Page 1

Application Report

SLLA032

TNETE2201 EVM Kit Setup and Usage

Boyd Barrie MSDS Applications Group

Abstract

The Texas Instruments (TIä) TNETE2201 EVM (evaluation module) k it is a tool used to

evaluate and design high-speed prototypes using the TNETE2201 Ethernet Transceiver

IC (10 mm x 10 mm TQFP plastic package). The EVM kit is used to evaluate device

parameters while acting as a guide for high-speed board layout. The high-speed

interface is selectable between a 50-W SMA connector and a GBIC standard interface.

The GBIC standard also provides a 75-W copper interface module and various fiber optic

options. Overall, the designer can use the EVM kit as a tool for successful evaluation

and design of an end product.

Contents

Introduction......................................................................................................................................................2

Board Layout and Configuration......................................................................................................................3

Test Configuration and Results........................................................................................................................4

Board Layouts, Schematics, and Bill of Materials............................................................................................6

Digital Signal Processing Solutions March 1999

Page 2

Application Report

SLLA032

Figures

Figure 1. GBIC Setup Modifications................................................................................................................4

Figure 2. Bit Error-Rate Ratio Test Configuration ...........................................................................................5

Figure 3. Eye Diagrams of High-Speed Serial Outputs...................................................................................5

Figure 4. TNETE2201 EVM Board Schematic................................................................................................7

Figure 5. TNETE2201 EVM Board Top Layer.................................................................................................9

Figure 6. TNETE2201 EVM Board GND Layer.............................................................................................10

Figure 7. TNETE2201 EVM Board VCC Layer.............................................................................................11

Figure 8. TNETE2201 EVM Board Bottom Layer..........................................................................................12

Tables

Table 1. Default Setup as Shipped..................................................................................................................3

Table 2. TNETE2201 EVM Board Bill of Materials..........................................................................................8

Introduction

The TNETE2201 EVM kit can act as a daughter board that plugs into new or existing

designs. By providing the appropriate cabling, the EVM kit can interface with just about

any test equipment or other reference designs. The EVM kit's high-speed serial interface

can use either the GBIC (Gigabit Interface Converter) standard interface or a 50-ohm

SMA connection. In addition, the GBIC specification allows the designer to choose either

a 75-ohm copper module or a selection of fiber-optics modules.

As the frequency of operation increases, the board designer must take special care to

ensure that the highest signal integrity is maintained. To achieve this, the board’s

impedance is controlled for both 50-ohm and 75-ohm high-speed transmission lines. In

addition, the 50-ohm impedance mismatches are reduced by designing the component

pad size to be as close as possible to the width of the connecting transmission line. Vias

are minimized and, when necessary, placed as close as possible to the device drivers.

Overall, the board layout is designed and optimized to support high-speed operation.

Thus, understanding impedance control and transmission line effects are crucial when

designing high-speed boards.

Some of the advanced features offered by the EVM kit include:

r

PCB (printed circuit board) designed for speeds in excess of 1.25 Gbps

r

Flexible—The EVM can be configured to operate with multiple device types and with

copper or fiber interfaces.

r

Integrated GBIC Interface eliminates the need for two boards.

r

All input/output signals are accessible for rapid prototyping.

r

Clock input is selectable for either 8/14 pin crystal or external clock input.

r

Power can be supplied either by banana jacks or a 20-pin connector.

r

Series terminated parallel outputs

TNETE2201 EVM Kit Setup and Usage 2

Page 3

Application Report

SLLA032

Board Layout and Configurat ion

The TNETE2201 EVM kit is designed to give the developer many options for operation.

Many of these options are selectable by DIP switch and others may require board

component removal or additions. The following sections provide guidelines to config ure

the EVM kit for different modes of operation.

