the programmed time interval and the t

Product Folder Links: TPL5010-Q1

(reset pulse width).

RSTn

is converted one time after

EXT

Submit Documentation FeedbackCopyright © 2016, Texas Instruments Incorporated

EXT

.

9

Page 10

WAKE

DONE

RSTn

DELAY/

M_RST

tt

M_RST

t ttDBt

tt

RSTn

+ tIPt

t

t

IP

t

tt

M_RST

t

NOT VALID M_RST VALID M_RST

ANY RESET

TPL5010-Q1

SNAS679 –SEPTEMBER 2016

www.ti.com

Programming (continued)

8.5.2 Manual Reset

If VDD is connected to the DELAY/M_RST pin, the TPL5010-Q1 recognizes this as a manual reset condition. In

this case the time interval is not set. If the manual reset is asserted during the POR or during the reading

procedure, the reading procedure is aborted and is re-started as soon as the manual reset switch is released. A

pulse on the DELAY/M_RST pin is recognized as a valid manual reset only if it lasts at least 20 ms (observation

time is 30 ms).

A valid manual reset resets all the counters inside the TPL5010-Q1. The counters restart only when the high

digital voltage at DELAY/M_RST is removed and the next t

RSTn

is elapsed.

Figure 10. Manual Reset

8.5.2.1 DELAY/M_RST

A resistance in the range between 500 Ω and 170 kΩ needs to be connected in order to select a valid time

interval. At the POR and during the reading of the resistance the DELAY/M_RST is connected to an analog

signal chain though a mux. After the reading of the resistance the analog circuit is switched off and the

DELAY/RST is connected to a digital circuit.

The manual reset detection is supported with a de-bounce feature which makes the TPL5010-Q1 insensitive to

the glitches on the DELAY/M_RST pin. When a valid manual reset signal is asserted on the DELAY/M_RST pin,

the RSTn signal is asserted LOW after a delay of t

tDB+ t

. Due to the asynchronous nature of the manual reset signal and its arbitrary duration, the LOW status

RSTn

. It remains LOW after a valid manual reset is asserted +

M_RST

of the RSTn signal maybe affected by an uncertainty of about ±5 ms.

A valid manual reset puts all the digital output signals at their default values:

• WAKE = LOW

• RSTn = asserted LOW

8.5.2.2 Circuitry

The manual reset may be implemented using a switch (momentary mechanical action). The TPL5010-Q1 offers 2

possible approaches according to the power consumption constraints of the application.

10

Submit Documentation Feedback Copyright © 2016, Texas Instruments Incorporated

Product Folder Links: TPL5010-Q1

Page 11

¸

¸

¹

·

¨

¨

©

§

a

Tcabb

R

EXT

2

1004

100

2

VIN

POWER MANAGEMENT

VOUT

GND

µC

GPIO

VDD

GND

Rp

GPIO

RSTn

TPL5010-Q1

VDD

GND

RSTn

WAKE

DELAY/

M_RST

DONE

R

EXT

Battery

-+

VIN

POWER MANAGEMENT

VOUT

GND

µC

GPIO

VDD

GND

Rp

GPIO

RSTn

TPL5010-Q1

VDD

GND

RSTn

WAKE

DELAY/

M_RST

DONE

R

EXT

Battery

-+

TPL5010-Q1

www.ti.com

SNAS679 –SEPTEMBER 2016

Programming (continued)

Figure 11. Manual Reset with SPST Switch

For use cases that do not require the lowest power consumption, using a single pole single throw switch may

offer a lower cost solution. The DELAY/M_RST pin may be directly connected to VDD with R

The current drawn from the supply voltage during the reset is given by VDD/R

EXT

.

in the circuit.

EXT

Figure 12. Manual Reset with SPDT Switch

The reset function may also be asserted by switching DELAY/M_RST from R

to VDD using a single pole

EXT

double throw switch, which will provide a lower power solution for the manual reset, because no current flows.

