Page 1

User's Guide

SLVUAN6–June 2016

TPD1E0B04 Evaluation Module

This user's guide describes the characteristics, operation, and use of the TPD1E0B04 EVM evaluation

module (EVM). This EVM includes six TPD1E0B04s in various configurations for testing. Five

TPD1E0B04s are configured for IEC 61000-4-2 compliance testing and one is configured for 2-port sparameter analysis. This user's guide includes setup instructions, schematic diagrams, a bill of materials,

and printed-circuit board layout drawings for the evaluation module.

Contents

1 Introduction ................................................................................................................... 2

2 Definitions..................................................................................................................... 2

3 Setup .......................................................................................................................... 3

3.1 IEC 61000-4-2 ESD Rating Tests ................................................................................ 3

3.2 Scattering Parameters ............................................................................................. 4

3.3 ±8-kV ESD Clamping Waveforms ................................................................................ 4

4 Board Layout ................................................................................................................. 6

5 Schematics ................................................................................................................... 6

6 Bill of Materials............................................................................................................... 7

List of Figures

1 Ideal Contact Discharge Waveform of the Output Current of the ESD Simulator at 4-kV ......................... 3

2 System Level ESD Test Setup............................................................................................. 4

3 TPD1E0B04EVM Top Layer and Silkscreen............................................................................. 6

4 TPD1E0B04EVM Schematic ............................................................................................... 6

List of Tables

1 IEC 61000-4-2 Test Levels ................................................................................................ 2

2 Waveform Parameters in Contact Discharge Mode..................................................................... 2

3 Bill of Materials............................................................................................................... 7

SLVUAN6–June 2016

Submit Documentation Feedback

Copyright © 2016, Texas Instruments Incorporated

TPD1E0B04 Evaluation Module

1

Page 2

Introduction

1 Introduction

Texas Instrument’s TPD1E0B04 evaluation module helps designers evaluate the operation and

performance of the TPD1E0B04 device. The TPD1E0B04 is a unidirectional TVS ESD protection diode for

HDMI 2.0 and USB 3.1 Gen II Super-speed data line protection. The TPD1E0B04 is rated to dissipate

ESD strikes at the maximum level specified in the IEC 61000-4-2 international standard (Level 4).

The EVM contains six TPD1E0B04s. Five TPD1E0B04s (D1 – D5) are configured with test points for

striking ESD to the protection pins. One TPD1E0B04 (D6) is configured with 2 SMA (J1 and J2)

connectors for 2-port analysis with a vector network analyzer. TPD1E0B04 (D6) can also be used for

capturing clamping waveforms with an oscilloscope during an ESD test. Caution must be taken when

capturing clamping waveforms during an ESD event so as not to damage the oscilloscope. A proper

procedure is outlined in Section 3.3.1.

2 Definitions

Contact Discharge — a method of testing in which the electrode of the ESD simulator is held in contact

with the device-under-test (DUT).

Air Discharge — a method of testing in which the charged electrode of the ESD simulator approaches

the DUT, and a spark to the DUT actuates the discharge.

