www.ti.com

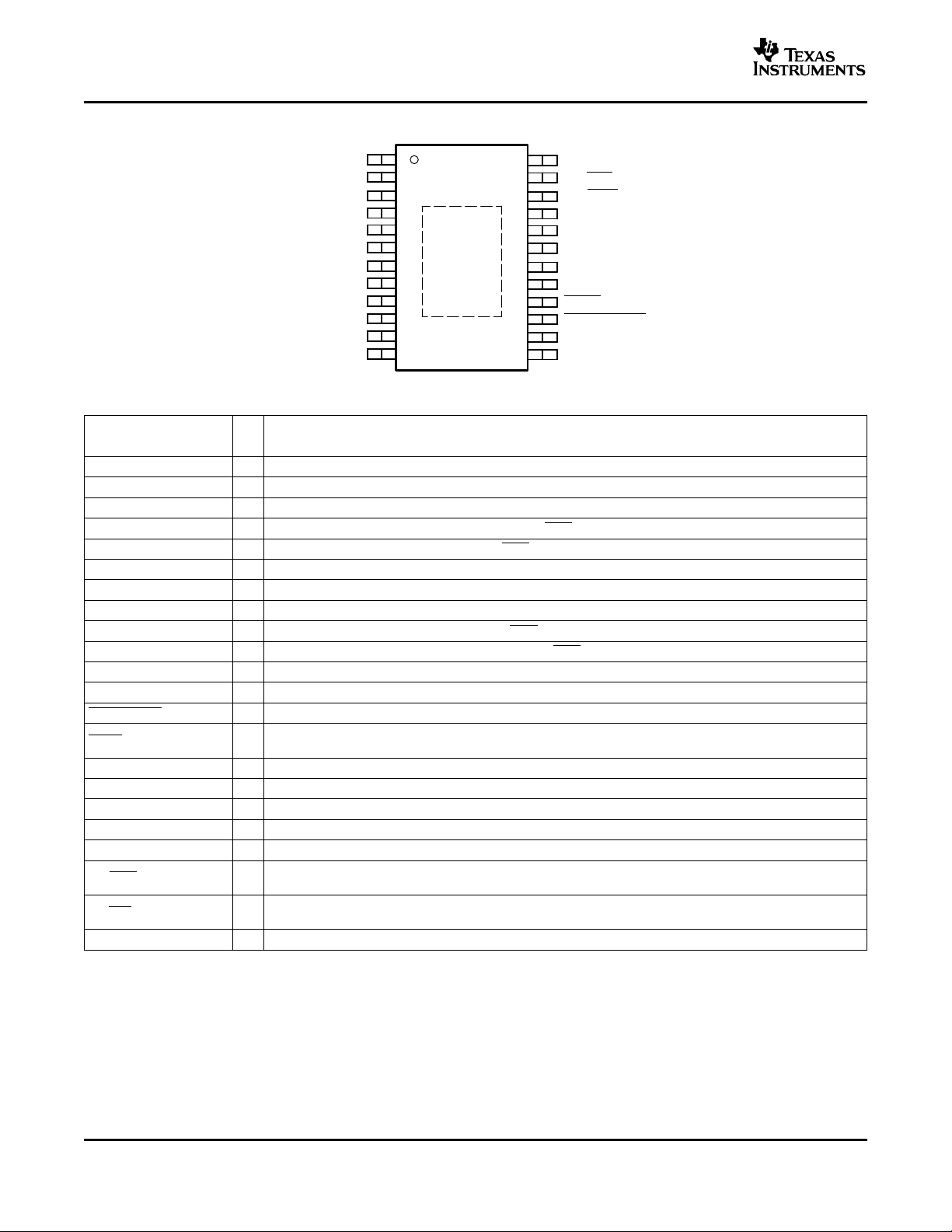

APPLICATION CIRCUIT

PGND

ROUT-

PV

DD

RHPIN

RLINEIN

RIN

V

DD

LIN

LLINEIN

LHPIN

PV

DD

LOUT-

1

ROUT+

SE/BTL

HP/LINE

VOLUME

SEDIFF

SEMAX

AGND

BYPASS

FADE

SHUTDOWN

LOUT+

PGND

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

C

S

C

i

V

DD

Right HP

Audio Source

C

i

C

i

C

S

C

i

C

i

C

i

C

S

Power Supply

Right Line

Audio Source

Left Line

Audio Source

Left HP

Audio Source

Power Supply

V

DD

100 kΩ

100 kΩ

C

C

In From DAC

or

Potentiometer

(DC Voltage)

C

(BYP)

System

Control

C

C

Right

Speaker

Left

Speaker

Headphone

s

1 kΩ

1 kΩ

-90

-80

-70

-60

-50

-40

-30

-20

-10

0

10

20

30

0 0.5 1 1.5 2 2.5 3 3.5 4 4.5 5

Volume [Pin 21] - V

DC VOLUME CONTROL

SE Volume,

SEDIFF [Pin 20] = 0 V

SE Volume,

SEDIFF [Pin 20] = 1 V

Volume - dB

BTL Volume

BTL Volume (dB) ∝ Volume (V)

SE Volume (dB) ∝ Volume (V) - SEDIFF

(V)

3-W STEREO AUDIO POWER AMPLIFIER

WITH ADVANCED DC VOLUME CONTROL

FEATURES DESCRIPTION

• Advanced DC Volume Control With 2-dB

Steps

From -40 dB to 20 dB

– Fade Mode

– Maximum Volume Setting for SE Mode

– Adjustable SE Volume Control

Referenced to BTL Volume Control

• 3 W Into 3- Ω Speakers

• Stereo Input MUX

• Differential Inputs

APPLICATIONS

• Notebook PC

• LCD Monitors

• Pocket PC

TPA6011A4

SLOS392A – FEBRUARY 2002 – REVISED JULY 2004

The TPA6011A4 is a stereo audio power amplifier

that drives 3 W/channel of continuous RMS power

into a 3- Ω load. Advanced dc volume control

minimizes external components and allows BTL

(speaker) volume control and SE (headphone) volume control. Notebook and pocket PCs benefit from

the integrated feature set that minimizes external

components without sacrificing functionality.

To simplify design, the speaker volume level is

adjusted by applying a dc voltage to the VOLUME

terminal. Likewise, the delta between speaker volume

and headphone volume can be adjusted by applying

a dc voltage to the SEDIFF terminal. To avoid an

unexpected high volume level through the

headphones, a third terminal, SEMAX, limits the

headphone volume level when a dc voltage is applied. Finally, to ensure a smooth transition between

active and shutdown modes, a fade mode ramps the

volume up and down.

PRODUCTION DATA information is current as of publication date.

Products conform to specifications per the terms of the Texas

Instruments standard warranty. Production processing does not

necessarily include testing of all parameters.

Please be aware that an important notice concerning availability, standard warranty, and use in critical applications of Texas

Instruments semiconductor products and disclaimers thereto appears at the end of this data sheet.

Copyright © 2002–2004, Texas Instruments Incorporated

www.ti.com

TPA6011A4

SLOS392A – FEBRUARY 2002 – REVISED JULY 2004

AVAILABLE OPTIONS

T

A

40 ° C to 85 ° C TPA6011A4PWP

(1) The PWP package is available taped and reeled. To order a taped

and reeled part, add the suffix R to the part number

(e.g., TPA6011A4PWPR).

ABSOLUTE MAXIMUM RATINGS

over operating free-air temperature range (unless otherwise noted)

V

SS

V

I

T

A

T

J

T

stg

(1) Stresses beyond those listed under "absolute maximum ratings" may cause permanent damage to the device. These are stress ratings

only, and functional operation of the device at these or any other conditions beyond those indicated under "recommended operating

conditions" is not implied. Exposure to absolute-maximum-rated conditions for extended periods may affect device reliability.

Supply voltage, VDD, PV

DD

Input voltage -0.3 V to VDD+0.3 V

Continuous total power dissipation See Dissipation Rating Table

Operating free-air temperature range -40 ° C to 85 ° C

Operating junction temperature range -40 ° C to 150 ° C

Storage temperature range -65 ° C to 150 ° C

Lead temperature 1,6 mm (1/16 inch) from case for 10 seconds 260 ° C

PACKAGE

24-PIN TSSOP (PWP)

(1)

(1)

UNIT

-0.3 V to 6 V

PACKAGE

RECOMMENDED OPERATING CONDITIIONS

V

SS

V

IH

V

IL

T

A

Supply voltage, VDD, PV

High-level input voltage

Low-level input voltage

Operating free-air temperature -40 85 ° C

DISSIPATION RATING TABLE

TA≤ 25 ° C DERATING FACTOR TA= 70 ° C TA= 85 ° C

POWER RATING ABOVE TA= 25 ° C POWER RATING POWER RATING

PWP 2.7 mW 21.8 mW/ ° C 1.7 W 1.4 W

DD

SE/ BTL, HP/ LINE, FADE 0.8 × V

SHUTDOWN 2 V

SE/ BTL, HP/ LINE, FADE 0.6 × V

SHUTDOWN 0.8 V

MIN MAX UNIT

4.0 5.5 V

DD

DD

V

V

2

www.ti.com

TPA6011A4

SLOS392A – FEBRUARY 2002 – REVISED JULY 2004

ELECTRICAL CHARACTERISTICS

TA= 25 ° C, V

| V

| Output offset voltage (measured differentially)

OO

PSRR Power supply rejection ratio V

| IIH| 1 µA

| IIL| V

I

DD

I

DD

I

DD(SD)

OPERATING CHARACTERISTICS

TA= 25 ° C, V

P

O

THD+N Total harmonic distortion + noise PO= 1 W, RL= 8 Ω , f = 20 Hz to 20 kHz <0.4%

V

OH

V

OL

V

(Bypass

)

B

OM

Z

I

= PV

DD

= 5.5 V (unless otherwise noted)

DD

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

V

= 5.5 V, Gain = 0 dB, SE/ BTL = 0 V 30 mV

DD

V

= 5.5 V, Gain = 20 dB, SE/ BTL = 0 V 50 mV

DD

= PV

DD

High-level input current (SE/ BTL, FADE, HP/ LINE, V

SHUTDOWN, SEDIFF, SEMAX, VOLUME) VI= V

Low-level input current (SE/ BTL, FADE, HP/ LINE,

SHUTDOWN, SEDIFF, SEMAX, VOLUME)

Supply current, no load mA

Supply current, max power into a 3- Ω load SHUTDOWN = 2 V, RL= 3 Ω , 1.5 A

DD

DD

V

DD

SHUTDOWN = 2 V

V

DD

SHUTDOWN = 2 V

V

DD

= 4.0 V to 5.5 V -42 -70 dB

DD

= PV

= 5.5 V,

DD

= PV

DD

DD

= PV

= 5.5 V, VI= 0 V 1 µA

DD

= PV

= 5.5 V, SE/ BTL = 0 V,

DD

= PV

= 5.5 V, SE/ BTL = 5.5 V,

DD

= 5 V = PV

, SE/ BTL = 0 V,

DD

6.0 7.5 9.0

3.0 5 6

PO= 2 W, stereo

Supply current, shutdown mode SHUTDOWN = 0.0 V 1 20 µA

= PV

DD

= 5 V, RL= 3 Ω , Gain = 6 dB (unless otherwise noted)

DD

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

Output power W

High-level output voltage RL= 8 Ω , Measured between output and V

THD = 1%, f = 1 kHz 2

THD = 10%, f = 1 kHz, V

= 5.5 V 3

DD

DD

700 mV

Low-level output voltage RL= 8 Ω , Measured between output and GND 400 mV

Bypass voltage (Nominally VDD/2) Measured at pin 17, No load, V

= 5.5 V 2.65 2.75 2.85 V

DD

Maximum output power bandwidth THD = 5% >20 kHz

Supply ripple rejection ratio f = 1 kHz, Gain = 0 dB, C

Noise output voltage BTL 36 µV

f = 20 Hz to20 kHz, Gain = 0 dB,

C

= 0.47 µF

(BYP)

= 0.47 µF

(BYP)