8.5.3 Timer Interval Selection Using External Resistance

In order to set the time interval, the external resistance R

is selected according the following formula:

EXT

where

• T is the desired time interval in seconds

• R

• a, b, c are coefficients depending on the range of the time interval (1)

is the resistance value to use in Ω

EXT

Product Folder Links: TPL5010-Q1

Submit Documentation FeedbackCopyright © 2016, Texas Instruments Incorporated

11

Page 12

¸

¸

¹

·

¨

¨

©

§

1284.0*2

8*1008889.25611284.0*49861.469861.46

100

2

EXT

R

TPL5010-Q1

SNAS679 –SEPTEMBER 2016

Programming (continued)

Table 2. Coefficients for Equation 1

SET

1 1 < T ≤ 5 0.2253 –20.7654 570.5679

2 5 < T ≤ 10 –0.1284 46.9861 –2651.8889

3 10 < T ≤ 100 0.1972 –19.3450 692.1201

4 100 < T ≤ 1000 0.2617 –56.2407 5957.7934

5 T > 1000 0.3177 –136.2571 34522.4680

EXAMPLE

Required time interval: 8 s

The coefficient set to be selected is the number 2. The formula becomes:

The resistance value is 10.18 kΩ.

Table 3 and Table 4 contain example values of tIPand their corresponding value of R

TIME

INTERVAL

RANGE (s)

a b c

EXT

www.ti.com

(2)

.

Table 3. First 9 Time Intervals

tIP(ms) RESISTANCE (Ω) CLOSEST REAL VALUE (Ω)

100 500 500 1.0 // 1.0

200 1000 1000 300 1500 1500 2.43 // 3.92

400 2000 2000 500 2500 2500 4.42 // 5.76

600 3000 3000 5.36 // 6.81

700 3500 3500 4.75 // 13.5

800 4000 4000 6.19 // 11.3

900 4500 4501 6.19 // 16.5

PARALLEL OF TWO 1% TOLERANCE

RESISTORS (kΩ)

Table 4. Most Common Time Intervals Between 1 s to 2 h

t

IP

1 s 5.20 5.202 7.15 // 19.1

2 s 6.79 6.788 12.4 // 15.0

3 s 7.64 7.628 12.7// 19.1

4 s 8.30 8.306 14.7 // 19.1

5 s 8.85 8.852 16.5 // 19.1

6 s 9.27 9.223 18.2 // 18.7

7 s 9.71 9.673 19.1 // 19.6

8 s 10.18 10.180 11.5 // 8.87

9 s 10.68 10.68 17.8 // 26.7

10 s 11.20 11.199 15.0 // 44.2

20 s 14.41 14.405 16.9 // 97.6

30 s 16.78 16.778 32.4 // 34.8

40 s 18.75 18.748 22.6 // 110.0

CALCULATED RESISTANCE (kΩ)

CLOSEST REAL

VALUE (kΩ)

PARALLEL OF TWO 1% TOLERANCE

RESISTORS (kΩ)

12

Submit Documentation Feedback Copyright © 2016, Texas Instruments Incorporated

Product Folder Links: TPL5010-Q1

Page 13

»

¼

º

«

¬

ª

100

EXT

D

R

INTR

»

¼

º

«

¬

ª

¸

¸

¹

·

¨

¨

©

§

c

R

b

R

aINTT

DD

ADC

100100100

1

2

2

DESIRED

ADCDESIRED

T

TT

Err 100

www.ti.com

Table 4. Most Common Time Intervals Between 1 s to 2 h (continued)

t

IP

50 s 20.047 20.047 28.7 // 66.5

1 min 22.02 22.021 40.2 // 48.7

2 min 29.35 29.349 35.7 // 165.0

3 min 34.73 34.729 63.4 // 76.8

4 min 39.11 39.097 63.4 // 102.0

5 min 42.90 42.887 54.9 // 196.0

6 min 46.29 46.301 75.0 // 121.0

7 min 49.38 49.392 97.6 // 100.0

8 min 52.24 52.224 88.7 // 127.0

9 min 54.92 54.902 86.6 // 150.0

10 min 57.44 57.437 107.0 // 124.0

20 min 77.57 77.579 140.0 // 174.0

30 min 92.43 92.233 182.0 // 187.0

40 min 104.67 104.625 130.0 // 536.00

50 min 115.33 115.331 150.0 // 499.00

1 h 124.91 124.856 221.0 // 287.00

1 h 30 min 149.39 149.398 165.0 // 1580.0

2 h 170.00 170.00 340.0 // 340.0

CALCULATED RESISTANCE (kΩ)

CLOSEST REAL

VALUE (kΩ)

PARALLEL OF TWO 1% TOLERANCE

RESISTORS (kΩ)

TPL5010-Q1

SNAS679 –SEPTEMBER 2016

8.5.4 Quantization Error

The TPL5010-Q1 can generate 1650 discrete timer intervals in the range of 100 ms to 7200 s. The first 9

intervals are multiples of 100 ms. The remaining 1641 intervals cover the range between 1 s to 7200 s. Because

they are discrete intervals, there is a quantization error associated with each value.