The EVM kit is normally delivered in a default configuration that requires external clock

and data inputs. The high-speed serial input and output are routed through the 50-ohm

transmission line path. The GBIC interface is not connected and would require some

resistor modifications to be functional. The default setup is useful for testing the board

and interface IC. The designer might consider testing the bit error rate, jitter, and eyediagram characteristics of the system. The TNETE2201 EVM is shipped with certain

components installed for default operation. Table 1 lists the default configuration.

Table 1. Default Setup as Shipped

Designator Function Condition (TNETE2201)

P5 CLK SEL Jumper installed between Pins 2 and 3

R1 TX Termination 200 ohm installed

R2 TX Termination 200 ohm installed

R5 Bias Net 365 ohm installed

R6 Bias Net 562 ohm installed

R8 WIZ OPTIO N Not installed

R9 WIZ OPTIO N Not installed

R16 CAP OPTION Zero ohm installed

R17 Bias Net Not installed

R21 WIZ OPTIO N Not installed

R22 WIZ OPTIO N Not installed

C13 Vcc Decouple 0.01 µF installed

C23 GBIC OPTION Not installed

C24 SMA OPTION 0.01 µF installed

C25 GBIC OPTION Not installed

C26 SMA OPTION 0.01 µF installed

C27 SMA OPTION 0.01 µF installed

C28 GBIC OPTION Not installed

C29 GBIC OPTION Not installed

C30 SMA OPTION 0.01 µF installed

C31 RX Termination 0.01 µF installed

C32 TX PLL Cap 0.0022 µF installed

C33 REF CLK Bias Net Zero 0hm installed

C34 TX PLL Cap 0.0022 µF installed

L1 Filter/Bias Ferrite installed

X1 OSC Not installed (not provided)

DIP1-1 PRBSEN X (OFF)

DIP1-2 TXRRAMP X (OFF)

DIP1-3 TXDIR X (OFF)

TNETE2201 EVM Kit Setup and Usage 3

Page 4

Application Report

SLLA032

Designator Function Condition (TNETE2201)

DIP1-4 LCKREFN X (OFF)

DIP1-5 TESTEN ON

DIP1-6 SYNCEN X (OFF)

DIP1-7 LOOPEN ON

DIP1-8 CLKEN X (OFF)

Note: X is a don't care state (default posi ti on).