BTL -63 dB

SE -57 dB

Input impedance (see Figure 26 ) VOLUME = 5.0 V 14 k Ω

RMS

RMS

3

www.ti.com

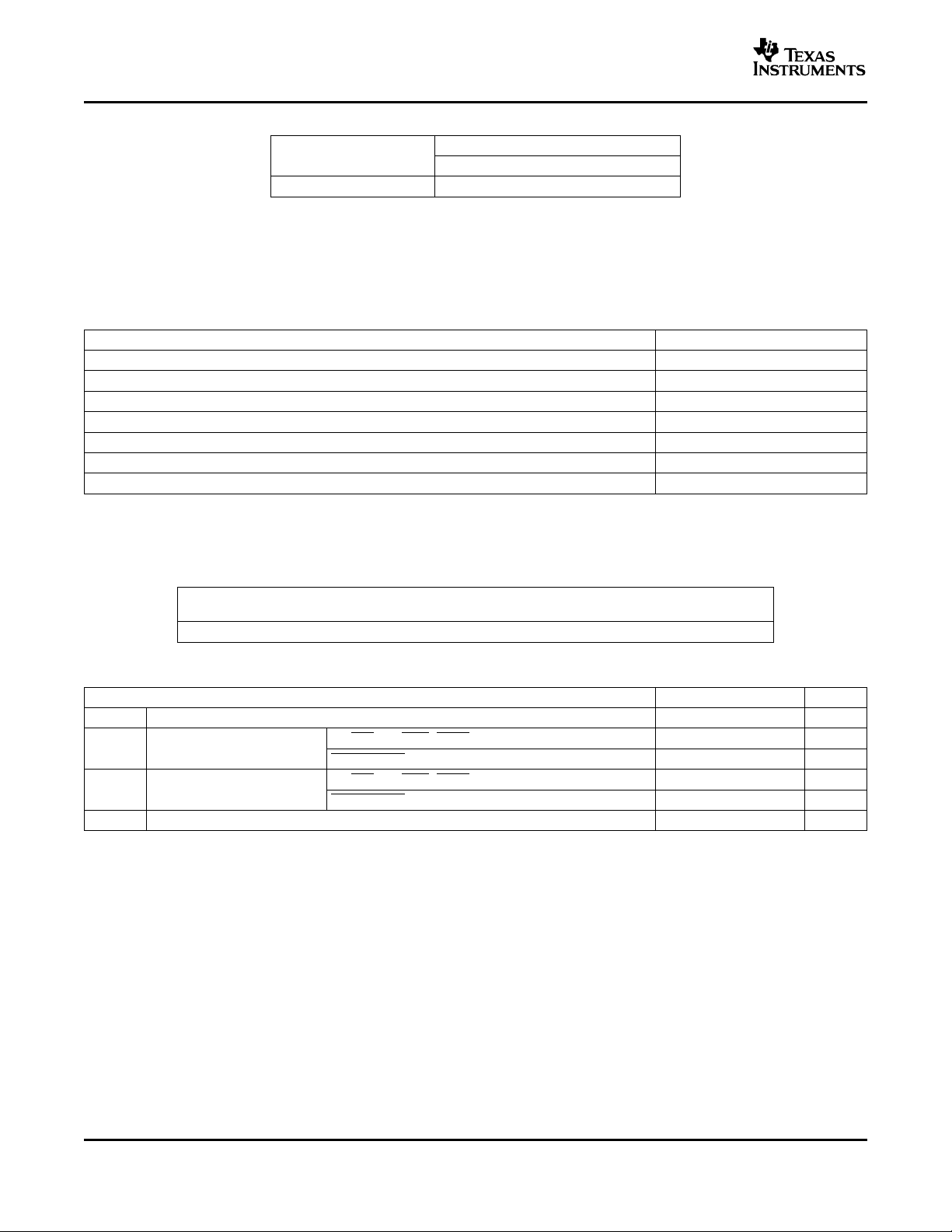

1

2

3

4

5

6

7

8

9

10

11

12

24

23

22

21

20

19

18

17

16

15

14

13

PGND

ROUT-

PV

DD

RHPIN

RLINEIN

RIN

V

DD

LIN

LLINEIN

LHPIN

PV

DD

LOUT-

ROUT+

SE/BTL

HP/LINE

VOLUME

SEDIFF

SEMAX

AGND

BYPASS

FADE

SHUTDOWN

LOUT+

PGND

PWP PACKAGE

(TOP VIEW)

TPA6011A4

SLOS392A – FEBRUARY 2002 – REVISED JULY 2004

Terminal Functions

TERMINAL

NAME NO.

PGND 1, 13 - Power ground

LOUT- 12 O Left channel negative audio output

PV

DD

LHPIN 10 I Left channel headphone input, selected when HP/ LINE is held high

LLINEIN 9 I Left channel line input, selected when HP/ LINE is held low

LIN 8 I Common left channel input for fully differential input. AC ground for single-ended inputs.

V

DD

RIN 6 I Common right channel input for fully differential input. AC ground for single-ended inputs.

RLINEIN 5 I Right channel line input, selected when HP/ LINE is held low

RHPIN 4 I Right channel headphone input, selected when HP/ LINE is held high

ROUT- 2 O Right channel negative audio output

ROUT+ 24 O Right channel positive audio output

SHUTDOWN 15 I Places the amplifier in shutdown mode if a TTL logic low is placed on this terminal

FADE 16 I

BYPASS 17 I Tap to voltage divider for internal midsupply bias generator used for analog reference

AGND 18 - Analog power supply ground

SEMAX 19 I Sets the maximum volume for single ended operation. DC voltage range is 0 to VDD.

SEDIFF 20 I Sets the difference between BTL volume and SE volume. DC voltage range is 0 to VDD.

VOLUME 21 I Terminal for dc volume control. DC voltage range is 0 to VDD.

HP/ LINE 22 I

SE/ BTL 23 I

LOUT+ 14 O Left channel positive audio output.

I/O DESCRIPTION

3, 11 - Supply voltage terminal for power stage

7 - Supply voltage terminal

Places the amplifier in fade mode if a logic low is placed on this terminal; normal operation if a logic high is

placed on this terminal

Input MUX control. When logic high, RHPIN and LHPIN inputs are selected. When logic low, RLINEIN and

LLINEIN inputs are selected.

Output MUX control. When this terminal is high, SE outputs are selected. When this terminal is low, BTL

outputs are selected.

4

www.ti.com

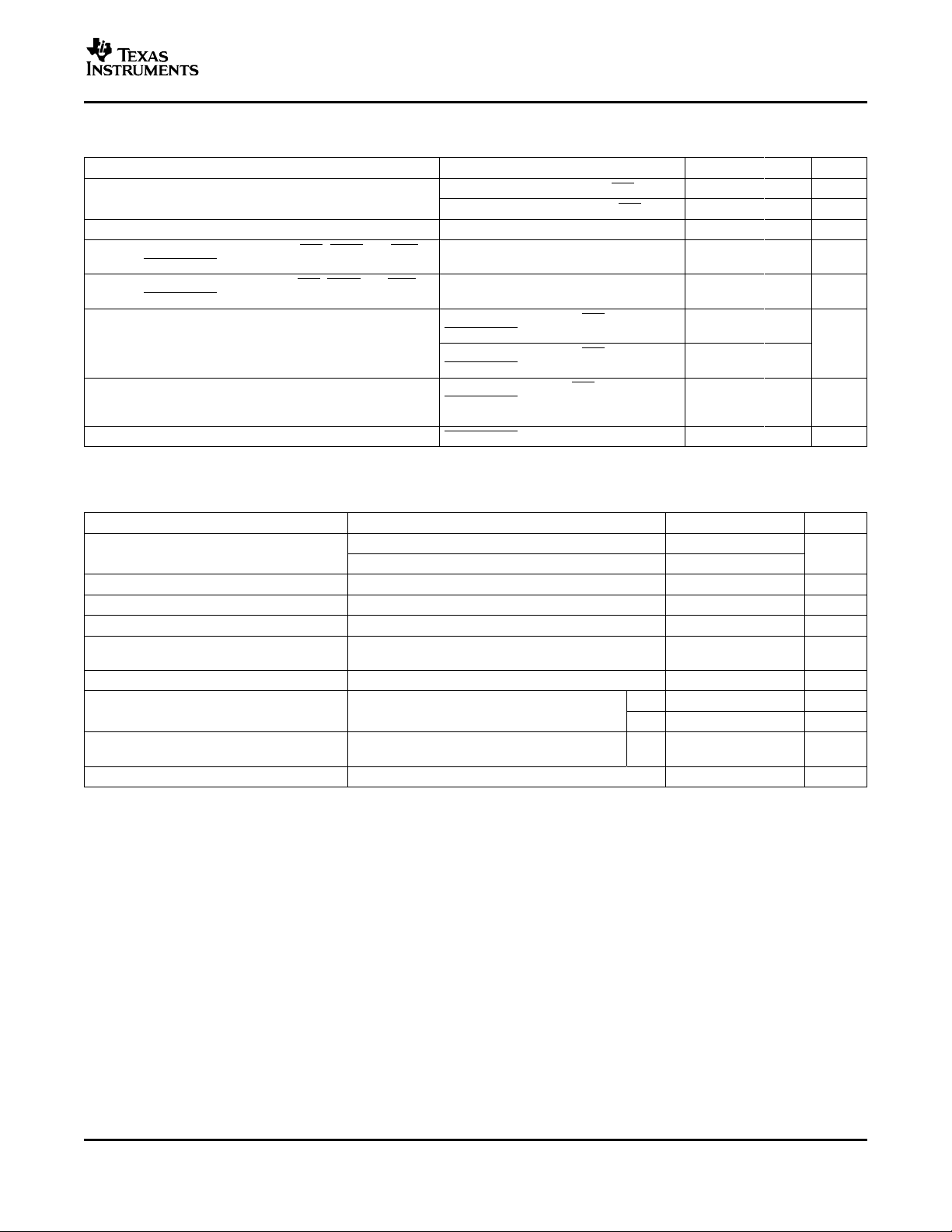

FUNCTIONAL BLOCK DIAGRAM

Power

Management

32-Step

Volume

Control

MUX

Control

R

MUX

RHPIN

ROUT+

SHUTDOWN

ROUT-

PV

DD

PGND

V

DD

BYPASS

AGND

LOUT+

LOUT-

RLINEIN

RIN

HP/LINE

VOLUME

SEDIFF

SEMAX

FADE

_

+

HP/LINE

_

+

_

+

BYP

_

+

BYP

BYP

EN

SE/BTL

L

MUX

_

+

HP/LINE

_

+

_

+

BYP

_

+

BYP

BYP

EN

SE/BTL

SE/BTL

LHPIN

LLINEIN

LIN

TPA6011A4

SLOS392A – FEBRUARY 2002 – REVISED JULY 2004

NOTE: All resistor wipers are adjusted with 32 step volume control.

5

www.ti.com

TPA6011A4

SLOS392A – FEBRUARY 2002 – REVISED JULY 2004

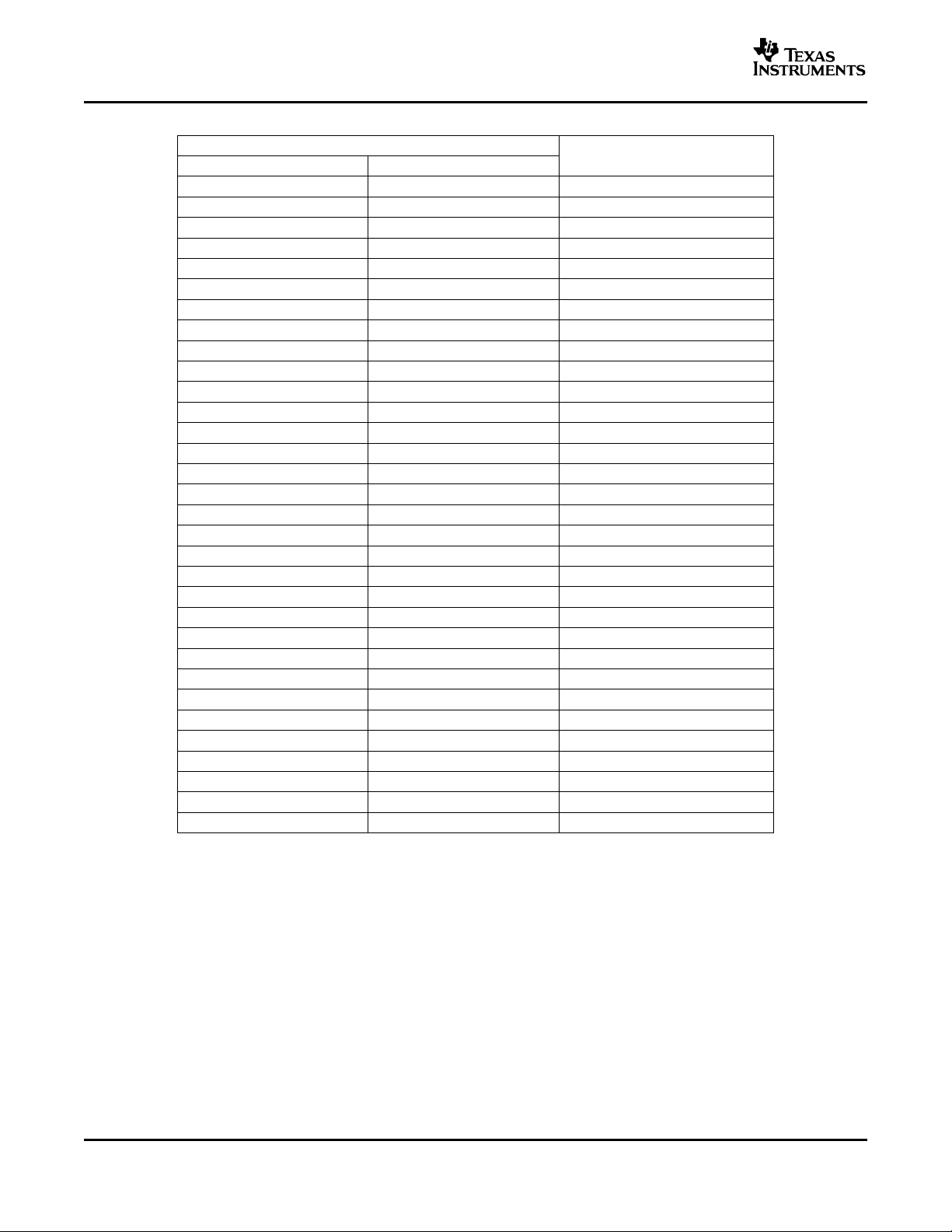

Table 1. DC Volume Control (BTL Mode, V

FROM (V) TO (V)

0.00 0.26 -85

0.33 0.37 -40

0.44 0.48 -38

0.56 0.59 -36

0.67 0.70 -34

0.78 0.82 -32

0.89 0.93 -30

1.01 1.04 -28

1.12 1.16 -26

1.23 1.27 -24

1.35 1.38 -22

1.46 1.49 -20

1.57 1.60 -18

1.68 1.72 -16

1.79 1.83 -14

1.91 1.94 -12

2.02 2.06 -10

2.13 2.17 -8

2.25 2.28 -6

2.36 2.39 -4

2.47 2.50 -2

2.58 2.61 0

2.70 2.73 2

2.81 2.83 4

2.92 2.95 6

3.04 3.06 8

3.15 3.17 10

3.26 3.29 12

3.38 3.40 14

3.49 3.51 16

3.60 3.63 18

3.71 5.00 20

(1) For other values of VDD, scale the voltage values in the table by a factor of VDD/5.

(2) Tested in production. Remaining gain steps are specified by design.