The quantization error can be evaluated according to the following formula:

Where:

where

• R

• a, b, c are the coefficients of the equation listed in Table 2 (5)

is the resistance calculated with Equation 1

EXT

8.5.5 Error Due to Real External Resistance

R

is a theoretical value and may not be available in standard commercial resistor values. It is possible to

EXT

closely approach the theoretical R

using two or more standard values in parallel. However, standard values

EXT

are characterized by a certain tolerance. This tolerance will affect the accuracy of the time interval.

The accuracy can be evaluated using the following procedure:

1. Evaluate the min and max values of R

EXT(REXT_MIN

, R

EXT_MAX

with Equation 1 using the selected commercial

resistance values and their tolerances.

2. Evaluate the time intervals (T

ADC_MIN[REXT_MIN

3. Find the errors using Equation 3 with T

ADC_MIN

], T

ADC_MAX[REXT_MAX

, T

ADC_MAX

.

]) with Equation 4.

The results of the formula indicate the accuracy of the time interval.

Submit Documentation FeedbackCopyright © 2016, Texas Instruments Incorporated

Product Folder Links: TPL5010-Q1

(3)

(4)

13

Page 14

3

Tolerance

Rnu

n

R

2

2

2

1

////

21

¸

¹

·

¨

©

§

¸

¹

·

¨

©

§

R

u

R

u

RuR

RR

TPL5010-Q1

SNAS679 –SEPTEMBER 2016

The example below illustrates the procedure.

• Desired time interval , T_desired = 600 s

• Required R

From Table 4, R

, from Equation 1, R

EXT

can be built with a parallel combination of two commercial values with 1% tolerance: R1=107

EXT

= 57.44 kΩ

EXT

kΩ, R2=124 kΩ. The uncertainty of the equivalent parallel resistance can be found using Equation 6.

Where uRn (n=1,2) represent the uncertainty of a resistance,

The uncertainty of the parallel resistance is 0.82%, meaning the value of R

56.96 kΩ and R

EXT_MAX

Using these value of R

586.85 s and T

ADC_MAX

= 57.90 kΩ.

, the digitized timer intervals calculated with Equation 4 are respectively T

EXT

= 611.3 s, giving an error range of –1.88% / +2.19%. The asymmetry of the error range is

may range between R

EXT

due to the quadratic transfer function of the resistance digitizer.

www.ti.com

EXT_MIN

ADC_MIN

(6)

(7)