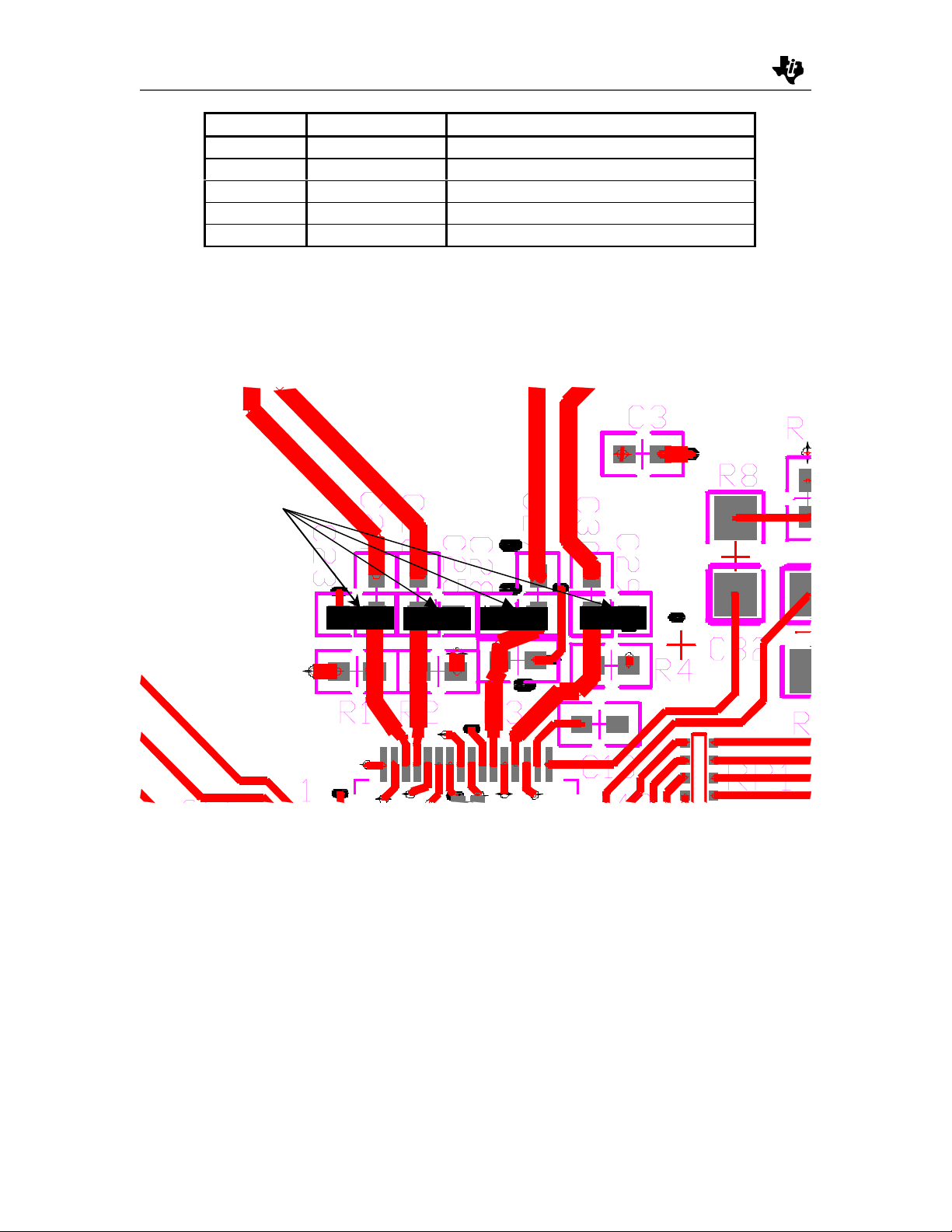

The GBIC Configuration requires a modification of the steering capacitors C23 through

C30. This requires removing C24, C26, C27, and C30 and soldering these capacitors in

locations C23, C25, C28, and C29 (see Figure 1).