VOLUME (PIN 21)

(1)

= 5 V)

DD

GAIN OF AMPLIFIER

(Typ)

(2)

(2)

(2)

6

www.ti.com

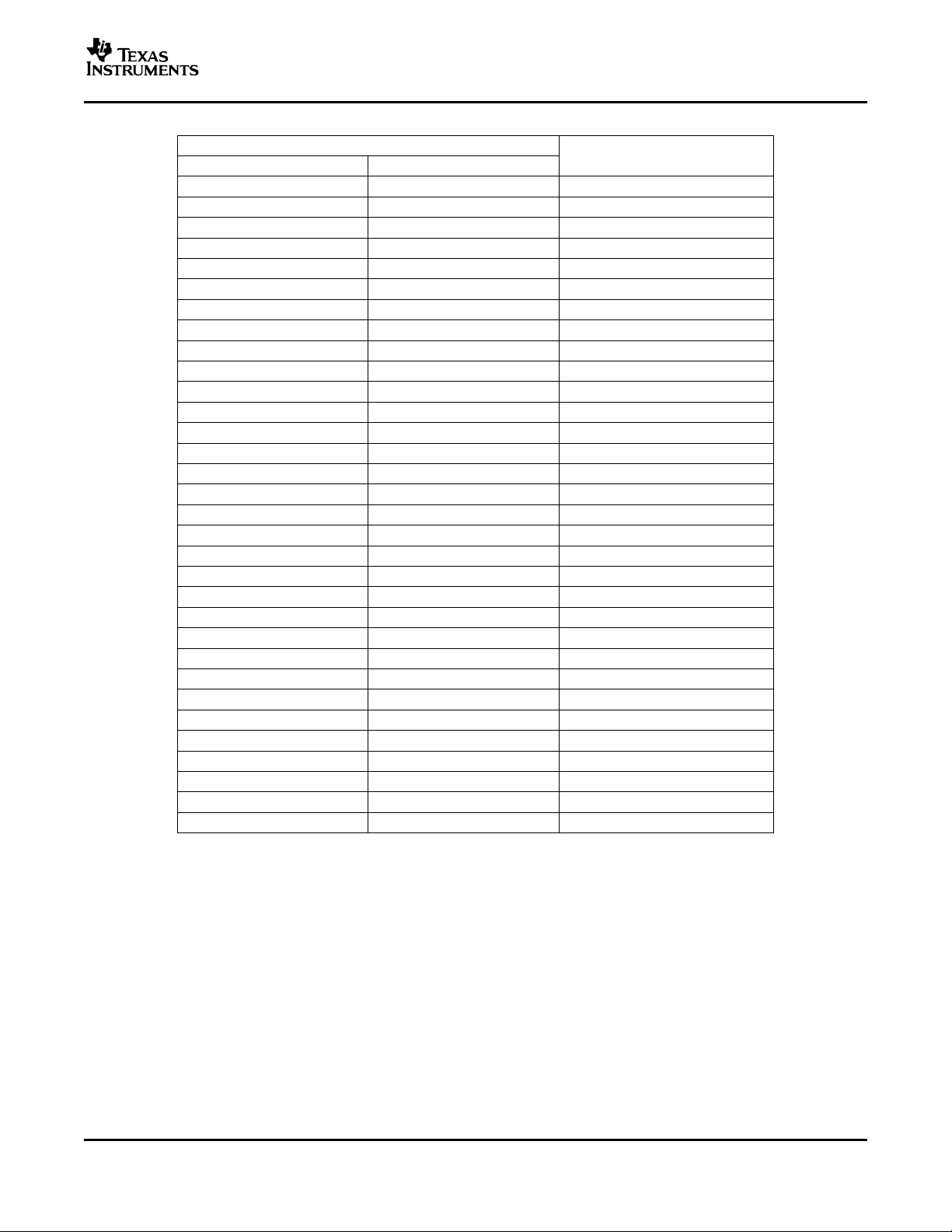

Table 2. DC Volume Control (SE Mode, V

DD

SE_VOLUME = VOLUME - SEDIFF or SEMAX

FROM (V) TO (V)

0.00 0.26 -85

0.33 0.37 -46

0.44 0.48 -44

0.56 0.59 -42

0.67 0.70 -40

0.78 0.82 -38

0.89 0.93 -36

1.01 1.04 -34

1.12 1.16 -32

1.23 1.27 -30

1.35 1.38 -28

1.46 1.49 -26

1.57 1.60 -24

1.68 1.72 -22

1.79 1.83 -20

1.91 1.94 -18

2.02 2.06 -16

2.13 2.17 -14

2.25 2.28 -12

2.36 2.39 -10

2.47 2.50 -8

2.58 2.61 -6

2.70 2.73 -4

2.81 2.83 -2

2.92 2.95 0

3.04 3.06 2

3.15 3.17 4

3.26 3.29 6

3.38 3.40 8

3.49 3.51 10

3.60 3.63 12

3.71 5.00 14

TPA6011A4

SLOS392A – FEBRUARY 2002 – REVISED JULY 2004

(1)

= 5 V)

GAIN OF AMPLIFIER

(Typ)

(2)

(2)

(2)

(2)

(1) For other values of VDD, scale the voltage values in the table by a factor of VDD/5.

(2) Tested in production. Remaining gain steps are specified by design.

7

www.ti.com

10

0.01

0.02

0.05

0.1

0.2

0.5

1

2

5

20 20 k100 1 k 10 k

VDD = 5 V

RL = 3 Ω

Gain = 20 dB

BTL

PO = 1.75 W

PO = 0.5 W

PO = 1 W

THD+N − Total Harmonic Distortion + Noise (BTL) − %

f − Frequency − Hz

10

0.01

0.02

0.05

0.1

0.2

0.5

1

2

5

20 20 k50 100 200 500 1 k 2 k 5 k 10 k

PO = 0.25 W

PO = 1.5 W

PO = 1 W

f − Frequency − Hz

THD+N − Total Harmonic Distortion + Noise (BTL) − %

VDD = 5 V

RL = 4 Ω

Gain = 20 dB

BTL

TPA6011A4

SLOS392A – FEBRUARY 2002 – REVISED JULY 2004

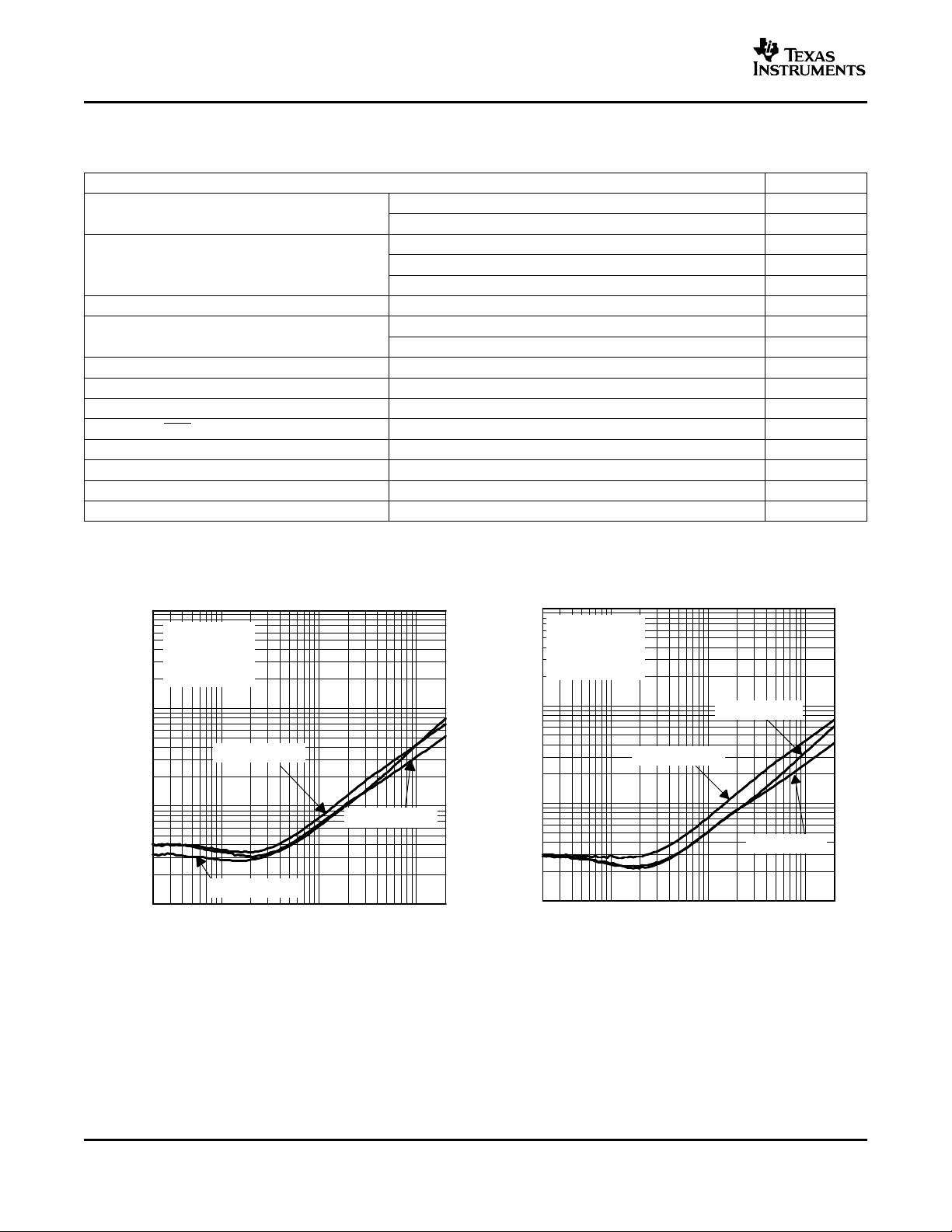

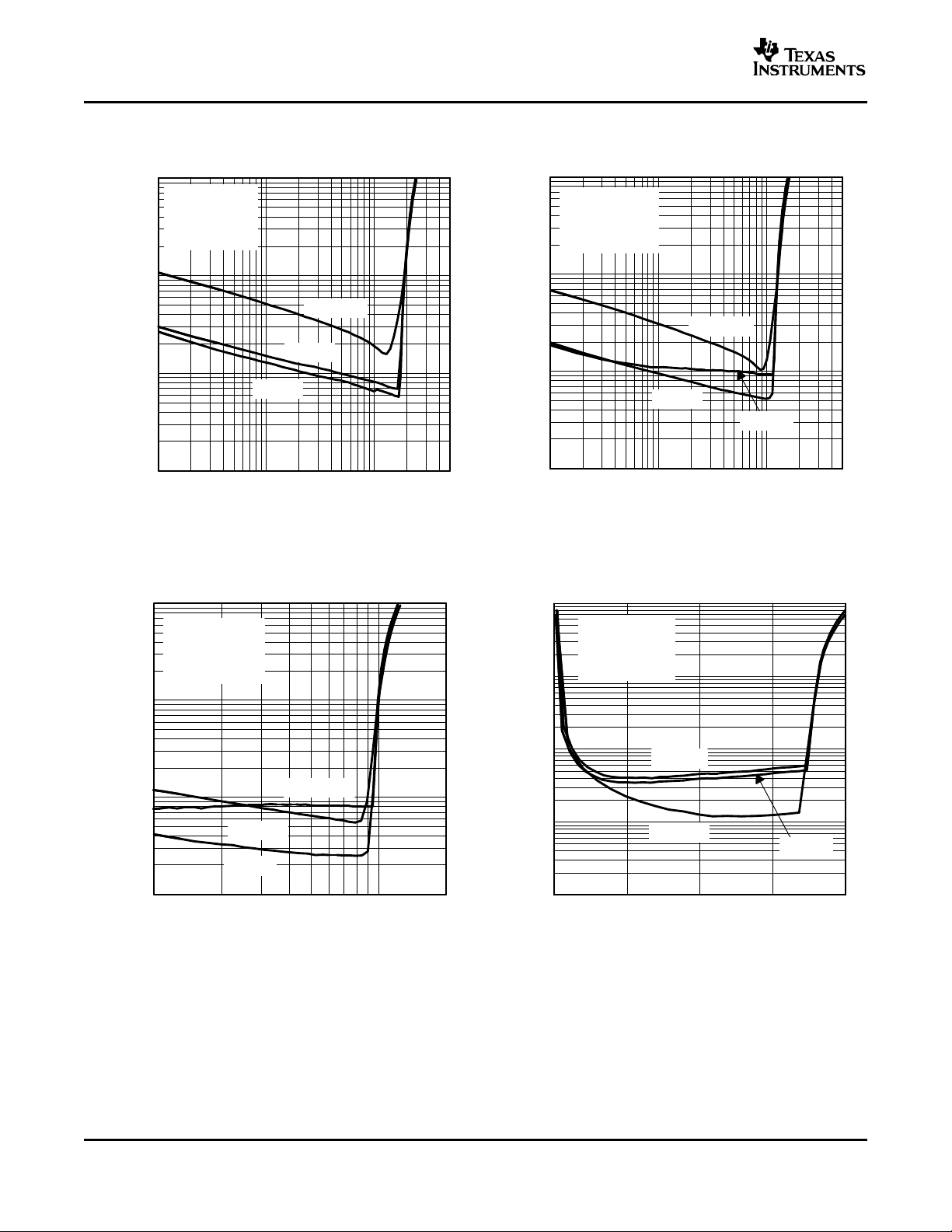

TYPICAL CHARACTERISTICS

Table of Graphs

THD+N Total harmonic distortion plus noise (BTL)

THD+N Total harmonic distortion plus noise (SE) vs Output power 9

Closed loop response 11, 12

I

CC

P

P

Supply current

Power Dissipation vs Output power 17, 18

D

Output power vs Load resistance 19, 20

O

Crosstalk vs Frequency 21, 22

HP/ LINE attenuation vs Frequency 23

PSRR Power supply ripple rejection (BTL) vs Frequency 24

PSRR Power supply ripple rejection (SE) vs Frequency 25

Z

V

Input impedance vs BTL gain 26

I

Output noise voltage vs Frequency 27

n

vs Frequency 1, 2 3

vs Output power 6, 7, 8

vs Frequency 4, 5

vs Output voltage 10

vs Temperature 13

vs Supply voltage 14, 15, 16

FIGURE

TOTAL HARMONIC DISTORTION + NOISE (BTL) TOTAL HARMONIC DISTORTION + NOISE (BTL)

