Page 1

YZH

AVDD

INL–

INL+

AGND

PGND

OUTL+

OUTL–

PVDDR

10 Fm

ToBattery

SDA

INR–

INR+

C 1 FINm

OUTR+

OUTR–

SCL

SDZ

I CClock

2

I CData

2

MasterShutdown

TPA2026D2

Digital

Baseband

Analog

Baseband

or

Codec

PVDDL

TPA2026D2

www.ti.com

SLOS649 –MARCH 2010

3.2-W/Ch Stereo Class-D Audio Amplifier with Fast Gain Ramp SmartGain™ AGC/DRC

Check for Samples: TPA2026D2

1

FEATURES

23

• Fast AGC Start-up Time: 5 ms

• Pin-Out Compatible with TPA2016D2

• Filter-Free Class-D Architecture

• 3.2 W/Ch Into 4 Ω at 5 V (10% THD+N)

• 750 mW/Ch Into 8 Ω at 3.6 V (10% THD+N)

• Power Supply Range: 2.5 V to 5.5 V

• Flexible Operation With/Without I2C

• Programmable DRC/AGC Parameters

• Digital I2C Volume Control

• Selectable Gain from 0 dB to 30 dB in 1-dB speaker from damage at high power levels and

Steps

• Selectable Attack, Release and Hold Times

• 4 Selectable Compression Ratios

• Low Supply Current: 3.5 mA

• Low Shutdown Current: 0.2 mA

• High PSRR: 80 dB

• AGC Enable/Disable Function

• Limiter Enable/Disable Function

• Short-Circuit and Thermal Protection

• Space-Saving Package

– 2,2 mm × 2,2 mm Nano-Free™ WCSP (YZH)

DESCRIPTION

The TPA2026D2 is a stereo, filter-free Class-D audio

power amplifier with volume control, dynamic range

compression (DRC) and automatic gain control

(AGC). It is available in a 2.2 mm x 2.2 mm WCSP

package.

The DRC/AGC function in the TPA2026D2 is

programmable via a digital I2C interface. The

DRC/AGC function can be configured to automatically

prevent distortion of the audio signal and enhance

quiet passages that are normally not heard. The

DRC/AGC can also be configured to protect the

compress the dynamic range of music to fit within the

dynamic range of the speaker. The gain can be

selected from 0 dB to +30 dB in 1-dB steps. The

TPA2026D2 is capable of driving 3.2 W/Ch at 5 V

into an 4-Ω load or 750 mW/Ch at 3.6 V into an 8-Ω

load. The device features independent software

shutdown controls for each channel and also provides

thermal and short circuit protection. The TPA2026D2

has faster AGC gain ramp during start-up than

TPA2026D2.

In addition to these features, a fast start-up time and

small package size make the TPA2026D2 an ideal

choice for cellular handsets, PDAs, and other

portable applications.

APPLICATIONS

• Wireless or Cellular Handsets and PDAs

• Portable Navigation Devices

• Portable DVD Player

• Notebook PCs

• Portable Radio

• Portable Games

• Educational Toys

• USB Speakers

1

Please be aware that an important notice concerning availability, standard warranty, and use in critical applications of Texas

Instruments semiconductor products and disclaimers thereto appears at the end of this data sheet.

2SmartGain, Nano-Free are trademarks of Texas Instruments.

3All other trademarks are the property of their respective owners.

PRODUCTION DATA information is current as of publication date.

Products conform to specifications per the terms of the Texas

Instruments standard warranty. Production processing does not

necessarily include testing of all parameters.

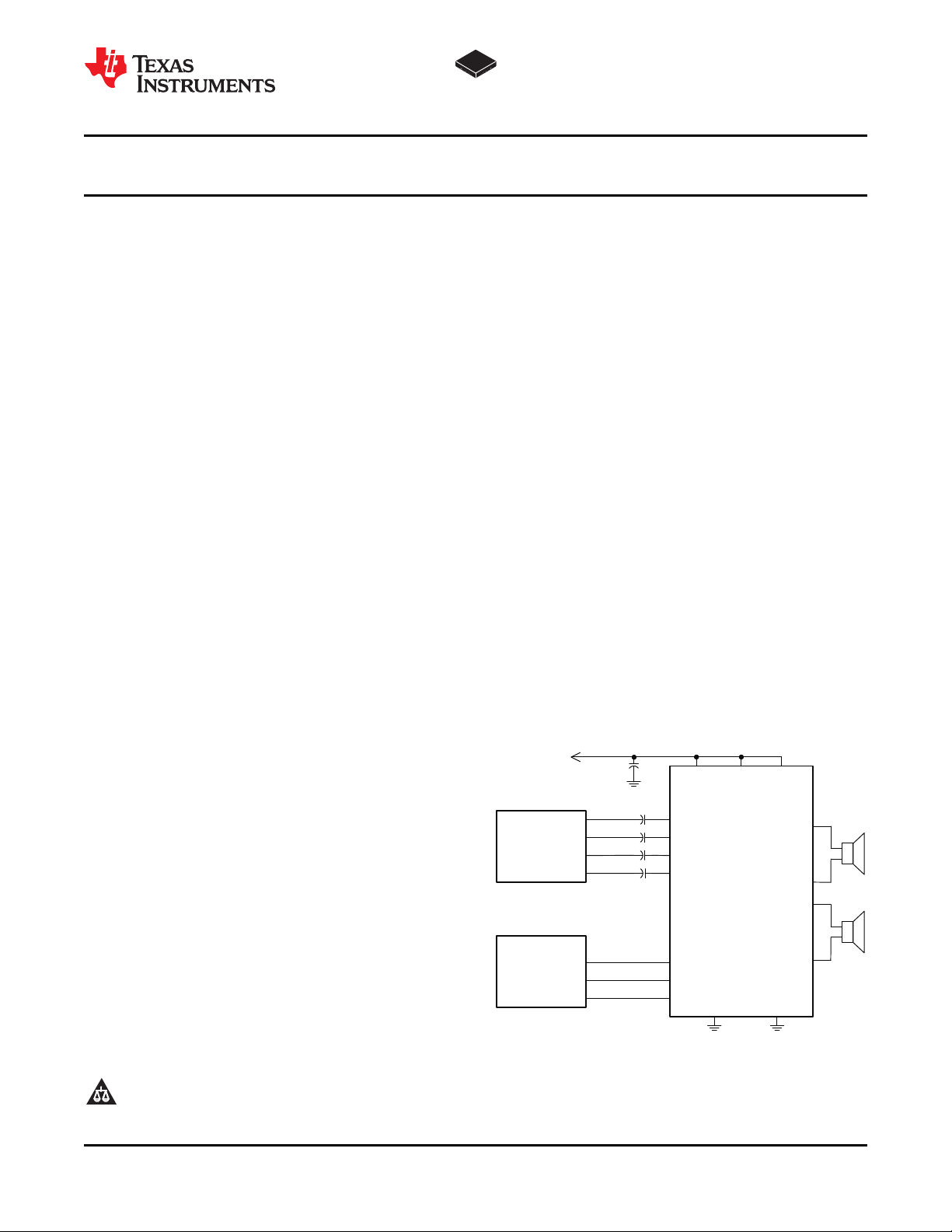

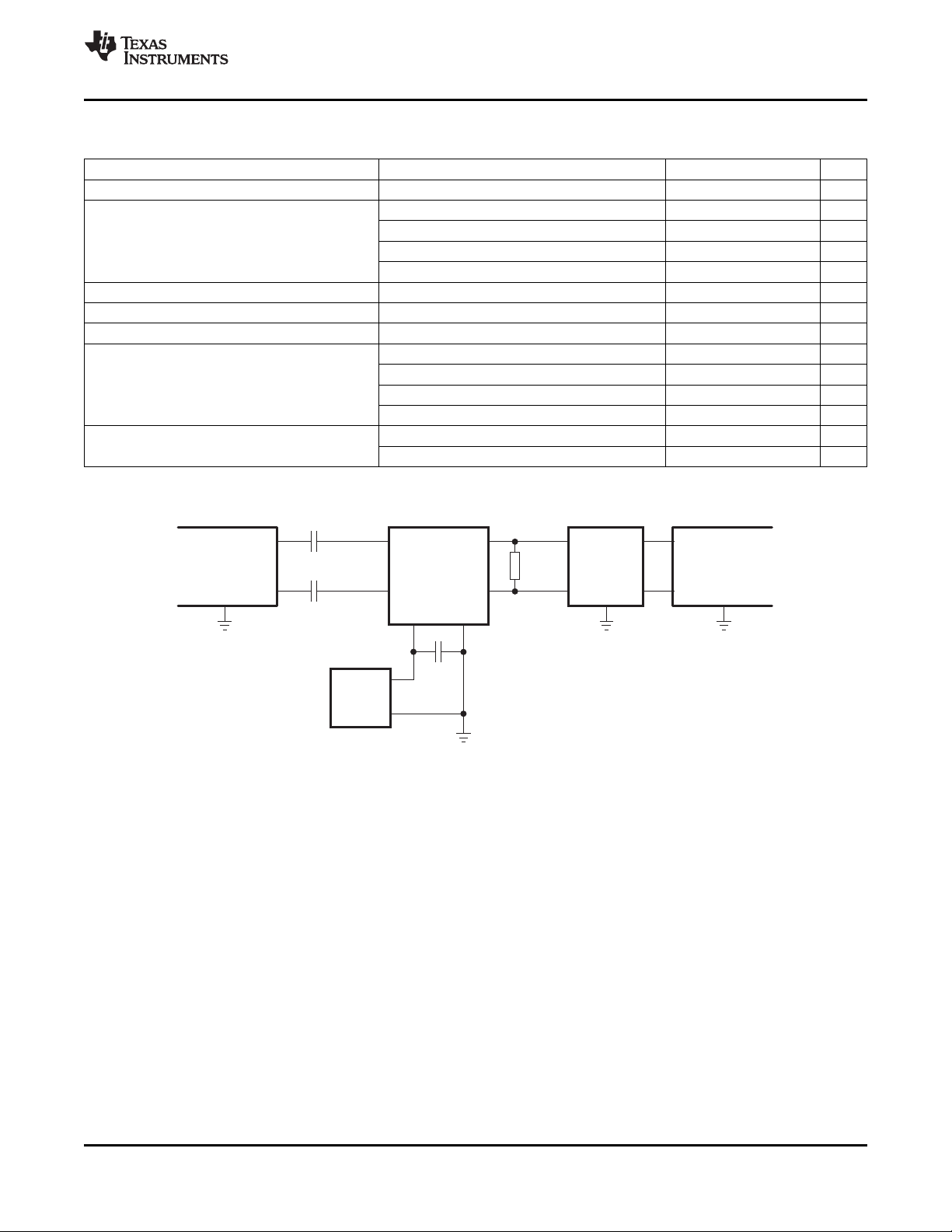

SIMPLIFIED APPLICATION DIAGRAM

Copyright © 2010, Texas Instruments Incorporated

Page 2

I2C Interface

& Control

INL+

INL-

SDA

OUTL+

OUTL-

SDZ

INR+

INR-

SCL

Class-D

Modulator

Volume

Control

Differential

Input Left

C

IN

1uF

Differential

Input Right

C

IN

1uF

I2C Interface

IC shutdown

Power

Stage

AGC

Reference

Volume

Control

Power

Stage

OUTR+

OUTR-

AGND PGND

Bias and

References

AVDD

PVDDR

PVDDL

AGC

Class-D

Modulator

PGND

OUTL–OUTR–OUTR+

INL–INR+ INL+INR–

AGNDSDASCLAVDD

PVDDLSDZPVDDR

OUTL+

D 1 D 2 D 3 D 4

C 1 C 2 C 3 C 4

B1 B3 B4B2

A1 A2 A3 A4

YZH(WCSP)PACKAGE

(TopView)

TPA2026D2

SLOS649 –MARCH 2010

These devices have limited built-in ESD protection. The leads should be shorted together or the device placed in conductive foam

during storage or handling to prevent electrostatic damage to the MOS gates.