=

=

14

Submit Documentation Feedback Copyright © 2016, Texas Instruments Incorporated

Product Folder Links: TPL5010-Q1

Page 15

Temp 29°C

CO 0PPM

TIME xx:xx

Date xx/xx/xxxx

DISPLAY

Button

ButtonButton

Button

KEYBOARD

GAS

SENSOR

VIN

POWER MANAGEMENT

VOUT

GND

Rp

100k

RST

µC

GPIO

GPIO

VDD

GND

SCL

LMP91000

SDA

VOUT

VREF

GND

SDA

SCL

ADC

CE

RE

WE

MENB

CE

RE

WE

VDD

VOLTAGE

REFERENCE

GND

VOUTVIN

Rp

100k

Rp

100k

Lithium

ion battery

-

+

GPIO

GPIO

GPIO

GPIO

TPL5010-Q1

VDD

GND

RSTn

WAKE

DELAY/

M_RST

DONE

R

EXT

TPL5010-Q1

www.ti.com

SNAS679 –SEPTEMBER 2016

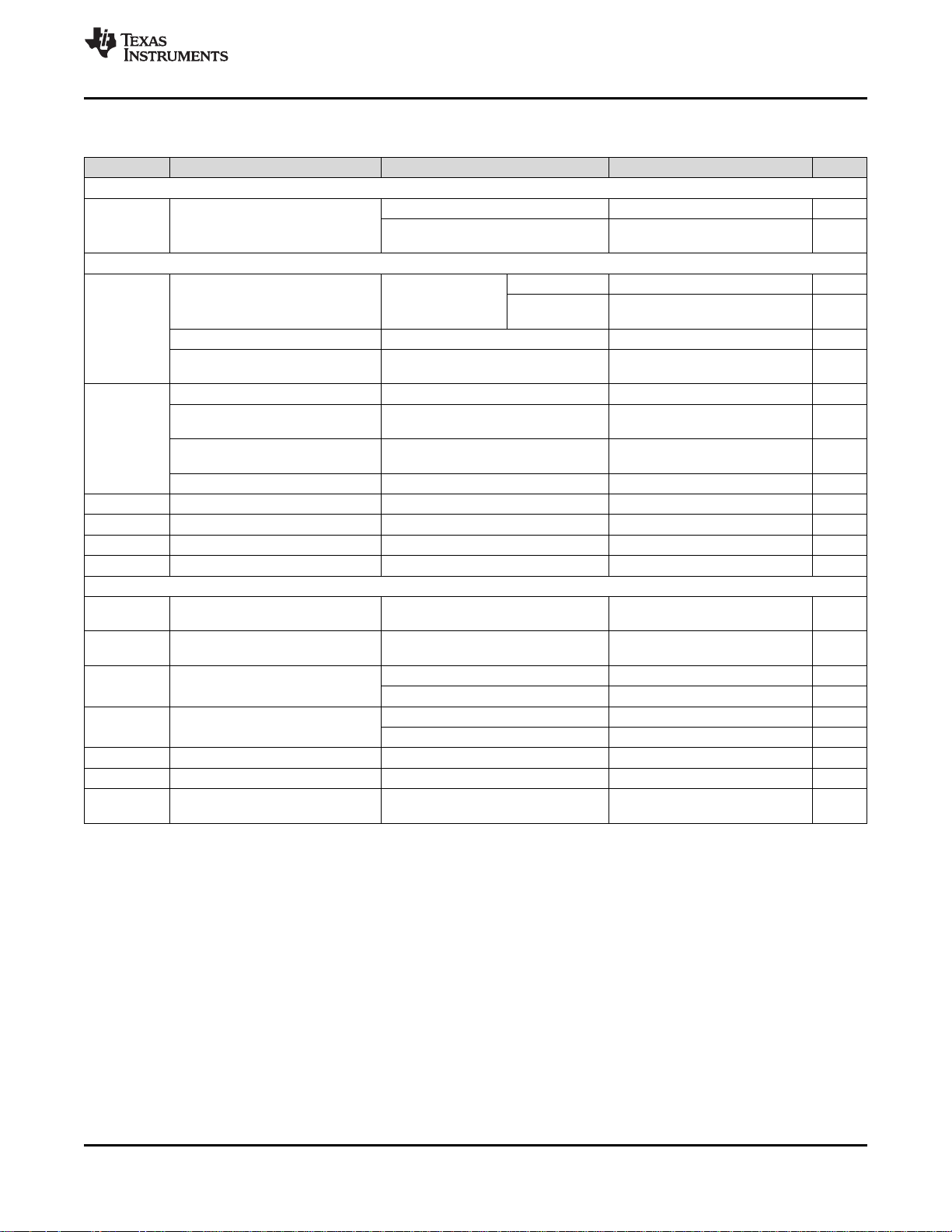

9 Application and Implementation

NOTE

Information in the following applications sections is not part of the TI component

specification, and TI does not warrant its accuracy or completeness. TI’s customers are

responsible for determining suitability of components for their purposes. Customers should

validate and test their design implementation to confirm system functionality.

9.1 Application Information

In battery-powered applications, one design constraint is the need for low current consumption. The TPL5010-Q1

is ideal for applications where there is a need to monitor environmental conditions at a fixed time interval. Often

in these applications, a watchdog or other internal timer in a µC is used to implement a wakeup function. Using

the TPL5010-Q1 to implement the watchdog function will consume only tens of nA, significantly improving the

power consumption of the system.