8

vs vs

FREQUENCY FREQUENCY

Figure 1. Figure 2.

www.ti.com

10

0.01

0.02

0.05

0.1

0.2

0.5

1

2

5

20

20 k50 100 200 500 1 k 2 k 5 k 10 k

f − Frequency − Hz

THD+N − Total Harmonic Distortion + Noise (SE) − %

PO = 75 mW

VDD = 5 V

RL = 32 Ω

Gain = 14 dB

SE

0.01

10

0.02

0.05

0.1

0.2

0.5

1

2

5

20 20 k50 100 200 500 1 k 2 k 5 k 10 k

PO = 1 W

VDD = 5 V

RL = 8 Ω

Gain = 20 dB

BTL

f − Frequency − Hz

THD+N − Total Harmonic Distortion + Noise (BTL) − %

PO = 0.25 W

PO = 0.5 W

10

0.01

0.02

0.05

0.1

0.2

0.5

1

2

5

20 20 k50 100 200 500 1 k 2 k 5 k 10 k

f − Frequency − Hz

THD+N − Total Harmonic Distortion + Noise (SE) − %

VO = 1 V

RMS

VDD = 5 V

RL = 10 kΩ

Gain = 14 dB

SE

PO − Output Power − W

THD+N − Total Harmonic Distortion + Noise (BTL) − %

0.01

10

0.02

0.05

0.1

0.2

0.5

1

2

5

0.01 100.1 1

f = 20 kHz

f = 1 kHz

f = 20 Hz

VDD = 5 V

RL = 3 Ω

Gain = 20 dB

BTL

TPA6011A4

SLOS392A – FEBRUARY 2002 – REVISED JULY 2004

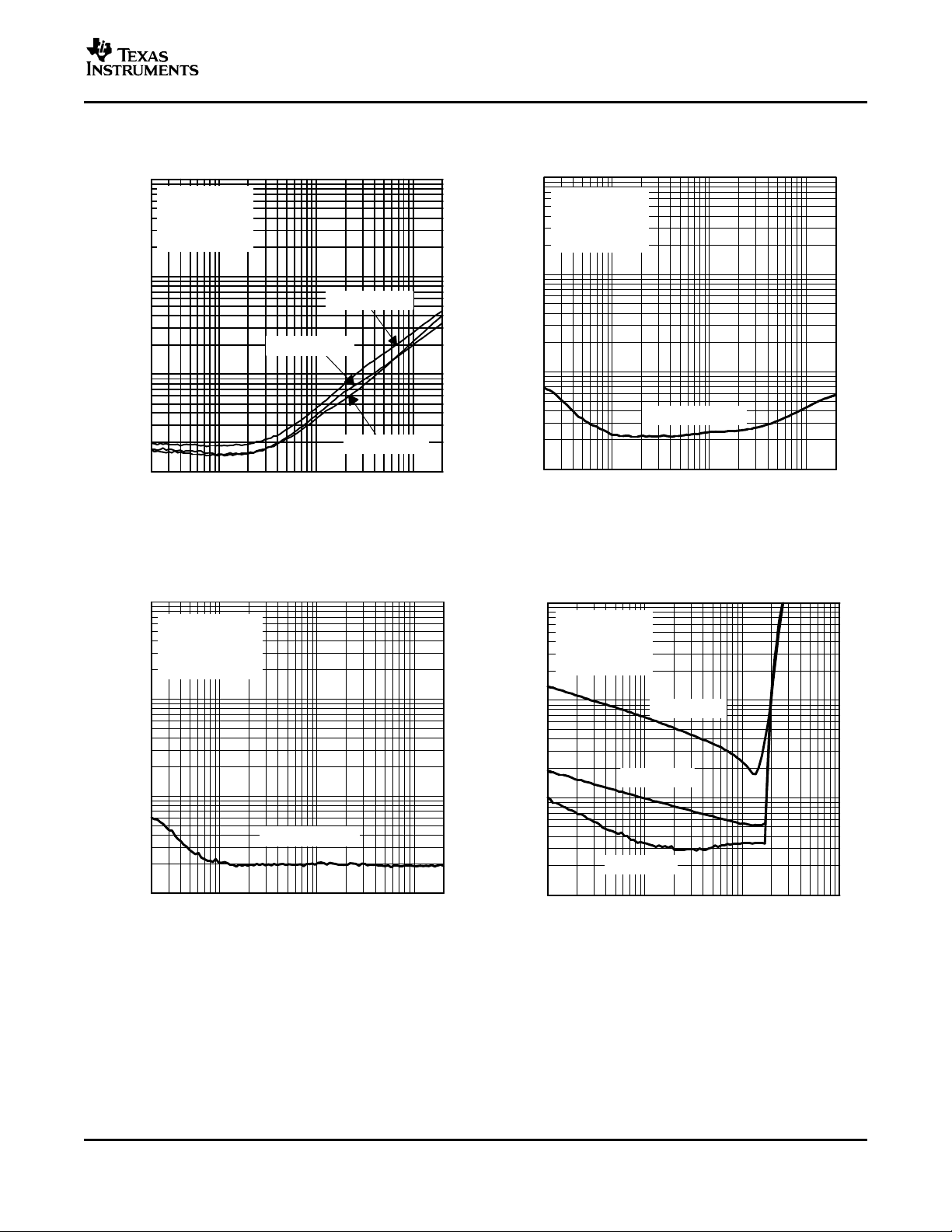

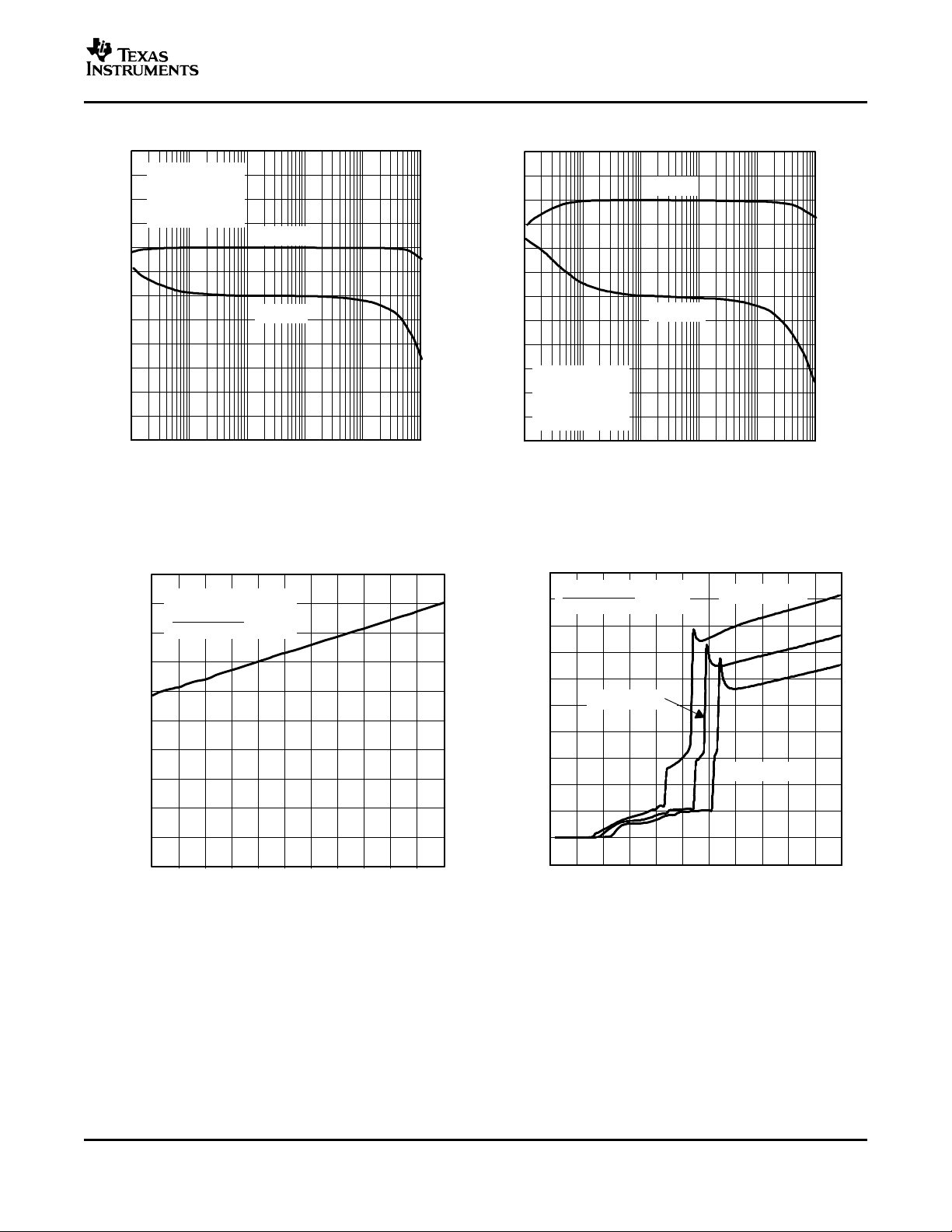

TOTAL HARMONIC DISTORTION + NOISE (BTL) TOTAL HARMONIC DISTORTION + NOISE (SE)

vs vs

FREQUENCY FREQUENCY

Figure 3. Figure 4.

TOTAL HARMONIC DISTORTION + NOISE (SE) TOTAL HARMONIC DISTORTION + NOISE (BTL)

vs vs

FREQUENCY OUTPUT POWER

Figure 5. Figure 6.

9

www.ti.com

10

0.01

0.02

0.05

0.1

0.2

0.5

1

2

5

50.02 0.05 0.1 0.2 0.5 1 2

PO − Output Power − W

THD+N − Total Harmonic Distortion + Noise (BTL) − %

1 kHz

20 kHz

VDD = 5 V

RL = 8 Ω

Gain = 20 dB

BTL

20 Hz

10

0.01

0.02

0.05

0.1

0.2

0.5

1

2

5

50.02 0.05 0.1 0.2 0.5 1 2

PO − Output Power − W

THD+N − Total Harmonic Distortion + Noise (BTL) − %

1 kHz

20 kHz

20 Hz

VDD = 5 V

RL = 4 Ω

Gain = 20 dB

BTL

10

0.001

0.002

0.005

0.01

0.02

0.05

0.1

0.2

0.5

1

2

5

0 500 m 1 1.5 2

VO − Output Voltage − rms

THD+N − Total Harmonic Distortion + Noise (SE) − %

1 kHz

20 kHz

20 Hz

VDD = 5 V

RL = 10 kΩ

Gain = 14 dB

SE

10

0.01

0.02

0.05

0.1

0.2

0.5

1

2

5

10 m 200 m50 m 100 m

PO − Output Power − W

THD+N − Total Harmonic Distortion + Noise (SE) − %

1 kHz

20 kHz

20 Hz

VDD = 5 V

RL = 32 Ω

Gain = 14 dB

SE

TPA6011A4

SLOS392A – FEBRUARY 2002 – REVISED JULY 2004

TOTAL HARMONIC DISTORTION + NOISE (BTL) TOTAL HARMONIC DISTORTION + NOISE (BTL)

vs vs

OUTPUT POWER OUTPUT POWER

Figure 7. Figure 8.

TOTAL HARMONIC DISTORTION + NOISE (SE) TOTAL HARMONIC DISTORTION + NOISE (SE)

vs vs

OUTPUT POWER OUTPUT VOLTAGE

10

Figure 9. Figure 10.

www.ti.com

150

120

90

60

30

0

−30

−80

−70

−60

−50

−40

−30

−20

−10

0

10

20

30

40

10 100 1 k 10 k 100 k 1 M

−180

−150

−120

−90

−60

180

Gain

Phase

VDD = 5 Vdc

RL = 8 Ω

Mode = BTL

Gain = 0 dB

f − Frequency − Hz

Closed Loop Gain − dB

Phase − Degrees

150

120

90

60

30

0

−30

−80

−70

−60

−50

−40

−30

−20

−10

0

10

20

30

40

10 100 1 k 10 k 100 k 1 M

−180

−150

−120

−90

−60

180

Gain

Phase

VDD = 5 Vdc

RL = 8 Ω

Mode = BTL

Gain = 20 dB

f − Frequency − Hz

Closed Loop Gain − dB

Phase − Degrees

0

1

2

3

4

5

6

7

8

9

10

−40 −25 5 20 35 50 65 95−10 110 125

− Supply Current − mA

TA − Free-Air Temperature − °C

I

DD

VDD = 5 V

Mode = BTL

SHUTDOWN = V

DD

80

−1

0

1

2

3

4

5

6

7

8

9

10

0

0.5 1 1.5 2 2.5 3 3.5 4 4.5 5 5.5

Mode = BTL

SHUTDOWN = V

DD

VDD − Supply Voltage − V

T

A

= 125°C

T

A

= 25°C

T

A

= −40°C

− Supply Current − mA

I

DD

SLOS392A – FEBRUARY 2002 – REVISED JULY 2004

CLOSED LOOP RESPONSE CLOSED LOOP RESPONSE

Figure 11. Figure 12.