www.ti.com

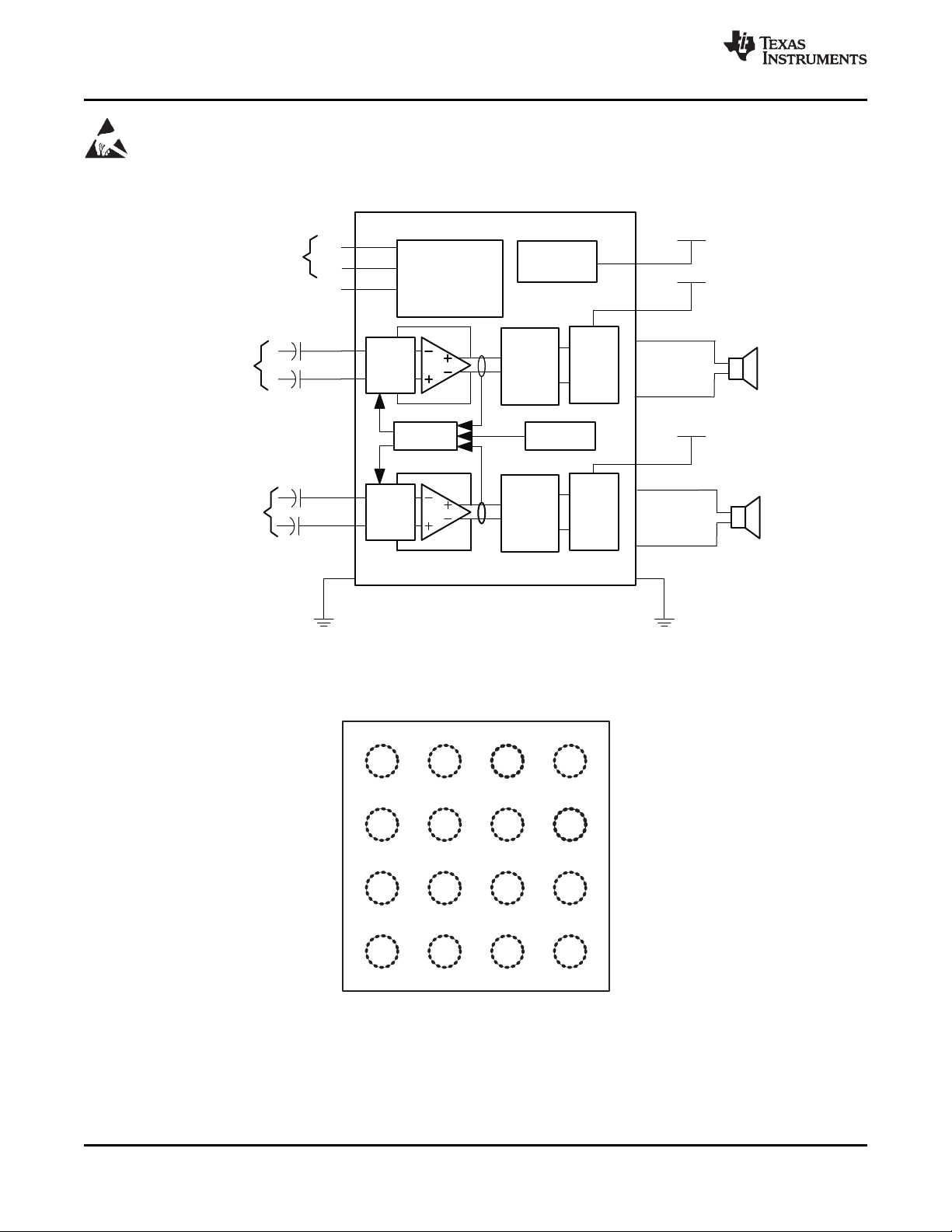

FUNCTIONAL BLOCK DIAGRAM

DEVICE PINOUT

2 Submit Documentation Feedback Copyright © 2010, Texas Instruments Incorporated

Product Folder Link(s): TPA2026D2

Page 3

TPA2026D2

www.ti.com

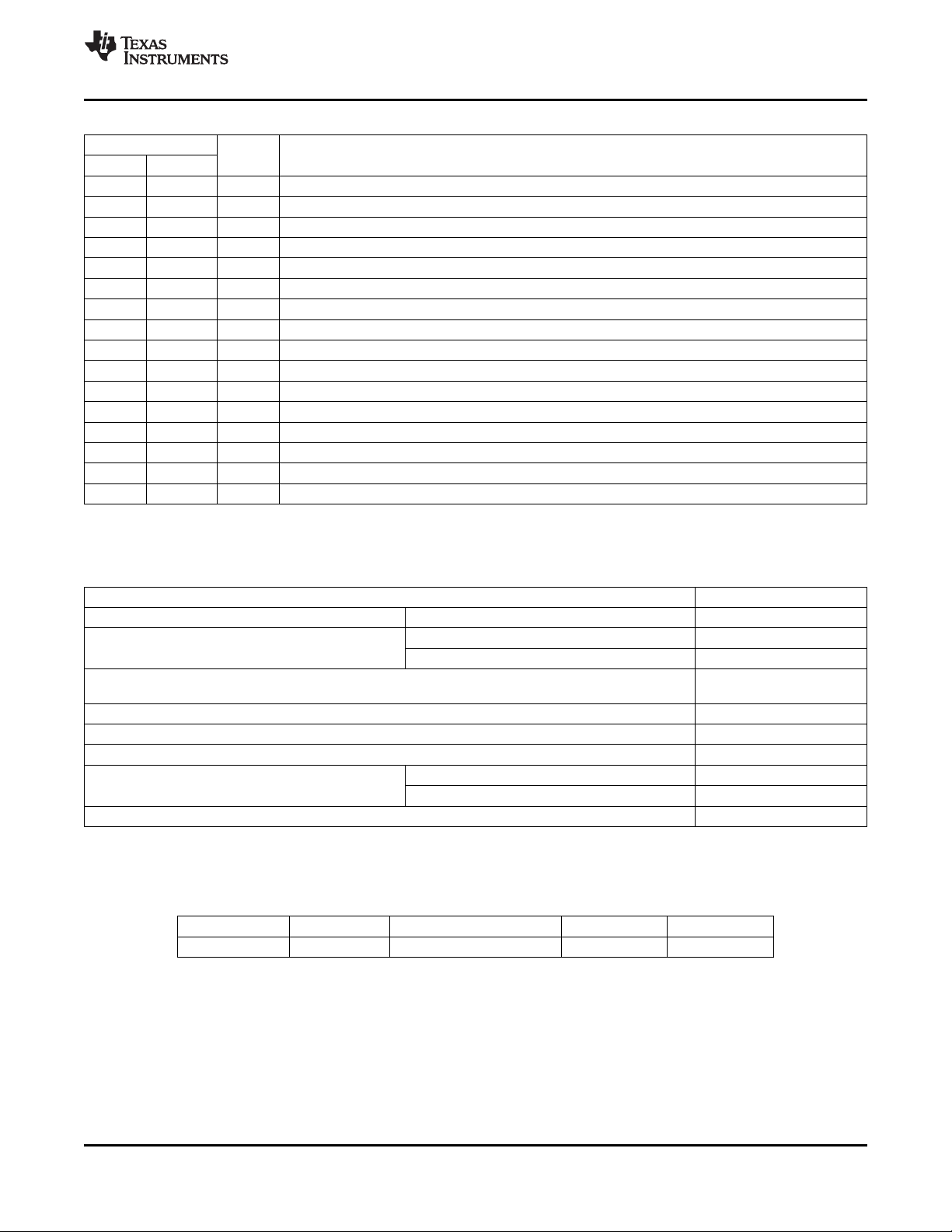

PIN FUNCTIONS

PIN

NAME WCSP

INR+ A2 I Right channel positive audio input

INR– A1 I Right channel negative audio input

INL+ A3 I Left channel positive audio input

INL– A4 I Left channel negative audio input

SDZ C2 I Shutdown terminal (active low)

SDA B3 I/O I2C data interface

SCL B2 I I2C clock interface

OUTR+ D1 O Right channel positive differential output

OUTR– D2 O Right channel negative differential output

OUTL+ D4 O Left channel positive differential output

OUTL– D3 O Left channel negative differential output

AVDD B1 P Analog supply (must be the same as PVDDR and PVDDL)

AGND B4 P Analog ground (all GND pins need to be connected)

PVDDR C1 P Right channel power supply (must be the same as AVDD and PVDDL)

PGND C3 P Power ground (all GND pins need to be connected)

PVDDL C4 P Left channel power supply (must be the same as AVDD and PVDDR)

I/O/P DESCRIPTION

SLOS649 –MARCH 2010

ABSOLUTE MAXIMUM RATINGS

(1)

over operating free-air temperature range (unless otherwise noted).

VALUE / UNIT

V

Supply voltage AVDD, PVDDR, PVDDL –0.3 V to 6 V

DD

Input voltage

Continuous total power dissipation

T

Operating free-air temperature range –40°C to 85°C

A

T

Operating junction temperature range –40°C to 150°C

J

T

Storage temperature range –65°C to 150°C

stg

ESD Electro-static discharge tolerance, all pins

R

Minimum load resistance 3.2 Ω

L

(1) Stresses beyond those listed under "absolute maximum ratings" may cause permanent damage to the device. These are stress ratings

only, and functional operation of the device at these or any other conditions beyond those indicated under "recommended operating

conditions" is not implied. Exposure to absolute-maximum-rated conditions for extended periods may affect device reliability.

DISSIPATION RATINGS TABLE

PACKAGE TA≤ 25°C DERATING FACTOR TA= 70°C TA= 85°C

16-ball WCSP 1.25 W 10 mW/°C 0.8 W 0.65 W

(1) Dissipations ratings are for a 2-side, 2-plane PCB.

SDZ, INR+, INR–, INL+, INL– –0.3 V to VDD+0.3 V

SDA, SCL –0.3 V to 6 V

See Dissipation Ratings

Table

Human body model (HBM) 2 KV

Charged device model (CDM) 500 V

(1)

Copyright © 2010, Texas Instruments Incorporated Submit Documentation Feedback 3

Product Folder Link(s): TPA2026D2

Page 4

TPA2026D2

SLOS649 –MARCH 2010

T

A

–40°C to 85°C

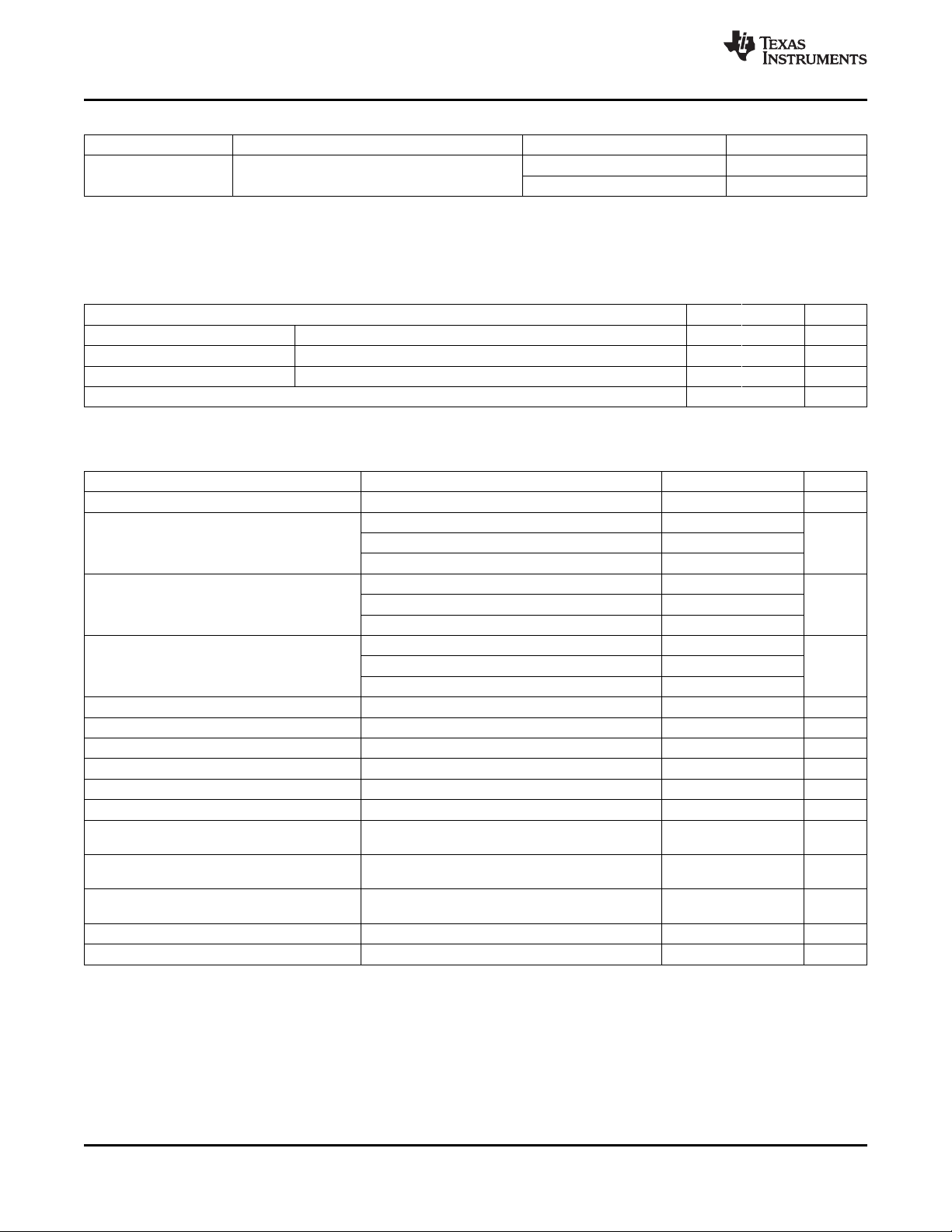

AVAILABLE OPTIONS

PACKAGED DEVICE

16-ball, 2,2 mm × 2,2 mm WCSP (+0.01 mm/

-0.09 mm tolerance)

(2)

(1)

PART NUMBER SYMBOL

TPA2026D2 YZHR NSV

TPA2026D2 YZHT NSV

www.ti.com

(1) For the most current package and ordering information, see the Package Option Addendum at the end of this document, or see the TI

Web site at www.ti.com

(2) The YZH package is only available taped and reeled. The suffix R indicates a reel of 3000; the suffix T indicates a reel of 250.

RECOMMENDED OPERATING CONDITIONS

MIN MAX UNIT

VDDSupply voltage AVDD, PVDDR, PVDDL 2.5 5.5 V

VIHHigh-level input voltage SDZ, SDA, SCL 1.3 V

VILLow-level input voltage SDZ, SDA, SCL 0.6 V

T

Operating free-air temperature –40 +85 °C

A

ELECTRICAL CHARACTERISTICS

at TA= 25°C, VDD= 3.6 V, SDZ = 1.3 V, and RL= 8 Ω + 33 mH (unless otherwise noted).

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

V

DD

I

SDZ

I

SWS

I

DD

f

SW

I

IH

I

IL

t

START

POR Power on reset ON threshold 2 2.3 V

POR Power on reset hysteresis 0.2 V

CMRR Input common mode rejection –70 dB

V

oo

Z

OUT

PSRR Power supply rejection ratio VDD= 2.5 V to 4.7 V -80 dB

Supply voltage range 2.5 3.6 5.5 V

SDZ = 0.35 V, VDD= 2.5 V 0.1 1

Shutdown quiescent current SDZ = 0.35 V, VDD= 3.6 V 0.2 1 µA

SDZ = 0.35 V, VDD= 5.5 V 0.3 1

SDZ = 1.3 V, VDD= 2.5 V 35 50

Software shutdown quiescent

current

SDZ = 1.3 V, VDD= 3.6 V 50 70 µA

SDZ = 1.3 V, VDD= 5.5 V 75 110

VDD= 2.5 V 3.5 4.5

Supply current VDD= 3.6 V 3.7 4.7 mA

VDD= 5.5 V 4.5 5.5

Class D switching frequency 275 300 325 kHz

High-level input current VDD= 5.5 V, SDZ = 5.8 V 1 µA

Low-level input current VDD= 5.5 V, SDZ = –0.3 V –1 µA

Start-up time 2.5 V ≤ VDD≤ 5.5 V no pop, CIN≤ 1 mF 5 ms

RL= 8 Ω, V

differential inputs shorted

Output offset voltage 2 10 mV

Output impedance in shutdown 2 kΩ

mode

VDD= 3.6 V, AV= 6 dB, RL= 8 Ω, inputs ac

grounded

SDZ = 0.35 V

= 0.5 V and V

icm

= VDD– 0.8 V,

icm

Gain accuracy Compression and limiter disabled, Gain = 0 to 30 dB –0.5 0.5 dB

4 Submit Documentation Feedback Copyright © 2010, Texas Instruments Incorporated

Product Folder Link(s): TPA2026D2

Page 5

TPA2026D2

IN+

IN–

OUT+

OUT–

V

DD

V

DD

GND

C

I

C

I

Measurement

Output

+

+

–

–

Load

30kHz

Low-Pass

Filter

Measurement

Input

+

–

1 Fm

TPA2026D2

www.ti.com

SLOS649 –MARCH 2010

OPERATING CHARACTERISTICS

at TA= 25°C, VDD= 3.6V, SDZ = 1.3 V, RL= 8 Ω +33 mH, and AV= 6 dB (unless otherwise noted).