9.2 Typical Application

The TPL5010-Q1 can be used in conjunction with environment sensors to build a low-power environment datalogger, such as an air quality data-logger. In this application, due to the monitored phenomena, the µC and the

front end of the sensor spend most of the time in the idle state, waiting for the next logging interval, usually a few

hundred of milliseconds. Figure 13 illustrates a data logging application based on a µC, and a front end for a gas

sensor based on the LMP91000.

Figure 13. Data-Logger

9.2.1 Design Requirements

The design is driven by the low current consumption constraint. The data are usually acquired on a rate that

ranges between 1 s and 10 s. The highest necessity is the maximization of the battery life. The TPL5010-Q1

helps achieve that goal because it allows putting the µC in its lowest power mode. The TPL5010-Q1 will take

care of the watchdog and the timing.

Product Folder Links: TPL5010-Q1

Submit Documentation FeedbackCopyright © 2016, Texas Instruments Incorporated

15

Page 16

Time

Current consumption

Without TPL5010-Q1

With TPL5010-Q1

TPL5010-Q1

SNAS679 –SEPTEMBER 2016

www.ti.com

Typical Application (continued)

9.2.2 Detailed Design Procedure

When the main constraint is the battery life, the selection of a low-power voltage reference, µC, and display is

mandatory. The first step in the design is the calculation of the power consumption of the devices in their

different mode of operations. For instance, the LMP91000 burns most of the power when in gas measurement

mode, then according to the connected gas sensor it has 2 idle states: stand-by and deep sleep. The same is

true for the µC, such as one of the MSP430 family, which can be placed in one of its lower power modes, such

as LMP3.5 or LMP4.5. In this case, the TPL5010-Q1 can be used to implement the watchdog and wakeup timing

functions.

After the power budget calculation it is possible to select the appropriate time interval which satisfies the

application constraints and maximize the life of the battery.

9.2.3 Application Curves

16

Submit Documentation Feedback Copyright © 2016, Texas Instruments Incorporated

Figure 14. Effect of TPL5010-Q1 on Current Consumption

Product Folder Links: TPL5010-Q1

Page 17

TPL5010-Q1

www.ti.com

SNAS679 –SEPTEMBER 2016

10 Power Supply Recommendations

The TPL5010-Q1 requires a voltage supply within 1.8 V and 5.5 V. A multilayer ceramic bypass X7R capacitor of

0.1 μF between VDD and GND pin is recommended.

11 Layout

11.1 Layout Guidelines

The DELAY/M_RST pin is sensitive to parasitic capacitance. It is suggested that the traces connecting the

resistance on this pin to GROUND be kept as short as possible to minimize parasitic capacitance. This

capacitance can affect the initial set up of the time interval. Signal integrity on the WAKE and RSTn pins is also

improved by keeping the trace length between the TPL5010-Q1 and the µC short to reduce the parasitic

capacitance.

11.2 Layout Example

Figure 15. Layout

Product Folder Links: TPL5010-Q1

Submit Documentation FeedbackCopyright © 2016, Texas Instruments Incorporated

17

Page 18

TPL5010-Q1

SNAS679 –SEPTEMBER 2016

www.ti.com

12 Device and Documentation Support

12.1 Receiving Notification of Documentation Updates

To receive notification of documentation updates, navigate to the device product folder on ti.com. In the upper

right corner, click on Alert me to register and receive a weekly digest of any product information that has

changed. For change details, review the revision history included in any revised document.

12.2 Community Resources

The following links connect to TI community resources. Linked contents are provided "AS IS" by the respective

contributors. They do not constitute TI specifications and do not necessarily reflect TI's views; see TI's Terms of

Use.

TI E2E™ Online Community TI's Engineer-to-Engineer (E2E) Community. Created to foster collaboration

among engineers. At e2e.ti.com, you can ask questions, share knowledge, explore ideas and help

solve problems with fellow engineers.

Design Support TI's Design Support Quickly find helpful E2E forums along with design support tools and

contact information for technical support.

12.3 Trademarks

E2E is a trademark of Texas Instruments.

All other trademarks are the property of their respective owners.

12.4 Electrostatic Discharge Caution

These devices have limited built-in ESD protection. The leads should be shorted together or the device placed in conductive foam

during storage or handling to prevent electrostatic damage to the MOS gates.