Figure 1. GBIC Setup Modifications

GBIC

INSTALLED

CAPACITORS

Test Configuration and Results

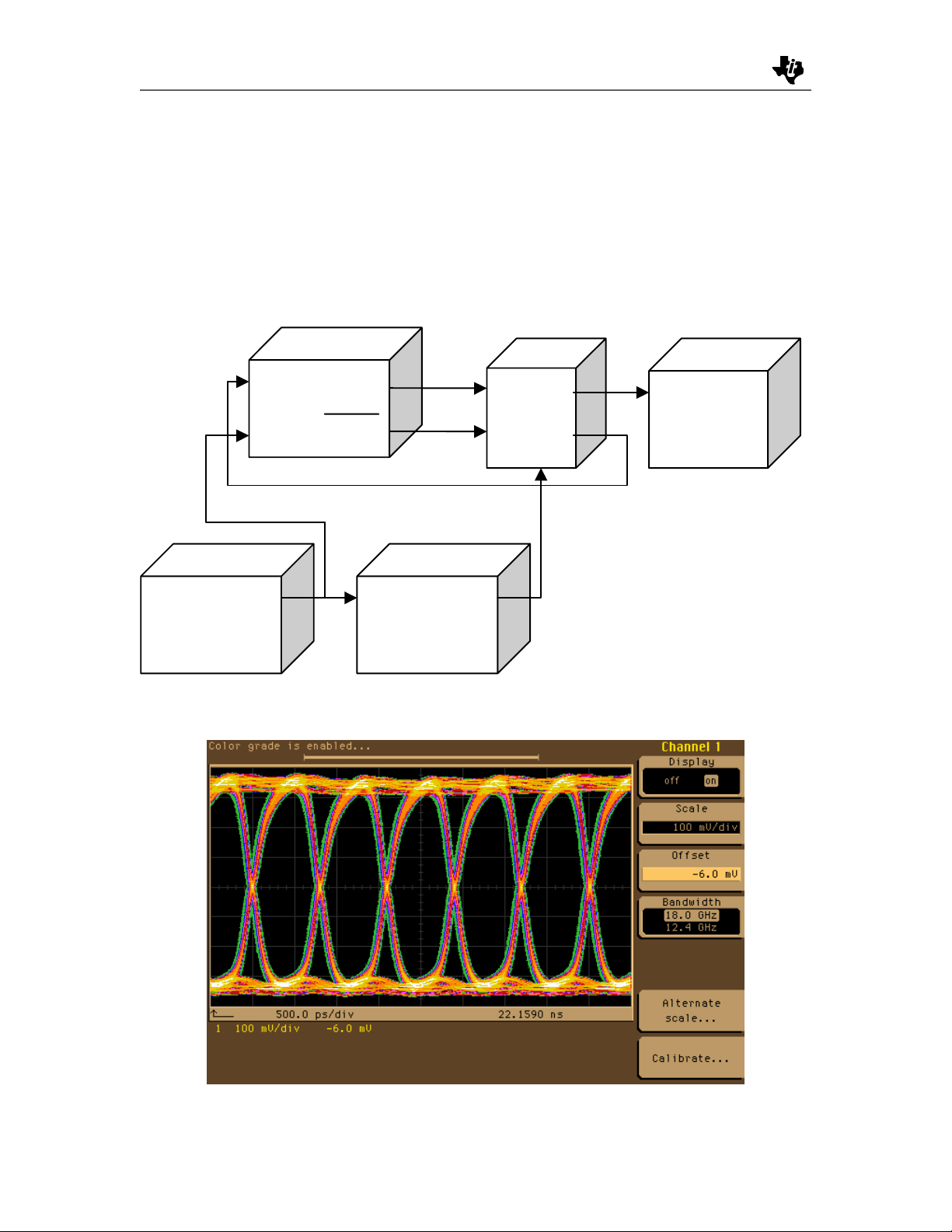

The serial Bit Error-rate Ratio Test (BERT) is useful for evaluating device and board

characteristics. Using this test, we can determine the eye diagram characteristics of the

system, as shown in Figure 3. The test setup is illustrated in Figure 2.

The HP71603B 3-Gbps Serial BERT outputs a high-speed serial stream to the test board

where the data is converted by the TNETE part to a 10-bit parallel format. The parallel

data is then looped back from the receiver to the transmitter. The pulse generator

provides a clock input to the transmitter. The external clock source is necessary because

the receiver's recovered clock is half the frequency necessary for transmission.

TNETE2201 EVM Kit Setup and Usage 4

Page 5

Application Report

SLLA032

Both the pulse generator and the BERT are synchronized with an external clock source.

The operator adjusts the variable phase delay to ensure that the clock meets the setup

and hold time of the data. The parallel data along with the clock is routed to the

transmitter where the data is serialized and captured by the oscilloscope. Figure 3 shows

an example eye diagram taken using this technique.

Figure 2. Bit Error-Rate Ratio Test Configuration

Wizard

(With parallel

ports looped)

RX-

RX+

External Clock

For Sync

Data In

Sync

HP71603B

BERT

Data Out

Data Out

Sync

(Variable Delay)

36”

36”

HP8133A

Pulse Generator

Clk Out

Figure 3. Eye Diagrams of High-Speed Serial Outputs

TX+

TX-

36”

REFCLK

HP54750A

Digital O’Scope

36”