TPA6011A4

SUPPLY CURRENT SUPPLY CURRENT

FREE-AIR TEMPERATURE SUPPLY VOLTAGE

Figure 13. Figure 14.

vs vs

11

www.ti.com

0

50

100

150

200

250

300

350

400

450

0 0.5 1 1.5 2 2.5 3 3.5 4 4.5 5

Mode = SD

SHUTDOWN = 0 V

VDD − Supply Voltage − V

− Supply Current −

I

DD

T

A

= 125°C

T

A

= 25°C

T

A

= −40°C

nA

1

2

3

4

5

6

7

0 0.5 1 1.5 2 2.5 3 3.5 4 4.5 5 5.5

Mode = SE

SHUTDOWN = V

DD

VDD − Supply Voltage − V

− Supply Current − mAI

DD

T

A

= 125°C

T

A

= 25°C

T

A

=−40°C

0

0

0.2

0.4

0.6

0.8

1

1.2

1.4

1.6

1.8

2

0 0.2 0.4 0.6 0.8 1 1.2 1.4 1.6 1.8 2

PO − Output Power − W

− Power Dissipation (PER CHANNEL) − WP

D

VDD = 5 V

BTL

4 Ω

8 Ω

3 Ω

0

20

40

60

80

100

120

140

160

180

200

0 100 150 200 250 30050

8 Ω

16 Ω

32 Ω

PO − Output Power − mW

VDD = 5 V

SE

− Power Dissipation (PER CHANNEL) − mWP

D

TPA6011A4

SLOS392A – FEBRUARY 2002 – REVISED JULY 2004

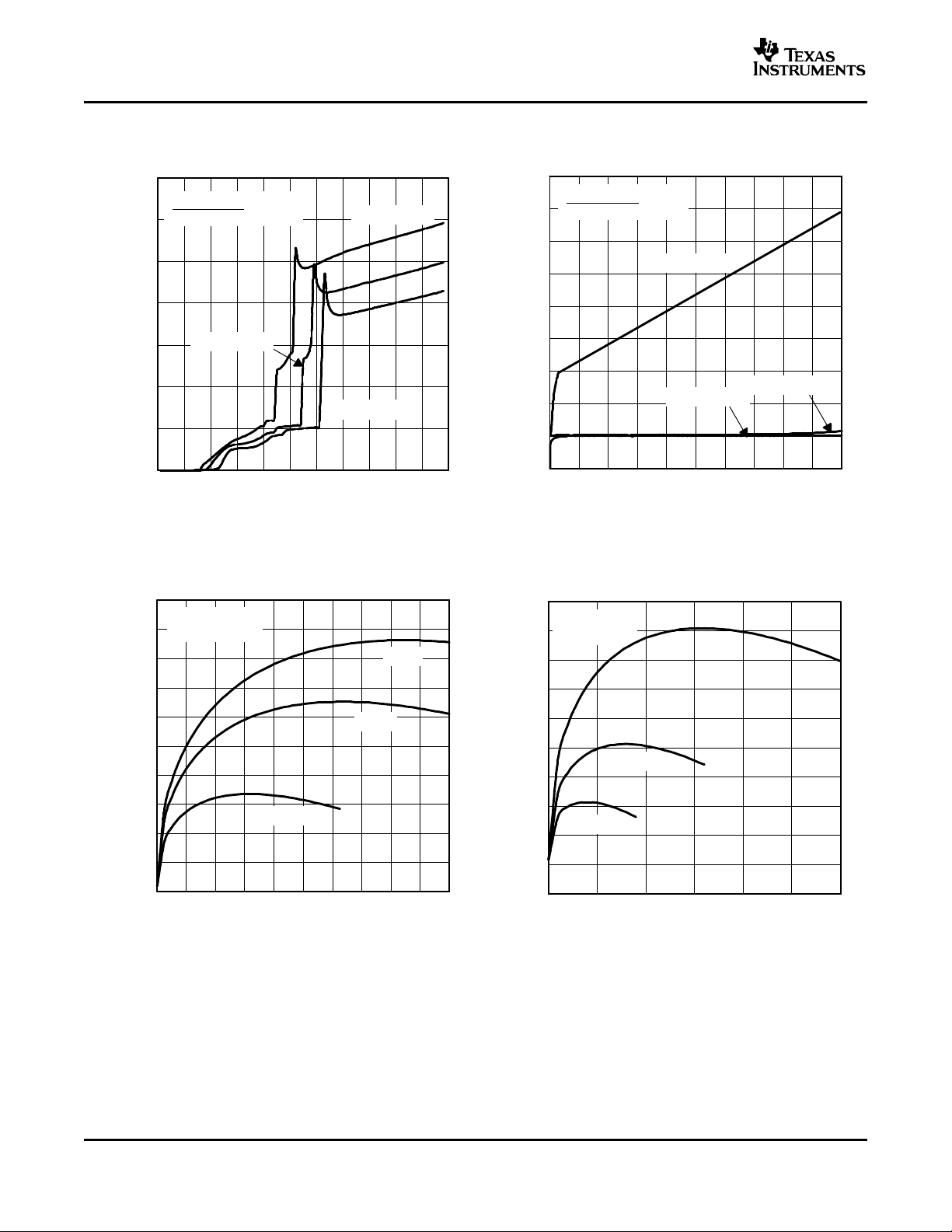

SUPPLY CURRENT SUPPLY CURRENT

vs vs

SUPPLY VOLTAGE SUPPLY VOLTAGE

Figure 15. Figure 16.

POWER DISSIPATION (PER CHANNEL) POWER DISSIPATION (PER CHANNEL)

vs vs

OUTPUT POWER OUTPUT POWER

12

Figure 17. Figure 18.

www.ti.com

0

0.2

0.4

0.6

0.8

1

1.2

1.4

1.6

1.8

2

2.2

0 8 16 24 32 40 48 56 64

RL − Load Resistance − Ω

− Output Power − WP

O

VDD = 5 V

THD+N = 1%

Gain = 20 dB

BTL

0

0.2

0.4

0.6

0.8

1

1.2

1.4

1.6

1.8

2

2.2

0 8 16 24 32 40 48 56 64

RL − Load Resistance − Ω

− Output Power − WP

O

VDD = 5.5 V

Gain = 20 dB

BTL

2.4

2.6

2.8

3

THD+N = 10%

THD+N = 1%

3.2

−120

0

−110

−100

−90

−80

−70

−60

−50

−40

−30

−20

−10

20 20 k100 1 k 10 k

f − Frequency − Hz

Crosstalk − dB

Left to Right

Right to Left

VDD = 5 V

PO = 1 W

RL = 8 Ω

Gain = 0dB

BTL

−120

0

−110

−100

−90

−80

−70

−60

−50

−40

−30

−20

−10

20 20 k100 1 k 10 k

f − Frequency − Hz

Crosstalk − dB

Left to Right

Right to Left

VDD = 5 V

PO = 1 W

RL = 8 Ω

Gain = 20 dB

BTL

SLOS392A – FEBRUARY 2002 – REVISED JULY 2004

OUTPUT POWER OUTPUT POWER

vs vs

LOAD RESISTANCE LOAD RESISTANCE

Figure 19. Figure 20.

TPA6011A4

CROSSTALK CROSSTALK

vs vs

FREQUENCY FREQUENCY

Figure 21. Figure 22.

13

www.ti.com

20 20 k100 1 k 10 k

f − Frequency − Hz

PSRR − Power Supply Rejection Ratio (BTL) − dB

0

−80

−70

−60

−50

−40

−30

−20

−10

VDD = 5 V

RL = 8 Ω

C

(BYP)

=0.47 µF

BTL

Gain = 1

Gain = 10

−120

0

−110

−100

−90

−80

−70

−60

−50

−40

−30

−20

−10

20 20 k100 1 k 10 k

f − Frequency − Hz

HP/Line Attenuation − dB

Line Active

HP Active

VDD = 5 V

VI = 1 V

RMS

RL = 8 Ω

BTL

20 20 k100 1 k 10 k

f − Frequency − Hz

PSRR − Power Supply Rejection Ratio (SE) − dB

−100

+0

−90

−80

−70

−60

−50

−40

−30

−20

−10

Gain = 14 dB

Gain = 0 dB

VDD = 5 V

RL = 32 Ω

C

(BYP)

=0.47 µF

SE

0

10

20

30

40

50

60

70

80

90

−40 −30 −20 −10

0

10 20

BTL Gain − dB

− Input Impedamce − Z

I

kΩ

TPA6011A4

SLOS392A – FEBRUARY 2002 – REVISED JULY 2004

HP/LINE ATTENUATION POWER SUPPLY REJECTION RATIO (BTL)

vs vs

FREQUENCY FREQUENCY

Figure 23. Figure 24.

POWER SUPPLY REJECTION RATIO (SE) INPUT IMPEDANCE

vs vs

FREQUENCY BTL GAIN

14

Figure 25. Figure 26.

www.ti.com

100

80

20

10 100 1 k

− Output Noise Voltage −

120

140

10 k 20 k

180

40

0

60

160

V

n

Vµ

RMS

Gain = 0 dB

VDD = 5 V

BW = 22 Hz to 22 kHz

RL = 8 Ω

BTL

Gain = 20 dB

f − Frequency − Hz

TPA6011A4

SLOS392A – FEBRUARY 2002 – REVISED JULY 2004

OUTPUT NOISE VOLTAGE

vs

FREQUENCY

Figure 27.

15

www.ti.com

PGND

ROUT-

PV

DD

RHPIN

RLINEIN

RIN

V

DD

LIN

LLINEIN

LHPIN

PV

DD

LOUT-

1

ROUT+

SE/BTL

HP/LINE

VOLUME

SEDIFF

SEMAX

AGND

BYPASS

FADE

SHUTDOWN

LOUT+

PGND

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

C

S

C

i

V

DD

Right HP

Audio Source

C

i

C

i

C

S

C

i

C

i

C

i

C

S

Power Supply

Right Line

Audio Source

Left Line

Audio Source

Left HP

Audio Source

Power Supply

V

DD

100 kΩ

100 kΩ

C

C

In From DAC

or

Potentiometer

(DC Voltage)

C

(BYP)

System

Control

C

C

Right

Speaker

Left

Speaker

Headphones

1 kΩ

1 kΩ

TPA6011A4

SLOS392A – FEBRUARY 2002 – REVISED JULY 2004

APPLICATION INFORMATION

SELECTION OF COMPONENTS

Figure 28 and Figure 29 are schematic diagrams of typical notebook computer application circuits.

A. A 0.1-µF ceramic capacitor should be placed as close as possible to the IC. For filtering lower-frequency noise

signals, a larger electrolytic capacitor of 10 µF or greater should be placed near the audio power amplifier.

Figure 28. Typical TPA6011A4 Application Circuit Using Single-Ended Inputs and Input MUX

16

www.ti.com

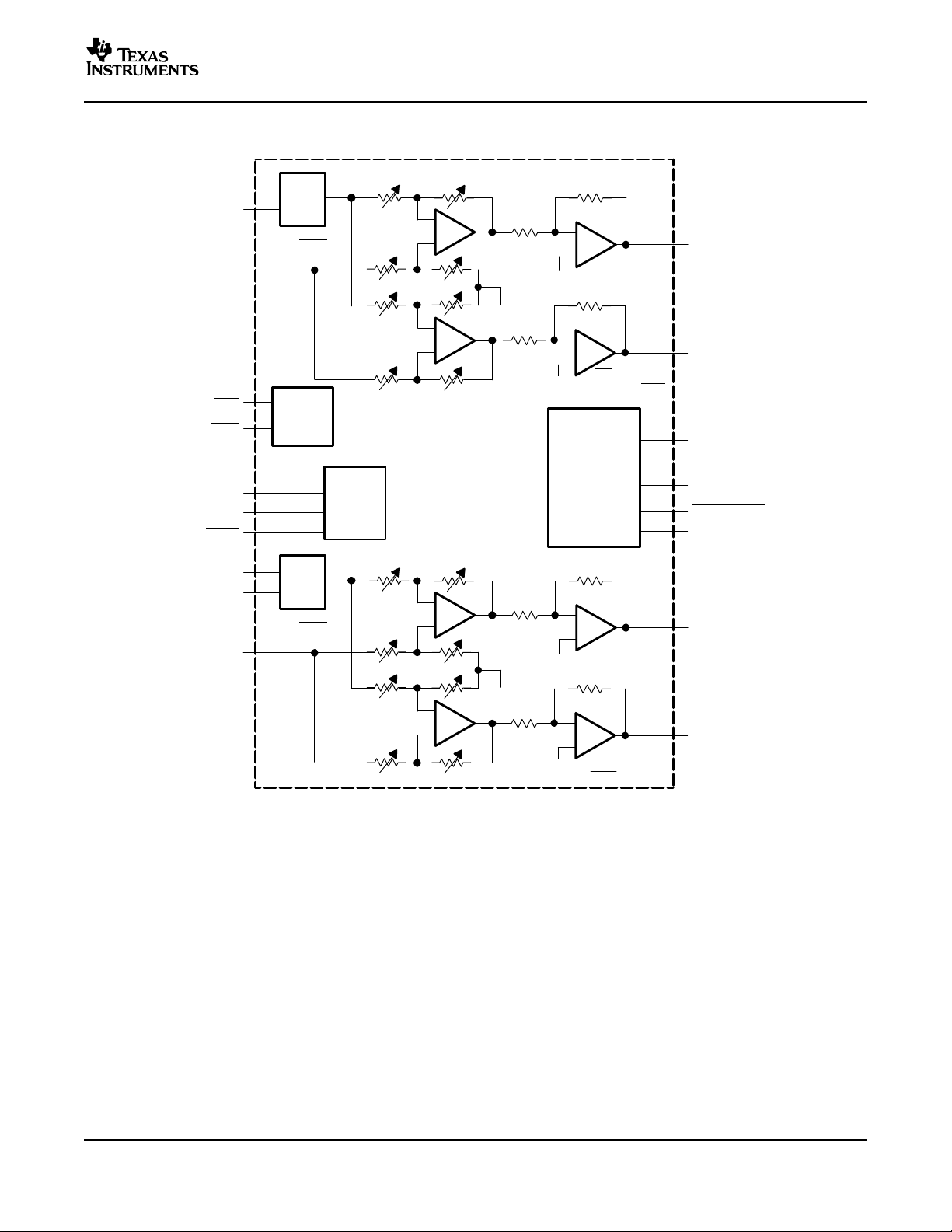

PGND

ROUT-

PV

DD

RHPIN

RLINEIN

RIN

V

DD

LIN

LLINEIN

LHPIN

PV

DD

LOUT-

1

ROUT+

SE/BTL

HP/LINE

VOLUME

SEDIFF

SEMAX

AGND

BYPASS

FADE

SHUTDOWN

LOUT+

PGND

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

C

S

NC

V

DD

C

i

C

i

C

S

C

i

C

i

C

S

Power Supply

Left Negative

Differential Input Signal

Power Supply

V

DD

100 kΩ

100 kΩ

C

C

In From DAC

or

Potentiometer

(DC Voltage)

C

(BYP)

System

Control

C

C

Right

Speaker

Left

Speaker

Headphones

1 kΩ

1 kΩ

NC

Left Positive Differential

Input Signal

Right Negative

Differential Input Signal

Right Positive

Differential Input Signal

APPLICATION INFORMATION (continued)

TPA6011A4

SLOS392A – FEBRUARY 2002 – REVISED JULY 2004

A. A 0.1-µF ceramic capacitor should be placed as close as possible to the IC. For filtering lower-frequency noise

SE/ BTL OPERATION

The ability of the TPA6011A4 to easily switch between BTL and SE modes is one of its most important cost

saving features. This feature eliminates the requirement for an additional headphone amplifier in applications

where internal stereo speakers are driven in BTL mode but external headphone or speakers must be

accommodated. Internal to the TPA6011A4, two separate amplifiers drive OUT+ and OUT-. The SE/ BTL input

controls the operation of the follower amplifier that drives LOUT- and ROUT-. When SE/ BTL is held low, the

amplifier is on and the TPA6011A4 is in the BTL mode. When SE/ BTL is held high, the OUT- amplifiers are in a

high output impedance state, which configures the TPA6011A4 as an SE driver from LOUT+ and ROUT+. IDDis

reduced by approximately one-third in SE mode. Control of the SE/ BTL input can be from a logic-level CMOS

source or, more typically, from a resistor divider network as shown in Figure 30 . The trip level for the SE/ BTL

input can be found in the recommended operating conditions table.

signals, a larger electrolytic capacitor of 10 µF or greater should be placed near the audio power amplifier.