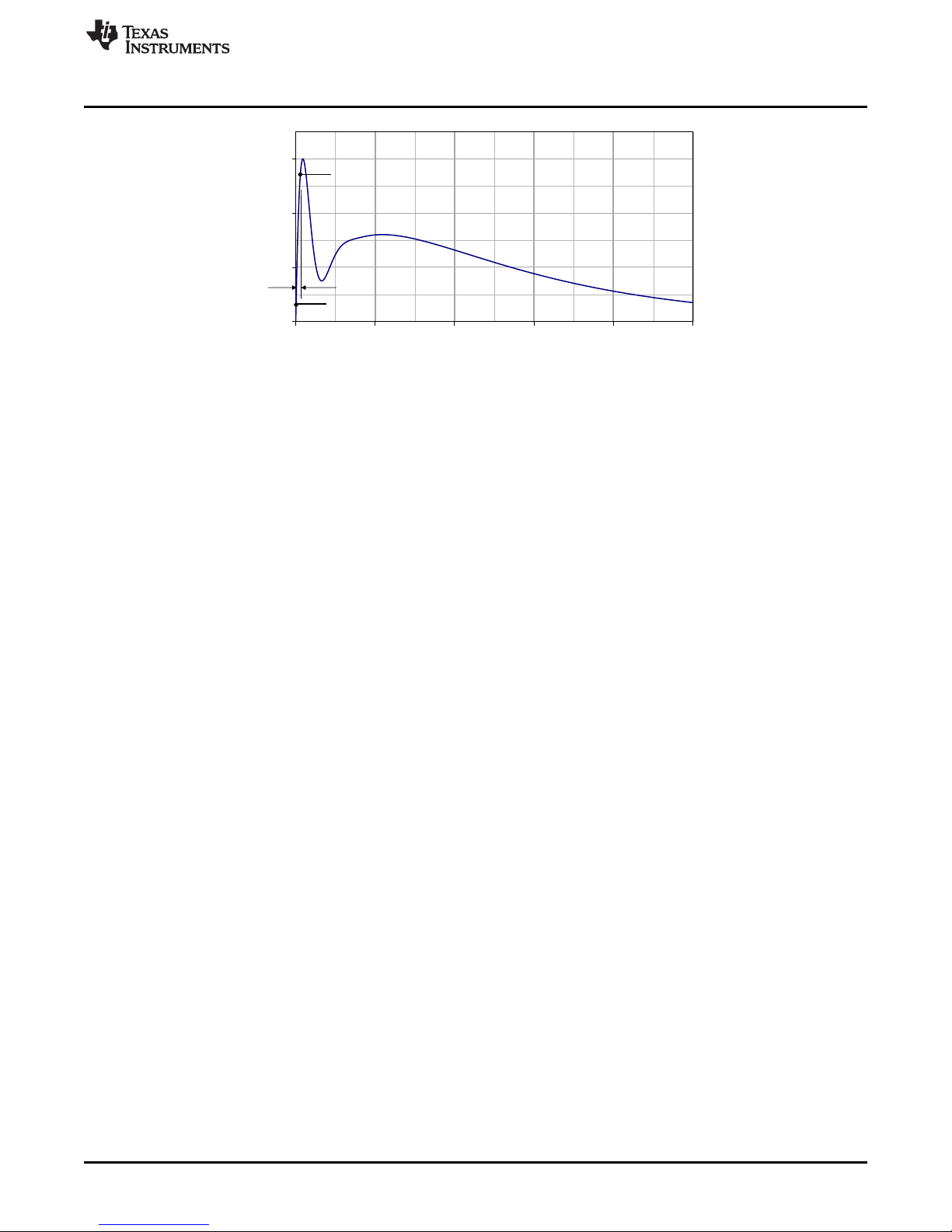

ESD Simulator — a device that outputs IEC 61000-4-2 compliance ESD waveforms shown in Figure 1

with adjustable ranges shown in Table 1 and Table 2.

IEC 61000-4-2 has 4 classes of protection levels. Classes 1 – 4 are shown in Table 1. Stress tests

must be incrementally tested to level 4 as shown in Table 2 until the point of failure. If the DUT

does not fail at 8-kV, testing can continue in 2-kV increments until failure.

www.ti.com

Contact Discharge Air Discharge

Class Test Voltage [± kV] Class Test Voltage [± kV]

1 2 1 2

2 4 2 4

3 6 3 8

4 8 4 15

Table 2. Waveform Parameters in Contact Discharge Mode

Stress Level Step Simulator Voltage

[kV]

1 2 7.5 0.8 4 2

2 4 15 0.8 8 4

3 6 22.5 0.8 12 6

4 8 30 0.8 16 8

Table 1. IEC 61000-4-2 Test Levels

Ipeak ±15%

[A]

Rise Time ±25%

[ns]

Current at 30 ns

±30% [A]

Current at 60 ns

±30% [A]

2

TPD1E0B04 Evaluation Module

Copyright © 2016, Texas Instruments Incorporated

Submit Documentation Feedback

SLVUAN6–June 2016

Page 3

0

10

20

30

0 20 40 60 80 100

Current (A)

Time (ns)

I

PEAK

90% I

PEAK

10% I

PEAK

800 ps 90/10 rise time

www.ti.com

Figure 1. Ideal Contact Discharge Waveform of the Output Current of the ESD Simulator at 4-kV

3 Setup

This section describes the intended use of the EVM. A generalized outline of the procedure given in IEC

61000-4-2 is described here. IEC 61000-4-2 must be referred to for a more specific testing outline. Basic

configurations for collecting s-parameters and ESD clamping waveforms are outlined as well.

3.1 IEC 61000-4-2 ESD Rating Tests

TPD1E0B04 (D1 – D5) can be used for destructive electrostatic discharge (ESD) pass or fail strikes.

Specifically, they can be used for both IEC 61000-4-2 air and contact discharge tests. The procedure in

Section 3.1.1 ensures proper testing setup and method for both discharge tests. Each IO has a Test Pad

(TP1 – TP5) directly connected to it for striking ESD.