Channel 1

TNETE2201 EVM Kit Setup and Usage 5

Page 6

Application Report

SLLA032

Board Layouts, Schematics, and Bill of Materials

TNETE2201 EVM Kit Setup and Usage 6

Page 7

Page 8

bom_list.txt

07/10/98 15:29:30 Electronics Design System Page: 0001

Bill of Materials

<<<From Job: fcge>>>

01-31xxx-xxx

TEXAS INSTRUMENTS INCORPORATED

Mixed Signal Products

T.I. Internal Data ENGINEER: RELEASED:________________

-----------------------------------------------------------------------------------------------------------------------------------ITEM| QTY | MFG | MFG PART# | Ref Des | DESCRIPTION | VALUE or FUNCTION | SOCKET

------------------------------------------------------------------------------------------------------------------------------------

1| 3 | PANASONIC | ECS-T1CX106R | C1,C35,C41 | CAPACITOR,TANT,SMT | 20%, 16V, 10uF |

2| 2 | AVX | 12061C222JATMA | C32,C34 | CAPACITOR,SMT1206 | 100V, 5%, 0.0022uF |

3| 35 | AVX | 06033G103JATMA | C2-C31,C36,C37 | CAPACITOR,SMT0603 | 25V,5%,0.01uF |

|* | | | C38-C40 | | |

4| 1 | AMP | 787653 | P4 | CONNECTOR,20PIN | RECEPT,R/A,20PIN,AMP |

5| 3 | CONCORD | 01-2520-3-044 | BJ(+5V) | CONNECTOR | BANANA,FEMALE,SWAGE MOUNT |

|* | | | BJ(RTN) | | |

|* | | | BJ(+3.3V) | | |

6| 5 | EFJOHNSON | 142-0701-801 | J1-J5 | CONNECTOR | SMA JACK,END LAUNCH,.062P |

7| 2 | MURATA ERIE | BLM21B03-PT | L1,L2 | FILTER,SMT0805 | FERRITE,6 OHMS@100MHz |

8| 2 | SAMTEC | TSW-110-07-G-D | P1,P6 | HEADER,2X10,.1CTRS | HEADER 2X 10 .1CTR |

9| 1 | SAMTEC | TSW-1-14-05-G-D | P2 | HEADER,MALE,2X14 | HEADER,MALE,2X14,.1CTRS |

10| 1 | ANY | HEADER,MALE,3PI | P5 | HEADER | MALE,3PIN,.100CC |

11| 1 | | DUT_PQFP_PJD64 | U1 | IC,TQFP,PJD,64PIN | DUT-USER DEFINED |

12| 3 | JUMPER | JUMPER-0603 | R16,R17 | JUMPER,SMT0603 | USER DEFINED JUMPER 0603 |

13| 1 | VARIES | OSC-COMBO-106.2 | X1 | OSCILLATOR,106.25MHz | OSC COMBO-106.25MHz | AMP/50935/X8

14| 4 | | RES1206(UN) | R8,R9,R21,R22 | RESISTOR,SMT,1206 | UN-INST |

15| 4 | AVX/KYOCERA | CRA3A4E500GI | RP1-RP4 | RES,SMT,8PIN,50OHM | SERIES CHIP RES ARRAY SMT |

16| 14 | DALE | CRCW06034701F | R7,R10-R14,R18 | RESISTOR,SMT,1/16W,1 | 4.70K OHM |

|* | | | R19,R23,R24 | | |

|* | | | R25-R28 | | |

17| 3 | DALE | CRCW060349R9F | R3,R4,R15 | RESISTOR,SMT,0603 | 49.9 OHM |

18| 2 | DALE | CRCW0603200F | R1,R2 | RESISTOR,SMT,0603 | 200 OHM |

19| 1 | DALE | CRCW0603365F | R5 | RESISTOR,SMT,0603 | 365 OHM |

20| 1 | DALE | CRCW0603562F | R6 | RESISTOR,SMT,0603 | 562 OHM |

21| 1 | C&K | BD08 | DIP1 | SWITCH,SPST,DIP16 | SWITCH,16P,SPST X 8 |

Total Part Count: 90

Total Parts Cost: 0

Page 1

Page 9

Page 10

Page 11

Page 12

Page 13

Application Report

SLLA032

TI Contact Numbers

INTERNET

TI Semiconductor Home Page

www.ti.com/sc

TI Distributors

www.ti.com/sc/docs/distmenu.htm

PRODUCT INFORMATION CENTERS

Americas

Phone +1(972) 644-5580

Fax +1(972) 480-7800

Email sc-infomaster@ti.com

Europe, Middle East, and Africa

Phone

Deutsch +49-(0) 8161 80 3311

English +44-(0) 1604 66 3399

Español +34-(0) 90 23 54 0 28

Francais +33-(0) 1-30 70 11 64

Italiano +33-(0) 1-30 70 11 67

Fax +44-(0) 1604 66 33 34

Email epic@ti.com

Japan

Phone