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

k

SVR

THD+N Total harmonic distortion + noise

Nfo

Nfo

FR Frequency response Av = 6 dB 20 20000 Hz

Po

h Efficiency

Power-supply ripple rejection ratio VDD= 3.6 Vdc with ac of 200 mVPPat 217 Hz –68 dB

f

= 1 kHz, PO= 550 mW, VDD= 3.6 V 0.1%

aud_in

f

= 1 kHz, PO= 1 W, VDD= 5 V 0.1%

aud_in

f

= 1 kHz, PO= 630 mW, VDD= 3.6 V 1%

aud_in

f

= 1 kHz, PO= 1.4 W, VDD= 5 V 1%

aud_in

Output integrated noise Av = 6 dB 44 mV

nF

Output integrated noise Av = 6 dB floor, A-weighted 33 mV

A

THD+N = 10%, VDD= 5 V, RL= 8 Ω 1.72 W

Maximum output power

max

THD+N = 10%, VDD= 3.6 V, RL= 8 Ω 750 mW

THD+N = 1%, VDD= 5 V, RL= 8 Ω 1.4 W

THD+N = 1% , VDD= 3.6 V, RL= 8 Ω 630 mW

THD+N = 1%, VDD= 3.6 V, RL= 8 Ω, PO= 0.63 W 90%

THD+N = 1%, VDD= 5 V, RL= 8 Ω, PO= 1.4 W 90%

TEST SET-UP FOR GRAPHS

(1) All measurements were taken with a 1-mF CI(unless otherwise noted).

(2) A 33-mH inductor was placed in series with the load resistor to emulate a small speaker for efficiency measurements.

(3) The 30-kHz low-pass filter is required, even if the analyzer has an internal low-pass filter. An RC low-pass filter (1 kΩ

4.7 nF) is used on each output for the data sheet graphs.

Product Folder Link(s): TPA2026D2

Copyright © 2010, Texas Instruments Incorporated Submit Documentation Feedback 5

Page 6

SCL

SDA

t

w(H)

t

w(L)

t

su1

t

h1

SCL

SDA

t

h2

t

(buf)

t

su2

t

su3

StartCondition

StopCondition

TPA2026D2

SLOS649 –MARCH 2010

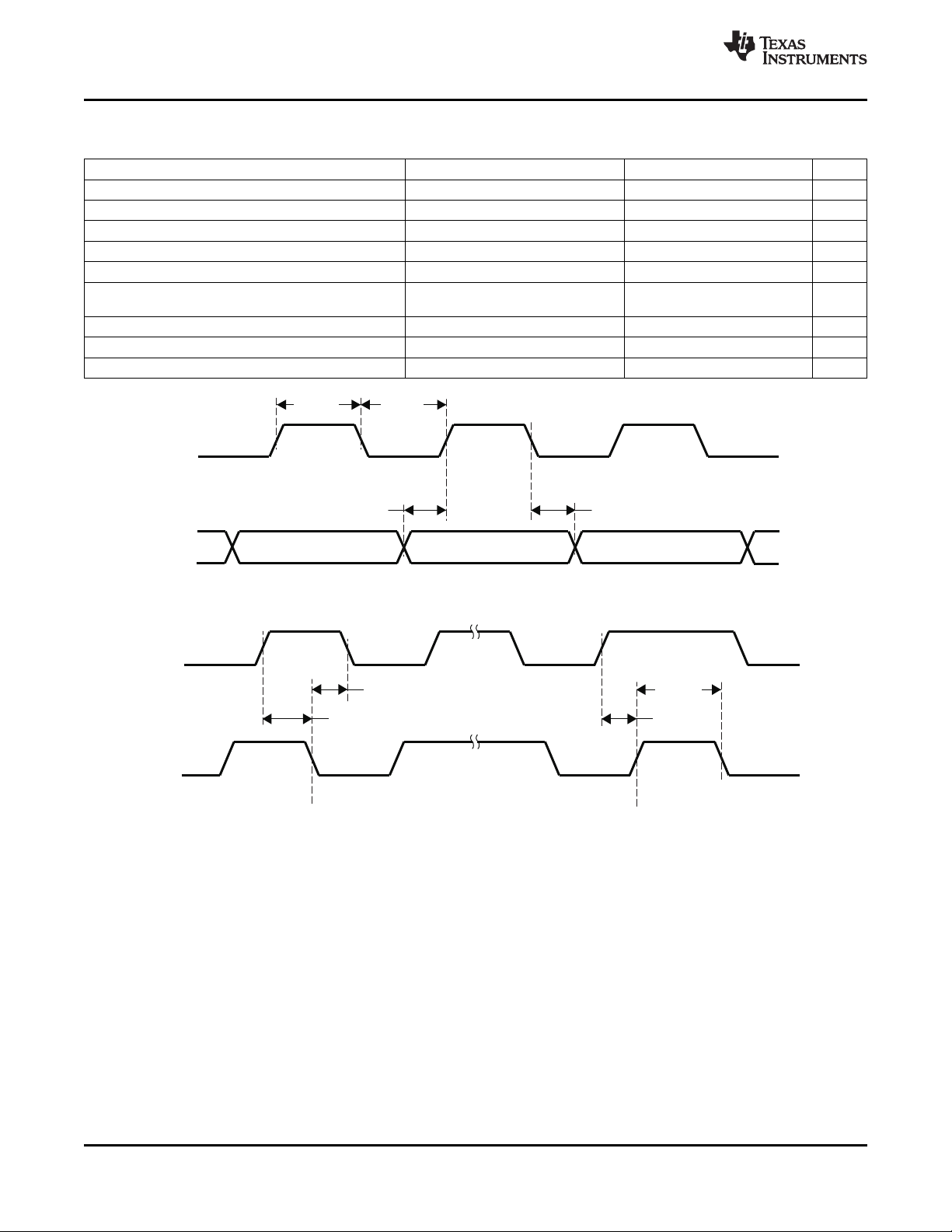

I2C TIMING CHARACTERISTICS

For I2C Interface Signals Over Recommended Operating Conditions (unless otherwise noted)

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

f

SCL

t

W(H)

t

W(L)

t

SU(1)

t

h1

t

(buf)

t

SU2

t

h2

t

SU3

Frequency, SCL No wait states 400 kHz

Pulse duration, SCL high 0.6 ms

Pulse duration, SCL low 1.3 ms

Setup time, SDA to SCL 100 ns

Hold time, SCL to SDA 10 ns

Bus free time between stop and start 1.3 ms

condition

Setup time, SCL to start condition 0.6 ms

Hold time, start condition to SCL 0.6 ms

Setup time, SCL to stop condition 0.6 ms

www.ti.com

Figure 1. SCL and SDA Timing

Figure 2. Start and Stop Conditions Timing

6 Submit Documentation Feedback Copyright © 2010, Texas Instruments Incorporated

Product Folder Link(s): TPA2026D2

Page 7

TPA2026D2

www.ti.com

SLOS649 –MARCH 2010

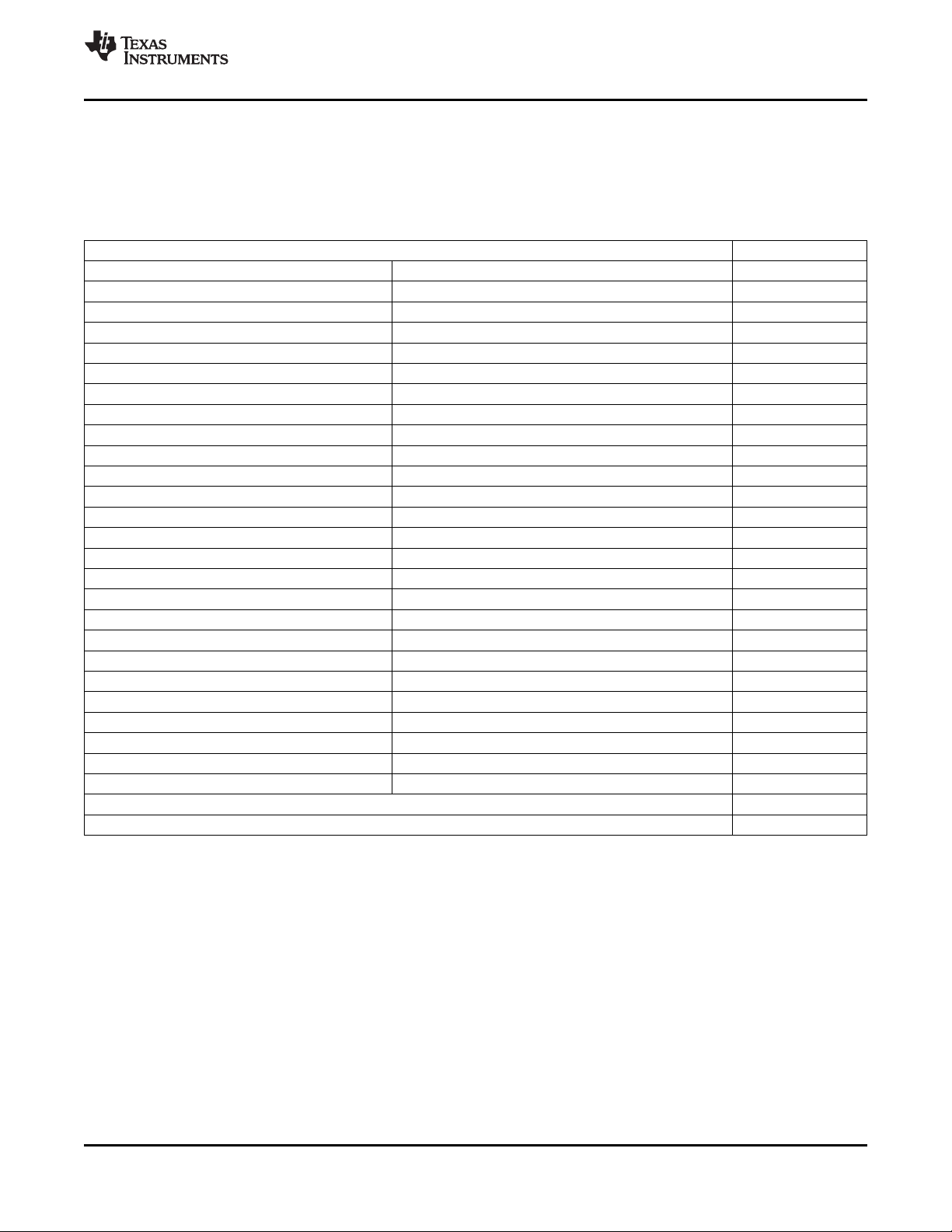

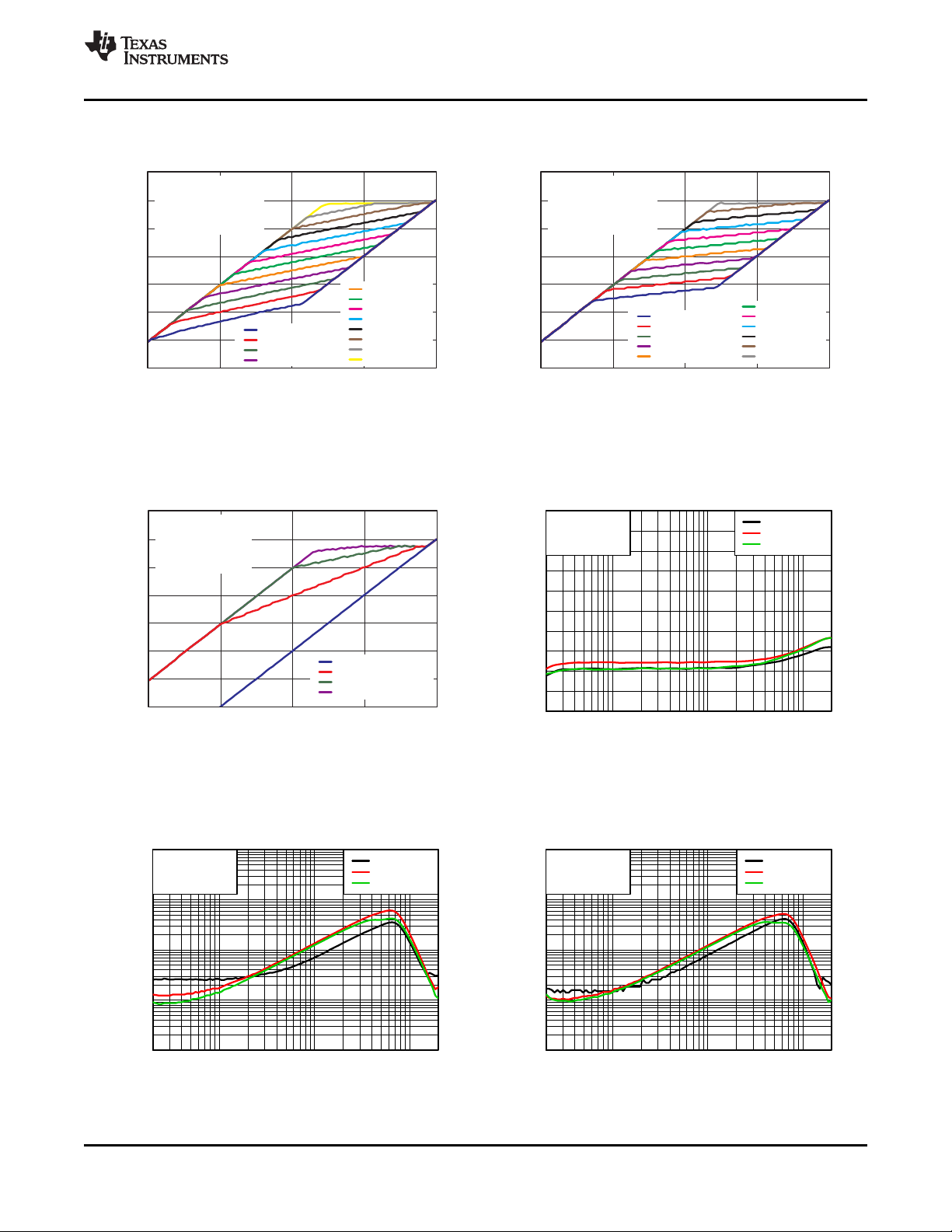

TYPICAL CHARACTERISTICS

with C

(DECOUPLE)

All THD + N graphs are taken with outputs out of phase (unless otherwise noted).

All data is taken on left channel.

= 1 mF, CI= 1 µF.