12.5 Glossary

SLYZ022 — TI Glossary.

This glossary lists and explains terms, acronyms, and definitions.

13 Mechanical, Packaging, and Orderable Information

The following pages include mechanical, packaging, and orderable information. This information is the most

current data available for the designated devices. This data is subject to change without notice and revision of

this document. For browser-based versions of this data sheet, refer to the left-hand navigation.

18

Submit Documentation Feedback Copyright © 2016, Texas Instruments Incorporated

Product Folder Links: TPL5010-Q1

Page 19

PACKAGE OPTION ADDENDUM

www.ti.com

PACKAGING INFORMATION

Orderable Device Status

TPL5010QDDCRQ1 ACTIVE SOT-23-THIN DDC 6 3000 RoHS & Green SN Level-1-260C-UNLIM -40 to 125 13VX

TPL5010QDDCTQ1 ACTIVE SOT-23-THIN DDC 6 250 RoHS & Green SN Level-1-260C-UNLIM -40 to 125 13VX

(1)

The marketing status values are defined as follows:

ACTIVE: Product device recommended for new designs.

LIFEBUY: TI has announced that the device will be discontinued, and a lifetime-buy period is in effect.

NRND: Not recommended for new designs. Device is in production to support existing customers, but TI does not recommend using this part in a new design.

PREVIEW: Device has been announced but is not in production. Samples may or may not be available.

OBSOLETE: TI has discontinued the production of the device.

Package Type Package

(1)

Drawing

Pins Package

Qty

Eco Plan

(2)

Lead finish/

Ball material

(6)

MSL Peak Temp

(3)

Op Temp (°C) Device Marking

(4/5)

(2)

RoHS: TI defines "RoHS" to mean semiconductor products that are compliant with the current EU RoHS requirements for all 10 RoHS substances, including the requirement that RoHS substance

do not exceed 0.1% by weight in homogeneous materials. Where designed to be soldered at high temperatures, "RoHS" products are suitable for use in specified lead-free processes. TI may

reference these types of products as "Pb-Free".

RoHS Exempt: TI defines "RoHS Exempt" to mean products that contain lead but are compliant with EU RoHS pursuant to a specific EU RoHS exemption.

Green: TI defines "Green" to mean the content of Chlorine (Cl) and Bromine (Br) based flame retardants meet JS709B low halogen requirements of <=1000ppm threshold. Antimony trioxide based

flame retardants must also meet the <=1000ppm threshold requirement.

(3)

MSL, Peak Temp. - The Moisture Sensitivity Level rating according to the JEDEC industry standard classifications, and peak solder temperature.

(4)

There may be additional marking, which relates to the logo, the lot trace code information, or the environmental category on the device.

(5)

Multiple Device Markings will be inside parentheses. Only one Device Marking contained in parentheses and separated by a "~" will appear on a device. If a line is indented then it is a continuation

of the previous line and the two combined represent the entire Device Marking for that device.

(6)

Lead finish/Ball material - Orderable Devices may have multiple material finish options. Finish options are separated by a vertical ruled line. Lead finish/Ball material values may wrap to two

lines if the finish value exceeds the maximum column width.

Important Information and Disclaimer:The information provided on this page represents TI's knowledge and belief as of the date that it is provided. TI bases its knowledge and belief on information

provided by third parties, and makes no representation or warranty as to the accuracy of such information. Efforts are underway to better integrate information from third parties. TI has taken and

continues to take reasonable steps to provide representative and accurate information but may not have conducted destructive testing or chemical analysis on incoming materials and chemicals.

TI and TI suppliers consider certain information to be proprietary, and thus CAS numbers and other limited information may not be available for release.

In no event shall TI's liability arising out of such information exceed the total purchase price of the TI part(s) at issue in this document sold by TI to Customer on an annual basis.