Figure 29. Typical TPA6011A4 Application Circuit Using Differential Inputs

17

www.ti.com

SE/BTL

ROUT+ 24

R

MUX

RHPIN

RLINEIN5

4

6 RIN

ROUT- 2

1 kΩ

C

O

330 µF

100 kΩ

23

100 kΩ

V

DD

Input

MUX

Control

22 HP/LINE

_

+

_

+

Bypass

_

+

Bypass

EN

_

+

Bypass

LOUT+

TPA6011A4

SLOS392A – FEBRUARY 2002 – REVISED JULY 2004

APPLICATION INFORMATION (continued)

Figure 30. TPA6011A4 Resistor Divider Network Circuit

Using a 1/8-in. (3,5 mm) stereo headphone jack, the control switch is closed when no plug is inserted. When

closed the 100-k Ω /1-k Ω divider pulls the SE/ BTL input low. When a plug is inserted, the 1-k Ω resistor is

disconnected and the SE/ BTL input is pulled high. When the input goes high, the OUT- amplifier is shut down

causing the speaker to mute (open-circuits the speaker). The OUT+ amplifier then drives through the output

capacitor (C

) into the headphone jack.

o

HP/ LINE OPERATION

The HP/ LINE input controls the internal input multiplexer (MUX). Refer to the block diagram in Figure 30 . This

allows the device to switch between two separate stereo inputs to the amplifier. For design flexibility, the

HP/ LINE control is independent of the output mode, SE or BTL, which is controlled by the aforementioned

SE/ BTL pin. To allow the amplifier to switch from the LINE inputs to the HP inputs when the output switches from

BTL mode to SE mode, simply connect the SE/ BTL control input to the HP/ LINE input.

When this input is logic high, the RHPIN and LHPIN inputs are selected. When this terminal is logic low, the

RLINEIN and LLINEIN inputs are selected. This operation is also detailed in Table 3 and the trip levels for a logic

low (V

SHUTDOWN MODES

The TPA6011A4 employs a shutdown mode of operation designed to reduce supply current (I

minimum level during periods of nonuse for battery-power conservation. The SHUTDOWN input terminal should

be held high during normal operation when the amplifier is in use. Pulling SHUTDOWN low causes the outputs to

mute and the amplifier to enter a low-current state, IDD= 20 µA. SHUTDOWN should never be left unconnected

because amplifier operation would be unpredictable.

18

) or logic high (V

IL

) can be found in the recommended operating conditions table.

IH

) to the absolute

DD

www.ti.com

TPA6011A4

SLOS392A – FEBRUARY 2002 – REVISED JULY 2004

Table 3. HP/ LINE, SE/ BTL, and Shutdown Functions

INPUTS

HP/ LINE SE/ BTL SHUTDOWN INPUT OUTPUT

X X Low X Mute

Low Low High Line BTL

Low High High Line SE

High Low High HP BTL

High High High HP SE

(1) Inputs should never be left unconnected.

FADE OPERATION

For design flexibility, a fade mode is provided to slowly ramp up the amplifier gain when coming out of shutdown

mode and conversely ramp the gain down when going into shutdown. This mode provides a smooth transition

between the active and shutdown states and virtually eliminates any pops or clicks on the outputs.

When the FADE input is a logic low, the device is placed into fade-on mode. A logic high on this pin places the

amplifier in the fade-off mode. The voltage trip levels for a logic low (V

recommended operating conditions table.

When a logic low is applied to the FADE pin and a logic low is then applied on the SHUTDOWN pin, the channel

gain steps down from gain step to gain step at a rate of two clock cycles per step. With a nominal internal clock

frequency of 58 Hz, this equates to 34 ms (1/24 Hz) per step. The gain steps down until the lowest gain step is

reached. The time it takes to reach this step depends on the gain setting prior to placing the device in shutdown.

For example, if the amplifier is in the highest gain mode of 20 dB, the time it takes to ramp down the channel

gain is 1.05 seconds. This number is calculated by taking the number of steps to reach the lowest gain from the

highest gain, or 31 steps, and multiplying by the time per step, or 34 ms.

After the channel gain is stepped down to the lowest gain, the amplifier begins discharging the bypass capacitor

from the nominal voltage of V

0.47-µF capacitor that is used in the application diagram in Figure 28 , the time is approximately 500 ms. This

time scales linearly with the value of bypass capacitor. For example, if a 1-µF capacitor is used for bypass, the

time period to discharge the capacitor to ground is twice that of the 0.47-µF capacitor, or 1 second. Figure 30

below is a waveform captured at the output during the shutdown sequence when the part is in fade-on mode.

The gain is set to the highest level and the output is at V

When a logic high is placed on the SHUTDOWN pin and the FADE pin is still held low, the device begins the

start-up process. The bypass capacitor will begin charging. Once the bypass voltage reaches the final value of

V

/2, the gain increases in 2-dB steps from the lowest gain level to the gain level set by the dc voltage applied

DD

to the VOLUME, SEDIFF, and SEMAX pins.

In the fade-off mode, the amplifier stores the gain value prior to starting the shutdown sequence. The output of

the amplifier immediately drops to V

shutdown is released, the bypass capacitor charges up to V

value stored in memory. Figure 31 below is a waveform captured at the output during the shutdown sequence

when the part is in the fade-off mode. The gain is set to the highest level, and the output is at V

amplifier is shut down.

The power-up sequence is different from the shutdown sequence and the voltage on the FADE pin does not

change the power-up sequence. Upon a power-up condition, the TPA6011A4 begins in the lowest gain setting

and steps up 2 dB every 2 clock cycles until the final value is reached as determined by the dc voltage applied to

the VOLUME, SEDIFF, and SEMAX pins.

/2 to ground. This time is dependent on the value of the bypass capacitor. For a

DD

(1)

when the amplifier is shut down.

DD

/2 and the bypass capacitor begins a smooth discharge to ground. When

DD

/2 and the channel gain returns immediately to the

DD

AMPLIFIER STATE

) or logic high (V

IL

) can be found in the

IH

when the

DD

19

www.ti.com

ROUT+

Device Shutdown

ROUT+

Device Shutdown

TPA6011A4

SLOS392A – FEBRUARY 2002 – REVISED JULY 2004

Figure 31. Shutdown Sequence in the Figure 32. Shutdown Sequence in the

Fade-on Mode Fade-off Mode

VOLUME, SEDIFF, AND SEMAX OPERATION

Three pins labeled VOLUME, SEDIFF, and SEMAX control the BTL volume when driving speakers and the SE

volume when driving headphones. All of these pins are controlled with a dc voltage, which should not exceed

V

.

DD

When driving speakers in BTL mode, the VOLUME pin is the only pin that controls the gain. Table 1 shows the

gain for the BTL mode. The voltages listed in the table are for V

table scale linearly. If V

= 4 V, multiply all the voltages in the table by 4 V/5 V, or 0.8.

DD

The TPA6011A4 allows the user to specify a difference between BTL gain and SE gain. This is desirable to avoid

any listening discomfort when plugging in headphones. When switching to SE mode, the SEDIFF and SEMAX

pins control the singe-ended gain proportional to the gain set by the voltage on the VOLUME pin. When SEDIFF

= 0 V, the difference between the BTL gain and the SE gain is 6 dB. Refer to the section labeled bridged-tied

load versus single-ended load for an explanation on why the gain in BTL mode is 2x that of single-ended mode,

or 6dB greater. As the voltage on the SEDIFF terminal is increased, the gain in SE mode decreases. The voltage

on the SEDIFF terminal is subtracted from the voltage on the VOLUME terminal and this value is used to

determine the SE gain.

Some audio systems require that the gain be limited in the single-ended mode to a level that is comfortable for

headphone listening. Most volume control devices only have one terminal for setting the gain. For example, if the

speaker gain is 20 dB, the gain in the headphone channel is fixed at 14 dB. This level of gain could cause

discomfort to listeners and the SEMAX pin allows the designer to limit this discomfort when plugging in

headphones. The SEMAX terminal controls the maximum gain for single-ended mode.

The functionality of the SEDIFF and SEMAX pin are combined to set the SE gain. A block diagram of the

combined functionality is shown in Figure 33 . The value obtained from the block diagram for SE_VOLUME is a

dc voltage that can be used in conjunction with Table 2 to determine the SE gain. Again, the voltages listed in

the table are for V

DD

= 5 V. The values must be scaled for other values of V

Table 1 and Table 2 show a range of voltages for each gain step. There is a gap in the voltage between each

gain step. This gap represents the hysteresis about each trip point in the internal comparator. The hysteresis

ensures that the gain control is monotonic and does not oscillate from one gain step to another. If a

potentiometer is used to adjust the voltage on the control terminals, the gain increases as the potentiometer is

turned in one direction and decreases as it is turned back the other direction. The trip point, where the gain

= 5 V. For a different V

DD

.

DD

, the values in the

DD

20

www.ti.com

SEMAX (V)

VOLUME-SEDIFF

SEDIFF (V)

-

+

VOLUME (V)

YES

NO

SE_VOLUME (V) = VOLUME (V) - SEDIFF (V)

SE_VOLUME (V) = SEMAX (V)

Is SEMAX>

(VOLUME-SEDIFF)

?

0

2

4

2.702.61 2.73 2.81

BTL Gain - dB

Voltage on VOLUME Pin - V

TPA6011A4

SLOS392A – FEBRUARY 2002 – REVISED JULY 2004

actually changes, is different depending on whether the voltage is increased or decreased as a result of the

hysteresis about each trip point. The gaps in Table 1 and Table 2 can also be thought of as indeterminate states

where the gain could be in the next higher gain step or the lower gain step depending on the direction the

voltage is changing. If using a DAC to control the volume, set the voltage in the middle of each range to ensure

that the desired gain is achieved.

A pictorial representation of the volume control can be found in Figure 34 . The graph focuses on three gain steps

with the trip points defined in Table 1 for BTL gain. The dotted line represents the hysteresis about each gain

step.

Figure 33. Block Diagram of SE Volume Control

Figure 34. DC Volume Control Operation

21

www.ti.com

C

IN

R

i

R

f

Input Signal

ƒ

3 dB

1

2 CR

i

f

c(highpass)

1

2 RiC

i

−3 dB

f

c

C

i

1

2 Rif

c

TPA6011A4

SLOS392A – FEBRUARY 2002 – REVISED JULY 2004

INPUT RESISTANCE

Each gain setting is achieved by varying the input resistance of the amplifier, which can range from its smallest

value to over six times that value. As a result, if a single capacitor is used in the input high-pass filter, the -3 dB

or cutoff frequency also changes by over six times.

Figure 35. Resistor on Input for Cut-Off Frequency

The input resistance at each gain setting is given in Figure 26 .

The -3-dB frequency can be calculated using Equation 1 .

(1)

INPUT CAPACITOR, C

In the typical application an input capacitor (C

proper dc level for optimum operation. In this case, C

i

) is required to allow the amplifier to bias the input signal to the

i

and the input impedance of the amplifier (R

i

) form a

i

high-pass filter with the corner frequency determined in Equation 2 .

The value of Ciis important to consider as it directly affects the bass (low frequency) performance of the circuit.

Consider the example where Riis 70 k Ω and the specification calls for a flat-bass response down to 40 Hz.

Equation 2 is reconfigured as Equation 3 .

In this example, C

consideration for this capacitor is the leakage path from the input source through the input network (C

is 56.8 nF, so one would likely choose a value in the range of 56 nF to 1 µF. A further

i

) and the

i

feedback network to the load. This leakage current creates a dc offset voltage at the input to the amplifier that

reduces useful headroom, especially in high gain applications. For this reason, a low-leakage tantalum or

ceramic capacitor is the best choice. When polarized capacitors are used, the positive side of the capacitor

should face the amplifier input in most applications as the dc level there is held at V

/2, which is likely higher

DD

than the source dc level. Note that it is important to confirm the capacitor polarity in the application.

(2)

(3)

22

www.ti.com

f

c(high)

1

2 RLC

(C)

−3 dB

f

c

TPA6011A4

SLOS392A – FEBRUARY 2002 – REVISED JULY 2004

POWER SUPPLY DECOUPLING, C

(S)

The TPA6011A4 is a high-performance CMOS audio amplifier that requires adequate power supply decoupling to

ensure the output total harmonic distortion (THD) is as low as possible. Power supply decoupling also prevents

oscillations for long lead lengths between the amplifier and the speaker. The optimum decoupling is achieved by

using two capacitors of different types that target different types of noise on the power supply leads. For higher

frequency transients, spikes, or digital hash on the line, a good low equivalent-series-resistance (ESR) ceramic

capacitor, typically 0.1 µF placed as close as possible to the device V

lead, works best. For filtering

DD

lower-frequency noise signals, a larger aluminum electrolytic capacitor of 10 µF or greater placed near the audio

power amplifier is recommended.