Setup

3.1.1 Test Method and Set-Up

An example test setup is shown in Figure 2. Details of the testing table and ground planes can be found in

the IEC 61000-4-2 test procedure. Ground the EVM using the banana connector J3. Discharge the ESD

simulator on any of the test points TP1 – TP5. Contact and air-gap discharge are tested using the same

simulator with the same discharge waveform. While the simulator is in direct contact with the test point

during contact, it is not during air-gap.

SLVUAN6–June 2016

Submit Documentation Feedback

Copyright © 2016, Texas Instruments Incorporated

TPD1E0B04 Evaluation Module

3

Page 4

ESD Simulator

Typical Position for

Direct Discharge

Ground Reference Plane

Power and Ground Connection

DUT or System

Horizontal Coupling

Plane (HCP)

To Wall

Ground

470 kO

470 kO

Non-conducting Table

Insulation

Setup

www.ti.com

3.1.2 Evaluation of Test Results

3.2 Scattering Parameters

3.3 ±8-kV ESD Clamping Waveforms

Figure 2. System Level ESD Test Setup

Connect the tested device on the EVM to a curve tracer both before and after ESD testing. After each

incremental level, if the IV-curve of the ESD protection diode shifts ±0.1 V, or leakage current increases by

a factor of ten, then the device is permanently damaged by ESD.

A TPD1E0B04 (D6) is configured with 2 SMA (J1 and J2) connectors to allow 2-port analysis with a vector

network analyzer. Connect Port 1 to J1 and Port 2 to J2. This configuration allows for the following

terminology in 2-port analysis:

• S11: Return loss

• S21: Insertion loss

A TPD1E0B04 (D6) has two SMA connectors (J1 and J2) which can be used for capturing clamping

waveforms with an oscilloscope during an ESD strike. Caution must be taken when capturing clamping

waveforms during an ESD event so as not to damage the oscilloscope. The procedures in Section 3.3.1

outlines a proper method.

4

TPD1E0B04 Evaluation Module

Copyright © 2016, Texas Instruments Incorporated

SLVUAN6–June 2016

Submit Documentation Feedback

Page 5

www.ti.com

3.3.1 Oscilloscope Setup

Without a proper procedure, capturing ESD clamping waveforms exposes the oscilloscope to potential

voltages higher than the rating of the equipment. Proper methodology can mitigate any risk in this

operation.

Recommended Measurement Equipment:

• One 2-GHz bandwidth (minimum of 1 GHz) oscilloscope.

• Two 10X 50-Ω attenuators

• One 50-Ω shielded SMA cable.

Procedure

In order to protect the oscilloscope, attenuation of the measured signal is required. Here is a procedure for

testing D3:

1. Ground the EVM using the banana connector J3.

2. Attach two 10X attenuators in series to the oscilloscope channel being used.

3. Attach the 50-Ω shielded SMA cable between J2 and the attenuators.

4. Set the scope attenuation factor to 100X.

5. Set the oscilloscope to trigger on a positive edge for (+) ESD and a negative edge for (–) ESD strikes.

The trigger voltage magnitude must be set to 20 V.

6. Following Section 3.1.1, strike contact ESD to J1.Pin1.

Recommended settings for the time axis is 20 ns/div and for the voltage axis is 10 V division.

The voltage levels of the ESD applied to J1.Pin1 must not exceed ±8 kV while capturing clamping

waveforms.

Setup

SLVUAN6–June 2016

Submit Documentation Feedback

Copyright © 2016, Texas Instruments Incorporated

TPD1E0B04 Evaluation Module

5

Page 6

Board Layout

4 Board Layout

This section provides the TPD1E0B04EVM board layout. TPD1E0B04EVM is a 4-layer board of FR408HR

at 0.062 inch thickness. Layers 2, 3, and 4 are ground planes and not shown here.

www.ti.com

5 Schematics

Figure 3. TPD1E0B04EVM Top Layer and Silkscreen

Figure 4. TPD1E0B04EVM Schematic

6

TPD1E0B04 Evaluation Module

Copyright © 2016, Texas Instruments Incorporated

Submit Documentation Feedback

SLVUAN6–June 2016

Page 7

www.ti.com

6 Bill of Materials

Bill of Materials

Table 3. Bill of Materials

Count RefDes Description Package

6 D1, D2, D3, D4,

D5, D6

2 J1, J2 Connector, TH, End launch

1 J3 Standard Banana Jack,

1-Channel ESD Protection

Device for Super-Speed (up

to 6 Gbps) Interface,

DPL0002A

SMA 50 Ω

Insulated, Black

Reference

DPL0002A TPD1E0B04DPL Texas Instruments

Connector, TH,

End launch SMA

6092 6092 Keystone

Part Number MFR

142-0761-881 Johnson

SLVUAN6–June 2016

Submit Documentation Feedback

Copyright © 2016, Texas Instruments Incorporated

TPD1E0B04 Evaluation Module

7

Page 8

IMPORTANT NOTICE

Texas Instruments Incorporated and its subsidiaries (TI) reserve the right to make corrections, enhancements, improvements and other

changes to its semiconductor products and services per JESD46, latest issue, and to discontinue any product or service per JESD48, latest

issue. Buyers should obtain the latest relevant information before placing orders and should verify that such information is current and

complete. All semiconductor products (also referred to herein as “components”) are sold subject to TI’s terms and conditions of sale

supplied at the time of order acknowledgment.