Table of Graphs

FIGURE

Quiescent supply current vs Supply voltage Figure 3

Supply current vs Supply voltage in shutdown Figure 4

Output level vs Input level Figure 5

Output level vs Input level Figure 6

Output level vs Input level Figure 7

Output level vs Input level Figure 8

Output level vs Input level Figure 9

Supply ripple rejection ratio vs Frequency, 8Ω Figure 10

Total harmonic distortion + noise vs Frequency Vsupply = 2.5V, 4Ω Figure 11

Total harmonic distortion + noise vs Frequency Vsupply = 2.5V, 8Ω Figure 12

Total harmonic distortion + noise vs Frequency Vsupply = 3.6V, 4Ω Figure 13

Total harmonic distortion + noise vs Frequency Vsupply = 3.6V, 8Ω Figure 14

Total harmonic distortion + noise vs Frequency Vsupply = 5.0V, 4Ω Figure 15

Total harmonic distortion + noise vs Frequency Vsupply = 5.0V, 8Ω Figure 16

Total harmonic distortion + noise vs Output power, 4Ω Figure 17

Total harmonic distortion + noise vs Output power, 8Ω Figure 18

Efficiency vs Output power (per channel), 4Ω Figure 19

Efficiency vs Output power (per channel), 8Ω Figure 20

Total power dissipation vs Total output power, 4Ω Figure 21

Total power dissipation vs Total output power, 8Ω Figure 22

Total supply current vs Total output power, 4Ω Figure 23

Total supply current vs Total output power, 8Ω Figure 24

Output power vs Supply voltage, 4Ω Figure 25

Output power vs Supply voltage, 8Ω Figure 26

TPA2026D2 vs TPA2016D2 Startup gain ramp Figure 27

TPA2026D2 vs TPA2016D2 Shutdown gain ramp Figure 28

Shutdown time Figure 29

Startup time Figure 30

Copyright © 2010, Texas Instruments Incorporated Submit Documentation Feedback 7

Product Folder Link(s): TPA2026D2

Page 8

VDD − Supply Voltage − V

0

2

4

6

8

10

2.5 3.5 4.5 5.5

I

DD

− Quiescent Supply Current − mA

G001

VDD − Supply Voltage − V

0

20

40

60

80

100

2.5 3.5 4.5 5.5

I

DD

− Supply Current − µA

G002

SDZ = 0 V

SDZ = VDD, SWS = 1

Input Level − dBV

−50

−40

−30

−20

−10

0

10

20

−40 −30 −20 −10 0 10

Output Level − dBV

G003

RL = 8 Ω + 33 µH

V

Supply

= 5 V

Fixed Gain = Max Gain = 30 dB

Compression Ratio = 1:1

Limiter Level = −6.5

Limiter Level = −4.5

Limiter Level = −2.5

Limiter Level = −0.5

Limiter Level = 1.5

Limiter Level = 3.5

Limiter Level = 5.5

Limiter Level = 7.5

Limiter Level = 9

Input Level − dBV

−50

−40

−30

−20

−10

0

10

20

−70 −50 −30 −10 10

Output Level − dBV

G004

Limiter Level = 9 dBV

RL = 8 Ω + 33 µH

V

Supply

= 5 V

Fixed Gain (2:1)

Compression Ratio = 2:1

Max Gain = 30 dB

Fixed Gain = −12

Fixed Gain = −9

Fixed Gain = −6

Fixed Gain = −3

Fixed Gain = 0

Fixed Gain = 3

Fixed Gain = 6

Fixed Gain = 9

Fixed Gain = 12

TPA2026D2

SLOS649 –MARCH 2010

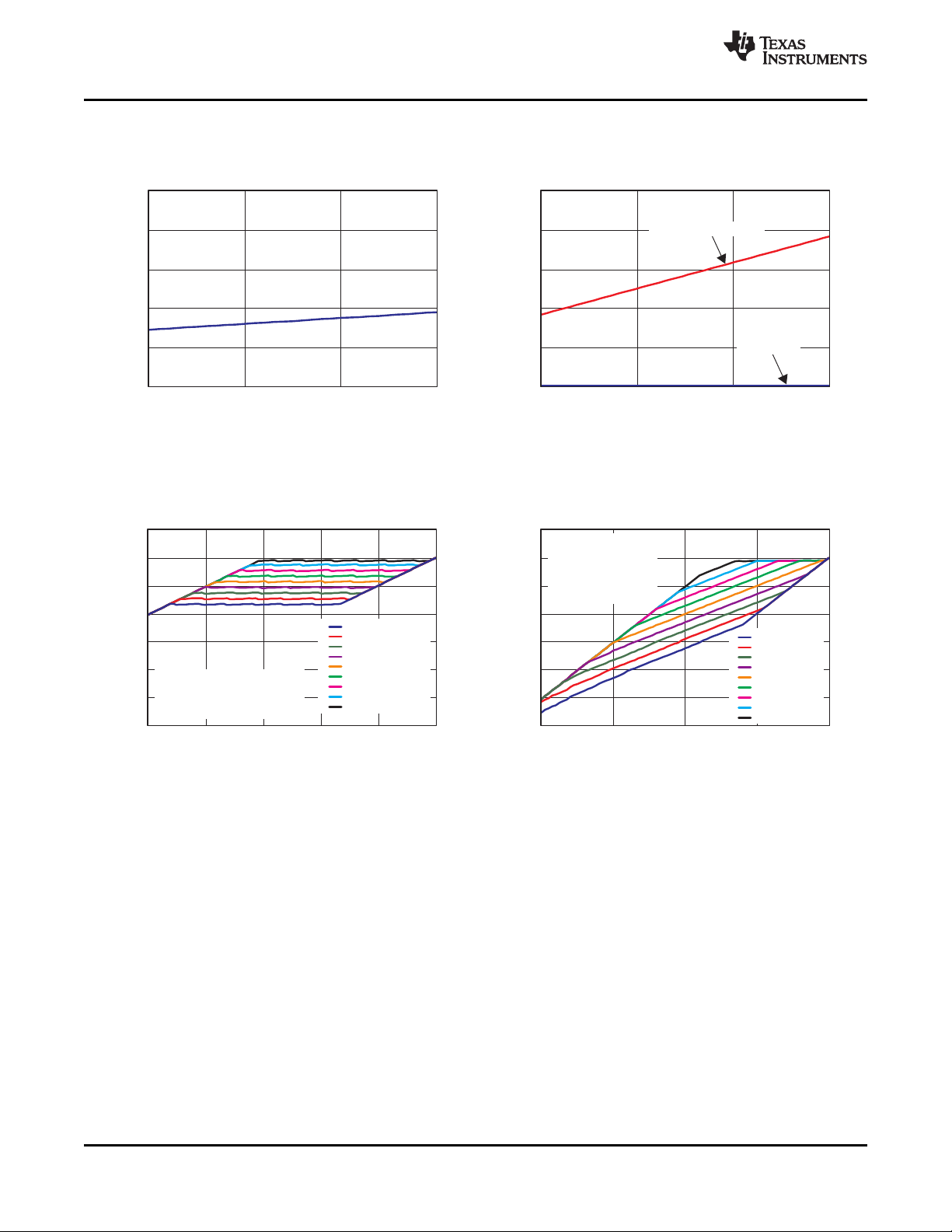

QUIESCENT SUPPLY CURRENT SUPPLY CURRENT

INPUT LEVEL WITH LIMITER ENABLED INPUT LEVEL WITH 2:1 COMPRESSION

www.ti.com

vs vs

SUPPLY VOLTAGE SUPPLY VOLTAGE IN SHUTDOWN

Figure 3. Figure 4.

OUTPUT LEVEL OUTPUT LEVEL

vs vs

Figure 5. Figure 6.

8 Submit Documentation Feedback Copyright © 2010, Texas Instruments Incorporated

Product Folder Link(s): TPA2026D2

Page 9

Input Level − dBV

−50

−40

−30

−20

−10

0

10

20

−70 −50 −30 −10 10

Output Level − dBV

G005

Limiter Level = 9 dBV

RL = 8 Ω + 33 µH

V

Supply

= 5 V

Compression Ratio = 4:1

Max Gain = 30 dB

Fixed Gain = −15

Fixed Gain = −12

Fixed Gain = −9

Fixed Gain = −6

Fixed Gain = −3

Fixed Gain = 0

Fixed Gain = 3

Fixed Gain = 6

Fixed Gain = −27

Fixed Gain = −24

Fixed Gain = −21

Fixed Gain = −18

Input Level − dBV

−50

−40

−30

−20

−10

0

10

20

−70 −50 −30 −10 10

Output Level − dBV

G006

Limiter Level = 9 dBV

RL = 8 Ω + 33 µH

V

Supply

= 5 V

Compression Ratio = 8:1

Max Gain = 30 dB

Fixed Gain = −12

Fixed Gain = −9

Fixed Gain = −6

Fixed Gain = −3

Fixed Gain = 0

Fixed Gain = 3

Fixed Gain = −27

Fixed Gain = −24

Fixed Gain = −21

Fixed Gain = −18

Fixed Gain = −15

f − Frequency − Hz

K

SVR

− Supply Ripple Rejection Ratio − dB

20 100 1k 10k 20k

−100

−80

−60

−40

−20

0

V

Supply

= 2.5 V

V

Supply

= 3.6 V

V

Supply

= 5.0 V

Gain = 6 dB

RL = 8 Ω + 33 µH

Left Channel

Input Level − dBV

−50

−40

−30

−20

−10

0

10

20

−70 −50 −30 −10 10

Output Level − dBV

G007

Compression Ratio = 1:1

Compression Ratio = 2:1

Compression Ratio = 4:1

Compression Ratio = 8:1

Limiter Level = 9 dBV

RL = 8 Ω + 33 µH

V

Supply

= 5 V

Fixed Gain = 0 dB

Max Gain = 30 dB

f − Frequency − Hz

THD+N − Total Harmonic Distortion + Noise − %

20 100 1k 10k 20k

0.001

0.01

0.1

1

10

PO = 25 mW

PO = 125 mW

PO = 300 mW

Gain = 6 dB

RL = 4 Ω + 33 µH

V

Supply

= 2.5 V

f − Frequency − Hz

THD+N − Total Harmonic Distortion + Noise − %

20 100 1k 10k 20k

0.001

0.01

0.1

1

10

PO = 25 mW

PO = 125 mW

PO = 200 mW

Gain = 6 dB

RL = 8 Ω + 33 µH

V

Supply

= 2.5 V

TPA2026D2

www.ti.com

SLOS649 –MARCH 2010

OUTPUT LEVEL OUTPUT LEVEL

vs vs

INPUT LEVEL WITH 4:1 COMPRESSION INPUT LEVEL WITH 8:1 COMPRESSION

Figure 7. Figure 8.

OUTPUT LEVEL SUPPLY RIPPLE REJECTION RATIO

vs vs

INPUT LEVEL FREQUENCY, 8Ω

Figure 9. Figure 10.

TOTAL HARMONIC DISTORTION + NOISE TOTAL HARMONIC DISTORTION + NOISE

FREQUENCY Vsupply = 2.5V, 4Ω FREQUENCY Vsupply = 2.5V, 8Ω

Copyright © 2010, Texas Instruments Incorporated Submit Documentation Feedback 9

Figure 11. Figure 12.

vs vs

Product Folder Link(s): TPA2026D2

Page 10

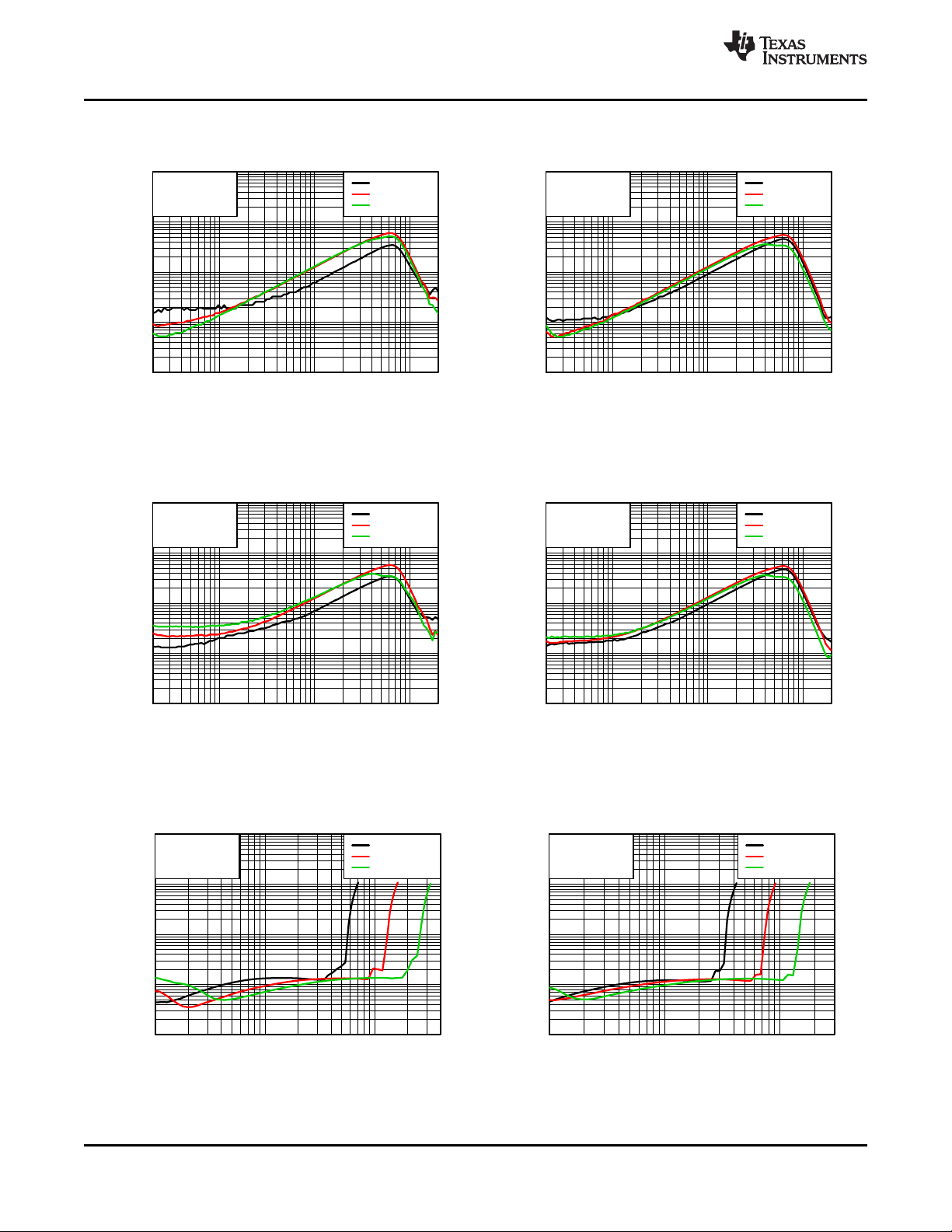

f − Frequency − Hz

THD+N − Total Harmonic Distortion + Noise − %

20 100 1k 10k 20k

0.001

0.01

0.1

1

10

PO = 50 mW

PO = 250 mW

PO = 700 mW

Gain = 6 dB

RL = 4 Ω + 33 µH

V

Supply

= 3.6 V

f − Frequency − Hz

THD+N − Total Harmonic Distortion + Noise − %

20 100 1k 10k 20k

0.001

0.01

0.1

1

10

PO = 50 mW

PO = 250 mW

PO = 500 mW

Gain = 6 dB

RL = 8 Ω + 33 µH

V

Supply

= 3.6 V

f − Frequency − Hz

THD+N − Total Harmonic Distortion + Noise − %

20 100 1k 10k 20k

0.001

0.01

0.1

1

10

PO = 100 mW

PO = 500 mW

PO = 1.75 W

Gain = 6 dB

RL = 4 Ω + 33 µH

V

Supply

= 5.0 V

f − Frequency − Hz

THD+N − Total Harmonic Distortion + Noise − %

20 100 1k 10k 20k

0.001

0.01

0.1

1

10

PO = 100 mW

PO = 500 mW

PO = 1 W

Gain = 6 dB

RL = 8 Ω + 33 µH

V

Supply

= 5.0 V

PO − Output Power (Per Channel) − W

THD+N − Total Harmonic Distortion + Noise − %

10m 100m 1 4

0.01

0.1

1

10

100

V

Supply

= 2.5 V

V

Supply

= 3.6 V

V

Supply

= 5.0 V

Gain = 6 dB

RL = 4 Ω + 33 µH

f = 1 kHz

PO − Output Power (Per Channel) − W

THD+N − Total Harmonic Distortion + Noise − %

10m 100m 1 3

0.01

0.1

1

10

100

V

Supply

= 2.5 V

V

Supply

= 3.6 V

V

Supply

= 5.0 V

Gain = 6 dB

RL = 8 Ω + 33 µH

f = 1 kHz

TPA2026D2

SLOS649 –MARCH 2010

TOTAL HARMONIC DISTORTION + NOISE TOTAL HARMONIC DISTORTION + NOISE

FREQUENCY Vsupply = 3.6V, 4Ω FREQUENCY Vsupply = 3.6V, 8Ω

TOTAL HARMONIC DISTORTION + NOISE TOTAL HARMONIC DISTORTION + NOISE

FREQUENCY Vsupply = 5.0V, 4Ω FREQUENCY Vsupply = 5.0V, 8Ω

www.ti.com

vs vs

Figure 13. Figure 14.

vs vs

Figure 15. Figure 16.