9-Mar-2021

Samples

Addendum-Page 1

Page 20

PACKAGE OPTION ADDENDUM

www.ti.com

OTHER QUALIFIED VERSIONS OF TPL5010-Q1 :

Catalog: TPL5010

•

NOTE: Qualified Version Definitions:

Catalog - TI's standard catalog product

•

9-Mar-2021

Addendum-Page 2

Page 21

PACKAGE OUTLINE

PIN 1

INDEX AREA

4X 0.95

1.9

SCALE 4.000

3.05

2.55

1.75

1.45

1

3

B

A

6

3.05

2.75

4

0.5

6X

0.3

0.2 C A B

SOT - 1.1 max heightDDC0006A

SOT

1.100

0.847

0.1 C

0.1

TYP

0.0

0 -8 TYP

0.20

0.12

TYP

0.6

0.3

SEATING PLANE

TYP

C

0.25

GAGE PLANE

4214841/B 11/2020

NOTES:

1. All linear dimensions are in millimeters. Any dimensions in parenthesis are for reference only. Dimensioning and tolerancing

per ASME Y14.5M.

2. This drawing is subject to change without notice.

3. Reference JEDEC MO-193.

www.ti.com

Page 22

EXAMPLE BOARD LAYOUT

SOT - 1.1 max heightDDC0006A

SOT

SOLDER MASK

OPENING

6X (0.6)

4X (0.95)

(R0.05) TYP

1

3

METAL

6X (1.1)

SYMM

(2.7)

LAND PATTERN EXAMPLE

EXPLOSED METAL SHOWN

SCALE:15X

METAL UNDER

SOLDER MASK

6

SYMM

4

SOLDER MASK

OPENING

EXPOSED METAL

EXPOSED METAL

0.07 MAX

ARROUND

NON SOLDER MASK

DEFINED

0.07 MIN

ARROUND

SOLDER MASK

DEFINED

SOLDERMASK DETAILS

NOTES: (continued)

4. Publication IPC-7351 may have alternate designs.

5. Solder mask tolerances between and around signal pads can vary based on board fabrication site.

4214841/B 11/2020

www.ti.com

Page 23

1

EXAMPLE STENCIL DESIGN

SOT - 1.1 max heightDDC0006A

SOT

SYMM

6X (1.1)

6X (0.6)

4X(0.95)

(R0.05) TYP

3

(2.7)

SOLDER PASTE EXAMPLE

BASED ON 0.125 THICK STENCIL

SCALE:15X

6

SYMM

4

4214841/B 11/2020

NOTES: (continued)

6. Laser cutting apertures with trapezoidal walls and rounded corners may offer better paste release. IPC-7525 may have alternate

design recommendations.

7. Board assembly site may have different recommendations for stencil design.

www.ti.com

Page 24

IMPORTANT NOTICE AND DISCLAIMER

TI PROVIDES TECHNICAL AND RELIABILITY DATA (INCLUDING DATASHEETS), DESIGN RESOURCES (INCLUDING REFERENCE

DESIGNS), APPLICATION OR OTHER DESIGN ADVICE, WEB TOOLS, SAFETY INFORMATION, AND OTHER RESOURCES “AS IS”

AND WITH ALL FAULTS, AND DISCLAIMS ALL WARRANTIES, EXPRESS AND IMPLIED, INCLUDING WITHOUT LIMITATION ANY

IMPLIED WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE OR NON-INFRINGEMENT OF THIRD

PARTY INTELLECTUAL PROPERTY RIGHTS.

These resources are intended for skilled developers designing with TI products. You are solely responsible for (1) selecting the appropriate

TI products for your application, (2) designing, validating and testing your application, and (3) ensuring your application meets applicable

standards, and any other safety, security, or other requirements. These resources are subject to change without notice. TI grants you

permission to use these resources only for development of an application that uses the TI products described in the resource. Other

reproduction and display of these resources is prohibited. No license is granted to any other TI intellectual property right or to any third party

intellectual property right. TI disclaims responsibility for, and you will fully indemnify TI and its representatives against, any claims, damages,

costs, losses, and liabilities arising out of your use of these resources.

TI’s products are provided subject to TI’s Terms of Sale (https:www.ti.com/legal/termsofsale.html) or other applicable terms available either

on ti.com or provided in conjunction with such TI products. TI’s provision of these resources does not expand or otherwise alter TI’s

applicable warranties or warranty disclaimers for TI products.IMPORTANT NOTICE

Mailing Address: Texas Instruments, Post Office Box 655303, Dallas, Texas 75265

Copyright © 2021, Texas Instruments Incorporated

Loading...

Loading...