TI warrants performance of its components to the specifications applicable at the time of sale, in accordance with the warranty in TI’s terms

and conditions of sale of semiconductor products. Testing and other quality control techniques are used to the extent TI deems necessary

to support this warranty. Except where mandated by applicable law, testing of all parameters of each component is not necessarily

performed.

TI assumes no liability for applications assistance or the design of Buyers’ products. Buyers are responsible for their products and

applications using TI components. To minimize the risks associated with Buyers’ products and applications, Buyers should provide

adequate design and operating safeguards.

TI does not warrant or represent that any license, either express or implied, is granted under any patent right, copyright, mask work right, or

other intellectual property right relating to any combination, machine, or process in which TI components or services are used. Information

published by TI regarding third-party products or services does not constitute a license to use such products or services or a warranty or

endorsement thereof. Use of such information may require a license from a third party under the patents or other intellectual property of the

third party, or a license from TI under the patents or other intellectual property of TI.

Reproduction of significant portions of TI information in TI data books or data sheets is permissible only if reproduction is without alteration

and is accompanied by all associated warranties, conditions, limitations, and notices. TI is not responsible or liable for such altered

documentation. Information of third parties may be subject to additional restrictions.

Resale of TI components or services with statements different from or beyond the parameters stated by TI for that component or service

voids all express and any implied warranties for the associated TI component or service and is an unfair and deceptive business practice.

TI is not responsible or liable for any such statements.

Buyer acknowledges and agrees that it is solely responsible for compliance with all legal, regulatory and safety-related requirements

concerning its products, and any use of TI components in its applications, notwithstanding any applications-related information or support

that may be provided by TI. Buyer represents and agrees that it has all the necessary expertise to create and implement safeguards which

anticipate dangerous consequences of failures, monitor failures and their consequences, lessen the likelihood of failures that might cause

harm and take appropriate remedial actions. Buyer will fully indemnify TI and its representatives against any damages arising out of the use

of any TI components in safety-critical applications.

In some cases, TI components may be promoted specifically to facilitate safety-related applications. With such components, TI’s goal is to

help enable customers to design and create their own end-product solutions that meet applicable functional safety standards and

requirements. Nonetheless, such components are subject to these terms.

No TI components are authorized for use in FDA Class III (or similar life-critical medical equipment) unless authorized officers of the parties

have executed a special agreement specifically governing such use.

Only those TI components which TI has specifically designated as military grade or “enhanced plastic” are designed and intended for use in

military/aerospace applications or environments. Buyer acknowledges and agrees that any military or aerospace use of TI components

which have not been so designated is solely at the Buyer's risk, and that Buyer is solely responsible for compliance with all legal and

regulatory requirements in connection with such use.

TI has specifically designated certain components as meeting ISO/TS16949 requirements, mainly for automotive use. In any case of use of

non-designated products, TI will not be responsible for any failure to meet ISO/TS16949.

Products Applications

Audio www.ti.com/audio Automotive and Transportation www.ti.com/automotive

Amplifiers amplifier.ti.com Communications and Telecom www.ti.com/communications

Data Converters dataconverter.ti.com Computers and Peripherals www.ti.com/computers

DLP® Products www.dlp.com Consumer Electronics www.ti.com/consumer-apps

DSP dsp.ti.com Energy and Lighting www.ti.com/energy

Clocks and Timers www.ti.com/clocks Industrial www.ti.com/industrial

Interface interface.ti.com Medical www.ti.com/medical

Logic logic.ti.com Security www.ti.com/security

Power Mgmt power.ti.com Space, Avionics and Defense www.ti.com/space-avionics-defense

Microcontrollers microcontroller.ti.com Video and Imaging www.ti.com/video

RFID www.ti-rfid.com

OMAP Applications Processors www.ti.com/omap TI E2E Community e2e.ti.com

Wireless Connectivity www.ti.com/wirelessconnectivity

Mailing Address: Texas Instruments, Post Office Box 655303, Dallas, Texas 75265

Copyright © 2016, Texas Instruments Incorporated

Loading...

Loading...