TOTAL HARMONIC DISTORTION + NOISE TOTAL HARMONIC DISTORTION + NOISE

POWER, 4Ω POWER, 8Ω

Figure 17. Figure 18.

10 Submit Documentation Feedback Copyright © 2010, Texas Instruments Incorporated

vs vs

Product Folder Link(s): TPA2026D2

Page 11

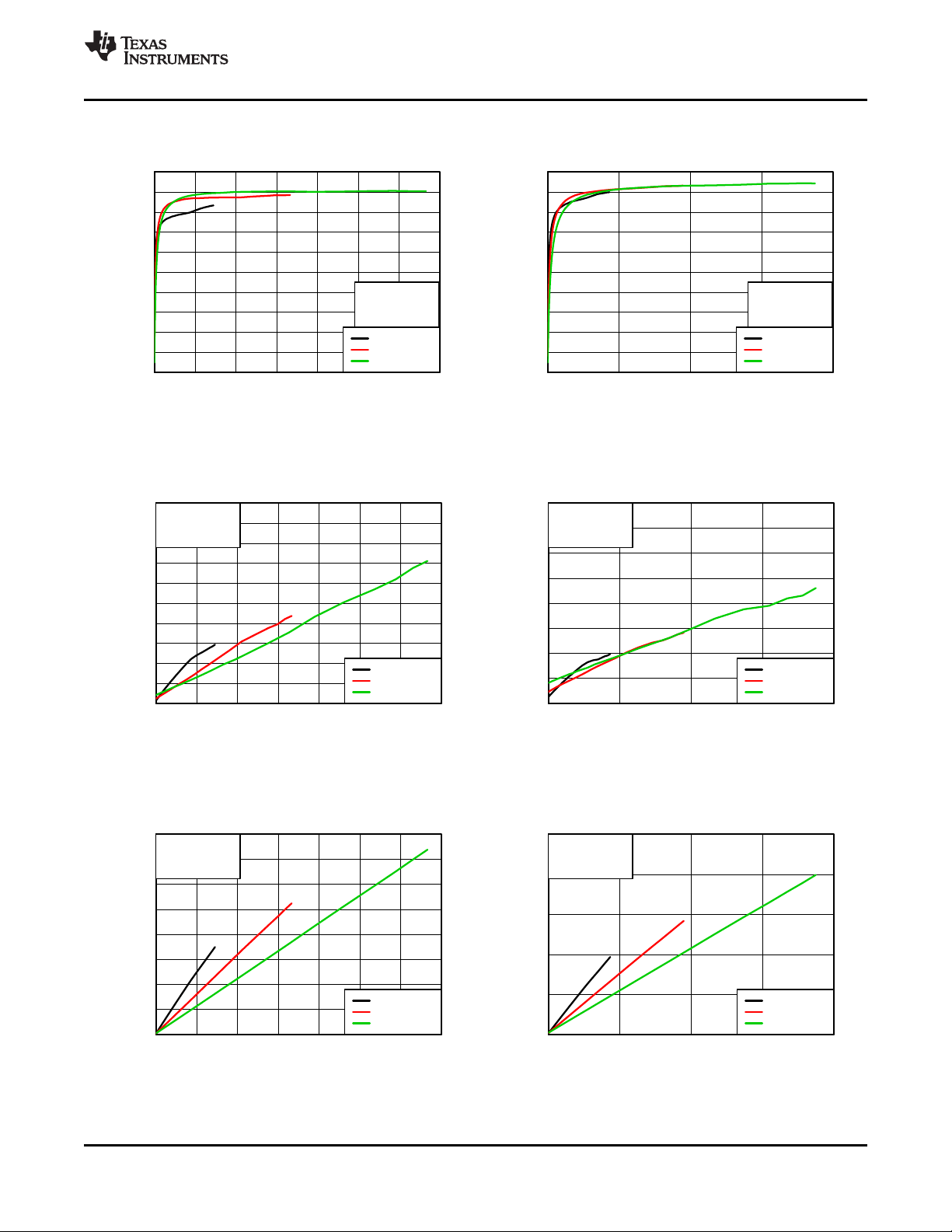

PO − Output Power (Per Channel) − W

Efficiency − %

0.0 0.5 1.0 1.5 2.0 2.5 3.0 3.5

0

20

40

60

80

100

V

Supply

= 2.5 V

V

Supply

= 3.6 V

V

Supply

= 5.0 V

Gain = 6 dB

RL = 4 Ω + 33 µH

f = 1 kHz

PO − Output Power (Per Channel) − W

Efficiency − %

0.0 0.5 1.0 1.5 2.0

0

20

40

60

80

100

V

Supply

= 2.5 V

V

Supply

= 3.6 V

V

Supply

= 5.0 V

Gain = 6 dB

RL = 8 Ω + 33 µH

f = 1 kHz

PO − Total Output Power − W

P

D

− Total Power Dissipation − W

0 1 2 3 4 5 6 7

0.0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1.0

V

Supply

= 2.5 V

V

Supply

= 3.6 V

V

Supply

= 5.0 V

Gain = 6 dB

RL = 4 Ω + 33 µH

f = 1 kHz

PO − Total Output Power − W

P

D

− Total Power Dissipation − W

0 1 2 3 4

0.0

0.1

0.2

0.3

0.4

V

Supply

= 2.5 V

V

Supply

= 3.6 V

V

Supply

= 5.0 V

Gain = 6 dB

RL = 8 Ω + 33 µH

f = 1 kHz

PO − Total Output Power − W

I

DD

− Total Supply Current − A

0 1 2 3 4 5 6 7

0.0

0.2

0.4

0.6

0.8

1.0

1.2

1.4

1.6

V

Supply

= 2.5 V

V

Supply

= 3.6V

V

Supply

= 5.0 V

Gain = 6 dB

RL = 4 Ω + 33 µH

f = 1 kHz

PO − Total Output Power − W

I

DD

− Total Supply Current − A

0 1 2 3 4

0.0

0.2

0.4

0.6

0.8

1.0

V

Supply

= 2.5 V

V

Supply

= 3.6V

V

Supply

= 5.0 V

Gain = 6 dB

RL = 8 Ω + 33 µH

f = 1 kHz

TPA2026D2

www.ti.com

SLOS649 –MARCH 2010

EFFICIENCY EFFICIENCY

vs vs

OUTPUT POWER (PER CHANNEL), 4Ω OUTPUT POWER (PER CHANNEL), 8Ω

Figure 19. Figure 20.

TOTAL POWER DISSIPATION TOTAL POWER DISSIPATION

vs vs

TOTAL OUTPUT POWER, 4Ω TOTAL OUTPUT POWER, 8Ω

Figure 21. Figure 22.

TOTAL SUPPLY CURRENT TOTAL SUPPLY CURRENT

TOTAL OUTPUT POWER, 4Ω TOTAL OUTPUT POWER, 8Ω

Copyright © 2010, Texas Instruments Incorporated Submit Documentation Feedback 11

Figure 23. Figure 24.

vs vs

Product Folder Link(s): TPA2026D2

Page 12

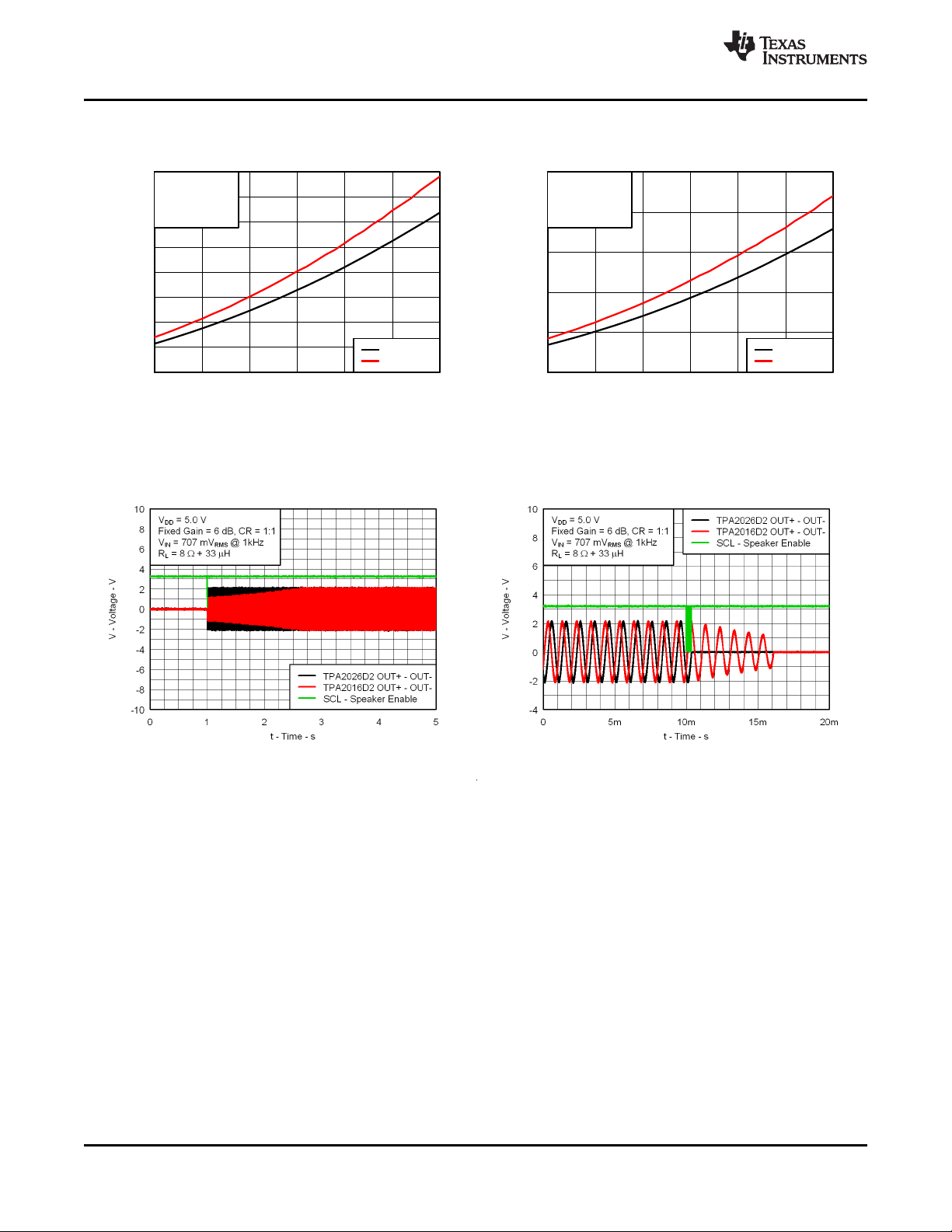

Vsupply − Supply Voltage − V

P

O

− Output Power − W

2.5 3.0 3.5 4.0 4.5 5.0 5.5

0.0

0.5

1.0

1.5

2.0

2.5

3.0

3.5

4.0

THD = 1%

THD = 10%

f = 1 kHz

Gain = 6 dB

RL = 4 Ω + 33 µH

WCSP

Vsupply − Supply Voltage − V

P

O

− Output Power − W

2.5 3.0 3.5 4.0 4.5 5.0 5.5

0.0

0.5

1.0

1.5

2.0

2.5

THD = 1%

THD = 10%

f = 1 kHz

Gain = 6 dB

RL = 8 Ω + 33 µH

WCSP

TPA2026D2

SLOS649 –MARCH 2010

TPA2016D2 STARTUP GAIN RAMP TPA2016D2 SHUTDOWN GAIN RAMP

www.ti.com

OUTPUT POWER OUTPUT POWER

vs vs

SUPPLY VOLTAGE, 4Ω SUPPLY VOLTAGE, 8Ω

Figure 25. Figure 26.

TPA2026D2 TPA2026D2

vs vs

Figure 27. Figure 28.

12 Submit Documentation Feedback Copyright © 2010, Texas Instruments Incorporated

Product Folder Link(s): TPA2026D2

Page 13

1

0.5

0.75

0.25

0

-0.25

-0.5

-0.75

-1

0 400m200m 600m 800m 1m 1.2m 1.6m1.4m 1.8m 2m

t-Time-s

Voltage-V

Output

SWS

Disable

1

0.5

0.75

0.25

0

-0.25

-0.5

-0.75

-1

0 2m1m 3m 4m 5m 6m 8m7m 9m 10m

t-Time-s

Voltage-V

Output

SWSEnable

TPA2026D2

www.ti.com

SLOS649 –MARCH 2010

Figure 29. Shutdown Time

Figure 30. Startup Time

Copyright © 2010, Texas Instruments Incorporated Submit Documentation Feedback 13

Product Folder Link(s): TPA2026D2

Page 14

TPA2026D2

SLOS649 –MARCH 2010

www.ti.com

APPLICATION INFORMATION

AUTOMATIC GAIN CONTROL

The Automatic Gain Control (AGC) feature provides continuous automatic gain adjustment to the amplifier

through an internal PGA. This feature enhances the perceived audio loudness and at the same time prevents

speaker damage from occurring (Limiter function).

The AGC function attempts to maintain the audio signal gain as selected by the user through the Fixed Gain,

Limiter Level, and Compression Ratio variables. Other advanced features included are Maximum Gain and Noise

Gate Threshold. Table 1 describes the function of each variable in the AGC function.

Table 1. TPA2026D2 AGC Variable Descriptions

VARIABLE DESCRIPTION

Maximum Gain The gain at the lower end of the compression region.

Fixed Gain The normal gain of the device when the AGC is inactive.

The fixed gain is also the initial gain when the device comes out of shutdown mode or when the AGC is

disabled.

Limiter Level The value that sets the maximum allowed output amplitude.

Compression Ratio The relation between input and output voltage.