International +81-3-3457-0972

Domestic 0120-81-0026

Fax

International +81-3-3457-1259

Domestic 0120-81-0036

Email pic-japan@ti.com

Asia

Phone

International +886-2-23786800

Domestic

Australia 1-800-881-011

TI Number -800-800-1450

China 10810

TI Number -800-800-1450

Hong Kong 800-96-1111

TI Number -800-800-1450

India 000-117

TI Number -800-800-1450

Indonesia 001-801-10

TI Number -800-800-1450

Korea 080-551-2804

Malaysia 1-800-800-011

TI Number -800-800-1450

New Zealand 000-911

TI Number -800-800-1450

Philippines 105-11

TI Number -800-800-1450

Singapore 800-0111-111

TI Number -800-800-1450

Taiwan 080-006800

Thailand 0019-991-1111

TI Number -800-800-1450

Fax 886-2-2378-6808

Email tiasia@ti.com

TI is a trademark of Texas Instruments Incorporated.

Other brands and names are the property of their respective owners.

TNETE2201 EVM Kit Setup and Usage 13

Page 14

Application Report

SLLA032

Texas Instruments and its subsidiaries (TI) reserve the right to make changes to their

products or to discontinue any product or service without notice, and advise customers to

obtain the latest version of relevant information to verify, before placing orders, that

information being relied on is current and complete. All products are sold subject to the

terms and conditions of sale supplied at the time of order acknowledgement, including

those pertaining to warranty, patent infringement, and limitation of liability.

TI warrants performance of its semiconductor products to the specifications applicable at

the time of sale in accordance with TI's standard warranty. Testing and other quality

control techniques are utilized to the extent TI deems necessary to support this warranty.

Specific testing of all parameters of each device is not necessarily performed, except

those mandated by government requirements.

CERTAIN APPLICATIONS USING SEMICONDUCTOR PRODUCTS MAY INVOLVE

POTENTIAL RISKS OF DEATH, PERSONAL INJURY, OR SEVERE PROPERTY OR

ENVIRONMENTAL DAMAGE (“CRITICAL APPLICATIONS"). TI SEMICONDUCTOR

PRODUCTS ARE NOT DESIGNED, AUTHORIZED, OR WARRANTED TO BE

SUITABLE FOR USE IN LIFE-SUPPORT DEVICES OR SYSTEMS OR OTHER

CRITICAL APPLICATIONS. INCLUSION OF TI PRODUCTS IN SUCH APPLICATIONS

IS UNDERSTOOD TO BE FULLY AT THE CUSTOMER'S RISK.

IMPORTANT NOTICE

In order to minimize risks associated with the customer's applications, adequate design

and operating safeguards must be provided by the customer to minimize inherent or

procedural hazards.

TI assumes no liability for applications assistance or customer product design. TI does

not warrant or represent that any license, either express or implied, is granted under any

patent right, copyright, mask work right, or other intellectual property right of TI covering

or relating to any combination, machine, or process in which such semiconductor

products or services might be or are used. TI's publication of information regarding any

third party's products or services does not constitute TI's approval, warranty, or

endorsement thereof.

Copyright Ó 1999 Texas Instruments Incorporated

TNETE2201 EVM Kit Setup and Usage 14

Loading...

Loading...