MIDRAIL BYPASS CAPACITOR, C

The midrail bypass capacitor (C

start-up or recovery from shutdown mode, C

(BYP)

(BYP)

) is the most critical capacitor and serves several important functions. During

determines the rate at which the amplifier starts up. The second

(BYP)

function is to reduce noise produced by the power supply caused by coupling into the output drive signal. This

noise is from the midrail generation circuit internal to the amplifier, which appears as degraded PSRR and

THD+N.

Bypass capacitor (C

for the best THD and noise performance. For the best pop performance, choose a value for C

) values of 0.47-µF to 1-µF ceramic or tantalum low-ESR capacitors are recommended

(BYP)

(BYP)

that is equal to

or greater than the value chosen for Ci. This ensures that the input capacitors are charged up to the midrail

voltage before C

OUTPUT COUPLING CAPACITOR, C

In the typical single-supply SE configuration, an output coupling capacitor (C

is fully charged to the midrail voltage.

(BYP)

(C)

) is required to block the dc bias at

(C)

the output of the amplifier, thus preventing dc currents in the load. As with the input coupling capacitor, the

output coupling capacitor and impedance of the load form a high-pass filter governed by Equation 4 .

The main disadvantage, from a performance standpoint, is the load impedances are typically small, which drives

the low-frequency corner higher, degrading the bass response. Large values of C

frequencies into the load. Consider the example where a C

of 330 µF is chosen and loads vary from 3 Ω ,4 Ω ,

(C)

are required to pass low

(C)

8 Ω , 32 Ω , 10 k Ω , and 47 k Ω . Table 4 summarizes the frequency response characteristics of each configuration.

Table 4. Common Load Impedances vs Low Frequency

Output Characteristics in SE Mode

R

L

3 Ω 330 µF 161 Hz

4 Ω 330 µF 120 Hz

8 Ω 330 µF 60 Hz

32 Ω 330 µF 15 Hz

10,000 Ω 330 µF 0.05 Hz

47,000 Ω 330 µF 0.01 Hz

C

(C)

LOWEST

FREQUENCY

(4)

23

www.ti.com

Power

V

(rms)

2

R

L

V

(rms)

V

O(PP)

2 2

R

L

2x V

O(PP)

V

O(PP)

-V

O(PP)

V

DD

V

DD

TPA6011A4

SLOS392A – FEBRUARY 2002 – REVISED JULY 2004

As Table 4 indicates, most of the bass response is attenuated into a 4- Ω load, an 8- Ω load is adequate,

headphone response is good, and drive into line level inputs (a home stereo for example) is exceptional.

USING LOW-ESR CAPACITORS

Low-ESR capacitors are recommended throughout this applications section. A real (as opposed to ideal)

capacitor can be modeled simply as a resistor in series with an ideal capacitor. The voltage drop across this

resistor minimizes the beneficial effects of the capacitor in the circuit. The lower the equivalent value of this

resistance, the more the real capacitor behaves like an ideal capacitor.

BRIDGED-TIED LOAD vs SINGLE-ENDED LOAD

Figure 36 shows a Class-AB audio power amplifier (APA) in a BTL configuration. The TPA6011A4 BTL amplifier

consists of two Class-AB amplifiers driving both ends of the load. There are several potential benefits to this

differential drive configuration, but, initially consider power to the load. The differential drive to the speaker

means that as one side is slewing up, the other side is slewing down, and vice versa. This in effect doubles the

voltage swing on the load as compared to a ground referenced load. Plugging 2 × V

where voltage is squared, yields 4 × the output power from the same supply rail and load impedance (see

Equation 5 ).

into the power equation,

O(PP)

(5)

Figure 36. Bridge-Tied Load Configuration

24

www.ti.com

f

(c)

1

2 R

LCC

R

L

C

(C)

V

O(PP)

V

O(PP)

V

DD

-3 dB

f

c

TPA6011A4

SLOS392A – FEBRUARY 2002 – REVISED JULY 2004

In a typical computer sound channel operating at 5 V, bridging raises the power into an 8- Ω speaker from a

singled-ended (SE, ground reference) limit of 250 mW to 1 W. In sound power that is a 6-dB improvement, which

is loudness that can be heard. In addition to increased power there are frequency response concerns. Consider

the single-supply SE configuration shown in Figure 37 . A coupling capacitor is required to block the dc offset

voltage from reaching the load. These capacitors can be quite large (approximately 33 µF to 1000 µF), so they

tend to be expensive, heavy, occupy valuable PCB area, and have the additional drawback of limiting

low-frequency performance of the system. This frequency limiting effect is due to the high-pass filter network

created with the speaker impedance and the coupling capacitance and is calculated with Equation 6 .

For example, a 68-µF capacitor with an 8- Ω speaker would attenuate low frequencies below 293 Hz. The BTL

configuration cancels the dc offsets, which eliminates the need for the blocking capacitors. Low-frequency

performance is then limited only by the input network and speaker response. Cost and PCB space are also

minimized by eliminating the bulky coupling capacitor.

(6)

Figure 37. Single-Ended Configuration and Frequency Response

Increasing power to the load does carry a penalty of increased internal power dissipation. The increased

dissipation is understandable considering that the BTL configuration produces 4 × the output power of the SE

configuration. Internal dissipation versus output power is discussed further in the crest factor and thermal

considerations section.

SINGLE-ENDED OPERATION

In SE mode (see Figure 37 ), the load is driven from the primary amplifier output for each channel (OUT+).

The amplifier switches single-ended operation when the SE/ BTL terminal is held high. This puts the negative

outputs in a high-impedance state, and effectively reduces the amplifier's gain by 6 dB.

BTL AMPLIFIER EFFICIENCY

Class-AB amplifiers are inefficient. The primary cause of these inefficiencies is voltage drop across the output

stage transistors. There are two components of the internal voltage drop. One is the headroom or dc voltage

drop that varies inversely to output power. The second component is due to the sinewave nature of the output.

The total voltage drop can be calculated by subtracting the RMS value of the output voltage from V

internal voltage drop multiplied by the RMS value of the supply current (I

rms) determines the internal power

DD

dissipation of the amplifier.

An easy-to-use equation to calculate efficiency starts out as being equal to the ratio of power from the power

supply to the power delivered to the load. To accurately calculate the RMS and average values of power in the

load and in the amplifier, the current and voltage waveform shapes must first be understood (see Figure 38 ).

DD

. The

25

www.ti.com

V

(LRMS)

V

O

I

DD

I

DD(avg)

Efficiency of a BTL amplifier

P

L

P

SUP

Where:

P

L

VLrms

2

R

L

, andV

LRMS

V

P

2

, therefore, P

L

V

P

2

2R

L

and

P

SUP

VDDIDDavg

and

IDDavg

1

0

V

P

R

L

sin(t) dt

1

V

P

R

L

[cos(t)]

0

2V

P

R

L

Therefore,

P

SUP

2 VDDV

P

R

L

Efficiency of a BTL amplifier

V

P

2

2 R

L

2 VDDV

P

R

L

V

P

4 V

DD

PL = Power delivered to load

P

SUP

= Power drawn from power supply

V

LRMS

= RMS voltage on BTL load

R

L

= Load resistance

VP 2 PLR

L

BTL

2 PLR

L

4 V

DD

Where:

Therefore,

VP = Peak voltage on BTL load

IDDavg = Average current drawn from the power supply

VDD = Power supply voltage

η

BTL

= Efficiency of a BTL amplifier

TPA6011A4

SLOS392A – FEBRUARY 2002 – REVISED JULY 2004

Figure 38. Voltage and Current Waveforms for BTL Amplifiers

Although the voltages and currents for SE and BTL are sinusoidal in the load, currents from the supply are very

different between SE and BTL configurations. In an SE application the current waveform is a half-wave rectified

shape, whereas in BTL it is a full-wave rectified waveform. This means RMS conversion factors are different.

Keep in mind that for most of the waveform both the push and pull transistors are not on at the same time, which

supports the fact that each amplifier in the BTL device only draws current from the supply for half the waveform.

The following equations are the basis for calculating amplifier efficiency.

substituting PL and PSUP into Equation 7 ,

Table 5 employs Equation 8 to calculate efficiencies for four different output power levels. Note that the efficiency

of the amplifier is quite low for lower power levels and rises sharply as power to the load is increased resulting in

a nearly flat internal power dissipation over the normal operating range. Note that the internal dissipation at full

output power is less than in the half power range. Calculating the efficiency for a specific system is the key to

proper power supply design. For a stereo 1-W audio system with 8- Ω loads and a 5-V supply, the maximum draw

on the power supply is almost 3.25 W.

26

(7)

(8)

www.ti.com

PdB 10Log

P

W

P

ref

10Log

4 W

1 W

6 dB

PW 10

PdB10

P

ref

= 250 mW (12-db crest factor)

= 125 mW (15-db crest factor)

= 63 mW (18-db crest factor)

= 500 mW (9-db crest factor)

= 1000 mW (6-db crest factor)

= 2000 mW (3-db crest factor)

TPA6011A4

SLOS392A – FEBRUARY 2002 – REVISED JULY 2004

Table 5. Efficiency vs Output Power in 5-V, 8- Ω BTL Systems

OUTPUT POWER EFFICIENCY PEAK VOLTAGE INTERNAL DISSIPATION

(W) (%) (V) (W)

0.25 31.4 2.00 0.55

0.50 44.4 2.83 0.62

1.00 62.8 4.00 0.59

1.25 70.2 4.47

(1) High peak voltages cause the THD to increase.

A final point to remember about Class-AB amplifiers (either SE or BTL) is how to manipulate the terms in the

efficiency equation to utmost advantage when possible. Note that in equation 8, V

indicates that as V

goes down, efficiency goes up.

DD

CREST FACTOR AND THERMAL CONSIDERATIONS

Class-AB power amplifiers dissipate a significant amount of heat in the package under normal operating

conditions. A typical music CD requires 12 dB to 15 dB of dynamic range, or headroom above the average power

output, to pass the loudest portions of the signal without distortion. In other words, music typically has a crest

factor between 12 dB and 15 dB. When determining the optimal ambient operating temperature, the internal

dissipated power at the average output power level must be used. From the TPA6011A4 data sheet, one can

see that when the TPA6011A4 is operating from a 5-V supply into a 3- Ω speaker, that 4-W peaks are available.

Use equation 9 to convert watts to dB.

(1)

0.53

is in the denominator. This

DD

Subtracting the headroom restriction to obtain the average listening level without distortion yields:

• 6 dB - 15 dB = -9 dB (15-dB crest factor)

• 6 dB - 12 dB = -6 dB (12-dB crest factor)

• 6 dB - 9 dB = -3 dB (9-dB crest factor)

• 6 dB - 6 dB = 0 dB (6-dB crest factor)

• 6 dB - 3 dB = 3 dB (3-dB crest factor)

To convert dB back into watts use equation 10.

This is valuable information to consider when attempting to estimate the heat dissipation requirements for the

amplifier system. Comparing the worst case, which is 2 W of continuous power output with a 3-dB crest factor,

against 12-dB and 15-dB applications significantly affects maximum ambient temperature ratings for the system.

Using the power dissipation curves for a 5-V, 3- Ω system, the internal dissipation in the TPA6011A4 and

maximum ambient temperatures is shown in Table 6 .

(9)

(10)

27

www.ti.com

P

D(max)

2V

2

DD

2

R

L

Θ

JA

1

Derating Factor

1

0.022

45°CW

TAMax TJMax ΘJAP

D

150 45(0.6 2) 96°C(15-dB crest factor

)

TPA6011A4

SLOS392A – FEBRUARY 2002 – REVISED JULY 2004

Table 6. TPA6011A4 Power Rating, 5-V, 3- Ω Stereo

PEAK OUTPUT POWER POWER DISSIPATION MAXIMUM AMBIENT

(W) (W/Channel) TEMPERATURE

4 2 W (3 dB) 1.7 -3 ° C

4 1 W (6 dB) 1.6 6 ° C

4 500 mW (9 dB) 1.4 24 ° C

4 250 mW (12 dB) 1.1 51 ° C

4 125 mW (15 dB) 0.8 78 ° C

4 63 mW (18 dB) 0.6 96 ° C

PEAK OUTPUT POWER POWER DISSIPATION MAXIMUM AMBIENT

(W) (W/Channel) TEMPERATURE

2.5 1250 mW (3-dB crest factor) 0.55 100 ° C

2.5 1000 mW (4-dB crest factor) 0.62 94 ° C

2.5 500 mW (7-dB crest factor) 0.59 97 ° C

2.5 250 mW (10-dB crest factor) 0.53 102 ° C

AVERAGE OUTPUT POWER

Table 7. TPA6011A4 Power Rating, 5-V, 8- Ω Stereo

AVERAGE OUTPUT POWER

The maximum dissipated power (P

a 3- Ω load. As a result, this simple formula for calculating P

However, in the case of a 3- Ω load, the P

The amplifier may therefore be operated at a higher ambient temperature than required by the P

) is reached at a much lower output power level for an 8- Ω load than for

D(max)

occurs at a point well above the normal operating power level.

D(max)

D(max)

may be used for an 8- Ω application.

formula for

D(max)

a 3- Ω load.

The maximum ambient temperature depends on the heat-sinking ability of the PCB system. The derating factor

for the PWP package is shown in the dissipation rating table. Use equation 12 to convert this to θ

.

JA.

To calculate maximum ambient temperatures, first consider that the numbers from the dissipation graphs are per

channel, so the dissipated power needs to be doubled for two channel operation. Given θ

, the maximum

JA

allowable junction temperature, and the total internal dissipation, the maximum ambient temperature can be

calculated using Equation 13 . The maximum recommended junction temperature for the TPA6011A4 is 150 ° C.