Noise Gate Threshold Below this value, the AGC holds the gain to prevent breathing effects.

Attack Time The minimum time between two gain decrements.

Release Time The minimum time between two gain increments.

Hold Time The time it takes for the very first gain increment after the input signal amplitude decreases.

14 Submit Documentation Feedback Copyright © 2010, Texas Instruments Incorporated

Product Folder Link(s): TPA2026D2

Page 15

ReleaseTime

E

Limiterthreshold

GAIN

A

C

B

D

AttackTime

Limiterthreshold

Limiterthreshold

HoldTime

INPUTSIGNAL

OUTPUTSIGNAL

Limiterthreshold

TPA2026D2

www.ti.com

SLOS649 –MARCH 2010

The AGC works by detecting the audio input envelope. The gain changes depending on the amplitude, the limiter

level, the compression ratio, and the attack and release time. The gain changes constantly as the audio signal

increases and/or decreases to create the compression effect. The gain step size for the AGC is 0.5 dB. If the

audio signal has near-constant amplitude, the gain does not change. Figure 31 shows how the AGC works.

A. Gain decreases with no delay; attack time is reset. Release time and hold time are reset.

B. Signal amplitude above limiter level, but gain cannot change because attack time is not over.

C. Attack time ends; gain is allowed to decrease from this point forward by one step. Gain decreases because the

amplitude remains above limiter threshold. All times are reset

D. Gain increases after release time finishes and signal amplitude remains below desired level. All times are reset after

the gain increase.

E. Gain increases after release time is finished again because signal amplitude remains below desired level. All times

are reset after the gain increase.

Figure 31. Input and Output Audio Signal vs Time

Since the number of gain steps is limited the compression region is limited as well. The following figure shows

how the gain changes vs. the input signal amplitude in the compression region.

Copyright © 2010, Texas Instruments Incorporated Submit Documentation Feedback 15

Product Folder Link(s): TPA2026D2

Page 16

Gain-dB

V -dBV

IN

V -dBV

OUT

V -dBV

IN

Increasing

FixedGain

Decreasing

FixedGain

FixedGain=6dB

FixedGain=3dB

1:1

TPA2026D2

SLOS649 –MARCH 2010

www.ti.com

Figure 32. Input Signal Voltage vs Gain

Thus the AGC performs a mapping of the input signal vs. the output signal amplitude. This mapping can be

modified according to the variables from Table 1.

The following graphs and explanations show the effect of each variable to the AGC independently and which

considerations should be taken when choosing values.

Fixed Gain: The fixed gain determines the initial gain of the AGC. Set the gain using the following variables:

• Set the fixed gain to be equal to the gain when the AGC is disabled.

• Set the fixed gain to maximize SNR.

• Set the fixed gain such that it will not overdrive the speaker.

Figure 33 shows how the fixed gain influences the input signal amplitude vs. the output signal amplitude state

diagram. The dotted 1:1 line is displayed for reference. The 1:1 line means that for a 1dB increase in the input

signal, the output increases by 1dB.

Figure 33. Output Signal vs Input Signal State Diagram Showing Different Fixed Gain Configurations

If the Compression function is enabled, the Fixed Gain is adjustable from –28dB to 30dB. If the Compression

function is disabled, the Fixed gain is adjustable from 0dB to 30dB.

Limiter Level: The Limiter level sets the maximum amplitude allowed at the output of the amplifier. The limiter

should be set with the following constraints in mind:

• Below or at the maximum power rating of the speaker

• Below the minimum supply voltage in order to avoid clipping

Figure 34 shows how the limiter level influences the input signal amplitude vs. the output signal amplitude state

diagram.

16 Submit Documentation Feedback Copyright © 2010, Texas Instruments Incorporated

Product Folder Link(s): TPA2026D2

Page 17

V -dBV

OUT

V -dBV

IN

Increasing

Limiter

Level

Decreasing

Limiter

Level

LimiterLevel= 500 mW

LimiterLevel= 630 mW

= 400LimiterLevel mW

V -dBV

OUT

V -dBV

IN

1:1

LargeFixedGain

Small

Fixed

Gain

Input signal initial amplitude - |Current input signal amplitude|

Output signal amplitude =

Compression ratio

0dBV | 32 dBV|

8dBV =

4

- -

-

TPA2026D2

www.ti.com

SLOS649 –MARCH 2010

Figure 34. Output Signal vs Input Signal State Diagram Showing Different Limiter Level Configurations

The limiter level and the fixed gain influence each other. If the fixed gain is set high, the AGC has a large limiter

range. The fixed gain is set low, the AGC has a short limiter range. Figure 35 illustrates the two examples:

Figure 35. Output Signal vs Input Signal State Diagram Showing Same Limiter Level Configurations with

Compression Ratio: The compression ratio sets the relation between input and output signal outside the limiter

level region. The compression ratio compresses the dynamic range of the audio. For example if the audio source

has a dynamic range of 60dB and compression ratio of 2:1 is selected, then the output has a dynamic range of

30dB. Most small form factor speakers have small dynamic range. Compression ratio allows audio with large

dynamic range to fit into a speaker with small dynamic range.

The compression ratio also increases the loudness of the audio without increasing the peak voltage. The higher

the compression ratio, the louder the perceived audio.

For example:

• A compression ratio of 4:1 is selected (meaning that a 4dB change in the input signal results in a 1dB signal

change at the output)

• A fixed gain of 0dB is selected and the maximum audio level is at 0dBV.

When the input signal decreases to –32dBV, the amplifier increases the gain to 24dB in order to achieve an

output of –8dBV. The output signal amplitude equation is:

In this example:

Copyright © 2010, Texas Instruments Incorporated Submit Documentation Feedback 17

Different Fixed Gain Configurations

Product Folder Link(s): TPA2026D2

(1)

(2)

Page 18

1

Gain change = 1 × Input signal change

Compression ratio

æ ö

-

ç ÷

è ø

1

24 dB = 1 × 32

4

æ ö

-

ç ÷

è ø

V -dBV

OUT

V -dBV

IN

Increasing

FixedGain

Decreasing

1 :1

2

:

1

4

:

1

8

:

1

1 :1

2

:

1

4

:

1

8

:

1

Rotation

Point@

lowergain

Rotation

Point@

highergain

TPA2026D2

SLOS649 –MARCH 2010

The gain change equation is:

Consider the following when setting the compression ratio:

• Dynamic range of the speaker

• Fixed gain level

• Limiter Level

• Audio Loudness vs Output Dynamic Range.

Figure 36 shows different settings for dynamic range and different fixed gain selected but no limiter level.

www.ti.com

(3)

(4)

Figure 36. Output Signal vs Input Signal State Diagram Showing Different Compression Ratio

The rotation point is always at VIN= 10dBV. The rotation point is not located at the intersection of the limiter

region and the compression region. By changing the fixed gain the rotation point will move in the y-axis direction

only, as shown in the previous graph.

Interaction Between Compression Ratio and Limiter Range: The compression ratio can be limited by the

limiter range. Note that the limiter range is selected by the limiter level and the fixed gain.

For a setting with large limiter range, the amount of gain steps in the AGC remaining to perform compression are

limited. Figure 37 shows two examples, where the fixed gain was changed.

1. Small limiter range yielding a large compression region (small fixed gain).

2. Large limiter range yielding a small compression region (large fixed gain).

18 Submit Documentation Feedback Copyright © 2010, Texas Instruments Incorporated

Configurations with Different Fixed Gain Configurations

Product Folder Link(s): TPA2026D2

Page 19

V

OUT

-dBV

V - dBV

IN

1:1

Large Limiter

Range

Small

Compression

Region

Large

Compression

Region

Small Limiter

Range

Rotation

Point @

lower gain

Rotation

Point @

higher gain

time

Gain-dB

InputSignal

Amplitude-Vrms

time

NoiseGateThreshold

No

Audio

Gaindoesnotchange

inthisregion

TPA2026D2

www.ti.com

SLOS649 –MARCH 2010

Figure 37. Output Signal vs Input Signal State Diagram Showing the Effects of the Limiter Range to the

Compression Region

Noise Gate Threshold: The noise gate threshold prevents the AGC from changing the gain when there is no

audio at the input of the amplifier. The noise gate threshold stops gain changes until the input signal is above the

noise gate threshold. Select the noise gate threshold to be above the noise but below the minimum audio at the

input of the amplifier signal. A filter is needed between delta-sigma CODEC/DAC and TPA2026D2 for

effectiveness of the noise gate function. The filter eliminates the out-of-band noise from delta-sigma modulation

and keeps the CODEC/DAC output noise lower than the noise gate threshold.

Figure 38. Time Diagram Showing the Relationship Between Input Signal Amplitude, Noise Gate

Maximum Gain: This variable limits the number of gain steps in the AGC. This feature is useful in order to

accomplish a more advanced output signal vs. input signal transfer characteristic.

For example, to prevent the gain from going above a certain value, reduce the maximum gain.

However, this variable will affect the limiter range and the compression region. If the maximum gain is

decreased, the limiter range and/or compression region is reduced. Figure 39 illustrates the effects.

Copyright © 2010, Texas Instruments Incorporated Submit Documentation Feedback 19

Threshold, and Gain Versus Time

Product Folder Link(s): TPA2026D2

Page 20

V -dBV

OUT

V -dBV

IN

MaxGain

= 22dB

MaxGain

= 30dB

1:1

TPA2026D2

SLOS649 –MARCH 2010

www.ti.com

Figure 39. Output Signal vs Input Signal State Diagram Showing Different Maximum Gains

A particular application requiring maximum gain of 22dB, for example. Thus, set the maximum gain at 22dB. The

amplifier gain will never have a gain higher than 22dB; however, this will reduce the limiter range.

Attack, Release, and Hold Time:

• The attack time is the minimum time between gain decreases.

• The release time is the minimum time between gain increases.

• The hold time is the minimum time between a gain decrease (attack) and a gain increase (release). The hold

time can be deactivated. Hold time is only valid if greater than release time.

Successive gain decreases are never faster than the attack time. Successive gain increases are never faster

than the release time.

All time variables (attack, release and hold) start counting after each gain change performed by the AGC. The

AGC is allowed to decrease the gain (attack) only after the attack time finishes. The AGC is allowed to increase

the gain (release) only after the release time finishes counting. However, if the preceding gain change was an

attack (gain increase) and the hold time is enabled and longer than the release time, then the gain is only

increased after the hold time.

The hold time is only enabled after a gain decrease (attack). The hold time replaces the release time after a gain

decrease (attack). If the gain needs to be increased further, then the release time is used. The release time is

used instead of the hold time if the hold time is disabled.

The attack time should be at least 100 times shorter than the release and hold time. The hold time should be the

same or greater than the release time. It is important to select reasonable values for those variables in order to

prevent the gain from changing too often or too slow.

Figure 40 illustrates the relationship between the three time variables.

20 Submit Documentation Feedback Copyright © 2010, Texas Instruments Incorporated

Product Folder Link(s): TPA2026D2

Page 21

InputSignal

Amplitue(Vrms)

GaindB

Attacktime

Releasetime

Timereset

Timeend

Holdtime

time

Holdtimernotusedafter

firstgainincrease

1

:

1

2:1

1:1

Noise Gate Threshold

Maximum

Gain

Fixed

Gain

Limiter

Level

Compression Region

Attack Time

R

e

l

e

a

s

e

T

im

e

4:1

8:1

10dBV

Rotation

Point

V

OUT

-dBV

V - dBV

IN

¥:1

TPA2026D2

www.ti.com

SLOS649 –MARCH 2010

Figure 40. Time Diagram Showing the Relation Between the Attack, Release, and Hold Time vs Input

Signal Amplitude and Gain

Figure 41 shows a state diagram of the input signal amplitude vs. the output signal amplitude and a summary of

how the variables from Table 1 described in the preceding pages affect them.

Copyright © 2010, Texas Instruments Incorporated Submit Documentation Feedback 21

Figure 41. Output Signal vs Input Signal State Diagram

Product Folder Link(s): TPA2026D2

Page 22

TPA2026D2

SLOS649 –MARCH 2010

www.ti.com

TPA2026D2 AGC OPERATION

The TPA2026D2 is controlled by the I2C interface. The correct start-up sequence is:

1. Apply the supply voltage to the AVDDand PVDD(L, R) pins.

2. Apply a voltage above VIHto the SDZ pin. The TPA2026D2 powers up the I2C interface and the control logic.

By default, the device is in active mode (SWS = 0). After 5 ms the amplifier will enable the class-D output

stage and become fully operational.

AGC STARTUP CONDITION

The amplifier gain at start-up depends on the following conditions:

1. Start-up from hardware reset (EN from 0 to 1): The amplifier starts up immediately at default fixed gain. AGC

starts controlling gain once the input audio signal exceeds noise gate threshold.

2. Start-up from software shutdown (SWS from 1 to 0): The amplifier starts up immediately at the latest fixed

gain during software shutdown, regardless the attack/ release time. For example:

– Audio is playing at fixed gain 6dB

– Devices goes to software shutdown (SWS = 1)

– Set fixed gain from 6 dB to 12 dB

– Remove software shutdown (SWS = 0)

– Amplifier starts up immediately at 12 dB

3. During audio playback with AGC on, gain changes according to attack/ release time. For example:

– Audio is playing at fixed gain 6 dB and 1:1 compression ratio

– Set fixed gain from 6 dB to 12 dB, at release time 500 ms / 6 dB

– Amplifier will take 500 ms to ramp from 6 dB to 12 dB

4. When SPKR_EN_R = 0, SPKR_EN_L = 0 and SWS = 0, the amplifier is set at fixed gain. The amplifier will

start up at fixed gain when either SPKR_EN_R and SPKR_EN_L transitions from 0 to 1.

CAUTION

Do not interrupt the start-up sequence after changing SDZ from VILto VIH.

Do not interrupt the start-up sequence after changing SWS from 1 to 0.

The default conditions of TPA2026D2 allows audio playback without I2C control. Refer to Table 4 for the entire

default conditions.

There are several options to disable the amplifier:

• Write SPK_EN_R = 0 and SPK_EN_L = 0 to the register (0x01, 6 and 0x01, 7). This write disables each

speaker amplifier, but leaves all other circuits operating.

• Write SWS = 1 to the register (0x01, 5). This action disables most of the amplifier functions.

• Apply VILto SDZ. This action shuts down all the circuits and has very low quiescent current consumption.

This action resets the registers to its default values.

CAUTION

Do not interrupt the shutdown sequence after changing SDZ from VIHto VIL.

Do not interrupt the shutdown sequence after changing SWS from 0 to 1.

22 Submit Documentation Feedback Copyright © 2010, Texas Instruments Incorporated

Product Folder Link(s): TPA2026D2

Page 23

Register(N)

8-BitDatafor 8-BitDatafor

Register(N+1)

TPA2026D2

www.ti.com

SLOS649 –MARCH 2010

TPA2026D2 AGC RECOMMENDED SETTINGS

Table 2. Recommended AGC Settings for Different Types of Audio Source (VDD= 3.6 V)

AUDIO COMPRESSION ATTACK TIME RELEASE TIME HOLD TIME FIXED GAIN LIMITER LEVEL

SOURCE RATIO (ms/6 dB) (ms/6 dB) (ms) (dB) (dBV)

Pop Music 4:1 1.28 to 3.84 986 to 1640 137 6 7.5

Classical 2:1 2.56 1150 137 6 8

Jazz 2:1 5.12 to 10.2 3288 — 6 8

Rap/Hip Hop 4:1 1.28 to 3.84 1640 — 6 7.5

Rock 2:1 3.84 4110 — 6 8

Voice/News 4:1 2.56 1640 — 6 8.5

GENERAL I2C OPERATION

The I2C bus employs two signals, SDA (data) and SCL (clock), to communicate between integrated circuits in a

system. The bus transfers data serially one bit at a time. The address and data 8-bit bytes are transferred most

significant bit (MSB) first. In addition, each byte transferred on the bus is acknowledged by the receiving device

with an acknowledge bit. Each transfer operation begins with the master device driving a start condition on the

bus and ends with the master device driving a stop condition on the bus. The bus uses transitions on the data

terminal (SDA) while the clock is at logic high to indicate start and stop conditions. A high-to-low transition on

SDA indicates a start and a low-to-high transition indicates a stop. Normal data-bit transitions must occur within

the low time of the clock period. Figure 42 shows a typical sequence. The master generates the 7-bit slave

address and the read/write (R/W) bit to open communication with another device, and then waits for an

acknowledge condition. The TPA2026D2 holds SDA low during the acknowledge clock period to indicate

acknowledgment. When this acknowledgment occurs, the master transmits the next byte of the sequence. Each

device is addressed by a unique 7-bit slave address plus R/W bit (1 byte). All compatible devices share the same

signals via a bidirectional bus using a wired-AND connection.

An external pull-up resistor must be used for the SDA and SCL signals to set the logic high level for the bus.

When the bus level is 5 V, use pull-up resistors between 1 kΩ and 2 kΩ.

Figure 42. Typical I2C Sequence

There is no limit on the number of bytes that can be transmitted between start and stop conditions. When the last

word transfers, the master generates a stop condition to release the bus. A generic data transfer sequence is

shown in Figure 42.

SINGLE-AND MULTIPLE-BYTE TRANSFERS

The serial control interface supports both single-byte and multi-byte read/write operations for all registers.

During multiple-byte read operations, the TPA2026D2 responds with data, one byte at a time, starting at the

register assigned, as long as the master device continues to respond with acknowledgments.

The TPA2026D2 supports sequential I2C addressing. For write transactions, if a register is issued followed by

data for that register and all the remaining registers that follow, a sequential I2C write transaction has occurred.

For I2C sequential write transactions, the register issued then serves as the starting point, and the amount of

data subsequently transmitted, before a stop or start is transmitted, determines the number of registers written.

Copyright © 2010, Texas Instruments Incorporated Submit Documentation Feedback 23

Product Folder Link(s): TPA2026D2

Page 24

A6 A5 A4 A3 A2 A1 A0

R/W

ACK A7 A6 A5 A4 A3 A2 A1 A0 ACK D7 D6 D5 D4 D3 D2 D1 D0 ACK

Start

Condition

Stop

Condition

Acknowledge Acknowledge Acknowledge

I2CDeviceAddressand

Read/WriteBit

Register DataByte

TPA2026D2

SLOS649 –MARCH 2010

www.ti.com

SINGLE-BYTE WRITE

As Figure 43 shows, a single-byte data write transfer begins with the master device transmitting a start condition

followed by the I2C device address and the read/write bit. The read/write bit determines the direction of the data

transfer. For a write data transfer, the read/write bit must be set to '0'. After receiving the correct I2C device

address and the read/write bit, the TPA2026D2 responds with an acknowledge bit. Next, the master transmits the

register byte corresponding to the TPA2026D2 internal memory address being accessed. After receiving the

register byte, the TPA2026D2 again responds with an acknowledge bit. Next, the master device transmits the

data byte to be written to the memory address being accessed. After receiving the register byte, the TPA2026D2

again responds with an acknowledge bit. Finally, the master device transmits a stop condition to complete the

single-byte data write transfer.

Figure 43. Single-Byte Write Transfer

24 Submit Documentation Feedback Copyright © 2010, Texas Instruments Incorporated

Product Folder Link(s): TPA2026D2

Page 25

Register

A6 A5 A0 R/W ACK A7 A6 A5 A4 A0 ACK A6 A5 A0 ACK

Start

Condition

Stop

Condition

Acknowledge Acknowledge Acknowledge

I2CDeviceAddressand

Read/WriteBit

Register DataByte

D7 D6 D1 D0 ACK

I2CDeviceAddressand

Read/WriteBit

Not

Acknowledge

R/WA1 A1

RepeatStart

Condition

A6 A0 ACK

Acknowledge

I2CDeviceAddressand

Read/WriteBit

R/WA6 A0 R/W ACK A0 ACK D7 D0 ACK

Start

Condition

Stop

Condition

Acknowledge Acknowledge Acknowledge

LastDataByte

ACK

FirstDataByte

RepeatStart

Condition

Not

Acknowledge

I2CDeviceAddressand

Read/WriteBit

Register

OtherDataBytes

A7 A6 A5 D7 D0 ACK

Acknowledge

D7 D0

TPA2026D2

www.ti.com

SLOS649 –MARCH 2010

MULTIPLE-BYTE WRITE AND INCREMENTAL MULTIPLE-BYTE WRITE

A multiple-byte data write transfer is identical to a single-byte data write transfer except that multiple data bytes

are transmitted by the master device to the TPA2026D2 as shown in Figure 44. After receiving each data byte,

the TPA2026D2 responds with an acknowledge bit.

Figure 44. Multiple-Byte Write Transfer

SINGLE-BYTE READ

As Figure 45 shows, a single-byte data read transfer begins with the master device transmitting a start condition

followed by the I2C device address and the read/write bit. For the data read transfer, both a write followed by a

read are actually executed. Initially, a write is executed to transfer the address byte of the internal memory

address to be read. As a result, the read/write bit is set to a '0'.

After receiving the TPA2026D2 address and the read/write bit, the TPA2026D2 responds with an acknowledge

bit. The master then sends the internal memory address byte, after which the TPA2026D2 issues an

acknowledge bit. The master device transmits another start condition followed by the TPA2026D2 address and

the read/write bit again. This time the read/write bit is set to '1', indicating a read transfer. Next, the TPA2026D2

transmits the data byte from the memory address being read. After receiving the data byte, the master device

transmits a not-acknowledge followed by a stop condition to complete the single-byte data read transfer.

Figure 45. Single-Byte Read Transfer

MULTIPLE-BYTE READ

A multiple-byte data read transfer is identical to a single-byte data read transfer except that multiple data bytes

are transmitted by the TPA2026D2 to the master device as shown in Figure 46. With the exception of the last

data byte, the master device responds with an acknowledge bit after receiving each data byte.

Figure 46. Multiple-Byte Read Transfer

Copyright © 2010, Texas Instruments Incorporated Submit Documentation Feedback 25

Product Folder Link(s): TPA2026D2

Page 26

TPA2026D2

SLOS649 –MARCH 2010

www.ti.com

Register Map

Table 3. TPA2026D2 Register Map

REGISTER Bit7 Bit6 Bit5 Bit4 Bit3 Bit2 Bit1 Bit0

1 SPK_EN_R SPL_EN_L SWS FAULT_R FAULT_L Thermal 1 NG_EN

2 0 0 ATK_time [5] ATK_time [4] ATK_time [3] ATK_time [2] ATK_time [1] ATK_time [0]

3 0 0 REL_time [5] REL_time [4] REL_time [3] REL_time [2] REL_time [1] REL_time [0]

4 0 0 Hold_time [5] Hold_time [4] Hold_tme [3] Hold_time [2] Hold_time [1] Hold_time [0]

5 0 0 FixedGain [5] FixedGain [4] FixedGain [3] FixedGain [2] FixedGain [1] FixedGain [0]

6 Limiter Limiter Level Limiter Level

Output Output Output

Disable [3] [2]

7 Max Gain [3] Max Gain [2] Max Gain [1] Max Gain [0] 0 0

The default register map values are given in Table 4.

REGISTER 0x01 0x02 0x03 0x04 0x05 0x06 0x07

Default C2h 01h 06h 0Fh 12h 19h C0h

Any register above address 0x08 is reserved for testing and should not be written to because it may change the

function of the device. If read, these bits may assume any value.

Some of the default values can be reprogrammed through the I2C interface and written to the EEPROM. This

function is useful to speed up the turn-on time of the device and minimizes the number of I2C writes. If this is

required, contact your local TI representative.

The TPA2026D2 I2C address is 0xB0 (binary 10110000) for writing and 0xB1 (binary 10110001) for reading. If a

different I2C address is required, contact your local TI representative. See the general I2C operation section for

more details.

The following tables show the details of the registers, the default values, and the values that can be programmed

through the I2C interface.

NoiseGate NoiseGate Output Limiter Output Limiter Output Limiter

Threshold [1] Threshold [2] Level [4] Level [1] Level [0]

Compression Compression

Ratio [1] Ratio [0]

Table 4. TPA2026D2 Default Register Values

26 Submit Documentation Feedback Copyright © 2010, Texas Instruments Incorporated

Product Folder Link(s): TPA2026D2

Page 27

TPA2026D2

www.ti.com

SLOS649 –MARCH 2010

IC FUNCTION CONTROL (Address: 1)

REGISTER

ADDRESS

01 (01H) – IC 7 SPK_EN_R 1 (enabled) Enables right amplifier

Function Control

SPK_EN_R: Enable bit for the right-channel amplifier. Amplifier is active when bit is high. This function is

SPK_EN_L: Enable bit for the left-channel amplifier. Amplifier is active when bit is high. This function is

SWS: Software shutdown control. The device is in software shutdown when the bit is '1' (control, bias

FAULT_L: This bit indicates that an over-current event has occurred on the left channel with a '1'. This bit

FAULT_R: This bit indicates that an over-current event has occurred on the right channel with a '1'. This

Thermal: This bit indicates a thermal shutdown that was initiated by the hardware with a '1'. This bit is

NG_EN: Enable bit for the Noise Gate function. This function is enabled when this bit is high. This

I2C BIT LABEL DEFAULT DESCRIPTION

6 SPK_EN_L 1 (enabled) Enables left amplifier

5 SWS 0 (enabled) Shutdown IC when bit = 1

4 FAULT_R 0 Changes to a 1 when there is a short on the right channel. Reset by writing

a 0.

3 FAULT_L 0 Changes to a 1 when there is a short on the left channel. Reset by writing a

0

2 Thermal 0 Changes to a 1 when die temperature is above 150°C

1 UNUSED 1

0 NG_EN 0 (disabled) Enables Noise Gate function

gated by thermal and returns once the IC is below the threshold temperature.

gated by thermal and returns once the IC is below the threshold temperature

and oscillator are inactive). When the bit is '0' the control, bias and oscillator are enabled.

is cleared by writing a '0' to it.

bit is cleared by writing a '0' to it.

deglitched and latched, and can be cleared by writing a '0' to it.

function can only be enabled when the Compression ratio is not 1:1.

AGC ATTACK CONTROL (Address: 2)

REGISTER

ADDRESS

02 (02H) – 7:6 Unused 00

AGC Control

I2C BIT

5:0 ATK_time 000101 AGC Attack time (gain ramp down)

ATK_time These bits set the attack time for the AGC function. The attack time is the minimum time

Copyright © 2010, Texas Instruments Incorporated Submit Documentation Feedback 27

LABEL DEFAULT DESCRIPTION

(1.28 ms/6 dB)

000001 0.1067 ms 1.28 ms 5.76 ms

000010 0.2134 ms 2.56 ms 11.52 ms

000011 0.3201 ms 3.84 ms 17.19 ms

000100 0.4268 ms 5.12 ms 23.04 ms

111111 6.722 ms 80.66 ms 362.99 ms

Per Step Per 6 dB 90% Range

(time increases by 0.1067 ms with every step)

between gain decreases.

Product Folder Link(s): TPA2026D2

Page 28

TPA2026D2

SLOS649 –MARCH 2010

www.ti.com

AGC RELEASE CONTROL (Address: 3)

REGISTER

ADDRESS

03 (03H) – AGC 7:6 Unused 00

Release

Control

I2C BIT

5:0 REL_time 001011 AGC Release time (gain ramp down)

REL_time These bits set the release time for the AGC function. The release time is the minimum time

LABEL DEFAULT DESCRIPTION

(0.9864 sec/6 dB)

000001 0.0137 s 0.1644 s 0.7398 s

000010 0.0274 s 0.3288 s 1.4796 s

000011 0.0411 s 0.4932 s 2.2194 s

000100 0.0548 s 0.6576 s 2.9592 s

111111 0.8631 s 10.36 s 46.6 s

Per Step Per 6 dB 90% Range

(time increases by 0.0137 s with every step)

between gain increases.

AGC HOLD TIME CONTROL (Address: 4)

REGISTER

ADDRESS

04 (04H) – 7:6 Unused 00

AGC Hold

Time Control

I2C BIT

5:0 Hold_time 000000 (disabled) AGC Hold time

Hold_time These bits set the hold time for the AGC function. The hold time is the minimum time between

LABEL DEFAULT DESCRIPTION

Per Step

000000 Hold Time Disable

000001 0.0137 s

000010 0.0274 s

000011 0.0411 s

000100 0.0548 s

(time increases by 0.0137 s with every step)

111111 0.8631 s

a gain decrease (attack) and a gain increase (release). The hold time can be deactivated.

28 Submit Documentation Feedback Copyright © 2010, Texas Instruments Incorporated

Product Folder Link(s): TPA2026D2

Page 29

TPA2026D2

www.ti.com

SLOS649 –MARCH 2010

AGC FIXED GAIN CONTROL (Address: 5)

REGISTER

ADDRESS

05 (05H) – 7:6 Unused 00

AGC Fixed

Gain Control

I2C BIT

5:0 Fixed Gain 000110 (6 dB) Sets the fixed gain of the amplifier: two's complement

Fixed Gain These bits are used to select the fixed gain of the amplifier. If compression is enabled, fixed

LABEL DEFAULT DESCRIPTION

Gain

100100 –28 dB

100101 –27 dB

100110 –26 dB

(gain increases by 1 dB with every step)

111101 –3 dB

111110 –2 dB

111111 –1 dB

000000 0 dB

000001 1 dB

000010 2 dB

000011 3 dB

(gain increases by 1dB with every step)

011100 28 dB

011101 29 dB

011110 30 dB

gain is adjustable from –28dB to 30dB. If compression is disabled, fixed gain is adjustable from

0dB to 30dB.