The internal dissipation figures are taken from the Power Dissipation vs Output Power graphs.

NOTE:

Internal dissipation of 0.6 W is estimated for a 2-W system with 15-dB crest factor per

channel.

Table 6 and Table 7 show that some applications require no airflow to keep junction temperatures in the

specified range. The TPA6011A4 is designed with thermal protection that turns the device off when the junction

temperature surpasses 150 ° C to prevent damage to the IC. Table 6 and Table 7 were calculated for maximum

listening volume without distortion. When the output level is reduced the numbers in the table change

significantly. Also, using 8- Ω speakers increases the thermal performance by increasing amplifier efficiency.

(11)

(12)

(13)

28

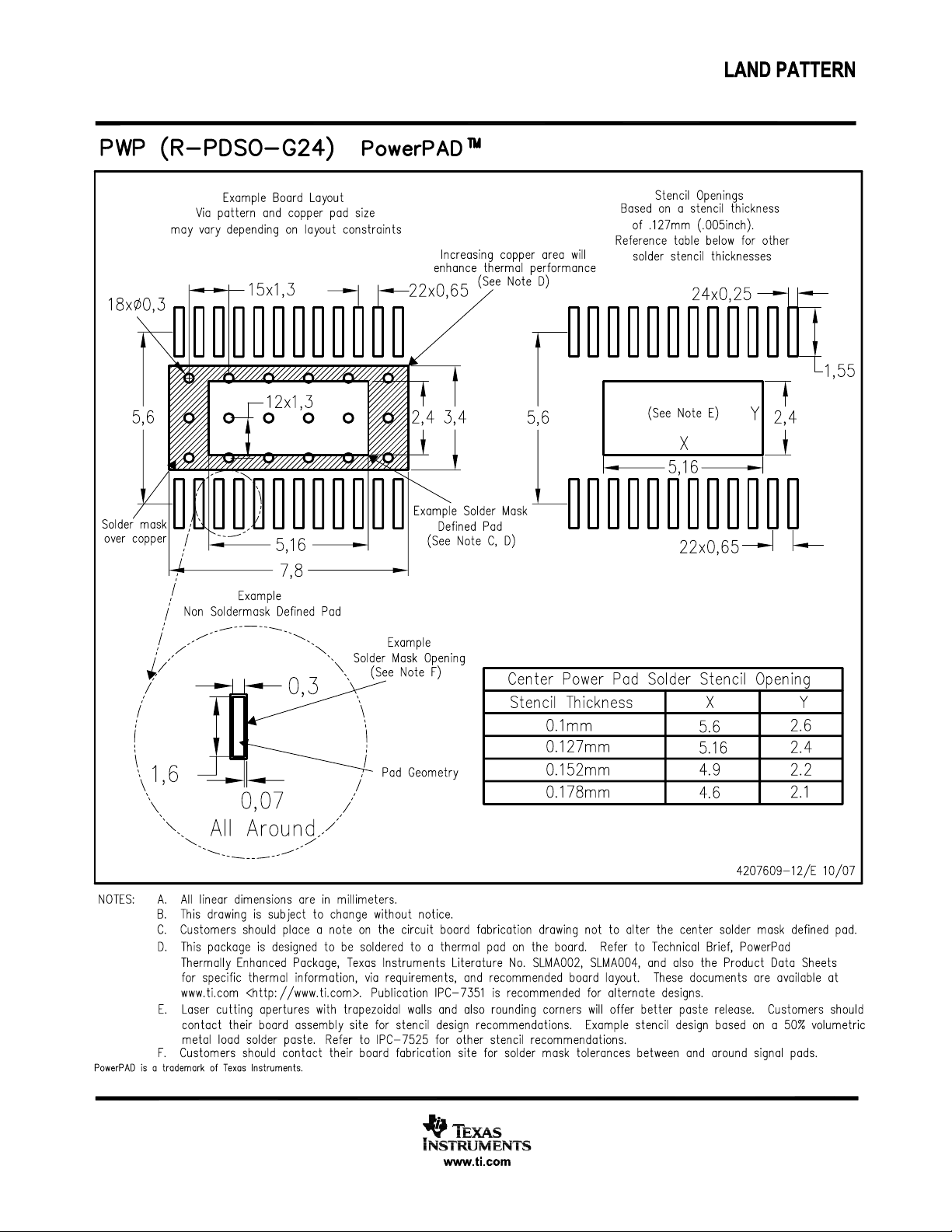

THERMAL PAD MECHANICAL DATA

www.ti.com

PWP (R-PDSO-G24)

THERMAL INFORMATION

This PowerPAD™ package incorporates an exposed thermal pad that is designed to be attached directly to an

external heatsink. When the thermal pad is soldered directly to the printed circuit board (PCB), the PCB can be

used as a heatsink. In addition, through the use of thermal vias, the thermal pad can be attached directly to a

ground plane or special heatsink structure designed into the PCB. This design optimizes the heat transfer from

the integrated circuit (IC).

For additional information on the PowerPAD package and how to take advantage of its heat dissipating abilities,

refer to Technical Brief, PowerPAD Thermally Enhanced Package, Texas Inst ruments Literature No. SLMA002

and Application Brief, PowerPAD Made Easy, Texas Instrume n ts Literature No. SL MA004. Both documents are

available at www.ti.com.

The exposed thermal pad dimensions for this package are shown in the following illustration.

24

13

Exposed Thermal Pad

2,40

1,65

1

NOTE: All linear dimensions are in millimeters

Exposed Thermal Pad Dimensions

12

5,16

4,10

Top View

PPTD030

PowerPAD is a trademark of Texas Instruments

PACKAGE OPTION ADDENDUM

www.ti.com

18-Jul-2006

PACKAGING INFORMATION

Orderable Device Status

(1)

Package

Type

Package

Drawing

Pins Package

Qty

Eco Plan

TPA6011A4PWP ACTIVE HTSSOP PWP 24 60 Green (RoHS &

no Sb/Br)

TPA6011A4PWPG4 ACTIVE HTSSOP PWP 24 60 Green (RoHS &

no Sb/Br)

TPA6011A4PWPR ACTIVE HTSSOP PWP 24 2000 Green (RoHS &

no Sb/Br)

TPA6011A4PWPRG4 ACTIVE HTSSOP PWP 24 2000 Green (RoHS &

no Sb/Br)

(1)

The marketing status values are defined as follows:

ACTIVE: Product device recommended for new designs.

LIFEBUY: TI has announced that the device will be discontinued, and a lifetime-buy period is in effect.

NRND: Not recommended for new designs. Device is in production to support existing customers, but TI does not recommend using this part in

a new design.

PREVIEW: Device has been announced but is not in production. Samples may or may not be available.

OBSOLETE: TI has discontinued the production of the device.

(2)

Eco Plan - The planned eco-friendly classification: Pb-Free (RoHS), Pb-Free (RoHS Exempt), or Green (RoHS & no Sb/Br) - please check

http://www.ti.com/productcontent for the latest availability information and additional product content details.

TBD: The Pb-Free/Green conversion plan has not been defined.

Pb-Free (RoHS): TI's terms "Lead-Free" or "Pb-Free" mean semiconductor products that are compatible with the current RoHS requirements

for all 6 substances, including the requirement that lead not exceed 0.1% by weight in homogeneous materials. Where designed to be soldered

at high temperatures, TI Pb-Free products are suitable for use in specified lead-free processes.

Pb-Free (RoHS Exempt): This component has a RoHS exemption for either 1) lead-based flip-chip solder bumps used between the die and

package, or 2) lead-based die adhesive used between the die and leadframe. The component is otherwise considered Pb-Free (RoHS

compatible) as defined above.

Green (RoHS & no Sb/Br): TI defines "Green" to mean Pb-Free (RoHS compatible), and free of Bromine (Br) and Antimony (Sb) based flame

retardants (Br or Sb do not exceed 0.1% by weight in homogeneous material)

(2)

Lead/Ball Finish MSL Peak Temp

CU NIPDAU Level-2-260C-1 YEAR

CU NIPDAU Level-2-260C-1 YEAR

CU NIPDAU Level-2-260C-1 YEAR

CU NIPDAU Level-2-260C-1 YEAR

(3)

(3)

MSL, Peak Temp. -- The Moisture Sensitivity Level rating according to the JEDEC industry standard classifications, and peak solder

temperature.

Important Information and Disclaimer:The information provided on this page represents TI's knowledge and belief as of the date that it is

provided. TI bases its knowledge and belief on information provided by third parties, and makes no representation or warranty as to the

accuracy of such information. Efforts are underway to better integrate information from third parties. TI has taken and continues to take

reasonable steps to provide representative and accurate information but may not have conducted destructive testing or chemical analysis on

incoming materials and chemicals. TI and TI suppliers consider certain information to be proprietary, and thus CAS numbers and other limited

information may not be available for release.

In no event shall TI's liability arising out of such information exceed the total purchase price of the TI part(s) at issue in this document sold by TI

to Customer on an annual basis.

Addendum-Page 1

PACKAGE MATERIALS INFORMATION

www.ti.com

TAPE AND REEL INFORMATION

11-Mar-2008

*All dimensions are nominal

Device Package

TPA6011A4PWPR HTSSOP PWP 24 2000 330.0 16.4 6.95 8.3 1.6 8.0 16.0 Q1

TPA6011A4PWPR HTSSOP PWP 24 2000 330.0 16.4 6.95 8.3 1.6 8.0 16.0 Q1

Type

Package

Drawing

Pins SPQ Reel

Diameter

(mm)

Reel

Width

W1 (mm)

A0 (mm) B0 (mm) K0 (mm) P1

(mm)W(mm)

Pin1

Quadrant

Pack Materials-Page 1

PACKAGE MATERIALS INFORMATION

www.ti.com

11-Mar-2008

*All dimensions are nominal

Device Package Type Package Drawing Pins SPQ Length (mm) Width (mm) Height (mm)

TPA6011A4PWPR HTSSOP PWP 24 2000 346.0 346.0 33.0

TPA6011A4PWPR HTSSOP PWP 24 2000 346.0 346.0 33.0

Pack Materials-Page 2

IMPORTANT NOTICE

Texas Instruments Incorporated and its subsidiaries (TI) reserve the right to make corrections, modifications, enhancements, improvements,

and other changes to its products and services at any time and to discontinue any product or service without notice. Customers should

obtain the latest relevant information before placing orders and should verify that such information is current and complete. All products are

sold subject to TI’s terms and conditions of sale supplied at the time of order acknowledgment.

TI warrants performance of its hardware products to the specifications applicable at the time of sale in accordance with TI’s standard

warranty. Testing and other quality control techniques are used to the extent TI deems necessary to support this warranty. Except where

mandated by government requirements, testing of all parameters of each product is not necessarily performed.

TI assumes no liability for applications assistance or customer product design. Customers are responsible for their products and

applications using TI components. To minimize the risks associated with customer products and applications, customers should provide

adequate design and operating safeguards.

TI does not warrant or represent that any license, either express or implied, is granted under any TI patent right, copyright, mask work right,

or other TI intellectual property right relating to any combination, machine, or process in which TI products or services are used. Information

published by TI regarding third-party products or services does not constitute a license from TI to use such products or services or a

warranty or endorsement thereof. Use of such information may require a license from a third party under the patents or other intellectual

property of the third party, or a license from TI under the patents or other intellectual property of TI.

Reproduction of TI information in TI data books or data sheets is permissible only if reproduction is without alteration and is accompanied

by all associated warranties, conditions, limitations, and notices. Reproduction of this information with alteration is an unfair and deceptive

business practice. TI is not responsible or liable for such altered documentation. Information of third parties may be subject to additional

restrictions.

Resale of TI products or services with statements different from or beyond the parameters stated by TI for that product or service voids all

express and any implied warranties for the associated TI product or service and is an unfair and deceptive business practice. TI is not

responsible or liable for any such statements.

TI products are not authorized for use in safety-critical applications (such as life support) where a failure of the TI product would reasonably

be expected to cause severe personal injury or death, unless officers of the parties have executed an agreement specifically governing

such use. Buyers represent that they have all necessary expertise in the safety and regulatory ramifications of their applications, and

acknowledge and agree that they are solely responsible for all legal, regulatory and safety-related requirements concerning their products

and any use of TI products in such safety-critical applications, notwithstanding any applications-related information or support that may be

provided by TI. Further, Buyers must fully indemnify TI and its representatives against any damages arising out of the use of TI products in

such safety-critical applications.

TI products are neither designed nor intended for use in military/aerospace applications or environments unless the TI products are

specifically designated by TI as military-grade or "enhanced plastic." Only products designated by TI as military-grade meet military

specifications. Buyers acknowledge and agree that any such use of TI products which TI has not designated as military-grade is solely at

the Buyer's risk, and that they are solely responsible for compliance with all legal and regulatory requirements in connection with such use.

TI products are neither designed nor intended for use in automotive applications or environments unless the specific TI products are

designated by TI as compliant with ISO/TS 16949 requirements. Buyers acknowledge and agree that, if they use any non-designated

products in automotive applications, TI will not be responsible for any failure to meet such requirements.

Following are URLs where you can obtain information on other Texas Instruments products and application solutions:

Products Applications

Amplifiers amplifier.ti.com Audio www.ti.com/audio

Data Converters dataconverter.ti.com Automotive www.ti.com/automotive

DSP dsp.ti.com Broadband www.ti.com/broadband

Clocks and Timers www.ti.com/clocks Digital Control www.ti.com/digitalcontrol

Interface interface.ti.com Medical www.ti.com/medical

Logic logic.ti.com Military www.ti.com/military

Power Mgmt power.ti.com Optical Networking www.ti.com/opticalnetwork

Microcontrollers microcontroller.ti.com Security www.ti.com/security

RFID www.ti-rfid.com Telephony www.ti.com/telephony

RF/IF and ZigBee® Solutions www.ti.com/lprf Video & Imaging www.ti.com/video

Mailing Address: Texas Instruments, Post Office Box 655303, Dallas, Texas 75265

Copyright © 2008, Texas Instruments Incorporated

Wireless www.ti.com/wireless

Loading...

Loading...