AGC CONTROL (Address: 6)

REGISTER

ADDRESS

06 (06H) – 7 Output Limiter 0 (enable) Disables the output limiter function. Can only be disabled when the AGC compression

AGC Control Disable ratio is 1:1 (off)

I2C BIT

6:5 NoiseGate 01 (4 mV

4:0 Output Limiter 11010 (6.5 dBV) Selects the output limiter level

Output Limiter This bit disables the output limiter function when set to 1. Can only be disabled when

Disable the AGC compression ratio is 1:1

NoiseGate Threshold These bits set the threshold level of the noise gate. NoiseGate Threshold is only

Output Limiter Level These bits select the output limiter level. Output Power numbers are for 8Ω load.

LABEL DEFAULT DESCRIPTION

) Select the threshold of the noise gate

Threshold

Level

rms

Output Power (Wrms) Peak Output Voltage

00000 0.03 0.67 –6.5

00001 0.03 0.71 –6

00010 0.04 0.75 –5.5

(Limiter level increases by 0.5dB with every step)

11101 0.79 3.55 8

11110 0.88 3.76 8.5

11111 0.99 3.99 9

functional when the compression ratio is not 1:1

Threshold

00 1 mV

01 4 mV

10 10 mV

11 20 mV

(Vp)

rms

rms

rms

rms

dBV

Copyright © 2010, Texas Instruments Incorporated Submit Documentation Feedback 29

Product Folder Link(s): TPA2026D2

Page 30

TPA2026D2

SLOS649 –MARCH 2010

www.ti.com

AGC CONTROL (Address: 7)

REGISTER

ADDRESS

07 (07H) – 7:4 Max Gain 1100 (30 dB) Selects the maximum gain the AGC can achieve

AGC Control

I2C BIT

3:2 Unused 00

1:0 Compression 10 (4:1) Selects the compression ratio of the AGC

Compression Ratio These bits select the compression ratio. Output Limiter is enabled by default when the

Max Gain These bits select the maximum gain of the amplifier. In order to maximize the use of the

LABEL DEFAULT DESCRIPTION

(gain increases by 1 dB with every step)

Ratio

compression ratio is not 1:1.

AGC, set the Max Gain to 30dB

Gain

0000 18 dB

0001 19 dB

0010 20 dB

1100 30 dB

Ratio

00 1:1 (off)

01 2:1

10 4:1

11 8:1

30 Submit Documentation Feedback Copyright © 2010, Texas Instruments Incorporated

Product Folder Link(s): TPA2026D2

Page 31

C

I I

1

f =

(2 R C )p ´ ´

I

I C

1

C =

(2 R f )p ´ ´

TPA2026D2

www.ti.com

DECOUPLING CAPACITOR C

S

SLOS649 –MARCH 2010

The TPA2026D2 is a high-performance Class-D audio amplifier that requires adequate power supply decoupling

to ensure the efficiency is high and total harmonic distortion (THD) is low. For higher frequency transients,

spikes, or digital hash on the line, a good low equivalent-series-resistance (ESR) 1-mF ceramic capacitor

(typically) placed as close as possible to the device PVDD (L, R) lead works best. Placing this decoupling

capacitor close to the TPA2026D2 is important for the efficiency of the Class-D amplifier, because any resistance

or inductance in the trace between the device and the capacitor can cause a loss in efficiency. For filtering

lower-frequency noise signals, a 4.7 mF or greater capacitor placed near the audio power amplifier would also

help, but it is not required in most applications because of the high PSRR of this device.

INPUT CAPACITORS C

I

The input capacitors and input resistors form a high-pass filter with the corner frequency, fC, determined in

Equation 5.

(5)

The value of the input capacitor is important to consider as it directly affects the bass (low frequency)

performance of the circuit. Speakers in wireless phones cannot usually respond well to low frequencies, so the

corner frequency can be set to block low frequencies in this application. Not using input capacitors can increase

output offset. Equation 6 is used to solve for the input coupling capacitance. If the corner frequency is within the

audio band, the capacitors should have a tolerance of ±10% or better, because any mismatch in capacitance

causes an impedance mismatch at the corner frequency and below.

(6)

YZH PACKAGE DIMENSIONS

The package dimensions for this YZH package are shown in the table below. See the package drawing at the

end of this data sheet for more details.

Packaged Devices D E

TPA2026D2YZH

Max = 2160µm Max = 2137µm

Min = 2100µm Min = 2077µm

BOARD LAYOUT

In making the pad size for the WCSP balls, it is recommended that the layout use non solder mask defined

(NSMD) land. With this method, the solder mask opening is made larger than the desired land area, and the

opening size is defined by the copper pad width. Figure 47 and Table 5 show the appropriate diameters for a

WCSP layout. The TPA2026D2 evaluation module (EVM) layout is shown in the next section as a layout

example.

Copyright © 2010, Texas Instruments Incorporated Submit Documentation Feedback 31

Product Folder Link(s): TPA2026D2

Page 32

TPA2026D2

SLOS649 –MARCH 2010

www.ti.com

Figure 47. Land Pattern Dimensions

Table 5. Land Pattern Dimensions

SOLDER PAD SOLDER MASK

DEFINITIONS OPENING THICKNESS THICKNESS

Non solder mask 275 mm × 275 mm Sq. (rounded

defined (NSMD) corners)

(1) Circuit traces from NSMD defined PWB lands should be 75 mm to 100 mm wide in the exposed area inside the solder mask opening.

Wider trace widths reduce device stand off and impact reliability.

(2) Best reliability results are achieved when the PWB laminate glass transition temperature is above the operating the range of the

intended application.

(3) Recommend solder paste is Type 3 or Type 4.

(4) For a PWB using a Ni/Au surface finish, the gold thickness should be less 0.5 mm to avoid a reduction in thermal fatigue performance.

(5) Solder mask thickness should be less than 20 mm on top of the copper circuit pattern

(6) Best solder stencil performance is achieved using laser cut stencils with electro polishing. Use of chemically etched stencils results in

inferior solder paste volume control.

(7) Trace routing away from WCSP device should be balanced in X and Y directions to avoid unintentional component movement due to

solder wetting forces.

COPPER PAD STENCIL

275 mm 375 mm

(+0.0, –25 mm) (+0.0, –25 mm)

(5)

COPPER STENCIL

1 oz max (32 mm) 125 mm thick

(1) (2) (3) (4)

(6) (7)

OPENING

COMPONENT LOCATION

Place all external components very close to the TPA2026D2. Placing the decoupling capacitor, CS, close to the

TPA2026D2 is important for the efficiency of the Class-D amplifier. Any resistance or inductance in the trace

between the device and the capacitor can cause a loss in efficiency.

TRACE WIDTH

Recommended trace width at the solder balls is 75 mm to 100 mm to prevent solder wicking onto wider PCB

traces. For high current pins (PVDD (L, R), PGND, and audio output pins) of the TPA2026D2, use 100-mm trace

widths at the solder balls and at least 500-mm PCB traces to ensure proper performance and output power for

the device. For the remaining signals of the TPA2026D2, use 75-mm to 100-mm trace widths at the solder balls.

The audio input pins (INR± and INL±) must run side-by-side to maximize common-mode noise cancellation.

32 Submit Documentation Feedback Copyright © 2010, Texas Instruments Incorporated

Product Folder Link(s): TPA2026D2

Page 33

100°C/W

JA DMAX

T T P C

A J

Max = Max - = 150 - 100 (0.4) = 110q °

Ferrite

ChipBead

Ferrite

ChipBead

1nF

1nF

OUTP

OUTN

TPA2026D2

www.ti.com

SLOS649 –MARCH 2010

EFFICIENCY AND THERMAL INFORMATION

The maximum ambient temperature depends on the heat-sinking ability of the PCB system. The derating factor

for the package is shown in the dissipation rating table. Converting this to qJAfor the WCSP package:

(7)

Given qJAof 100°C/W, the maximum allowable junction temperature of 150°C, and the maximum internal

dissipation of 0.4 W (0.2 W per channel) for 1.5 W per channel, 8-Ω load, 5-V supply, from Figure 15, the

maximum ambient temperature can be calculated with the following equation.

(8)

Equation 8 shows that the calculated maximum ambient temperature is 110°C at maximum power dissipation

with a 5-V supply and 8-Ω a load. The TPA2026D2 is designed with thermal protection that turns the device off

when the junction temperature surpasses 150°C to prevent damage to the IC. Also, using speakers more

resistive than 8-Ω dramatically increases the thermal performance by reducing the output current and increasing

the efficiency of the amplifier.

OPERATION WITH DACS AND CODECS

In using Class-D amplifiers with CODECs and DACs, sometimes there is an increase in the output noise floor

from the audio amplifier. This occurs when output frequencies of the CODEC/DAC mix with the Class-D

switching frequency and create sum/difference components in the audio band. The noise increase can be solved

by placing an RC low-pass filter between the CODEC/DAC and audio amplifier. The filter reduces high

frequencies that cause the problem and allows proper performance.

SHORT CIRCUIT AUTO-RECOVERY

When a short circuit event happens, the TPA2026D2 goes to low duty cycle mode and tries to reactivate itself

every 110 µs. This auto-recovery will continue until the short circuit event stops. This feature can protect the

device without affecting the device's long term reliability. FAULT bit (register 1, bit 3) still requires a write to clear.

FILTER FREE OPERATION AND FERRITE BEAD FILTERS

A ferrite bead filter can often be used if the design is failing radiated emissions without an LC filter and the

frequency sensitive circuit is greater than 1 MHz. This filter functions well for circuits that just have to pass FCC

and CE because FCC and CE only test radiated emissions greater than 30 MHz. When choosing a ferrite bead,

choose one with high impedance at high frequencies, and low impedance at low frequencies. In addition, select a

ferrite bead with adequate current rating to prevent distortion of the output signal.

Use an LC output filter if there are low frequency (< 1 MHz) EMI sensitive circuits and/or there are long leads

from amplifier to speaker. Figure 48 shows typical ferrite bead and LC output filters.

Figure 48. Typical Ferrite Bead Filter (Chip bead example: TDK: MPZ1608S221A)

Copyright © 2010, Texas Instruments Incorporated Submit Documentation Feedback 33

Product Folder Link(s): TPA2026D2

Page 34

PACKAGE OPTION ADDENDUM

www.ti.com 26-Apr-2010

PACKAGING INFORMATION

Orderable Device Status

(1)

Package

Type

Package

Drawing

Pins Package

Qty

Eco Plan

TPA2026D2YZHR ACTIVE DSBGA YZH 16 3000 Green (RoHS &

(2)

Lead/Ball Finish MSL Peak Temp

SNAGCU Level-1-260C-UNLIM

(3)

no Sb/Br)

TPA2026D2YZHT ACTIVE DSBGA YZH 16 250 Green (RoHS &

SNAGCU Level-1-260C-UNLIM

no Sb/Br)

(1)

The marketing status values are defined as follows:

ACTIVE: Product device recommended for new designs.

LIFEBUY: TI has announced that the device will be discontinued, and a lifetime-buy period is in effect.

NRND: Not recommended for new designs. Device is in production to support existing customers, but TI does not recommend using this part in

a new design.

PREVIEW: Device has been announced but is not in production. Samples may or may not be available.

OBSOLETE: TI has discontinued the production of the device.

(2)

Eco Plan - The planned eco-friendly classification: Pb-Free (RoHS), Pb-Free (RoHS Exempt), or Green (RoHS & no Sb/Br) - please check

http://www.ti.com/productcontent for the latest availability information and additional product content details.

TBD: The Pb-Free/Green conversion plan has not been defined.

Pb-Free (RoHS): TI's terms "Lead-Free" or "Pb-Free" mean semiconductor products that are compatible with the current RoHS requirements

for all 6 substances, including the requirement that lead not exceed 0.1% by weight in homogeneous materials. Where designed to be soldered

at high temperatures, TI Pb-Free products are suitable for use in specified lead-free processes.

Pb-Free (RoHS Exempt): This component has a RoHS exemption for either 1) lead-based flip-chip solder bumps used between the die and

package, or 2) lead-based die adhesive used between the die and leadframe. The component is otherwise considered Pb-Free (RoHS

compatible) as defined above.

Green (RoHS & no Sb/Br): TI defines "Green" to mean Pb-Free (RoHS compatible), and free of Bromine (Br) and Antimony (Sb) based flame

retardants (Br or Sb do not exceed 0.1% by weight in homogeneous material)

(3)

MSL, Peak Temp. -- The Moisture Sensitivity Level rating according to the JEDEC industry standard classifications, and peak solder

temperature.

Important Information and Disclaimer:The information provided on this page represents TI's knowledge and belief as of the date that it is

provided. TI bases its knowledge and belief on information provided by third parties, and makes no representation or warranty as to the

accuracy of such information. Efforts are underway to better integrate information from third parties. TI has taken and continues to take

reasonable steps to provide representative and accurate information but may not have conducted destructive testing or chemical analysis on

incoming materials and chemicals. TI and TI suppliers consider certain information to be proprietary, and thus CAS numbers and other limited

information may not be available for release.

In no event shall TI's liability arising out of such information exceed the total purchase price of the TI part(s) at issue in this document sold by TI

to Customer on an annual basis.

Addendum-Page 1

Page 35

PACKAGE MATERIALS INFORMATION

www.ti.com 20-Jul-2010

TAPE AND REEL INFORMATION

*All dimensions are nominal

Device Package

TPA2026D2YZHR DSBGA YZH 16 3000 180.0 8.4 2.35 2.35 0.81 4.0 8.0 Q1

Type

Package

Drawing

Pins SPQ Reel

Diameter

(mm)

Reel

Width

W1 (mm)

A0

(mm)B0(mm)K0(mm)P1(mm)W(mm)

Pin1

Quadrant

Pack Materials-Page 1

Page 36

PACKAGE MATERIALS INFORMATION

www.ti.com 20-Jul-2010

*All dimensions are nominal

Device Package Type Package Drawing Pins SPQ Length (mm) Width (mm) Height (mm)

TPA2026D2YZHR DSBGA YZH 16 3000 190.5 212.7 31.8

Pack Materials-Page 2

Page 37

D: Max =

2164 µm, Min =

2104 µm

E: Max =

2142 µm, Min =

2082 µm

Page 38

IMPORTANT NOTICE

Texas Instruments Incorporated and its subsidiaries (TI) reserve the right to make corrections, modifications, enhancements, improvements,

and other changes to its products and services at any time and to discontinue any product or service without notice. Customers should

obtain the latest relevant information before placing orders and should verify that such information is current and complete. All products are

sold subject to TI’s terms and conditions of sale supplied at the time of order acknowledgment.

TI warrants performance of its hardware products to the specifications applicable at the time of sale in accordance with TI’s standard

warranty. Testing and other quality control techniques are used to the extent TI deems necessary to support this warranty. Except where

mandated by government requirements, testing of all parameters of each product is not necessarily performed.

TI assumes no liability for applications assistance or customer product design. Customers are responsible for their products and

applications using TI components. To minimize the risks associated with customer products and applications, customers should provide

adequate design and operating safeguards.

TI does not warrant or represent that any license, either express or implied, is granted under any TI patent right, copyright, mask work right,

or other TI intellectual property right relating to any combination, machine, or process in which TI products or services are used. Information

published by TI regarding third-party products or services does not constitute a license from TI to use such products or services or a